Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about "Textile treatment by pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

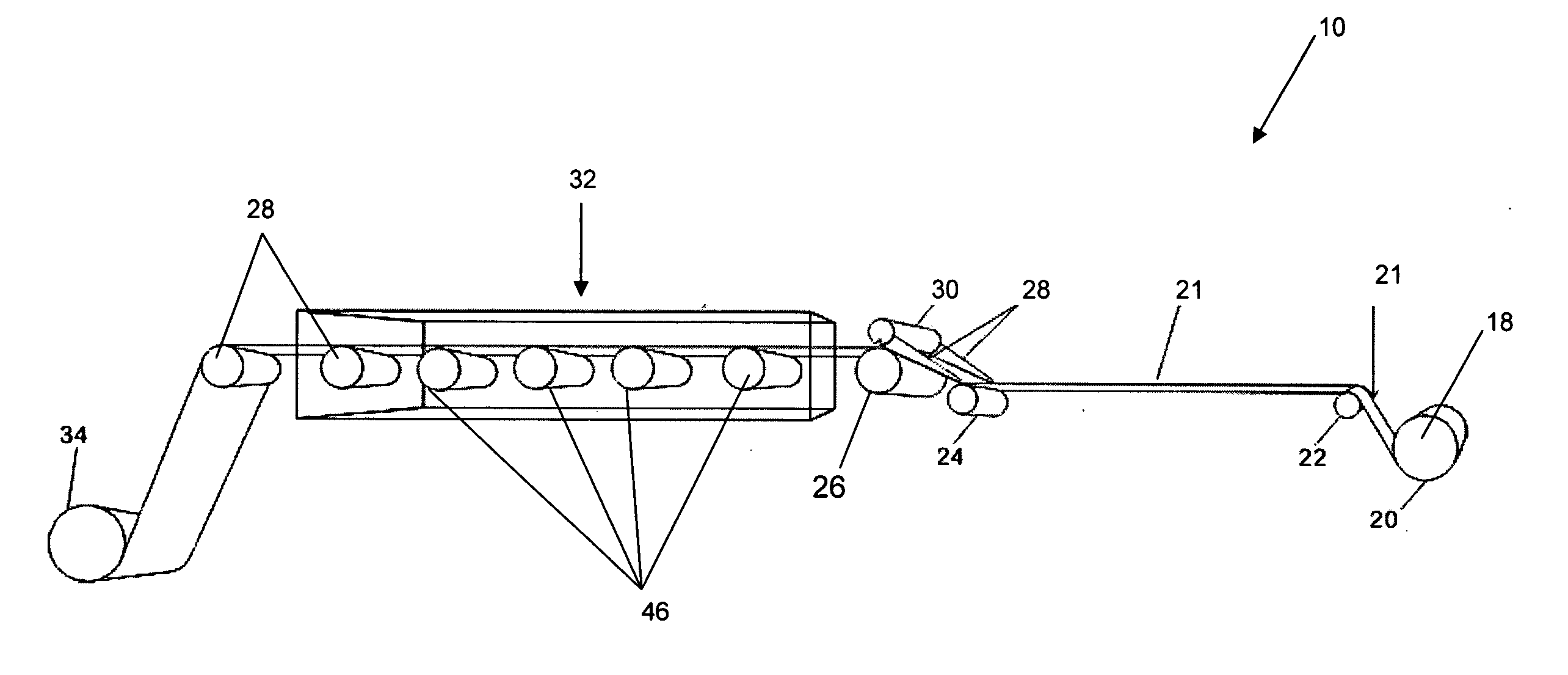

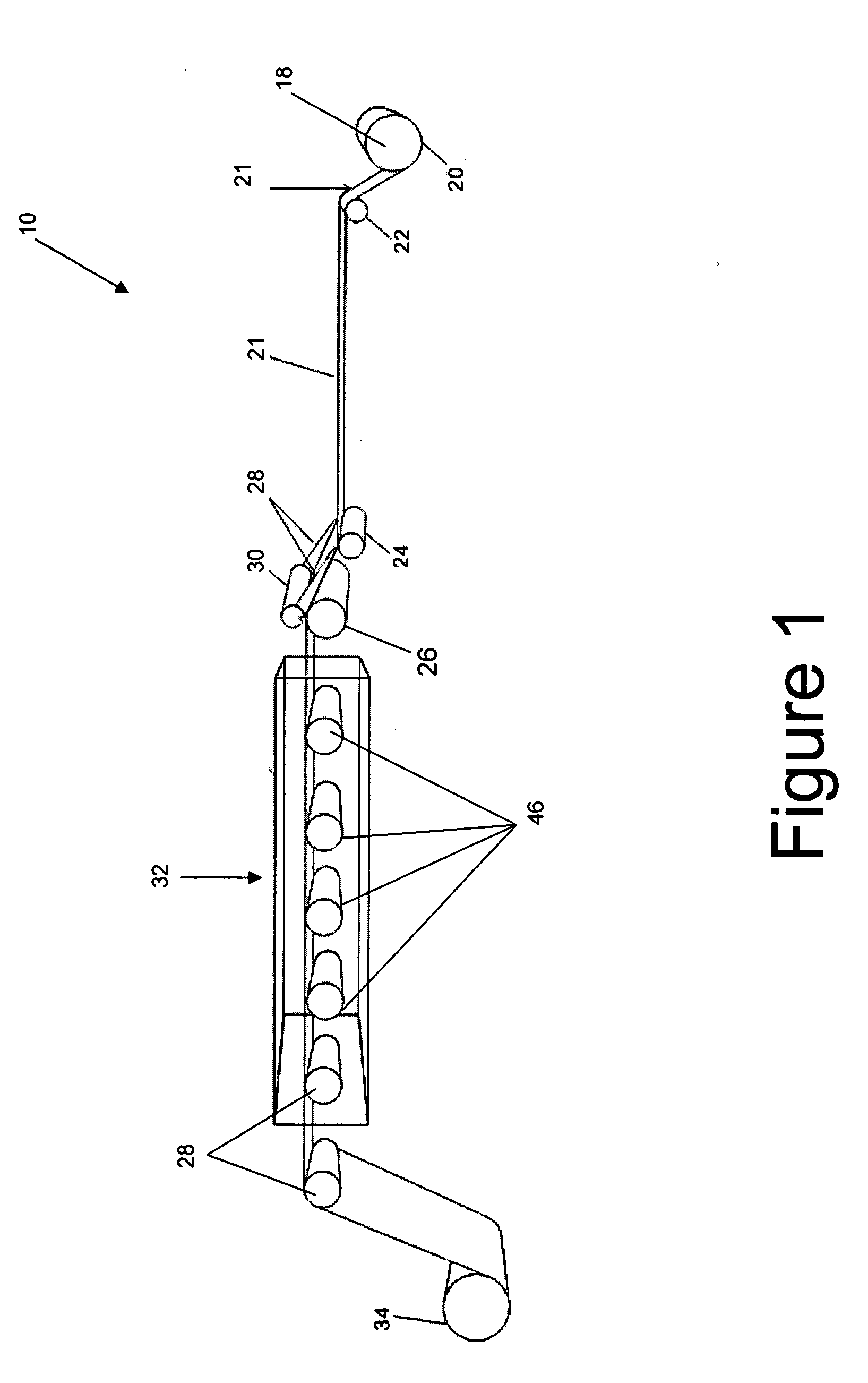

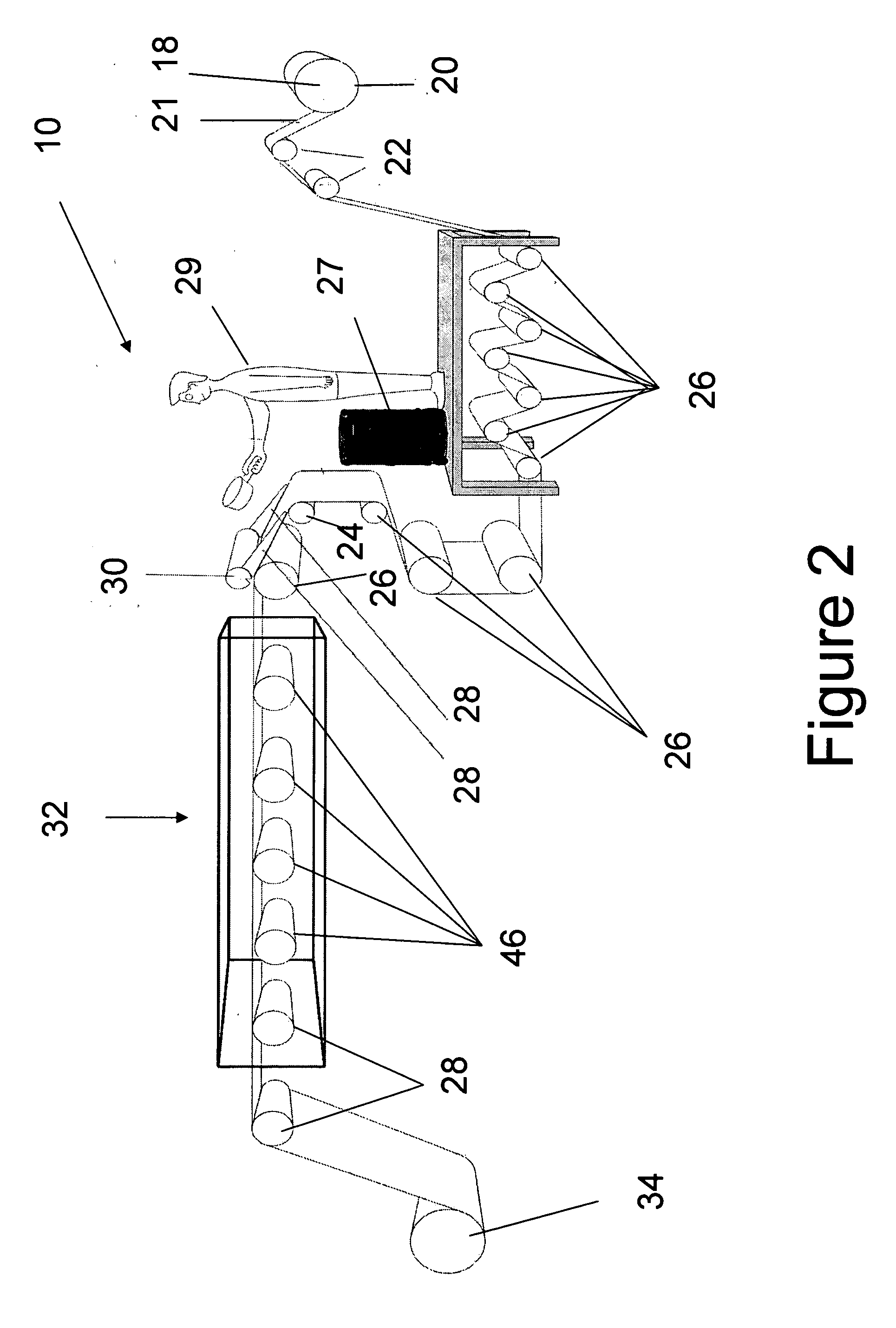

Hybrid fiber tows containning both nano-fillers and continuous fibers, hybrid composites, and their production processes

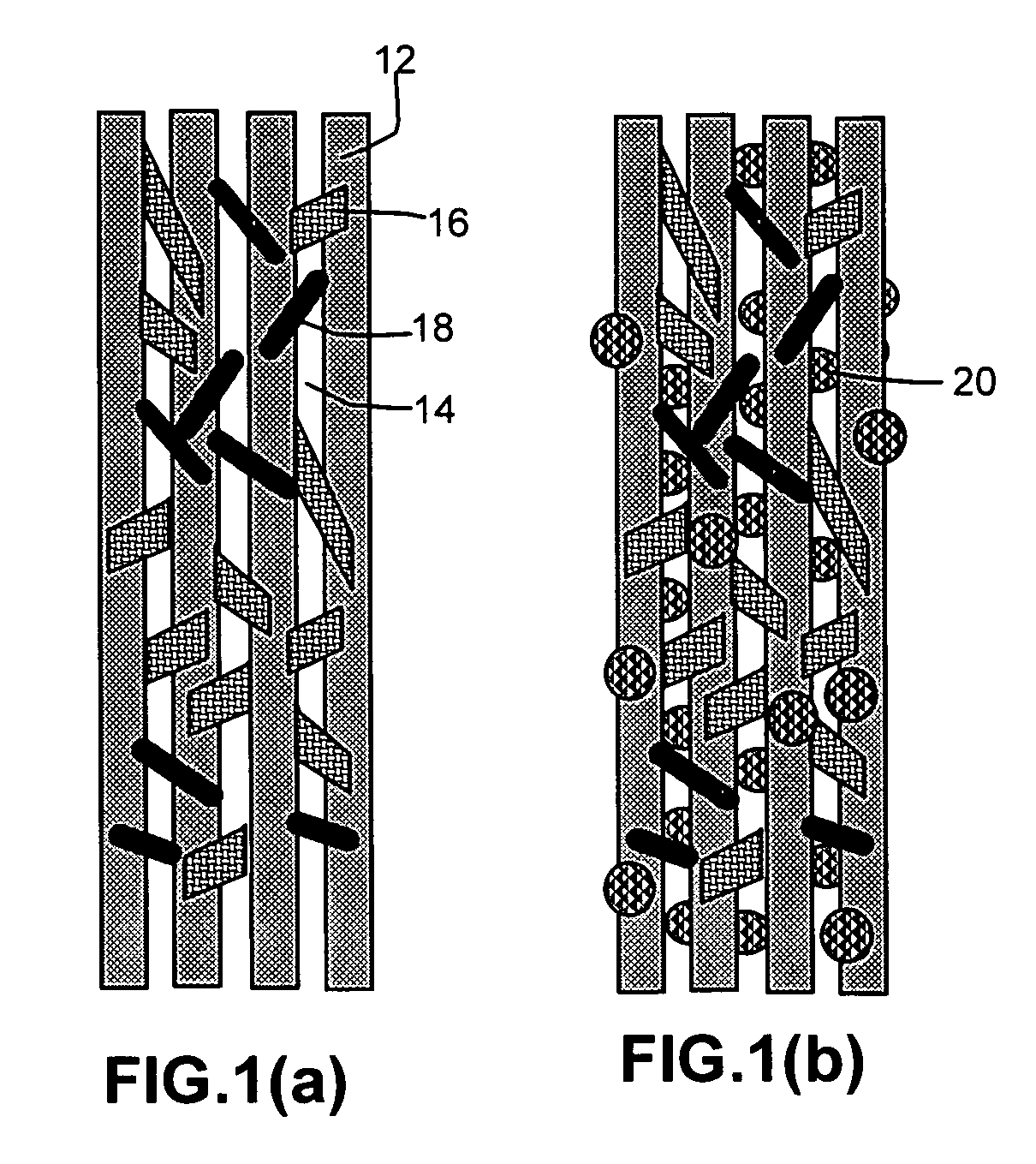

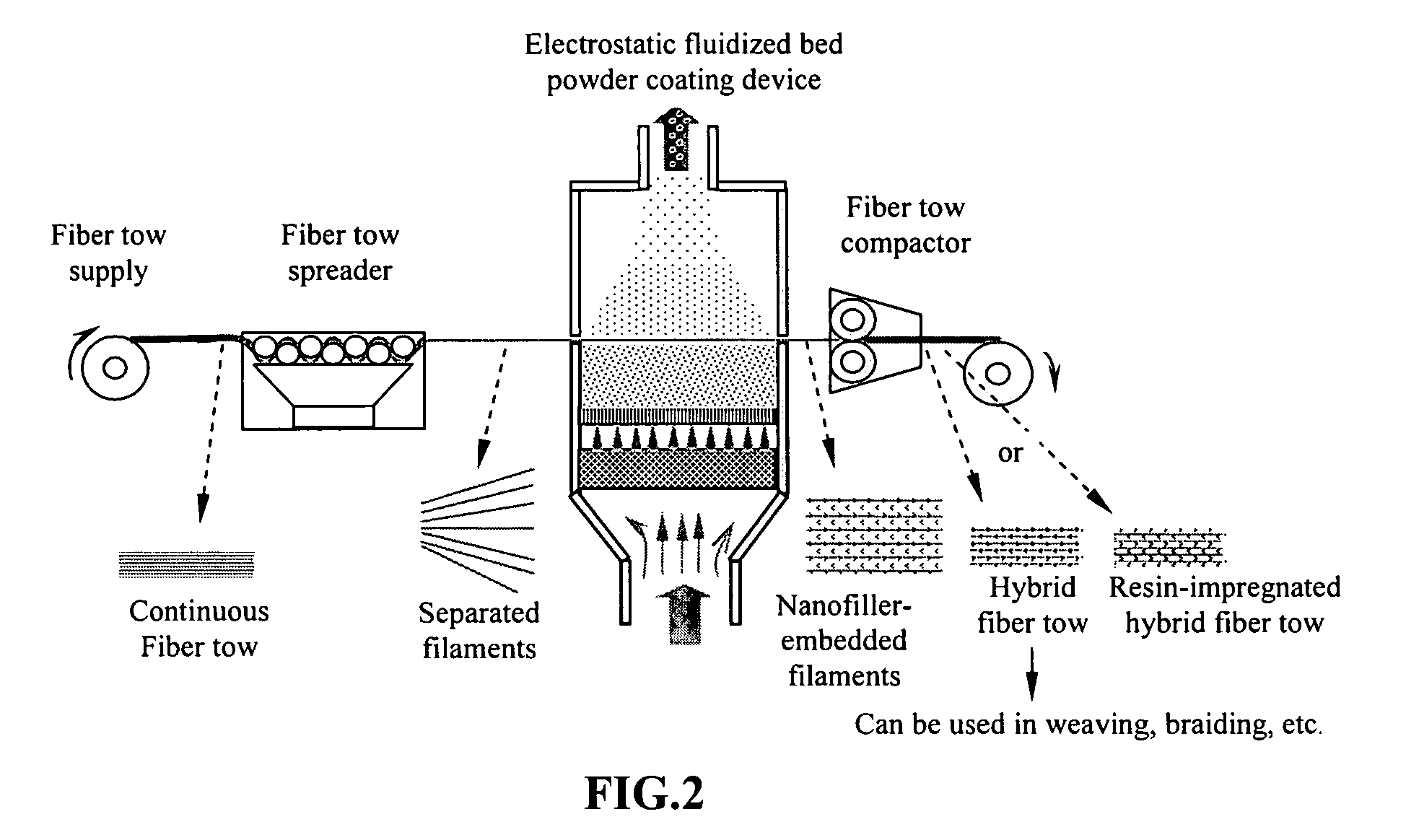

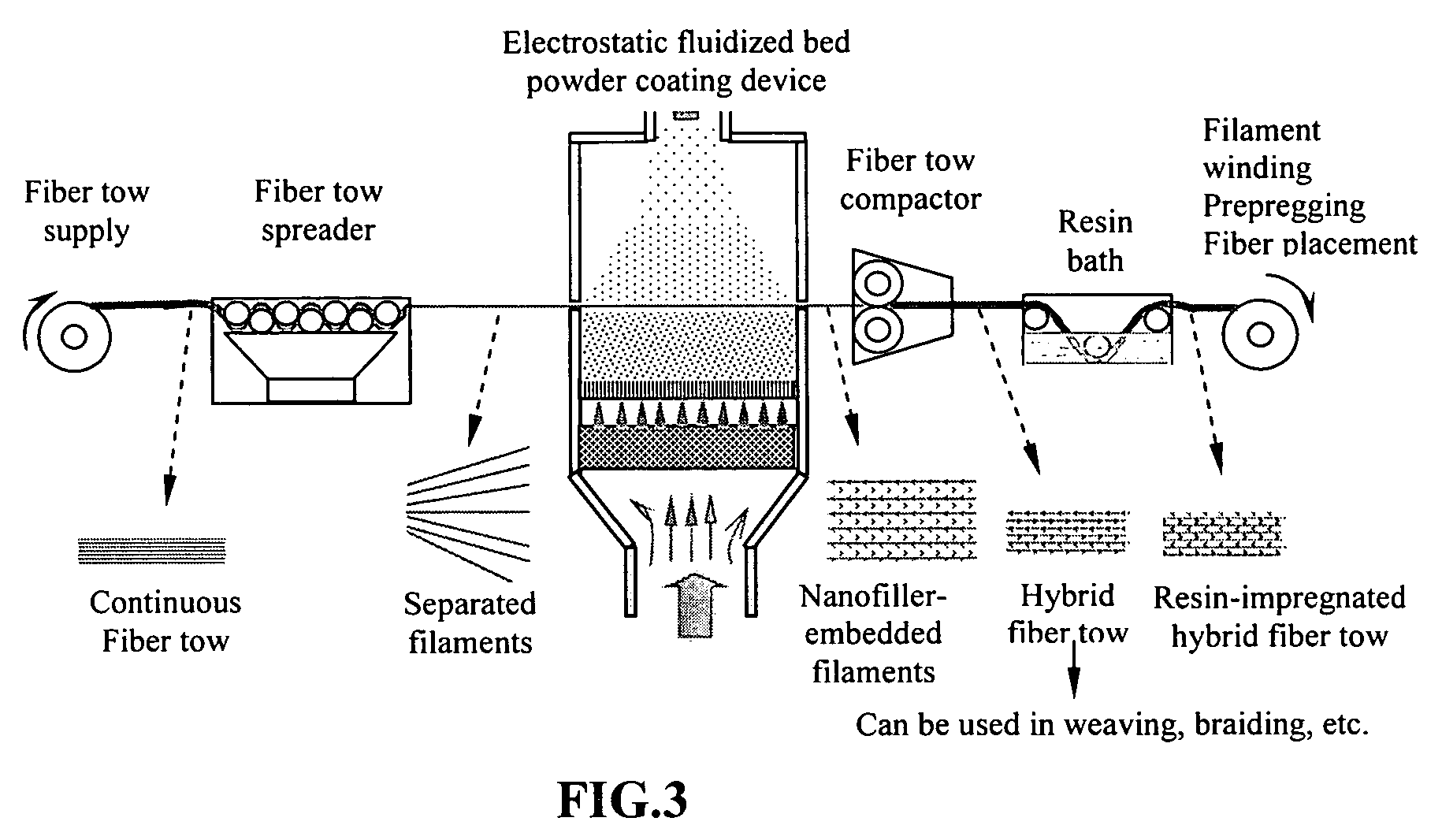

Disclosed is a hybrid fiber tow that comprises multiple continuous filaments and nanoscale fillers embedded in the interstitial spaces between continuous filaments. Nanoscale fillers may be selected from a nanoscale graphene plate, non-graphite platelet, carbon nano-tube, nano-rod, carbon nano-fiber, non-carbon nano-fiber, or a combination thereof. Also disclosed are a hybrid fiber tow impregnated with a matrix material and a composite structure fabricated from a hybrid fiber tow. The composite exhibits improved physical properties (e.g., thermal conductivity) in a direction transverse to the continuous fiber axis. A roll-to-roll process for producing a continuous fiber tow or matrix-impregnated fiber tow and an automated process for producing composite structures containing both continuous filaments and nanoscale fillers are also provided.

Owner:NANOTEK INSTR

Ageing-resistant heat-insulation tarpaulin and production method thereof

InactiveCN101792975AImprove waterproof performanceGood insulation performanceHeating/cooling textile fabricsTextile treatment by pouringFiberPre treatment

The invention discloses an ageing-resistant heat-insulation tarpaulin. The tarpaulin is composed of a polymer cloth base and an ageing-resistant heat-insulation coating which is coated on the polymer cloth base in a casting mode. After aging is quickened for 236 hours by simulating natural manual work, the tensile strength of the tarpaulin is improved by at least 10%, the elongation at break thereof is improved by at least 5% than the elongation at break before aging, the ultraviolet reflectivity thereof is more than or equal to 80%, and the infrared obstruction rate thereof is more than or equal to 85%. The invention also discloses a preparation method thereof, comprising the following step: pretreating a heat-insulation material by utilizing a surface treating agent; and premixing the heat-insulation material with accessory ingredients such as vinyl type polymer, antioxidant and the like, then putting the heat-insulation material and the accessory ingredients into a double-screw extrusion casting coating machine to be fused, plasticized and extruded out to be casted and coated on the polymer fiber cloth base, and carrying out cooling shaping and reeling by utilizing a cooling roll to obtain the ageing-resistant heat-insulation tarpaulin. The tarpaulin product obtained by the invention has favourable water proofness, heat-insulating property and ageing-resistant property, wide application range, no pollution in the production process, small energy consumption, low cost and easy popularization and application.

Owner:SICHUAN UNIV

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

Antimicrobial nonwoven fabric

InactiveUS20140308867A1Easy to separateReduce microbial loadPhysical treatmentBiochemical fibre treatmentSurgical AttireWound dressing

The present invention relates to woven or nonwoven fabric material having antimicrobial activity, and to its uses ranging from wound dressing, facial masks, surgical drapes and surgical clothing, to filter materials and similar applications where the antimicrobial effects are employed, as well as to a process for the preparation of the woven or nonwoven fabric material.

Owner:AR METALLIZING NV

Fully automatic garment dyeing machine

ActiveCN101748574AHigh degree of automationEasy to controlTextile treatment containersTextile treatment machine arrangementsPulp and paper industryFully automatic

The invention discloses a fully automatic garment dyeing machine which comprises a frame, a dyeing cylinder arranged on the frame, a dye feed cylinder and a computer controller. An electromotor is arranged at the lower end of the dyeing cylinder and connected with one end of a rotating shaft through a transmission belt; the other end of the rotating shaft is connected with a rotating cage arranged inside the dyeing cylinder; a machine door is arranged on one side of the dyeing cylinder; a temperature sensor is arranged in the dyeing cylinder; and a heating cavity is formed on the outer side at the lower end of the dyeing cylinder. The fully automatic garment dyeing machine with the structure has the advantages of high automation and convenient control; and steam can not be directly sprayed to the dyeing cylinder when the dyeing cylinder is heated, so that the water bathing ratio in the dyeing cylinder is not influenced, and the dyeing effect is improved.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

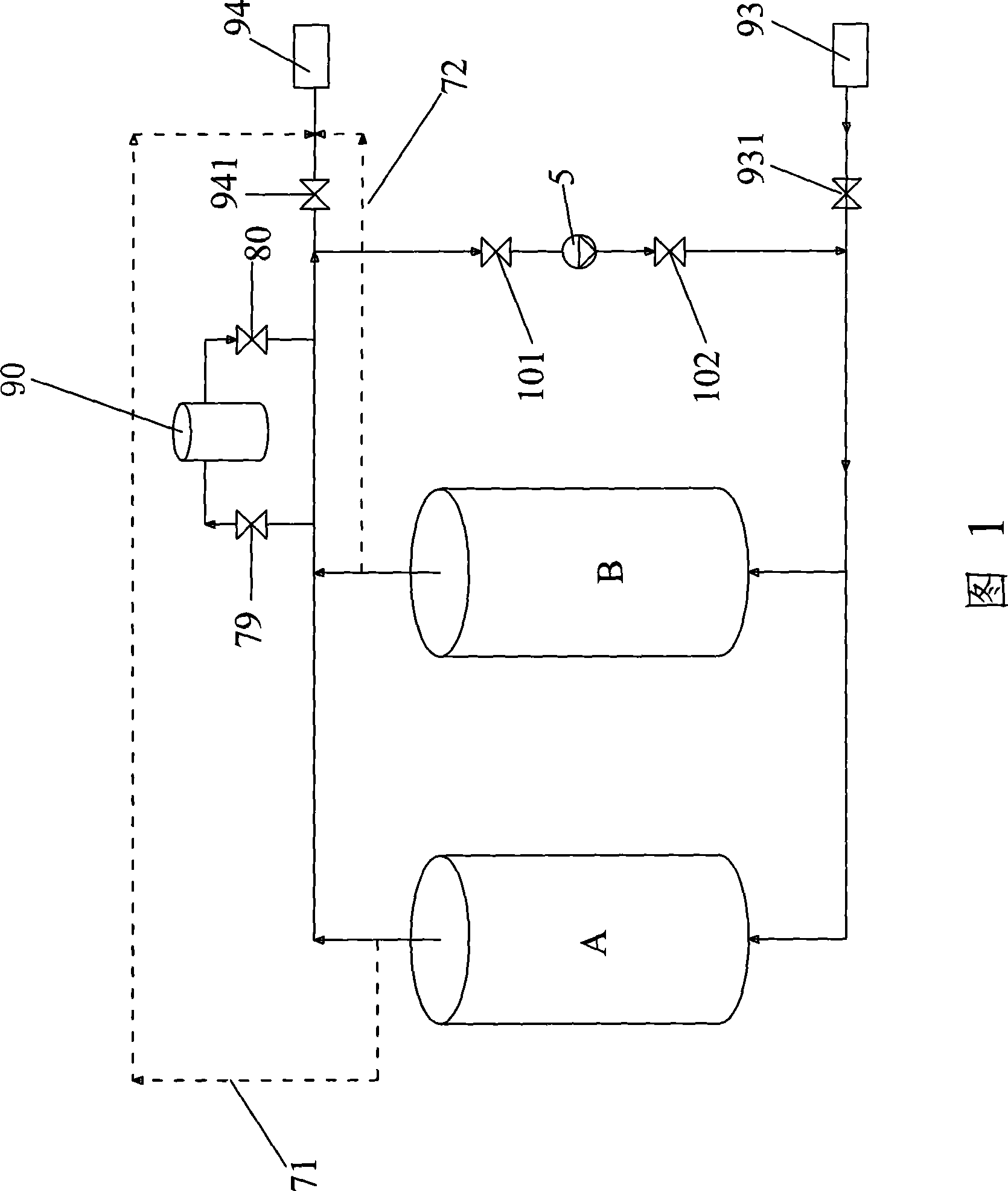

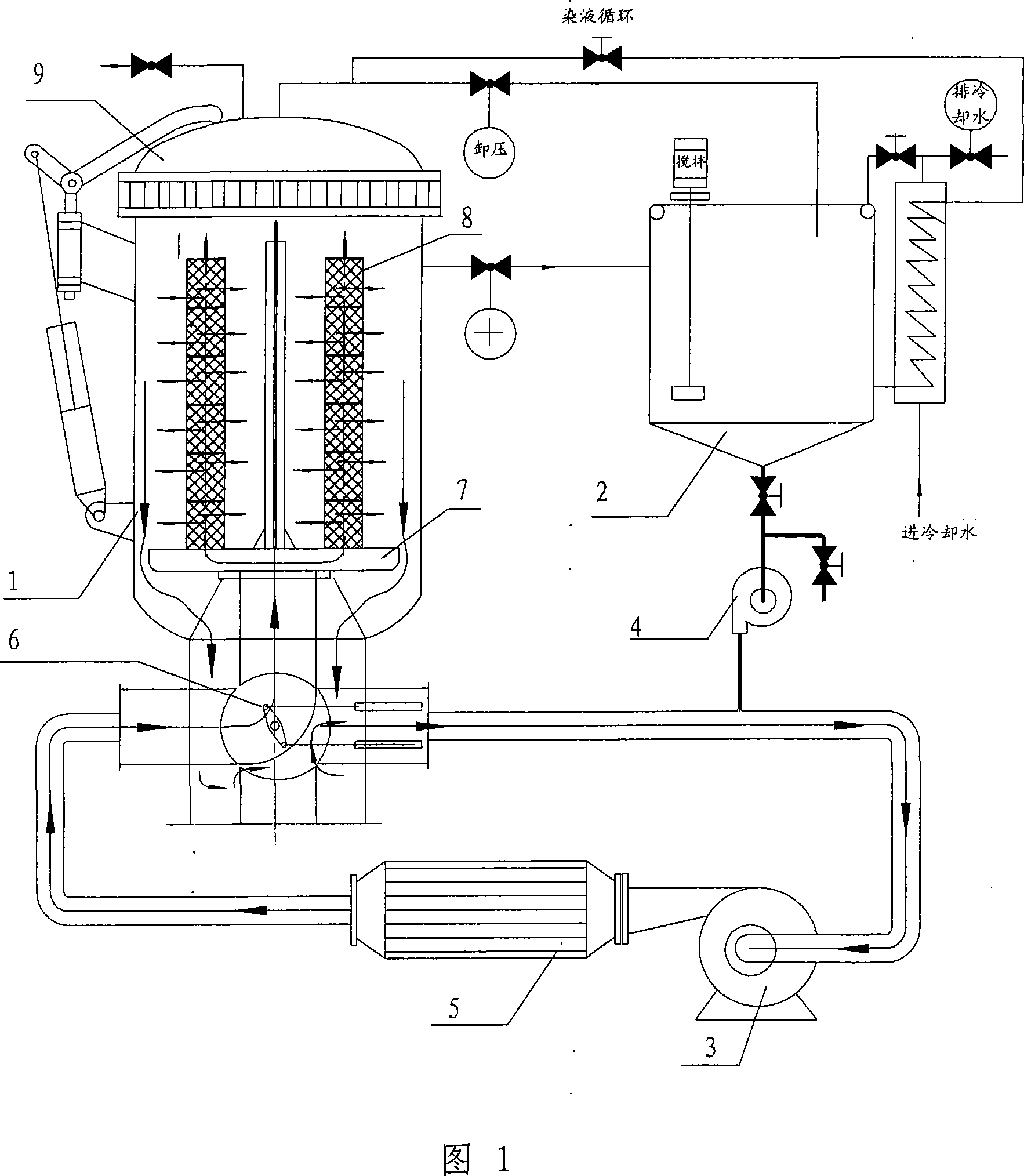

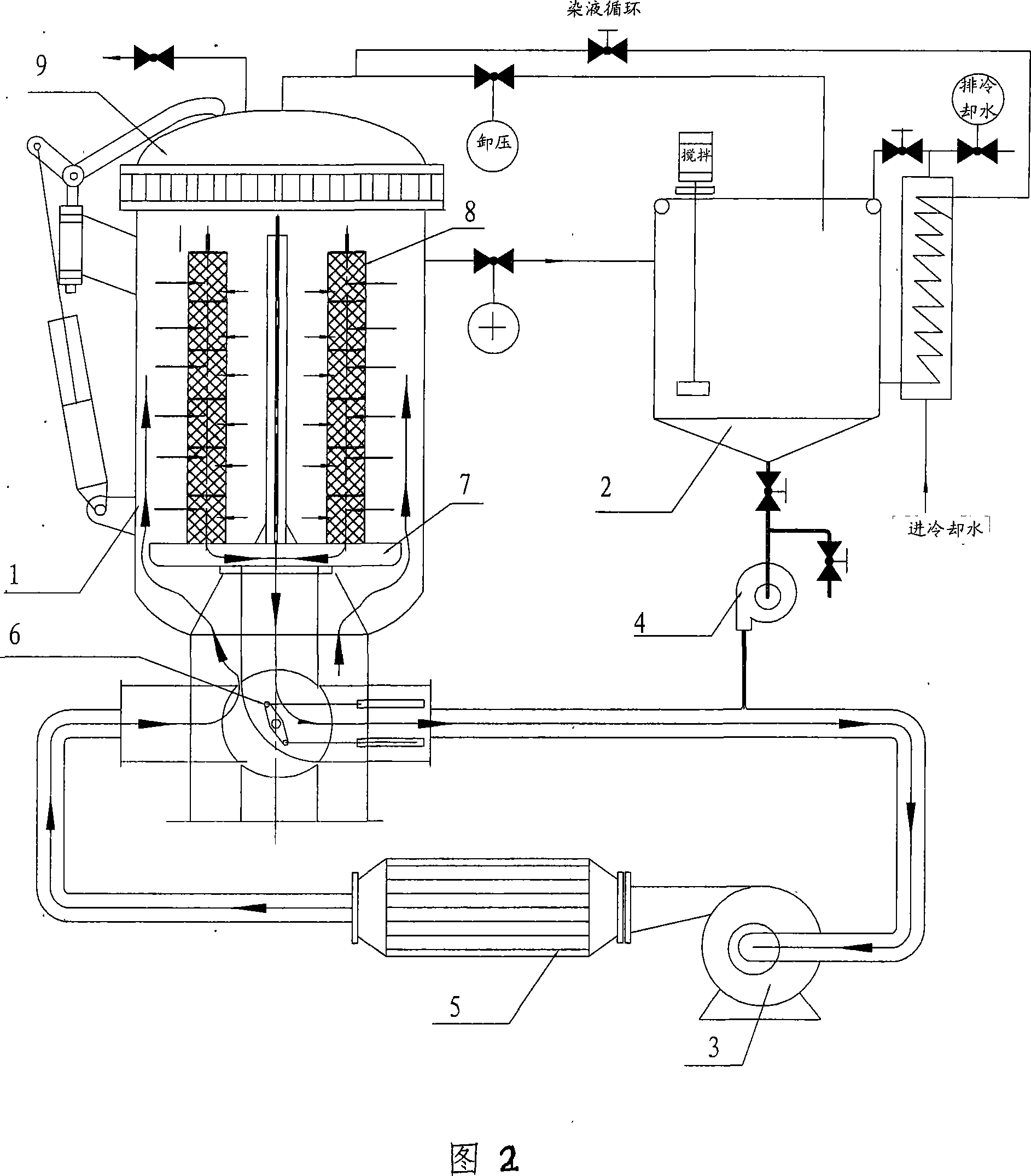

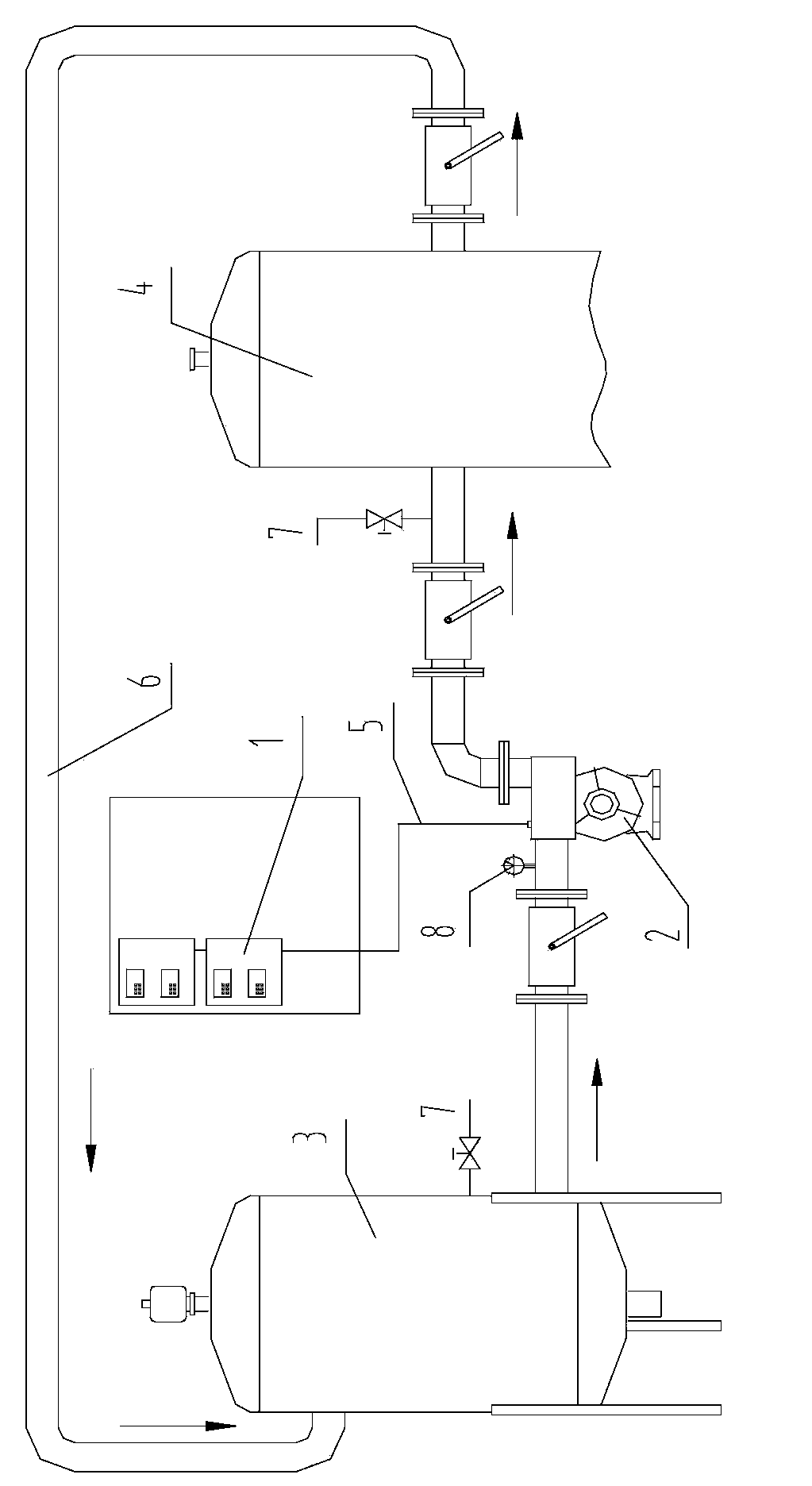

Supercritical CO2 anhydrous yarn warp dyeing system and dyeing method thereof

InactiveCN101413191ALow costIncrease capacityTextile treatment sample takingTextile treatment containersYarnProcess engineering

The invention discloses a supercritical CO2 anhydrous warp beam dyeing system and a dyeing method thereof. The system comprises a CO2 pressure supply device, a circulating pump, a separation and recovery device and two or more than two dyeing kettles which are arranged in parallel, wherein the dyeing kettles are arranged in parallel and connected in series with the circulating pump to form a closed dyeing circuit; a shutoff valve is respectively arranged on both ends of the circulating pump; the CO2 pressure supply device and the separation and recovery device are connected between the shutoff valves and the dyeing kettles respectively; and an outlet of each dyeing kettle is connected with an independent recovery bypass which is communicated with the separation and recovery device and independent of the closed dyeing circuit which is formed by the dyeing kettles and the circulating pump, so that different dyeing kettles can perform dyeing and recovery of CO2 simultaneously. The system can perform dyeing and recovery of the CO2 simultaneously and respectively, reduces consumption of the CO2 to the maximum degree, reduces the cost, can realize discontinuous operation and improve the production efficiency, and has quick dyeing speed.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Silver thiosulfate complex or silver-ammonia complex-containing hygroscopic silver-containing product and preparation method thereof

ActiveCN104083800ABroad spectrum antibacterialHigh antibacterial activityFibre treatmentTwo or more solvent application treatmentAdditive ingredientMoisture absorption

The invention relates to a silver thiosulfate complex or silver-ammonia complex-containing hygroscopic silver-containing product and a preparation method thereof. The invention discloses a hygroscopic silver-containing antibacterial product which comprises a silver thiosulfate complex or a silver-ammonia complex as an antibacterial ingredient, the silver thiosulfate complex or the silver-ammonia complex is evenly distributed and combined on the inner side and / or surface, the hygroscopic silver-containing antibacterial product comprises 0.01-10 wt% of silver, and the moisture absorption ability of the hygroscopic silver-containing antibacterial product is 6g / g and above. The invention also provides a preparation method of the hygroscopic silver-containing antibacterial product as well as a silver-containing antibacterial product dressing prepared from the hygroscopic silver-containing antibacterial product. The hygroscopic silver-containing antibacterial product has a very wide antibacterial spectrum, shows strong antibacterial activity to gram-negative bacteria and gram-positive bacteria, is rapid in effect, has light stability, and can be widely applied to chronic infections exudative wounds.

Owner:FOSHAN UNITED MEDICAL TECH

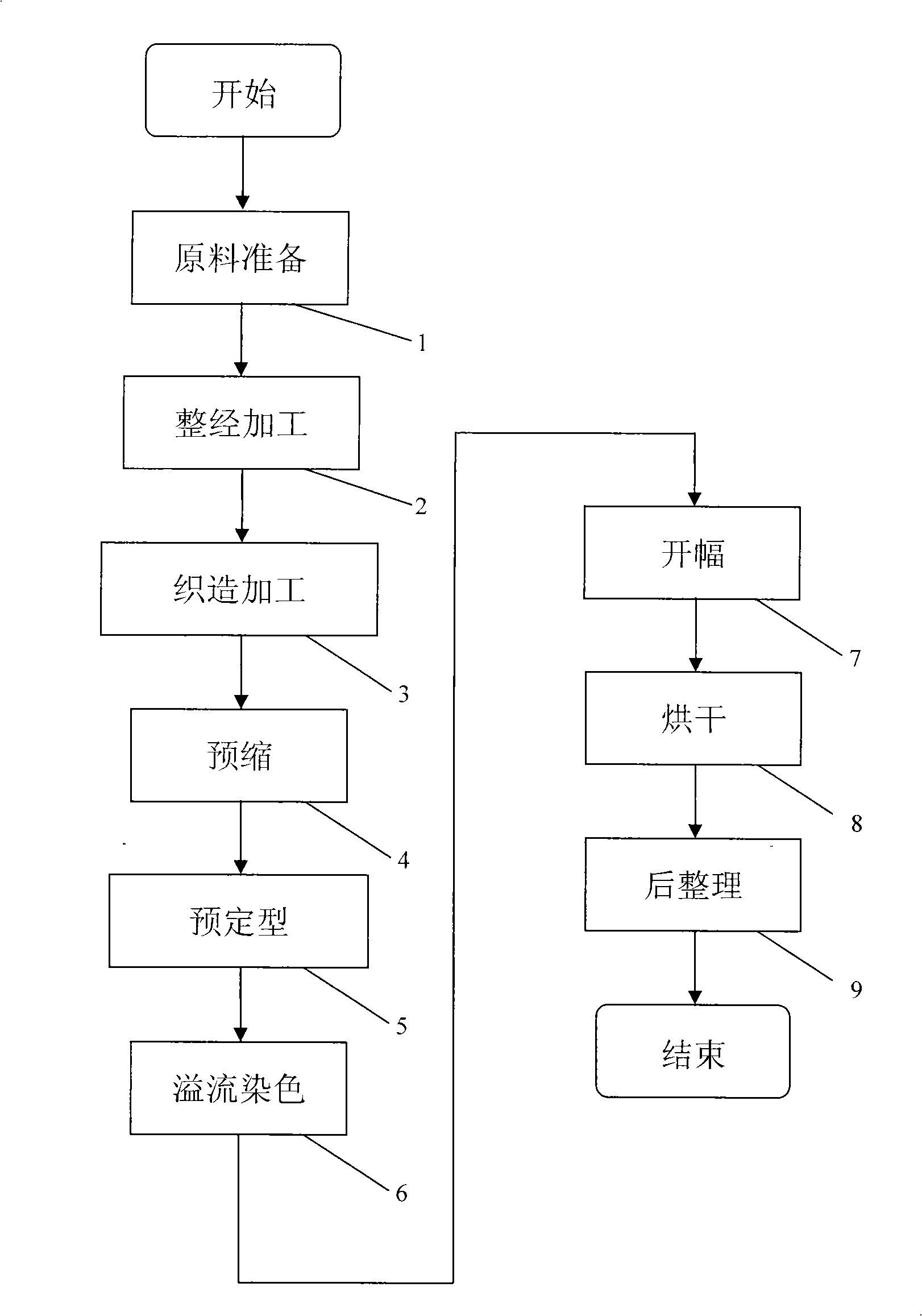

Process for making two-face jacquard

InactiveCN101338481AComfortable to wearComfortable and beautiful to wearFibre typesWarp knittingAfter treatmentEngineering

The present invention discloses a double jacquard fabric manufacturing process, which sequentially includes the procedures as follows: preparing raw materials, warping, weaving, pre-shrinking, pre-forming, overflow dyeing, expanding, after treatment and other procedures. The present invention adopts the brocade polyurethane flexible knitted jacquard fabric to make high-level casual clothes and fashion fabric after technical treatment, which has the advantages of obvious double-surface effect and excellent performance, thick and soft fabric hand feeling, being flexible but straight, moisture absorption and sweat discharging, air permeability, wear resistance, wrinkle resistance, good mode holding nature, corrosion resistance, no mildew and comfortable wearing. The present invention improves the use limit of the flexible knitted fabric in the clothing market and widens the application range. As a novel knitted green environmental-protection fabric, the double-cooling jacquard fabric has the advantages of plain and simple style, excellent physical performance, double-sided application and pleasant and comfortable wearing.

Owner:HAINING DEJUN KNITTING & DYEING GROUP

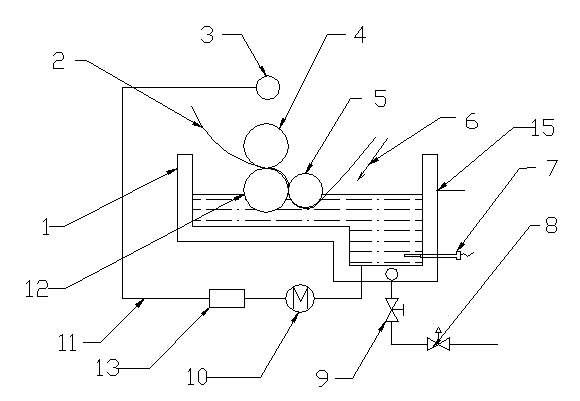

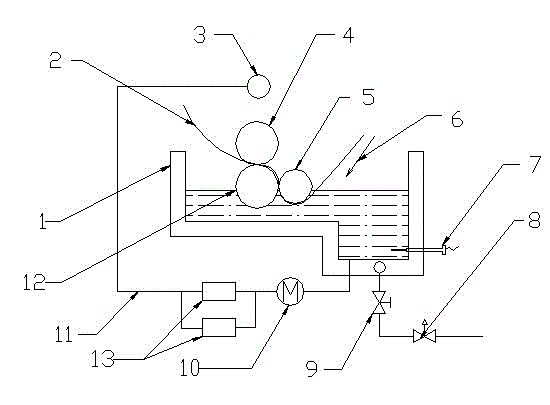

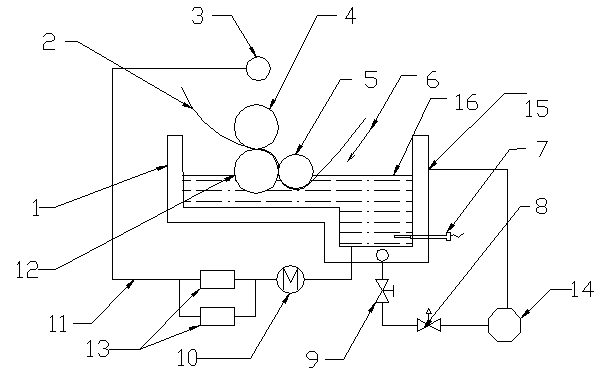

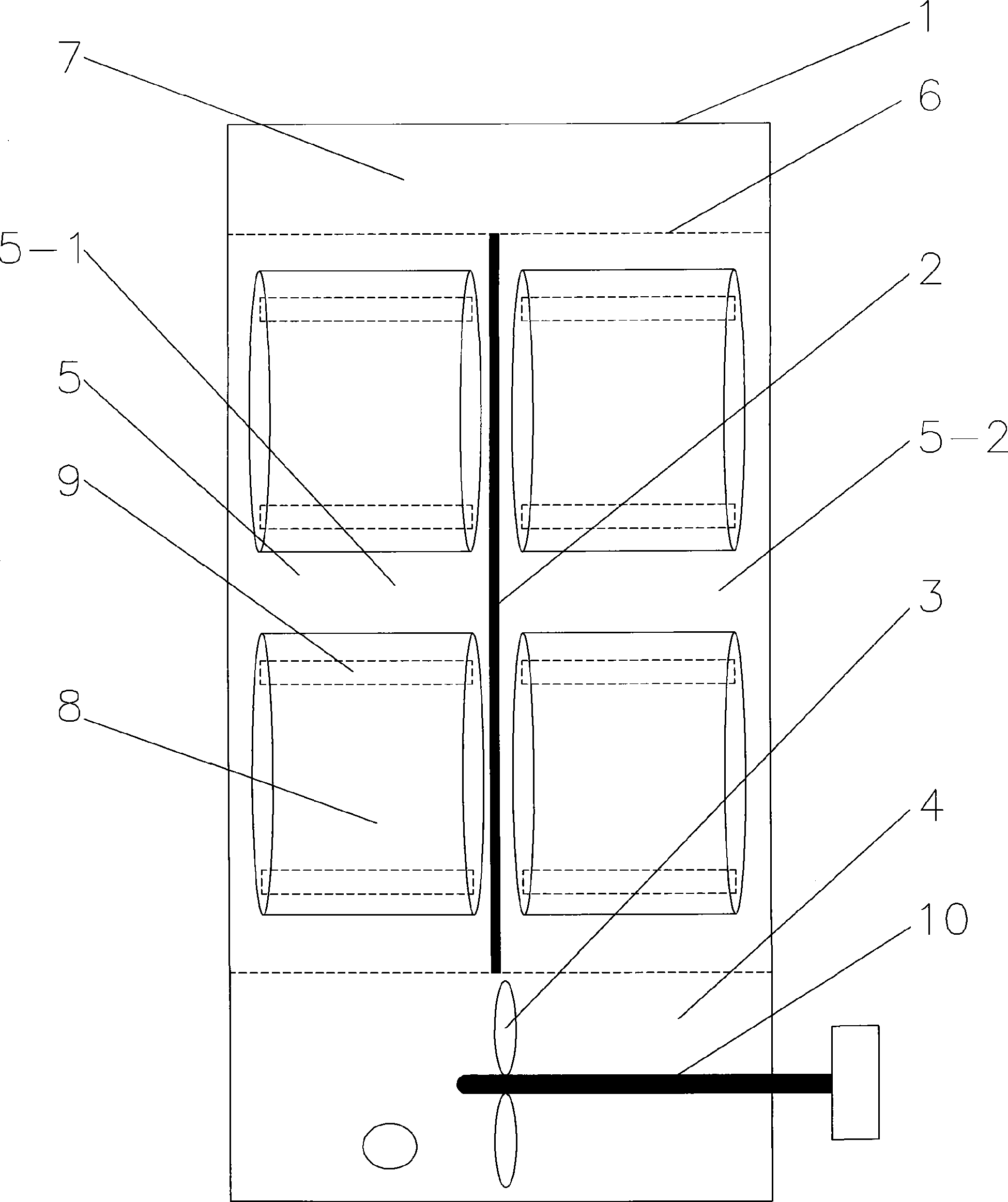

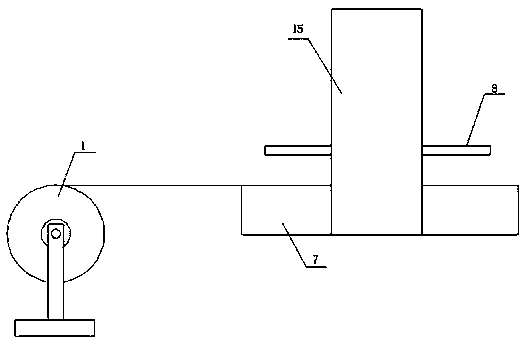

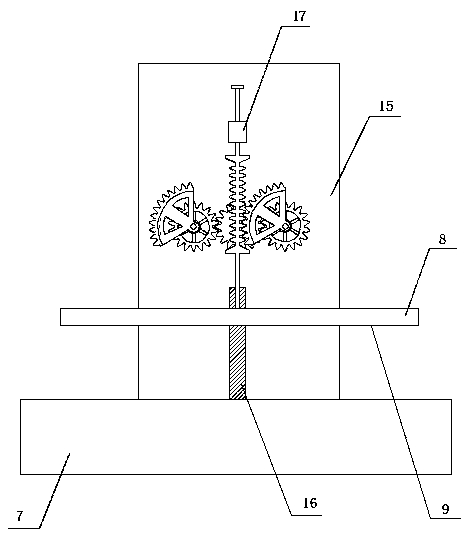

Secondary sizing device of glass fiber

ActiveCN104153136AGuaranteed pureAdjustable temperatureTextile treatment machine arrangementsTextile treatment by pouringGlass fiberYarn

The invention provides a secondary sizing device of glass fiber. The secondary sizing device of the glass fiber comprises a pulp pool, a sizing system, a pulp pool heating system and a filtering device, wherein the sizing system comprises a sizing roller set and a pulp pouring device, and the sizing roller set is arranged in the pulp pool, is used for sizing warp yarns of the glass fiber, and comprises at least three sequentially-arranged sizing rollers; the pulp pouring device comprises a pulp pouring pipe and a pulp pouring head; the pulp pool heating system comprises a heat preservation layer and a temperature adjusting device, the heat preservation layer is arranged on the outer side of the pulp pool in an enclosing mode, and the temperature adjusting device comprises a temperature sensor, a controller and a temperature adjusting actuating mechanism; the filtering device is used for filtering pulp in the pulp pouring device and is fixedly arranged on the pulp pouring pipe. According to the secondary sizing device of the glass fiber, the pulp pool heating device is arranged, the temperature of the pulp in the pulp pool can be adjusted, the situation that the quality of glass fiber cloth is affected by pulp oxidation film forming is avoided, and the production cost is reduced.

Owner:TAIJIA GLASS FIBER

Method for processing oil palm fiber

ActiveCN101476164AEasy to handleLow costDry-cleaning apparatus for textilesVegetable materialOil and greasePlant fibre

The invention discloses a method for treating oil palm fiber which has characteristics that: dipping oil palm fiber in water with temperature 40-90 DEG. C, PH value 7-8, washing, natural insolating or drying after dehydration. The method is summed up by experiments that is simple and has low cost for washing grease layer and impurity on the oil palm fiber. The method includes steps as follows: placing the oil palm fiber into hot water with temperature 40-90 DEG. C, PH value 7-8 to dip that has better effect than normal temperature and does not need turning and stirring the oil palm fiber for avoiding knotting or breaking, adding surface active agent for treating more cleanly and reducing dipping time. Oilness rate of the treated oil palm fiber reduces 0.5%, sugar rate of the treated oil palm fiber reduces lower than 0.3%, odor degree special for the oil palm fiber reduces properly that is suitable for producing a plant fibre spring-mattress contained with fragrance special by the oil palm, and reduces possibility of mildewed and insert living greatly.

Owner:GUIZHOU DAZIRAN TECH

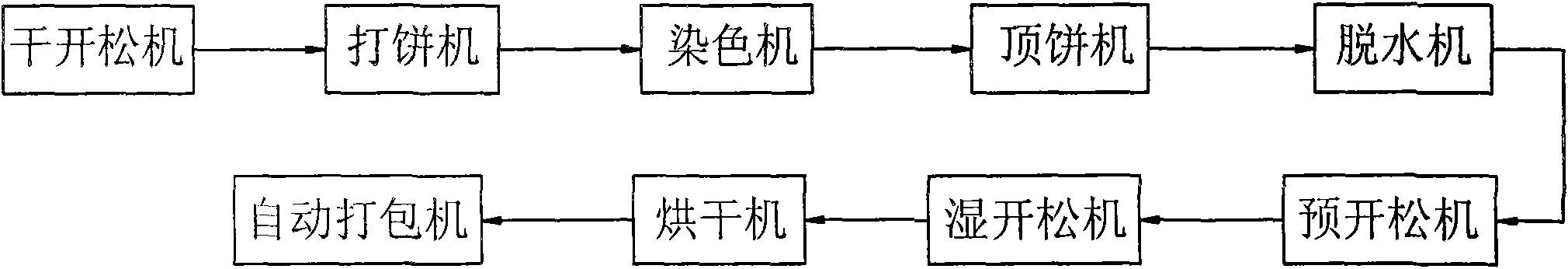

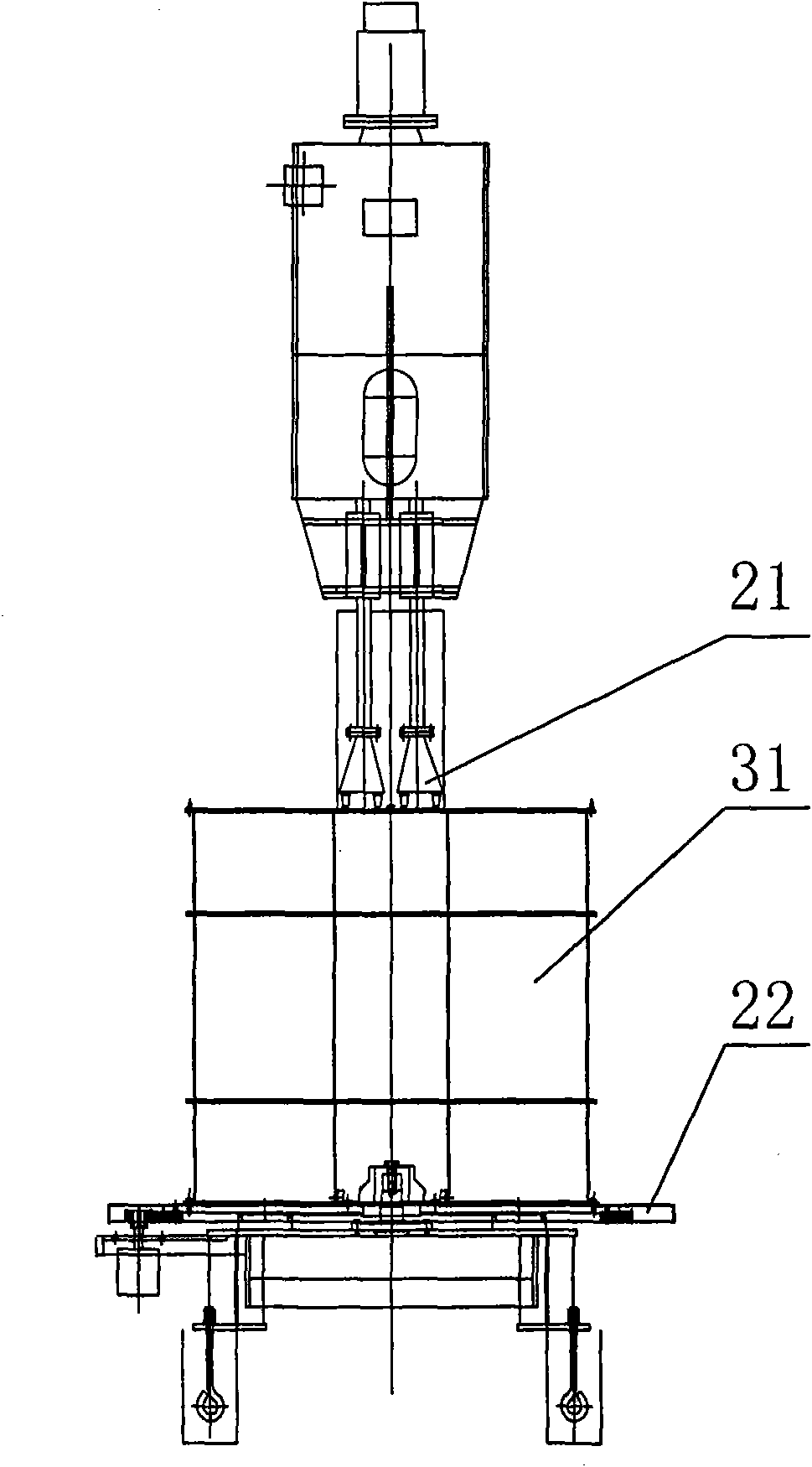

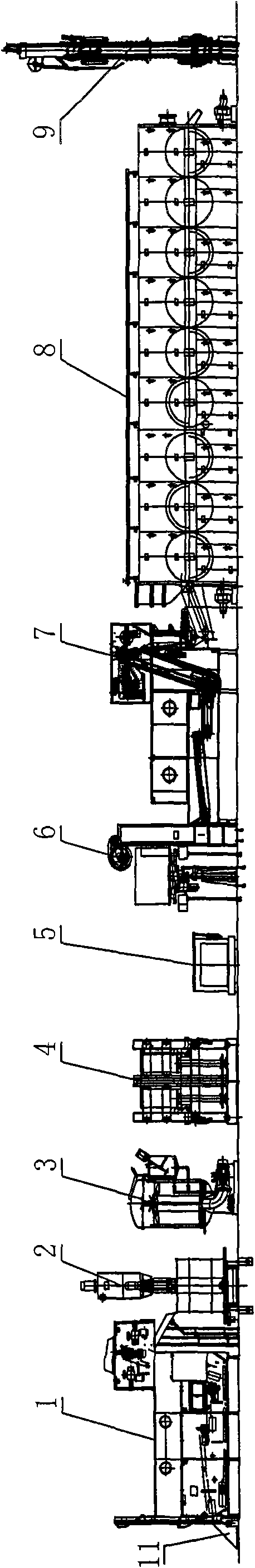

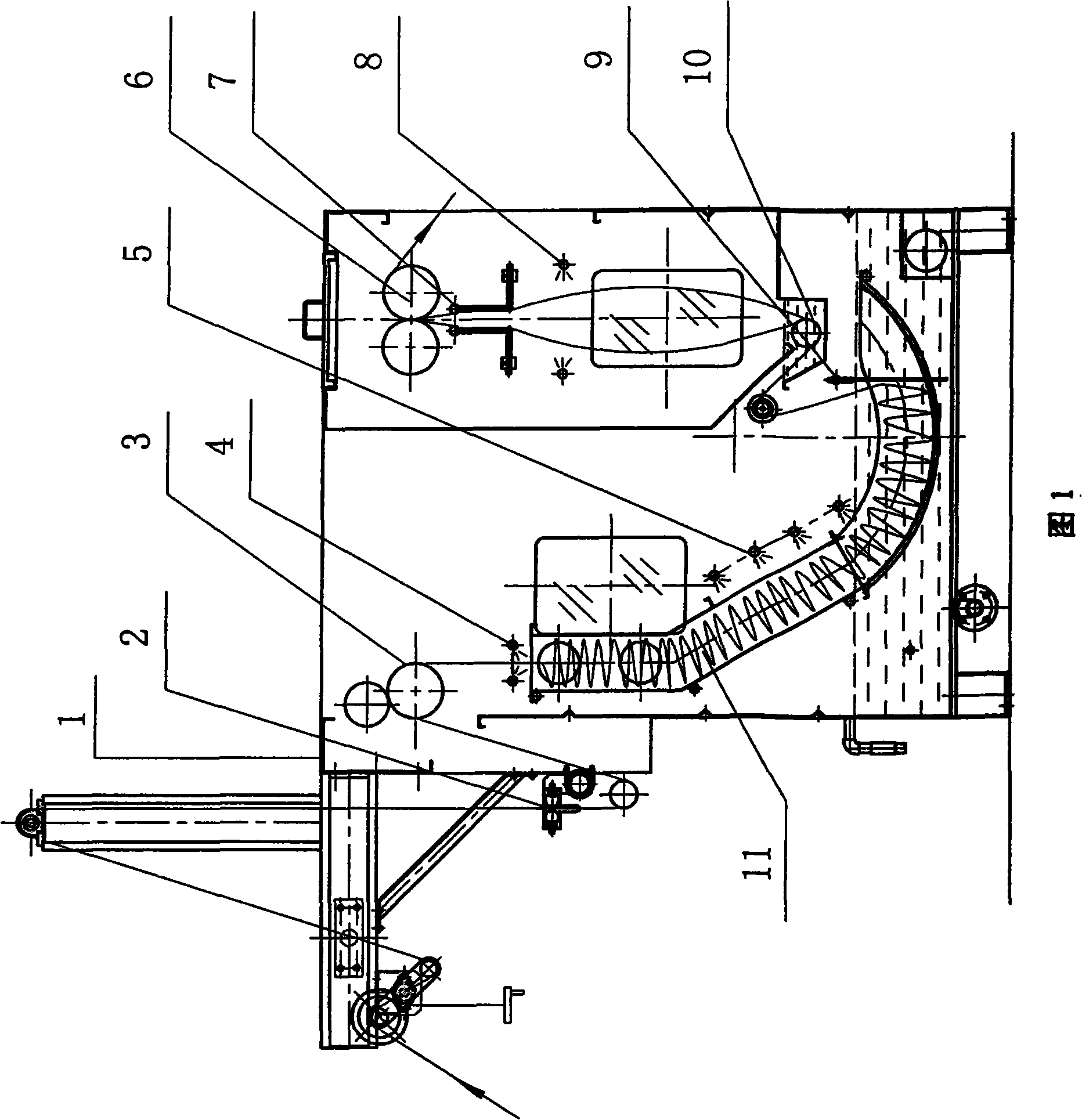

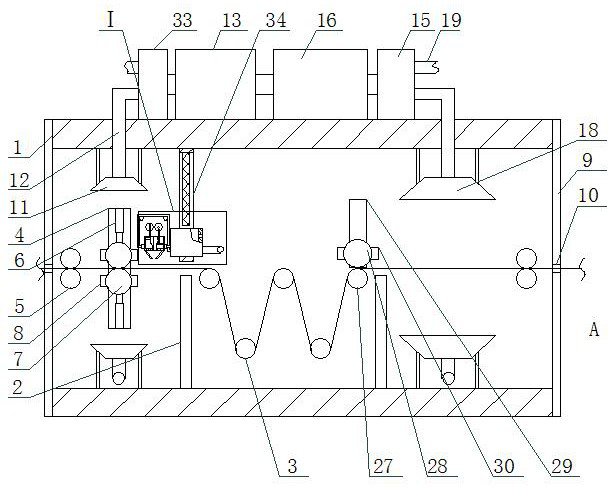

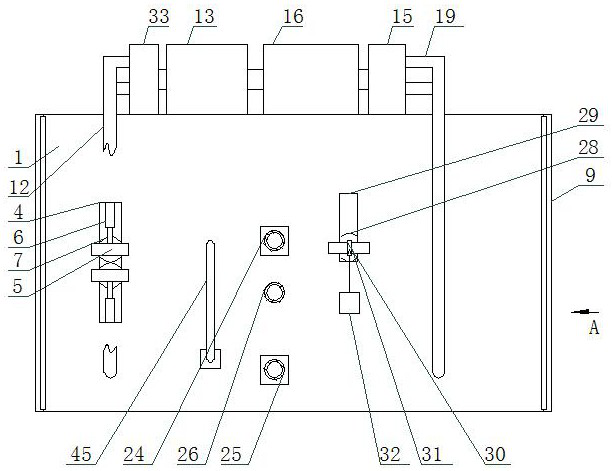

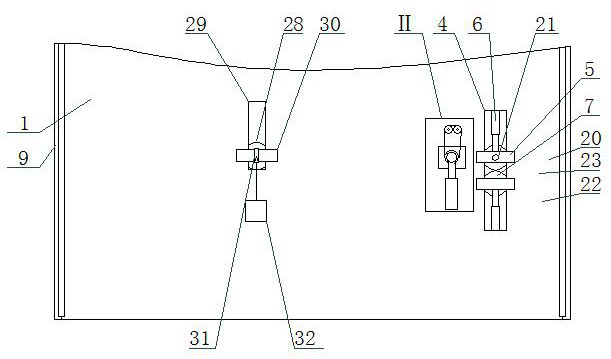

Automatic processing system for dyeing loose fibers

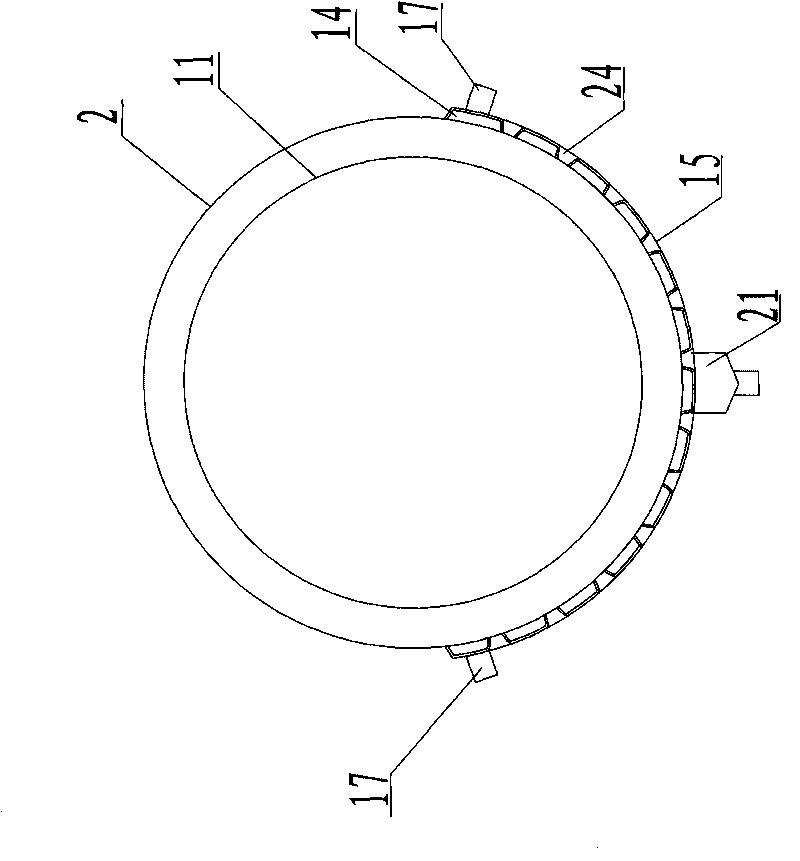

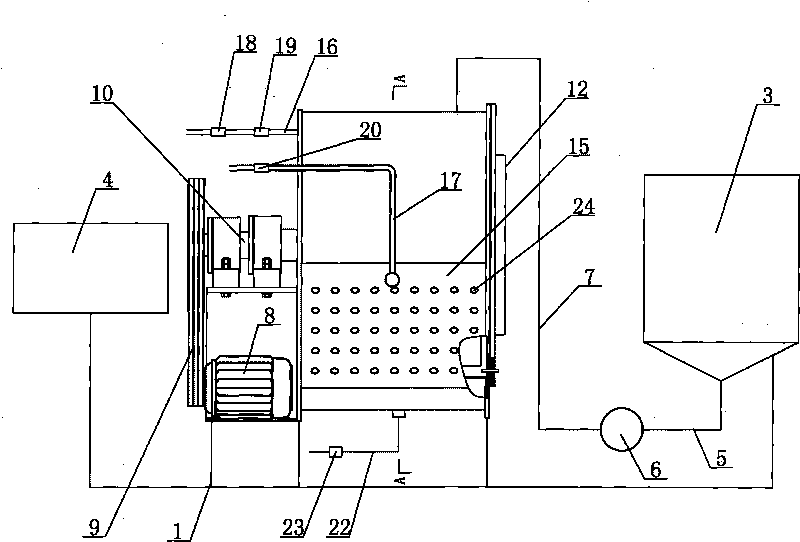

ActiveCN101629365AImprove the degree of automated productionIncrease productivityTextile treatment machine partsFibre cleaning/openingCircular discProduction line

The invention discloses an automatic processing system for dyeing loose fibers. The system comprises a dry opening machine, a disk forming machine, a dyeing machine, a dewatering machine, a wet opening machine, a drying machine and an automatic packing machine which are sequentially connected, wherein, a pre-opening machine is connected between the dewatering machine and the wet opening machine, the pre-opening machine comprises a rotatable disk, the disk is installed on a lifting rack, and a cotton peeling roller is arranged above the disk. A hydraulic disk jacking machine can also be arranged between the dyeing machine and the dewatering machine. The invention is the first automatic production line for dyeing the loose fibers, can be suitable for dyeing various fibers, and can increase the degree of automatic production, shortens the production period of entire dyeing processing, increases the production efficiency, reduces the intensity of labor production, and especially greatly increases safety.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Dyeing technique for cotton fiber cheese

InactiveCN101215789AReduce usageReduce processing costsDyeing processTextile treatment by pouringCotton fibreEngineering

The invention discloses a dyeing technique of cotton fiber cheese, the process flow of the dyeing technique of the cotton fiber cheese comprises preprocessing cotton fiber cheese in a main vat, dyeing and finally processing in turn. The invention is characterized in that in the upper flow process, when water gets into the main vat, water-inlet water level in the main vat is located on one second to two thirds of the total height of stacking of the cheese in the main vat, and water level control model of water inlet adopts a continuous way, dyeing process adopts a salt pre-adding technique, namely anhydrous sodium sulfate is firstly added, and dyeing is followed. Since the invention changes the original dye with full vat of water to a no full vat of water, and the water level control way of water inlet adopts a continuous way, salt pre-adding technique is adopted in the dyeing process, therefore, the invention can reduce energy consumption, improve rate of dye-up-take of dye, lower sewage treatment cost, and reduce the pollution to environment, and the working properties are excellent.

Owner:LUTAI TEXTILE

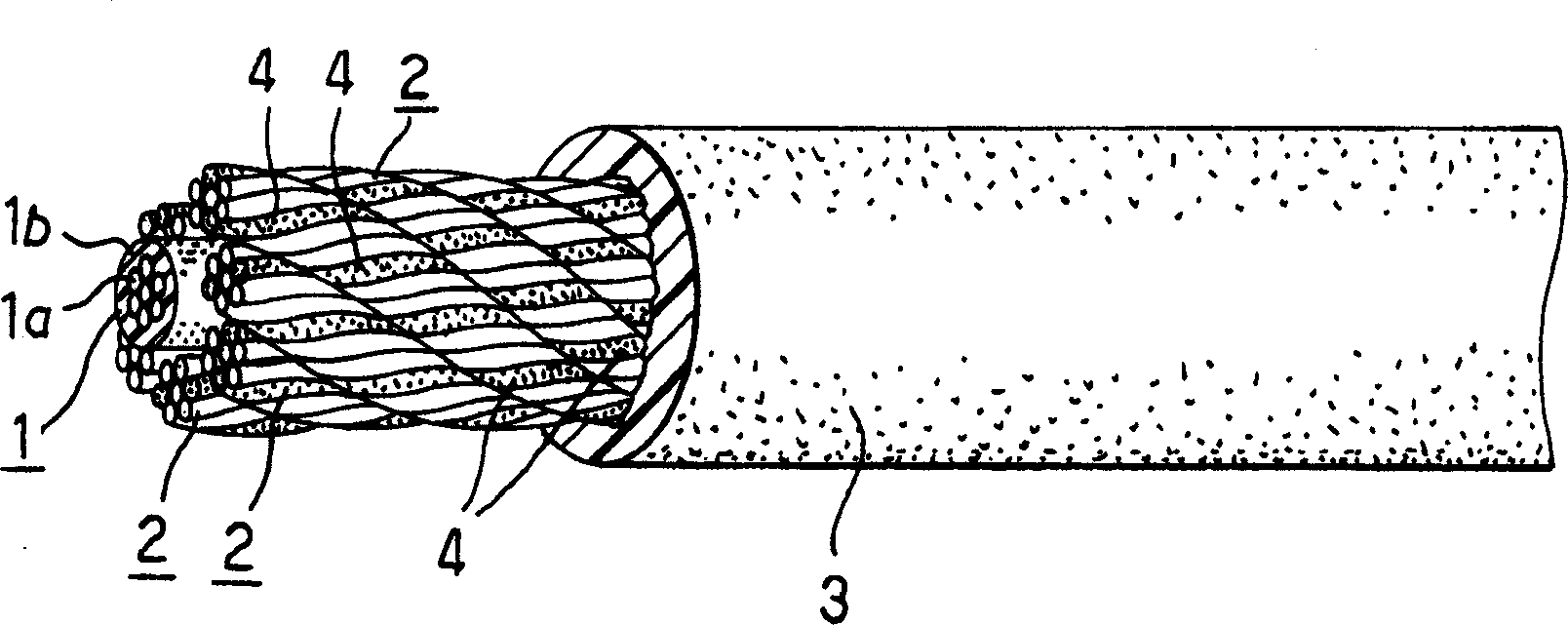

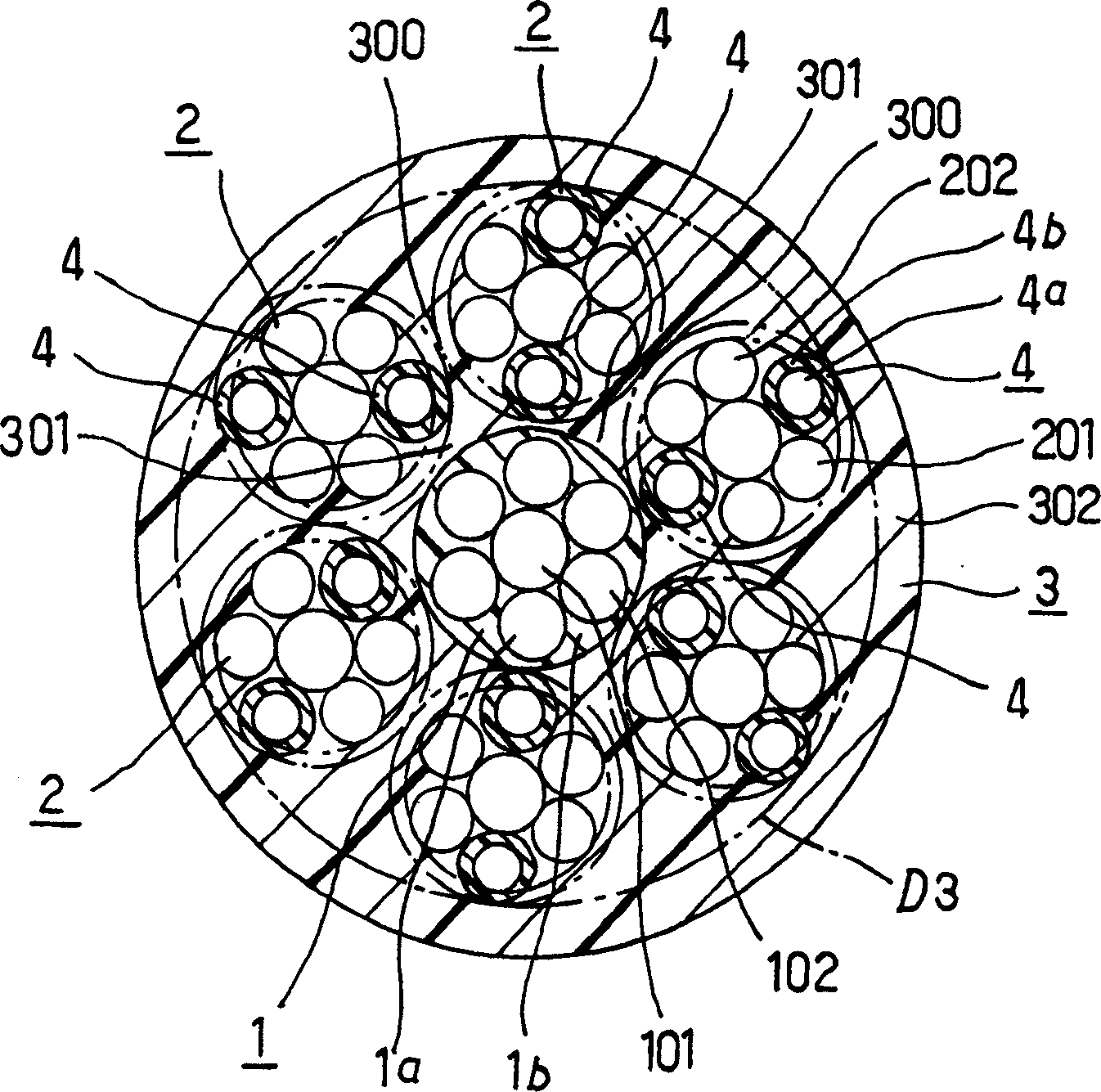

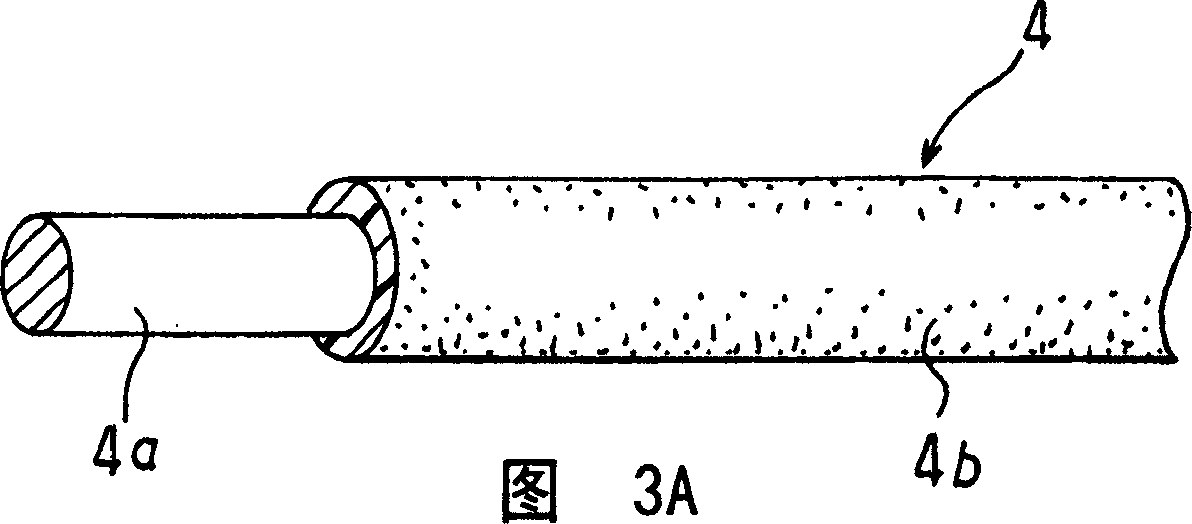

Wrapped steel wire

A steel cable rope well-suited for the application to an elevator or a cargo-handling machine, in which each of side strands is constructed by twisting ordinary linear members together with at least one resinous linear member that is larger in diameter than each of the ordinary linear members. Owing to the existence of the resinous linear member of the relatively larger diameter, gaps are respectively defined between the individual side stands and a core rope and between the respectively adjacent side strands, and a resin for outer layer coating is pressed and packed through the gaps, thereby to prevent wear ascribable to the touch between a core rope and the outer side strands, as well as wear ascribable to the touch between the adjacent outer side strands, and wear ascribable to the metal touch between a sheave and the outer side strands.

Owner:TOKYO ROPE MFG +1

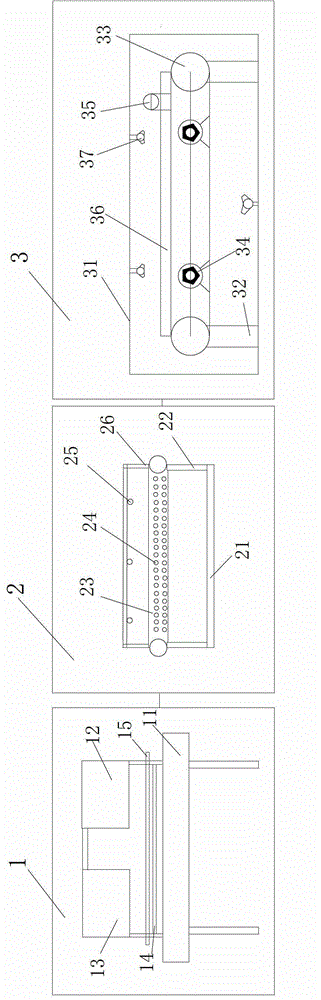

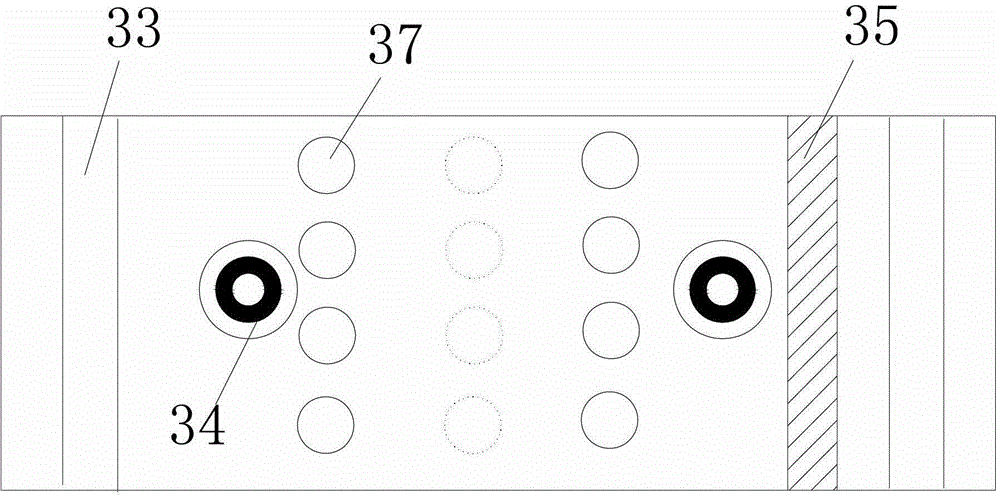

Bonding lining cloth production line

ActiveCN102972889ADry evenlyImprove dispensingLiquid surface applicatorsGarmentsProduction linePulp and paper industry

The invention discloses a bonding lining cloth production line which comprises a dispensing and powdering device, a circular net spraying device and a drying and shaping device. Glue on base cloth is heated and cured by arranging an infrared tube, therefore, the glue is prevented from permeating the base cloth; and an iron plate is arranged above the infrared tube, therefore, the heat of the infrared tube is uniformly dispersed, the base cloth is uniformly dried, and the dustproof effect is achieved. The effect of dispensing and powdering the base cloth is improved; in addition, a plurality of spraying devices are arranged above a circular net, therefore, water is automatically sprayed to the circular net, grouting holes in the circular net are prevented from being blocked, and thus nonuniform pasting of the lining cloth due to point leakage when size is coated by the circular net is prevented, and the sizing effect is improved. In addition, a plurality of groups of duct nozzles are arranged in a box body, and two nozzle openings are arranged in each duct nozzle, therefore the lining cloth is completely dried more uniformly and the drying speed is increased; and a cloth pressing roll is arranged behind a cloth delivering mechanism, the lining cloth is sized after being dried, thus the drying and shaping operation is simplified. The bonding lining cloth produced by adopting the whole production line has the advantages of being good in quality and less in consumed manpower resources, and lowering production cost.

Owner:ZHEJIANG KINGSAFE INTERLINING

Dye process of mixed fabric of cuprammonium fiber and rayon

InactiveCN101046068AAnti-crack performanceFeel goodLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonEngineering

The dyeing process of cuprammonium rayon includes the following steps: water washing, refining and dyeing. In the water washing step, stains on the cuprammonium rayon is eliminated initially; the refining step eliminates sizing material, grease and stains, improves the hand feeling, and raises the dyeing permeability and homogeneity. The dyed cuprammonium rayon fabric is hygroscopic, air permeable and comfortable.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Synchronous padding method for raw spinning cake

ActiveCN101109139AProtective moldingOptimize process flowTextile treatment by pouringLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention discloses a method for synchronous pressure dyeing for crude spinning cake in the post treatment and dyeing of spinning cake, with which, the two processes, namely the pressure washing and dyeing of crude spinning cakes are combined into one, and the pressure washing and dyeing are completed in one apparatus. The procedures for that are: loading yarn, pre treatment before dyeing, dyeing, and post treatment after dyeing. The invention improves the process flow, reduces the times for touching the spinning cakes, guarantees the shaping of spinning cakes; optimizes the post treatment, combines the pressure washing with the dyeing, improves the efficiency of post treatment, and reduces the load of pressure washing; changes the single circulation that goes from inner to outer into inner-outer alternative circulation, reduces difference between the inner and outer layer, and improves the dyeing quality.

Owner:北京市文化科技融资租赁股份有限公司

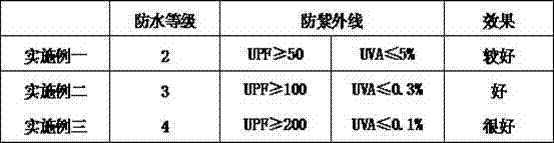

Coating process for waterproof and anti-ultraviolet fabric

ActiveCN103046340AGood waterproof and UV resistanceBright colorFibre treatmentTextile treatment by pouringUltravioletSlurry

The invention discloses a coating process for a water-proof and anti-ultraviolet fabric, which comprises the following steps: primer coating, PA bright silver glue coating and PU pearl glue coating, and is characterized in that a tailor-made PA black slurry is adopted during the primer coating; a tailor-made PA bright silver glue is adopted during the PA bright silver glue coating; a tailor-made PU pearl glue is adopted during the PU pearl glue coating; and a certain amount of an anti-tackiness agent and uvio-resistant powder are added in the PA black slurry. The coating process which adopts tailor-made PA black slurry, the tailor-made PA bright silver glue and the tailor-made PU pearl glue for coating allows the fabric to have good waterproof and anti-ultraviolet performances, to have bright colors and to be suitable for social fashion.

Owner:ZHEJIANG BLUESTAR HLDG GRP

Processing method of leather compound base cloth

InactiveCN101994202AQuality improvementReduce production turnaround timeWeft knittingWarp knittingEngineeringEnergy consumption

The invention discloses a processing method of a leather compound base cloth, which changes the disadvantage of the traditional method for bleaching blank cloth in bleaching cylinder. In the invention, the blank cloth is directly placed in a washing groove to carry out non-overflow washing, thereby shortening the production turning time and reducing the occurrence of snagging and other problems; in addition, since stentering and shaping are directly carried out on the blank cloth after non-overflow washing, various physical requirements of the base cloth can be reached, and the generation of folds is avoided, and the quality of the leather compound cloth is improved, water and electric energy consumption is reduced to a large extent, the resources are saved and the production cost is reduced.

Owner:CHANGSHU CITY YUHENG KNITTING

Pre-processing technology of alginate fibre fabric

InactiveCN101392441AWon't be lostEasy to dyeBiochemical fibre treatmentFibre typesFiberPolymer science

The invention provides a preliminary treatment technology of a seaweed fiber fabric, which belongs to the processing technology in the printing and dyeing production field of the textile. The technology includes the following steps: adding water in a water tank, placing the seaweed fiber fabric into the water which is heated, adding 301L nerbanase, penetrant CWA and Kier boiling agent 88ECO into the water and evenly mixing the mixture to form treating fluid, rotating the seaweed fiber fabric in the treating fluid for 15-17 circles, then draining the treating fluid from the water tank, adding water into the water tank for a plurality of times, and placing the seaweed fiber fabric into the water which is heated for a plurality of times for processing so as to finish the pre-treatment process. The treated seaweed fiber fabric can reach the desizing grade requirement of semi-finished seaweed fiber fabrics, and the metal cations and alginate in the seaweed fiber fabrics can not be lost and the physical property or the physical index can not be destroyed during the subsequent dyeing and finishing process; good dyeing or bleaching effect can be obtained in the next dyeing and finishing process if the process is complete.

Owner:HUAFANG

Terylene harness cord thread and preparing method thereof

The invention relates to terylene harness wire and its manufacturing method. It includes the following steps: making terylene folded yarn; making terylene cabled yarn; winding to drum yarn and inducting into special device; drawing; gum dipping; combing; drawing curing; wax dipping; polishing; winding; hank reeling. The product of the invention has the advantages of stable quality, strong single line strength, good antifriction and weathering resistance. The method has advanced manufacturing technique, low energy consumption, no slurry residue and waste discharge.

Owner:严建民 +2

Production process for fire retardant nonwoven fabric belts

InactiveCN101289795ASimple production processImprove performanceFibre treatmentLiquid/gas/vapor removalWinding machinePolyester

Owner:张云

J-shape stacked pickling tank for knitting tubular open width refining rinsing combination machine

InactiveCN101289791ANo creaseNo blemishesLiquid/gas/vapor removal by squeezing rollersTextile treatment by spraying/projectingMechanical engineeringSmelting

The invention relates to a J-shaped stacking and steeping box for a knitted cylinder type open-width smelting and bleaching machine, comprising a steeping box body (1), a J-shaped stacking box (11), a cloth feeding spray device (4), a stacking spray device (5), an isochronous controller (9), a cloth discharge spray device (8), a blowing and bubbling device (7), water seals (10), a cloth feeding roller (3) and a cloth discharge roller (6), wherein, the cloth feeding spray device (4) is arranged above a grey cloth inlet of the J-shaped stacking box (11); the stacking spray device (5) is arranged on the side of the J-shaped stacking box (11); the isochronous controller (9) is arranged near a circular outlet of the J-shaped stacking box (11); the cloth discharge spray device (8) and the blowing and bubbling device (7) are arranged above the circular outlet of the J-shaped stacking box (11); and the water seals (10) are arranged under the cloth discharge spray device (8); the cloth feeding roller (3) is arranged on the upper front of the the cloth feeding spray device (4); and the cloth discharge roller (6) is arranged above the cloth discharge spray device (8) and the blowing and bubbling device (7). The J-shaped stacking and steeping box has the characteristics that: the surface of grey cloth can not be damaged and fuzzed and has no fold and grinding flaw; the water and the energy are saved; the efficiency is high; the production cost is low; the bleaching technique is stable; etc.

Owner:张琦

Automatic cleaning mechanism for flame-retardant polyester fabric and silk-woven fabric

ActiveCN111893679APlay a moisturizing roleIncrease elasticityMechanical cleaningPressure cleaningPolyesterMechanical engineering

The invention provides an automatic cleaning mechanism for a flame-retardant polyester fabric and a silk-woven fabric. The automatic cleaning mechanism comprises a box body, wherein openings are formed in the two sides of the box body; the two sides of the box body are hinged to double-leaf doors with locking functions correspondingly; fabric through grooves are formed in the two double-leaf doorscorrespondingly; two vertical and parallel lower partition plates are fixedly arranged on the bottom surface of the inner wall of the box body; a square fixing frame is arranged right above one lowerpartition plate; a vertical gas-liquid separation net is fixedly arranged on the top surface of the inner wall of the fixing frame; and the top surface of the fixing frame is fixedly connected with the top surface of the box body, and a bearing box with an opening in the top surface is fixedly arranged on the bottom surface of the inner wall of the fixing frame. According to the automatic cleaning mechanism, used parts are common and low in price, and production and manufacturing are facilitated; a vibration motor rotates to drive cleaning liquid in an extrusion box to be extruded out, so that the cleaning liquid is sprayed on the fabric, and the situation that the fabric is damaged due to the fact that a vibration shaft vibrates the fabric is avoided; and meanwhile, the cleaning liquid left in drying gas can be recycled.

Owner:淄博大洋阻燃制品有限公司

Production process of fabric

InactiveCN103031680AUnique memory functionAchieve a completely iron-free effectSucessive textile treatmentsHeating/cooling textile fabricsYarnPolytrimethylene terephthalate

The invention discloses a production process of fabric, and the production process comprises the following steps of (1) warping polytrimethylene terephthalate (PTT) yarns in batches; (2) scaling pulp axis; (3) padding PTT yarns into pulp, and drying the PTT yarns to be made into a PTT beam which is coated with pulp film; (4) installing the PTT beam into a warp rebeaming machine warp shaft frame to be coiled collectively into a warp beam; (5) dividing the warp beam into three strands on a lease machine; (6) sequentially penetrating PPT yarns on the warp beam into a harness wire and reeds according to a fabric drafting method and a reeding way; (7) weaving the yarns into fabric; (8) desizing the fabric; (9) dying the fabric; and (10) thermally setting the fabric to be made into the finished product fabric. Due to the adoption of the production process, the fabric has a unique memory function, a completely iron-free effect can be realized, softness in touching can be realized, the fabric is bright in color, and a wicking perspiration function and ultraviolet resistance function also can be realized.

Owner:JIANGSU HUANGGUOSHU GARMENT

Dipping and showering alternate type hank dyeing method

InactiveCN101503851AUniform colorEmission reductionTextile treatment machine arrangementsTextile treatment by pouringYarnEngineering

The invention discloses a dip and spray alternate hank dyeing method, which is to perform dip dyeing and spray dying on hank yarns alternately regularly, and comprises that: one part of the hank yarns are placed into dye solution for dip dyeing and the other part of the hank yarns are sprayed with the dye solution for spray dyeing; and then the two parts of the hank yarns are subjected to the dipdyeing and spray dyeing alternately and interchangeably at intervals, and the step is repeated until the dyeing is completed. The dip dyeing and spray dyeing alternate method can effectively reduce the minimum dyeing bath ratio. The designed dip and spray alternate hank dyeing method effectively reduces the minimum dyeing bath ratio to less than 1:14, can reduce water quantity by 30 percent and vapor quantity by about 25 percent compared with the prior dip dyeing method, and can effectively achieve the aims of saving energy and water and reducing the discharge amount of sewage and carbon dioxide. Through the dyeing method, the dyed hank yarns have even color and meet the requirement of weaving sweaters, and the color fastness can meet the pure wool standard of International Wool Secretariat IWS through detection.

Owner:ZHEJIANG HOUYUAN TEXTILE

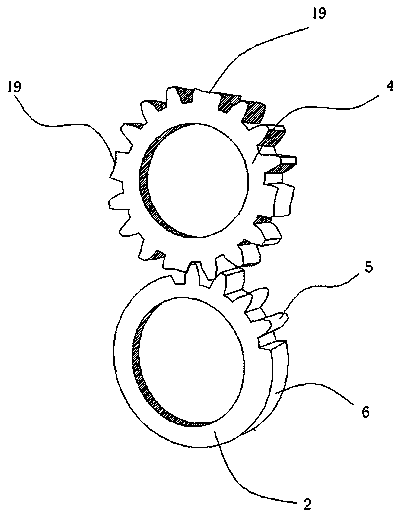

Polyester filament fabric printing and dyeing equipment

InactiveCN110644162AReduce the number of installationsReduced installation structureTextile treatment machine arrangementsRotary pressesPolyesterGear wheel

The invention discloses polyester filament fabric printing and dyeing equipment, which comprises a feeding mechanism, including a conveying roller and a driving device for driving the conveying rollerto rotate, wherein the driving device comprises a first driving wheel, a rotating motor and a first driven wheel, and the first driving wheel is provided with a toothed portion and a non-toothed portion; a printing and dyeing mechanism, including a printing and dyeing table and a printing and dyeing body; and a printing and dyeing body driving mechanism, including a second driving wheel, a seconddriven wheel and a transmission bar, wherein sector gears are coaxially and fixedly arranged on the second driving wheel and the second driven wheel respectively, the two sector gears are alternatelymeshed with the transmission rod, the transmission rod is connected with the printing and dyeing body, and the second driving wheel is in transmission connection with the first driving wheel. the whole printing and dyeing operation can be completed just by supplying power to the first driving wheel, setting power sources for other parts is not required, and cost is reduced; meanwhile, linkage isgenerated between the feeding mechanism and the printing and dyeing mechanism.

Owner:JIANGSU JINDA TEXTILE IND

Process for using polyurethane resin to coat a plurality of sequins attached to a material

InactiveUS20090274864A1Test may passDecorative surface effectsLayered productsMechanical engineeringCoating

A method of coating a roll of material with a plurality of sequins comprising steps of (1) passing a roll of material with a plurality of sequins with the sequins on an upper surface of said roll of material through two wooden guards; (2) passing said roll of material with a plurality of sequins with the sequins on said upper surface of said roll of material through a coating device, (3) passing said roll of material with a plurality of sequins with the sequins on said upper surface of said roll of material through a scrapper device to ensure the evenness of said roll of material; (4) passing said roll of material with a plurality of sequins with the sequins on said upper surface of the material through a drying room; and (5) rolling said roll of material into a second roll through a roller. This method is repeated four times to ensure that the material will be able to pass the physical and mechanical tests imposed by the Consumer Product Safety Commission.

Owner:TSAI CHUNG CHING

Yarn ozone bleaching device and bleaching method

The invention discloses a yarn ozone bleaching device and bleaching method. The yarn ozone bleaching device comprises an ozone generator, a gas-liquid mixing pump, a water storage tank, a bleaching reaction tank, a suction pipeline, a circulation pipeline, a sampling port and a pressure gage. The method includes the steps that high concentration ozone gas is prepared through the ozone generator, the ozone gas enters the gas-liquid mixing pump through the suction pipeline, the gas-liquid mixing pump absorbs the ozone gas from the water absorption side of the water storage tank, the ozone gas is efficiently dissolved in water in a pump inside pressurization mixing mode, so that high concentration ozone water is obtained, the high pressure ozone water is directly injected into the bleaching reaction tank through the pump, yarns to be bleached are completely soaked into the high pressure and high concentration ozone water, the ozone water is circulated continuously, ozone is added continuously, and the concentration of the ozone water is kept. The yarn ozone bleaching device and bleaching method have the advantages that pollution-free ozone bleaching is conducted on the yarns, after bleaching is completed, the ozone water can still be recycled after purification treatment, and the purpose of energy saving and emission reduction is effectively achieved.

Owner:SHAOYANG TEXTILE MACHINERY

Antibiotic radiation proof treatment method for fabric and clothes

This invention provides a antibacterial and radiation protection processing method for the textile and clothing, it can realize as follows, adding 10%-20% CuSO4 and 2%-4% AgNO3 to the water solution to get the mixture, getting some cell polysaccharide to the acetum to get the concentration of 0.003-0.01g / ml mixture, then mixing the two mixture as the ratio 1:3-3:1, at last adding 2-6% dispersant. The pH value of the solution is 3.5-4.5 by the sodium hydrate and acetum. The textile or clothing can be infused into the mixture for 20-60min, then put into the high temperature stream room for 15-20min at 80-100deg.C, at last the clothing or textile was washed, dehydrated and dried to get the complex antibacterial textile and clothing. The processing clothing and textile has stronger antibacterial and radiation protection function, and it is good for the health of human body.

Owner:QINGDAO RED COLLAR GROUP CO LTD

Cotton bamboo fiber blending broad width woven fabric and production method thereof

ActiveCN106939464AHigh surface glossRetain AntibacterialLiquid/gas/vapor open-width material treatmentTextile storage in superimposed formFiberTechnical specifications

The invention discloses a cotton bamboo fiber blending broad width woven fabric and a production method thereof. The production technical flow process sequentially comprises the steps of blank cloth turning and stitching, singeing, amylase desizing, boiling-off, oxygen bleaching, pre-tentering, half mercerizing, dyeing, tentering, formaldehyde-free anti-shrinkage sorting, pre-shrinking, calendering and the like. The cotton bamboo fiber blending broad width woven fabric has the advantages that the surface glossiness is high; the warp and weft water washing dimension change rate is -3.0 percent to +1.0 percent; the fastness to soaping is greater than or equal to 4 stage; the fracture strength is greater than or equal to 280 N. The production method of a product has the advantages that the operation is easy; the environment-friendly effect is achieved; the product safety can reach requirements of GB18401 National Textile Product Basic Safety Technical Specification class A: baby and infant products.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com