Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

959results about How to "Improve dye uptake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

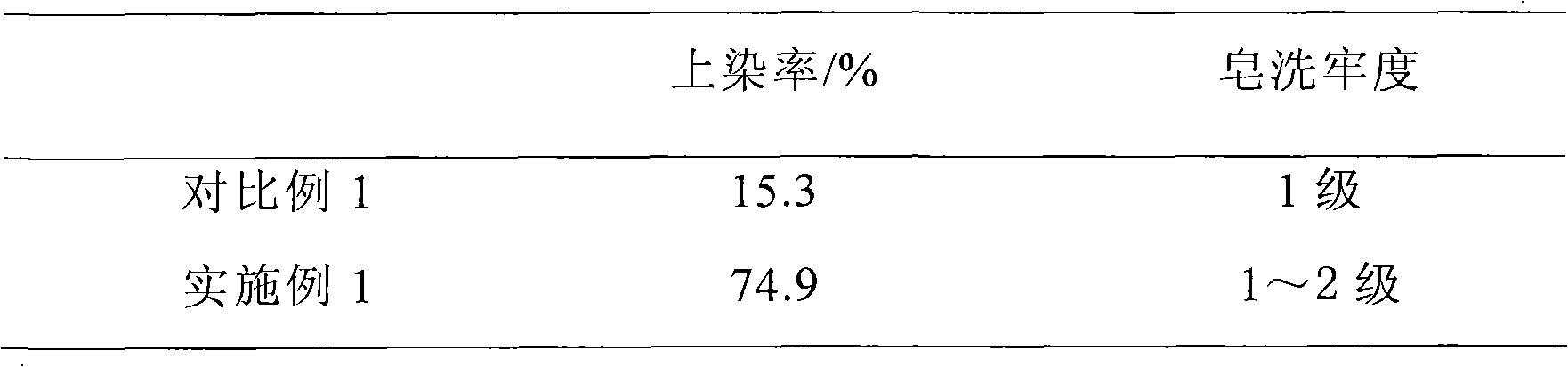

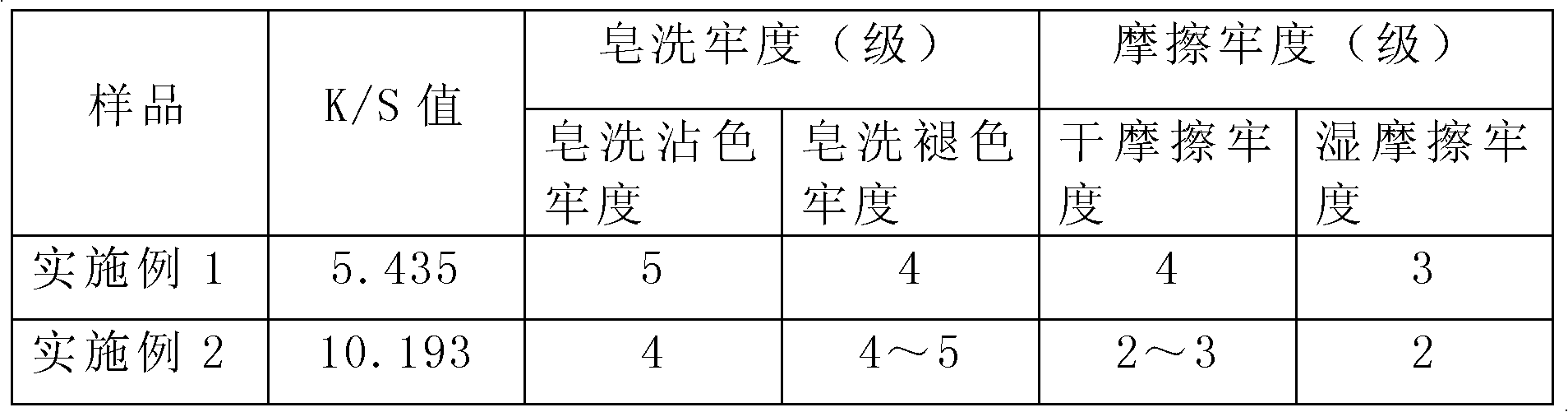

Cation modified dyeing method of ceiba fiber textiles

The invention relates to a cation modified dyeing method of ceiba fiber textiles, which comprises the following steps: immerging the ceiba fiber textiles into a cation modifying agent solution after alkali treatment and bleaching; carrying out cationization modifying treatment for 20 to 60 min; carrying out water washing and baking; then, carrying out dyeing treatment by anionic dyestuff; and next, obtaining products through water washing and baking. Compared with the prior art, the invention adopts the cation modified ceiba fiber method so that the fiber modified by cations has positive charges, the bonding force of anionic dyestuff and the fiber is enhanced through the effect of Coulomb attraction, and the adsorption on dyestuff anions is enhanced. Thereby, the invention improves the dye uptake of the dyestuff, shortens the dyeing time, and saves water and auxiliary agents, and in addition, the salt consumption can be reduced, or even the salt-free dyeing can be realized. In addition, both the water washing fastness and the light fastness of dyeing textiles are improved.

Owner:SHANGHAI UNIV OF ENG SCI

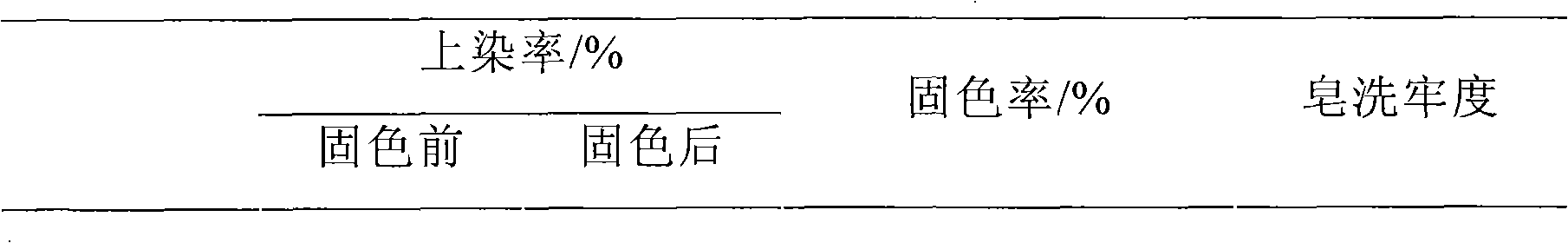

Natural dye dying method based on cotton fiber modification

ActiveCN101187175AImprove adsorption capacityImprove dye uptakeDyeing processCotton fibreNatural dye

The invention relates to a dyeing method of natural dye material of cotton fabric, which belongs to the field of fabric dyeing and finishing technique and comprises: processing the modifying liquid by use of the modifying agent containing anode ions group, firstly modifying the cotton fabric and dyeing the fabric with the natural dyeing material, after cleaning, fulfilling the dyeing with the natural dye material of cotton fabric, wherein due to the modifying process on the cotton fabric in advance, the anode ion base is introduced into the cotton fabric to strengthen the combination ability from the cotton fabric to the natural dye material of cathode ion, which effectively improves the cotton fabric dyeing rate, color depth and dyeing evenness and distinctly improves the anti-washing and anti-abrasion firmness of the dyed cotton fabric. The process has simple operation, even dyeing and wide application prospect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

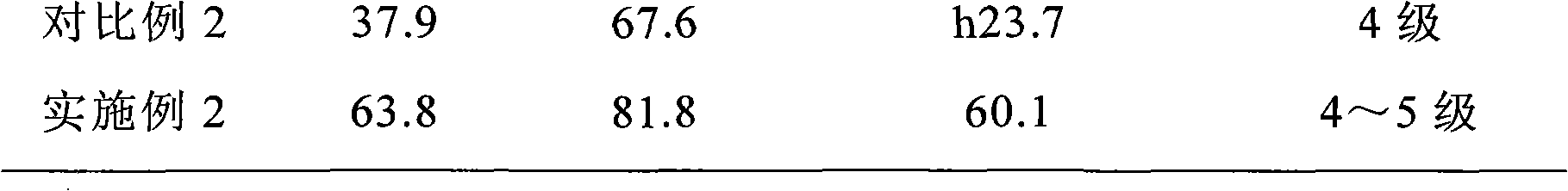

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

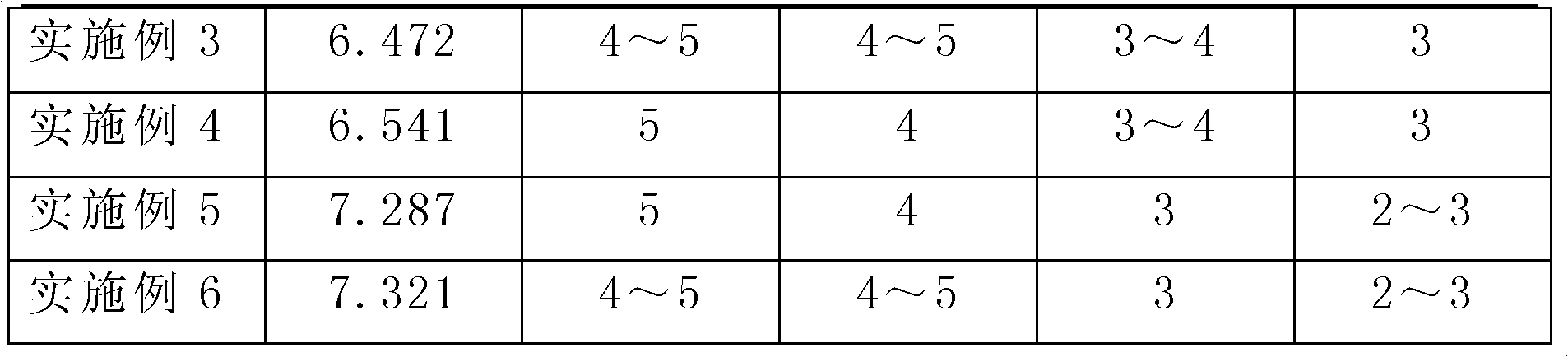

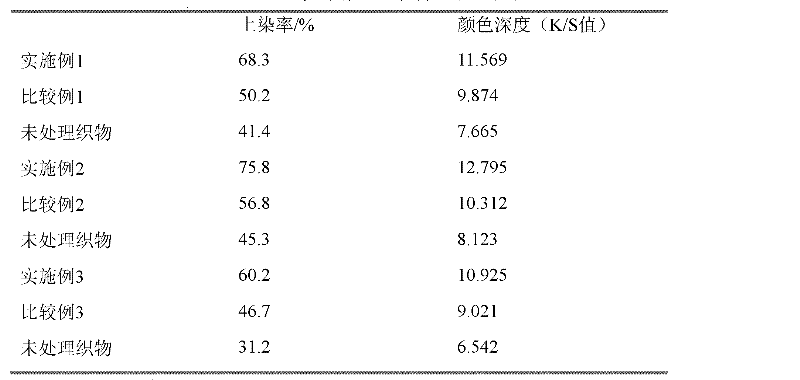

A method for improving the dyeing depth of cellulose fiber fabrics with chitosan

ActiveCN102268823AImprove accessibilityImprove responseDyeing processVegetal fibresEpoxyCooking & baking

The invention relates to a method for improving the dye depth of cellulose fiber fabrics by using chitosan. In the method, a polycarboxylic acid solution is used as a solvent and a cross-linking agent of chitosan and epoxy chloropropane is used as a cross-linking agent, and chitosan is covalently grafted to the surface of the cellulose fiber fabrics through padding, preliminary drying and baking at a high temperature. The combining strength of chitosan and the cellulose fiber fabrics is increased greatly, the electrostatic repulsion between the cellulose fiber fabrics and anionic dyes is reduced, the dye-uptake of dyes and the color depth of the fabrics are improved obviously, and the crease resistance of the cellulose fiber fabrics processed by using the method is improved obviously.

Owner:CHANGZHOU UNIV

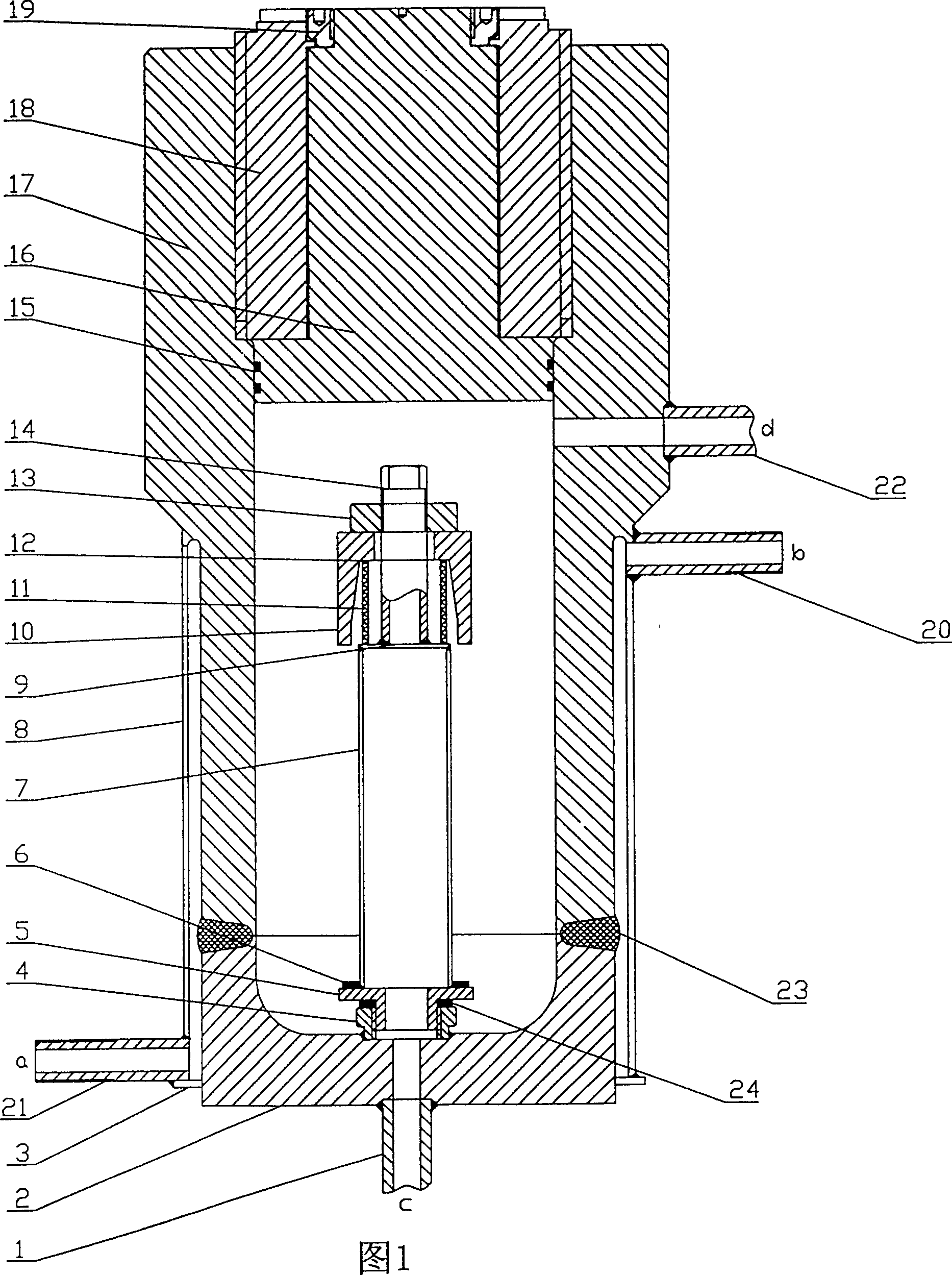

Supercritical carbon dioxide dyeing device and its process

InactiveCN1766194AReduce pollutionImprove dye uptakeSolvent treatment with solvent recoveryTextile/flexible product manufactureCo2 storageHigh pressure

The invention discloses a supercritical carbon dioxide dyeing device, which comprises mainly a CO2 storage tank (H01), a dye kettle (H06), and a dyeing kettle (H07). Wherein, the dyeing technique comprises: cooling the CO2 from HO1 into liquid to send into preheater (HO5) connected to HO6 with carbon-dioxide high-pressure pump (HO4); sending supercritical carbon dioxide to HO7 by HO6; driving the dyed carbon dioxide to pass separator (HO8) and second condenser (HO9) and return to said storage tank (HO1). This invention can recycle 100% residual dye and carbon dioxide as dyeing medium, saves water and dye resource, and reduces pollution.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Ecological dyeing method for dyeing cotton fabric with mulberry red natural dye

InactiveCN101851868AImprove protectionNo allergic reactionDyeing processVegetal fibresEngineeringNatural dye

The invention relates to an ecological dyeing method for dyeing a cotton fabric with mulberry red natural dye, comprising the following steps: preprocessing the cotton fabric and then dyeing the preprocessed cotton fabric with the mulberry red natural dye; adding metal salt for fixation; and soaping the fabric after fixation and then fixing colors to obtain the dyed fabric with even color, wherein washing fastness can reach 3-4degrees. The ecological dyeing method has simple dyeing process, high dye-uptake, good pigment stability and wide market prospect.

Owner:CHANGZHOU GOLDEN SPRING TEXTILE +1

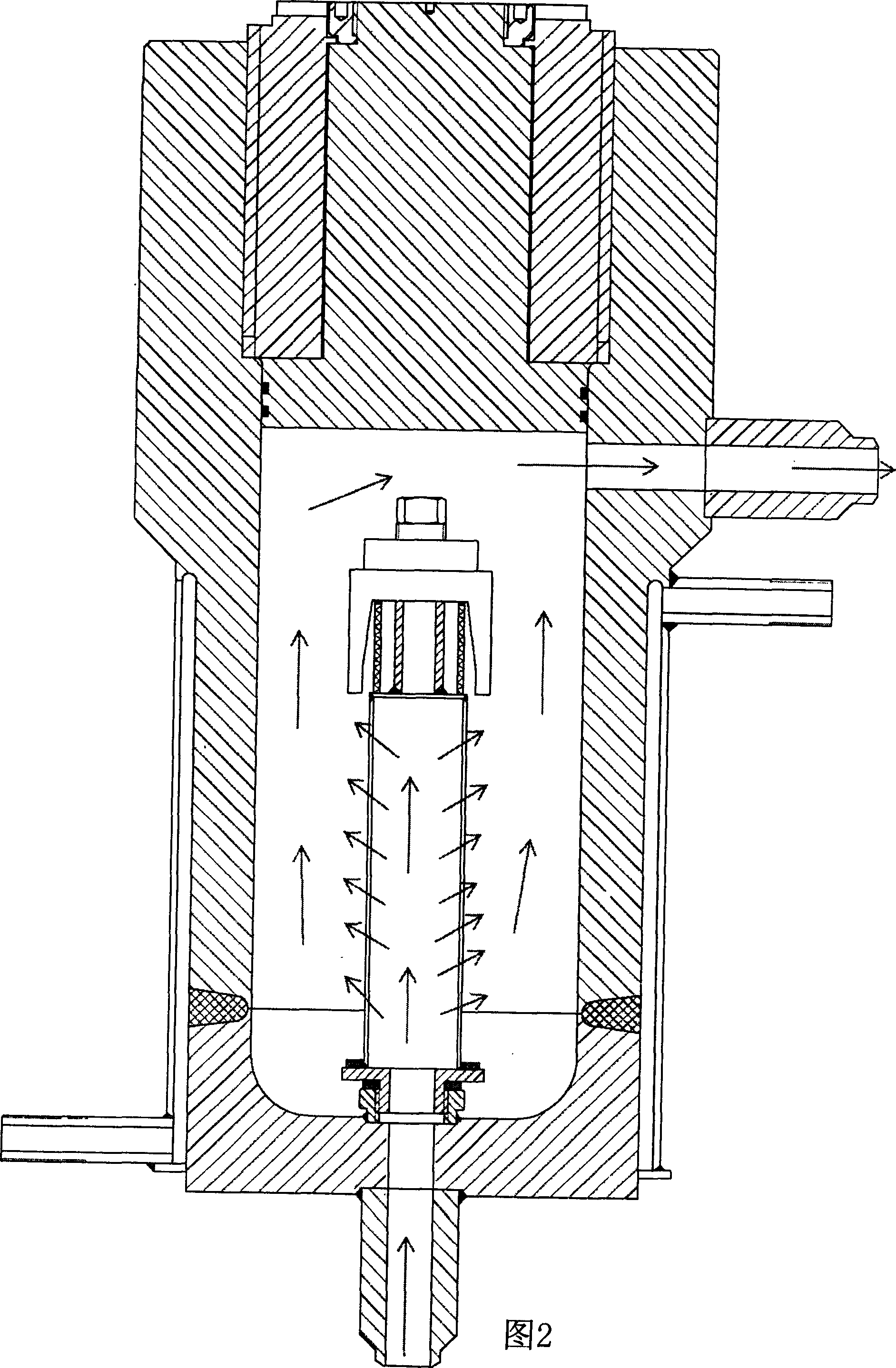

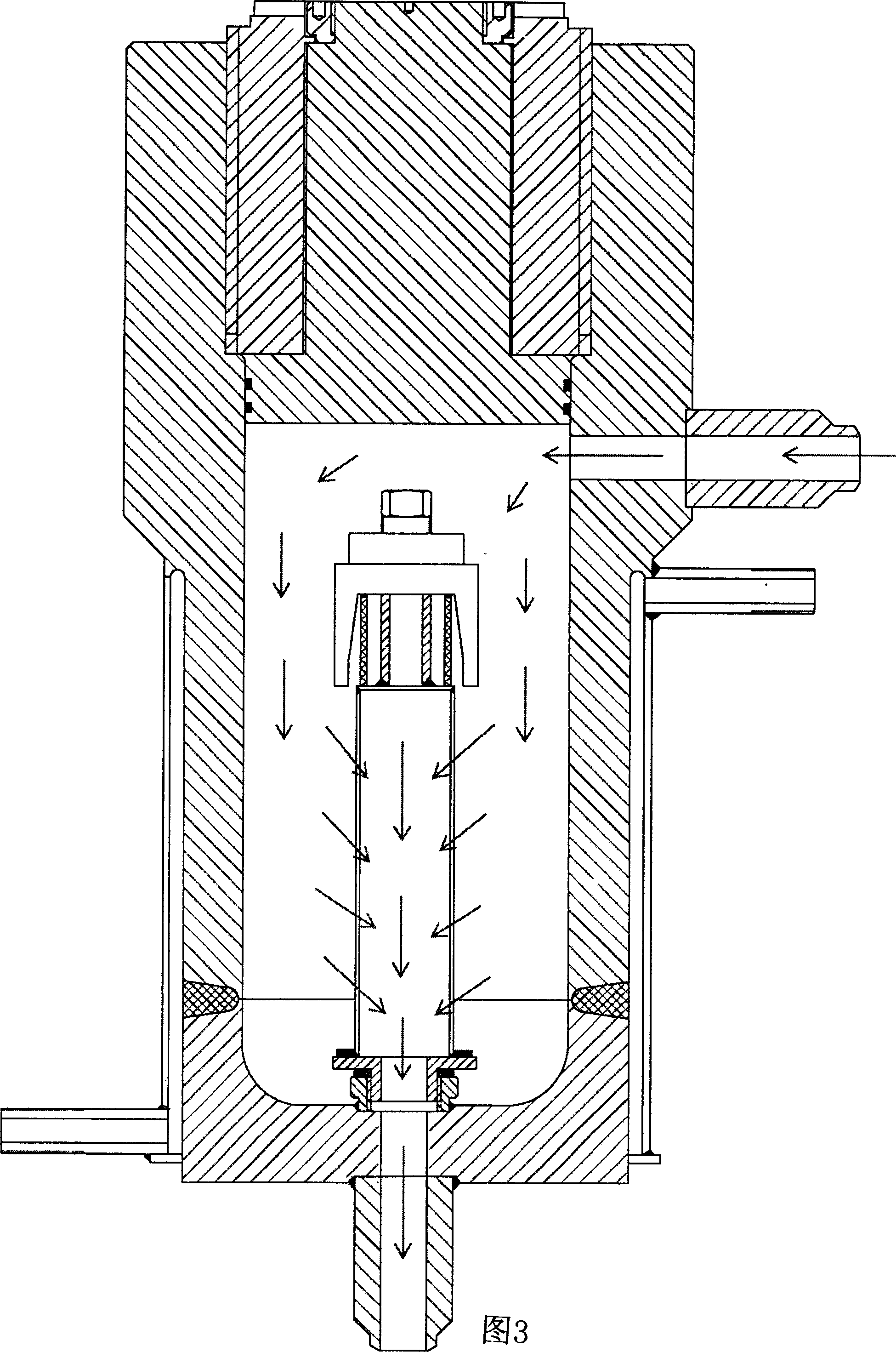

Dying still in supercritical CO2 dyeing device

InactiveCN1807742ARealize the operation process of dynamic dyeingReduce dye liquor vortexTextile treatment containersDyeing processEngineeringMechanical engineering

This invention discloses a dyeing kettle of the over-critical carbon-dioxide dyeing device, which is to use for the dyeing of the textile, including arranging the barrel and the sealed convex shoulder flat that is on the upper part of the barrel; the center opening of the barrel's bottom connects with the first connector, the inside center opening of barrel connects with the inner barrel by the support cell; the wall of the inner barrel is arranged with the filter hole uniformly, the upper of the inner barrel connects with the second cover; the barrel wall opening of the barrel's upper connects with the second connector; the under part of the barrel connects with the nip cover, which has the ring space with the barrel, and the upper of the ring space is sealed in the protruding stage that outside the barrel, and the first cover is sealed in the under part, one side of the ring space's under part opening connects with the first adapter, and the other side of upper part opening connects with the second adapter. This invention realizes the combining of the technology of the textile internal dyeing and external dyeing, and the dynamic dyeing in the over-critical dyeing method.

Owner:DALIAN POLYTECHNIC UNIVERSITY

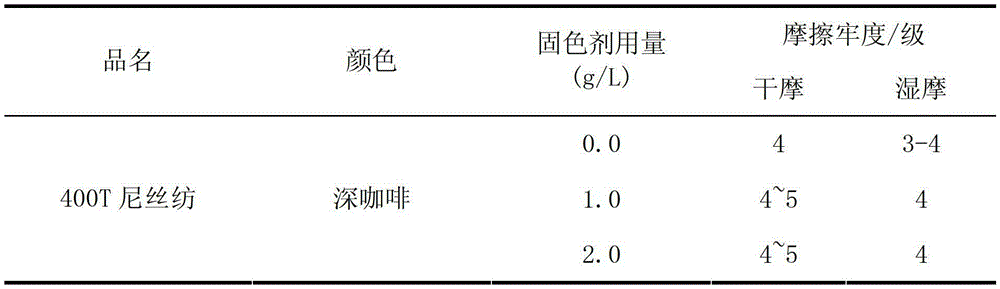

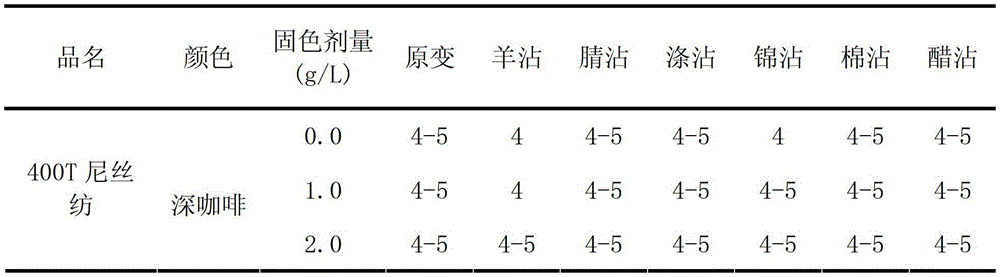

Process for producing high-density nylon fabric

ActiveCN103147304AImprove dye uptakeImproves UV resistanceFibre typesDyeing processCross-linkNylon material

The invention discloses a process for producing a high-density nylon fabric. The process comprises the following steps of: unwinding and sewing; treating before desizing; presetting; dyeing; fixing color; dewatering; scutching; after-finishing; calendaring; detecting, folding and packaging. The process is characterized in that the phenomenon that the fabric gets yellow at high temperature can be reduced and the dyeing rate of the fabric can be improved because a yellowing resisting agent is used in the process of presetting, the ultraviolet resisting capacity of the fabric can be well improved because an ultraviolet absorbing agent is used in the process of dyeing, the tearing strength of the fabric can be improved because a right amount of a cross-linking agent and a tearing-fastness improving agent are added into a setting and finishing solution, and the excellent down penetration effect of the fabric can be achieved without using a chemical additive coating because the process of calender finishing is adopted.

Owner:SHENGHONG GRP CO LTD

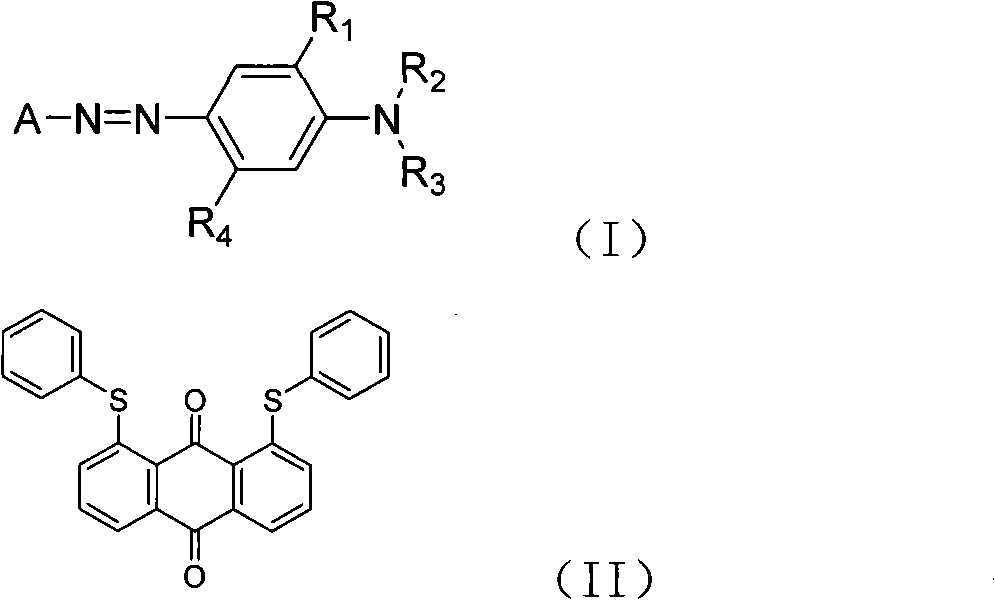

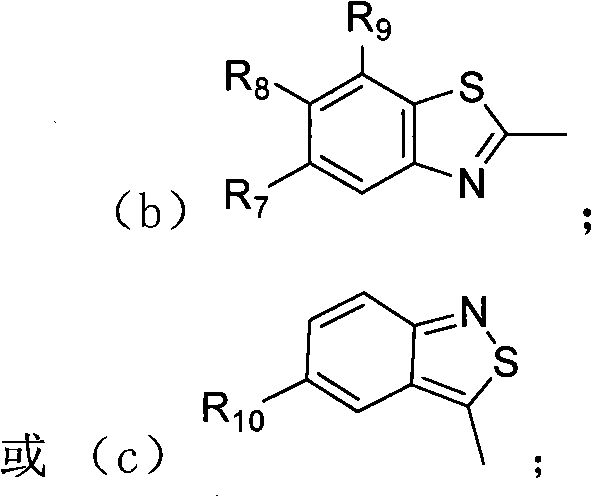

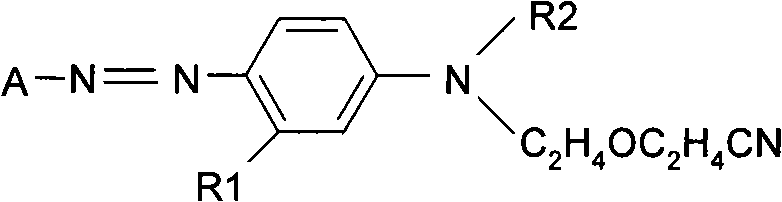

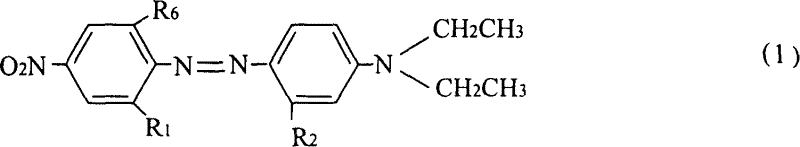

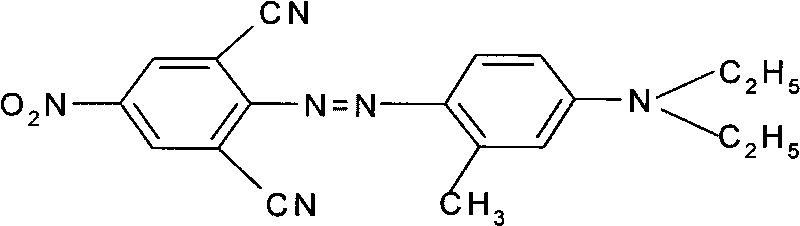

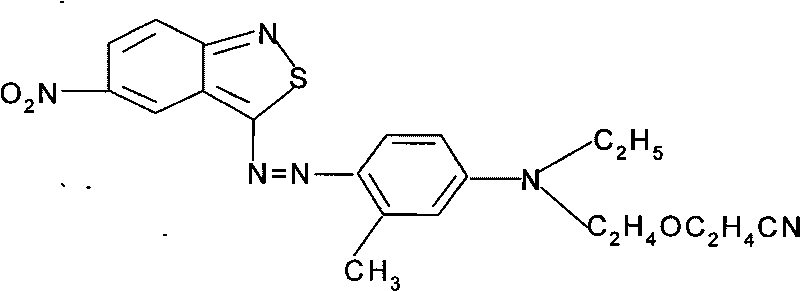

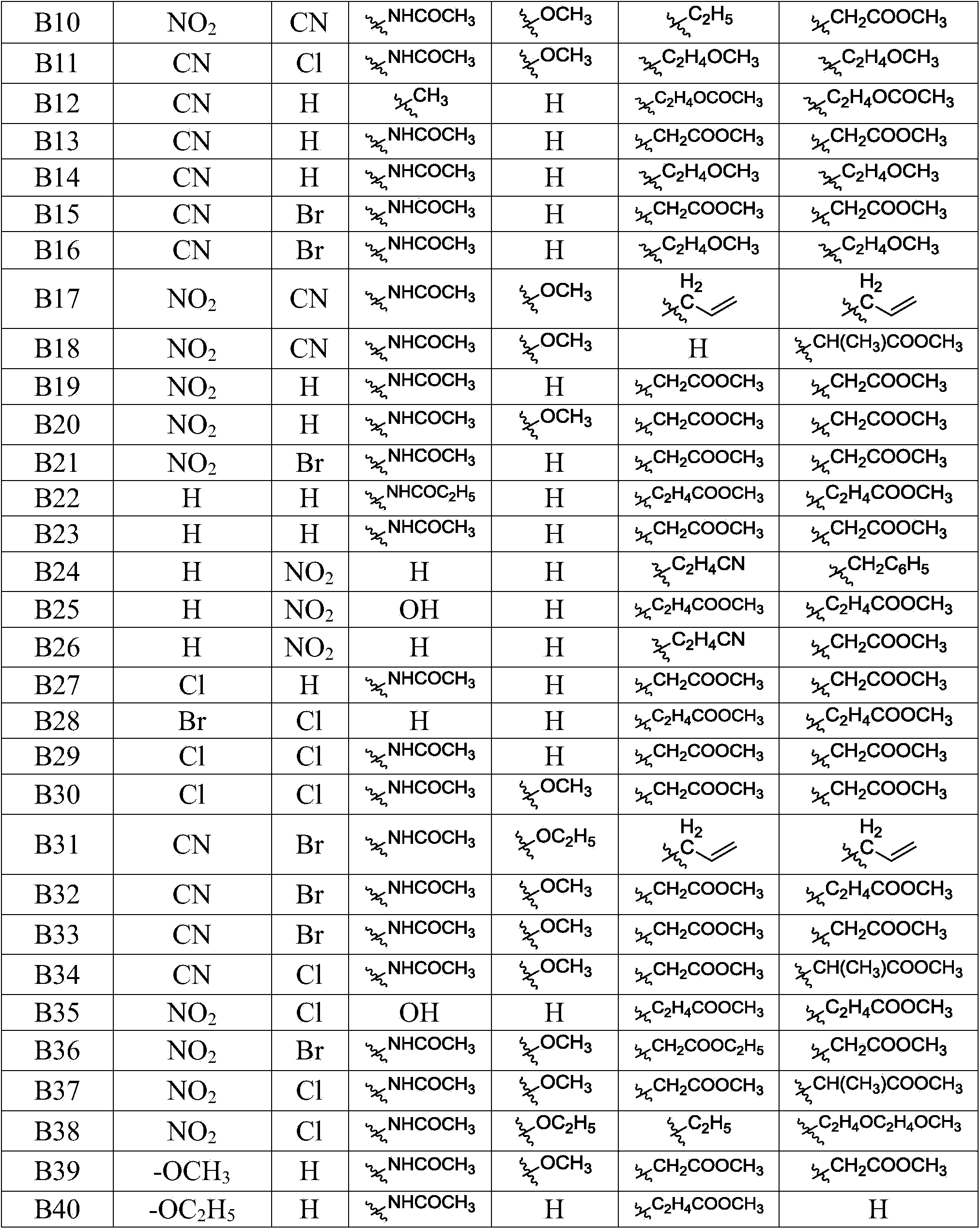

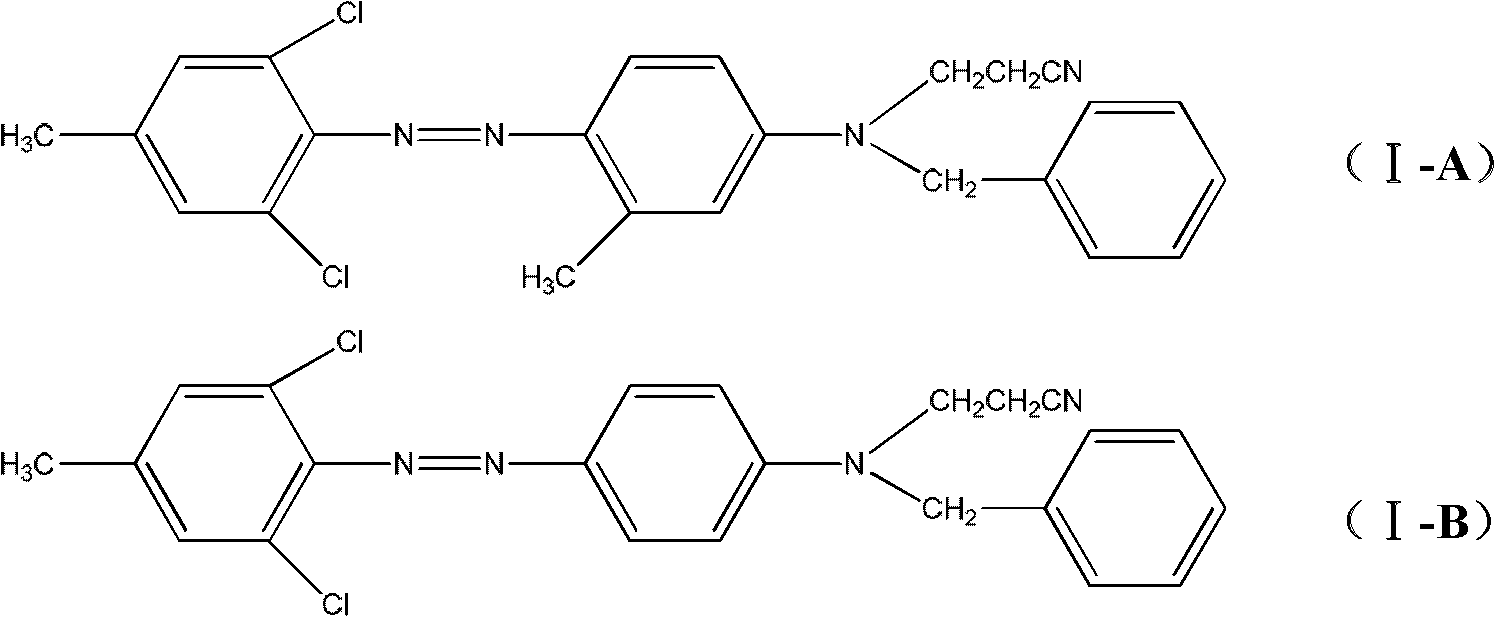

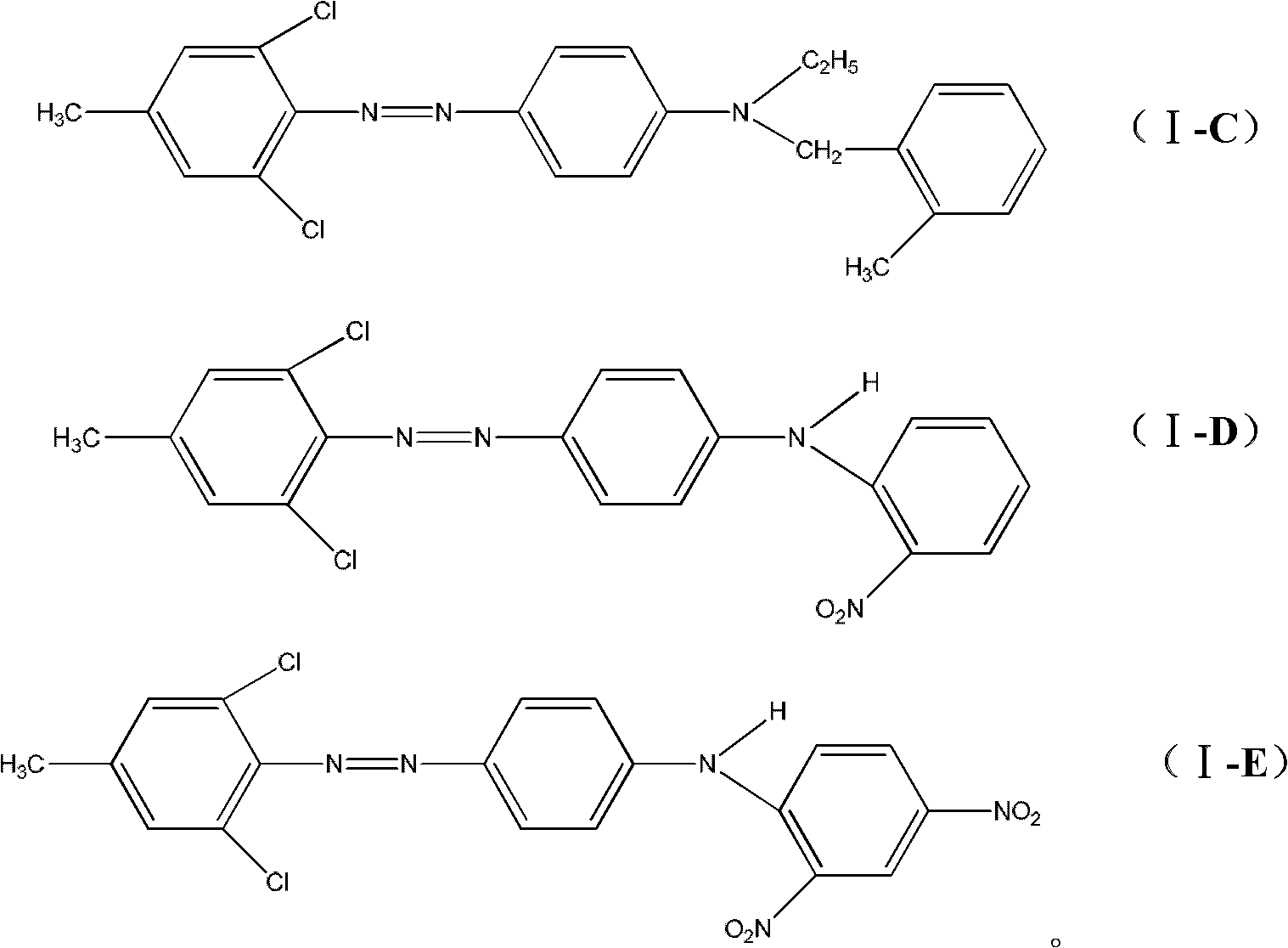

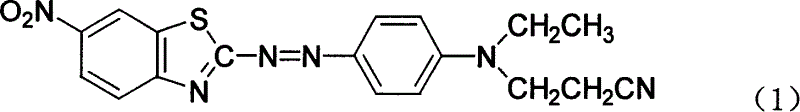

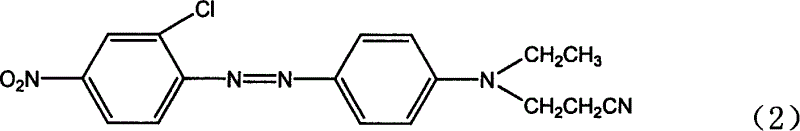

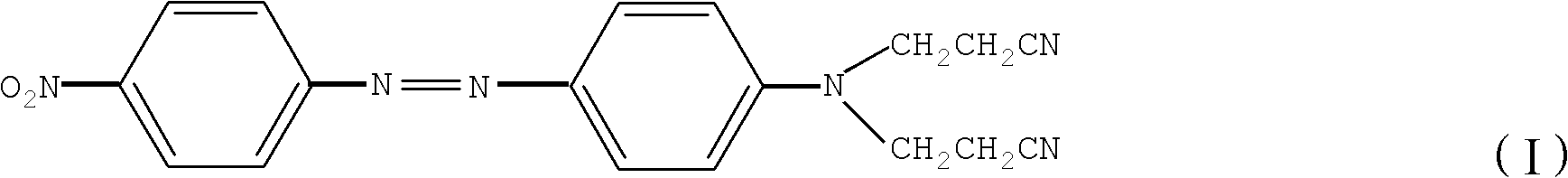

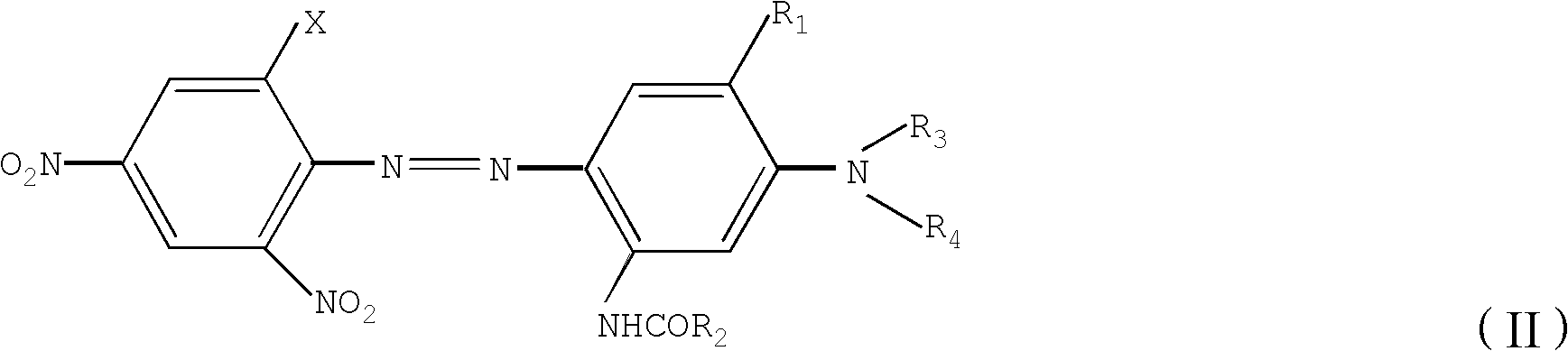

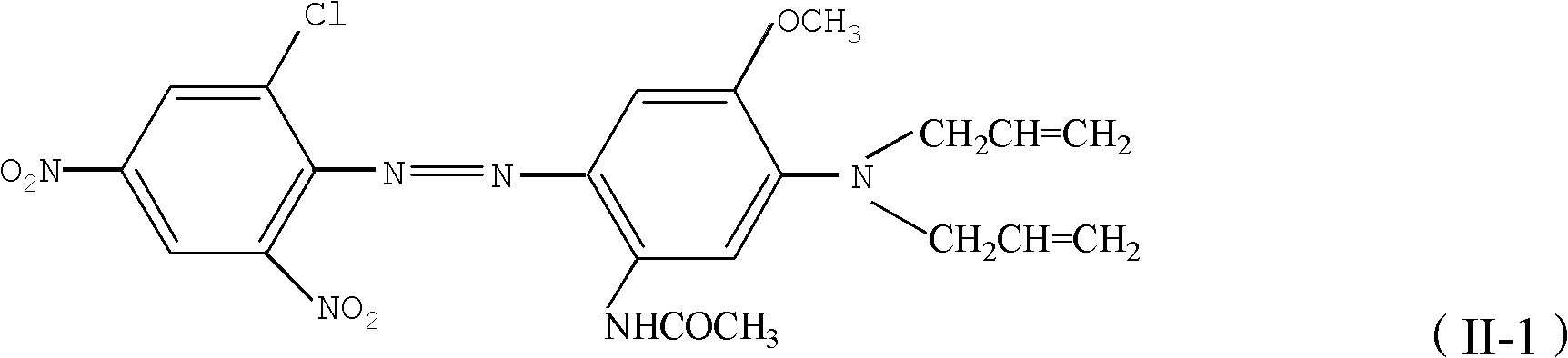

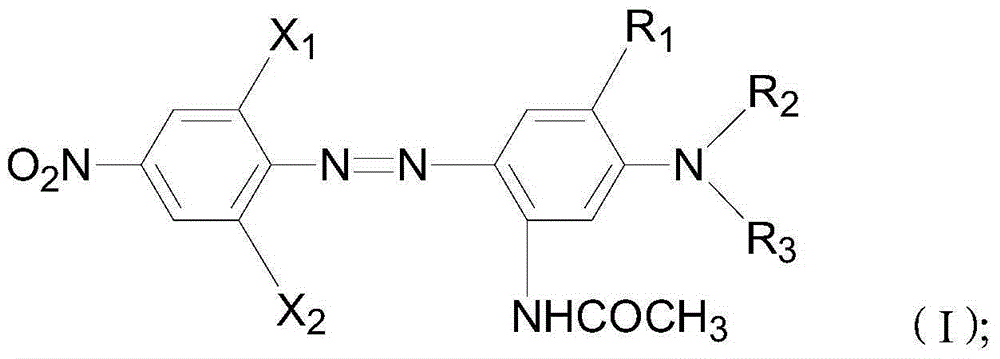

Azo dye composition and application thereof

ActiveCN101265369AChromatography is completeBright shadeOrganic dyesDyeing processAlkalinityDisperse dye

The invention relates to an azo dye compound and the application thereof. The compound is the combination of at least two dyes with A in the general formula (I) selected from any structure of (a), (b) or (c); any combination with A to be at least one from (a), at least one from (b) or at least one from (c); or the combination of at least one dye shown by the general formula (1) and at least one general disperse dye, or / and a dye as shown by the formula (2). Each substituent is shown as the claim of right. The compound can dye polyester and blended fabric thereof under the condition of strong alkalinity with pH more than or equal to 11 and less than or equal to 14; the alkalinity condition can effectively remove slurry and oil on the fabric, and overcomes the defect that decomposition products can be separated out in an acid bath, and cause dyeing defect. The cloth and the fabric adopting the azo dye compound are neat and have excellent styles. In addition, the polyester fiber and the blended fabric thereof can be pretreated with alkalinity and be dyed in a bath and at one step, thus improving the efficiency, and reducing the manufacturing cost and the waste water from dyeing.

Owner:浙江昱泰染化科技有限公司

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

Composite environmental protection type grey disperse dyes

An environmental protection type composite disperse gray dye with high dye uptake, fastness, reproducibility and sublimation fastness contains proportionally dye monomers A, B and C and assistant.

Owner:ZHEJIANG RUNTU

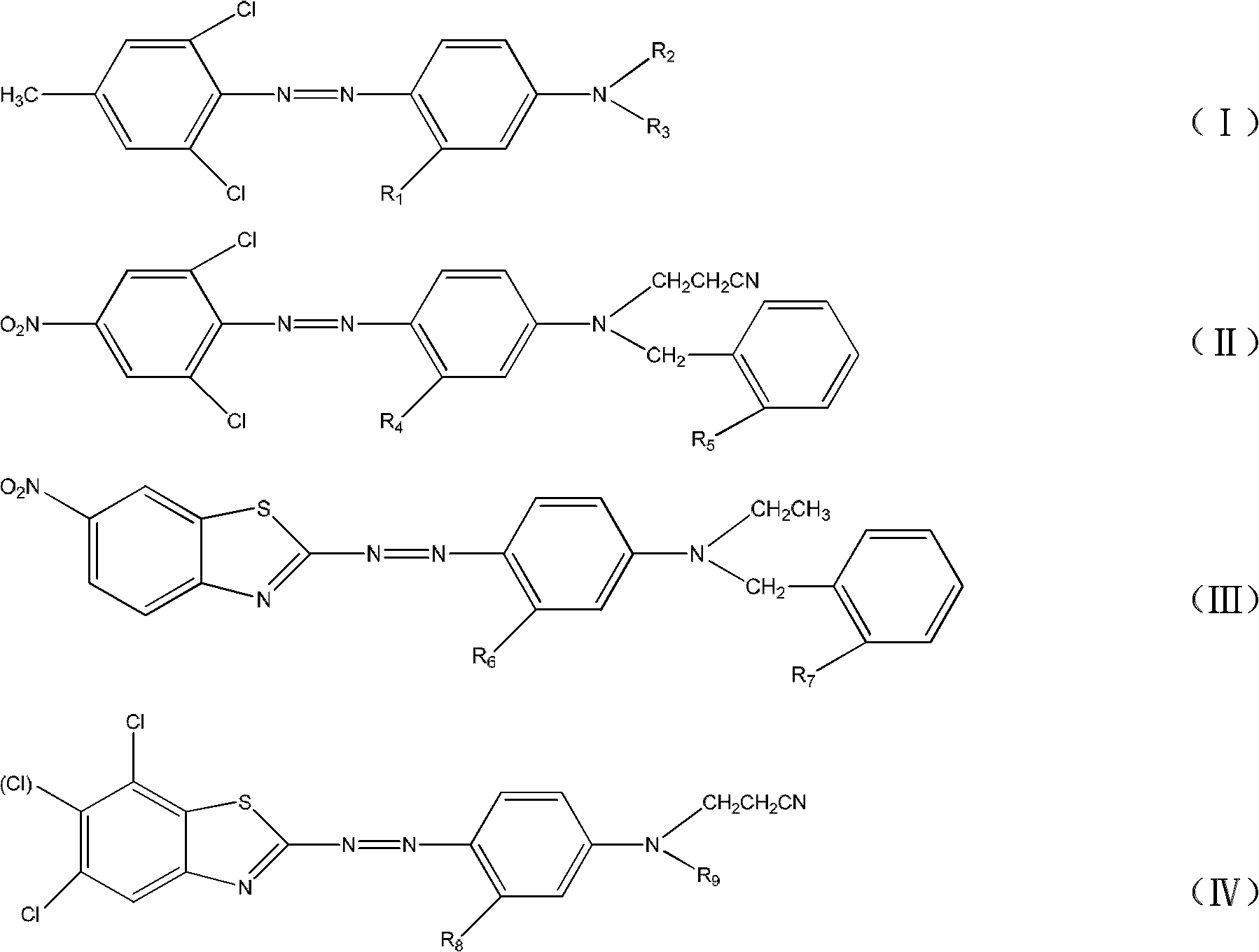

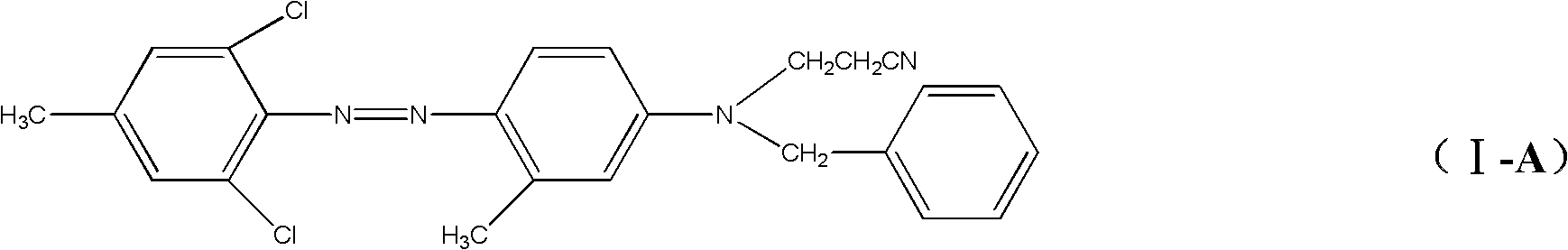

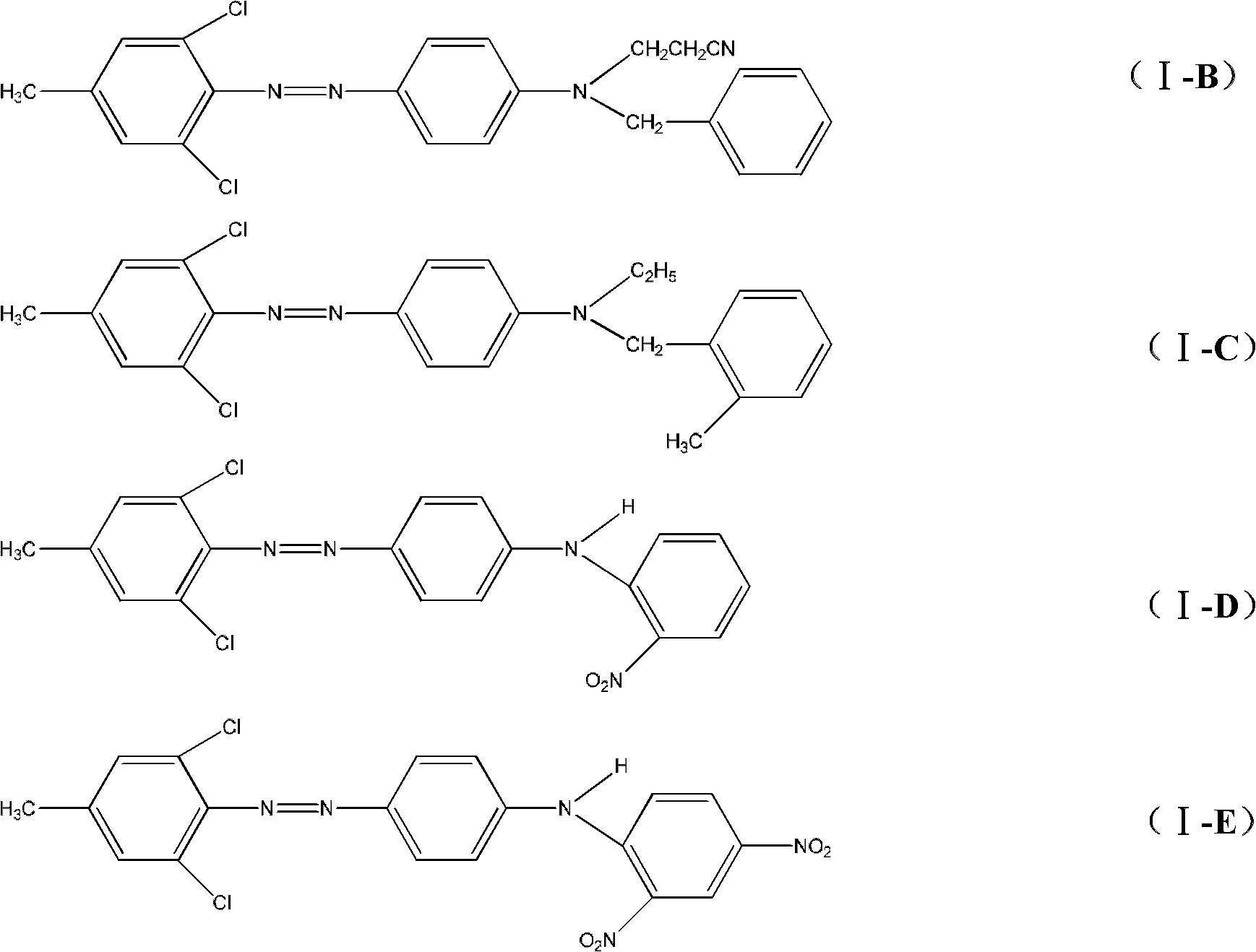

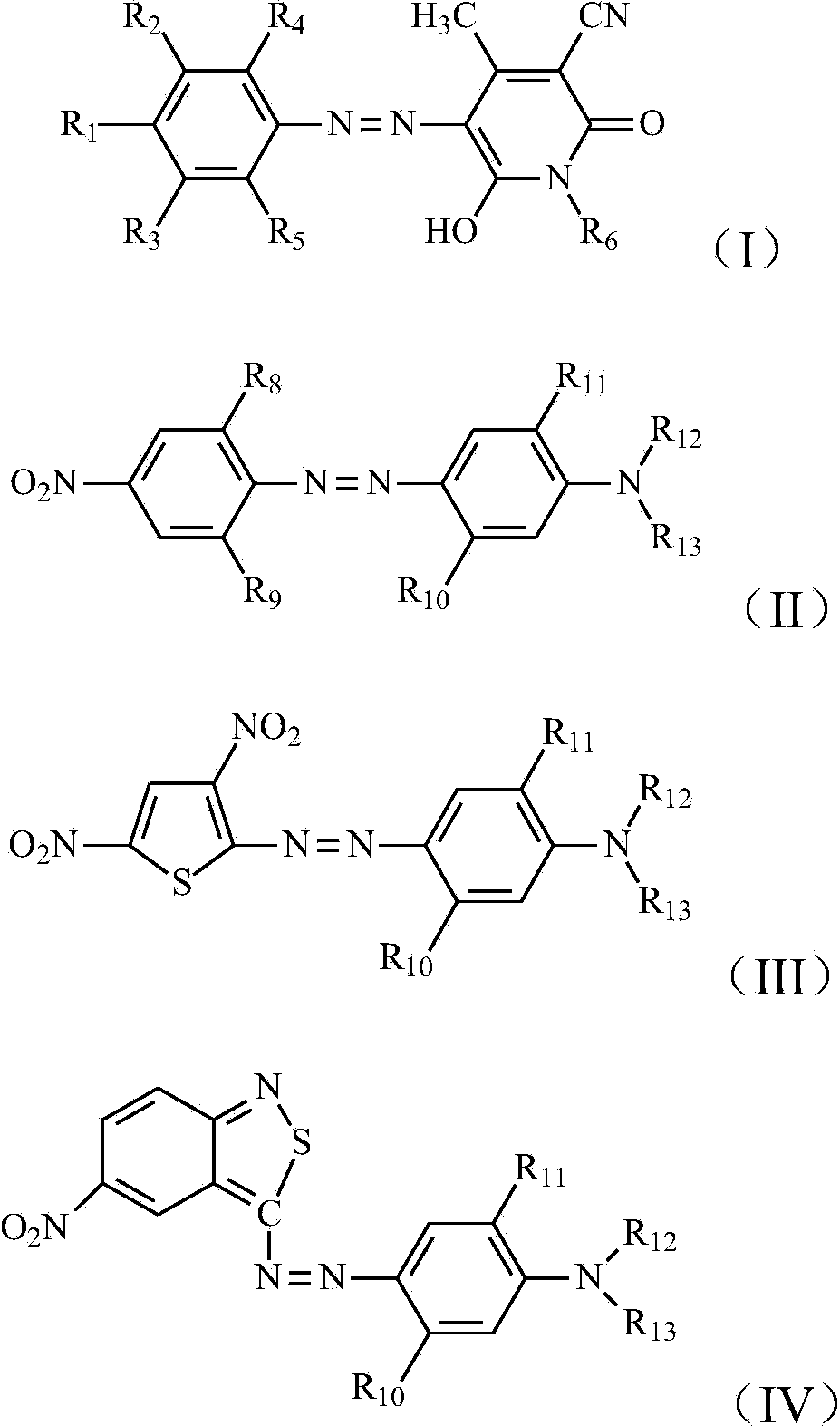

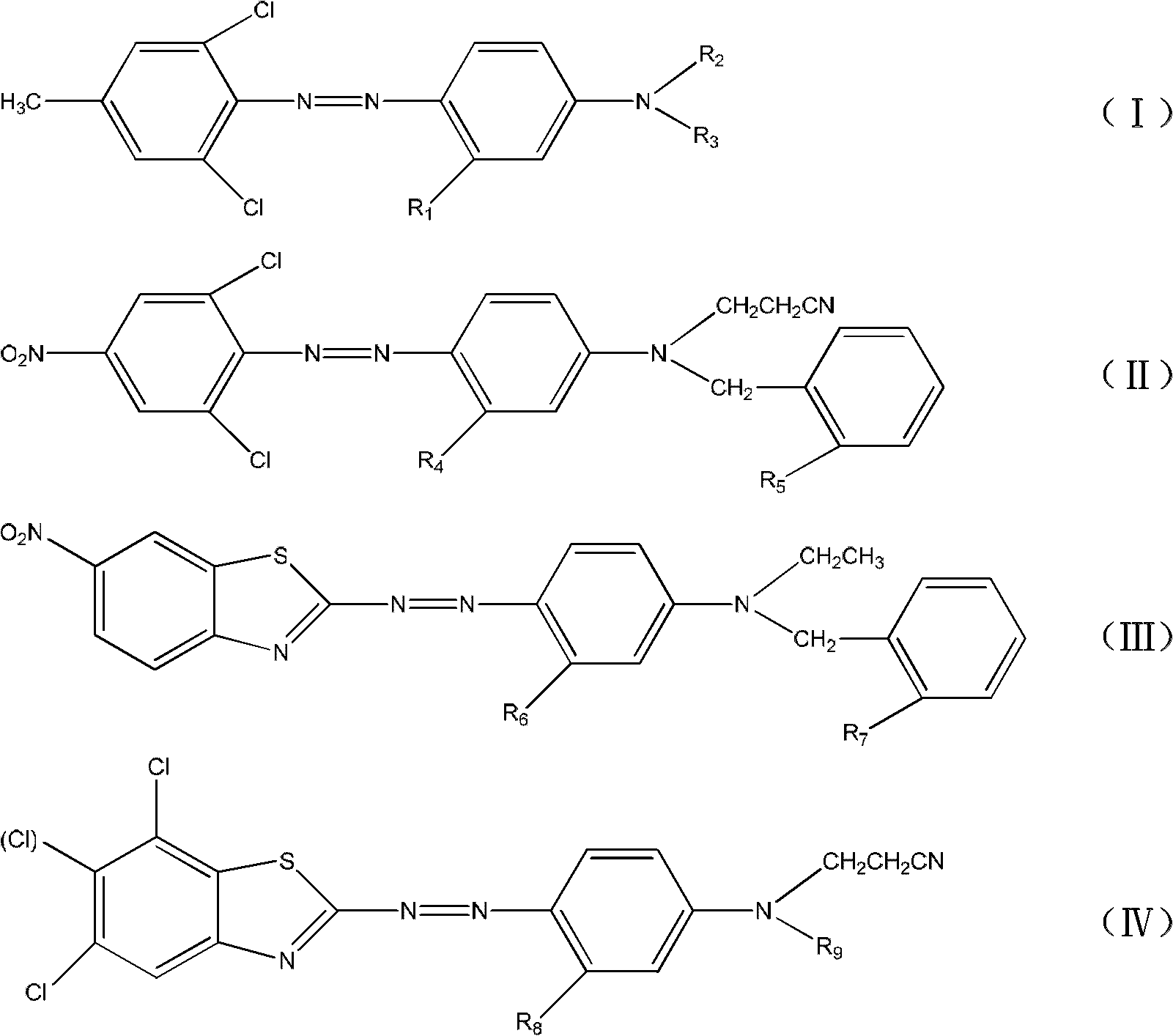

Disperse dye composition for disperse/reactive dye combination printing, and preparation and application thereof

ActiveCN102660145AAchieve one-step printing technologyImprove cleanlinessOrganic dyesDyeing processDisperse dyeYELLOW DYE

The invention relates to a disperse dye composition for disperse / reactive dye combination printing, and preparation and application thereof. The disperse dye composition comprises 2-4 of yellow dyes disclosed as a general formula (I), orange dyes disclosed as a general formula (II), blue dyes disclosed as a general formula (III) and red dyes disclosed as a general formula (IV), wherein the number of dyes disclosed as each general formula does not exceed two. The disperse dye composition is used for a disperse / reactive dye combination printing method. The disperse dye composition is suitable for disperse / reactive dye combination printing technique of terylene / cotton and terylene / viscose blend fabrics, and has the advantages of simple technological process, higher production efficiency, lower production cost and less printing wastewater; the printed fabric has the advantages of smooth cloth cover and favorable fabric style; and Compared with the traditional printing, the invention implements disperse / reactive dye one-step printing technology of terylene / cotton and terylene / viscose blend fabrics.

Owner:ZHEJIANG WANFENG CHEM

Preparation method of hydrolysis-resistant modified polylactic acid fibers

InactiveCN102660797AFeel goodGood flexibilityMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterHydrolysis

The invention relates to a preparation method of hydrolysis-resistant modified polylactic acid fibers. The preparation method comprises the following steps of uniformly mixing 70 to 98.9 parts by weight of polylactic acid, 1 to 30 parts by weight of one or more low-molecular weight polyesters and 0.1 to 5.0 parts by weight of multifunctional polycarbodiimides, carrying out melt blending granulation of the mixture to obtain master batches, carrying out vacuum drying of the master batches, carrying out melt spinning and winding to obtain winded wires, and carrying out drafting to obtain the hydrolysis-resistant modified polylactic acid fibers. The preparation method is simple, has a low cost and is suitable for large-scale production. The hydrolysis-resistant modified polylactic acid fibers have excellent handle and softness, realize low temperature dying, have high dye-uptake in high temperature dying and have good hydrolysis resistance so that the problem of mechanical property degradation produced in high temperature treatment is avoided.

Owner:DONGHUA UNIV

Method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water

The invention relates to a method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water and belongs to the technical field of textile printing and dyeing processing. The dye liquor applies organic solvent soluble in water and lower than water in boiling point, and dye is soluble in water and insoluble in organic solvent, so that effective liquor ratio is lowered, distribution coefficient of dye on fiber is changed, and dye uptake is of dye is increased. Adding the organic solvent allows boiling point of the dye liquor to reduce, energy is saved, water consumption in dyeing process is greatly reduced, the organic solvent can be recycled and reused, and discharge of waste liquor is reduced. The dyeing process includes performing twice-soaking and twice-rolling accelerant solution to textile, and solid accelerant is prevented from being precipitated out at a great amount by being added in dyeing process. The method is low in water consumption, utilization rate of dye is increased, energy consumption is low, the organic solvent can be recycled and reused, and cleaning and dyeing are achieved simultaneously.

Owner:WUHAN TEXTILE UNIV

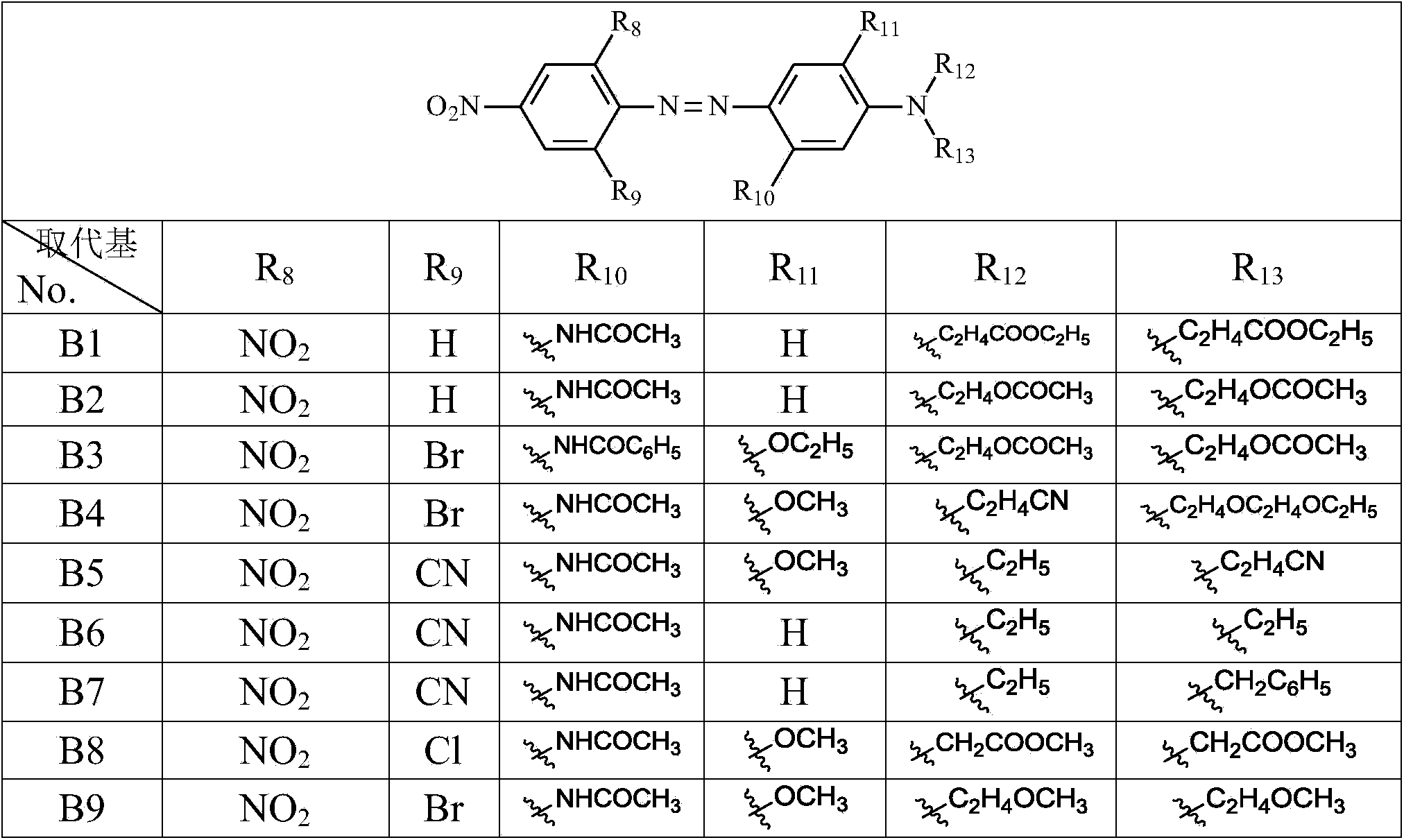

Blue disperse dye mixture

ActiveCN101705020AImprove performanceImprove dye uptakeMonoazo dyesDyeing processDisperse dyePhotochemistry

The invention discloses a blue disperse dye mixture for printing and dyeing polyester materials, which is characterized by comprising the following components in percentage by weight: 5 to 20 percent of dye A, 3 to 28 percent of dye B, 12 to 30 percent of dye C, 0 to 25 percent of dye D, and 45 to 70 percent of dispersant. The blue disperse dye mixture has the characteristics of high dye uptake, good dyeing reproducibility, good leveling property, good fastness and the like, and particularly has excellent dye uptake and wet fastness, and wide dyeing pH range.

Owner:烟台澳土复合材料有限公司

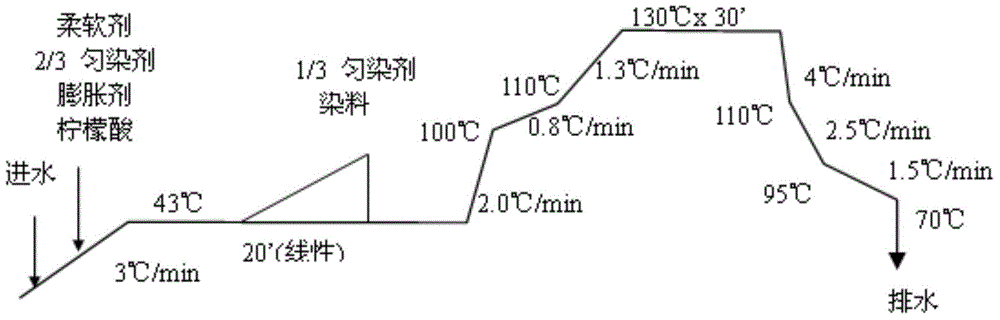

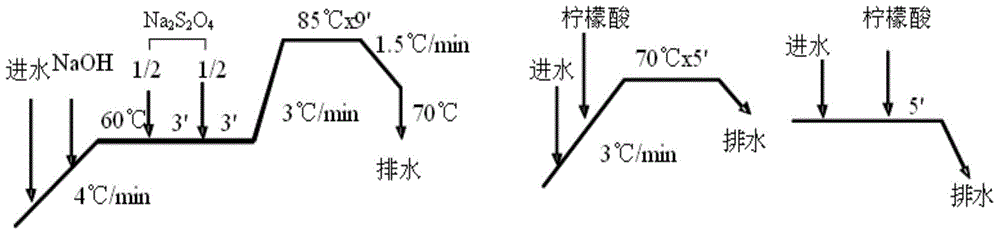

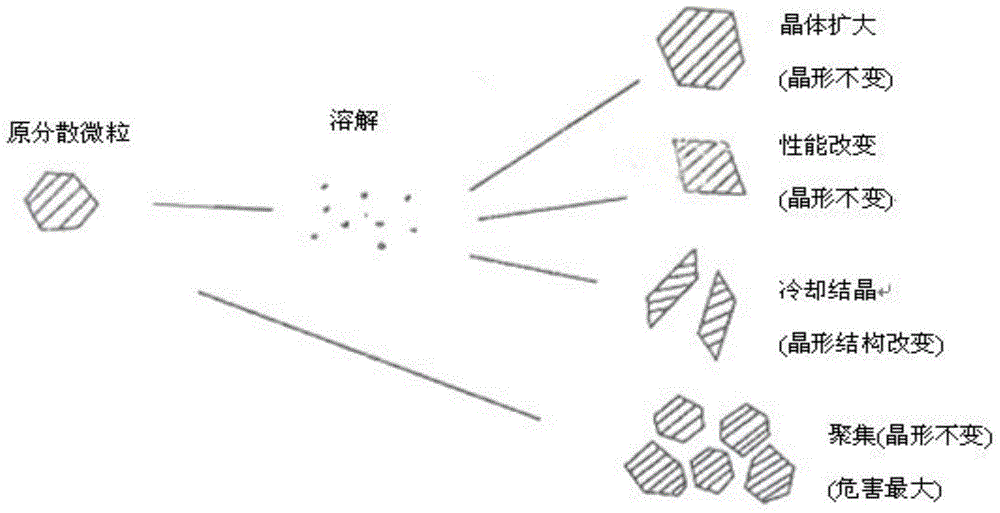

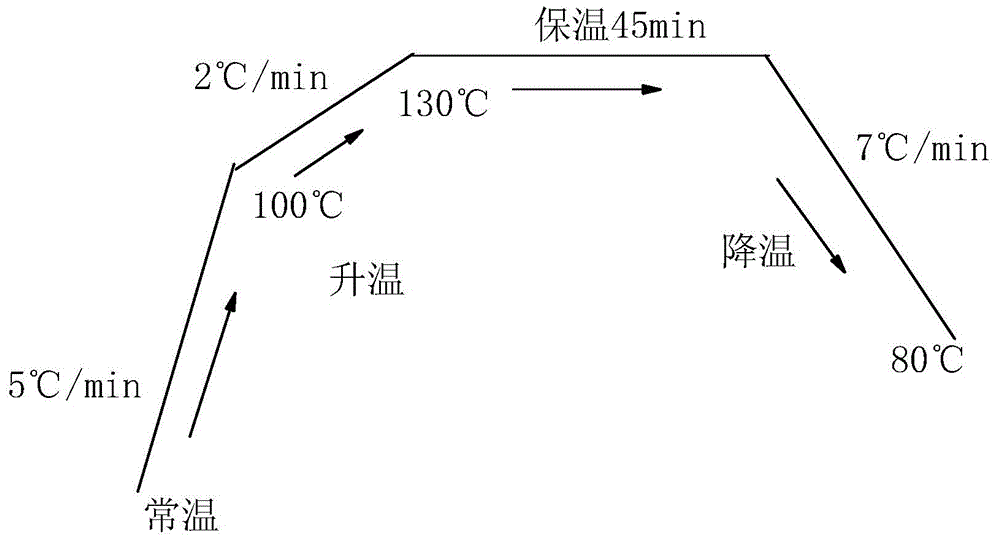

Method for dyeing superfine terylene fabric

ActiveCN104878618AGuaranteed color fastnessImprove dye uptakeDyeing processDisperse dyeColour fastness

The invention discloses a method for dyeing a superfine terylene fabric. The method comprises the following dyeing steps: adding a softening agent, part of a leveling agent, and an expansive agent into the soppy superfine terylene fabric to prepare a working solution; adding a pH regulator to regulate the pH value of the working solution to 3.5-4.0; heating the working solution with the adjusted pH value to 43 DEG C, and adding disperse dye and the residual leveling agent to prepare a dye liquor; carrying out heating and dyeing. The method aims at dyeing of a brightly colored superfine terylene fabric, and has the advantages the softening agent, the leveling agent and the expansive agent are added simultaneously, and the pH value of the dye liquor is regulated to 3.5-4.0, so that poor leveling property, uneven dyeing and other quality problems existing in a low-bath-ratio dyeing process can be solved; moreover, the dye-uptake rate of the disperse dye can be improved, secondary aggregation of the disperse dye in a high-temperature descending process is prevented, all color fastness indices of the superfine terylene fabric exceed 4-level, the dyeing property is improved, and the dyeing effect is ideal; the method further has the advantages of being environment-friendly and low in energy consumption.

Owner:PACIFIC (PANYU) TEXTILES LTD

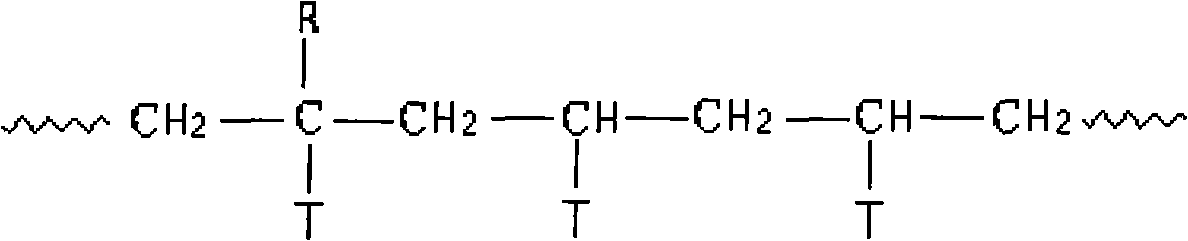

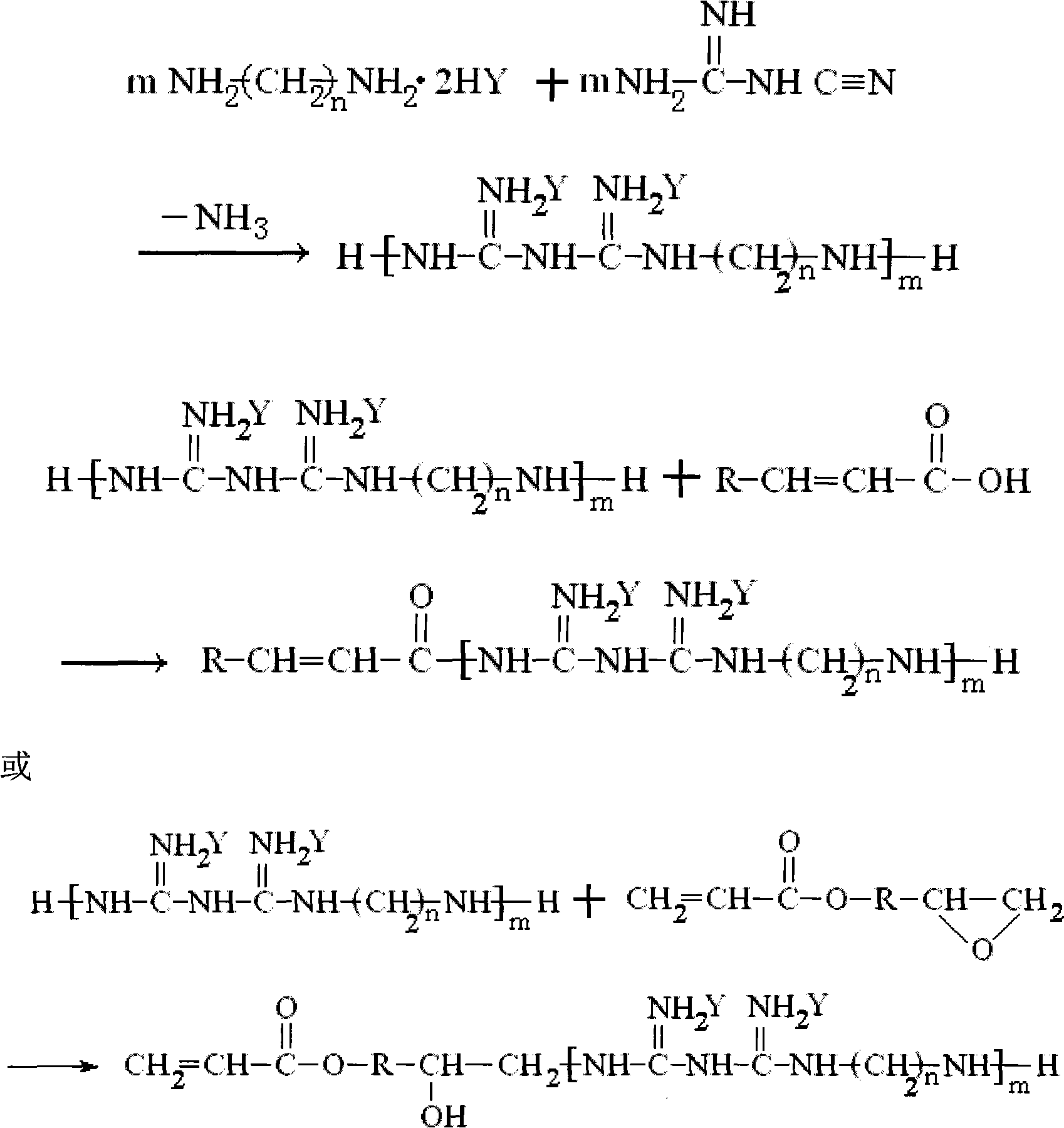

Polyolefin functional master batch, preparation method thereof and use thereof

ActiveCN101812160AAntibacterialAntistaticConjugated synthetic polymer artificial filamentsDisperse dyePolymer science

The invention relates to a polyolefin functional master batch, a preparation method thereof and use thereof. The functional master batch is prepared by blending a polyolefine resin, a guazatine oligomer, an olefin monomer, an initiator and the like and by a method of solvent graft, solid phase graft or melt graft and has a structural formula below, wherein in the formula, R represents the guazatine oligomer grafted to molecular chains of the polyolefin, and T may be hydrogen, chlorine, methyl, or phenyl. Compared with the prior art, by blending the functional master batch prepared by the invention with the corresponding polyolefin, various products, including fibers, thin films, water pipes and other plastic products, which have high antimicrobial performance and long-lasting effect and is safe and nontoxic to human bodies can be manufactured; and meanwhile, the acidic dye and disperse dye uptake of polyolefin fibers can be improved greatly, and the surface polarity, antistatic performance and paint film adhesion of polyolefin materials can be improved.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

Navy blue or black disperse dye

ActiveCN104087015AProtect the environmentImprove dye uptakeOrganic dyesDyeing processDisperse dyePhotochemistry

The invention discloses a navy blue or black disperse dye. The navy blue or black disperse dye contains a navy blue or black disperse dye composition and an additives. The navy blue or black disperse dye composition comprises one or more of dye A shown as formula (I), one or more of dye B shown as formula (II), one or more of dye C shown as formula (III), and one or more of dye D shown as formula (IV). The navy blue or black dye provided by the invention has the advantages of high dye-uptake, good deep dyeing property, excellent elevating power, excellent color fastness, and good level dyeing property. (formula (I), formula (II), formula (III), formula (IV)).

Owner:SHANGHAI ANOKY GRP

Natural plant hair dye

InactiveCN1923164AStrong penetrating powerAchieve the effect of dyed black hairCosmetic preparationsHair cosmeticsCelluloseSide effect

The invention relates to a hair dye, especially a natural plant hair dye. Wherein, it is formed by mixed A and B solutions; A agent is formed by agent and metal chelant, while the agent can be guar gum, polyquaternary ammonium salt or glycol cellulose, and the chelant can be soluble ferric salt or ferrous salt; B agent contains pomegranate bark extractive and glycol cellulose; while it also can contain logwood extractive as color agent. The invention has short dye time, uniform dye and washing resistance, nearly without side effects.

Owner:SHANGHAI BAIMAO +1

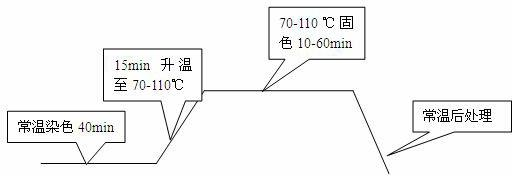

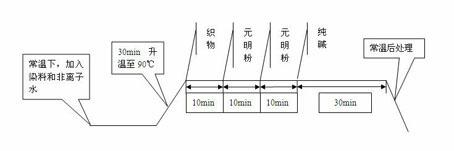

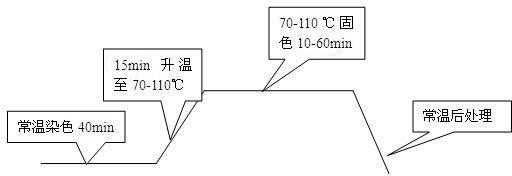

Dyeing process of pure cotton fabric

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

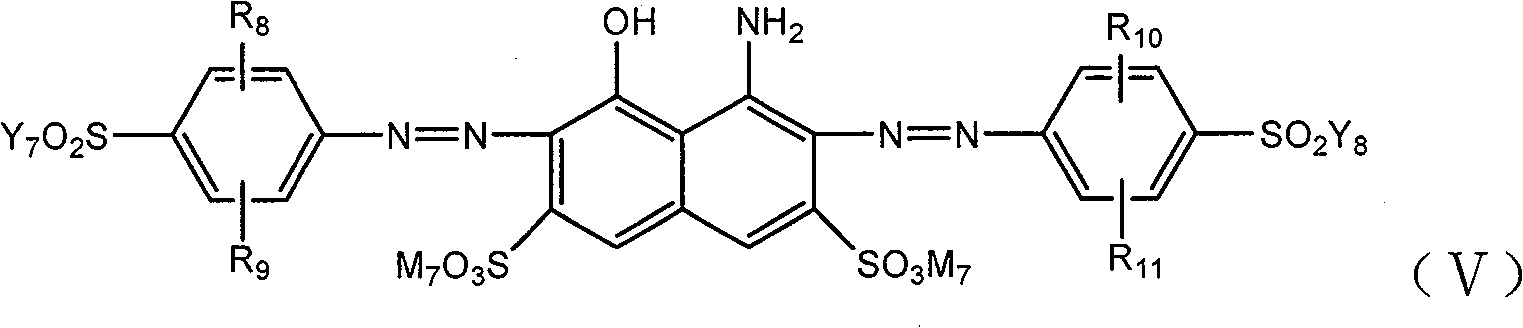

Active black dye

The invention relates to active black dye which essentially comprises fuchsine component A, orange yellow component B and navy component C, and is based on the component A, the component B and the component C; the weight percentage of the component A is 1 to 25 percent, the weight percentage of the component B is 1 to 25 percent, and the weight percentage of the component C is 50 to 95 percent; and the component A comprises at least a dye shown as formula (I) and a dye shown as formula (II), the component B comprises at least a dye shown as formula (III) and a dye shown as formula (IV), and the component C comprises at least a dye shown as formula (V). The active black dye has the advantages of high product solubility, strong salt and alkali resistance, high uptake date and color fixing rate, excellent dyeing fastness and environmental protection.

Owner:ZHEJIANG LONGSHENG GROUP +1

Oxidation-resistant disperse dye composition and preparation and application thereof

ActiveCN102660146AImprove oxidation resistanceWide concentration rangeFibre treatmentOrganic dyesDisperse dyeYELLOW DYE

The invention relates to an oxidation-resistant disperse dye composition and preparation and an application thereof. The oxidation-resistant disperse dye composition comprises the combination of any 2-4 of a yellow dye shown as a general formula (I), an orange dye shown as a general formula (II), a blue dye shown as a general formula (III) and a red dye shown as a general formula (IV), not more than two types of dyes are shown as each general formula; and the oxidation-resistant disperse dye composition is applied to pre-treatment dyeing of dacron or polyester-cotton blended fabrics. The disperse dye composition can be used for dyeing polyesters and blended fabrics thereof under the strong oxidative condition that the mass concentration of H2O2 is 0.1-0.5 percent, and an obtained fabric has the advantages of stable chromatic light, bright color, neat cloth cover and excellent fabric style; and according to the disperse dye composition, pretreatment and one-bath and one-step dyeing of polyester fiber or blended fabrics thereof are realized, efficiency is increased, production cost is reduced, and dyeing waste water is reduced.

Owner:ZHEJIANG WANFENG CHEM +1

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Compound dispersion red dye

InactiveCN1597790AImprove dye uptakeGood dyeing reproducibilityOrganic dyesDyeing processPolyesterPolymer chemistry

The invention relates to a compound dispersive red dye, especially relating to a polyester material printing and dyeing compound dispersive red dye, containing the following components in weight percent: monomer A 20%-45%, monomer B 5%-15% and auxiliary. It has the advantages of high dyeing ratio, good dyeing repeatability, good dyeing uniformity, excellent fastness, approach of coloured light to dispersive red S-5BL, etc.

Owner:ZHEJIANG LONGSHENG GROUP

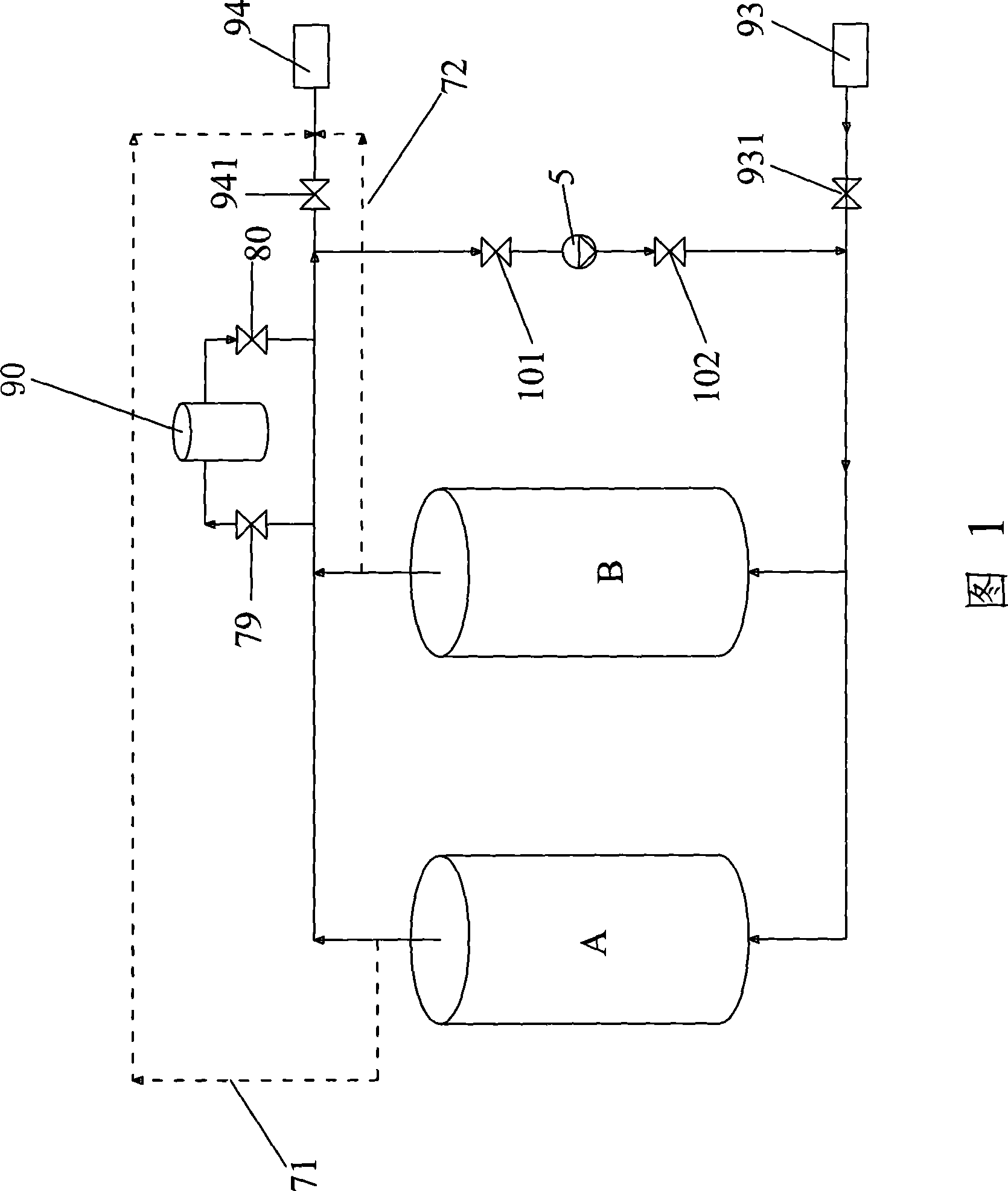

Supercritical CO2 anhydrous yarn warp dyeing system and dyeing method thereof

InactiveCN101413191ALow costIncrease capacityTextile treatment sample takingTextile treatment containersYarnProcess engineering

The invention discloses a supercritical CO2 anhydrous warp beam dyeing system and a dyeing method thereof. The system comprises a CO2 pressure supply device, a circulating pump, a separation and recovery device and two or more than two dyeing kettles which are arranged in parallel, wherein the dyeing kettles are arranged in parallel and connected in series with the circulating pump to form a closed dyeing circuit; a shutoff valve is respectively arranged on both ends of the circulating pump; the CO2 pressure supply device and the separation and recovery device are connected between the shutoff valves and the dyeing kettles respectively; and an outlet of each dyeing kettle is connected with an independent recovery bypass which is communicated with the separation and recovery device and independent of the closed dyeing circuit which is formed by the dyeing kettles and the circulating pump, so that different dyeing kettles can perform dyeing and recovery of CO2 simultaneously. The system can perform dyeing and recovery of the CO2 simultaneously and respectively, reduces consumption of the CO2 to the maximum degree, reduces the cost, can realize discontinuous operation and improve the production efficiency, and has quick dyeing speed.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Shape dyeing process for cotton/fibers

The invention relates to a shape dyeing process for cotton / fibers. The process is characterized in that: cone yarns and yarn beams are placed in the same yarn carrier and dyed by the following steps at the same: 1, bleaching scouring; 2, dyeing; 3, neutralizing and soaping; and 4, color fixing and smoothing treatment. The process has the advantages that: the conventional idea and mode of production is broken through and the one-bath dyeing of two kinds of yarn shapes is realized; and by using the one-bath dyeing of the yarn beams, the process flow of yarn-dyed cloth is simplified, efficiency and carrying rate are improved, a production period is shortened, simultaneously a dye uptake rate is improved, the emission of sewage and environmental pollution are reduced, a utilization rate of equipment is increased, the production dilemma caused by insufficient dyeing equipment is reduced, the cost is reduced, and the requirements on level-dyeing property, repeatability and fastness of the conventional dyeing level are met.

Owner:LUTAI TEXTILE

Modified polylactic acid fiber excellent in performance

ActiveCN104818543AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentCellulose diacetateCellulose acetate

The invention discloses a modified polylactic acid fiber excellent in performance. The modified polylactic acid fiber is prepared by use of a method and the method comprises the steps of adding such raw materials as PDLLA polylactic acid, PLLA polylactic acid, hydroxypropyl starch, cellulose diacetate, nano tourmaline powder, nano talcum powder, chitosan powder and nano montmorillonoid powder to a high-speed mixer, and dispersing at a high speed to obtain a modified polylactic acid mixture, forming a modified polylactic acid master batch from the evenly mixed modified polylactic acid mixture by virtue of melt blending and extruding in a twin-screw extruder, and drying in vacuum, feeding the modified polylactic acid functional master batch slices and the vacuum-dried common polylactic acid slices into the high-speed mixer for evenly mixing, and spinning the mixture by use of a quinquangular spinneret orifice on a melt spinning machine, thereby obtaining the modified polylactic acid fiber.

Owner:CHANGXING YONG XIN TEXTILE PRINTING DYEING

High-fastness black and blue disperse dye composite

ActiveCN102002259AImprove dye uptakeBright shadeOrganic dyesDyeing processDisperse dyePolymer science

The invention discloses a high-fastness black and blue disperse dye composite, which comprises the following components in percentage by weight: 7 to 42 percent of component A, 45 to 90 percent of component B and 3 to 13 percent of aids, wherein the component A is a compound shown by a formula (I), and the component B is one or more of compounds shown by a formula (II). The high-fastness black and blue disperse dye composite provided by the invention has excellent levelling property, beautiful and bright color light, strong deep dyeing property, high color yield and excellent fastness such as sublimation resistance fastness, washing resistance fastness, friction resistance fastness and the like, and particularly by the addition of the component A, the sublimation fastness of the black and blue disperse dye composite is improved obviously.

Owner:ZHEJIANG RUNTU

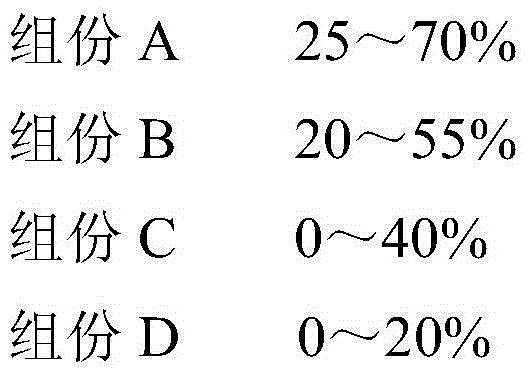

Environment-friendly type composite disperse green dye composition and dye

InactiveCN105038314AGood compatibilityIncrease coverageOrganic dyesDyeing processRubbingPhotochemistry

The invention discloses an environment-friendly type composite disperse green dye composition and a dye. The environment-friendly type composite disperse green dye composition comprises the following components in mass fraction: 25-70% of one or more components A with structures as shown in formula (I), 20-55% of one or more components B with structures as shown in formula (II), 0-40% of one or more components C with structures as shown in formula (III) and 0-20% of one or more components D with structures as shown in formula (IV). The disperse green dye prepared from the disperse green dye composition disclosed by the invention is high in lifting power, good in deep dyeing property and excellent in light fastness, fastness to rubbing, fastness to sublimation and the like. The dye is suitable for dyeing and printing of dacron and blended fabrics thereof, and is an economical and environment-friendly disperse green dye with high washing fastness.

Owner:ZHEJIANG DIBANG CHEM

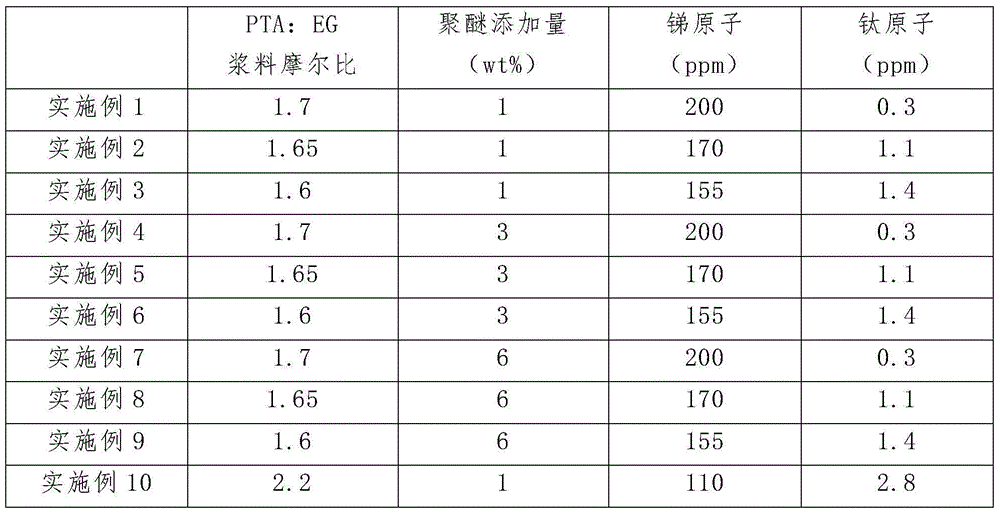

A continuous preparing method for polyether modified copolyester

ActiveCN105585701AChange the order of additionQuick responseMonocomponent copolyesters artificial filamentPolymer scienceCopolyester

The invention relates to a continuous preparing method for polyether modified copolyester. The method includes mixing an ethylene glycol solution of a titanium catalyst, terephthalic acid and ethylene glycol to prepare slurry, esterifying, mixing an ethylene glycol solution of an antimony catalyst, an ethylene glycol solution of polyether and an intermediate that is bis(hydroxyethyl) terephthalate, pre-polymerizing, performing condensation polymerization, and the like. Problems that polyether macromolecules are prone to thermal degradation and are degraded into chain segments with low molecular weights at high temperature with long reaction time, and modification effects of the chain segments with low molecular weights on polyesters are weakened are overcome by the preparing method. The polyether that is a modifying agent in the prepared polyether modified copolyester is uniform in distribution and stable in molecular weight. A copolyester product is excellent and stable in performance and good in spinnability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com