Activated dark blue to black dye compositioncombination and dye product

A technology of black dye and reactive navy, applied in the field of reactive navy to black dye compositions and dye products, can solve the problems of weak dye depth, difficult cleaning of dyed fabrics, insufficient blackness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

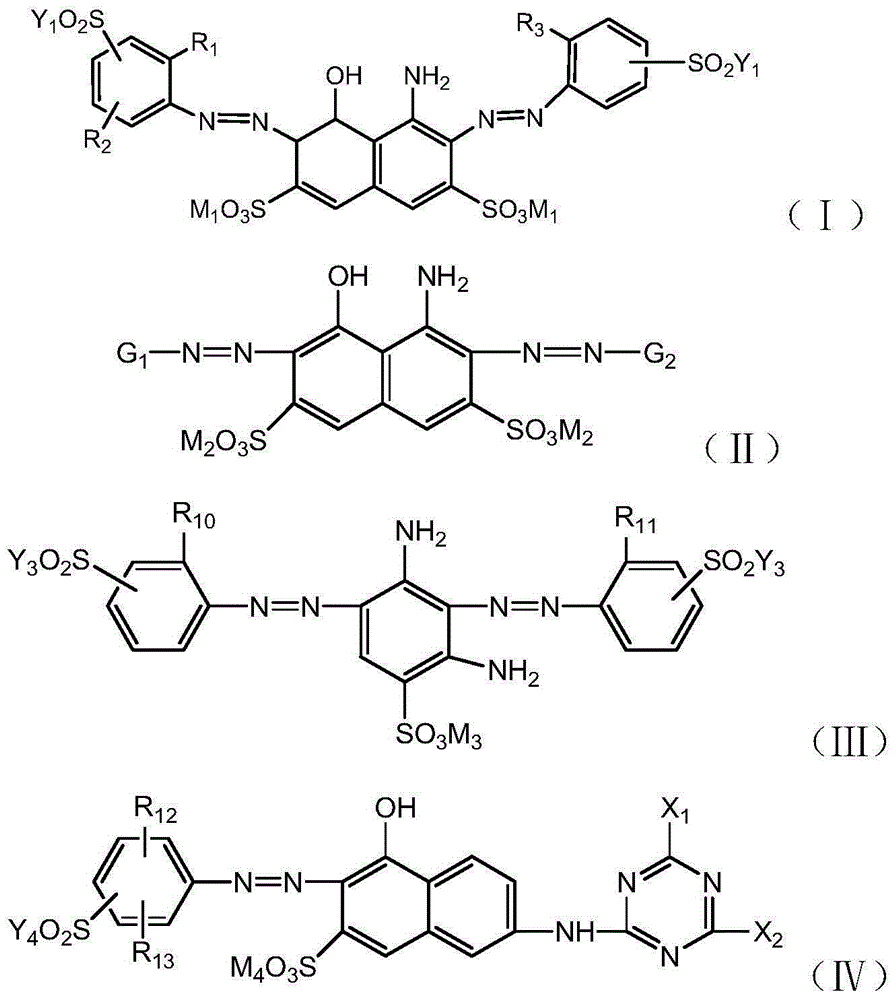

[0084] Mechanically mix 90 parts of the dye compound represented by formula (I-1), 10 parts of the dye compound represented by formula (II-1) and 15 parts of sodium sulfate, and the obtained dye product dyes cotton in navy blue.

[0085]

Embodiment 2

[0087] With 58 parts of dye compounds shown in formula (I-1), 8 parts of dye compounds shown in formula (II-1), 19 parts of dye compounds shown in formula (III-1), 15 parts of formula (IV-1 ) The dye compound shown in ) and 10 parts of sodium sulfate are mechanically mixed, and the dye product dyed cotton obtained is black.

[0088]

Embodiment 3~50

[0090] Mechanically mix the dyestuffs listed in Table 1 to dye cotton from navy blue to black:

[0091] Table 1

[0092]

[0093]

[0094]

[0095] Dyeing example:

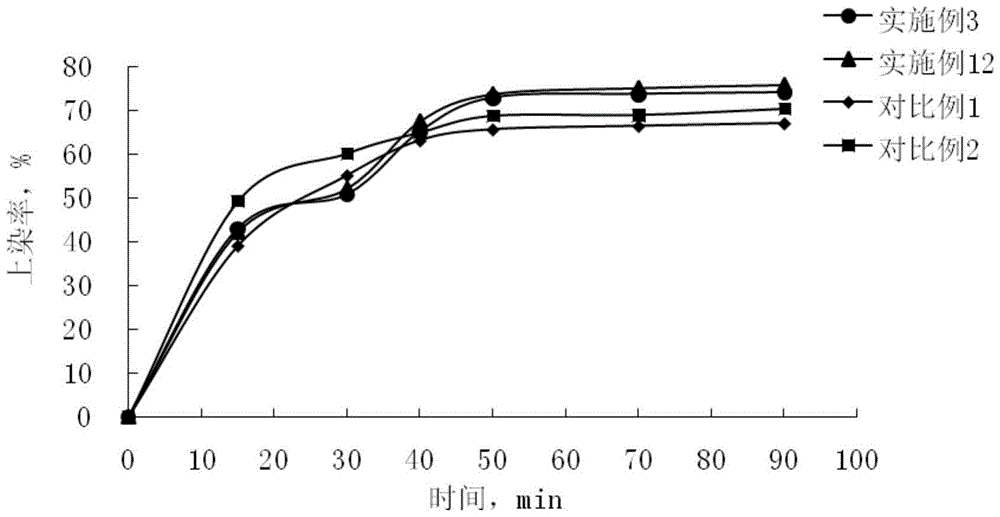

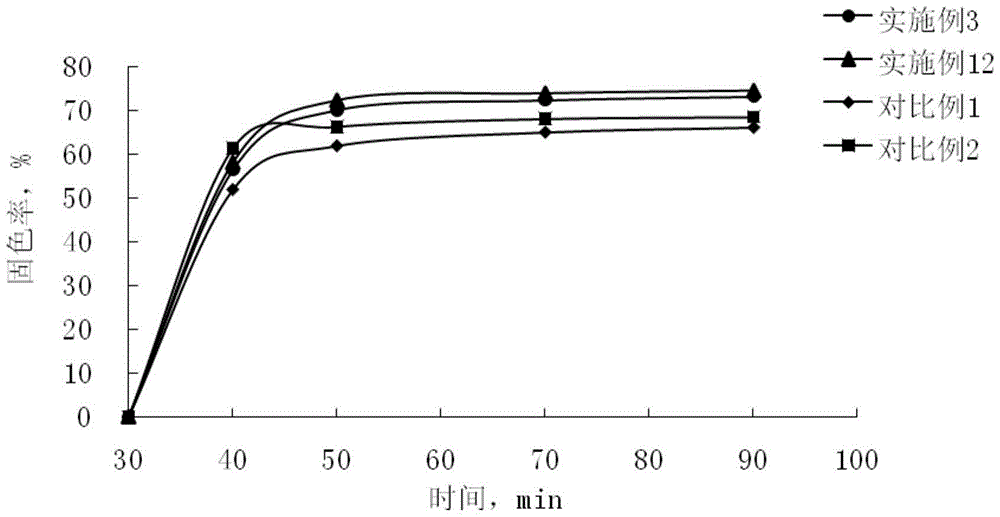

[0096]Add the dye products obtained in Examples 1 to 50 respectively to the dyeing bath containing 60g / L sodium sulfate (dye concentration 2.0%, bath ratio 1:25), and the temperature is raised to 60°C at 2°C / min. Cotton fabrics were dyed for 30 minutes, added soda ash to make the concentration 15g / L, and dyed at this temperature for 45 minutes, then washed the dyed matter, soaped with non-ionic detergent for 15 minutes, rinsed and dried. Test its color fastness to washing and rubbing according to the methods determined in GB / T3921-2008 and GB / T3920-2008 respectively, and the results are as follows:

[0097] Washing fastness: fading ≥ 4 ~ 5 grades, cotton staining ≥ 4 ~ 5 grades, nylon staining ≥ 4 ~ 5 grades, polyester staining ≥ 4 ~ 5 grades;

[0098] Rubbing fastness: dry rubbing ≥ 4 to 5 grades; wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com