Preparation method of moisture-absorbing and sweat-releasing ECDP fiber

A moisture-absorbing and sweat-wicking fiber technology, which is applied in the fields of spinning and polyester polymerization, can solve problems such as damage to segmental regularity and crystallinity, no research on fiber moisture-wicking and sweat-wicking capabilities, and affect production safety, etc., to improve flow Denaturation and spinnability, avoiding self-aggregation problems, and improving moisture absorption and perspiration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

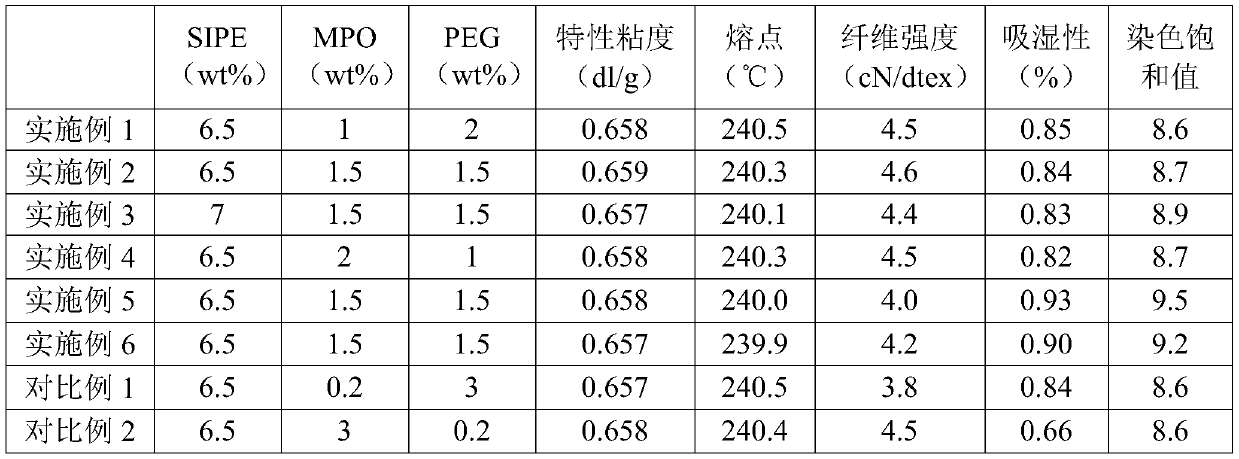

Examples

preparation example Construction

[0049] A preparation method for moisture absorption and perspiration ECDP fibers, comprising the following steps:

[0050] (1) The first esterification: mix terephthalic acid, ethylene glycol, catalysts and additives, beat and stir evenly, and transfer the obtained slurry to the first esterification tank for the first esterification. React at ~60kPa, control the esterification rate to over 80%; Among them, the catalyst is at least one of antimony trioxide, antimony acetate, and antimony glycol, and the auxiliary agent is trimethyl phosphate, triethyl phosphate, phosphoric acid At least one of tripropyl ester and triphenyl phosphate; the molar ratio of terephthalic acid, ethylene glycol, catalyst and additive is 1:1.1~1.5:0.0002~0.0004:0.00005~0.0001;

[0051] (2) Pre-esterification of isophthalic acid-5-sulfonate: add isophthalic acid-5-sulfonate and ethylene glycol into the pre-esterification kettle, react at 120-180°C for 2-5 hours, The end point of the reaction is when the...

Embodiment 1

[0062] A preparation method for moisture absorption and perspiration ECDP fibers, comprising the following steps:

[0063] (1) The first esterification: mix terephthalic acid, ethylene glycol, ethylene glycol antimony and triethyl phosphate, make a beating and stir evenly, and the resulting slurry is transported to the first esterification kettle for the first esterification. ℃, 60kPa reaction, control the esterification rate of 85% or more; wherein, the molar ratio of terephthalic acid, ethylene glycol, ethylene glycol antimony, and trimethyl phosphate is 1:1.1:0.0003:0.0001;

[0064] (2) Pre-esterification of isophthalic acid-5-sodium sulfonate: add isophthalic acid-5-sodium sulfonate and ethylene glycol into the pre-esterification kettle, react at 180°C for 3 hours, and wait for the amount of water received When the theoretical value is reached, it is the end of the reaction, and the reaction temperature in the whole reaction process does not exceed 180°C; wherein, the mola...

Embodiment 2

[0071] A preparation method for moisture absorption and perspiration ECDP fibers, comprising the following steps:

[0072] (1) The first esterification: mix terephthalic acid, ethylene glycol, ethylene glycol antimony and triethyl phosphate, make a beating and stir evenly, and the resulting slurry is transported to the first esterification kettle for the first esterification. ℃, 60kPa reaction, control the esterification rate of 85% or more; wherein, the molar ratio of terephthalic acid, ethylene glycol, ethylene glycol antimony, and trimethyl phosphate is 1:1.1:0.0003:0.0001;

[0073] (2) Pre-esterification of isophthalic acid-5-sodium sulfonate: add isophthalic acid-5-sodium sulfonate and ethylene glycol into the pre-esterification kettle, react at 180°C for 3 hours, and wait for the amount of water received When the theoretical value is reached, it is the end of the reaction, and the reaction temperature in the whole reaction process does not exceed 180 ° C; wherein, the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leaf width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com