Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Good dyeing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

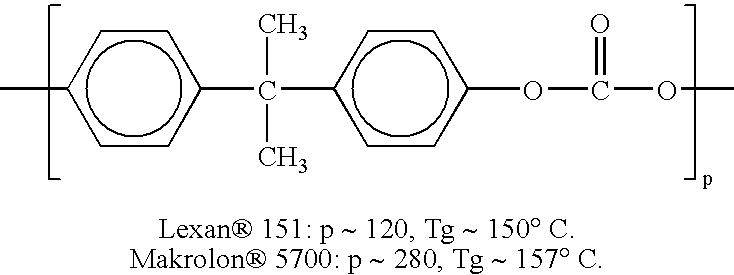

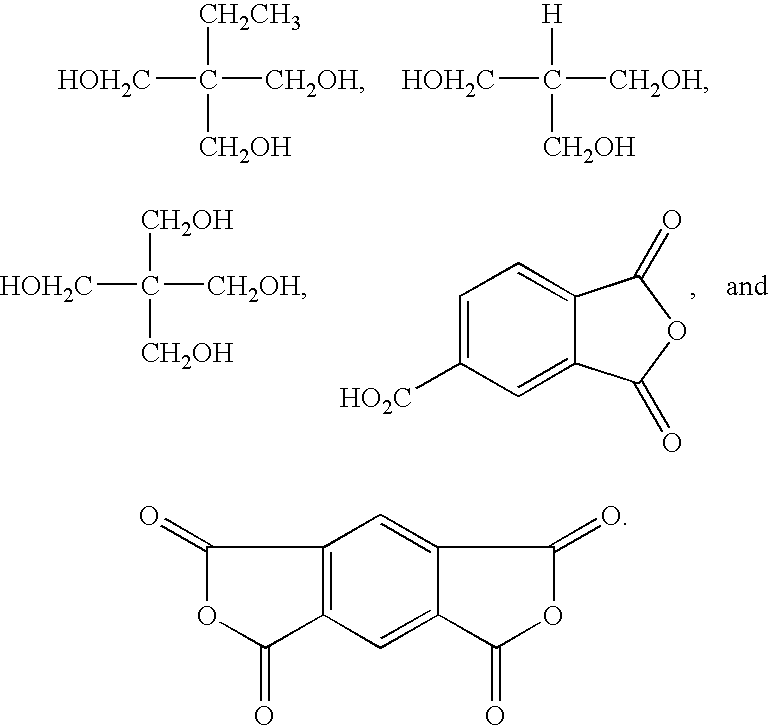

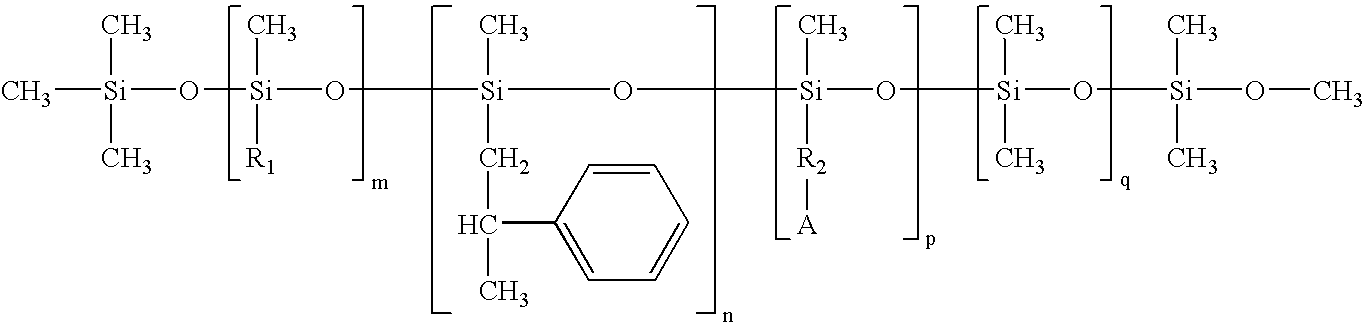

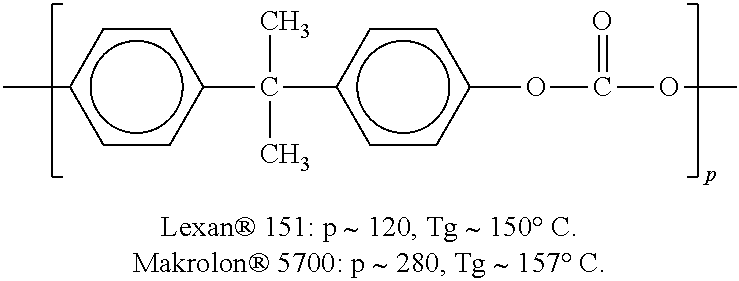

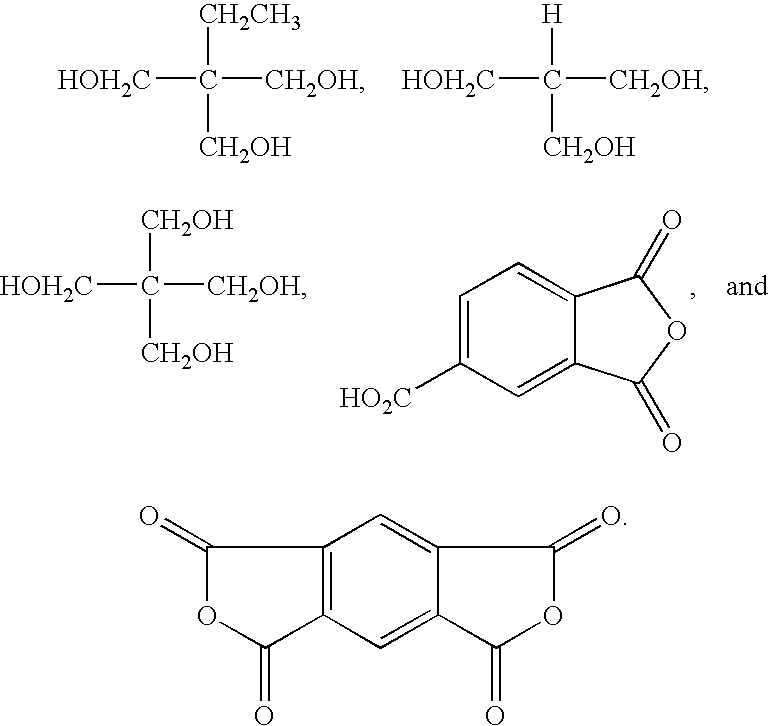

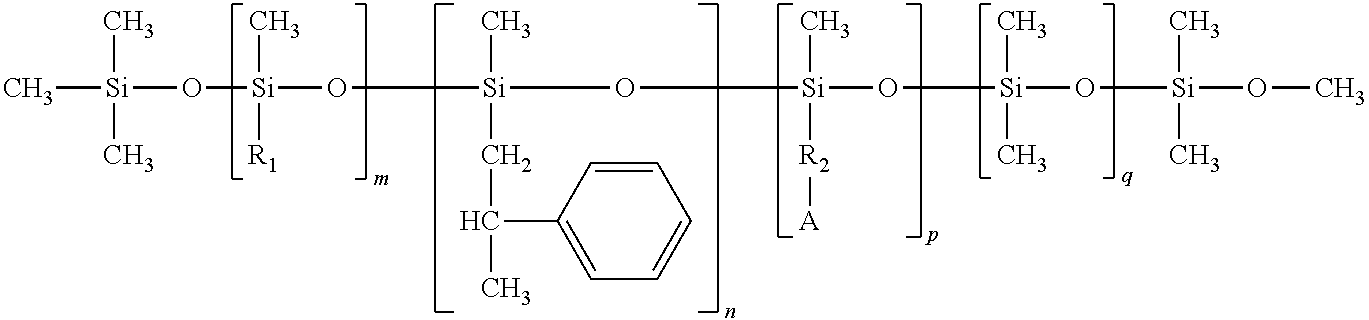

Aqueous subbing for extruded thermal dye receiver

ActiveUS20080220190A1Increase heightGood imaging propertiesLiquid surface applicatorsPattern printingImage recordingRecord element

The present invention relates to an image recording element comprising a support having thereon an aqueous subbing layer and an extruded dye receiving layer, wherein the image recording element is a thermal dye receiver. The present invention also relates to a method of making a thermal dye receiving element comprising providing a support for an imaging element; applying an aqueous subbing layer to the support; and extruding thereon at least one thermal dye receiving layer.

Owner:KODAK ALARIS INC

Composite environmental protection type disperse dyes

An environmental protection type composite disperse green dye with high dyeing uniformity, producibility and dye uptake contains proportionally dye monomers A, B, C and D and assistant.

Owner:ZHEJIANG RUNTU

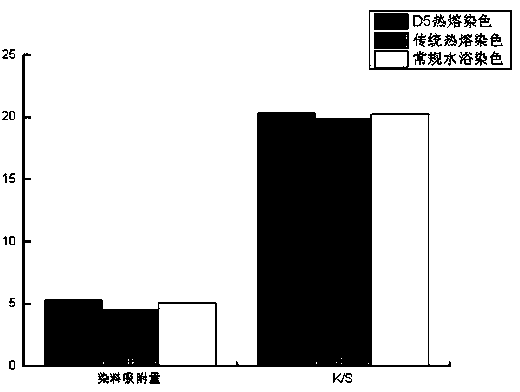

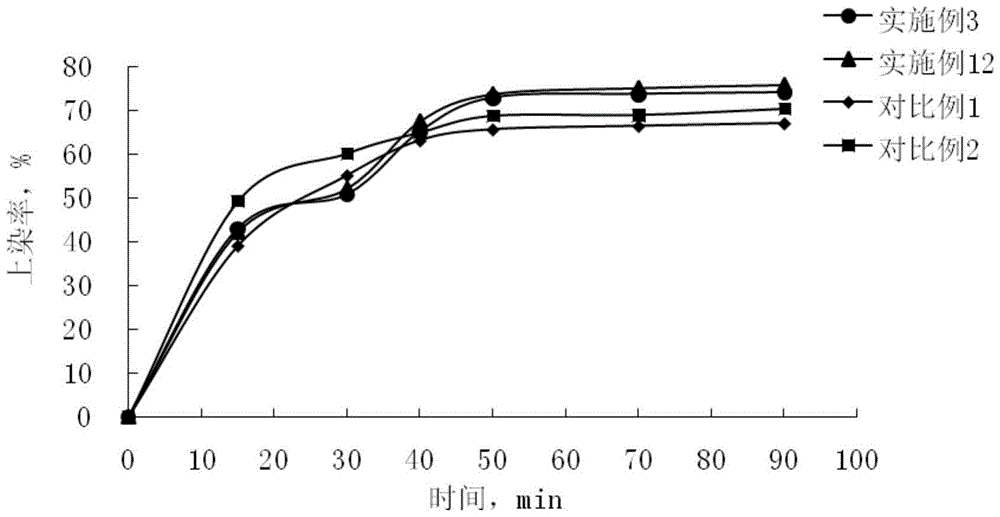

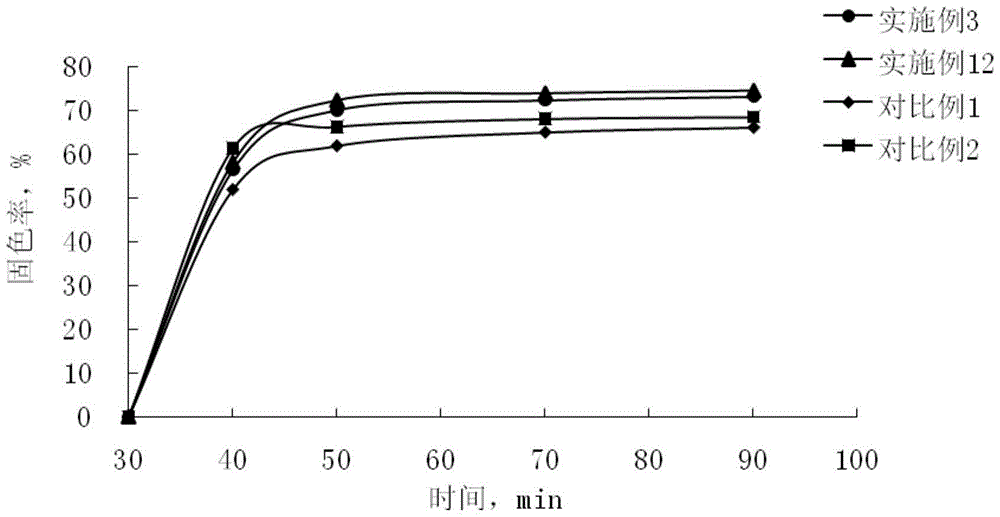

Reactive dye ecological dyeing method of silk fabrics

InactiveCN102767099ASave water for dyeingEasy to operateDyeing processSodium bicarbonateSodium Bicarbonate Solution

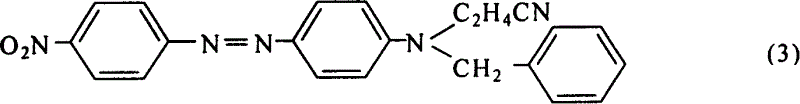

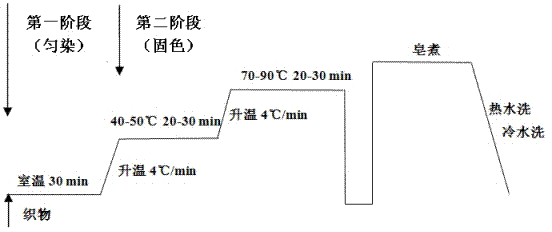

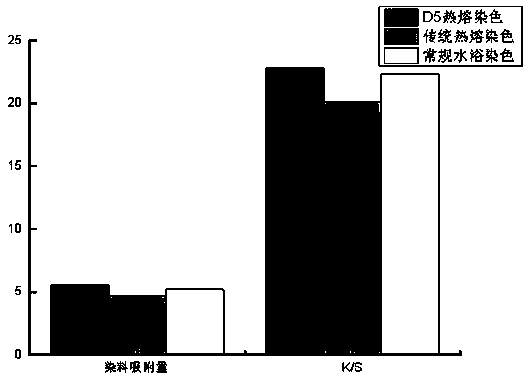

The invention provides a reactive dye ecological dyeing method of silk fabrics, which comprises the following steps of: (1) even dyeing: using reactive dye and decamethyl cyclopenta siloxane (D5) according to the mass ratio of 1:10 to 50 to prepare a reactive dye / D5 suspending dispersed liquid; padding the silk fabrics in 30 to 90 g / l of sodium bicarbonate solution; and dyeing the silk fabrics in the reactive dye / D5 suspending dispersed liquid with the rolling liquid rate of 160 to 200% at room temperature for 25 to 35 minutes, wherein the rolling liquid rate is used for ensuring even dyeing of the silk fabrics; and (2) color fixing: heating a mixture system obtained from the step (1) to 40 to 50 DEG C, and keeping the temperature for 20 to 30 minutes; then heating to 70 to 90 DEG C, and keeping the temperature for 20 to 30 minutes; and taking the silk fabrics out, and performing soap boiling. In the process of dyeing provided by the invention, an electrolyte is not added for dyeing acceleration, the dyeing rate of the dye is close to 100%, the fixing rate is higher than that of traditional bath dyeing, and the fastness of the fabrics is good after dyeing. Because the electrolyte is not needed for dyeing acceleration, the burden of treating dyeing waste water is effectively reduced, and the ecological environment is protected.

Owner:ZHEJIANG SCI-TECH UNIV

Thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as medium

InactiveCN104278576ASave water for dyeingReduce sublimationDyeing processDisperse dyeEcological environment

The invention discloses a disperse dye thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as a medium. The method comprises the following steps: (1) pretreating polyester fabric; (2) adding a certain amount of pure disperse dyes into a dyeing medium D5, controlling the amount of the dyeing medium D5, so that a ratio of the weight of a to-be-dyed fabric to the weight of the medium D5 is 1:10 to 1:30, dyeing in a dyeing machine, heating the system to 90-100 DEG C, preserving the temperature for 5-10 minutes, heating to the temperature of 180-200 DEG C, and performing thermosol fixation, wherein the fixation time is 10-30 minutes; and (3) performing reduction clearing on the dyed fabric according to a GB2394-80 method after dyeing. According to the method, non-aqueous medium dyeing is adopted, lots of water resources are saved, the thermosol temperature can be obtained under normal pressure, the conventional dyeing equipment can be adopted, the operation is simple, pure disperse dyes are adopted for dyeing, lots of dispersing aids are saved, the utilization rate of the dyes is improved, wastewater emission is reduced, and ecological environment protection is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

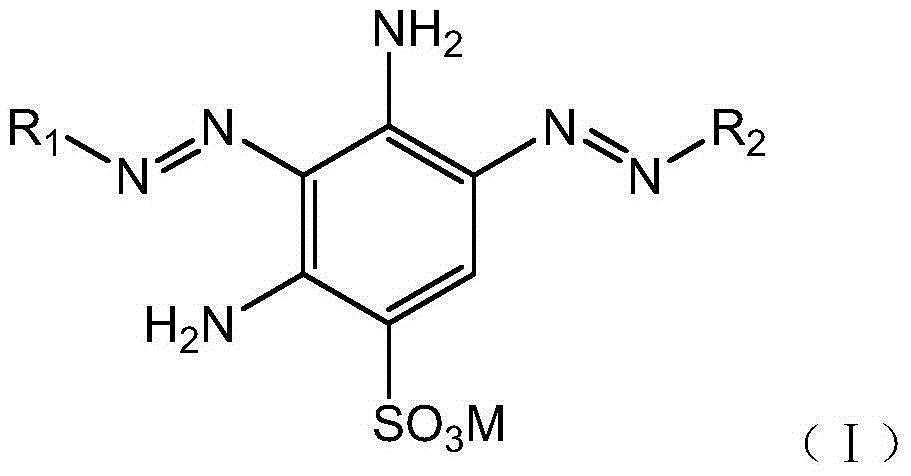

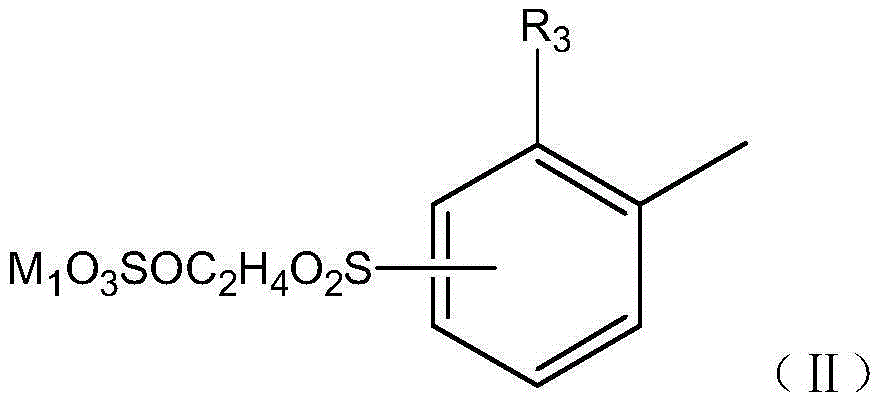

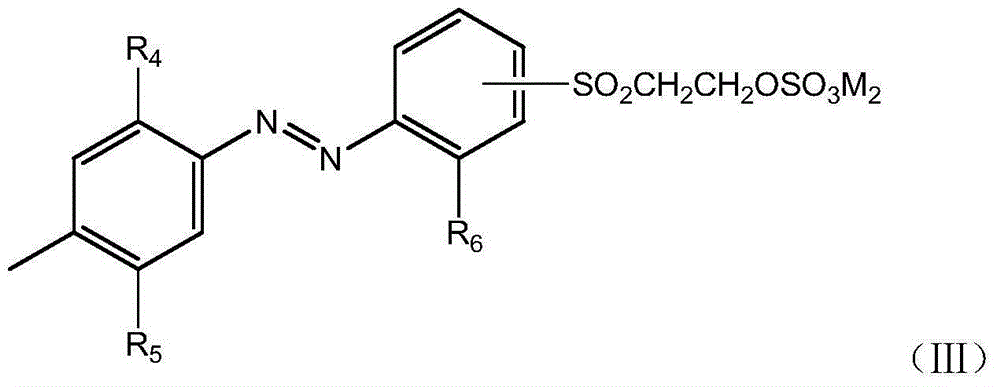

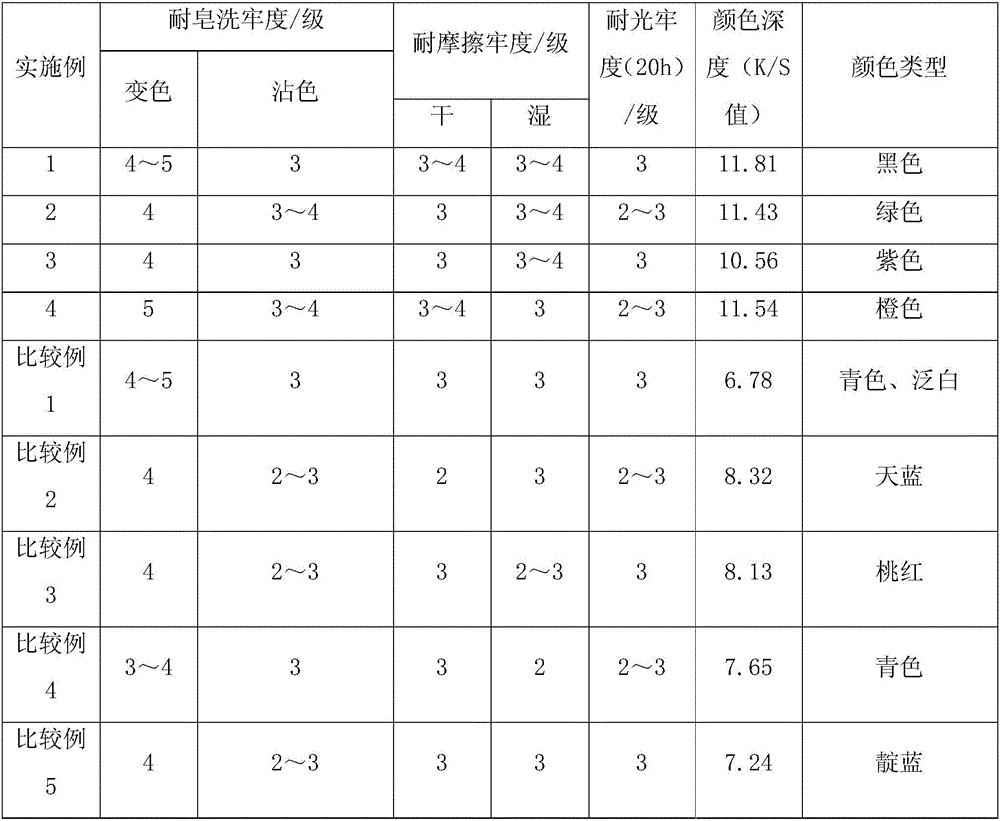

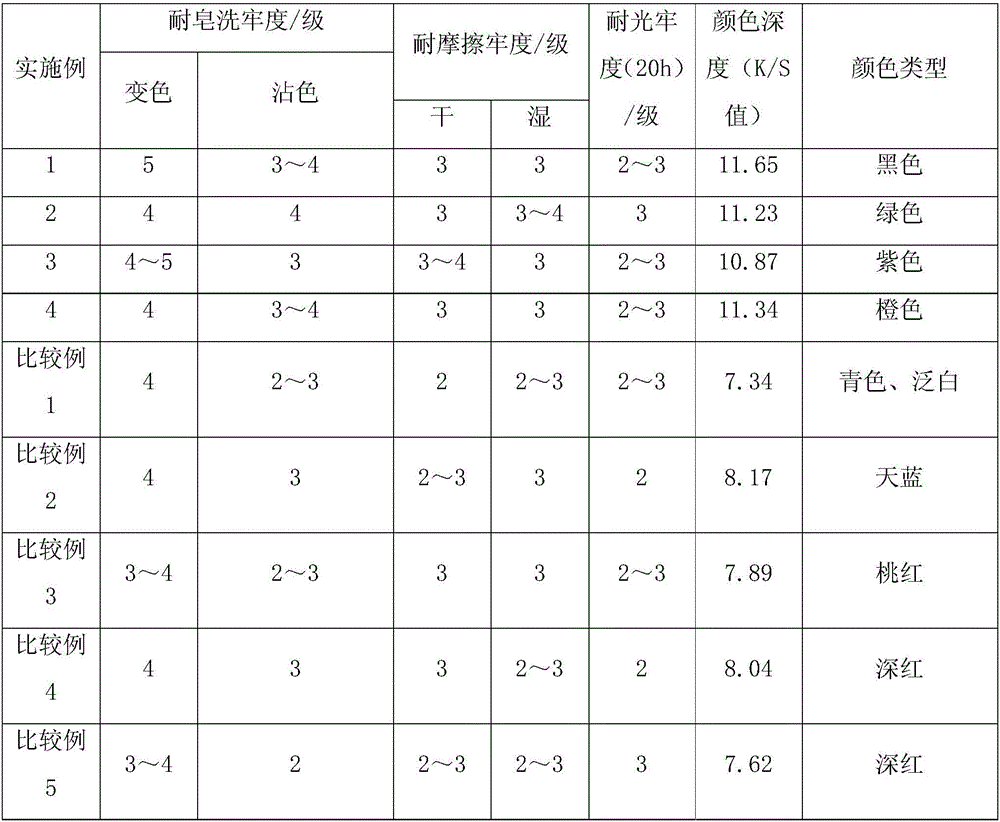

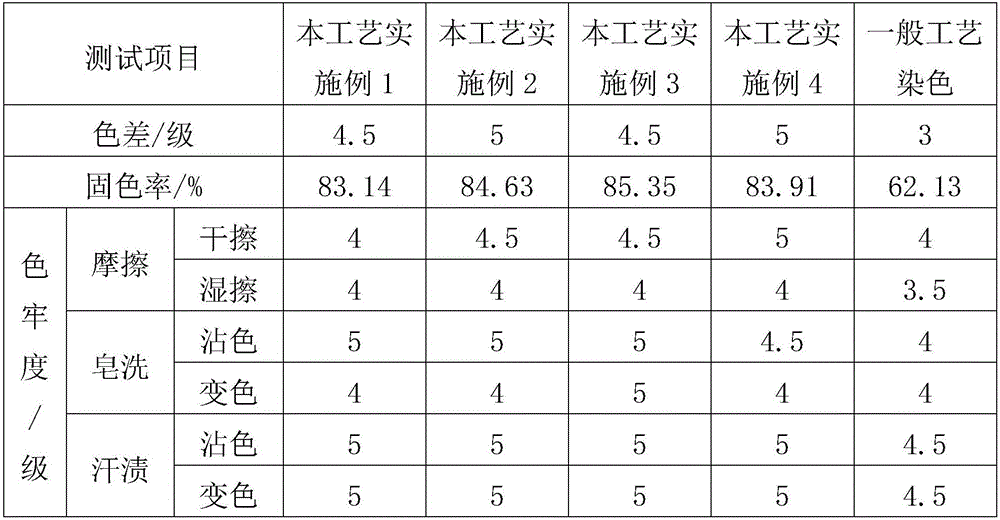

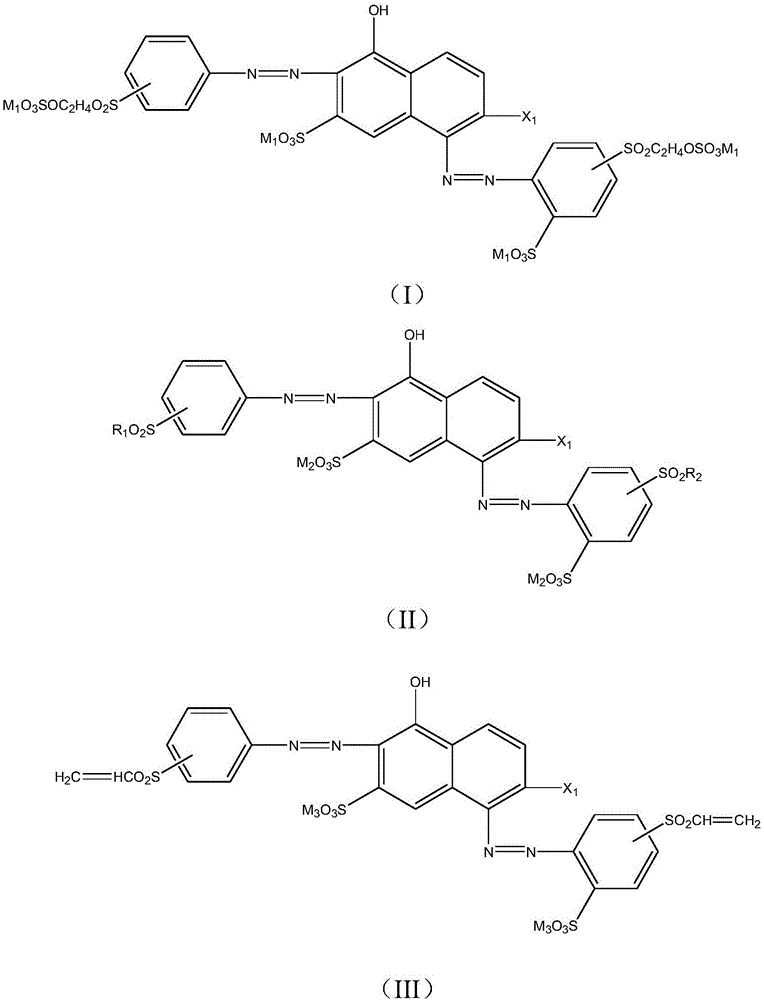

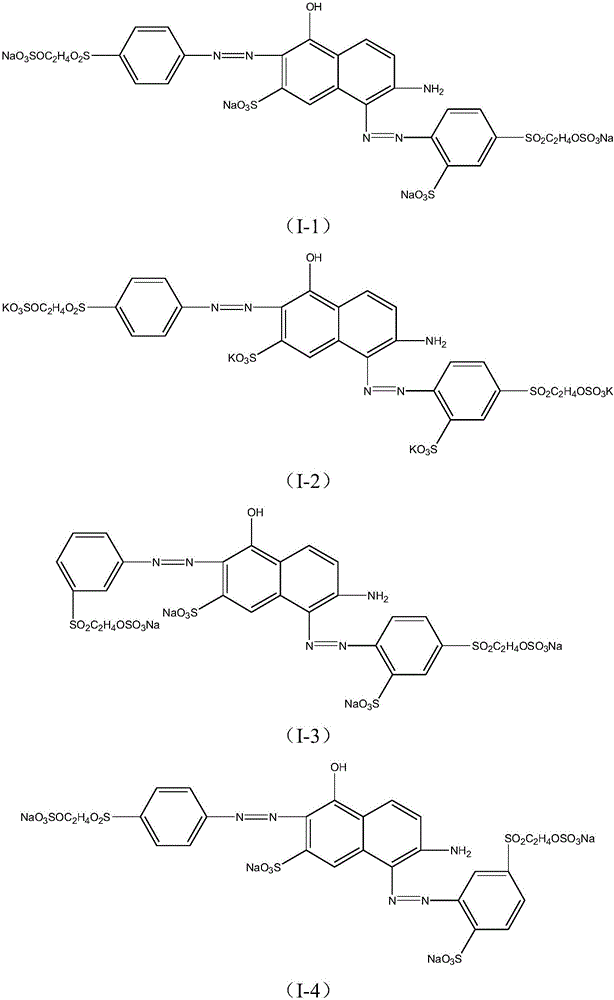

Brown polyazo reactive dye compound, and preparation method and application thereof

ActiveCN105176139ANovel structureImprove performanceReactive dyesDyeing processCombustionCellulose fiber

The invention discloses a brown polyazo reactive dye compound, and a preparation method and an application thereof. The structure of the brown reactive dye compound is represented by general formula (I), one of R1 and R2 in the formula (I) is selected from groups represented by general formula (II), the other one of the R1 and R2 is selected from groups represented by general formula (III), and R3 in the formula (II) is H, -OCH3 or -SO3M; -SO2OCH2CH2OSO3M is positioned in the para-position or the meta-position of an azo group; and in the formula (III), R4 is -NHCONH2 or -NHCOCH3, R5 is H or -OCH3, R6 is H, -OCH3 or -SO3M, and M1 and M2 respectively and independently are H or alkali metals. The dye compound is suitable for printing and dyeing cellulose fibers, and has the advantages of excellent dye uptake, high color fixing rate, excellent launderability, excellent friction resistance, excellent color fastness, and good combustion stability with the fibers.

Owner:ZHEJIANG LONGSHENG GROUP +1

Technology for color matching dyeing with vegetable dyes

ActiveCN106087475AAvoid the problem of uneven dyeingPure colorDyeing processLiquid/gas/vapor textile treatmentSugarColor matching

The invention belongs to the technical field of vegetable dye dyeing and particularly relates to a technology for color matching dyeing with vegetable dyes. A special auxiliary is added, the dyeing environment (the pH of a dyeing solution) is controlled, and then vegetable dyes are matched and then used for dyeing fabric, so that the influences of sugar and pectin remaining in the natural plant dyes on diffusion of different dyes and the nonuniform dyeing generated after color matching of the dyes are avoided. By using the technology for dying, the color of the fabric is very pure, a good dyeing rate and excellent fastness are achieved, and the damage of organic chemical dyes to the skin of the human body is avoided.

Owner:宁波原真生态纺织科技有限公司

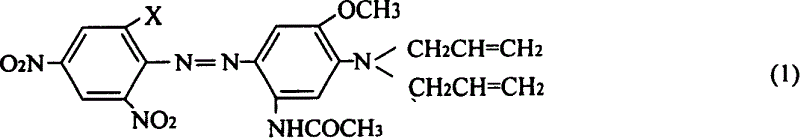

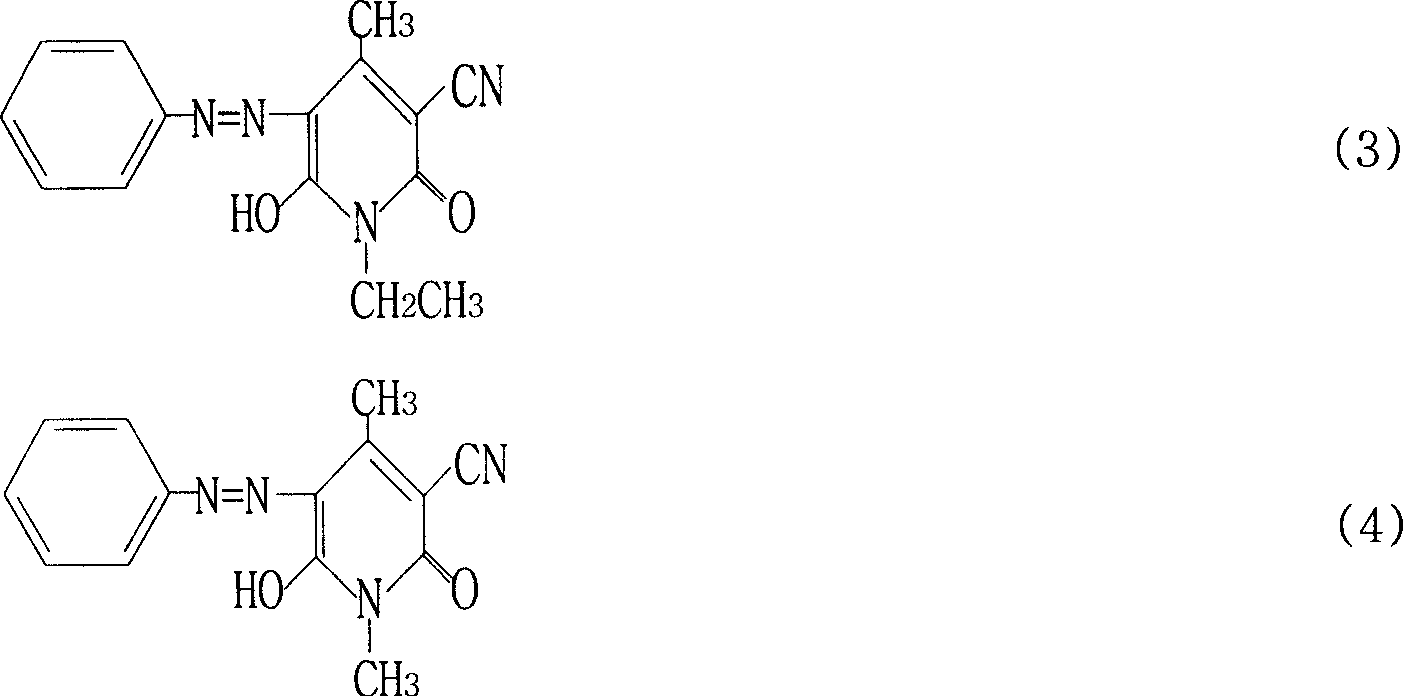

Composite dye composition, composite disperse dye and preparation method thereof

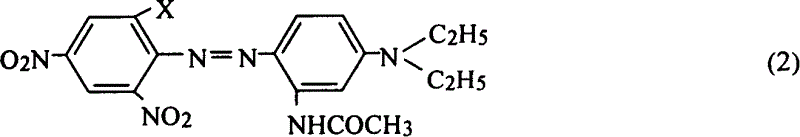

The invention relates to a composite dye composition, composite disperse dye and a preparation method thereof. The composite dye composition is composed of compounds as shown in a formula (I-a), a formula (I-b), a formula (II) and a formula (III). The composite disperse dye prepared from the composite dye composition has good comprehensive fastness property and high lifting force, and is suitable for dyeing and printing terylene and blend fabrics.

Owner:ZHEJIANG RUNTU

Color-matching dyeing process based on plant dyes

ActiveCN106087476AAvoid the problem of uneven dyeingPure colorDyeing processLiquid/gas/vapor textile treatmentSugarSkin surfaces

The invention belongs to the technical field of dyeing of plant dyes, and particularly relates to a color-matching dyeing process based on the plant dyes. A specific additive is added to control a dyeing environment (the pH value of a dyeing liquid), and a fabric is dyed after plant dyes are matched, so that the influence of sugar and pectin retained in natural plant dyes to diffusion of different dyes is avoided, and the problem that the dyeing color is not uniform after multiple dyes are matched is solved. By adopting the color-matching dyeing process provided by the invention, the fabric is very pure in color, excellent in dyeing rate and very good in fastness, and damage of organic chemical dyes to human skin can be avoided.

Owner:宁波原真生态纺织科技有限公司

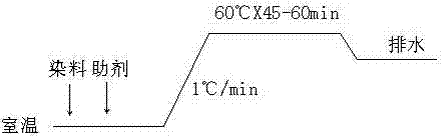

Disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric

ActiveCN106223076APreserve surface hydrophilic propertiesGood dyeing rateDyeing processDisperse dyePre treatment

The invention discloses a disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric. The method comprises the following steps: S1, pretreatment: padding a polyester cotton fabric to be dyed in a finishing liquid, conducting two dipping and two rolling, pre-drying at 60-80 DEG C, baking at 120-140 DEG C, washing with cold water and drying; S2, polyester dyeing: immersing the polyester in a disperse dye, insulating at 65-75 C, and insulating at 110-130 DEG C; S3, cotton dyeing: adding a quaternary ammonium salt cationic etherifying agent, stirring for reaction, adding a reactive dye, insulating at 70-80 DEG C, adding a dyeing auxiliary, insulating, adding soda ash, and insulating at 60-100 DEG C; and S4, posttreatment: conducting an initial washing, soaping and post washing. The disperse reactive dye one-bath two-step dip dyeing method for polyester cotton fabric has the advantages of simple process, easy industrial implementation, wide dye application, uniform coloration, high fixation rate and good levelness.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

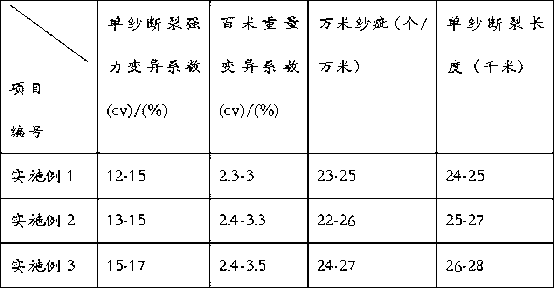

Process of producing polyacrylic fiber dyeable with both cationic dye and acid dye

ActiveCN1986918AEase of production and managementGood dyeing rateFilament/thread formingDyeing processSolventChemistry

The process of producing polyacrylic fiber dyeable with both cationic dye and acid dye includes dissolving polyacrylonitrile resin A and polyacrylonitrile resin B in the weight ratio of 1 to (0.6-1.6) in solvent of water solution of NaSCN in the 35- 58 wt% concentration to form raw spinning liquor with total solid content of 8-20 %; spinning the raw spinning liquor through the 8-15 wt% concentration water solution of NaSCN inside the coagulating bath to form nascent fiber; and post-treatment of the nascent fiber to produce polyacrylic fiber product. The third monomer for resin A is sodium methyl acryl sulfonate or 2-acrylamido-2-methyl propyl sulfonic acid and accounts for 0.8-5.0 wt%; and that for resin B is one of N, N-dimethyl amido ethyl methyl acrylate nitrate, N-dimethyl amido ethyl methyl acrylate hydrochloride or N-dimethyl amido ethyl methyl acrylate sulfate and accounts for 3.3-12.5 wt%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

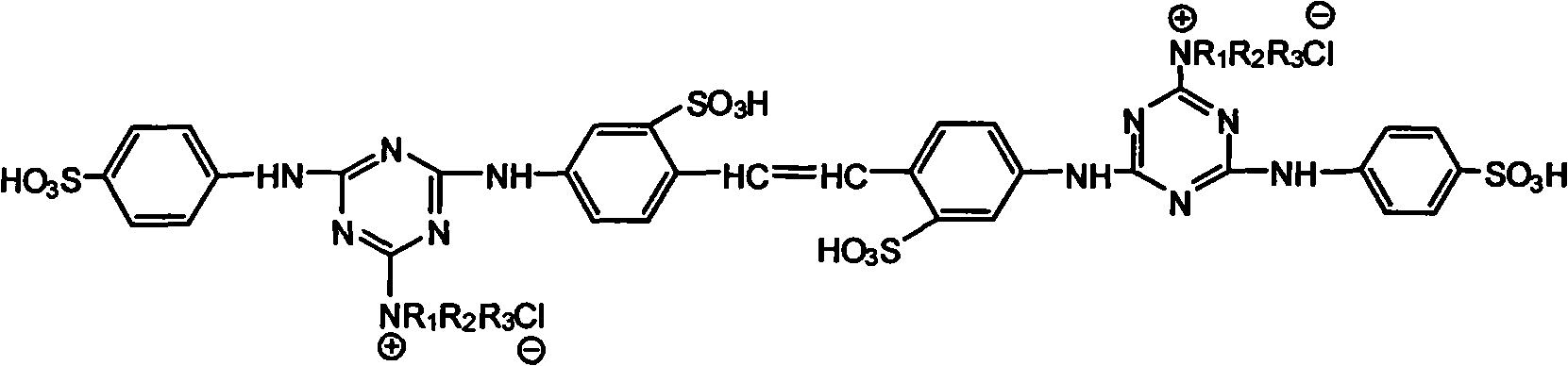

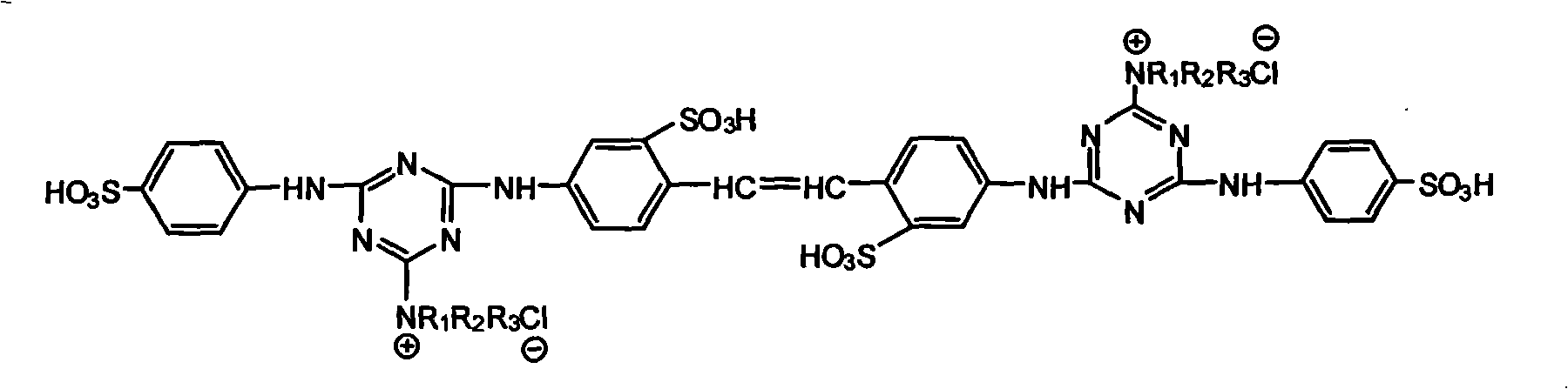

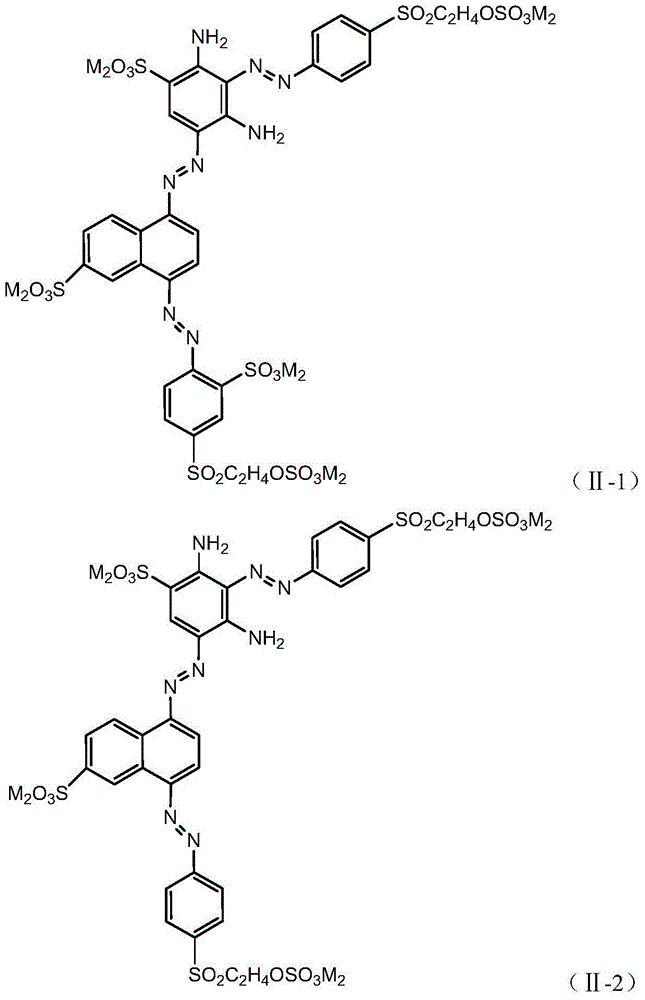

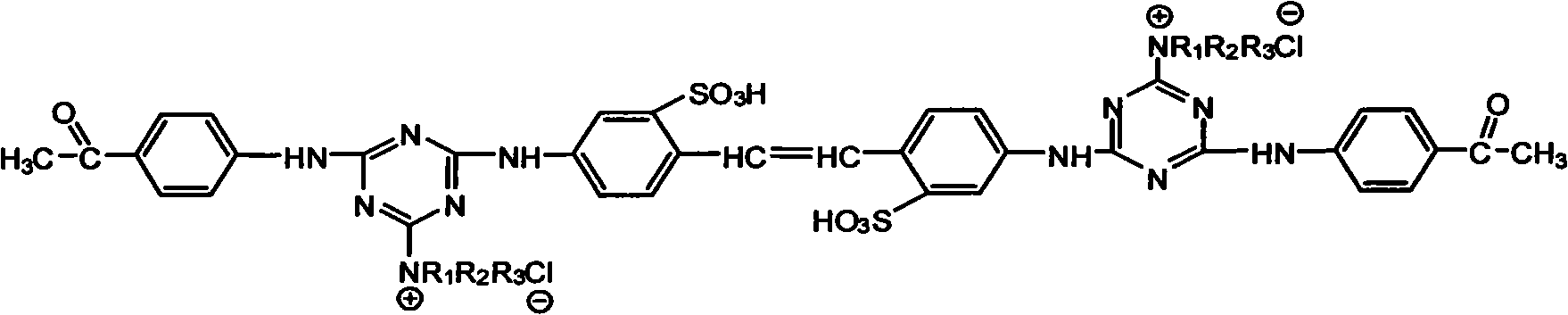

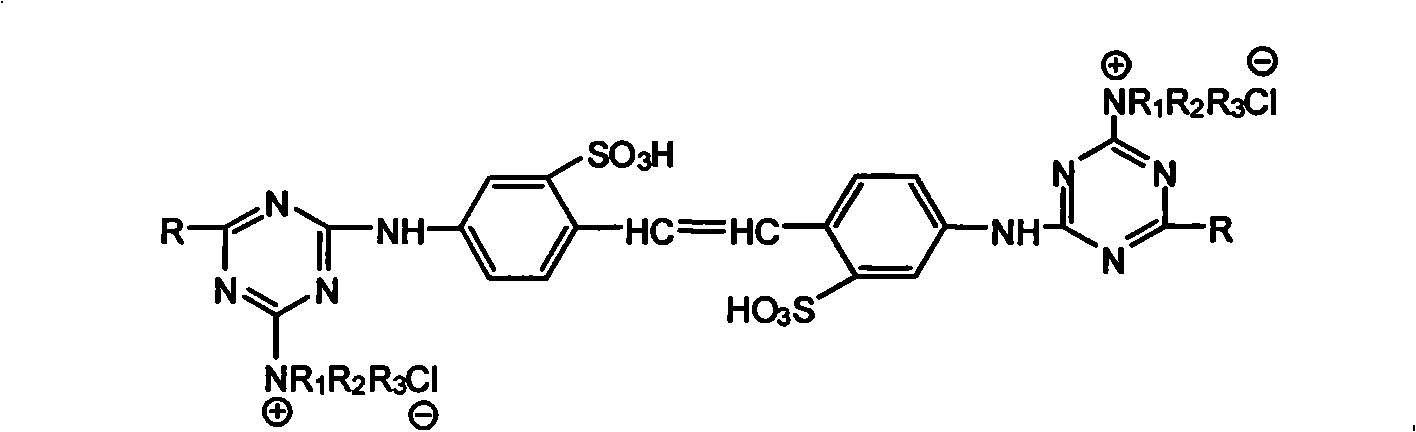

Amphiprotic triazine-DSD acid fluorescent whitener of tetra-sulfonic acid, synthesizing method thereof and applications

InactiveCN101307033AGood dyeing rateGood color fixation rateOrganic chemistryDetergent dyesSulfanilic acidQuaternary ammonium cation

The invention relates to a tetrasulfonic acid series of amphoteric triazine-DSD acidic fluorescent whitening agents, as well as synthesis and an application of the same. The series of fluorescent whitening agents are mainly applied to papermaking paint printing ink and textile. The synthesis adopts the following steps that: a. cyanuric chloride reacts with aminobenzene sulfonic acid at a temperature between 0 and 5 DEG C for 2.5 h, with pH value controlled to be between 1.8 and 2.1, so as to synthesize one-step condensation product; b. the one-step condensation product reacts with 4, 4'-diaminodiphenylethylene-2, 2'-disulfonic acid at a temperature between 40 and 45 DEG C for 2.5 h, with pH value controlled to be between 3.5 and 4.5, so as to synthesize two-step condensation product; the two-step condensation product reacts with a series of tertiary amine compounds at a temperature between 78 and 85 DEG C for 2.5 h, with pH value controlled to be between 7.5 and 8.5, so as to synthesize a series of amphoteric triazine-DSD acidic fluorescent whitening agents containing quaternary ammonium salt groups. Application results show that: the fluorescent whitening agents can be used under neutral / alkaline conditions, and has higher dye uptake rate and better whitening effect under acidic conditions.

Owner:SHANDONG UNIV

Dyeing and finishing process of coffee-yarn blended and knitted fabric

ActiveCN104727163ARealize medium and dark double dyeing processAccelerated adsorption and dispersionFibre treatmentDyeing processColour fastnessYarn

The invention discloses a dyeing and finishing process of a coffee-yarn blended and knitted fabric. The dyeing and finishing process is characterized by comprising the following steps: preparing grey fabric, pretreating, dyeing, soaping, softening and carrying out after finishing, wherein a mild pre-treatment degreasing process is adopted; and an active double-dyeing process of firstly dyeing, dispersing and dyeing is adopted to dye, so that the difficulty in dying with the same color of the blended and knitted fibers is solved; through control on a finishing agent and the amount of the finishing agent in the after finishing process of the coffee-yarn blended and knitted fabric, the problems of same color and different colors in the dyeing process of the coffee-yarn blended and knitted fabric are solved; good air permeability and relatively good rubbing fastness are obtained; and meanwhile, a plurality of efficacies that the coffee-yarn blended and knitted fabric is capable of absorbing stink, removing an odor, storing heat, keeping warm, absorbing moisture and drying quickly in an far infrared manner are taken into account.

Owner:浙江七色彩虹科技有限公司

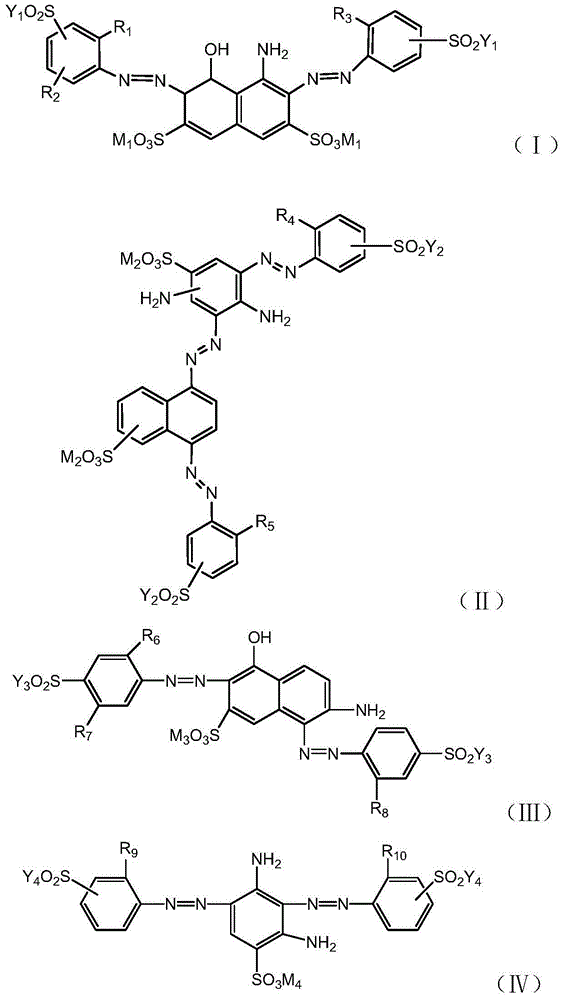

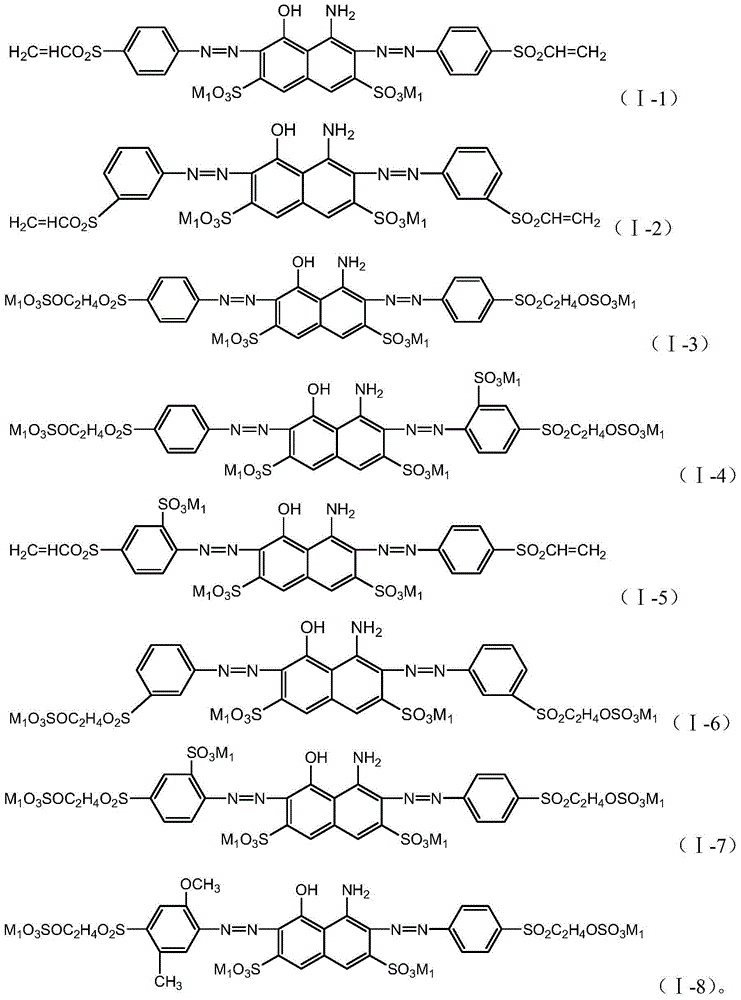

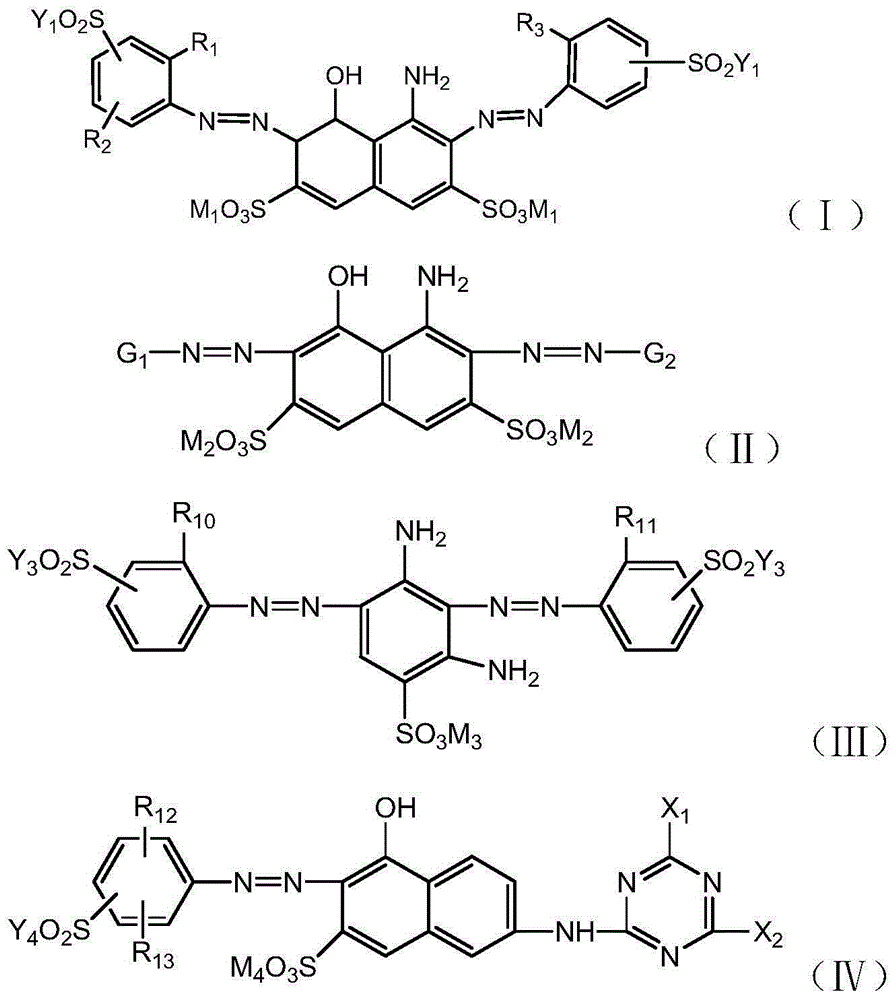

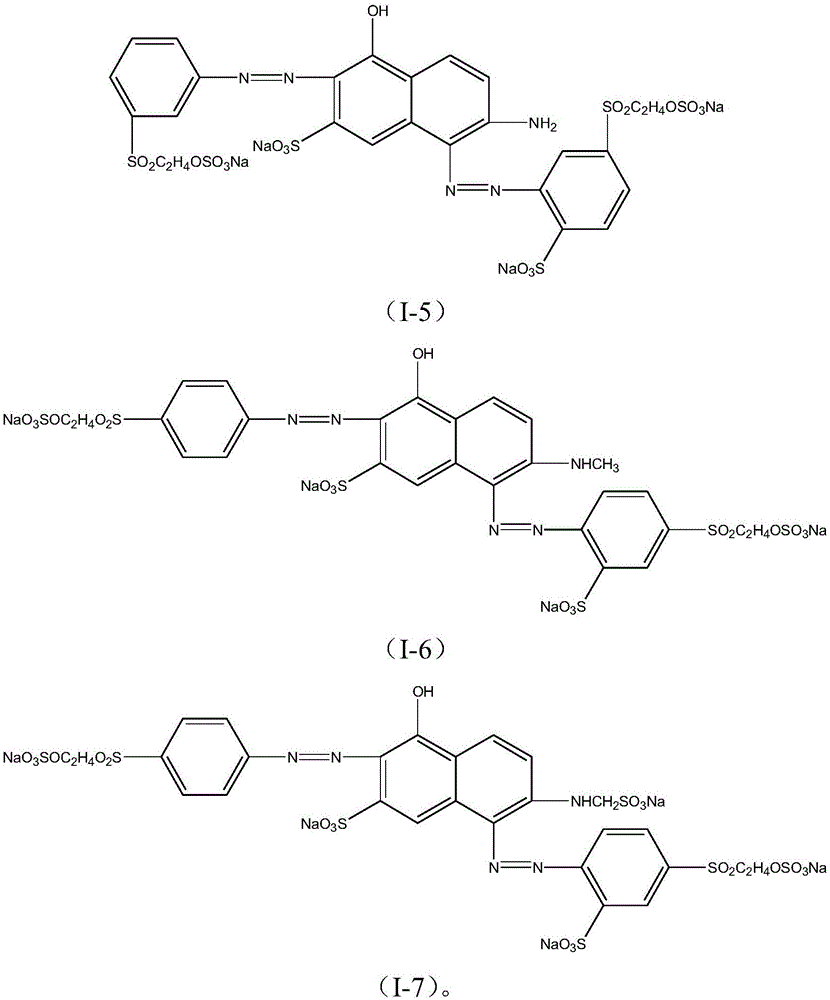

Active dye composition in dark blue to black and dye product

The invention relates to active dye composition in dark blue to black and a dye product. The dye composition comprises, in parts by weight, 45-95 parts of a component A, 5-55 parts of a component B and 0-40 parts of a component C, wherein the component A is selected from at least one compound represented by the formula (I), the component B is selected from at least one compound represented by the formula (II), and the component C is selected from at least one compound represented by the formula (III) and / or the formula (IV). The active dye product in dark blue to black comprises the dye composition. The dye product is good in deep dyeing property, excellent in improvement power, high in dye up-take, high in color fixation, good in compatibility and excellent in color fastness; during dyeing, the dye is small in use amount, easy to wash, clear in residual liquid, stable in salt and alkali resistance, excellent in metamerism, stable in dyeing property and applicable to different technologies of dip dyeing, pad dyeing, printing and the like.

Owner:SHANGHAI KEHUA DYESTUFF IND +1

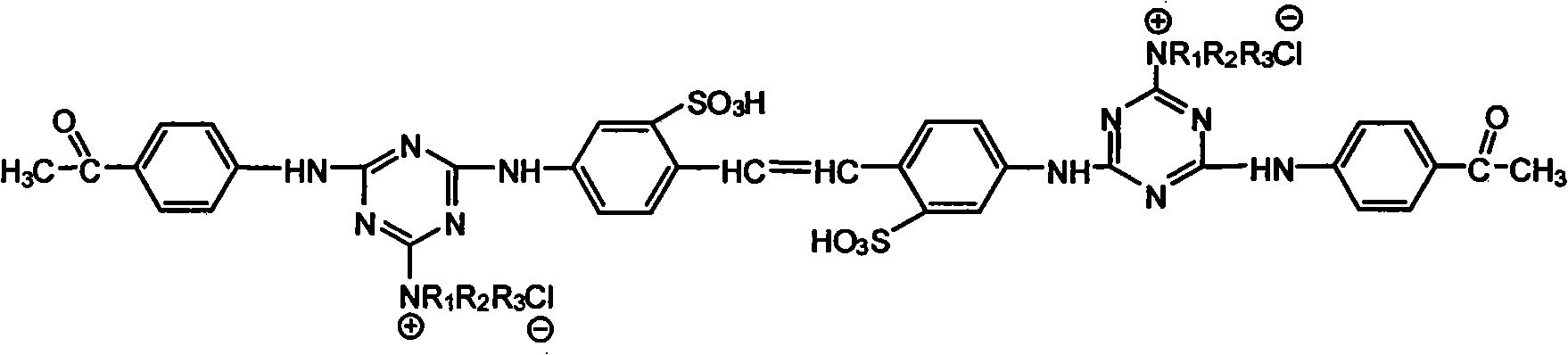

Fluorescent whitening agent containing p-aminoacetophenone group quaternary ammonium salt, synthesis and use thereof

InactiveCN101298438AGood dyeing rateGood color fixation rateOrganic chemistryDetergent dyesWhitening AgentsTriazine

The invention relates to a series of whitening agents containing p-aminoacetophenone radical hyamine fluorescence as well as synthesis and applications thereof; the series of whitening agent are mainly applied to paper making, dope, printing ink and weaving. The invention adopts the following synthetic steps of: a, using cyanuric chloride to react with p-aminoacetophenone for 2.5h under the temperature of 0 to 5 DEG C, controlling the pH between 1.8 to 2.1 and synthesizing a primary condensation product; b, using the primary condensation product to react with 4, 4'-Diaminostilbene-2, 2'-disulfonic acid for 2.0h under the temperature of 40 to 50 DEG C, controlling the pH between 3.8 to 4.2 and synthesizing a secondary condensation product; c, using the secondary condensation product to react with a series of tertiary amine compounds for 2.5h under the temperature of 80 to 85 DEG C, controlling the pH between 7.8 to 8.2 and synthesizing a series of p-aminoacetophenone radical hyamine triazine-DSD acid fluorescence whitening agents. The application result shows that; the whitening agents not only can be used under neutral conditions and alkaline conditions, but also has higher dying rate under acidic conditions and better whitening effect.

Owner:SHANDONG UNIV

Activated dark blue to black dye compositioncombination and dye product

The invention discloses an activated dark blue to black dye compositioncombination and a dye product. The dye compositioncombination comprises a component A, a component B and a component C, wherein the component A is selected from at least one compound as shown in formula (I); the component B is selected from at least one compound as shown in formula (II); the component C is selected from at least one compound as shown in formula (III) and / or formula (IV); the quantity of the parts by weight of the component A is 1 to 99; the quantity of the parts by weight of the component B is 1 to 99; the quantity of the parts by weight of the component C is 0 to 50. The dye product comprises the dye compositioncombination. The dye compositioncombination and the dye product are good in deep dyeing property, excellent in promoting capacity, high in dyeing rate and fixation rate, good in compatibility, and excellent in color fastness, small in use level, easy to wash and clear in residual liquor during printing and dyeing process, stable in dyeing property, and applicable to technologies of dip dyeing, pad dyeing and , printing and the like.

Owner:ZHEJIANG LONGSHENG GROUP +1

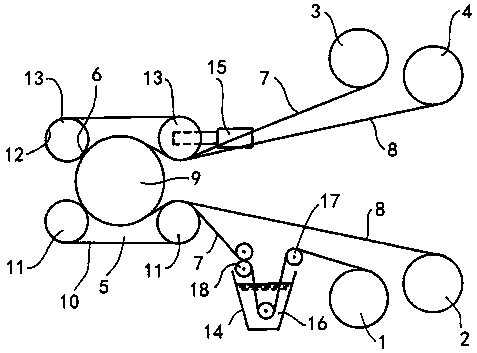

Method of yarn-bundle-shape continuous back-flow silkete

InactiveCN101525826AImprove labor productivityWater saving is obviousMercerising of yarns/threads/filamentsYarnSewage

The invention relates to a method of yarn bundle-shape continuous back-flow silkete, which includes the following steps: 200 to 1000 billet yarns are combined into a yarn bundle, and 1 to 36 yarn bundles are arranged for parallel running; the 1 to 36 yarn bundles continuously run on a silkete machine set and sequentially pass through an immersing and rolling alkali tank 1, a ventilating drum 1, an immersing and rolling alkali tank 2, a ventilating drum 2, an alkali-removing steam box, an alkali-removing eluting tank, a water scrubbing tank 1 and a water scrubbing tank 2 to fall into a yarn container in a wet-yarn type. The method of yarn-bundle-shape continuous back-flow silkete realizes the continuous production of yarn silkete, reduces sewage discharging amount, has the yarn-bundle running of the yarn, high production efficiency, uniform silkete quality and high yarn utilizing rate, enables the yarn silkete to be the normal preprocessing technology, and is helpful for improving the product grade of yarn dyed fabric and knitted fabric.

Owner:DONGHUA UNIV

Red active dye composition and preparation method and use thereof

ActiveCN105778560AHigh color fixing rateGood dyeing rateOrganic dyesDyeing processFiberPhotochemistry

A red active dye composition and a preparation method and use thereof are provided. The red active dye composition comprises component B shown in formula (II), optional component A shown in formula (I), optional component C shown in formula (III) and an optional aid. The red active dye composition is suitable for dyeing various fiber materials, is high in color fixing rate and good in color fastness and has excellent comprehensive performances.

Owner:ZHEJIANG RUIHUA CHEM

Flax mulberry fiber blend dyeing knitting yarn and manufacture method

ActiveCN102704128AProtect from harmQuality improvementBiochemical fibre treatmentDry-cleaning apparatus for textilesYarnPolymer science

Owner:JIANGSU HUAXIN LINEN TEXTILE

Technology for dyeing linen-cotton fabric by using indigo pigment

InactiveCN106811990AGood dyeing rateGood wear fastnessDry-cleaning apparatus for textilesDyeing processEnvironmental chemistryDyeing

The invention relates to technology for dyeing linen-cotton fabric by using indigo pigment. The dyeing technology comprises the following steps: (1) putting a linen-cotton fabric in a high-temperature water bath with an alkali agent, a reductant and a refining agent dissolved for refining, putting the refined fabric in a high-temperature water bath with an oxidant and an oxidation control agent dissolved for oxidation, and washing the oxidized fabric with a detergent and water at a high temperature; (2) putting the pre-treated fabric in a dyeing liquid with a dispersant, an alkali agent and a reductant dissolved for dyeing, and adding an accelerating agent and a coloring stabilizer to the dyeing liquid during a dyeing process; (3) leaching the dyed fabric with a sodium bicarbonate solution; (4) putting the leached fabric in a water bath with an oxidant and an oxidation control agent dissolved for oxidation; (5) washing the oxidized fabric with acid; and (6) soaping the acid-washed fabric at high temperature, taking the soaped fabric out, washing the obtained fabric and performing natural airing. According to the indigo pigment dyeing technology, the fabric is provided with high dye up-taking rate, is good in wear fastness and washing fastness, and facilitates automatic operation.

Owner:苑少纯

Aqueous subbing for extruded thermal dye receiver

ActiveUS7910519B2Good dyeing rateEffectively printed in thermal printerLiquid surface applicatorsPattern printingImage recordingRecord element

The present invention relates to an image recording element comprising a support having thereon an aqueous subbing layer and an extruded dye receiving layer, wherein the image recording element is a thermal dye receiver. The present invention also relates to a method of making a thermal dye receiving element comprising providing a support for an imaging element; applying an aqueous subbing layer to the support; and extruding thereon at least one thermal dye receiving layer.

Owner:KODAK ALARIS INC

Dyeing method based on cotton fabric active dye cationic modifier

InactiveCN107740295AIncrease electrostatic attractionImprove dye uptakeDyeing processChemical industrySodium carbonate

The invention belongs to the technical field of dye chemical industry and discloses a dyeing method based on a cotton fabric active dye cationic modifier. The dyeing method comprises the following steps: (1) carrying dyeing treatment by adding cotton fiber into a glutamate aqueous solution or a phenylalanine salt aqueous solution, carrying out temperature-increasing treatment, taking the cotton fiber out, washing the cotton fiber to obtain modified cotton fiber; (2) carrying out dyeing treatment by dyeing the modified cotton fiber according to a conventional process, wherein the content of reactive dye in a dyeing solution is 1-2wt%, the content of sodium carbonate is 5-10g / L, the content of sodium chloride is 23-30g / L, and dyeing for 40-60 minutes under the dyeing condition at the temperature of 50-70 DEG C; and (3) carrying out aftertreatment of the dyed cotton fiber according to the conventional process to obtain the dyed cotton fiber. The method is capable of not changing all the properties of the cotton fabric after carrying out aftertreatment, even obtaining excellent dyeing effect, effectively reducing the consumption of salt and alkali, achieving low-temperature dyeing, achieving environment-friendly dyeing and reducing the cost.

Owner:ZHAOQING UNIV

Synthesis method for acid red R3G adapted for virgin pulp spray

InactiveCN101125964AHigh yieldReduce consumptionReactive dyesDyeing processSynthesis methodsDissolution

The invention relates to a synthesis method of protoplasm spray drying acid red R3G, comprising the steps of dissolution of 2-amino-5-naphthol-7-sulfonic acid, one-step condensation, diazoniation, coupling and finally two-step condensation. The 2-amino-5-naphthol-7-sulfonic acid is dissolved before the one-step condensation through that the 2-amino-5-naphthol-7-sulfonic acid is added to water and stirred evenly; then pH of the solution is adjusted to 7 through sodium hydroxide solution of 30 percent and the temperature rises to 60-70 DEG C; after the full dissolution, the solution is provided with a bush, the temperature is decreased to 25-15 DEG C and the solution is stirred for two hours under the temperature; then precipitated 2-amino-5-naphthol-7-sulfonic acid is filtered and filtering cake is pressed and dried for purpose in one-step condensation; the finished process is after the completion of dye synthesis, the strength of the 2-amino-5-naphthol-7-sulfonic acid is adjusted to the strength of finished product through glauber salt and spay dried under the temperature of outlet ranging from 90-110 DEG C and the finished produce can be packed directly at last. Compared with the products of the prior art, the acid red R3G of the invention improves 10 percent of yield, and eliminates waste water with salt generated from salt precipitation technique, which not only saves raw materials but also shortens production time, improves product economic benefit, eliminate discharge of waste water and facilitates environmental protection.

Owner:TIANJIN DEK CHEM

Formula of compound active dye used for household textile fabrics

The invention relates to a formula of a compound active dye used for household textile fabrics, and belongs to the technical field of textile printing and dyeing. The formula of the compound active dye comprises, by weight, 50-70 parts of a difluorochloropyrimidine dye, 20-30 parts of a triarylmethane dye, 10-20 parts of a nitroso dye, 60-75 parts of a vinyl sulfone dye, 5-15 parts of Rubia cordifolia plant dye extract, 15-25 parts of a heptamethine cyanine dye, 2-8 parts of sodium thiosulfate, 5-15 parts of sodium chloride, 10-15 parts of disodium hydrogen phosphate, 25-35 parts of sodium dihydrogen phosphate, 5-15 parts of sodium hydroxide, 5-15 parts of sodium carbonate, 20-30 parts of urea, 10-20 parts of 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole and 5-15 parts of carbon nanotubes. The active dye has excellent fastness, excellent wet fastness, bright color, excellent performances and strong applicability, the hue and the performances of the active dye can meet the fiber and clothing requirements in the market, the addition of the 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole improves the anti-ultraviolet property of the active dye, and the presence of the carbon nanotubes improves the antistatic performance of the active dye.

Owner:NANTONG WEIXING TEXTILE TECH CO LTD

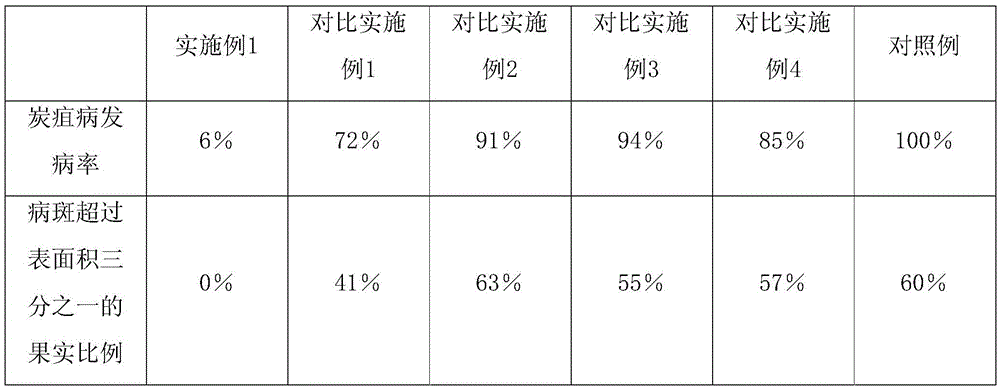

Process for preparing natural green persimmon dye based on bacillus subtilis fermentation method and application of obtained dye

PendingCN105624201AAvoid the phenomenon of "sticking to the wall"Avoid damageBiocideMicroorganism based processesAlcoholSugar

The invention provides a process for preparing natural green persimmon dye based on a bacillus subtilis fermentation method and application of the obtained dye, belongs to the field of preparation and application of the natural dye, and particularly relates to the process for preparing the natural green persimmon dye based on a fermentation method and application of the obtained dye. A saccharomycete fermentation mode is adopted, carbohydrate constituents are completely decomposed and converted into ethyl alcohol while the green persimmon dye is extracted, and the phenomenon of wall sticking, caused by the fact that the proportion of sugar in extract is too high in the following drying process, of a drying machine is avoided. The green persimmon extract is obtained in a bacillus subtilis fermentation environment, and a byproduct generated through bacillus subtilis fermentation and the green persimmon extract coordinate on the aspect of preventing and treating anthracnose. The extract achieves bacterium resistance and ultraviolet resistance properties after dyeing fabric.

Owner:CHANGZHOU UNIV

High-efficiency fabric printing and dyeing device

InactiveCN107620182AEnhance layeringImprove efficiencyLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor textile treatmentEngineeringDyeing

The invention provides a high-efficiency fabric printing and dyeing device. The device is used for dyeing a first fabric and a second fabric which are fed to a dyeing system in a parallel mode at thesame time, the first fabric and the second fabric are fed to the dyeing system at the same time through a second fabric feeding system and a first fabric feeding system respectively, the first fabricis located above the second fabric, a dyeing mechanism in the dyeing device is located above a first to-be-dyed fabric, the first to-be-dyed fabric and a second to-be-dyed fabric which are fed to thedyeing system in a parallel mode at the same time are dyed in the dyeing device at the same time, dye from the dyeing mechanism in the dyeing device is firstly used for dyeing the first to-be-dyed fabric located above the second to-be-dyed fabric, after the first to-be-dyed fabric is completely dyed, dye permeates the first to-be-dyed fabric to reach the second to-be-dyed fabric located below thefirst to-be-dyed fabric, and the dye flowing out from the first to-be-dyed fabric is used for dyeing the second to-be-dyed fabric located below the first to-be-dyed fabric. The device has the advantages of being good in effect, uniform in color tone and high in efficiency.

Owner:浙江一诺环保科技有限公司

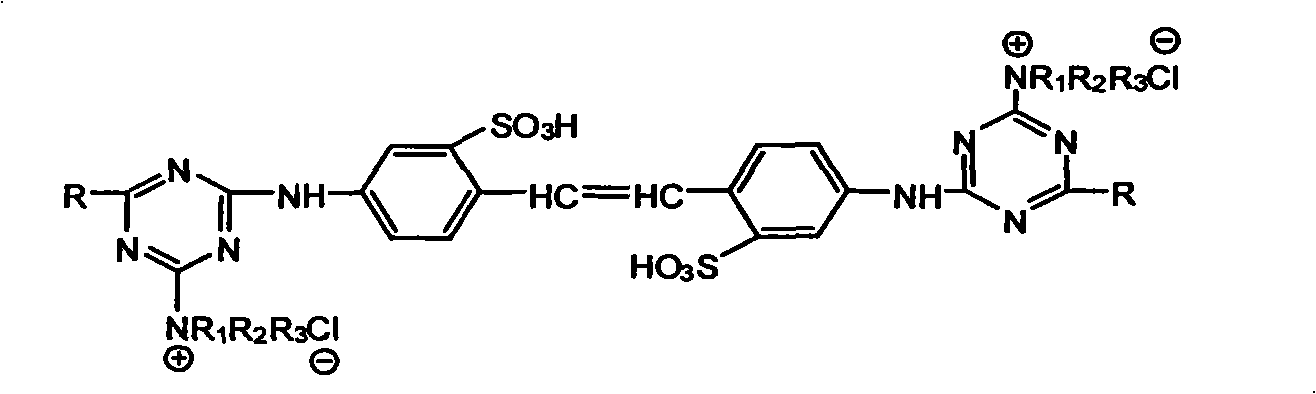

Amino-chloro-benzene-containing quaternary ammonium salt type fluorescent whitener, synthesizing method thereof and applications

InactiveCN101307031AWhiteness stabilityIncrease the scope of applicationOrganic chemistryDetergent dyesPhenyl groupCyanuric chloride

The invention relates to a series of fluorescent whitening agents containing amino chlorophenyl group quaternary ammonium salt, as well as synthesis and an application of the same. The series of fluorescent whitening agents is mainly applied to papermaking paint printing ink and textile. The synthesis adopts the following steps that: a. cyanuric chloride reacts with amino-chloro-benzene at a temperature between 0 and 5 DEG C for 2.5 h, with pH value controlled to be between 1.8 and 2.1, so as to synthesize one-step condensation product; b. the one-step condensation product reacts with 4, 4'-diaminodiphenylethylene-2, 2'-disulfonic acid at a temperature between 40 and 45 DEG C for 2.5 h, with pH value controlled to be between 3.5 and 4.5, so as to synthesize two-step condensation product; c. the two-step condensation product reacts with a series of tertiary amine compounds at a temperature between 78 and 85 DEG C for 3.0 h, with pH value controlled to be between 7.8 and 8.5, so as to synthesize a series of triazine-DSD acidic fluorescent whitening agents containing amino chlorophenyl group quaternary ammonium salt. Application results show that: the fluorescent whitening agents can be used under neutral / alkaline conditions, and has higher dye uptake rate and better whitening effect under acidic conditions.

Owner:SHANDONG UNIV

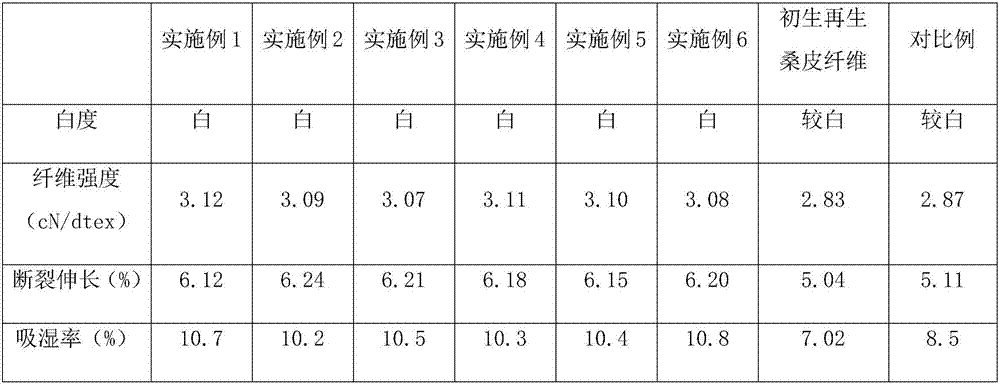

Completely efficient refining agent for regenerated mulberry bark fibre and application method of completely efficient refining agent

InactiveCN107059390AReduce lossesImprove stabilityMonocomponent cellulose artificial filamentBiochemical treatment with enzymes/microorganismsPectinaseFiber

The invention provides a completely efficient refining agent for regenerated mulberry bark fiber and an application method of the completely efficient refining agent. The completely efficient refining agent comprises hydrogen peroxide, neutral cellulase, pectinase, laccase, alpha-amylase, polyether silicone oil, sucrose fatty acid esters, alkyl glucosides and EDTA. The application method includes adding degummed mulberry bark fiber into NMMO ionic liquid, and then adding antioxidants, heating with stirring to obtain transparent colloidal spinning solution mixed uniformly, subjecting the spinning solution to deaeration and then to wet spinning, carrying out drawing and drying to obtain primary regenerated mulberry bark fiber; placing the primary regenerated mulberry bark fiber in the completely efficient refining agent, heating while vibrating, and then taking a product out to obtain the regenerated mulberry bark fiber. To the primary regenerated mulberry bark fiber, the completely efficient refining agent which is the combination of biological scoured enzymes and chemical reagents can refine the regenerated mulberry bark fiber completely efficiently in a mild and efficient way so that the prepared generated mulberry bark fiber is more uniform, tough, soft, comfortable, and excellent in comprehensive performance.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

High dye uptake disperse dye composition and preparation method and application thereof

InactiveCN105647235AGood soaping fastnessGood perspiration fastnessOrganic dyesDyeing processDisperse dyeChemical compound

The invention relates to a high dye uptake disperse dye composition and a preparation method and application thereof. The disperse dye composition is prepared from a compound shown in the formula I with the content accounting for 5-25% of the total mass of the dye composition, a compound shown in the formula II with the content accounting for 5-25% of the total mass of the dye composition, a compound shown in the formula III with the content accounting for 0.5-10% of the total mass of the dye composition, a compound shown in the formula IV with the content accounting for 0.5-8% of the total mass of the dye composition, and the balance additive. The preparation method comprises the steps that the compounds in the formulas I, II, III and IV and the additive are mixed to be uniform and are ground and subjected to spray drying so as to obtain the high dye uptake disperse dye composition. The disperse dye composition is applied to dyeing of hydrophobic fiber or fiber blends. The disperse dye composition has the good soaping fastness, perspiration fastness, sublimation fastness and whiteness pitching fastness. The preparation method is simple in technology, low in cost and good in application prospect.

Owner:俞杏英

Brightyellow combined dispersible dye

ActiveCN1850913AEasy to liftGood dyeing rateOrganic dyesDyeing processDisperse dyeHigh concentration

The invention discloses a compounding dispersing dye that is suitable for dye printing polyester material. The invention could make the bright yellow product that has high concentration, and reduce polluted water. It has good dyeing repeatability and good color fastness.

Owner:ZHEJIANG RUNTU

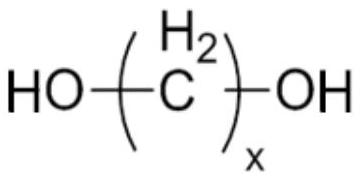

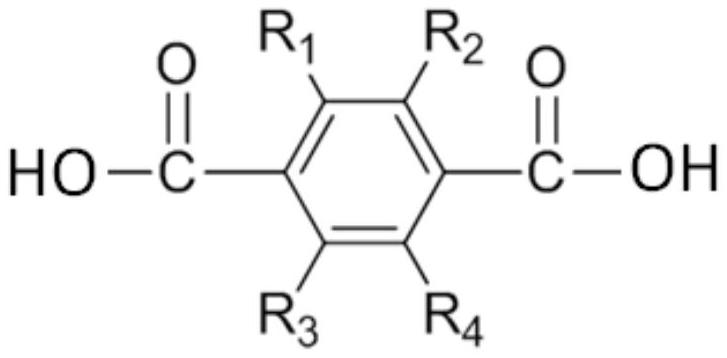

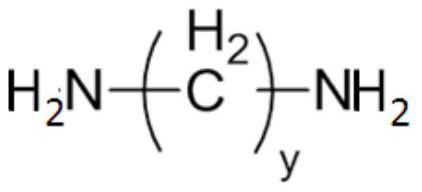

Polyesteramide, preparation method thereof and fiber

ActiveCN111825838ALow yellow indexImprove thermal stabilityMonocomponent polyamides artificial filamentPolymer sciencePtru catalyst

The invention provides polyesteramide, a preparation method thereof and a fiber. The preparation method of the polyesteramide comprises the following steps: in an inert atmosphere, carrying out esterification reaction on terephthalic acid and / or derivatives thereof and dihydric alcohol in an esterification reaction kettle in the presence of a catalyst; after the esterification reaction is finished, adding a dibasic acid amine salt aqueous solution into the esterification reaction kettle for an amidation reaction, wherein the mass concentration of the dibasic acid amine salt aqueous solution is20-80%; and after the amidation reaction is finished, transferring the amidation product into a polycondensation reaction kettle to carry out polycondensation reaction, finishing the polycondensationreaction when the intrinsic viscosity of the polycondensation product reaches 0.3-1.8 dL / g, and collecting the polycondensation product to obtain the polyesteramide. According to the preparation method provided by the invention, the problem that yellowing is easy to occur in a polyesteramide synthesis process at the present stage can be solved, so that the obtained polyesteramide has a relativelylow yellow index.

Owner:CATHAY R&D CENT CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com