Preparation method of high-purity pyrimethanil and equipment used for preparing high-purity pyrimethanil

A pyrimethamine, high-purity technology, applied in the field of pesticide preparation, can solve the problems that it is difficult to meet the requirements, the original drug product cannot meet the requirements, etc., and achieves the effects of reducing the solubility, reducing the generation of acetone, and reducing hydrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

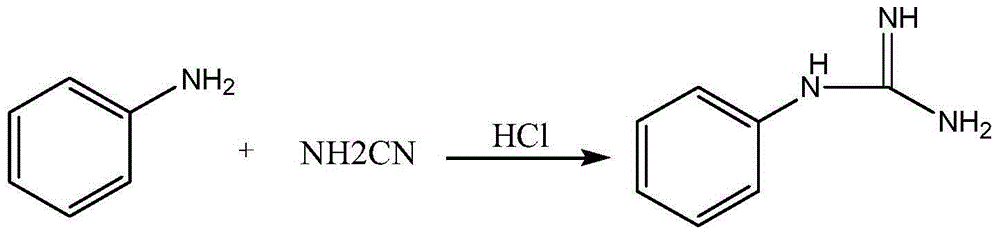

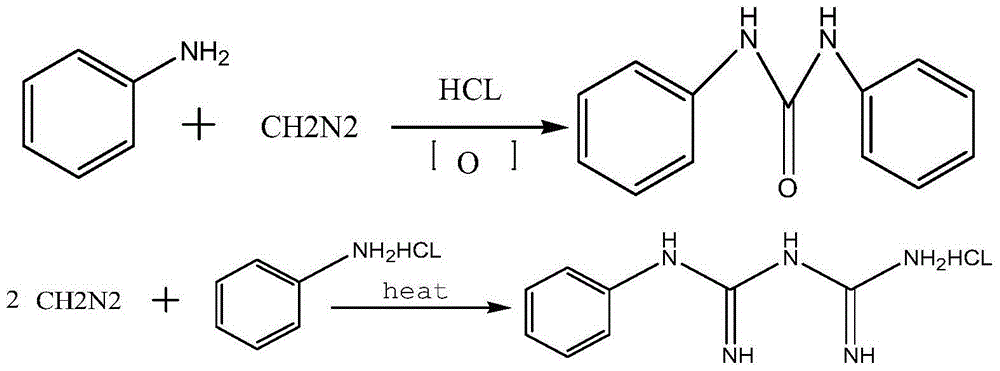

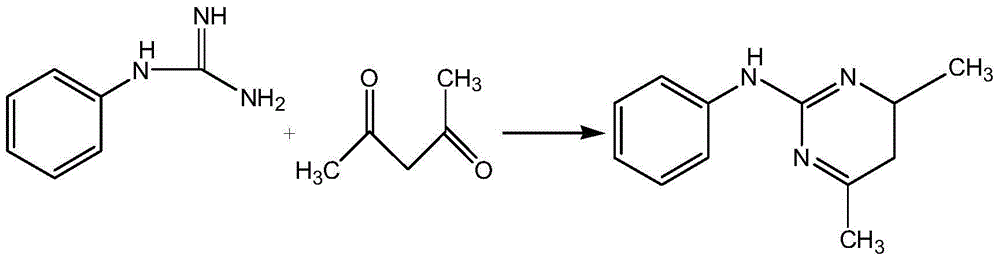

Method used

Image

Examples

Embodiment 1

[0037] in each batch

[0038] Aniline: 16.4Kmol (99%)

[0039] Hydrochloric acid: 15.7Kmol (30%)

[0040] Cyanamide: 16.6Kmol (30%)

[0041] Sodium carbonate: 16.4Kmol (99%)

[0042] Acetylacetone: 19.7Kmol (99%)

[0043] Feed nitrogen into the reaction kettle, replace the oxygen in the reaction kettle (oxygen content ≤ 2%), add 16.4Kmol aniline to the reaction kettle, start stirring after the aniline is added, raise the temperature to 50°C, and drop Add 11.8Kmol of hydrochloric acid once, control the reaction temperature at 50-60°C, and finish the dropwise addition in 1 hour. After the dropwise addition, raise the temperature to 80°C, start dropping 8.3Kmol of cyanamide once, and control the temperature at 80-85°C. Cyanamide, control the temperature at 85-90°C. After the dropwise addition, raise the temperature to 100°C, and keep the temperature for 5 hours; after the heat preservation reaction, cool to 60°C, put the prepared saturated sodium carbonate solution (50°C) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com