Non-woven mesh fabric warp gluing machine

A grid cloth and non-woven technology, applied in the field of non-woven grid cloth warp yarn gluing machine, can solve the problems of wasting rubber material, blocking reed, affecting production efficiency, etc., and achieves good quality of finished products, normal warp yarn positioning, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

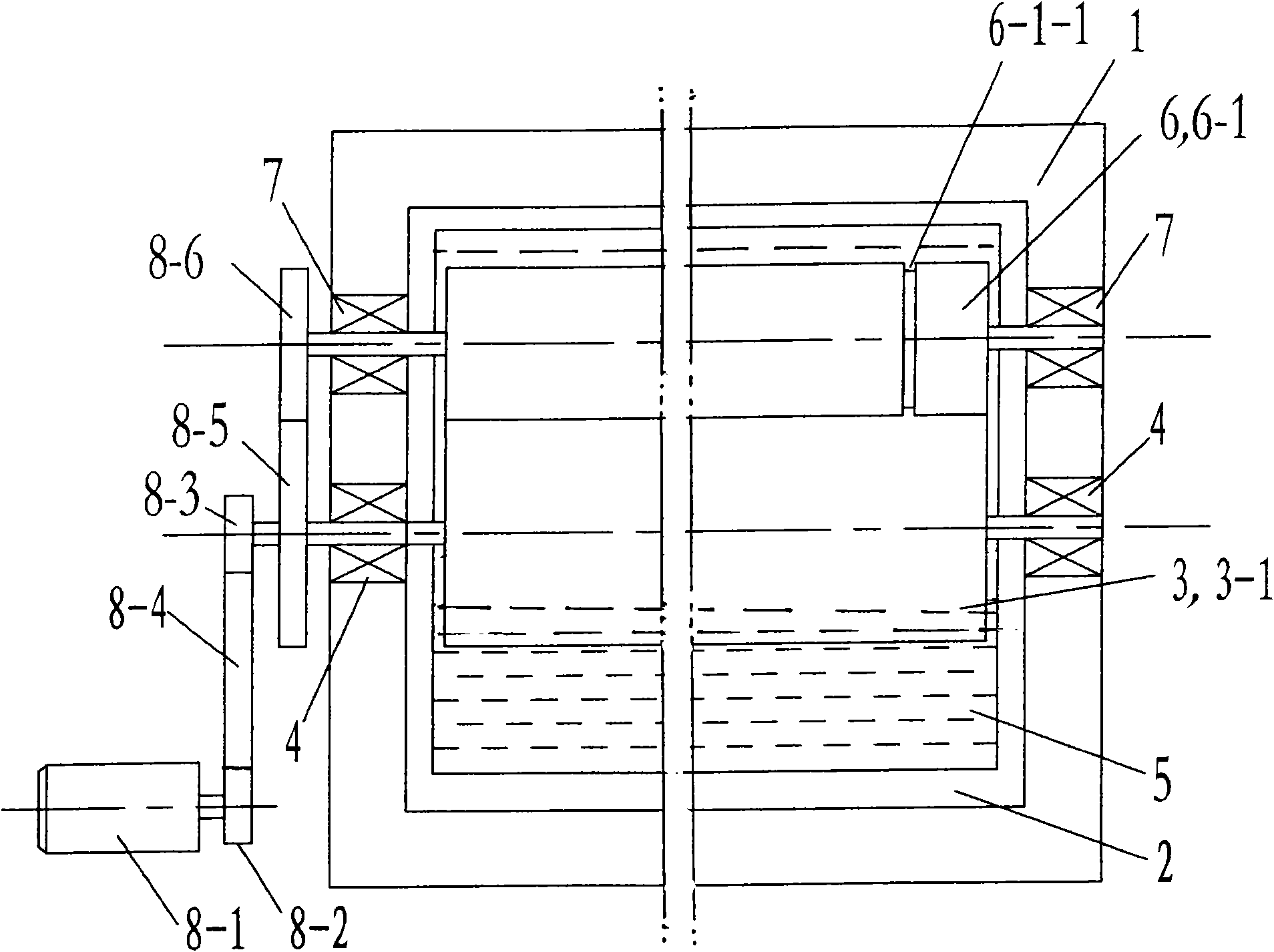

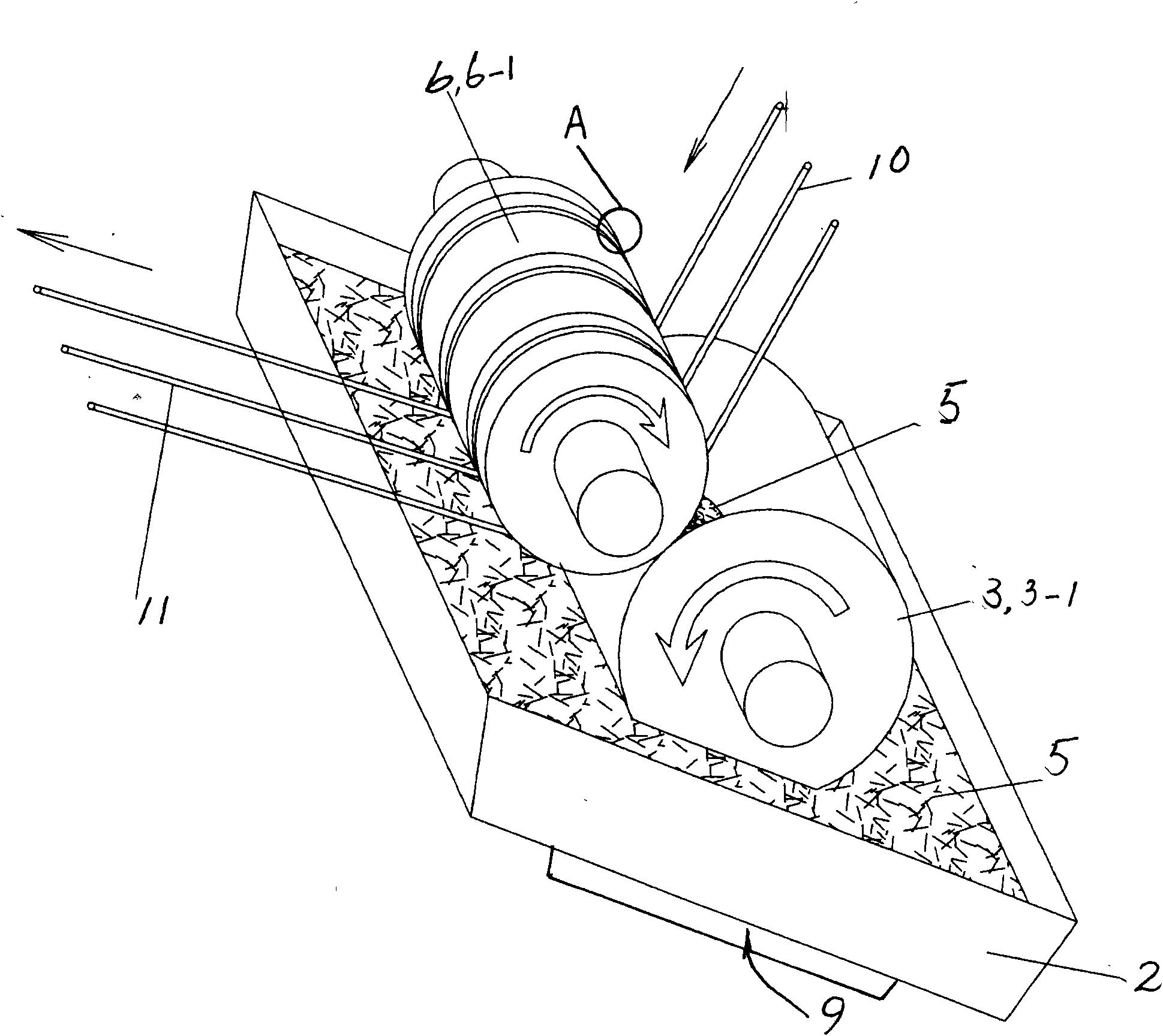

[0025] One of the specific implementation modes, as attached figure 1 , 2 , 3 shown.

[0026] A non-woven mesh warp gluing machine, comprising:

[0027] A frame 1; the frame (1) is made of section steel;

[0028] A rubber storage tank 2; the rubber storage tank 2 is fixedly connected with the frame 1; the rubber storage tank 2 is made of stainless steel;

[0029] An upper rubber roller assembly 3; the upper rubber roller assembly 3 is fixedly connected with the frame 1 through the first bearing seat 4 pairs; the roller 3-1 of the upper rubber roller assembly 3 is partially submerged in the rubber storage tank 2 Under the liquid surface of the glue solution 5;

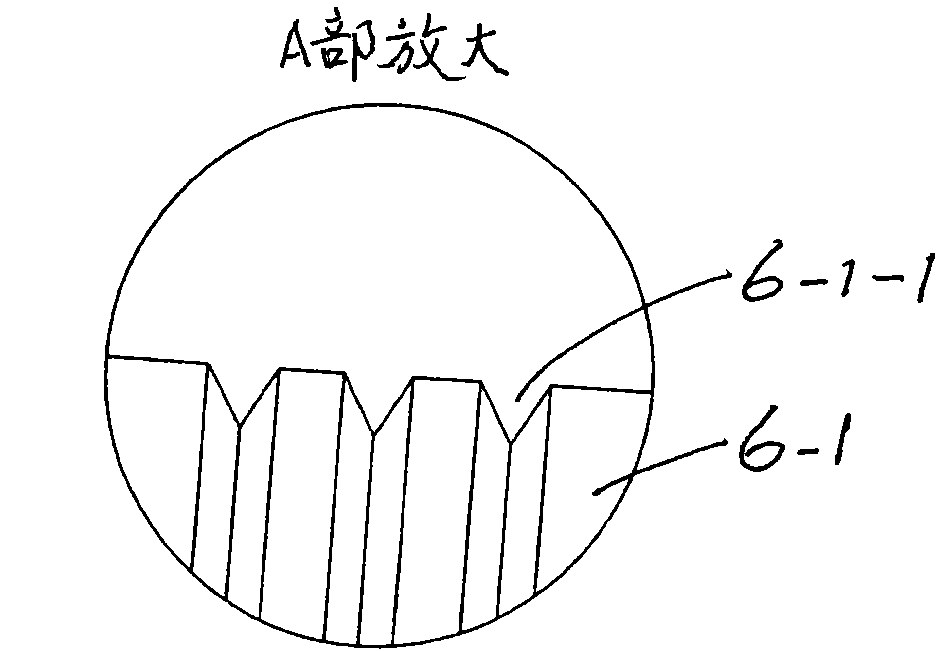

[0030] A positioning guide roller assembly 6; the surface of the roller 6-1 of the positioning guide roller assembly 6 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com