Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Oxygen control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing high-performance powder metallurgy product by coating alloy powder with organic matter

ActiveCN108465806AIncrease oxygen contentImprove mechanical propertiesTransportation and packagingMetal-working apparatusChemical reactionAlloy

The invention provides a method of preparing a high-performance powder metallurgy product by coating alloy powder with an organic matter, and belongs to the field of powder metallurgy. The method comprises the following steps that the surface of the alloy powder is coated with a layer of an organic matter film by a solution coating method, the organic matter is dissolved in a solvent, a layer of aliquid film is formed on the surface of the alloy powder, after the solvent is removed, the alloy powder can be uniformly coated with the organic matter, any chemical reactions are not required, thesurface of the alloy powder is coated with the layer of the organic matter film, and the purpose that the easy-to-oxidize alloy powder is isolated from oxygen is achieved. The possibility that the surface of the easy-to-oxidize alloy powder can react with the oxygen is very high, the mechanical performance of a formed alloy component is relatively poor due to the increase of the oxygen content inthe forming process, and the organic matter is used for coating, so that the oxygen control effect in the forming process can be achieved effectively; and the oxidation resistance of the alloy powdercan be improved through the coating treatment in the forming process, so that the relatively low oxygen content and the good mechanical performance are advantageously kept after the forming is carriedout.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing TiAl-based alloy formwork by wax mold casting

The invention relates to the field of precision casting, in particular to a method for preparing a shuttering for an investment casting TiAl-based alloy with low cost and strong stability. The method comprises the following steps: preparing slurry of which flow cup viscosity is 10 to 25 seconds from Y2O3 powder of 200 to 400 meshes on granularity and silica sol according to a weight ratio of 2:1-3:1; then, coating the slurry on a wax mould, sprinkling electric melting Y2O3 sand of which sand granularity is 40 to 100 meshes on the wax mould, and drying the wax mould; preparing slurry of which flow cup viscosity is 10 to 30 seconds by adopting Al2O3 powder of 200 to 400 meshes on granularity and silica sol according to a weight ratio of 3:1-4:1, coating the second layer, sprinkling electric melting Al2O3 sand of which sand granularity is 40 to 80 meshes on the wax mould, and drying the wax mould; preparing slurry by adopting bauxite and silica sol according to a weight ratio of 3:1-4:1, and sprinkling coal gangue sand of which sand granularity is 16 to 24 meshes on the wax mould; after three layers, finally hanging the bauxite slurry, and drying the slurry; and then removing wax, and sintering the mould. The method has the advantages of simple shuttering preparation process and low cost of the shuttering, can effectively control reaction of a TiAl-based alloy cast and a shuttering surface material, reduce oxygen feeding amount of the alloy, and is suitable for casting a TiAl-based alloy cast.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of mold shell preparation method of precision casting titanium alloy

InactiveCN102284678AChemically stableOxygen controlFoundry mouldsFoundry coresSurface layerShell molding

The invention discloses a method for preparing a precision casting titanium alloy mold shell. The method comprises four steps of preparing a surface layer, preparing a transition layer, preparing a reinforcement layer, dewaxing and sintering. The shell-making process of the invention is simple, the cost of the shell mold is low, and the reaction between the titanium alloy casting and the surface layer material of the shell mold can be effectively controlled, the oxygen intake amount of the alloy can be reduced, and the titanium alloy casting is suitable for casting.

Owner:WUXI HUAYE IRON & STEEL

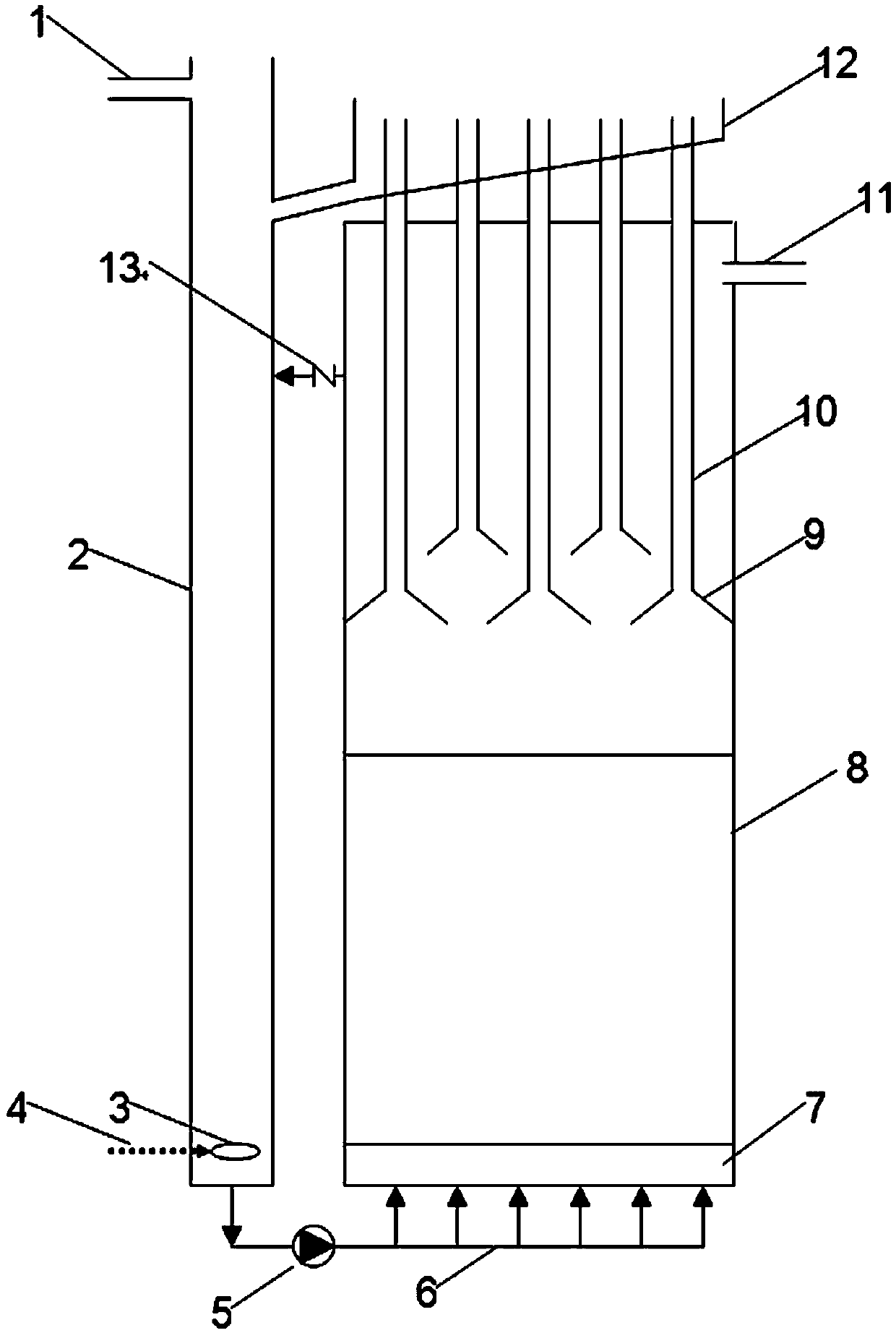

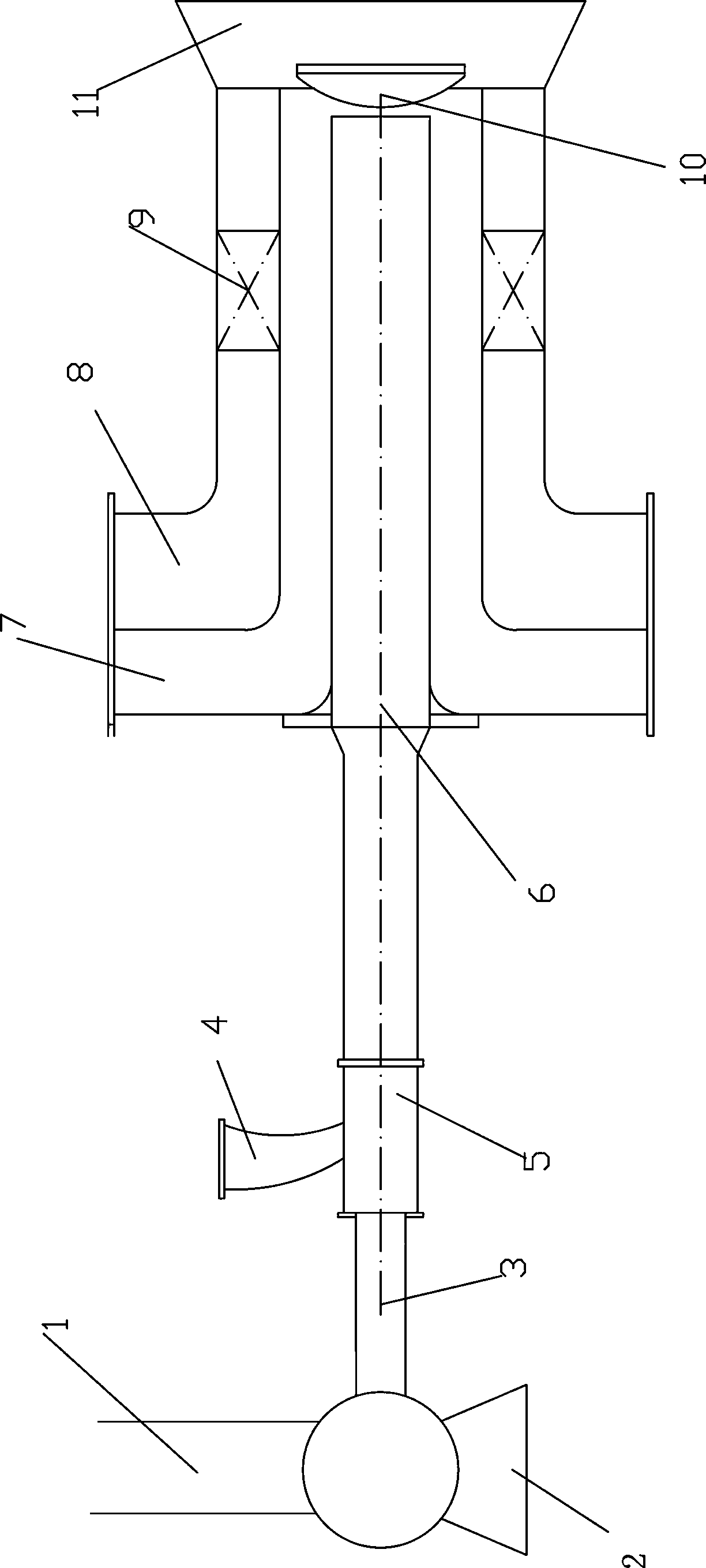

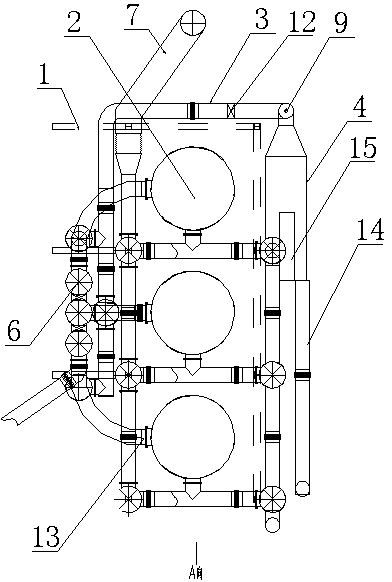

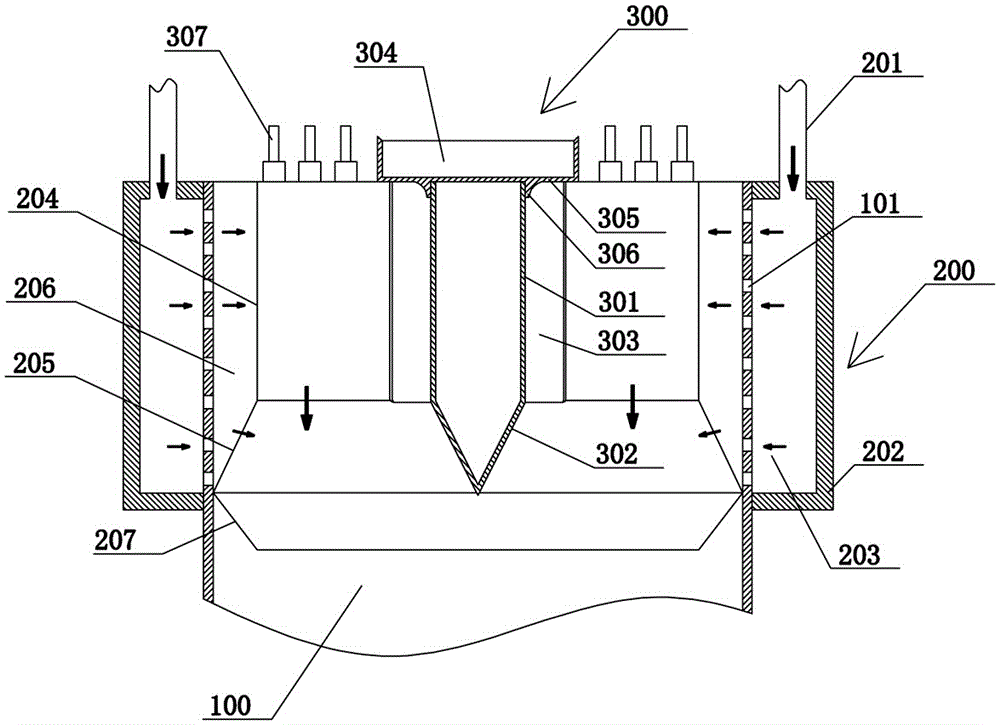

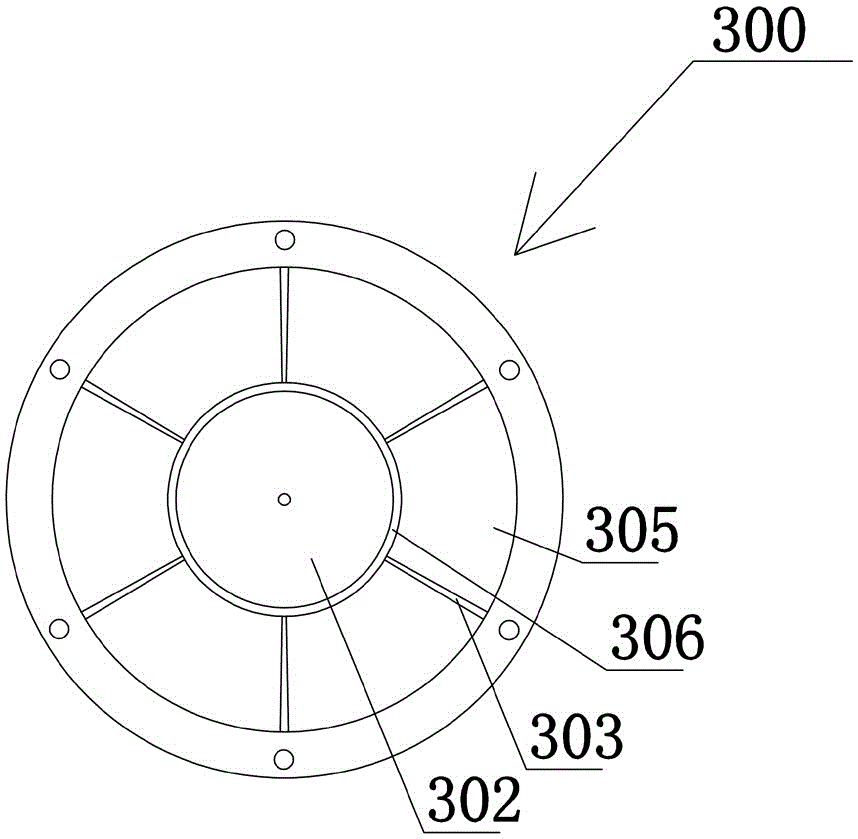

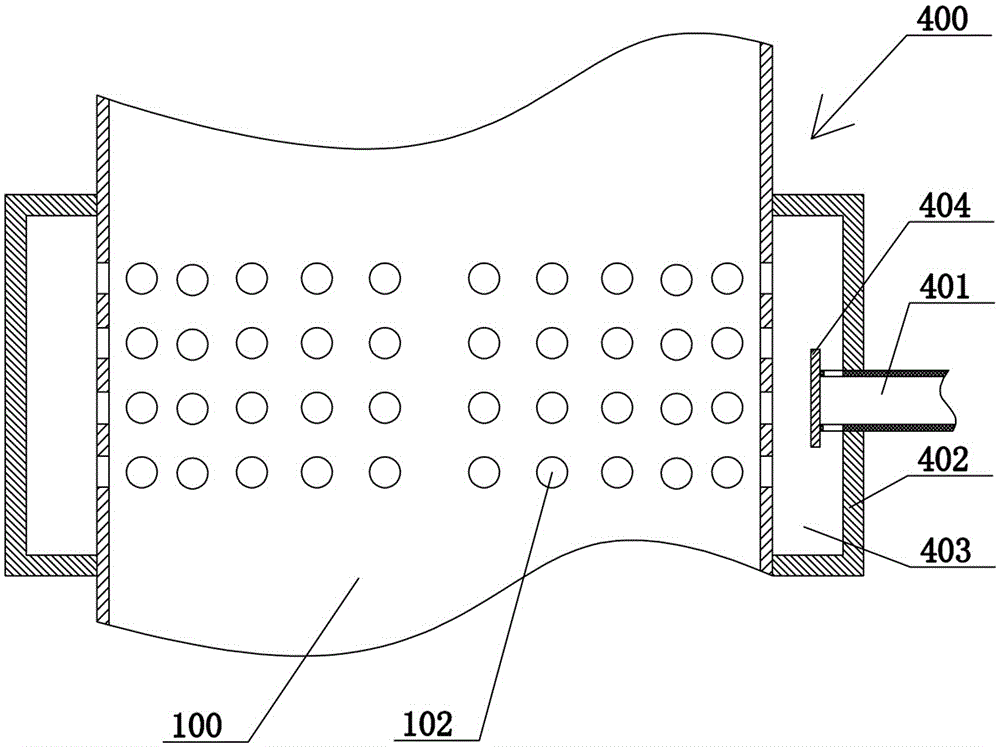

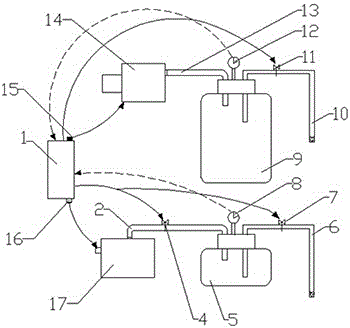

Device and method for treating high-concentration ammonia-nitrogen wastewater in aeration-anaerobic circulation mode

ActiveCN105502657AAvoid inefficienciesAchieve proper oxygenationWater treatment parameter controlTreatment with aerobic and anaerobic processesNitrite nitrogenHigh concentration

The invention discloses a device for treating high-concentration ammonia-nitrogen wastewater in an aeration-anaerobic circulation mode. The device comprises an oxygenating column, a water inlet pump, a sludge reactor and a refluxing tank. An aerator is arranged at the bottom of the oxygenating column, a water distributing pipe is arranged at the bottom of the sludge reactor, oxygen-dissolved wastewater is pumped into the water distributing pipe through the water inlet pump, the refluxing tank is communicated with the oxygenating column, and gas generated by purifying the wastewater pushes the wastewater into the refluxing tank, the wastewater then flows into the oxygenating column to be oxygenated again, and circulating purifying is achieved. According to a wastewater treatment method, the oxygen dissolved in the denitriding process can only be supplied by oxygen dissolved in a water body, accurate supply control over electronic acceptors is achieved, it is guaranteed that ammonia nitrogen can only be converted into nitrite nitrogen, a proper environment is provided for smoothly carrying out the anaerobic ammonia oxidation process in the same reactor, the defect that an original anaerobic ammonia oxidation technology is quite prone to insufficient aeration or excessive aeration is overcome, the electronic acceptors are properly supplied in the denitriding process, and ammonia nitrogen in the wastewater is stably removed.

Owner:BEIJING UNIV OF TECH

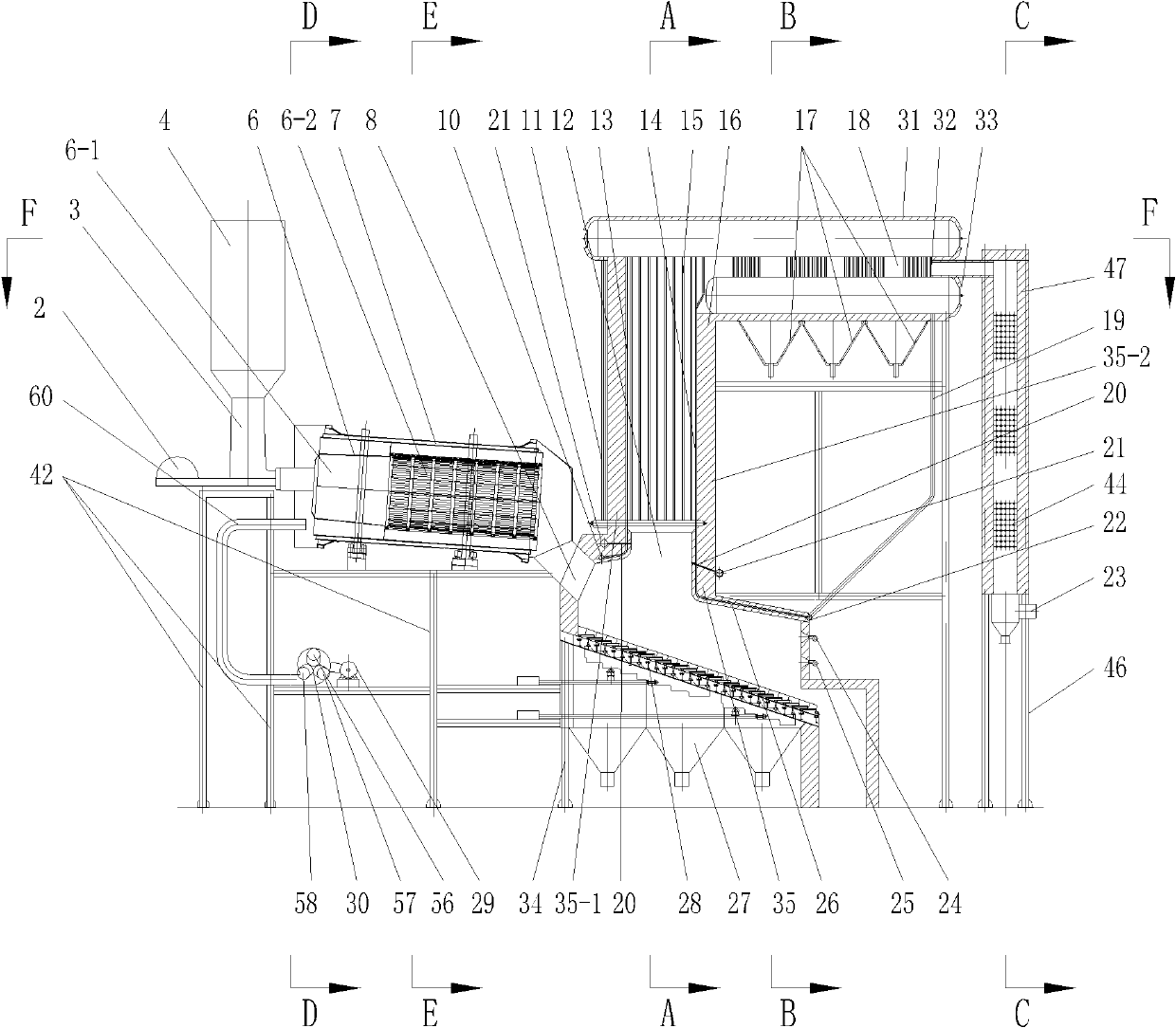

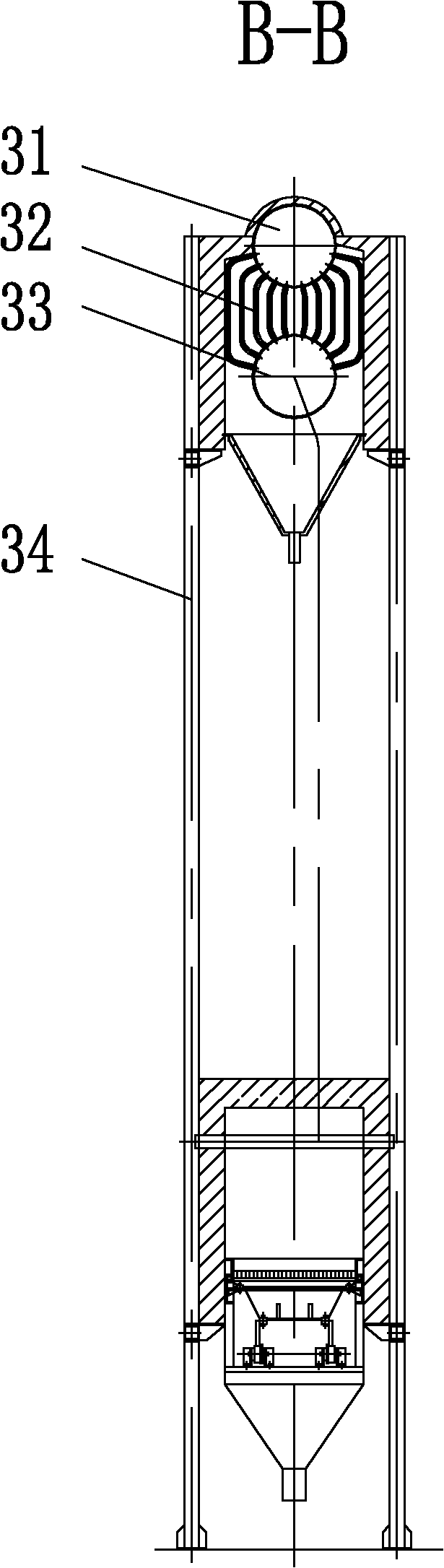

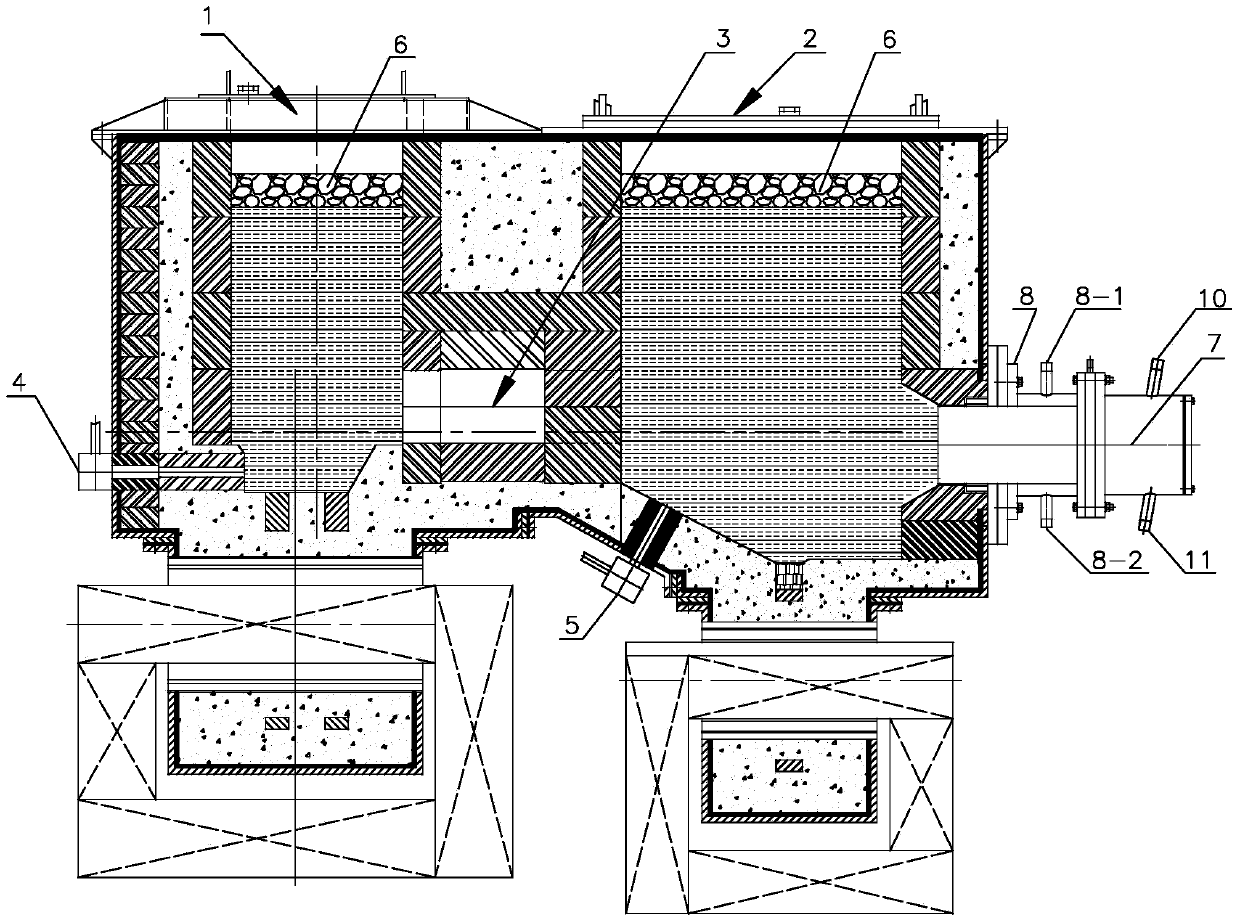

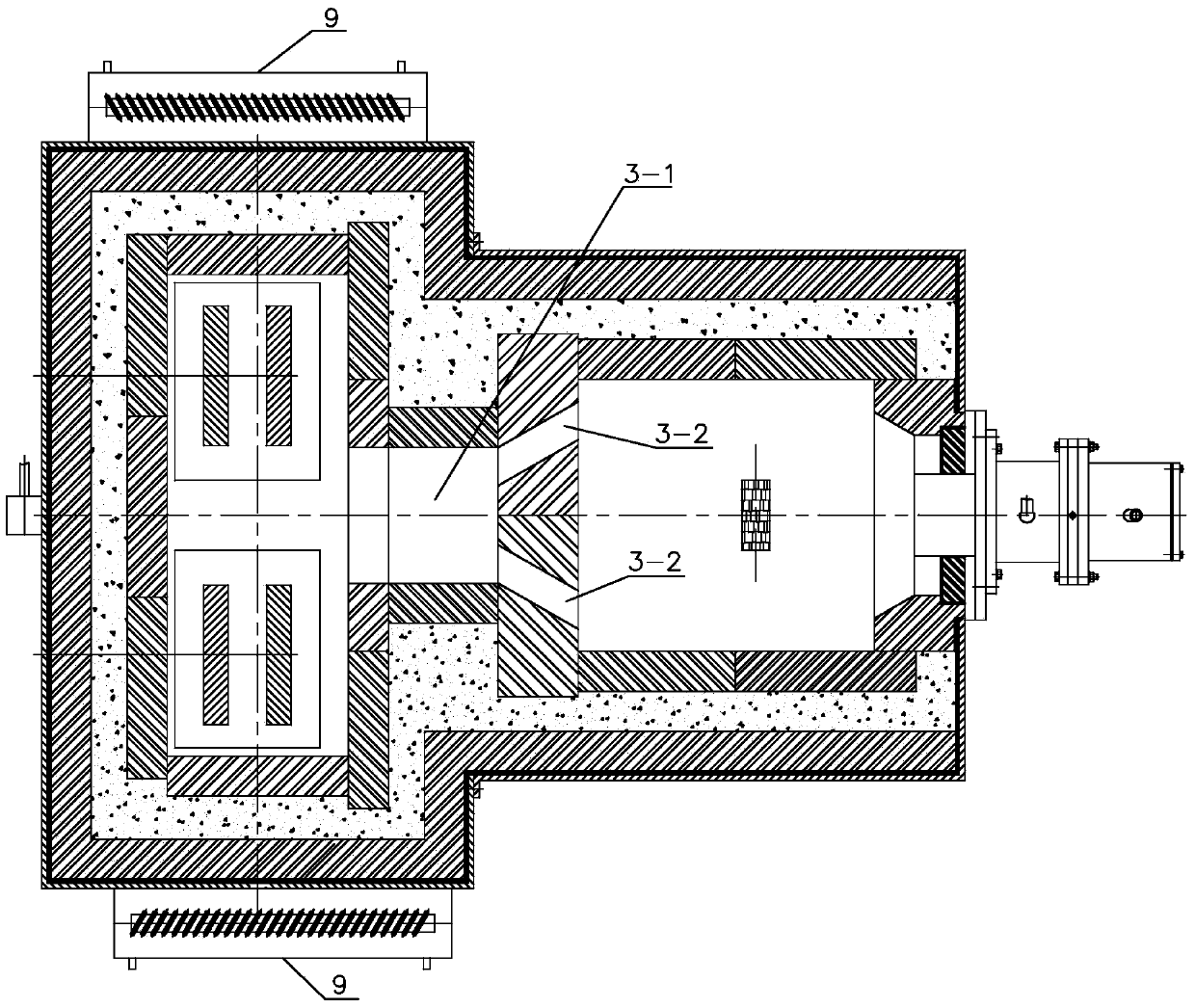

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

Large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process and connected furnace

The invention relates to a large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process. An oxide layer and particles are removed from the standby cathode copper surface, in addition, preheating treatment is carried out, and the preheating temperature is controlled to be 280 DEG C to 300 DEG C; pretreated cathode copper is placed into a smelting furnace to be smelted, the smelting temperature is controlled to be 1180 to 1230 DEG C, inert gas is introduced into the bottom of the smelting furnace, a calcined charcoal layer floats above molten copper to be used as the coverage, and the molten copper is stirred through electromagnetic stirring; then, the smelted molten copper flows into a heat insulation furnace, inert gas is introduced into the bottom of the heat insulation furnace, the calcined charcoal layer floats above molten copper to be used as the coverage, and the temperature inside the heat insulation furnace is controlled to be 1180 to 1230 DEG C; the molten copper in the heat insulation furnace is guided out, a graphite crystallizer is subjected to water cooling, and high-purity oxygen-free copper cast blanks are obtained. The process has the advantages that the oxygen content of the cast blanks can be effectively controlled, the production cost is reduced, products can completely reach TU1 standards, and the yield can reach more than 90 percent.

Owner:JIANGSU XINGRONG MEILE COPPER IND

Vacuum-processing apparatus, vacuum-processing method, and storage medium

ActiveCN104350174AOxygen controlStable resistance valueElectric discharge tubesSolid-state devicesSputteringOxygen

[Problem] To provide a processing apparatus and processing method for stabilizing the resistance value of metal oxide film between substrates when a metal oxide film is formed on a substrate. [Solution] A target (31a) composed of a member for absorbing oxygen and a target (31b) composed of metal are disposed inside a vacuum container (2) capable of plasma sputtering, and a substrate (S) is conveyed into the vacuum chamber (2). The substrate (S) is covered with a cover plate (43), the target (31a) is sputtered and formed into a film inside the vacuum chamber (2), and oxygen inside the vacuum chamber (2) is made to adsorb onto the film. The cover plate (43) is moved from above the substrate S, the target (31b) is sputtered, and a metal film is formed on the substrate (S). The required amount of oxygen is fed from the cover plate (43), which has again been moved over the substrate (S), and a metal film is formed into a metal oxide film. The substrate (2) on which the target (31a) has been sputtered, on which oxygen inside the vacuum container (2) has been adsorbed, and on which a metal oxide film has been formed is conveyed out from the interior of the vacuum container (2).

Owner:TOKYO ELECTRON LTD

Modified grate furnace waste incineration device

ActiveCN105351944AAdjust the temperature reasonablyReasonable adjustment of oxygen contentIncinerator apparatusThermal energyFlue gas

The invention discloses a modified grate furnace waste incineration device. An air vent is formed in the rear arch of a hearth of a waste incineration furnace, is connected with the air chamber of a fire grate at the drying section of an incinerator through a pipeline, and is also connected with an outlet flue of the hearth of the incinerator through the pipeline; the coal economizer outlet of a waste heat boiler joins the pipeline connected with the air vent of the rear arch of the hearth through the pipeline; a circulating fan is further arranged on the pipeline; an air conditioning bypass is arranged at the inlet of the circulating fan. According to the invention, partial hot smoke containing certain content of oxygen at the tail part of the hearth and the partial hot smoke at the outlet of the coal economizer are recycled, so that drying and preheating of waste and disturbance and combustion support of smoke are met, the fed combustion air amount and the total smoke amount can be effectively reduced, the oxygen content of a combustion area is reasonably controlled, improvement of the waste combustion quality is facilitated, improvement of the utilization efficiency of combustion thermal energy is also facilitated, and the content of pollutants in the discharged flue gas is decreased.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

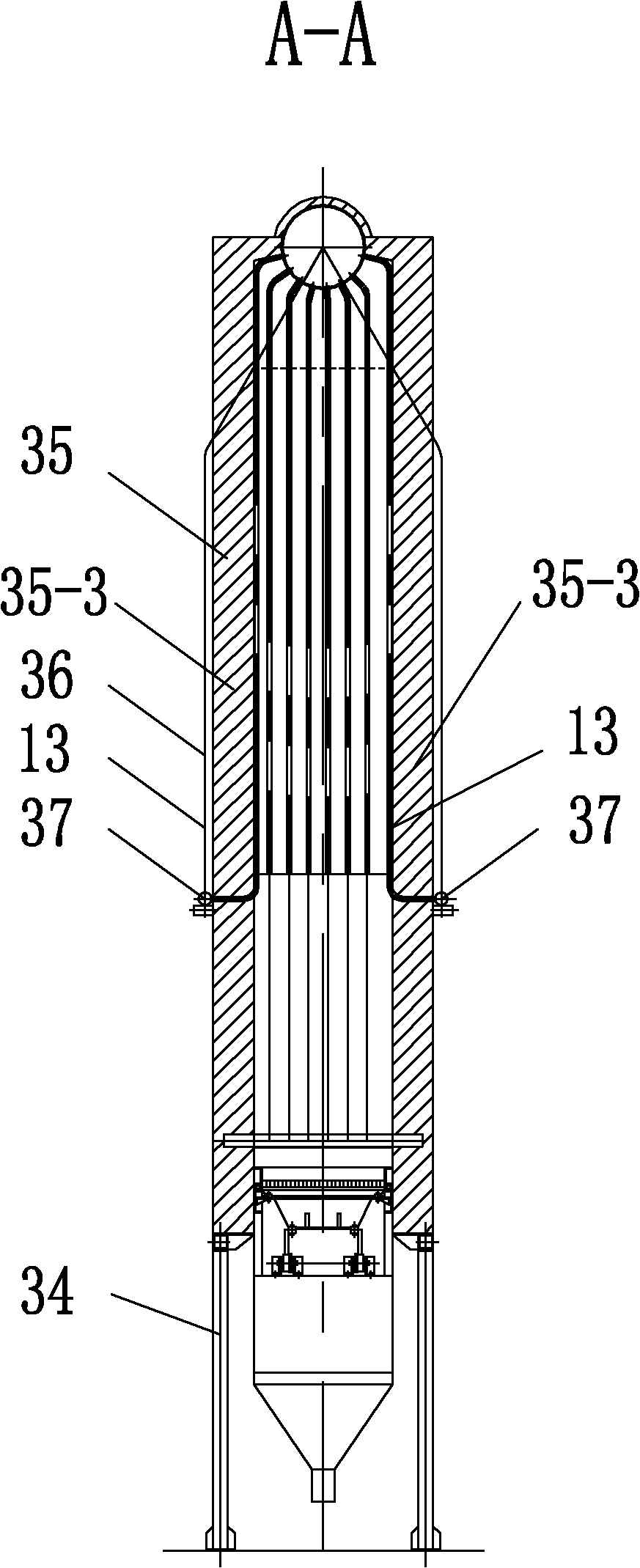

Medium-and-low temperature hot fume powder feeding type coal powder combustion device and combustion process thereof

InactiveCN104180368AShort ignitionReduce heatPulverulent fuel combustion burnersLump/pulverulent fuel feeder/distributionCombustorNitrogen oxides

The invention discloses a medium-and-low temperature hot fume powder feeding type coal powder combustion device and a combustion process thereof. The coal powder combustion device comprises a Roots blower, a fume circulating pipeline, a coal powder mixer composed of an air pipe and a powder feeding pipe and a combustor. The combustor comprises a primary air central pipe, inner secondary air pipes, outer secondary air pipes, a bluff body and a flaring. By the use of the medium-and-low temperature hot fume powder feeding type coal powder combustion device and the combustion process thereof, the problems such as long ignition time, high fuel consumption, poor flame stability and adaptability to different coal types and high NOX (nitrogen oxides) discharge of the coal powder combustor applied to an industrial boiler are solved.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

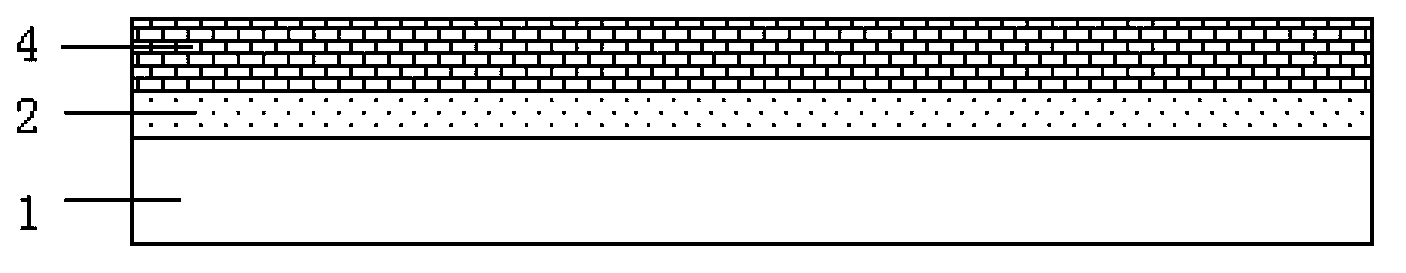

A mold shell for precision casting titanium alloy

The invention discloses a mold shell for precision casting titanium alloy. The mold shell is composed of 1 layer layer, 2 layers of transition layer, 4 layers of reinforcement layer and a sand layer between each layer, wherein the surface layer contains 200-400 Boron nitride powder, the sand layer between the surface layer and the transition layer is fused mullite sand with a particle size of 40-100 mesh; the first transition layer contains 200-400 mesh Y2O3 powder, and the second transition layer Contains 200-400 mesh Al2O3 powder, the sand layer between the first transition layer and the second transition layer and between the second transition layer and the reinforcement layer is fused mullite sand with a particle size of 40-80 mesh; The 4 reinforcement layers all contain bauxite, and the 3 sanding layers between the 4 reinforcement layers are coal gangue sands of 16-24 mesh.

Owner:WUXI HUAYE IRON & STEEL

Method for preparing sintered neodymium iron boron magnets in 3D cold printing mode

ActiveCN109590461AControl oxidationOxygen controlAdditive manufacturing apparatusTransportation and packagingOrganic filmSlurry

The invention provides a method for preparing sintered neodymium iron boron magnets in a 3D cold printing mode and belongs to the field of powder metallurgy. By wrapping the surfaces of neodymium ironboron magnetic powder with layers of oxygen-free organic film, the magnetic powder is prevented from being oxidized in the 3D cold printing process, meanwhile, printing slurry is prepared by adoptinga low-molecular-weight and low-oxygen gelatin system, printing orientation forming of the magnets is achieved through magnetizing, and after isostatic cool pressing and sintering are performed, sintered neodymium iron boron parts in complex shapes are finally obtained. Oxygen-free organic matter is adopted for wrapping the surfaces of the neodymium iron boron powder which is oxidized easily, theoxidation problem of the magnetic powder in the forming process is controlled, the 3D cold printing neodymium iron boron slurry is prepared by adopting the low-molecular-weight and low-oxygen gelationsystem, and the oxygenation situation of the magnets in the forming process are further controlled. The sintered neodymium iron boron magnets prepared through the method provided by the invention have the good magnetic performance, near-net forming of all complex shapes can be achieved, cutting machining of magnet complex parts is omitted, the production cost is greatly lowered, and resources aresaved.

Owner:UNIV OF SCI & TECH BEIJING

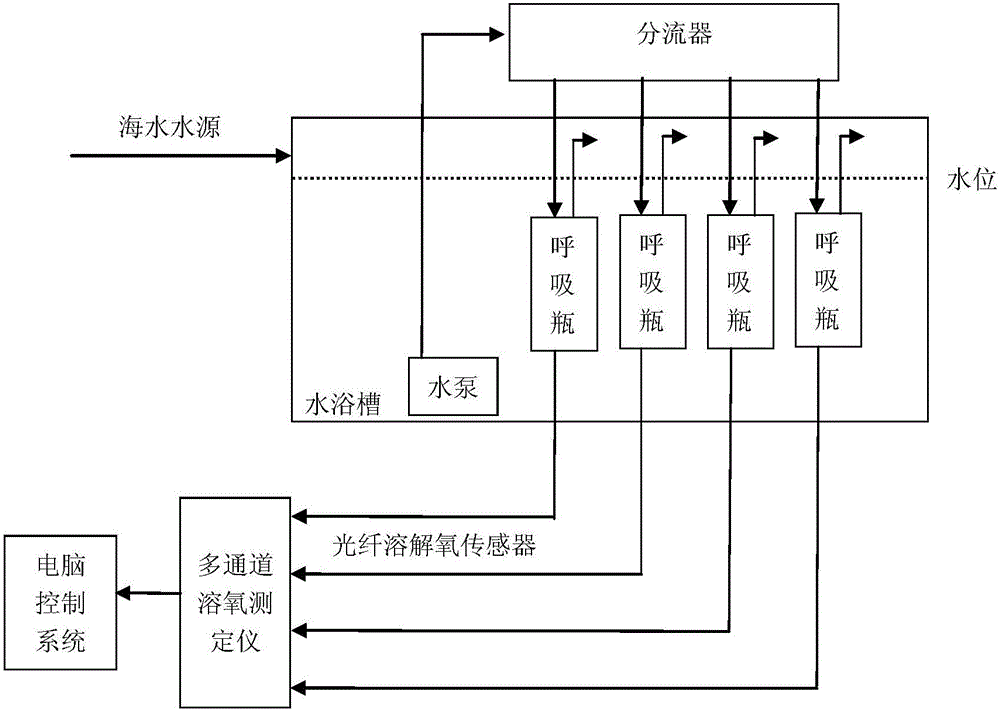

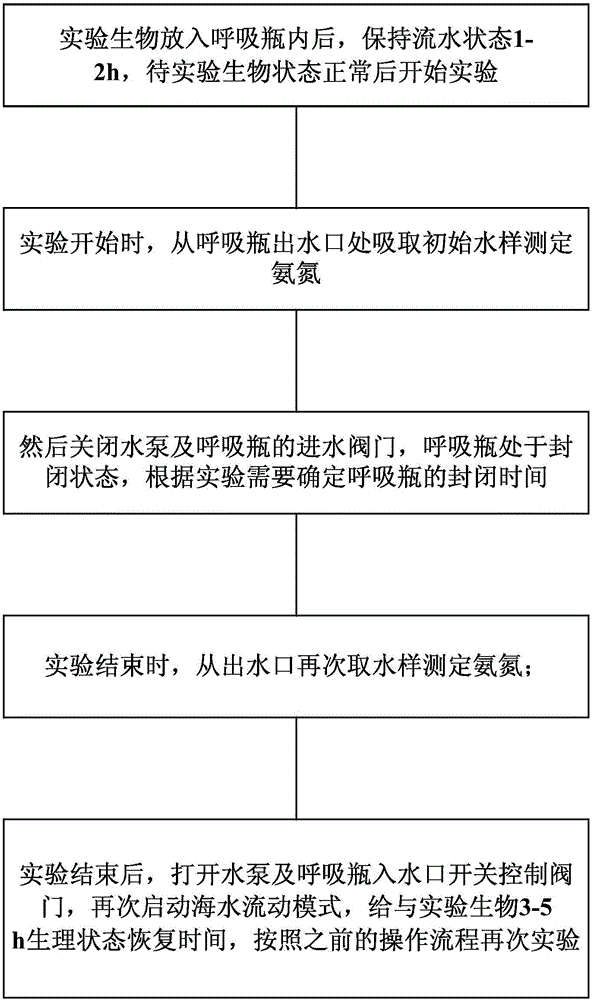

Metabolism physiological measurement system and method for marine organisms

ActiveCN105052784AOxygen controlControl conditionClimate change adaptationPisciculture and aquariaWater bathsEngineering

The invention provides a metabolism physiological measurement system for marine organisms. The metabolism physiological measurement system comprises a water bath tank, a water pump, a splitter, breathing bottles, a water level control pipe, a multichannel dissolved oxygen determinator and a computer control system. According to the metabolism physiological measurement system for the marine organisms, disclosed by the invention, the opening time and the closing time of multiple groups of the breathing bottles are freely controlled under the condition of water bath of on-site water temperature, the accurate control of metabolism physiological experimental conditions such as oxygen consumption and ammonia excretion is realized, a computer acquires the dynamic changes of dissolved oxygen in a real-time manner through optical fiber dissolved oxygen sensors assembled on the breathing bottles, and key physiological metabolism parameters such as an oxygen consumption rate and an ammonia excretion rate are accurately determined.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

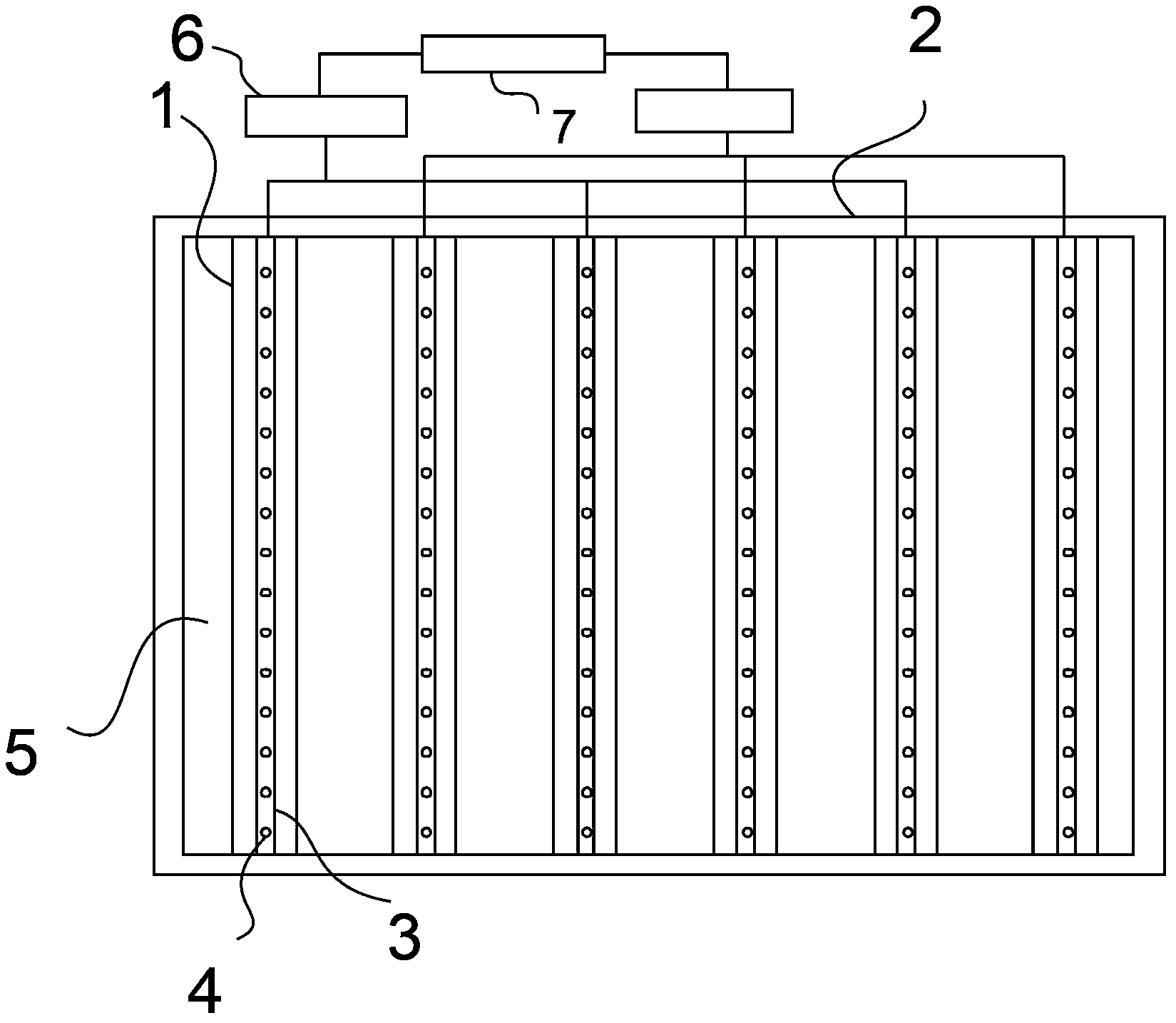

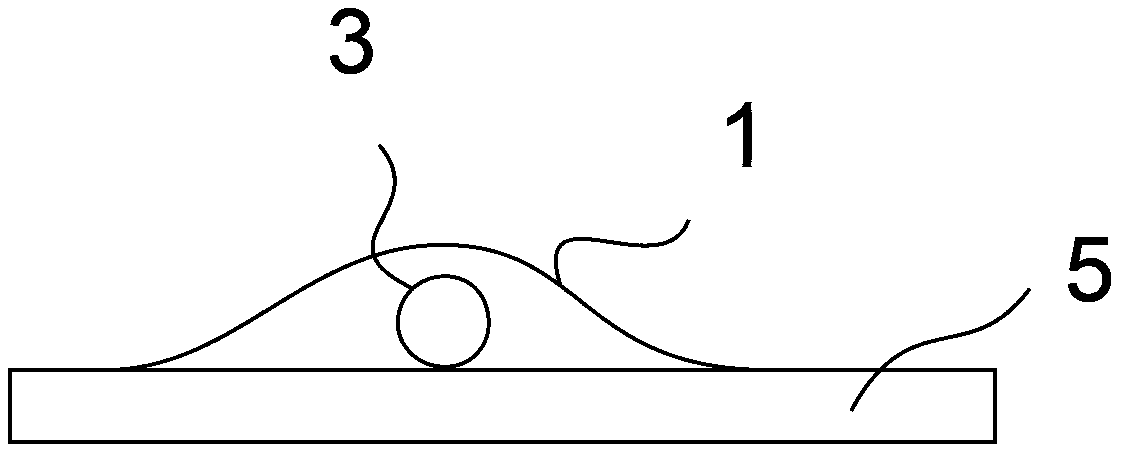

Parallel-line-type oxygen supply system of aquaculture pond

The invention relates to a parallel-line-type oxygen supply system of an aquaculture pond. The parallel-line-type oxygen supply system comprises multiple longitudinally-parallel oxygen supply pipelines, a supporting limiting filter net, two electromagnetic valves and an oxygen pump, the oxygen supply pipelines are arranged at the bottom of the aquaculture pond, the supporting limiting filter net is arranged on the oxygen supply pipelines, the oxygen pump is connected with the electromagnetic valves, multiple ventilation holes are formed in each oxygen supply pipeline along the extending direction, height of the supporting limiting filter net is larger than diameter of each oxygen supply pipeline, and the electromagnetic valves control opening and closing of the oxygen supply pipelines in a spaced manner respectively. The oxygen supply pipelines supply oxygen to the whole aquaculture pond, the supporting limiting filter net effectively prevents deviation of the oxygen supply pipelines and blockage of the ventilation holes of the oxygen supply pipelines, and large-area oxygen supply is realized through control; oxygen supply quantity of the oxygen supply pipelines is controlled by controlling the electromagnetic valves to be opened or closed half or fully, and oxygen is supplied to the aquaculture pond according to different needs. The supporting limiting filter nets and the bottom of the aquaculture pond are in round-corner transition connection, so that difficulty in cleaning of dead corners formed by dirt is avoided.

Owner:TIANJIN SENXIN AQUACULTURE

Vertical gas furnace and melting method for fusing and reducing metal material

The invention provides a vertical gas furnace and a melting method for fusing and reducing a metal material, and relates to the technical field of metal melting. The vertical gas furnace comprises a furnace body (1), burners (2), a first pipeline (21), a second pipeline (22), a main pipeline (20) and a third pipeline (23), wherein the burners (2) are arranged on the side wall of the furnace body (1); the first pipeline (21) and the second pipeline (22) communicate with the burners (2); the main pipeline (20) directly communicates with the burners (2) and communicateswith the first pipeline (21) and the second pipeline (22) separately; the third pipeline (23) communicates with the first pipeline (21); and regulating valves (24) are arranged at positions of connection inlets of the burners (2), the first pipeline (21), the second pipeline (22) and the third pipeline (23) separately. According to the melting method for fusing and reducing the metal material by using the vertical gas furnace, proportions of gas, oxygen and air inside the furnace are controlled accurately, and the temperature of melted iron can reach 1450-1500 DEG C; and the oxidation burning loss of the melted iron is controlled effectively.

Owner:YANTAI SANFENG GAS ENERGY SAVING TECH CO LTD

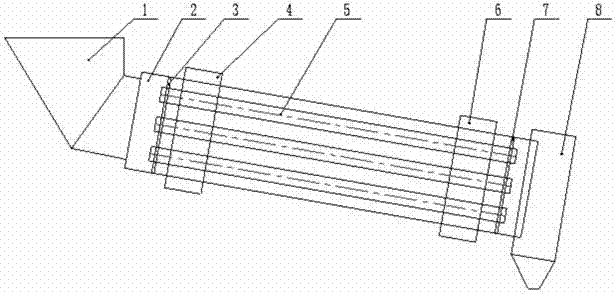

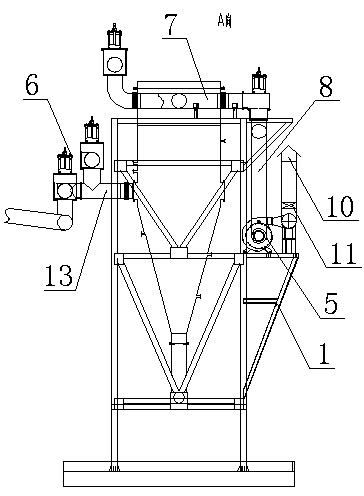

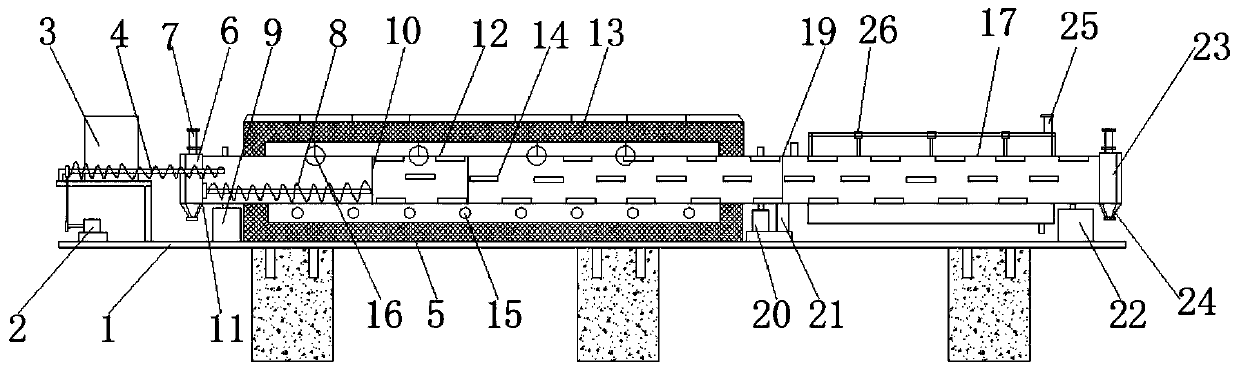

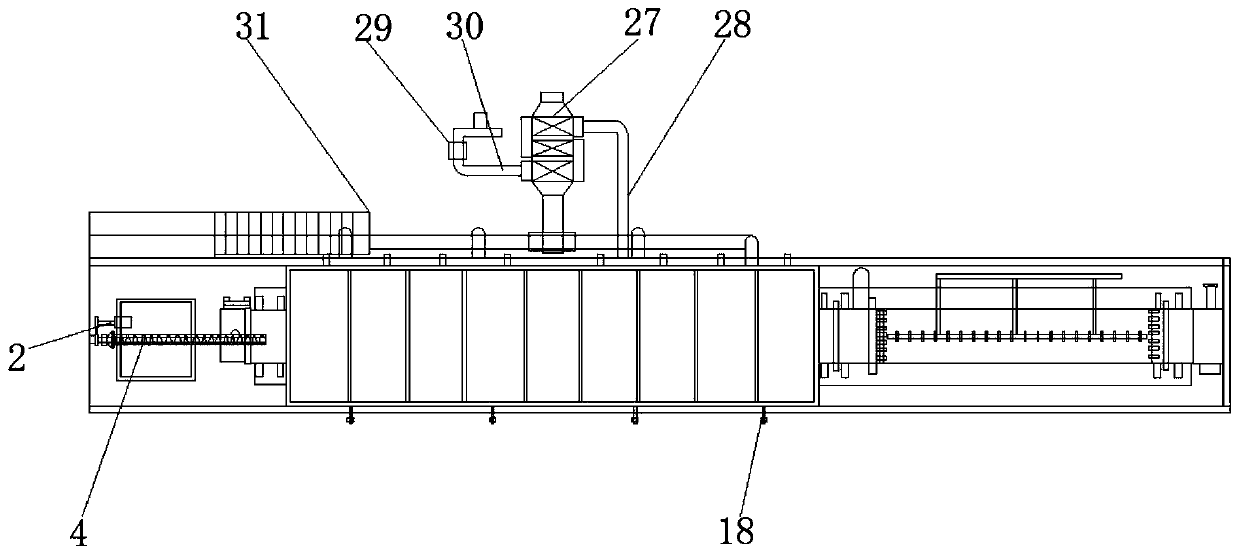

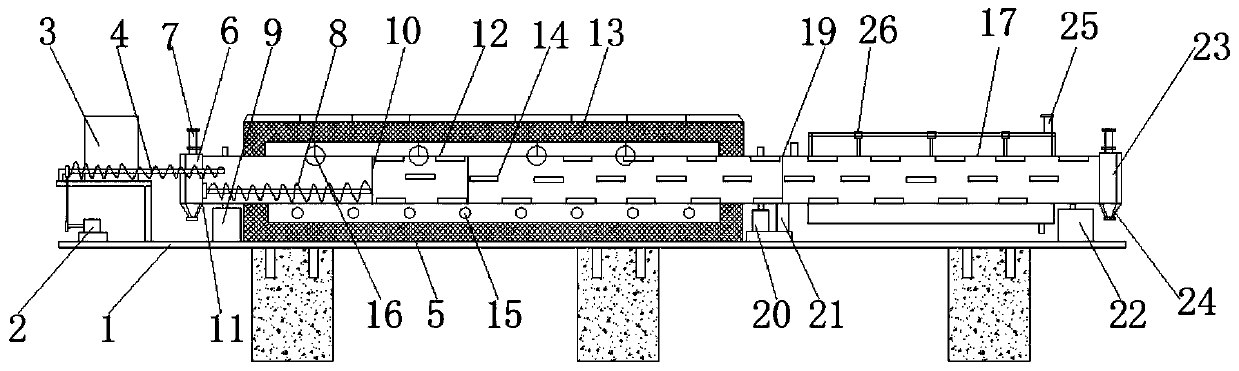

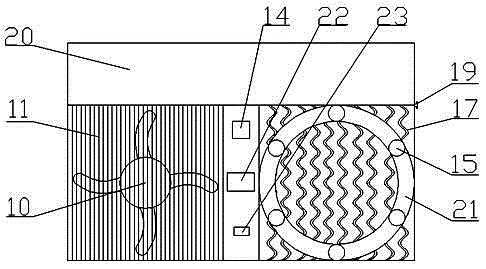

Rotary drum drying device

ActiveCN103591778ASimple structureEasy to operateDrying chambers/containersDrying machines with non-progressive movementsDrum dryingEngineering

The invention discloses a rotary drum drying device which comprises a feed bin, a large rotary drum body, a feed end plate, an air inlet, a plurality of small rotary drum bodies, an air outlet, a discharge end plate and a discharge outlet. The small rotary drum bodies are combined with the large rotary drum body to form a combination. The axis of each small rotary body is parallel with that of the large rotary drum body. The small rotary drum bodies are disposed in the large rotary drum body. The front end and the rear end of the combination are sealed to form a sealed bin. The feed bin is mounted at the front-end extension part of the small rotary drum bodies. The discharge outlet is formed at the rear-end extension part of the small rotary drum bodies. The discharge end plate for controlling discharge amount and timing is disposed between the rear ends of the small rotary drum bodies and the discharge outlet. The rotary drum drying device is simple in structure, easy to operate, and wide in adjustable range, indirect contact drying is used, materials are operated in a slide manner, fume with low oxygen content is used directly, and environment protection requirements are met.

Owner:TANGSHAN SHENZHOU MFG

Preheating process of dust remover for filtering combustible dusty gas

ActiveCN103961955AGuaranteed Safe FiltrationRealize circulating heatingDispersed particle filtrationThermodynamicsProcess engineering

The invention discloses a preheating process of a dust remover for filtering combustible dusty gas. The preheating process comprises a dust remover cold-air exhausting period, a temperature rise period and a gas replacement-adjustment period and specifically comprises the steps of inputting high-temperature gas through a hot air pipeline to exhaust low-temperature gas in the dust remover in the cold-air exhausting period, entering the temperature rise period after the low-temperature gas is exhausted, raising the temperature to 330-1200 DEG C, carrying out gas replacement and adjustment, and entering a conventional filtering-dust removal process link after adjusting the oxygen content in the dust remover to a safety range in the gas replacement-adjustment period. The preheating process is novel and ingenious, has a good utilization effect in a booting preheating link of the dust remover, realizes the innovation of the preheating process of the high-temperature dust remover, is suitable for preheating the dust remover for filtering the high-temperature and high-tar-content dusty gas and guarantees a good filtering effect, long service cycle and high economic benefit of a filter core.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

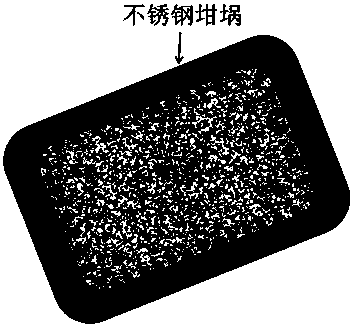

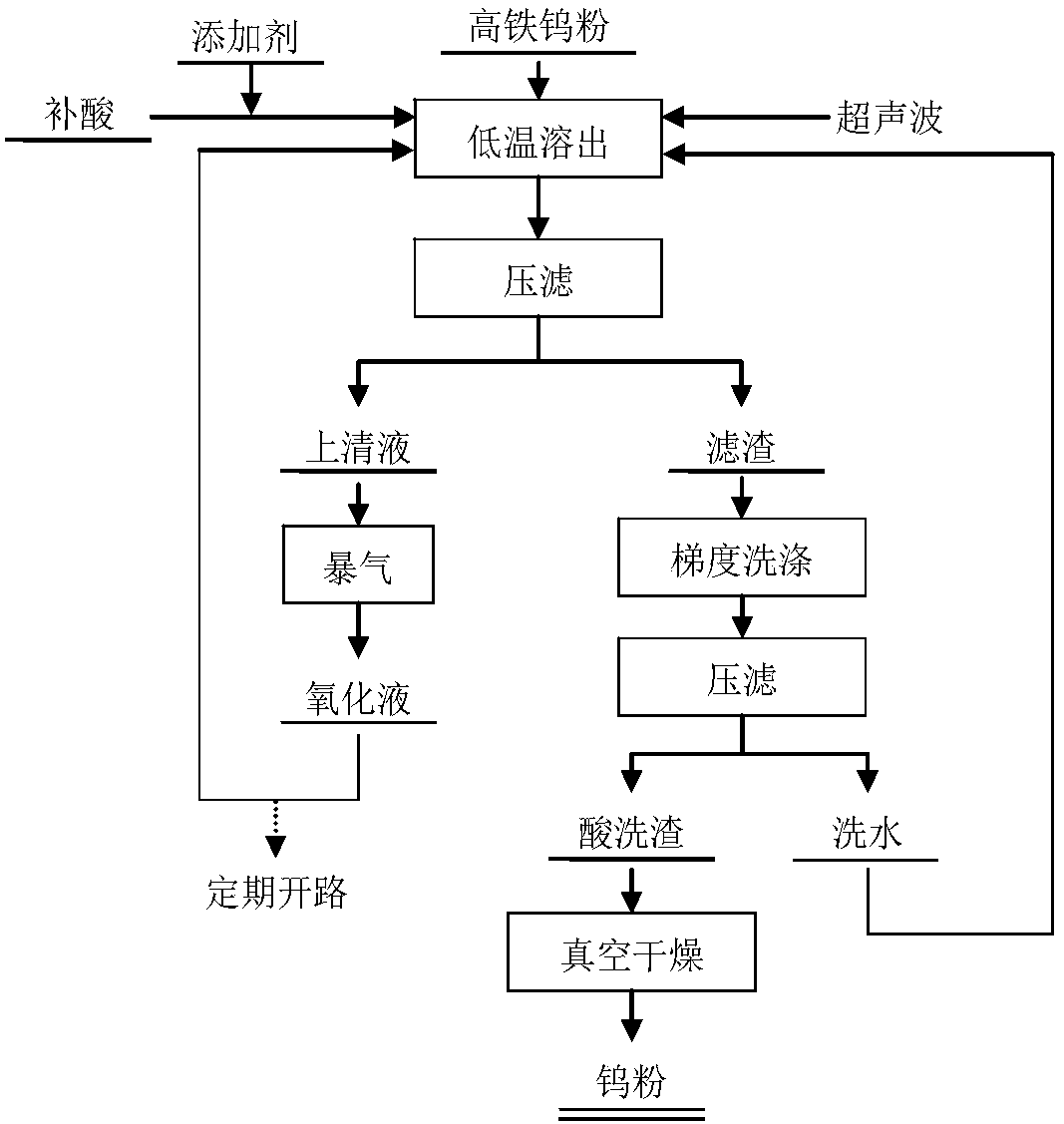

Method for removing iron and regenerating tungsten powder from high-iron reduced tungsten powder

ActiveCN108580879APrevent oxidationOxygen controlTransportation and packagingMetal-working apparatusNonferrous metalIron removal

The invention discloses a method for removing iron and regenerating tungsten powder from high-iron reduced tungsten powder, and belongs to the field of nonferrous metallurgy. The method is characterized in that the high-iron tungsten powder is used as a raw material, and is mixed with an acidic high-valence iron dissolution liquid and an additive, the low-temperature dissolution treatment is carried out at the temperature of 3-15 DEG C under an ultrasonic condition for iron removal, after dissolution, the insoluble tungsten powder and a ferrous dissolution liquid are obtained through separation, the gradient washing treatment is carried out on the insoluble tungsten powder, so that the residual ferrous dissolution liquid is fully washed out, moreover, the phenomenon that the iron is hydrolyzed and is left in the tungsten powder is avoided, and drying and cooling are carried out on the washed wet tungsten powder to obtain a pure tungsten powder product. According to the method, the ironis simply and efficiently removed from high-iron-containing boat charge generated in the tungsten powder reduction process, moreover, purification and regeneration of the tungsten powder are realized, the system water is completely recycled, no waste water and waste residue are discharged, and the method is suitable for the tungsten powder which is at the edge of a boat and generated in various tungsten oxide reduction processes and the tungsten powder product polluted by an iron ware, and has the advantages of being high in raw material adaptability, simple in technological process, thoroughin iron removal, clean and environment-friendly.

Owner:江西翔鹭钨业有限公司

Technology for heat treatment on alloy cold headed steel

InactiveCN102417968AOxygen controlLow costFurnace typesHeat treatment process controlShielding gasDry heat

The invention discloses a technology for heat treatment on alloy cold headed steel. The technology for heat treatment on alloy cold headed steel comprises the following steps of drying the interior of a heat treatment electric furnace at a temperature of 180 to 250 DEG C, putting alloy cold headed steel needing to be treated into the dried heat treatment electric furnace, covering the dried heat treatment electric furnace with a furnace lid, opening a gas outlet, keeping a gas outlet opening state for 1 to 5 minutes, closing the gas outlet, and carrying out heating, heat preservation and cooling processes on the alloy cold headed steel in the heat treatment electric furnace according to a certain heating curve. The technology for heat treatment on alloy cold headed steel does not need anyprotective gas in heat treatment, can control oxygen content in the heat treatment electric furnace, and realizes heating, heat preservation and cooling of the alloy cold headed steel. An alloy cold headed steel wire treated by the technology provided by the invention has the characteristics that an oxygen layer can be fully cleaned up in 15% of hydrochloric acid, wherein cleaning time is 10 minutes; a part which belongs to a semi-decarburized layer and has the thickness below 0.05 millimeters is decarburized fully; a spheroidization rate is above 85%; and the alloy cold headed steel wire fully exceeds JIS standard level II. The technology for heat treatment on alloy cold headed steel needs simple equipment and has a low cost.

Owner:无锡翱天钢丝制品有限公司

Method for improving in-plane uniformity of reliability of SONOS flash device

InactiveCN103633030AIncrease oxygen contentGood oxygen content uniformitySemiconductor/solid-state device manufacturingIn planePartial oxidation

The invention discloses a method for improving the in-plane uniformity of the reliability of a SONOS flash device. The method comprises the following steps: 1) preparing a tunneling oxide layer on a silicon substrate; 2) preparing a silicon nitride layer on the tunneling oxide layer; 3) performing ISSG oxidation on the silicon nitride layer through the RadOx oxidation process to form a silicon oxynitride barrier layer; 4) preparing a silicon nitride trap layer on the silicon oxynitride barrier layer; 5) and performing partial oxidation on the silicon nitride trap layer through the RadOx oxidation process to form a top-layer high-oxygen-containing silicon oxynitride barrier layer. According to the invention, the in-plane uniformity of the reliability of the final SONOS flash device product can be greatly improved; and at the same time, advantages of intuition and convenience can be realized for the control of daily processes.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

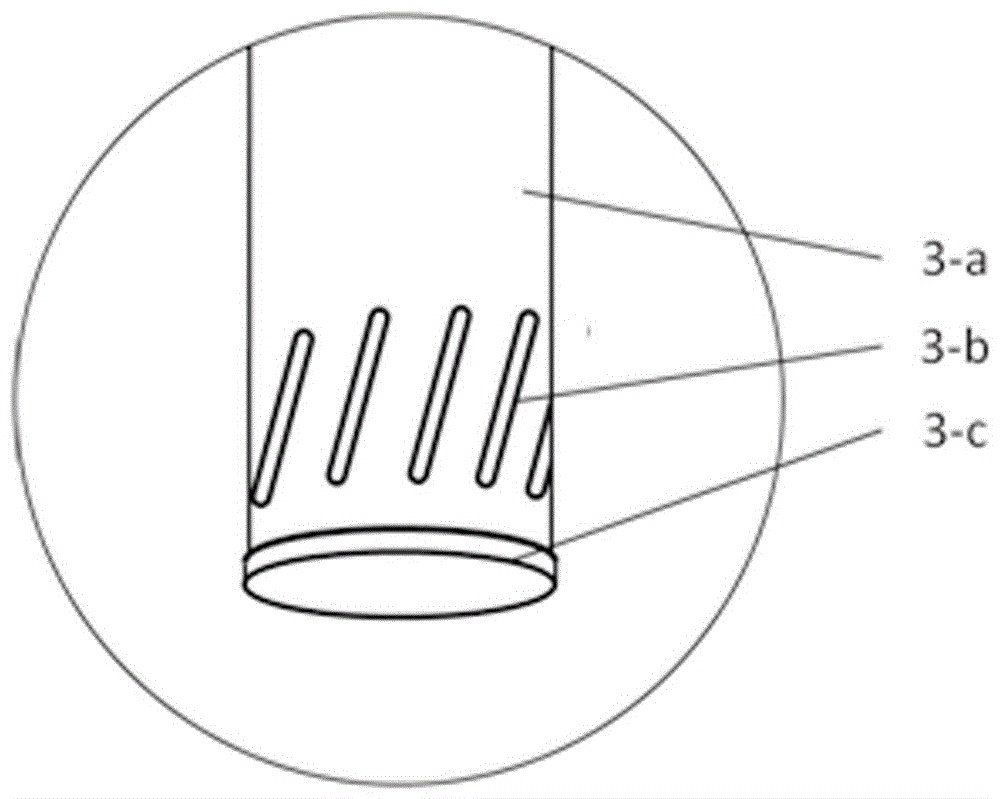

Spinning channel system

InactiveCN105040131AGuaranteed stabilitySmooth full contactArtificial thread manufacturing machinesDry spinning methodsCylindrical channelFiber

The invention belongs to the technical field of spinning devices, and relates to a spinning channel system. The spinning channel system comprises a cylindrical channel body, an upper air feed mechanism, a flow correcting mechanism, a main air return mechanism, an auxiliary air return mechanism and a bottom air return mechanism. The upper air feed mechanism and the flow correcting mechanism are arranged at the top of the cylindrical channel body, and the upper air feed mechanism is arranged on the periphery of the flow correcting mechanism; the main air return mechanism is fixedly arranged in the middle of the cylindrical channel body and located between the upper air feed mechanism and the auxiliary air return mechanism; the auxiliary air return mechanism is arranged on the lower portion of the cylindrical channel body and located above the bottom air return mechanism; the bottom air return mechanism is arranged at the bottom of the cylindrical channel body. While increasing the air volume of the channel, the spinning channel system ensures stability of airflow, so that the character of final spandex fiber finished products tends to be stable, and product differentiation is reduced.

Owner:ZHEJIANG BAOLIAN FIBER SCI & TECH CO LTD

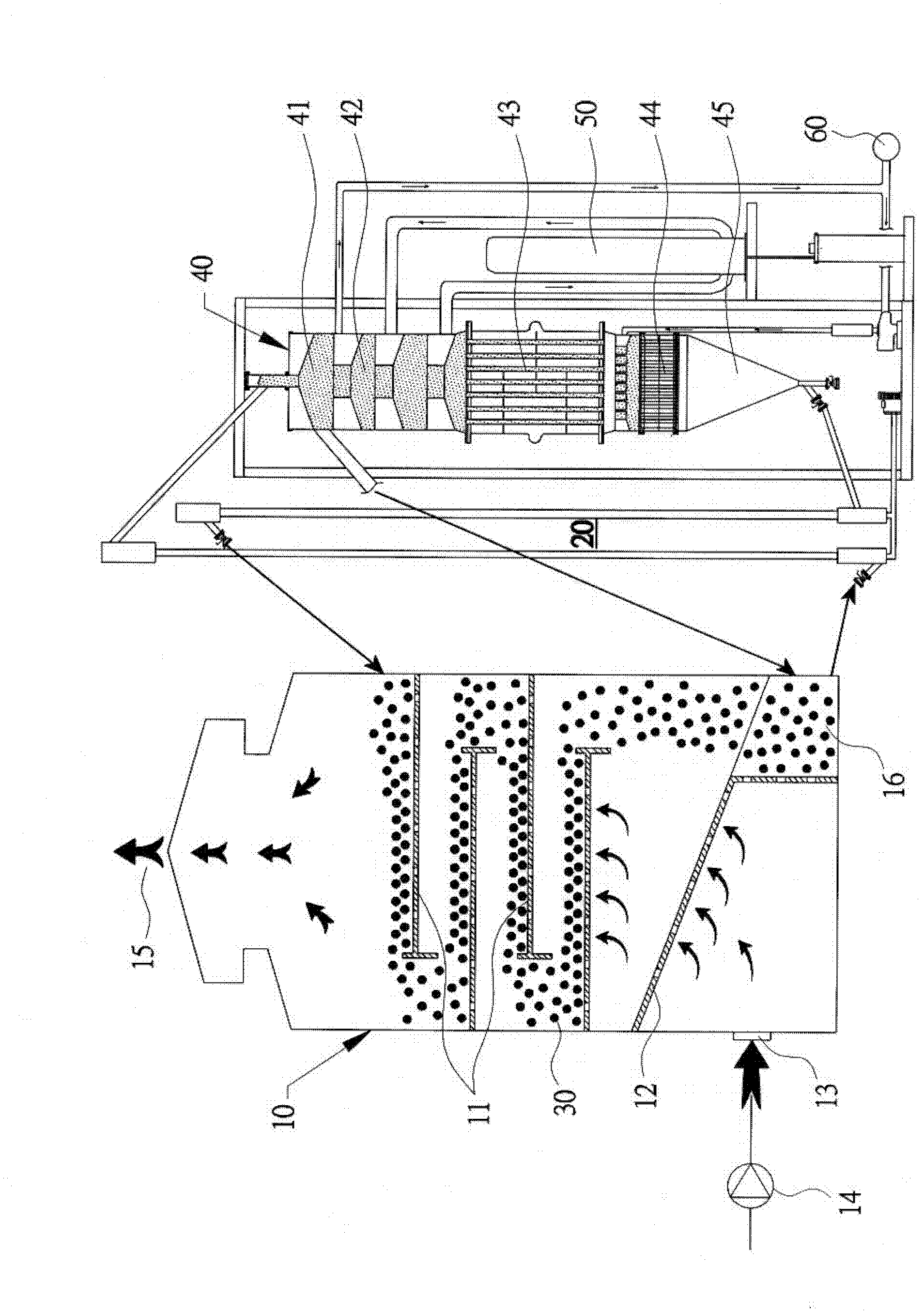

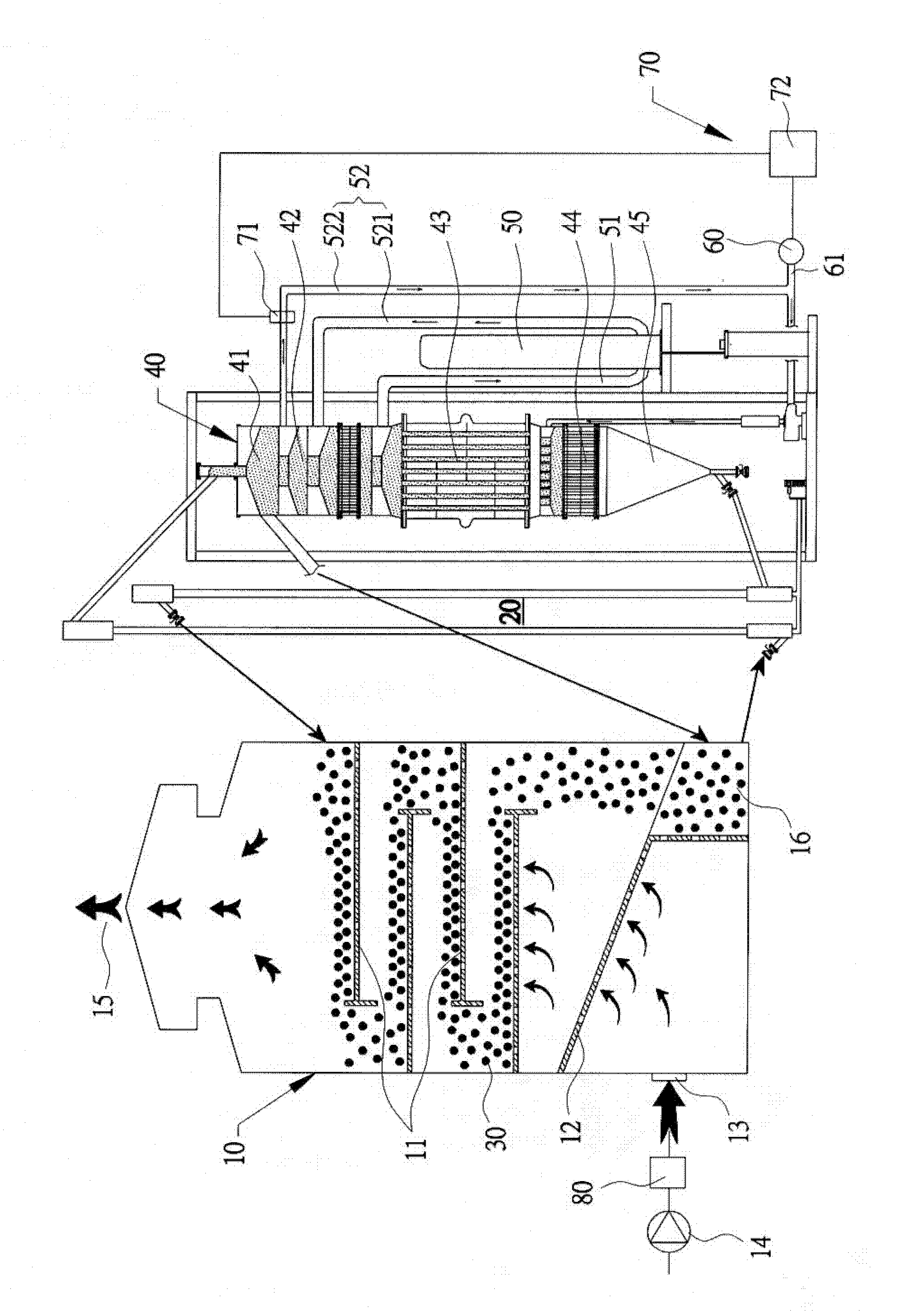

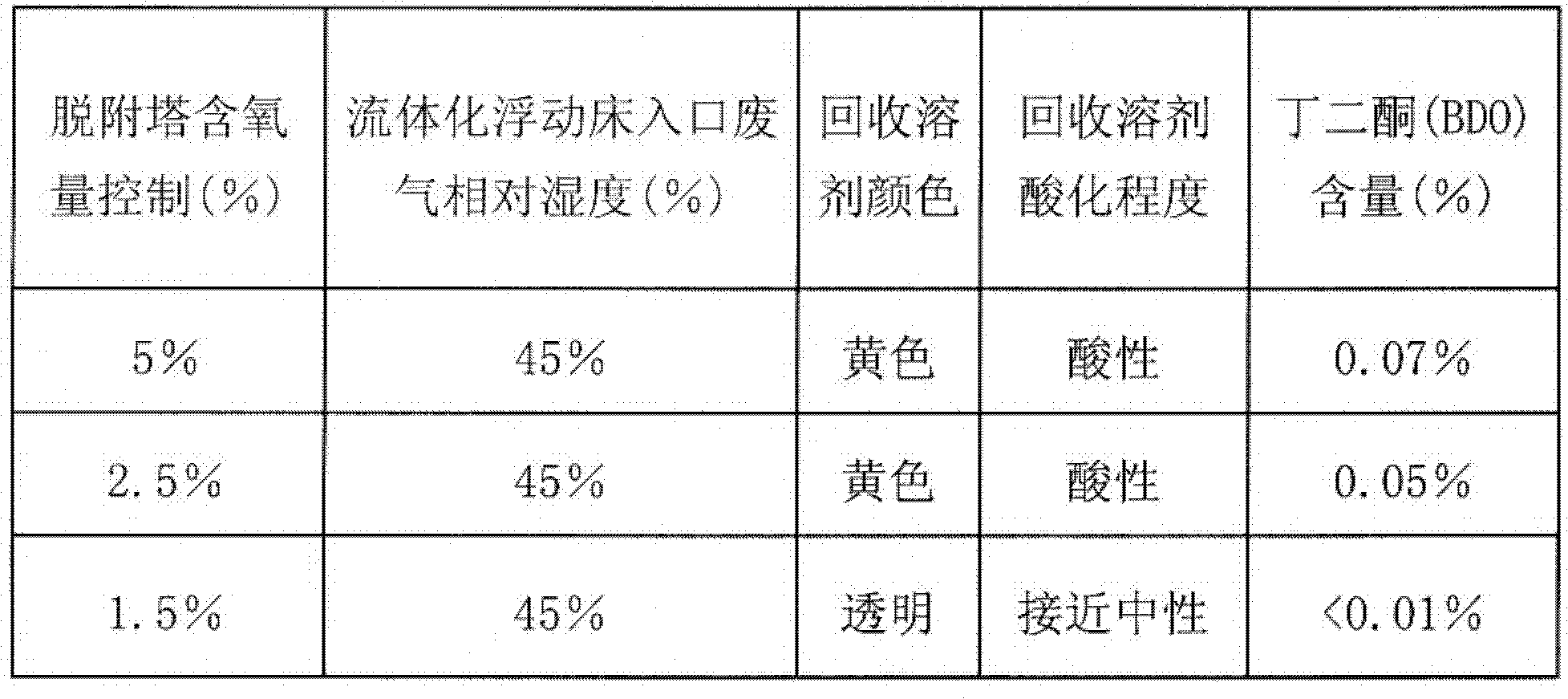

Organic solvent recovery apparatus for increasing recovery quality, method and uses thereof

ActiveCN103007684AImprove recycling qualityOxygen controlDispersed particle separationVapor condensationSolventEnvironmental chemistry

The invention relates to an organic solvent recovery apparatus for increasing recovery quality, a method and uses thereof. The recovery method comprises: an absorption process, wherein an absorption material is adopted to absorb organic waste gas; a desorption process, wherein a desorption air stream is adopted to desorb the organic waste gas absorbed by the absorption material; an oxygen content control process, wherein an oxygen content of the air stream during desorption or after desorption is maintained to less than 1.5%, more preferably less than 0.5%; and a condensation recovery process, wherein high concentration organic gas in the desorbed air stream is subjected to condensation recovery. According to the apparatus and the method, the efficacy that the oxygen content of the desorption process is controlled so as to increase solvent recovery quality is provided.

Owner:JG ENVIRONMENTAL TECH

Method for preparing titanium alloy mold shell

InactiveCN107695283AEnsure the firmness of the bondLow costFoundry mouldsMoulding machinesCeramicTitanium dioxide

The invention discloses a method for preparing a titanium alloy mold shell. The method for preparing the titanium alloy mold shell comprises the steps that firstly, titanium dioxide sol is prepared and serves as a binder, then is mixed with boron nitride powder and Al2O3 powder and slurry is prepared for manufacturing the titanium alloy mold shell, finally, dewaxing and sintering are conducted, and the environment-friendly titanium alloy mold shell with good stability is obtained. According to the method for preparing the titanium alloy mold shell, boron nitride is used as a surface layer, Y2O3 and Al2O3 are used as a transition layer, electro-melting mullite is used as a stuccoing layer, combination firmness of the surface layer and the back layer is ensured, selection and combination ofkinds of ceramics solve the problems of low precision, poor stability and existing of certain harm in existing titanium alloy mold shell preparing, and the cost is low.

Owner:BAOJI YONGSHENGTAI TITANIUM IND

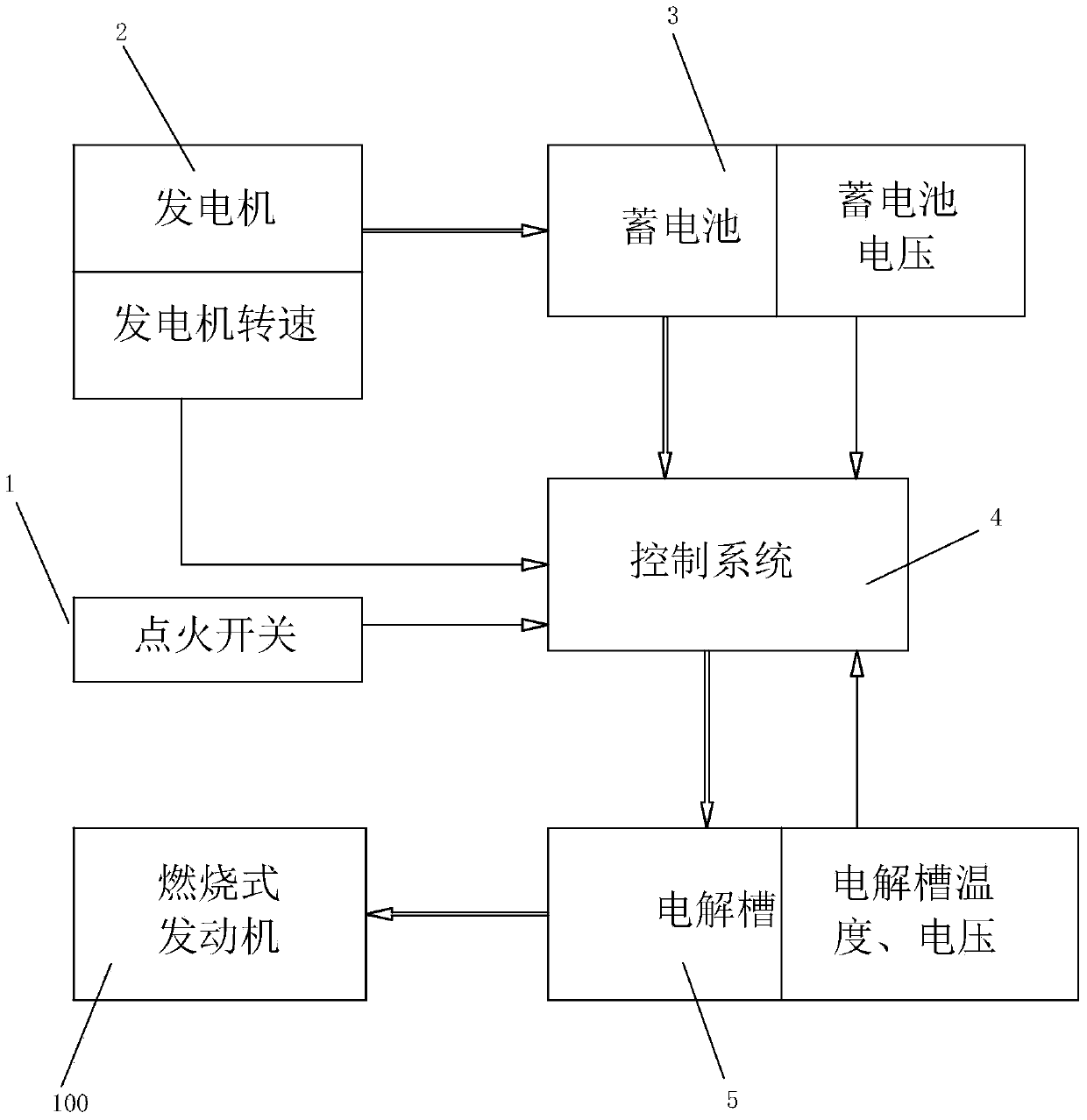

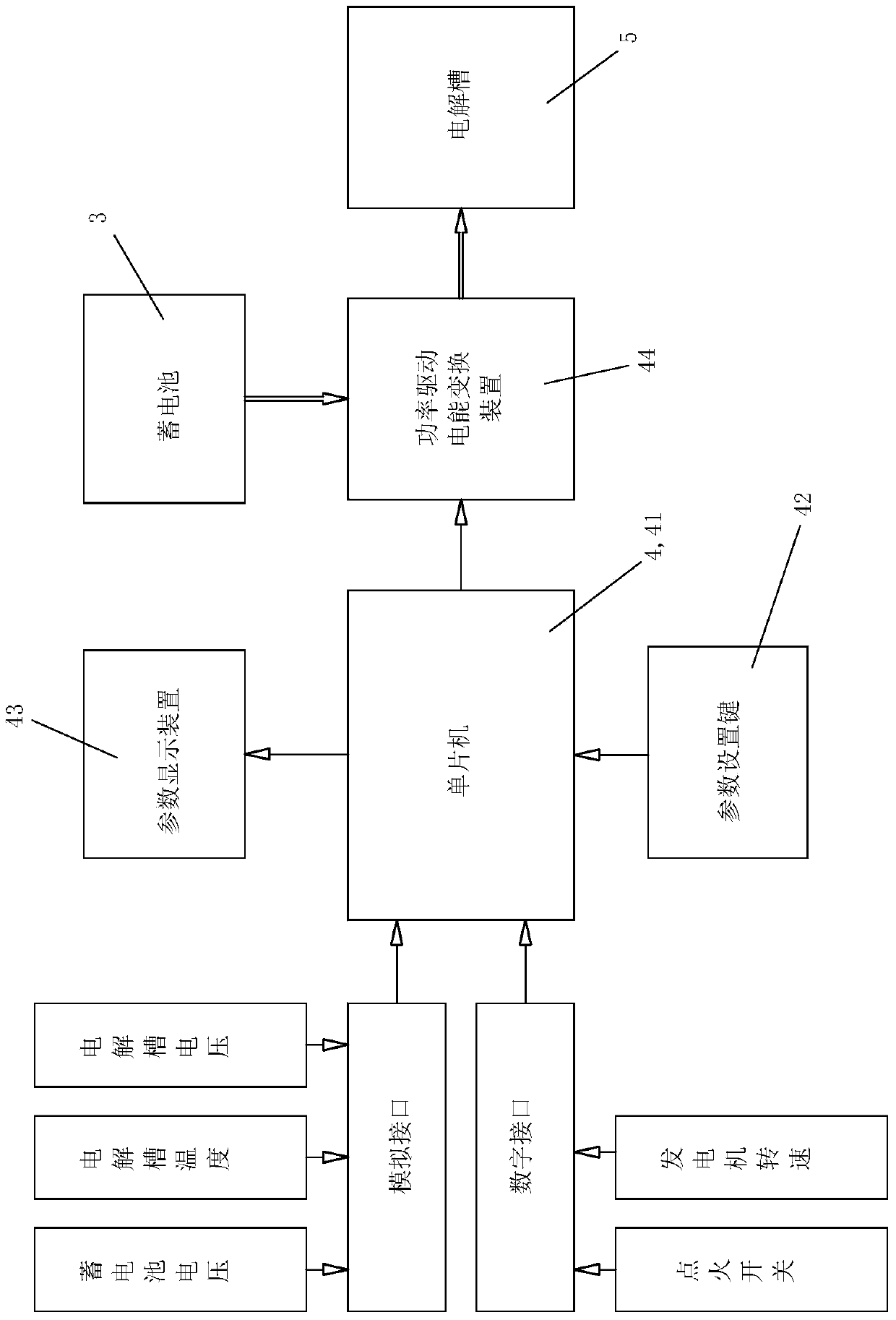

Auxiliary device for combustion engine

InactiveCN104196654AImprove work efficiencySimple structureElectrolysis componentsNon-fuel substance addition to fuelMicrocontrollerElectricity

The invention discloses an auxiliary device for a combustion engine. The auxiliary device is characterized by comprising an ignition switch, a power generator, a storage battery, a control system, an electrolytic tank and electrolyte. The control system comprises a single chip microcomputer, a parameter setting key, a parameter display device and a power-drive electric energy conversion device. The parameter setting key is in electric signal connection with the single chip microcomputer. The single chip microcomputer is in electric signal connection with the parameter display device. The single chip microcomputer is in electric signal connection with the power-drive electric energy conversion device. The ignition switch is connected with the single chip microcomputer of the control system by a digital interface. A rotational speed sensor is arranged in the power generator and is connected with the single chip microcomputer of the control system by the digital interface. An anode and a cathode are arranged in the electrolytic tank. A gas outlet is formed in the electrolytic tank and is communicated with a gas inlet pipeline of the combustion engine via a corresponding pipeline. A positive pole and a negative pole of the storage battery are respectively electrically connected with the anode and the cathode of the electrolytic tank by the power-drive electric energy conversion device of the control system.

Owner:曹鉴清

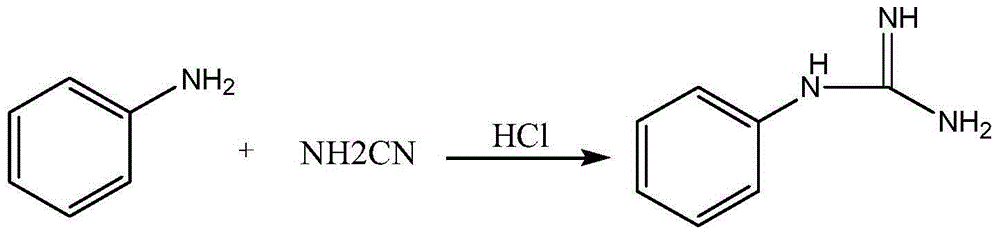

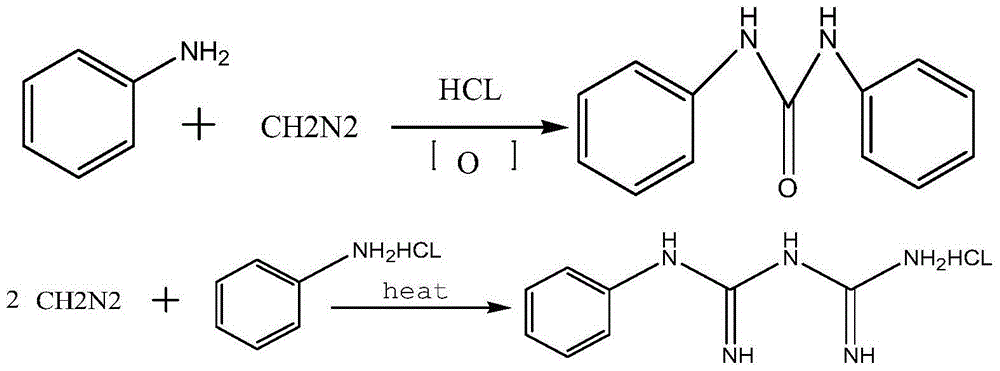

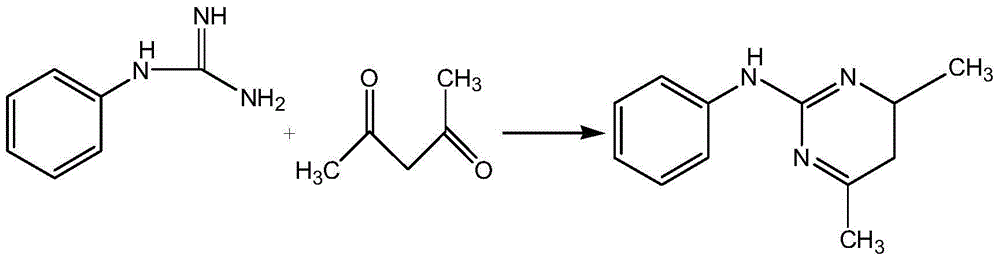

Preparation method of high-purity pyrimethanil and equipment used for preparing high-purity pyrimethanil

The invention discloses a preparation method of high-purity pyrimethanil. The method comprises the following steps: by taking phenylamine, hydrochloric acid, hydrogen cyanamide, sodium carbonate and acetylacetone as raw materials, charging nitrogen to protect during the whole process, adding hydrochloric acid and hydrogen cyanamide twice respectively, and strictly controlling the molar amount of hydrochloric acid to synthesize phenylguanidine carbonate; carrying out cyclization dehydration on the obtained phenylguanidine carbonate and acetyl benzophenone to prepare pyrimethanil. The invention further discloses equipment for preparing high-purity pyrimethanil by using the preparation method of high-purity pyrimethanil.

Owner:利民化学有限责任公司

A preheating process of dust collector for filtering combustible dust-laden gas

ActiveCN103961955BGuaranteed Safe FiltrationRealize circulating heatingDispersed particle filtrationCold airThermodynamics

The invention discloses a dust collector preheating process for filtering combustible dust-containing gas, which includes a cold air discharge stage, a temperature rise stage and a gas replacement adjustment stage of the dust collector. The low-temperature gas in the device enters the heating stage after the low-temperature gas is discharged, and the temperature is raised to 330-1200°C for gas replacement adjustment. After the gas replacement adjustment stage adjusts the oxygen content in the dust collector to a safe range, it enters the conventional filtration and dust removal process. The invention is novel and ingenious in design, has a good effect in the preheating link of the dust collector, realizes the innovation of the preheating process of the high temperature dust collector, and is suitable for preheating the dust collector for filtering dusty gas with high temperature and high tar content, ensuring The filter element has good filtering effect, long service life and high economic benefit.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

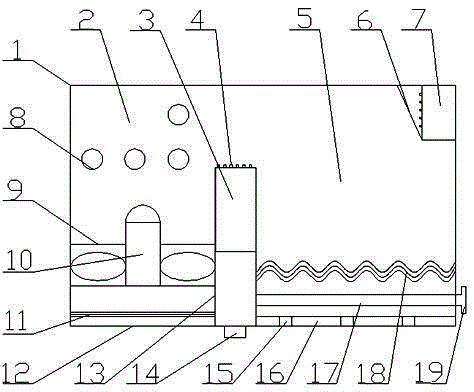

Low-temperature environment-friendly carbonization device for recycling waste lithium ion batteries

InactiveCN111153397AAccurate temperature controlOxygen controlWaste accumulators reclaimingCarbon preparation/purificationTemperature controlHazardous substance

The invention provides a low-temperature environment-friendly carbonization device for recycling waste lithium ion batteries, and relates to the field of solid waste recycling. The low-temperature environment-friendly carbonization device for recycling waste lithium ion batteries comprises a base. The upper surface of the base is fixedly connected with a heating furnace body. One side of the heating furnace body is fixedly connected with a feeding sealing box. A furnace tube inner screw is fixedly connected to the end, close to the feeding sealing box, in the heating furnace body. A spiral check ring is arranged at the end, away from the feeding sealing box, of the furnace tube inner screw. A rotary roasting body is arranged in the heating furnace body and located on one side of the furnace tube inner screw. Through reasonable structural design, the device is higher in heat energy utilization rate and more accurate in temperature control. A material inlet and a material outlet adopt amaterial accumulation sealing mode, so that the oxygen content in the equipment can be effectively controlled, the oxidation degree of copper and aluminum is reduced, and the recovery rate of valuablesubstances is further greatly improved. Useless organic substances are subjected to carbonization treatment, and harmful substances are reduced.

Owner:江苏鼎健环保科技有限公司

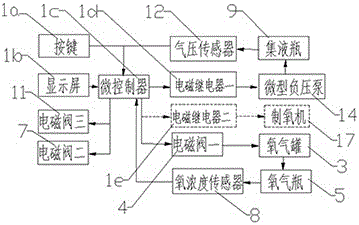

Negative-pressure oxygen-carrying wound treatment device

InactiveCN105920685APromote formationPromote recoveryBathing devicesIntravenous devicesOxygen deliveryEngineering

The invention provides a negative-pressure oxygen-carrying wound treatment device, and belongs to the field of medical apparatus. The wound treatment device disclosed by the invention is provided with a control module, as well as oxygen production equipment and an oxygen delivery pipe which are sequentially connected, and negative-pressure equipment, a negative-pressure tube, a liquid collection bottle and a drainage tube which are sequentially connected. An oxygen production control end is arranged on the control module for controlling the oxygen production equipment and a negative-pressure control end is arranged on the control module for controlling the negative-pressure equipment; and an oxygen bottle, which is provided with an oxygen concentration sensor, is arranged for regulating and controlling an oxygen concentration supplied to a wound and an air pressure sensor is arranged for regulating and controlling a negative-pressure vacuum degree supplied to the wound. The wound treatment device disclosed by the invention has a function of alternately supplying negative pressure and oxygen to the wound, so that a clinical working efficiency is improved and the disease recovery of a patient is promoted; and the wound treatment device has the characteristics of simple structure, good using effect and broad application scope to occasions.

Owner:ZHENDE MEDICAL CO LTD

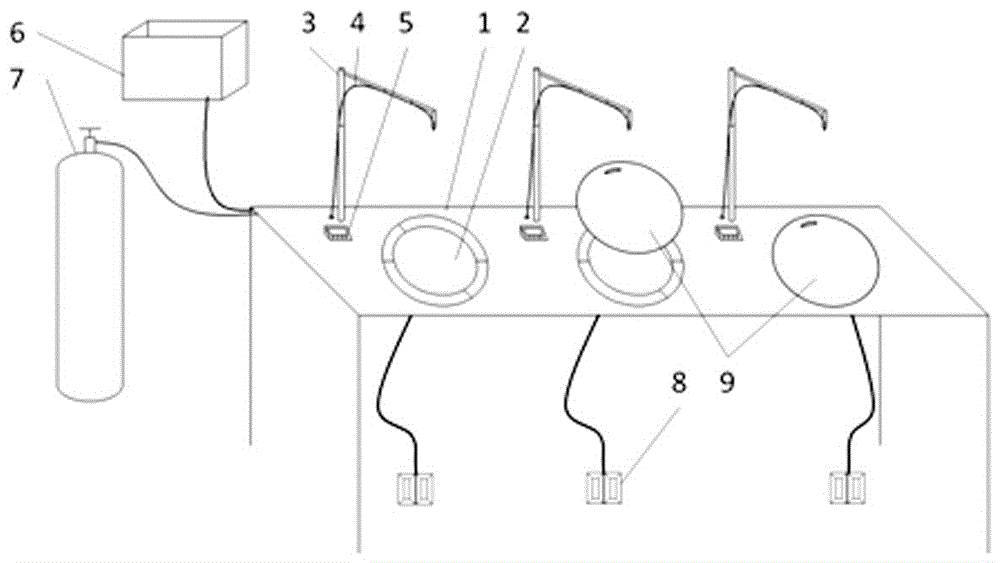

Aquatic product seedling watering, oxygenating and packaging work table

InactiveCN106508776AAvoid harmSimple and strong structurePisciculture and aquariaWrapper twisting/gatheringWater storageAquatic product

The invention aims at providing an aquatic product seedling watering, oxygenating and packaging work table, and belongs to the technical field of aquatic product machines. The structure of the aquatic product seedling watering, oxygenating and packaging work table comprises a workbench main body formed by supporting a table top through feet, a hole is formed in the table top, an electronic platform scale is erected in the hole, and a display screen, displaying the weight, of the electronic platform scale is arranged on the table top; a water pipe is erected on the table top, the water outlet end of the water pipe is located over the platform scale, and the water inlet end of the water pipe is connected with a water pump or arranged on water storage equipment located at a high position; the table top is further provided with a gas pipe which is arranged along the water pipe and bound on the water pipe, the gas outlet end of the gas pipe and the water outlet end of the water pipe are bound to the same position, and the gas inlet end of the gas pipe is connected with an oxygen bottle. According to the aquatic product seedling watering, oxygenating and packaging work table, line production cooperation is convenient, the packaging effect is guaranteed while the labor intensity and the requirements on worker experience are reduced, damage to aquatic product seedlings in the packaging process is avoided, and the very good practicability and applicability to multiple kinds of seedling fields or seedlings are achieved.

Owner:BEIHAI YISHENGYUAN AGRI TRADE CO LTD

Air purifier for livestock breeding

InactiveCN105258234AQuality improvementIncrease humidityLighting and heating apparatusSpace heating and ventilation detailsUltravioletAir blower

The invention discloses an air purifier for livestock breeding. The air purifier comprises a shell, a left air purification chamber, an aerator, ultraviolet sterilization lamps, an air blower, an air inlet, separation plates, medicine dispersing openings, a water curtain, electric heating wires, a water tank and an air humidifier. The water tank is arranged on the upper portion of the shell. A filter screen is fixed between the air inlet and the air blower. The air blower and the shell are fixedly connected through a supporting frame. The ultraviolet sterilization lamps are fixedly connected with the shell. The air humidifier is mounted between the two separation plates. An air humidifier switch is arranged between a motor switch and an electric heating wire switch. The aerator is arranged on the right upper portion of the shell. The water curtain is fixedly mounted between the electric heating wires and an air outlet. The water curtain and a throttling valve penetrate the shell to be fixedly connected. The medicine dispersing openings are evenly distributed in a fixator. The filter screen is used for filtering air, two air purification chambers are used for purifying air, and powdery medicine is placed in the medicine dispersing openings, so that disease propagation is reduced, and air quality is improved.

Owner:LEIYANG XINGNONG ANIMAL HUSBANDRY CO LTD

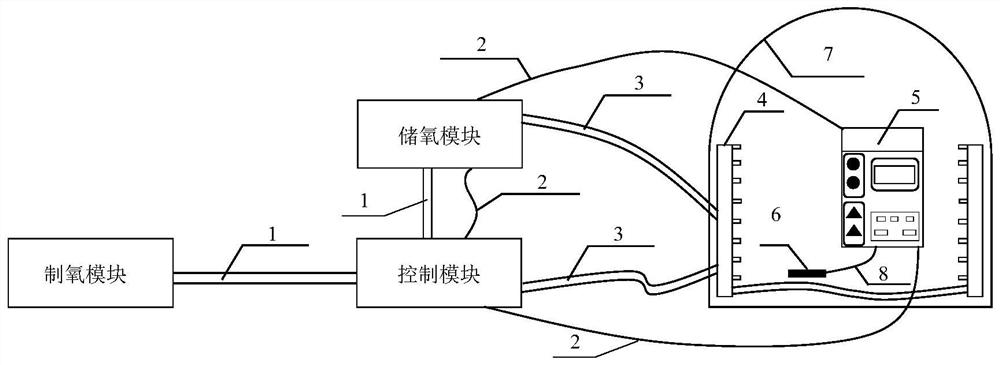

Intelligent oxygen supply system for tunnel face in plateau area

PendingCN112922659ASolve wasteImprove operational efficiencyTunnel/mines ventillationSafety equipmentsOxygen monitoringEnvironmental engineering

The invention relates to the technical field of oxygen generation and oxygen supply, in particular to an intelligent oxygen supply system for a tunnel face in a plateau region. The intelligent oxygen supply system comprises an oxygen generation module, a control module, an oxygen storage module and a tunnel face oxygen supply module, wherein the oxygen generation module is installed nearby the tunnel face and used for purifying oxygen in air; the control module is used for controlling the amount of oxygen flowing into the tunnel face and the oxygen storage module; the oxygen storage module is used for storing the oxygen purified by the oxygen generation module and supplying oxygen to the tunnel face; and the tunnel face oxygen supply module is used for releasing oxygen, monitoring the oxygen content of the tunnel face, controlling the amount of oxygen flowing into the tunnel face from the oxygen generation module and controlling the amount of oxygen flowing into the tunnel face from the oxygen storage module.

Owner:CIVIL ENG OF CHINA CONSTR SECOND ENG BURESU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com