Cation modified dyeing method of ceiba fiber textiles

A cationic modifier and kapok fiber technology, which can be used in dyeing, textile and papermaking, fiber treatment, etc., can solve the problems of weak binding force and poor fastness, improve binding force, reduce salt consumption, and improve dyeing rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

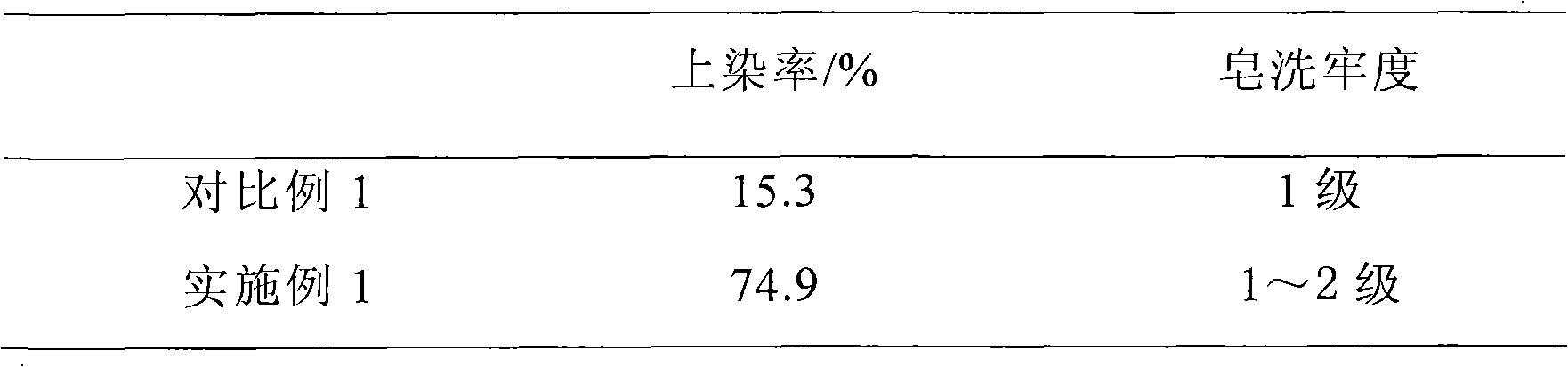

Embodiment 1

[0024] A cationic modified dyeing method for kapok fiber textiles. The method includes three steps of pretreatment, cationic modification and dyeing.

[0025] (1) Kapok fiber textile pretreatment:

[0026] Kapok → alkali treatment → washing → drying → hydrogen peroxide bleaching treatment → washing → drying.

[0027] Among them, kapok fiber textiles use kapok loose fiber, and the alkali treatment solution and hydrogen peroxide bleaching treatment solution use water as the solvent, and the components are as follows:

[0028] a. Alkaline treatment solution: sodium hydroxide, 10g / L; penetrant JFC, 1g / L; flat addition of O, 1g / L; sodium silicate, 2g / L; bath ratio, 1:30.

[0029] b. Hydrogen peroxide bleaching solution: 30% hydrogen peroxide, 20g / L; oxygen bleaching stabilizer sodium silicate, 1g / L; adjust the pH value to 10.5-11 with sodium hydroxide; bath ratio, 1:30.

[0030] Specific operation:

[0031] The kapok loose fiber is immersed in an alkali treatment solution, treated at 100°C for...

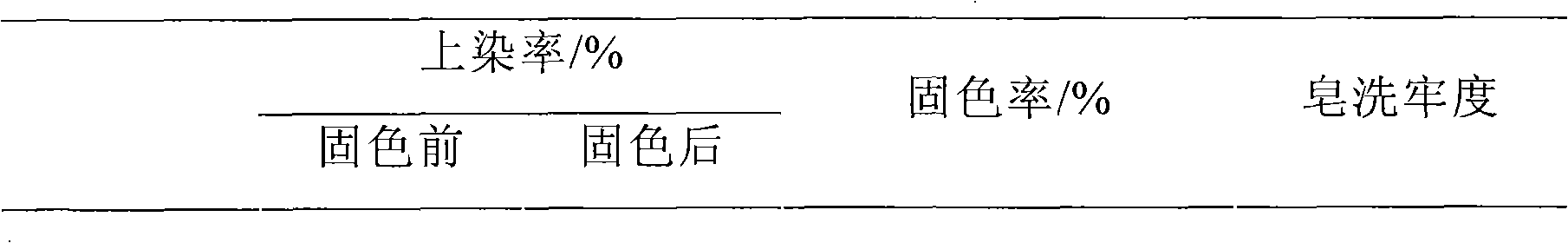

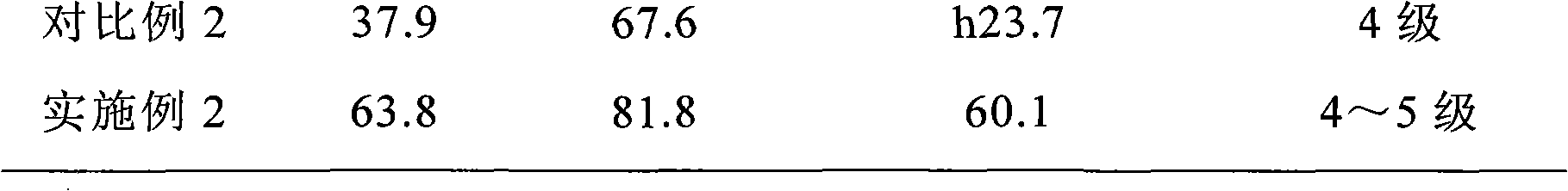

Embodiment 2

[0043] A cationic modified dyeing method for kapok fiber textiles. The method includes three steps of pretreatment, cationic modification and dyeing.

[0044] The first two steps are the same as in Example 1, and the third step is dyed with reactive dyes.

[0045] Reactive dye dyeing→washing→drying.

[0046] Reactive dye dyeing solution: reactive dye (Ciba FN-R), 1% (o.w.f); penetrant JFC, 2g / L; electrolyte sodium chloride, 20g / l; bath ratio, 1:50.

[0047] Specific operation:

[0048] Shake the reactive dye solution for 10 minutes at 60℃, then take the kapok fiber after quantitative pretreatment, immerse it in the dye solution, dye it at 60℃ for 30min, test the dye uptake rate, and add alkali sodium carbonate (10g / L), fix the color at 60℃ for 60min, and test the dye uptake, take it out, wash with water, and dry.

Embodiment 3

[0060] A cationic modified dyeing method for kapok fiber textiles, the method includes the following steps:

[0061] (1) Put the kapok fiber textile in a caustic soda solution added with surfactant and sodium silicate, control the temperature at 95 ℃ for alkali treatment for 3 hours and wash and dry, and then soak the alkali-treated textile in the bleach solution Carry out bleaching treatment and water washing and drying to remove the wax and impurities on the surface of the kapok fiber and bleach the kapok fiber;

[0062] (2) Immerse the kapok fiber textile treated in step (1) into the cationic modifier solution added with penetrant, adjust the pH to 6, the bath ratio 1:10, and the control temperature to 20°C. Carry out cationization modification treatment for 90 minutes;

[0063] (3) Control the temperature to 90℃, shake the anionic dye solution for 10 minutes, then put the cationized modified kapok fiber textile in the anionic dye, dye it for 60 minutes, take it out after dyeing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com