Low-temperature environment-friendly carbonization device for recycling waste lithium ion batteries

A technology of lithium ion battery and carbonization device is applied in the field of low temperature environmental protection carbonization device for recycling waste lithium ion battery, which can solve the problems of reducing the recovery rate of useful value, low utilization rate of heat energy, harmful substances, etc., so as to reduce the generation of harmful substances , High utilization rate of heat energy, the effect of reducing the degree of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

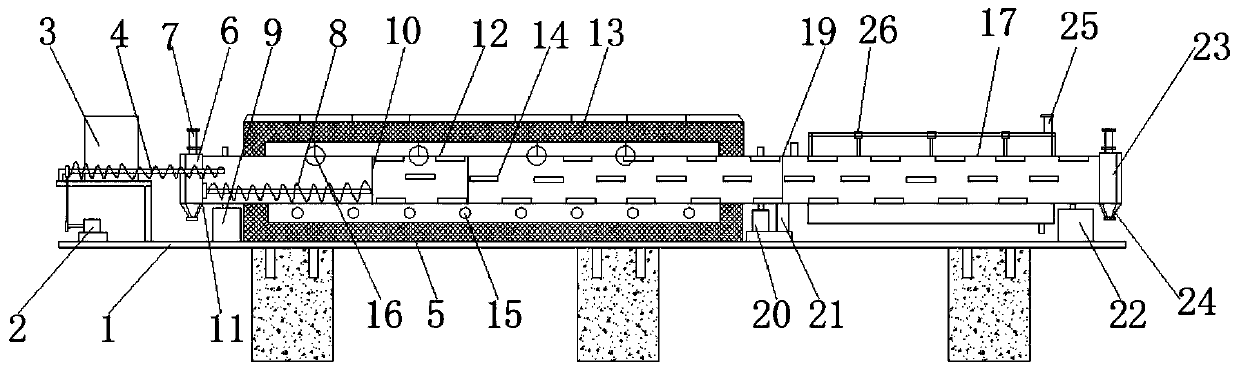

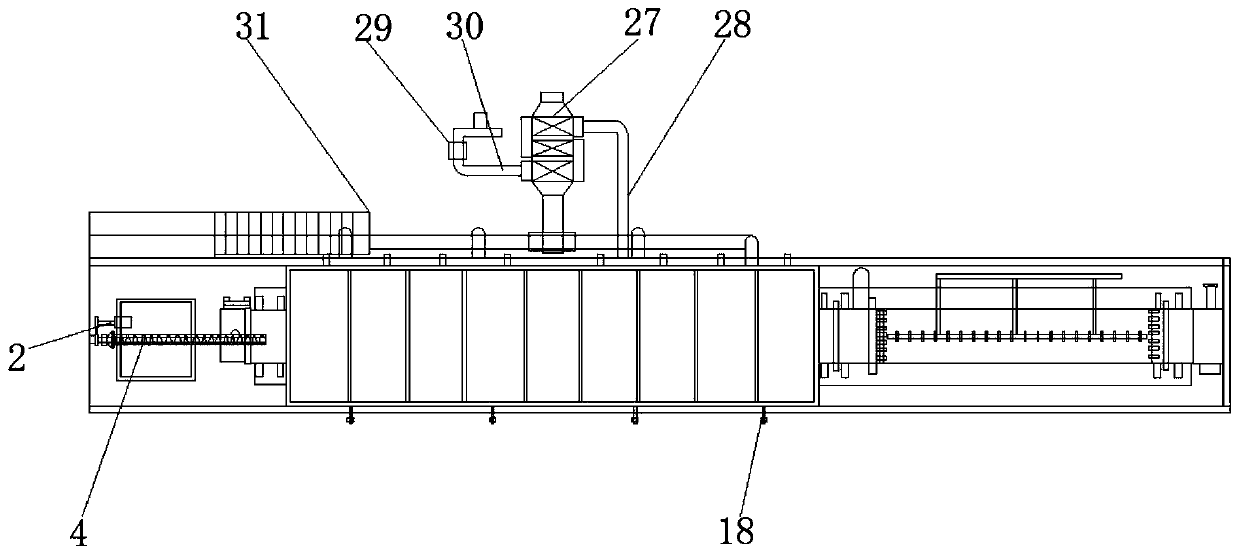

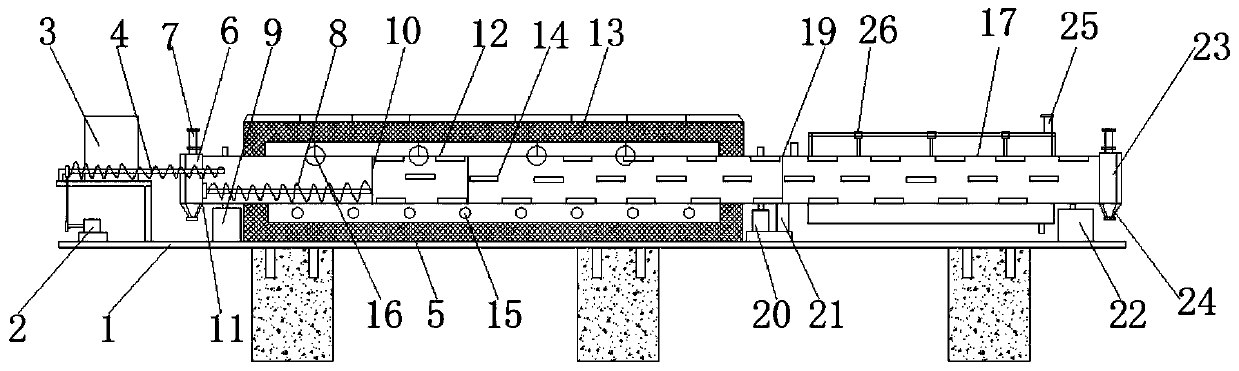

[0027] Such as Figure 1-2 As shown, the embodiment of the present invention provides a low-temperature environment-friendly carbonization device for recycling waste lithium ion batteries, including a base 1, a heating furnace body 5 is fixedly connected to the upper surface of the base 1, and one side of the heating furnace body 5 is fixedly connected to a The feed sealing box 6, the inside of the heating furnace body 5 and the end close to the feed sealing box 6 are fixedly connected with the furnace tube inner screw 8, and the end of the furnace tube inner screw 8 away from the feed sealing box 6 is provided with a spiral retaining ring 10, the heating furnace The inside of the body 5 is provided with a rotating roasting main body 12 on one side of the inner spiral 8 of the furnace tube, so that the roasting effect is better and more ideal. The inside of the heating furnace body 5 is provided with a natural gas combustion heating device 15, and one end of the rotating roasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com