Dyeing method for protein fiber non-aqueous medium

A protein fiber and dyeing method technology, applied in the dyeing field of protein fiber non-aqueous medium, can solve the problems affecting consumers' wearing, care and aesthetics, poor performance of dyed fabrics, poor hand feeling, etc., achieve small dyeing loss, reduce water Dosage, Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

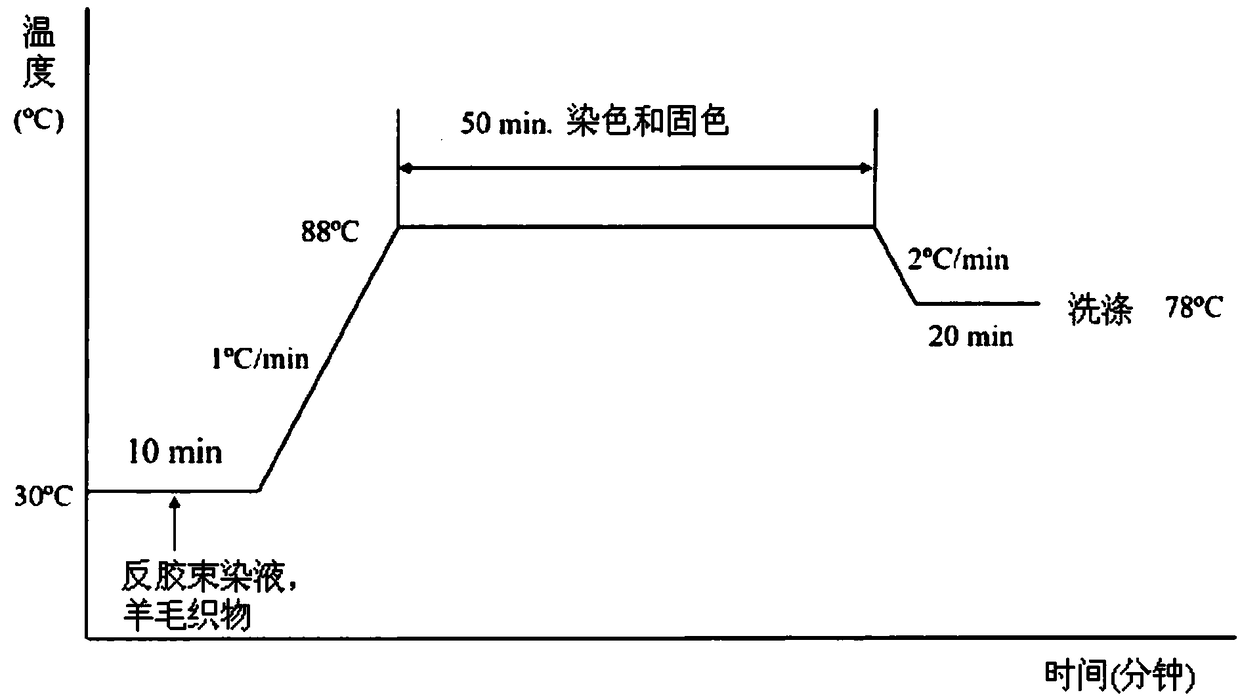

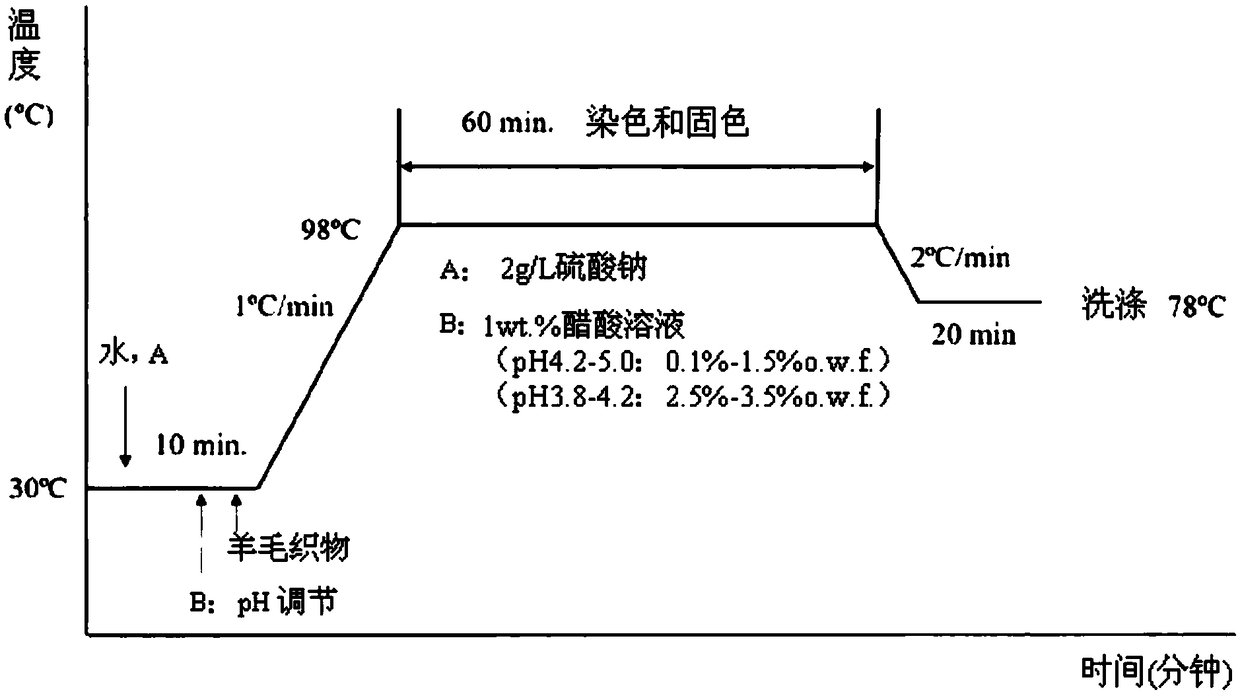

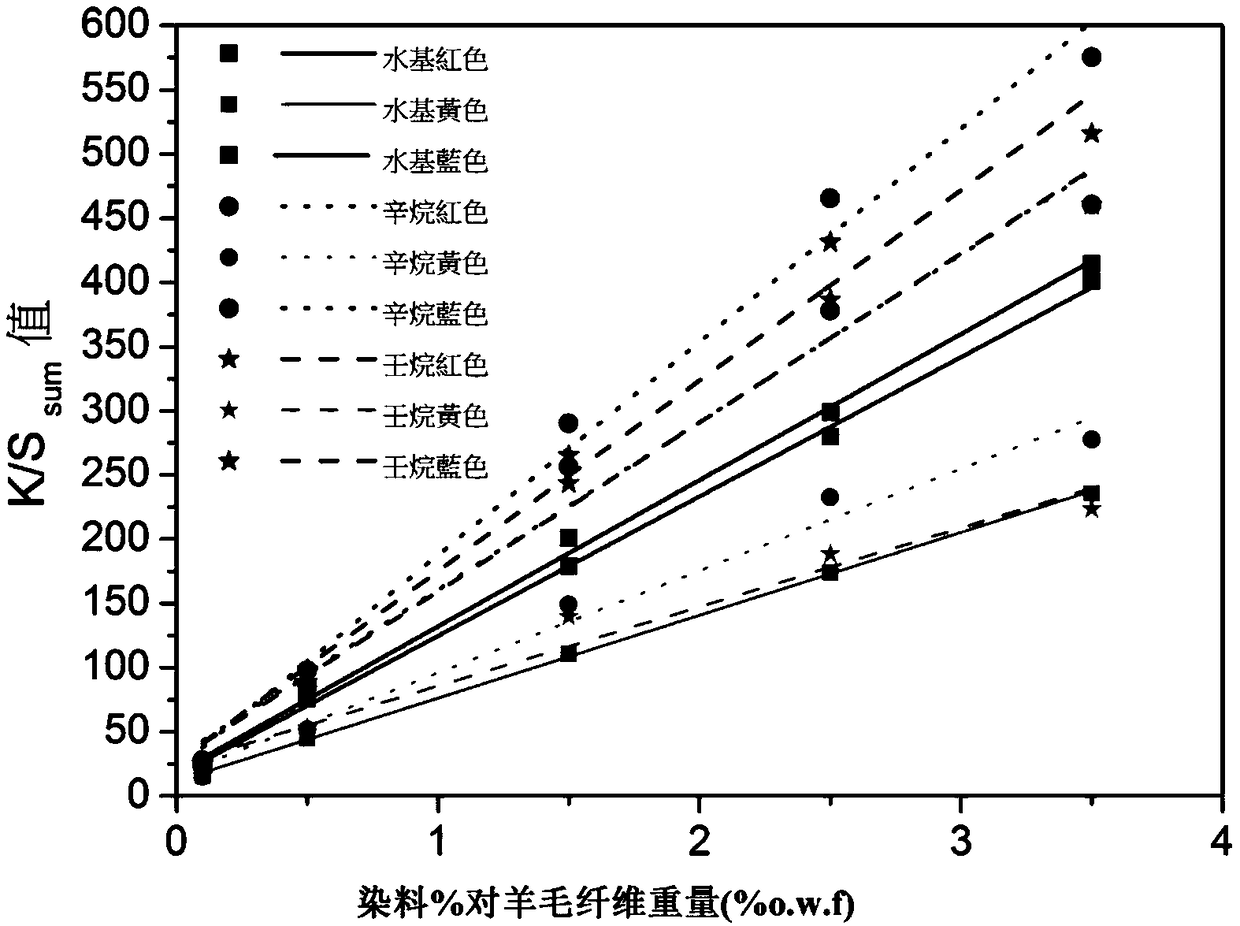

[0047] Example 1: Wool Dyeing and Fixation in n-Octane Using Non-ionic Surfactant Reverse Micelles (No Salt)

[0048] A series of nonionic polyethylene glycol-12-tridecyl ether reverse micelles were prepared by a simple injection method at room temperature. 0.0011 mol (0.78 g) of nonionic surfactant and 0.0088 mol (1.16 g) of co-surfactant (n-octanol) were premixed in a beaker by stirring, and the molar ratio was 1:8. The resulting mixture was dissolved in 10 mL of n-octane to prepare a reverse micellar solution.

[0049] Dissolve a certain amount of Realan Red reactive dye in a very small amount of water to make 0.5mL reactive dye solution with a mass percentage of 5%. Slowly inject the reactive dye solution into the above-mentioned reverse micellar solution. After vigorously stirring for 2 minutes, the solution was clarified, and the dye solution in which the micro-aqueous phase of the reactive dye was encapsulated by reverse micelles was obtained.

[0050] Wool fabric (1 ...

Embodiment 2

[0056] Corresponding to Example 1, the difference is that in this example, n-nonane is used as the organic solvent.

Embodiment 3~4

[0058] Corresponding to Example 1, the only difference is that the Realan Red reactive dyes are replaced by Realan Blue reactive dyes and Realan Yellow reactive dyes respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com