Textile printing and dyeing device

A technology of textile printing and dyeing and printing and dyeing boxes, which is applied in the field of textile processing, can solve the problems that fabric rolls of different sizes cannot be fixed and unfolded, and achieve the effect of improving the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

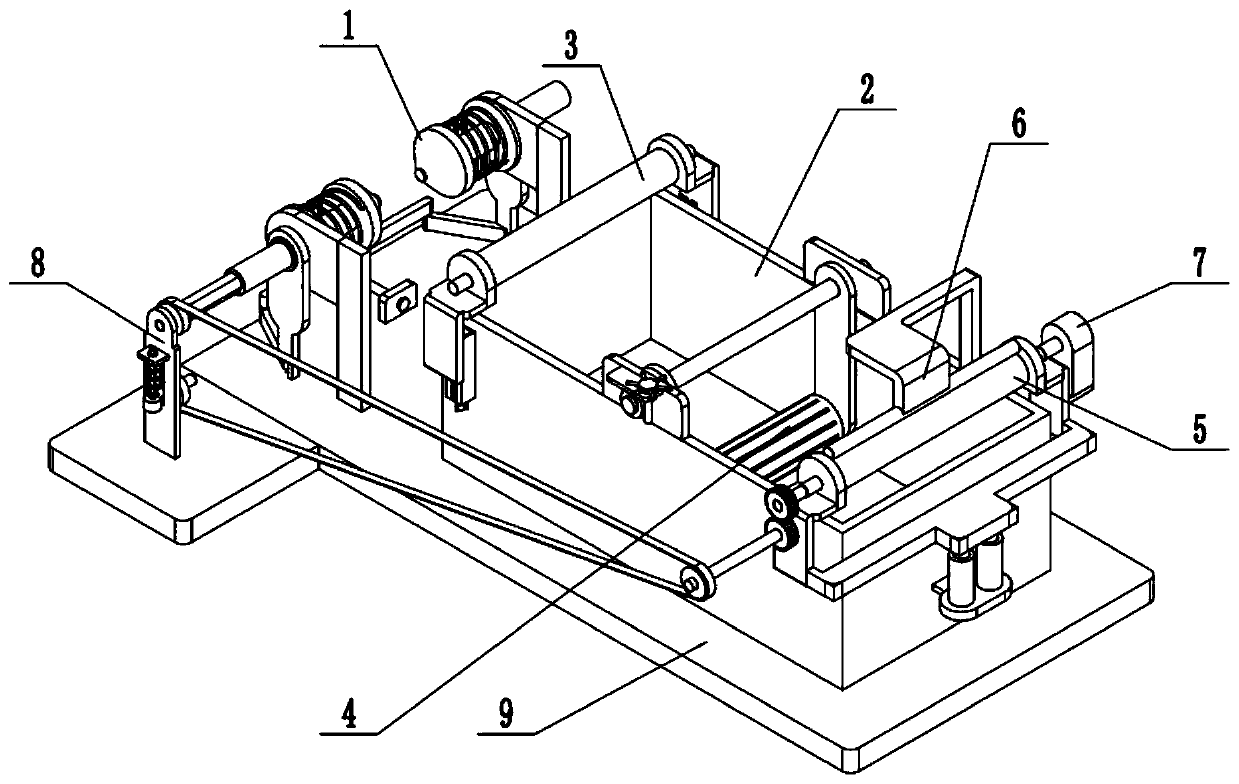

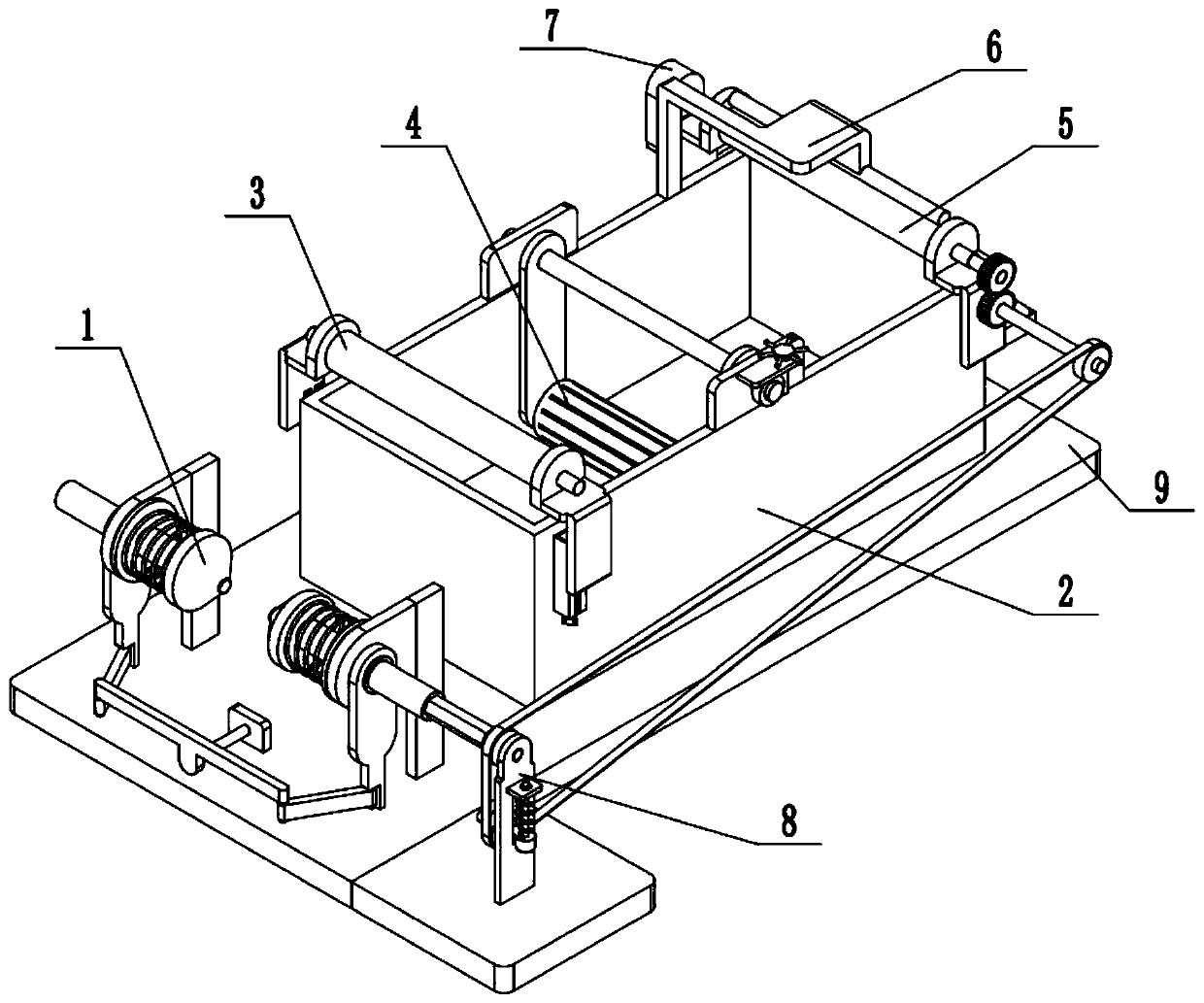

[0032] Such as Figure 1-13 As shown, a textile printing and dyeing device includes a cloth roll clamping mechanism 1, a printing and dyeing box 2 with a hollow top surface, a cloth feeding guide roller mechanism 3, a printing and dyeing guiding roller mechanism 4, a cloth outlet guiding roller mechanism 5, and an auxiliary cloth pressing mechanism 6 , a drive mechanism 7, a linkage mechanism 8 and a base plate 9, the cloth roll clamping mechanism 1 is fixedly connected to the left end of the base plate 9 top surface; the printing and dyeing box 2 is fixedly connected to the middle end of the base plate 9 top surface; The cloth feeding guide roller mechanism 3 is fixedly connected to the upper end on the left side of the printing and dyeing box 2; the printing and dyeing guiding roller mechanism 4 is fixedly connected to the upper end in the middle of the printing and dyeing box 2; Fixedly connected to the upper end of the right side of the printing and dyeing box 2, the auxil...

specific Embodiment approach 2

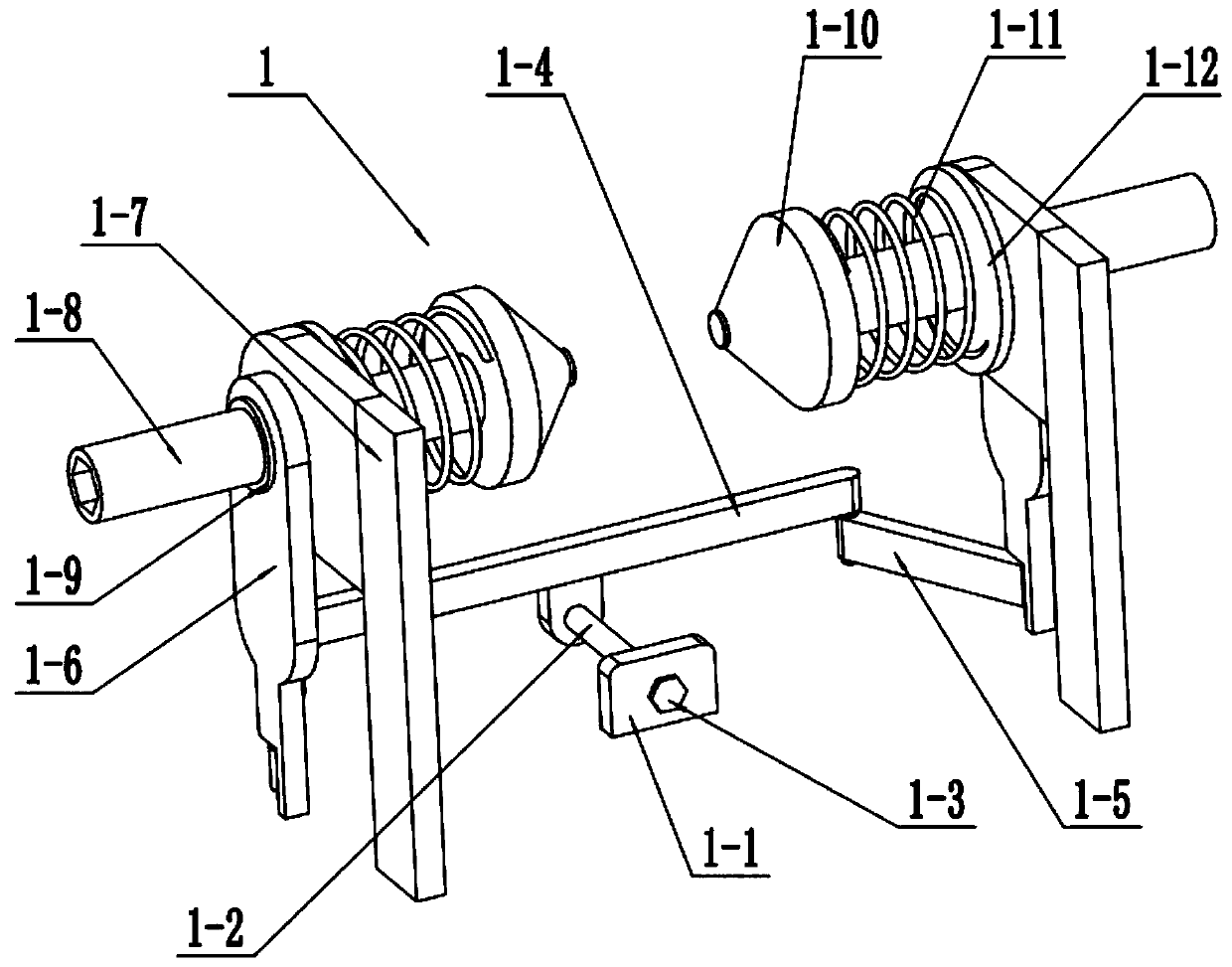

[0033] Such as Figure 1-13 As shown, the cloth roll clamping mechanism 1 includes a fixed seat plate 1-1, a guide shaft 1-2, a limit block 1-3, a push-pull plate 1-4, a push-pull connecting rod 1-5, a movable frame plate 1- 6. Fixed frame plate 1-7, movable shaft 1-8, limit ring 1-9, tapered top tight head 1-10 without cone tip, compression spring 1-11 and spring plate 1-12; The seat plate 1-1 is fixedly connected to the left end of the top surface of the base plate 9; the left and right ends of the guide shaft 1-2 are respectively fixedly connected to the push-pull plate 1-4 and the limit block 1-3, and the center of the guide shaft 1-2 The ends are slidingly fitted and connected to the fixed seat plate 1-1; the front and rear ends of the push-pull plate 1-4 are respectively connected to the left end of a push-pull connecting rod 1-5 through hinge shafts, and the right ends of two push-pull connecting rods 1-5. They are respectively connected to a movable frame plate 1-6 th...

specific Embodiment approach 3

[0034] Such as Figure 1-13 As shown, the cloth feeding guide roller mechanism 3 includes a cloth feeding guide roller body 3-1, a first guide roller shaft 3-3, a lifting bracket plate 3-4, a T-shaped slider 3-5, a first pressure spring 3-6, adjusting screw 3-7, adjusting valve 3-8 and chute frame 3-9; the cloth feeding guide roller body 3-1 is located at the upper end of the printing and dyeing box 2, and the cloth feeding guide roller body 3-1 is fixedly connected At the middle end of the first guide roller shaft 3-3, the front and rear ends of the first guide roller shaft 3-3 rotate respectively and are connected to the upper end of a lifting shaft frame plate 3-4, and the two lifting shaft frame plates 3-4 The lower ends of the lower ends are respectively fixedly connected to the outer ends of a T-shaped slider 3-5, and the inner ends of the two T-shaped sliders 3-5 are respectively slidingly fitted and connected in a chute frame 3-9; the adjusting screw rod 3-7 The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com