Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2049results about "Textile treatment containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

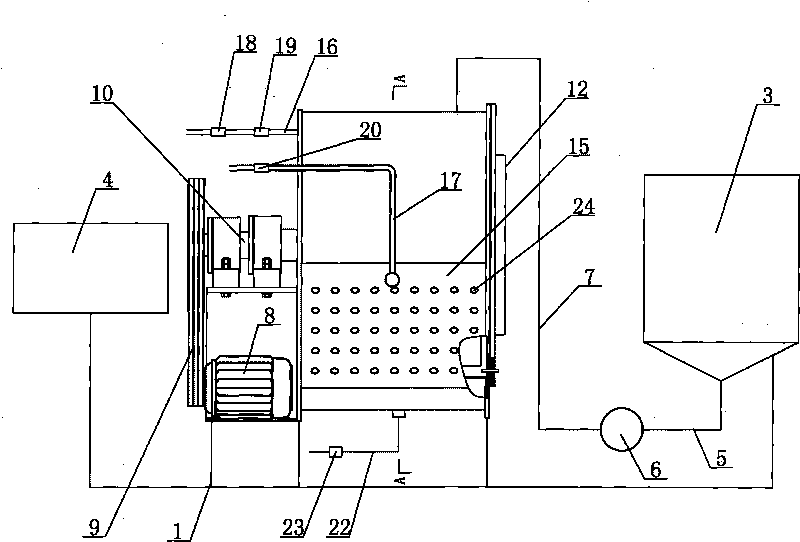

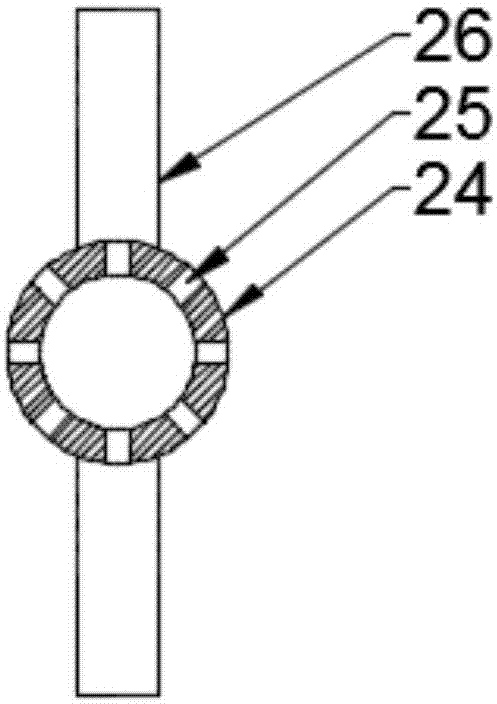

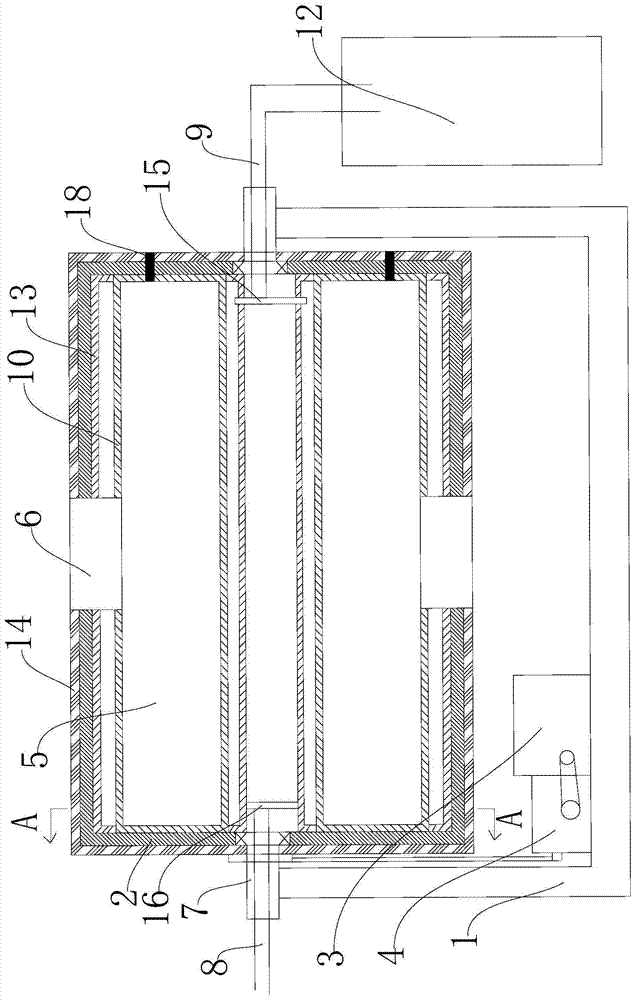

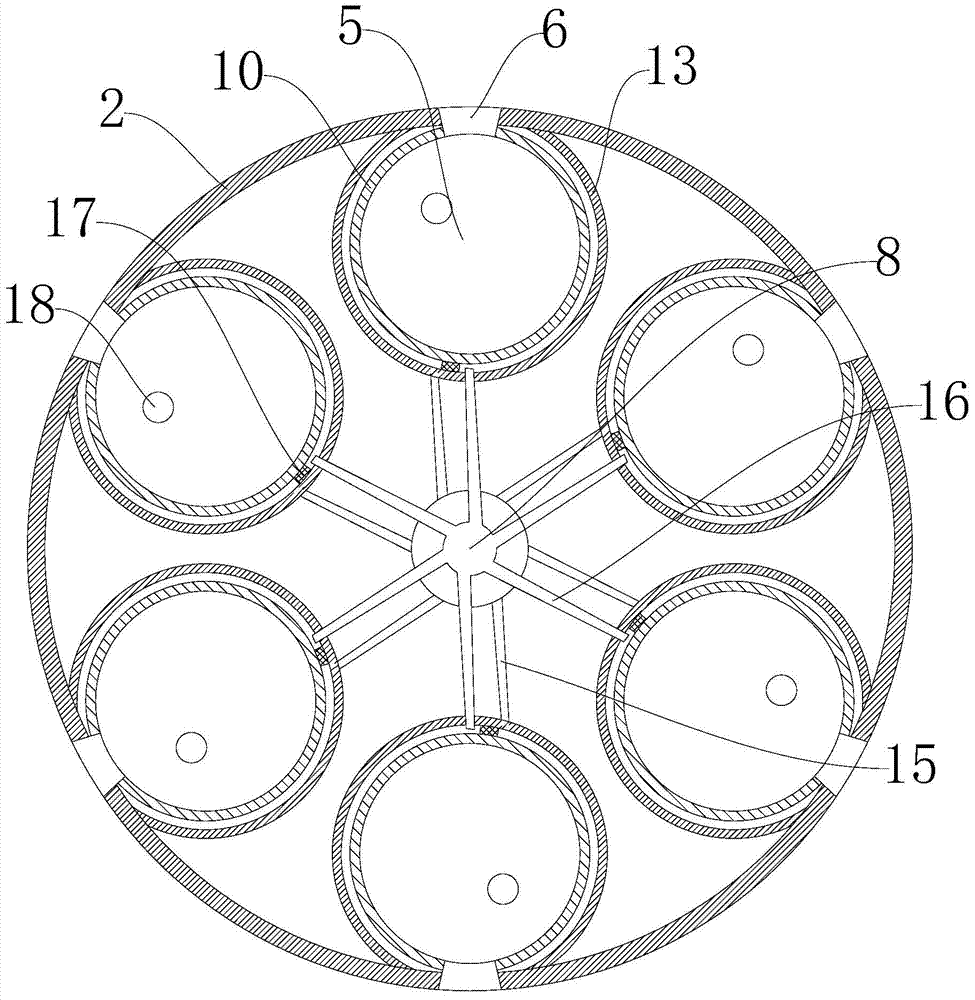

Supercritical carbon dioxide cheese dyeing kettle and waterless supercritical carbon dioxide cheese dyeing method

ActiveCN102787459ATextile treatment containersSolvent treatment with solvent recoveryEngineeringDrill

The invention relates to a supercritical carbon dioxide cheese dyeing kettle and a waterless supercritical carbon dioxide cheese dyeing method. In the dyeing kettle, when carbon dioxide fluid enters a distribution tray from an inlet, blades start rotating clockwise under the effect of pressure; inserted drill rods are driven to rotate by a rotation part; and the rotating speed of the inserted drill rods is increased along with the increase of pressure in a cylinder body. When a cheese is dyed, the cheese on the inserted drill rods is dyed at a speed of 0.2-0.5 r / s. When the rotating cheese is dyed, the cheese is subjected to the pressure of the fluid flowing out from a central shaft; the rotation and bicirculation of the cheese dyeing are realized; the uniform dyeing effect of the dyed cheese can be improved; and the migration ability and the diffusibility can be improved.

Owner:晋江国盛新材料科技有限公司

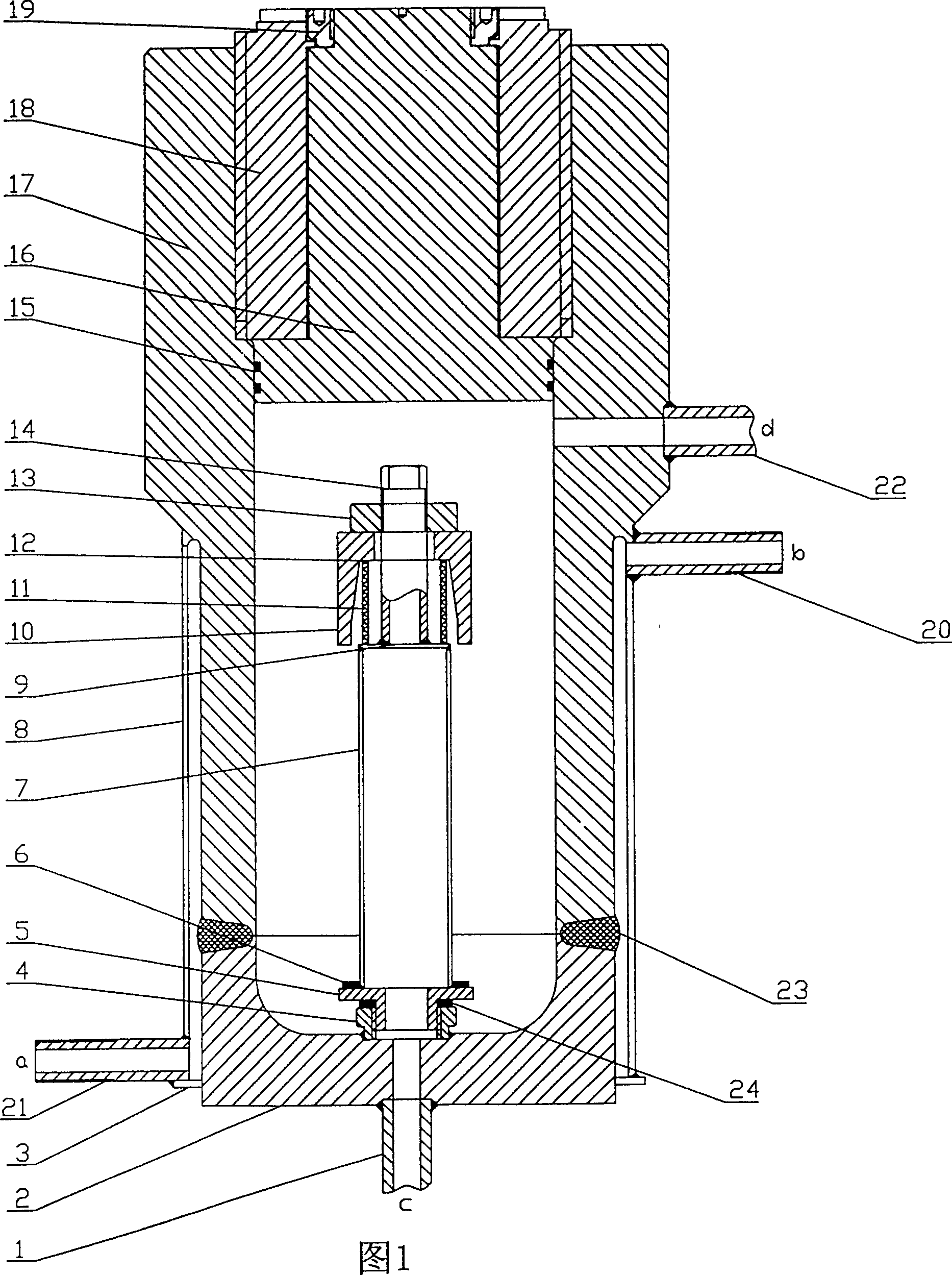

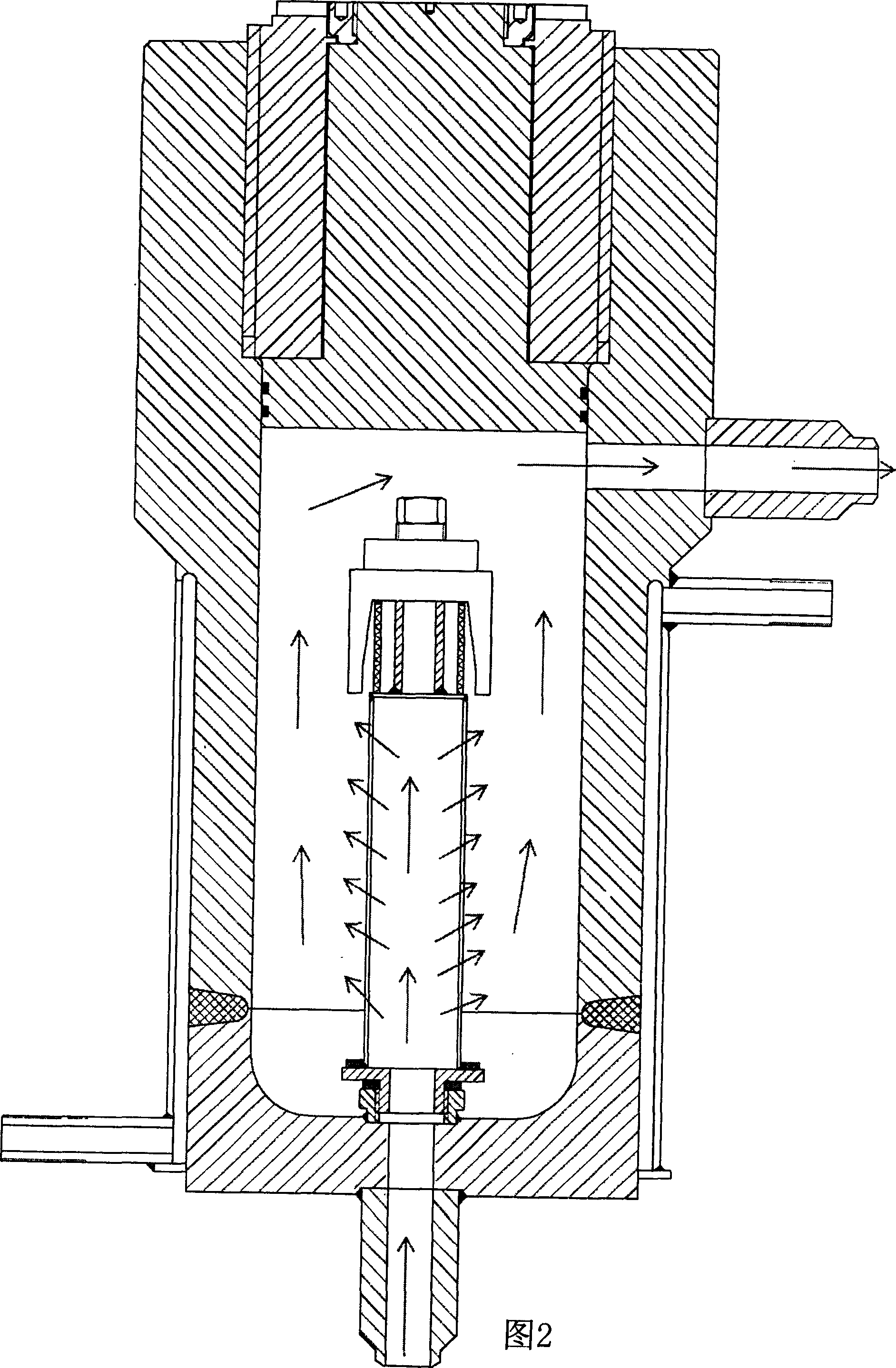

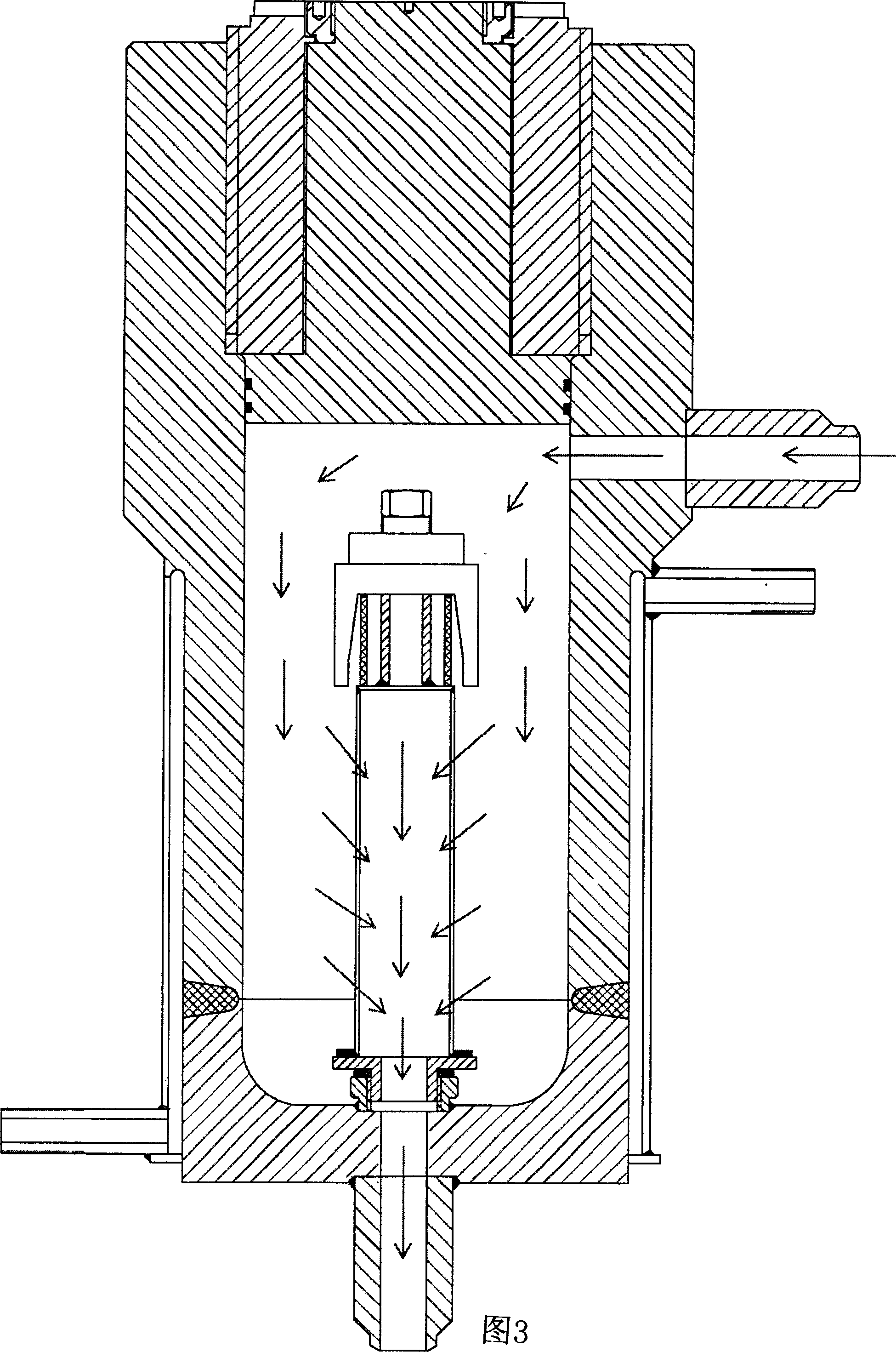

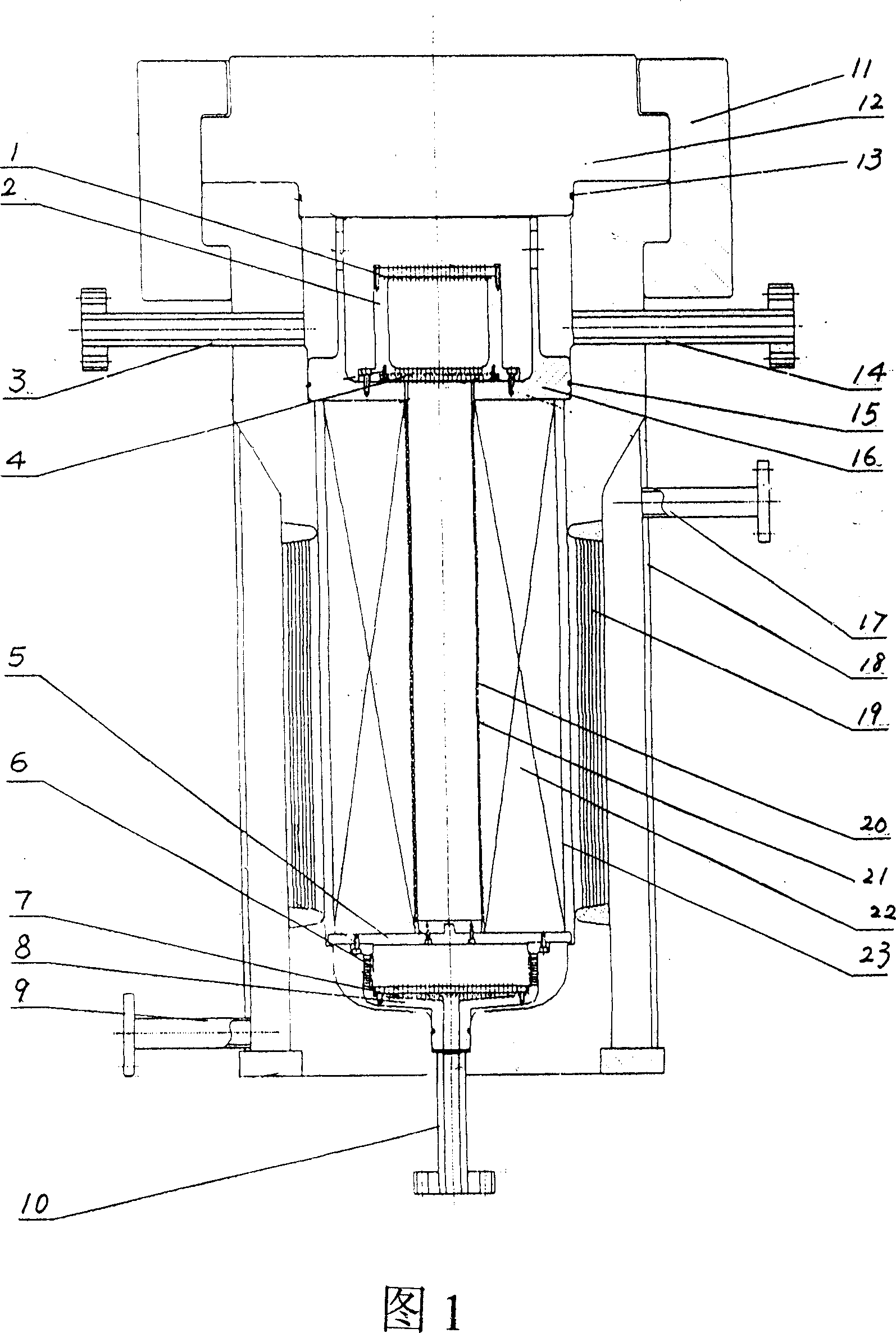

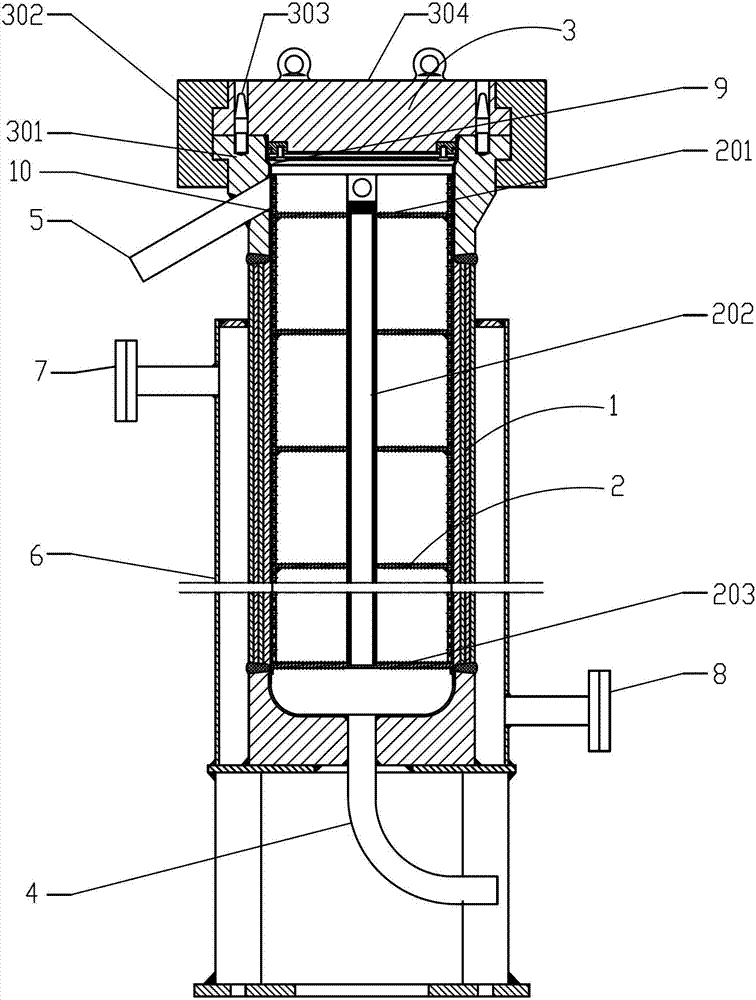

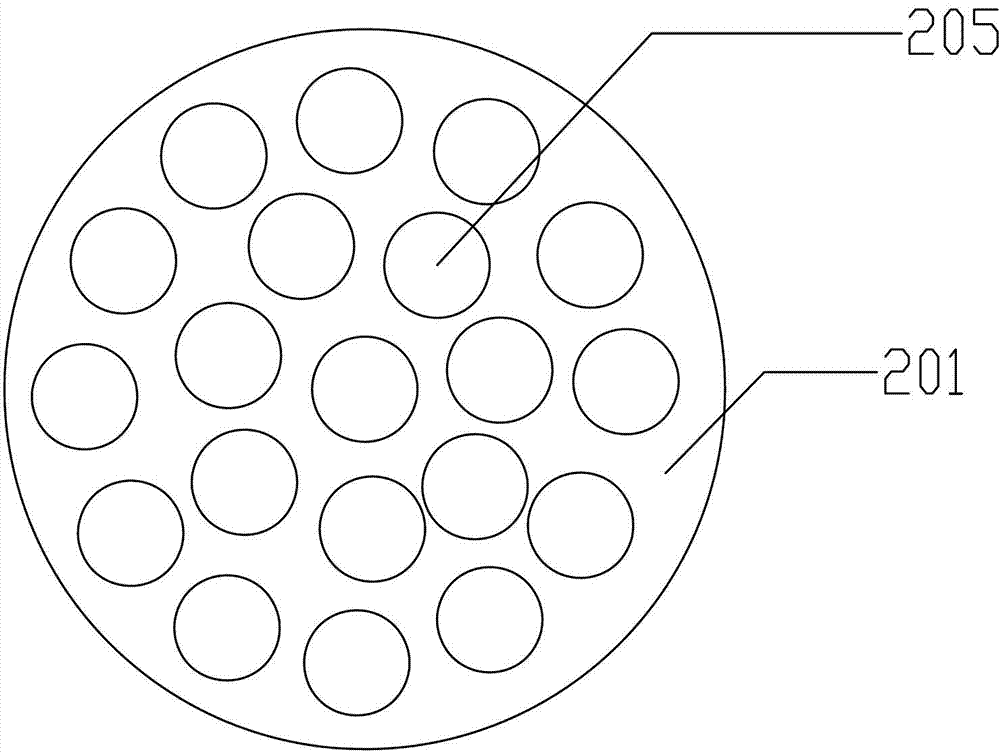

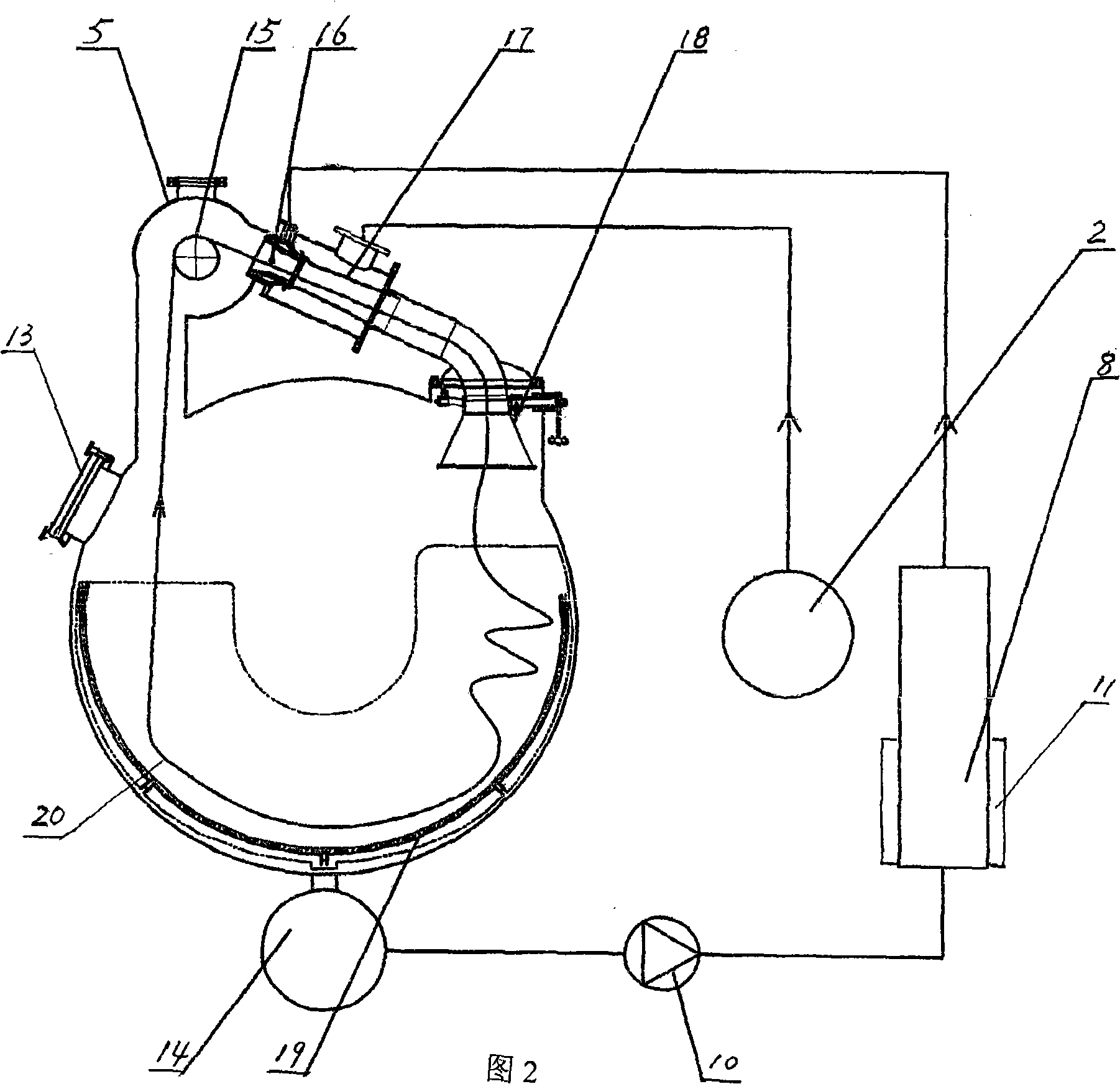

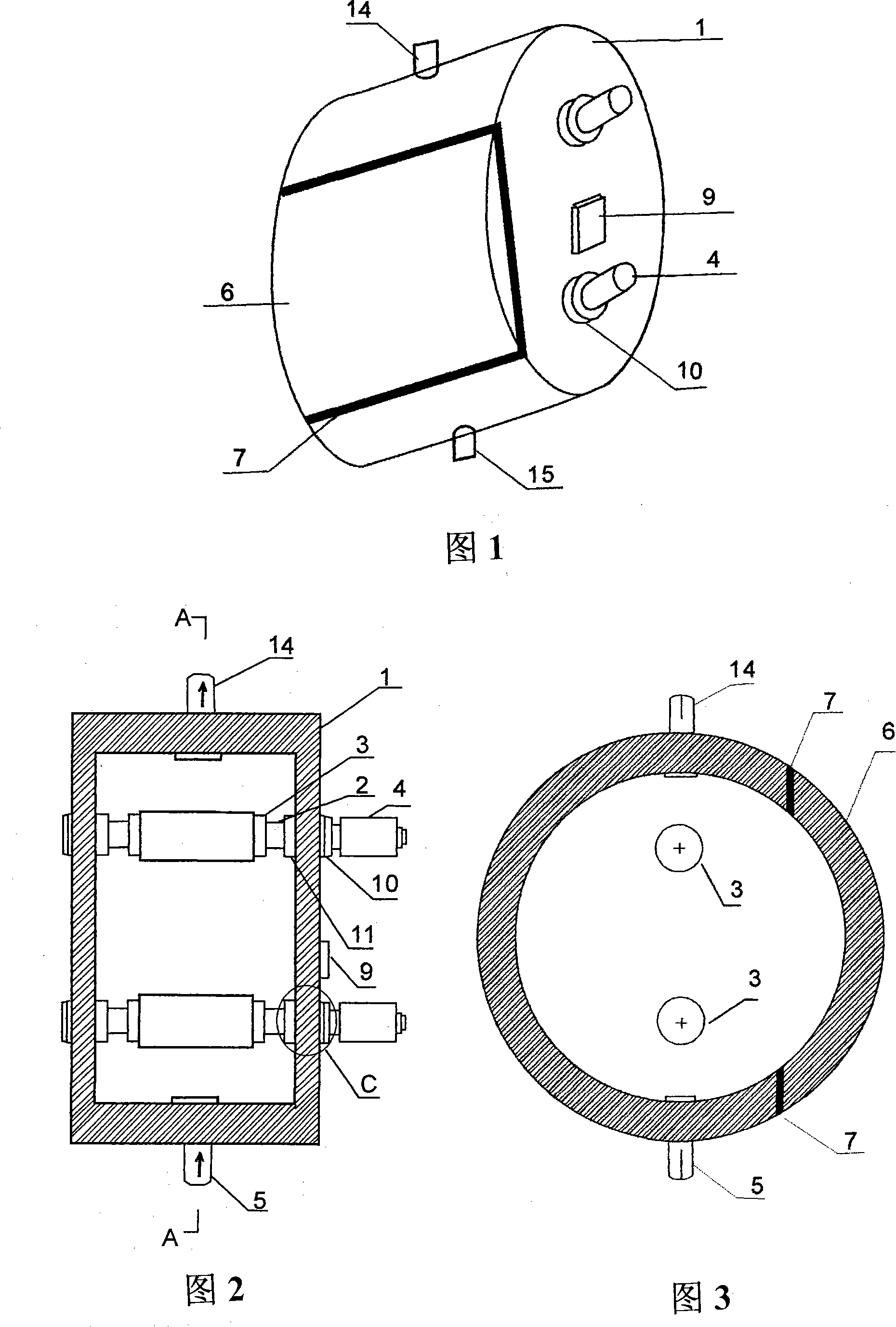

Dying still in supercritical CO2 dyeing device

InactiveCN1807742ARealize the operation process of dynamic dyeingReduce dye liquor vortexTextile treatment containersDyeing processEngineeringMechanical engineering

This invention discloses a dyeing kettle of the over-critical carbon-dioxide dyeing device, which is to use for the dyeing of the textile, including arranging the barrel and the sealed convex shoulder flat that is on the upper part of the barrel; the center opening of the barrel's bottom connects with the first connector, the inside center opening of barrel connects with the inner barrel by the support cell; the wall of the inner barrel is arranged with the filter hole uniformly, the upper of the inner barrel connects with the second cover; the barrel wall opening of the barrel's upper connects with the second connector; the under part of the barrel connects with the nip cover, which has the ring space with the barrel, and the upper of the ring space is sealed in the protruding stage that outside the barrel, and the first cover is sealed in the under part, one side of the ring space's under part opening connects with the first adapter, and the other side of upper part opening connects with the second adapter. This invention realizes the combining of the technology of the textile internal dyeing and external dyeing, and the dynamic dyeing in the over-critical dyeing method.

Owner:DALIAN POLYTECHNIC UNIVERSITY

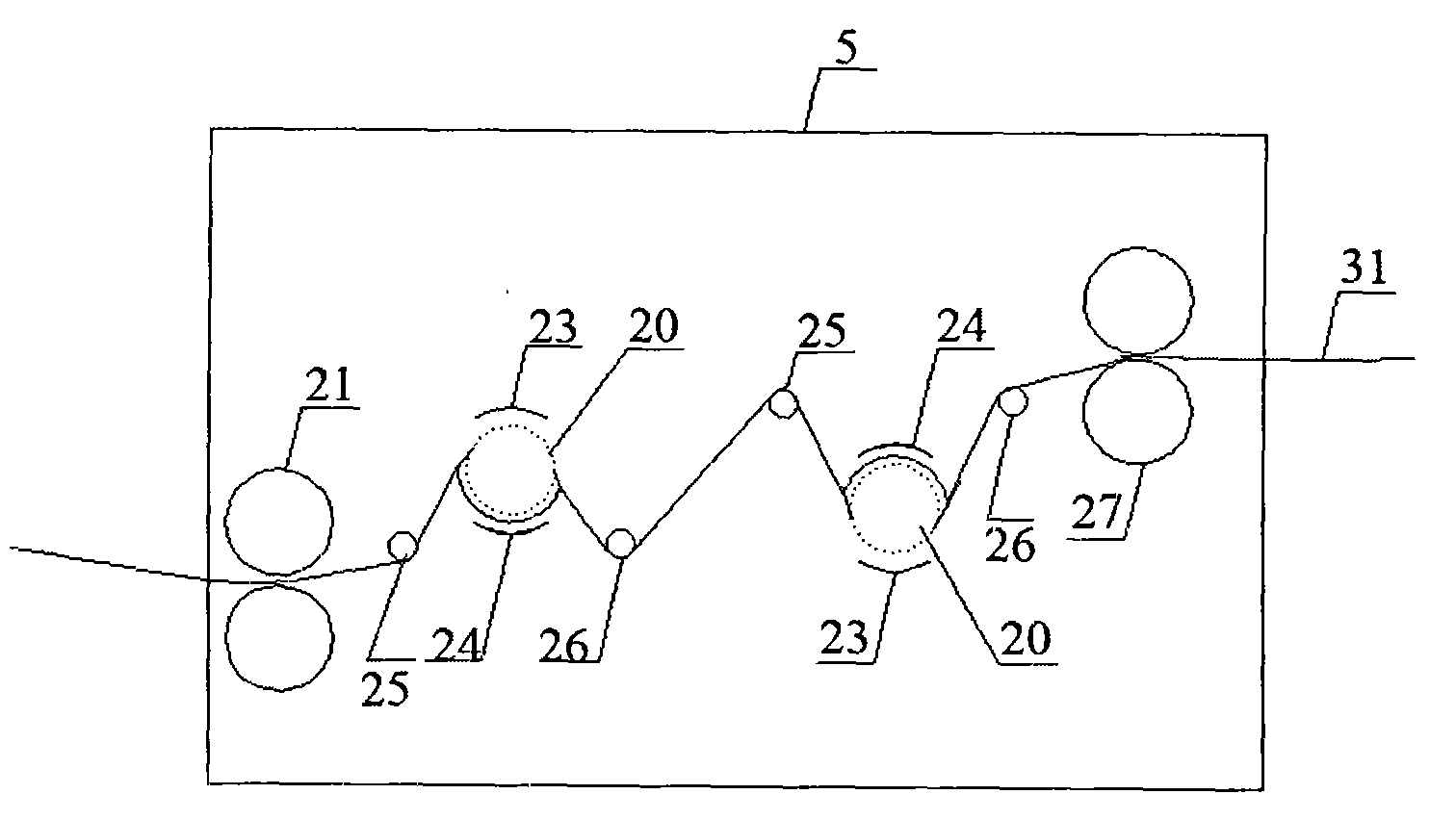

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

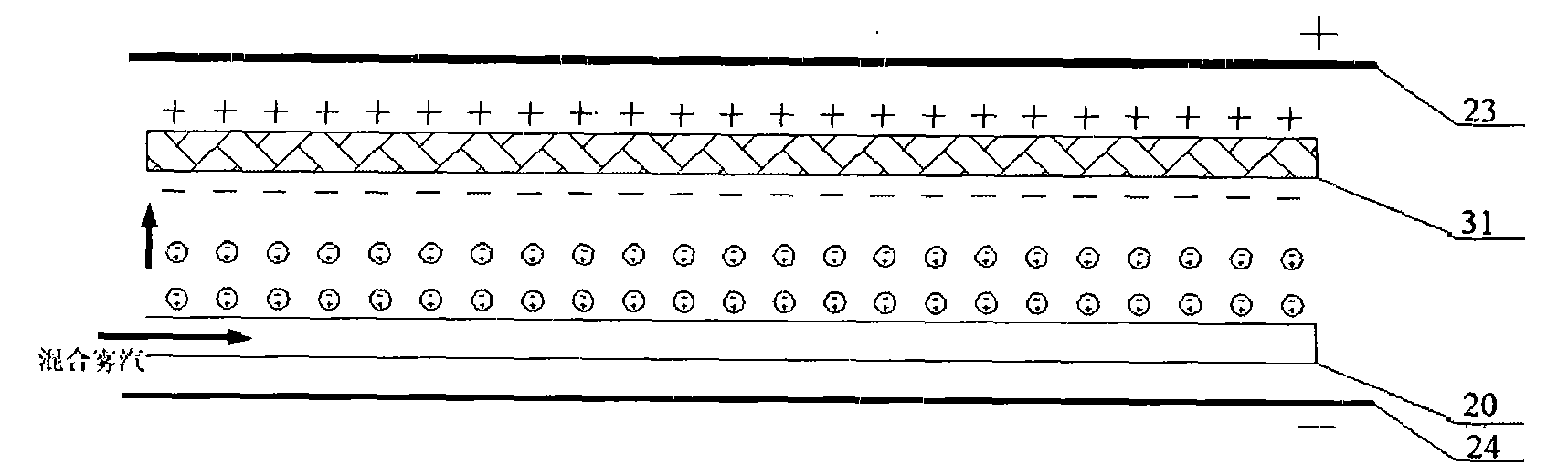

Textile dyeing method

InactiveCN102002834AIncrease profitSmall particle sizeTextile treatment containersTextile treatment with treating outlet contectFiberTextile printer

The invention relates to a method for dyeing textile materials and products thereof, and belongs to the field of textile printing and dyeing processing. In the method, prepared dye solution is subjected to ultrasonic atomization to form dye solution microbeads, and the dye solution microbeads directionally infiltrate the textile under the action of certain pressure and an electric field so as to complete the dyeing process. Due to the adoption of the technical scheme, dye solution atomized microbeads prepared from the dye solution through a high-frequency ultrasonic atomizer have smaller grain size, a small dispersion range on the textile and more fine and smooth dyeing effect; the dye solution atomized microbeads enter fibers more easily under the action of the air pressure and the electric field, and have better dyeing effect; and the atomized microbeads carry less solution, the utilization rate of the dye is high, water can be saved and the environmental pollution is lightened. The dyeing method has a wide application range, low energy consumption and light pollution, and is suitable for small-batch and multi-variety printing technology development direction.

Owner:WUHAN TEXTILE UNIV

Dyeing caldron in supercritical CO2 dyeing device

InactiveCN1944762ALow flow resistanceTextile treatment containersLiquid/gas/vapor textile treatmentArchitectural engineeringSupercritical carbon dioxide

The present invention is dyeing caldron of supercritical CO2 dyeing apparatus and relates to fabric dyeing technology. The dyeing caldron has one upper fabric baffle to form one upper cavity, one upper dye box in the upper cavity, one lower fabric baffle to form one lower cavity, one CO2 flowing channel between the lower fabric baffle and the inner caldron wall, one lower dye box in the lower cavity, one porous tube coaxial with the caldron fixed to the upper fabric baffle and the lower fabric baffle, and one stainless steel filtering net to cover the outer surface of the porous tube. The present invention integrates the functions of both dye caldron and the dyeing caldron, and has simplified conveying pipeline, lowered flowing resistance and simultaneous dye dissolving and fabric adsorption in the same caldron.

Owner:MASSON GROUP

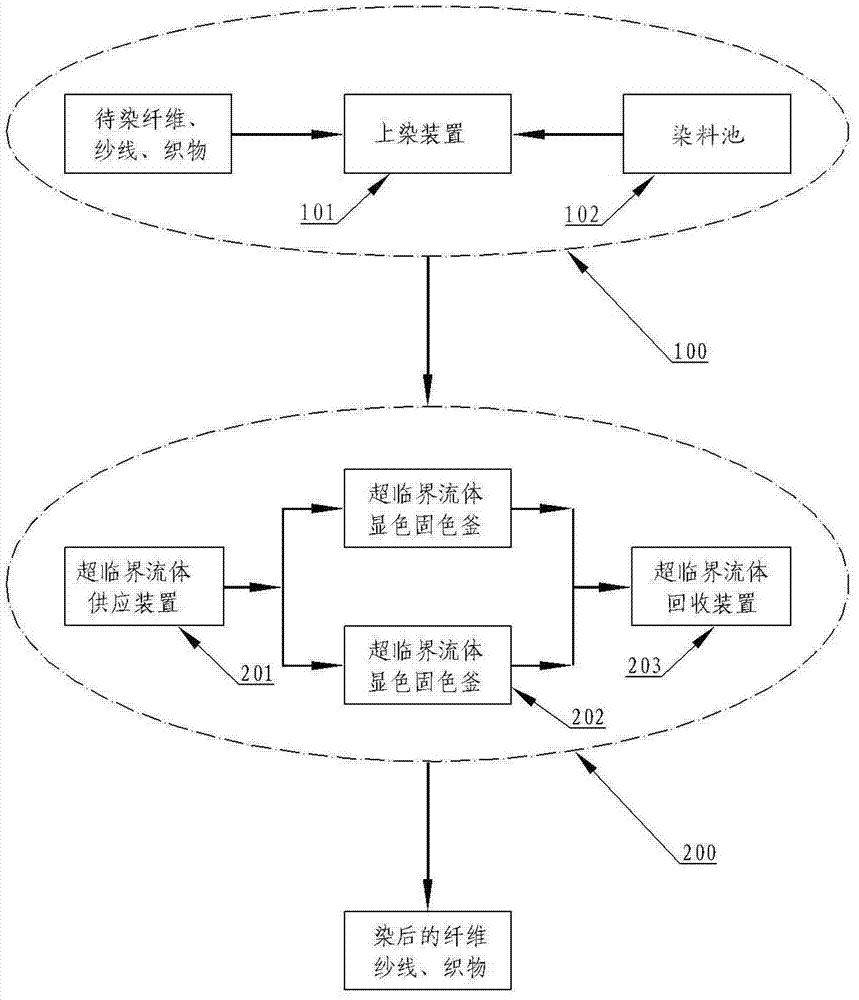

Method and device for static dyeing by adopting supercritical fluid

ActiveCN102817194AMigration does not occurSolve uncontrollable difficultiesTextile treatment containersChemical fixing of textilesSystem pressureStationary state

The invention discloses a method for static dyeing by adopting supercritical fluid. The method comprises the following steps of: (1) dyeing: placing an object to be dyed in an uptake dyeing system for uptake dyeing; (2) static developing and color fixing with the supercritical fluid: placing the dyed object to be dyed in the step (1) in a supercritical fluid developing and color fixing kettle, and adding the supercritical fluid in the supercritical fluid developing and color fixing kettle for the developing and color fixing of the object to be dyed in the static supercritical fluid; and (3) after the developing and color fixing are completed, eliminating system pressure to recover the supercritical fluid, and opening the supercritical fluid developing and color fixing kettle for taking out the object to be dyed. In the method for static dyeing by adopting supercritical fluid, the supercritical fluid is in a stationary state in the developing and color fixing process, so that the phenomenon of dye migration cannot occur, the dyeing quality is easy to control, and the dyeing system does not need to be cleaned in the replacement of the dyeing color. Meanwhile, the invention also discloses a device for realizing the method for static dyeing by adopting the supercritical fluid.

Owner:陈志刚

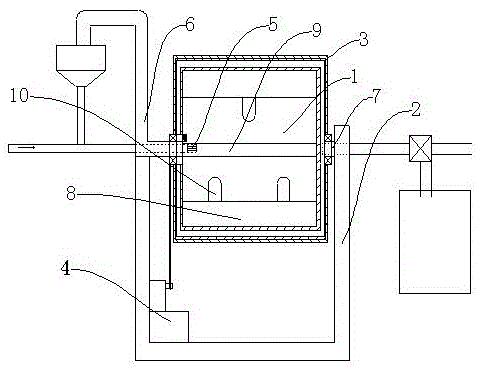

Fully automatic garment dyeing machine

ActiveCN101748574AHigh degree of automationEasy to controlTextile treatment containersTextile treatment machine arrangementsPulp and paper industryFully automatic

The invention discloses a fully automatic garment dyeing machine which comprises a frame, a dyeing cylinder arranged on the frame, a dye feed cylinder and a computer controller. An electromotor is arranged at the lower end of the dyeing cylinder and connected with one end of a rotating shaft through a transmission belt; the other end of the rotating shaft is connected with a rotating cage arranged inside the dyeing cylinder; a machine door is arranged on one side of the dyeing cylinder; a temperature sensor is arranged in the dyeing cylinder; and a heating cavity is formed on the outer side at the lower end of the dyeing cylinder. The fully automatic garment dyeing machine with the structure has the advantages of high automation and convenient control; and steam can not be directly sprayed to the dyeing cylinder when the dyeing cylinder is heated, so that the water bathing ratio in the dyeing cylinder is not influenced, and the dyeing effect is improved.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

Novel energy-saving emission-reduction environmental-protection method and device

InactiveCN101671966AReduce consumptionEmission reductionTextile treatment containersDry-cleaning apparatus for textilesDyeingWastewater

The invention relates to a novel energy-saving emission-reduction environmental-protection method and a device; comprising the following processes: printing and dyeing and after finishing; the printing and dyeing process comprises rinsing, washing, acid cleaning, washing and dyeing, and the after finishing process comprises washing, acid cleaning, soaping, washing, color fixation and softening; the method is characterized in that: in the washing procedure and acid-cleaning procedure before the dyeing procedure, water produced by the washing procedure is contained in a recycling pond, and thenthe water in the recycling pond is used by the acid-cleaning procedure. Compared with the prior art, the method has the advantages of water, power and steam saving and waste water disposal reduction.

Owner:FOSHAN ZHONGFANGLIAN INSPECTION TECH SERVICE CO LTD

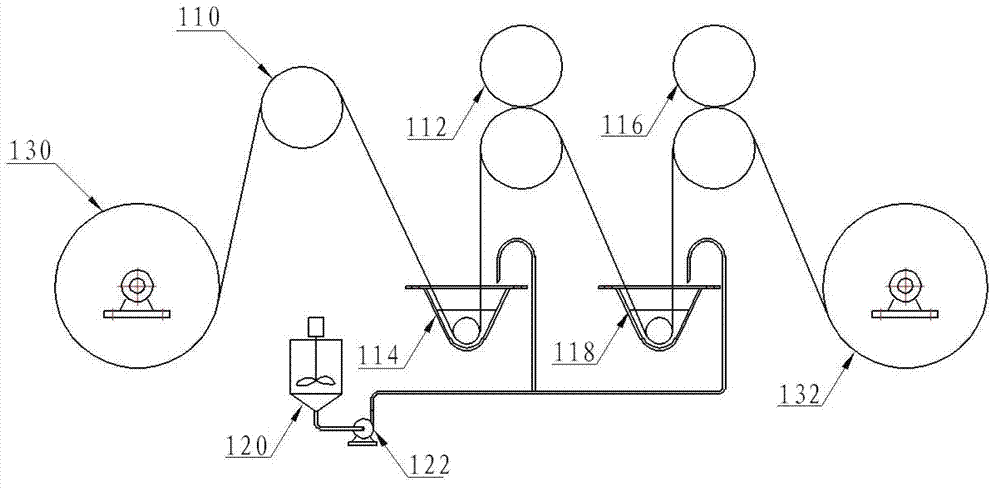

Device and method for fabric dyeing with supercritical carbon dioxide fluid

ActiveCN101824716AAvoid unwindingAvoid looseTextile treatment containersDyeing processTime ratioEngineering

The invention discloses a method for improving the level-dyeing property of fabric in supercritical carbon dioxide fluid and a device thereof. The method adopts special seamless warp beam which consists of an inner layer and an outer layer is adopted, a seamless woven wrapper of a cylindrical net shape is sleeved outside the outermost layer of wound fabric, and process parameters such as the time ratio between fluid circulation and static dyeing, and the like are controlled reasonably, thereby realizing the uniform dyeing of piece fabric in the supercritical carbon dioxide fluid. Since the method adopts the warp shaft mode with a reasonable structure, the fabric winding way and the process condition, the supercritical fluid containing a soluble dye can penetrate through the wound fabric uniformly, thereby reducing the non-uniform pressure loss in the fluid flow during circulation, the sudden change of the fluid path and the unevenness of the fluid circulation, and improving the uniform dyeing effect on the piece fabric. The technical method of the invention has the advantages of simple equipment and process, convenient operation, high efficiency, energy conservation and emission reduction.

Owner:中科首望无水染色智能装备(苏州)有限公司

Identical reaction kettle reel-to-reel plasma ultrasonic supercritical non-aqueous dyeing

InactiveCN101555665AFast anhydrous dyeing rateImprove solubilityTextile treatment containersPhysical treatmentUltrasonic sensorExhaust valve

The invention discloses an identical reaction kettle reel-to-reel plasma ultrasonic supercritical non-aqueous dyeing system, comprising a general control console, a carbon dioxide storage bottle, a high-pressure pump, a dye tank, a heat exchange device, a reaction kettle, a dye recycling tank, a filter, a condenser, a liquid carbon dioxide storage tank, a flow meter, a valve and a pipeline, and characterized in that the reaction kettle is provided with an upper electrode and a lower electrode of a plasma generator, an exhaust valve and a vacuum pump, is internally provided with one or a plurality of groups of reel-to-reel or axis-to-axis wind and relative motors, is also internally provided with one or a plurality of groups of agitating devices and relative motors, and is embedded with an ultrasonic transducer connected with an ultrasonic wave generation device. The plasma realizes the modification for the surface of material, the ultrasonic wave disperses the dyes uniformly, the supercritical carbon dioxide realizes non-aqueous dyeing, and the reel-to-reel way realizes non-intermittent continuous industry production. The invention can meet the most rigorous environment-friendly demand and product safety demand.

Owner:冷博

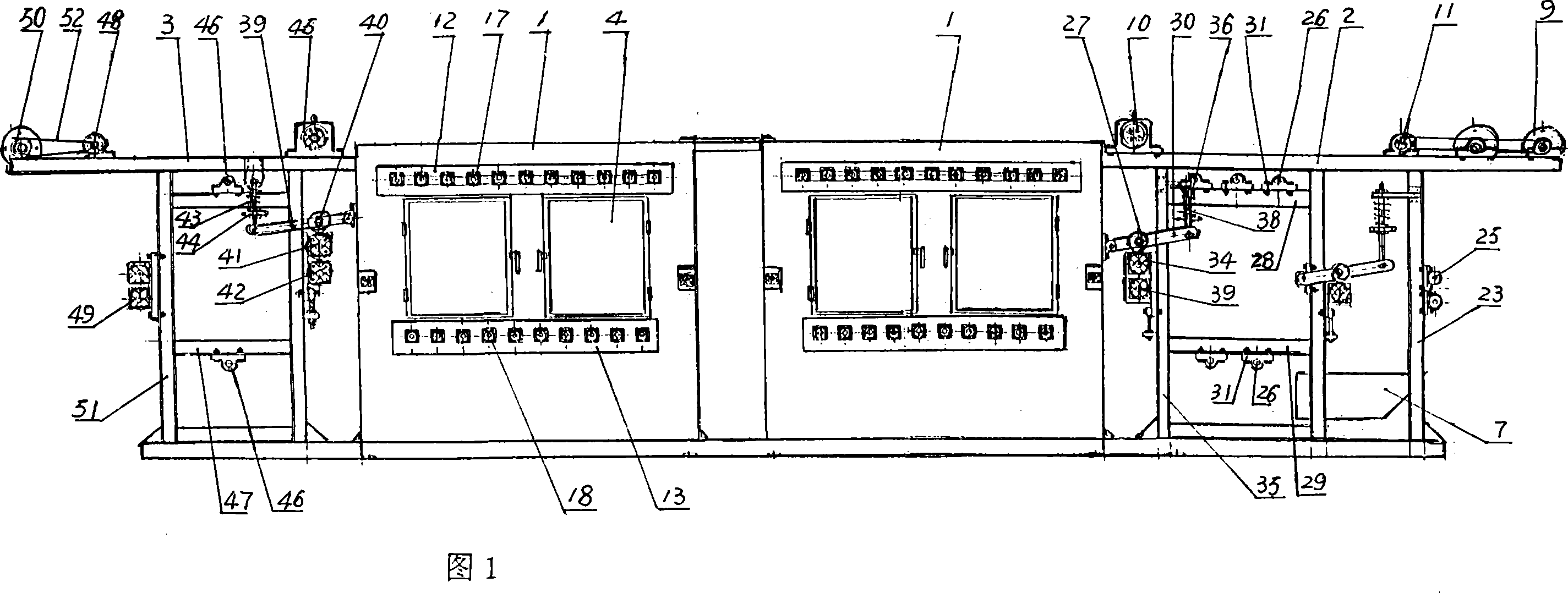

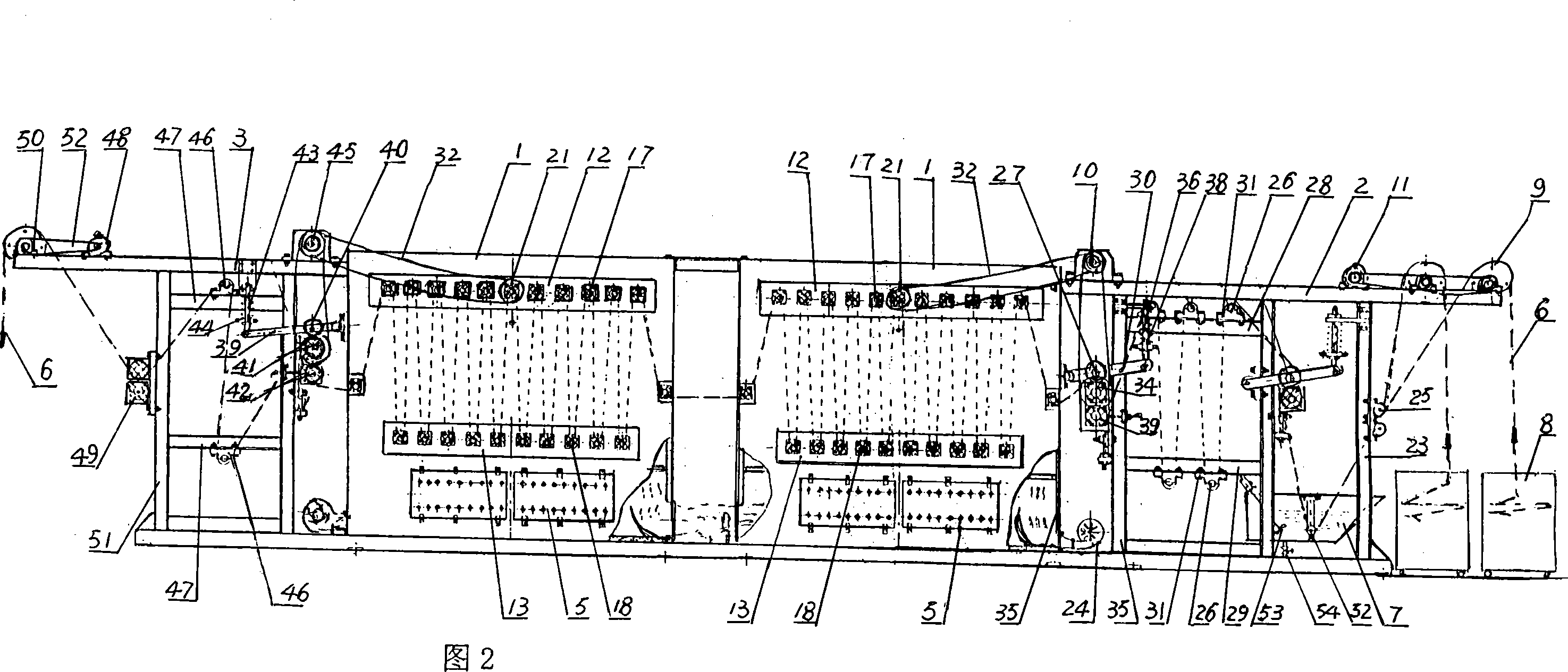

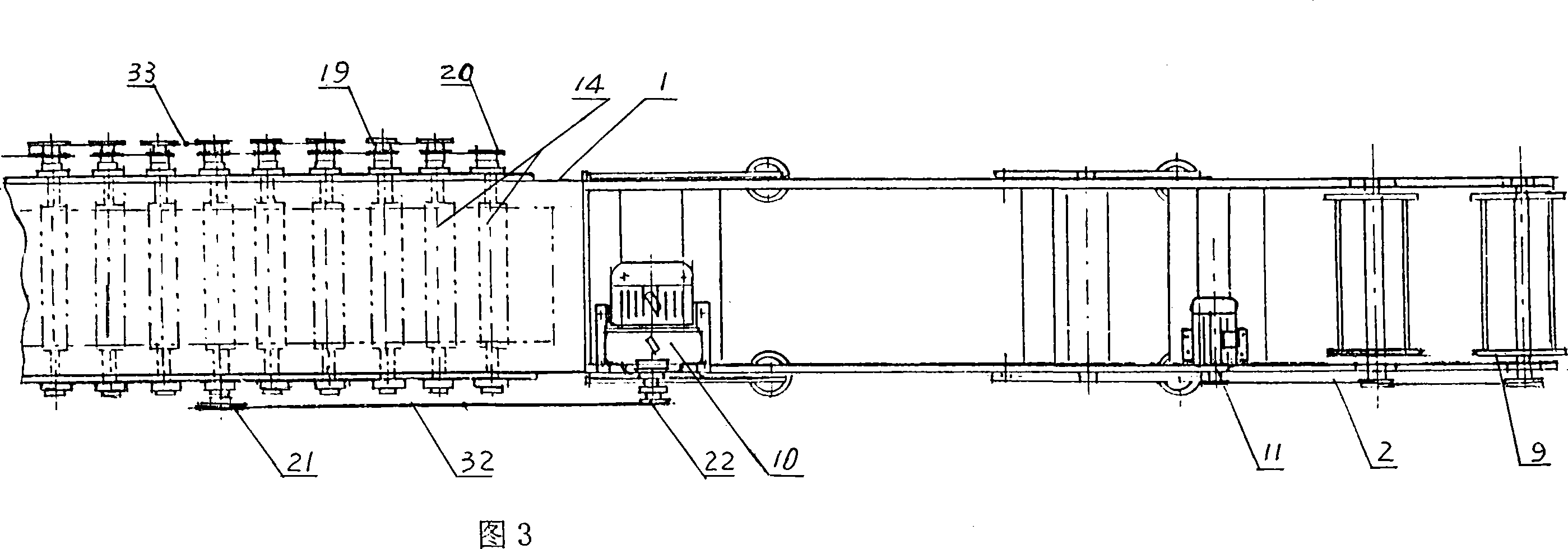

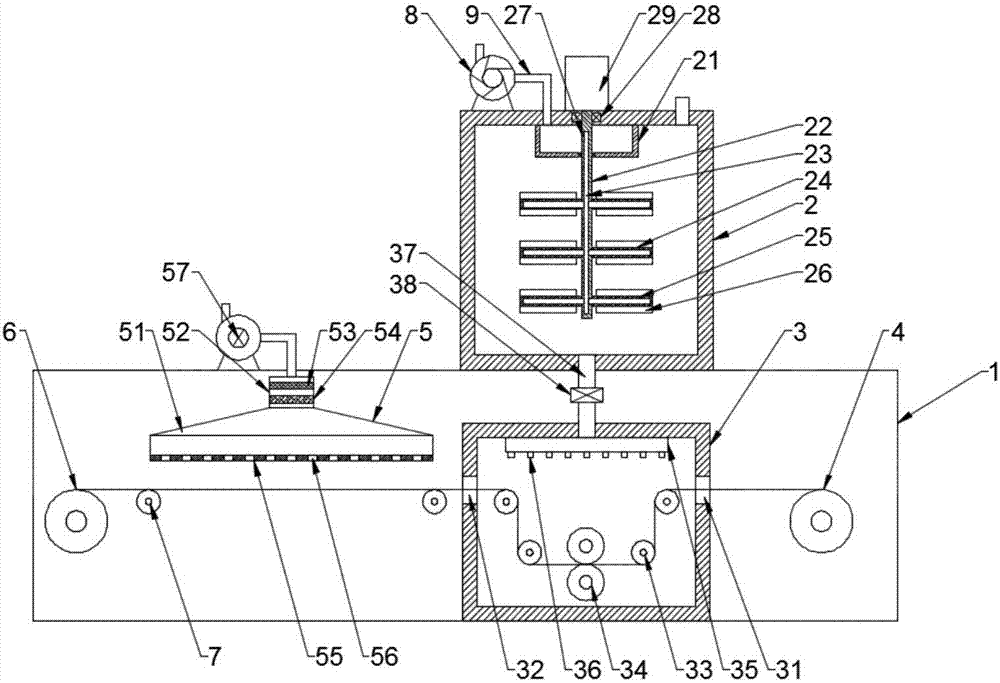

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

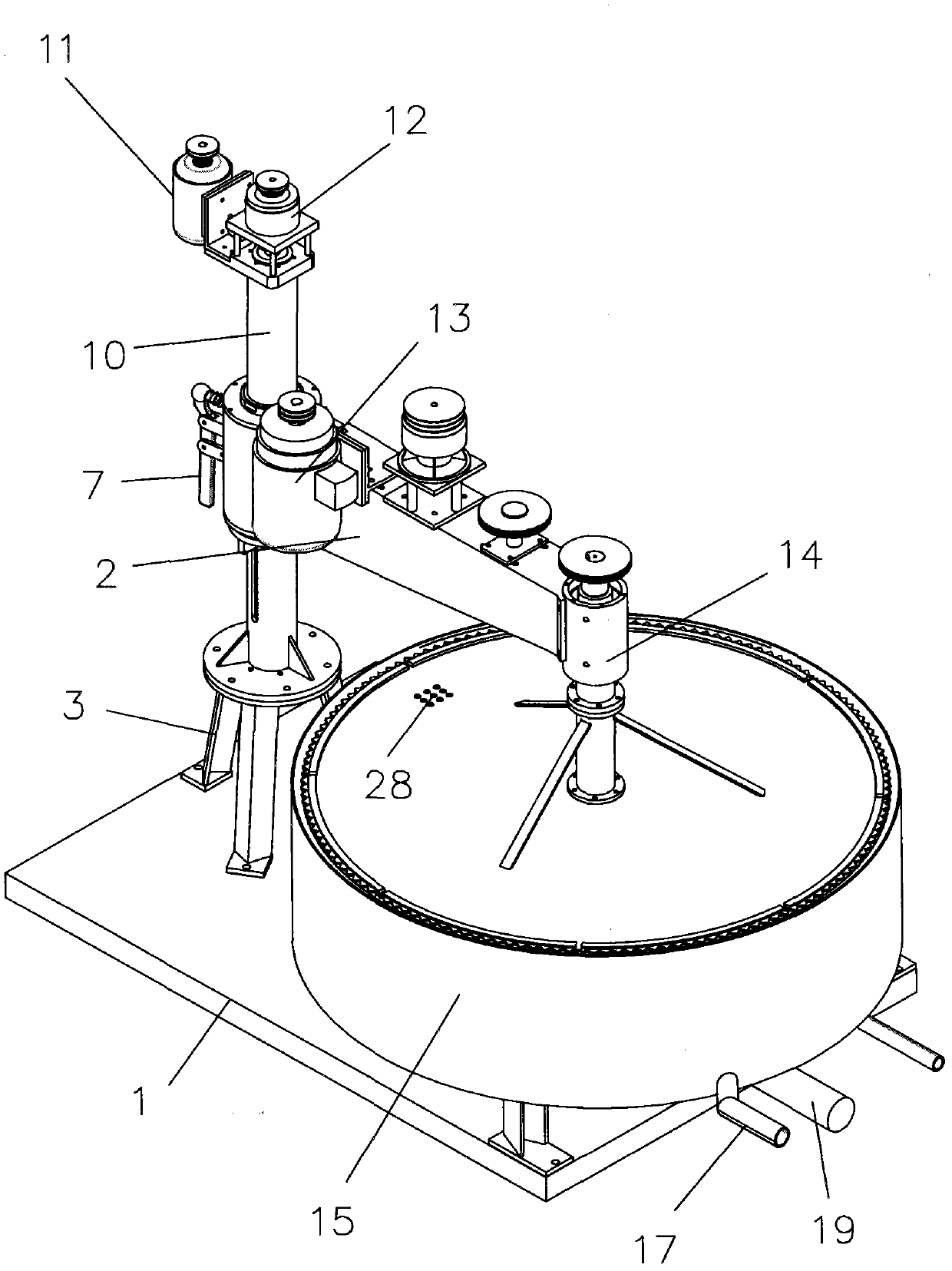

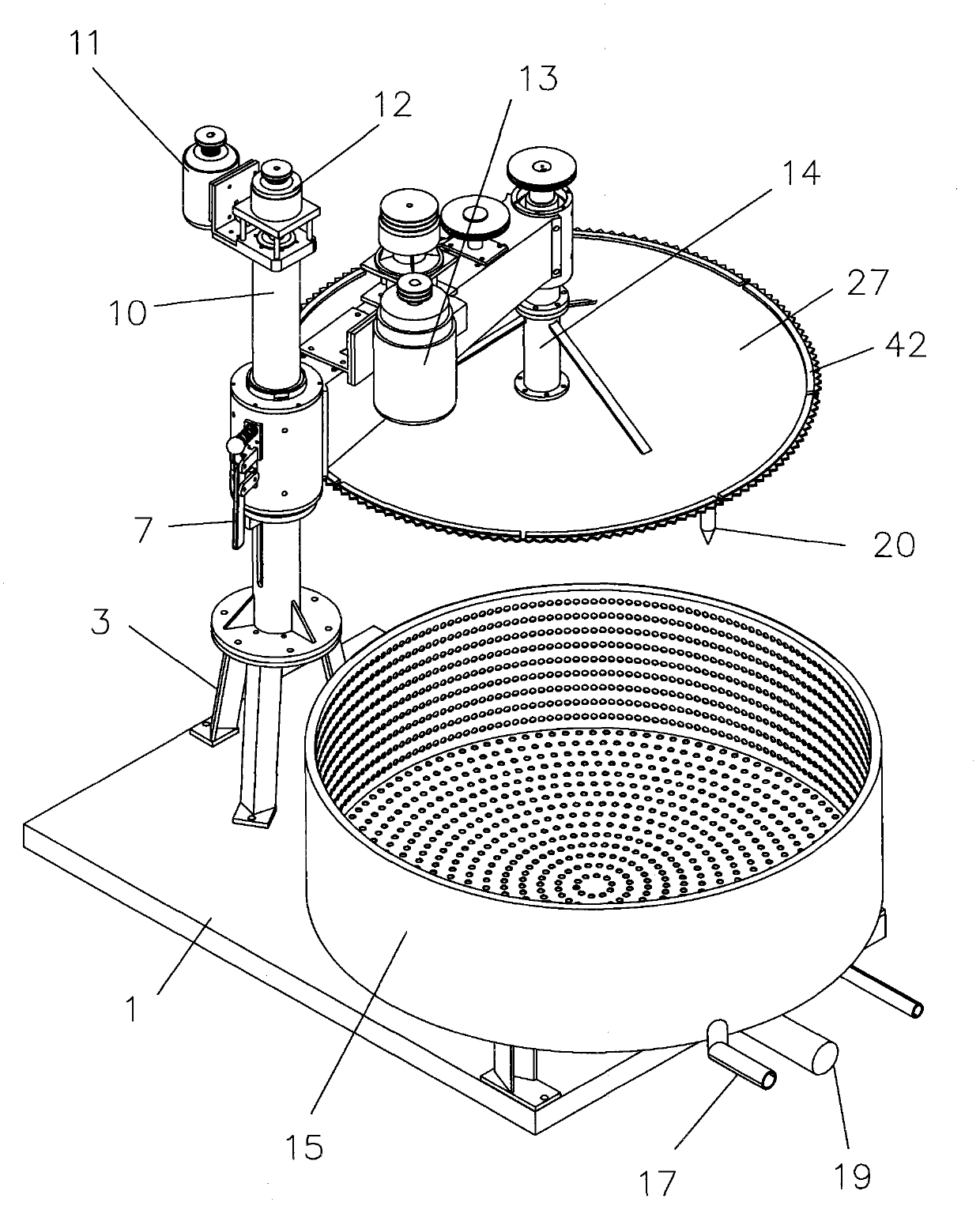

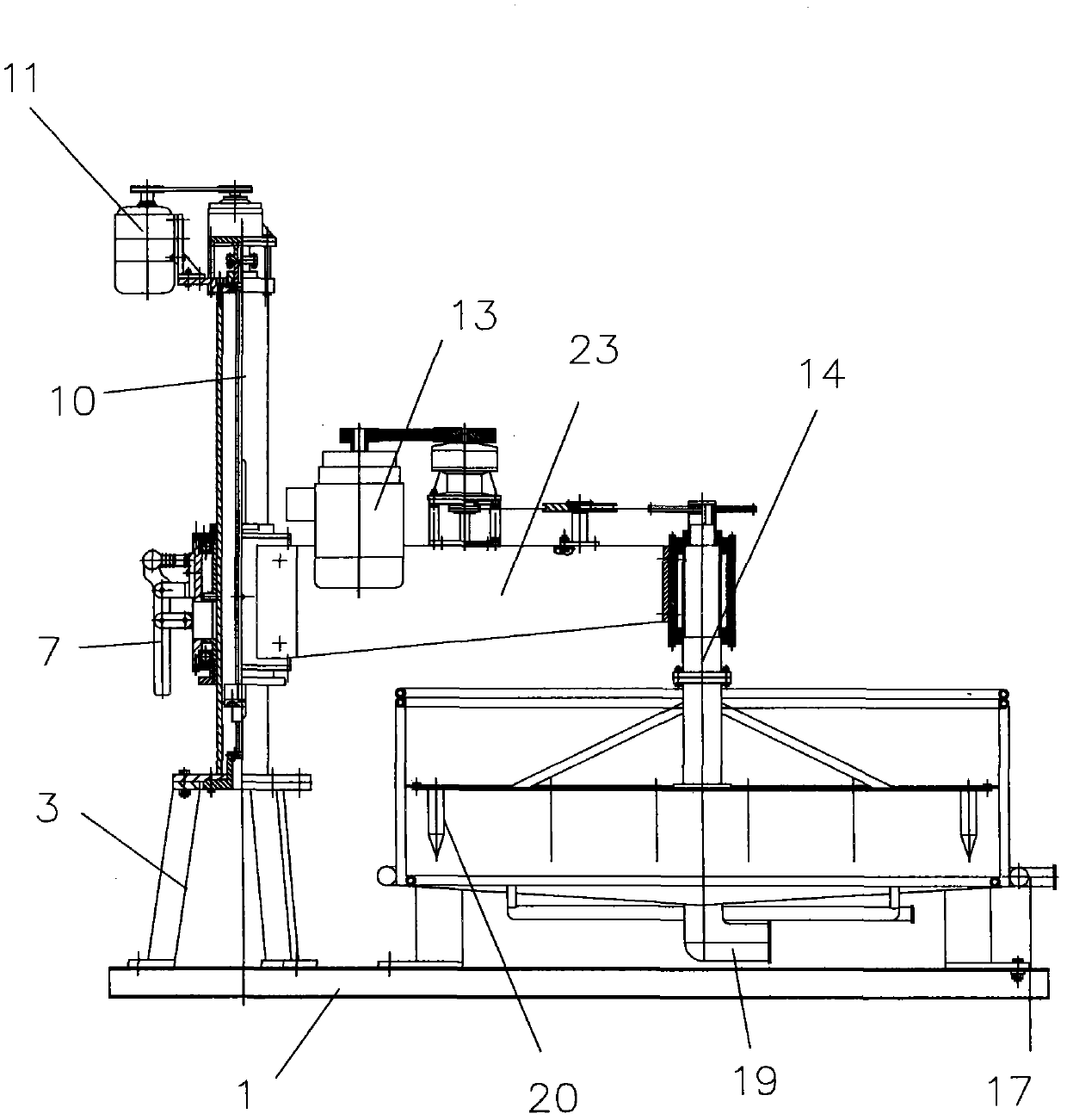

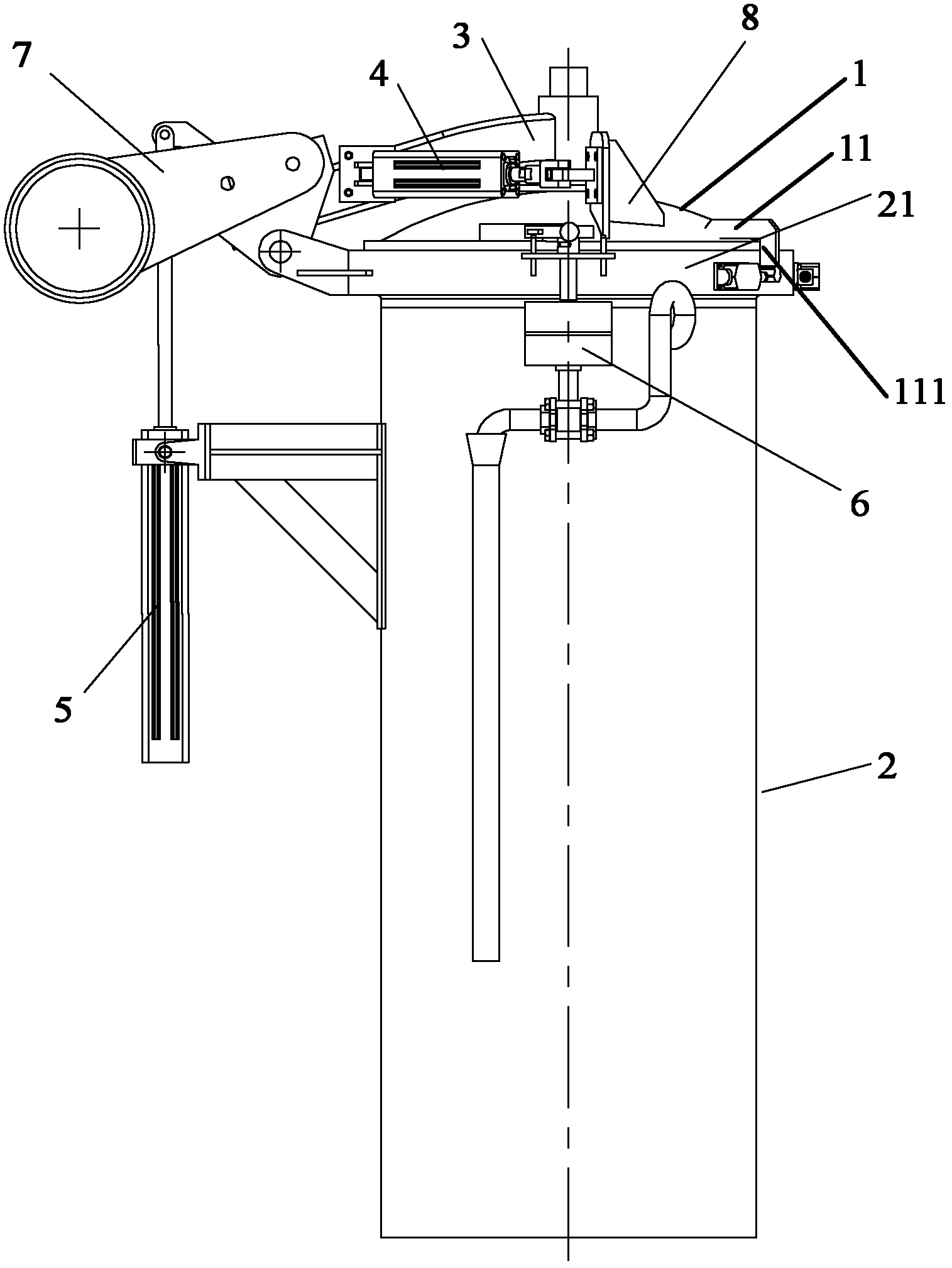

Automatic wig dyeing machine

The invention mainly discloses an automatic wig dyeing machine which comprises a base, a triangular frame, a barrel body, a lifting mechanism, a cantilever mechanism and a stirring mechanism, wherein the base is provided with the triangular frame for fixing the lifting mechanism; one end of the cantilever mechanism is mounted on the lifting mechanism, and the stirring mechanism is mounted at the other end of the cantilever mechanism; the cantilever mechanism moves vertically on the lifting mechanism and drives a stirrer to move up and down; the stirrer can be placed in the barrel body when moving downwards, and is at certain distance higher than the barrel body when moving upwards; the cantilever mechanism is provided with a handle controlling the cantilever mechanism to rotate or to be fixed in a horizontal plane; a main motor is mounted in the cantilever mechanism; the stirring mechanism is driven to rotate through a speed reducing mechanism; and a stirring rod of the stirring mechanism is inserted into the hair to be dyed in the barrel body and rotates along with the stirring mechanism. The automatic wig dyeing machine disclosed by the invention realizes sufficient dyeing, obviously improves the dyeing quality, effectively prevents the wig products from being twisted, and is an automatic dyeing machine which has low pollution, low labor cost, high dyeing quality and low price and is easy to operate.

Owner:ZHONGBEI UNIV

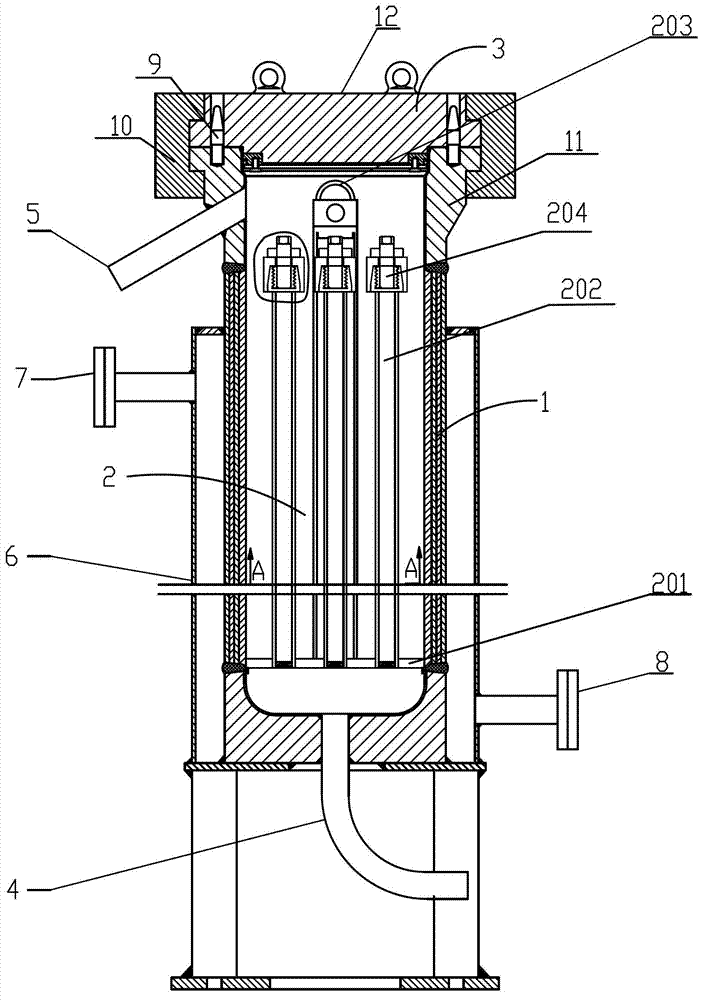

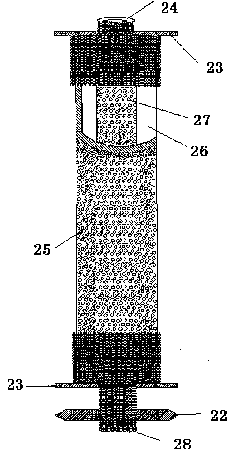

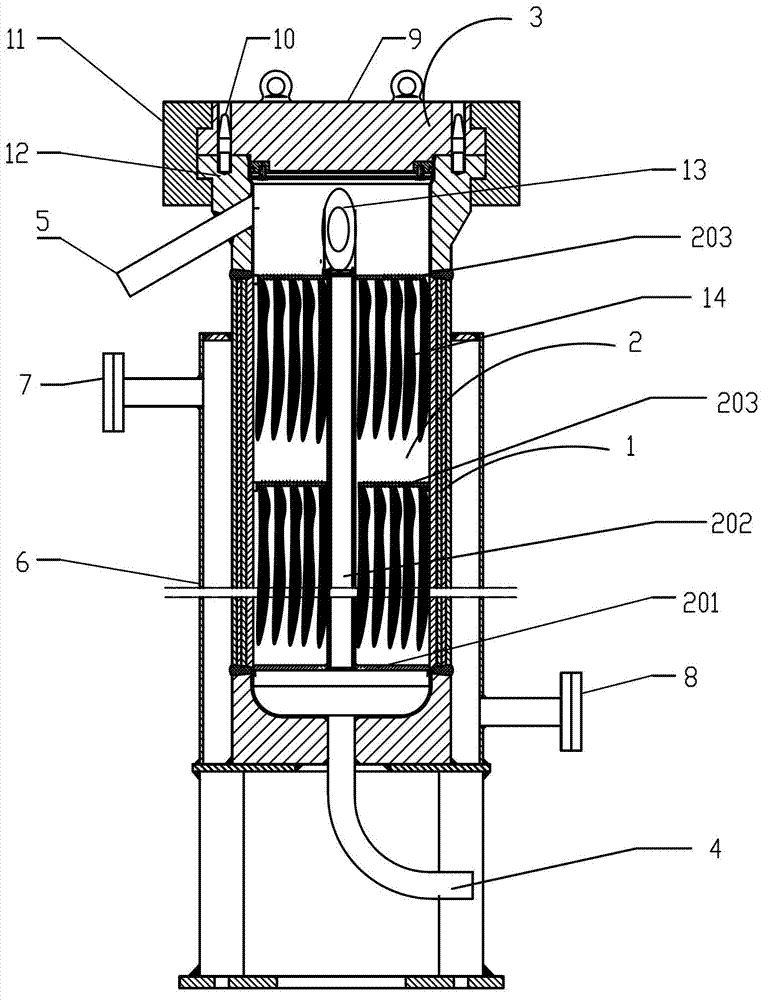

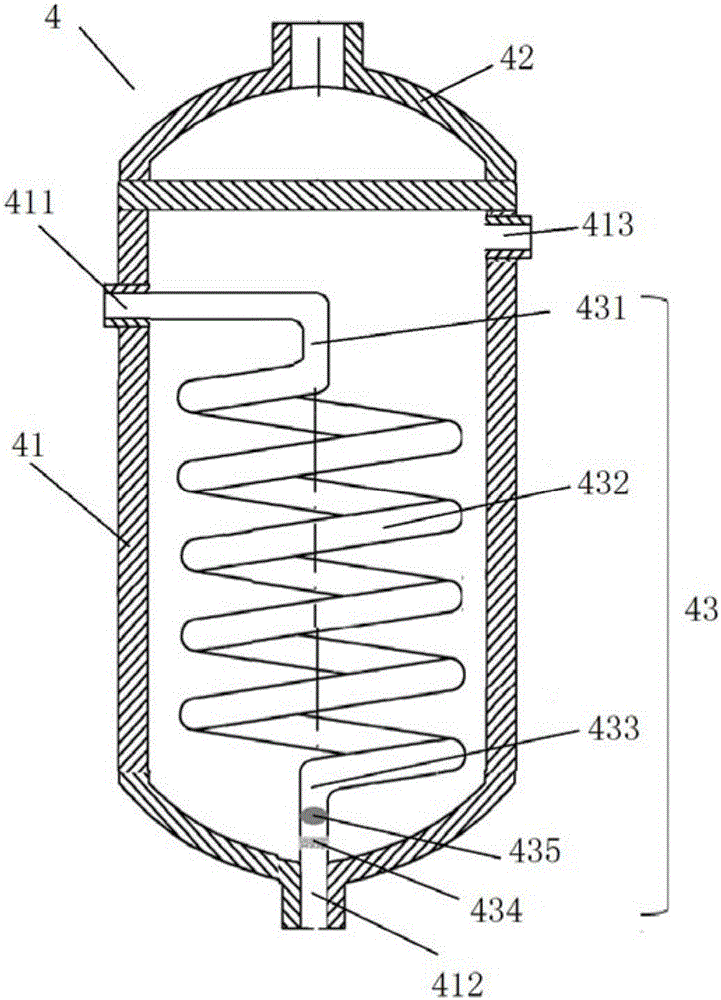

Supercritical carbon dioxide hairball dyeing kettle and waterless dyeing method thereof

ActiveCN102776738AMeet the development requirementsSimple and convenient production and processingTextile treatment containersSolvent treatment with solvent recoveryHairballSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide hairball dyeing kettle which comprises a cylinder body and a hairball dyeing barrel body fixed in the cylinder body, wherein a movable sealing cover is fixed at the upper end of the cylinder body, and the lower end of the cylinder body is provided with a carbon dioxide liquid outlet; a carbon dioxide liquid inlet is arranged at the upper part of the cylinder body; a heating clamping sleeve is fixed outside the cylinder body; a heating medium outlet is arranged at the upper end of one side of the heating clamping sleeve, and a heating medium inlet is arranged at the lower end of the other side of the heating clamping sleeve; the supercritical carbon dioxide hairball dyeing kettle is characterized in that a hole III is formed in the wall of the hairball dyeing barrel body; a central pipe is fixed to the centre of the hairball dyeing barrel body, and at least one upper limiting cover is fixed to the central pipe; the central pipe has a multi-pore shaft structure; a hole I is formed in a supporting plate at the bottom of the barrel body; a central hole Ia is corresponding to an internal chamber of the central pipe; and a hole II is formed in the upper limiting cover. According to the supercritical carbon dioxide hairball dyeing kettle increased, the direct contacting surface area of the a hairball and the dyeing liquid can be increased, and improves the influence due to the gravity in hairball dyeing can be improved, and the dyeing speed and the dye pickup can be improved, as well as the dyeing uniformity is improved.

Owner:晋江国盛新材料科技有限公司

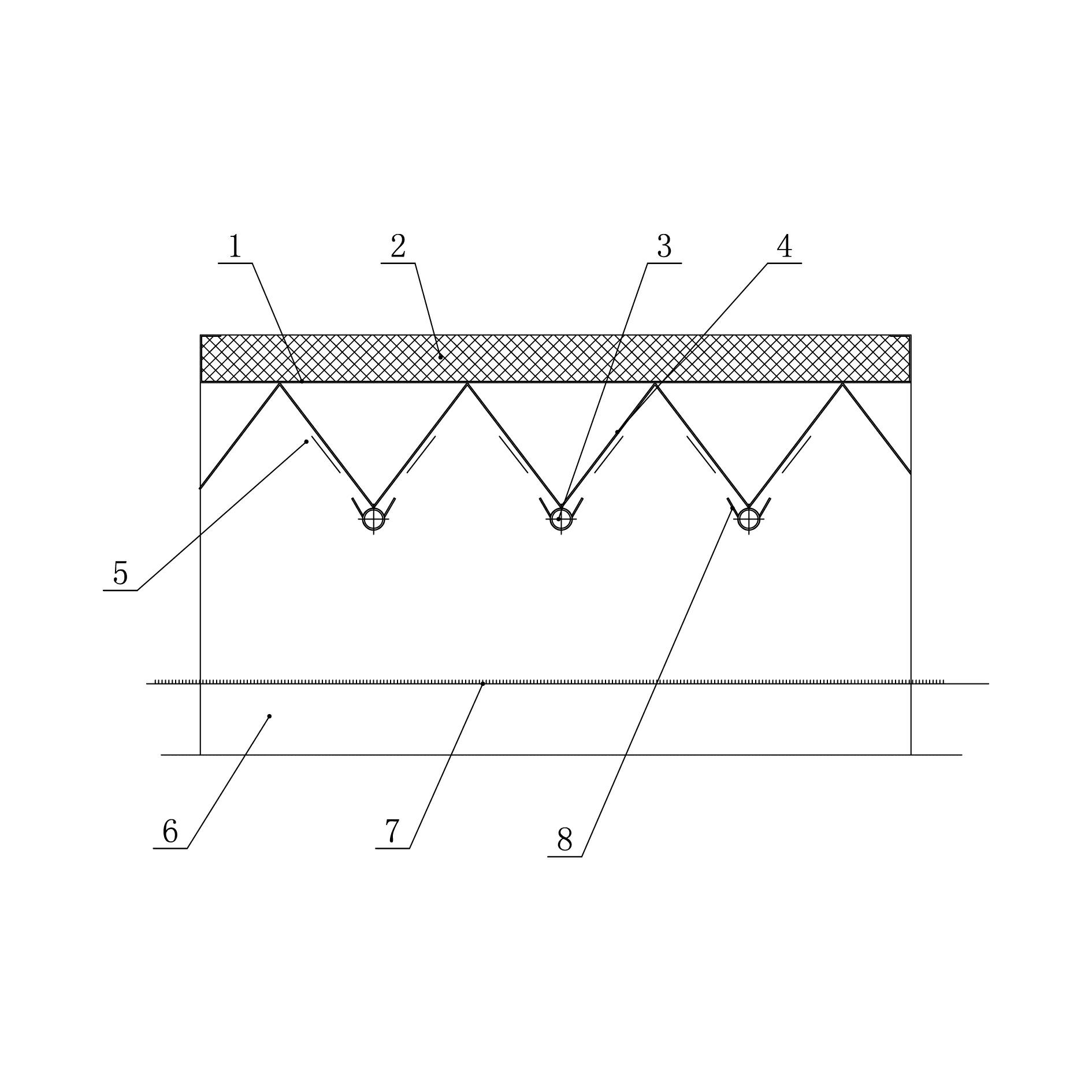

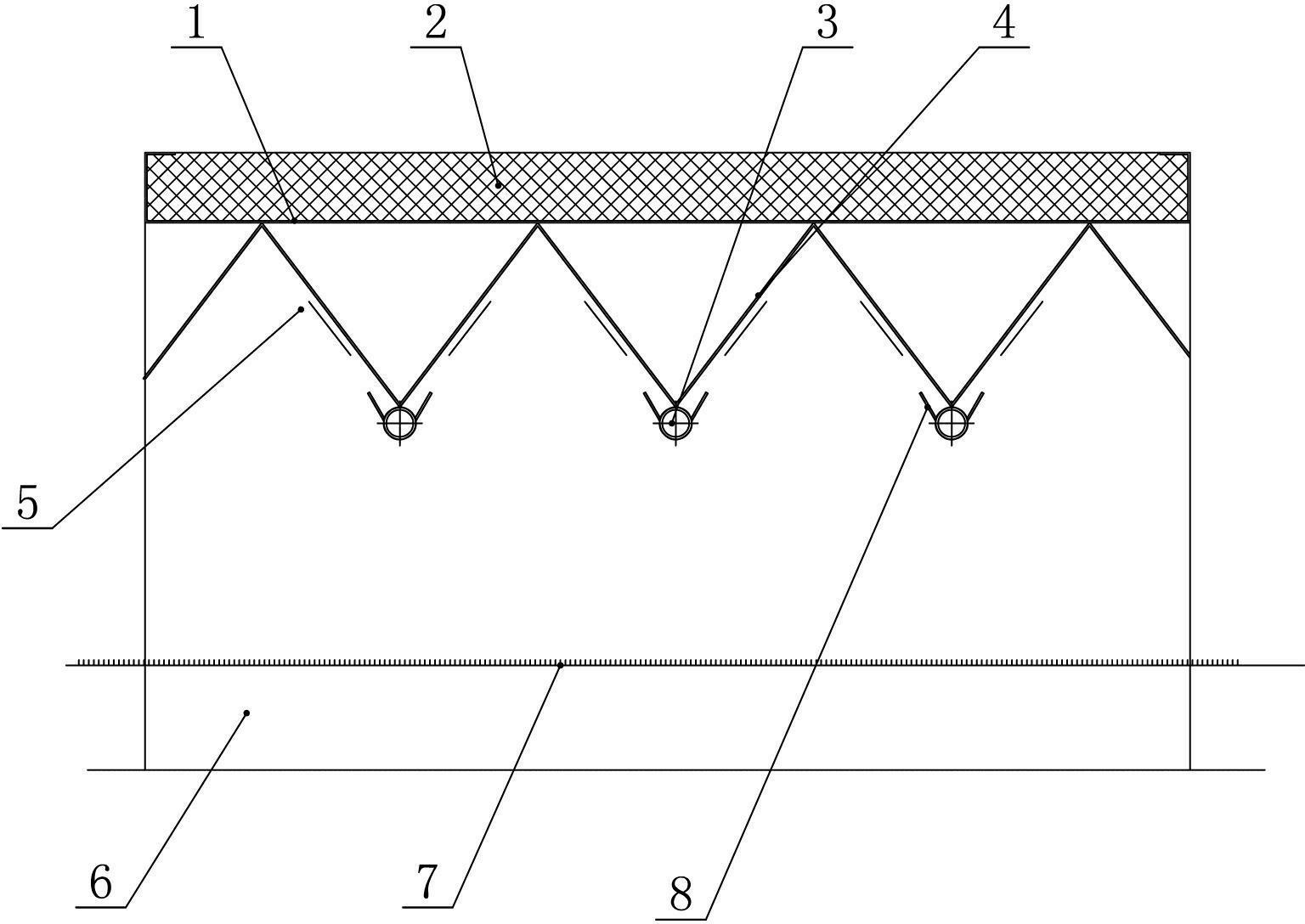

V-shaped drop-proof steaming box

InactiveCN102535069APut an end to drippingHas the function of heating and heat preservationTextile treatment containersEngineering

The invention discloses a V-shaped drop-proof steaming box comprising a box top and a steaming chamber, wherein the steaming chamber is positioned below the box top; a V-shaped groove is mounted at the lower part of the box top; an indirect heating pipe is arranged at the lower end of the bottom of the V-shaped groove; water stopping fins are mounted on two side surfaces of the indirect heating pipe; and heat insulation cotton is arranged above the box top. The V-shaped drop-proof steaming box is used in printing industries; and a V-shaped drop-proof structure simultaneously has heating and heat insulation functions to the interior of the steaming box to ensure the stable temperature in the steaming box, and can fully meet the stringent requirements on steaming conditions for printing and dyeing carpets.

Owner:山东源丰印染机械有限公司

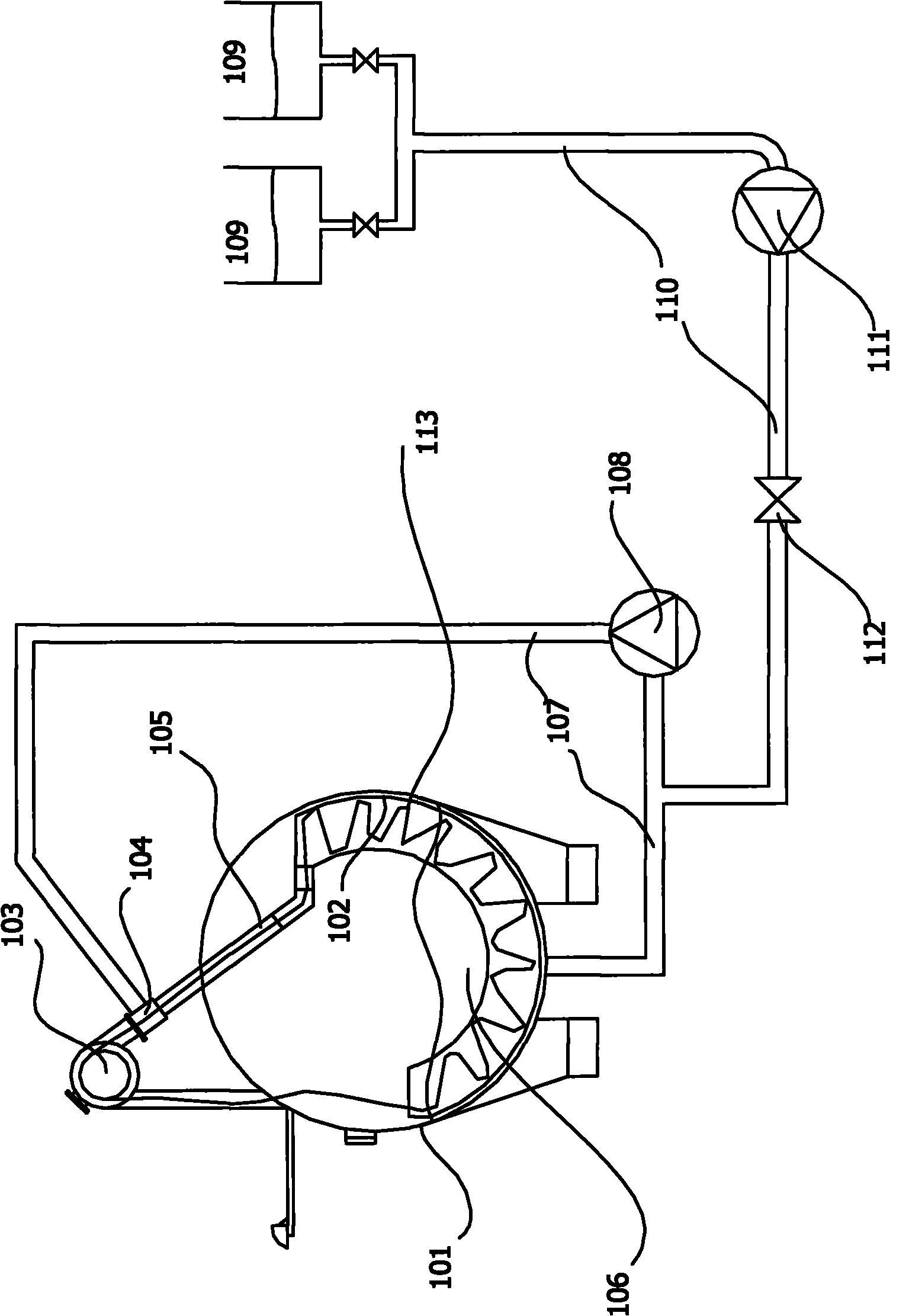

High-temperature high-pressure air flow dyeing machine

InactiveCN101280496AFully contactedReduce consumptionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsAir filterHigh pressure

The invention relates to a high temperature and high pressure air flow dyeing machine, in which the high pressure air flow is utilized for the dyeing of textiles after the dyeing atomization, which comprises a cylinder, a lifting wheel, and a feed cylinder and is characterized in that the cylinder is in a horizontal arrangement and internally provided with a dye vat. The upper wall of the cylinder corresponded to both ends of the dye vat is provided with two openings. The inside of one opening is provided with a cloth placing mechanism, and the upper part of the other opening is provided with a wheel shell communicated with the position between two openings through pipelines. The lifting wheel is disposed inside the wheel shell. The inside of the pipeline between the wheel shell and the cloth placing mechanism is provided with a nozzle and a spray head. The outside of the cylinder is provided with a heat exchanger, a feed pump and a fan. The lower part of the cylinder is provided with a backflow mechanism. The heat exchanger is provided with an inlet and an outlet. The outlet thereof is connected to a nozzle through the pipelines, and the inlet thereof is communicated with the feed cylinder, which is communicated to the bottom cavity of the cylinder through the feed pump, the backflow mechanism and the pipelines. The air outlet of the fan is linked with the spray head, and the air inlet of the fan is communicated to the cylinder through an air filter. With the adoption of such a dyeing machine to dye textiles, the production costs can be reduced.

Owner:唐佳伟

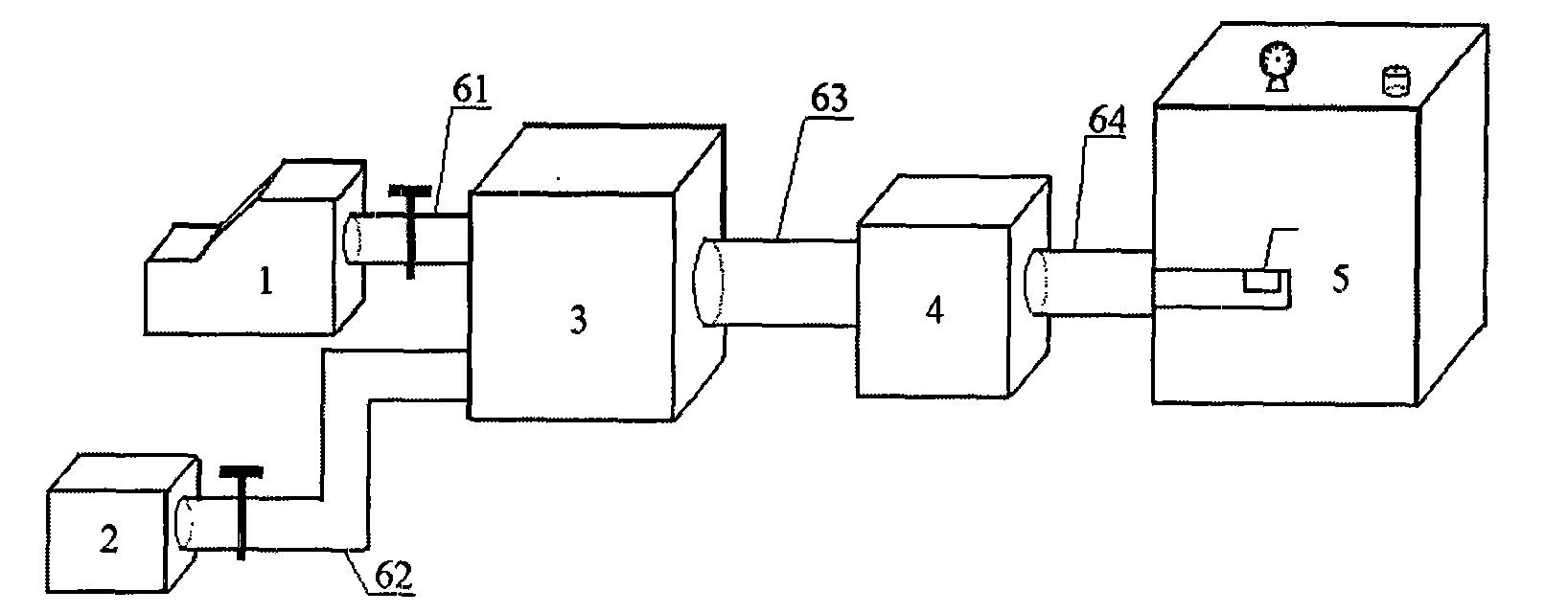

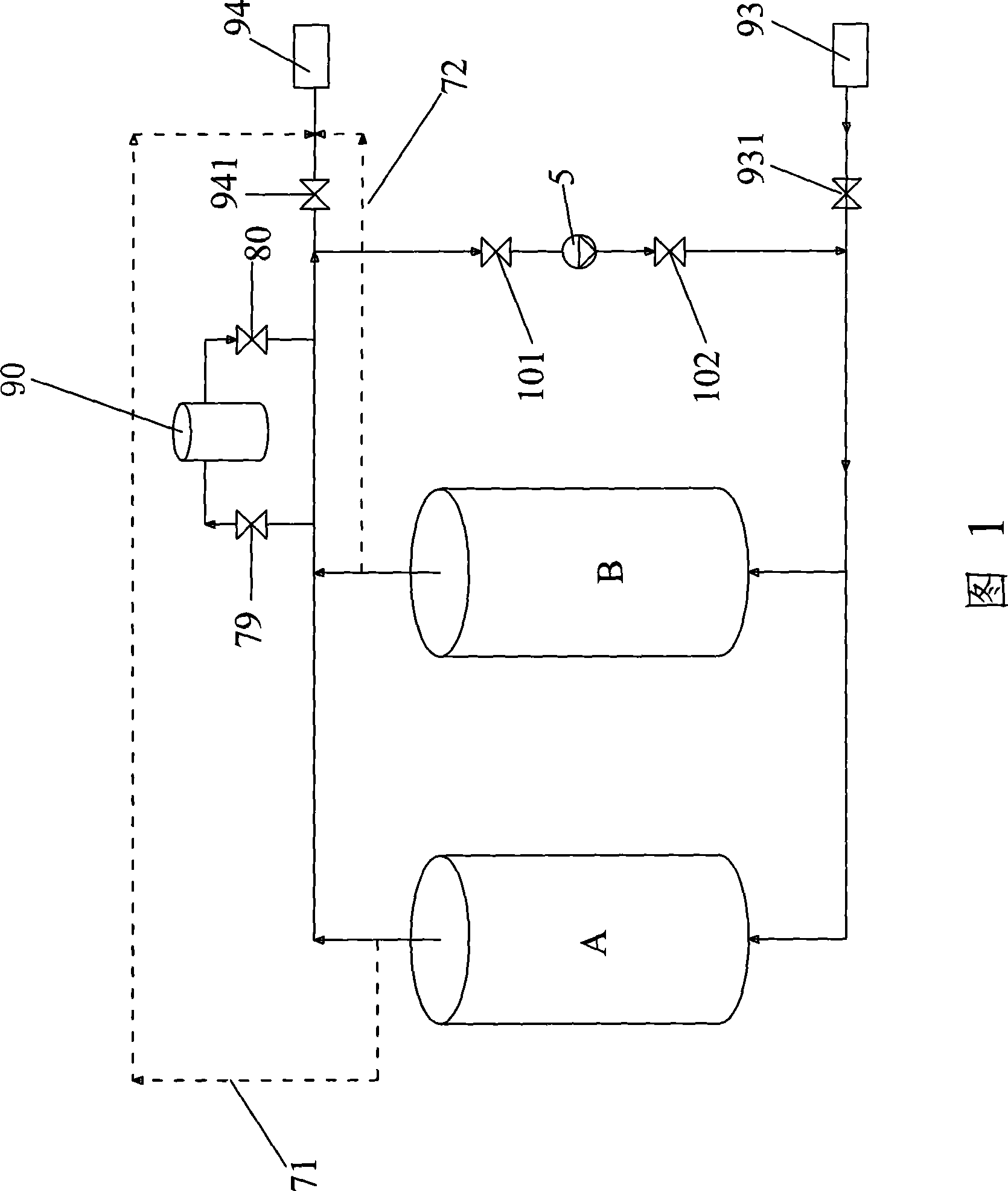

Supercritical CO2 anhydrous yarn warp dyeing system and dyeing method thereof

InactiveCN101413191ALow costIncrease capacityTextile treatment sample takingTextile treatment containersYarnProcess engineering

The invention discloses a supercritical CO2 anhydrous warp beam dyeing system and a dyeing method thereof. The system comprises a CO2 pressure supply device, a circulating pump, a separation and recovery device and two or more than two dyeing kettles which are arranged in parallel, wherein the dyeing kettles are arranged in parallel and connected in series with the circulating pump to form a closed dyeing circuit; a shutoff valve is respectively arranged on both ends of the circulating pump; the CO2 pressure supply device and the separation and recovery device are connected between the shutoff valves and the dyeing kettles respectively; and an outlet of each dyeing kettle is connected with an independent recovery bypass which is communicated with the separation and recovery device and independent of the closed dyeing circuit which is formed by the dyeing kettles and the circulating pump, so that different dyeing kettles can perform dyeing and recovery of CO2 simultaneously. The system can perform dyeing and recovery of the CO2 simultaneously and respectively, reduces consumption of the CO2 to the maximum degree, reduces the cost, can realize discontinuous operation and improve the production efficiency, and has quick dyeing speed.

Owner:HONG KONG PRODUCTIVITY COUNCIL

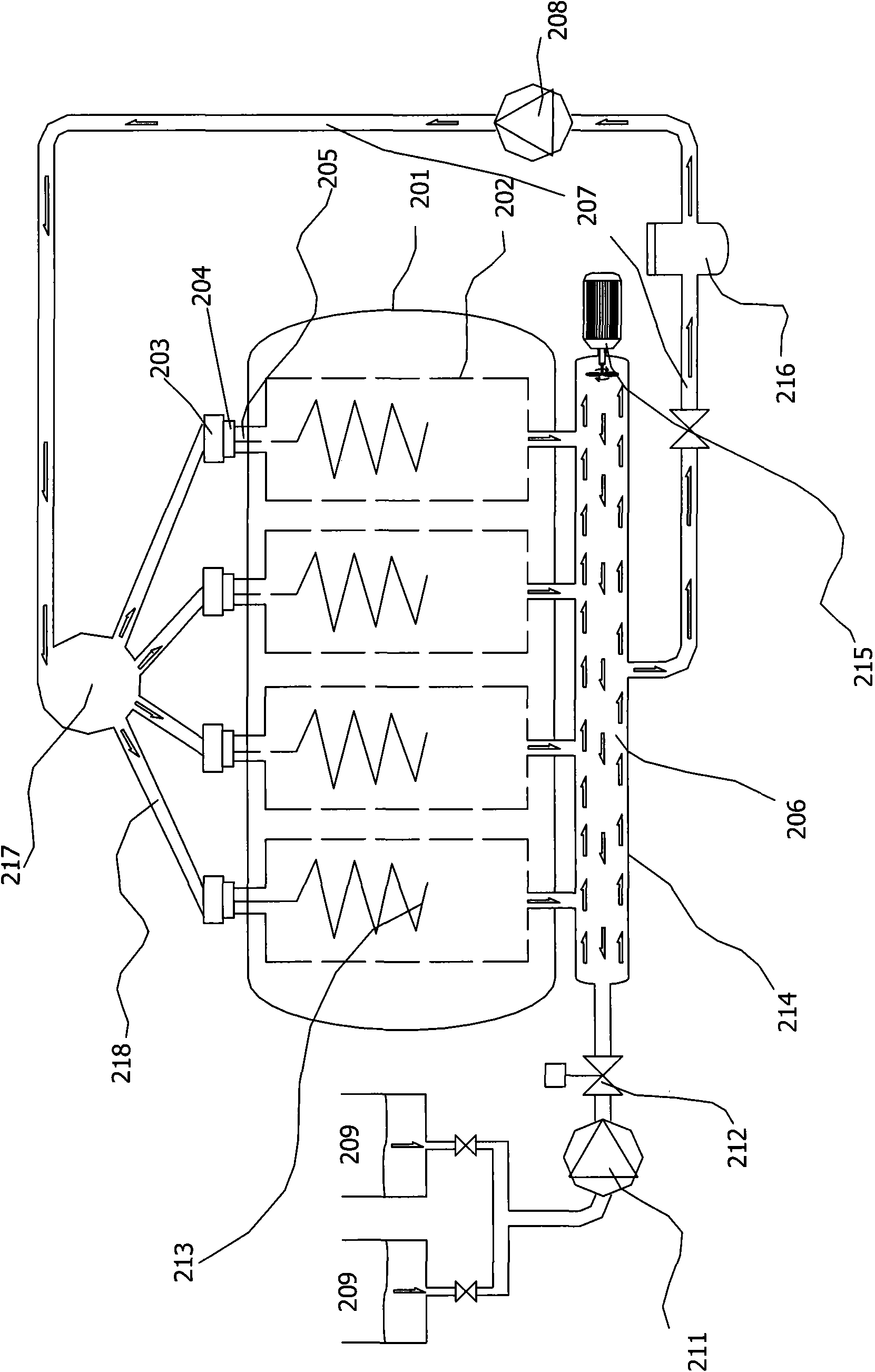

Overflow dyeing machine

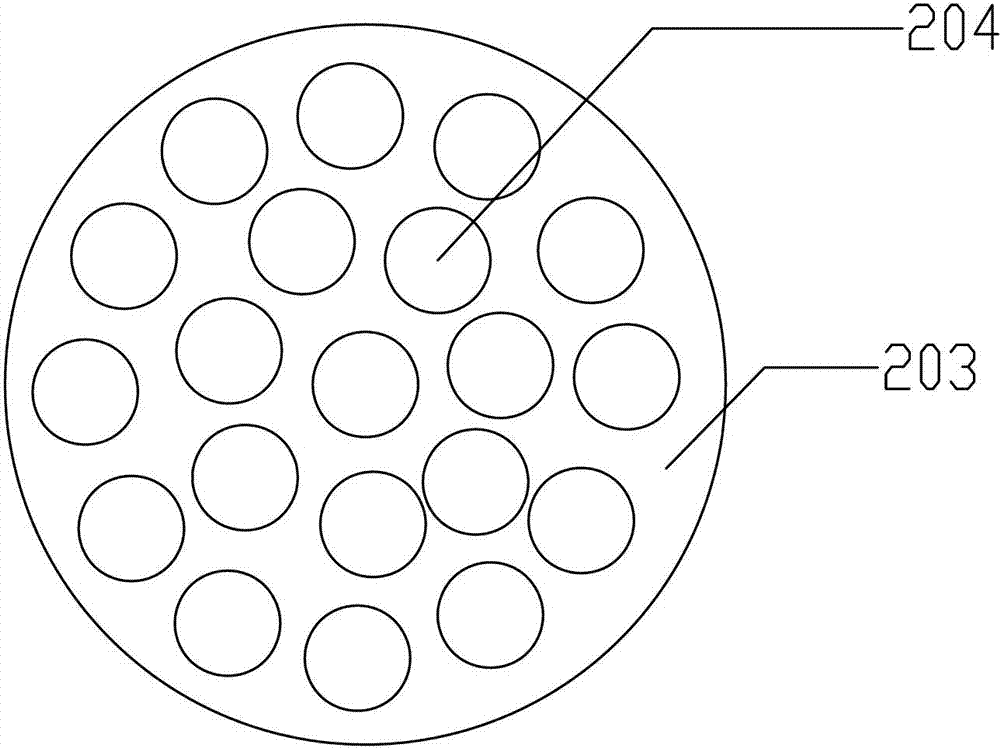

InactiveCN101962887ASimple structureWell mixedTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsLiquid storage tankEngineering

The invention discloses an overflow dyeing machine. The overflow dyeing machine comprises a main machine body (201), wherein a dye vat (202) is arranged in the main machine body (201); a cloth lifting pulley (203) is arranged outside the main machine body (201); nozzles (204) are arranged over the main machine body (201); the outlet of the dye vat (202) is communicated with the inlets of the nozzles (204) through a circulation pipeline (207); the outlet of a chemical material vat (209) is communicated with the circulation pipeline (207); a liquid storage tank (214) is also arranged on the circulation pipeline (207); the liquid storage tank (214) is communicated with the outlet of the chemical material vat (209) and the outlet of the dye vat (202) respectively; and a main pump (208) is arranged on the circulation pipeline (207) which connects the outlet of the liquid storage tank (214) and the inlets of the nozzles (204). The overflow dyeing machine provided by the invention has the advantages that: the structure is simple; a dyeing liquid is uniformly mixed; due to the liquid supply balance among the plurality of nozzles, surface contamination of a fabric and blockage of the nozzles is effectively prevented and dyeing is more uniform; the working efficiency is improved; and the technical time is shortened.

Owner:田立法

Double-vat-body dyeing machine

InactiveCN103526483AAvoid entanglementStir wellTextile treatment sample takingTextile treatment containersYarnHydraulic cylinder

The invention relates to a dyeing device used in the textile industry, in particular to a double-vat-body dyeing machine. The double-vat-body dyeing machine comprises a dye vat and yarn hangers arranged in the dye vat, wherein the dye vat is divided into a left vat body and a right vat body by a division board. The double-vat-body dyeing machine is characterized in that a braking chamber is arranged in the center of the vat, and a hydraulic cylinder and a rotating shaft which is fixedly connected with the hydraulic cylinder are arranged in the braking chamber; the rotating shaft is movably connected with a transverse frame, and the yarn hangers are fixedly installed on the transverse frame. Due to the adoption of the structure and the double-vat-body structural design, yarns to be dyed with two different colors can be dyed at the same time; through the matching of the braking chamber, the rotating shaft and the transverse frame, a stirring device capable of rotating by 180 degrees is formed, and the phenomenon of yarn twisting caused by large-amplitude rotation is avoided; through the matching of the transverse frame and a square groove in the braking chamber, the transverse frame can move vertically, accordingly, dye liquor can be stirred more sufficiently, and a better dyeing effect can be achieved.

Owner:WUJIANG KESHIDA TEXTILE

Supercritical dyeing pot

InactiveCN101148813AConsistent color yieldGuaranteed stabilityTextile treatment containersDyeing processYarnTextile printer

The present invention is one supercritical dyeing tank, and belongs to the field of textile printing and dyeing equipment making technology. The supercritical dyeing tank consists of one tank, two driving shafts with winding roller inside the tank, two motors outside the tank in the locations corresponding to the driving shafts, one permanent magnet and one magnetic coupler separately inside and outside the tank, one ball channel with balls between the permanent magnet and the tank, etc. Two winding rollers with wound fabric or yarn can rotate in both forward and reverse directions, so that the fabric or yarn can move inside the dyeing tank under supercritical state for contacting with the dye uniformly and homogeneous dyeing.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Woolen sweater dyeing machine

InactiveCN105568594ASituation that causes knotsReduce usageTextile treatment containersLiquid/gas/vapor article treatmentDyeing wastewaterAtmospheric pressure

The invention relates to the field of dyeing equipment, in particular to a woolen sweater dyeing machine. The woolen sweater dyeing machine comprises a machine frame, wherein a rotary drum is arranged on the machine frame, the outside of the rotary drum is wrapped with a layer of outer housing, a power mechanism in driving connection with the rotary drum is arranged on the machine frame, and a dye atomization mechanism, an air pressure balancing mechanism and a steam heating mechanism are arranged on the machine frame. Two main baffles are arranged on the inner wall of the rotary drum at an interval, an auxiliary baffle is arranged between the adjacent main baffles, and one or more radial shifting rods are arranged on the radial end face of each main baffle. A feeding door is arranged on the rotary drum between one group of adjacent main baffles and the auxiliary baffle and on the outer housing. The woolen sweater dyeing machine is simple in structure, can effectively utilize the rotary drum to dye woolen sweaters, does not cause a knitting phenomenon, is stable in using performance and reduces the using amount of water for dyeing and discharge of dyeing wastewater.

Owner:TONGXIANG NEW ERA FUR

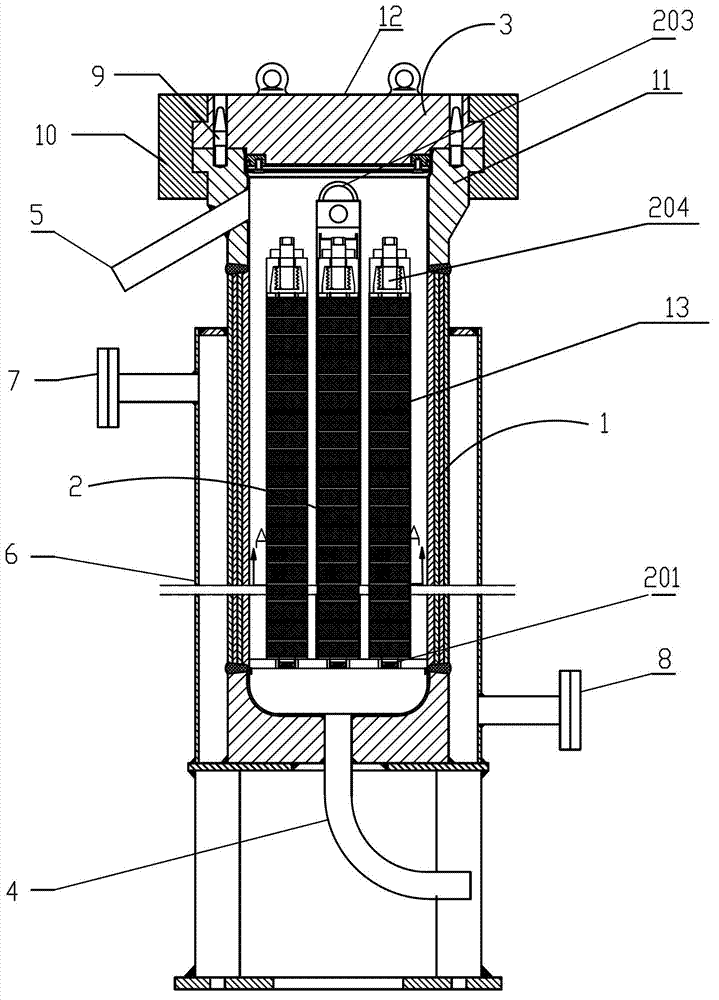

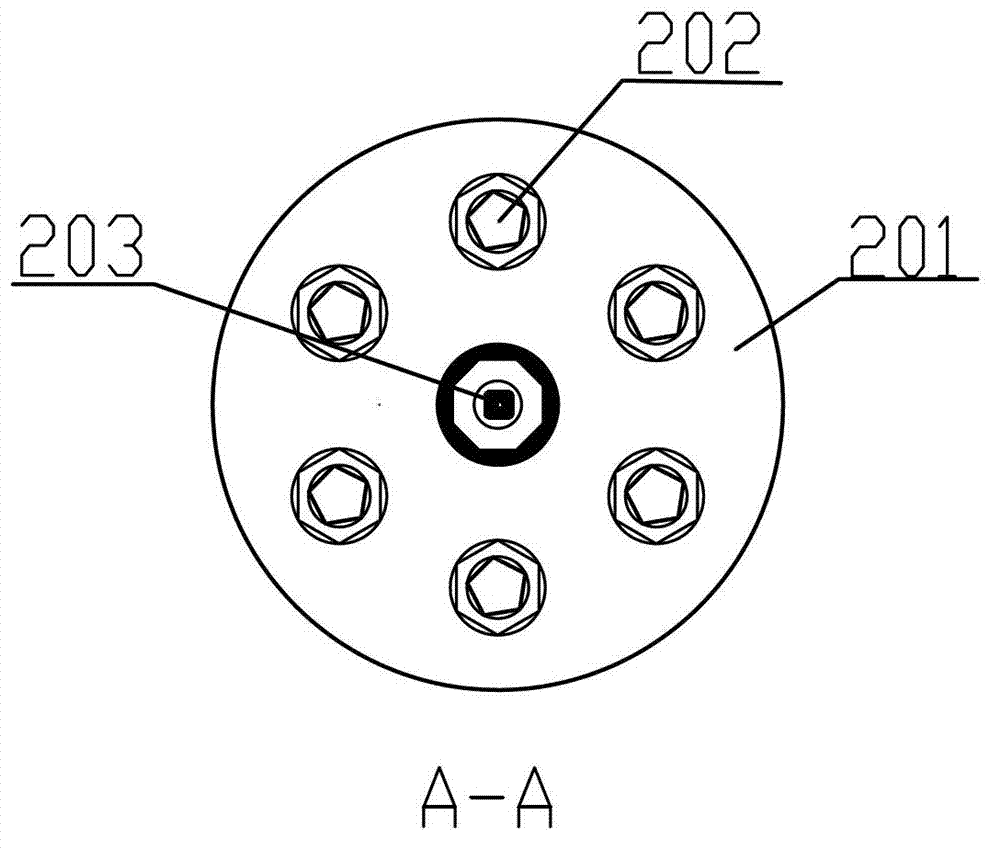

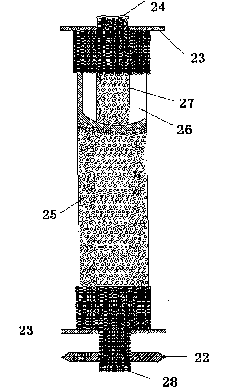

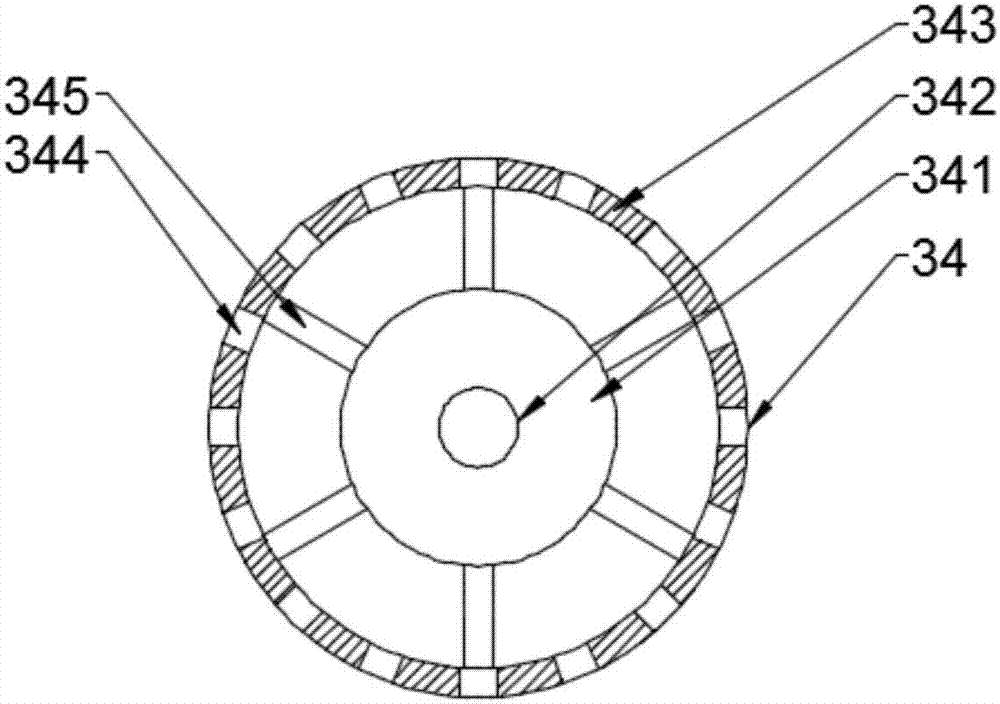

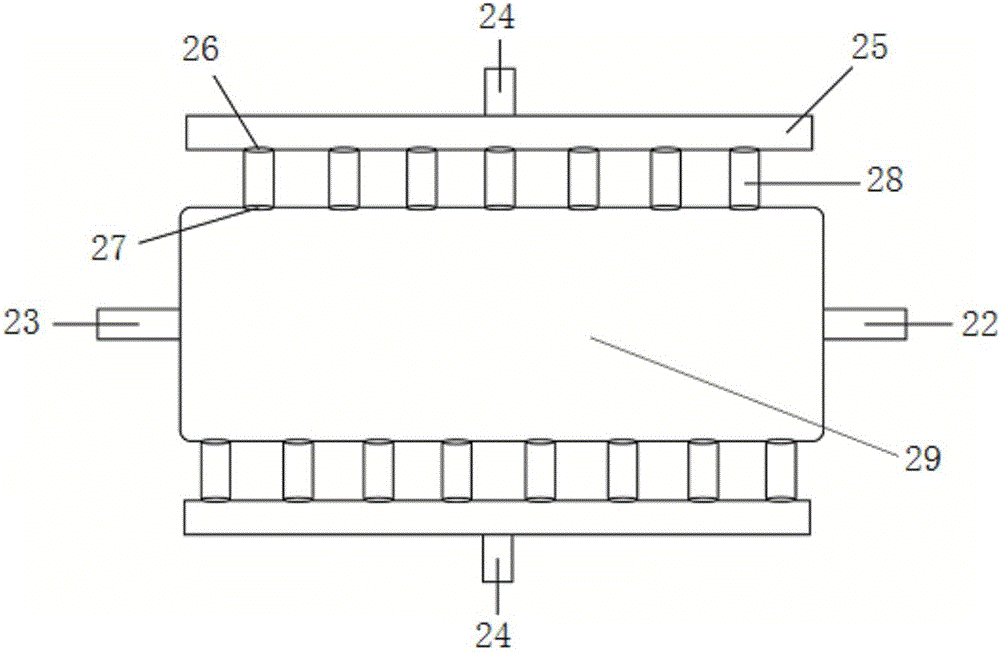

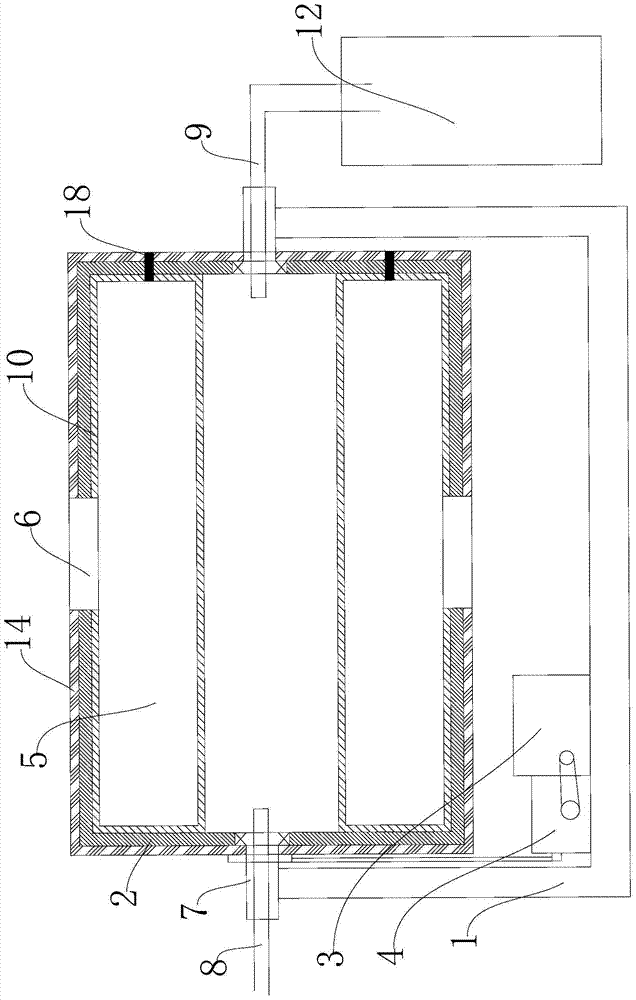

Supercritical carbon dioxide skein dyeing kettle and waterless dyeing method thereof

ActiveCN102776739AGood level dyeingHigh fastnessTextile treatment containersSolvent treatment with solvent recoveryDistributorSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide skein dyeing kettle which comprises a cylinder and a skein support. The skein support is fixed in the cylinder; a movable sealing cover is fixed at the upper end of the cylinder, a carbon dioxide fluid inlet is arranged at the lower end of the cylinder, and a carbon dioxide fluid outlet is further arranged on the upper portion of the cylinder; a heating jacket is fixed on the outer side of the cylinder; a heating medium outlet is arranged at the upper end of one side of the heating jacket, and a heating medium inlet is arranged at the lower end of the other side of the heating jacket. The supercritical carbon dioxide skein dyeing kettle is characterized in that the skein support consists of a bottom distributor, a supporting tube and two skein frames; the two skein frames are fixed on the supporting tube; the supporting tube is fixed on the bottom distributor and is of a porous shaft structure; a hole is arranged on the bottom distributor; and an inner cavity of the supporting tube corresponds to the hole I.

Owner:晋江国盛新材料科技有限公司

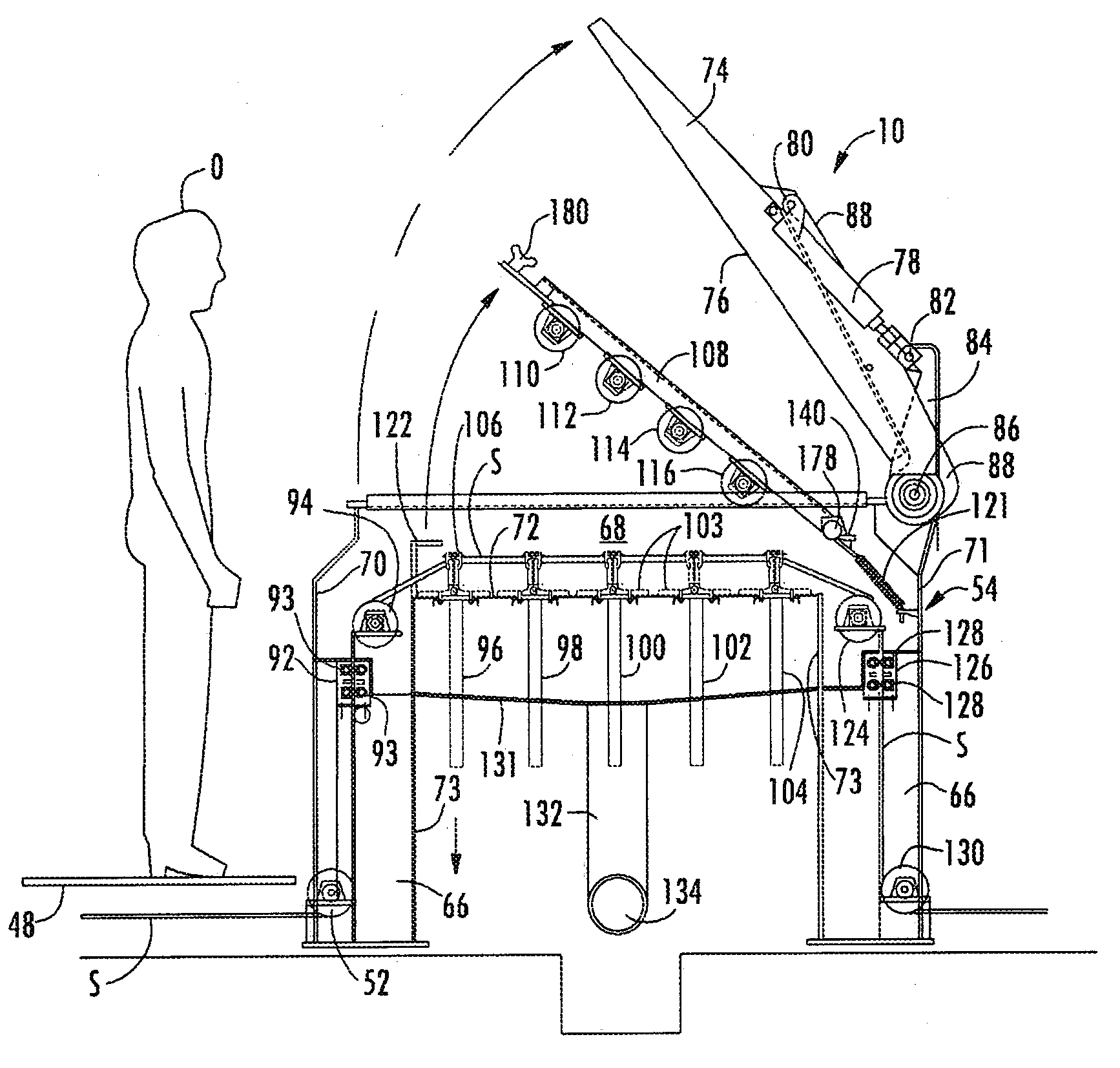

Apparatus for dyeing textile substrates with foamed dye

ActiveUS7913524B2Increases the amount of inert nitrogen in the chamber environmentReduce tensionTextile treatment containersOther washing machinesEngineeringIndigo dye

An apparatus for dyeing a textile substrate using a plurality of applicators that each apply an increment of a total dye application. In one form a reduced indigo dye in a leuco-state is applied in an inert atmosphere substantially isolated from oxidizing substances. In another form the foamed dye is applied while open to the atmosphere. In both forms holddown rollers or inverted applicators are located between applicators at decreasing depths to minimize increases in tension as the substrate travels over successive applicator faces.

Owner:GASTON SYST INC

High-efficiency oil-removing washing machine

PendingCN107604568ASolve anti-stickingSolve cleanupSucessive textile treatmentsTextile treatment containersWater resourcesWater flow

The invention discloses a high-efficiency oil-removing washing machine. The high-efficiency oil-removing washing machine includes a washing machine box, washing grooves are formed in the washing machine box, detachable water grooves are mounted on the portions, above cloth rollers, of the interiors of the washing grooves through brackets, and the detachable water grooves are convenient to mount and clean; cloth guide rolls are mounted on the portions, above the detachable water grooves, of the interior of the washing machine box, and spray devices are mounted on the portions, above the cloth guide rollers, of the interior of the washing machine box; after entering the washing machine box, fabric firstly is subjected to spray washing through the spray devices and then passes through gaps between the washing grooves and the detachable water grooves, the fabric is washed by means of water flow and the cloth rollers, the washing process is long, and effects are good; filter screen devicesare mounted at openings in the tops of the detachable water grooves, after being filtered by the filter screen devices, and circulating water is input into an oil-removing filter to carry out secondary oil removing and then is input into the washing grooves to be used for washing. By the adoption of the high-efficiency oil-removing washing machine, the problems of sticking and cleaning in an oil-removing washing technology are solved, energy consumption is reduced, water resources are saved, the automation degree of the washing technology is improved, operation processes are simplified, and labor costs are reduced.

Owner:SHAOXING LIANKE MACHINERY

Cloth dyeing and drying integrated machine

InactiveCN107419464ADyeing completion time shortenedEase of mass productionTextile treatment containersLiquid/gas/vapor removalElectric machineryEngineering

The invention discloses a cloth dyeing and drying integrated machine, which comprises a machine body, a stirring box, a cloth dyeing box and a drying device. The top of the machine body is provided with a stirring box and a blower. The top wall of the inner cavity is provided with a revolving air box, a rotating shaft is provided in the mixing box, an air passage is provided in the rotating shaft, a number of stirring tubes are uniformly arranged on the rotating shaft, and a finished product roller and a drying device are arranged in sequence from left to right in the body. , dyeing box and raw material roller, the left and right side walls of the dyeing box are respectively provided with discharge holes and feeding holes, the inner cavity of the dyeing box is provided with a guide roller group and a dyeing roller group, and the inner cavity of the dyeing box is topped. The wall is equipped with a spraying device, and the drying device includes an air outlet hood, a heating box and a blower; the present invention realizes all processing procedures from rendering to drying of white cloth by setting a dyeing box and a drying device on the body, so that the dyeing of the cloth The time is greatly shortened, which is convenient for large-scale production; the setting of the mixing box can homogenize the dyes for dyeing cloth, which is convenient for later coloring of the cloth.

Owner:冯飞燕

Energy-saving dyeing apparatus for textile

InactiveCN101294339AImprove thermal efficiencySave electricityTextile treatment containersTextile treatment machine arrangementsUltrasonic sensorLow voltage

An energy-conserving textile dyeing device comprises a metal dye vat (10) and liquid transport pipes (20), wherein a heat pump heating unit (31), an electromagnetic heating unit (32) and a low-voltage electric heating unit (33) of a heating device (30) are arranged on the dye vat (10); and an inorganic anticorrosive coating (40) is applied on the inner surfaces of the dye vat (10) and the liquid transport pipes. An ultrasonic transducer (60) is also arranged in the dye vat (10), and a heat insulating layer (80) is applied on the outer surfaces of dye vat (10) and the liquid transport pipes (20). By adopting the above technical scheme, the novel dyeing device has the advantages of high heat efficiency, reduced power consumption, less heat loss and good dyeing effect, thus reducing the production cost and protecting the environment.

Owner:杨栋 +1

Reduction steam box

InactiveCN106521852APrevent spillageIncrease profitTextile treatment containersTextile treatment carriersEngineeringMoisture sensor

The invention discloses a reduction steam box. The box comprises a steam box body, a steam generator and a controller. The steam box body bottom surface is provided with support legs. A cloth guide roller and a moisture sensor are placed in the steam box body. The inner upper side of the steam box body is provided with a steam chamber. The bottom surface of the steam chamber is evenly provided with several steam through holes. The steam generator is connected with the steam chamber through a steam pipe. The steam pipe is provided with an motor regulation valve. The left side of the steam box body is provided with a cloth entrance and two cloth entrance gland devices. The right side of the steam box body is provided with a cloth exit and two cloth exit gland devices. The cloth entrance gland device and the cloth exit gland device are connected by the steam pipe and the steam generator. The box enhances the temperature and moisture uniformity in the steam box body, reduces the steam leakage in the steam box, and enhances the fabric quality and the utilization rate of steam.

Owner:宿迁市恒信纺织有限公司

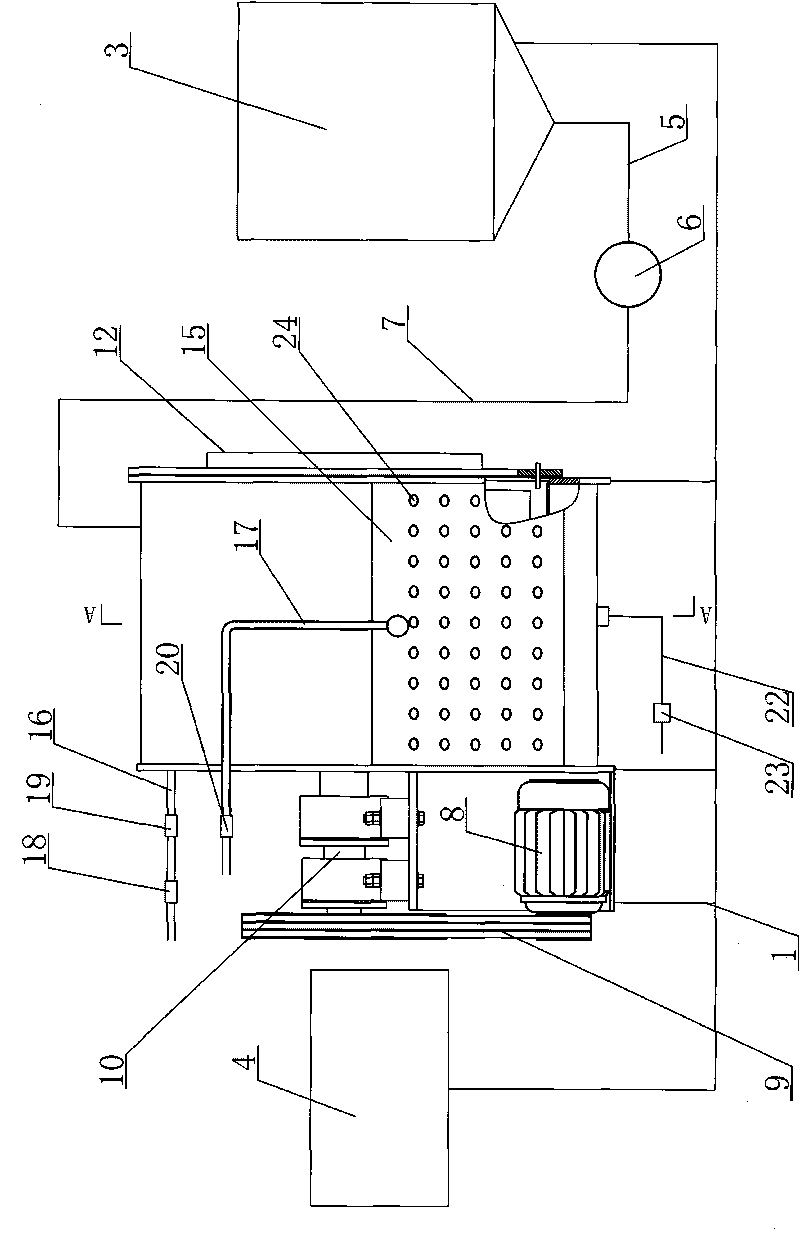

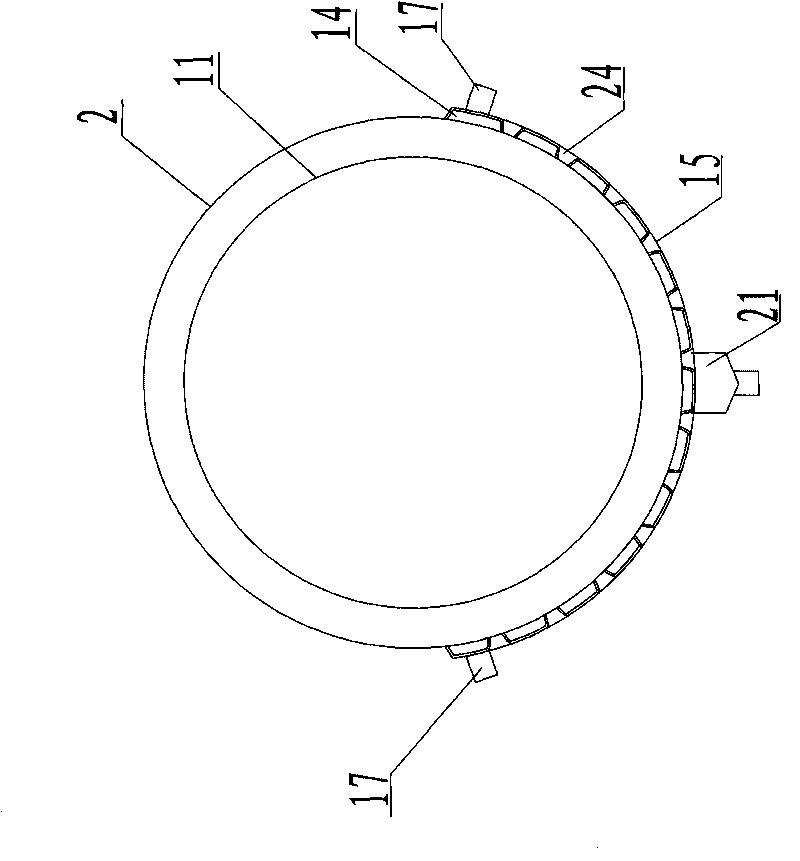

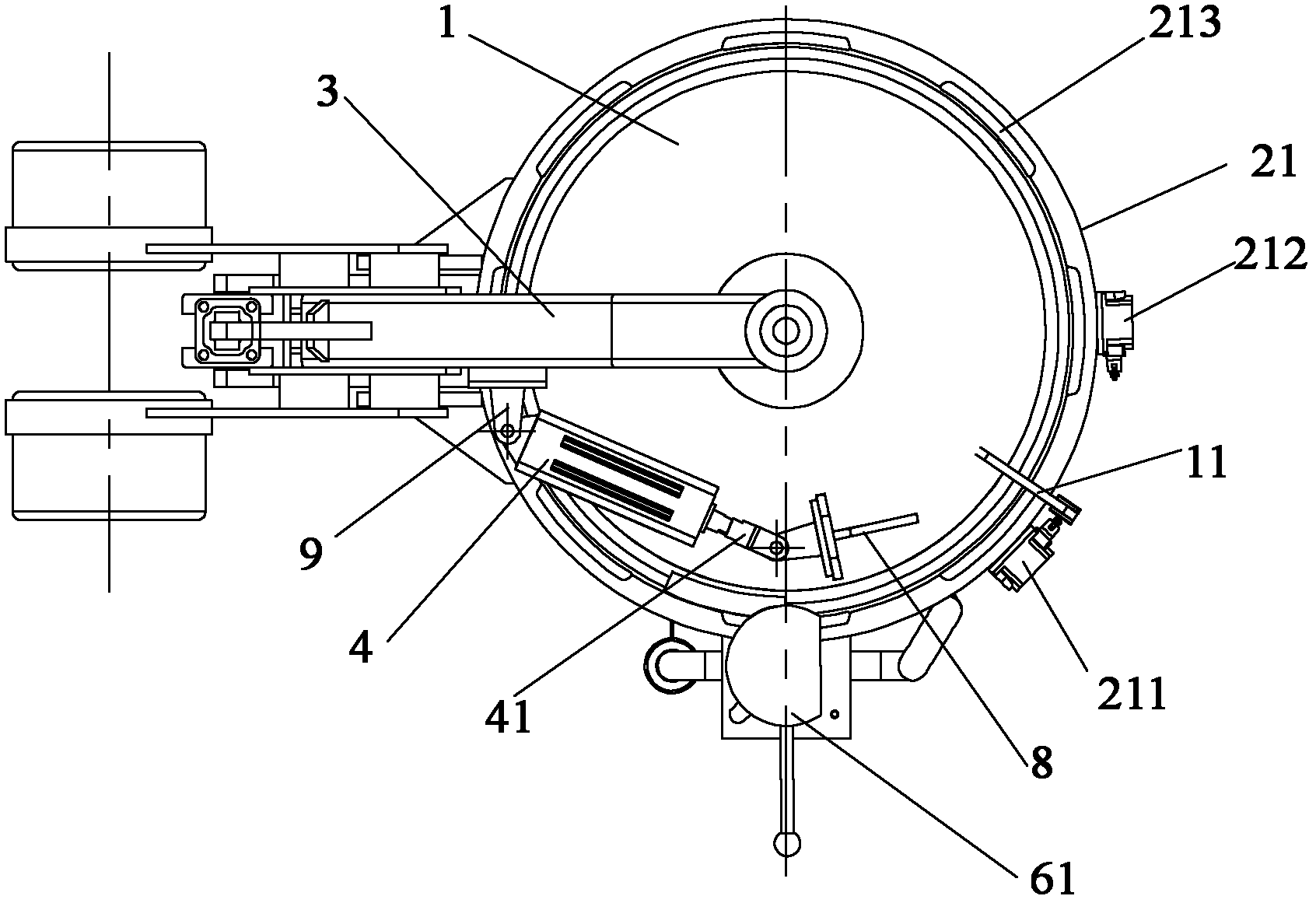

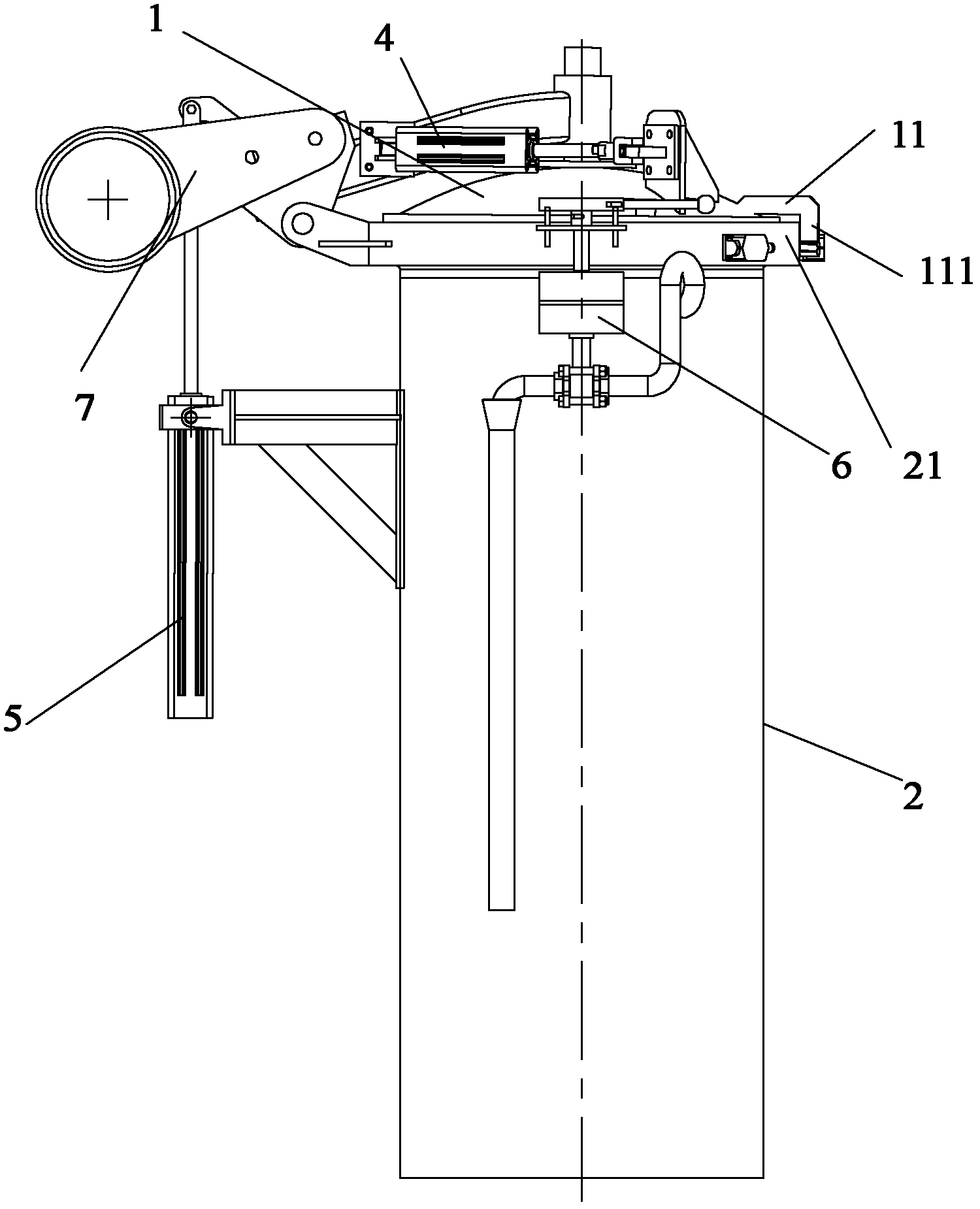

Automatic cylinder cover locking device and cheese dyeing machine comprising same

ActiveCN102587054ALarge operating forceLabor savingTextile treatment containersLiquid/gas/vapor treatment of definite length materialsEngineeringMechanization

The invention provides an automatic cylinder cover locking device and a cheese dyeing machine with the automatic cylinder cover locking device. The automatic cylinder cover locking device is arranged between a cylinder cover and a cylinder body, the cylinder cover is provided with teeth uniformly distributed along the circumference, the upper end of the cylinder body is provided with a clamping hoop supporting the cylinder cover, the clamping hoop is provided with an annular groove for holding the teeth and an annular flange positioned above the annular groove, and the annular flange is provided with slots matched with the teeth. The automatic cylinder cover locking device also comprises a suspension arm and a driving device, wherein the suspension arm is arranged above the cylinder cover, a first end of the suspension arm is pivoted with the cylinder cover, and a second end of the suspension arm is pivoted with the clamping hoop; the driving device is provided with a driving end which is connected to a position on the cylinder cover, deviating from the central axis of the cylinder cover, to drive the cylinder cover to rotate around the central axis of the cylinder cover, so as to lock or unlock the cylinder cover. With the automatic cylinder cover locking device and the cheese dyeing machine with the automatic cylinder cover locking device, labor force is saved, the production efficiency is high, the labor cost is lowered, the mechanization level and automation level of equipment are improved, and realization of automatic production is facilitated.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Flax thick yarn supercritical CO2 biological enzyme scouring device and scouring method thereof

ActiveCN106676788AReduce usageReflect the concept of modern lifeTextile treatment containersTextile treatment machine arrangementsYarnBreaking strength

The invention discloses a flax thick yarn supercritical CO2 biological enzyme scouring device and a scouring method thereof. Flax thick yarn is placed in supercritical CO2 fluid where a biological enzyme scouring agent is dissolved, flax fibers are swollen for 10-30 min at 30-40 DEG C and 8-15 MPa; the flax thick yarn is scoured for 30-60 min under dynamic conditions of a flow velocity of supercritical CO2 at 10-50 g / min at 40-60 DEG C and 15-25 MPa; the flax thick yarn is processed through a scouring-separation combined process for 10-30 min at 40-60 DEG C and 15-25 MPa; after the scouring, the weight loss rate of the flax thick yarn is 6-12%, the residual gum rate is 7-15%, the single fiber breaking strength is 6-13 cN / dtex, and the elongation at break is 4.5-8.5%. The whole scouring process is free of pollution and has zero release, requirements of commercialized production are met, and the modern life idea of fashionable bast fiber spinning and green bast fiber spinning is embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

Efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine and fur dyeing method

InactiveCN103938383AConsistent temperatureAvoid wastingTextile treatment containersLiquid/gas/vapor treatment machines driving mechanismsMotor driveEngineering

The invention relates to the field of fur dyeing devices, in particular to an efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine which can simultaneously conduct dyeing of different colors on fur. The efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine comprises a machine frame, an outer cavity, a motor, a gearbox and dyeing cylinders, wherein the motor drives the outer cavity to rotate through the gearbox, the outer cavity is connected with the machine frame through shafts at the two ends, the dyeing cylinders are fixed inside the outer cavity and make contact with the inner wall of the outer cavity, feeding doors are formed in the positions where the dyeing cylinders make contact with the inner wall of the outer cavity, and a plurality of partition plates are arranged in the annular wall in each dyeing cylinder at equal intervals. Fur raw materials, corresponding dye and corresponding additives can be added to different dyeing cylinders, and therefore dyeing of different colors can be simultaneously conducted on fur, production efficiency is improved, and meanwhile energy waste can be avoided; by means of heating conducted through steam, the temperature inside the whole outer cavity can be kept uniform, and therefore the temperatures of the dyeing cylinders are kept the same, and the dyeing effect is improved.

Owner:TONGXIANG NEW ERA FUR

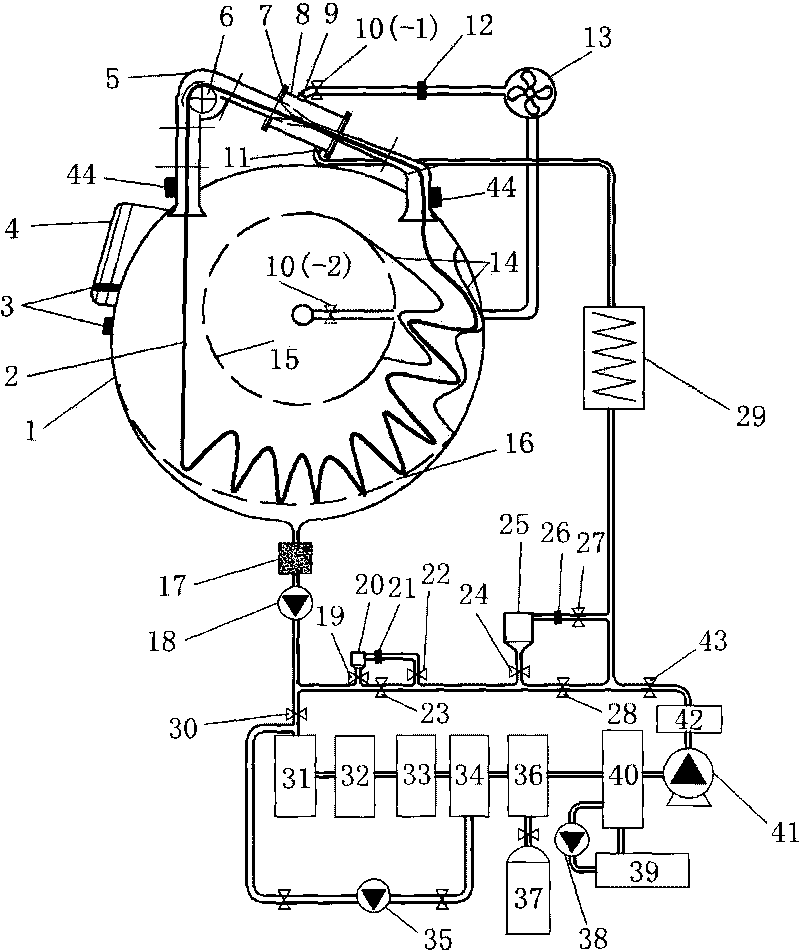

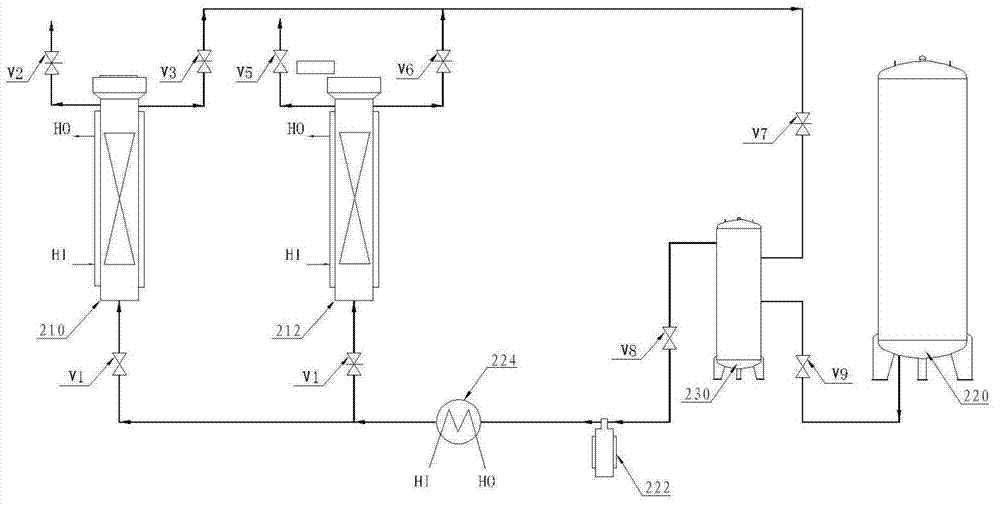

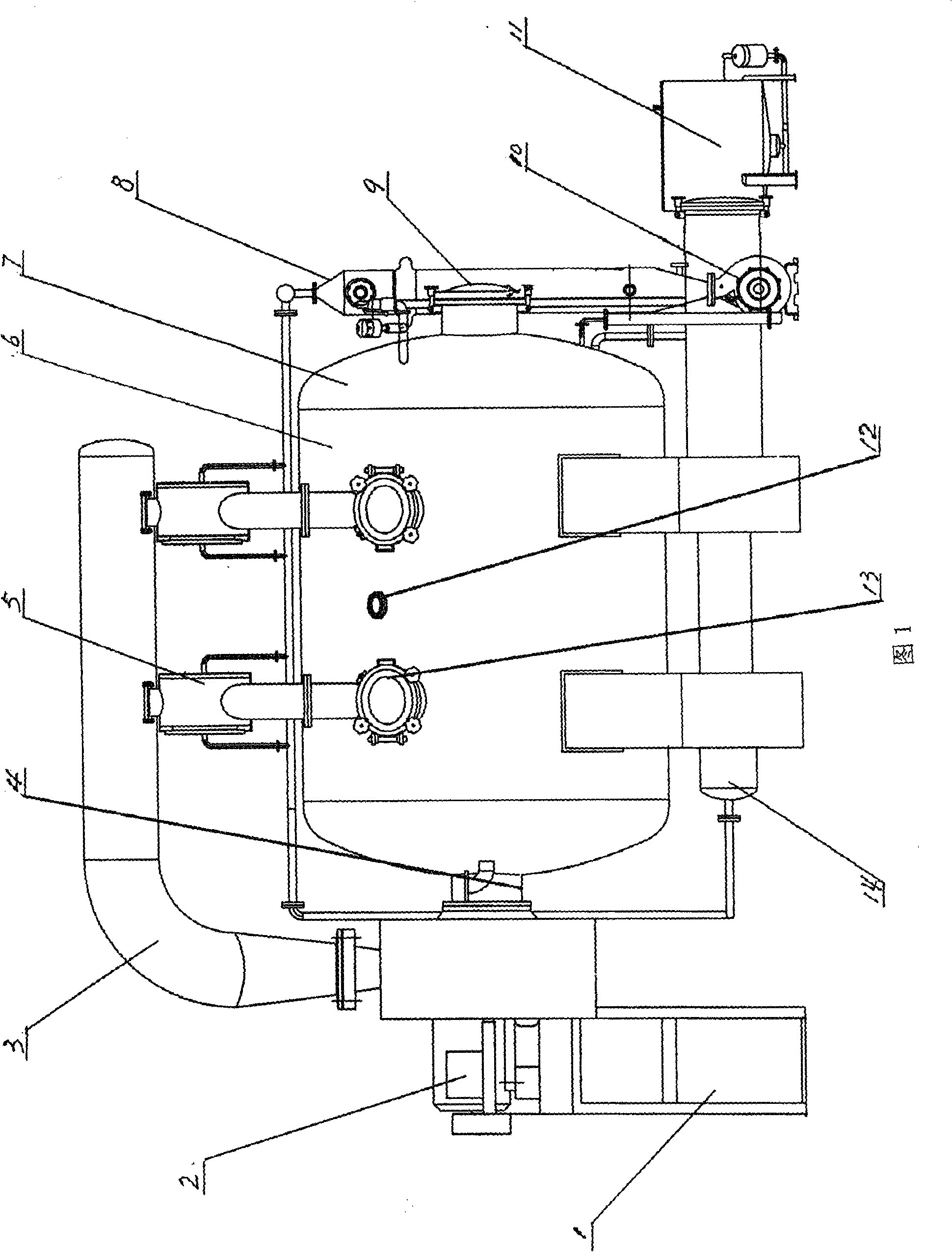

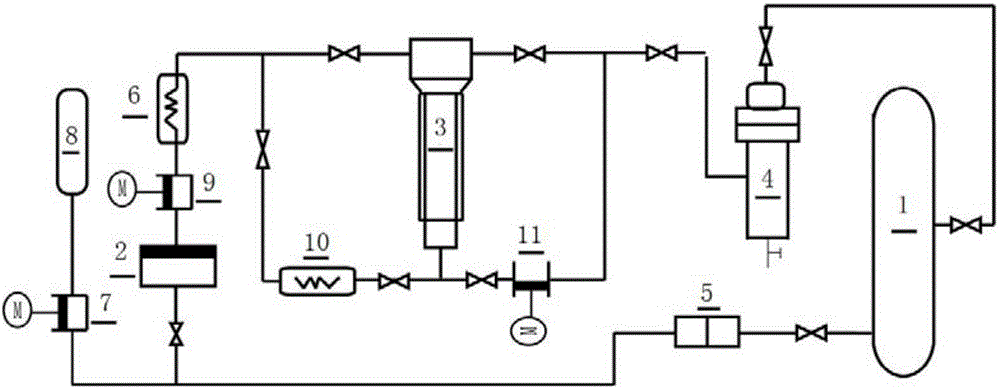

Consecutive production plant for supercritical carbon dioxide dyeing, and consecutive dyeing method

InactiveCN1958923AReduce energy consumptionGuarantee the industrialization of dyeing continuous productionTextile treatment containersSolvent treatment with solvent recoveryProcess engineeringHigh pressure

The present invention relates to a supercritical carbon dioxide dyeing continuous production equipment and its continuous dyeing method for dyeing fabrics. Said equipment includes a dyeing circulation system device which is connected after preheater by means of pipeline, can be cut off by valve and can be independently operated and a dye and carbon dioxide recovery system deice which is placed after the above-mentioned dyeing circulation system device, can be cut off by valve and can be independently operated. Said dye and carbon dioxide recovery system also is communicated with carbon dioxide storage tank by means of pipeline. Besides, said invention also provides the concrete steps of said continuous dyeing method by utilizing the above-mentioned equipment.

Owner:MASSON GROUP

Popular searches

Textile solvent-dyeing Liquid/gas/vapor roped fabric treatment Vibration treatment Textile treatment by pouring Drying solid materials with heat Liquid/gas/vapor removal by squeezing rollers Heating/cooling textile fabrics Textile/flexible product manufacture Hearth type furnaces Textile treatment rollers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com