Method and apparatus for automatically delivering cheese dyeing assistants

A technology for dyeing auxiliaries and cheese yarn, applied in the field of cheese yarn dyeing, can solve the problems of miscellaneous storage of medicine barrels on the production site, reduce productivity, time-consuming and labor-intensive, etc., and reduce environmental pollution and damage to operators. One-time sample rate, saving management time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

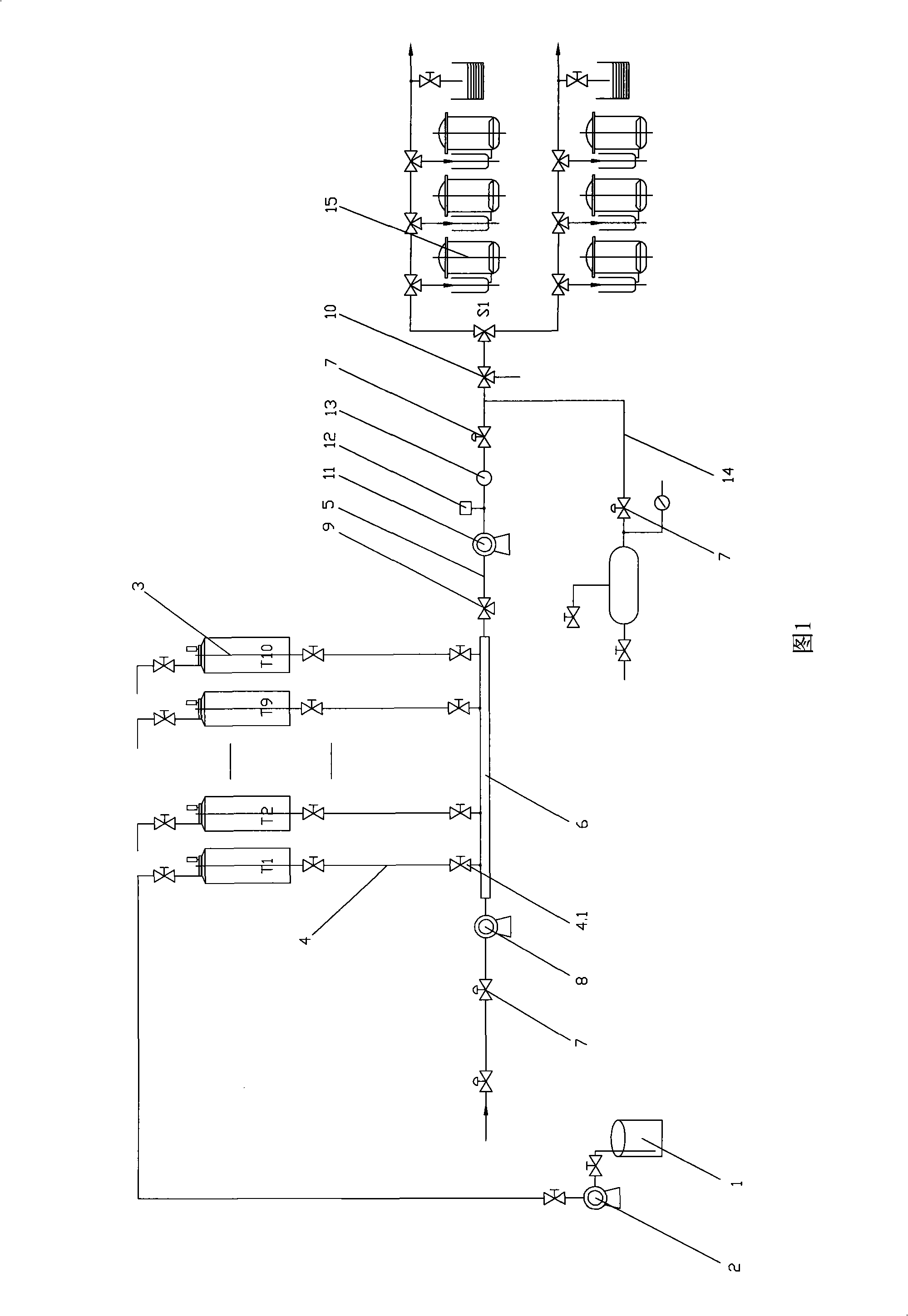

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0023] Referring to Figure 1, the storage tank 1 is connected with 10 auxiliary storage tanks 3 through the pressure pump 2 and the feeding pipeline. The pipeline 4 is connected to the middle end of the main pipeline 6. Each pipeline 4 is provided with a metering valve on the top and a metering valve 4.1 on the bottom. One end of the main pipeline 6 is provided with a water pump 8 and two control valves 7 in sequence. The delivery pipeline 5 is provided with a front three-way valve 9, a metering pump 11, a pressure sensor 12, a mass flow meter 13, a control valve 7 and a rear three-way valve 10 in sequence on the delivery pipeline 5. One end of the delivery pipeline 5 is connected to the dyeing machine area. A plurality of dyeing machines 15 are arranged in the machine area, a pressure sensor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com