A continuous preparing method for polyether modified copolyester

A technology of polyether modification and copolyester, which is applied in the direction of single-component copolyester rayon, etc., can solve the problems of polyether macromolecule decomposition, achieve stable molecular weight, reduce the possibility of decomposition, and speed up the reaction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

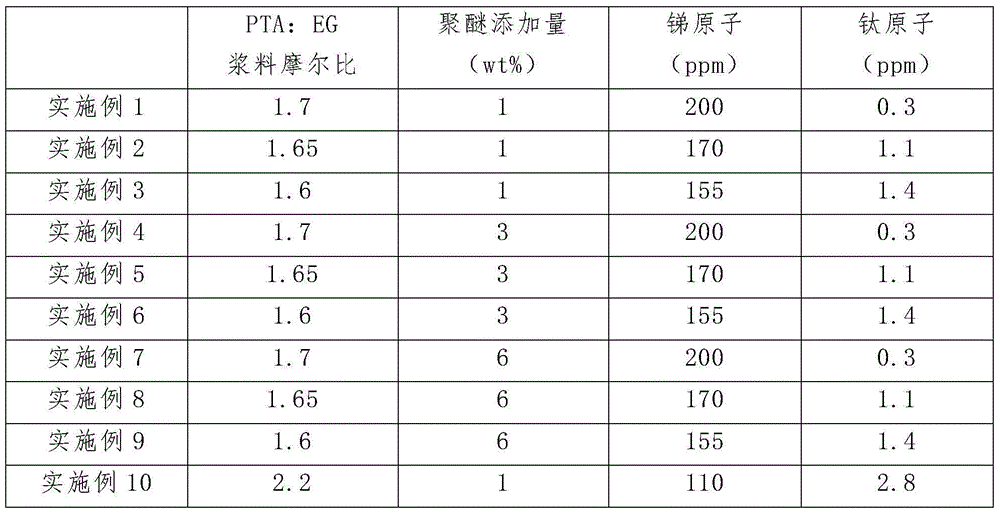

Examples

Embodiment

[0043] The raw materials terephthalic acid and ethylene glycol are added into the beating tank according to the proportioning ratio, and are beaten under stirring; after the titanium series catalyst (titanium glycolate) enters the preparation area, ethylene glycol is added to dilute the catalyst concentration to 0.04wt%. After the preparation is completed, it is transported to the slurry preparation tank to participate in the preparation of the slurry.

[0044] The slurry is sent quantitatively and continuously into the horizontal agitated esterification reaction kettle with a gear pump, and is stirred at a gauge pressure of 0.08MPa and a temperature of 260°C for esterification to generate an intermediate bishydroxyethyl terephthalate, which is reacted until esterification The rate is at least 92%. The water generated in the esterification process is distilled out with the ethylene glycol. After the water is separated by the fractionating tower, 99wt% of the ethylene glycol is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com