Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about How to "Guaranteed dyeing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

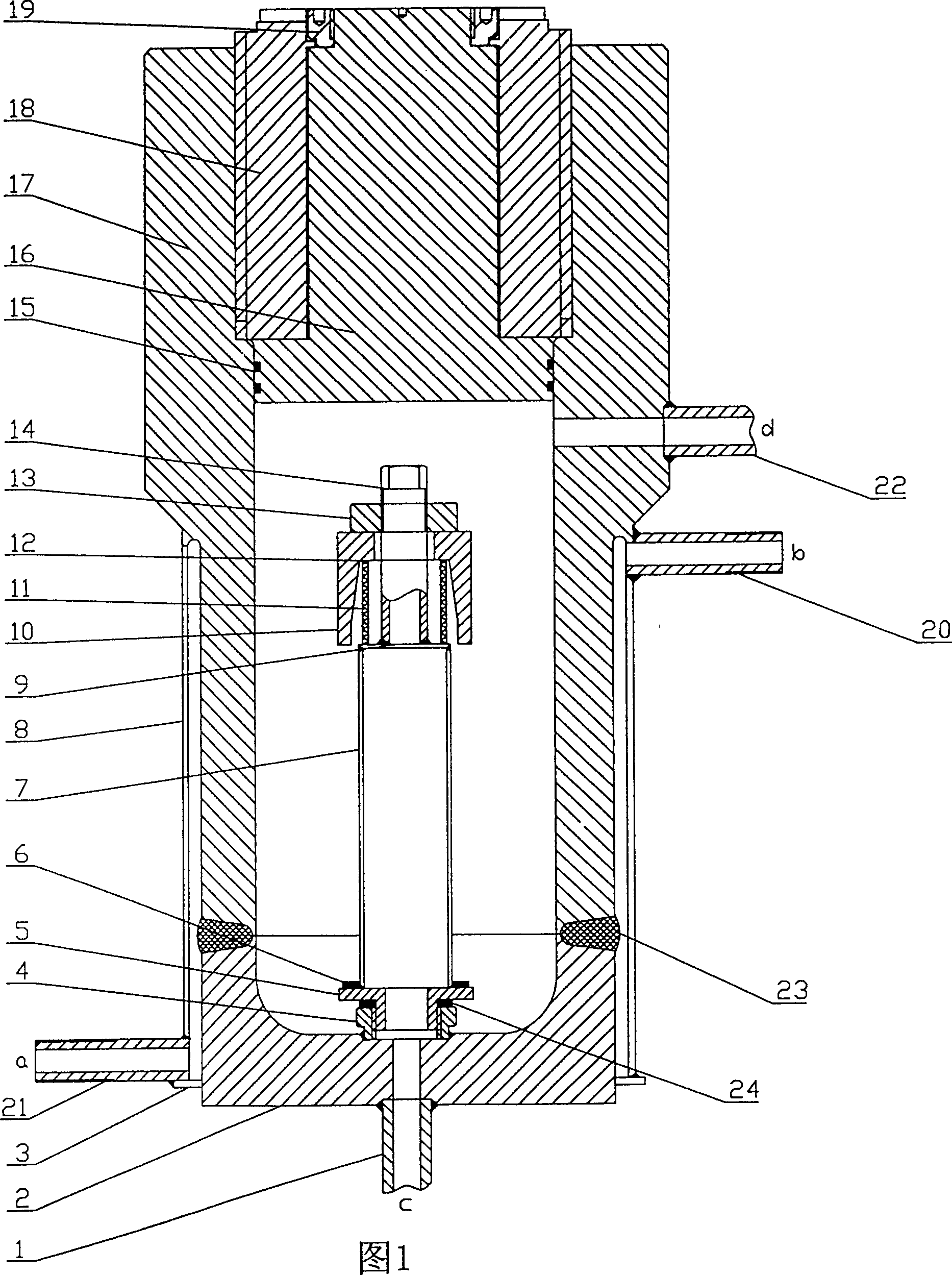

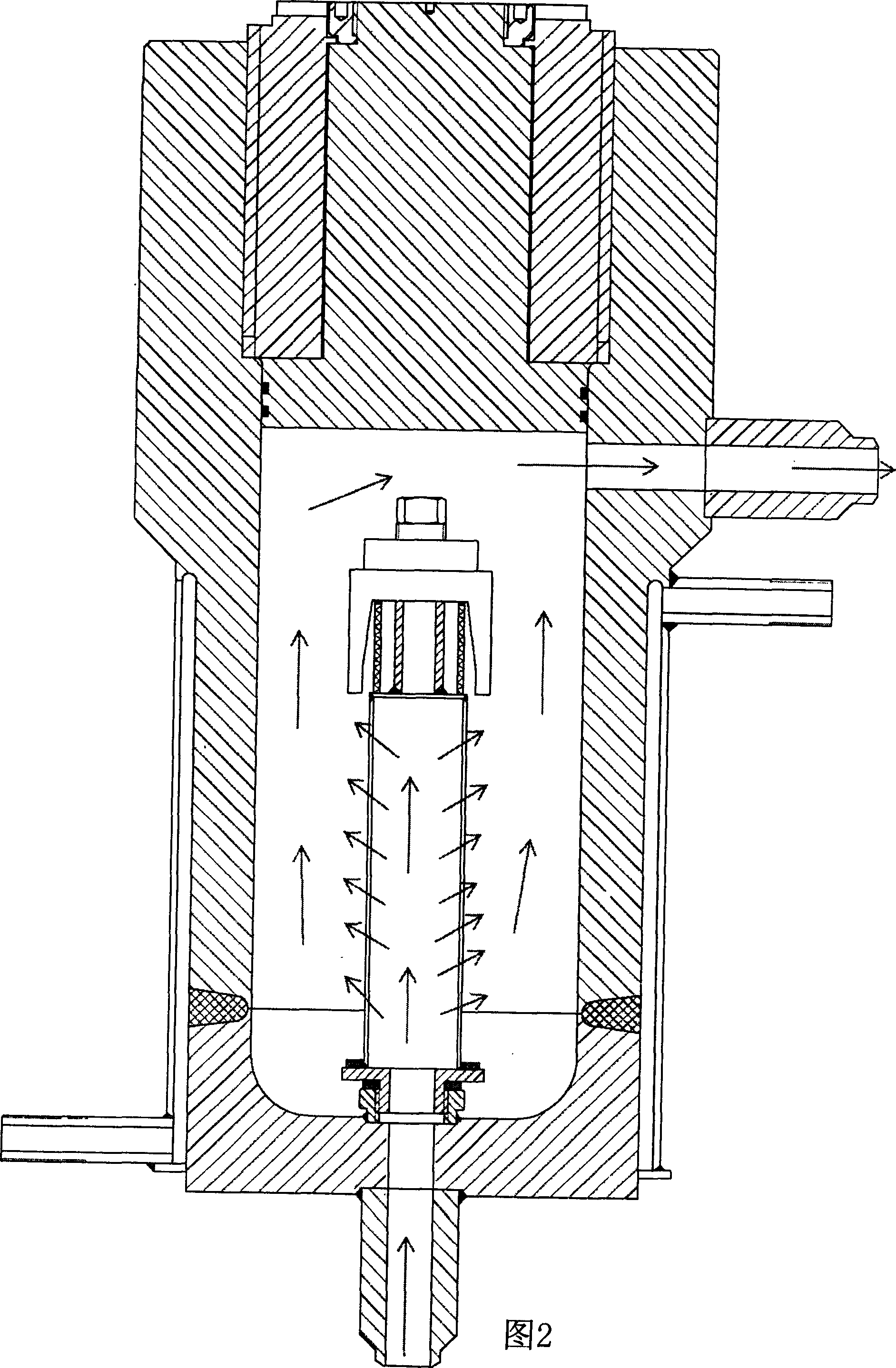

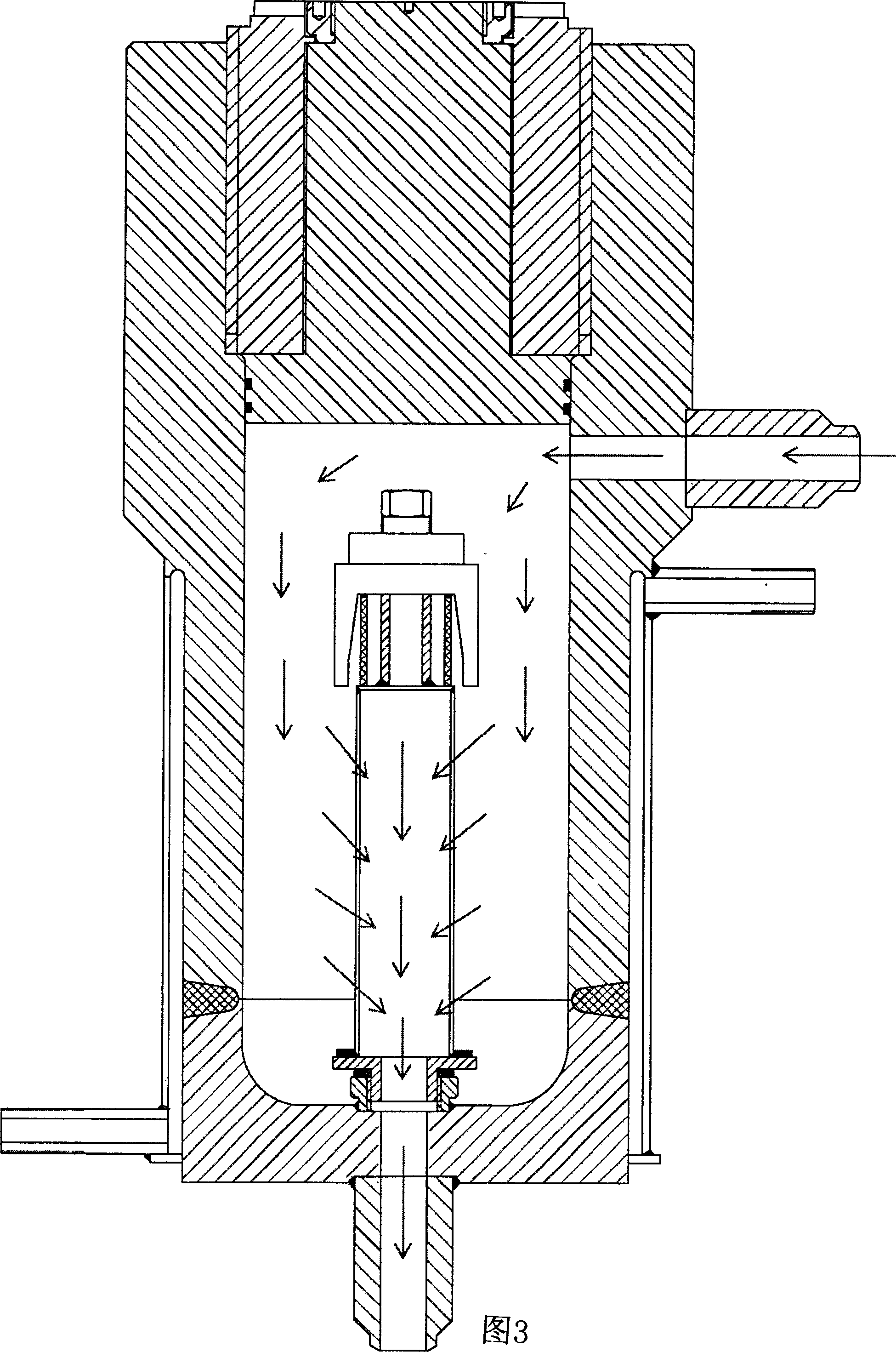

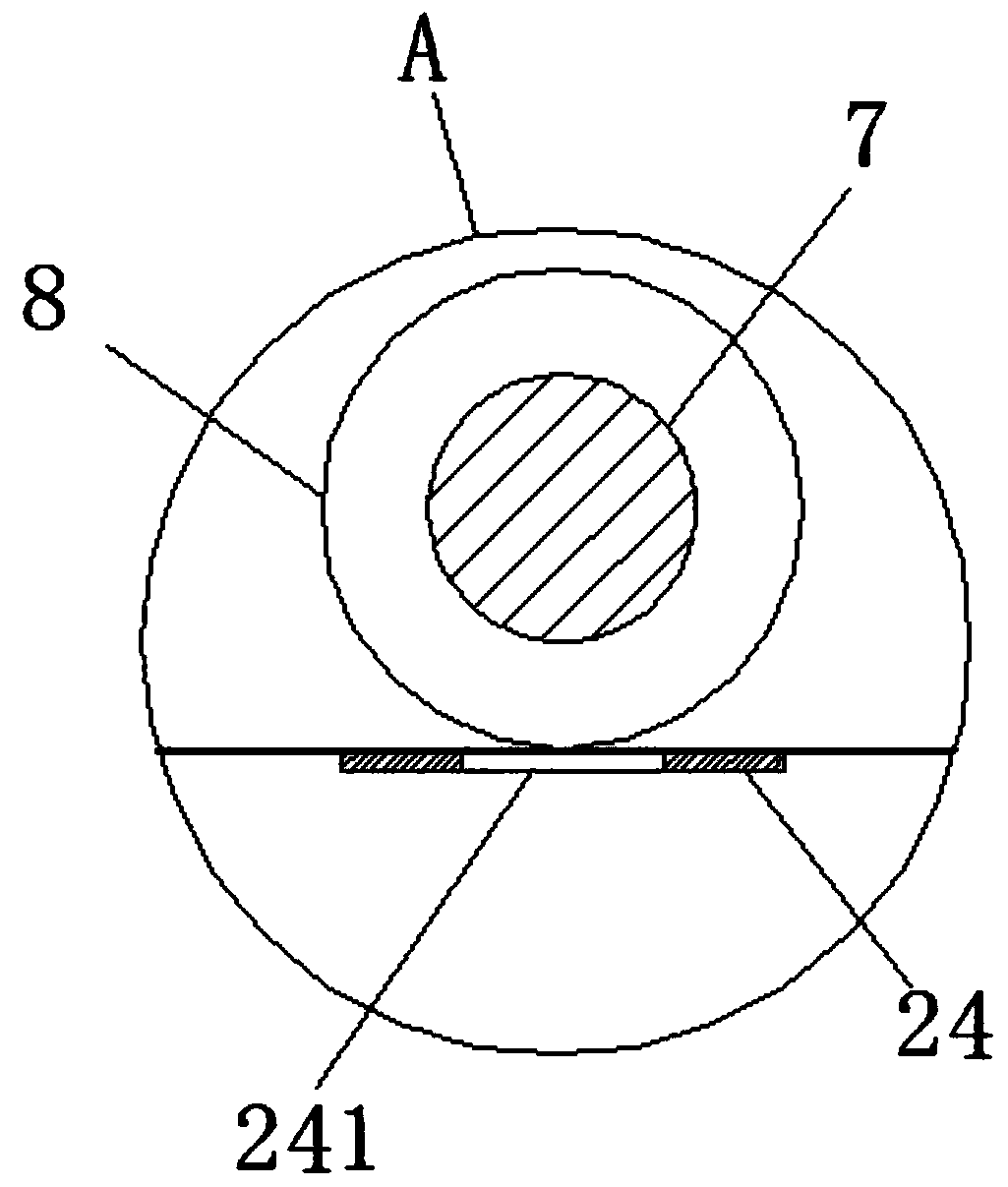

Dying still in supercritical CO2 dyeing device

InactiveCN1807742ARealize the operation process of dynamic dyeingReduce dye liquor vortexTextile treatment containersDyeing processEngineeringMechanical engineering

This invention discloses a dyeing kettle of the over-critical carbon-dioxide dyeing device, which is to use for the dyeing of the textile, including arranging the barrel and the sealed convex shoulder flat that is on the upper part of the barrel; the center opening of the barrel's bottom connects with the first connector, the inside center opening of barrel connects with the inner barrel by the support cell; the wall of the inner barrel is arranged with the filter hole uniformly, the upper of the inner barrel connects with the second cover; the barrel wall opening of the barrel's upper connects with the second connector; the under part of the barrel connects with the nip cover, which has the ring space with the barrel, and the upper of the ring space is sealed in the protruding stage that outside the barrel, and the first cover is sealed in the under part, one side of the ring space's under part opening connects with the first adapter, and the other side of upper part opening connects with the second adapter. This invention realizes the combining of the technology of the textile internal dyeing and external dyeing, and the dynamic dyeing in the over-critical dyeing method.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Simplified thin-layer liquid-based cytology detection method

InactiveCN1967196ACheap methodGood effectMicrobiological testing/measurementSurgical needlesLiquid base cytologyCervical cells

The invention discloses a simple thin liquid-based cytology examine method applied for the gynecological examination, the cervical cancer general examine and the cervical cancer preceding lesion of selected crowd, the steps including: using the cervical cells brush and the scraper to collect samples, put samples in the liquid-based cell preservation solution, add base liquid cell processing solution, oscillate, centrifugally separate, take and discard the supernatant samples liquid, using adding samples gun to assimilate sediment samples, smear, sheet drying, using 95% ethanol marinate or spray for fixed, washing and dyeing. The invention has simple method, small steps, high positive detection rate, low misdiagnosis rate, low cost, and it can effectively eliminate the red blood cells, mucus and other interference components from the cervical cytology detection specimens, with good sheet-producing result.

Owner:绵竹市人民医院

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

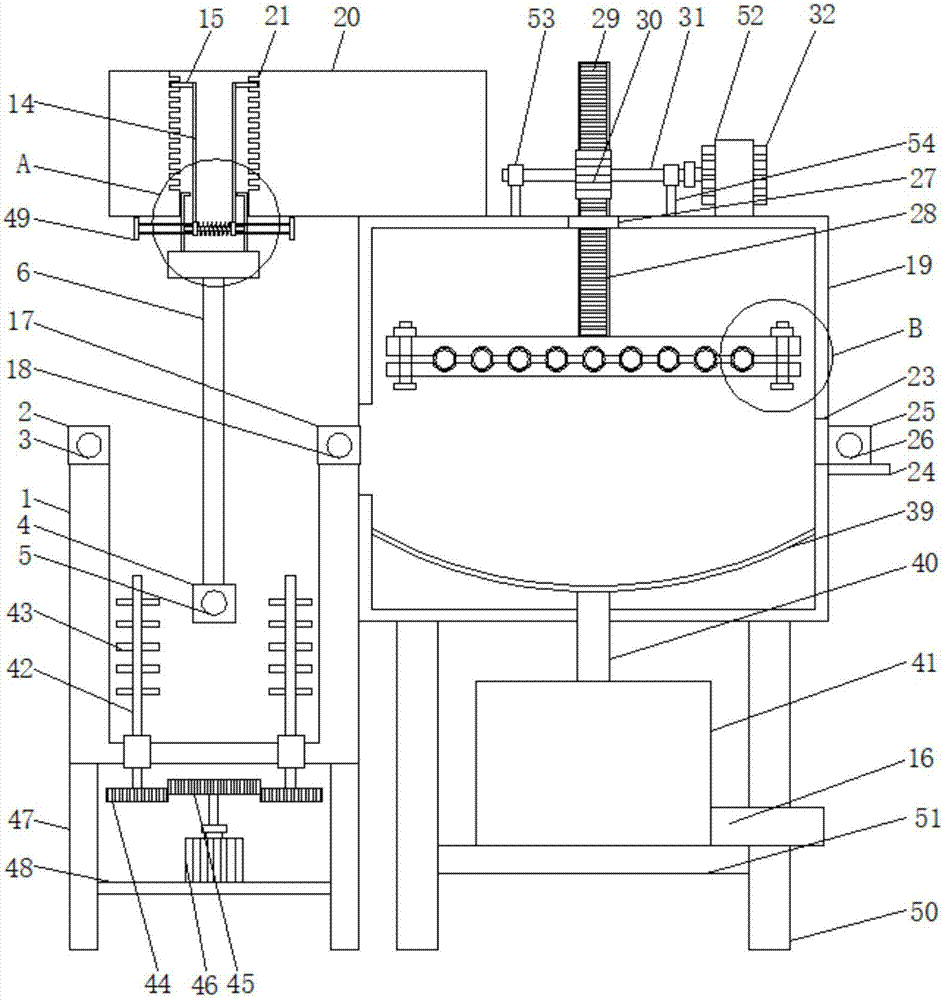

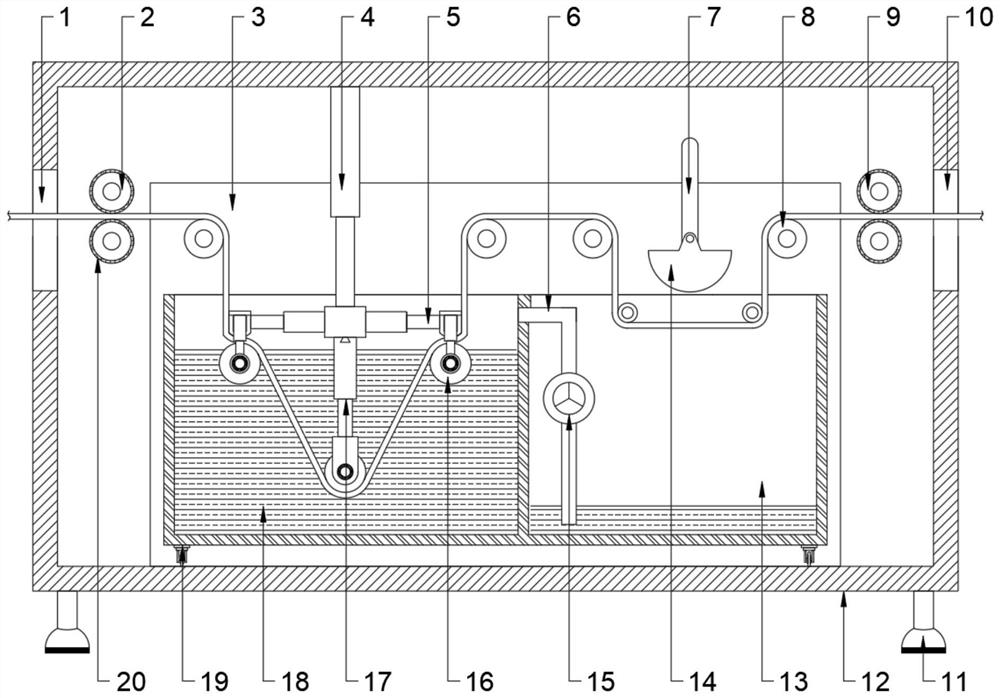

Dip dyeing device for textile fabric

InactiveCN107326578AFully dyedControl timeLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringThreaded rod

The invention discloses a dip-dyeing device for textile cloth, which comprises a paint bucket, a movable shaft is connected to the middle part inside the installation pipe, a compression spring is connected between two movable sleeves, and the top of the movable sleeve is connected to There is a clamping rod, the top of one side of the clamping rod is connected with a clamping block, the two sides of the inner wall of the installation groove are equidistantly provided with clamping slots, the inner side of the clamping slot is clamped with the clamping block, and the front of the adjustment plate It is connected with a rack, and the upper side of the front of the rack is meshed with a transmission gear, and the inside of the transmission gear is connected with a rotating shaft. The top of the threaded rod passes through the movable plate and is screwed with the nut. The two arcs Electric heating pipes are connected between the tanks. The invention has the advantages of being able to control the dyeing time of the cloth and the drying degree of the cloth after dyeing, and solves the problem that it is difficult to control the dyeing time of the cloth and the inconvenient control of the drying degree of the cloth will reduce the dyeing effect of the cloth.

Owner:范威

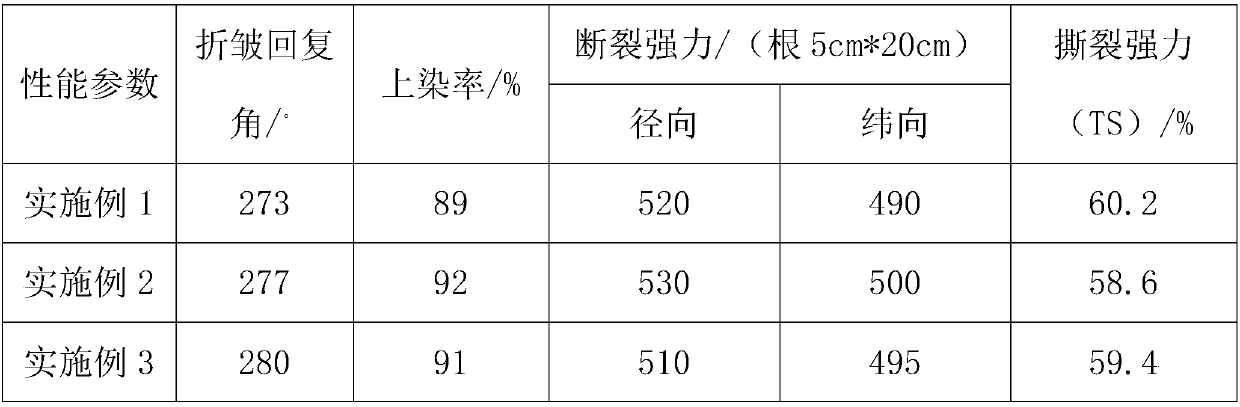

Wool and cashmere printing and dyeing auxiliary

The invention relates to the field of production auxiliaries of wool products, in particular to a wool and cashmere printing and dyeing auxiliary. The wool and cashmere printing and dyeing auxiliary comprises sodium carboxy methyl cellulose, sodium diethylhexyl sulfosuccinate, citric acid, ethylene oxide, amino silicon oil, di-rhamnolipid, peroxidase and deionized water. The wool and cashmere printing and dyeing auxiliary comprises, by mass, 10-15 parts of sodium carboxy methyl cellulose, 3-8 parts of sodium diethylhexyl sulfosuccinate, 12-16 parts of citric acid, 8-14 parts of ethylene oxide, 5-10 parts of amino silicon oil, 3-6 pars of di-rhamnolipid, 1-3 parts of peroxidase and 40-60 parts of deionized water. According to the wool and cashmere printing and dyeing auxiliary, due to the combination ratio of the carboxy methyl cellulose, the citric acid and the amino silicon oil, dyeing and fixation of the dye on a wool and cashmere product are effectively improved, color fastness is improved, the color increasing and protecting performance can be improved, and the dyeing effect is ensured.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

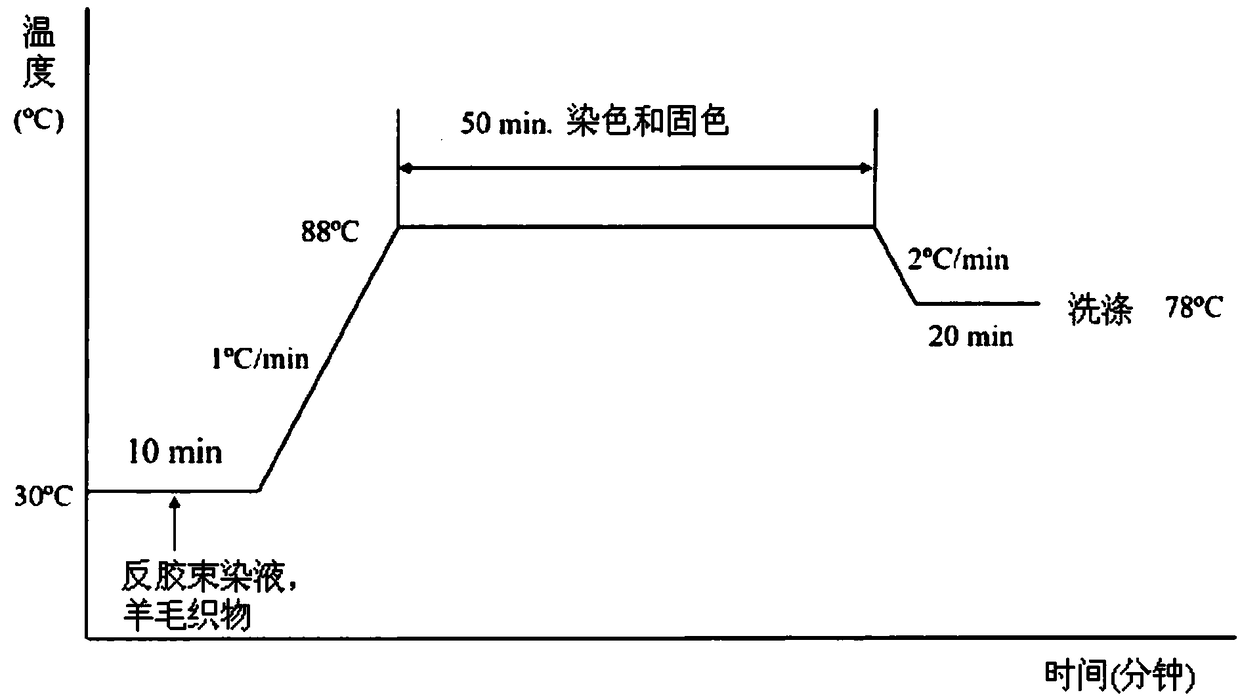

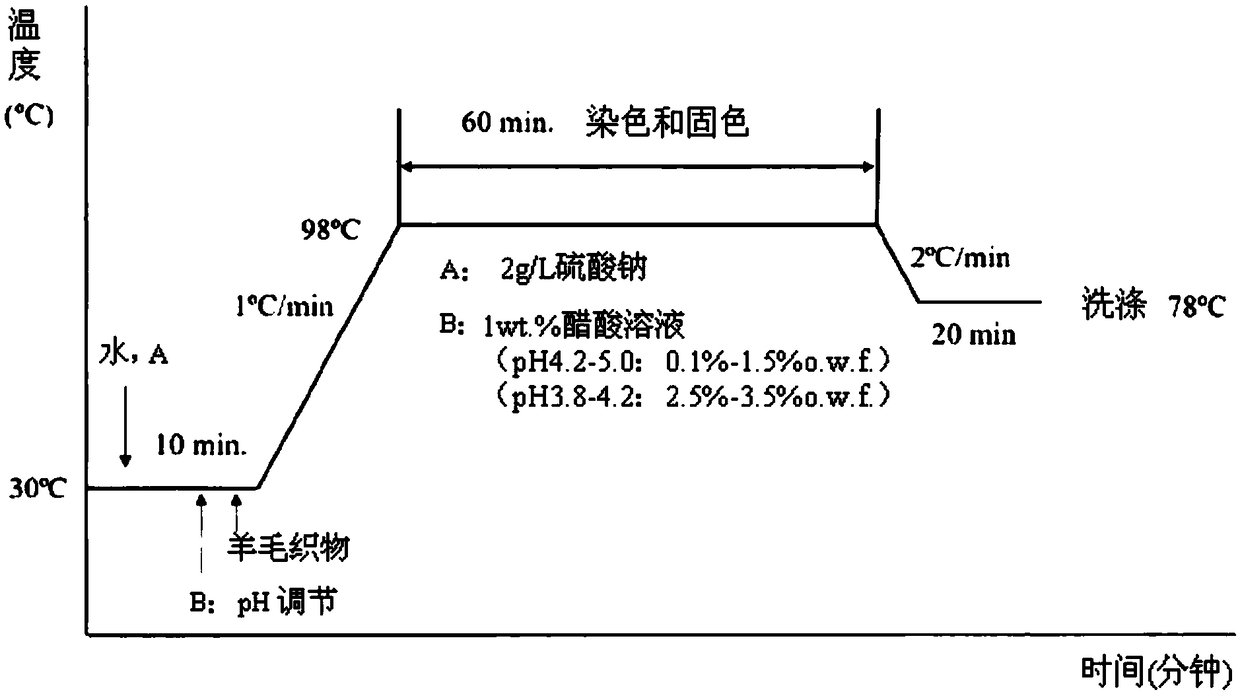

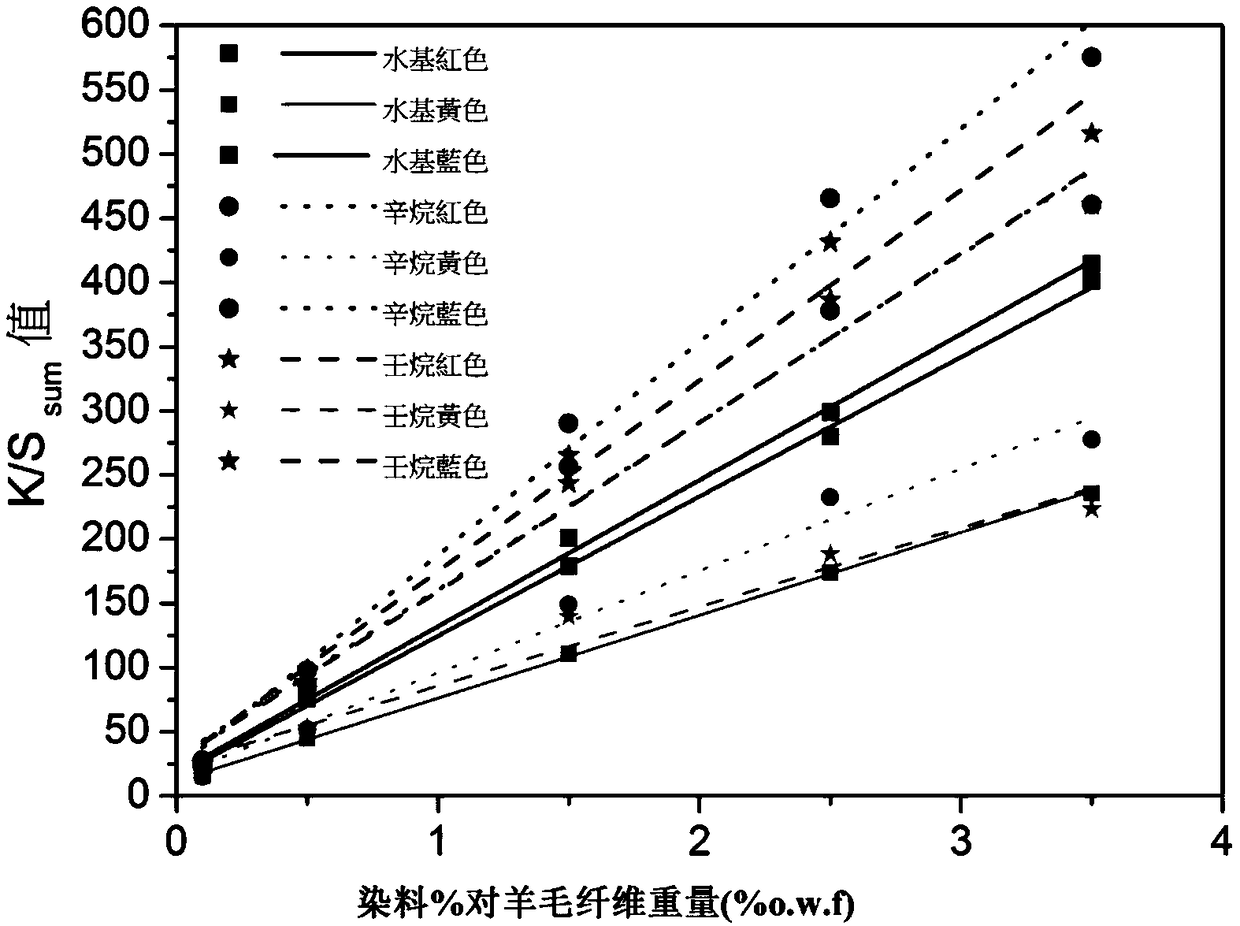

Dyeing method for protein fiber non-aqueous medium

The invention provides a dyeing method for a protein fiber non-aqueous medium, comprising the following steps: S1, a dyeing liquid is provided. The dyeing liquid comprises a reactive dye and a reversemicelle solution for encapsulating the micro-aqueous phase of the reactive dye; the reactive dye is a water-soluble reactive dye for protein fibers; the reverse micelle solution is formed by mixing and dissolving a surfactant and a cosurfactant in an organic solvent; the surfactant is a nonionic surfactant, and the organic solvent is alkane having C7 or above; and S2, the protein fiber undergoesdyeing and fixation in the dyeing liquid at the temperature of less than or equal to 90 DEG C so as to obtain dyed fiber. The protein fiber such as wool and the like undergoes dyeing and fixation in one bath by one step. According to the non-aqueous medium dyeing method of encapsulating the micro-aqueous phase of the reactive dye by using reverse micelles, there is no need to add salt or regulatepH value, and the dyeing temperature is low. Experiments show that the dyed wool has no obvious fiber damage and the dyeing effect is good. The method of the invention can reduce the processing amountof colored wastewater and is environmentally friendly.

Owner:THE HONG KONG POLYTECHNIC UNIV

Housing, preparation method thereof, and electronic equipment

InactiveCN108990328AAvoid damageGradient stableElectrical apparatus casings/cabinets/drawersEngineeringElectric equipment

The invention discloses a housing and a preparation method thereof, an electronic equipment, wherein the method comprises the following steps: forming a transparent ink layer on a first surface of a substrate; Forming a gradient color by dipping on the transparent ink layer; A dye protective layer is formed on the surface of the transparent ink layer after dyeing to seal the gradient color formedby dipping. The invention realizes stable gradient color.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

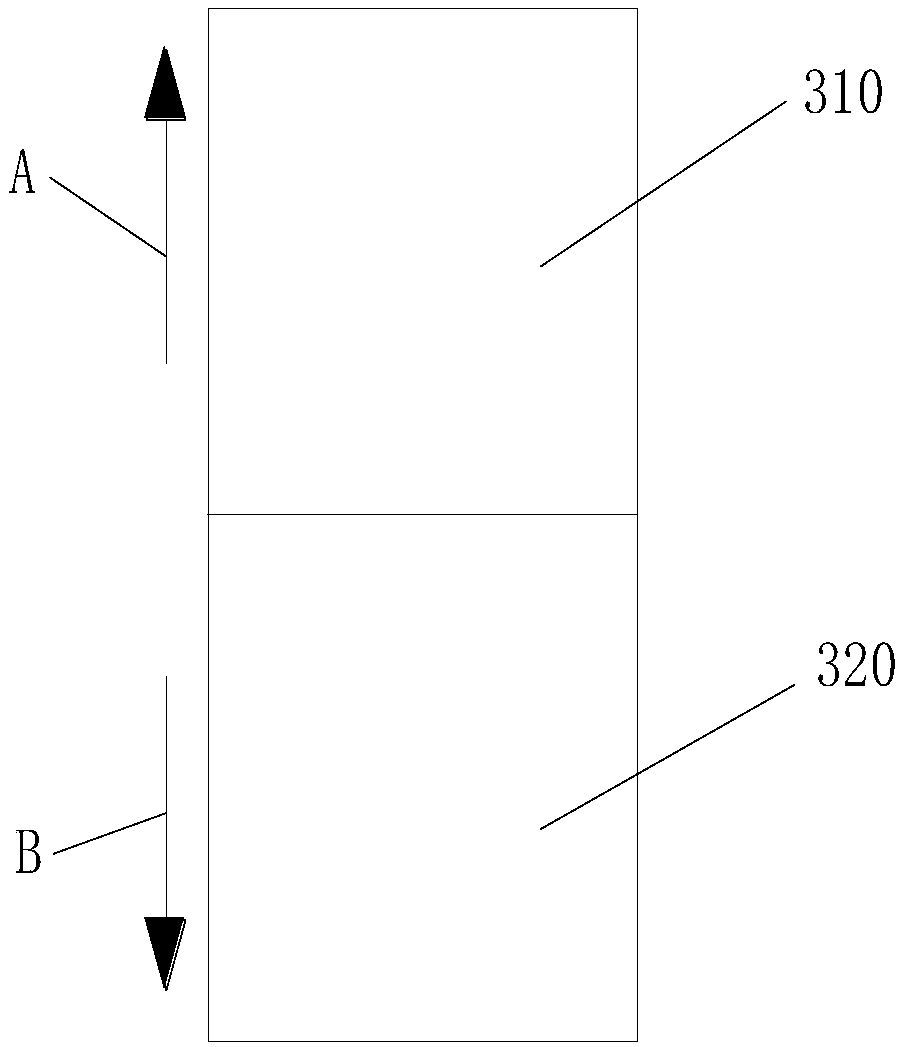

Ramie fabric and wrinkle-resistant dyeing and finishing process thereof

PendingCN109629266AReduce pollutionGuaranteed dyeing effectWrinkle resistant fibresDyeing processWrinkle skinFiber

The invention discloses a wrinkle-resistant dyeing and finishing process of a ramie fabric. The process includes the following steps that S1, pretreatment is performed; S2, wrinkle-resistant finishingis performed, wherein the ramie fabric obtained through the pretreatment in the step 1 is immersed in finishing liquid at 45-55 DEG C, the bath ratio is 1:25:35, immersion and rolling are performed twice respectively, the rolling rate is 80-95%, pre-drying is performed at 70-90 DEG C, steaming is performed under humidity at 110-120 DEG C, and drying is performed after water washing at 60-70 DEGC; S3, reactive dyeing is performed, wherein the ramie fabric obtained through wrinkle-resistant finishing in the step 2 is immersed into dyeing liquid formed by reactive dye, the bath ratio is 1:(20-30), the temperature is increased to 40-50 DEG C, heat preservation is performed, dyeing is performed, the temperature is increased to 60-80 DEG C, an alkaline agent is added, heat preservation is performed, the temperature rises to 90-100 DEG C, heat preservation and dyeing are performed, and after the temperature is reduced to room temperature, water washing, soaping and drying are performed insequence. The invention further discloses the ramie fabric. Quaternary ammonium salt of chitosan, oxidized microcrystalline cellulose, metal oxide sol and sodium tartrate cooperate and serve as a wrinkle-resistant finishing solution of the ramie fabric, through cooperation with wet steaming, cross-linking of ramie fibers is effectively promoted, and the wrinkle-resistant performance is improved.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Anti-splashing textile dyeing vat

InactiveCN108385316AStir wellImprove the heating effectTextile treatment containersLiquid/gas/vapor removal by squeezing rollersTextile dyeingWater pipe

The invention discloses an anti-splashing textile dyeing vat. The anti-splashing textile dyeing vat comprises a cover, a dyeing chamber, a vat body, a filtering chamber and an anti-splashing plate, wherein the internal bottom end of the vat body is provided with the filtering chamber; the dyeing chamber is arranged above the filtering chamber and inside the vat body; one side of the internal bottom end of the filtering chamber is provided with a water pump, and the output end of the water pump is connected with a water pipe extending inside the dyeing chamber; a separating plate is arranged between the dyeing chamber and the filtering chamber, the inside of the separating plate is provided with a heating pipe in a ring shape, and the middle of the bottom of the separating plate is providedwith a motor; the output end of the motor extends into the dyeing chamber and is fixedly provided with a stirring shaft, the inside of the dyeing chamber above the stirring shaft is provided with theanti-splashing plate, and connecting rods are uniformly fixed between the anti-splashing plate and the inner wall of the vat body. By means of the anti-splashing plate which is in a conical shape andis provided with an internal leakage mesh, the anti-splashing textile dyeing vat can reduce impact force between dye and the anti-splashing plate and further avoid splashing of the dye.

Owner:XIANGSHUI COUNTY XINHONG TEXTILE CO LTD

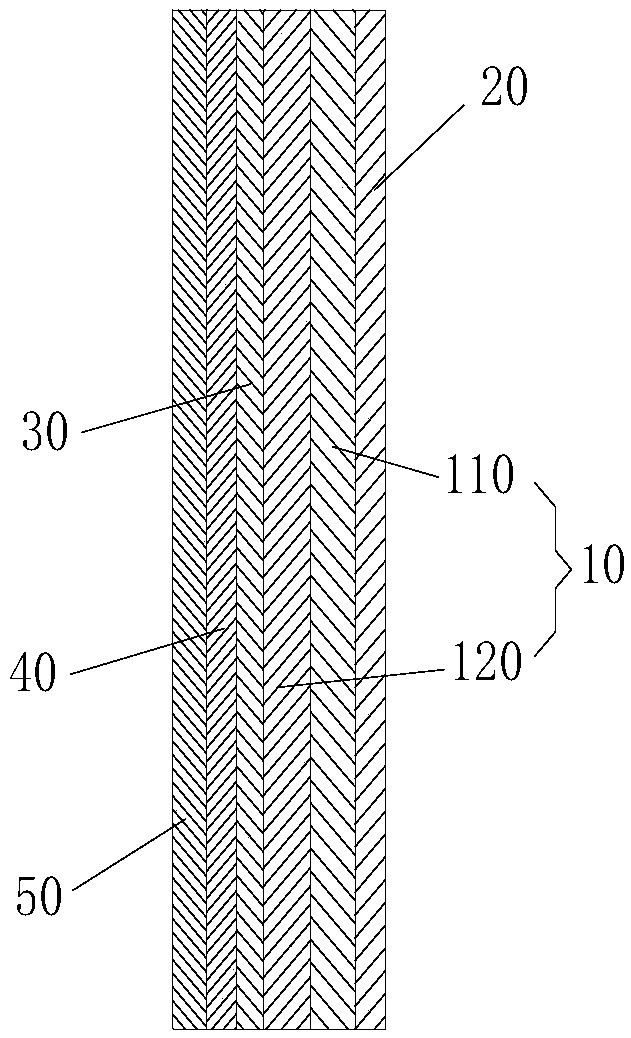

Life cultivation and health preservation underwear fabric and preparation method thereof

ActiveCN104805574AGood fabric effectGood health careFabric breaking/softeningWeft knittingAgricultural engineeringOperability

The invention discloses a life cultivation and health preservation underwear fabric. A corn fiber underwear fabric is a fabric with an inner layer and an outer layer, the inner layer of the fabric is made of corn fiber filaments, the outer layer of the fabric is made of blended yarns formed by blending corn fibers and natural fibers, the weight percent content of the corn fiber filaments in the corn fiber underwear fabric is 20-50%, the balance is the blended yarns, the weight percent content of the corn fibers in the blended yarns is 20-80%, and the balance is the natural fibers. The fabric has fine life cultivation and health preservation effects and excellent wearing comfort, hand feeling, size stability and crease resistance, and is a high-quality material of underwear. The invention further provides a preparation method of the life cultivation and health preservation underwear fabric. The preparation method includes the steps: (1) weaving; (2) bleaching; (3) dyeing; (4) post-treatment. The preparation method is simple in process step and high in operability, and damage to the strength of the corn fibers can be effectively avoided.

Owner:润益(嘉兴)新材料有限公司

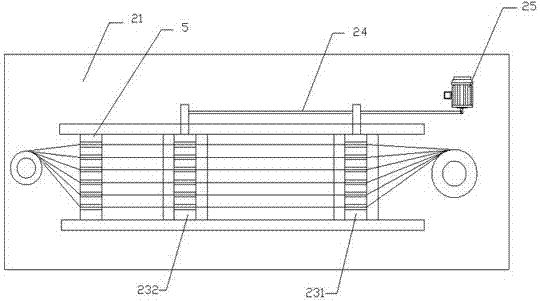

Uniform cloth dye smearing device for textile printing and dyeing

InactiveCN108677425AGuaranteed dyeing effectImprove dyeing qualityTextile treatment machine partsLiquid/gas/vapor textile treatmentTextile printerTextile printing

The invention discloses a uniform cloth dye smearing device for textile printing and dyeing. The uniform cloth dye smearing device comprises a secondary dyeing and uniform smearing device and a uniform smearing device; a secondary dyeing roller is mounted on the secondary dyeing and uniform smearing device, and the lower end of the secondary dyeing and uniform smearing device is fixed on a bottomplate; two removable sponges are symmetrically mounted on the uniform smearing device, and the lower end of the uniform smearing device is fixed on the bottom plate through a supporting leg. The uniform cloth dye smearing device for textile printing and dyeing, disclosed by the invention, has the benefits that a dyeing effect is ensured, and the dyeing quality is high.

Owner:绍兴民程纺织科技有限公司

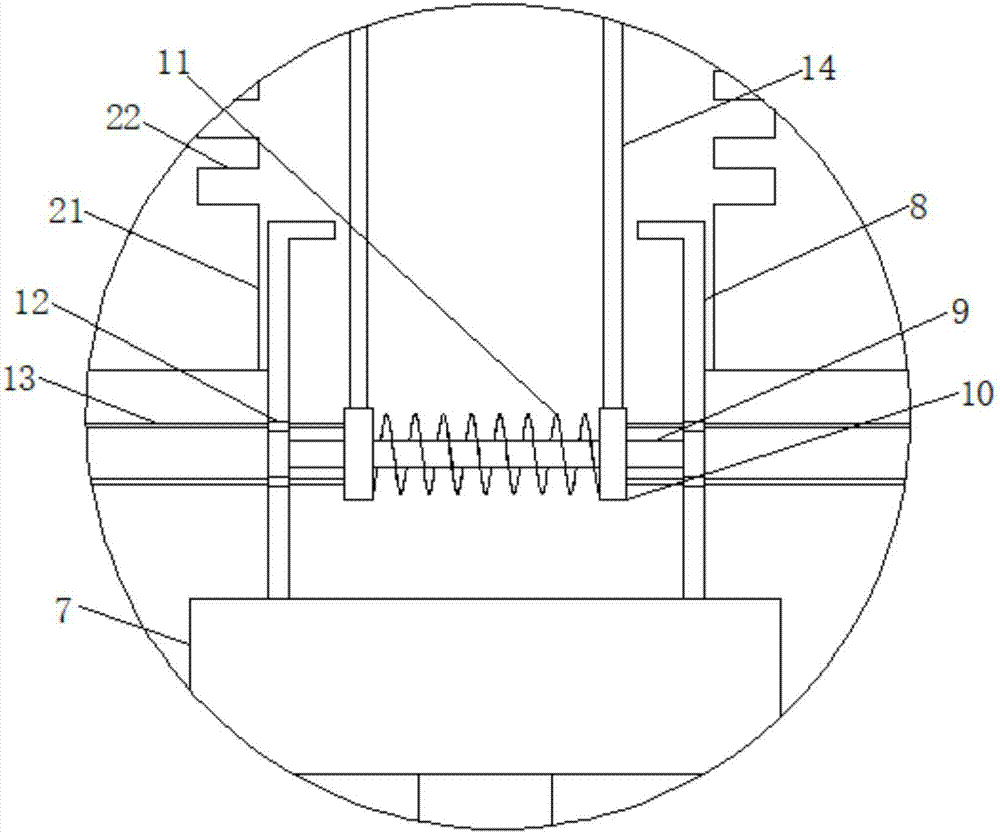

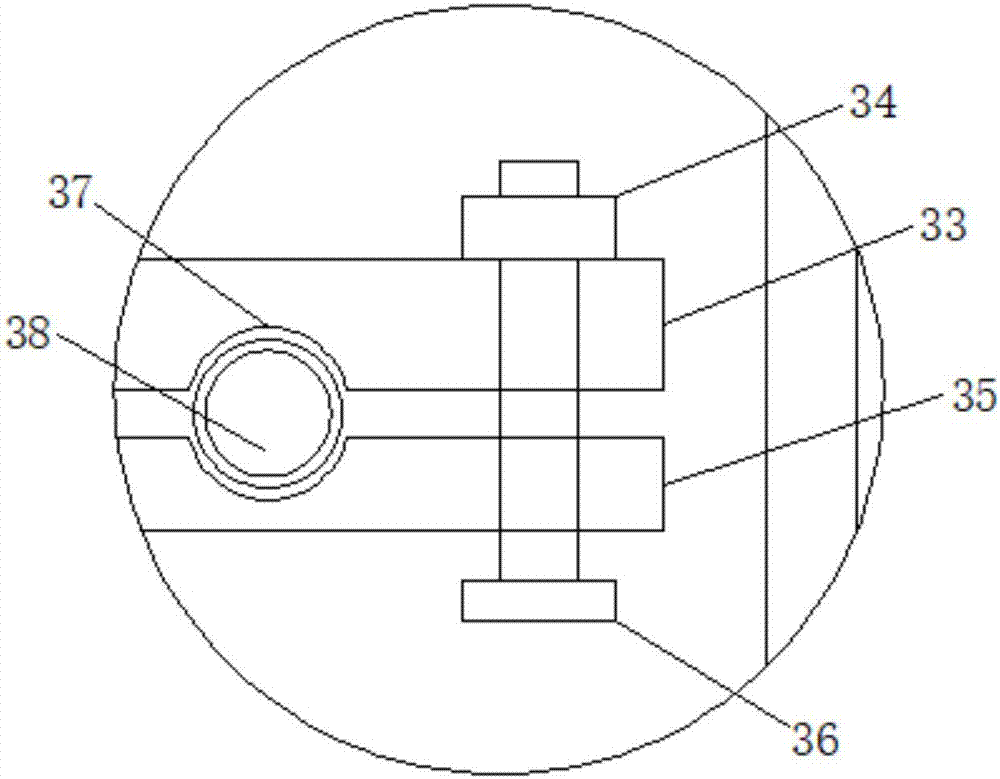

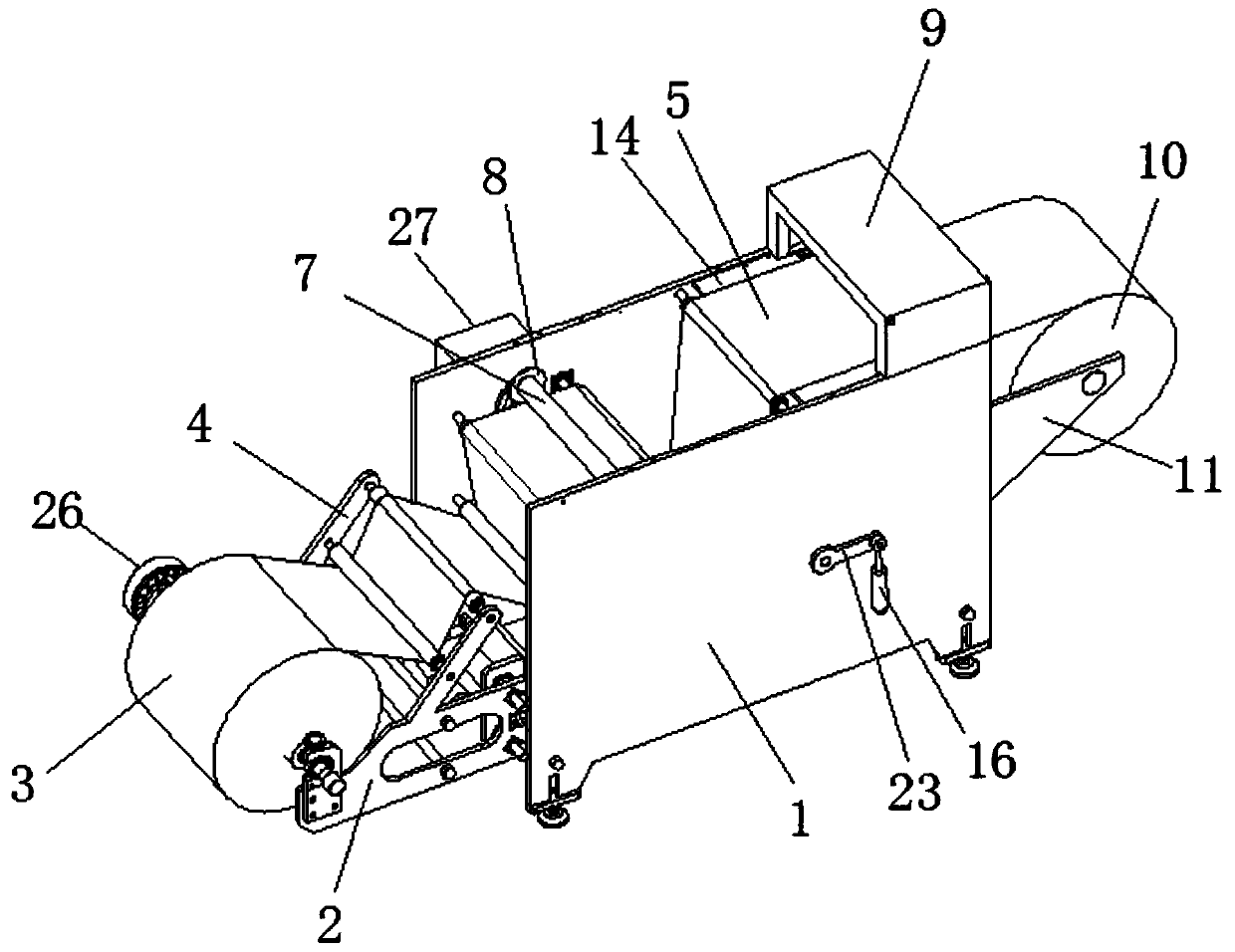

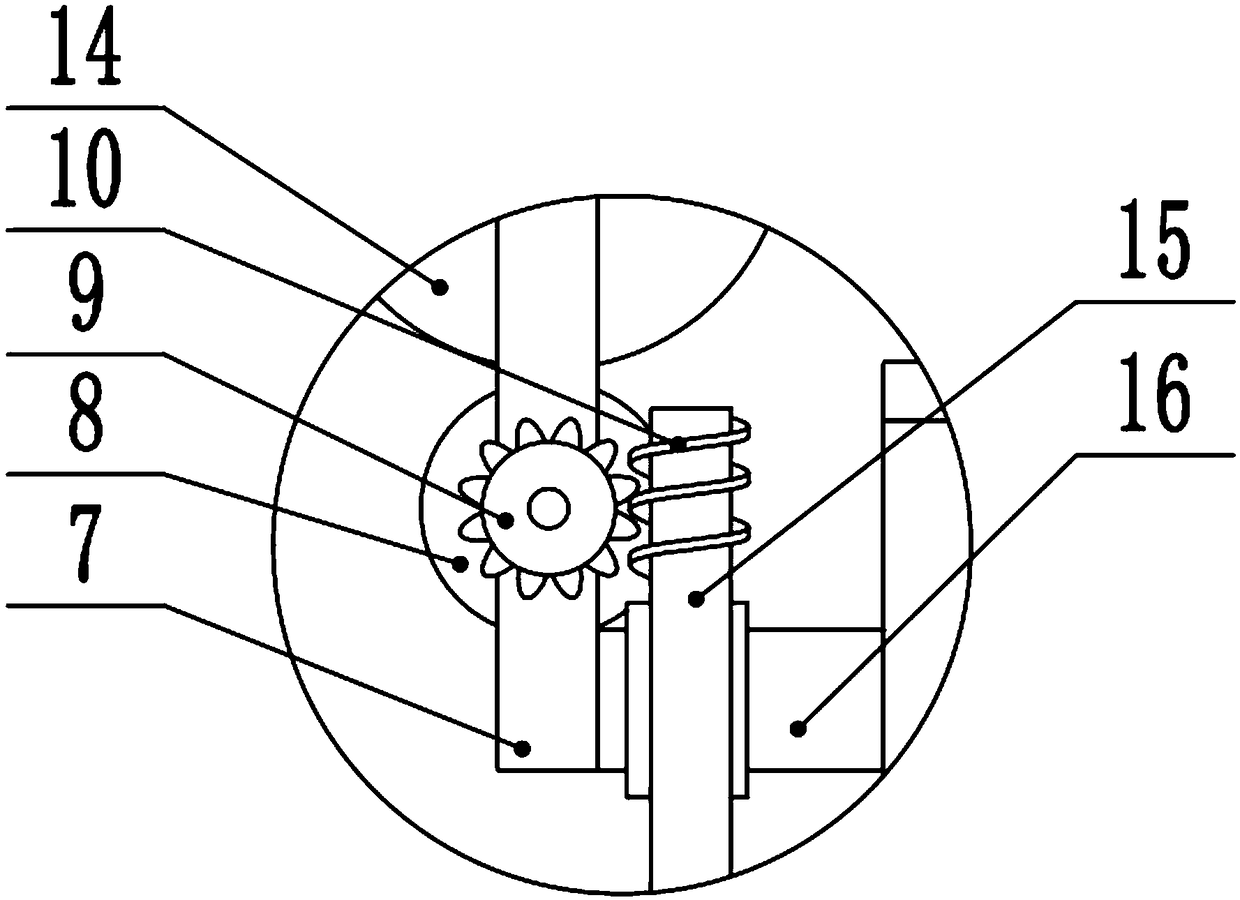

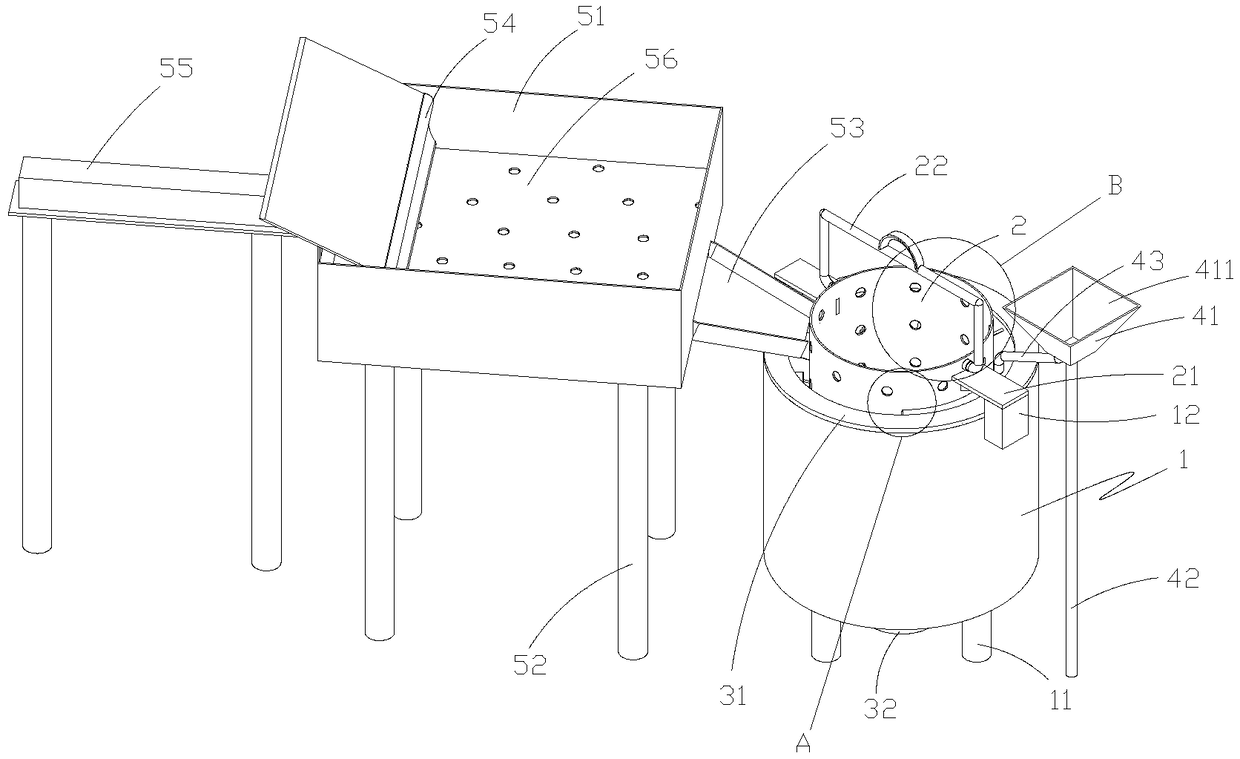

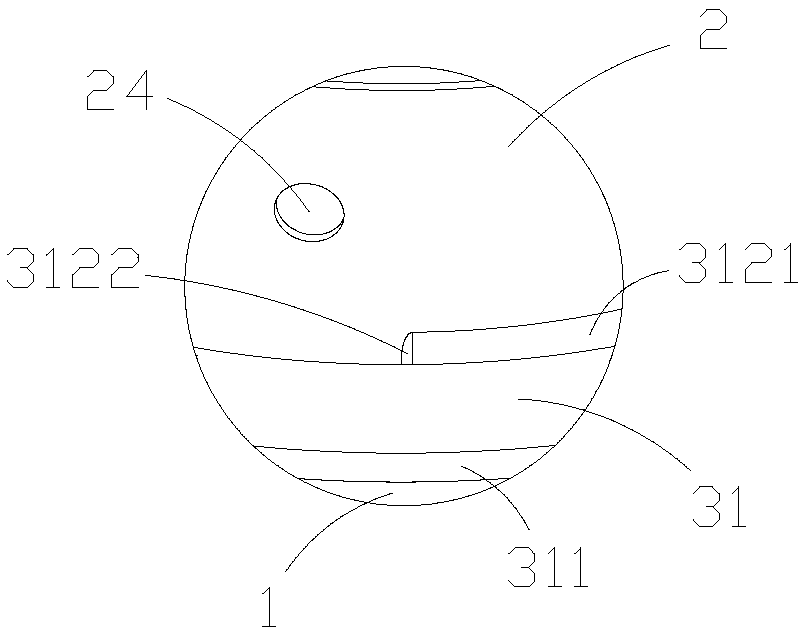

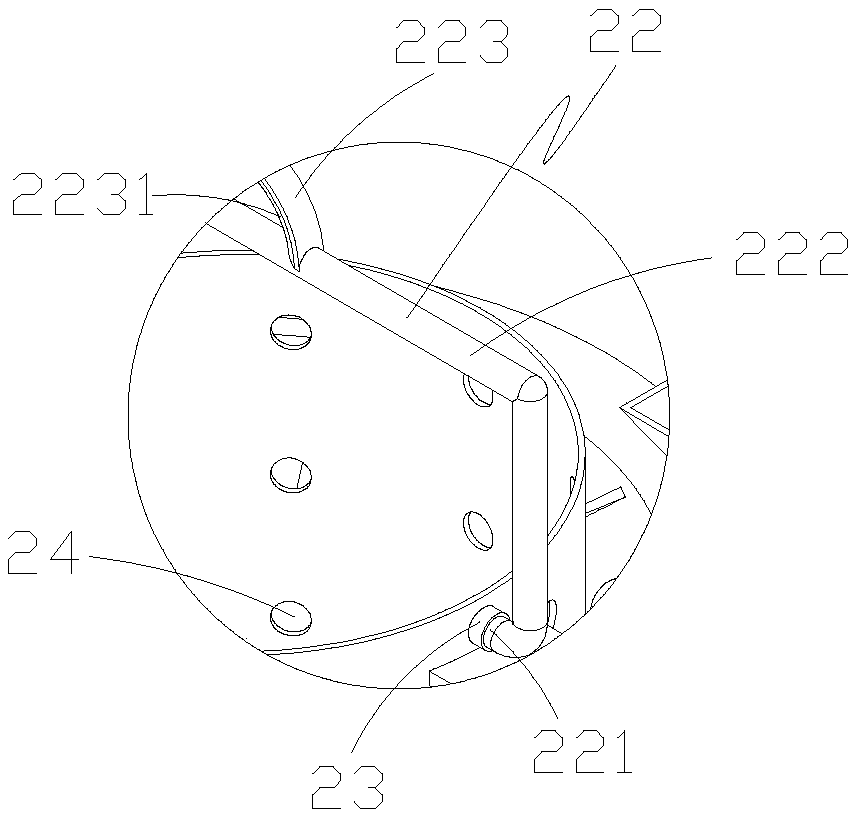

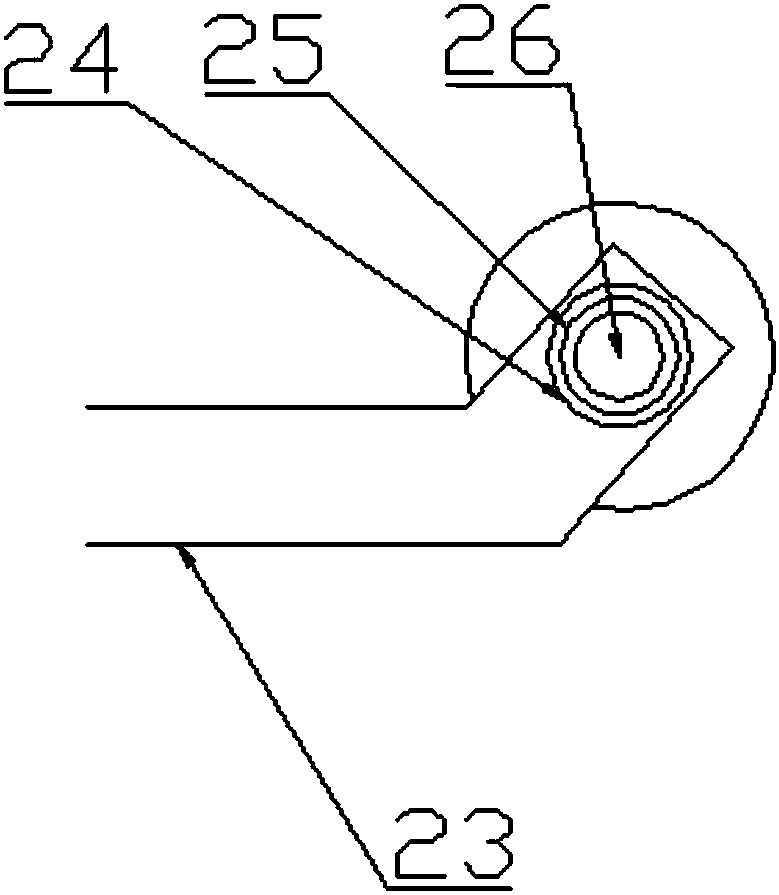

Cotton-wool dyeing device

InactiveCN103526481AGuaranteed uniformityGuaranteed dyeing effectTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentYarnPulp and paper industry

The invention relates to textile dyeing equipment, in particular to a cotton-wool dyeing device. The cotton-wool dyeing device comprises a cylinder which is provided with a yarn inlet and a yarn outlet, a central shaft is arranged in the cavity of the cylinder and is movably connected to the inner walls of two side ends of the cylinder, and the central shaft is connected with stirring blades and driven by a stirring motor; two sides of the cylinder are provided with power gears respectively, a fixing block is arranged on the end face of each power gear, and the side end faces of the cylinder are fixedly connected with the gears through the fixing blocks; a transmission gear is arranged at the upper end of the cylinder, the power gears on the two sides of the cylinder are connected through the transmission gear, and the transmission gear is driven by a motor; the central shaft penetrates through the centers of the power gears; one power gear is provided with a yarn inlet hole which is matched with a yarn inlet pipe, and the yarn inlet pipe is detachably matched with the yarn inlet. By means of the cotton-wool dyeing device, yarns cannot be stacked on the bottom of the cylinder during dyeing, dyeing uniformity of the yarns is guaranteed, stirring speed can be adjusted to adapt to properties of cotton-wool dye according to the properties of the cotton-wool dye, and dyeing quality of cotton wool is guaranteed.

Owner:WUJIANG KESHIDA TEXTILE

Dyeing process of suit fabric

ActiveCN110373845AFast attachmentFast dryingSucessive textile treatmentsSevering textilesYarnEngineering

The invention discloses a dyeing process of suit fabric. The dyeing process comprises steps as follows: cleaning of the suit fabric, burr removal, dyeing and drying and winding. A cutting blade is used for cutting two sides of the suit fabric to remove burrs, and the quality of the dyed suit fabric is guaranteed; a movable roller is arranged on the suit fabric to press the suit fabric, so that thesuit fabric is kept in a tensioned state during dyeing, yarn of the suit fabric is in an open state to facilitate penetration of dye, and the dyeing effect is improved; an electric hot plate heats the dye in a dye tank, control of temperature of the dye is facilitated, the best dyeing temperature is mastered, and the dyeing effect is guaranteed; the suit fabric passes below a drying mechanism, anair knife above the suit fabric dries the dyed suit fabric, the drying speed is high, the dye can quickly adhere to the suit fabric, and the working efficiency is high.

Owner:安徽弋尚纺织科技有限公司

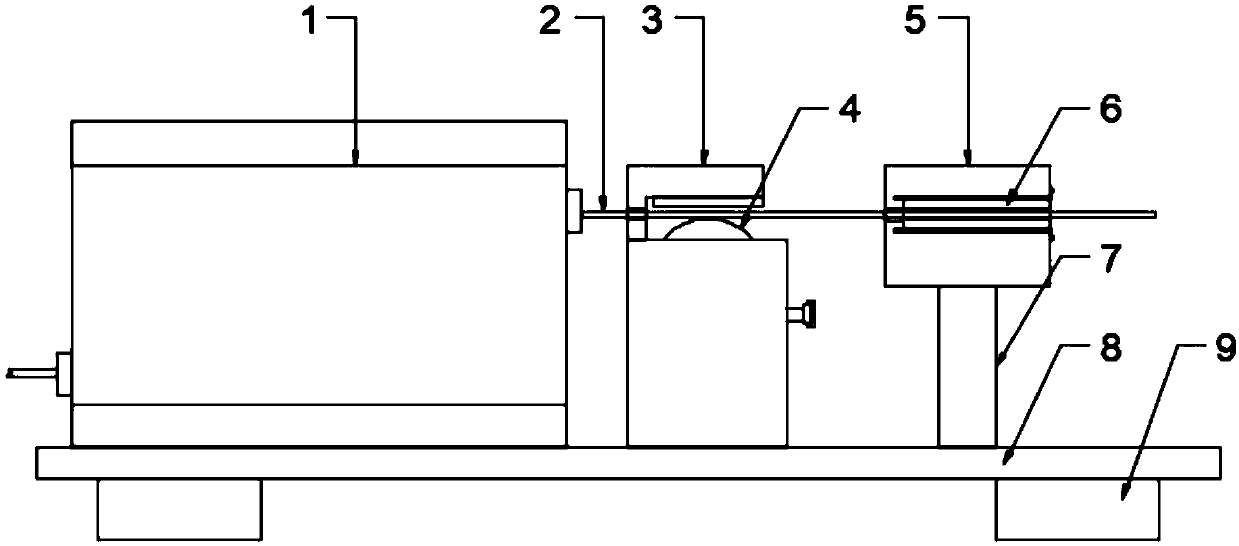

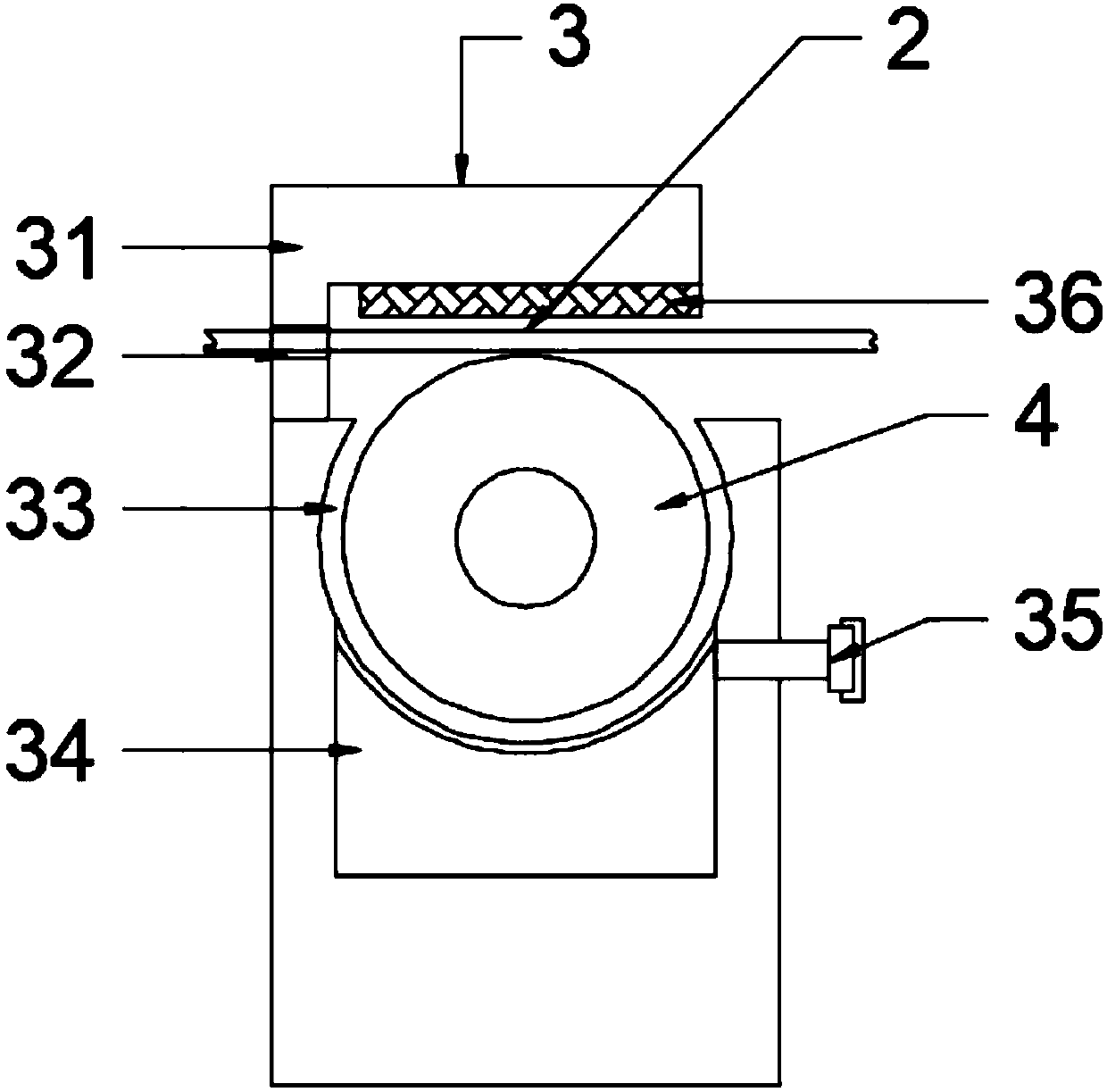

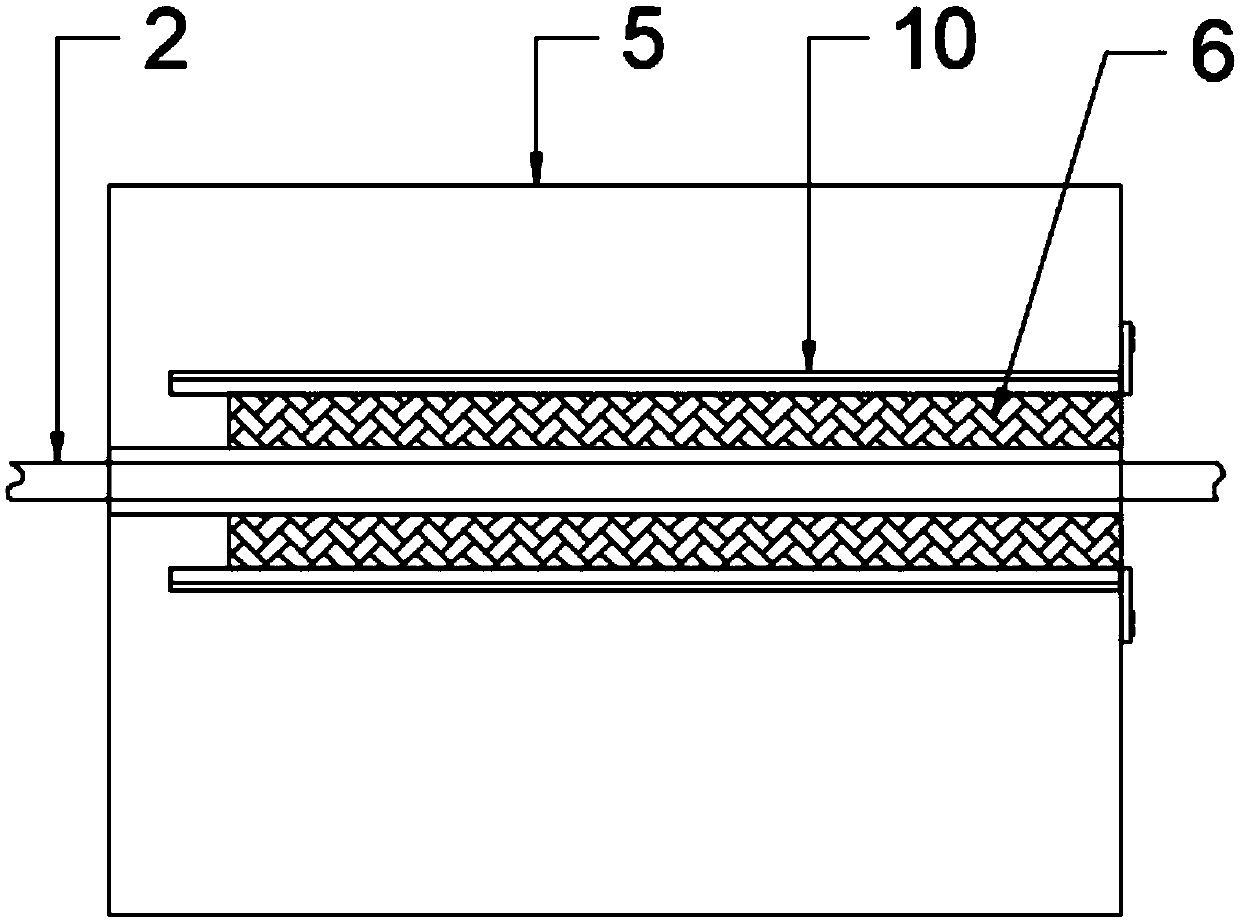

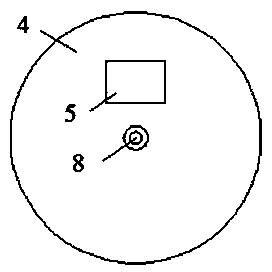

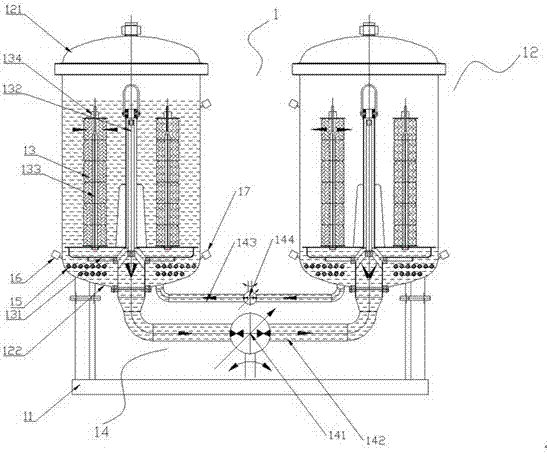

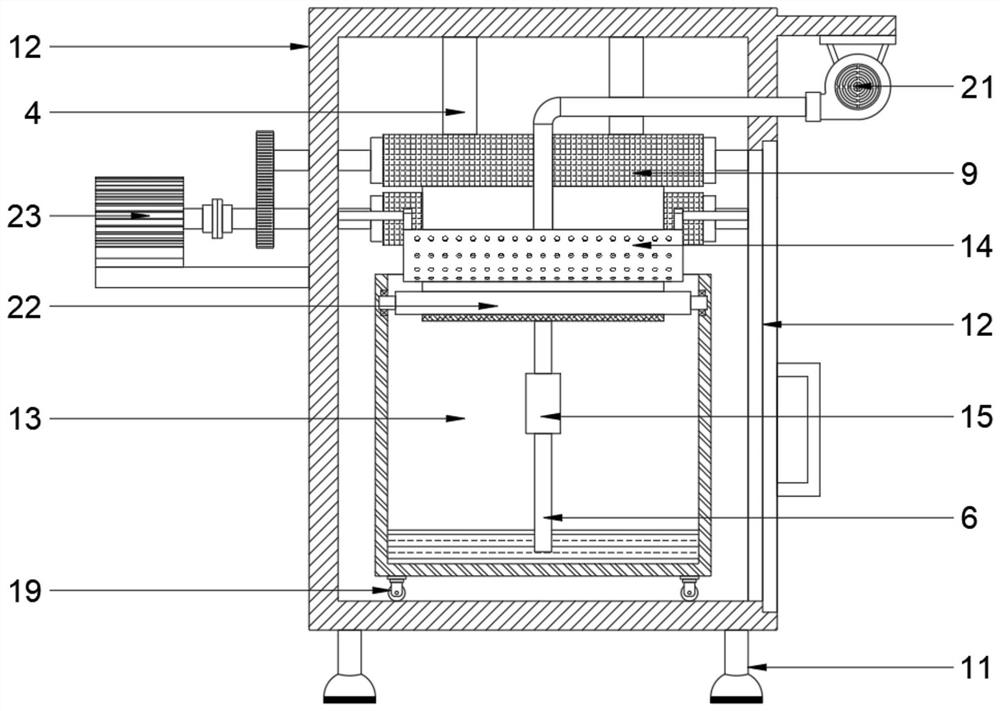

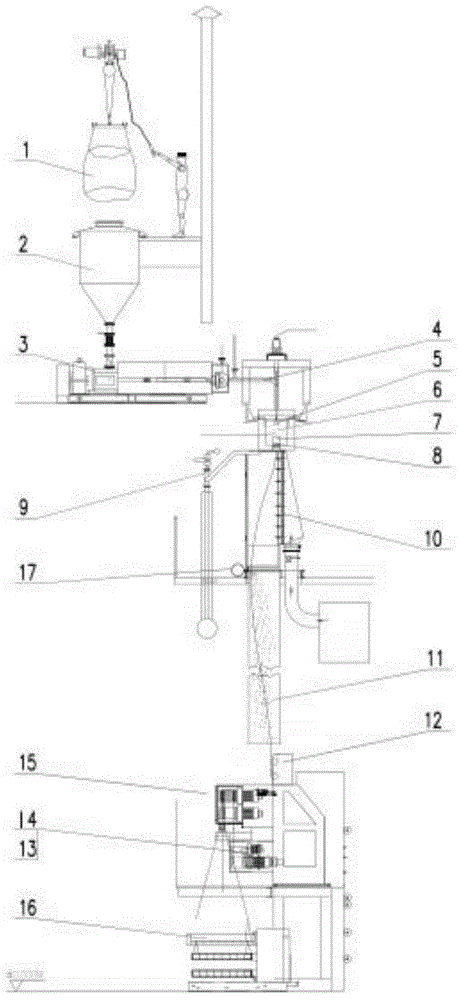

Cone yarn dyeing system

InactiveCN107338595AShort dyeing timeReduce energy consumptionTextile treatment containersTextile treatment machine arrangementsYarnEngineering

The invention relates to a cone yarn dyeing system which is characterized by comprising a high-pressure circular dip dyeing mechanism and a normal-pressure brush dyeing mechanism, wherein the high-pressure circular dip dyeing mechanism is connected in series with the normal-pressure brush dyeing mechanism; the high-pressure circular dip dyeing mechanism performs dip dyeing on cone yarns to achieve primary dyeing; and the cone yarns after the dip dyeing are subjected to brush dyeing by the normal-pressure brush dyeing mechanism to achieve secondary dyeing. According to the system, the traditional single vat dyeing is now changed into double vat yarn dyeing; with the adoption of a bidirectional circulation pump, the front and back dyeing of the yarns in two vats can be achieved; technical requirements are met; a dyeing effect is guaranteed; compared with the traditional dyeing machine, the dyeing system only requires half of a dyeing solution to dye the same quantity of the yarns; the consumption of the dyeing solution is greatly reduced; at the same time, the consumption of heating steam can also be reduced with the reduction of the consumption of the dyeing solution; and the production cost is greatly lowered.

Owner:朱爱民

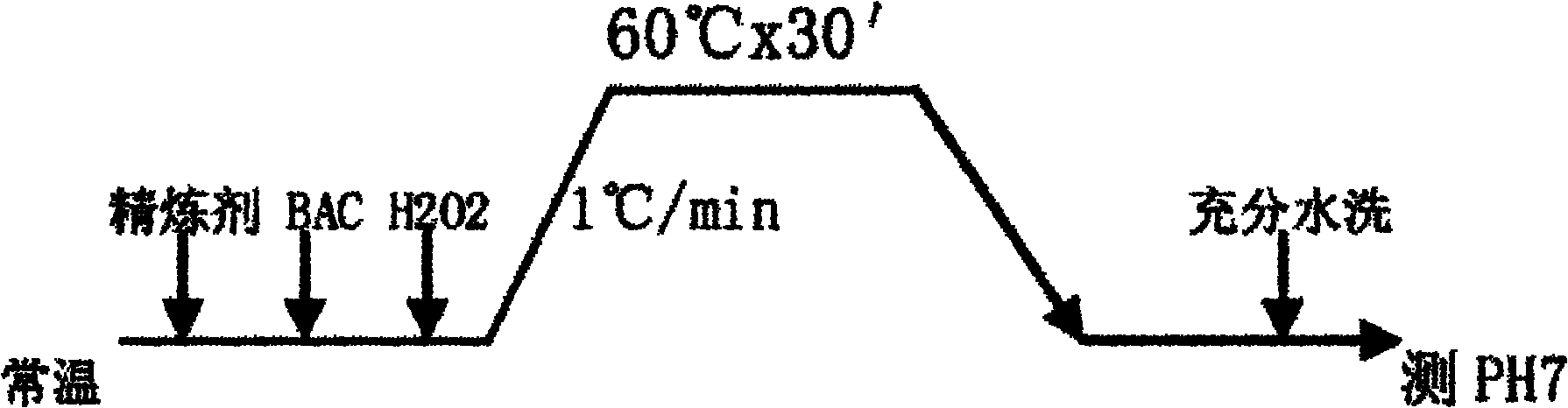

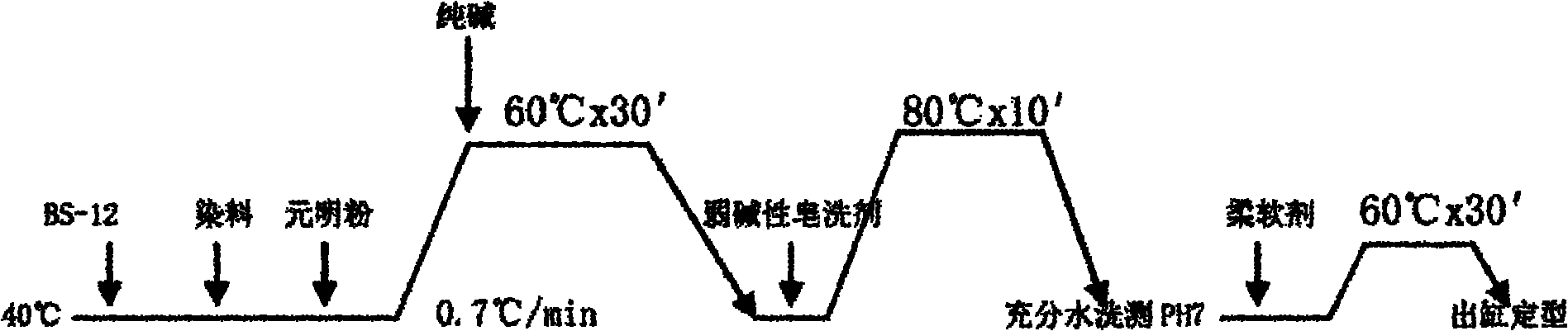

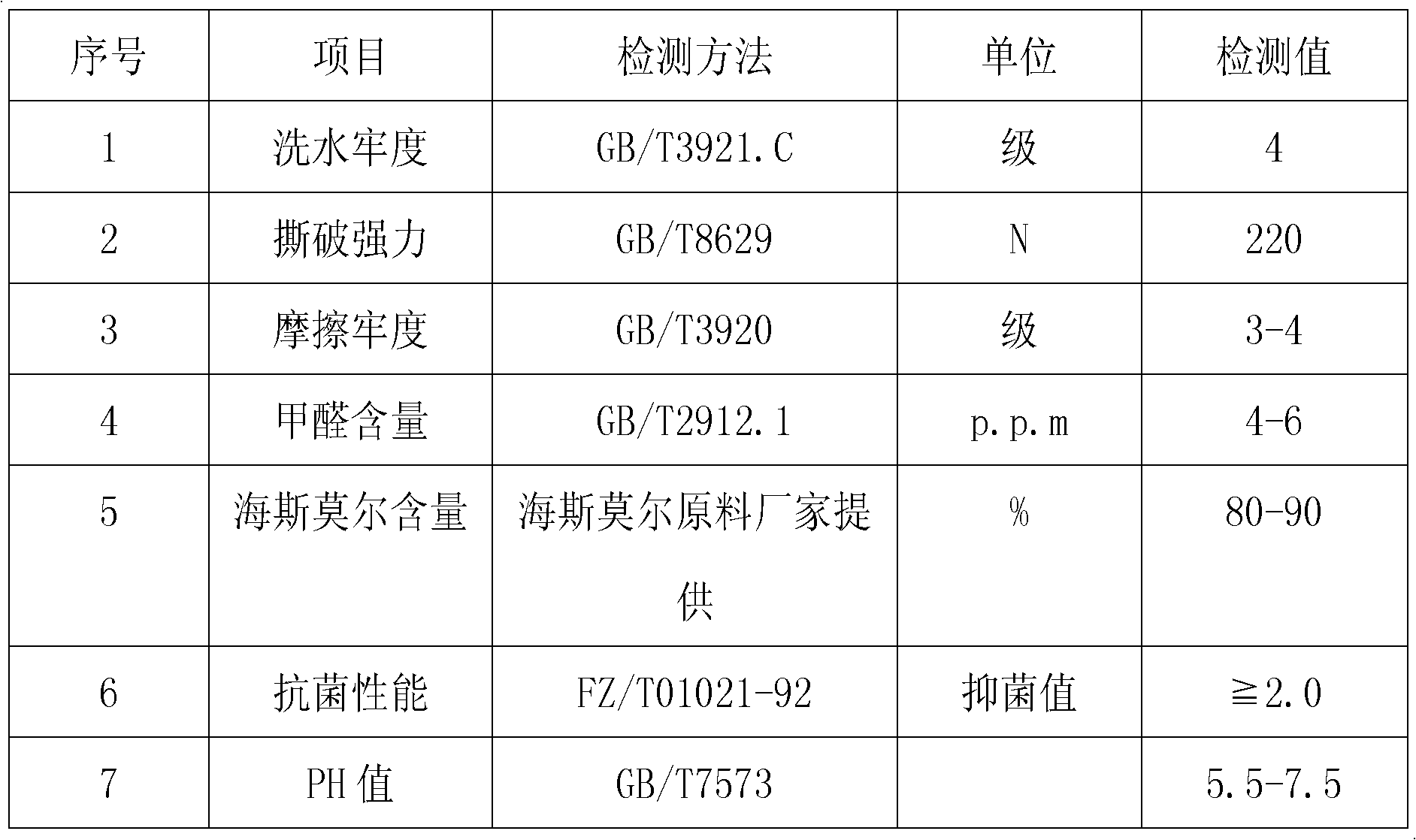

Dyeing and finishing technology for Hismer blended fabric

ActiveCN102115975AGood moisture absorptionGood moisturizing effectDyeing processVegetal fibresSURFACTANT BLENDEthylene

The invention designs a dyeing and finishing technology for a Hismer blended fabric, which mainly comprises a pretreatment process and a dyeing process and specifically comprises the following steps: firstly, placing a Hismer blended fabric into a mixed solution containing a refining agent, an anionic surfactant BAC and hydrogen peroxide, treating for 30 minutes at the temperature of 60 DEG C, and then carrying out pretreatment; during dyeing, adding an amphoteric surfactant BS-12 into a dyeing bath at 40 DEG C; then placing the Hismer blended fabric into a dyeing tank, slowly adding divinylsulfone reactive dyes and a dyeing assistant in batches, and fixing color for 30 minutes at the temperature kept to be 60 DEG C in the presence of alkalescence with the pH of 9-10; after color fixing, adding an alkalescent soaping agent and soaping by preserving the temperature to be 80 DEGC, and sufficiently washing in water till the pH value is 7 after the soaping is finished; and finally, treating with a neutral cationic softening agent for 30 minutes by preserving the temperature to be 60 DEG C so as to soften the Hismer blended fabric, taking the fabric out of the dyeing tank after a handfeel requirement is met, and sizing.

Owner:ZHEJIANG JIAMING DYEING & FINISHING CO LTD

Chemical fiber dyeing technology with ultraviolet protection function

InactiveCN104695240AReduce pollutionAvoid damageFibre treatmentHeating/cooling textile fabricsFiberAnti bacteria

The invention provides a chemical fiber dyeing technology with the ultraviolet protection function. The chemical fiber dyeing technology comprises pretreatment, pre-shaping, dyeing, washing, soaping, color fixing, softening treatment, drying, shaping and rolling. The natural dyestuff of sophora flower bud is adopted, aluminum potassium sulfate dodecahydrate is used as a mordant, the dyeing effect is better, and the washability is greatly enhanced; meanwhile, due to the performance of the sophora flower bud, dyed chemical fiber has the good ultraviolet protection performance and the antibacterial and oxidation resistance; the washing technology and the color fixing technology are added, the dyeing firmness is good, green and environment-friendly and aldehyde-free TCD-R is adopted in the color fixing technology, and the chemical fiber obtained after color fixing is dried step by step, so that the firmness of the chemical fiber is greatly improved; the softening treatment technology is added, the fabric color firmness and flexibility are improved, the fabric roughness is lightened, and the fabric is fluffy and full of elasticity.

Owner:TAICANG TIANLONG CHEM FIBER

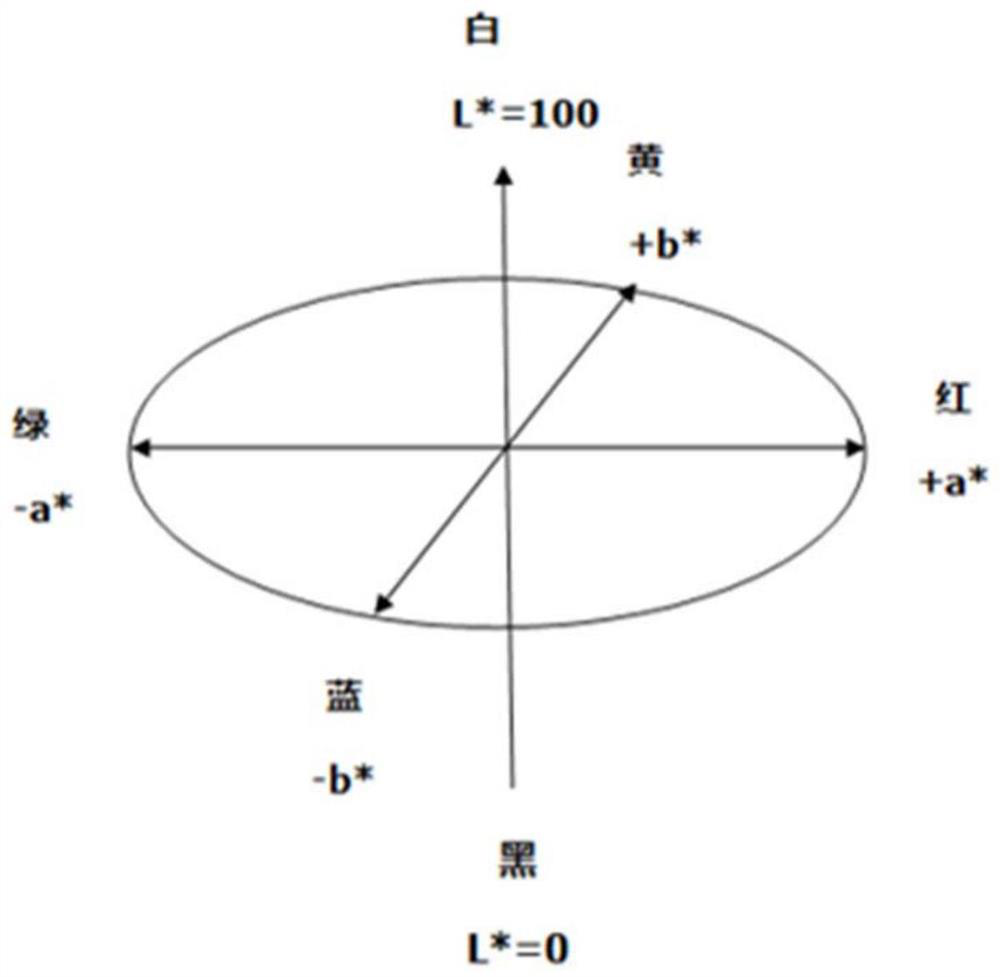

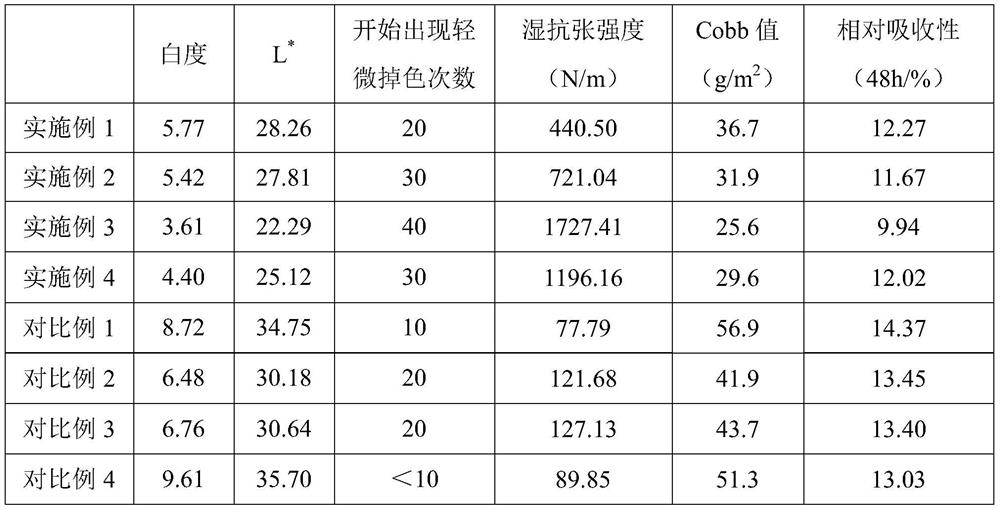

Dyed paper as well as preparation method and application thereof

ActiveCN111926613AReduce pollutionReduce consumptionWater-repelling agents additionPaper coatingWet strengthViscose fiber

The invention discloses dyed paper as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) shredding natural-color bamboo pulp and natural-color bagasse pulp, adding the shredded natural-color bamboo pulp and natural-color bagasse pulp into water, fully soaking, defibering, fishing out, squeezing to obtain mixed pulp I, adding viscose fibers and a dye, adding water to adjust the concentration of the pulp to 10 + / -2 mass%, and grinding the pulp until the beating degree is 15-30 degrees SR to obtain dyed pulp; (2) heating the dyed pulp to 45-80 DEG C, then sequentially adding a color fixing agent, a wet strength agent and a sizing agent, and continuously stirring uniformly to obtain mixed pulp II; carrying out papermaking to obtain wet paper sheets; and finally, squeezing, drying and calendaring the wet paper sheets to obtain the dyed paper. A series of color fixing agents, wet strength agents and sizing agents are adopted underthe heating condition, paper pulp coloring is facilitated, the dye-uptake rate and color uniformity of paper are improved, paper de-coloration is reduced, dyed paper is endowed with an excellent mechanical performance, and industrialization can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

A cloth dyeing apparatus for textile printing and dyeing

ActiveCN108914451AReduce tensionReduce work intensityTextile treatment carriersLiquid/gas/vapor textile treatmentTextile printerReciprocating motion

The invention relates to the field of textile printing and dyeing. A cloth dyeing apparatus for textile printing and dyeing is disclosed, including a base; a stand column is fixedly connected to the middle portion of the base; a dyeing tank is fixedly connected to the top of the stand column; the left side of the base is fixedly connected to a motor; an output shaft of the motor is fixedly connected with a first belt pulley; the first belt pulley is connected with a second belt pulley via a belt; the second belt pulley is fixedly connected to a main shaft; the left and right sides of the mainshaft are fixedly connected with second bevel gears, and the second bevel gears are engaged with first bevel gears. The apparatus is applicable to textile production activities; driven rollers on theleft and right sides are driven to rotate simultaneously by the motor and a contact sensor is provided, so that cloth realizes left and right reciprocating motion and the dyeing effect is ensured; a tension frame with a gravity effect is added, so that the tension of cloth in the dyeing process is kept constant, and the dyeing effect is improved. The whole apparatus is reasonable in design and simple in operation, reduces the work intensity of operators, and is suitable for popularization and use.

Owner:江苏翔鹰纺织科技有限公司

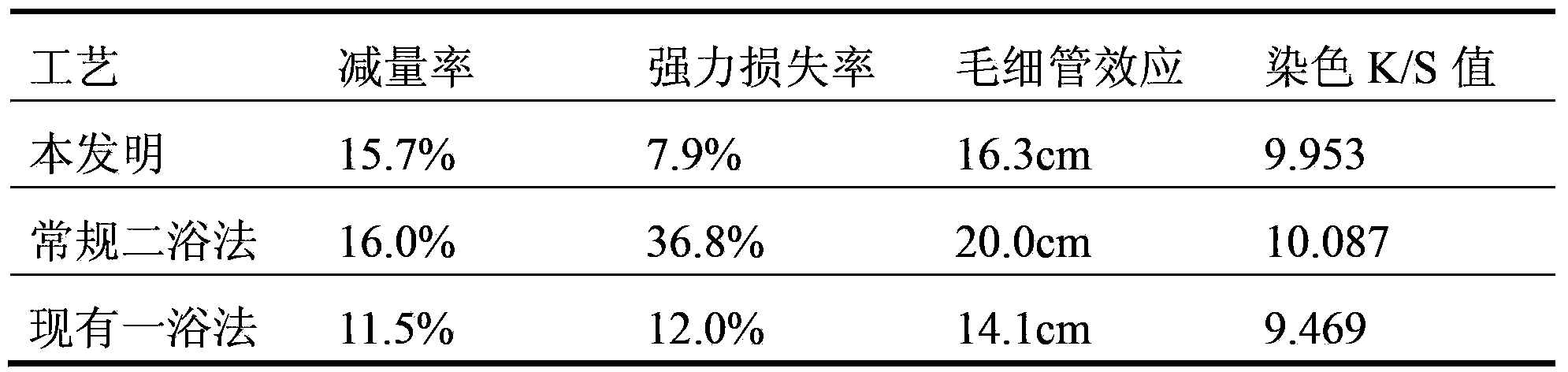

Terylene deweighting dyeing assistant, and preparation method and use thereof

ActiveCN104120609AEmission reductionGuaranteed polyester dyeing effectDyeing processAlkanePollutant emissions

The invention discloses a terylene deweighting dyeing assistant, and a preparation method and a use thereof. A raw material formula of the terylene deweighting dyeing assistant comprises, by mass, 10-15% of ethylene glycol monobutyl ether, 10-15% of 1,4-butanolide, 10-20% of fatty alcohol polyoxyethylene ether, 10-20% of secondary alkane sulphonate, and the balance water, wherein the molecular formula of the fatty alcohol polyoxyethylene ether is RO-(CH2CH2O)n-H, n is 7-9 or 15-20, and R is a C12-18 alkyl group; and the molecular formula of the secondary alkane sulphonate is R'SO3Na, and R' is a C10-13 alkyl group. The terylene deweighting dyeing assistant guarantees the terylene dyeing effect and the silk like effect and adopts a one-bath technology; and compared with traditional technologies, the technology has the advantages of saving of a lot of time, energy and substances, and great reduction of the pollutant emission.

Owner:QINGYUAN RUIHUA ADDITIVES CO LTD

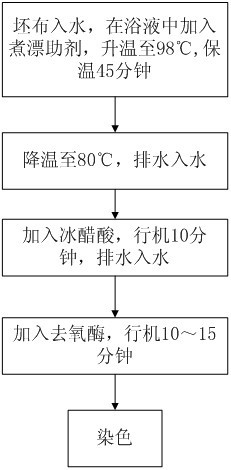

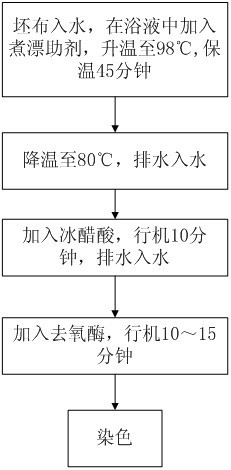

Dyeing pre-treatment method of cotton fabric

ActiveCN102321968AGuaranteed dyeing effectRealize energy saving and cost reductionBiochemical fibre treatmentBleaching apparatusEnzymePre treatment

The invention discloses a dyeing pre-treatment method of a cotton fabric, which specifically comprises the following steps that: a gray fabric is put into water, a scouring and bleaching additive is added to a first bath liquid, and the temperature is raised to 98 DEG C, and is kept holding for 45 minutes; after holding, the first bath liquid is cooled to 80 DEG C, and is discharged, and then thefabric is put into a second bath liquid; glacial acetic acid is added into the second bath liquid, and the second bath liquid is discharged, and then is put into a third bath liquid after the operation is carried out for 10 minutes; deoxy enzyme is added into the third bath liquid, and the operation is carried out for 10 to 15 minutes; and finally, dyeing is carried out. In the dyeing pre-treatment method of the cotton fabric, on the basis of ensuring the dyeing property, energy saving and cost reduction are realized.

Owner:JIANGSU JINCHENZHEN TEXTILE

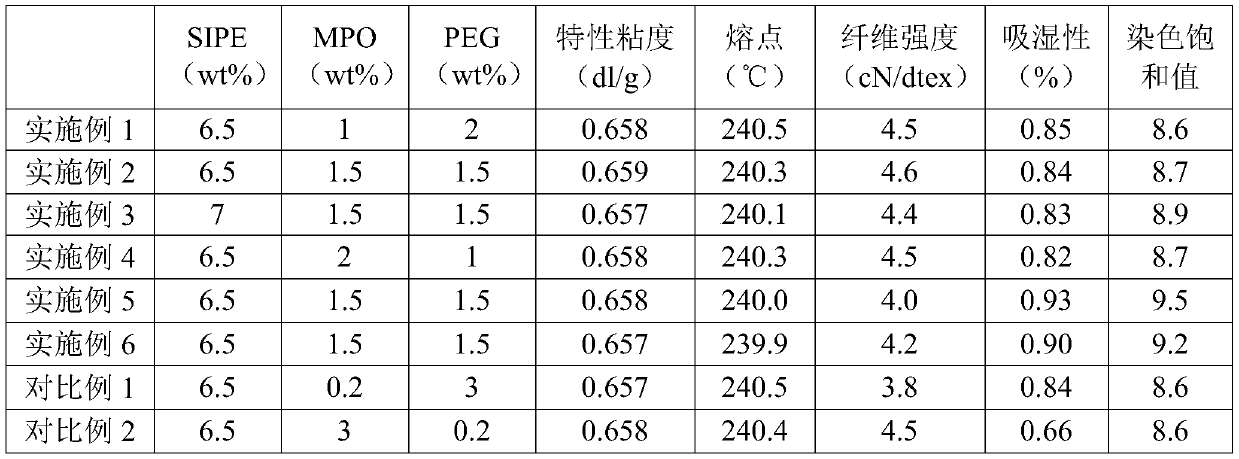

Preparation method of moisture-absorbing and sweat-releasing ECDP fiber

ActiveCN111304781AAvoid self-aggregation problemsGuaranteed stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsIsopropylene glycolPropylene glycol

The invention relates to the field of polyester polymerization and spinning, and discloses a preparation method of moisture-absorbing and sweat-releasing ECDP fiber. The preparation method comprises the following steps of performing first esterification on terephthalic acid, ethylene glycol, a catalyst and an auxiliary agent which are used as raw materials; performing pre-esterification on m-phthalic acid-5-sulfonate and ethylene glycol which are used as raw materials; performing second esterification on a first esterification product, an m-phthalic acid-5-sulfonate pre-esterification product,2-methyl-1,3-propylene glycol and a compound anti-ether agent which are used as raw materials; performing pre-polycondensation on a second esterification product and polyethylene glycol which are used as raw materials; performing final polycondensation on a pre-polycondensation product which is used as a raw material; performing cooling and granulating on a final polycondensation product to obtain slices; and drying, spinning and elasticizing the slices to obtain a finished product of the moisture-absorbing and sweat-releasing ECDP fiber. The preparation method disclosed by the invention caneffectively improve the dyeing property and the moisture-absorbing and sweat-releasing property of polyester fiber, ensures the strength of the polyester fiber, and is stable and safe in production.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Cloth dyeing equipment for textile processing

InactiveCN112226971AImprove dyeing efficiencyImprove dyeing effectTextile treatment containersLiquid/gas/vapor treatment machines driving mechanismsDyeingEngineering

The invention discloses cloth dyeing equipment for textile processing. The equipment comprises a box body and a dyeing assembly arranged in the box body, the dyeing assembly comprises a clamping device, a dye box and an air blowing device, the dye box is placed at the bottom of the box body, the interior of the dye box is divided into a dyeing cavity and a backflow cavity, and the backflow cavitycommunicates with the dyeing cavity through a backflow pipe provided with a backflow pump. The clamping device comprises dyeing lifting rods, a dyeing supporting plate, bidirectional telescopic rods,dyeing baffles, clamping telescopic rods and dyeing rollers. The dyeing baffles and the dyeing rollers are adopted and cooperate with the clamping telescopic rods and supporting telescopic rods, clothwith different thicknesses can be clamped, meanwhile, the dyeing length of the cloth is adjusted, meanwhile, dyeing missing caused by clamping of the cloth is avoided, and the dyeing efficiency is improved; the dyeing lifting rods are adopted, so that the cloth moves up and down in dye and is in full contact with the dye, and the dyeing effect is improved; and a blower and a ventilation pipe areadopted, a ventilation cavity and air outlet holes are used for uniformly blowing air to the cloth, and the cloth is quickly air-dried.

Owner:张美

High-efficiency yarn dyeing device

InactiveCN110670279AFree relaxationFully relaxTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsYarnSpinning

The invention discloses a high-efficiency yarn dyeing device, which comprises a dyeing bin, a dyeing liquid box and spraying pipes; a driving motor is mounted on the dyeing bin, one side of the driving motor is in transmission connection with a driving shaft through a belt and a pulley, and the driving shaft is erected on a platform through a first bearing block and a bracket. In the invention, the plurality of spraying pipes for hanging yarns are arranged inside the dyeing bin; the driving shaft which is in transmission connection via the belt and the belt pulley is driven to rotate by the driving motor; a worm arranged on the driving shaft is in transmission connection with a turbine mounted on hollow shafts; the spraying pipes connected with the hollow shafts in a one-to-one correspondence mode rotate synchronously, and a dyeing liquid is sprayed onto yarns through nozzles to uniformly dye the yarns; the manner of synchronously driving multiple spraying pipes to rotate for dyeing helps improve dyeing efficiency of the device, and allows the yarns suspended on the spraying pipes to be freely untwisted until the twist is balanced, so that the tension in spinning is eliminated.

Owner:傅全辉

Buffer solution for immunohistochemical detection quality control product as well as preparation method and application of buffer solution

ActiveCN114667997AStable in natureAccelerate evaporationDead animal preservationMaterial analysisAntigenSodium azide

The invention discloses a buffer solution for an immunohistochemical detection quality control product, and belongs to the technical field of immunohistochemical detection. The buffer solution is prepared from the following components in percentage by mass: 0.2 to 1 percent of carbomer, 30 to 40 percent of alcohol, 0.1 to 0.25 percent of triethanolamine, 0.005 to 0.015 percent of sodium azide and the balance of deionized water. By adjusting the solvent and viscosity of the buffer solution and adding the stabilizer and the antibacterial agent, the gel has the characteristics of rapid volatilization, difficult diffusion, stable property, ultralow temperature storage resistance and the like, and solves the problems of easy cross contamination, uneven tissues / cells and easy stacking in the prior art. Meanwhile, the buffer solution disclosed by the invention can ensure the stability of tissue / cell antigens in the buffer solution for a longer time, so that ultra-long-term preservation is realized. The preparation method of the buffer solution is simple and easy to operate, and the buffer solution is wide in application, can be suitable for different tissues or cells, and has huge popularization value.

Owner:HANGZHOU BIOLYNX TECH CO LTD

Printing and dyeing equipment for textile dyeing

ActiveCN109234948AEasy to take outGuaranteed dyeing effectTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringTextile dyeing

The invention discloses printing and dyeing equipment for textile dyeing. The equipment comprises a base, a dip dyeing bucket arranged on the base and a stirring device cooperating with the base, andthe stirring device comprises a dye bath bucket rotationally cooperating with the base; and the base is provided with a rotating structure used for achieving the rotating cooperation between the dye bath bucket and the base. The printing and dyeing equipment for textile dyeing has the advantages that through the cooperative arrangement of the dye bath bucket, the dip dyeing bucket and the base, dyeing of textile can be completed by soaking the textile in a dye liquor, and the textile cannot be pulled by external force, thereby avoiding the problem that the textile is damaged; the dye bath bucket can rotate relative to the base, so that the dye liquor in the dye bath bucket flows, not only can dyestuff deposition be avoided, but also textile dyeing can be accelerated, thereby greatly improving the printing and dyeing effect and efficiency.

Owner:SHAOXING UNIVERSITY

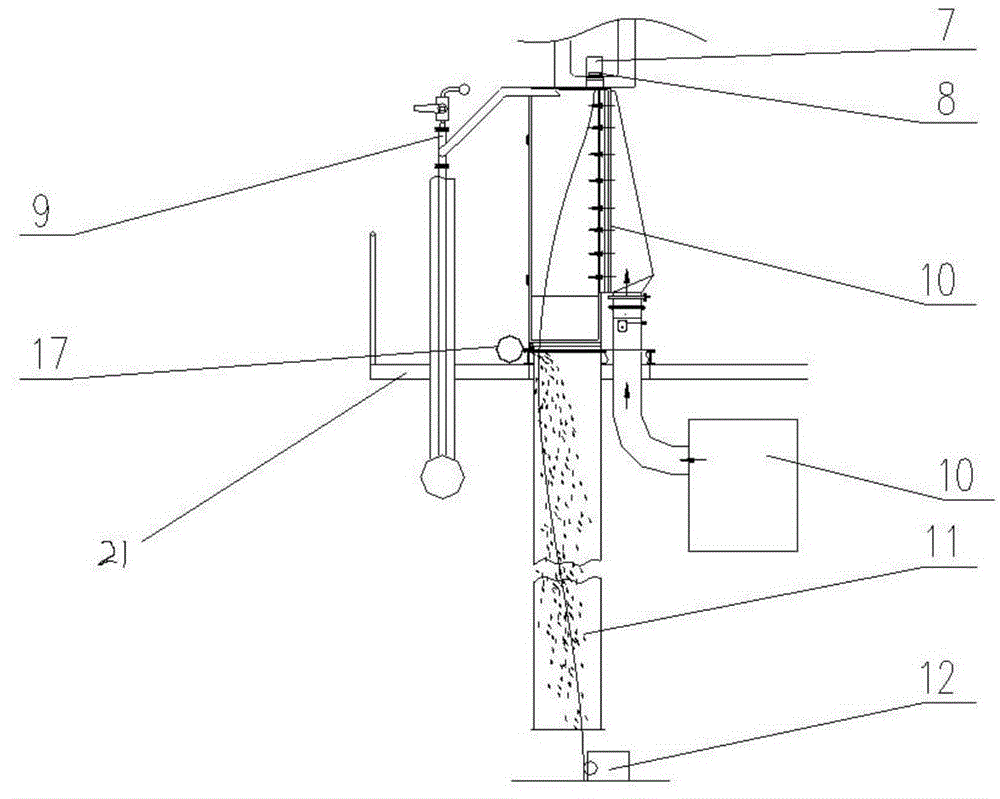

Spray humidifier and chemical fiber spinning machine

ActiveCN104947217AHigh dyeing rateSolve for uniformityArtificial thread manufacturing machinesWater filterInlet valve

The invention discloses a spray humidifier. The spray humidifier is used for humidifying a fiber belt inside a spinning channel instead of humidification on the whole spinning environment. The spray humidifier comprises a tank, a water inlet valve, a water filter and a channel humidification tube. Water mist is sprayed through cooperation of all components and is brought into the spinning channel via the fiber belt which moves downwards, so the fiber belt can fully and evenly absorb moisture in the spinning channel, and local humidification can be performed according to a fiber movement track. According to the spray humidifier, the problems that due to humidification on the whole environment, energy waste, equipment damage and staff injury are caused are solved, and meanwhile the problems that the dye uptake of existing fibers is low, and dyeing is uneven can be solved. Moreover, local humidification has little influence on the humidity of the environment, will not harm equipment or staff and can guarantee the dye uptake and the dyeing effect, thereby improving product quality.

Owner:BEIJING CHONGLEE MACHINERY ENG

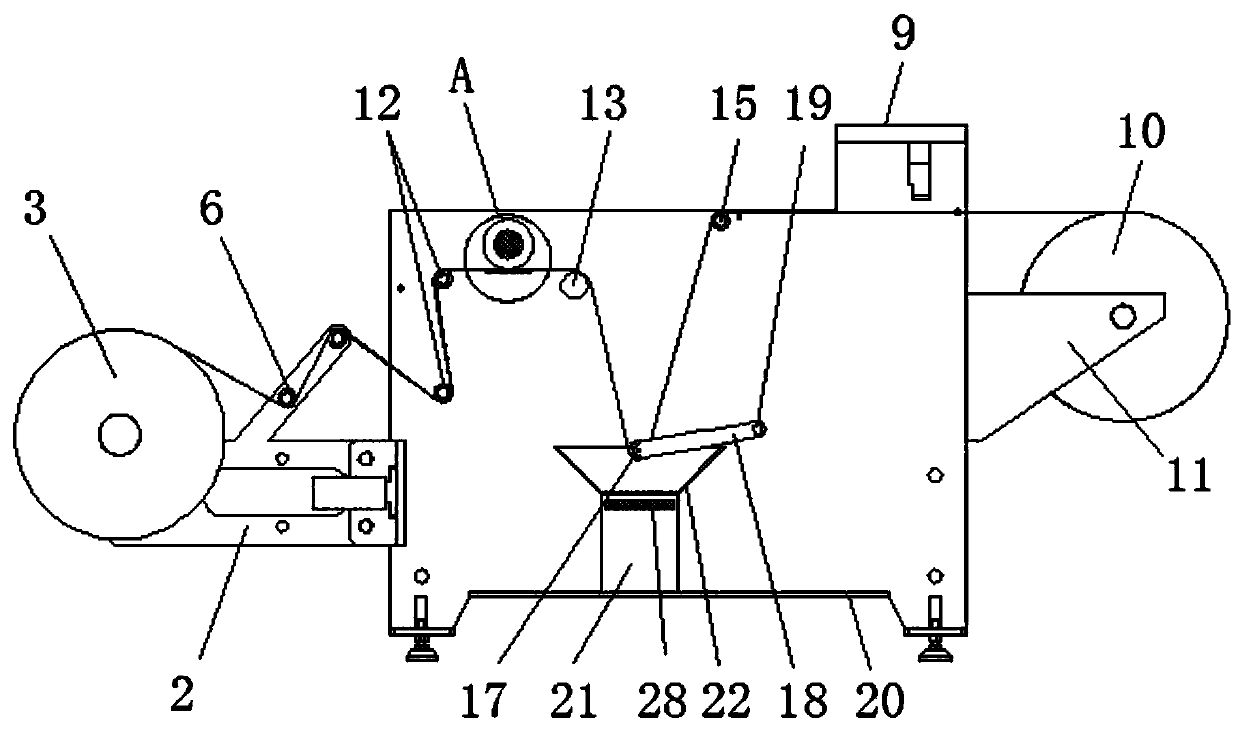

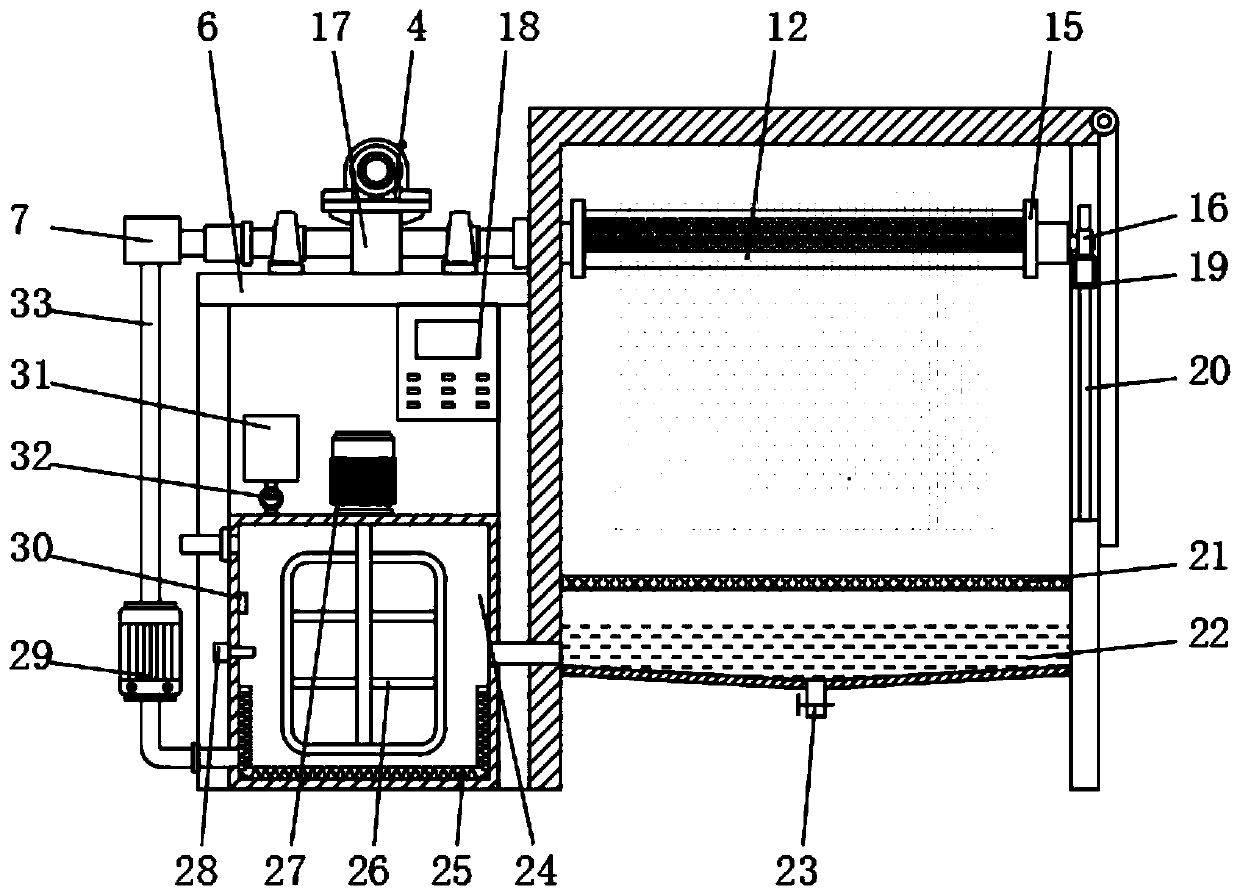

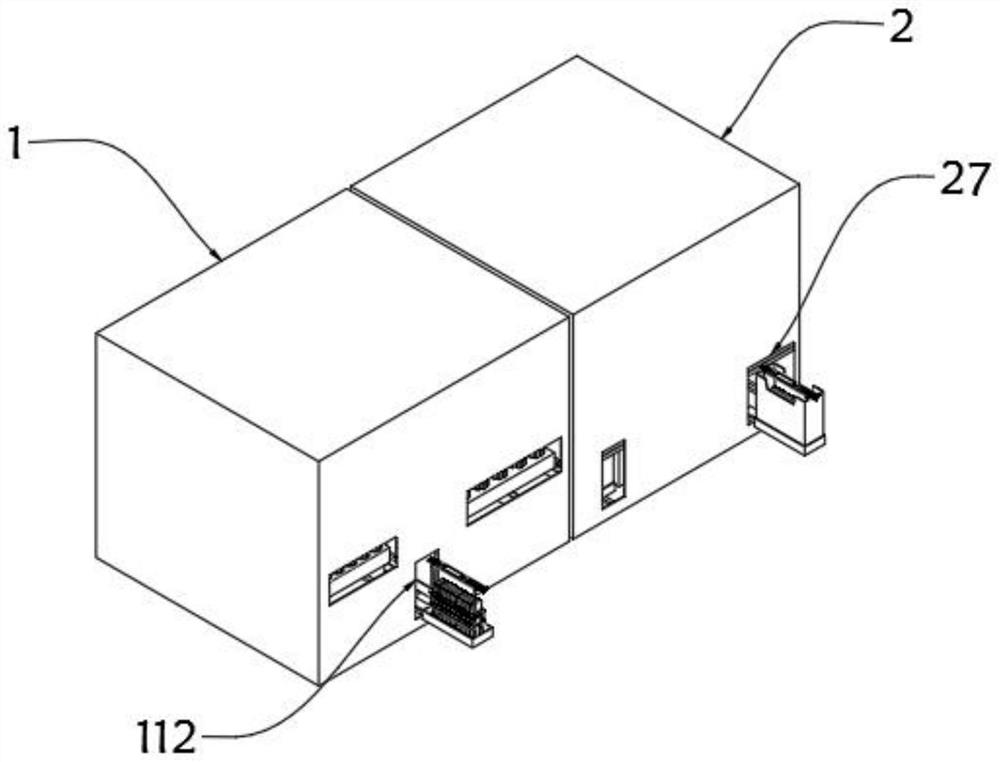

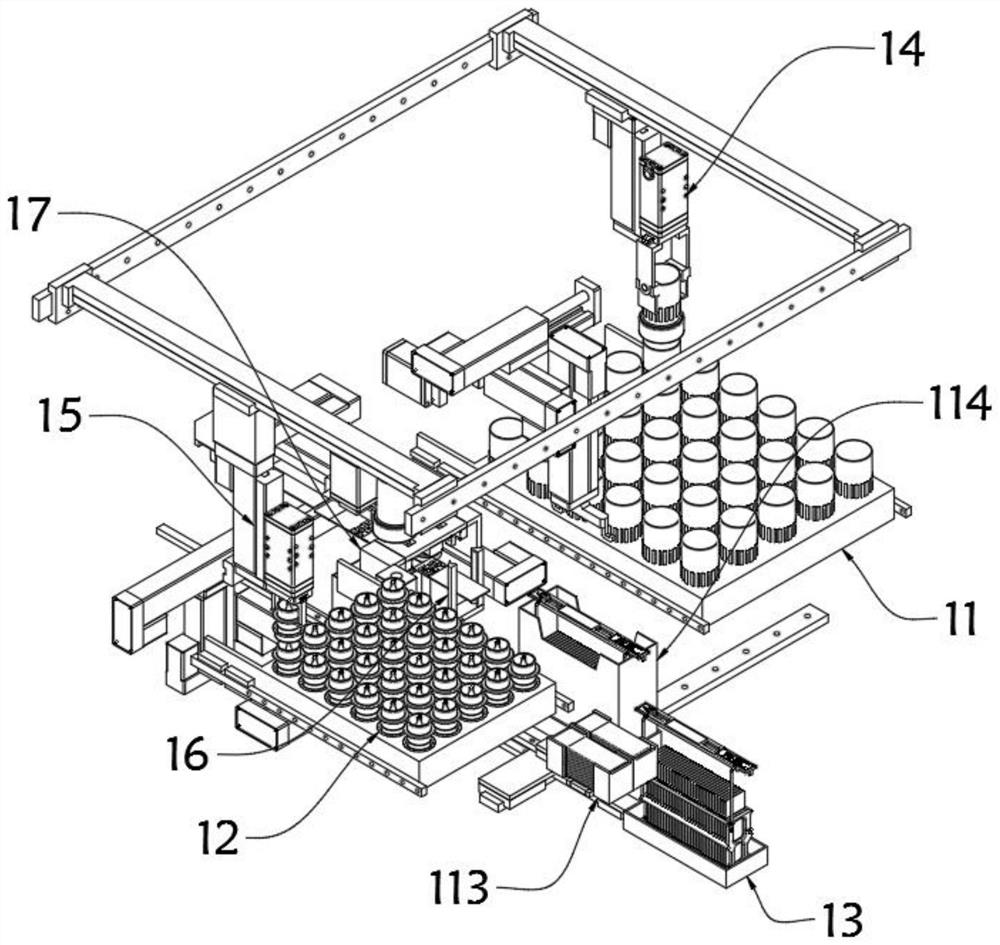

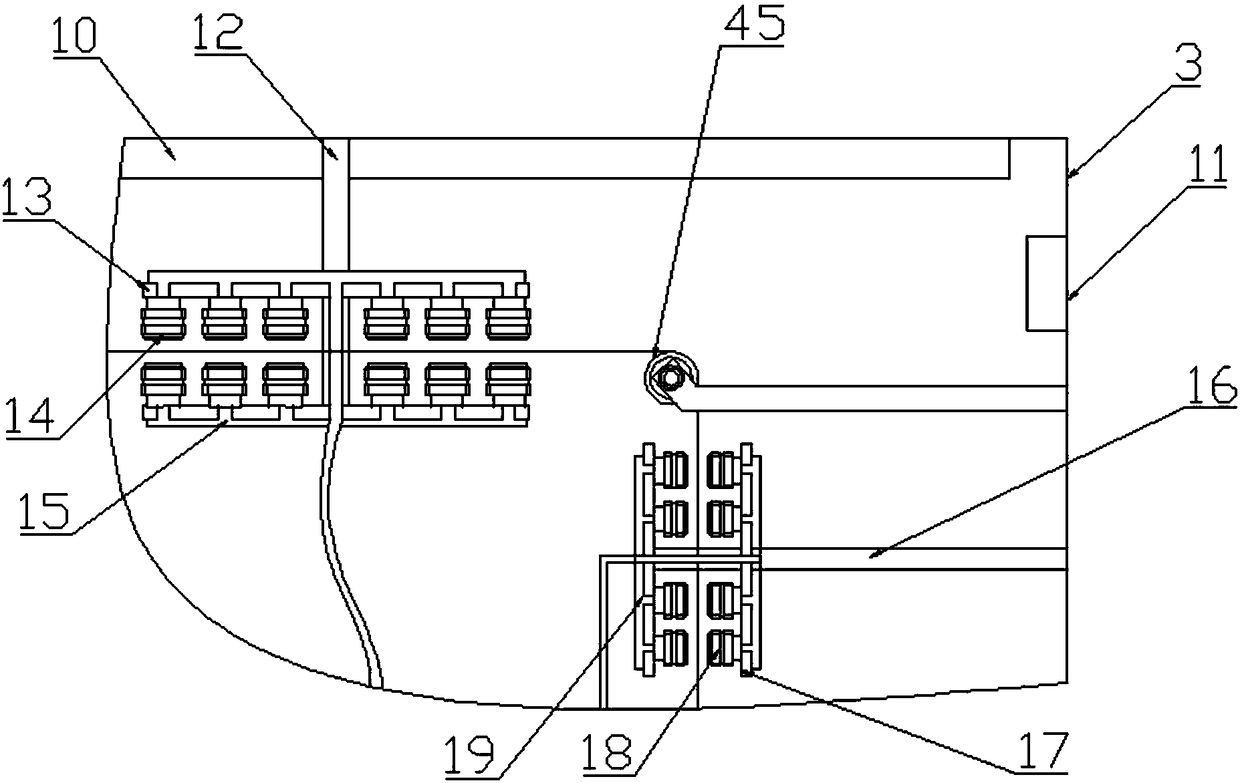

Full-automatic rapid slice-making dyeing machine

PendingCN113533006ANo human intervention requiredConsistent slide codingPreparing sample for investigationTransfer mechanismIndustrial engineering

The invention discloses a full-automatic rapid slide-making dyeing machine which comprises an automatic slide-making mechanism, a multi-dye-vat automatic dip dyeing mechanism and an automatic transfer mechanism, the automatic slide-making mechanism comprises a sample carrier drawer, a filter cup membrane cylinder carrier drawer, a slide rack carrier drawer and a slide carrier drawer, and a sample bottle operation module is arranged above the sample carrier drawer; and a filter cup and membrane cylinder operation module is arranged above the filter cup and membrane cylinder carrying lattice drawer, a clamping jaw assembly is arranged on one side of the slide rack carrying lattice drawer, and a slide making module is arranged on one side of the clamping jaw assembly. According to the full-automatic rapid slide-making dyeing machine, samples and slice-making consumables only need to be loaded on the machine at a time, the machine automatically achieves full-process treatment of recognition, code printing, code scanning, slice making, racking, transferring, dyeing and the like on batch samples, and the full-automatic rapid slice-making dyeing machine is provided with a slice sealing and transferring connector and can be in online operation with slice sealing equipment, and is used for transferring the dyed sample wafer into wafer sealing equipment for wafer sealing treatment. Manual intervention is not needed in the whole process.

Owner:HUBEI TAIKANG MEDICAL EQUIP

Preparation method for colorful gambiered canton silk and product and application of colorful gambiered canton silk

The invention belongs to the technical field of textile materials, relates to a preparation method, product and application of colorful gambiered canton silk and discloses novel colorful gambiered canton silk. The preparation method of the colorful gambiered canton silk comprises the steps of primary greige soaking and airing, secondary greige soaking and airing, silk boiling, soaking and airing, slurry treatment, sand washing, primary dyeing, secondary dyeing and softening. Compared with the prior art, the method is simple in process, short in production period and conforms to the modern concepts of low carbon, environmentally friendliness and energy saving; usage of consumable items in the dyeing process is saved, and the same preparation effect is achieved as well, the process cost is reduced, and the demand of a larger market group is met; the prepared colorful gambiered canton silk overcomes the defect that gambiered canton silk fabrics are single in color, the prepared colorful gambiered canton silk is high in color fastness and bright in color, and the gambiered canton silk fabrics have higher practicality and great market prospects in application to clothes.

Owner:SHENZHEN LIANGZI FASHION IND

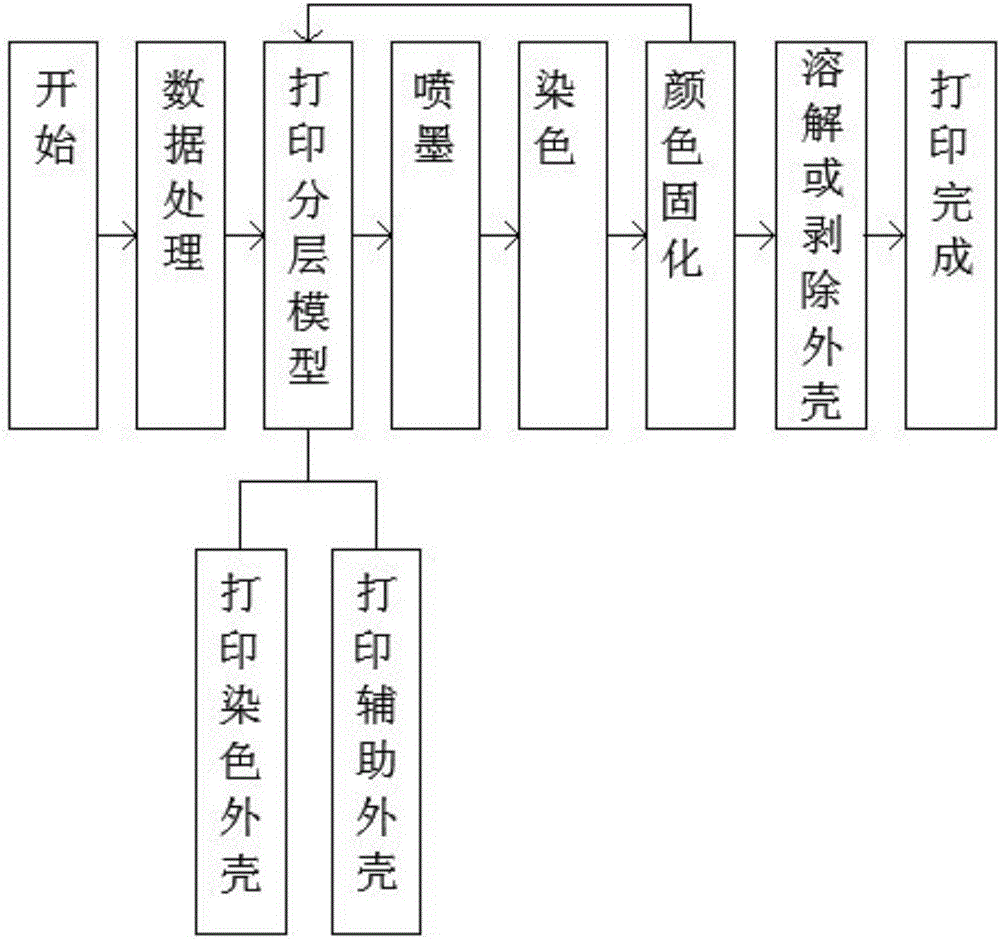

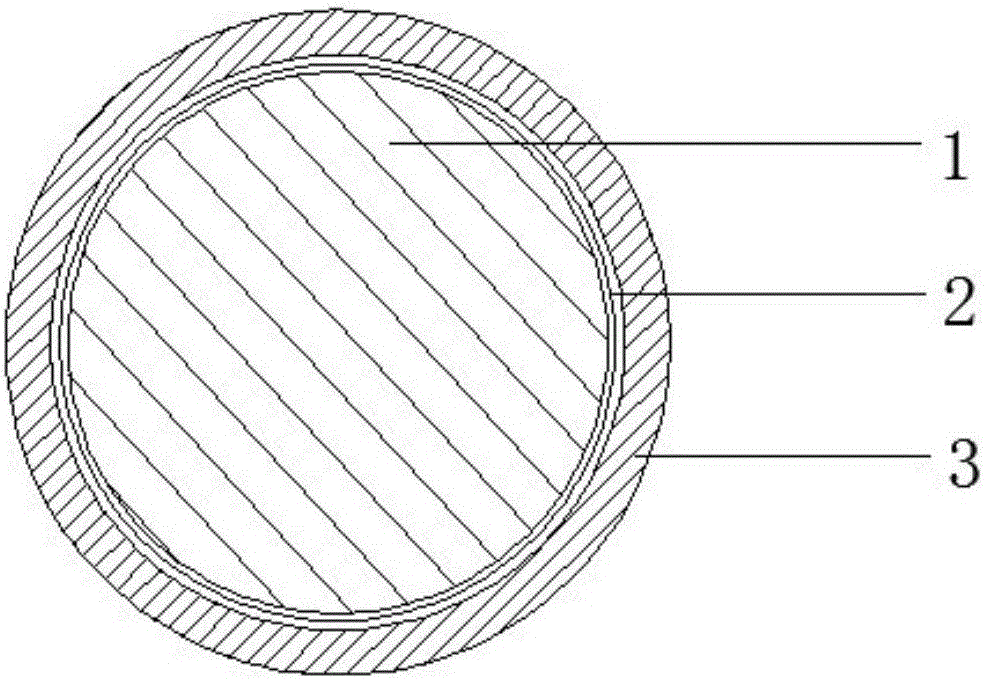

3D printing method for dyeing of lateral vertical surface

InactiveCN105773966AUniform and complete dyeingMeet the needs of side elevation stainingAdditive manufacturing apparatusDuplicating/marking methodsEngineeringPigment

The invention relates to a 3D printing method for dyeing of a lateral vertical surface. The 3D printing method for dyeing of the lateral vertical surface comprises the following steps that (1) printing preparation and data processing are conducted, specifically, a vertical color printer is started, and processing is conduced, so that a hierarchical model of a 3D printed object is obtained; (2) the hierarchical model is printed, and an arc-shaped crack is formed between a dyed shell and an auxiliary shell; (3) ink jetting is conducted, and the printer is controlled by a processor to drip pigment ink into the arc-shaped crack formed between the dyed shell and the auxiliary shell; (4) dyeing is conducted; (5) color curing is conducted; (6) the next working cycle is conducted, and printing is conducted on the dyed shell subjected to dyeing and the auxiliary shell, so that the next hierarchical model is generated; (7) the shells are dissolved or stripped; and (8) printing is completed, after printing of all hierarchical models and dyeing are completed, the auxiliary shell is removed, the dyed lateral vertical outer surface of the 3D printed object is exposed, and the colored 3D printed object is obtained. The printing method is easy to implement, both the manufacturing cost of printing equipment and the manufacturing cost of printing materials are low, the printing effect is good, the application range is wide, and the 3D printing method has good application prospects.

Owner:朱沫

Environmental protection device for textile dyeing

InactiveCN108547084AEasy accessReduce consumptionTextile treatment containersTextile treatment machine arrangementsHigh pressure waterEngineering

The invention discloses an environmental protection device for textile dyeing. The device comprises a base, the base is provided with a dyeing mechanism, the dyeing mechanism is provided with a dyeingbox bracket, a box body, a cloth inlet, a cloth outlet, a first cloth driving roller, a second cloth driving roller, a third cloth driving roller, a cloth extrusion mechanism, a potential of hydrogensensor, a heater, a temperature sensor and a spray mechanism, the spray mechanism consists of a first spray head support rod, a first spray head carrier plate, a first high pressure spray head, a first high pressure pipeline, a second spray head support rod, a second spray head carrier plate, a second high pressure spray head, a second high pressure pipeline, a high pressure water pump and a flowdivider, a dye circulation adding mechanism is arranged on the left side of the dyeing mechanism, the right side of the dyeing mechanism is provided with a drying mechanism, and a controller is arranged on one side of the outer surface of the box body. The device has the advantages of simple structure and strong practicability.

Owner:安辉织染(佛山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com