Textile fabric rapid cleaning equipment

A technology for cleaning equipment and textile fabrics, which is applied in the direction of textile material equipment configuration, textile material processing, and textile material carrier processing, etc. It can solve the problems of twisting and winding of textile fabrics, long cleaning process time, waste of water resources, etc., and achieve saving Water resources, good washing effect, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

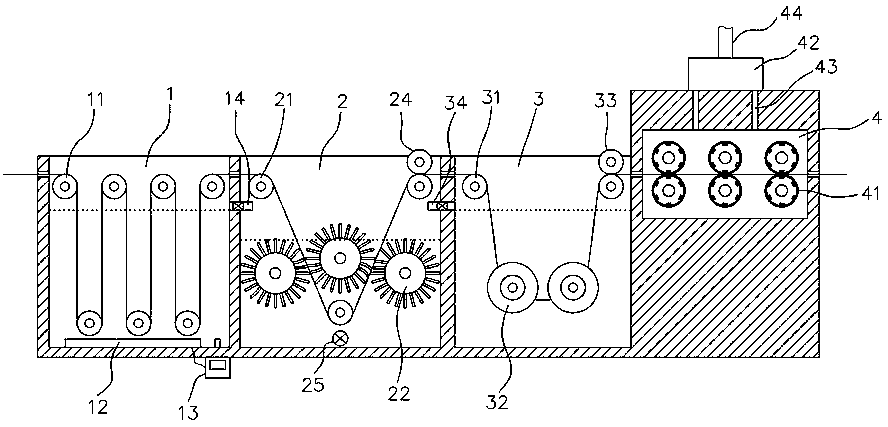

[0029] Reference Figure 1-5 , A rapid cleaning equipment for textile fabrics, comprising a base body, and a soaking tank 1, a washing tank 2, a rinsing tank 3, and a drying chamber 4 are sequentially opened in the base body from left to right;

[0030] A plurality of first guide rollers 11 are rotatably installed on the inner wall of the soaking tank 1, and the plurality of first guide rollers 11 are symmetrically and staggeredly distributed, and the inner bottom of the soaking tank 1 is provided with a heating device;

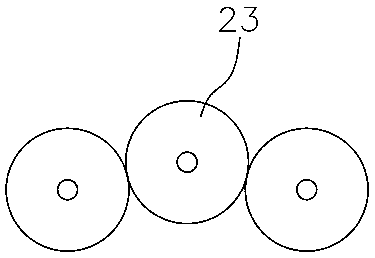

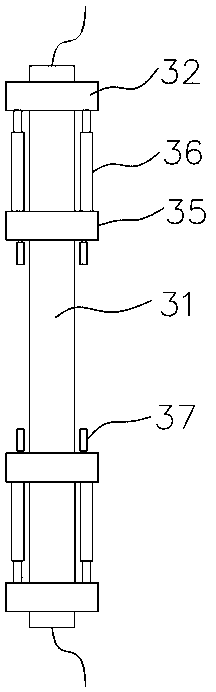

[0031] The inner wall of the washing tank 2 is rotatably connected with two second guide rollers 21 and a first squeeze roller set 24, and the two second guide rollers 21 and one first squeeze roller set 24 are distributed in a "V" shape. 2 The inner wall is rotatably connected with three washing rollers 22 through a rotating shaft, and the three washing rollers 22 are distributed in an inverted arc shape. The same side ends of the three rotating shafts pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com