Cheese dyeing method and cheese dyeing production device

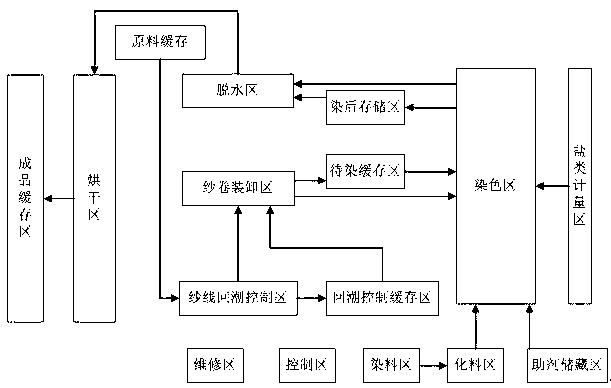

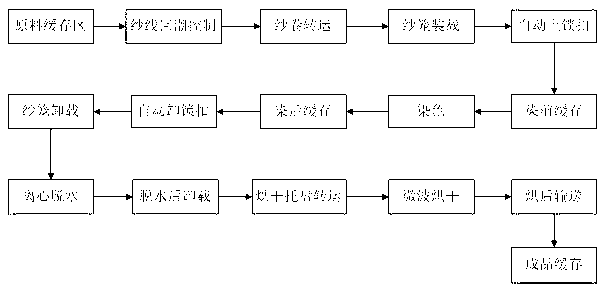

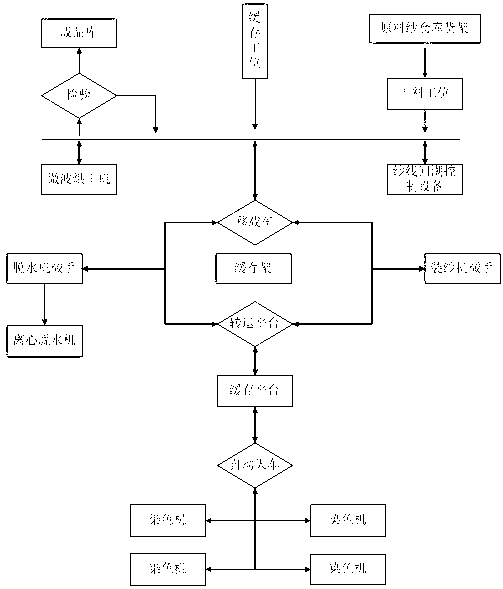

A technology of dyeing method and production device, which is applied in liquid/gas/steam yarn/filament processing, textile and paper making, liquid/gas/steam processing of textile materials with a certain length, etc., which can solve the problem of low automation level and low production efficiency , labor shortage and other issues, to achieve the effect of improving the level of automation, improving production efficiency and reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0084] Example 1, cheese reactive dye pretreatment / dyeing one-bath ultra-short rapid dyeing and fixing process

[0085] 1.0417Kg / piece, 480 pieces of 32 S × 2 pure cotton knitting gray yarns, placed in a certain type of dyeing vat, with a liquor ratio of 1:10. A certain type of Kehuasu black, a small amount of certain blue, the total amount of dye is 6.5%; some sodium sulfate and accelerator; add materials and heat up according to the following operation methods: add cold water to the tank, and the bath ratio is about 10; turn on the main pump, etc. Conventional operation; the dye is melted in a small bucket in advance and then poured into the chemical vat, the return water is appropriate, heated to an appropriate temperature with steam until the dye is completely dissolved, and added to the dye vat within 5 to 10 minutes; then the chemical vat is returned to water Appropriately, the sodium sulfate is poured into heating and stirring, and all the sodium sulfate is melted and a...

example 2

[0086] Example 2, ultra-short rapid dyeing and fixing process of cheese with reactive dyes

[0087] A pre-treated pure cotton knitting cheese 2120Kg, navy blue (B-GD) 0.45125%, black (MZ-RH), sodium sulfate 80g / L, accelerator 4g / L. Dyeing with a certain type of pneumatic dyeing cylinder with a bath ratio of 7-8. Adding materials, heating, heat preservation, post-treatment etc. are carried out with reference to example 1, but after heat preservation is finished, add water washing once before soap boiling; Time 5 hours. According to this method, even with the traditional pretreatment, the water can be controlled within 90 tons / ton of cloth dyed, and the steam consumption is reduced from 6 to 8 tons / ton of cloth dyed to 3.9 tons / ton of cloth dyed; electricity consumption is 400 Degree / dyed per ton of yarn.

example 3

[0088] Example 3, ultra-short rapid dyeing and fixing process of reactive dyes dyed cheese with extremely small liquor ratio

[0089] 1.0417Kg / piece, 780 pieces of 32 S × 2 cotton knitting bobbins; dyed rose purple, depth 3.65% (o.w.f); put the yarn into a certain type of non-small bath ratio common dyeing vat, add water until the yarn is just in contact with the yarn frame chassis; according to the core technology in the patent with the publication number CN101168928A, the pump test machine is turned on until the water flow can maintain normal circulation and the liquid is soaked in the yarn. In the so-called half-tank of water; subtract 30% of the original dye dosage of soda ash proofing (a small sample of 1:10), subtract 60-70% of sodium anhydride, and subtract 10% of accelerator (refer to the depth of incoming samples for details). It depends on the situation of making small samples); the feeding, operation, and post-processing steps are carried out with reference to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com