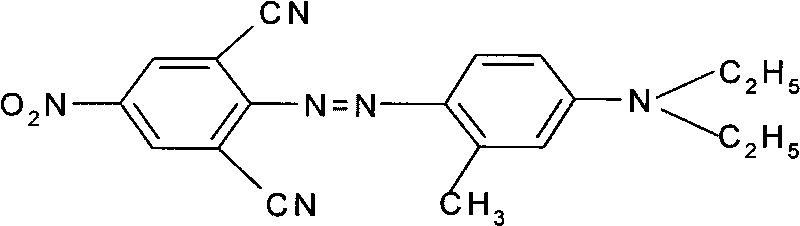

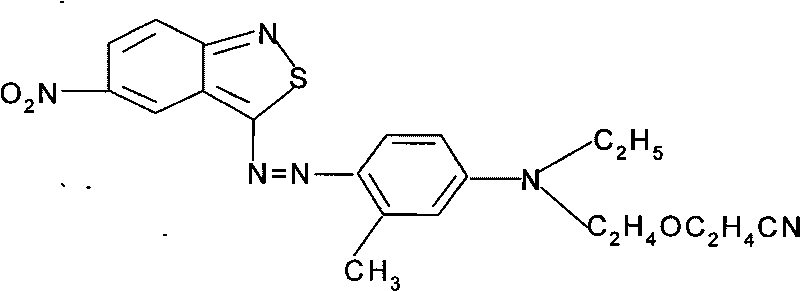

Blue disperse dye mixture

A technology of disperse dyes and mixtures, applied in azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of low dyeing rate, poor dyeing reproducibility, limited application range, etc., and achieve light fastness and wet Excellent fastness, wide range of PH value, good dyeing reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Get 40% of the mixture of 5% dye A, 13% dye B, 12% dye C and 70% naphthalenesulfonic acid formaldehyde condensate and methyl naphthalenesulfonic acid formaldehyde condensate and lignosulfonate by weight percentage % for mixing, beating and pre-grinding after mixing, and then use a sand mill to grind and disperse to make the particle size reach 1-2 microns, then add the remaining naphthalenesulfonic acid formaldehyde condensate and methyl naphthalenesulfonic acid formaldehyde condensate and lignin The mixture of sulfonates is standardized, and then dried in a spray drying tower to obtain the finished product.

Embodiment 2

[0042] Take 50% of 8% dye A, 12% dye B, 15% dye C, 10% dye D and 45% naphthalene sulfonic acid formaldehyde condensate by weight, mix and pre-grind, then use sand mill Machine grinding and dispersing to make the particle size reach 1-2 microns, then adding the remaining naphthalenesulfonic acid formaldehyde condensate for standardization, and then drying in a spray drying tower to obtain the finished product.

Embodiment 3

[0044] Get 60% of the mixture of 6% dye A, 3% dye B, 2% dye C, 1% dye D and 65% naphthalenesulfonic acid formaldehyde condensate and methylnaphthalenesulfonic acid formaldehyde condensate %After mixing, beating and pre-grinding, and then use a sand mill to grind and disperse to make the particle size reach 1-2 microns, then add the remaining mixture of naphthalenesulfonic acid formaldehyde condensate and methyl naphthalenesulfonic acid formaldehyde condensate for standardization, and then The finished product is obtained by drying in a spray drying tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com