Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

664results about "Liquid/gas/vapor treatment machines driving mechanisms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

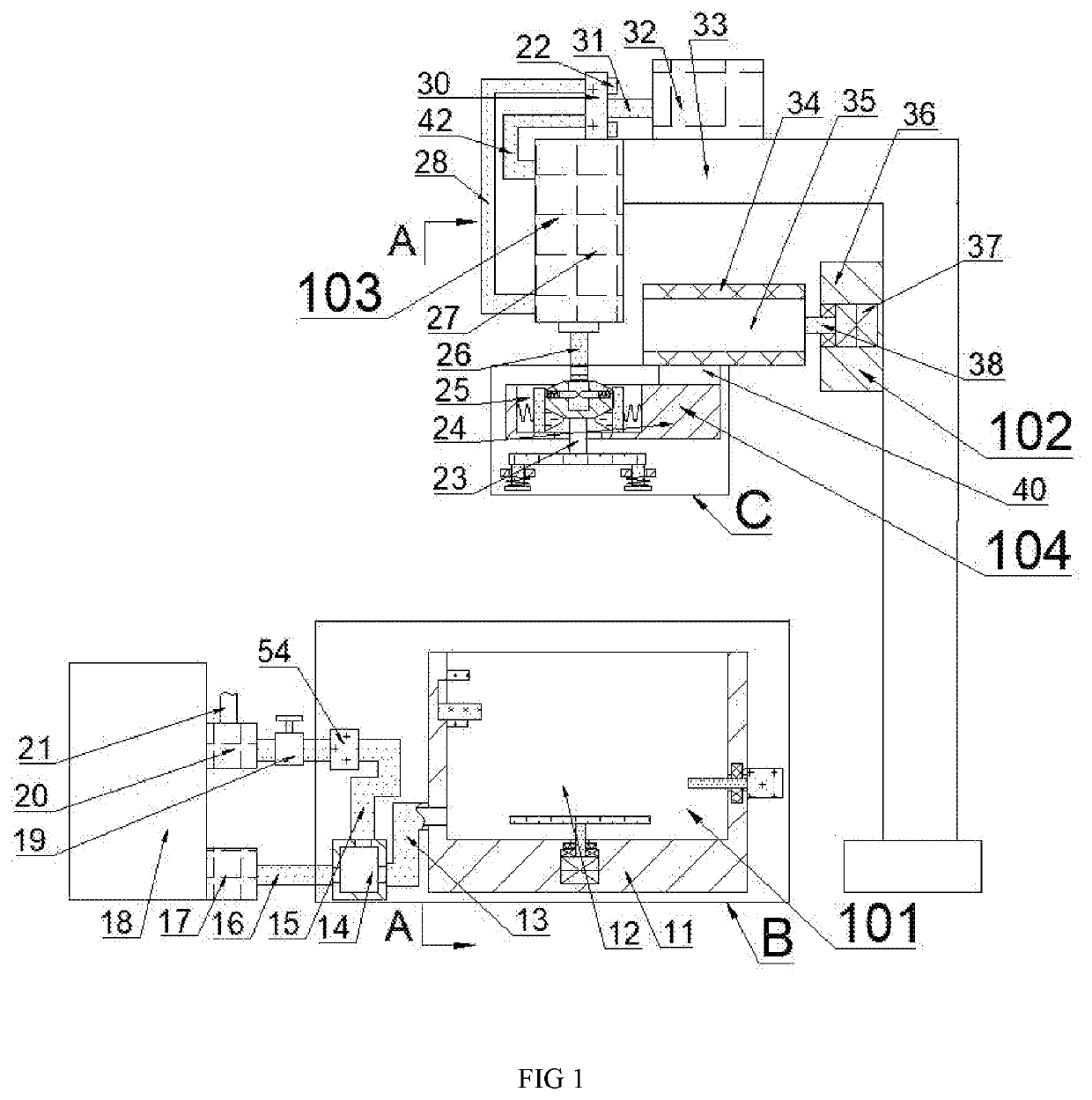

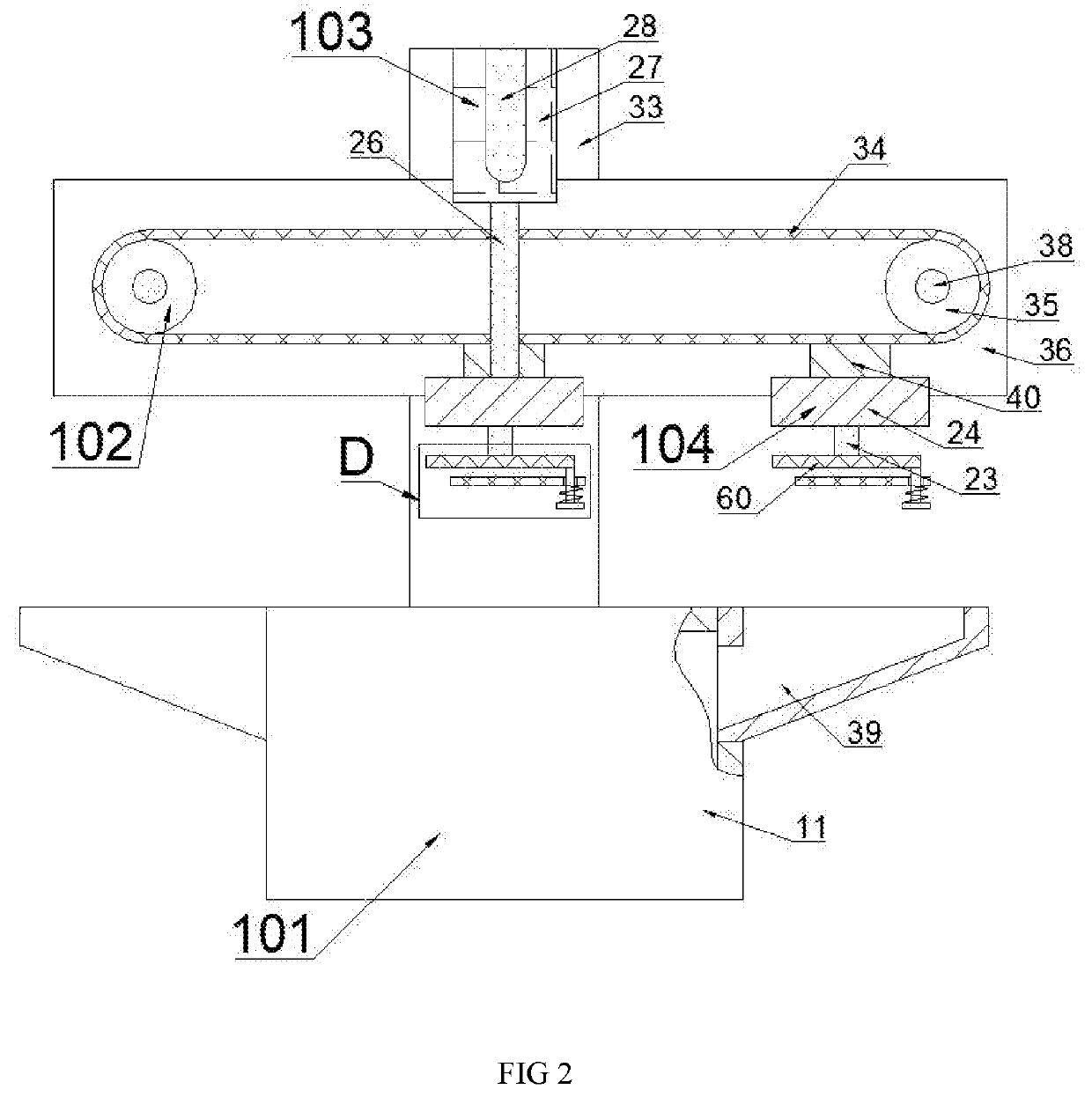

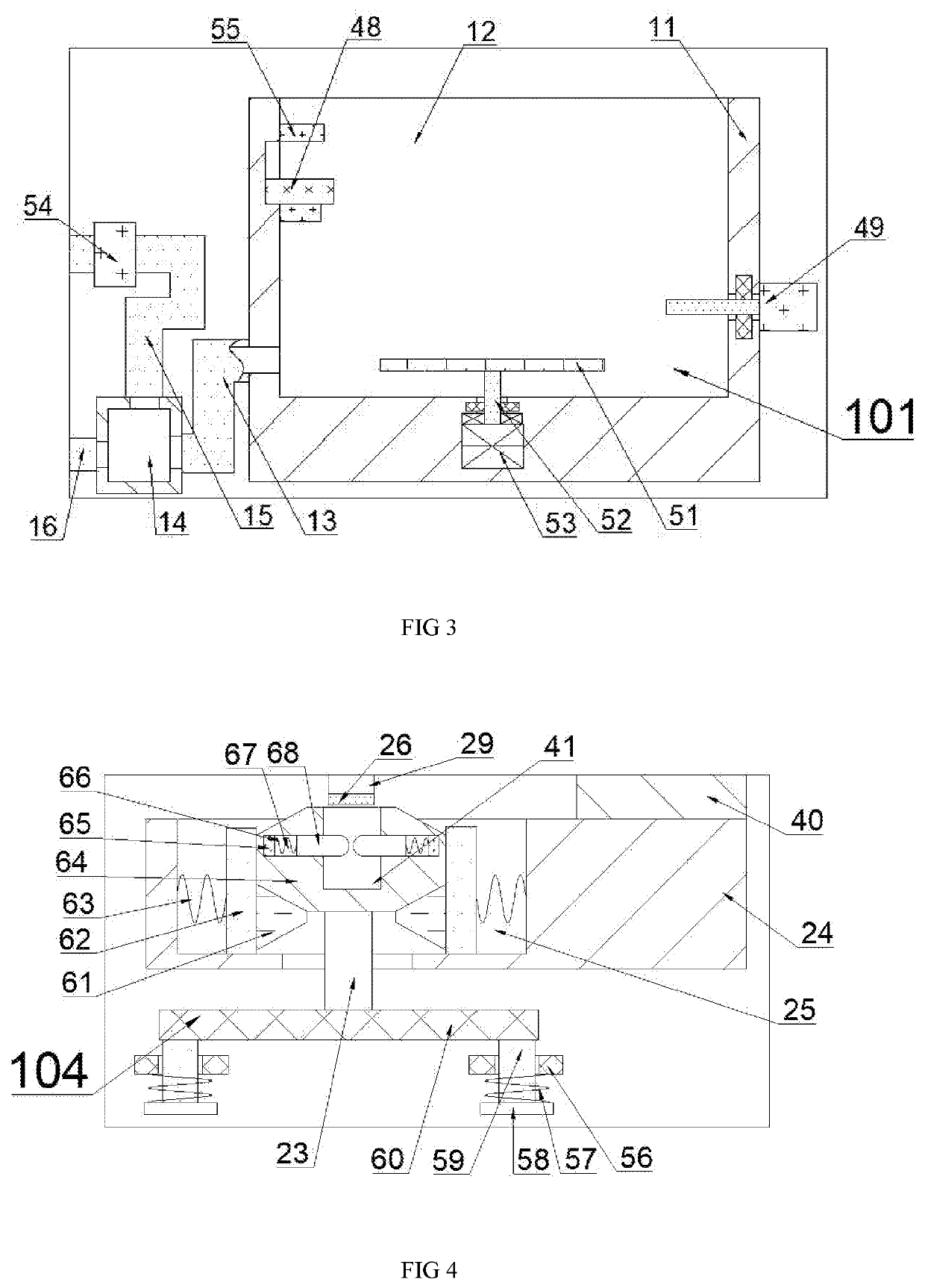

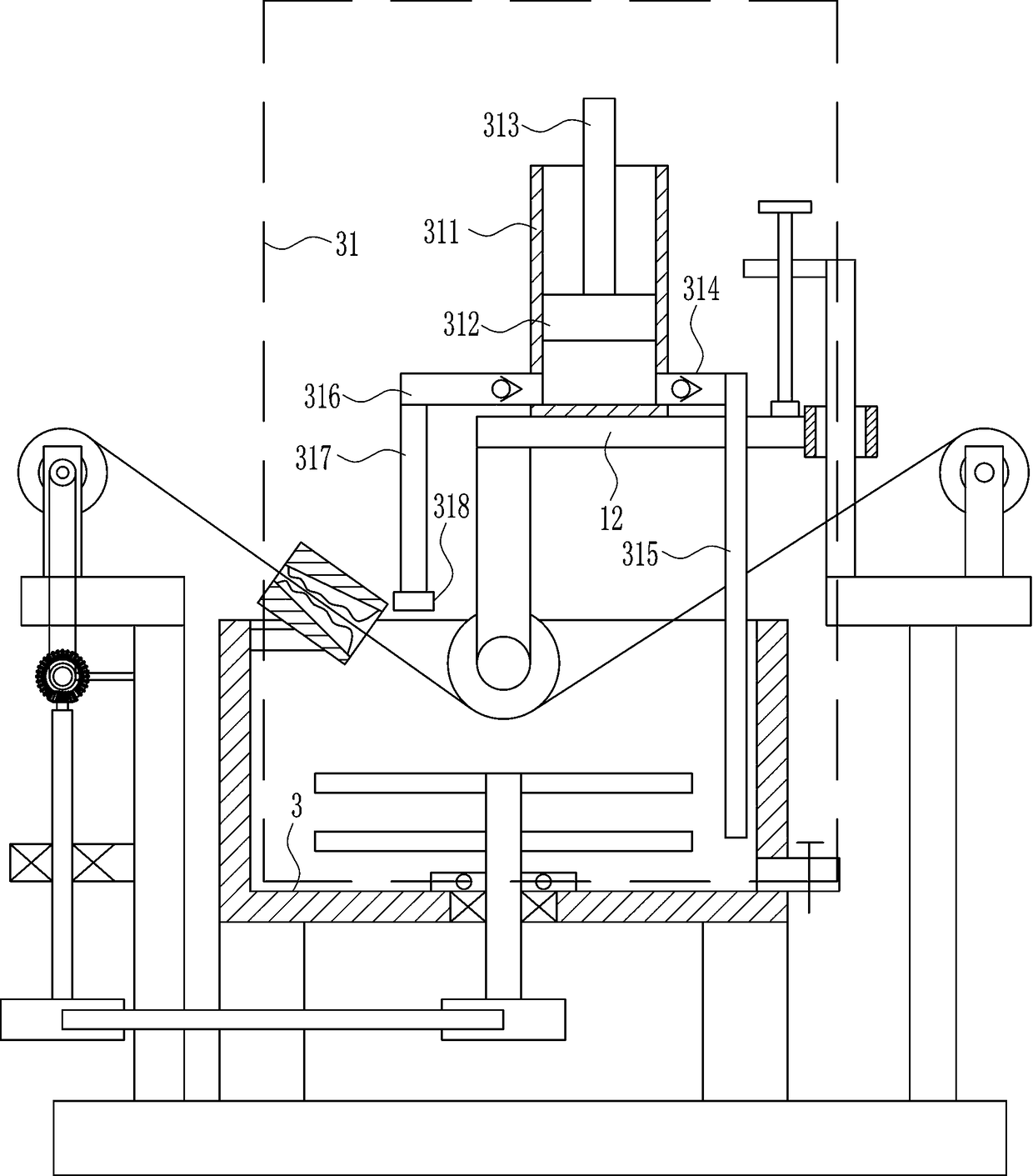

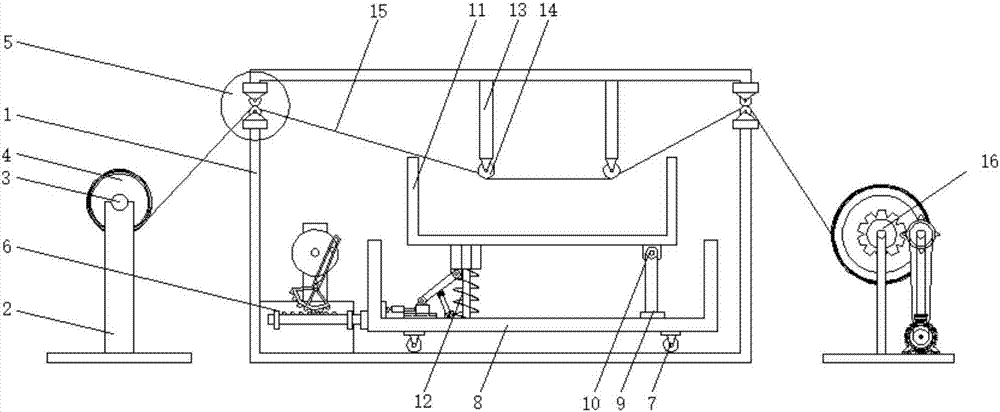

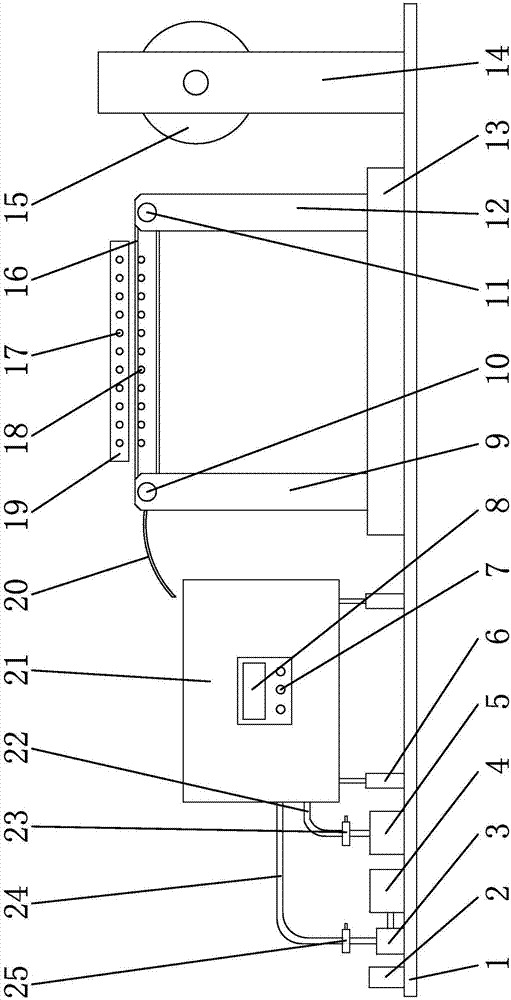

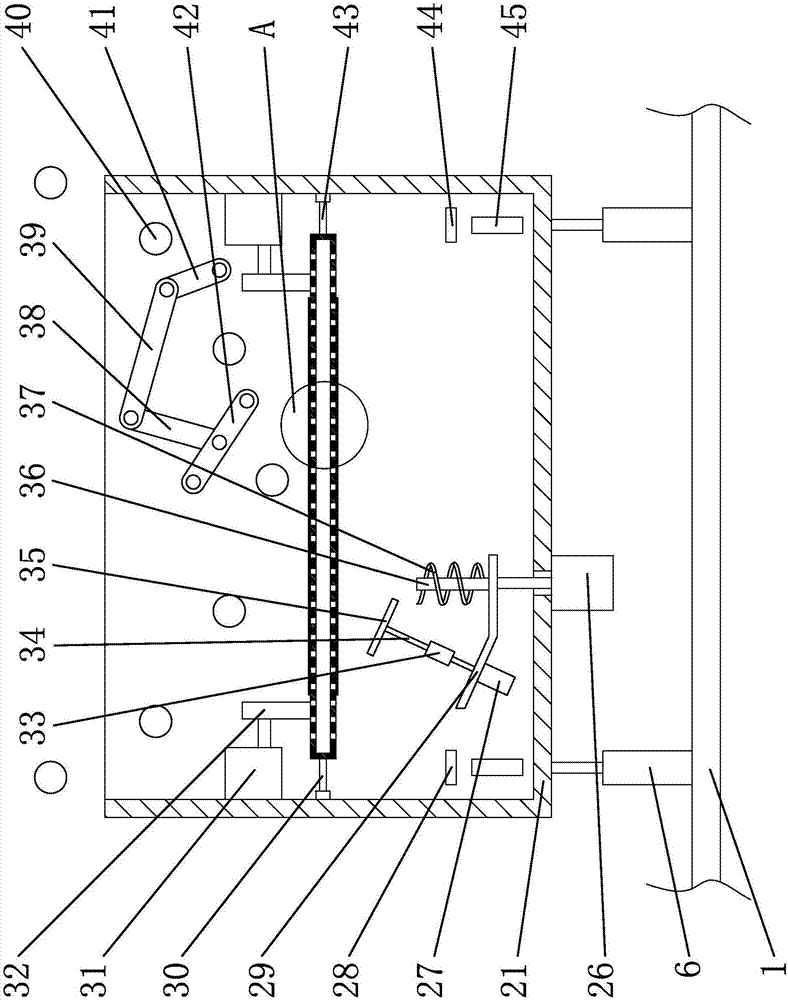

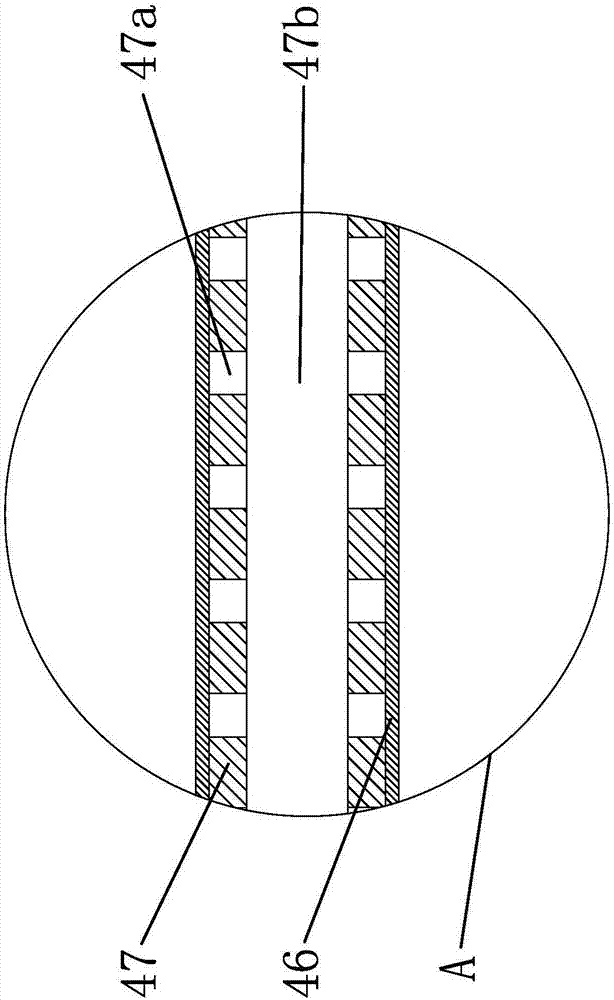

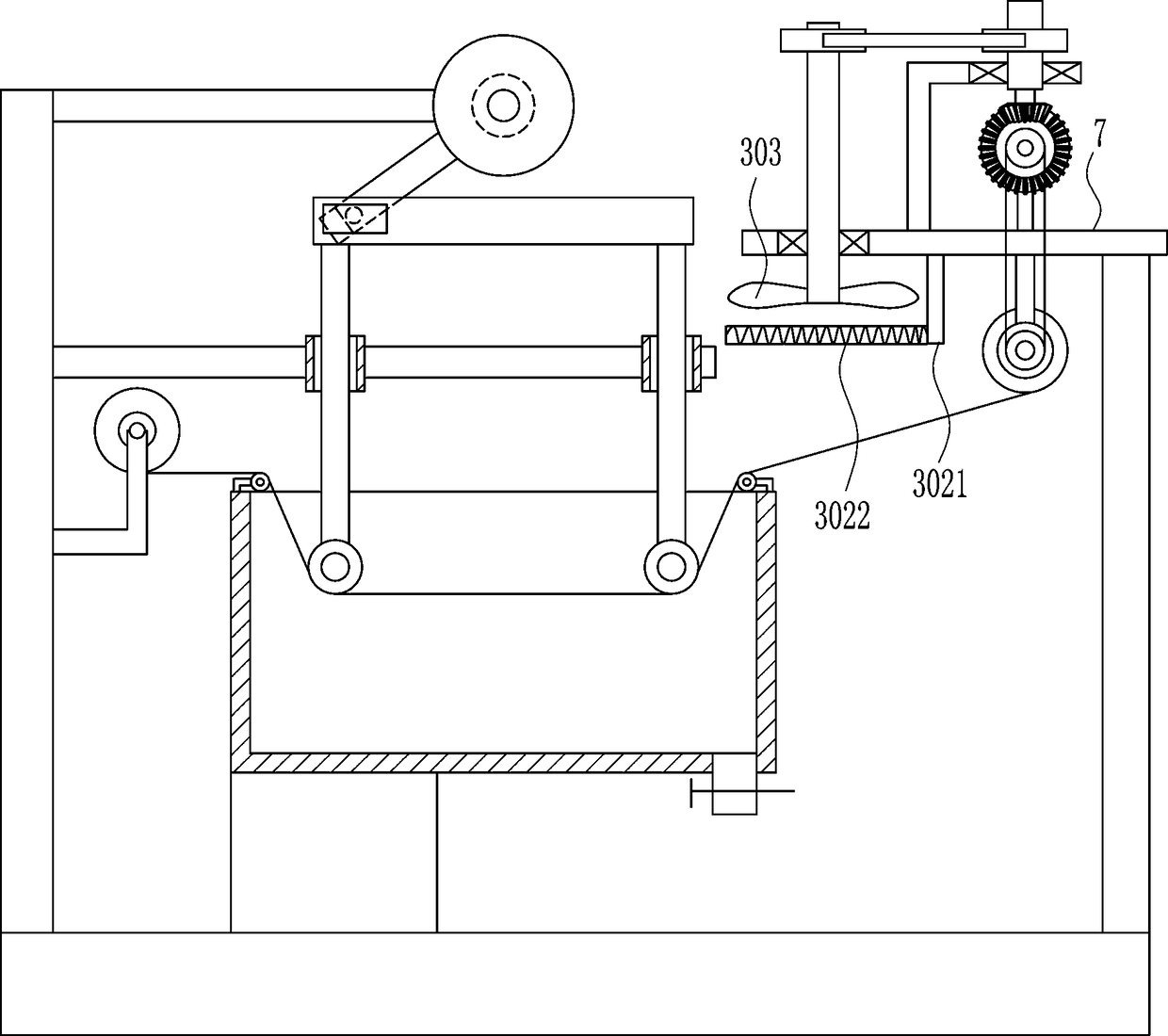

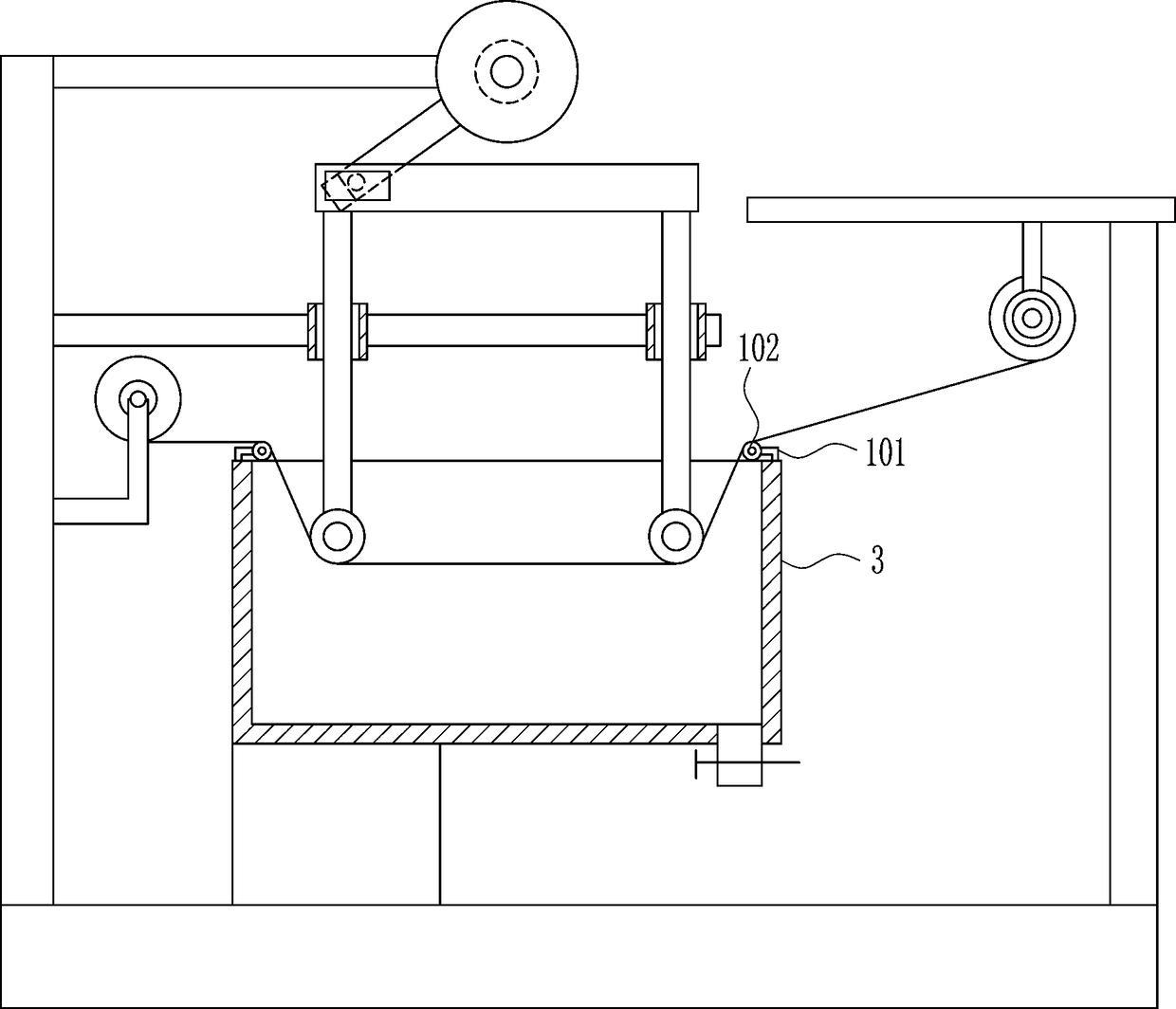

Blue calico printing and dyeing equipment imitating traditional process

InactiveUS20200181821A1Quality improvementIncrease productivityLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalProcess engineeringMechanical engineering

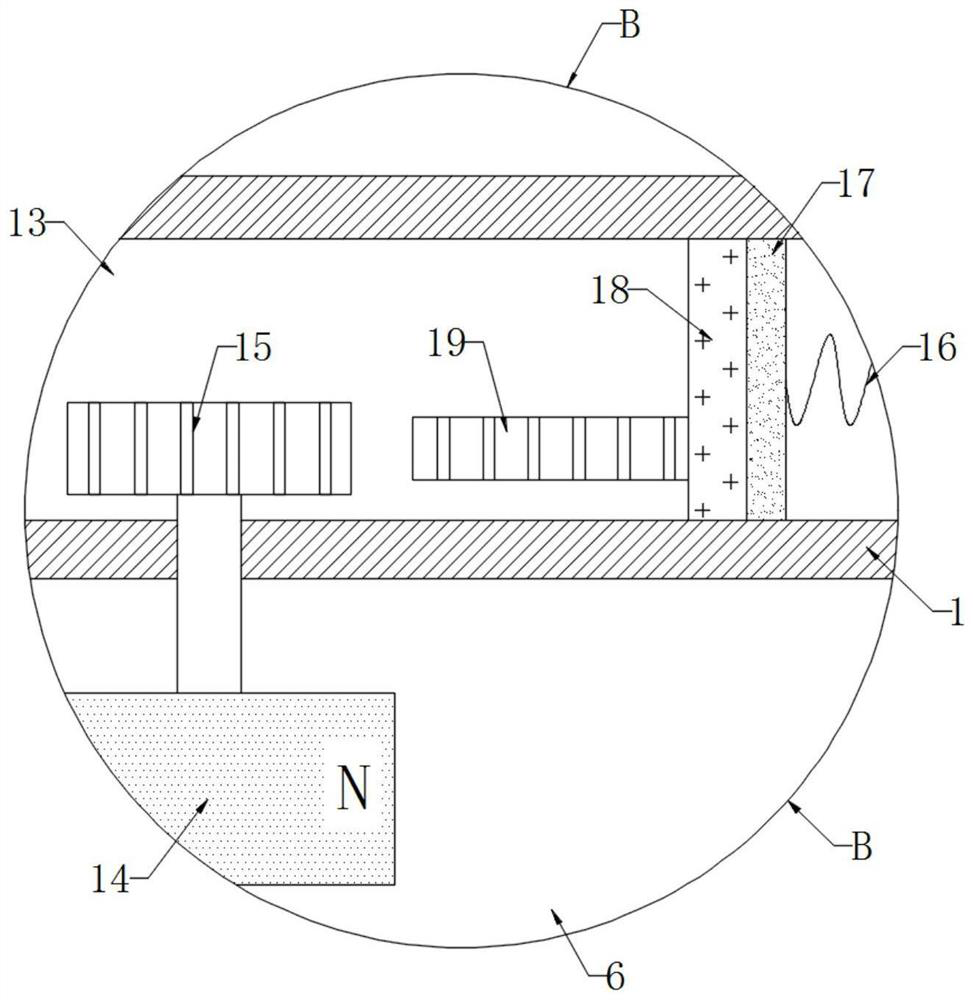

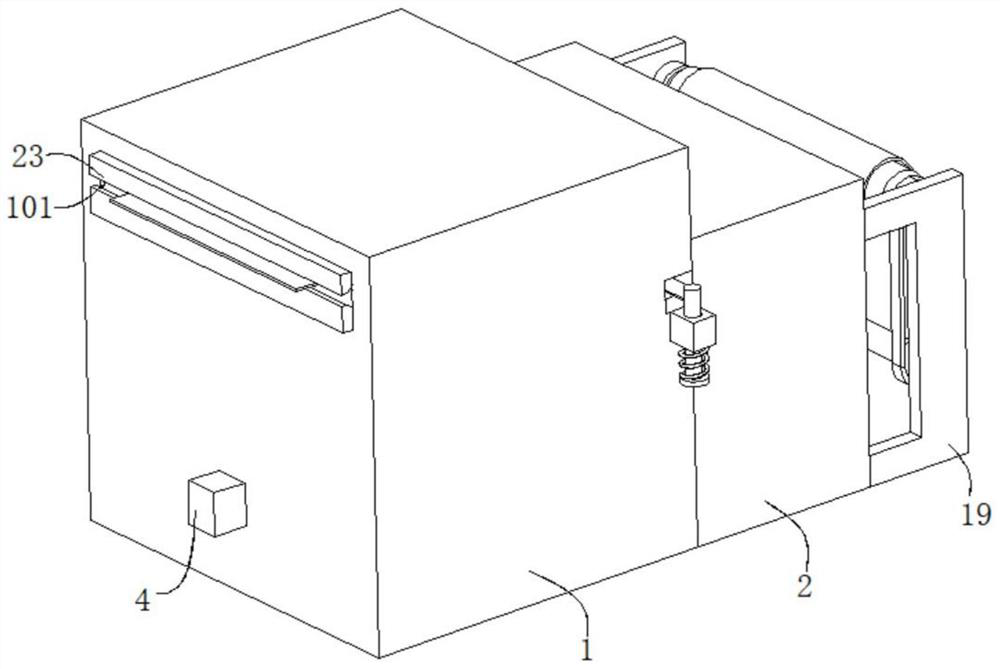

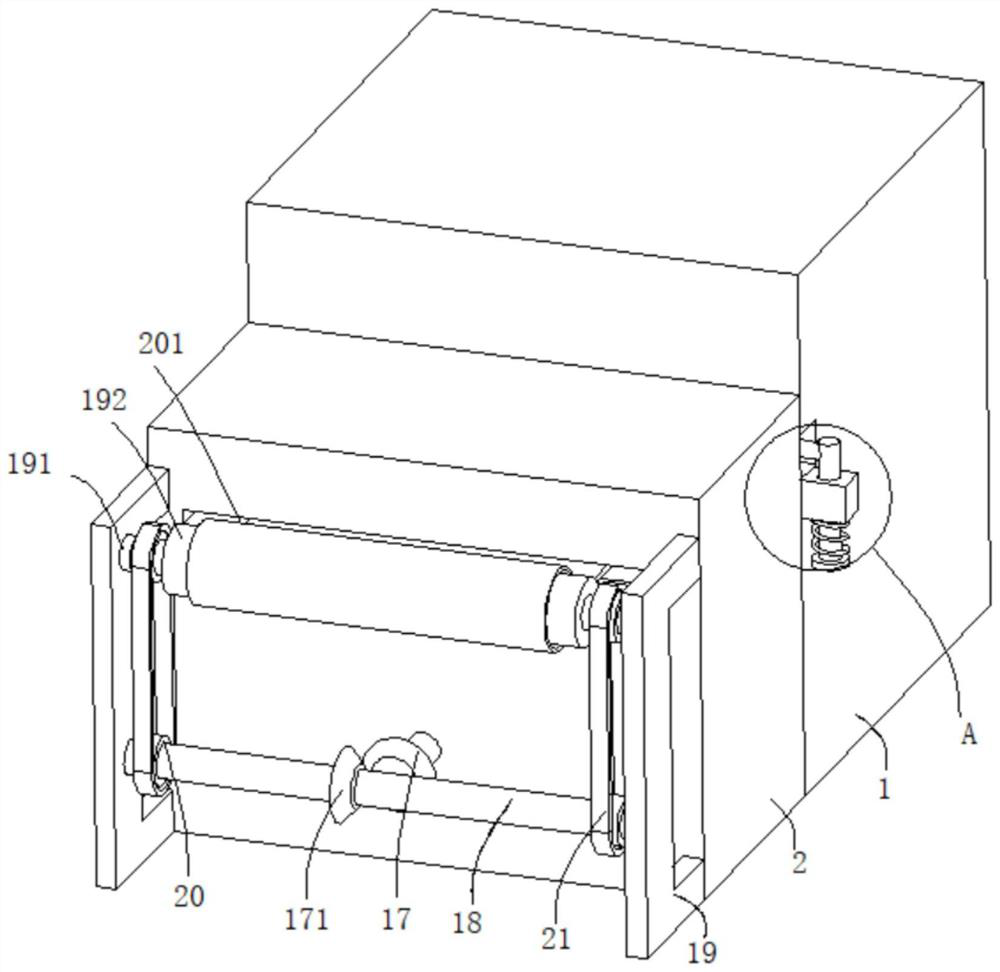

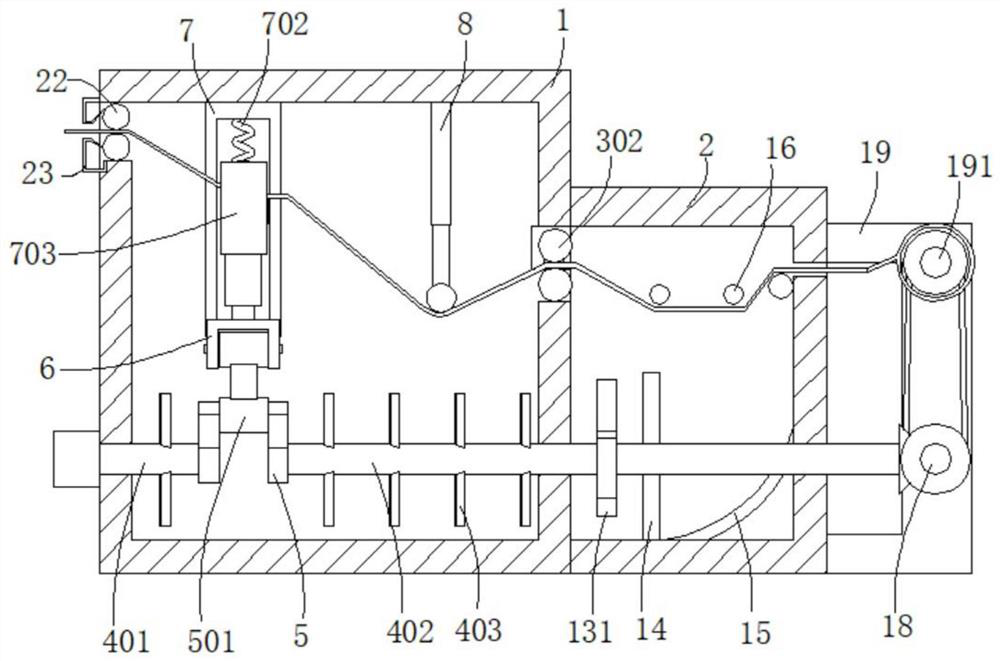

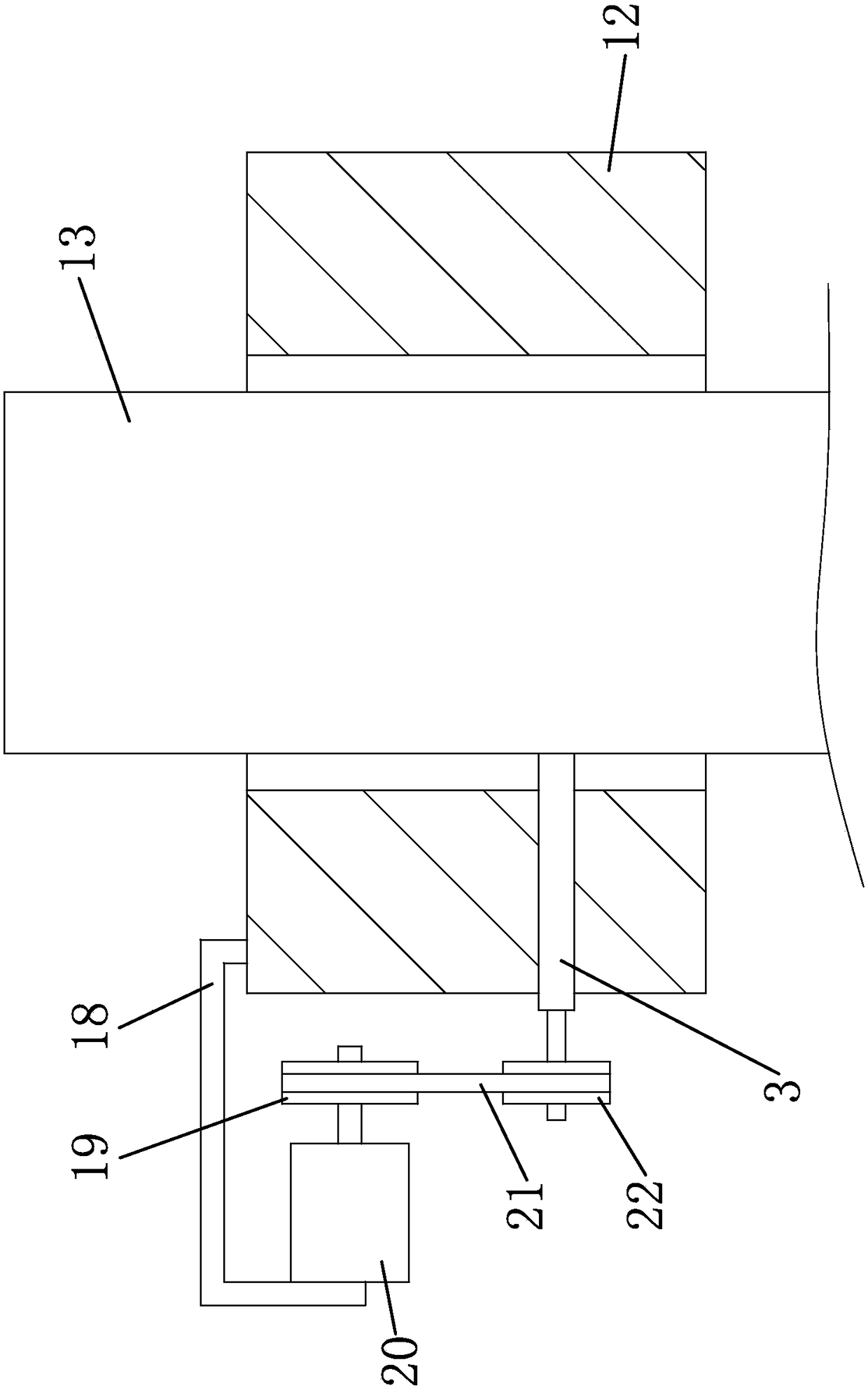

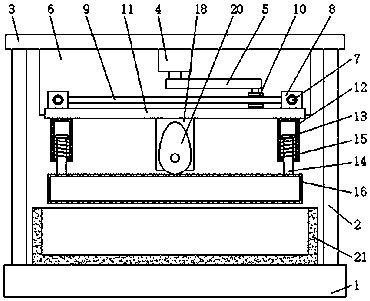

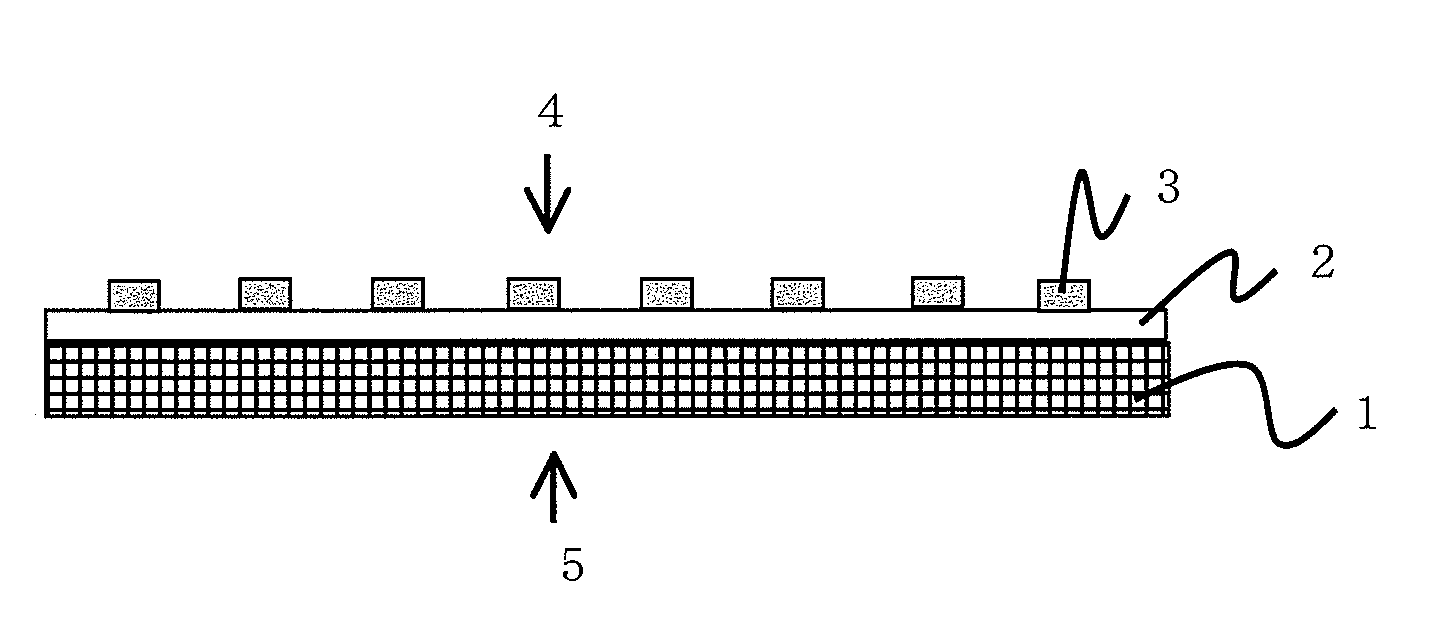

The invention discloses a blue printing cloth printing and dyeing device which imitates the traditional process, and includes a dye box. A dyeing device is provided on the right side of the dye box, and an L-shaped support post is provided on the right side of the dye box. A conveying device for conveying cloth is provided on the column, and a lifting device on the upper side of the conveying device is provided on the support column. The lifting device provides lifting movement for the dyeing cloth. As for the holding device for holding the cloth, the cloth dyeing cylinder of the present invention can indirectly detect the concentration of the dye solution through the PH value detection, and the liquid level detection mechanism and the PH value detector can be used to control the liquid pump supply to achieve automatic control of the dye solution concentration and The liquid level height improves the printing and dyeing quality. The conveying mechanism drives the two groups of clamping mechanisms to move to the upper side of the cloth dyeing cylinder and the air-drying place. The lifting mechanism can drive the clamping mechanism to lower into the cloth dyeing cylinder for dyeing. Therefore, the present invention can replace manual Printing and dyeing with traditional techniques can improve production efficiency.

Owner:WANG MING

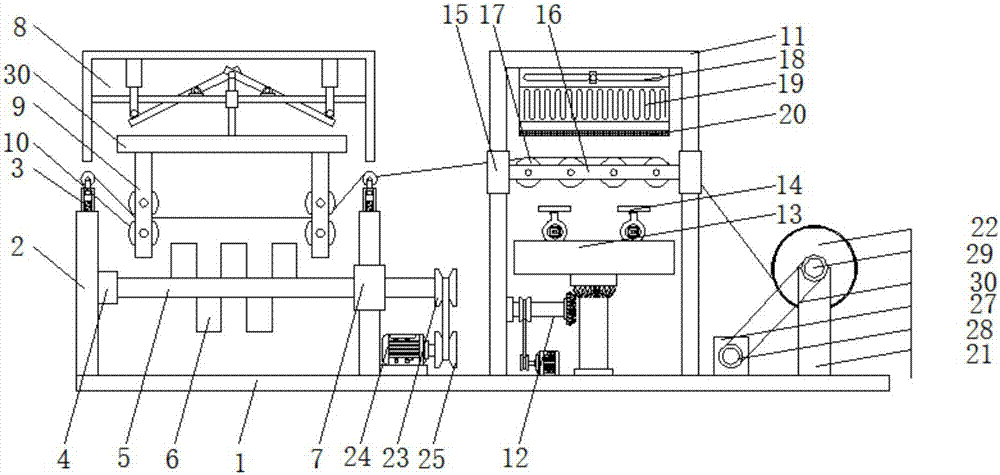

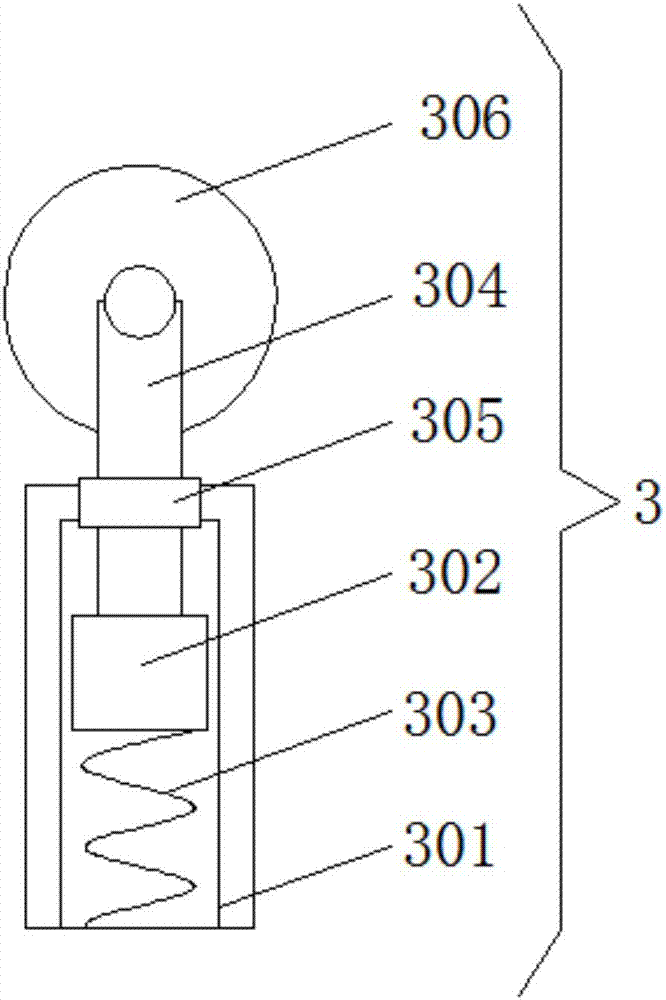

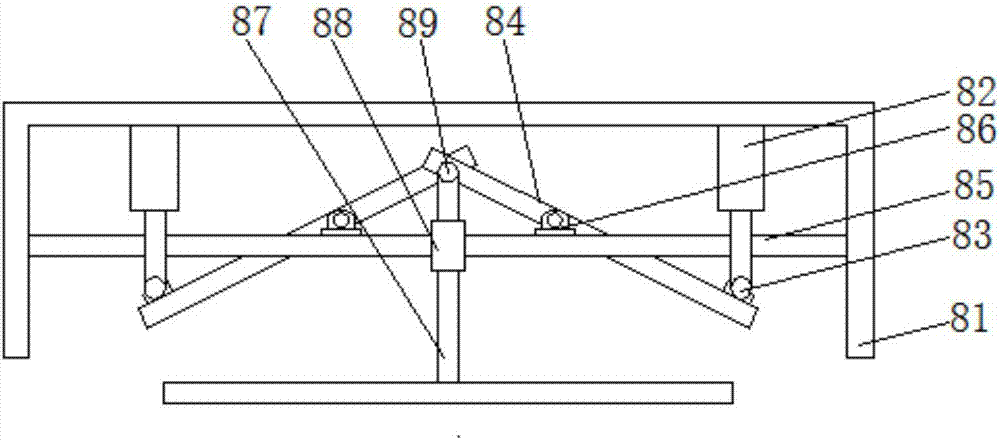

Textile fabric dyeing equipment

ActiveCN108277594AAvoid color inconsistenciesNo precipitationLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringSediment

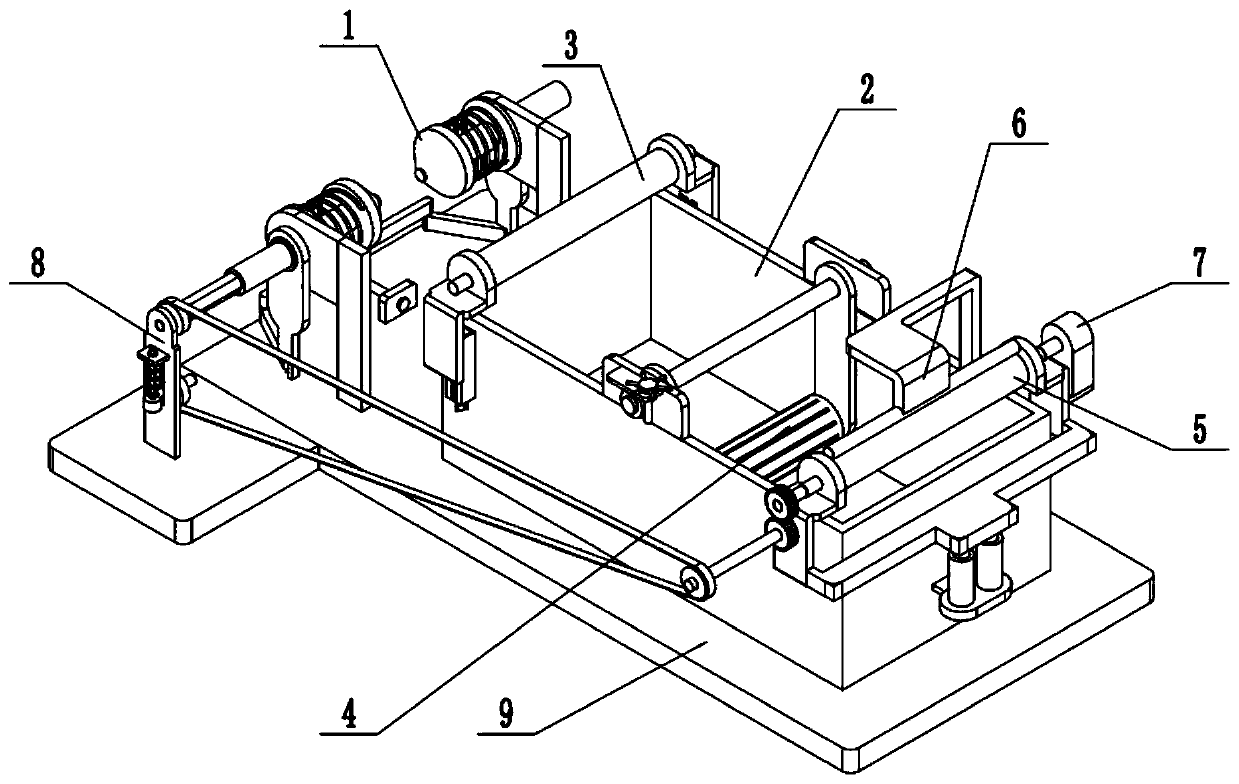

The invention relates to textile processing equipment, in particular to textile fabric dyeing equipment. The to-be-solved technical problem is to provide the textile fabric dyeing equipment capable ofstirring dye, so that no sediment occurs in the dye, the fabric is dyed uniformly, the upper and lower layers of the fabric both can be dyed with the dye at same depth in a dyeing process. In order to solve the above technical problem, the invention provides the textile fabric dyeing equipment, the textile fabric dyeing equipment comprises a bottom plate, brackets, a dye box, a discharging tube,a valve, a first supporting plate, a first mounting plate, a first connecting rod, and a first sleeve wheel, a guiding rail, a guiding sleeve, a second connecting rod and the like, wherein the left and right sides of the bottom plate both are connected to the brackets, and the dye box is connected between the upper ends of the brackets. According to the textile fabric dyeing equipment, the effectsthat the dye is stirred, so that no sediment occurs in the dye, the fabric is dyed uniformly, and the upper and lower layers of the fabric both can be dyed with the dye at same depth in the dyeing process are achieved.

Owner:嘉兴市永泰五金塑料有限责任公司

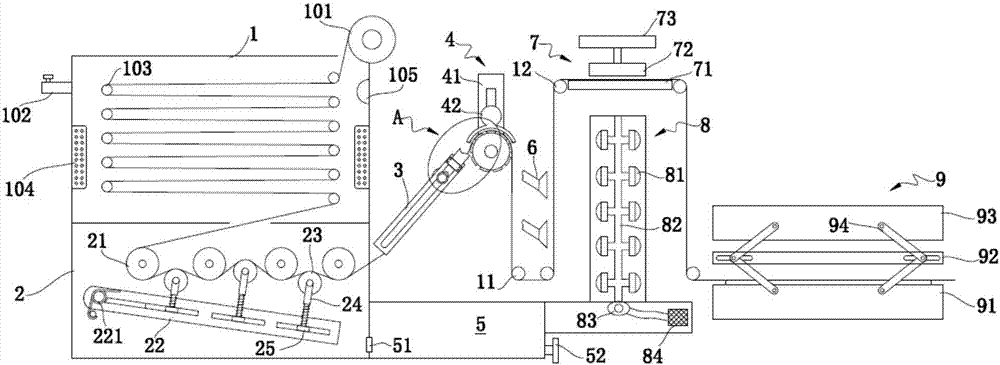

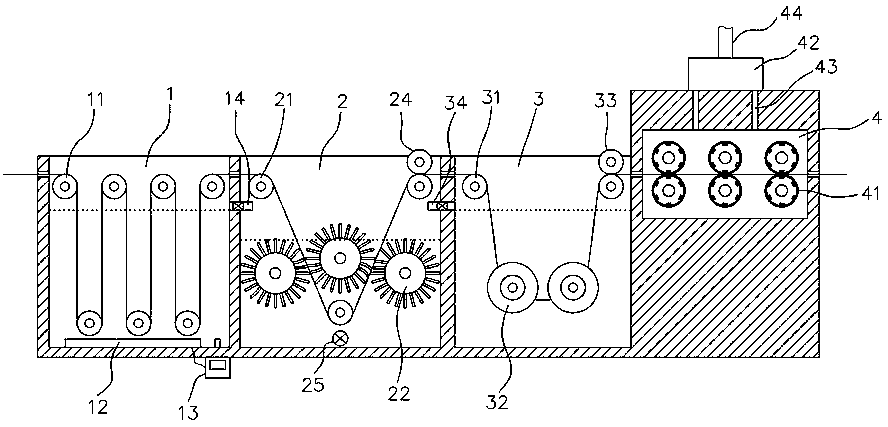

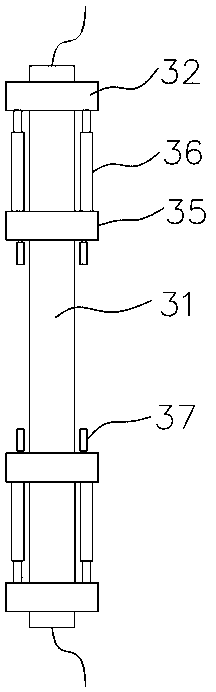

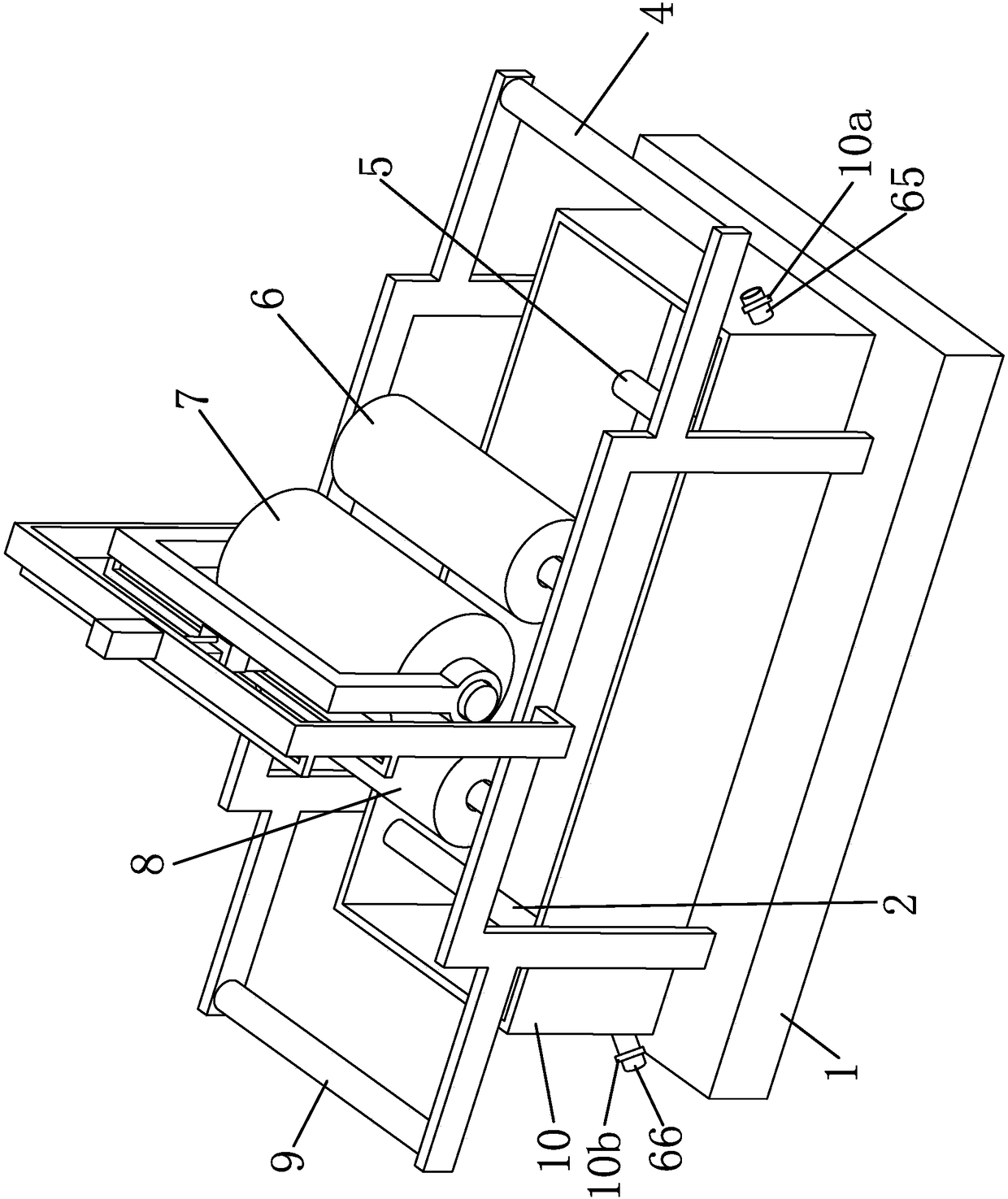

Printing and dyeing equipment

ActiveCN107974786AUniform dyeingAutomatically adjust the tensionLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersPulp and paper industryTextile dyeing

The invention provides printing and dyeing equipment. The printing and dyeing equipment comprises a dyeing box, a dewatering and drying mechanism and a printing machine which are arranged from left toright sequentially. The dewatering and drying mechanism comprises a dewatering mechanism, a water absorbing mechanism, an ironing mechanism and a drying machine which are arranged from left to rightsequentially. The dewatering mechanism comprises a guide rail frame. A water pressing roller is mounted in a groove of the guide rail frame movably through a wheel. An air cylinder is arranged on theright side of the guide rail frame. A piston rod of the air cylinder is connected with the water pressing roller. The water absorbing mechanism comprises a water pressing plate and a water absorbing roller. The printing and dyeing equipment has the advantages that centrifugal dewatering is not needed after textile dyeing through the dewatering and drying mechanism, so that flattening degree of textiles is guaranteed, and flattening on a scutcher is not needed; the dyeing equipment, the dewatering and drying equipment and the printing equipment are combined, so that equipment replacement time during working is reduced, dyeing and printing can be completed on one equipment, and working efficiency is improved.

Owner:TONGXIANG LONGXIANG PRINTING & DYEING CO LTD

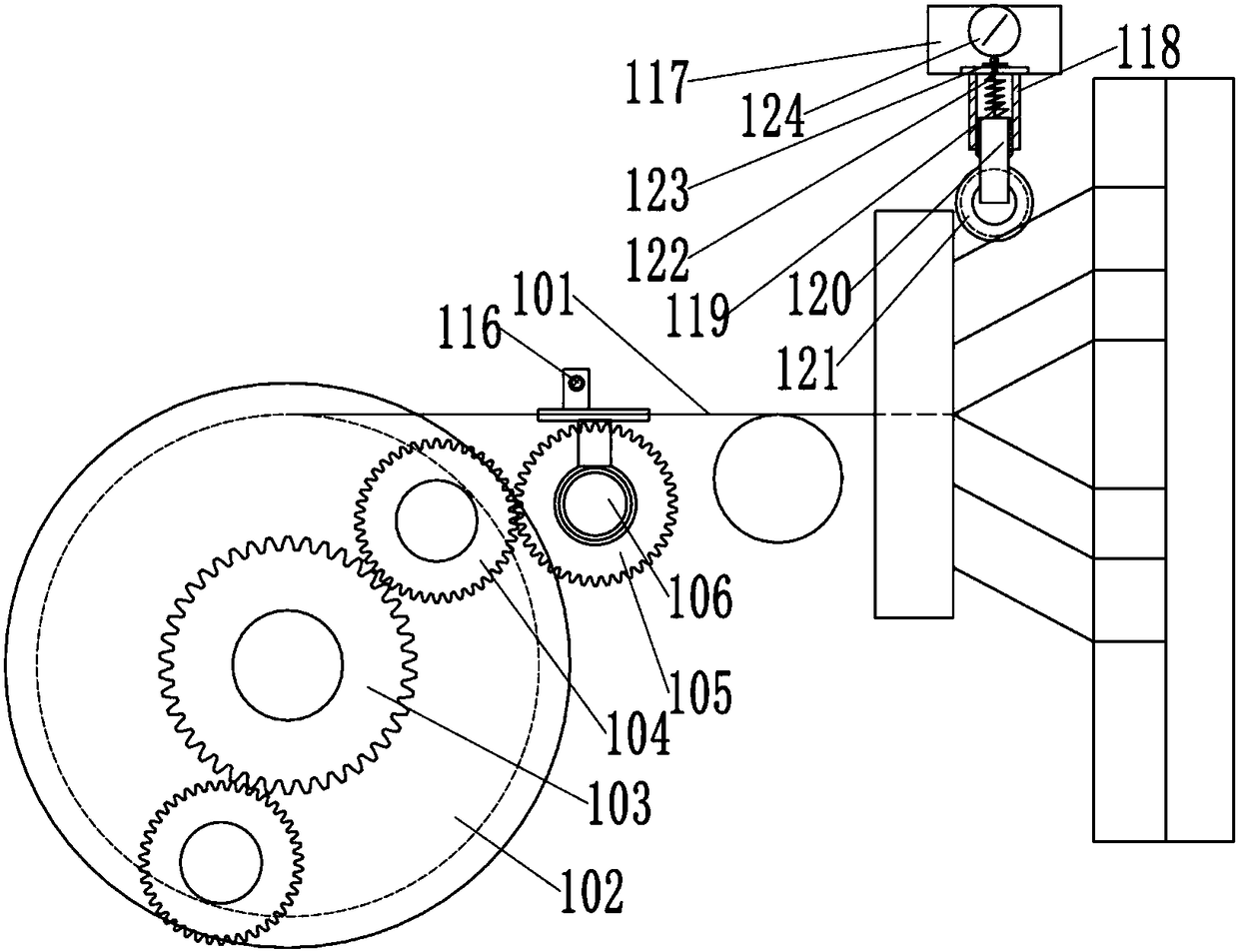

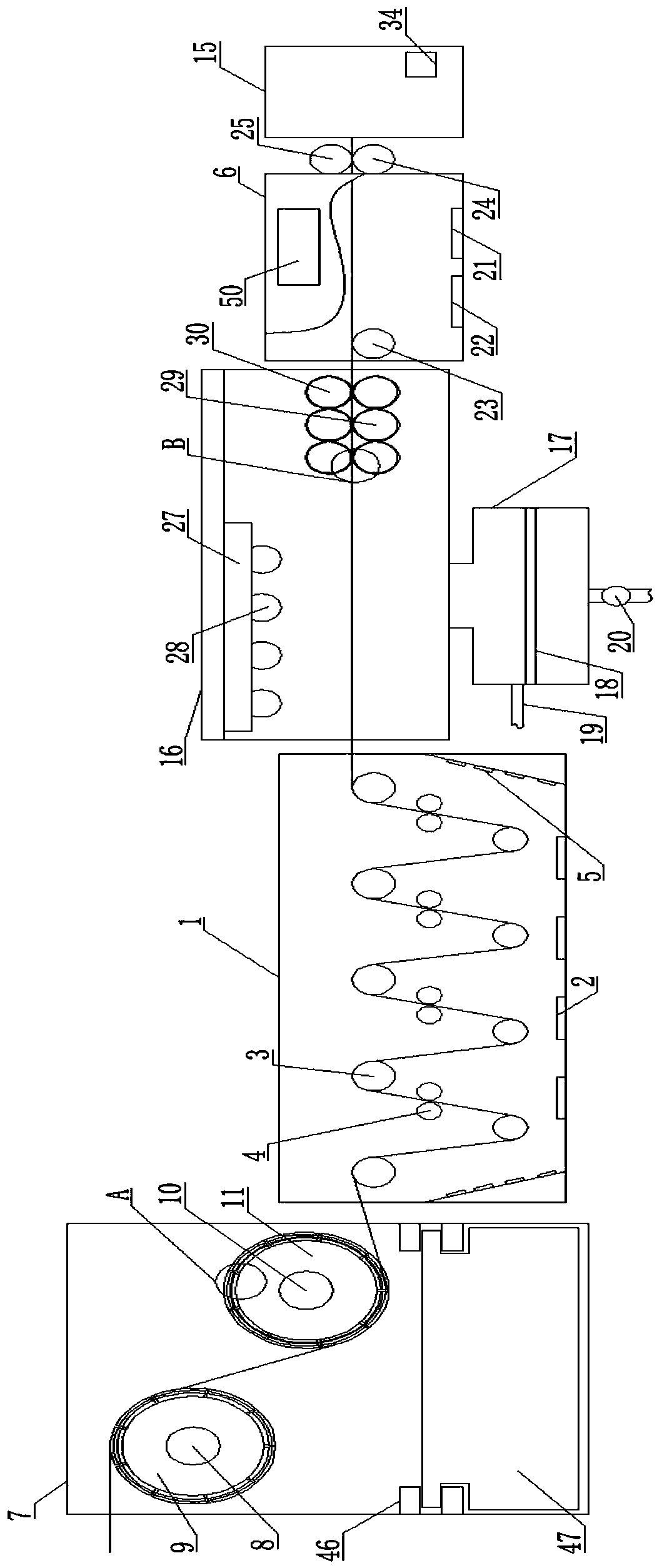

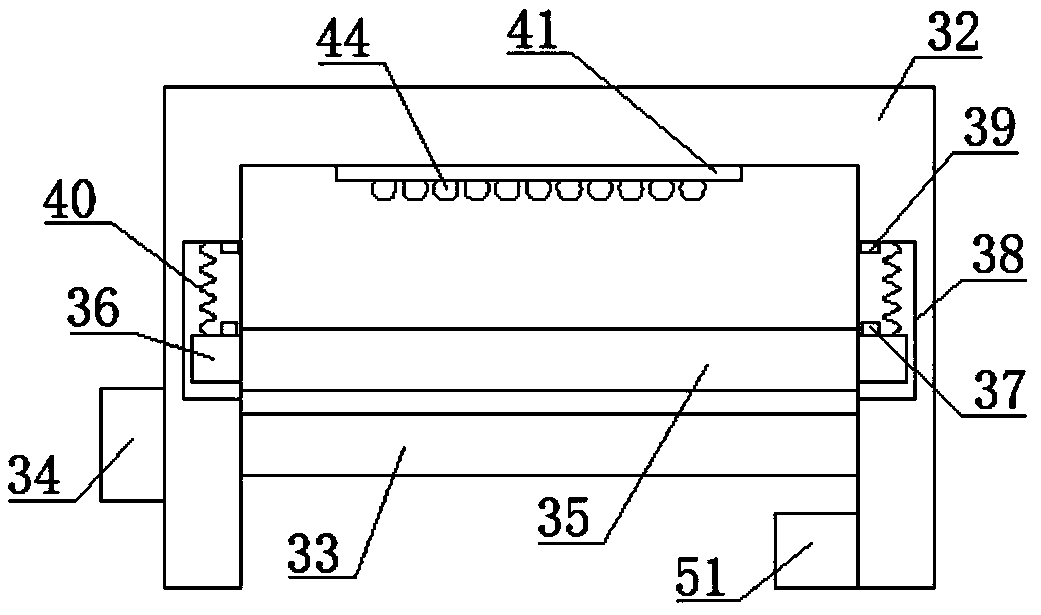

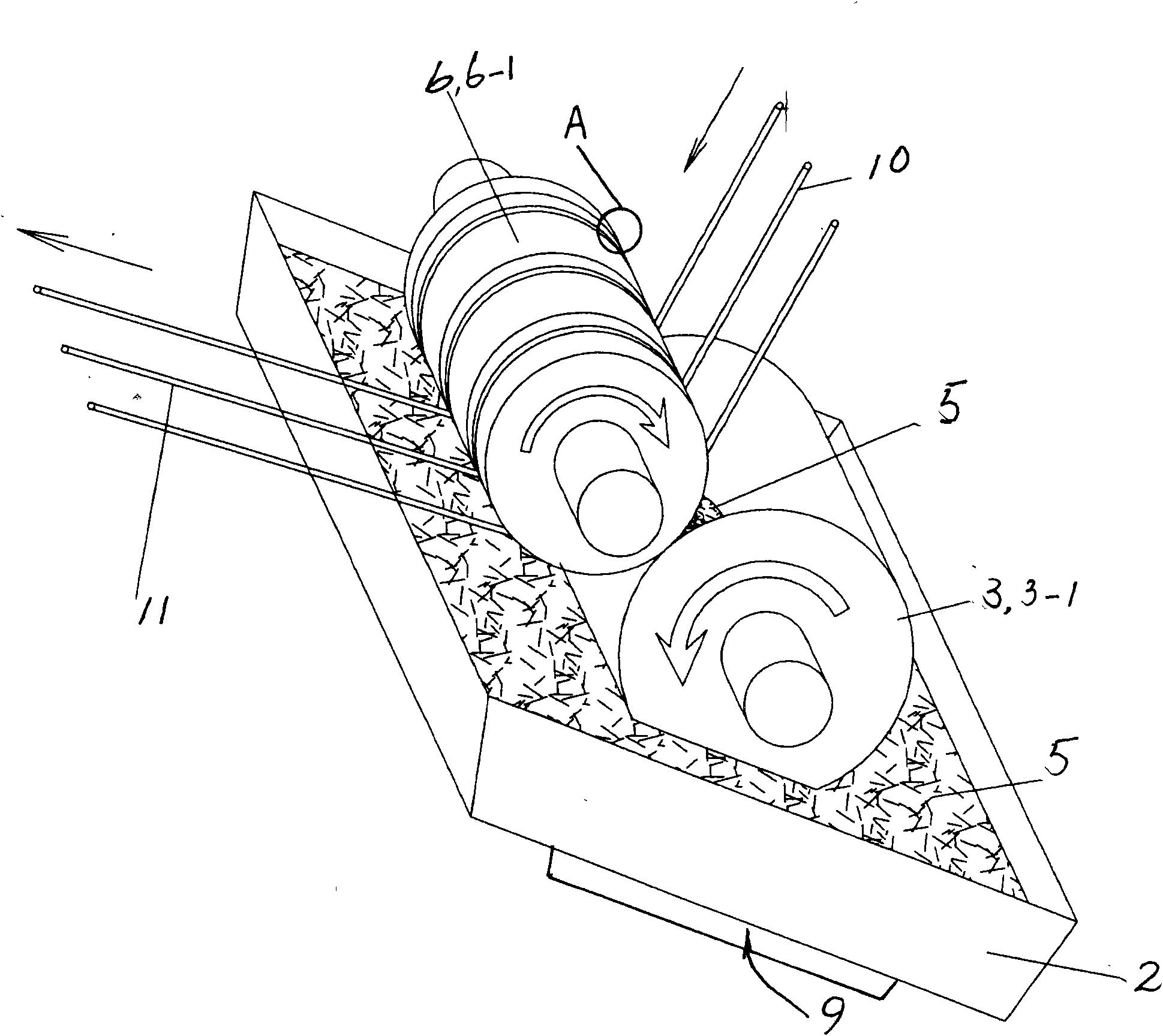

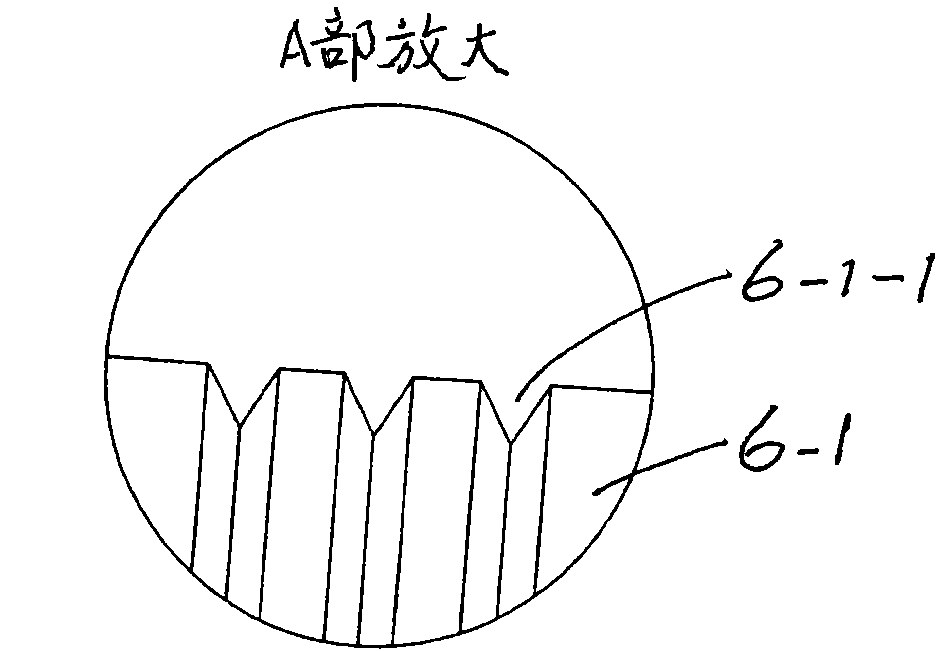

Rope-shaped washing machine

InactiveCN105133228AEnsure safetyLabor savingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor roped fabric treatmentWater channelPulp and paper industry

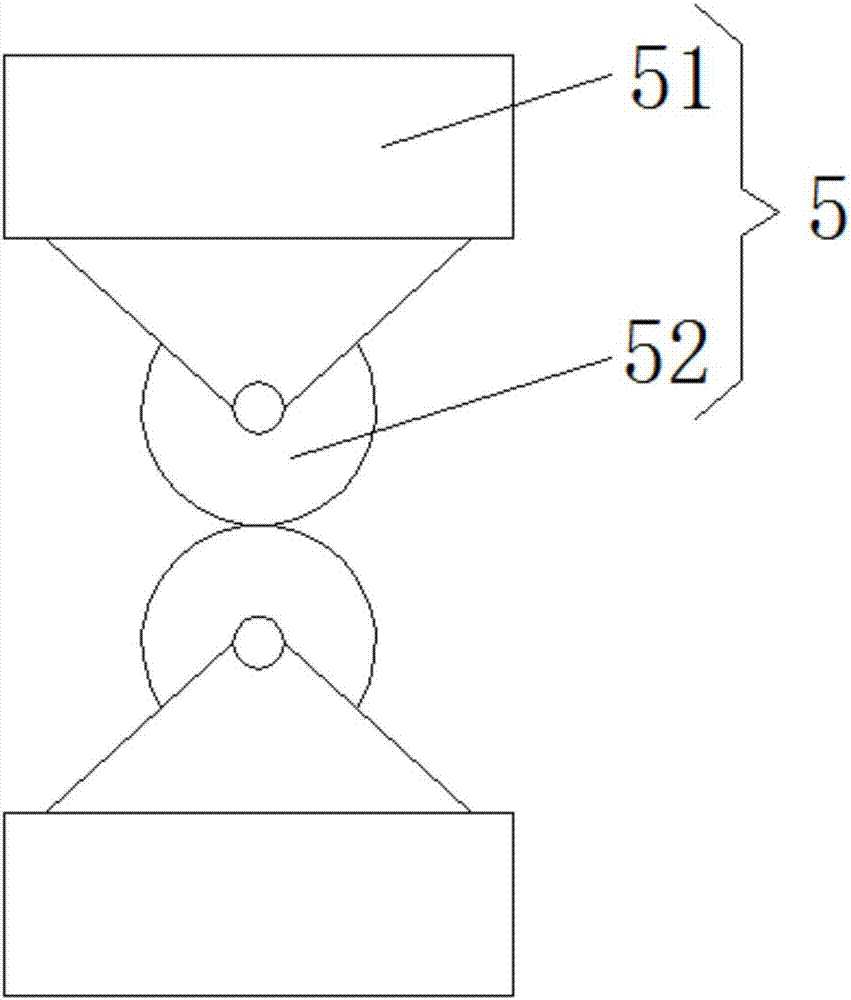

The invention relates to a rope-shaped washing machine and belongs to the technical field of printing and dyeing equipment. The rope-shaped washing machine comprises a plurality of unit grooves. Each unit groove comprises a water channel (1), wherein a roller set and a cloth falling roller (5) are arranged above the water channel (1), and the roller set and the cloth falling roller (5) are provided with partition plates (8); the roller set, the cloth falling roller (5) and the water channel (1) located below the roller set and the cloth falling roller (5) are divided into a plurality of unit grids (9) through the partition plates (8), and a braking assembly (7) is arranged on one side of the roller set of each unit grid (9). According to the rope-shaped washing machine, the synchronous state of fabric in each unit groove and the stacking amount of cloth in each groove body can be self-adjusted, so that labor is saved, production efficiency is improved, and operation safety of workers is guaranteed.

Owner:江阴市永欣印染机械有限公司

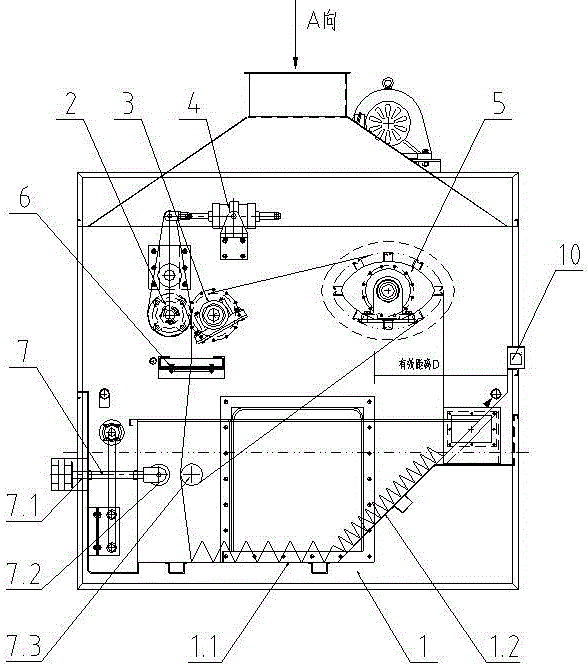

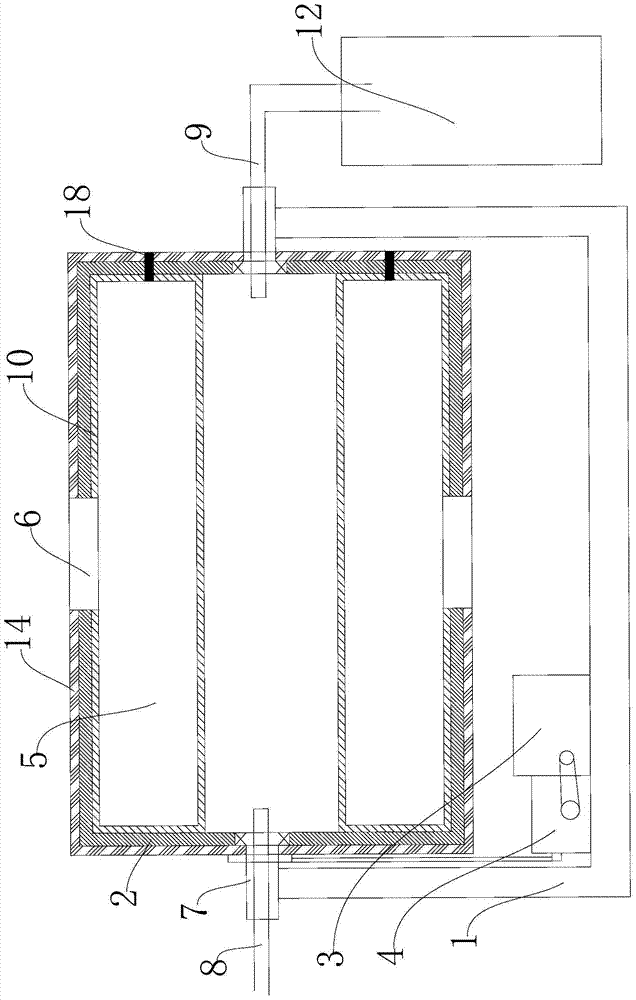

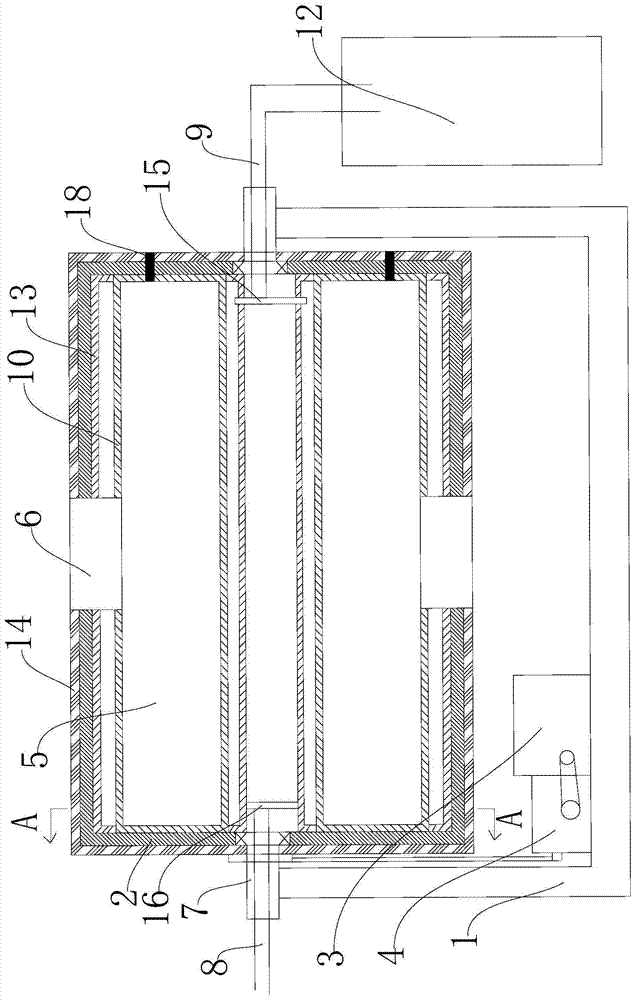

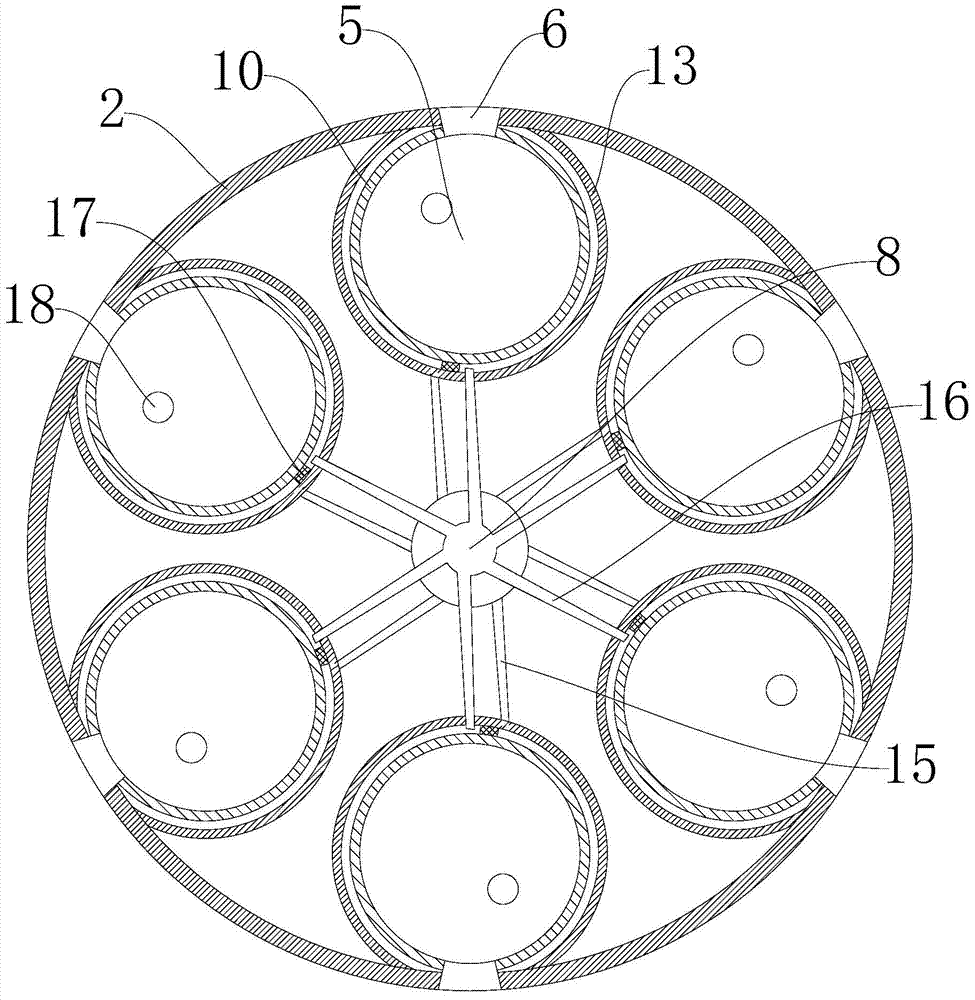

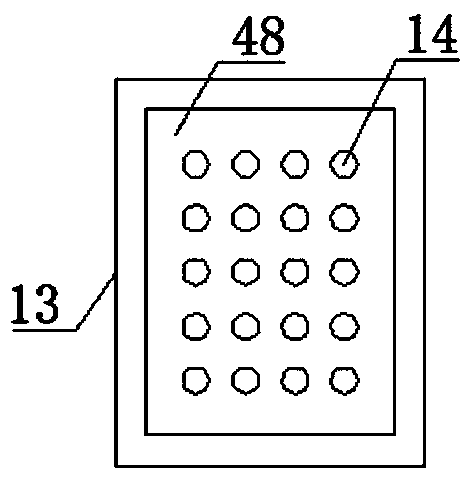

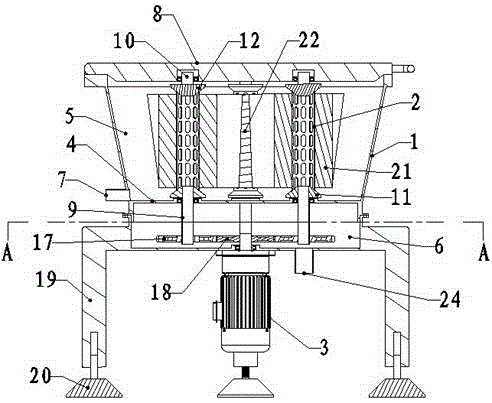

Efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine and fur dyeing method

InactiveCN103938383AConsistent temperatureAvoid wastingTextile treatment containersLiquid/gas/vapor treatment machines driving mechanismsMotor driveEngineering

The invention relates to the field of fur dyeing devices, in particular to an efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine which can simultaneously conduct dyeing of different colors on fur. The efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine comprises a machine frame, an outer cavity, a motor, a gearbox and dyeing cylinders, wherein the motor drives the outer cavity to rotate through the gearbox, the outer cavity is connected with the machine frame through shafts at the two ends, the dyeing cylinders are fixed inside the outer cavity and make contact with the inner wall of the outer cavity, feeding doors are formed in the positions where the dyeing cylinders make contact with the inner wall of the outer cavity, and a plurality of partition plates are arranged in the annular wall in each dyeing cylinder at equal intervals. Fur raw materials, corresponding dye and corresponding additives can be added to different dyeing cylinders, and therefore dyeing of different colors can be simultaneously conducted on fur, production efficiency is improved, and meanwhile energy waste can be avoided; by means of heating conducted through steam, the temperature inside the whole outer cavity can be kept uniform, and therefore the temperatures of the dyeing cylinders are kept the same, and the dyeing effect is improved.

Owner:TONGXIANG NEW ERA FUR

Quick dyeing device for textile fabric

InactiveCN107401013ADyeing speed is fastEnough timeLiquid/gas/vapor treatment machines driving mechanismsTextile treatment carriersEngineeringDyeing

The invention discloses a quick dyeing device for a textile fabric. The quick dyeing device comprises an external frame. Textile fabric spacing devices are symmetrically arranged on two sides of the outer wall of the external frame; a shake device is fixedly connected to the bottom end of the interior of the external frame; the bottom end of the interior of the external frame and a place on the right side of the shake device is fixedly connected with a shake frame via shake wheels; a dyeing tank is fixedly connected to the top end of a supporting leg via a first fixed rotation block; a movable device is fixedly connected to on the bottom of the dyeing tank and on the left side of the supporting leg; two hanging rods are symmetrically fixed on the top end of the interior of the external frame; dyeing baffle wheels are rotationally connected to the bottom end of the hanging rods; and a textile fabric winding device is arranged on the right side of the outer of the external frame. The quick dyeing device for the textile fabric relates to the technical field of textile equipment machinery. Problems of low dyeing efficiency, great time consumption, uneven dyeing and resource waste of a textile fabric dyeing device in the prior art can be solved; and dyeing efficiency and quality can be improved.

Owner:HUZHOU BOREN TEXTILES

Loom beam yarn color weaving method and special equipment

InactiveCN101082156AImprove wear resistanceGuarantee the quality of dyeingLiquid/gas/vapor treatment machines driving mechanismsDyeing processYarnState of art

The present invention relates to yarn processing method, and is especially loom beam yarn dyeing and weaving process, in which the dyed loom beam yarn in wet state is woven directly in a loom and the contained floated color and other residues in the yarn are eliminated through water washing of the gray cloth. The present invention has obvious technological advantages, including no sizing step, once water washing and stoving resulting in greatly reduced water consumption and sewage draining, intuitive dyeing step favorable to high fabric quality, and 4-6 times raised dyeing production efficiency.

Owner:营口中基纺织有限公司

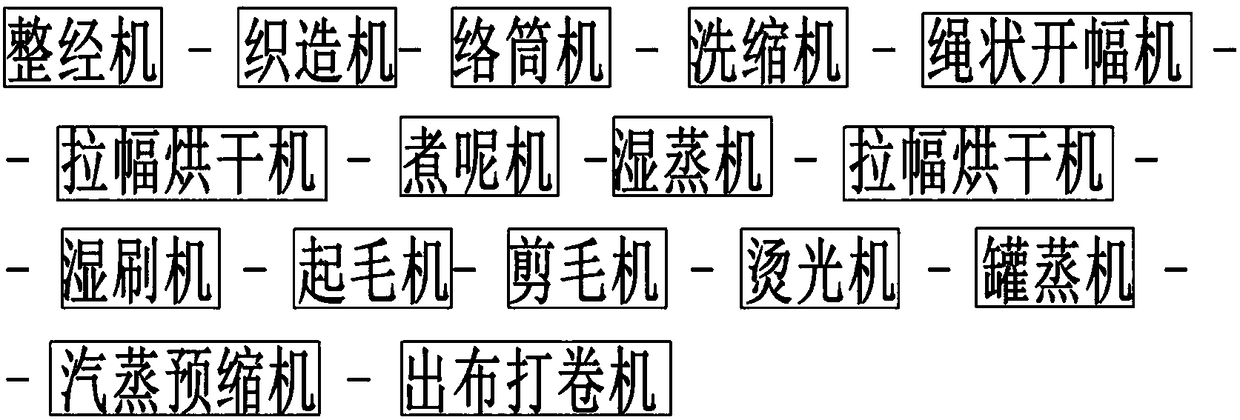

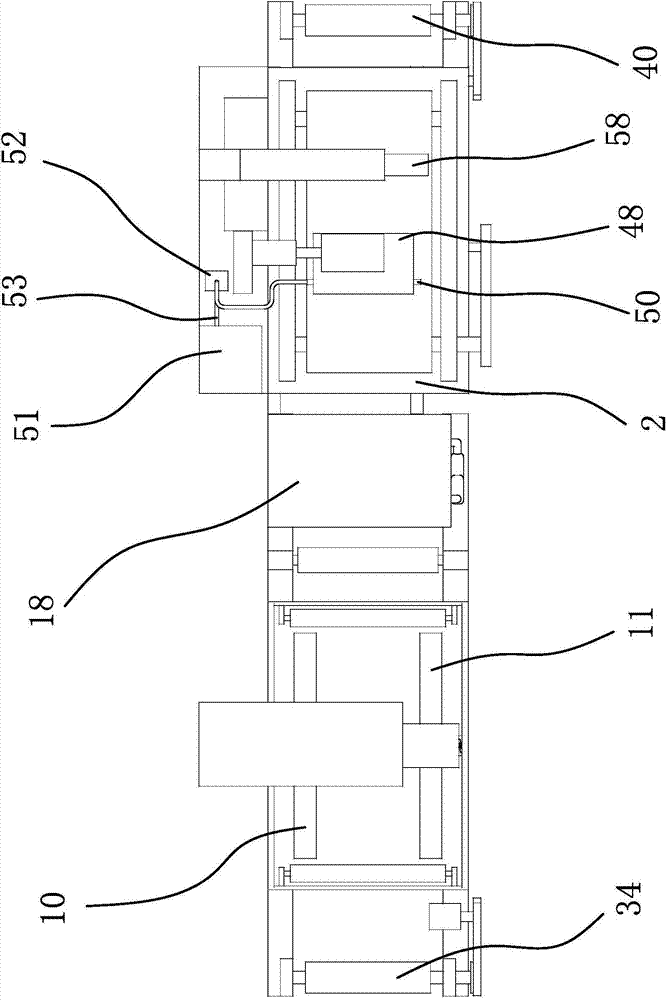

Cashmere fabric assembly line and process

InactiveCN108251936ALiquid/gas/vapor treatment machines driving mechanismsWarping machinesWinding machinePulp and paper industry

The invention relates to a cashmere fabric assembly line and a process. The cashmere fabric assembly line comprises a warping machine, a weaving machine, a winding machine, a washing shrinking machine, a rope opener, a stentering drying machine, a crabbing machine, a wet steaming machine, another stentering drying machine, a wet brushing machine, a raising machine, a shearing machine, a natural luster finishing machine, a pot steaming machine, a steam pre-shrinking machine and / or a cloth discharge rolling machine which are sequentially connected with one another according to working procedures. The cashmere fabric assembly line and the process have the advantages of reasonable design, compact structure and convenience in use.

Owner:安美桥(南宫)羊绒制品有限公司

Integrated efficient dyeing and finishing device for textile fabric

InactiveCN109355838AGuaranteed liquidityGuaranteed uniformityMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsEnvironmental resistanceBristle

The invention discloses an integrated efficient dyeing and finishing device for textile fabric. The device comprises a fixation dyeing box, and multiple vibration plates, rolling shafts, brushing rollers and heating strips are installed in the fixation dyeing box; a drying box is arranged at one side of the fixation dyeing box, and a dust removal box is arranged at the outer side of the fixation dyeing box; a first dust removal roller and a second removal roller are arranged in the dust removal box; multiple arc static plates are both installed on the outer surface of the first dust removal roller and the outer surface of the second dust removal roller, and an arc brushing plate is arranged between each arc static plate and the second dust removal roller or between each arc static plate and the first dust removal roller; multiple evenly-distributed carding bristles are arranged on each arc brushing plate; a rolling device is connected to one side of the drying box, and a rinsing box isconnected to the outer side of the drying box; a dye filter box is connected to the lower portion of the rinsing box, and a filter screen, a return pipe and a water pump are arranged on the dye filter box. The integrated efficient dyeing and finishing device for the textile fabric has the advantages that the dyeing quality and working efficiency can be improved, dyeing is even, the utilization rate of dye is high, the environment is protected, the drying speed is high, sterilization is achieved, the cloth rolling effect is good, and the device is convenient to clean.

Owner:湖州市菱湖石淙兴吴绸厂

Textile fabric uniform dyeing and drying integrated device

InactiveCN107419457AReach without being damagedTo achieve the purpose of drying textile cloth in all directionsLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalRotary stageEngineering

The invention discloses a textile fabric uniform dying and drying integrated device. The textile fabric uniform dying and drying integrated device comprises a base plate, a dyeing tank is fixedly connected to the top of the base plate, constant tension devices are fixedly connected to both top ends of the two walls of the dyeing tank, a rotary shaft is rotatably connected to a rotary shaft fixing block, stirring blades are fixedly connected to the rotary shaft, a shaft rotary tank is arranged at the end, away from the rotary shaft fixing block, of the inner wall of the dyeing tank, one end of the rotary shaft penetrates through and is rotatably connected to the shaft rotary tank, a movable device is arranged over the dyeing tank, a rotary device is fixedly connected to the top of the inside of a drying chamber, and two air blowers are fixedly connected to the bottom of a rotary table. The invention relates to the technical field of textile equipment machinery. The textile fabric uniform dying and drying integrated device solves the problems that a textile fabric dyeing device does not have the drying capability and is low in dyeing efficiency and long in consumed time, the textile fabric dyeing and production efficiency is improved, and the worker labor is lowered.

Owner:HUZHOU BOREN TEXTILES

Yarn printing and dyeing device

ActiveCN104611862AUniform concentrationUniform temperatureLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsYarnIndustrial engineering

The invention discloses a yarn printing and dyeing device. The yarn printing and dyeing device comprises a printing and dyeing support and a printing and dyeing transmission mechanism. The printing and dyeing support is provided with a printing and dyeing pool. The printing and dyeing transmission mechanism is arranged above the printing and dyeing pool and comprises a motor axle, a main driving shaft, a first printing and dyeing shaft, a first air drying shaft, a second printing and dyeing shaft, a centrifugal shaft, a second air drying shaft and a steam guidance shaft, all of which are installed on the printing and dyeing pool through the support from left to right in sequence. According to the printing and dyeing device, printed and dyed yarn can be primarily air-dried through the first air drying shaft which is arranged behind the first printing and dyeing shaft and provided with a four-blade fan, and the effect is better when secondary printing and dyeing is carried out; the centrifugal shaft with a centrifugal cylinder is arranged behind the position where secondary printing and dyeing is conducted, the redundant dye pasted to the yarn can be thrown to the centrifugal cylinder through the centrifugal shaft under the action of centrifugal force, rapid air drying can be achieved through a fan on the second air drying shaft, and the air drying effect is good.

Owner:JIANGSU SHUANGYING TEXTILE TECH

Dyeing device for textile fabric

InactiveCN108004699AImprove dyeing efficiencyUniform dyeingLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a dyeing device for textile fabric and solves the technical problem that existing dyeing devices are simple in structure, incapable of stirring dye in dyeing tanks and nonuniform in dyeing. The dyeing device comprises a rack, a first lifting cylinder is fixed on the rack, a piston rod of the first lifting cylinder is vertically upward, the end of the piston rod of the firstlifting cylinder is connected with a dyeing vat with an opening in the upper portion, one end of the dyeing vat serves as an input end while the other end of the same serves as an output end, an isolating plate is arranged in the middle of the dyeing vat through a detachable structure and divides the inside of the dyeing vat into an upper dyeing portion and a lower stirring portion, a shifting mechanism for shifting fabric and a stirring mechanism for stirring dye are arranged on the dyeing vat, the shifting mechanism is positioned in the upper dyeing portion, the stirring mechanism is positioned in the lower stirring portion, and a conveying mechanism is used for conveying fabric into the dyeing vat is arranged on one side, close to the input end, of the rack. The dyeing device has the advantage of uniformity in dyeing.

Owner:孙艳

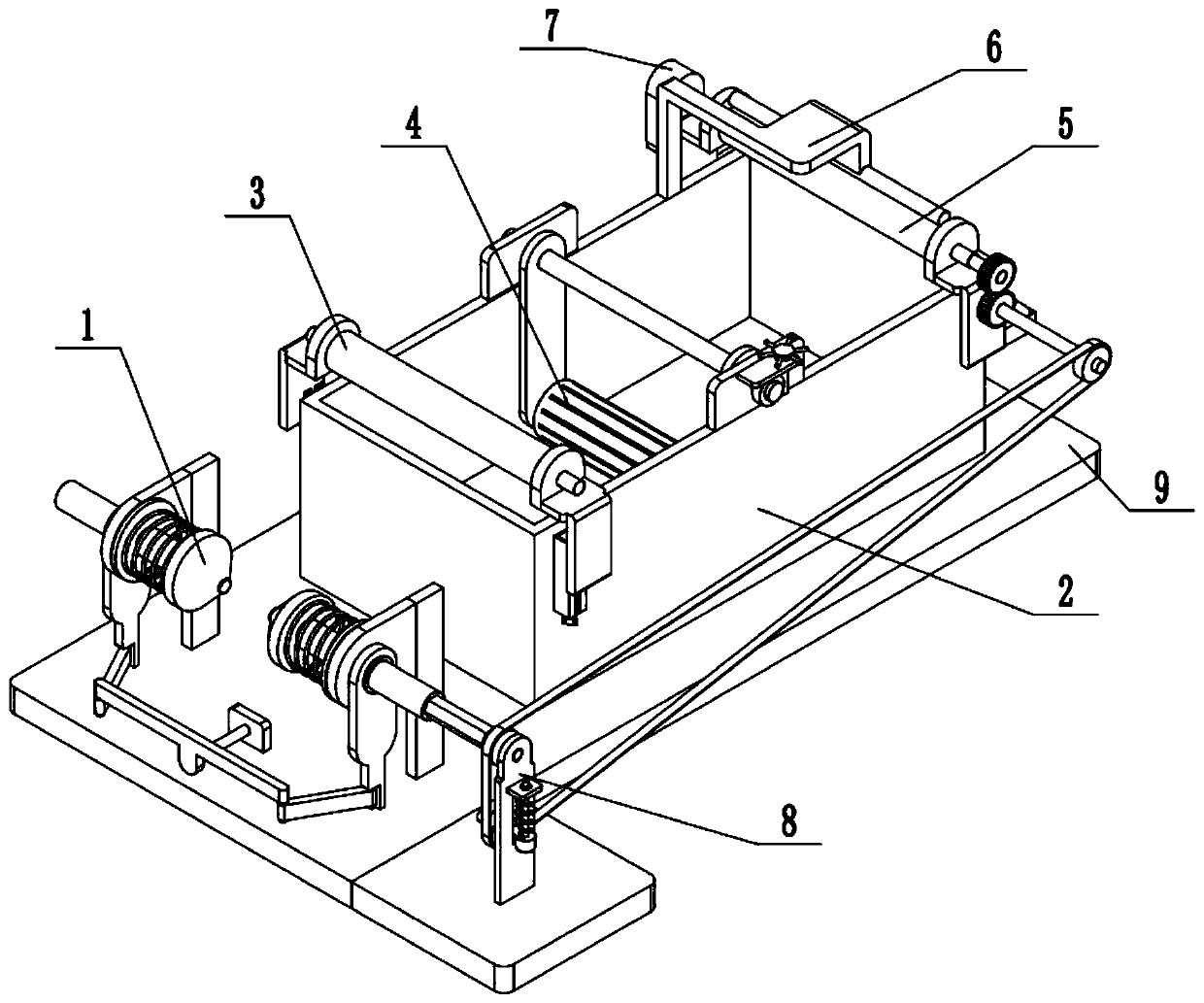

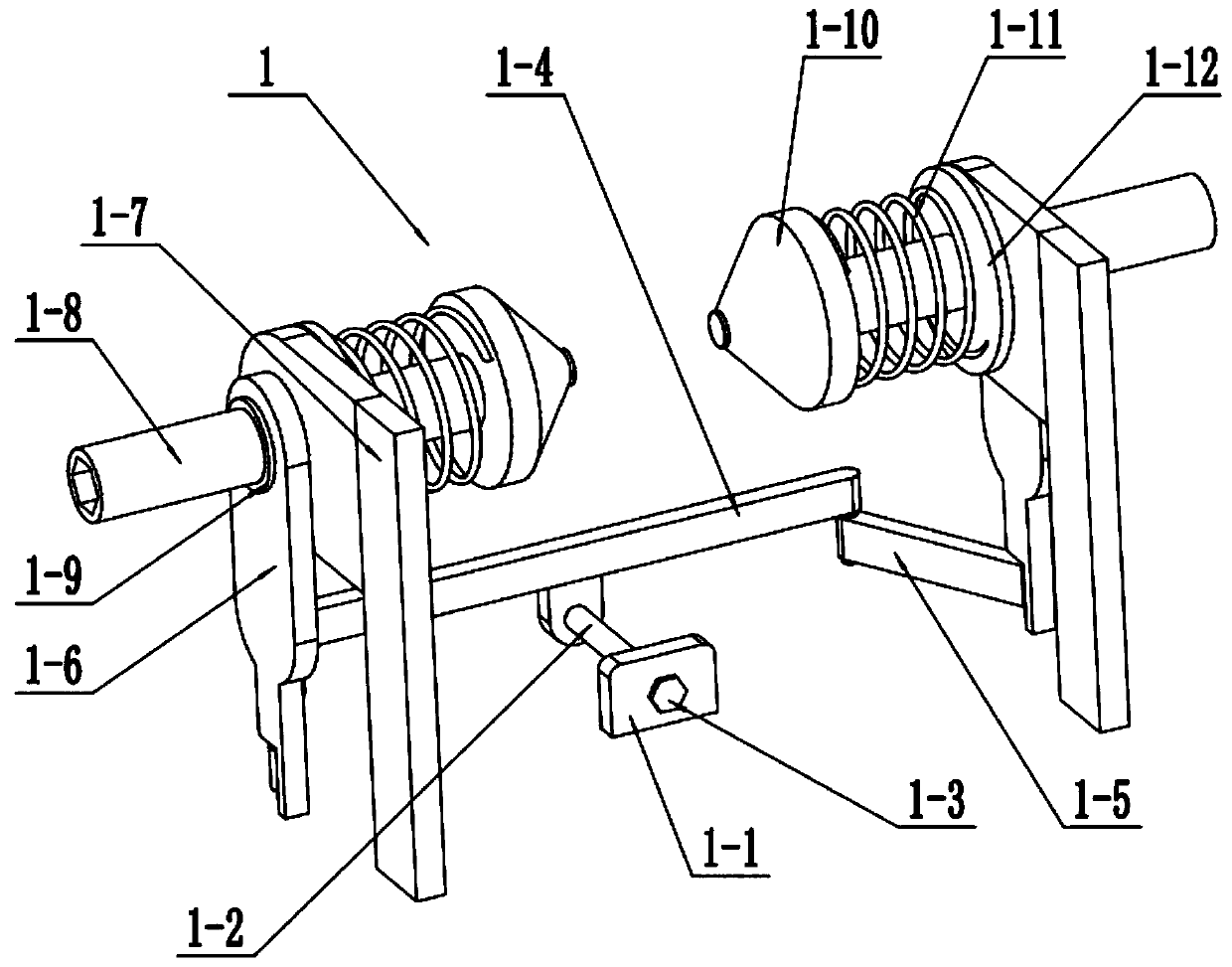

Textile printing and dyeing device

InactiveCN109797503ASolve the problem that the cloth rolls to be printed and dyed in different sizes cannot be fixed and unfoldedImprove flatnessLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalState of artTextile printer

The invention relates to the technical field of the textile processing and in particular to a textile printing and dyeing device. The textile printing and dyeing device comprises a cloth roll clampingmechanism, a top hollowed printing and dyeing box, a cloth feeding guide roller mechanism, a printing and dyeing guide roller mechanism, a cloth discharging guide roller mechanism, an auxiliary clothpressing mechanism, a driving mechanism, a linkage mechanism and a base plate. The cloth roll clamping mechanism is fixedly connected to a left end of a top surface of the base plate. The printing and dyeing box is fixedly connected to a middle end of the top surface of the base plate. The cloth feeding guide roller mechanism is fixedly connected to an upper end of the left side of the printing and dyeing box. The printing and dyeing guide roller mechanism is fixedly connected to an upper end of the middle of the printing and dyeing box. The provided textile printing and dyeing device aims toeffectively solve a problem in an existing technology that the printing and dyeing device cannot fix and unfold different sizes of cloth rolls to be printed and dyed. The interior of the textile printing and dyeing device is provided with the cloth roll clamping mechanism. The cloth roll clamping mechanism is capable of fixing and unfolding the different sizes of the cloth rolls.

Owner:高炆圣

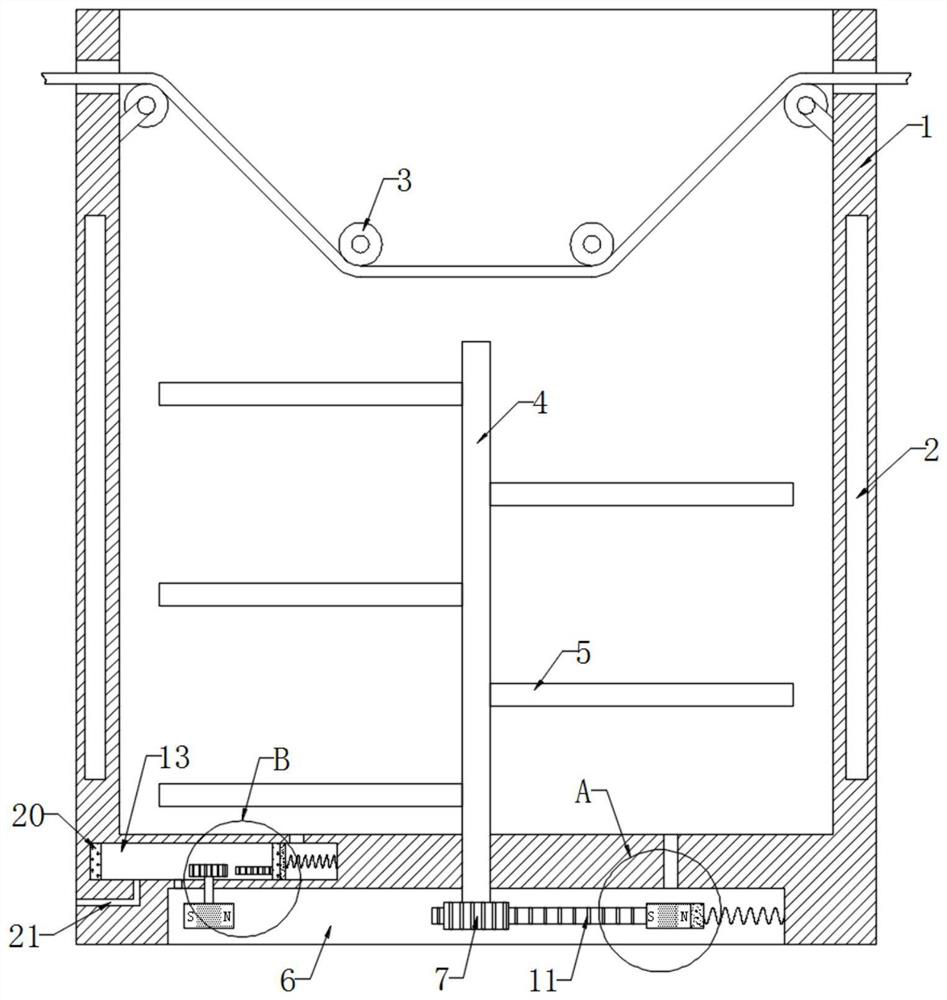

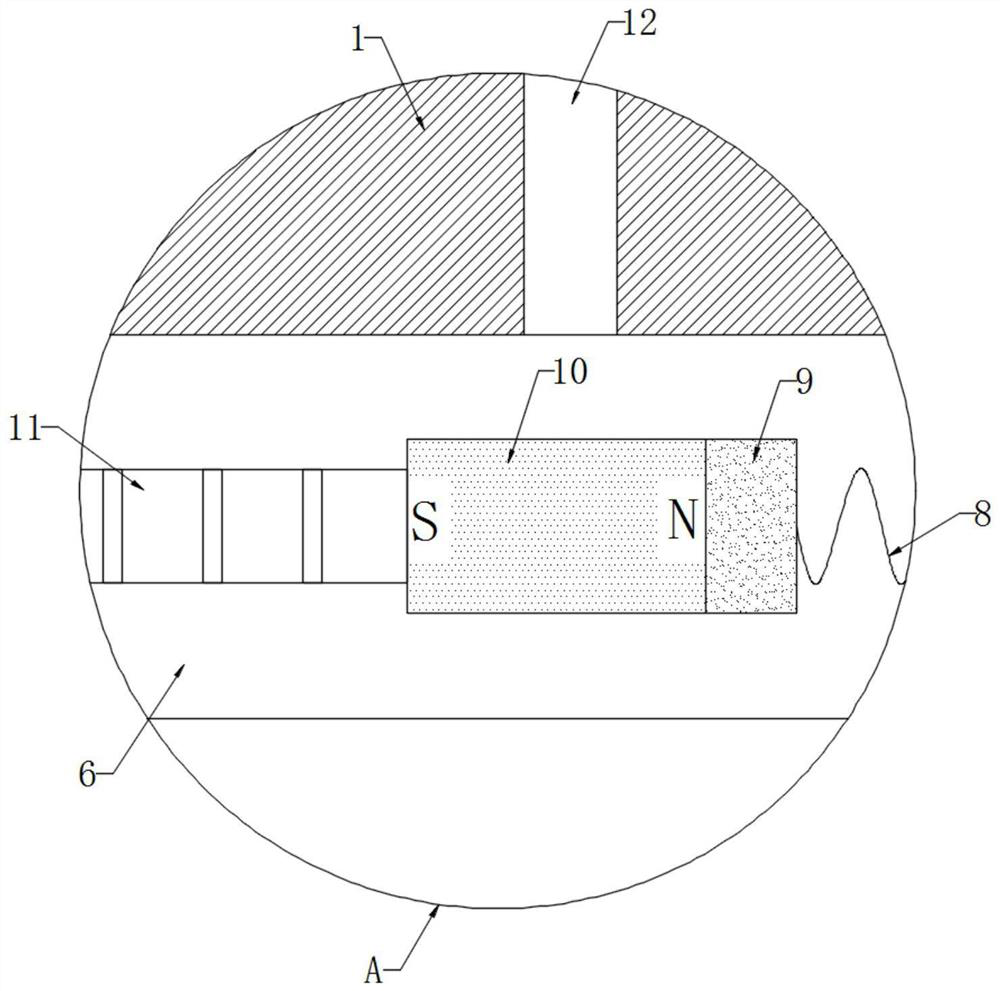

High-efficiency uniform dyeing method for textile fabrics

InactiveCN111996704ASave energyUniform dyeingLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsPolymer scienceElectric power equipment

The invention discloses a high-efficiency uniform dyeing method for textile fabrics. The high-efficiency uniform dyeing method for the textile fabrics comprises the following steps of S1, blending; S2, heating; S3, dyeing; and S4, drying. A dyeing device is also involved in the dyeing method, and comprises a dyeing tank, wherein a heating ring is embedded to the inner wall of the dyeing tank; discharge holes are symmetrically formed in the side walls of the dyeing tank; multiple drive rollers are symmetrically and rotatably connected to the inner wall of the dyeing tank through rotary shafts;vertical rods are rotatably connected to the bottom part in the dyeing tank; and multiple stirring rods are fixedly connected to the side walls of the vertical rods. According to the high-efficiency uniform dyeing method for the textile fabrics provided by the invention, when the temperature in a groove reaches to a critical value on a first temperature control chip, magnetism is produced on an electromagnet, the electromagnet further drives a toothed plate to slide leftwards under the action of a magnetic attraction force of a permanent magnet block, a first gear is driven to rotate, a stirring rod is further rotated to stir dyestuffs in the dyeing tank, and heat energy generated in the dyeing tank enables the electromagnet to work, so that the magnetic force drives the stirring rod to rotate, no power equipment is needed for driving, and the energy is saved.

Owner:刘琳

Cloth soaking, printing and dyeing device and using method thereof

InactiveCN111826854AFast realization of printing and dyeingAvoid uneven printing and dyeingMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsMechanical engineeringDyeing

The invention discloses a cloth soaking, printing and dyeing device and a using method of the cloth soaking, printing and dyeing device, and belongs to the technical field of printing and dyeing. Thecloth soaking, printing and dyeing device comprises a dye box and a drying box, a through hole is connected between the dye box and the drying box, the dye box communicates with the drying box, a feeding hole is formed in the outer wall of the dye box, a discharge hole is formed in the outer wall of the drying box, the outer wall of the dye box is connected with a motor, the output end of the motor is connected with a first rotating shaft, the first rotating shaft is rotationally connected to the inner wall of the dye box, a second rotating shaft is rotationally connected to the inner wall ofthe dye box through a bearing, stirring blades are connected to the outer walls of the first rotating shaft and the second rotating shaft, cams are connected to the ends, away from the inner wall of the dye box, of the first rotating shaft and the second rotating shaft, and a connecting piece is fixedly connected between the two cams. With the technical scheme, the dye immersion into cloth can beaccelerated, so that the printing and dyeing efficiency is improved, meanwhile, the cloth can be rapidly dried, thus the situation that printing and dyeing are uneven after the cloth is rolled up is avoided, and the printing and dyeing effect of the cloth can be guaranteed.

Owner:浙江七色彩虹科技有限公司

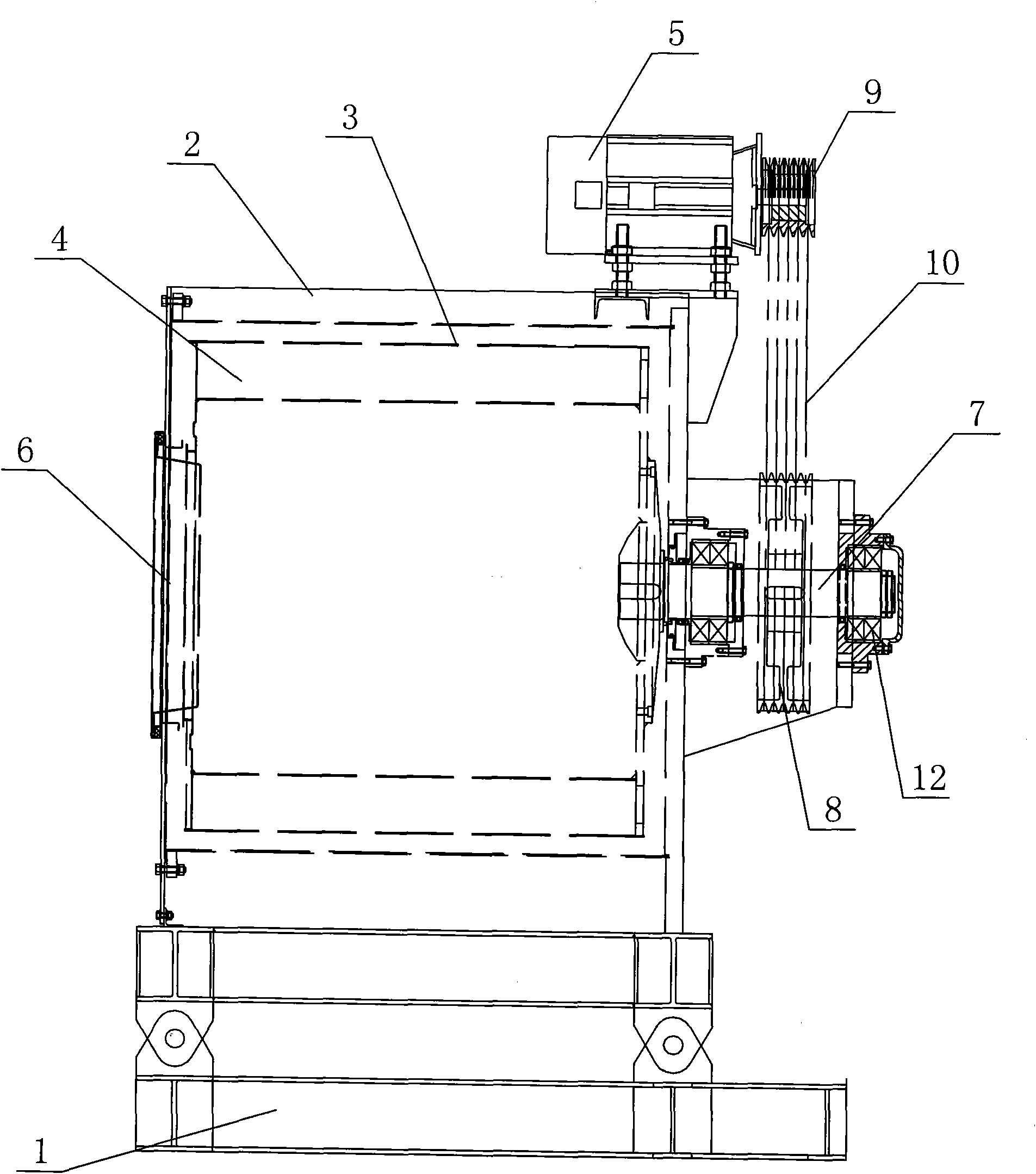

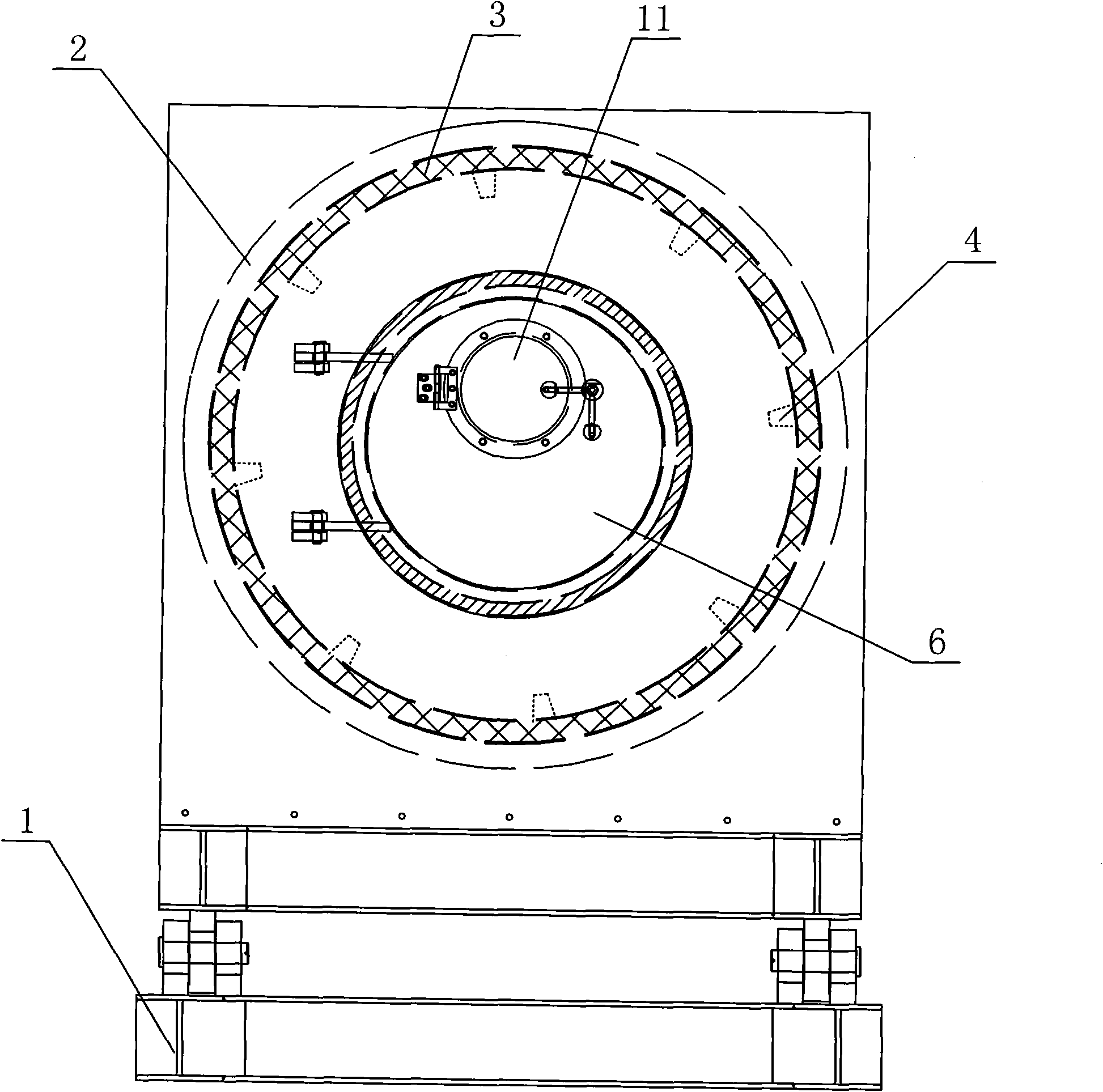

360-degree rotating drum type dyeing machine with low bath ratio

InactiveCN102182027ASimple structureImprove dyeing efficiencyLiquid/gas/vapor treatment machines driving mechanismsTextile treatment rollersMotor driveTransmission belt

The invention discloses a 360-degree rotating drum type dyeing machine with low bath ratio. The dyeing machine comprises a box body arranged on a dyeing machine base; one end of the box body is provided with a door, an open rotating drum is arranged in the box body, the open end of the rotating drum is arranged corresponding to the door, and a transmission shaft is fixed at the other end of the box body; the transmission shaft is connected with a power output shaft of a power device through a transmission belt, and the power device drives the rotating drum to rotate through the transmission belt; and a plurality of through holes are uniformly distributed on the side wall of the rotating drum, and a plurality of reinforcing plates are fixed on the inner side of the side wall of the rotating drum. According to the 360-degree rotating drum type dyeing machine with low bath ratio, the open rotating drum is arranged in the box body, a motor drives the rotating drum to rotate in the box body, and dyeing solution flows into the rotating drum from the through holes on the side wall of the rotating drum to dye the textiles in the rotating drum; and the dyeing machine has simple structure, integrates multiple functions of dyeing, washing and dehydrating, and has low bath ratio and high dyeing efficiency.

Owner:无锡赛腾机电科技有限公司

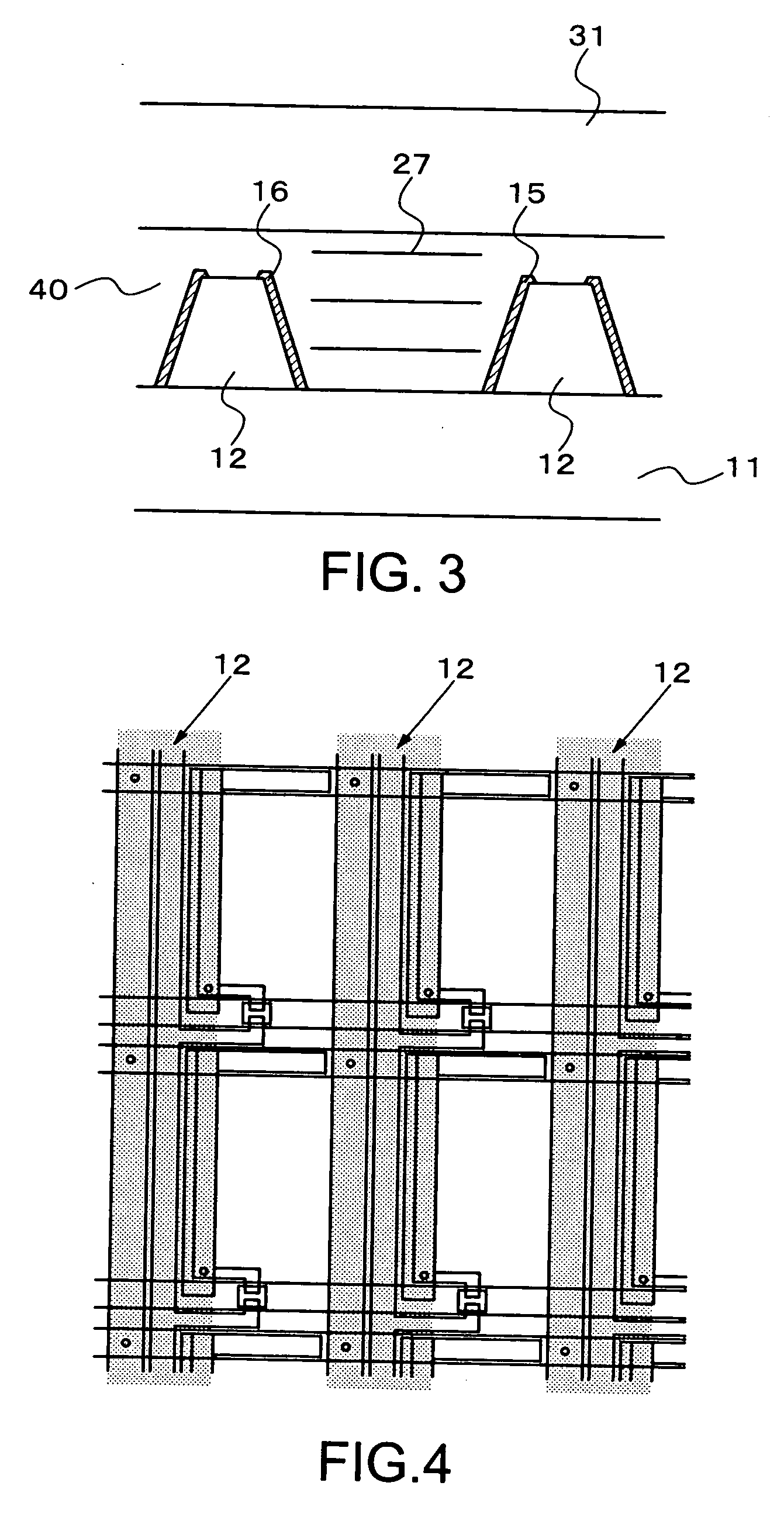

Active matrix liquid crystal display device

ActiveUS20060215100A1Increase the aperture ratioIncrease brightnessLiquid/gas/vapor treatment machines driving mechanismsDyeing processActive-matrix liquid-crystal displayElectrical and Electronics engineering

In a region where data wirings are formed on a TFT substrate, convex parts, each having a trapezoidal cross section or the like, are formed. A pixel electrode is formed on one of side faces of the convex part, and a common electrode is formed on the other side face. Furthermore, the pixel electrodes and the common electrodes are set to face each other between the convex parts adjacent to each other.

Owner:HANNSTAR DISPLAY CORPORATION

Textile knitting wool dyeing and drying equipment

ActiveCN108468169ANo precipitationAvoid stickingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalEngineeringFeeding tube

The invention relates to textile processing equipment, in particular to the textile knitting wool dyeing and drying equipment. The technical purpose of the invention is to provide the textile knittingwool dyeing and drying equipment which stirs dye so that precipitation does not occur to affect the quality of the dyeing, and dries knitting wool in time during the dyeing process. In order to achieve the above technical purpose, the invention provides the textile knitting wool dyeing and drying equipment, and the equipment comprises a bottom plate, a fixing seat, a dye box, a valve, a feeding tube, a first supporting plate, a connecting plate, a connecting block, a first electric wheel, a first sleeve wheels, a second support plate and the like; the fixing seat is connected to the left sideof the bottom plate, the dye box is connected to the upper end of the fixing seat, the feeding tube is connected to the lower side of the dye box, and the valve is connected to the feeding tube. Theequipment achieves the effect of stirring the dye so that no precipitation occurs to affect the quality of the dyeing, and drying the knitting wool in time during the dyeing process.

Owner:ZHANGJIAGANG YANGZI DYEING & FINISHING CO LTD

Textile fabric rapid cleaning equipment

InactiveCN111364188AQuick washEasy to reuseLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersProcess engineeringMechanical engineering

The invention discloses textile fabric rapid cleaning equipment. The textile fabric rapid cleaning equipment comprises a base body, a soaking tank, a washing tank, a rinsing tank and a drying cavity are sequentially formed in the base body from left to right, a plurality of first guide rollers are rotationally installed on the inner wall of the soaking tank and are distributed in a symmetrically staggered mode, a heating device is arranged at the bottom end in the soaking tank, and two second guide rollers and a first extrusion roller set are rotationally connected to the inner wall of the washing tank. The textile fabric rapid cleaning equipment has the advantages that the first guide rollers, the second guide rollers, third guide rollers and drying rollers are arranged in the soaking tank, the washing tank, the rinsing tank and the drying cavity respectively, textile fabric is integrally dragged according to a fixed track, the situation that subsequent use is difficult due to distortion in the traditional washing process is avoided; liquid levels in the soaking tank and the rinsing tank are higher than the liquid level in the washing tank, water can be drained through a first water draining pipe, a second water draining pipe and a third water draining pipe, follow-up water recycling is facilitated, and water resources are saved.

Owner:李华宁

Active matrix liquid crystal display device

ActiveUS7688413B2Effective areaIncrease the aperture ratioLiquid/gas/vapor treatment machines driving mechanismsDyeing processActive-matrix liquid-crystal displayElectrical and Electronics engineering

In a region where data wirings are formed on a TFT substrate, convex parts, each having a trapezoidal cross section or the like, are formed. A pixel electrode is formed on one of side faces of the convex part, and a common electrode is formed on the other side face. Furthermore, the pixel electrodes and the common electrodes are set to face each other between the convex parts adjacent to each other.

Owner:HANNSTAR DISPLAY CORPORATION

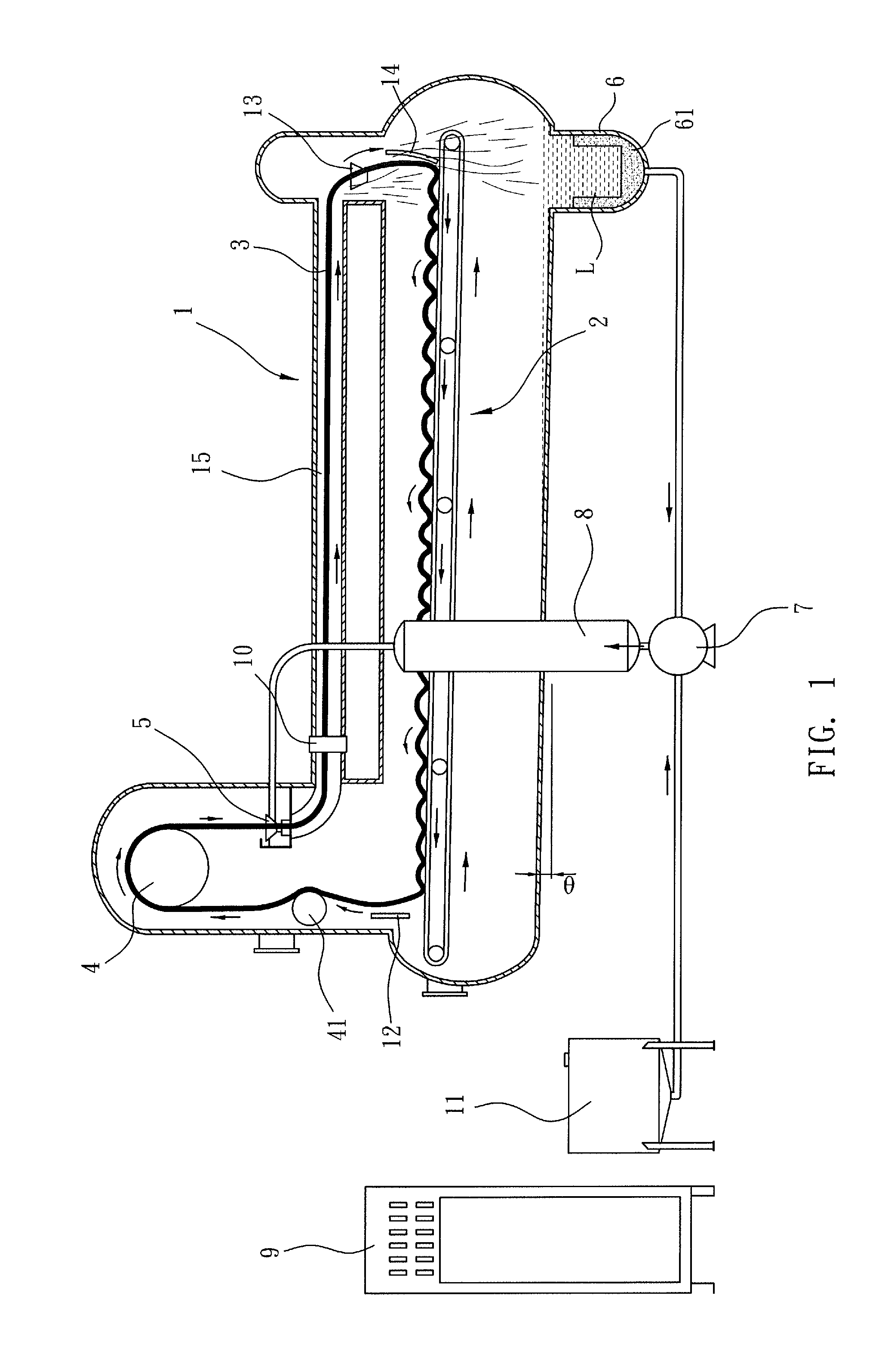

Up-Inclined Coveyor-Driving Fabric Dyeing Machine

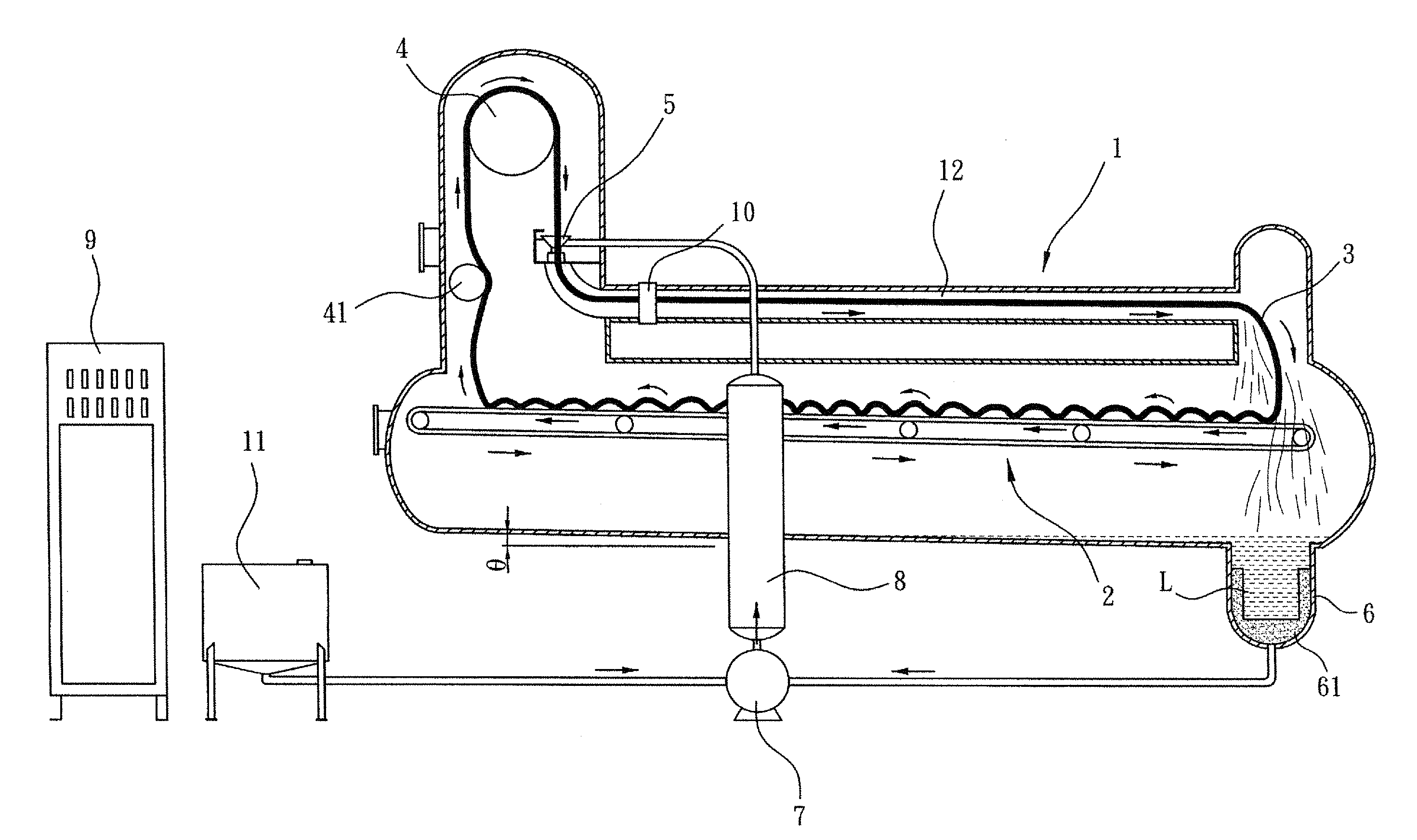

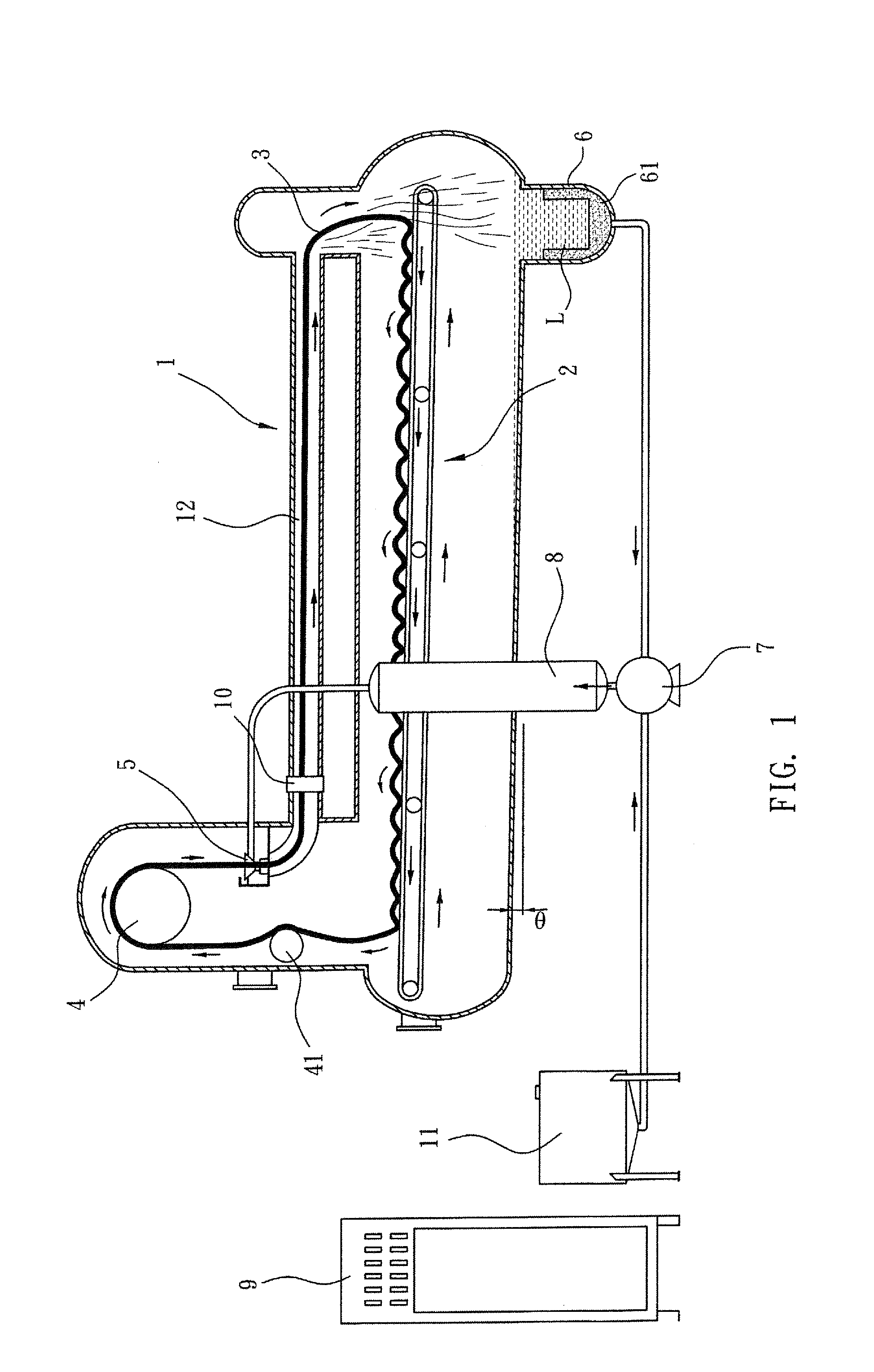

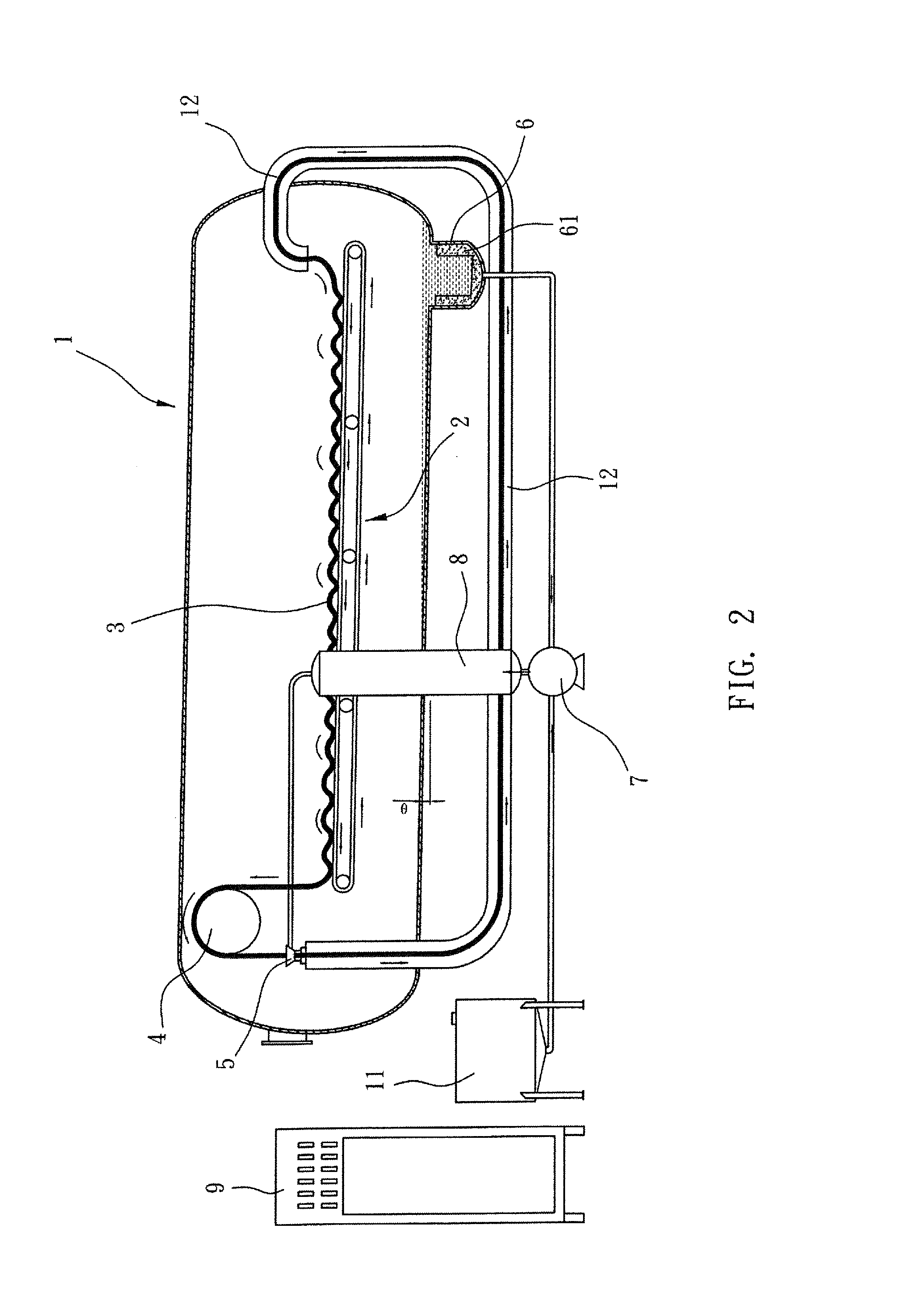

InactiveUS20150337471A1Reduce the amount requiredGood effectLiquid/gas/vapor treatment machines driving mechanismsTextile treatment containersLiquid storage tankDyeing

An up-inclined conveyor-driving fabric dyeing machine includes a machine body that is arranged in a front-high-and-rear-low up-inclined configuration. A liquid storage tank is mounted to a bottom of a rear end of the machine body to receive dye liquid falling down from a rear end of a dyeing tube. Thus, the amount of the dye liquid used can be greatly reduced. Further, with such an up-inclined configuration of the dyeing machine, the dyeing tube can be arranged in a horizontal or slightly inclined manner to reduce the heights of a fabric guide roller and the conveyor and thus reduce the distance between the fabric guide roller and the conveyor device, thereby reducing the stretching force and tensile force applied to the fabric during the dyeing process.

Owner:CHANG

Processing equipment for denim fabric

ActiveCN104775262ADye thoroughlyImprove color fastnessLiquid/gas/vapor treatment machines driving mechanismsSolvent-treatmentState of artDenim

The invention provides processing equipment for denim fabric, and belongs to the technical field of textile machines. The processing equipment for the denim fabric solves the problem that the denim fabric cannot be evenly colored in the prior art. The processing equipment for the denim fabric comprises a rack, a material placing mechanism and a material collecting mechanism are arranged at the two ends of the rack, and a workbench is fixed on the rack. A dyeing groove and a drying box are arranged between the material placing mechanism and the workbench, and a dyeing device is arranged in the dyeing groove. The dyeing device comprises a first lower clamping block, a second lower clamping block, a first upper clamping block, a second upper clamping block and a clamping mechanism. A snowflake wash device is arranged between the rack and a working plate. The snowflake wash device comprises a first sliding cylinder, a first adjusting cylinder and a friction plate. The friction plate is provided with a liquid spraying structure. A laser device is arranged between the rack and the working plate. The laser device comprises a second sliding cylinder, a second adjusting cylinder and a laser gun. The processing equipment for the denim fabric has the advantages that the denim fabric can be in a tightened state in the dyeing process, the denim fabric can be processed to achieve a klunky snowflake effect, and patterns can be engraved.

Owner:HAINING DENIM WEAVING CO LTD

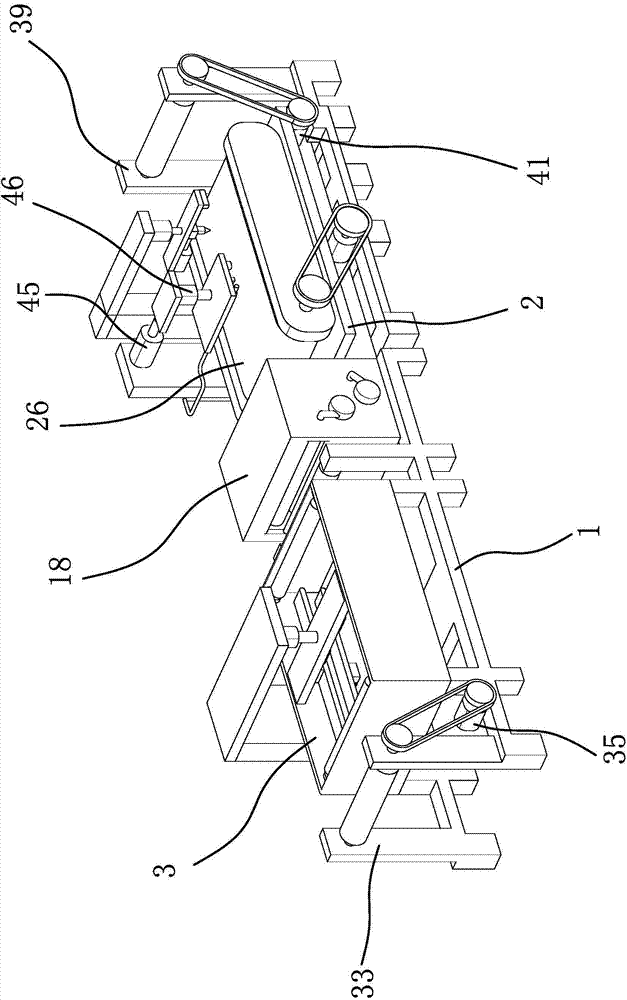

Circulation protection device of conveyor-driven fabric dyeing machine

ActiveUS20150337472A1Easy to operateImprove throughputLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of propelled fabricsEngineeringComputer program

A circulation protection device is provided for a conveyor-driven fabric dyeing machine that includes a machine body having a front end in which a fabric circulation detection idler and a fabric movement sensor are mounted and a rear end in which a rear fabric guide and a fabric management device are mounted. Control is conducted with a computer program so that when the fabric circulation detection idler detects the fabric is not in movement, the conveyor is shut down; and when the fabric movement sensor detects the fabric is moving excessively fast or slow or gets jamming and stopped, the conveyor is controlled to automatically adjust the speed thereof or stops operation. When the fabric falls from a dyeing tube down to a conveyor, the rear fabric guide adjusts an entry angle of the fabric and the fabric management device allows the fabric to be orderly deposited on the conveyor.

Owner:CHANG

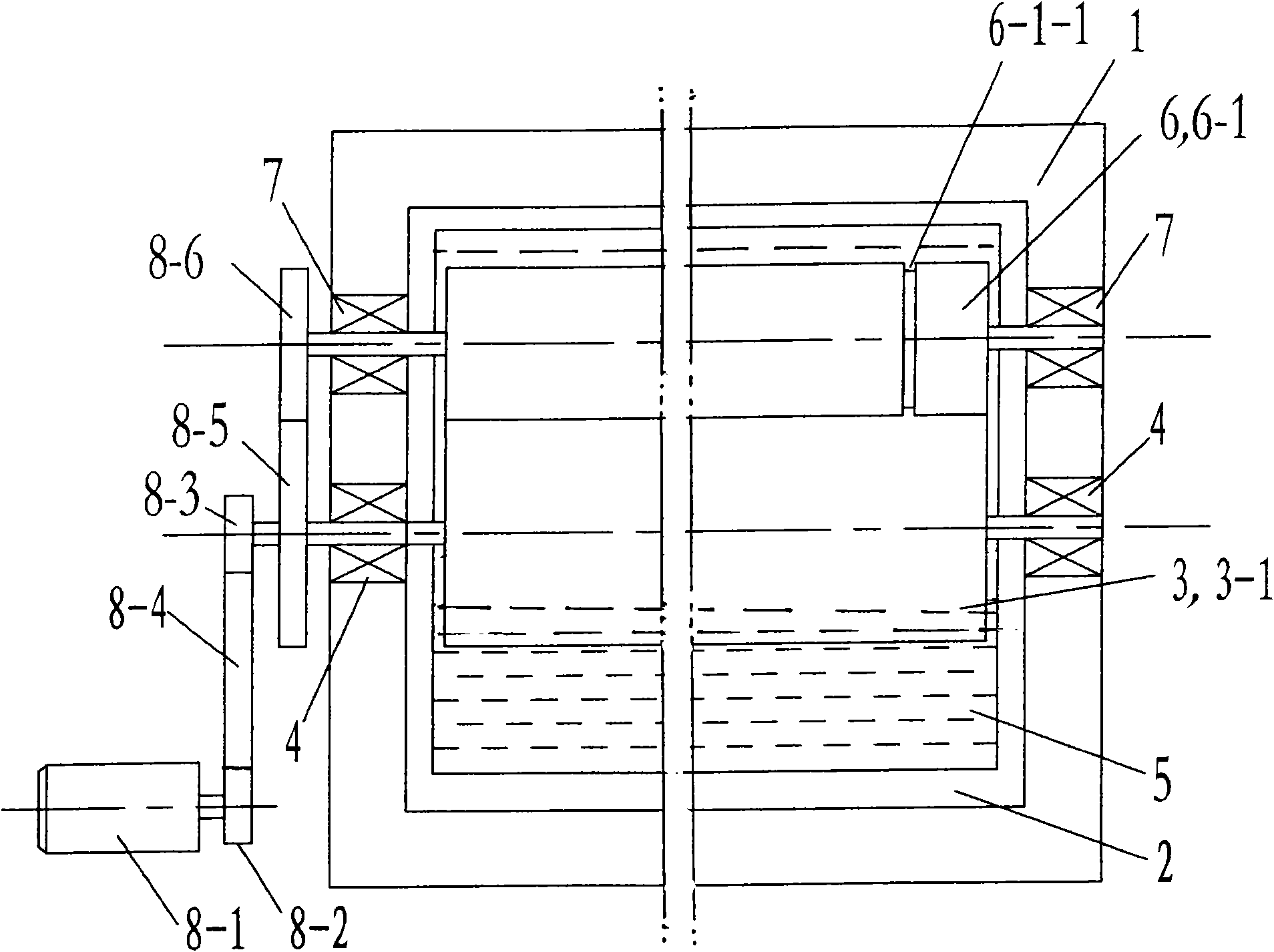

Device and method for cone yarn fixation aftertreatment

PendingCN106676792ASolve the technical problem that the liquid-carrying rate is higher than the liquid-carrying rate near the main shaft of the dehydratorEvenly charged rateLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of definite length materialsYarnPulp and paper industry

The invention relates to the technical field of reactive dyeing equipment, in particular to a device for cone yarn fixation aftertreatment. The device comprises a barrel body, a yarn barrel rotating shaft, a yarn barrel and a driving motor. The barrel body is divided into a dehydration chamber and a negative pressure chamber by a partition plate and provided with a water outlet communicated with the lower portion of the dehydration chamber. The yarn barrel rotating shaft is installed in the dehydration chamber, the driving motor is connected with the yarn barrel rotating shaft, the yarn barrel is tubular, through holes are evenly distributed in the outer circle surface of the yarn barrel, the yarn barrel is installed on the yarn barrel rotating shaft, the yarn barrel can be communicated with the negative pressure chamber through the yarn barrel rotating shaft, and the barrel body is provided with a negative pressure device interface communicated with the negative pressure chamber. The device for cone yarn fixation aftertreatment can make the liquid carrying rate of each part uniform after cone yarn fixation, and a fixation effect is improved.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

Dyeing device for silk fabrics

PendingCN107354633ASolution refiningSolve the problem of separate dyeingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalProduction lineEngineering

The invention discloses a dyeing device for silk fabrics. The dyeing device comprises a box body. One side of the inner wall of the box body is fixedly connected with a heating box, and a heater is fixedly connected to the bottom of the inner wall of the heating box. A first motor, a control box, a fixing agent box, a liquid pump and a second motor are fixedly connected to the bottom of the inner wall of the box body. The first motor is connected with a sliding block through a screw rod, the top of the box body is fixedly connected with a third motor, an output shaft of the third motor is in transmission connection with a first belt pulley and a second belt through a first rotating device, the top of the fixing agent box is fixedly connected with a dye tank, the end of a liquid outlet of the liquid pump communicates with a spray head through an infusion tube, and a drying box is fixedly connected to one side of the inner wall of the box body. The invention relates to the technical field of silk fabric processing. According to the dyeing device for the silk fabrics, the problem that refining and dyeing are performed respectively is solved; after being dyed, the silk fabrics can enter the drying box quickly and efficiently to be dried, a production line space is effectively utilized, and the cost is reduced.

Owner:浙江德清华丝纺织有限公司

Cheese dyeing device

InactiveCN108978073AImprove dyeing efficiencySimple structureLiquid/gas/vapor treatment machines driving mechanismsTextile treatment containersEngineeringPiston rod

The invention provides a cheese dyeing device comprising a base. Columns are arranged on left and right sides of the base, a beam is arranged between the columns, a cylinder is arranged at a lower endof the beam, a piston rod is arranged at a lower end of the cylinder, and a lower end of the piston rod is provided with a cover plate. A motor is arranged in a middle portion of the cover plate, a motor rod is arranged at a lower end of the motor, a rotating plate is arranged at a lower end of the cover plate, and the motor rod passes the cover plate to be connected to the rotating plate. Creelsare distributed on the rotating plate, a dye bucket is arranged under the creels, an upper end of a right side of the dye bucket is provided with a water inlet pipe, and a lower end of a left side ofthe dye bucket is provided with a water outlet pipe. The cheese dyeing device has the advantages of simple structure, easy operation and the great improvement of working efficiency.

Owner:WUHU FUCHUN DYEING & WEAVING

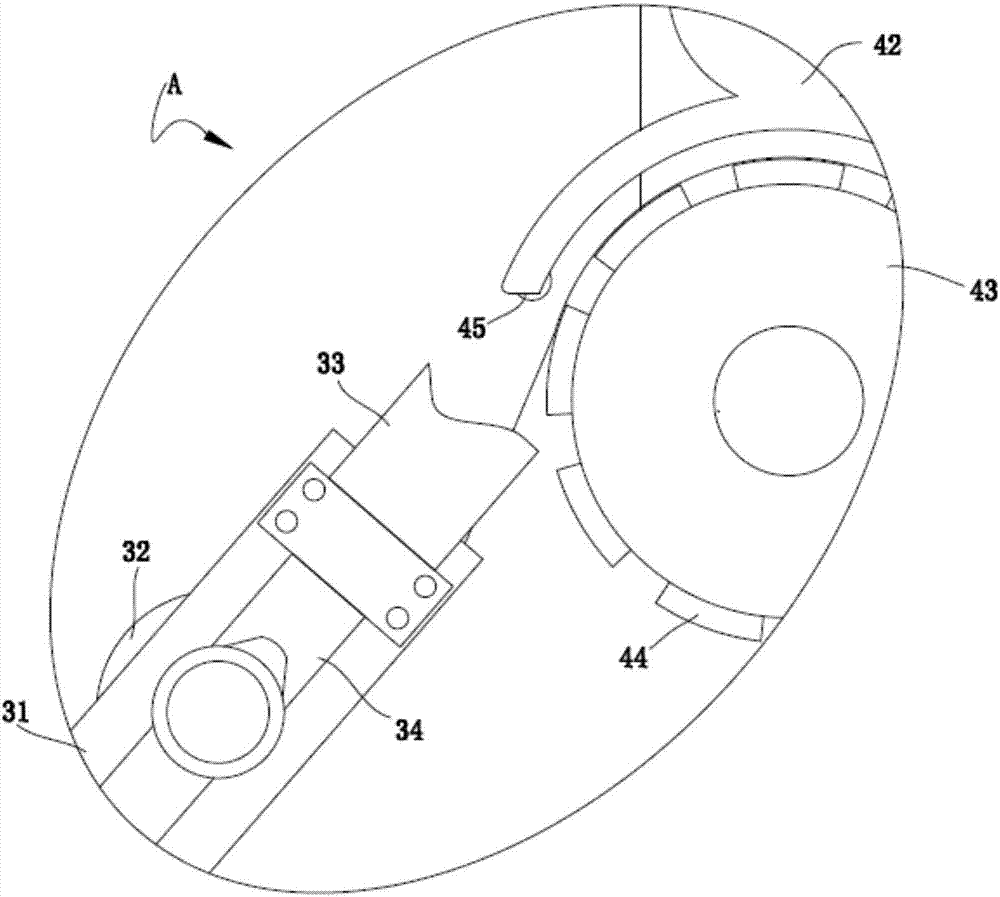

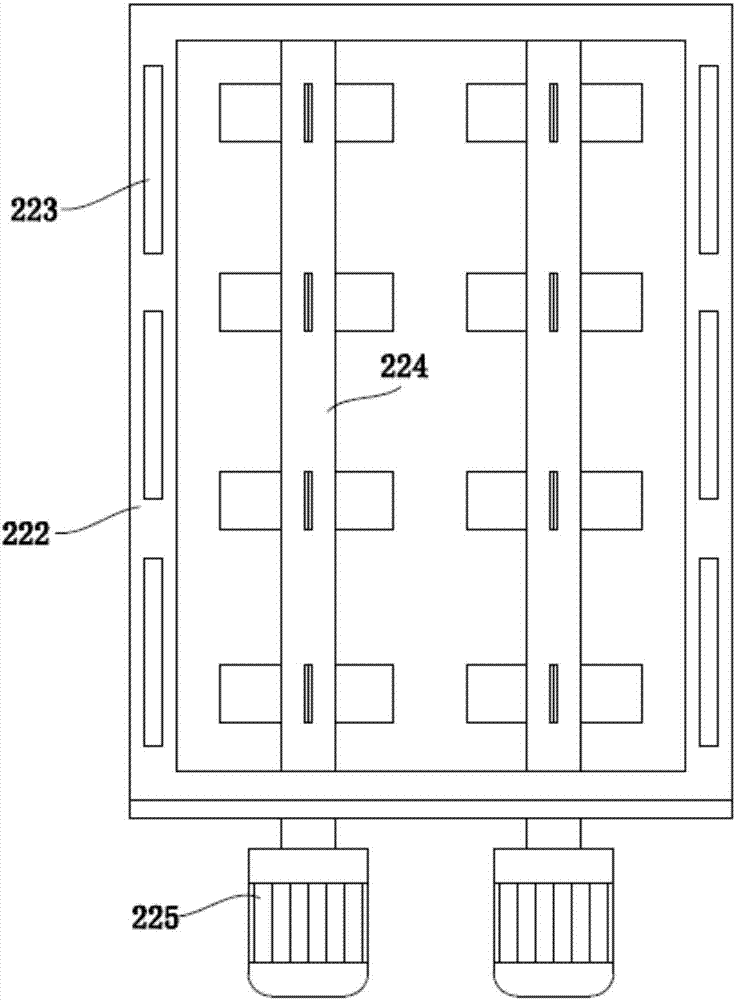

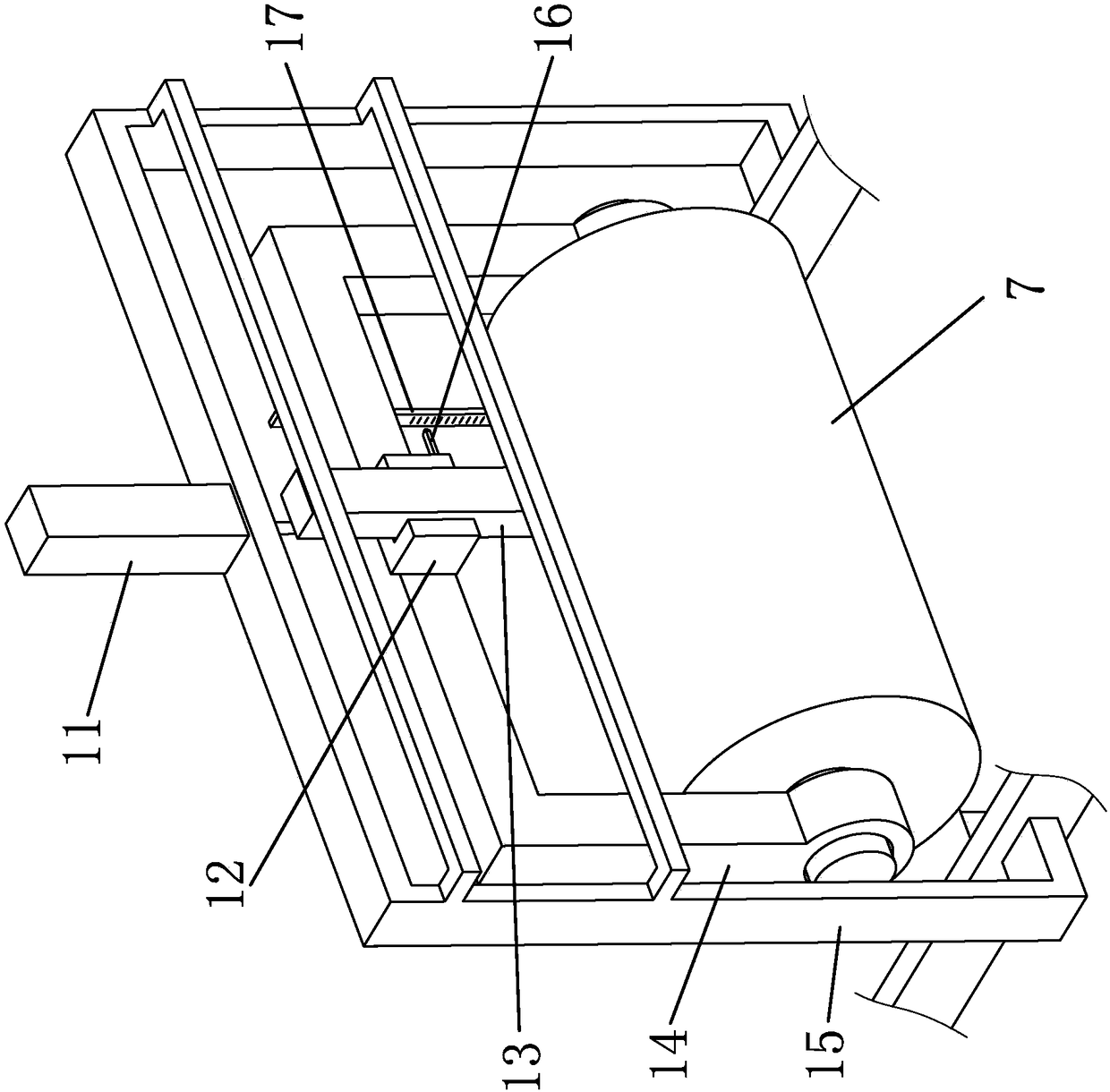

Non-woven mesh fabric warp gluing machine

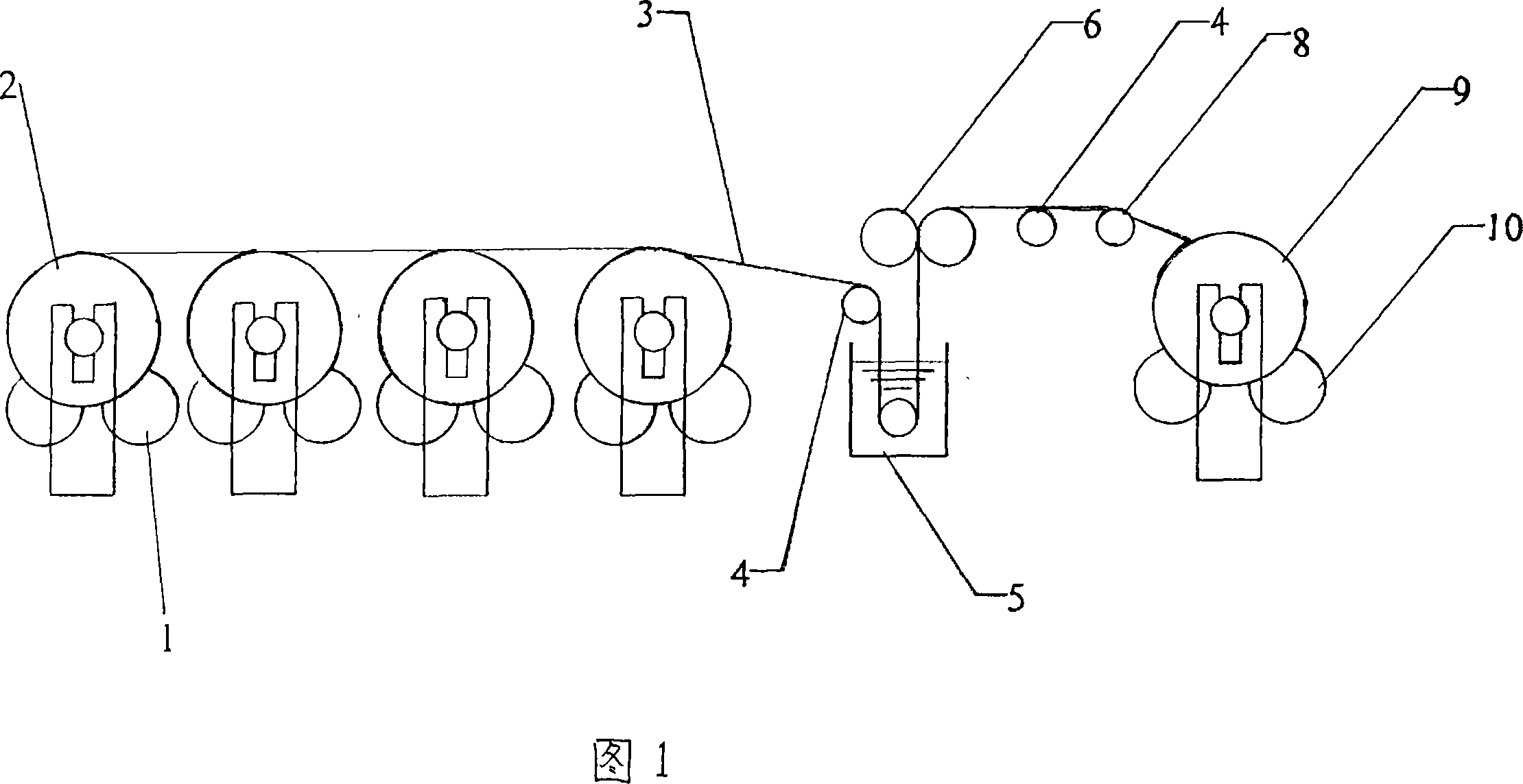

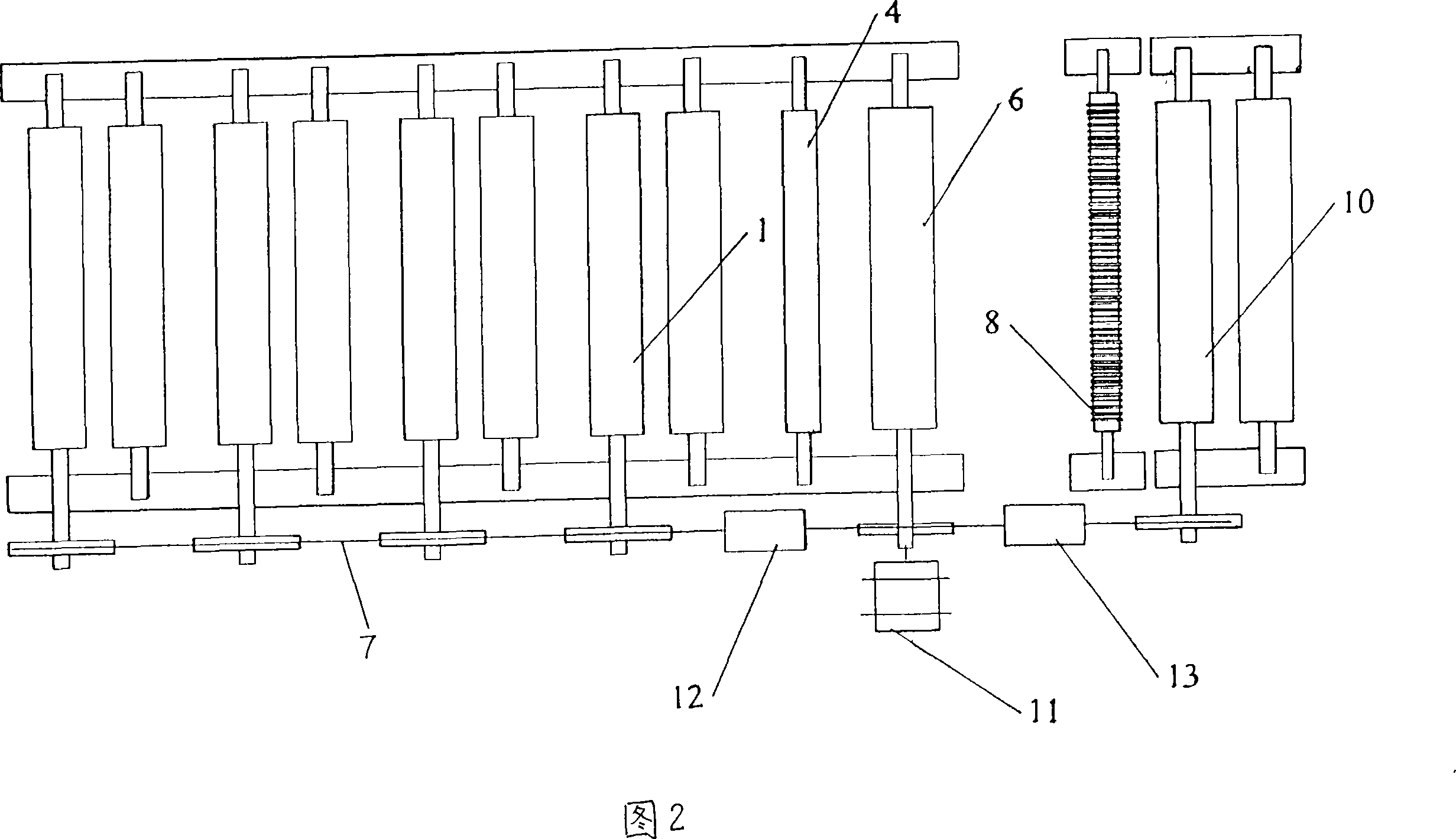

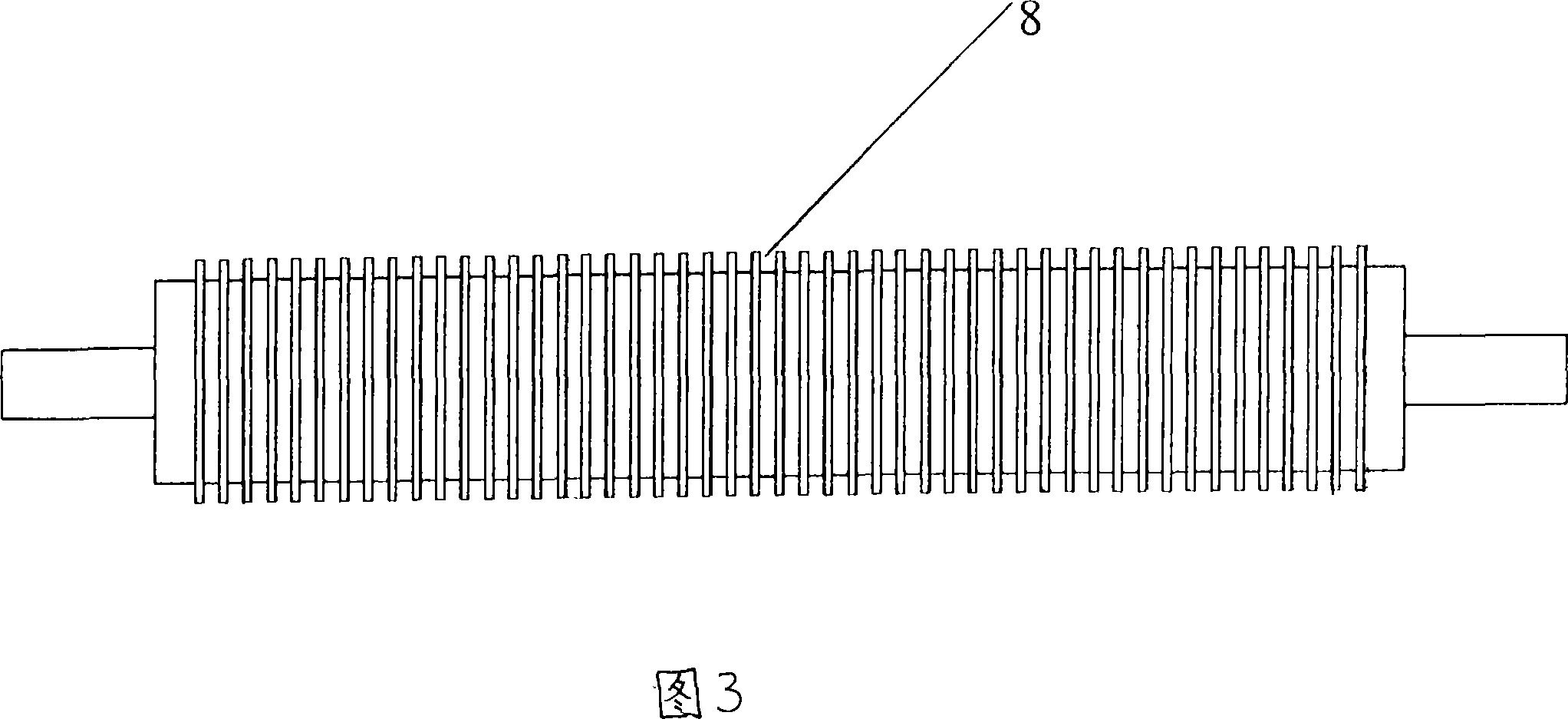

ActiveCN101818420AMeet secret requirementsFulfil requirementsLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsYarnPulp and paper industry

The invention discloses a non-woven mesh fabric warp gluing machine, which is mainly characterized by comprising a stand (1), a glue storing tank (2), a gluing roller assembly (3), a yarn positioning and guiding roller assembly (6) and a transmission assembly (8). The invention has the characteristics of reasonable structure, normal warp positioning, good gluing quality, high production efficiency and the like.

Owner:CHANGZHOU NEWLAND COMPOSITE MATERIAL

Production method of nano-anion textile fabric

InactiveCN108239834AShorten the timeRapid productionSucessive textile treatmentsLiquid/gas/vapor treatment machines driving mechanismsState of artCooking & baking

The invention provides a production method of a nano-anion textile fabric. According to the production method, the technical problems that a specific production method is not disclosed in the prior art, the production speed only depending on experience is low, and the like are solved. The production method comprises the following steps: (a) dipping a textile fabric into finishing liquid by virtueof a padding system, wherein the padding time is 10-20 seconds, and the padding rate is 75%-85%; (b) pre-drying: pre-drying the fabric at 140-150 DEG C for 20-30 seconds; (c) baking: baking the fabricat 158-166 DEG C for 5-10 minutes; (d) washing: firstly washing the fabric with cold water at 15-25 DEG C for 4-8 minutes, and washing the fabric with hot water at 60-70 DEG C for 1-3 minutes; and (e) drying: drying the fabric again at 110-120 DEG C, so as to obtain the nano-anion textile fabric. The production method has the advantage of high production speed.

Owner:嘉兴涌锦服饰有限公司

Bleaching device for producing textiles

InactiveCN108457024AControl liftEasy to take outLiquid/gas/vapor treatment machines driving mechanismsArchitectural engineeringTextile production

The invention discloses a bleaching device for producing textiles. The bleaching device comprises a base, wherein support pillars are fixed on four sides of the top end of the base; a top plate is fixed at the top ends of the support pillars; a servo motor is mounted at the bottom end of the top plate; a transmission rod is fixed on an output shaft of the servo motor; vertical plates are fixed ontwo sides of the bottom end of the top plate; two groups of guide rods are fixed between the vertical plates and are in sliding connection with movable blocks; a connection rod is fixed between the movable blocks and is in sliding connection with a sliding block; a fixed plate is fixed at the bottom ends of the two groups of movable blocks; sleeve rods are fixed on two sides of the bottom end of the fixed plate; stop blocks are arranged in the sleeve rods; movable rods are fixed at the bottom ends of the stop blocks; the bottom ends of the movable rods extend to the outside of the sleeve rodsand are fixed with storage baskets. The bleaching device is ingenious in design, reasonable in structure, simple to operate and high in flexibility; the labor is reduced; the storage baskets can be conveniently controlled to rise and fall; the bleaching efficiency of the device can be improved; the textiles can be more uniformly bleached; the popularization of the bleaching device is facilitated.

Owner:南陵百绿汇农业科技有限公司

Waterproof moisture-permeable fabric for clothing and clothing

ActiveUS8108949B2Easy to recycleImprove appearance qualityLiquid/gas/vapor treatment machines driving mechanismsWarp knittingPolyesterPolymer resin

Waterproof moisture-permeable fabric for clothing which includes, on one side of a polyester fabric A, a waterproof moisture-permeable layer B including a colorless transparent polyester film stacked, and a white or gray resin C partially stacked, and clothing including the waterproof moisture-permeable fabric. Preferably, a moisture-permeable polymer resin D containing inorganic fine particles is stacked on the waterproof moisture-permeable layer B, and the white or gray resin C is partially stacked thereon.

Owner:TEIJIN FRONTIER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com