Magnetoplumbite permanent magnetic ferrite and method of producing the same

A technology of permanent magnet ferrite and magnetoplumbite, which is applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problem of not being able to obtain high magnetic properties and intrinsic coercive force at the same time, and achieve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

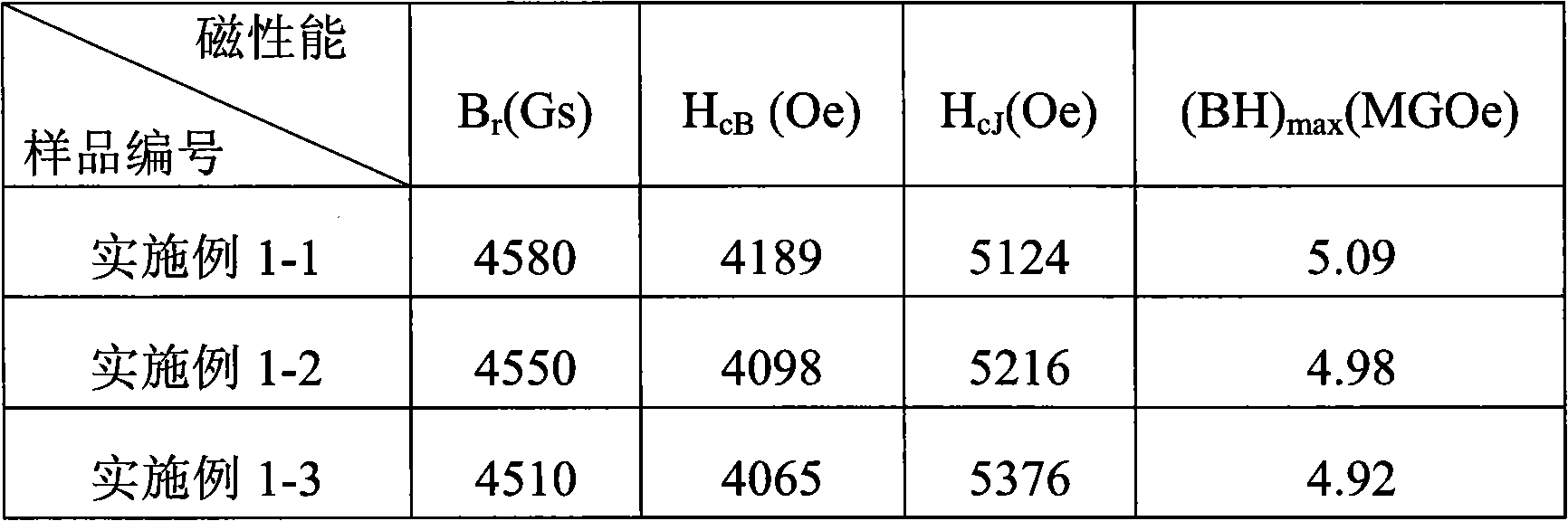

Embodiment 1

[0039] The batching process selects various raw material requirements and corresponding weight percentages as follows:

[0040] (1) Iron red: the purity of Fe 2 o 3 Content≥99.5wt%, Cl - The original average particle size of particles with ion content ≤ 0.1wt% is 1.6μm, and the weight percentage is 83.4%;

[0041] (2) Strontium carbonate: where the purity of SrCO 3 ≥98.0wt%, the original average particle size of the particles is 2.1μm, and the weight percentage is 4.31%;

[0042] (3) Calcium carbonate: the purity of which is CaCO 3 ≥99.0wt%, the original average particle size of the particles is 4.2μm, and the weight percentage is 2.42%;

[0043] (4) Lanthanum oxide: where the purity La 2 o 3 ≥99.0wt%, the original average particle size of the particles is 4.5μm, and the weight percentage is 7.08%;

[0044] (5) Cobalt trioxide: the purity of Co 2 o 3 ≥99.0wt%, the original average particle size of the particles is 2.5μm, and the weight percentage is 2.78%.

[0045] ...

Embodiment 2

[0062] Raw material selection is the same as embodiment 1, and the various raw materials that constitute these main components are weighed so that the main components after firing are as follows:

[0063] Composition formula: Sr 1-x-y Ca x La y Fe 2n-z co z o 19 , where x=0.2, y=0.4, z=0.3, n=5.0, 5.3, 5.6, 5.8. The above four groups of tests are respectively numbered as Examples 2-1, 2-2, 2-3, and 2-4.

[0064] The raw materials weighed according to the above composition were mixed and ball milled in a wet ball mill for 5 hours, and the average particle size after mixing was about 0.8 μm, then dried in an oven, and then pelletized, pre-fired in the air at 1250 ° C, and kept for 1 hour , to obtain granular calcined material.

[0065] Then, take by weighing 450 grams of four kinds of coarse pulverization calcined materials produced in the above-mentioned way respectively, add 0.6wt% SiO 2 , 0.8wt% CaCO 3 , 0.3wt% Cr 2 o 3 , add 1.0wt% calcium gluconate as a dispersan...

Embodiment 3

[0073] Except that the Sr part in the main component is replaced by Ba, all the other additives are the same as in Example 1. Where Ba is added in the form of barium carbonate, BaCO in the raw material barium carbonate 3 ≥98.0wt%, the original average particle size of the particles is 3.1 μm. After taking the same pre-fired material preparation process as the embodiment, it detects that its main phase can be expressed as: Sr 0.19 Ba 0.16 Ca 0.23 La 0.43 Fe 10.89 co 0.35 o 19 . Then take the substantially same coarse pulverization process as in Example 1, the secondary wet fine pulverization process, after the magnetic field forming process and the corresponding sintering process, measure its sample magnetic properties as shown in table 4:

[0074] Table 4 The main component is Sr 0.19 Ba 0.16 Ca 0.23La 0.43 Fe 10.89 co 0.35 o 19 Sample magnetic properties

[0075]

[0076] The above test results show that the use of part of Ba instead of Sr can promote the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com