Housing, preparation method thereof, and electronic equipment

A shell and substrate technology, applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, etc., can solve the problems of low product yield, poor production capacity, unstable gradient color, etc., to ensure the yield and fineness, guarantee Good effect of dyeing effect and gradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

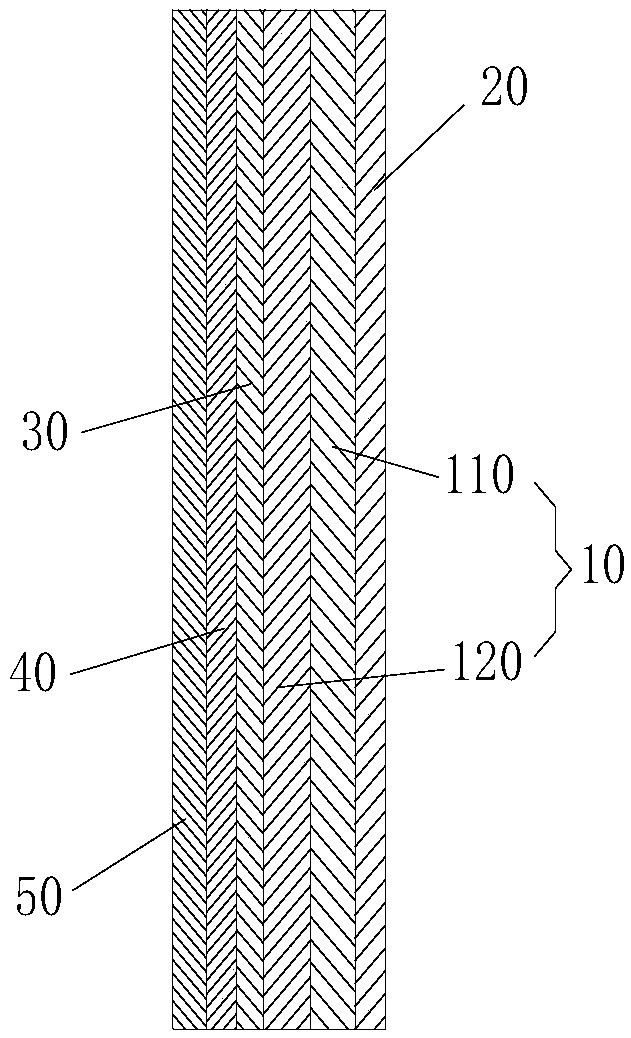

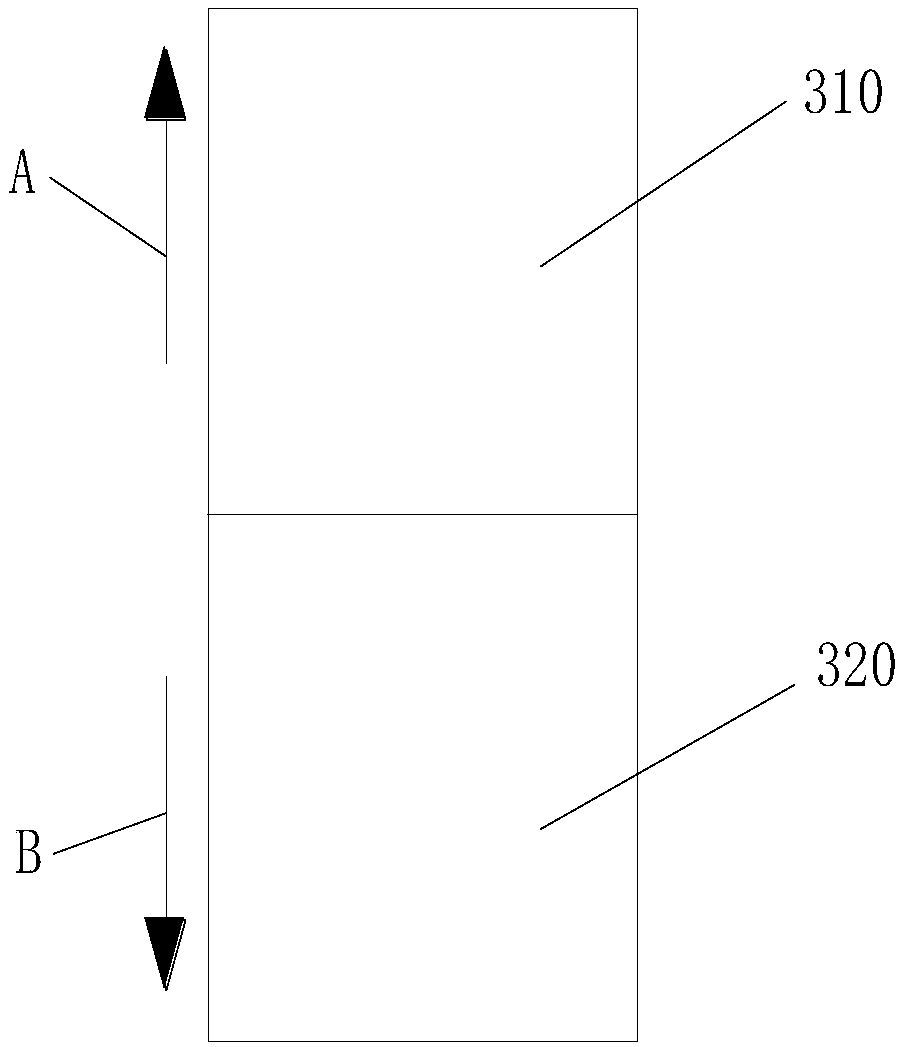

[0021] In a first aspect, an embodiment of the present invention provides a shell manufacturing method. figure 1 A schematic cross-sectional structure diagram of an embodiment of the housing of the present invention is shown. figure 2 A schematic cross-sectional structure diagram of another embodiment of the housing of the present invention is shown. image 3 A schematic diagram showing a transparent ink layer of another embodiment of the casing of the present invention. see Figure 1 to Figure 3 , in the embodiment of the present invention, the preparation method of the shell includes the following steps:

[0022] Forming a transparent ink layer 30 on the first surface of the substrate 10;

[0023] Form gradient colors on the transparent ink layer 30 by dipping;

[0024] A dye protective layer 40 is formed on the surface of the dyed transparent ink layer 30 to seal the gradient color formed by exhaust dyeing.

[0025] In the shell preparation method provided by the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com