Device for producing space dye yarn

A technology of yarn and dye liquor, applied in the field of textile printing and dyeing, can solve the problems of high cost, low efficiency of section dyeing process of natural fiber yarn, heavy pollution, etc., achieve low cost, less amount of dye liquor residue, and good comprehensive benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

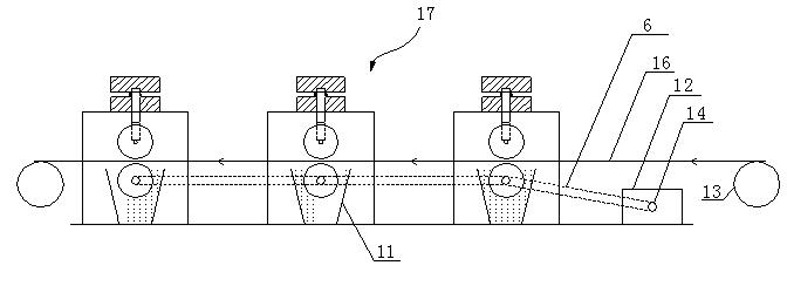

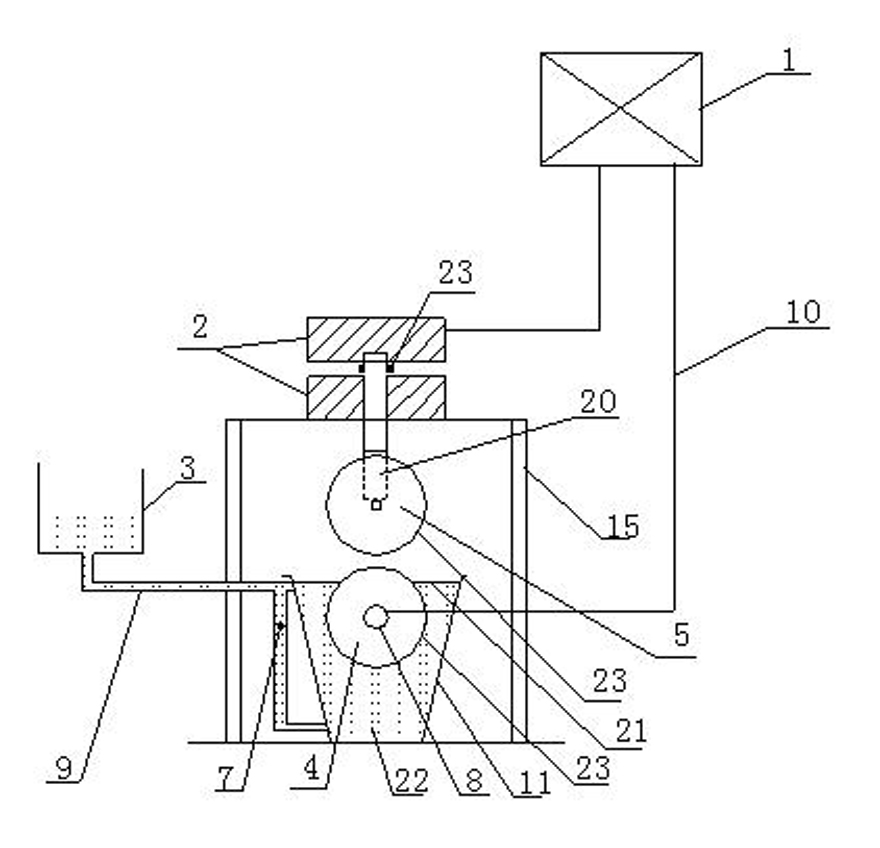

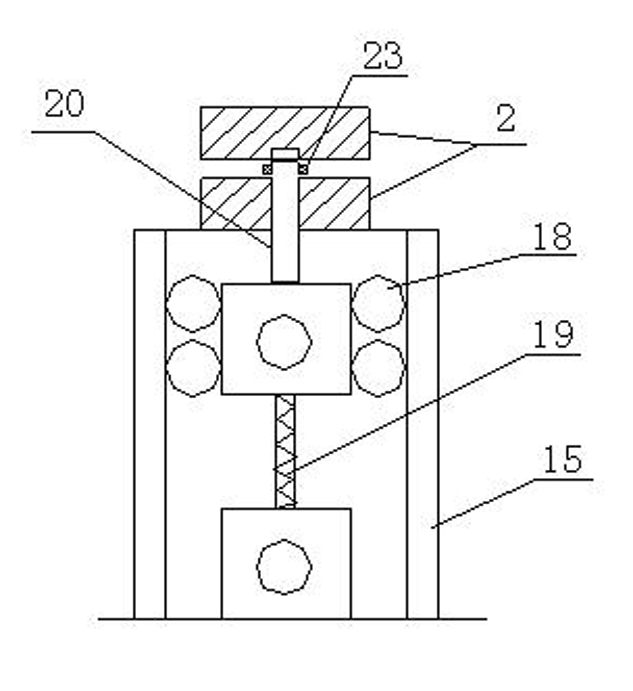

[0017] Below in conjunction with the accompanying drawings, the present invention will be further described through specific embodiments—specific implementation devices and the specific implementation process applied to 32s / 2 cotton yarn base color dyeing and section dyeing in one step.

[0018] Such as figure 1 , figure 2 As shown, the device has three groups of paddle cars 17 arranged along the front and rear direction of the yarn, and guide rollers 13 are arranged at the front and rear ends, and a dye solution tank 11 is arranged below each group of pad cars 17, and the dye solution tank 11 The delivery pipe 9 is connected to the corresponding section dye solution configuration barrel 3 , and the section dye solution 22 flows from the section dye solution configuration barrel 3 into the dye solution tank 11 through the delivery pipe 9 . A liquid level controller 7 is arranged in the dye liquor tank 11 , and the liquid level controller 7 controls the liquid level 21 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com