Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

799results about How to "Good level dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

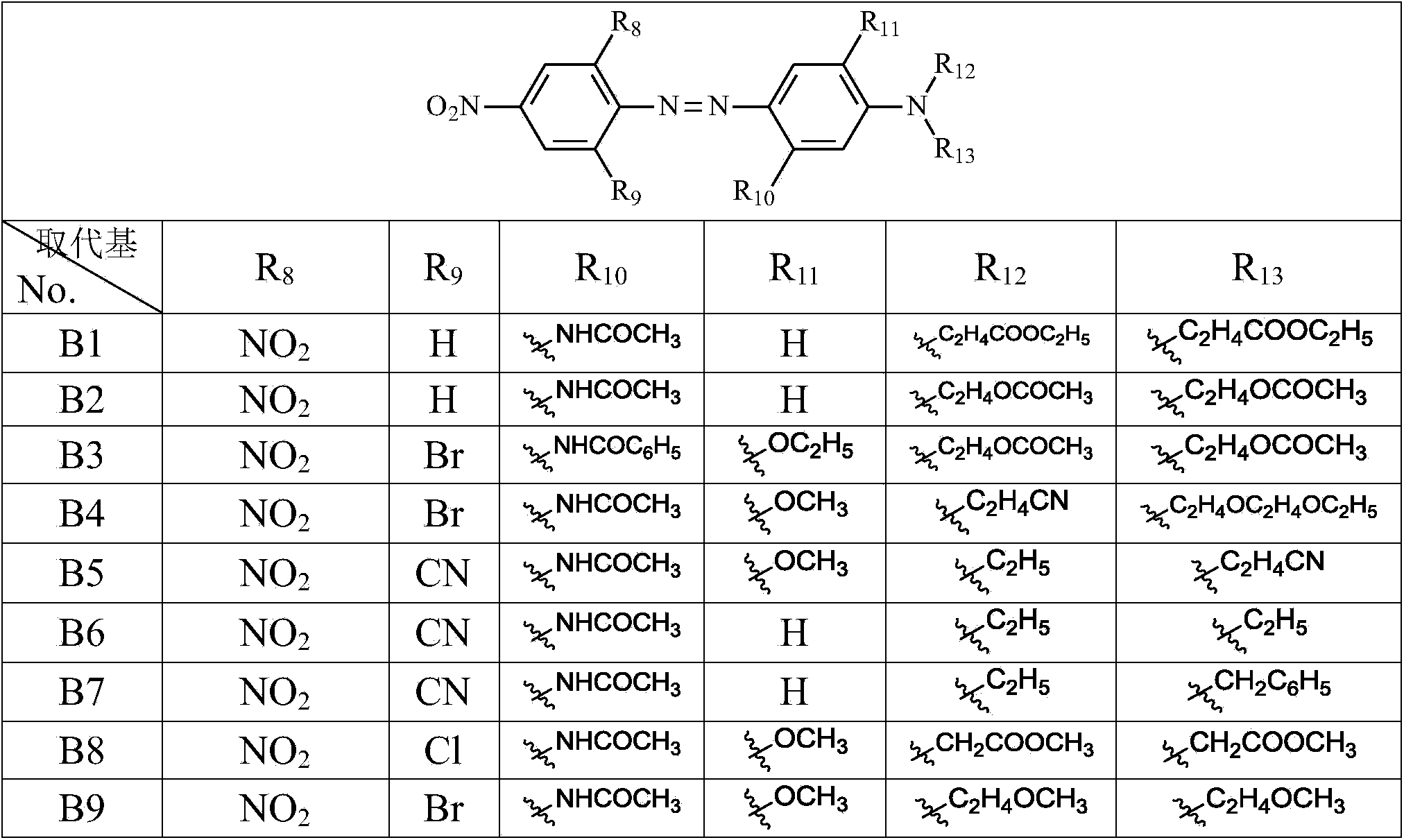

Environment-friendly disperse dye composition

ActiveCN101768376AIncrease profitProtect the environmentOrganic dyesDyeing processDisperse dyeSewage

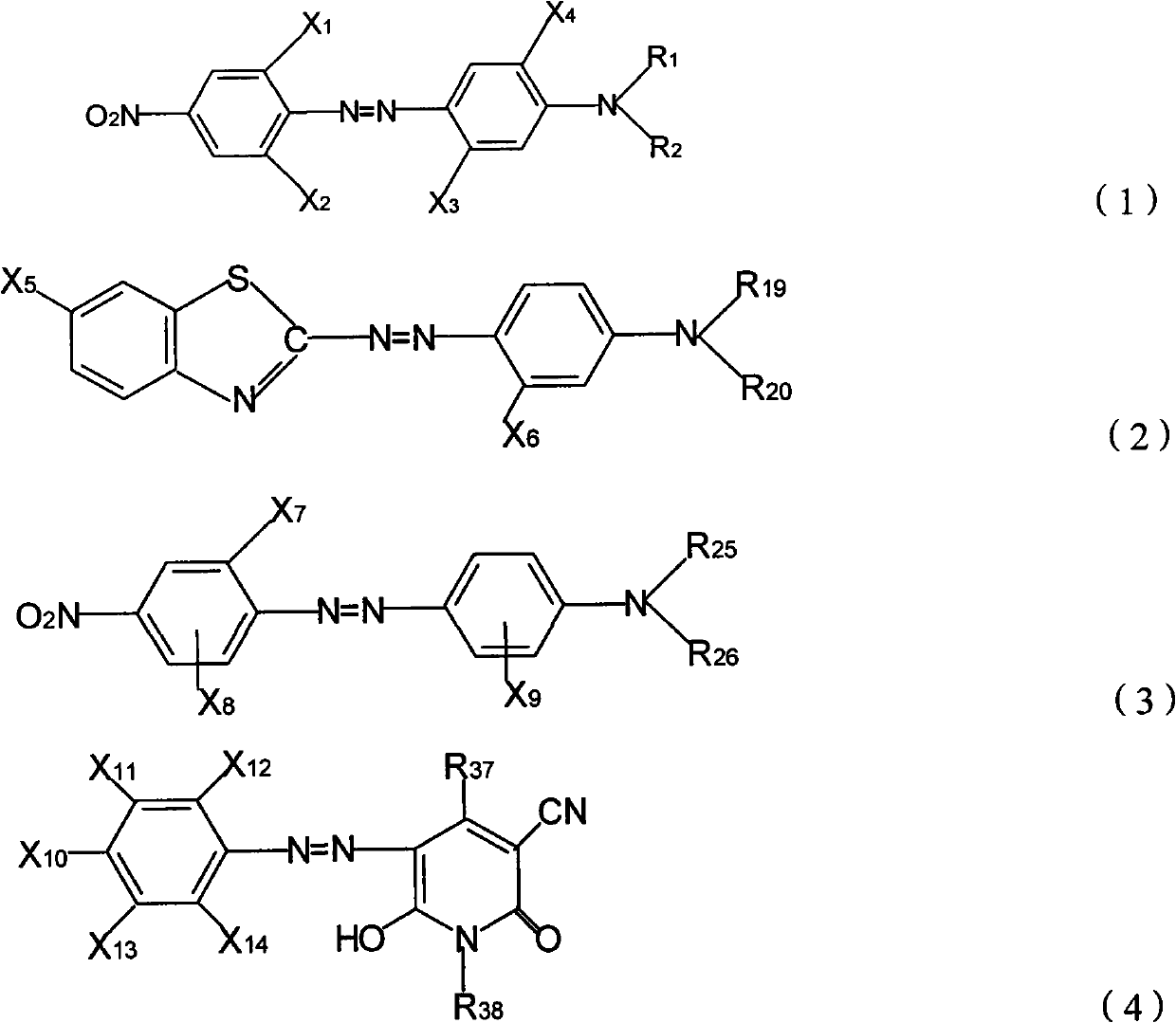

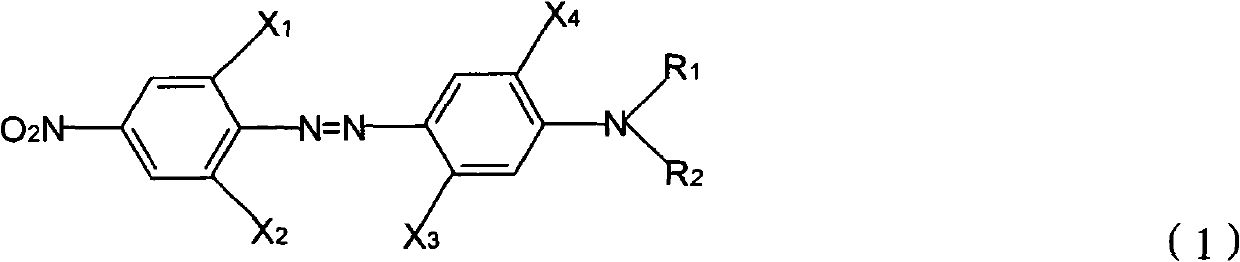

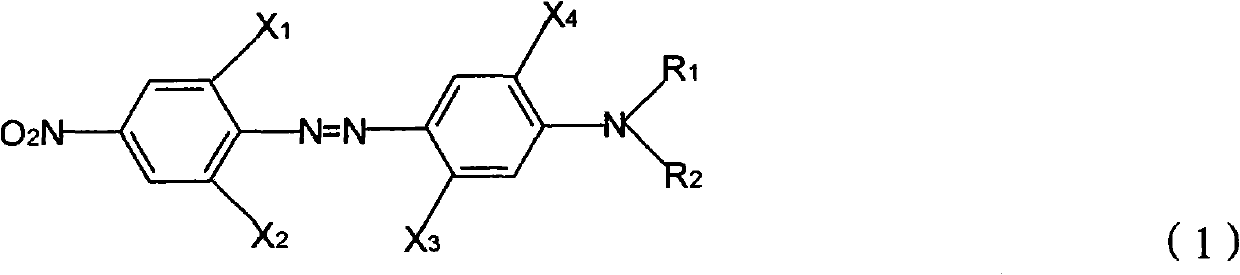

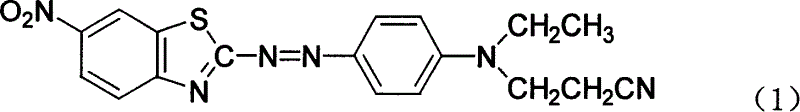

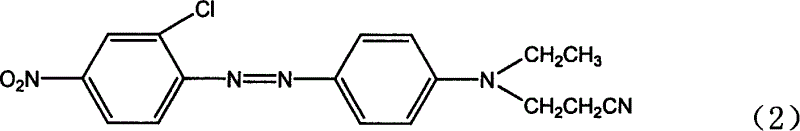

The invention discloses an environment-friendly disperse dye composition, which comprises the following components by weight percent: 10-75% of dye monomer A as shown in formula (1), 2-35% of dye monomer B as shown in formula (2), 8-50% of dye monomer C as shown in formula (3), and 1-10% of dye monomer D as shown in formula (4). The disperse dye composition can be regulated to obtain colored lights such as black, blue, grey, brown and the like; the obtained dye composition is an environment-friendly dye, and has wide suitable range of the pH value, good pile-on property, strong covering performance, good lifting power, colour yield, levelling property and various fastness, and can greatly improve the utilization rate of the dye and reduce the dye sewage.

Owner:ZHEJIANG RUNTU

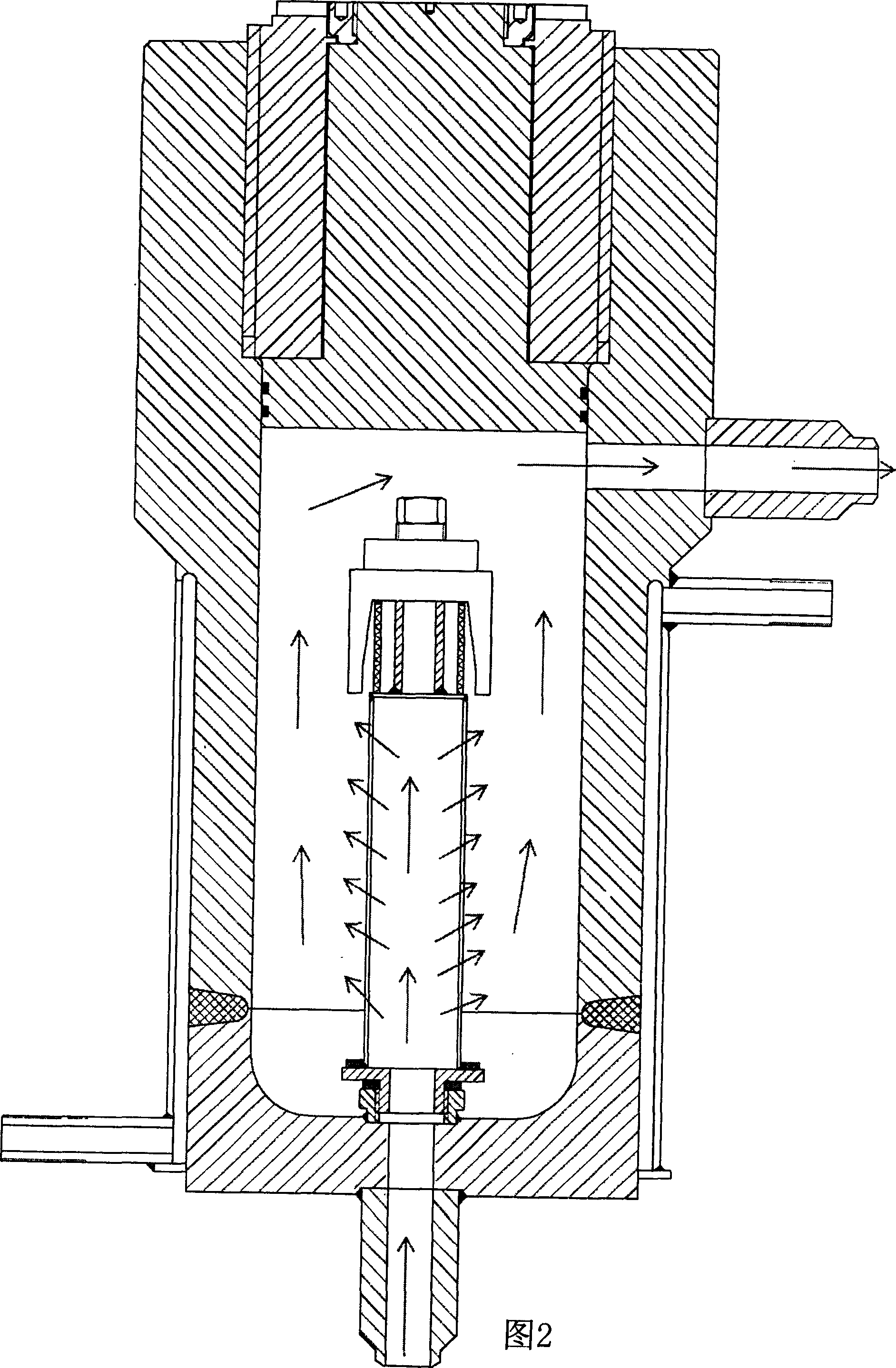

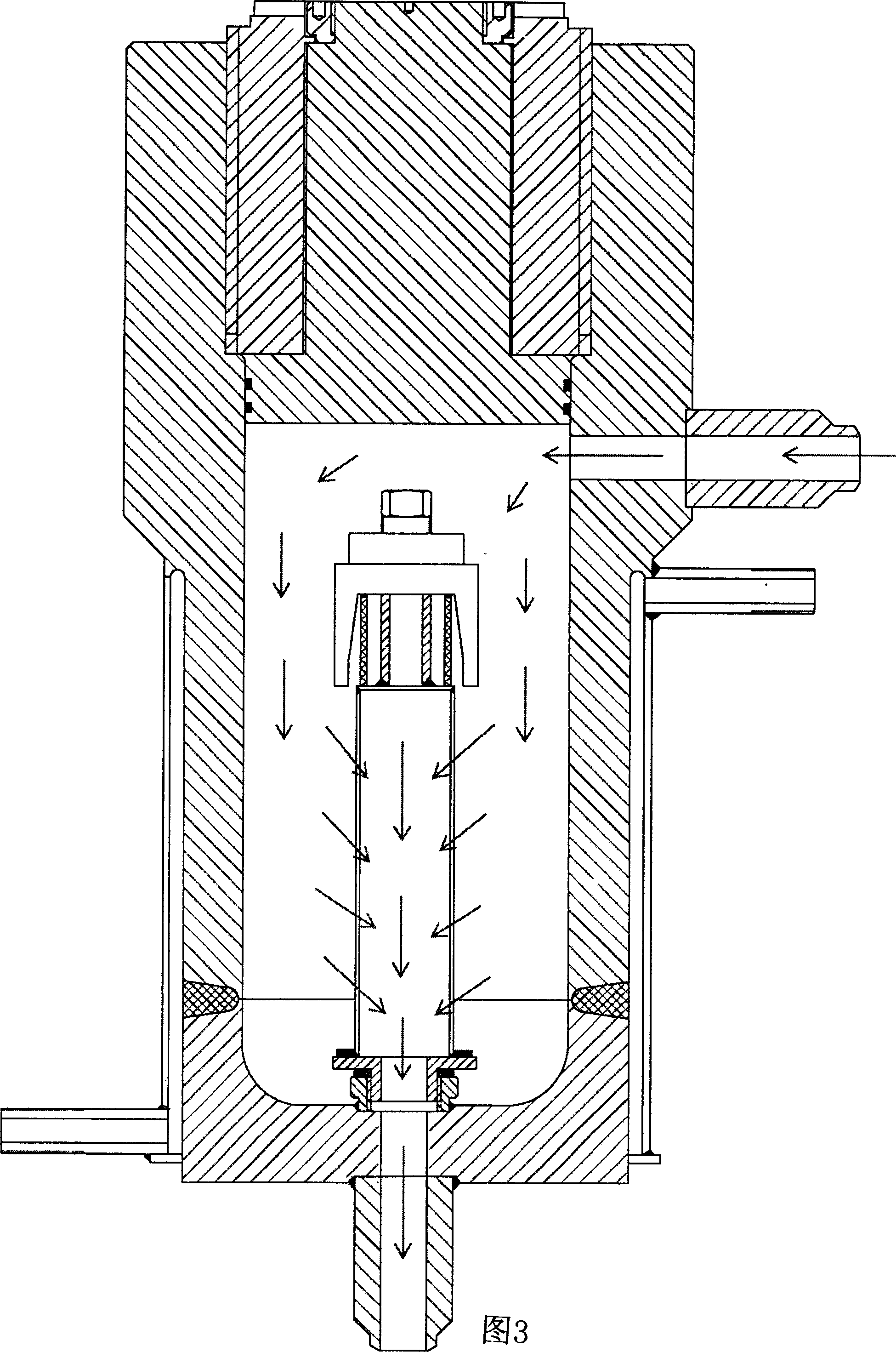

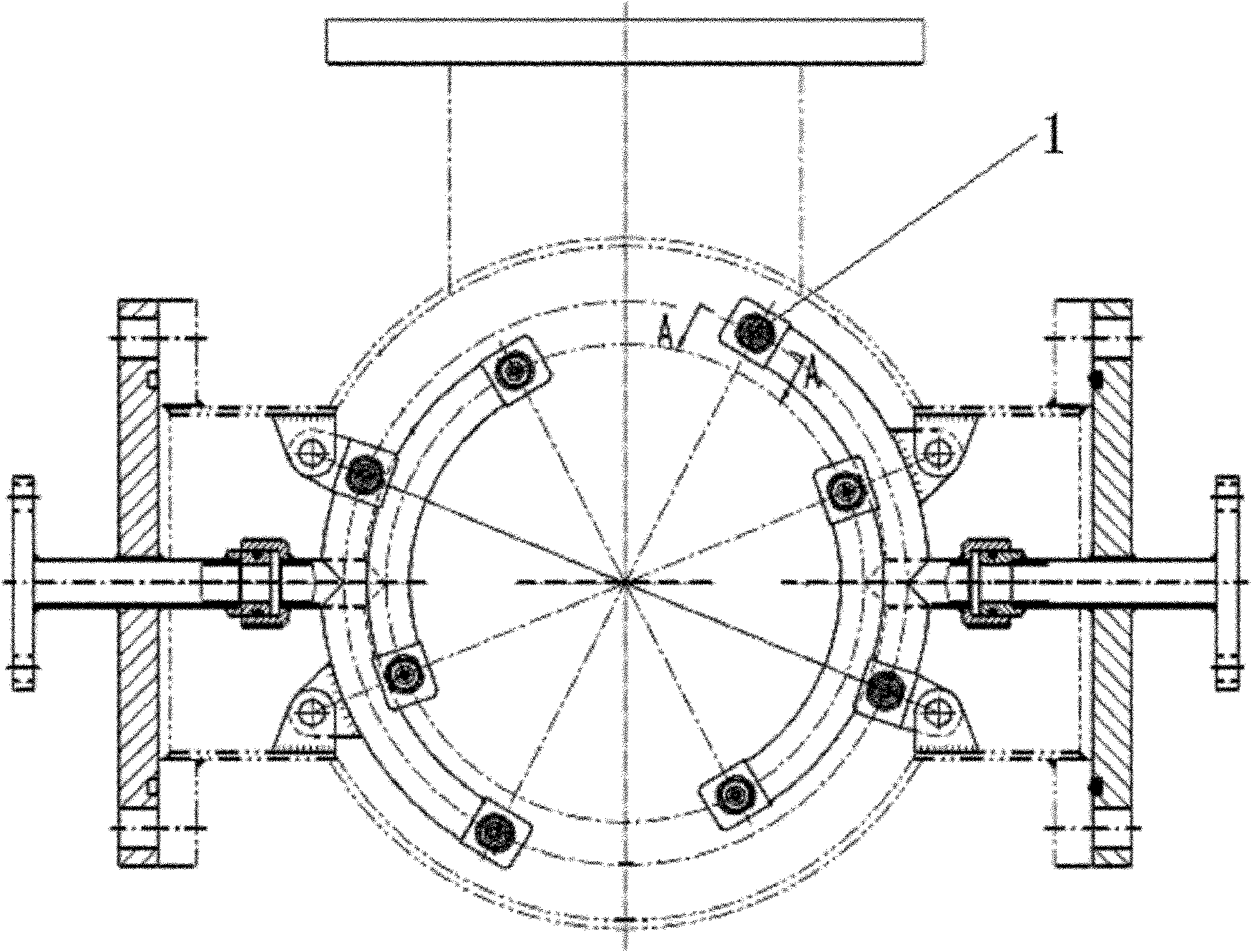

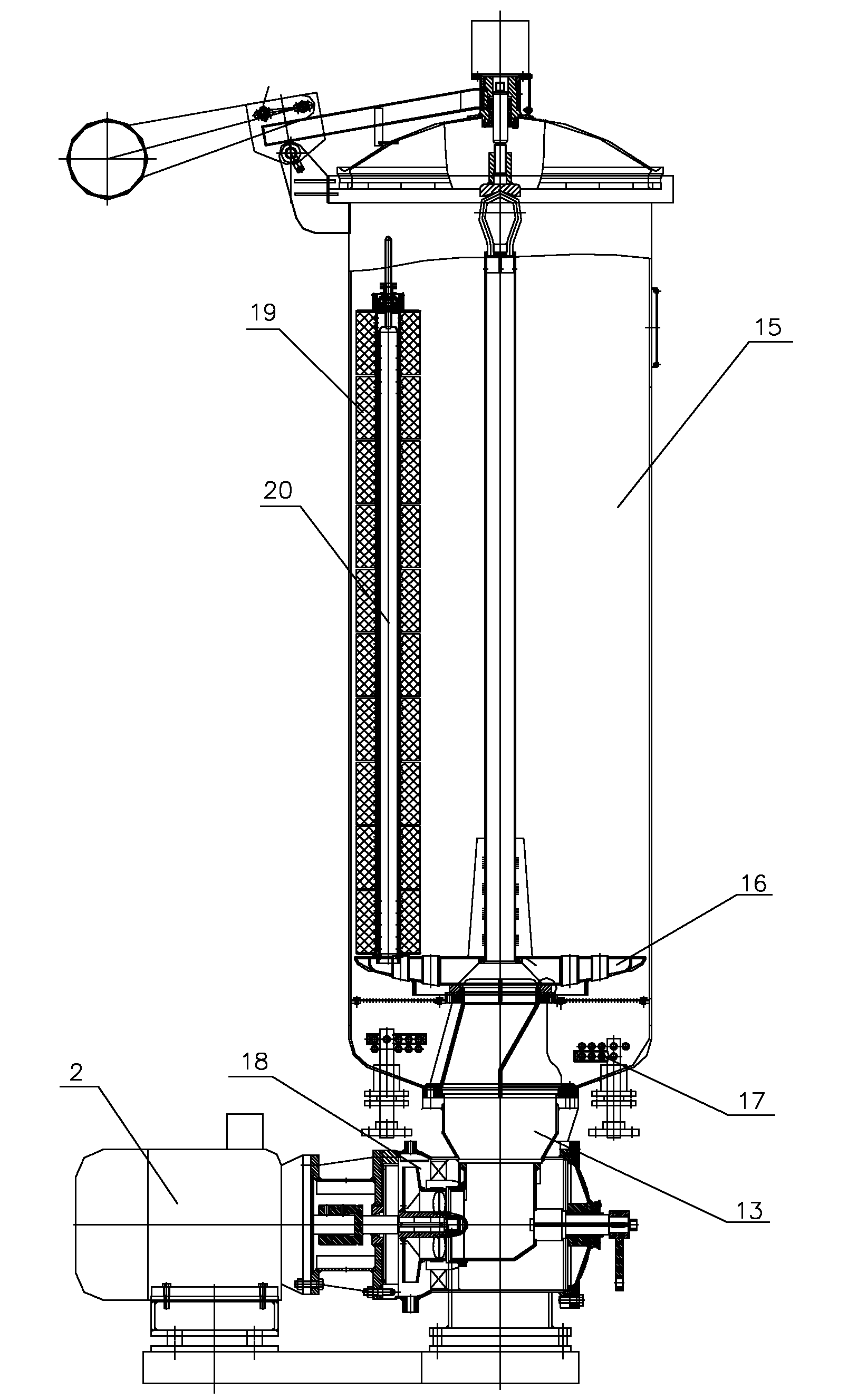

Dying still in supercritical CO2 dyeing device

InactiveCN1807742ARealize the operation process of dynamic dyeingReduce dye liquor vortexTextile treatment containersDyeing processEngineeringMechanical engineering

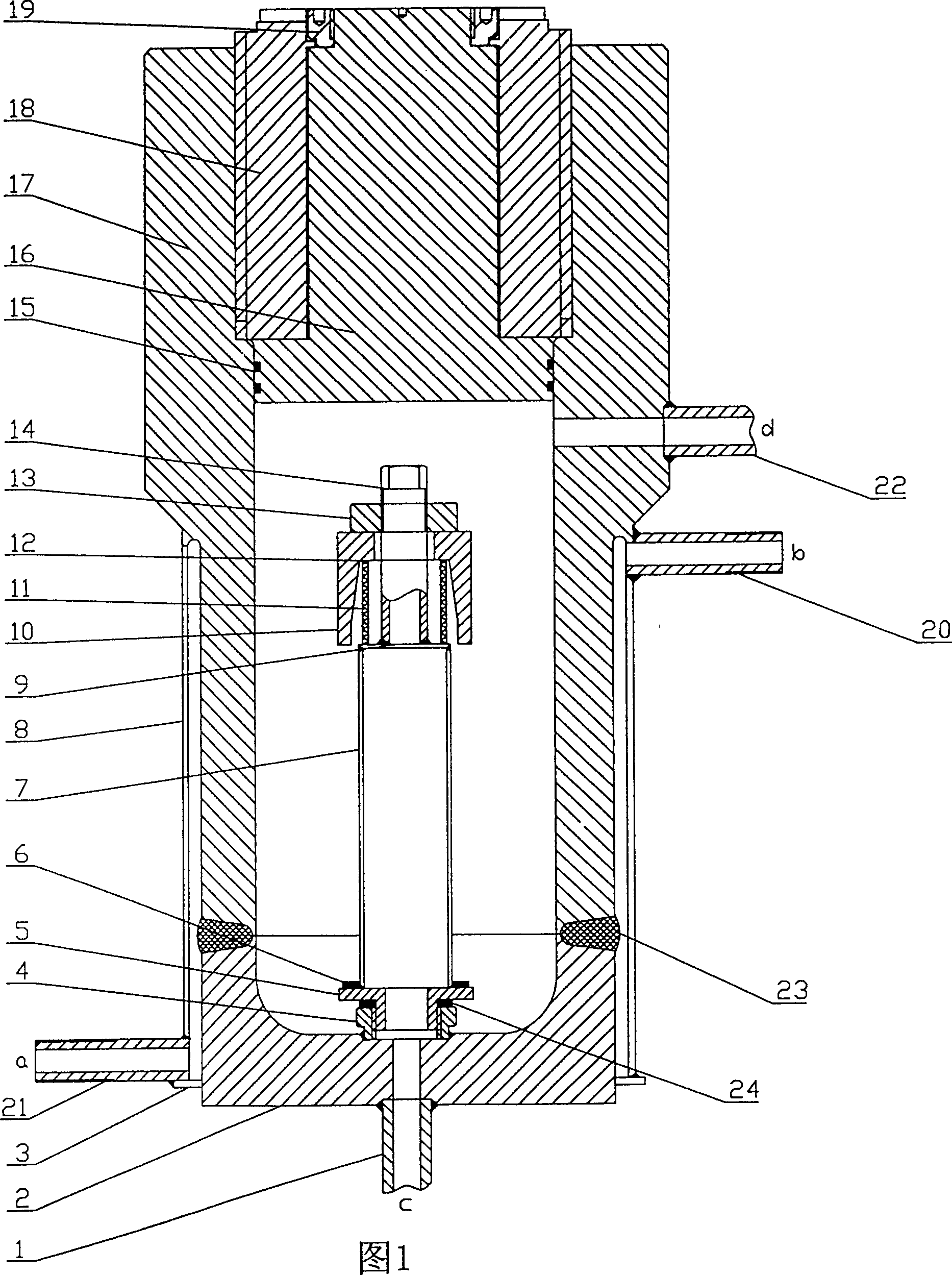

This invention discloses a dyeing kettle of the over-critical carbon-dioxide dyeing device, which is to use for the dyeing of the textile, including arranging the barrel and the sealed convex shoulder flat that is on the upper part of the barrel; the center opening of the barrel's bottom connects with the first connector, the inside center opening of barrel connects with the inner barrel by the support cell; the wall of the inner barrel is arranged with the filter hole uniformly, the upper of the inner barrel connects with the second cover; the barrel wall opening of the barrel's upper connects with the second connector; the under part of the barrel connects with the nip cover, which has the ring space with the barrel, and the upper of the ring space is sealed in the protruding stage that outside the barrel, and the first cover is sealed in the under part, one side of the ring space's under part opening connects with the first adapter, and the other side of upper part opening connects with the second adapter. This invention realizes the combining of the technology of the textile internal dyeing and external dyeing, and the dynamic dyeing in the over-critical dyeing method.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

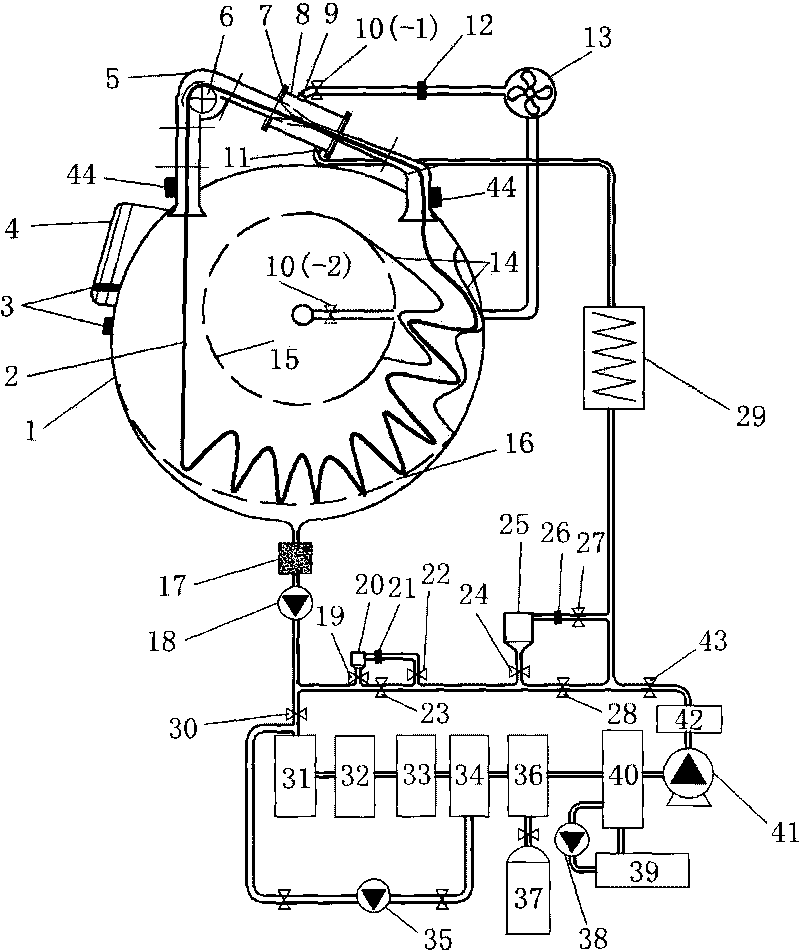

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

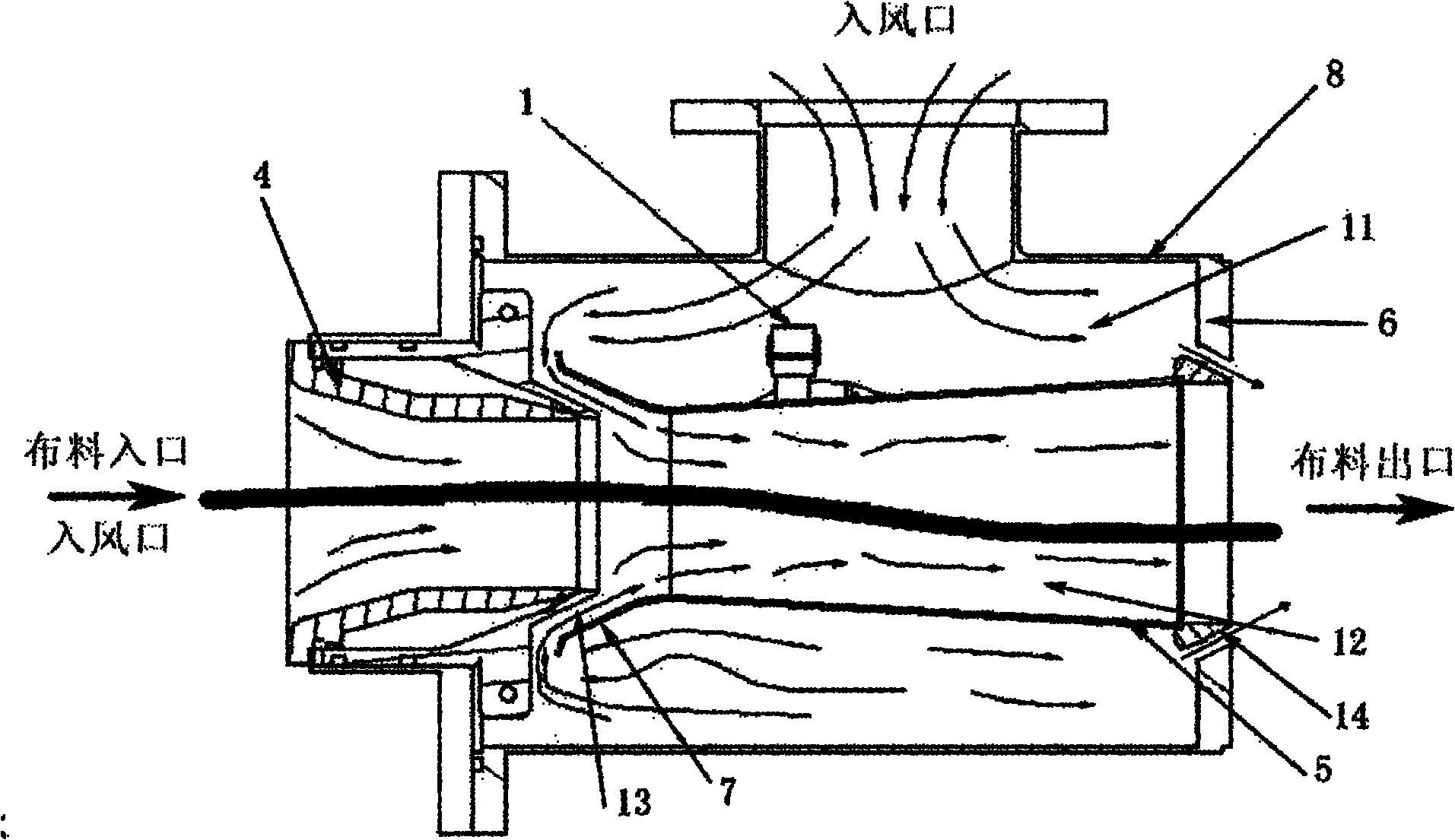

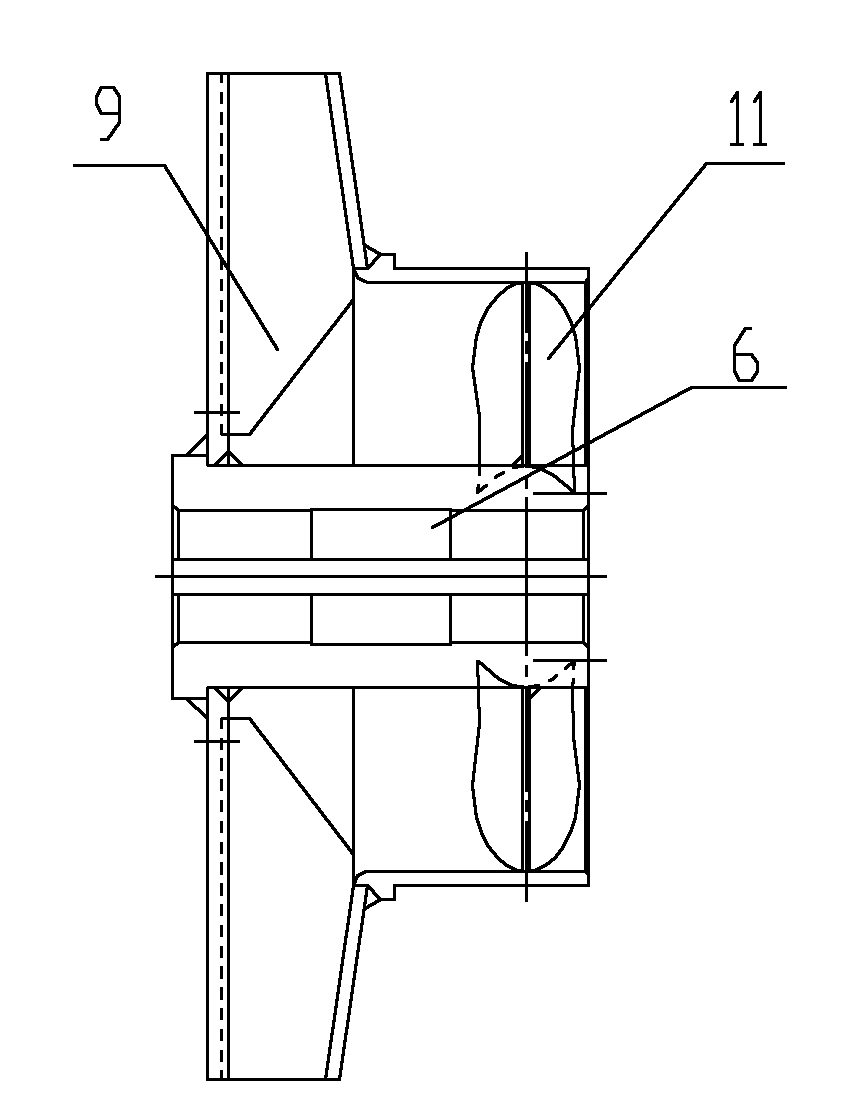

Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

InactiveCN102080318AGood level dyeingSuitable for processing environmentLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsSpray nozzleHigh pressure

The invention discloses an atomizing nozzle structure of a high-temperature high-voltage air flow dyeing machine and control method thereof. The nozzle structure comprises a front nozzle cover, an inner main stream pipe, a rear nozzle head and a sleeve, wherein the sleeve is sleeved outside the inner main stream pipe, and two ends of the sleeve are respectively connected with the front nozzle cover and the rear nozzle head through a connecting piece; the sleeve is provided with an air inlet which is connected with a fan; and the sleeve and the inner main stream pipe form a circular outer chamber atomizing region; a nozzle head is arranged in the outer chamber atomizing region and is fixed on the outer wall of the inner main stream pipe, and the nozzle head is connected with a dye liquid pipeline; and the outer chamber atomizing region is provided with two outlets which are connected with a channel through which the cloth to be dyed passes in the inner main stream pipe. The invention also provides a control method based on the atomizing nozzle structure of the high-temperature high-voltage air flow dyeing machine. According to the types of the cloth to be dyed, the number of the nozzle heads started in the nozzle structure, the flow rate of the nozzle heads, the air flow of the fan and the temperature process curves adopted are defined. According to the invention, the levelling property is high, and the problem of cloth blocking can not happen.

Owner:高勋绿色智能装备(广州)有限公司

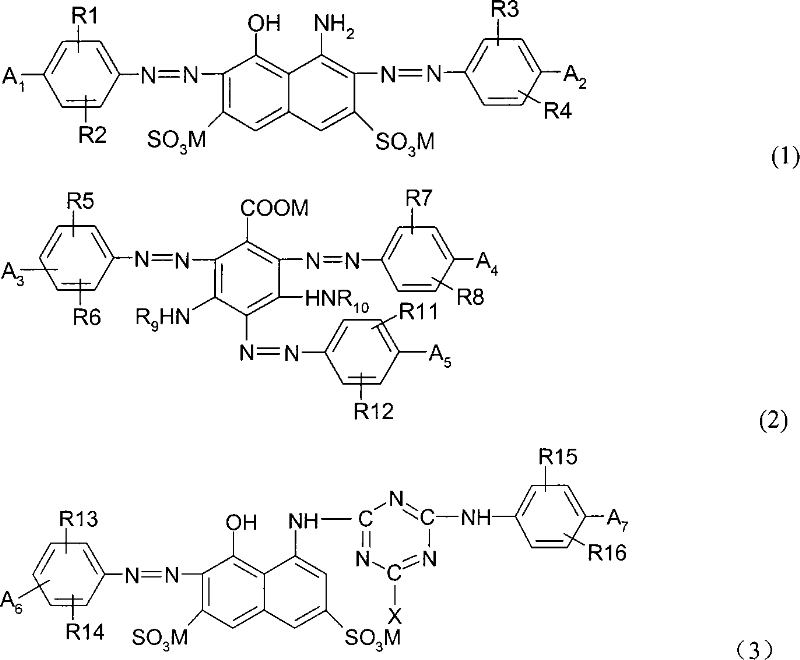

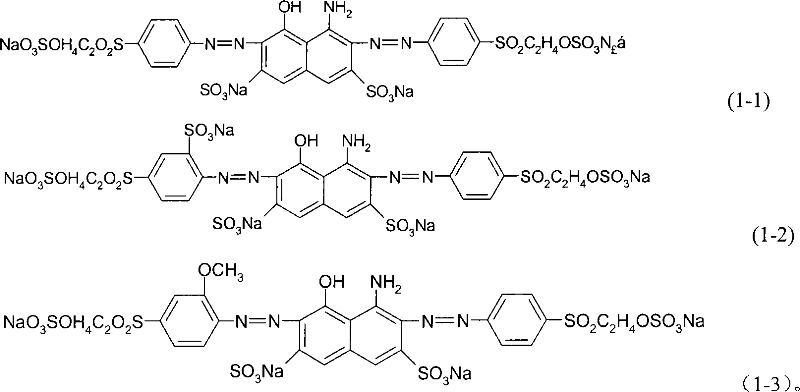

Composite active black dye

The present invention relates to a kind of disazo dyestuffs composition, the described composite active blank dyestuff mainly contains four dyestuffs, said invention also provides their structure formulas. The described composite dyestuff is suitable for dyeing dark colour fabrics, such as cellulose fibre, cotton fibre and synthetic fibre, etc., and has good level-dyeing property, repeatability, high dyeing fastness, fastness to washing and wet rubbing fastness.

Owner:SHANGHAI KEHUA DYESTUFF IND

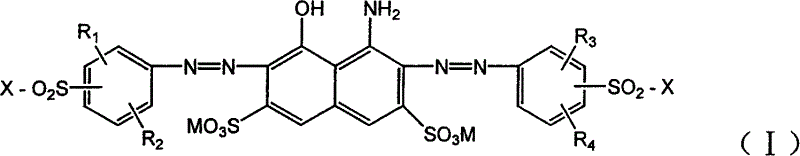

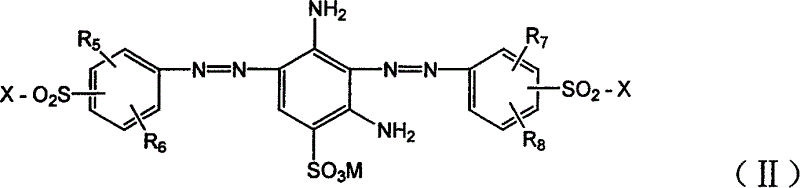

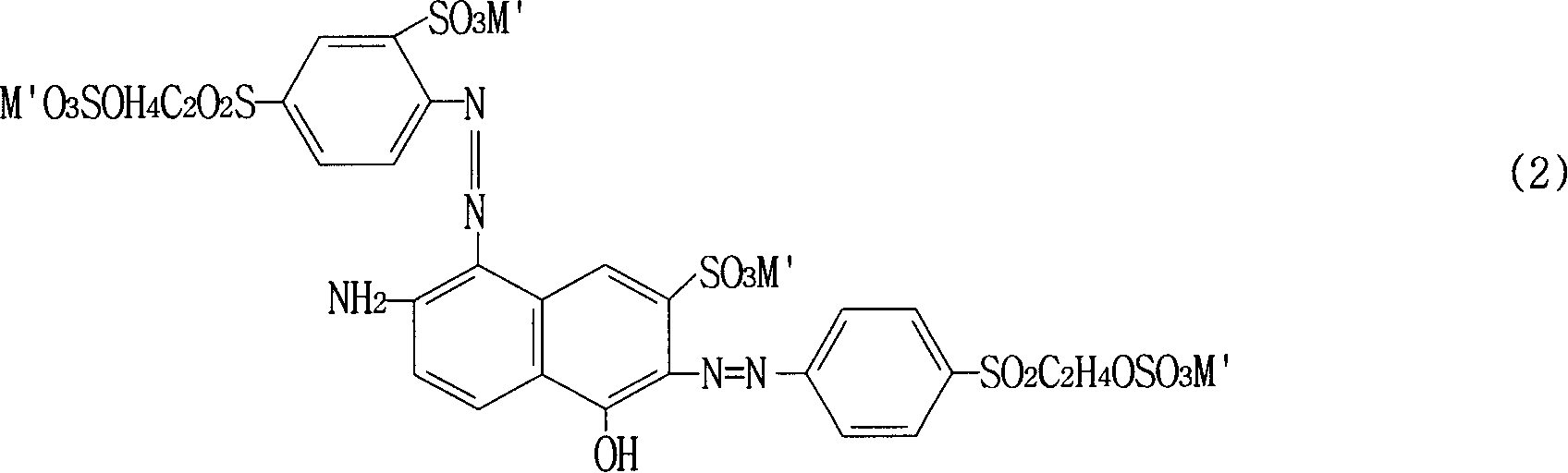

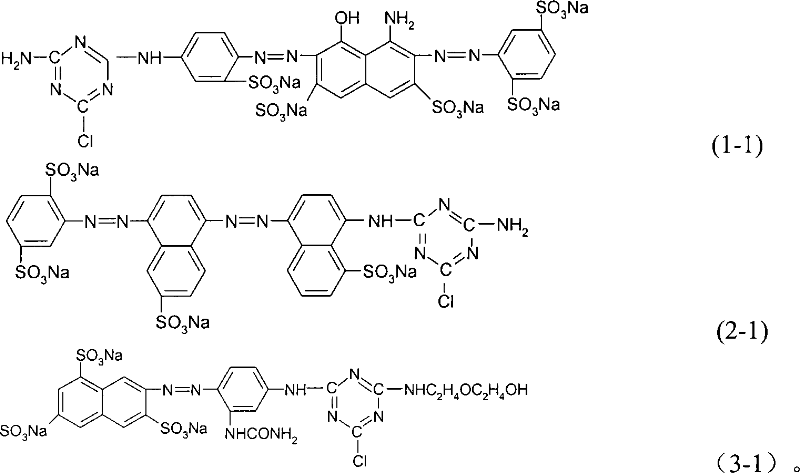

Compound active black dye

ActiveCN101037546AGood level dyeingHigh color fixing rateOrganic dyesDyeing processFiberPhotochemistry

The invention provides a composite reactive black dye, which is confected by (counted by weight quotient): dye shown by formula (1) of 50-80 quotient, dye shown by formula (2) of 15-40 quotient and dye shown by formula (3) of 5-10 quotient. Advantages of the dye are: level-dyeing property and fixation yield is high, quantity of the dye for dyeing fibrous material is small, and not fixed dye is easy to clean.

Owner:HUBEI COLOR ROOT TECH CO LTD

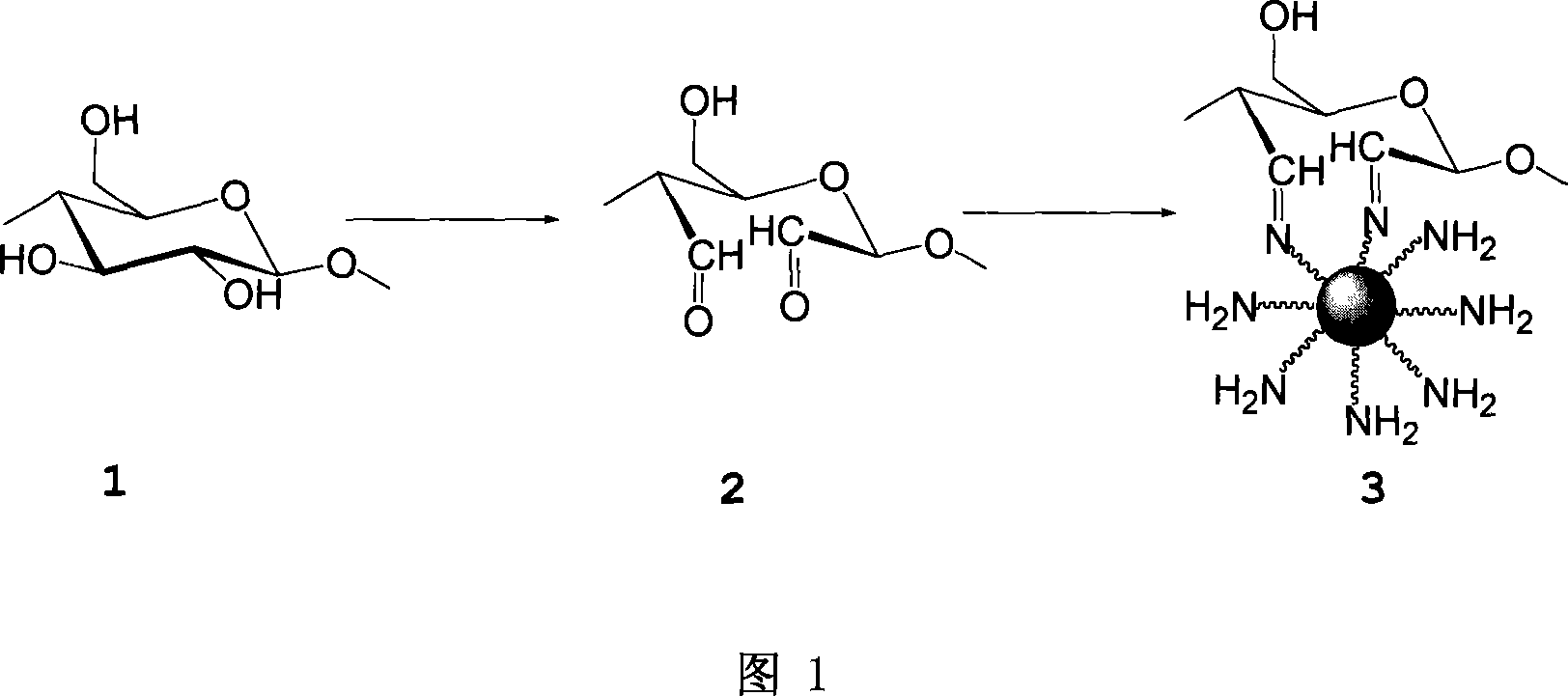

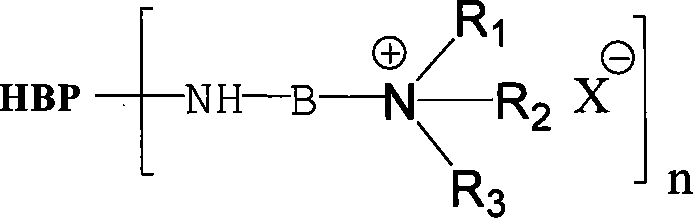

Fibrilia grafting amination modifying process

InactiveCN101225602AQuick responseImprove grafting efficiencyDyeing processVegetal fibresFiberReaction rate

The invention discloses a linen fiber modification method, in particular to a linen fiber graft aminization modification craft, belonging to the technical field of printing and dyeing, which is characterized in that the linen fiber is selectively oxidized with oxidant solution such as sodium periodate, and oxidation linen fiber is obtained; the surface aldehyde group of the oxidation linen fiber is reacted with the surface amino of amine-terminated overbranched compound and the quaternary ammonium salt, which are combined by covalent bond, and the graft aminization linen fiber is prepared; the abundant amino, imino group and quaternary ammonium branched chain are introduced on the surface of obtained fiber, which can increase significantly the dyeing performance of linen fiber, and simultaneously increase the pliability softness, hygroscopicity and antibacterial performance of linen fiber. The linen fiber modification method has the advantages of fast reaction rate, high graft efficiency, good fastness, convenient and easy operation, realization of non-salt dyeing for linen fiber after modification treatment, environment protection, simplified normal dyeing craft and wide potential application.

Owner:SUZHOU UNIV

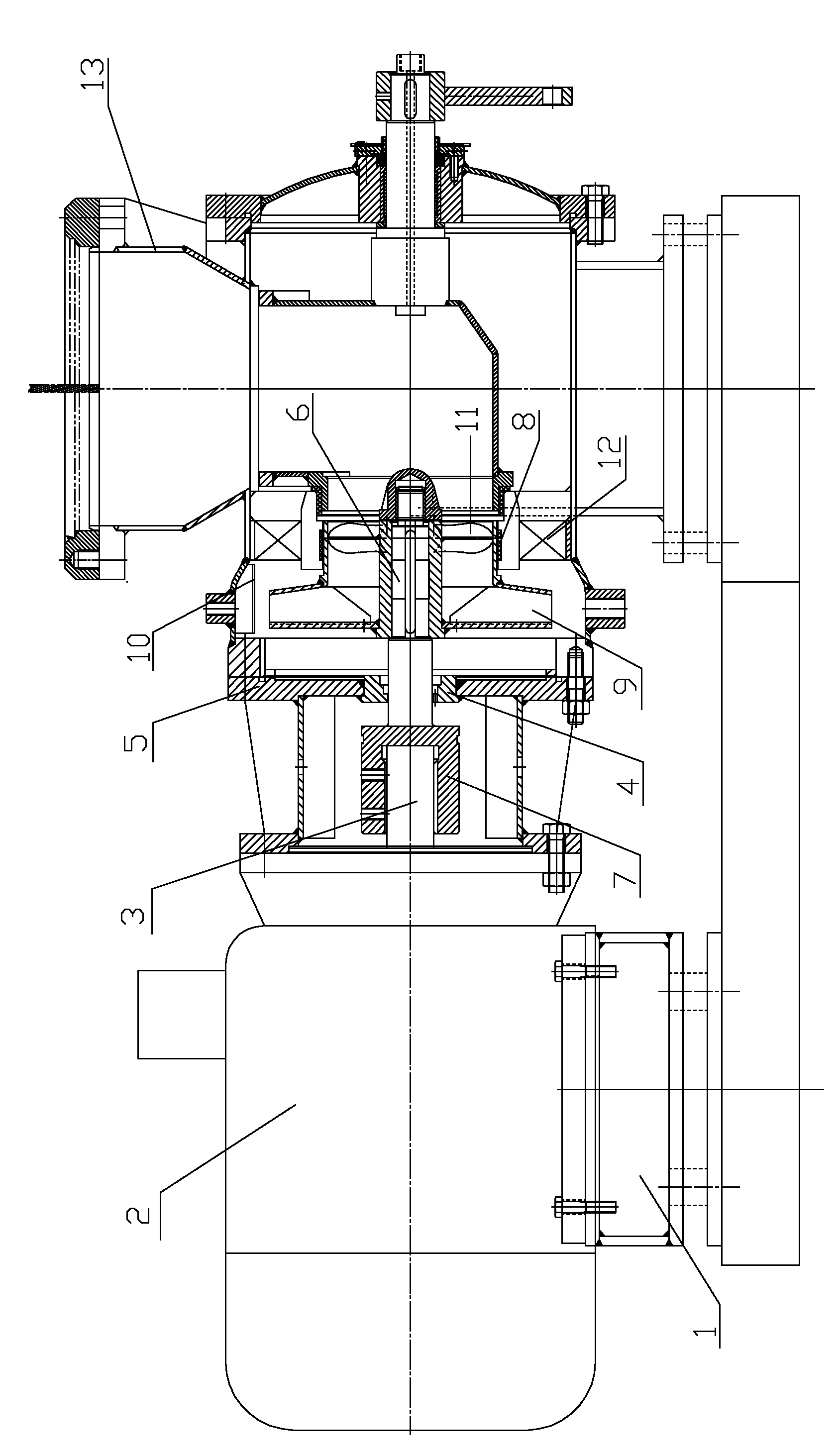

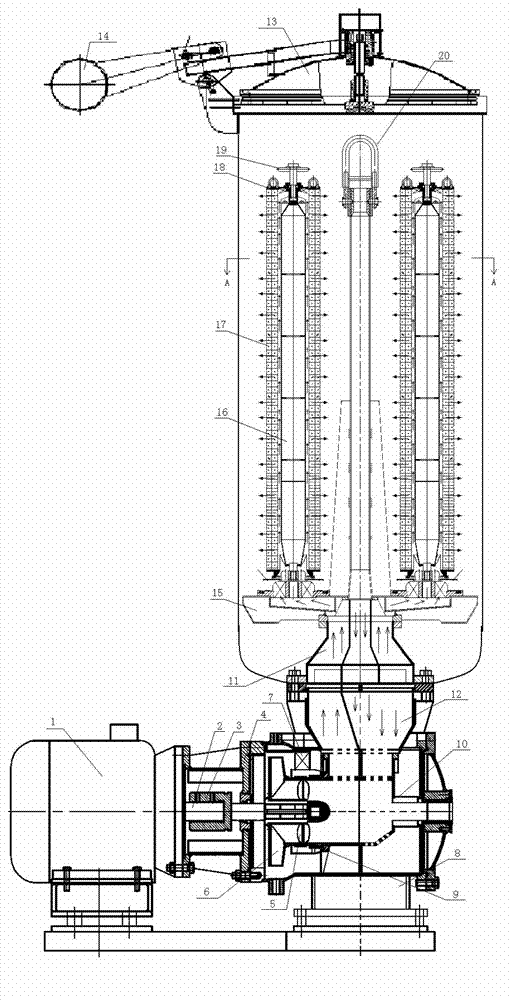

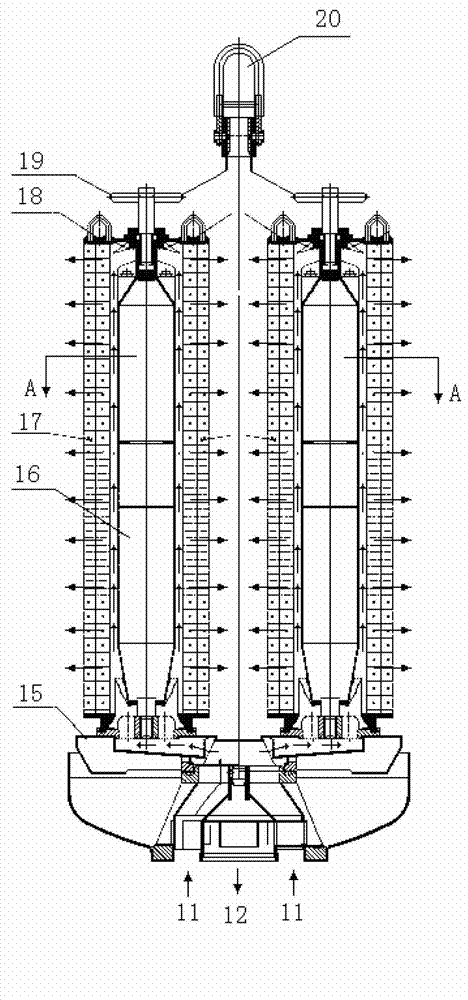

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

Salt-free dyeing method for calcium alginate fiber

ActiveCN103981744AImprove soaping fastnessGood level dyeingFibre treatmentDyeing processAluminium saltsChemistry

The invention discloses a salt-free dyeing method for calcium alginate fiber, and belongs to the technical field of textile science. According to the method, an aqueous aluminum sulfate solution is adopted to pretreat the calcium alginate fiber to be dyed, then a direct dye is adopted to perform salt-free dyeing, and finally an aqueous calcium chloride solution is adopted to perform fixation. When the method is adopted for dyeing of the calcium alginate fiber, the dye-uptake rate of the dye to the fiber is not less than 90%, the levelling property and the permeability property of the fiber are excellent, and the soaping fastness is not less than the fourth level. The method avoids the use of table salt, acids, alkalis, and other chemical agents, and has characteristics of low cost, less damage to the mechanical properties of the calcium alginate fiber, not more than 10% of the strength loss of the dyed fiber, eco-environment protection, rapid and convenient treatment, recovery and reutilization for dyeing waste water, and zero release.

Owner:QINGDAO TIANYI GROUP

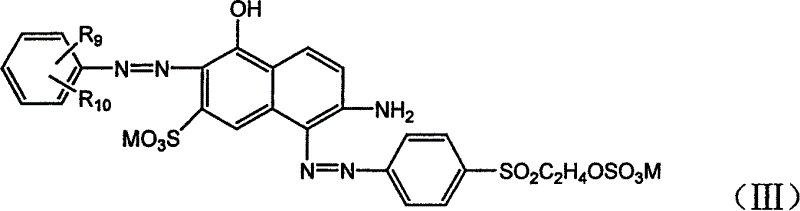

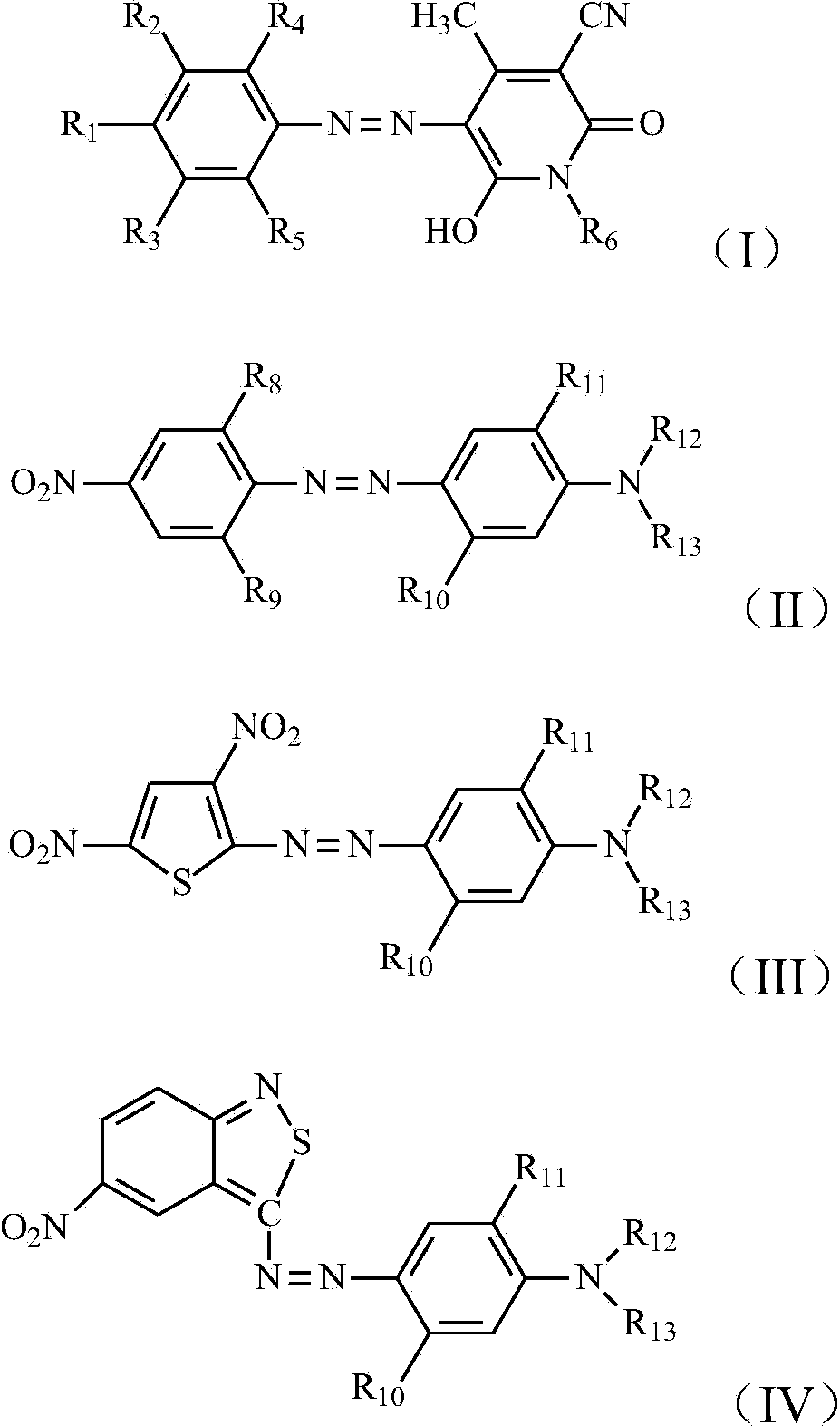

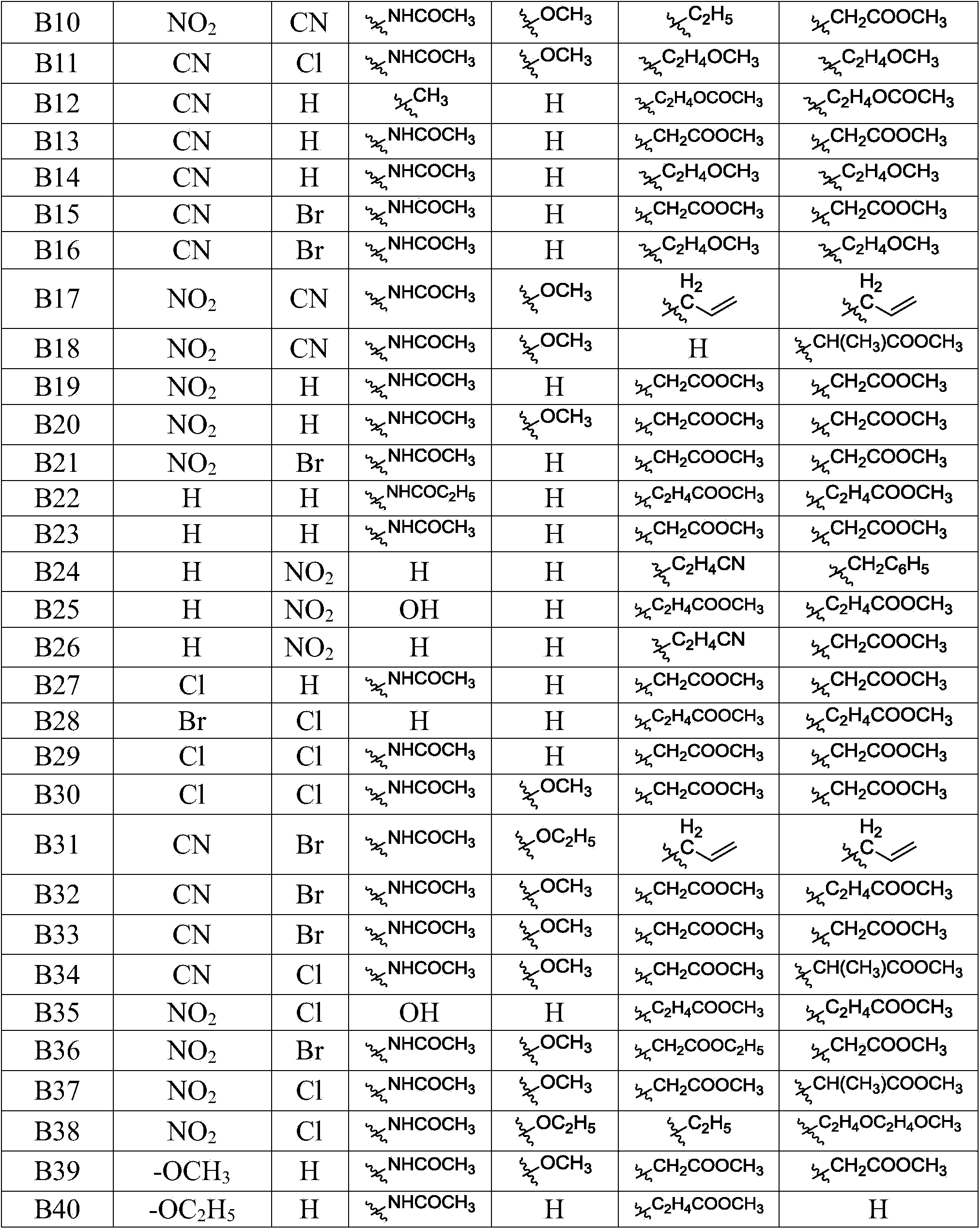

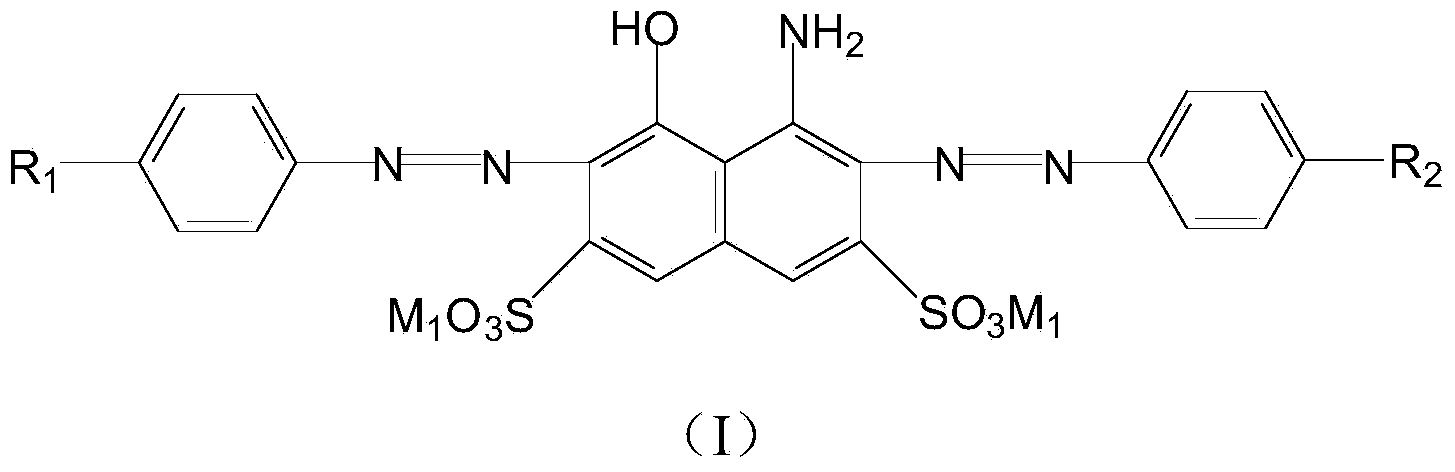

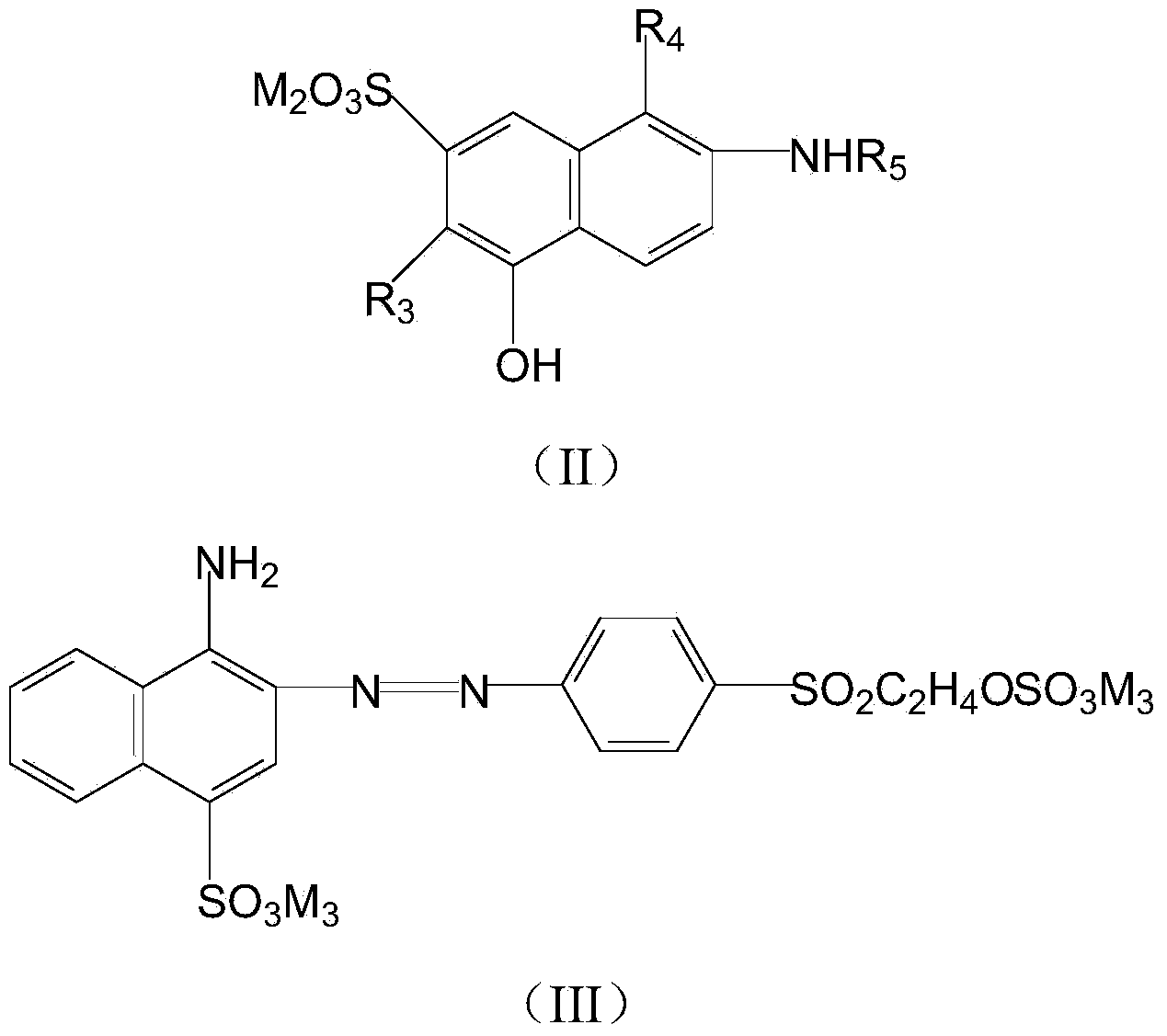

Navy blue or black disperse dye

ActiveCN104087015AProtect the environmentImprove dye uptakeOrganic dyesDyeing processDisperse dyePhotochemistry

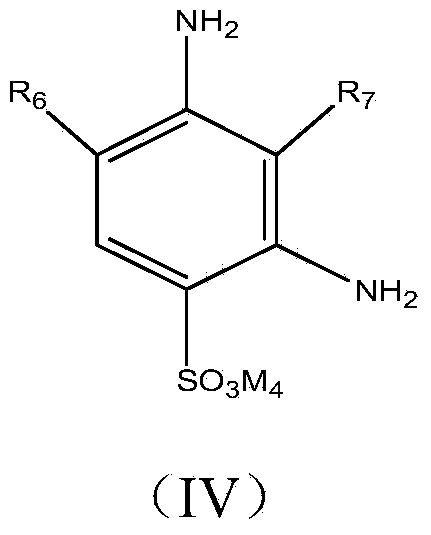

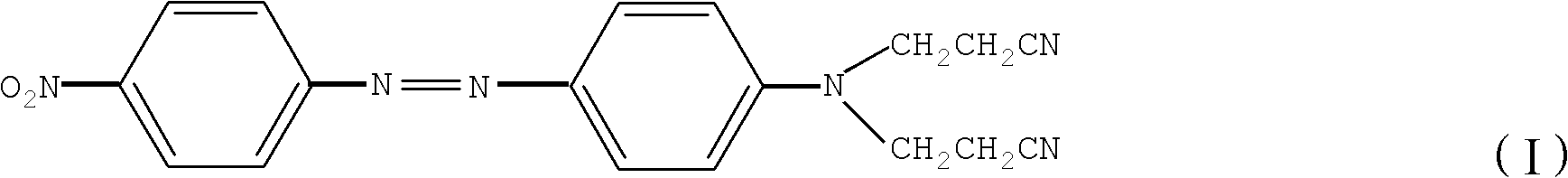

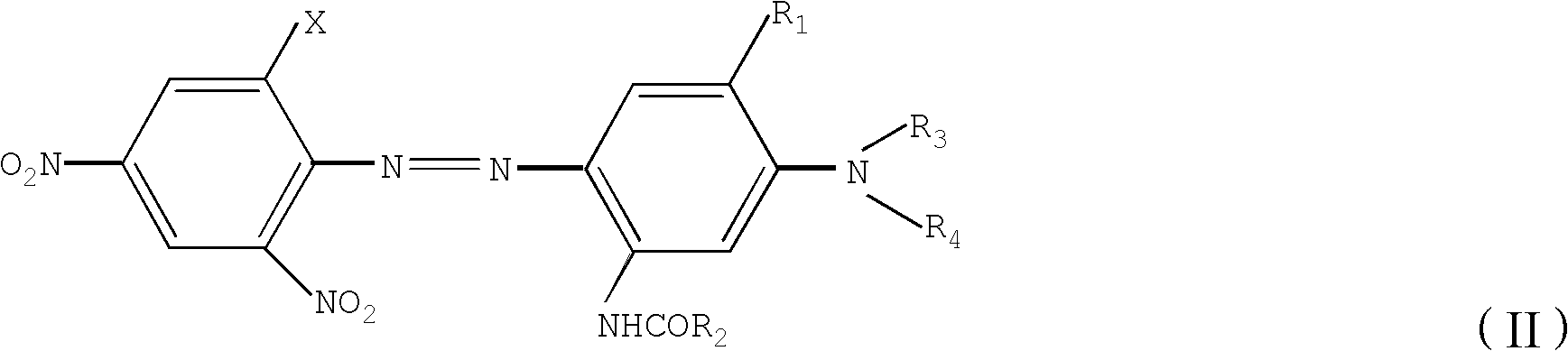

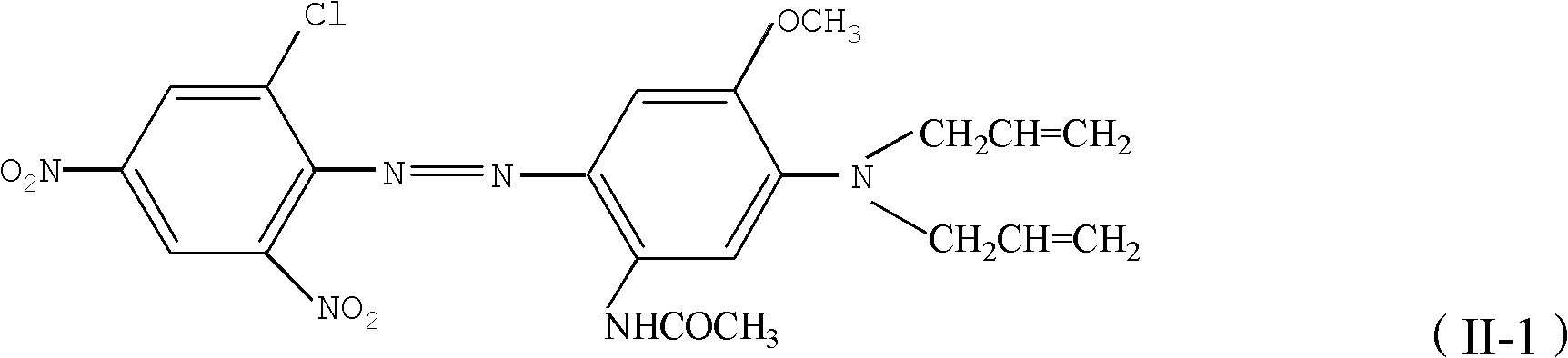

The invention discloses a navy blue or black disperse dye. The navy blue or black disperse dye contains a navy blue or black disperse dye composition and an additives. The navy blue or black disperse dye composition comprises one or more of dye A shown as formula (I), one or more of dye B shown as formula (II), one or more of dye C shown as formula (III), and one or more of dye D shown as formula (IV). The navy blue or black dye provided by the invention has the advantages of high dye-uptake, good deep dyeing property, excellent elevating power, excellent color fastness, and good level dyeing property. (formula (I), formula (II), formula (III), formula (IV)).

Owner:SHANGHAI ANOKY GRP

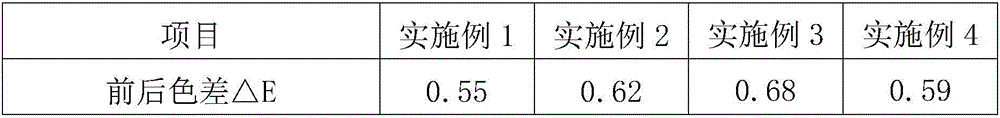

Compound black reactive dye composition, and applications thereof and fiber or fiber textile made thereby

ActiveCN104059387AImprove dyeing effectGood blacknessOrganic dyesDyeing processCellulose fiberProtein fiber

The invention relates to a compound black reactive dye composition, and applications thereof and a fiber or fiber textile made thereby, belonging to the field of reactive dyes. Particularly, the invention relates to a compound black reactive dye composition applicable to printing and dyeing cotton, rayon, hemp, regenerative fiber or textiles thereof, or to printing and dyeing polyamide fiber, cellulose fiber, protein fiber or textiles thereof. The invention further relates to applications of the compound black reactive dye composition, and fiber or fiber textile made by the compound black reactive dye composition.

Owner:ZHEJIANG RUIHUA CHEM

High-fastness turquoise blue disperse dye composition

The invention provides an environment-friendly and economical high-fastness turquoise blue disperse dye composition with bright colored light, good leveling property, good elevating power and excellent washing fastness and sublimation fastness. The high-fastness turquoise blue disperse dye composition mainly comprises the following components in parts by weight: 50-90 parts of a component A shown by a formula (I), 0.1-10 parts of a component B shown by a formula (II) and 0.1-45 parts of a component C shown by a formula (III). After being commercialized, the turquoise blue disperse dye composition provided by the invention can be ground to be in a liquid state by a sand mill or a grinder, and can be in the shape of powder or particle after being subjected to spray drying, so that the turquoise blue disperse dye composition is suitable for dyeing of polyester and a blended fabric thereof, and particularly suitable for dyeing of a spandex blended fabric, and has the characteristics of good elevating power, small contamination to spandex, excellent washing fastness, excellent color fastness to sublimation and the like.

Owner:ZHEJIANG LONGSHENG GROUP

Cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics

InactiveCN102191692AReduce dosageReduce wasted waterBiochemical fibre treatmentDry-cleaning apparatus for textilesElectricityChemical oxygen demand

The invention relates to a cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics, comprising the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a non-ionic surfactant into an enzyme working solution, wherein the pH of a processing bath is 6-7.5; padding the fabrics into the working solution; carrying out heat preservation; (2) washing the processed fabrics with cold water; padding the fabrics into a hydrogen peroxide bleaching solution containing the controlled decomposition additive of hydrogen peroxide; and steaming, washing with water and drying to obtain the finished products. In the method, high-density strong base is not required to serve as a scouring agent, thepH value of pretreatment waste water is 7-8, the chromaticity is low, the COD (Chemical Oxygen Demand) value is lowered by 30% compared with that of the traditional alkali kiering pretreatment technology, the water is saved by 10-30%, and the steam and electricity can be saved by 20%. The indexes (whiteness, capillary effect, water absorption, cotton seed hull strainaway rate, desizing rate, strong force and the like) of the processed cotton and cotton-type fabric all reach the quality indexes of a semi-product, cotton seed hulls can be completely removed, and the fabrics have vivid color andgood levelling property after being dyed.

Owner:DONGHUA UNIV

Efficient and continuous dyeing process method for textile fabric through wet-state steaming

InactiveCN101858019AShort processIncrease productivitySucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersVapor pressureAir volume

The invention provides an efficient and continuous dyeing process method for textile fabric through wet-state steaming, which belongs to the fabric dyeing method. The process method comprises the following steps in sequence: fabric soaking in dyeing solution, bake-steaming for color fixation, water washing and drying and feeding. During the drying and feeding procedure, the humidity of mixed gas in the reaction steam box is 25-35 percent, the temperature of the mixed gas is 120-130 DEG C, the air volume of the mixed gas is 4m3 / s, and the processing time is 2-3 minutes; the saturated vapor pressure is 0.15-0.2MPa; and during the water washing procedure, the content of the water softener B in lotion is 2-3g / L, and the rest is water. The dyeing process method shortens the process flow, thereby not only improving the production efficiency, but also saving the energy. In addition, compared with the traditional dyeing process, the dyeing process method has the advantages of high color fixing speed, high color fixing rate, bright color, no dye transfer, low alkali consumption, good reproducibility, good levelness, good penetration and the like. Therefore, the invention can be used for obtaining good washing-resistant and friction-resistant fastness.

Owner:YUYUE HOME TEXTILE

Compound dispersion red dye

InactiveCN1597790AImprove dye uptakeGood dyeing reproducibilityOrganic dyesDyeing processPolyesterPolymer chemistry

The invention relates to a compound dispersive red dye, especially relating to a polyester material printing and dyeing compound dispersive red dye, containing the following components in weight percent: monomer A 20%-45%, monomer B 5%-15% and auxiliary. It has the advantages of high dyeing ratio, good dyeing repeatability, good dyeing uniformity, excellent fastness, approach of coloured light to dispersive red S-5BL, etc.

Owner:ZHEJIANG LONGSHENG GROUP

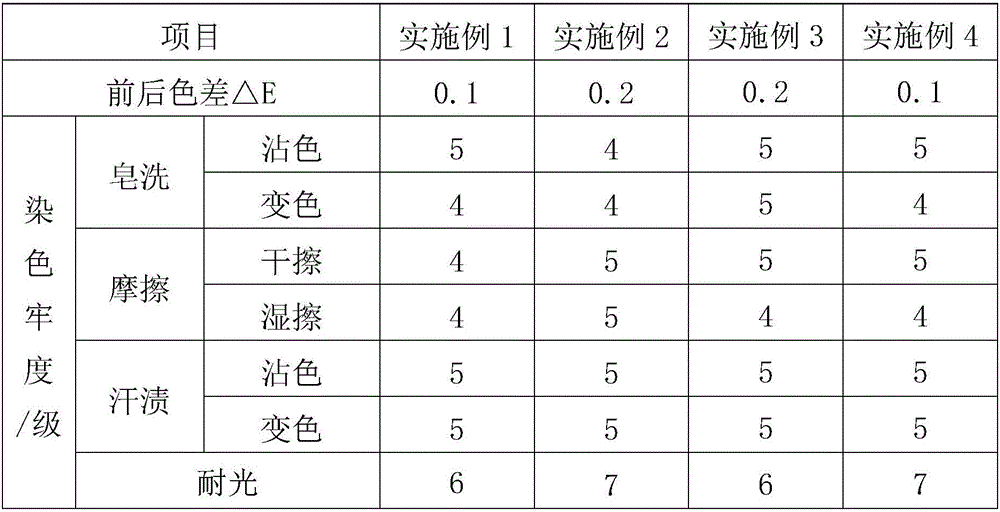

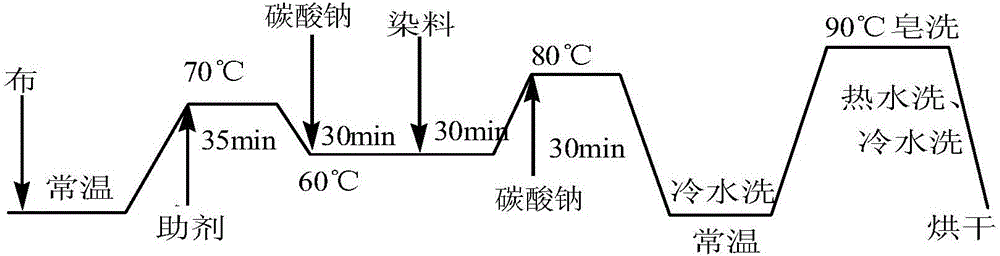

Reactive dye cosolvent staining method for cellulose fabric

The invention relates to a reactive dye cosolvent staining method for a cellulose fabric. The method comprises the following steps of: adding a solvent into an aqueous solution of a reactive dye, thus obtaining a cosolvent solution of the dye; soaking the cellulose fabric in the dyeing solution under room temperature, and raising the temperature to the dyeing temperature of 40-100 DEG C; and adding the solvent and sodium carbonate, raising the temperature to the fixation temperature of 40-100 DEG C, keeping the temperature for 30-60 minutes, taking the fabric out, and washing, soaping and washing to obtain the product. The method is simple, is easily industrialized, can obtain higher dye-uptake and higher fixation rate compared with the traditional reactive dye staining process, and has high leveling property.

Owner:DONGHUA UNIV

High-fastness black and blue disperse dye composite

ActiveCN102002259AImprove dye uptakeBright shadeOrganic dyesDyeing processDisperse dyePolymer science

The invention discloses a high-fastness black and blue disperse dye composite, which comprises the following components in percentage by weight: 7 to 42 percent of component A, 45 to 90 percent of component B and 3 to 13 percent of aids, wherein the component A is a compound shown by a formula (I), and the component B is one or more of compounds shown by a formula (II). The high-fastness black and blue disperse dye composite provided by the invention has excellent levelling property, beautiful and bright color light, strong deep dyeing property, high color yield and excellent fastness such as sublimation resistance fastness, washing resistance fastness, friction resistance fastness and the like, and particularly by the addition of the component A, the sublimation fastness of the black and blue disperse dye composite is improved obviously.

Owner:ZHEJIANG RUNTU

Blue disperse dye compound

ActiveCN102732061AHigh affinityGood level dyeingOrganic dyesDyeing processColored lightFine chemical

The invention discloses a blue disperse dye compound, which belongs to the technical field of fine chemical engineering. The blue disperse dye compound provided in the invention comprises, by mass, 50 to 70% of component A, 6 to 10% of component B and 0.4 to 1.0% of component C, with the balance being auxiliary agents. The blue disperse dye compound has brilliant colored light, good dispersibility and color fastness and superior level-dyeing properties, and is especially applicable to printing and dyeing of terylene and terylene / spandex fabrics.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Auxiliary agent of formulation for dyeing Terylene

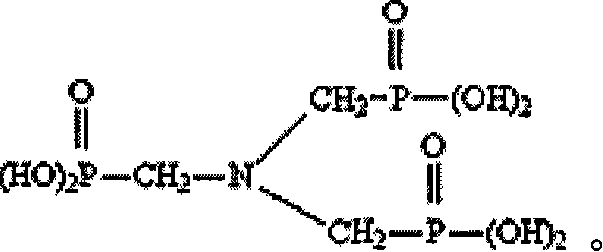

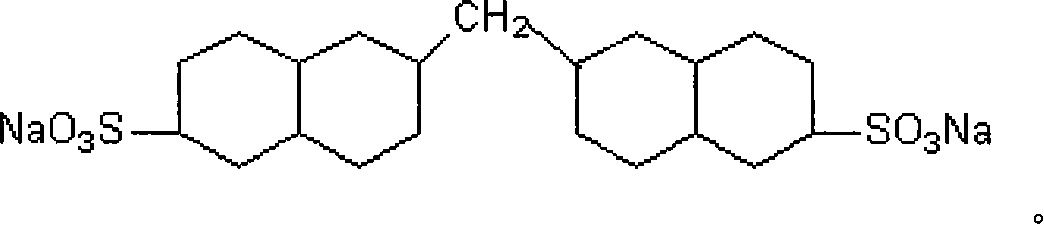

This invention discloses an aid used in terylene dyeing characterizing in including the following components in weight percentage: acid aid 10-20%, organic phosphonic acid 2-5%, organic carboxylic acid 3-7%, naphthalenesulfonate 10-18%, PEG 400 single oleic acid ester 5-8%, non-ion PAA 0-2%, polytrimethylene polyethenoxy aether 0-3% and water.

Owner:夏建明 +1

Dispersion-reduction dyeing process for cotton-polyester blended fabric

ActiveCN106087463AImprove reducibilityImprove dyeing effectSucessive textile treatmentsDyeing processDisperse dyeVat dye

The invention discloses a dispersion-reduction dyeing process for a cotton-polyester blended fabric. The dispersion-reduction dyeing process comprises a disperse dyestuff treating procedure and a vat dye treating procedure which are successively carried out. The disperse dyestuff treating procedure comprises dyeing, reduction cleaning, washing and pickling; the vat dye treating procedure comprises dip padding with a vat dye suspension, dip padding with a reducing solution, steaming, oxidation, soaping, hot washing and drying; in the disperse dyestuff treating procedure, a disperse dyestuff microcapsule method is used for dyeing; and in the vat dyestuff treating procedure, vat dye wet rapid-steaming pad dyeing process is employed. The dispersion-reduction dyeing process for the cotton-polyester blended fabric has the advantages of good level dyeing effect, small chromatic aberration and high color fastness, and is simple in process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Reactive beta-cyclodextrin quaternary ammonium salt as well as preparation method and application thereof

The invention relates to reactive beta-cyclodextrin quaternary ammonium salt as well as a preparation method and application thereof. The reactive beta-cyclodextrin quaternary ammonium salt is synthesized through two steps, namely, step 1, taking beta-cyclodextrin, choline chloride and epoxy chloropropane as raw materials to be subjected a ring opening substitution reaction to generate beta-cyclodextrin quaternary ammonium salt; step 2, taking the beta-cyclodextrin quaternary ammonium salt and a compound as raw materials to be subjected to a substitution reaction to generate the reactive beta-cyclodextrin quaternary ammonium salt. The reactive beta-cyclodextrin quaternary ammonium salt has no toxic or side effect; when being used for salt-free dyeing of an active dyestuff of cotton fabric, the reactive beta-cyclodextrin quaternary ammonium salt has relatively good dyeing effect; the pollution to the environment by salt in wastewater is reduced and treatment pressure of dyeing and finishing wastewater is alleviated; the dyed fabric has relatively good dyeing effect; the dyeing rate of the active dyestuff is 65 percent to 85 percent and the color fixation rate is 55 percent to 70 percent; the dry rubbing fastness is more than grade 4 and the wet rubbing fastness is more than grade 3.

Owner:那坡同益新丝绸科技实业有限公司

Ultralow liquor ratio zipper dyeing machine and dyeing process thereof

InactiveCN103088574AHollow volume reductionReduced cavity cross-sectional areaPump componentsTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses an ultralow liquor ratio zipper dyeing machine and dyeing process thereof. The dyeing machine comprises a tube cylinder, a cylinder cover and a zipper warp beam plate frame embedded into the tube cylinder. The zipper warp beam plate frame comprises a zipper plate seat, a hollow water drum, a zipper woven belt, a zipper tube sleeve, a locking bolt, and a zipper frame lifting ring. The lower end of the hollow water drum is fastened on the zipper plate seat, the zipper tube sleeve is sleeved on the outer side of the hollow water drum, and a diversion inlet and a diversion outlet are arranged below the zipper plate seat and connected with an infusion pump through a horn-shaped pipe sleeve. The dyeing process comprises the stages of scouring and bleaching, dyeing and water scrubbing. According to the ultralow liquor ratio zipper dyeing machine and the dyeing process thereof, a lift range required by zipper woven belt dyeing water level can be achieved when the height of dye liquor in the dyeing machine is lower than the zipper plate seat, the effect of ultralow liquor ratio zipper dyeing is achieved, the dyeing machine has a lower dying liquor ratio than a traditional zipper dying machine, and the purposes of saving electric energy, steam and the dye liquor, shortening dyeing and finishing periods, and saving energy and reducing emission are achieved.

Owner:高勋绿色智能装备(广州)有限公司

Dyeing and finishing process for polyester blended fiber fabric

ActiveCN106223003ASoft touchImprove water absorptionHeating/cooling textile fabricsHeat resistant fibresDisperse dyeAfter treatment

The invention discloses a dyeing and finishing process for a polyester blended fiber fabric. The process comprises the following steps of 1, pretreatment, wherein the polyester blended fiber fabric is sequentially subjected to scouring, bleaching and enzyme washing; 2, mercerizing and sizing, wherein the fabric is subjected to padding of alkali liquor under the room temperature for pre-sizing; 3, dyeing, wherein the fabric is soaked into dye liquor formed by disperse dyes, dyeing is performed under the temperature of 30-40 DEG C, temperature is increased to 90-110 DEG C at the heating rate being 0.8-1 DEG C / min, washing is performed through warm water, infrared ray pre-heating is performed, and then hot-blast air drying is performed; padding is performed again under the room temperature to reduce the suspended solid dye liquor formed by dyes, a reduction solution is subjected to padding, steam reduction and oxidation are performed, washing is performed through warm water, soaping is performed, and then washing and drying are performed; 4, after-treatment, wherein soft and flame-proof treatment is performed in sequence. According to the dyeing and finishing process for the polyester blended fiber fabric, the touch feeling, elasticity and other properties of the fabric are improved remarkably, dyeing is uniform, the color fastness is high, and the color is full.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Active composite dye

ActiveCN1858118AGood synchronization of dyeingGood level dyeingOrganic dyesDyeing processCelluloseCompound c

The active composite dye includes at least one of compound A, at least one of compound B and at least one of compound C, with the compounds A, B and C being shown. The active composite dye is suitable for dyeing cellulose or protein fiber, and has the composition meeting the environmental and ecological requirement of Oeko-Tex Standard 100. The active composite dye has high build-up, good level dyeing property, good color reproduction, high dye uptake and other excellent performance.

Owner:ZHEJIANG RUIHUA CHEM

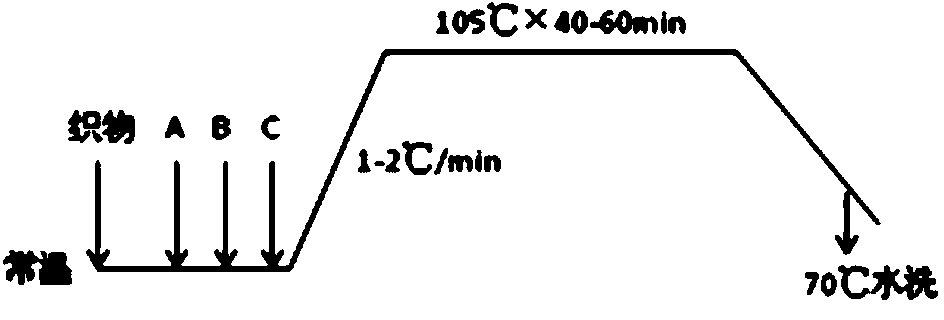

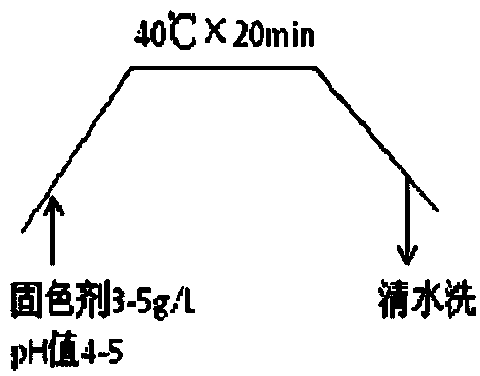

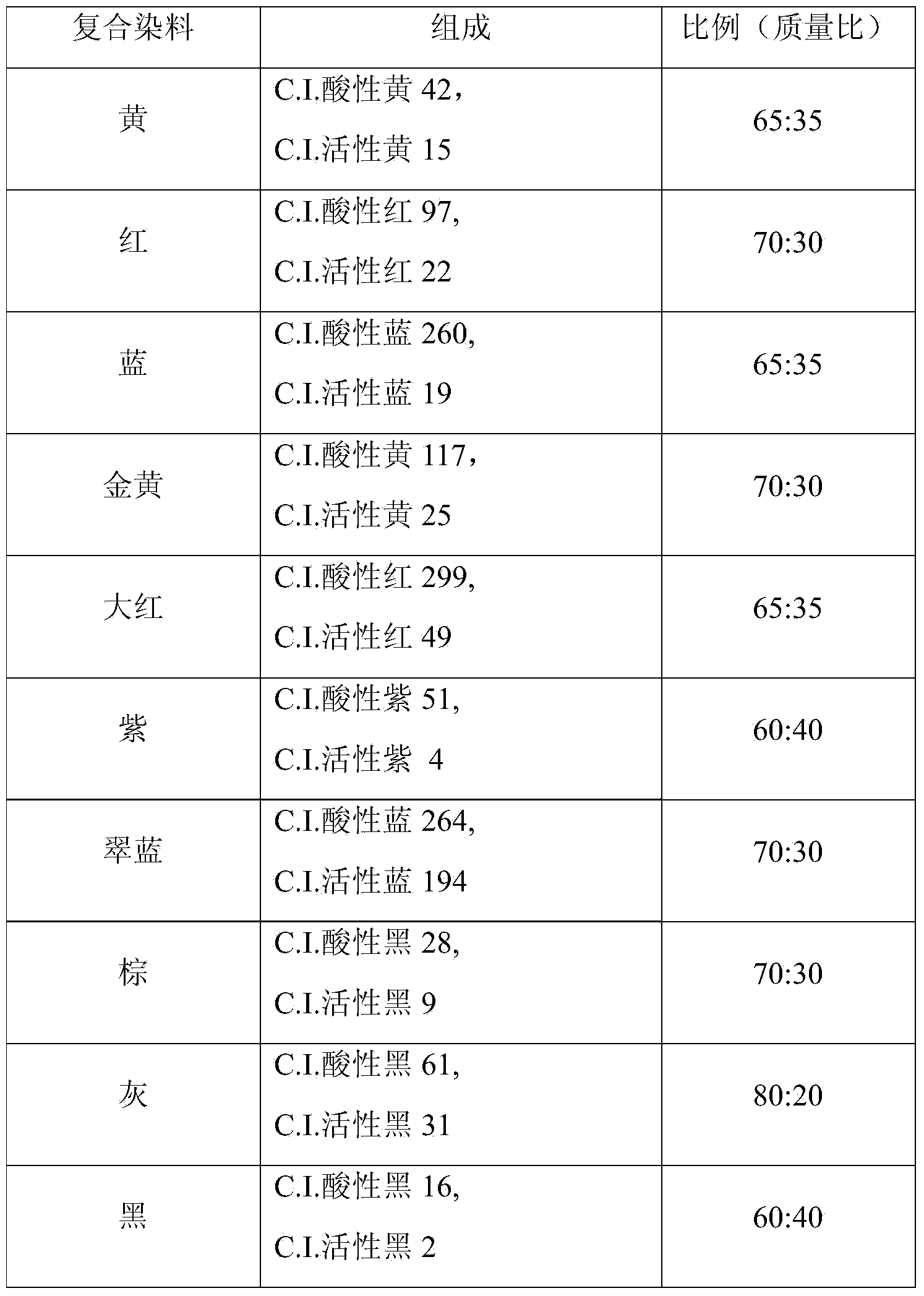

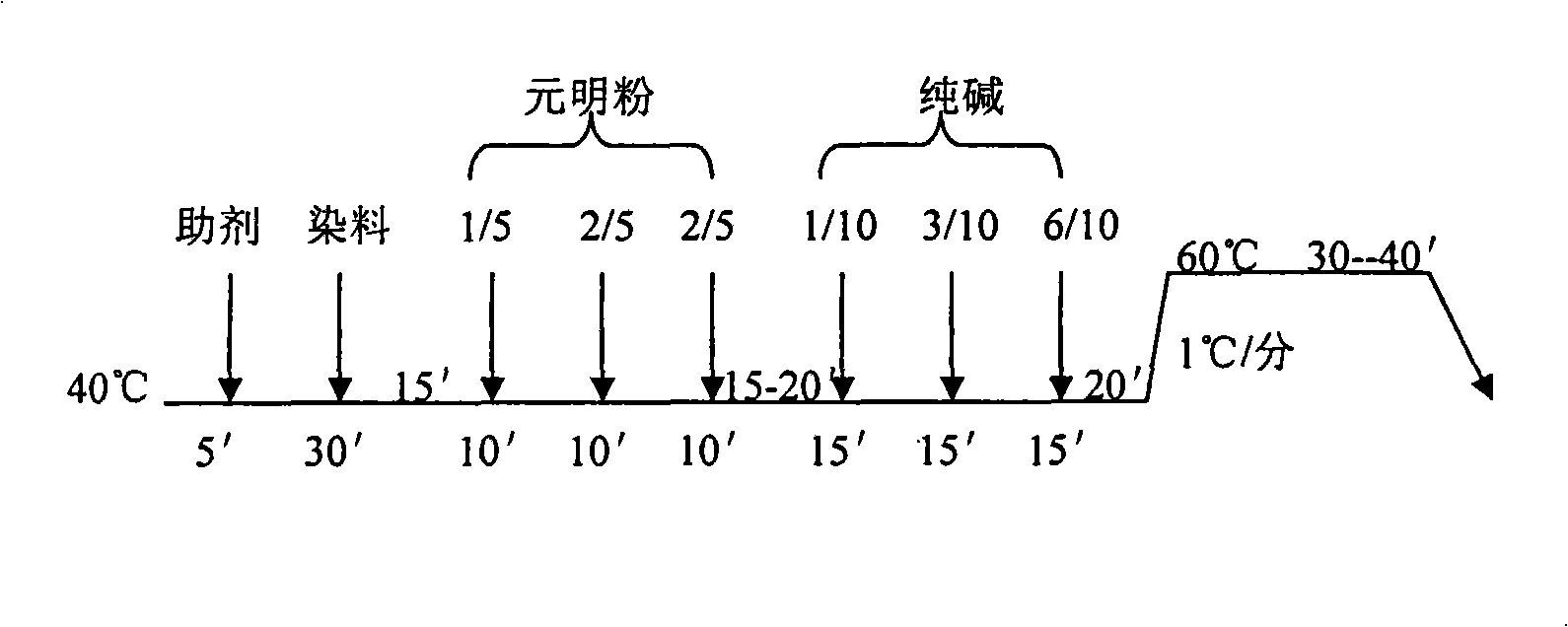

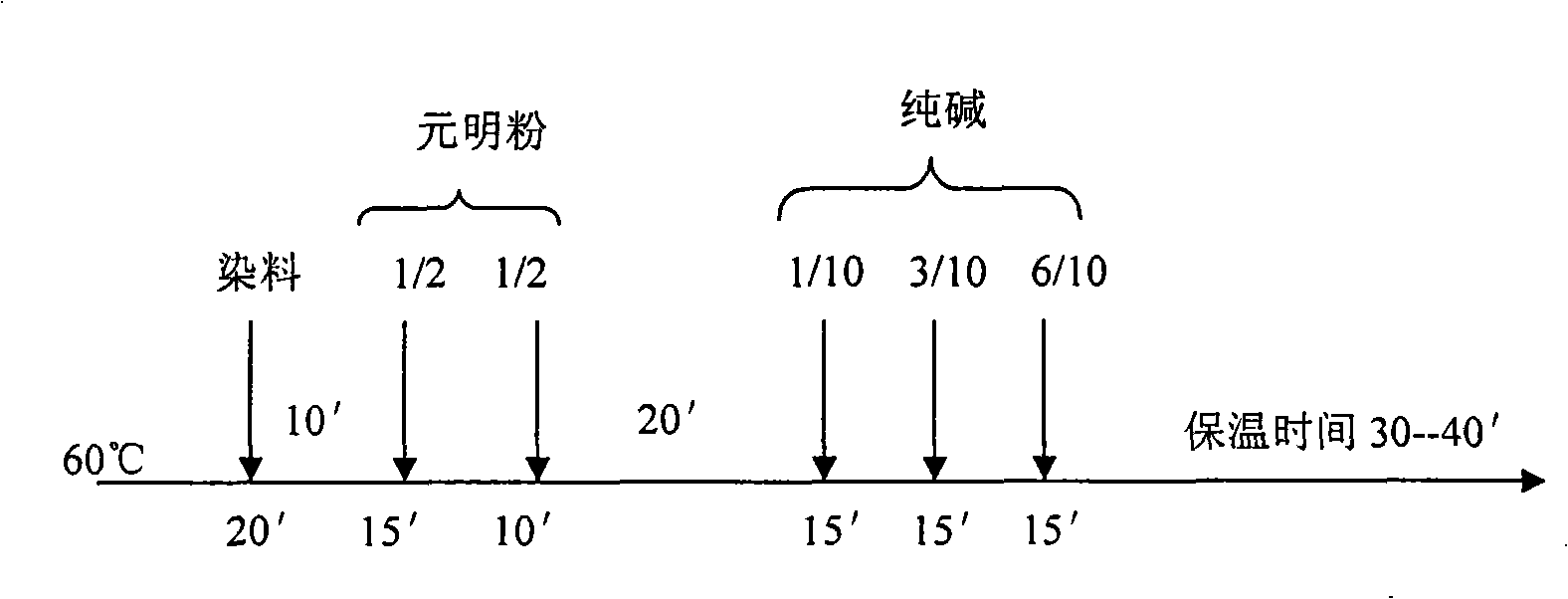

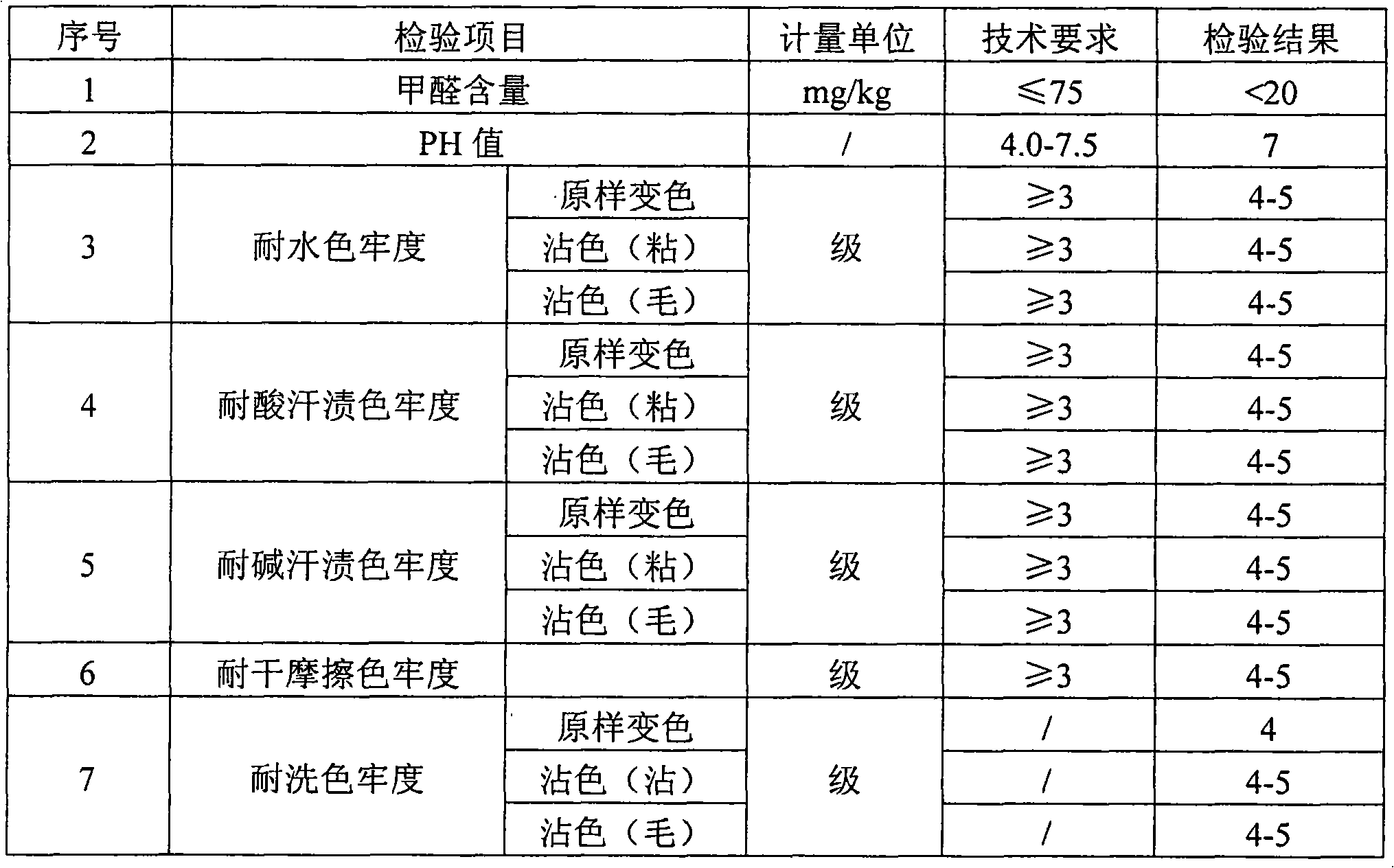

Nylon sea-island microfiber leather fabric composite dye and application thereof

ActiveCN103525123AConsistent dyeingApplicable dyeingOrganic dyesDyeing processAcid dyeIncrease temperature

The invention relates to nylon sea-island microfiber leather fabric composite dye and application thereof. The dye is formed by combining acid dye and active dye. The application is as follows: at normal temperature, sequentially adding an acid level dyeing penetrating agent and composite dye to a dye bath, regulating pH value to 5-6, soaking a fabric in the dye bath, increasing temperature to 105-110 DEG C, preserving for 40-60min, and completely washing at 70-80 DEG C to obtain the dyed fabric; soaking the dyed fabric in a fixation bath, increasing temperature to 40-50 DEG C, preserving for 20-30min and washing. The composite dye formed by combining the acid dye and the active dye, is free from components violating against national technical standard for safety, can consistently dye poly urethane (PU) and nylon superfine fiber, and in particular can dye nylon microfiber leather. The composite dye is complete in chromatography, good in compatibility, synchronous to dye and easy to control quality.

Owner:DONGHUA UNIV +1

Nursing type mixed fabric and production method thereof

InactiveCN101525803AHas broad-spectrum antibacterial functionStrong persistenceWeft knittingWarp knittingGramNational standard

The invention discloses a nursing type mixed fabric and a production method thereof. The nursing type mixed fabric is characterized by being formed by mixing milk silk fibres, Modal fibres, Newdal fibres and urethane elastic fibres which are taken as raw materials and being counted by raw material percentage by weight, a finished fabric is made of the following raw materials by weight: 10-55 percent of milk silk fibres, 20-50 percent of Modal fibres, 20-60 percent of Newdal fibres and 2-8 percent of urethane elastic fibres, and the gram weight of the finished fabric is 250-300g / M<2>. The nursing type mixed fabric has the aroma of milk silk, good heat preservation and ventilation property, natural skin nursing function and soft, smooth and silky feel. The invention also provides two coloration methods aiming at the nursing type mixed fabric. With the two coloration methods, each dyefastness index reaches or surpasses national standards.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

Jacquard acetic acid filament home textile fabric and production method thereof

ActiveCN106012214AGood coloring effectSoft touchHeating/cooling textile fabricsDry-cleaning apparatus for textilesSocial benefitsAcetic acid

The invention provides a jacquard acetic acid filament home textile fabric. Warp is semi-dull polyester filaments with the specification of 50D / 72F, and warp density is 200 pieces per inch. Weft is 75 D acetic acid filaments, and weft density is 96.5 pieces per inch. The structure is a large jacquard fabric. The breadth of the finished product is 160 cm. A production method of the fabric includes the steps that firstly, weaving is conducted, wherein weaving is conducted through warping by means of a warping machine, sizing by means of a filament sizing machine, re-beaming by means of a combining machine, leasing by means of a leasing machine, drafting and weaving by means of a rapier jacquard loom; secondly, dyeing is conducted, wherein dyeing is conducted through unwinding, desizing, dyeing, dewatering, scotching and setting. The fabric is flat, fine, smooth in cloth surface, soft in hand feeling, light, thin, cool, easy to wash, quick to dry, high in color fastness, good in air permeability, gentle and elegant. Reagents of the fabric successfully meet the requirement for comfort and cool of home textile summer quilt fabric of people, and the fabric has high addition value and wide market prospects and is remarkable in economic and social benefit.

Owner:JIANGSU YUEDA HOME TEXTILE

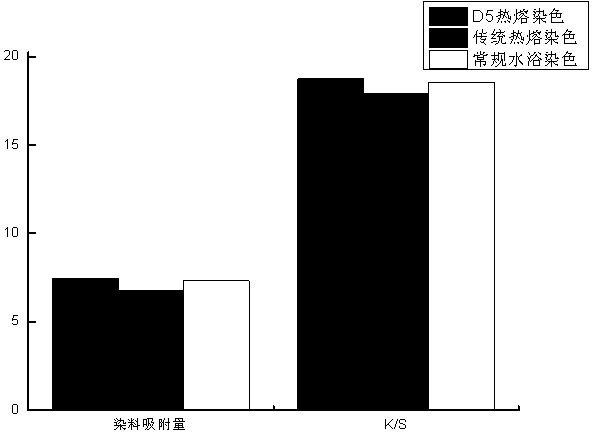

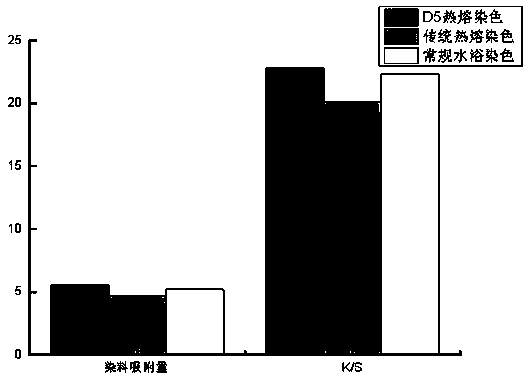

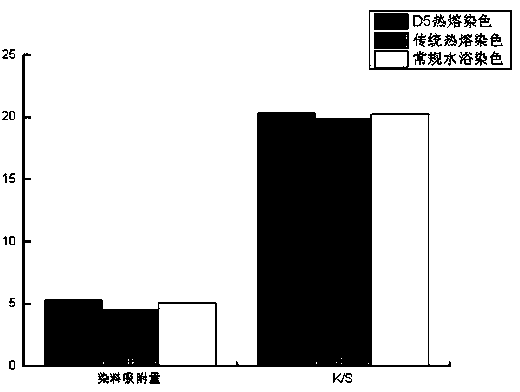

Thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as medium

InactiveCN104278576ASave water for dyeingReduce sublimationDyeing processDisperse dyeEcological environment

The invention discloses a disperse dye thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as a medium. The method comprises the following steps: (1) pretreating polyester fabric; (2) adding a certain amount of pure disperse dyes into a dyeing medium D5, controlling the amount of the dyeing medium D5, so that a ratio of the weight of a to-be-dyed fabric to the weight of the medium D5 is 1:10 to 1:30, dyeing in a dyeing machine, heating the system to 90-100 DEG C, preserving the temperature for 5-10 minutes, heating to the temperature of 180-200 DEG C, and performing thermosol fixation, wherein the fixation time is 10-30 minutes; and (3) performing reduction clearing on the dyed fabric according to a GB2394-80 method after dyeing. According to the method, non-aqueous medium dyeing is adopted, lots of water resources are saved, the thermosol temperature can be obtained under normal pressure, the conventional dyeing equipment can be adopted, the operation is simple, pure disperse dyes are adopted for dyeing, lots of dispersing aids are saved, the utilization rate of the dyes is improved, wastewater emission is reduced, and ecological environment protection is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

Black dye mixer and preparation method and application thereof

The invention provides a black dye mixture, which is mixed by (counted by weight quotient): dye shown by formula (1) of 50-80 quotient, dye shown by formula (2) of 9-30 quotient and dye shown by formula (3) of 4-20 quotient. The black dye mixture owns property of high level-dyeing property, high fixation yield and high jet black degree, and can combine with cotton, hemp, yarn, thread, hair and polyamide to form covalent bond. Moreover, the black dye contains no harmful arylamine and heavy metal element and does not decompose harmful matter to human body during using process.

Owner:佛山市焱基化工染料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com