Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2277results about "Liquid/gas/vapor yarns/filaments treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for mercerized knitted bedding fabric

InactiveCN102433678AMoisturize evenlySoft touchMercerising of indefinite length fabricsSingeingTextile printerPolymer science

The invention discloses a processing method for a mercerized knitted bedding fabric. The processing method mainly adopts a production technology of double-calcination single yarn, first refining and then mercerizing, and grey yarn is sequentially subjected to yarn singeing, yarn steaming, knitting, grey cloth singeing, refining, dewatering, cylinder drying, mercerizing, dyeing, dewatering, scutching, drying, printing, forming and pre-shrinking and finally is checked and stored in a cabin. The mercerized knitted bedding fabric has the advantages of high conformality, low shrinkage, wide width and the like, and can meet the requirement on the knitted bedding fabric; compared with a woven fabric, the mercerized knitted bedding fabric has higher elasticity, water absorption and air permeability, is more smooth and fine in handfeel, and has better comfortableness.

Owner:WUHU SHENGLUO TEXTILE INDAL

Low-temperature scouring and bleaching agent and preparation method thereof and preprocessing technique

InactiveCN101037842AReduce the bleaching temperatureThe effect of the pretreatment process is obviousBleaching apparatusTextile treatment by spraying/projectingTextile printerBenzene

The present invention realtes to a low temperature scouring and bleaching agent belonging to the pretreatment process technology field of the textile printing and dyeing industry, a manufacturing method thereof and a pretreatment process. Said low temperature scouring and bleaching agent consists of promoter QR2010 consisting of carbon tetrachloride, acetic acid esters, alkyl benzenes, emulsifying agents and scouring agents; promoter QR2011 consisting of potassium hydroxide, carbonates and penetrating agents; and promoter QR2020 consisting of acyls and nitriles activating agents and builders. Said three promoters are prepared using routine methods and are deposited solely. When used, the three promoters, together with hydrogen peroxide, are mixed according to different proportions to prepare solutions. Said low temperature scouring and bleaching agent is capable of annealing, boiling and bleaching a variety of cotton as well as cotton blending textiles at any temperature ranging from 40 DEG C to 80 DEG C, and being processed at different scouring and bleaching equipments, with a whiteness of higher than 80% and a capillary effect of 10-20 cm. Compared with the process in existing, the amount used of hydrogen peroxide activating agent is 1 / 7 to 1 / 5 of that originally used, the total energy consumption is reduced, the tonnage of used water is decreased, and billet flaws such as holes bleached by oxygen and lycra folded crepes sourced and bleached are avoided.

Owner:SHANGHAI QIRUI TEXTILE CHEM

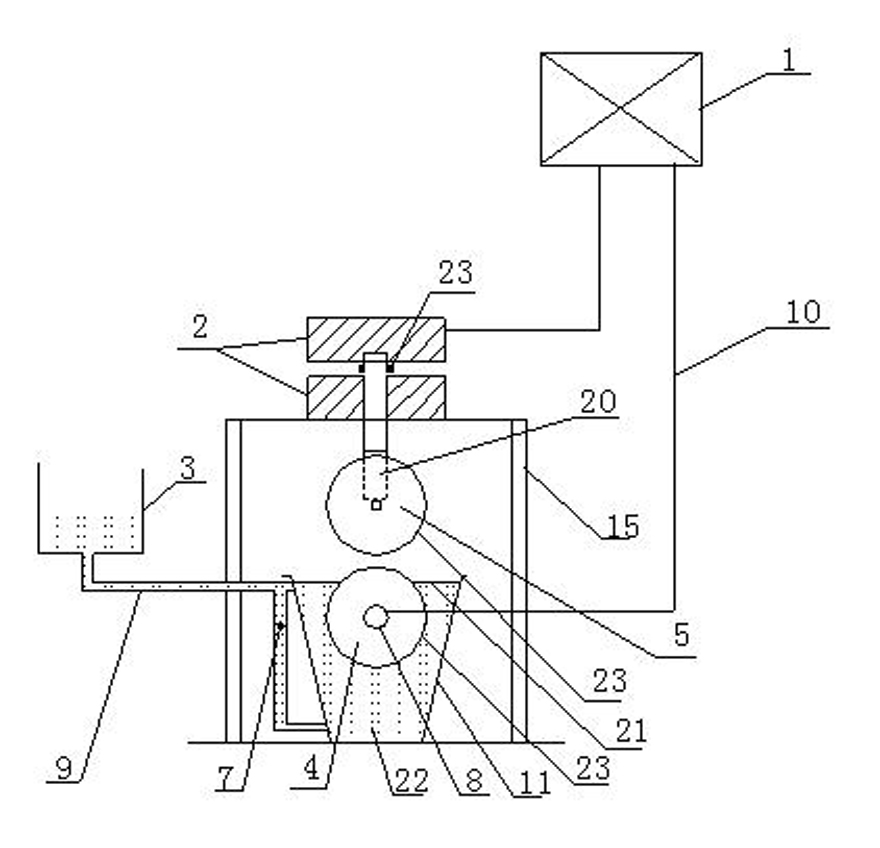

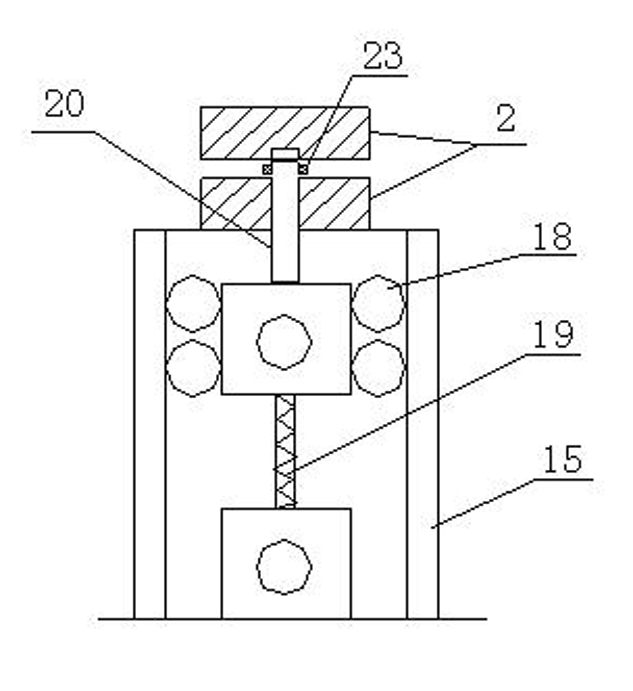

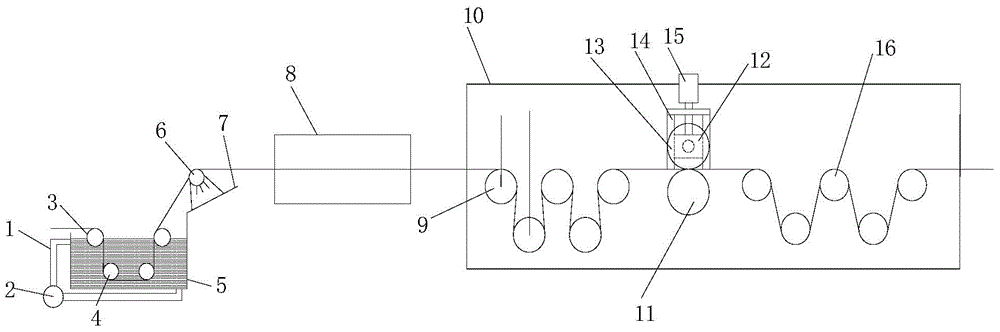

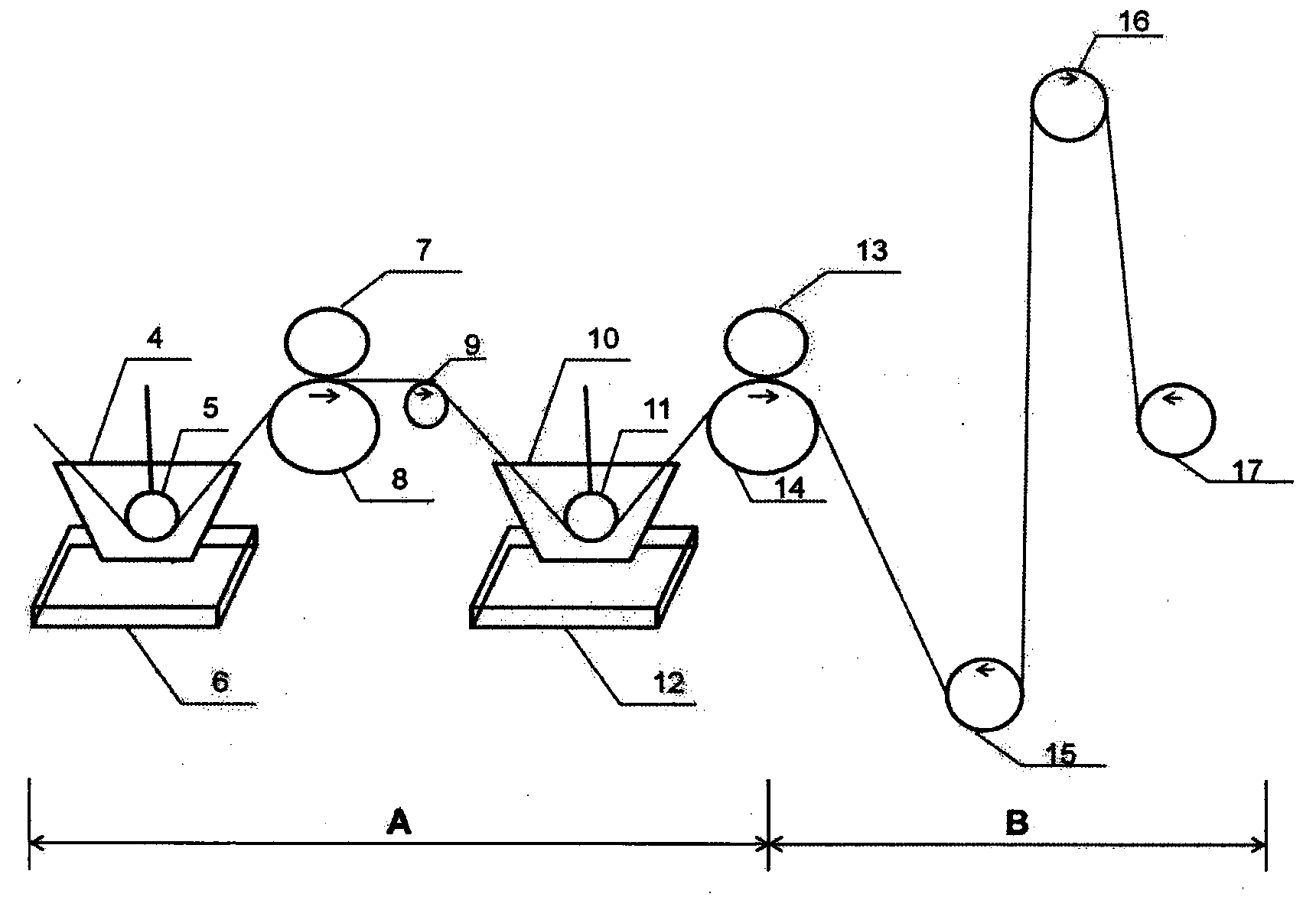

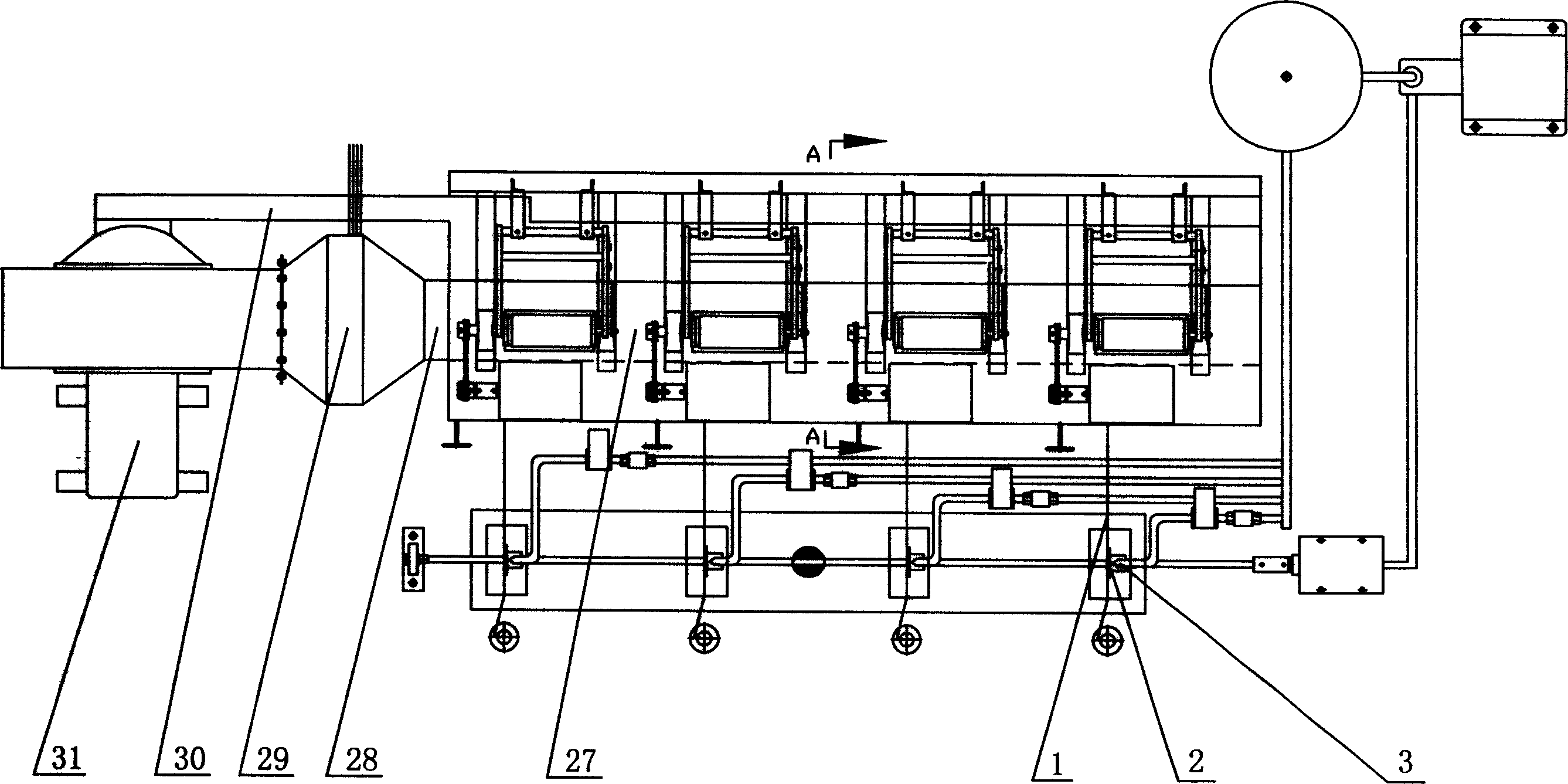

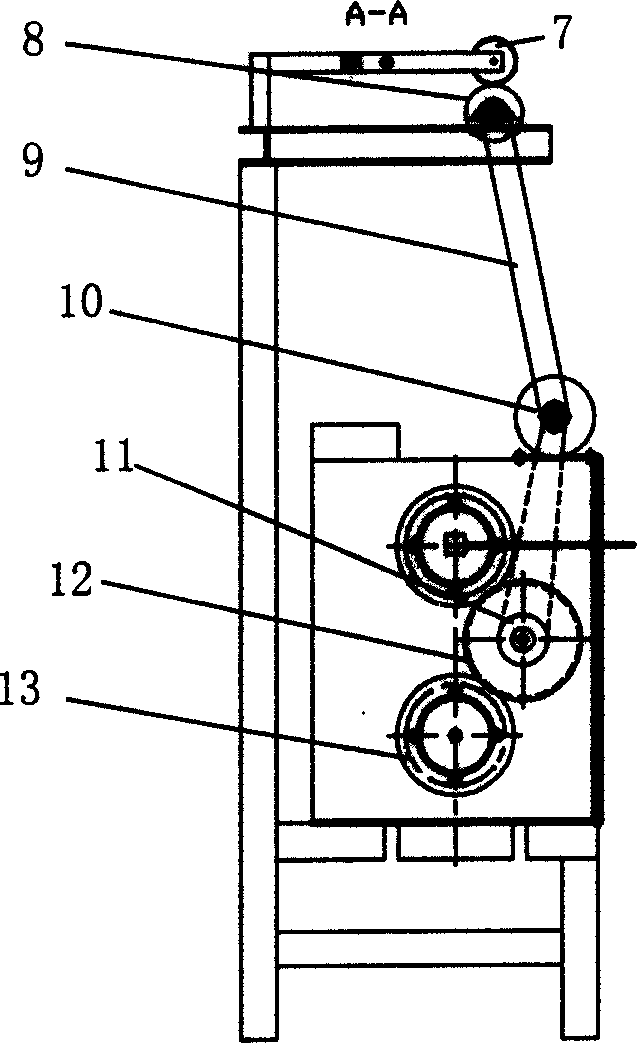

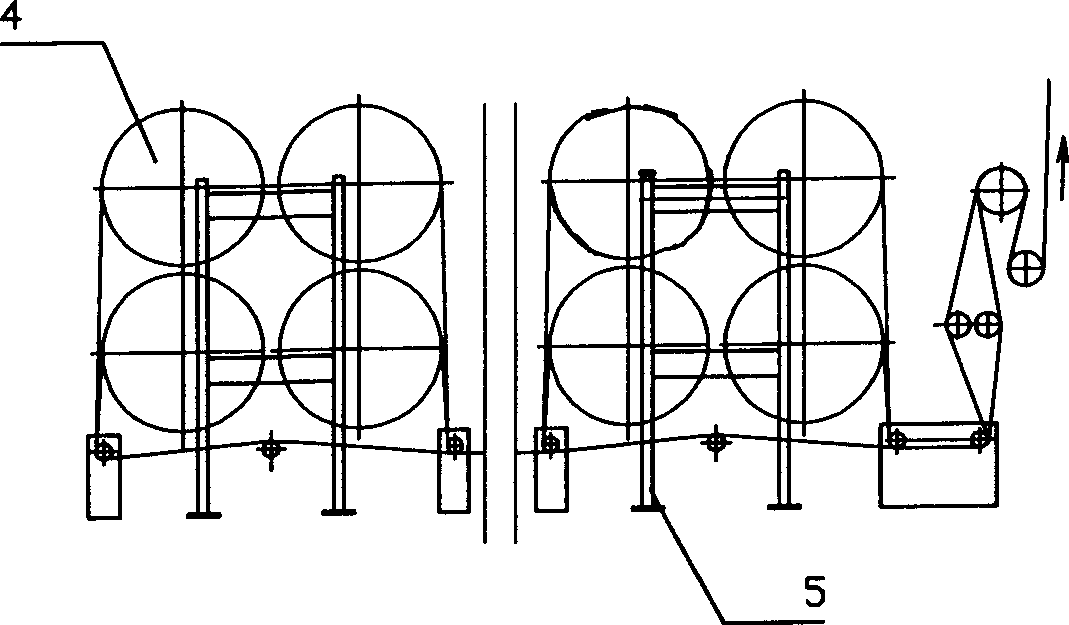

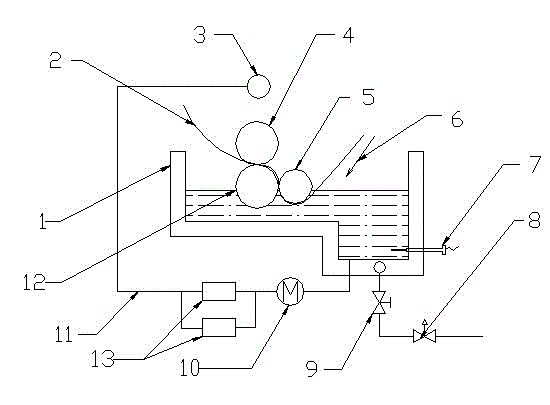

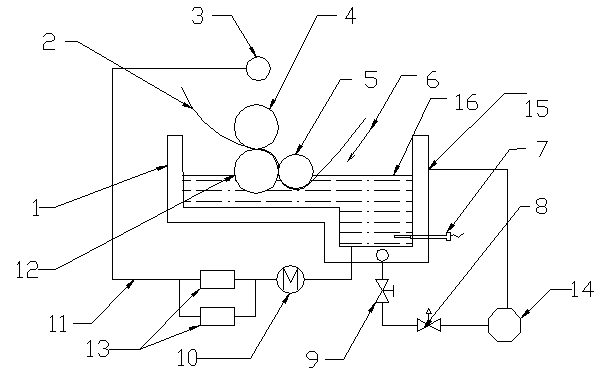

Device for producing space dye yarn

ActiveCN102021775AReduce in quantityReduce the number of rootsTextile treatment machine partsLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention relates to a device for producing space dye yarn, comprising at least one group of padders. A dye liquor slot for holding space dye liquor is arranged below each group of padders; the inside of the dye liquor slot is connected with a corresponding space dye liquor preparation bucket through a feed delivery pipe; each group of padders comprises a stand, a bottom roll and a top roll; at least part of outer wall surface of the bottom roll is soaked in the space dye liquor of the dye liquor slot; when the top roll is upwards lifted, the top roll and the bottom roll are separated, and the yarn passes through a gap between the top roll and the bottom roll; when the top roll is pressed downwards, the outer wall surface of the top roll and the outer wall surface of the bottom roll are appressed, the bottom roll drive the top roll to rotate to make the yarn pass through the rolling points of the top roll and the bottom roll, and the outer wall surface of the bottom roll adheres to the space dye liquor in the rotation to apply the space dye liquor to the yarn. By utilizing the device to carry out the space dye, the space dye liquor residual is little, and the space dye processing efficiency is high. The space dye process and a yarn grounding dye process can be also continuously finished at one time so that the space dye cost is reduced and the comprehensive benefit is good.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

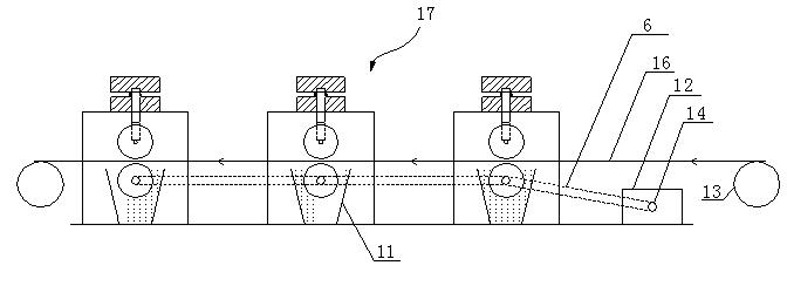

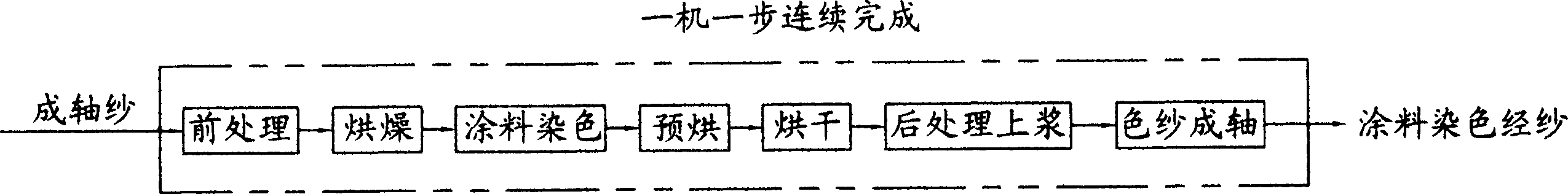

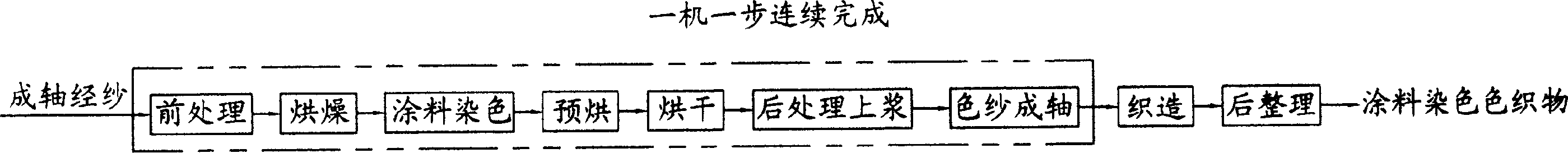

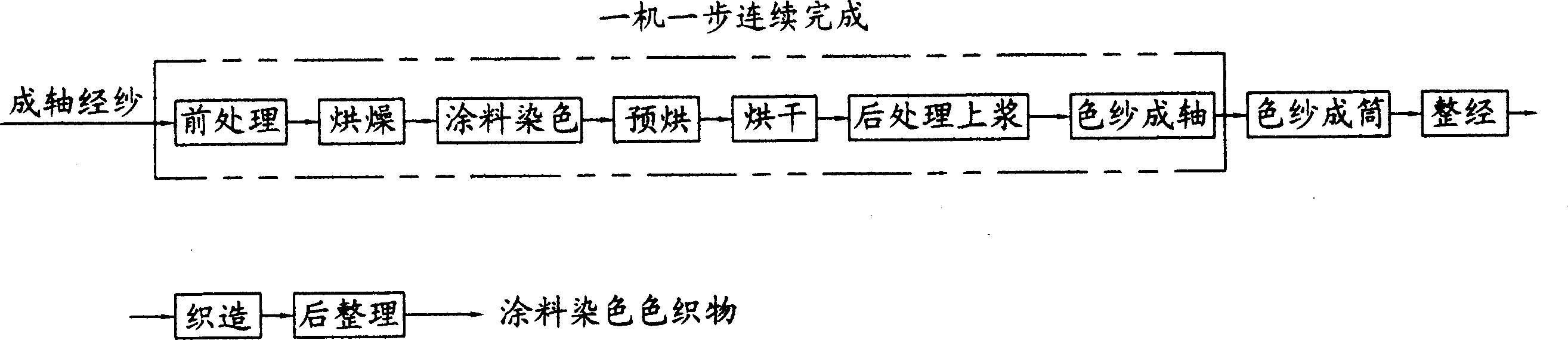

Pigment dyed colored cloth production method

InactiveCN1884659AQuality improvementGood processing depthSucessive textile treatmentsSingeingSewageEnergy consumption

The invention discloses a manufacturing method of paint dyeing weaver with oxford textile, chambray and denim, which comprises the following steps: predisposing warp; drying; dyeing; predrying; drying; after-treating; shafting warp; weaving; dressing; finishing one step by one machine continually. The invention satisfies large batch and scale manufacturing request, which is fit for producing original paint dyeing and other pain dyeing weaver product.

Owner:常州市森容纺织品有限公司

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465AImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

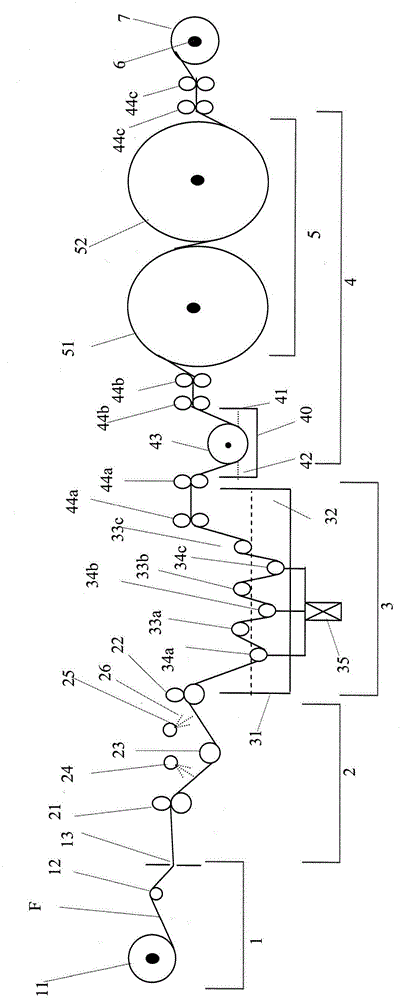

Production method of speck yarn

ActiveCN102011278ANot easy to fall offIncrease productivityTextile treatment with treating outlet contectLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention relates to a production method of speck yarn. The production method contains a speck machining process and the machining process contains a process that a plurality of parallel yarns pass through at least one nozzle in a progressive manner in turn; during the process, the nozzle sprays a staining solution to the yarns intermittently; in the spraying process of the nozzle, the spray-painting of at least one color is realized by controlling the color and concentration of the staining solution sprayed by each nozzle, the advancing lengths of the yarns under the spraying state and intermittent state relatively to each nozzle are controlled respectively to limit the speck section lengths sprayed by the corresponding nozzles and the intermittent section lengths on the yarns; and by controlling the ratio of the frequency of the back and forth movement of each nozzle to the advancing speed of the yarns respectively, the density of the specks sprayed by the nozzles on the yarns can be limited. The specks of the speck yarn prepared by the method in the invention are difficult to fade. In addition, the dyeing of the specks and the dyeing of the bottom color can be performed continuously, thus the cost is low and the comprehensive benefit is good.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

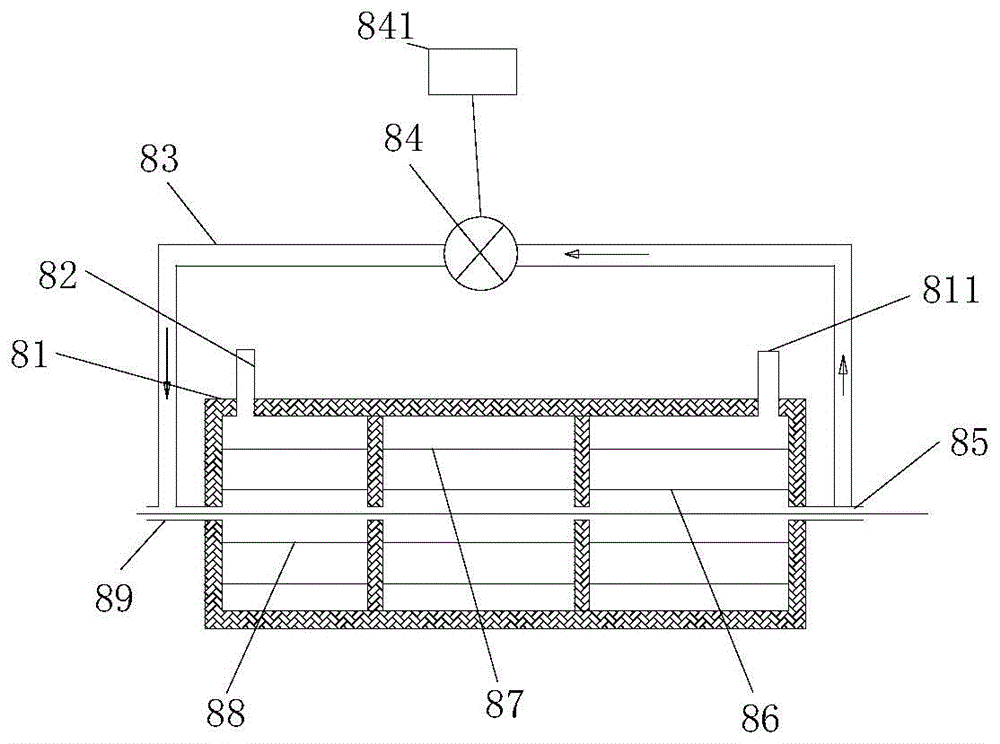

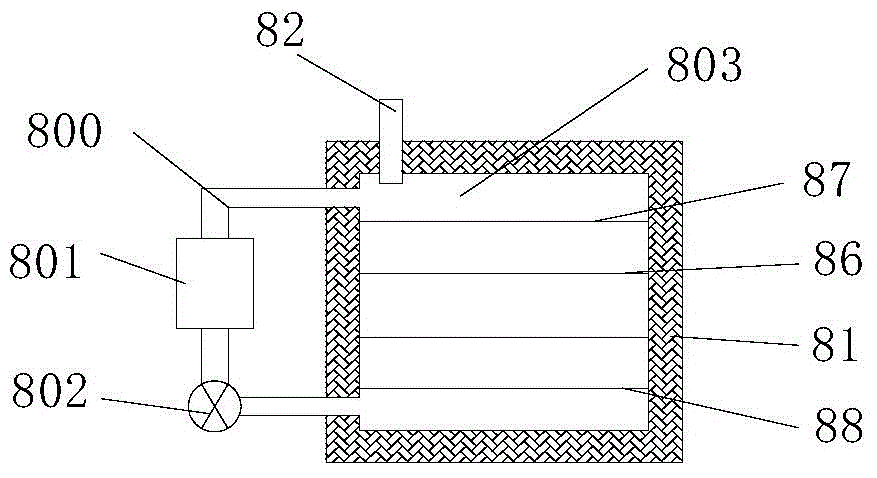

Sizing, drying and shaping device for polyacrylonitrile-based carbon fiber

ActiveCN103334246AGuaranteed uniformityImprove uniformityHeating/cooling textile fabricsLiquid/gas/vapor removal by gas jetsCarbon fibersWorking environment

The invention belongs to a generation device for a polyacrylonitrile-based carbon fiber and particularly relates to a sizing, drying and shaping device for the polyacrylonitrile-based carbon fiber. The sizing, drying and shaping device comprises a sizing device for sizing a carbon fiber, a drying device for the sized carbon fiber as well as a shaping device for shaping the dried carbon fiber, wherein the sizing device comprises a sizing groove for accommodating slurry; a circulating pipeline is arranged on the outer side of the sizing groove; one end of the circulating pipeline is connected with the bottom of the sizing groove; the other end of the circulating pipeline is connected with the upper edge of the sizing groove; a circulating pump is arranged on the circulating pipeline; a guiding roller which is partially immersed in the slurry and an immersing roller which is completely immersed in the slurry are arranged in the sizing groove; a reflowing plate which is arranged in an extending manner is arranged on the outlet edge of the sizing groove; and an air purge device is fixedly arranged above the reflowing plate. According to the sizing, drying and shaping device disclosed by the invention, the sizing is uniform, the shape of tows is good; the pollution of air to the carbon fiber is reduced in the sizing and drying; and meanwhile, the work environment is improved and the work comfortableness of workers is improved.

Owner:ZHONGJIAN TECH CO LTD

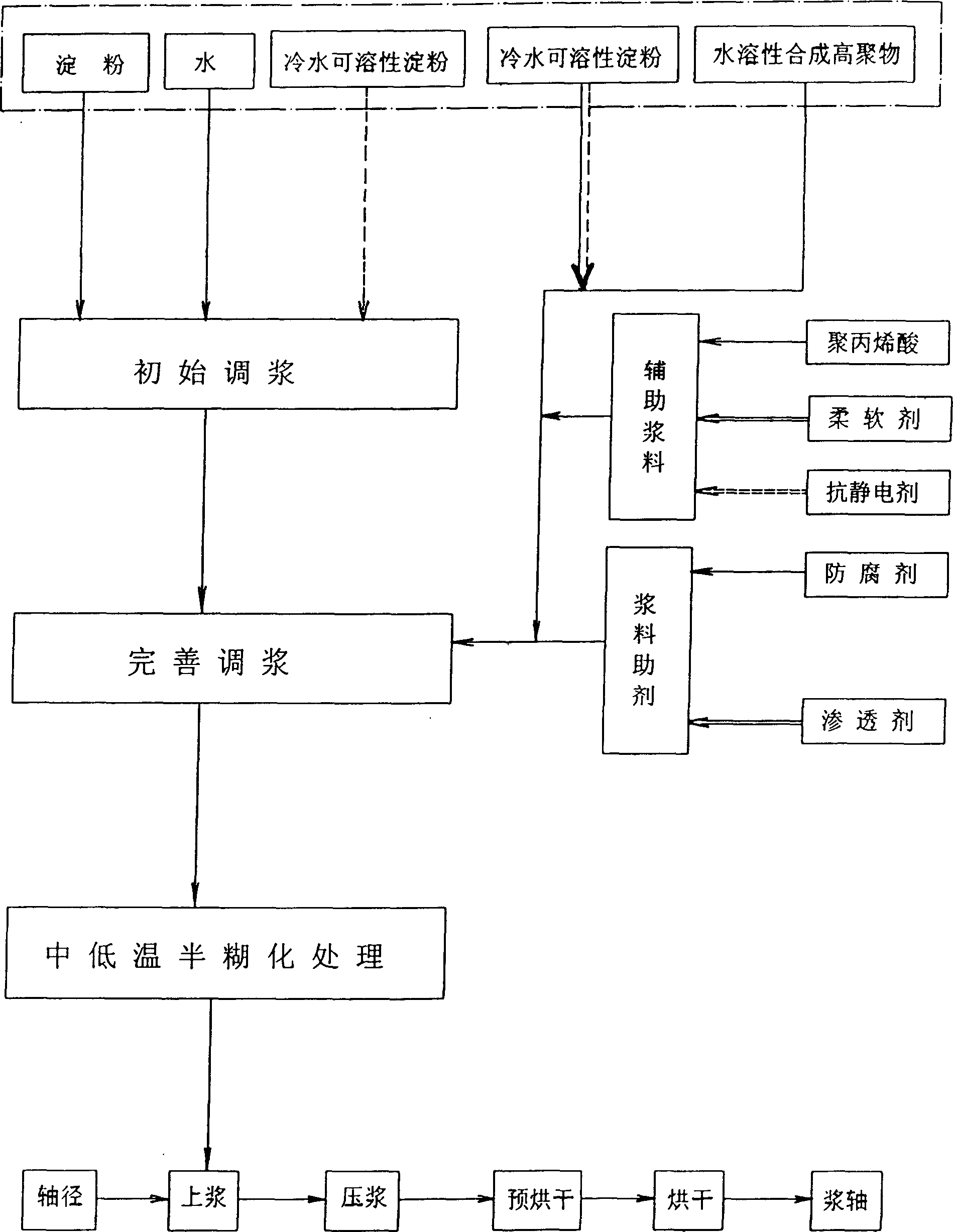

Middle and low temperature semi-pasted warp sizing method

The invention discloses a middle low-temperature gelatinization warp sizing method. Using 70-90 wt% starch, 0-20 wt% cold water soluble starch, 5-25 wt% soluble synthetic polymer, 1-5 wt% polyacrylic acid, 1-5 wt% softening agent, 1-5 % antistatic agent, 0.1-0.5 wt% preservative, 0.1-0.5 wt% penetrant of all slurry and 5-8 times water of all slurry as raw material; Slowly agitating starch and water for 5-15min to initialize plasm, adding cold water soluble starch, soluble synthetic polymer, polyacrylic acid, softening agent, antistatic agent, preservative, penetrant and slowly agitating for 5-15min to perfect plasm, heating to 45-60DEG C, pH 6.5-7.5, viscosity 5-10 seconds under rapid agitation for half gelatinization of starch, sizing in room temperature -60DEG C, squeezing in 3-20KN, prebaking in 85-95DEG C, drying in 115-130DEG C. Using in warp sizing. The effect of energy and time saving is good.

Owner:苏州泰和特科技有限公司

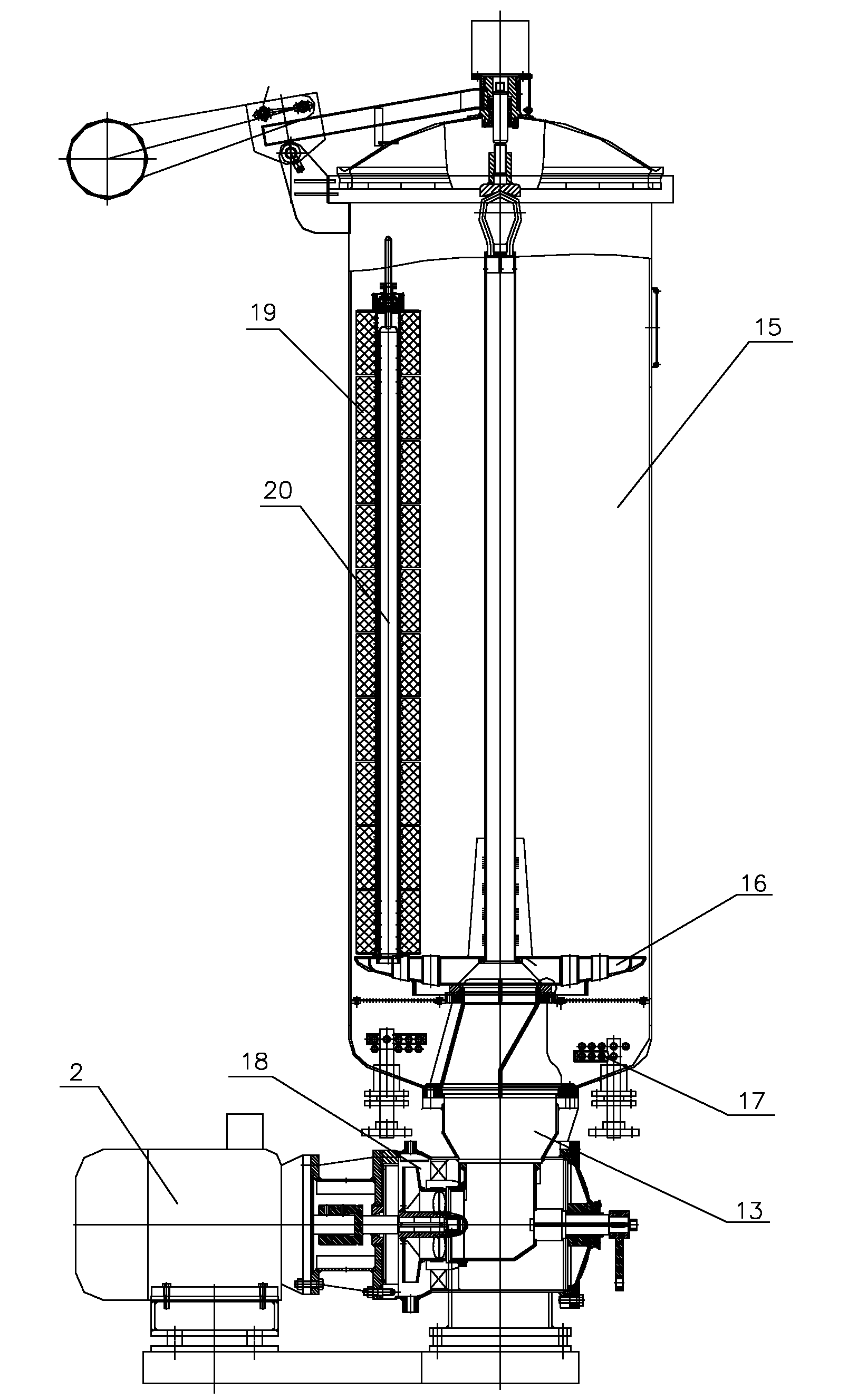

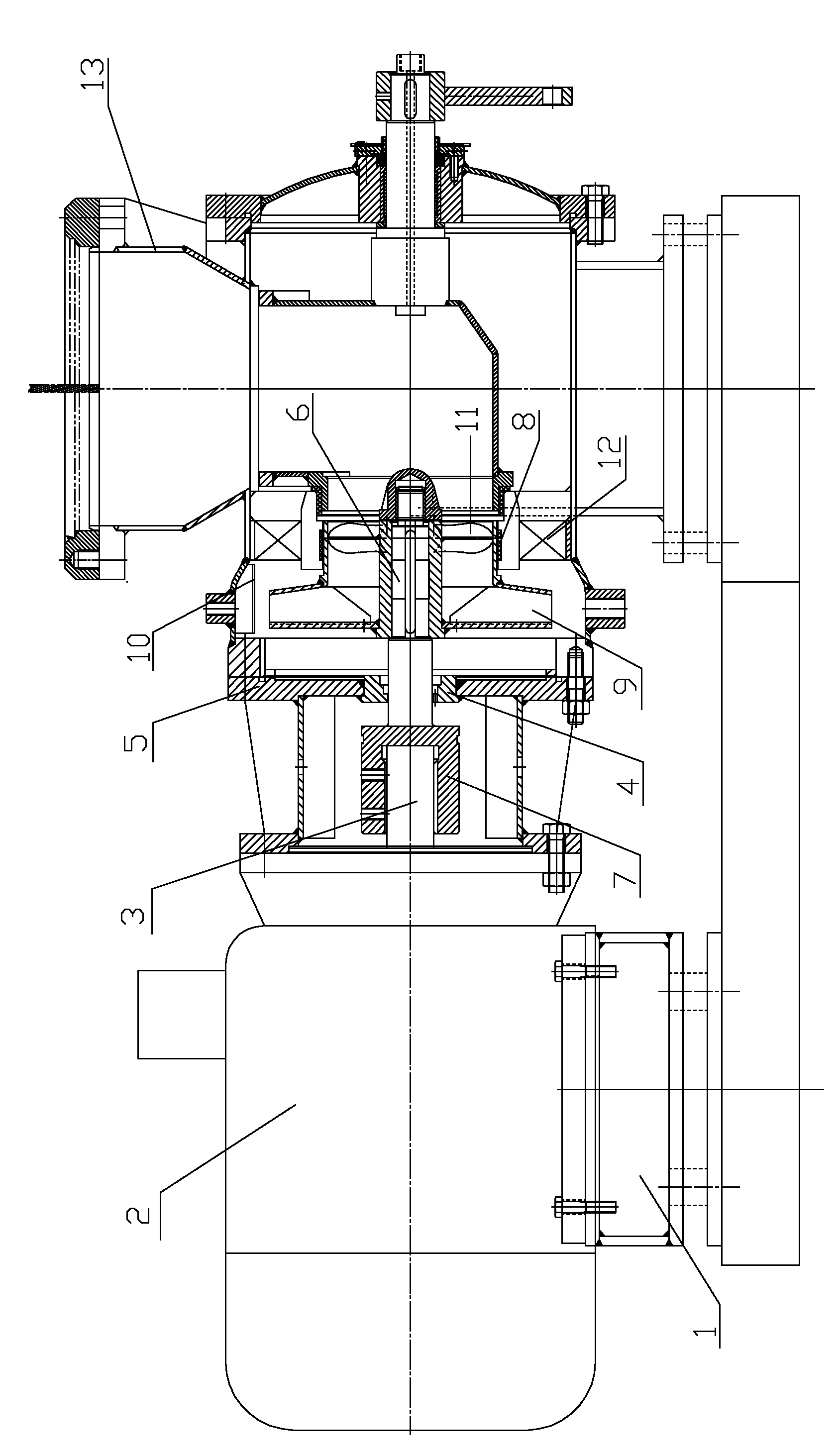

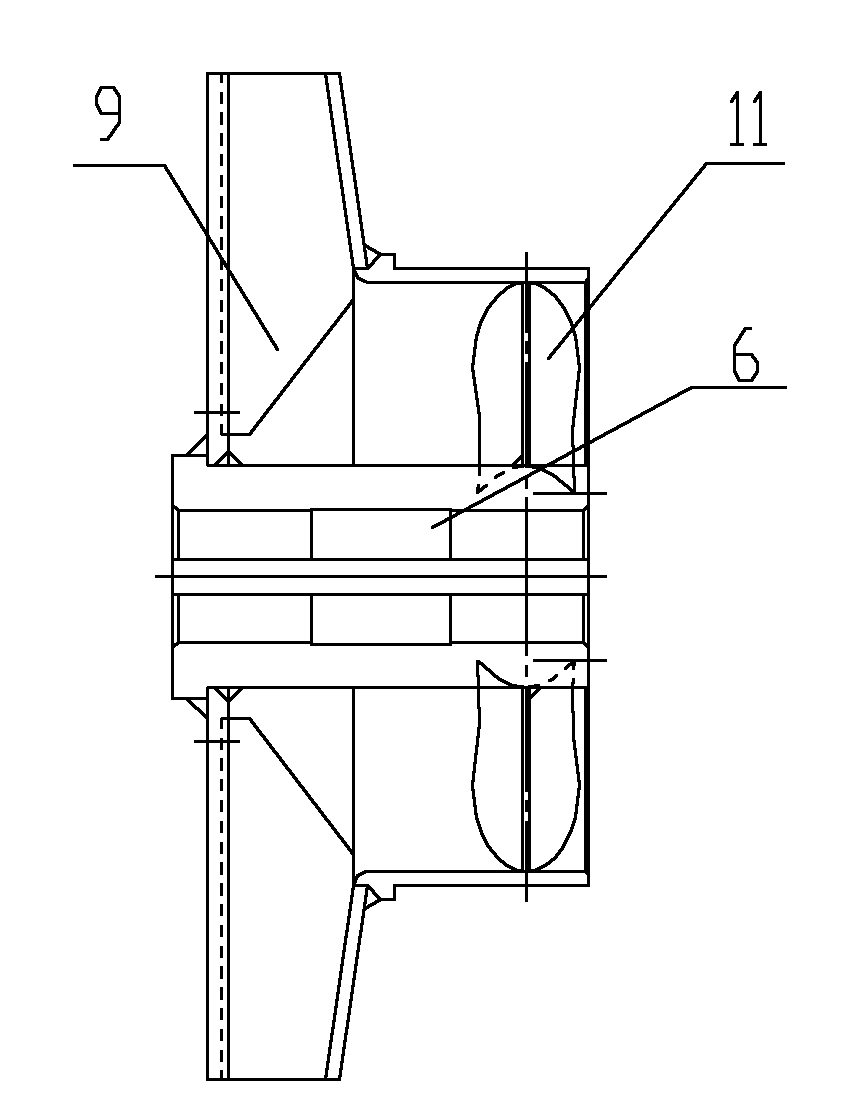

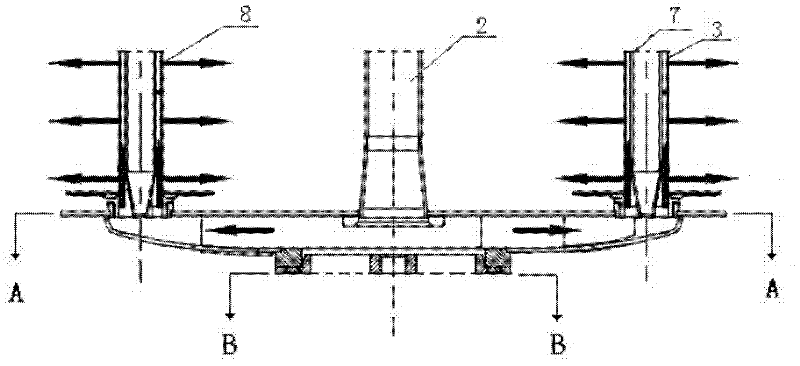

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

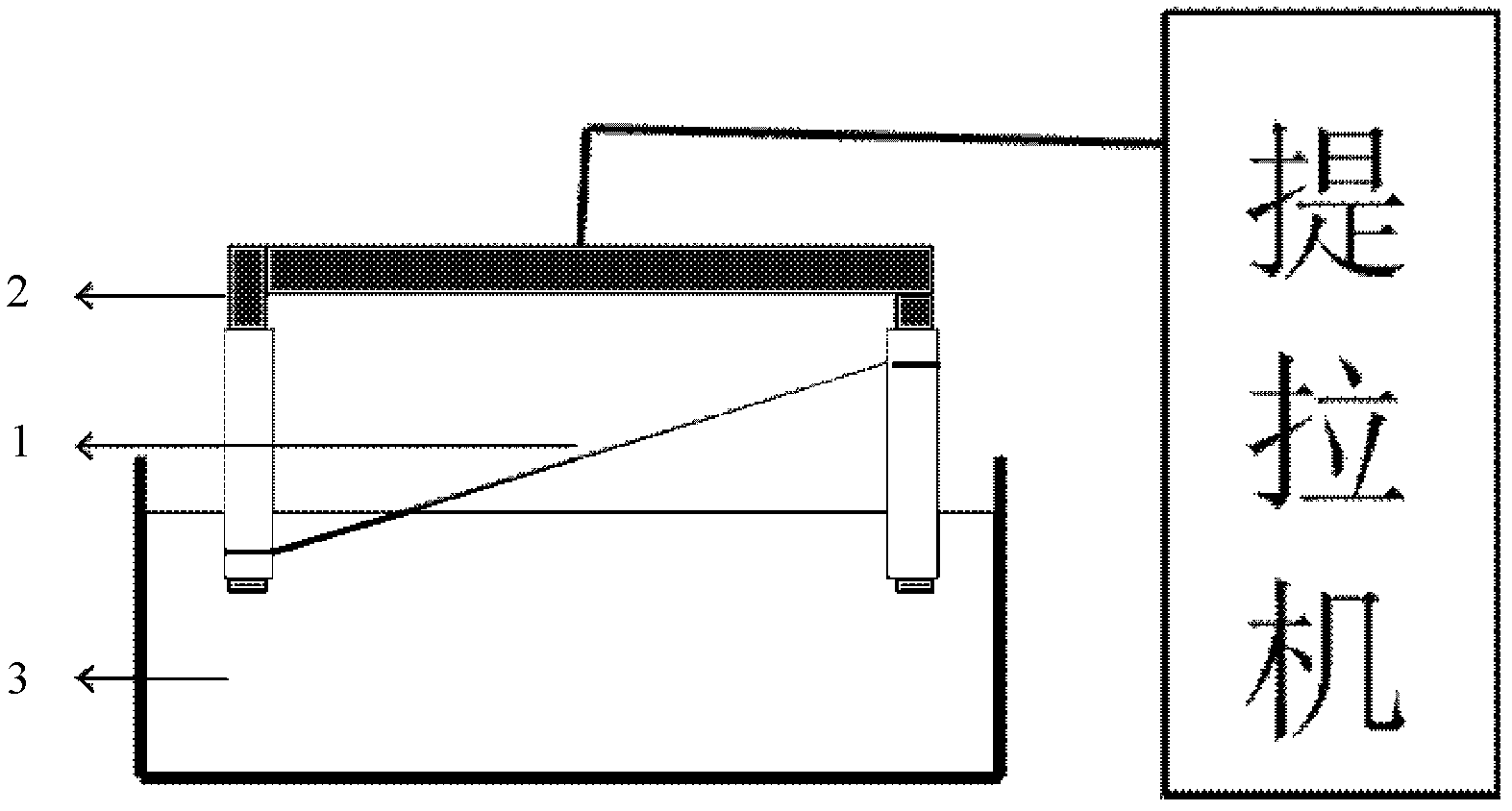

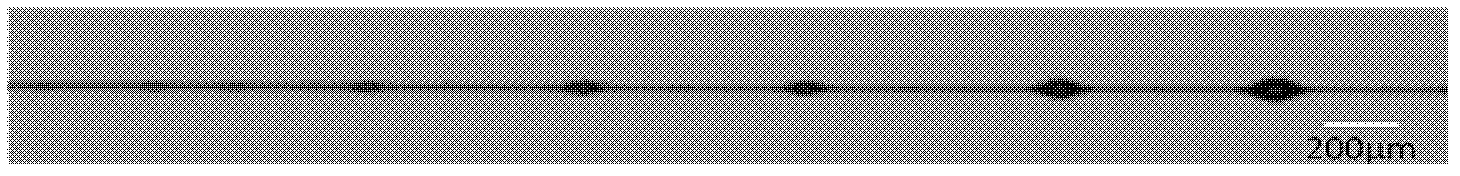

Preparation method of freshwater collecting fibers with transmission function and application thereof

The invention discloses a preparation method of freshwater collecting fibers with a transmission function and an application thereof and belongs to the technical field of chemical bionics. The preparation method comprises the following steps of: completely soaking a support fixed with the fibers in a prepared polymer solution with the mass fraction of 5-9% for lifting and pulling, wherein raised nodes, which are sequentially arrayed according to the size, are generated on the fibers, and finally drying to obtain the freshwater collecting fibers. The freshwater collecting fibers are woven intothe freshwater collecting fiber net for carrying out freshwater collection; and the freshwater collecting fiber net can be used for collecting freshwater in fog so that the visibility of air can be increased; and the freshwater collecting fiber net has high water collection efficiency and can be used for removing fog. The heights of the raised nodes on the surfaces of the fibers prepared by the method are uniformly increased from small to large and are controlled; the surfaces of the fibers are provided with more microscopic bulges or micropores so that the collision probability and the spreading speed of water drops in air can be increased, and the efficiency of collecting water is increased; and the freshwater collecting fibers are suitable for coastal deserts, islands, ocean ships, foggy mountain areas and the like; and the cost of the freshwater collecting fiber for collecting the freshwater is far lower than the cost for the desalination of sea water.

Owner:BEIHANG UNIV

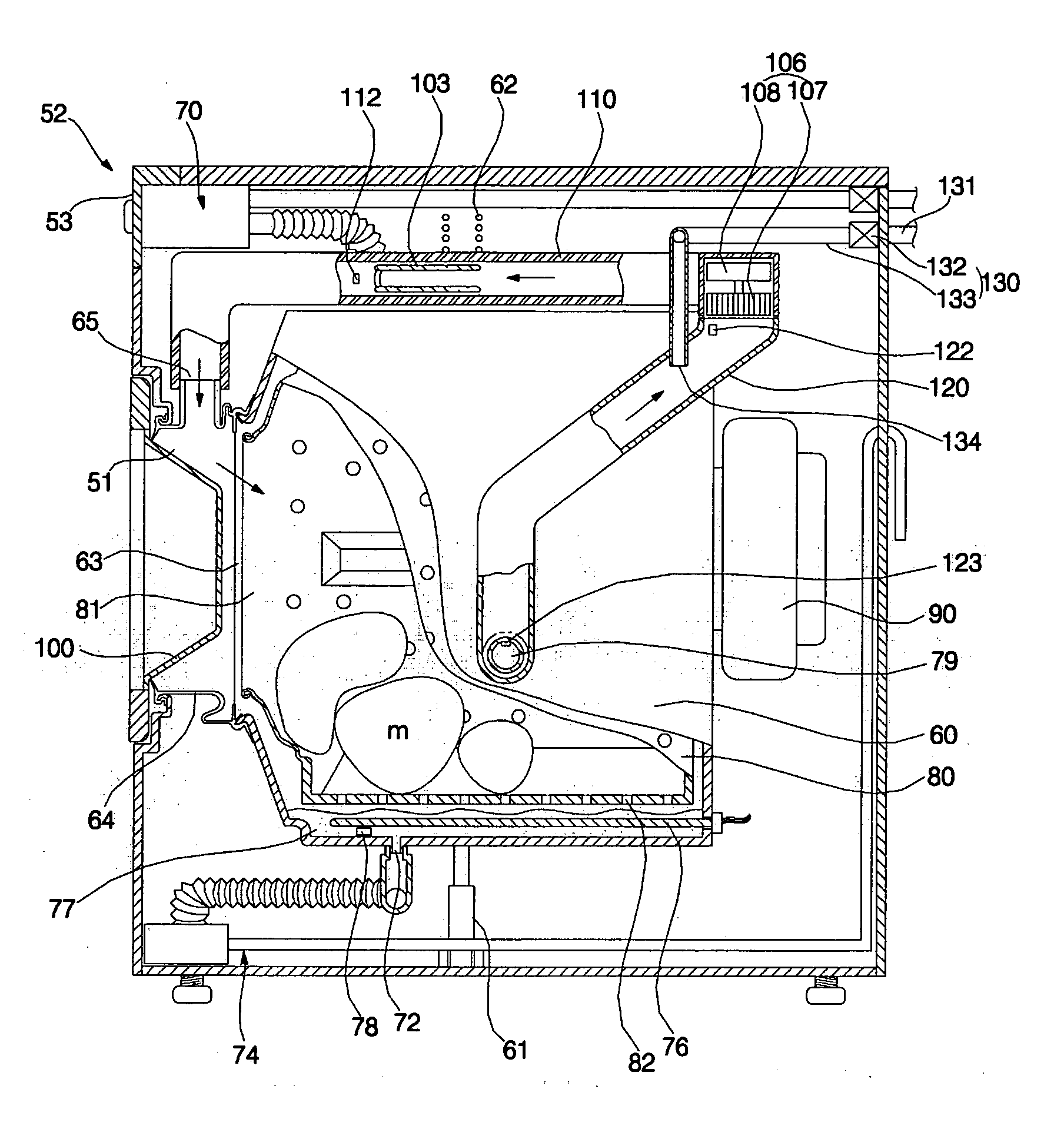

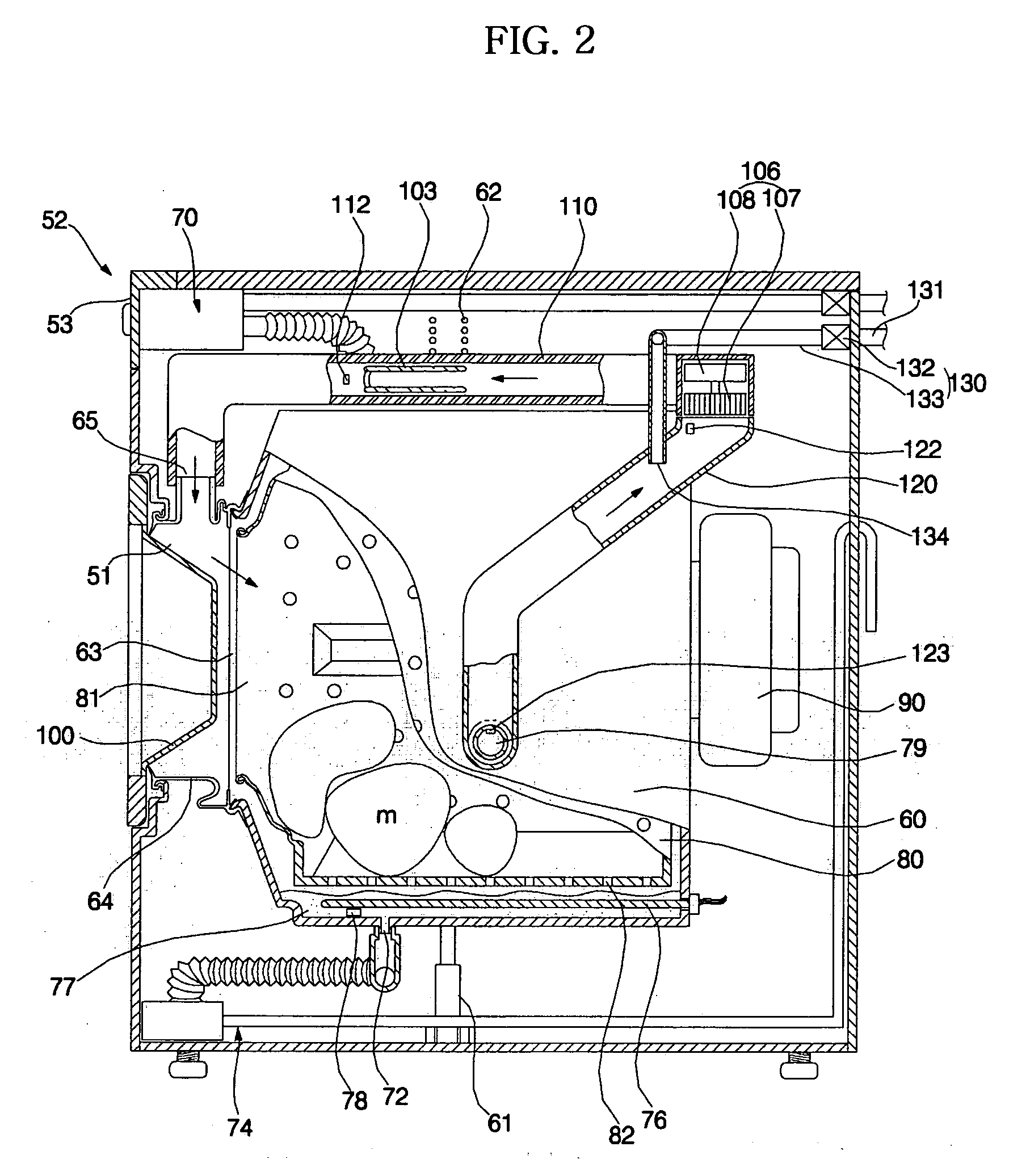

Drying control method for washing machines with drying functions/drying machines

InactiveUS20060101587A1Easy to operateEffective controlOther washing machinesControl devices for washing apparatusProcess engineeringMoisture

A drying control method for washing machines with drying functions / drying machines includes measuring an air temperature of heated air passing through a heater duct by a heater during a drying operation of the washing machine with drying function or the drying machine, and measuring at least one of the temperature of air before being heated and the temperature of air after being heated about the heater. The method further includes calculating a load, calculating a moisture content and controlling a drying operation.

Owner:LG ELECTRONICS INC

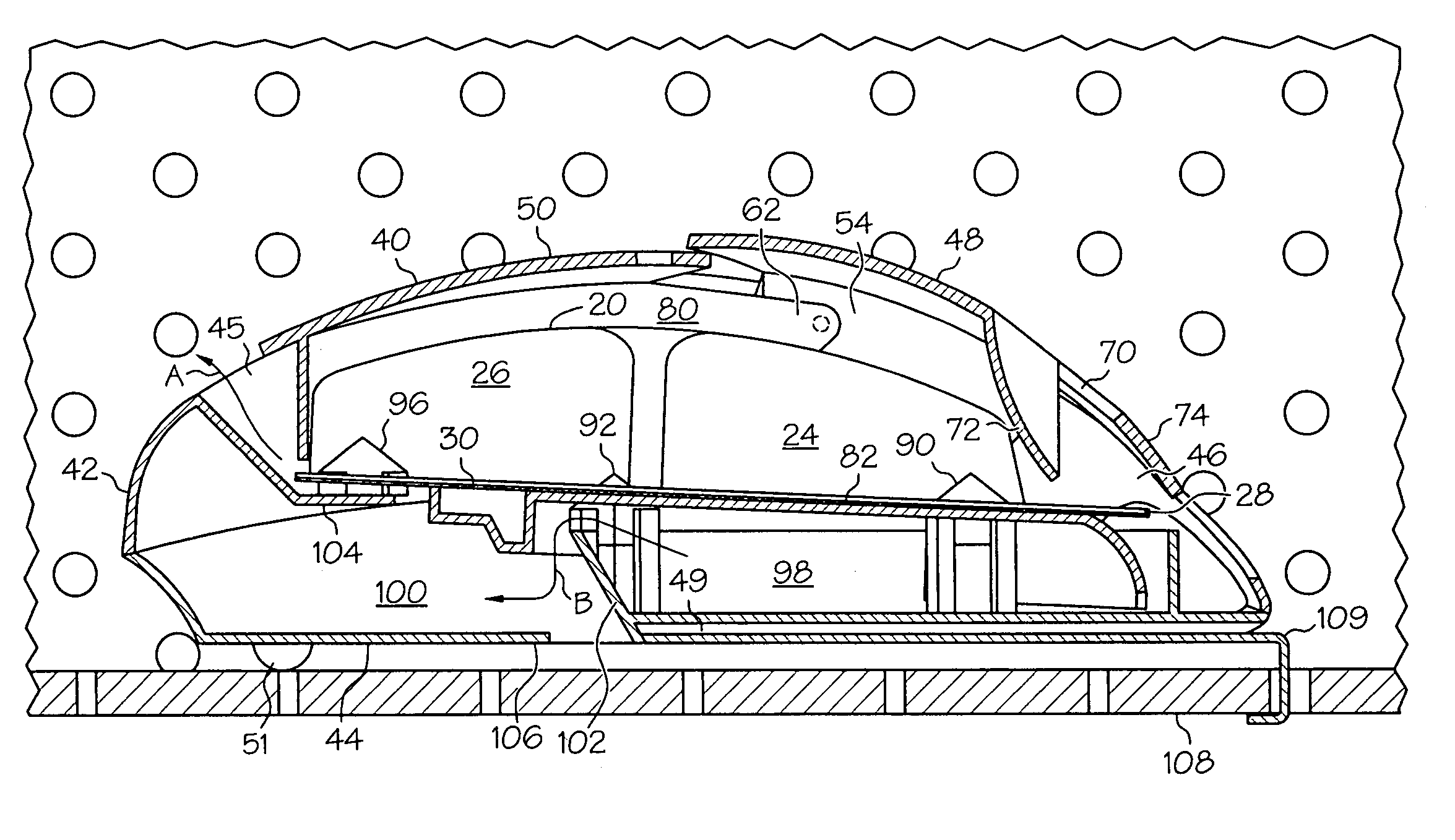

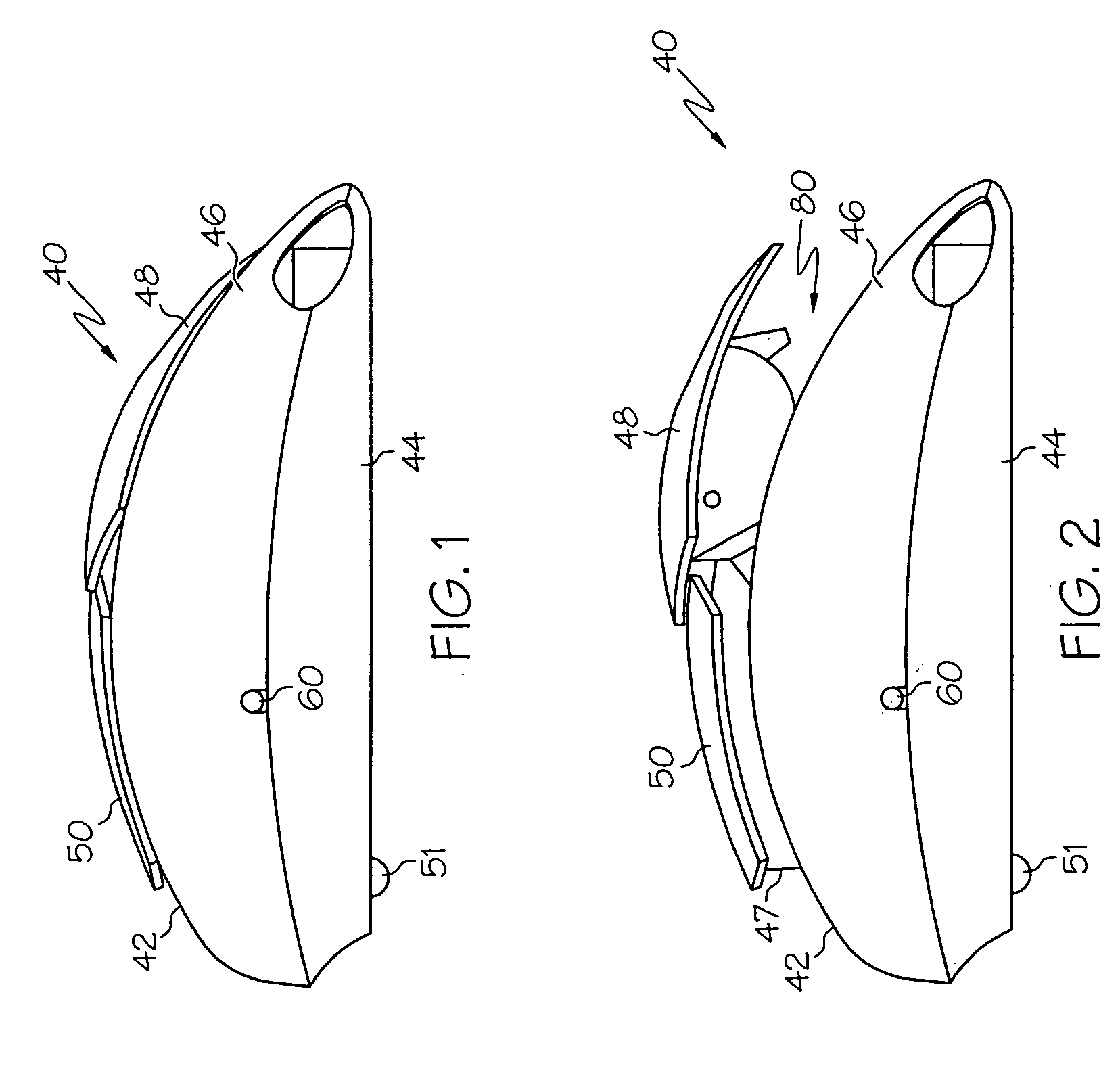

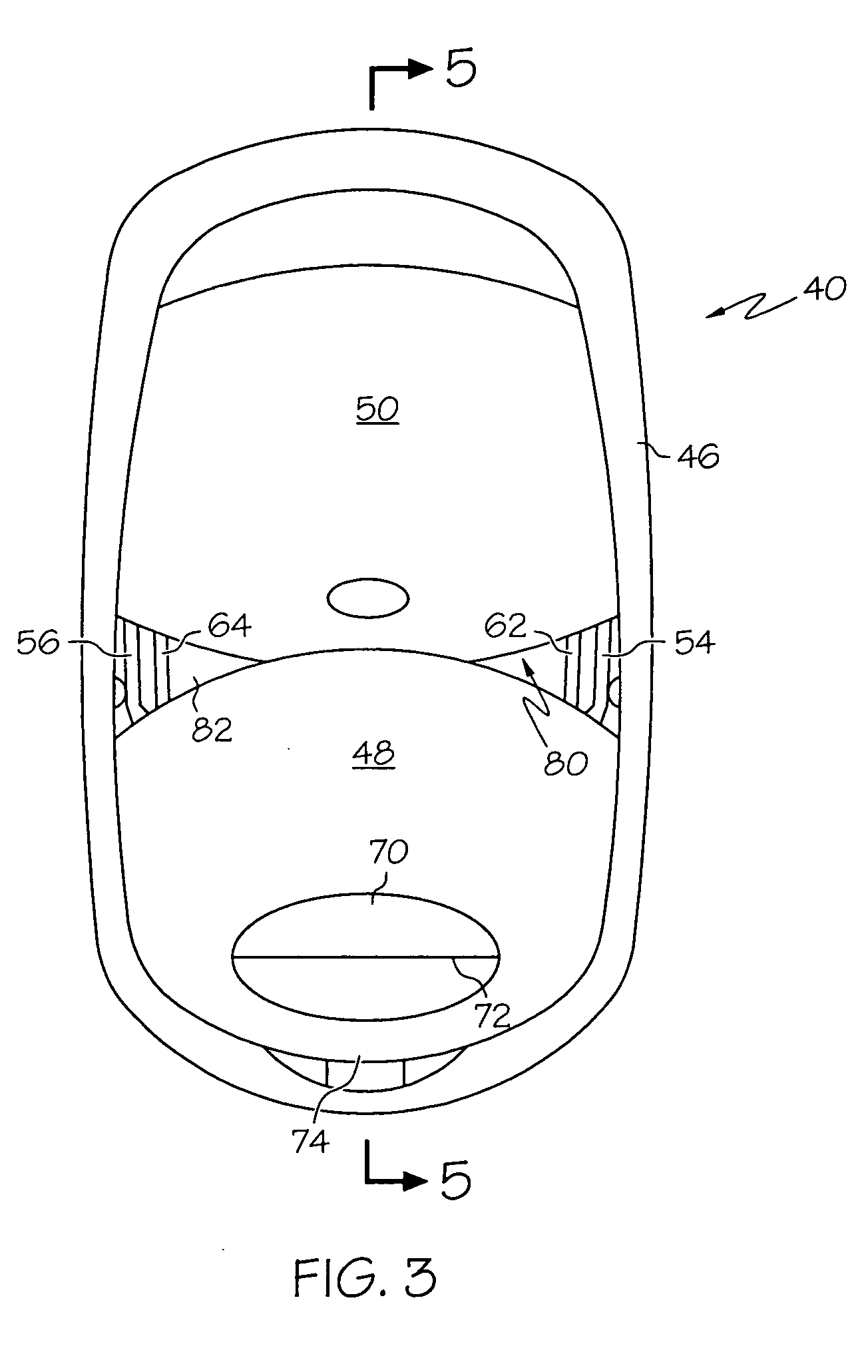

Systems, dispensers and methods for laundry additives

InactiveUS20050188731A1Easy to useHand rubbing apparatusCoin-freed apparatus detailsEngineeringLaundry

A system for introducing laundry additive materials to an automatic washing machine comprises a unit dose package including a first compartment containing a first laundry additive material, a second compartment containing a second laundry additive material, and optionally at least a third compartment containing a third laundry additive material, and a dispenser. The dispenser is adapted for interchangeable use with unit dose packages containing two, three or more compartments, and includes a housing structure comprising a first chamber adapted to receive the unit dose package. The housing structure is arrangeable in a first position to receive the unit dose package and a second position to secure the unit dose package in the first chamber. The dispenser further includes first compartment piercing elements adapted to open the first compartment and, if included, the third compartment; a second compartment piercing element adapted to open the second compartment; and a second chamber in fluid communication with the first chamber. The first compartment piercing elements are adapted to open the first compartment and the third compartment, if included, by arranging the housing structure from the first position to the second position, and at least the first compartment and the third compartment, if included, are adapted to then release the first laundry additive material and the third laundry additive material, if included, for gravitational flow for use in a wash cycle. The second compartment of the unit dose package is adapted to release the second laundry additive material to the second chamber during a spin cycle.

Owner:THE PROCTER & GAMBLE COMPANY +1

Dyeing technology of nylon-imitating high-elastic polyester yarn

InactiveCN103498350AImprove featuresEnsure stabilityFibre typesHeating/cooling textile fabricsTextile printerPolyester

The invention relates to the technical field of textile printing and dyeing, and provides a dyeing technology of a nylon-imitating high-elastic polyester yarn. According to the dyeing technology, by combining of low-elastic polyester and twisting into high-elastic polyester, the nylon yarn dyeing problem can be solved and an elastic hand feeling effect of the nylon yarn can be achieved, and the dyeing technology comprises a polyester yarn dyeing preprocessing process, a yarn reeling process, high temperature preforming, a dyeing process, a reduction cleaning process, a finishing process and a dehydration drying process.

Owner:福建锦丰印染有限公司

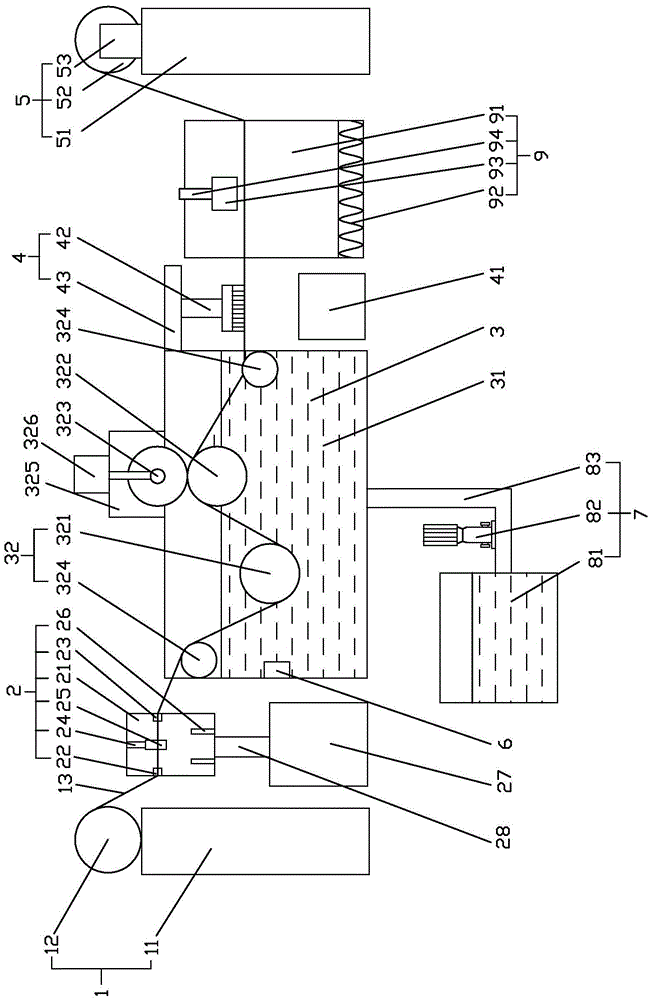

Sizing machine

InactiveCN105624951AThe sizing effect is not idealControl tensionTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnFixed frame

The invention mainly discloses a sizing machine. According to the technical scheme, the sizing machine comprises a yarn releasing device, a pre-cleaning device, a sizing mechanism, a sizing agent recovering device and a yarn withdrawing device, wherein the pre-cleaning device comprises a dust collector, the dust collector comprises a yarn inlet, a yarn outlet, dust collecting heads and an impurity box, and a yarn guiding ring is arranged inside the dust collector; the sizing mechanism comprises a sizing agent tank and sizing equipment, the sizing equipment comprises an immersing roller, a sizing roller and squeezing rollers, supports are arranged on two sides of the sizing agent tank, the squeezing rollers are movably connected onto the supports, and air cylinders are arranged on the supports and connected with the squeezing rollers; the sizing agent recovering device comprises a fixed frame, a sizing agent brush and a recovering tank; a water level sensor is arranged in the sizing agent tank, a replenishing device is arranged on one side of the sizing agent tank, and the sizing agent water level sensor is electrically connected with the replenishing device. The sizing machine is uniform in sizing and little in waste, yarn before sizing can be cleaned so as to avoid pollution of the sizing agent tank, and the sizing agent in the sizing agent tank is replenished timely.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Elastic filament and processing method for drum dyeing of elastic yarn

ActiveCN1807741AFully contractedFlat surfaceLiquid/gas/vapor yarns/filaments treatmentBobbinPulp and paper industry

The invention relates to a flexible filament and its flexible yarn barrel dye process method, which has the following steps: convoluting the flexible filament or flexible yarn loosely around the slippery paper tube, wrapping them with the netted fabric; pressing the netted plastic tube that the dye barrel yarn used into the paper core, dropping out the wrapped paper tube; rewrapping the exchanged barrel yarn with the plastic tube again and putting them in cross and parallel direction into the flexible yarn swelling, contracting and shaping device, and they receive the first contracting through temperature rising, then the second contracting through the second temperature rising; after the yarn is tightened in the netted plastic tube, caging and dyeing; rising when dyeing to make the yarn contract again; after dyeing, soap washing - water washing - dehydrating - drying-semi - finished product checking - waxing - bobbin-winding - product checking - product casing or weaving.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

Processing equipment and method for continuous fiber tows

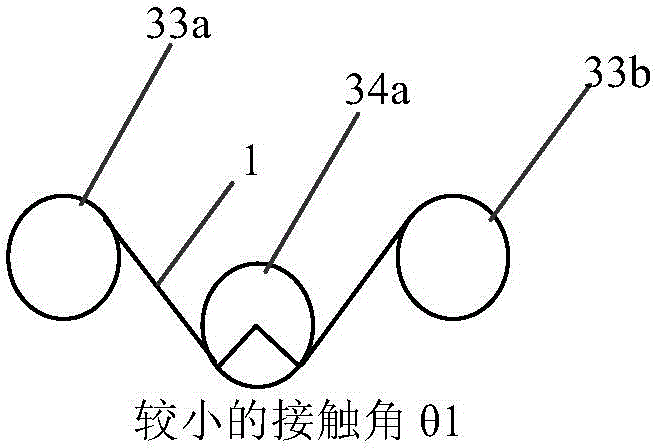

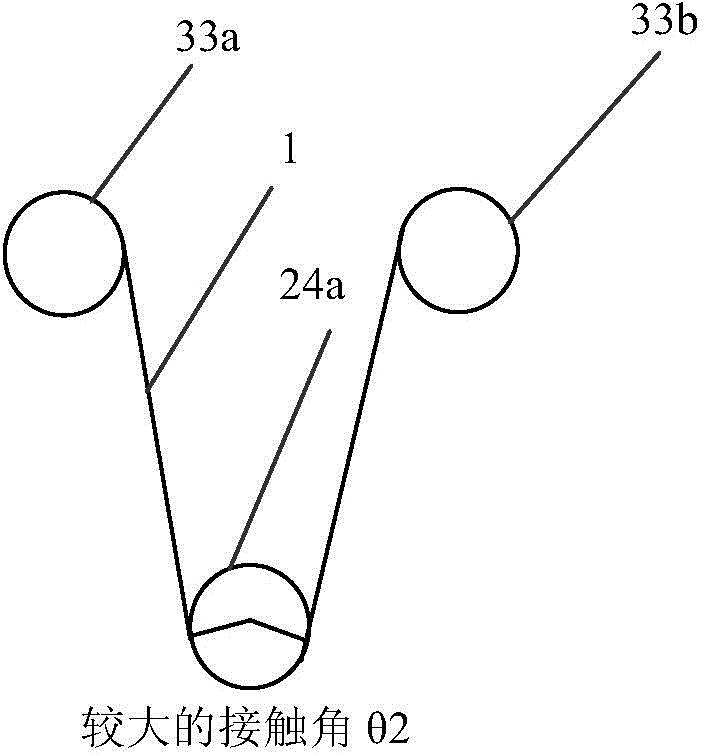

The invention relates to processing equipment and method for continuous fiber tows. The processing equipment comprises a desizing unit, an unfolding and dispersing unit and a sizing unit, wherein the desizing unit uses a fluid washing mode to enable fiber tows to desize, the unfolding and dispersing unit comprises round bars, tension braking rollers and a tension brake which are alternatively arranged, the round bars and the tension braking rollers are used for controlling the contact angles between the fiber tows and the adjacent round bars, the tension brake is connected to each tension braking roller and then used for regulating the tension generated when the tension braking rollers rotate, and the sizing unit is used for conducting re-sizing and drying on the fiber tows. The method for the continuous fiber tows is achieved through the above equipment, the fiber tows after being processed have lowered and uniform fiber distribution density and stable and consistent fiber tow widths, and therefore the fiber tows together with heat plastic plastics can directly be made into heat plastic composite materials or various types of composite material products.

Owner:FORMOSA TAFFETA CO LTD

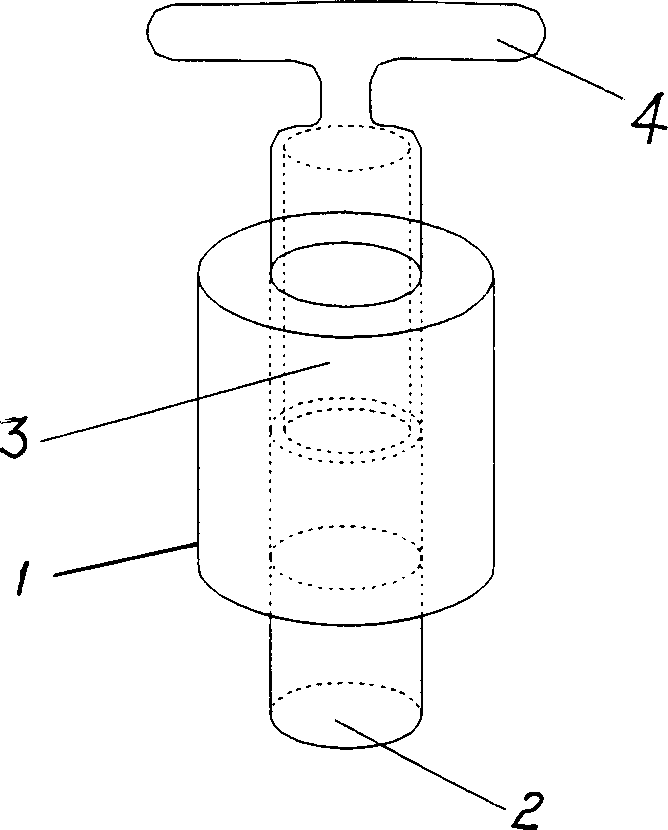

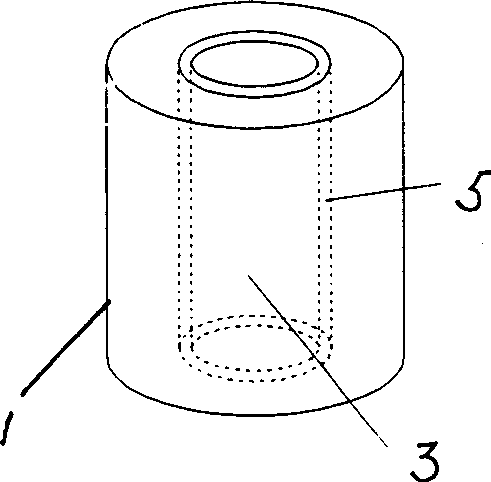

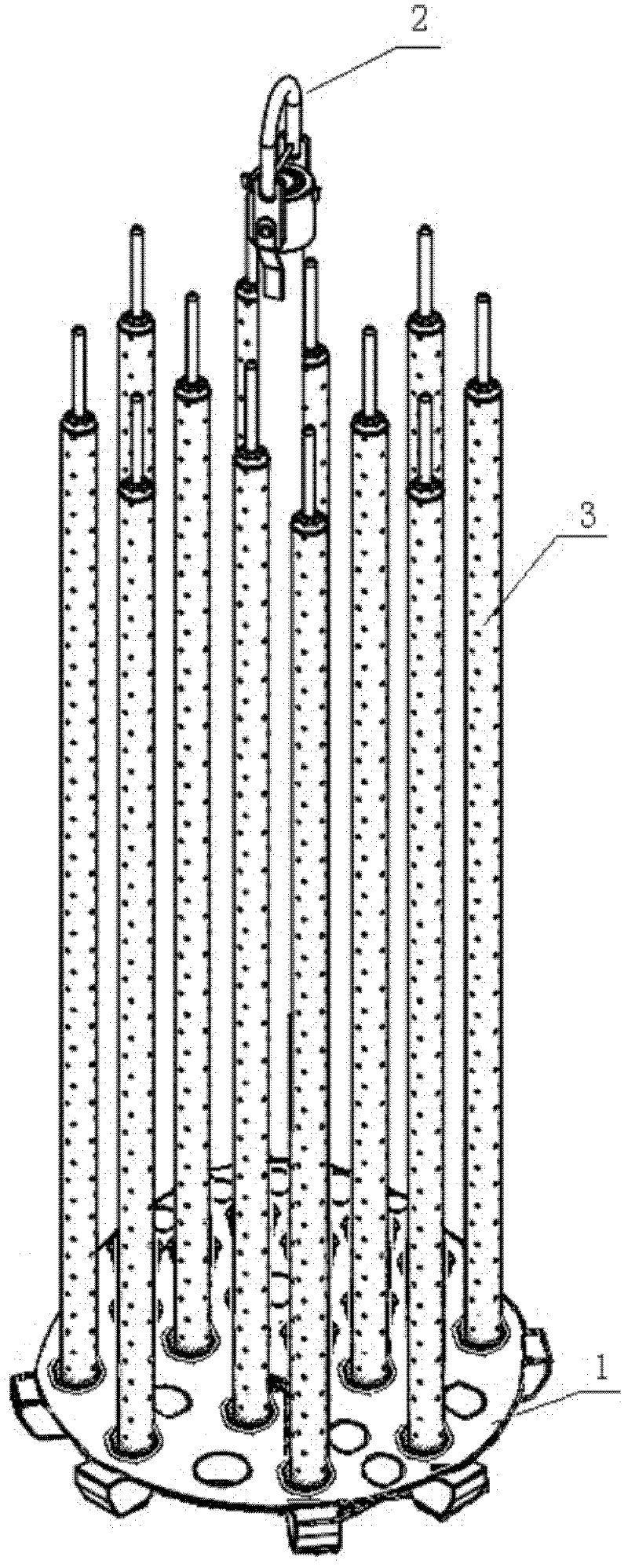

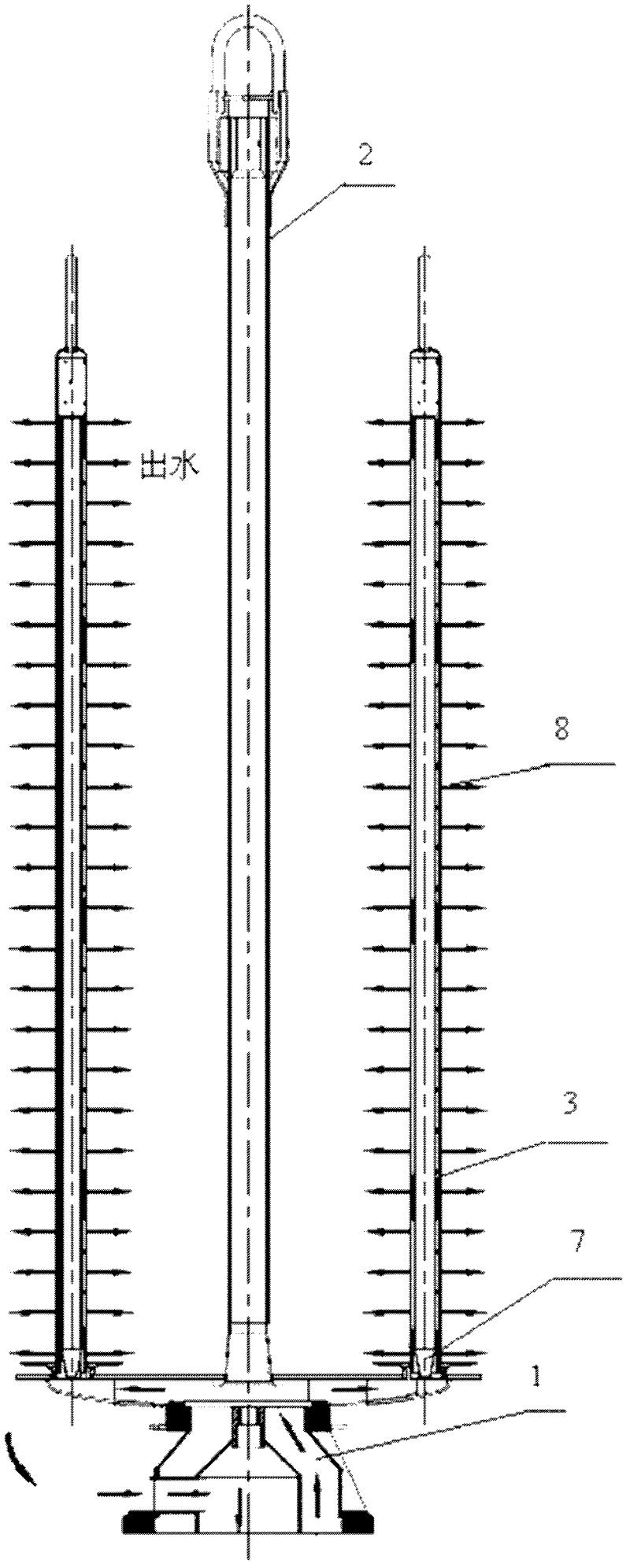

A creel device for an ultra-low liquor ratio yarn dyeing machine

InactiveCN102296436AReduce the cross-sectional areaGuaranteed coaxialityTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentWater bathsYarn

The invention discloses a creel device of a yarn dyeing machine with an ultra-low bath ratio, which comprises a sand table, a suspender and a yarn rod, wherein the upper surface of the sand table is in a disk shape; the lower end of the sand table is in a cavity structure; the yarn rod is in a hollow barrel structure; a water drum is arranged in the barrel of the yarn rod and is in a hollow or solid columnar structure; the center line of the yarn rod and the center line of the water drum are same; the ratio of the hollow internal diameter of the yarn rod and the external diameter of the waterdrum is 10:7-9; and the barrel of the yarn rod is evenly provided with a plurality of water outlets along the circumference of horizontal cross sections of different heights. The hollow barrel of theyarn rod disclosed by the invention is provided with the water drum, which is favorable for reducing the volume of dye liquor in the yarn rod and for reducing a water bath ratio; under the same main pump power, the water drum is favorable for improving the practical lift of a pipeline relatively, the flow rate of the dye liquor in the yarn rod is improved, the levelling property of cheeses of upper layers and lower layers can be better guaranteed, and the one-time success rate for dyeing is improved; and from the bottom to the top, the water outlets on the barrel of the yarn rod at the outer side of the water drum are thicker at the higher place of the yarn rod, which is favorable for realizing the purpose of even dye transfer.

Owner:高勋绿色智能装备(广州)有限公司

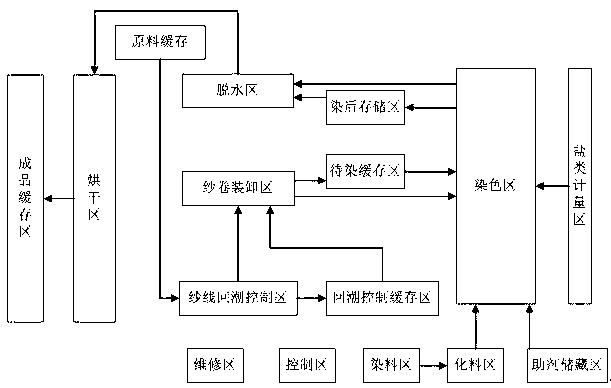

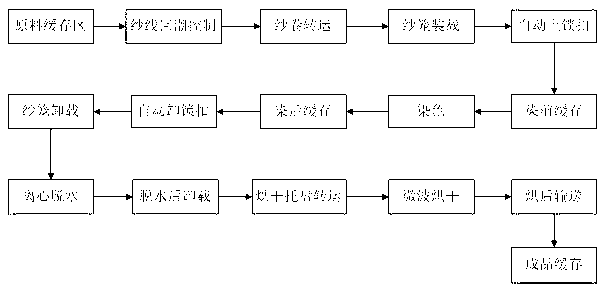

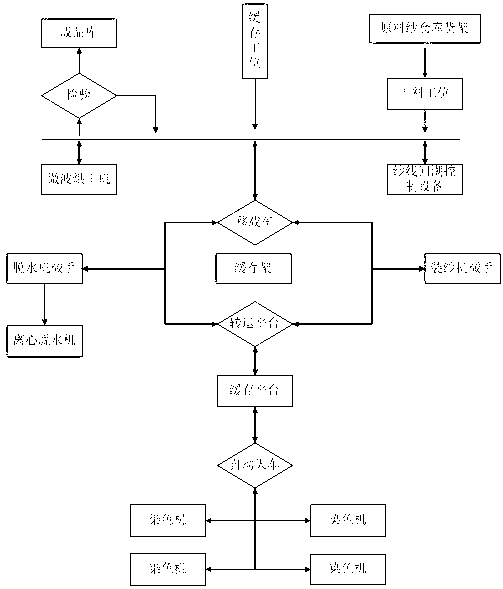

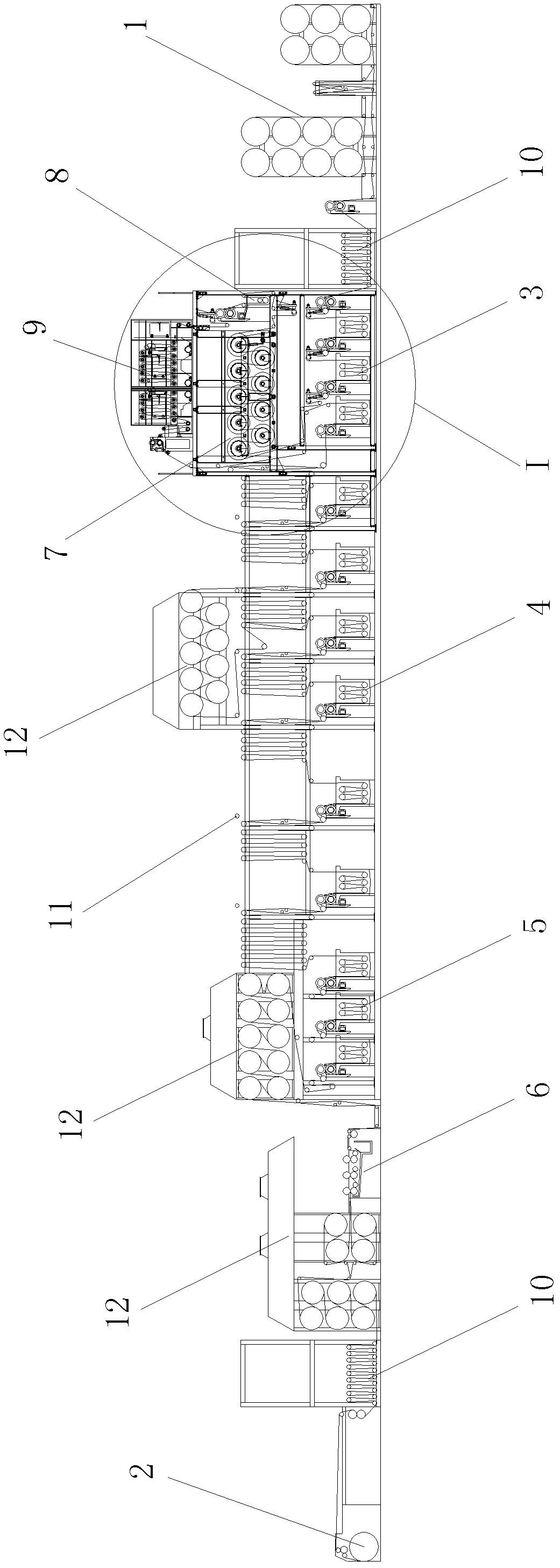

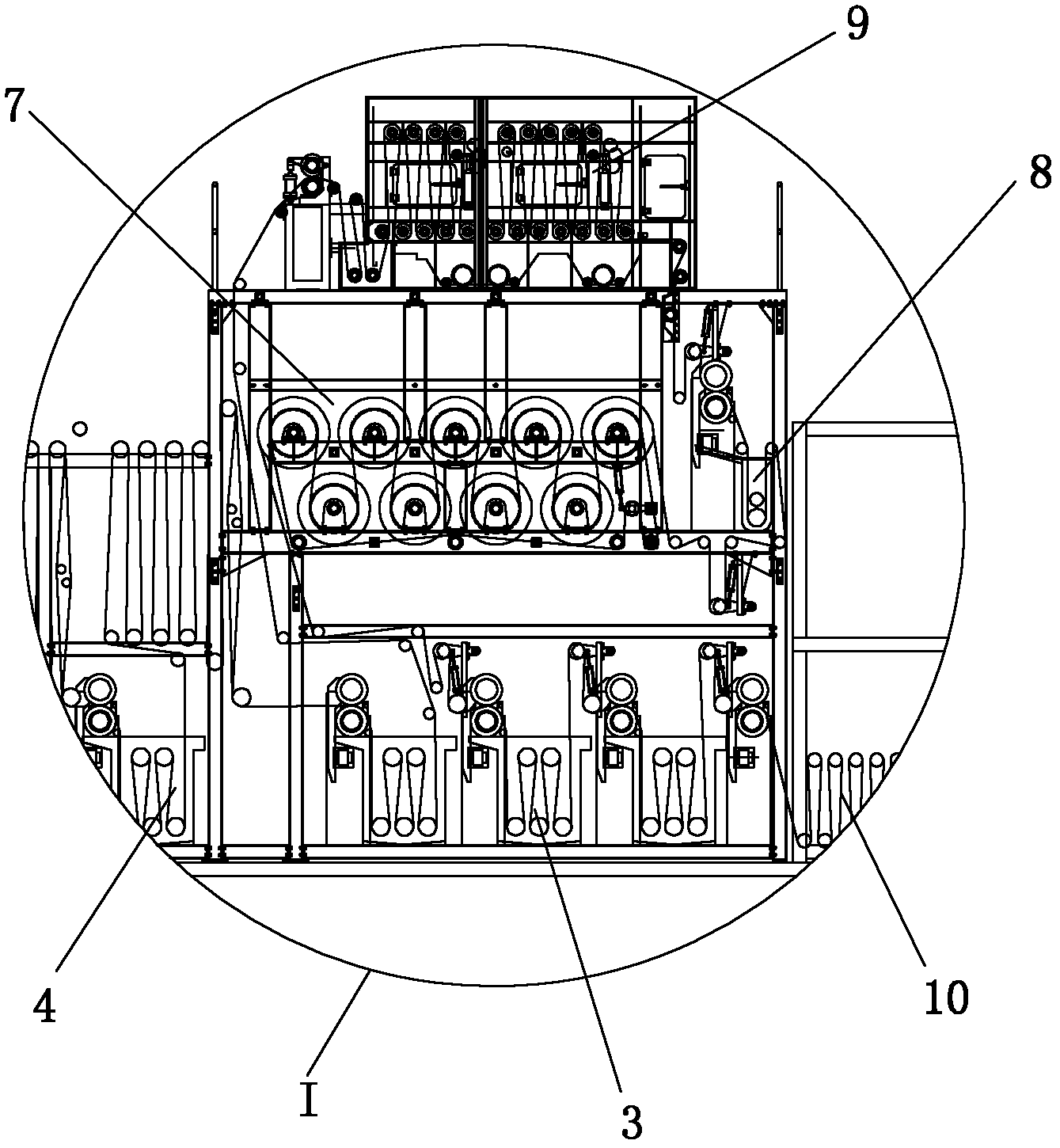

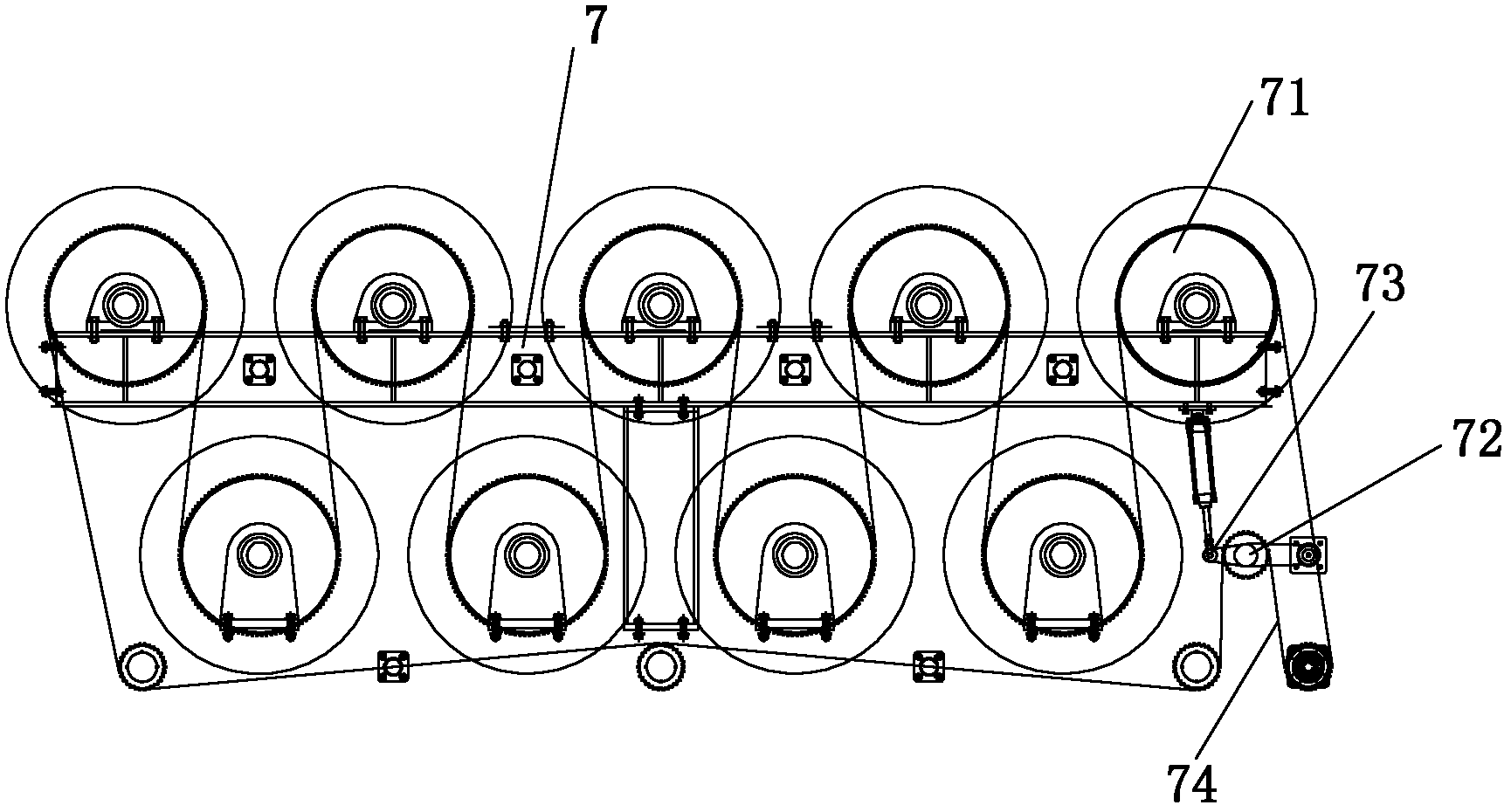

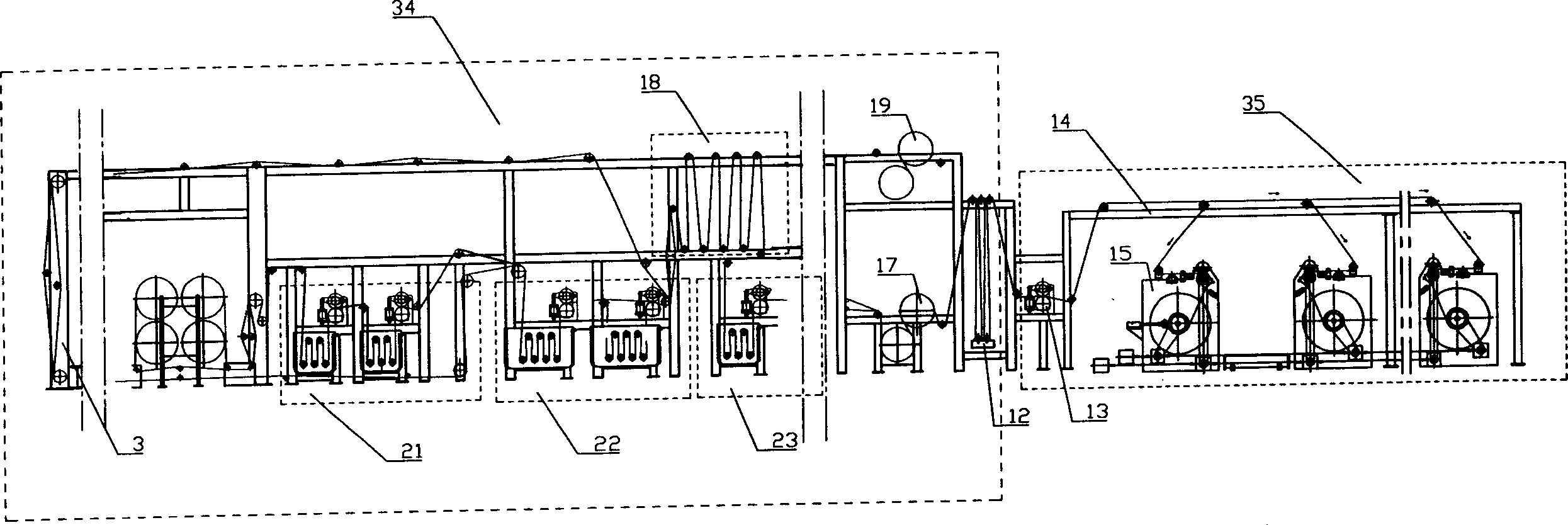

Cheese dyeing method and cheese dyeing production device

ActiveCN103225189AIncrease the level of automationIncrease productivitySucessive textile treatmentsLiquid/gas/vapor treatment of definite length materialsYarnMicrowave

The invention provides a cheese dyeing method and a cheese dyeing production device. The cheese dyeing method comprises the following steps of yarn return control: yarn return control equipment is adopted to carry out return control on a cheese; yarn cage loading: a yarn loading robot is adopted to load the cheese subjected to return control in a yarn cage; yarn cage transferring: an automatic crown block is adopted to transfer the yarn cage to a pre-dyeing cache region, and then is transferred into a vertical dyeing machine from the pre-dyeing cache region; dyeing: the vertical dyeing machine is adopted to dye the cheese subjected to return control; automatic dye weighing; dissolving and dispatching; liquid additive accurate metering and conveying; automatic powder salt additive weighing and conveying; dewatering: the dyed cheese is dewatered; and drying: a microwave drying machine is adopted to dry the dewatered cheese. In the technical scheme, various automatic devices are adopted to improve the automatic dyeing level of the cheese.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

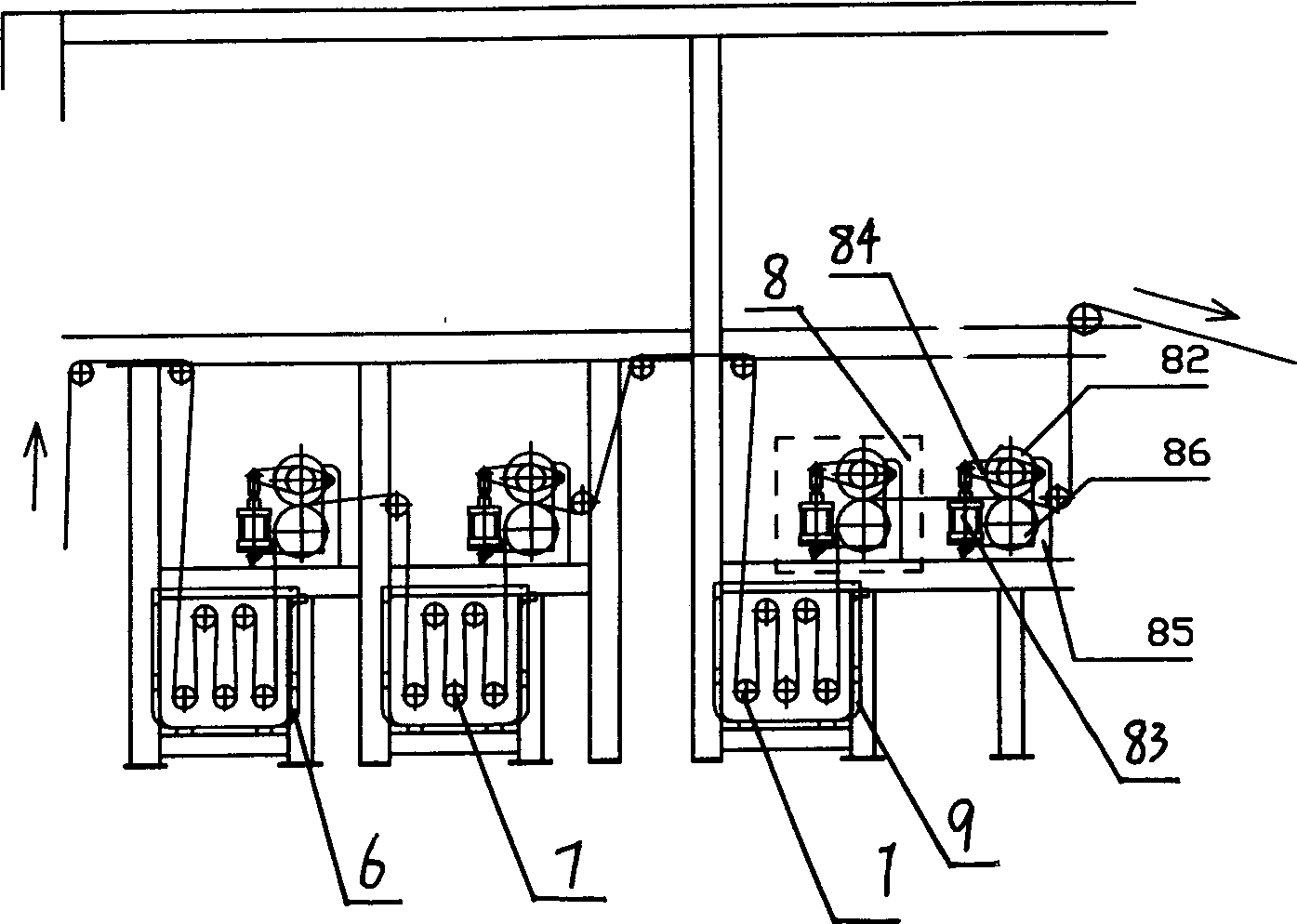

Multifunctional denim warp dyeing machine

InactiveCN102605582ARealize compound dyeingImprove dyeing effectSucessive textile treatmentsLiquid/gas/vapor removalPulp and paper industryPre treatment

The invention provides a multifunctional denim warp dyeing machine, which comprises a to-be-dyed warp rack and a dyed warp reel. A warp pretreatment tank, a warp dyeing groove, a washing tank and a slashing tank are successively arranged between the to-be-dyed warp rack and the dyed warp reel, wherein the warp pretreatment tank is used for removing impurities of warps and washing the warps, the warp dyeing tank is used for dyeing the warps by indigo dyes or sulfur dyes, the washing tank is used for washing the dyed warps, a combined drying barrel, a small colorful dyeing tank and a steaming box are successively disposed between the warp pretreatment tank and the warp dyeing tank, the combined drying barrel is used for colorfully dyeing the warps, and the small colorful dyeing tank dyes the warps by reduced dyes. The problems that when warps are dyed, a color selection range is narrow, color fastness is poor, and the warps cannot be dyed by bright-colored dyes are resolved; after the dyed warps are woven into denim, the characteristics that the warps of the denim are colorful while wefts of the denim are white can be kept; composite dyeing by the aid of the indigo dyes or the sulfur dyes can be realized, and a dyeing effect is good.

Owner:HAINING DENIM WEAVING CO LTD

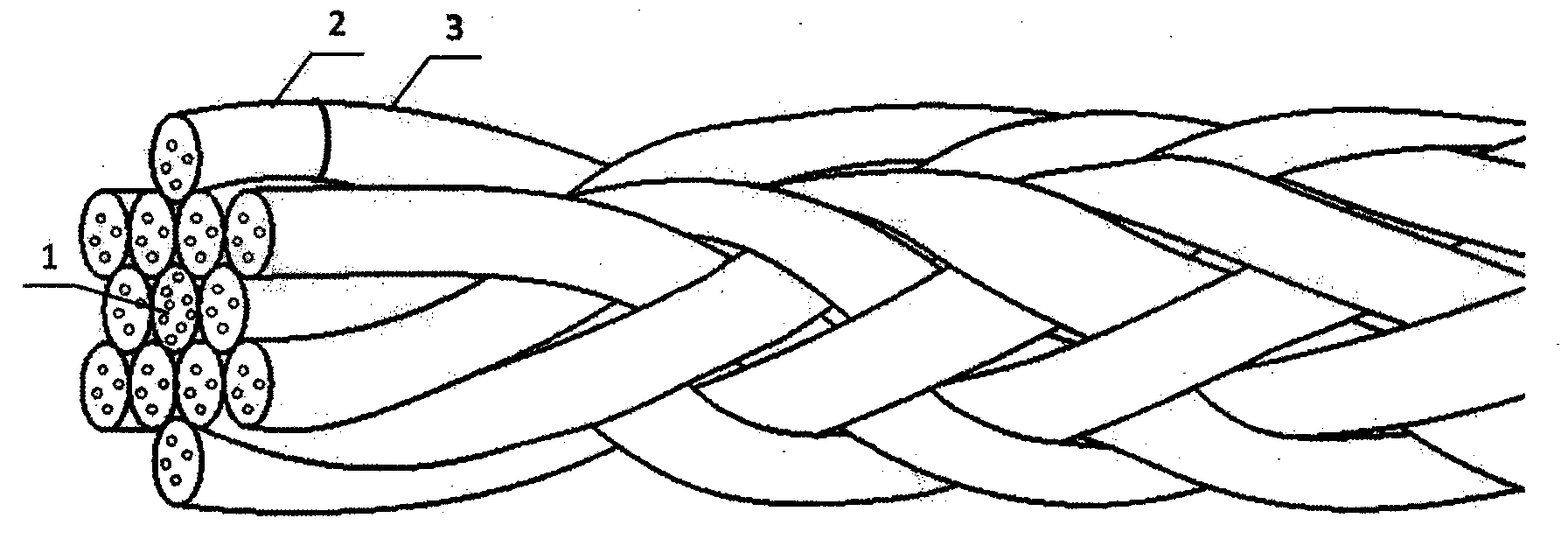

Long-acting controlled-release antibacterial real silk woven type surgical suture and preparing method thereof

InactiveCN103816564ABactericidalBacteriostaticSuture equipmentsTextile treatment machine arrangementsControlled releaseYarn

The invention provides a long-acting controlled-release antibacterial real silk woven type surgical suture and a preparing method thereof. The long-acting controlled-release antibacterial real silk woven type surgical suture is characterized by including heart yarn and weaving yarn that are woven, wherein the surfaces of the heart yarn and the weaving yarn are coated with antibacterial coatings; the antibacterial coatings contain macromolecular absorbing material and quinolone antibacterial drugs. As the weaving yarn contains antibacterial drugs, the long-acting controlled-release antibacterial real silk woven type surgical suture has the functions of sterilization and bacteriostasis; as the antibacterial drugs are uniformly dispersed in the macromolecular absorbing material, can be slowly released along with the swelling and degradation of the macromolecular absorbing material, so that the long-acting controlled-release antibacterial real silk woven type surgical suture has the long-acting controlled-release antibacterial effect.

Owner:DONGHUA UNIV

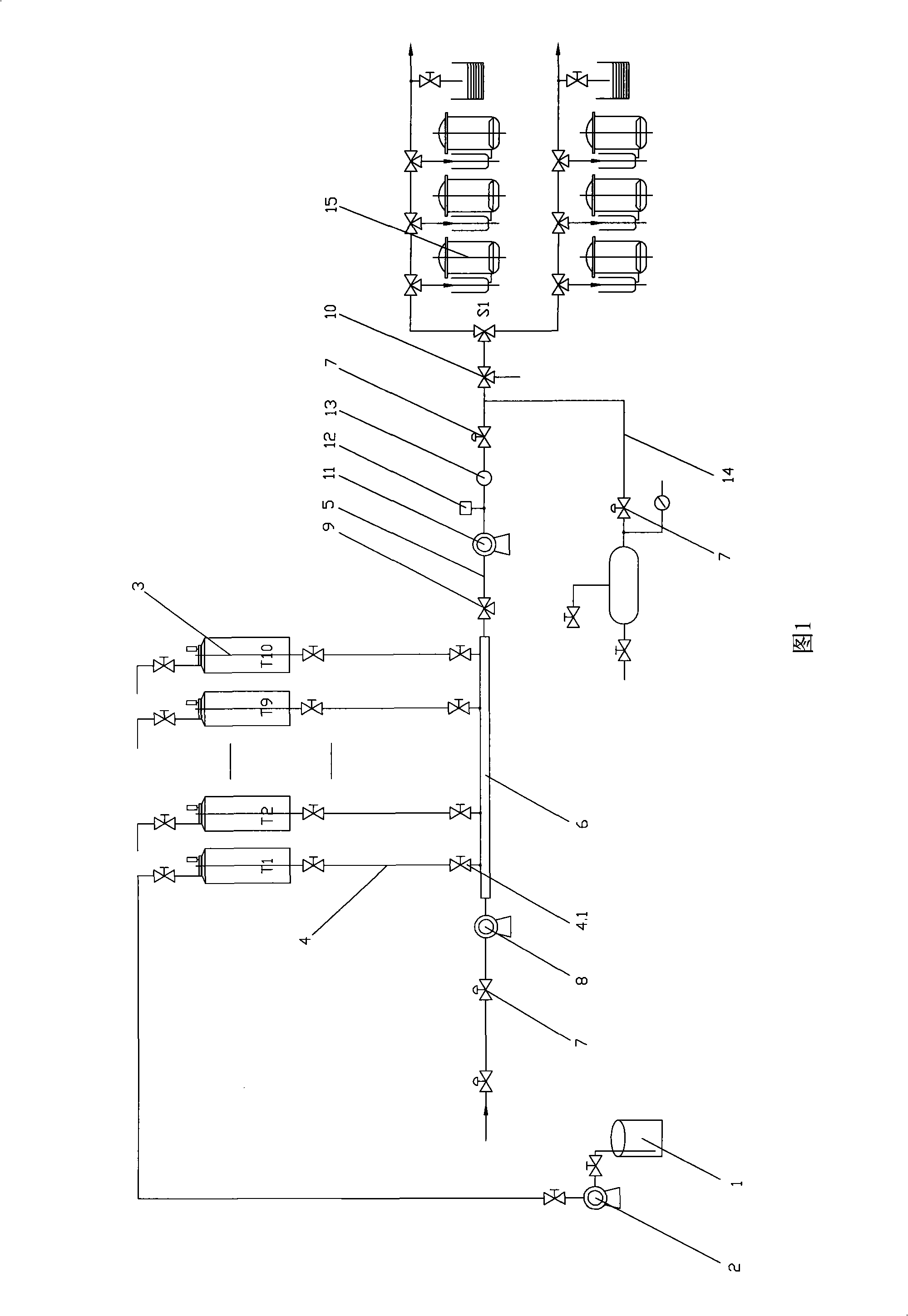

Method and apparatus for automatically delivering cheese dyeing assistants

InactiveCN101302693AAvoid miscastingAvoid overshootingTextile treatment machine arrangementsPipeline systemsAir compressionProduction rate

The invention discloses an automatic dispatching method for a cheese dyeing addition agent and a device thereof, and comprises the following steps: (a) a pressure pump is adopted for transmitting a stock solution of the addition agent from a storing bucket into an addition agent storing bucket; (b) a main pipeline is permeated with water; (c) a central microcomputer control unit determines a dyeing machine and an addition agent formulation that is needed by the dyeing of the dyeing machine; (d) the central microcomputer control unit simultaneously and correspondingly transmits a signal of the determined formulation and addition amount of the addition agent to a scale valve, a scale pump and a mass flowmeter, and controls the addition amount of the addition agent formulation by the mass of the water passing through the mass flowmeter, and when the converted amount of the water passing through the mass flowmeter equals to the addition amount of the addition agent formulation, the scale valve and the scale pump are closed; (e) the main pipeline is permeated with water, and the addition agent formulation is transmitted into the corresponding dyeing machine through air compression. The automatic dispatching method of the cheese dyeing addition agent raises the first pass rate and the production efficiency of products, implements just-in-time and firstly accurate production, and achieves the clean production which saves energy, reduces consumption, and has low cost, security, reliability and less pollution.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

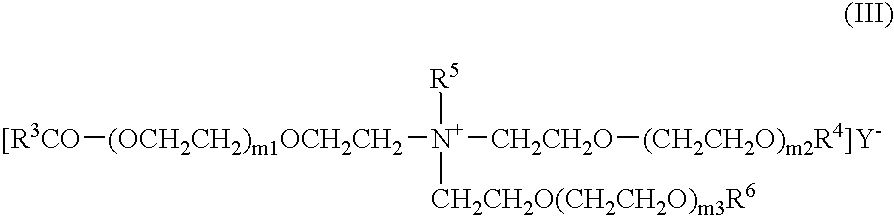

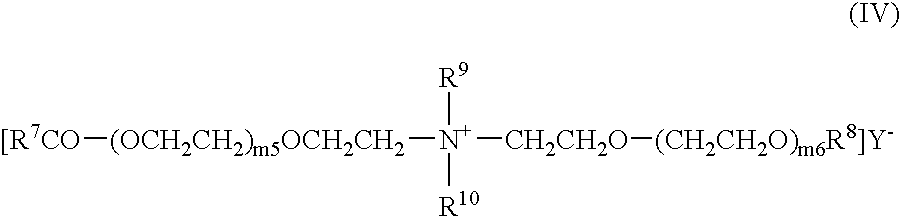

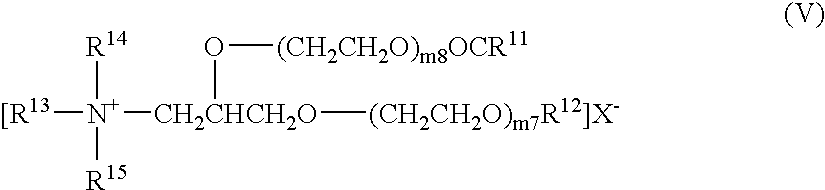

Textile finishing agents

InactiveUS20060258558A1Organic detergent compounding agentsNon-ionic surface-active compoundsFiberYarn

A method for treating fibers, yarns or textiles to improve the sensory effect for a user or weaver of a fabric article. The method treats the fiber, yarns or textiles with an emulsion containing 15-30% by weight of a mixture of waxes having melting points in the range of 35° C. to 60° C. including a lipophilic wax matrix; 10%-20% by weight of emulsifier which are at least one of alkyl or alkenyl oligoglycosides or alkyl ether sulfates, 1%-10% by weight of a crystal regulator which can be partial esters of C12-22 fatty acids with at least one of glycerol, polyglycerol and sorbitan. The mean particle size of the wax crystals is not greater than 6 μm. The emulsion includes water and auxiliaries and additives.

Owner:COGNIS IP MANAGEMENT GMBH

Sizing process of fine denier circular hole bright polyamide multifilament

InactiveCN102828369AReduce incidenceImprove flatnessLiquid/gas/vapor removalBeaming machinesPolyamideEngineering

The invention discloses a sizing process of a fine denier circular hole bright polyamide multifilament. By adjusting the technological parameters of four procedures such as warping, sizing, re-beaming and weaving, a good size film is formed on the surface of the fine denier circular hole polyamide filament and is convenient for weaving, the production efficiency is above 95% and a series of problems such as low weaving efficiency of multifilament woolen fabrics of fine denier circular hole bright polyamide multifilament series are solved.

Owner:WUJIANG FUHUA WEAVING

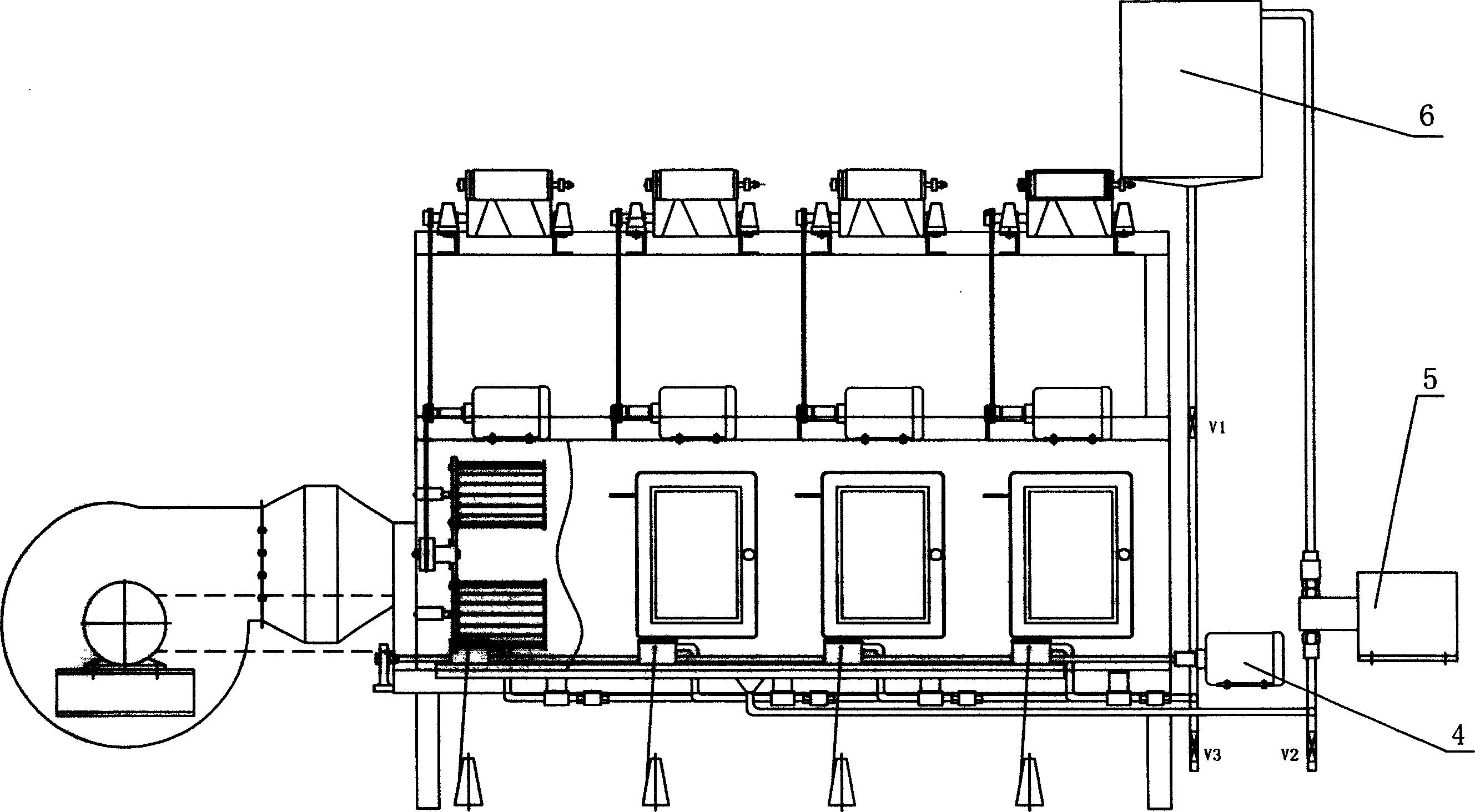

Single yarn dyeing machine

ActiveCN1594706AHigh yarn dyeing efficiencyAvoid yarn breakageLiquid/gas/vapor yarns/filaments treatmentYarnBobbin

The invention relates to a single yarn dyeing machine, which is characterized in that the dye in the dyeing unit locates at a high position which communicates to the nozzles (four in a group) through pipe V1, V2, V3-Vn. The motor controlled by transducer drives the dyeing disc through rotary shaft. The motor shaft of the winding unit sets two belt pulley, in which one of which drives the belt pulley on the groove drum shaft by belt, another drives the belt pulley on the overdrive clutching mechanism through belt. The yarn after dyeing enters the oven and winds uniformly on the rotary spinning drum. The dried yarn winds on the bobbin through groove drum. The invention can regulate the distance of the dyeing yarn, avoids yarn breakage, not only dyes the yarn into homogeneous segment but also heterogeneous segment.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Double-vat-body dyeing machine

InactiveCN103526483AAvoid entanglementStir wellTextile treatment sample takingTextile treatment containersYarnHydraulic cylinder

The invention relates to a dyeing device used in the textile industry, in particular to a double-vat-body dyeing machine. The double-vat-body dyeing machine comprises a dye vat and yarn hangers arranged in the dye vat, wherein the dye vat is divided into a left vat body and a right vat body by a division board. The double-vat-body dyeing machine is characterized in that a braking chamber is arranged in the center of the vat, and a hydraulic cylinder and a rotating shaft which is fixedly connected with the hydraulic cylinder are arranged in the braking chamber; the rotating shaft is movably connected with a transverse frame, and the yarn hangers are fixedly installed on the transverse frame. Due to the adoption of the structure and the double-vat-body structural design, yarns to be dyed with two different colors can be dyed at the same time; through the matching of the braking chamber, the rotating shaft and the transverse frame, a stirring device capable of rotating by 180 degrees is formed, and the phenomenon of yarn twisting caused by large-amplitude rotation is avoided; through the matching of the transverse frame and a square groove in the braking chamber, the transverse frame can move vertically, accordingly, dye liquor can be stirred more sufficiently, and a better dyeing effect can be achieved.

Owner:WUJIANG KESHIDA TEXTILE

PTT (poly(trimethylene terephthalate)) memory fabric production process

InactiveCN101736487ASoft touchShinyWarping machinesHeating/cooling textile fabricsFiberPolyethylene terephthalate

The invention relates to a PTT (poly(trimethylene terephthalate)) memory fabric, in particular to a PTT memory fabric production process. The production process comprises the following steps of: batch warping, starching, shaft combining, leasing, looming healding, weaving, pretreatment of dying and finishing, alkali quantity decreasing, dying, waterproof processing and thermal forming. The fabric has unique memory function and comfortable hand feel, the performance of smoothing by touching the fabric enables the product to achieve an effect of totally ironing free, and favorable draping effect and recovery capability enable the fabric to become one of fashionable functional fabrics. Fibers of the fabric are completely biodegradable under certain condition and the fabric is an environmental-protection and green product.

Owner:杭州宏峰纺织集团有限公司

New dyeing process of polyester air-varying yarn

InactiveCN102277698AFully elasticFull moisture wickingLiquid/gas/vapor removal by centrifugal forceLiquid/gas/vapor yarns/filaments treatmentYarnTextile printer

The invention relates to the technical field of textile printing and dyeing and provides a novel dyeing process for polyester air textured yarns. By the process, a dyeing solution can fully penetrate yarns on the inner layer and the outer layer of a cheese during dyeing, so that the yarns of the cheese are free of inner and outer layer chromatic aberration. The novel dyeing process comprises a loose cheese winding procedure, a steaming and forming procedure, a second loose cheese winding procedure, a dyeing procedure, a post-arranging procedure and a dehydrating and drying procedure.

Owner:福建锦丰印染有限公司

Warp dyeing and multi-shaft winding process, warp dyeing and multi-shaft winding machine

This invention belongs to the yarn dye technique filed, the main technique as follows: unreeling a plurality of t yarns which reel around the warping shaft in parallel, then laminating the unreeled yarns to the flake yarns, and then dyeing them into the indigo colour or disparting them into many flake yarns with lesser head share after dyeing by coating, then reeling the flake yarns around another pluralities of warp beams which is for the warp thread cartridge-made machine to produce the cheese. The character of this invention is that it combines the warp thread dyeing with the multiracial convolution, so the technique flow process is short.

Owner:祁江汀

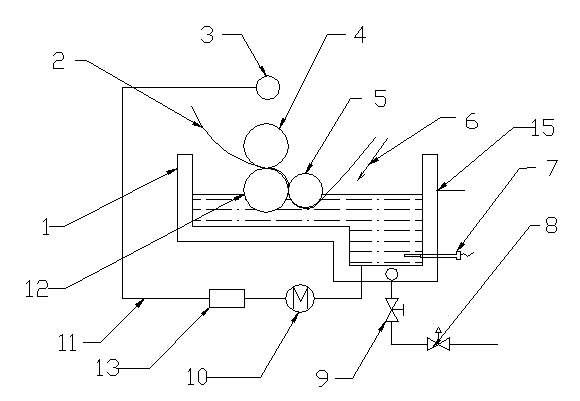

Secondary sizing device of glass fiber

ActiveCN104153136AGuaranteed pureAdjustable temperatureTextile treatment machine arrangementsTextile treatment by pouringGlass fiberYarn

The invention provides a secondary sizing device of glass fiber. The secondary sizing device of the glass fiber comprises a pulp pool, a sizing system, a pulp pool heating system and a filtering device, wherein the sizing system comprises a sizing roller set and a pulp pouring device, and the sizing roller set is arranged in the pulp pool, is used for sizing warp yarns of the glass fiber, and comprises at least three sequentially-arranged sizing rollers; the pulp pouring device comprises a pulp pouring pipe and a pulp pouring head; the pulp pool heating system comprises a heat preservation layer and a temperature adjusting device, the heat preservation layer is arranged on the outer side of the pulp pool in an enclosing mode, and the temperature adjusting device comprises a temperature sensor, a controller and a temperature adjusting actuating mechanism; the filtering device is used for filtering pulp in the pulp pouring device and is fixedly arranged on the pulp pouring pipe. According to the secondary sizing device of the glass fiber, the pulp pool heating device is arranged, the temperature of the pulp in the pulp pool can be adjusted, the situation that the quality of glass fiber cloth is affected by pulp oxidation film forming is avoided, and the production cost is reduced.

Owner:TAIJIA GLASS FIBER

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com