Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4468results about "Electric heating for furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

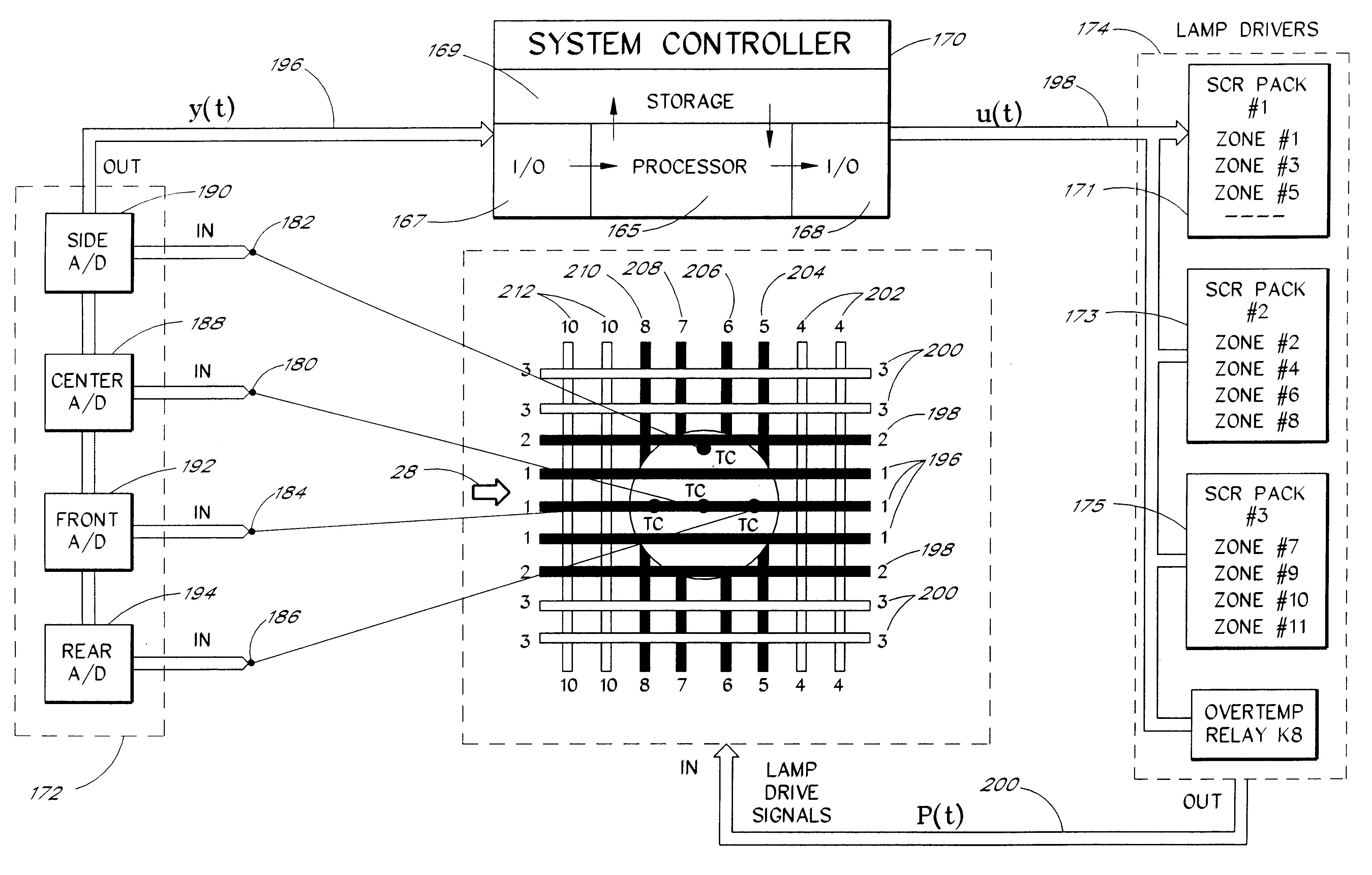

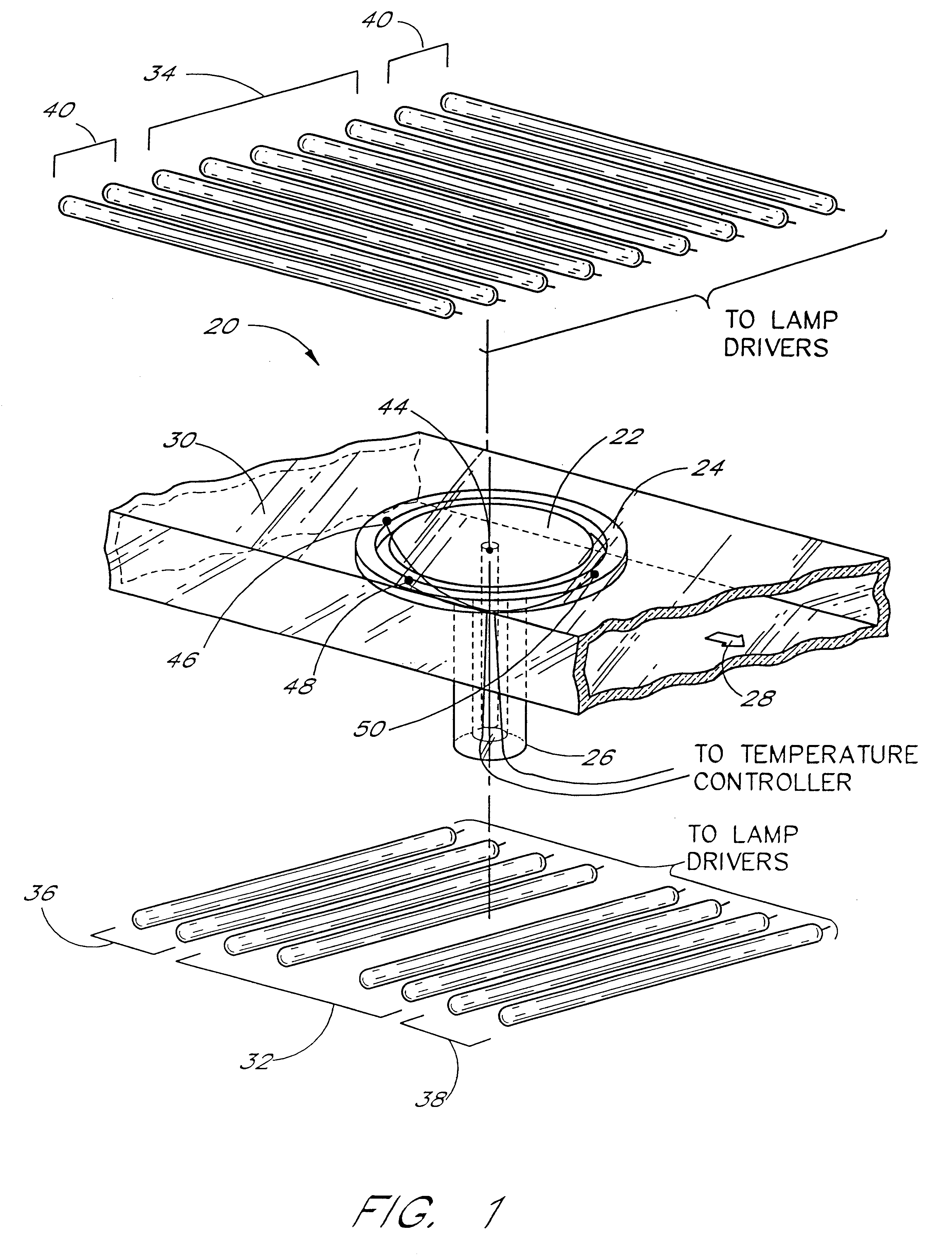

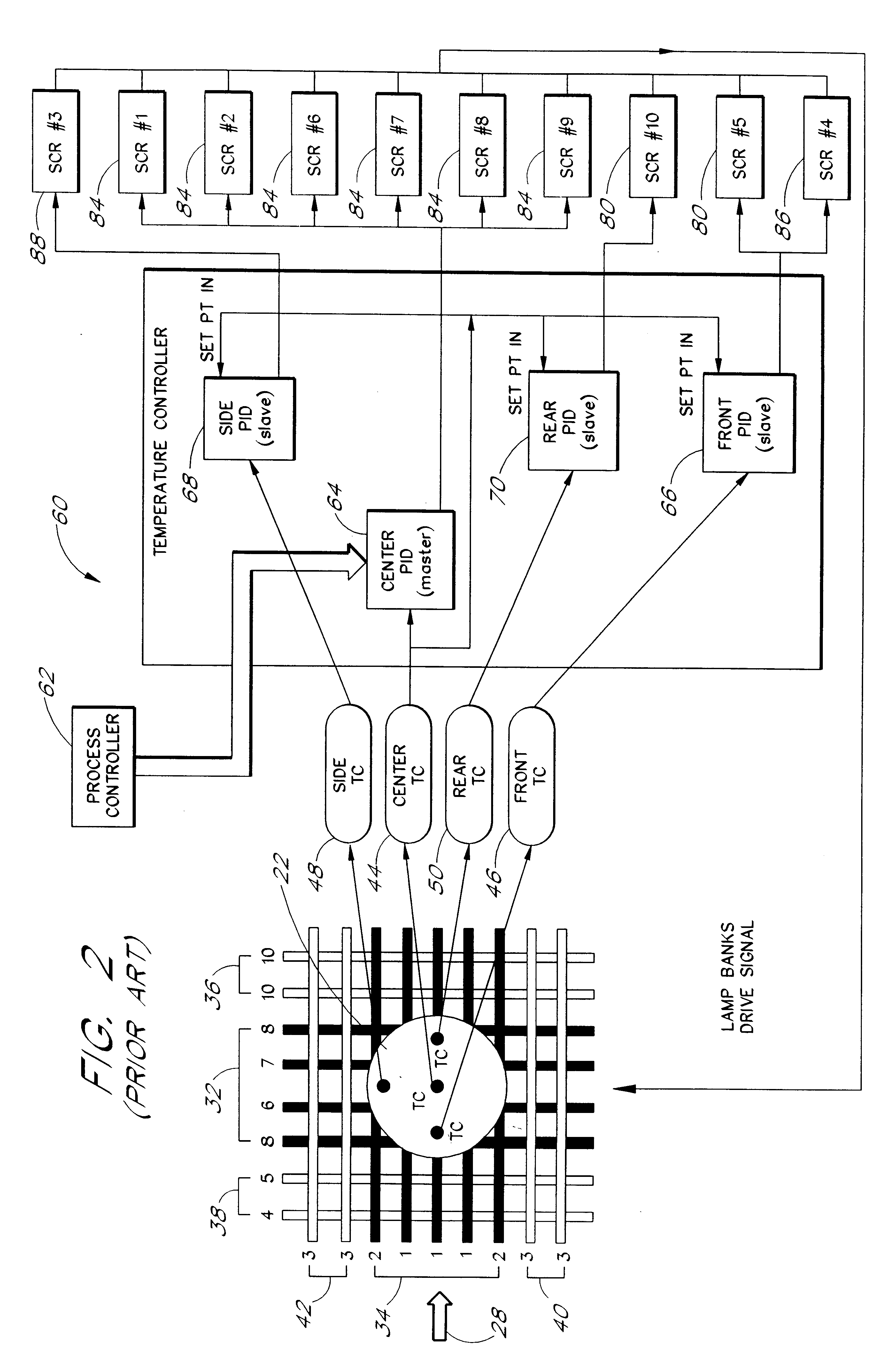

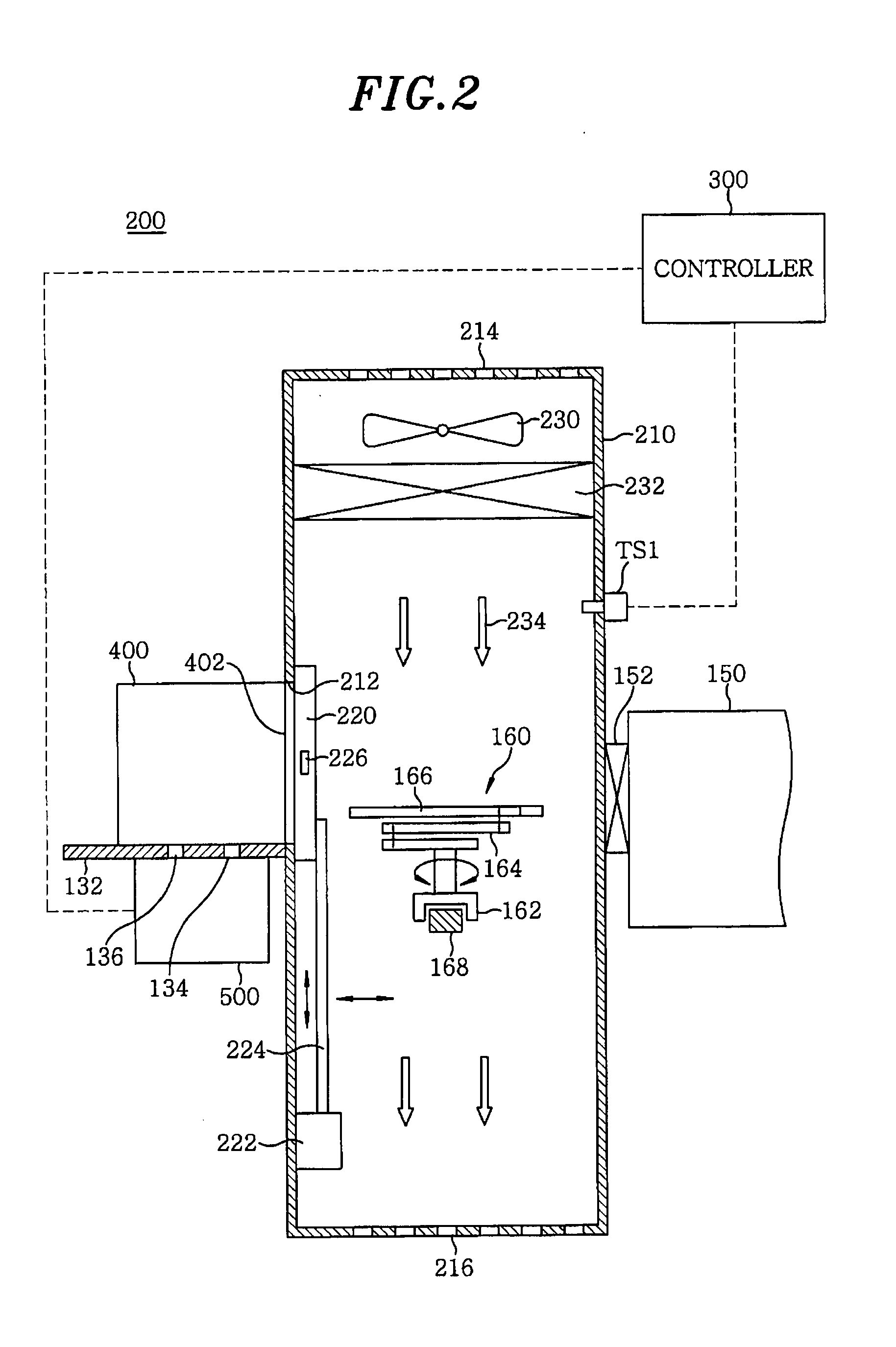

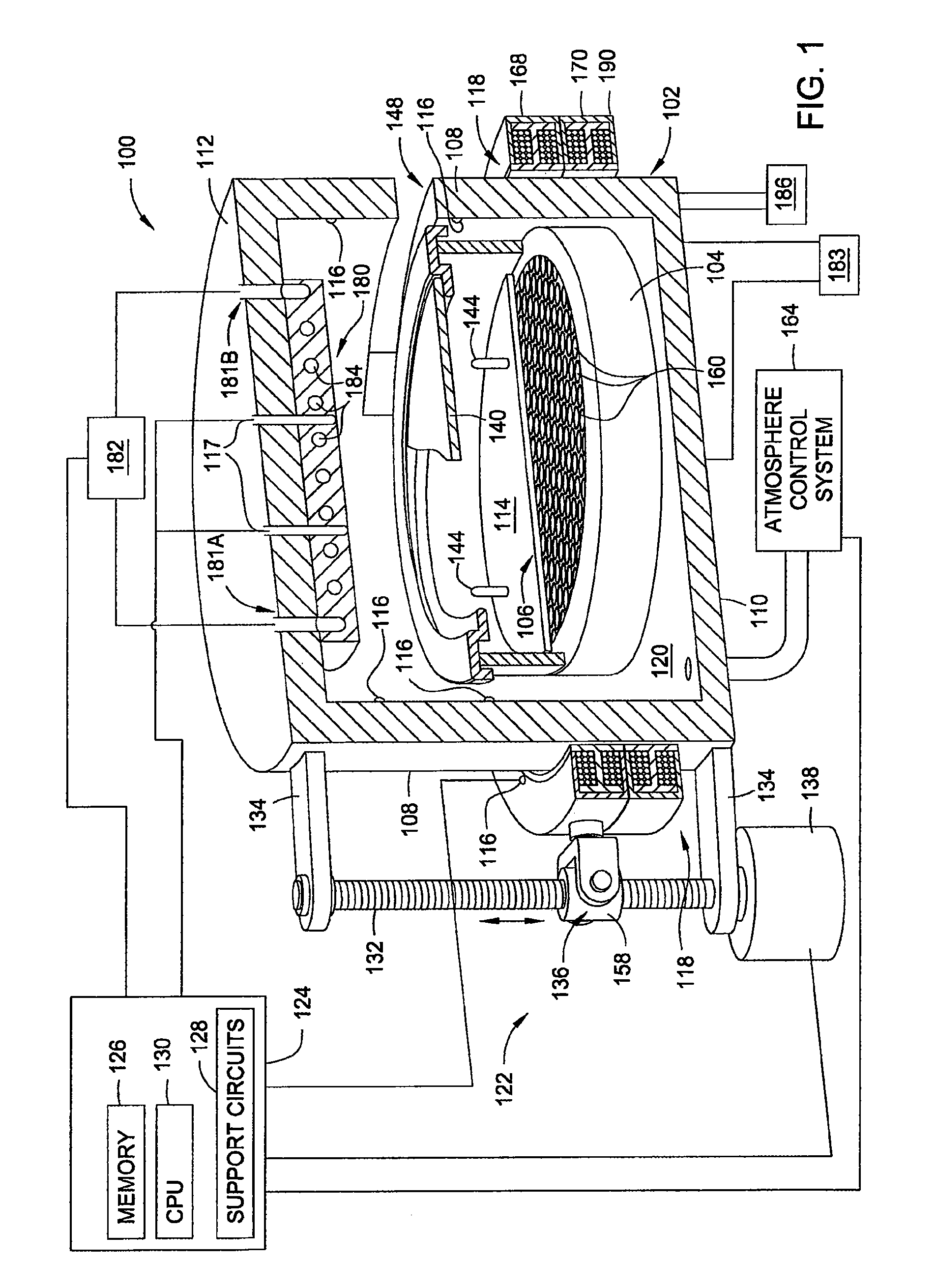

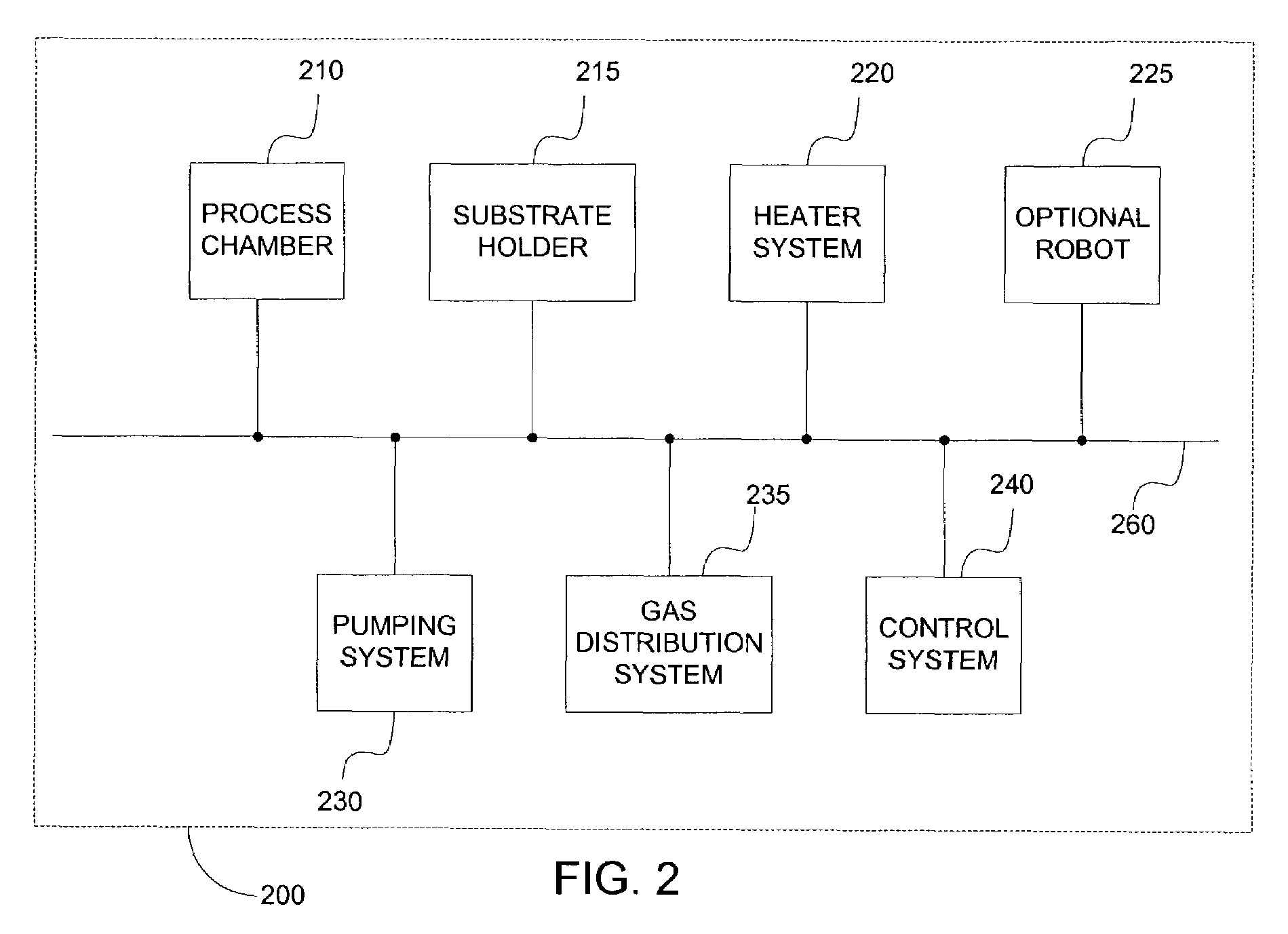

Model-based predictive control of thermal processing

InactiveUS6207936B1Baking ovenSemiconductor/solid-state device manufacturingTemperature controlTemperature response

A nonlinear model-based predictive temperature control system is described for use in thermal process reactors. A multivariable temperature response is predicted using a nonlinear parameterized model of a thermal process reactor. The nonlinear parameterized model is implemented using a neural network. Predictions are made in an auto-regressive moving average fashion with a receding prediction horizon. Model predictions are incorporated into a control law for estimating the optimum future control strategy. The high-speed, predictive nature of the controller renders it advantageous in multivariable rapid thermal processing reactors where fast response and high temperature uniformity are needed.

Owner:ASM AMERICA INC

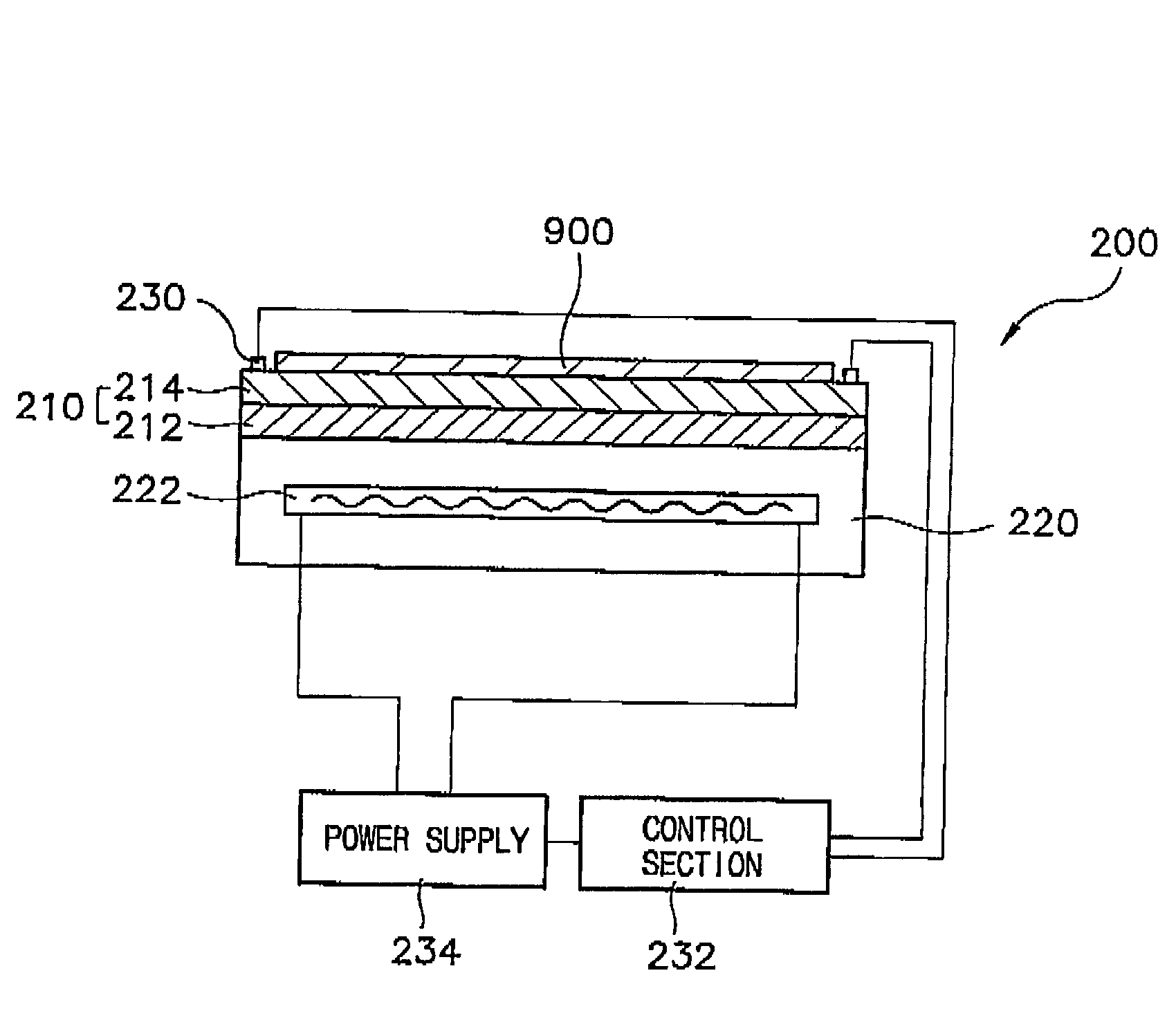

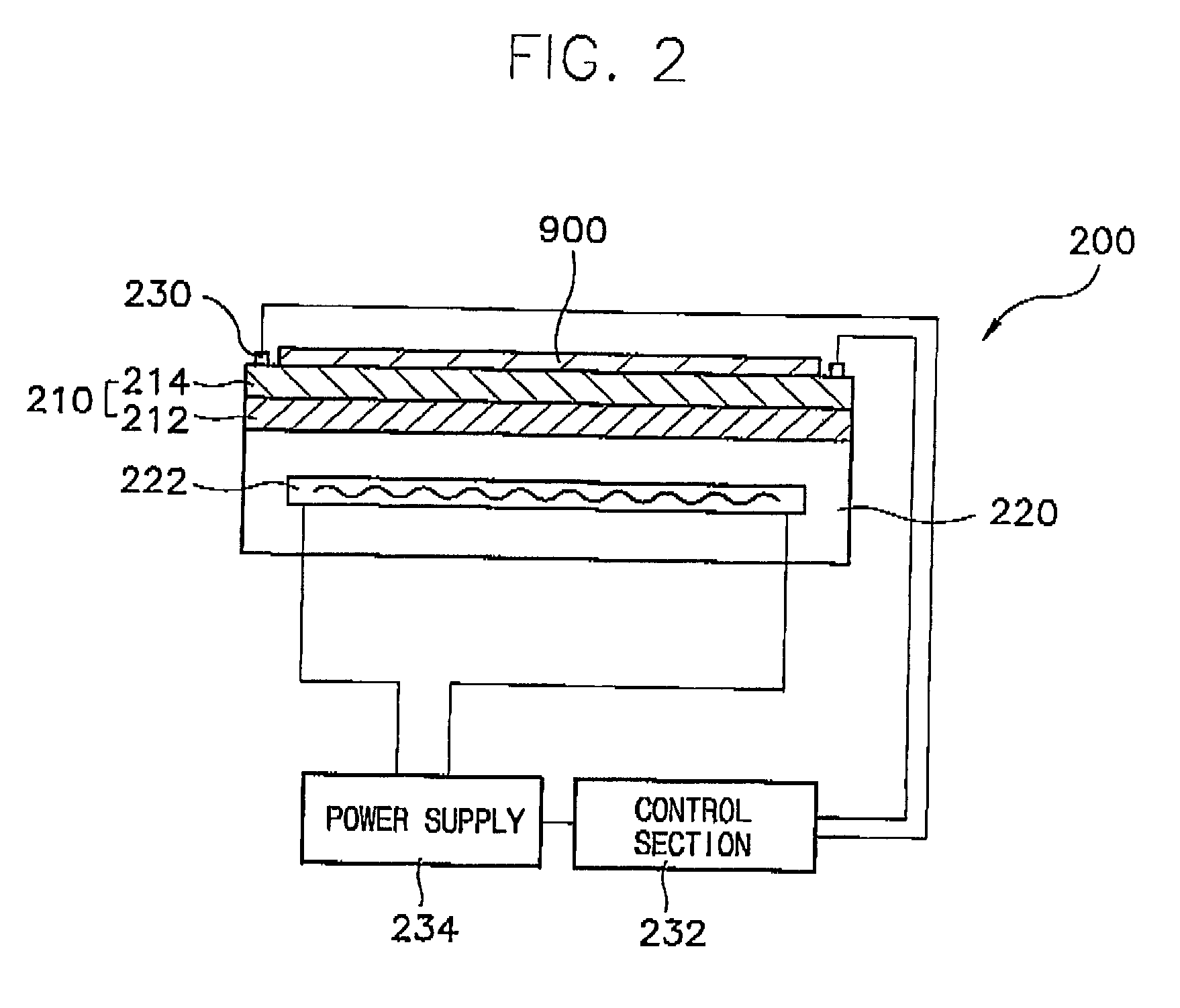

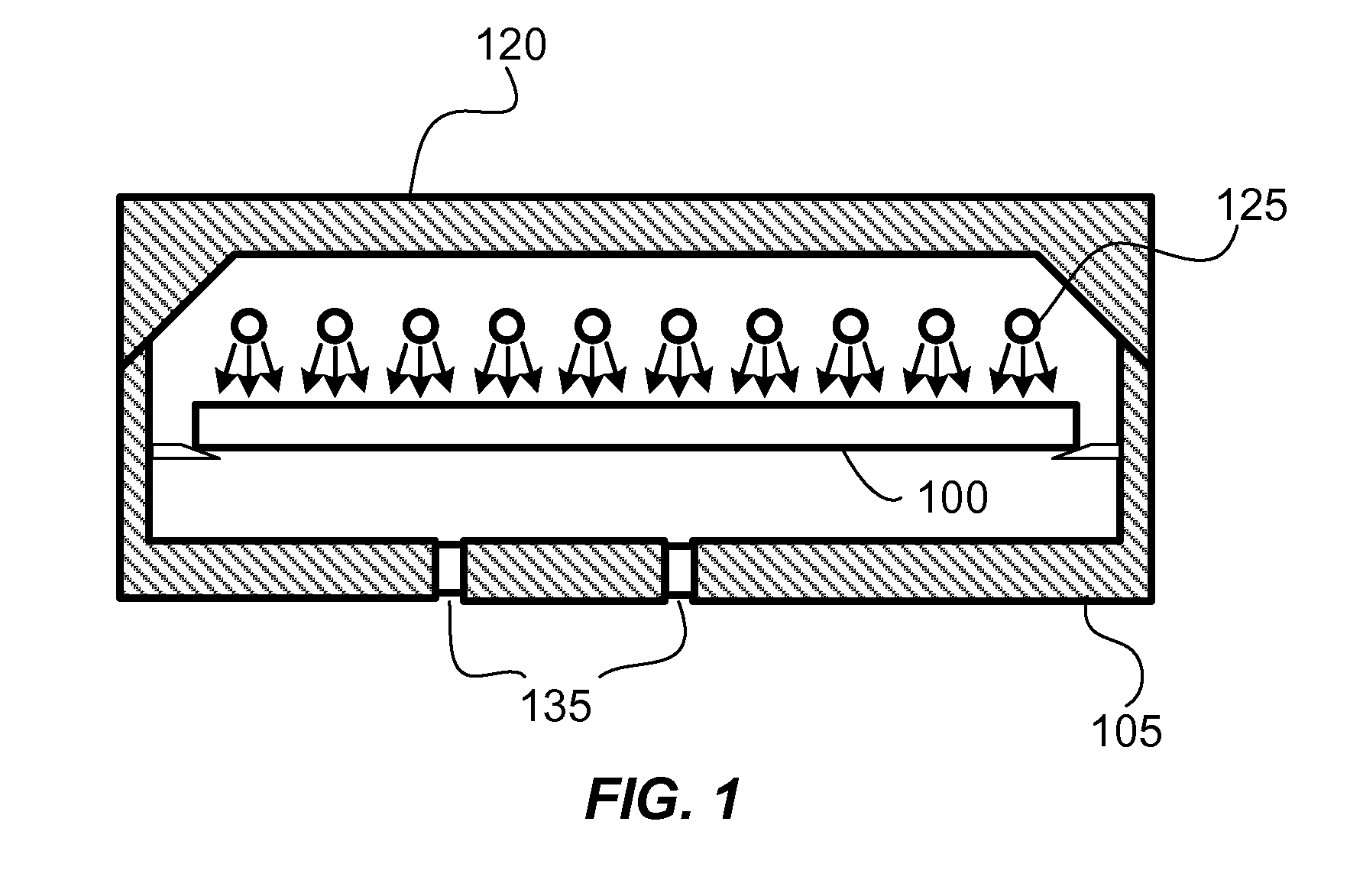

Apparatus for processing a substrate including a heating apparatus

InactiveUS20030066826A1Drying solid materials with heatMuffle furnacesProduction rateDevice material

An apparatus for heating a substrate of a semiconductor device includes a hot plate, on which a semiconductor substrate is placed, and a heater for heating the hot plate. The hot plate is preferably a composite plate including a plurality of plates having different thermal conductivities from each other. For example, a first plate adjacent to the heater can be made of aluminum, which has a relatively high thermal conductivity. A second plate, laminated on top of the first plate, can be made of titanium or stainless steel, which both have a thermal conductivity lower than aluminum. A composite hot plate as disclosed herein is better able to maintain a constant temperature and a uniform temperature distribution in order to more uniformly heat a substrate and to reduce an amount of energy required for the heating process. In addition, the reliability and productivity of the semiconductor device manufactured by the apparatus can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

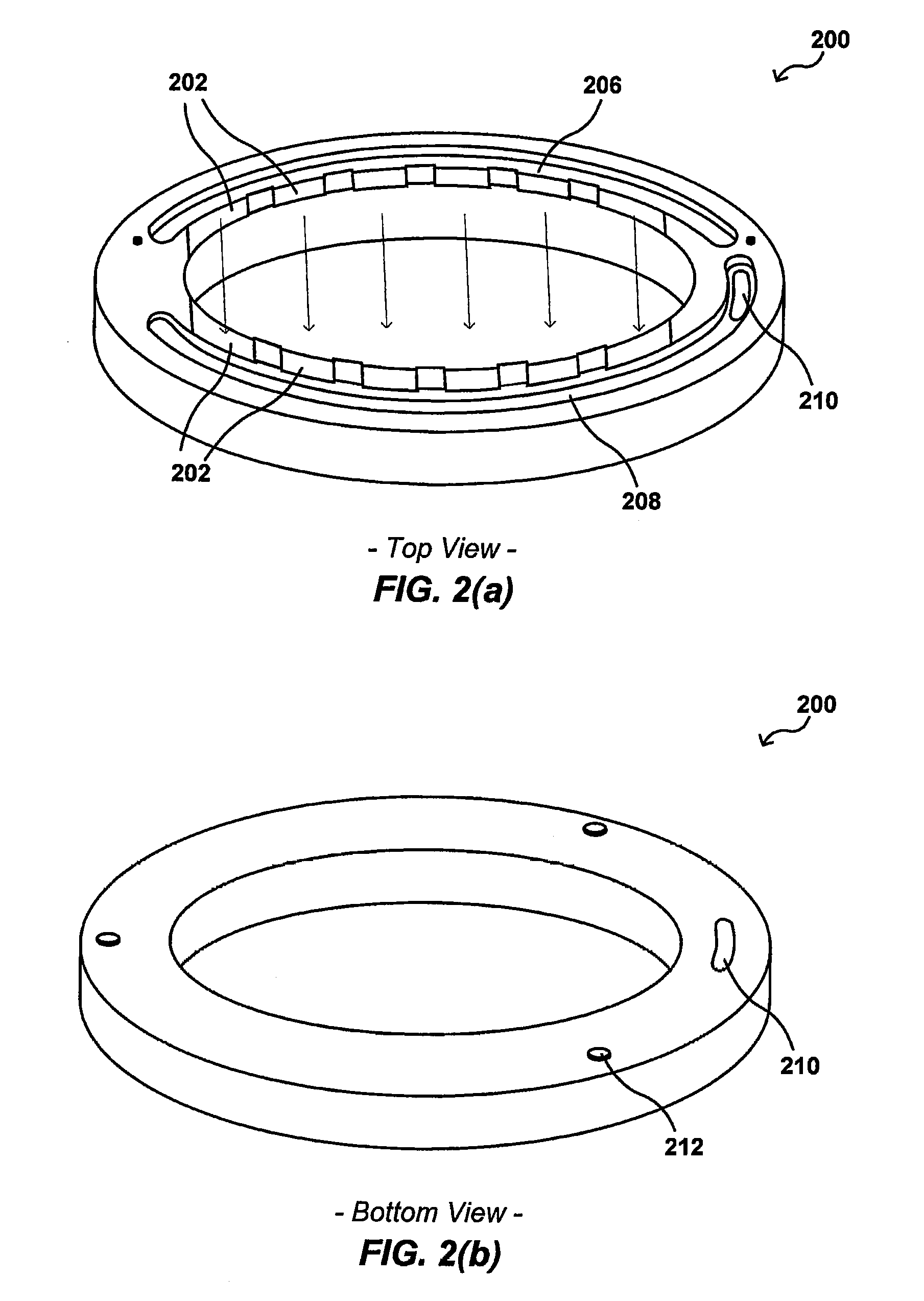

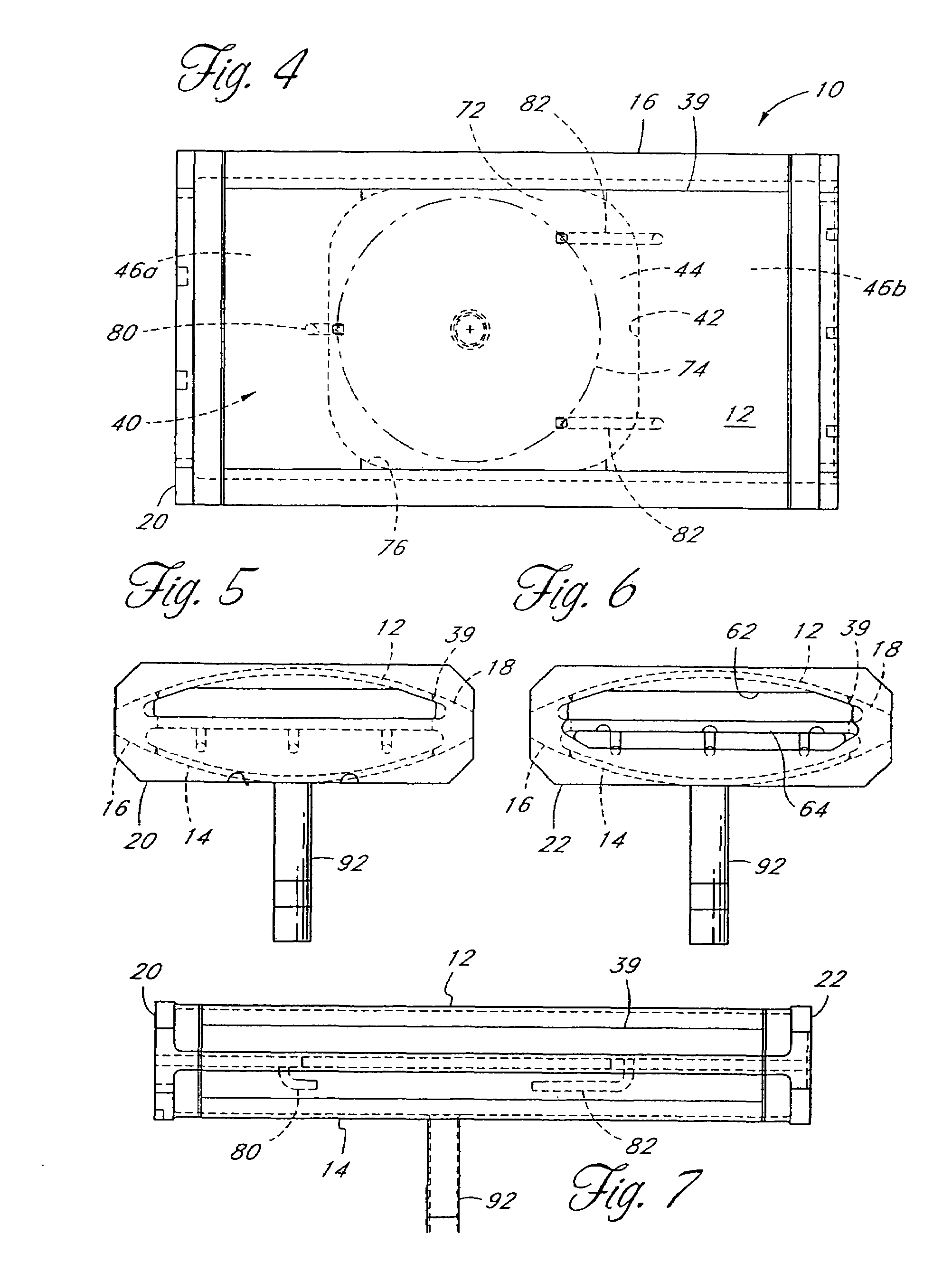

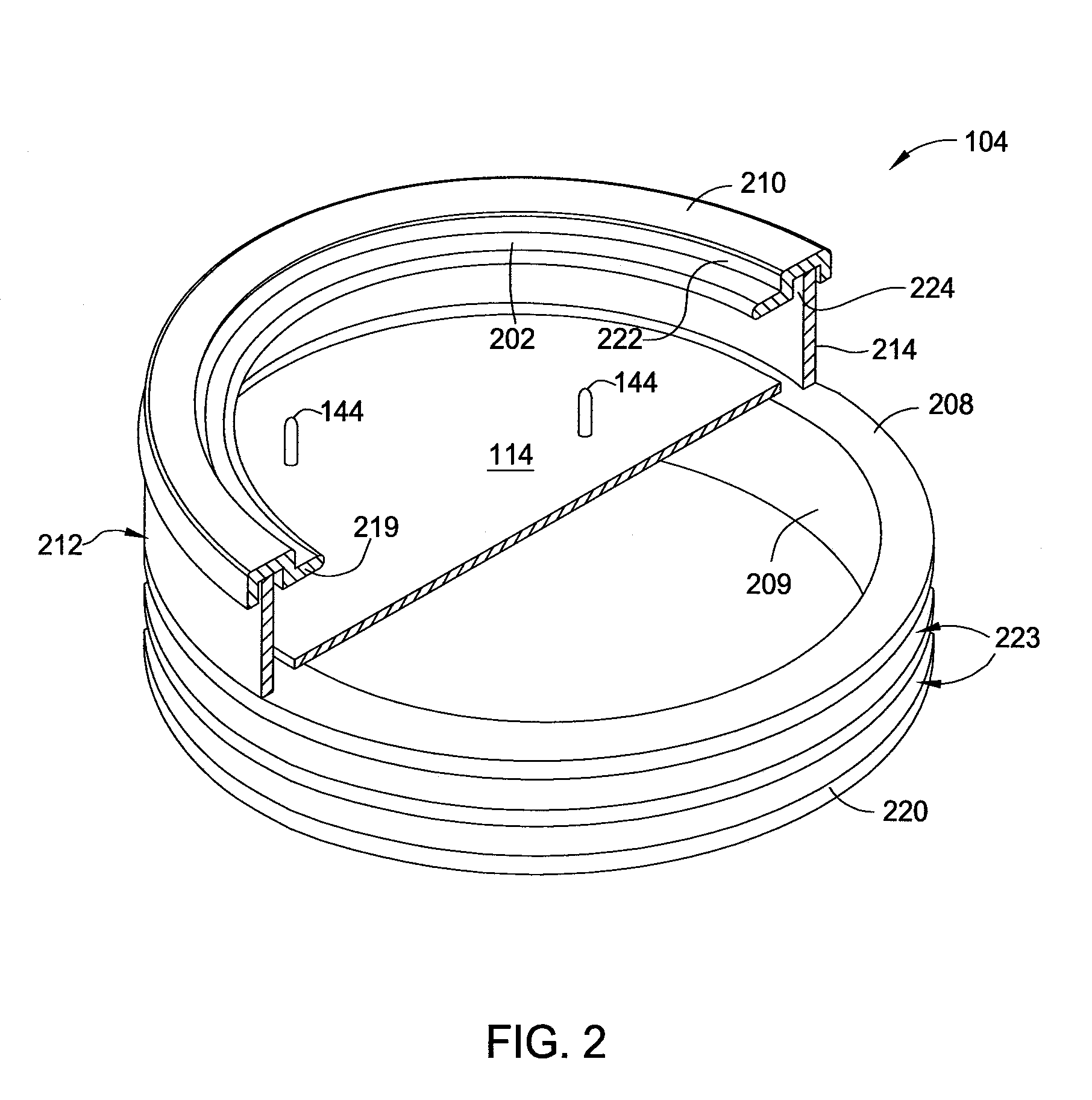

Increased tool utilization/reduction in mwbc for UV curing chamber

ActiveUS20070298362A1Avoid collectingHigh emissivitySemiconductor/solid-state device manufacturingCharge manipulationUV curingInjection port

A pump liner is used to direct a laminar flow of purge gas across a workpiece to remove contaminants or species outgassed or otherwise produced by the workpiece during processing. The pump liner can take the form of a ring having a plurality of injection ports, such as slits of a variety of shapes and / or sizes, opposite a plurality of receiving ports in order to provide the laminar flow. The flow of purge gas is sufficient to carry a contaminant or outgassed species from the processing chamber in order to prevent the collection of the contaminants on components of the chamber. The pump liner can be heated, via conduction and irradiation from a radiation source, for example, in order to prevent the condensation of species on the liner. The pump liner also can be anodized or otherwise processed in order to increase the emissivity of the liner.

Owner:APPLIED MATERIALS INC

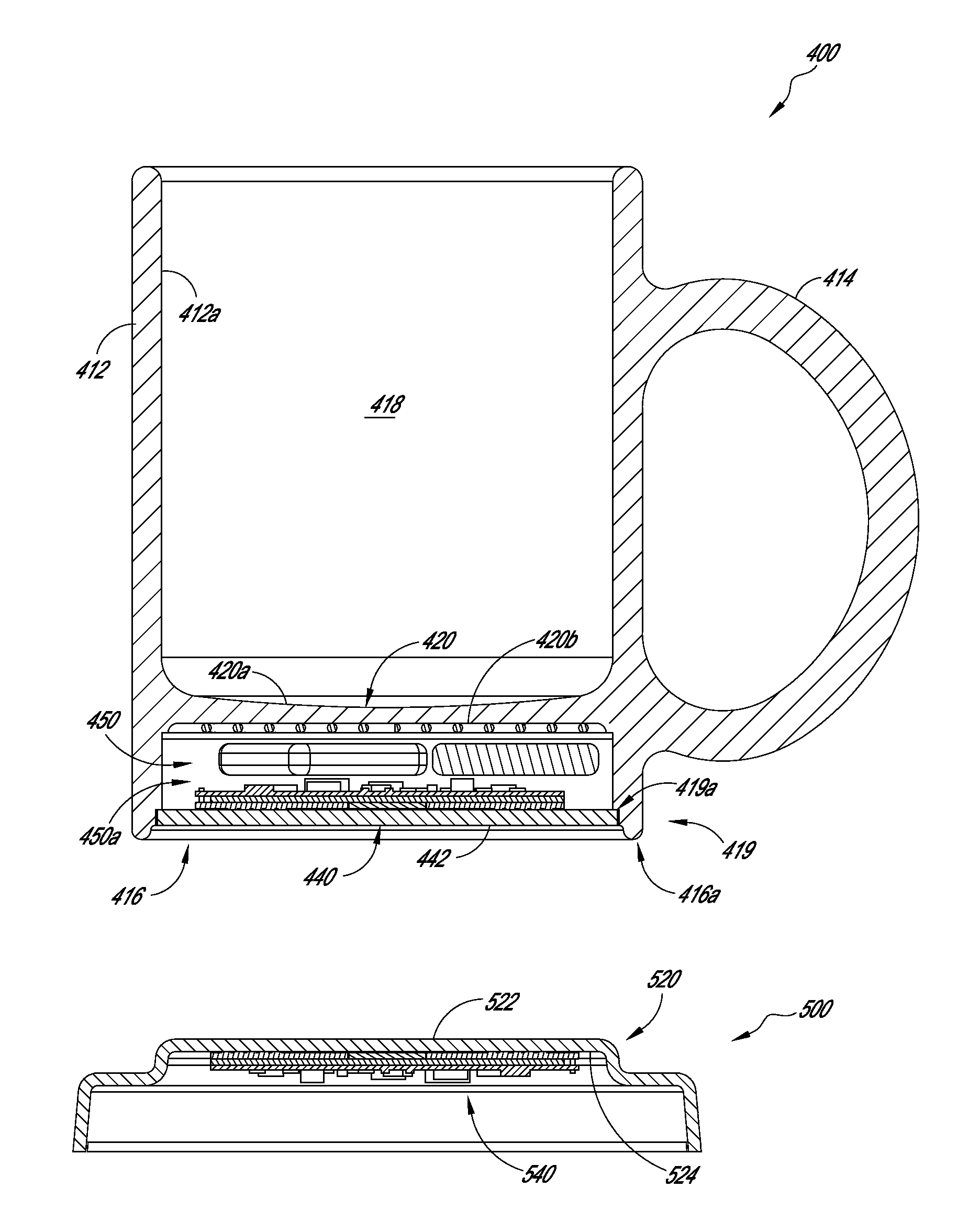

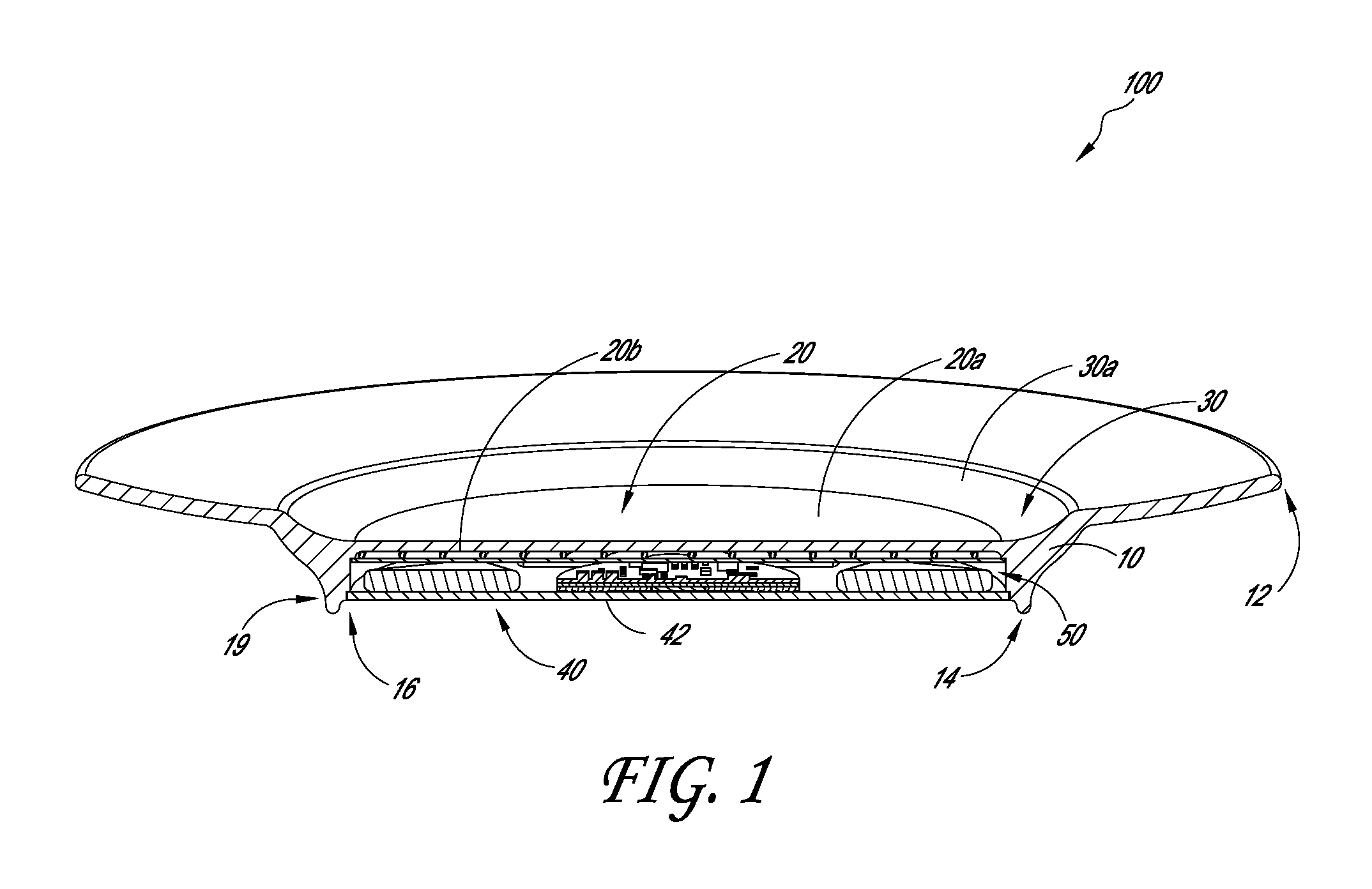

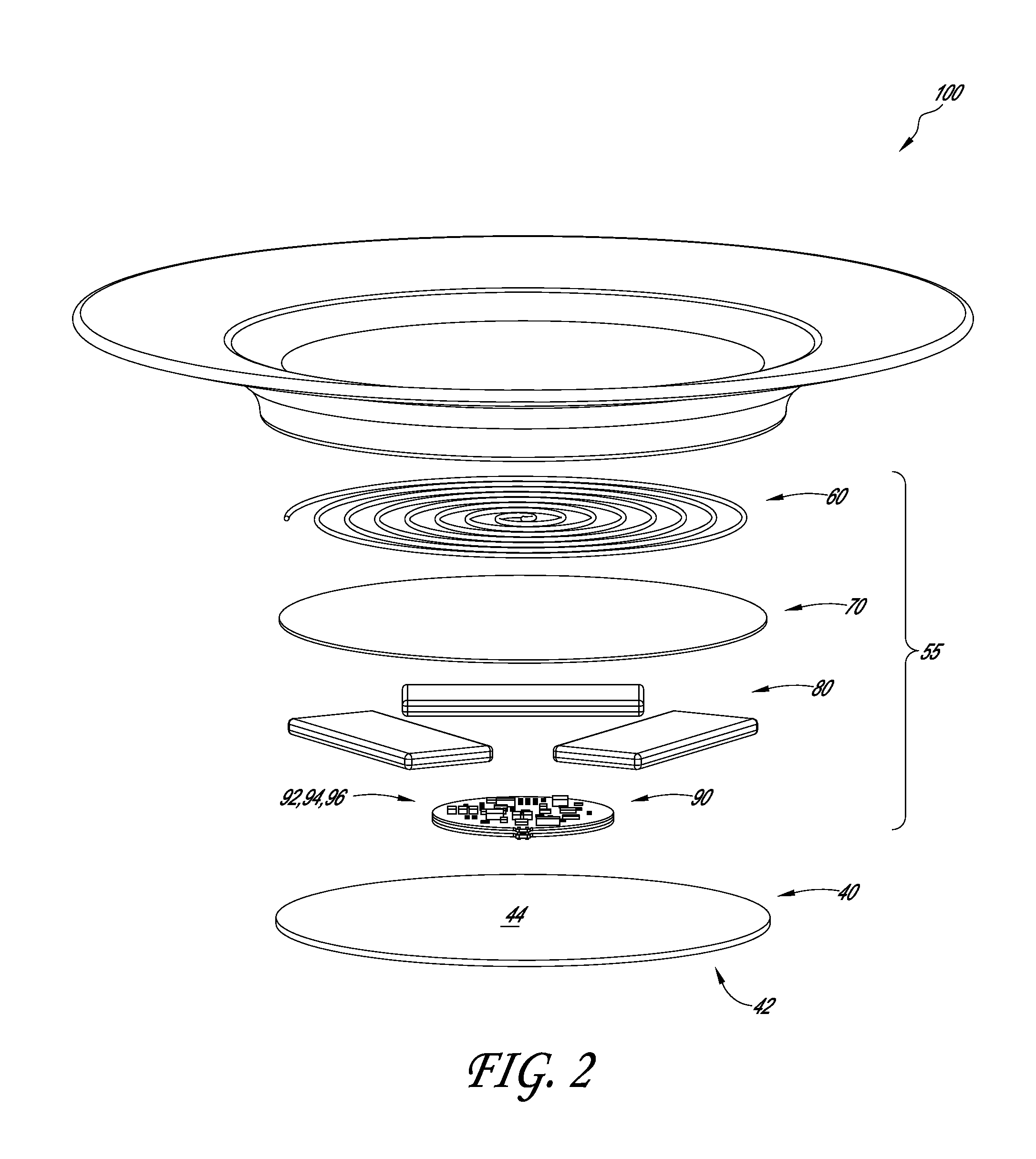

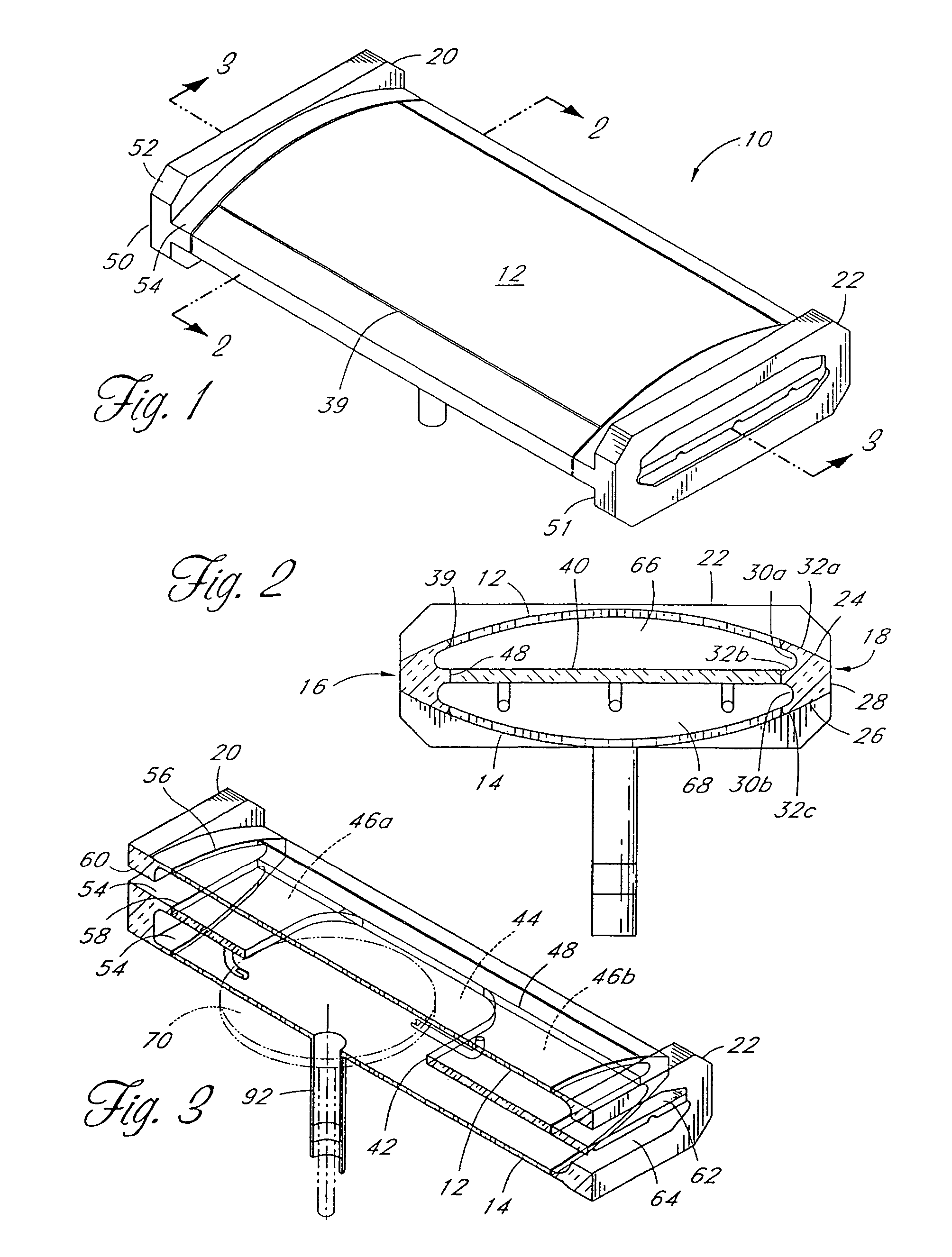

Heated or cooled dishwasher safe dishware and drinkware

An actively heated mug or travel mug is provided. The mug or travel mug can include a body that receives a liquid therein and a heating system at least partially disposed in the body. The heating system can include one or more heating elements that heat a surface of the receiving portion of the body and one or more energy storage devices. The mug or travel mug can include a wireless power receiver that wirelessly receives power from a power source and control circuitry configured to charge one or more power storage elements and to control the delivery of electricity from the one or more power storage elements to the one or more heating elements. The mug or travel mug also can have one or more sensors that sense a parameter of the liquid or sense a parameter of the heating system and communicates the sensed information to the control circuitry. The control circuitry can turn on, turn off, and / or operate the heating element to actively heat at least a portion of the body to maintain the liquid in a heated state generally at a user selected temperature setting based at least in part on the sensed parameter information. The mug or travel mug can also be paired with a remote device or mobile electronic device to send or receive communications or commands.

Owner:EMBER TECH INC

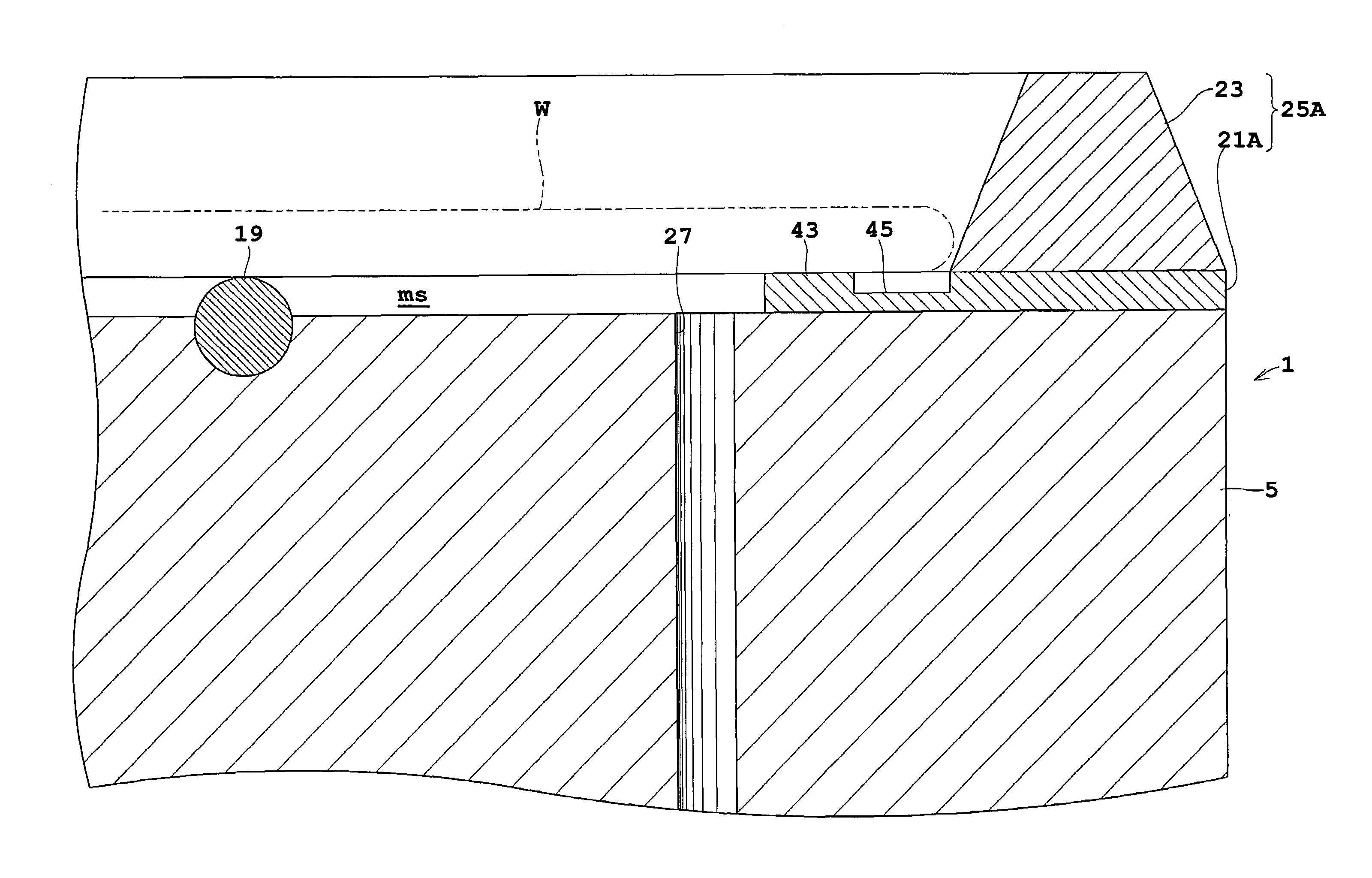

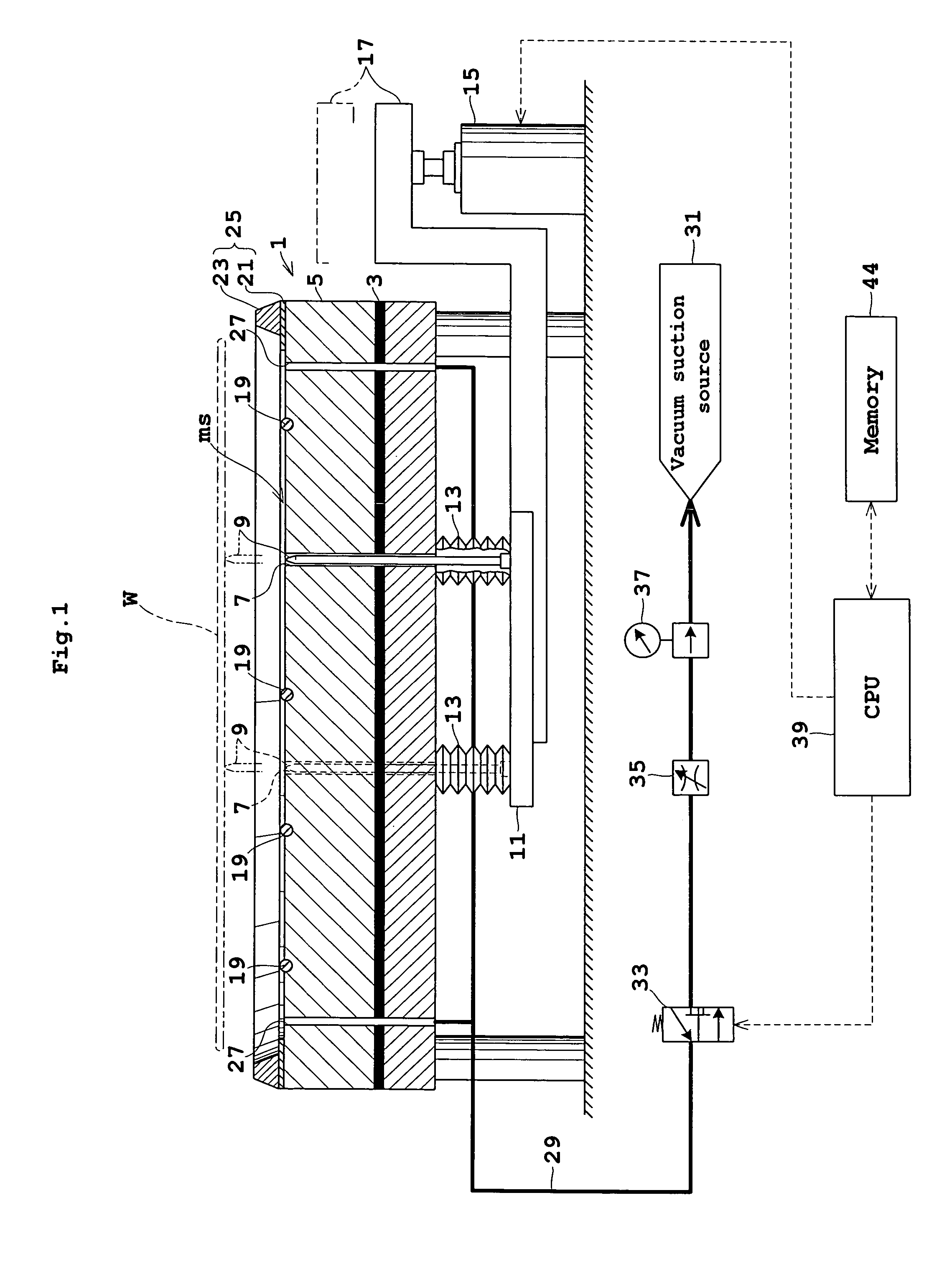

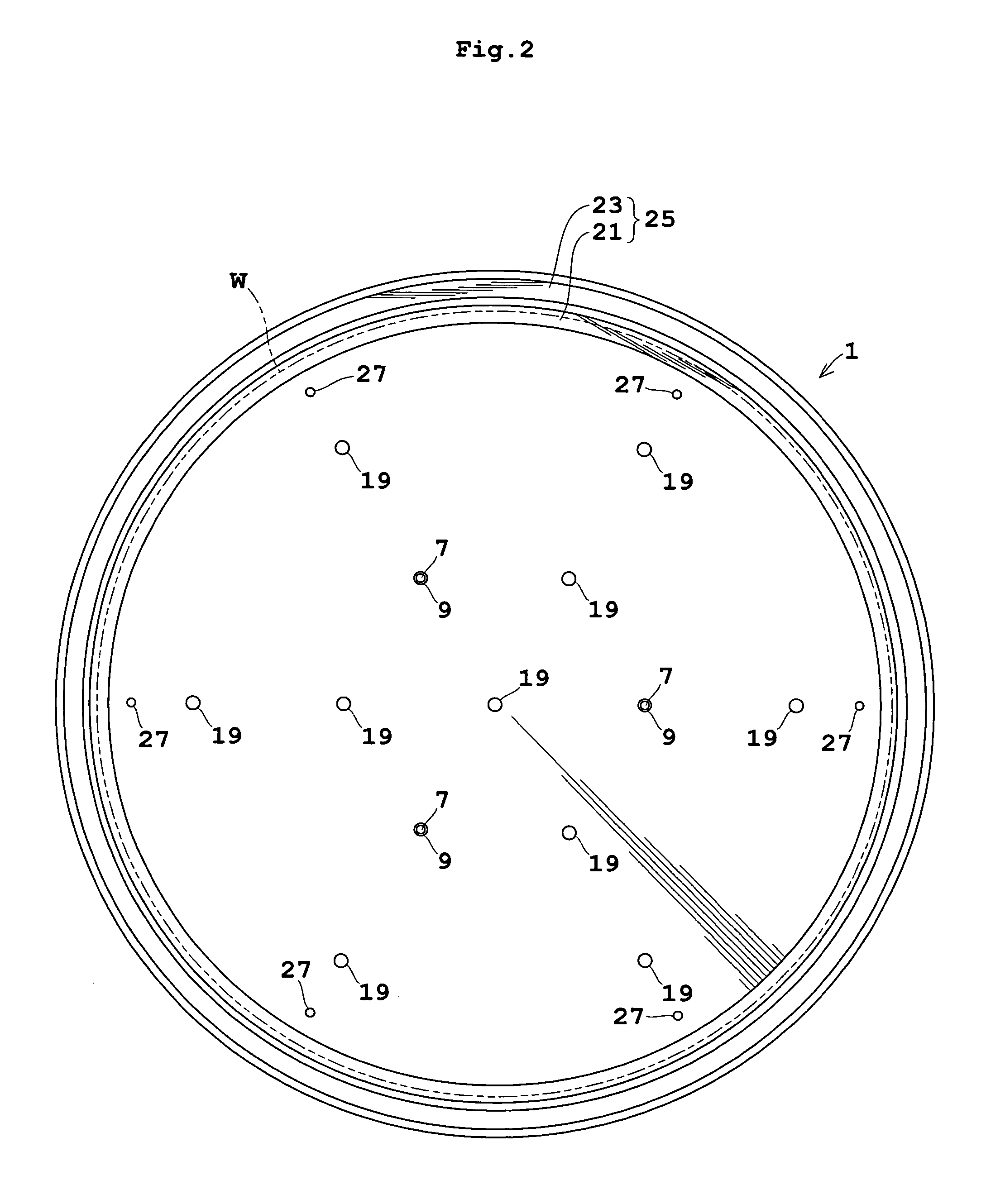

Substrate heat treatment apparatus

ActiveUS7432476B2Efficient actionEfficient use ofMuffle furnacesSemiconductor/solid-state device manufacturingMechanical engineeringHeat treated

Owner:DAINIPPON SCREEN MTG CO LTD

Substrate heat treatment apparatus

ActiveUS8003919B2Efficient heat treatmentEfficiently inhibiting sagging of a substrateMuffle furnacesCharge supportsIsoetes triquetraEngineering

Owner:DAINIPPON SCREEN MTG CO LTD

Substrate support

InactiveUS6917755B2Minimize damageProvide spaceDrying solid materials with heatMuffle furnacesSupport surfaceEngineering

An apparatus for supporting a substrate is described that has a ball adapted to minimize damage between the substrate support and the substrate supported thereon. In one embodiment, an apparatus for supporting a substrate includes ball disposed on an inclined ball support surface. The ball support surface is adapted to bias the ball toward one side of the ball support surface thereby providing space for the ball to roll as the substrate supported thereon changes in length when exposed to thermal influences. In another embodiment, the apparatus further comprises a cage adapted to capture the ball to the ball support surface.

Owner:APPLIED MATERIALS INC

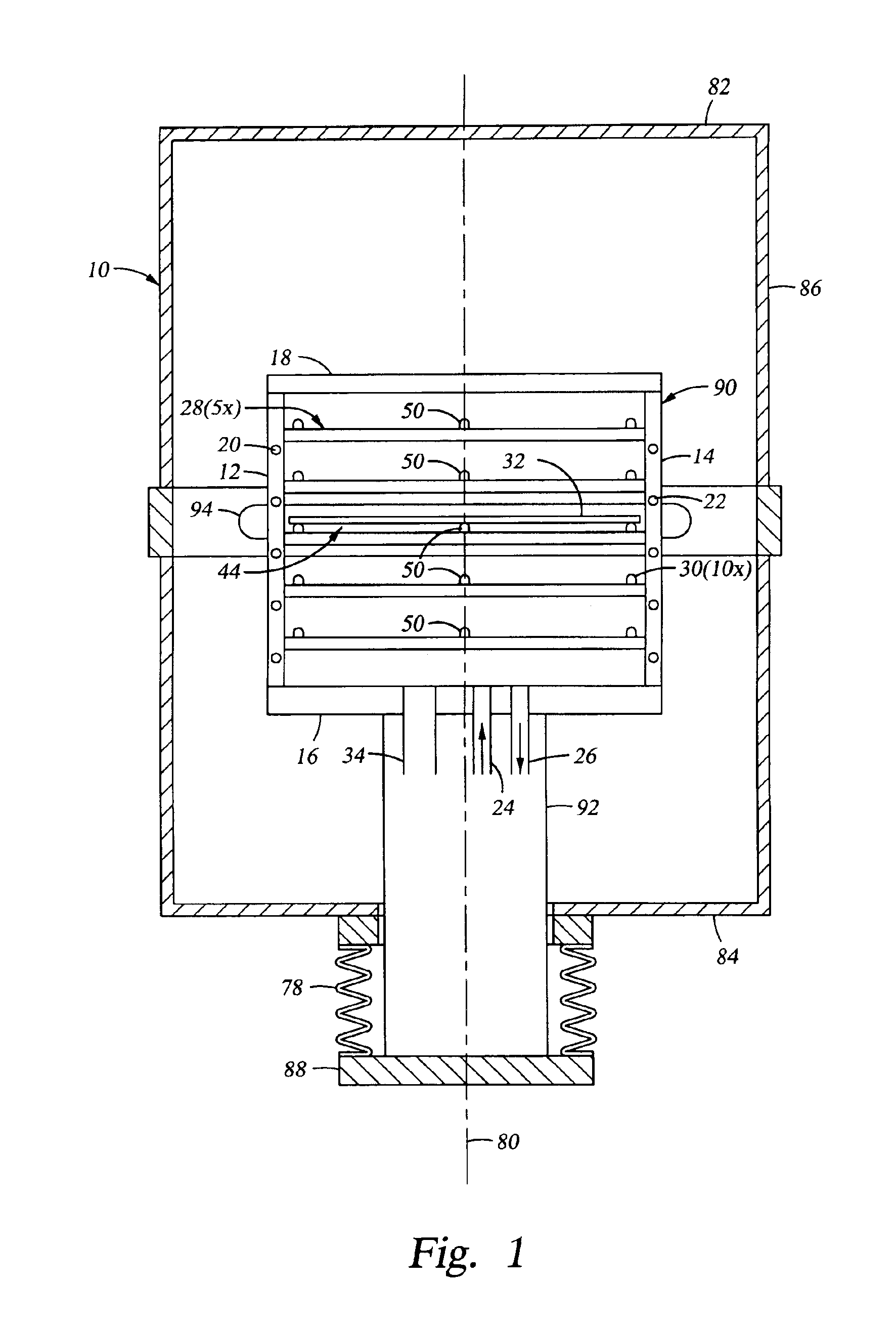

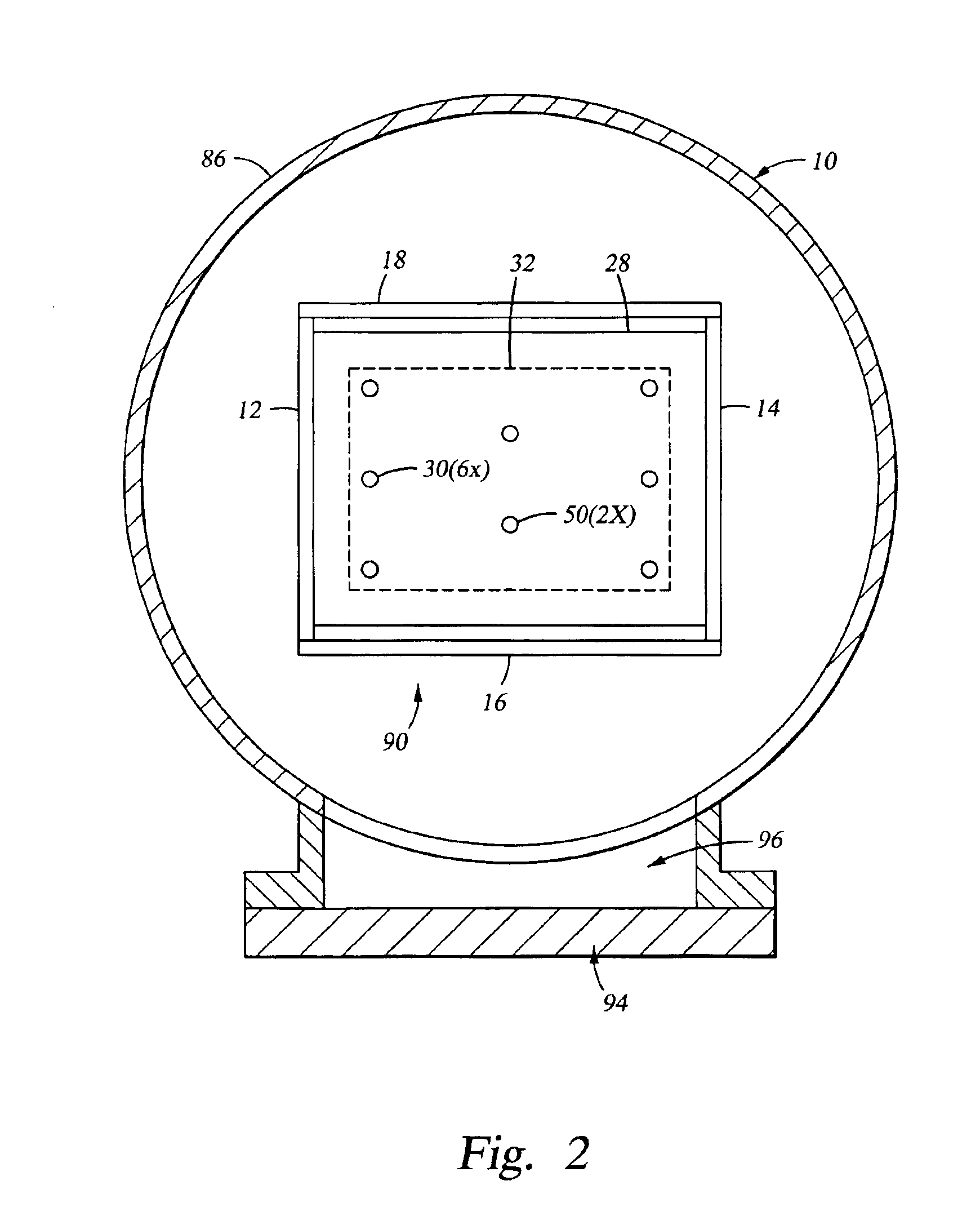

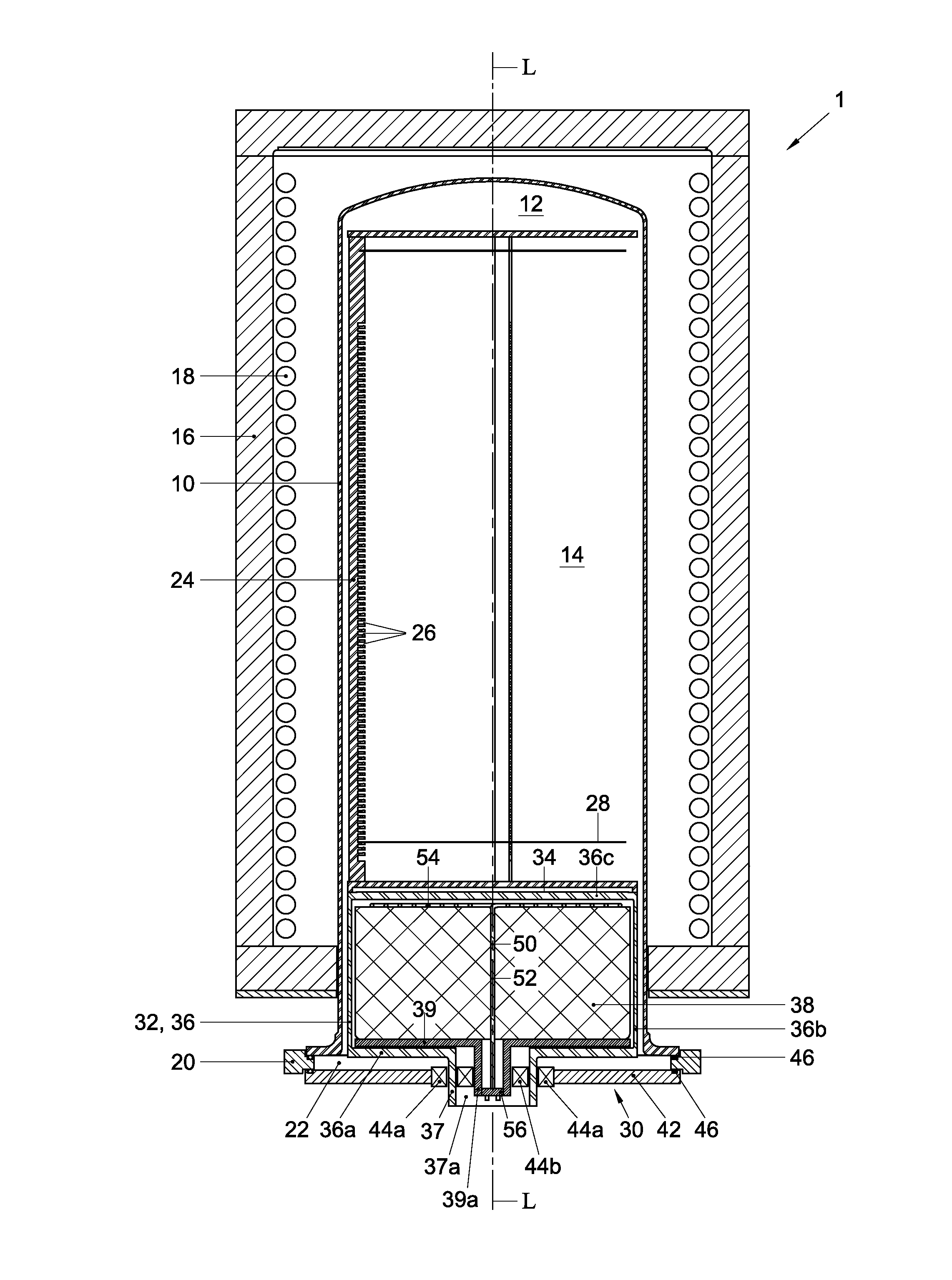

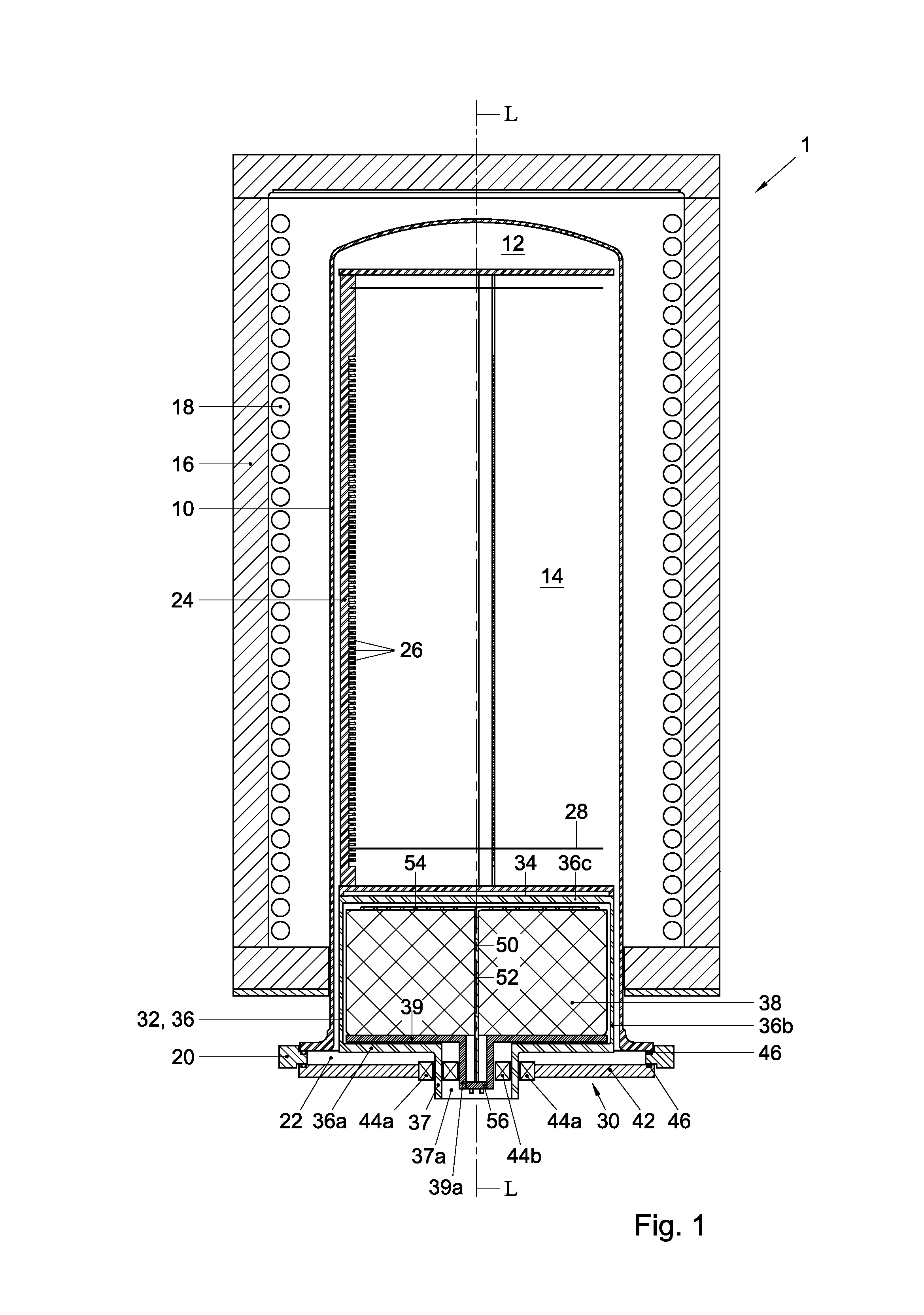

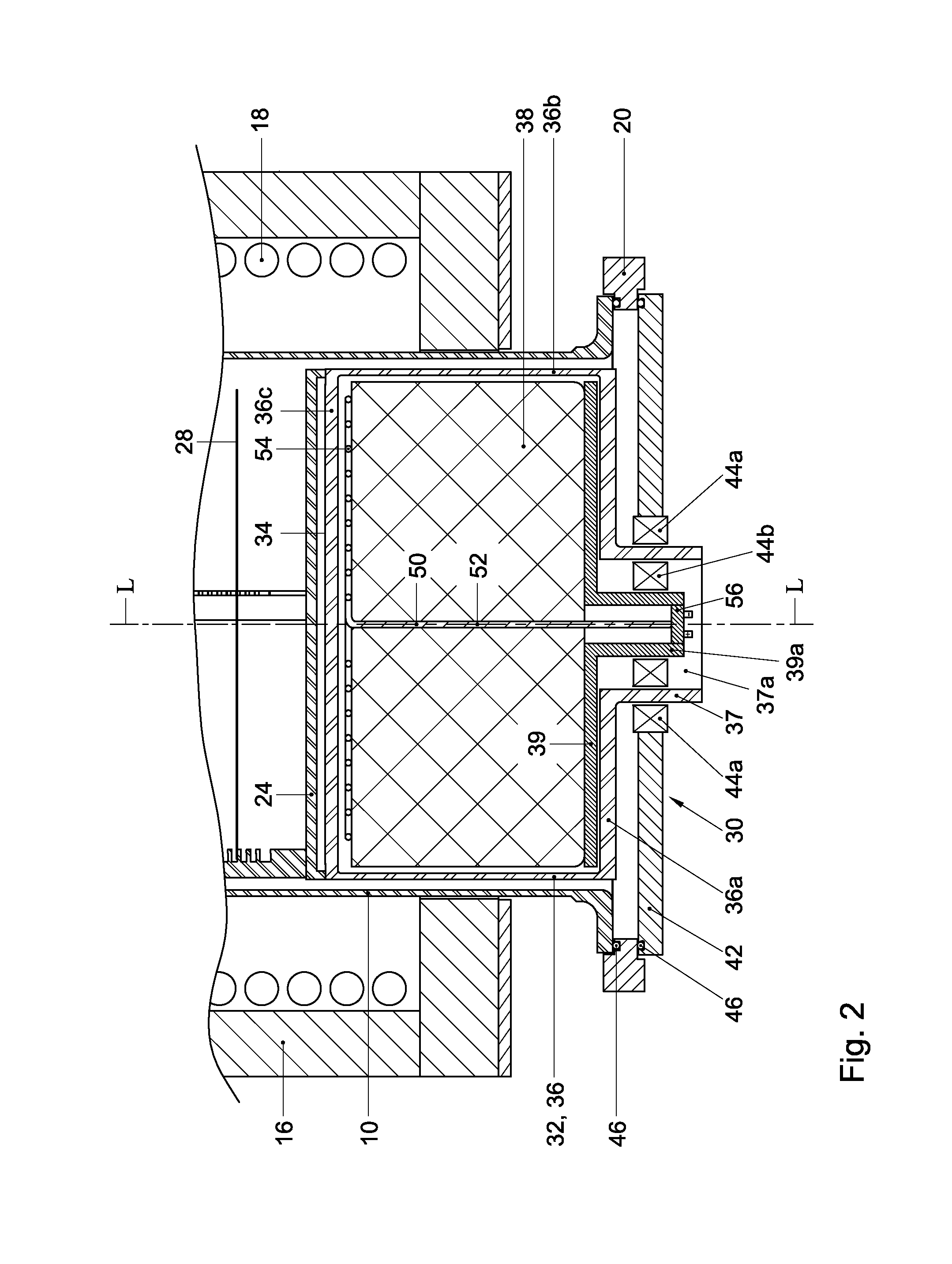

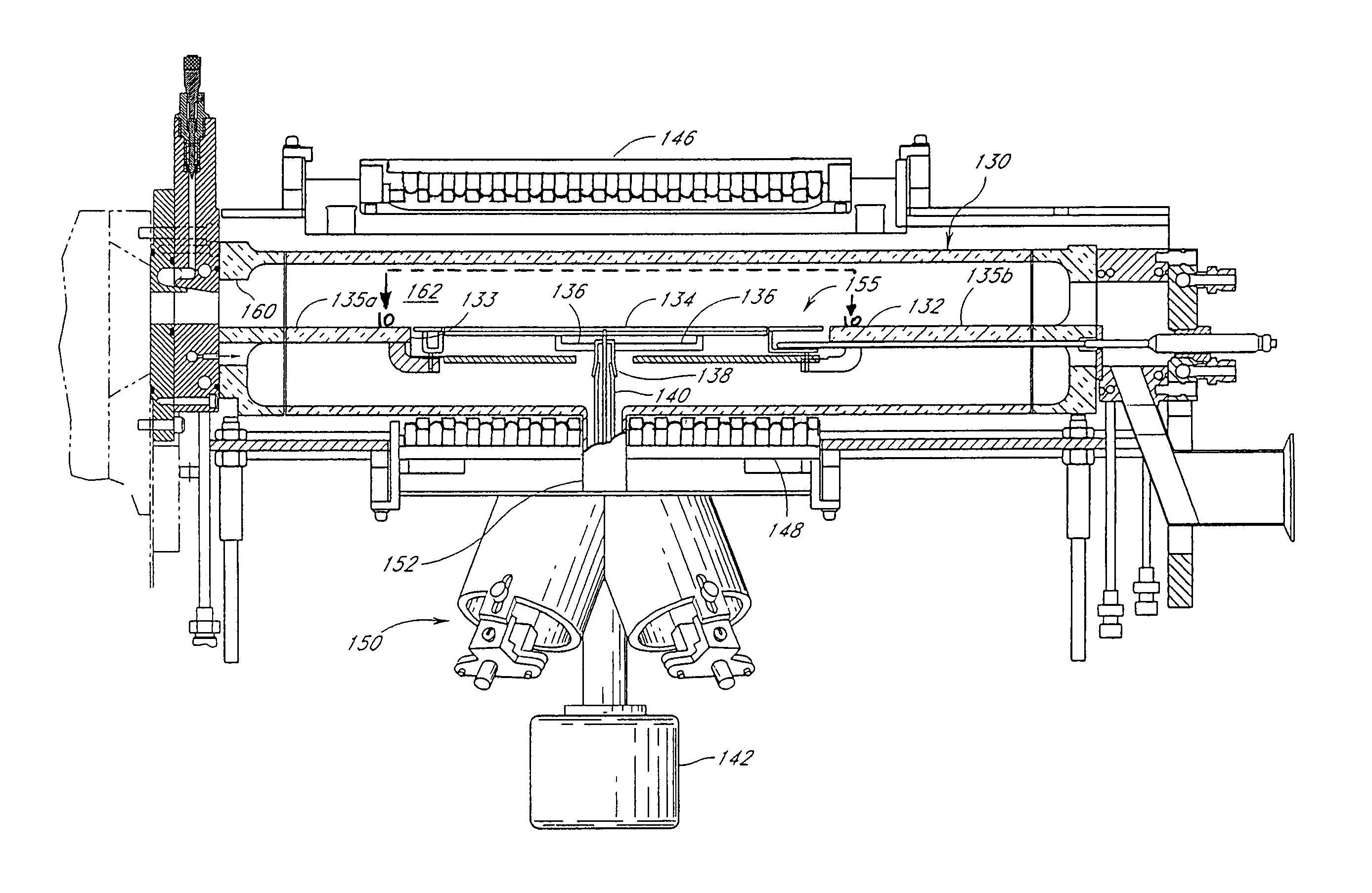

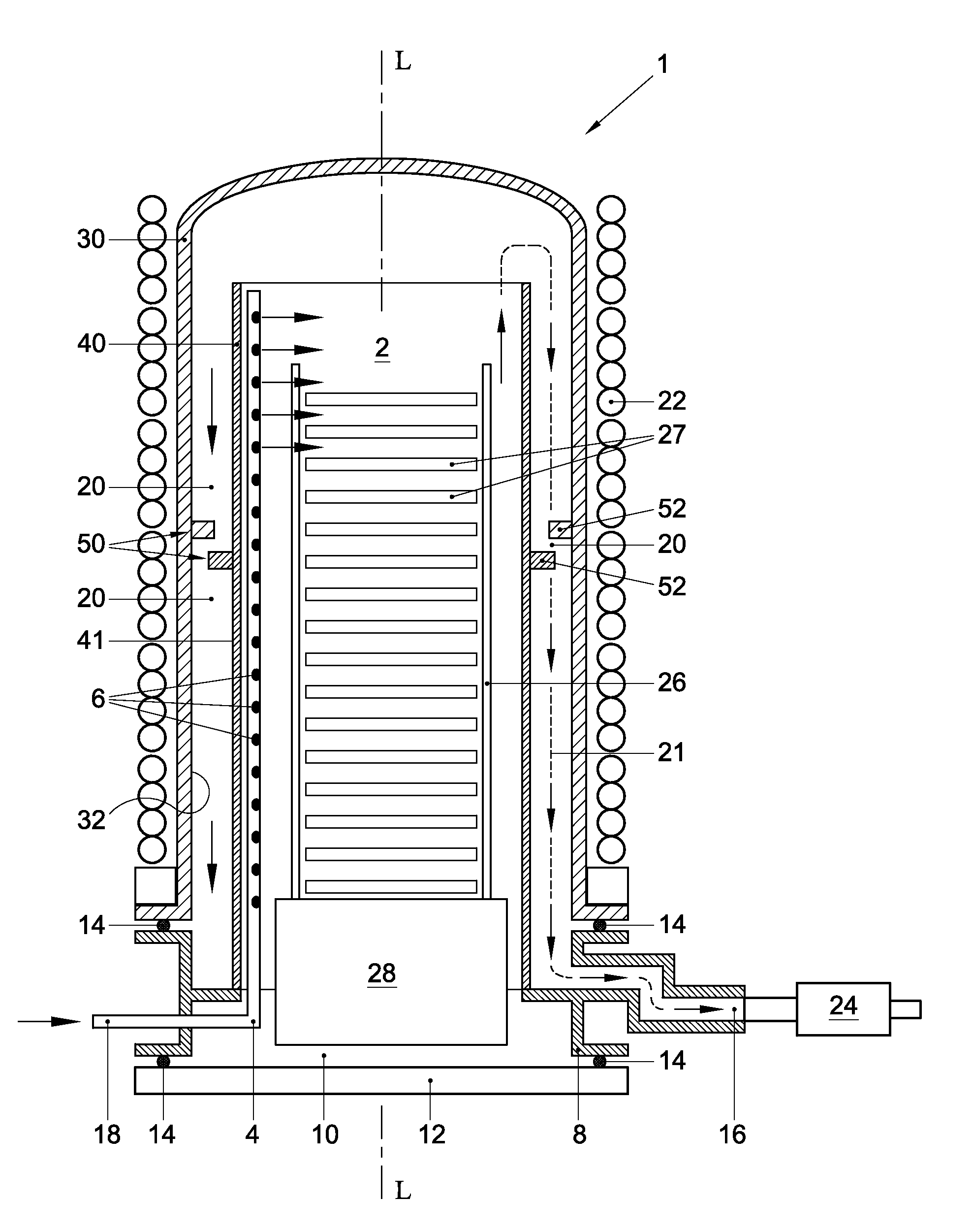

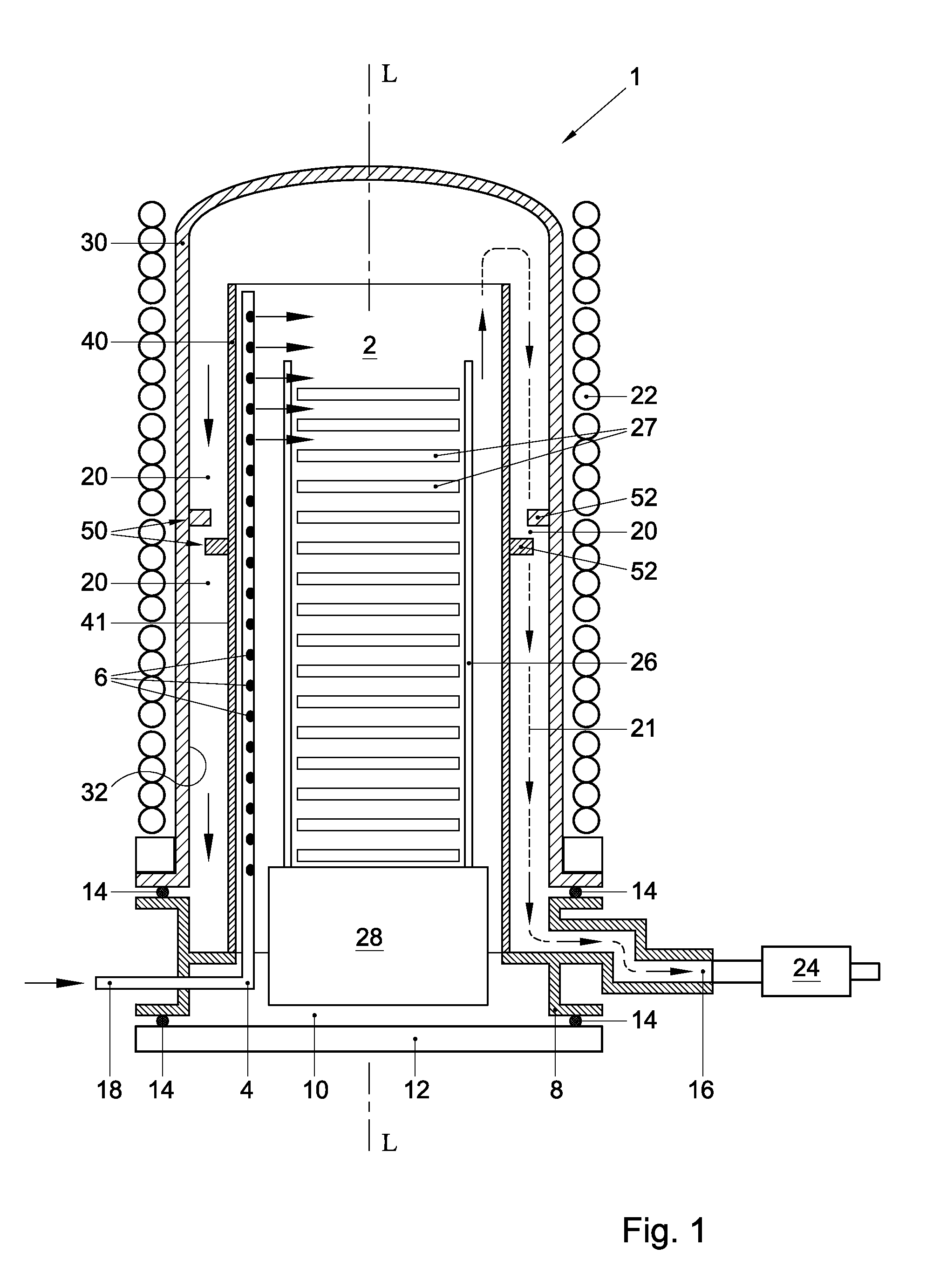

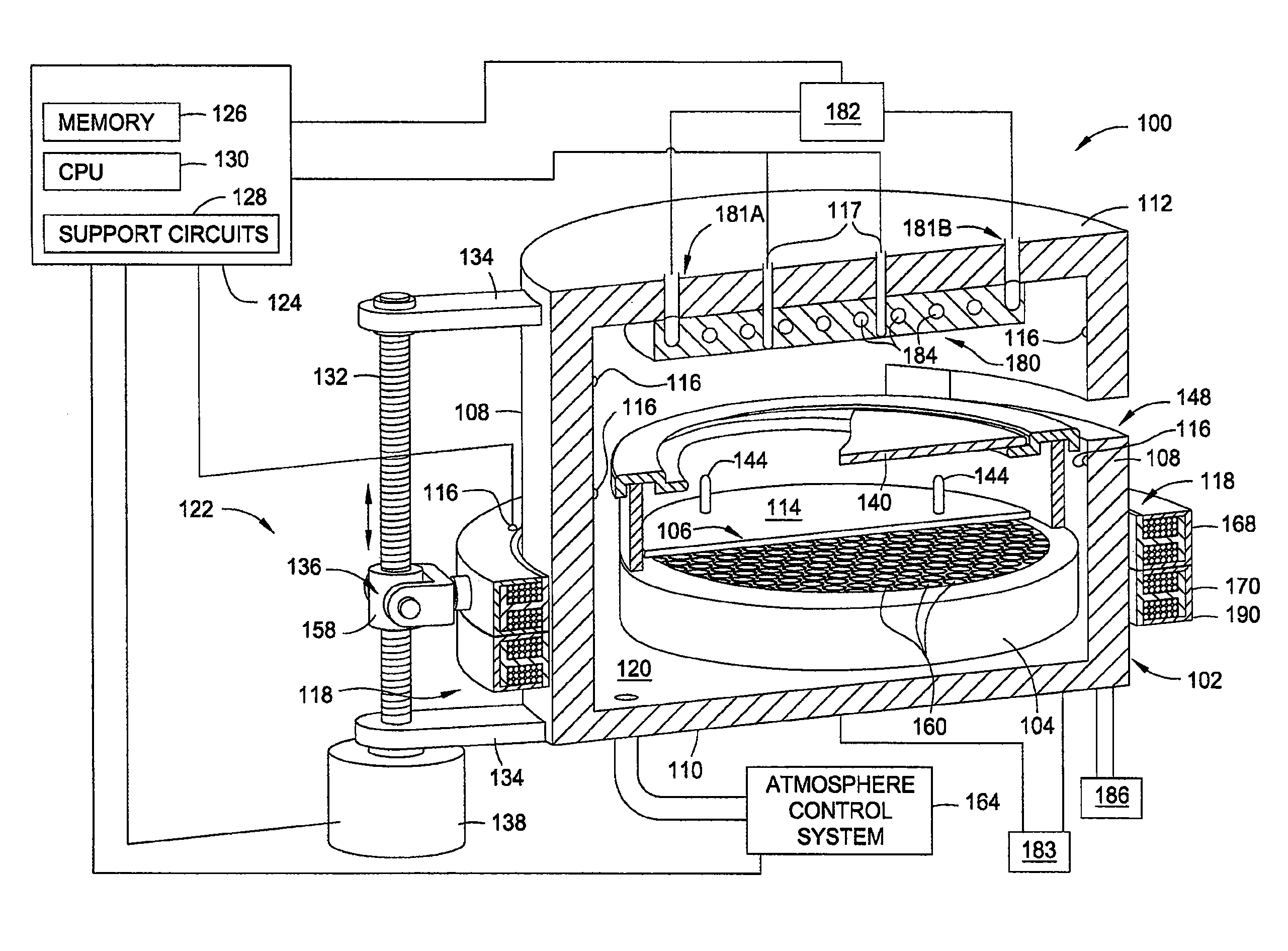

Wafer processing apparatus with heated, rotating substrate support

ActiveUS9018567B2Easy constructionEasy and economical to constructMuffle furnacesCharge supportsEngineeringSemiconductor

A semiconductor substrate processing apparatus (1), comprising a substrate support assembly (30), including a substrate support (32) defining an outer support surface (34) for supporting a substrate or substrate carrier (24) thereon, and a heater (50) comprising a heat dissipating portion (54) that is disposed within the substrate support (32) and that extends underneath and substantially parallel to the support surface (34), said substrate support (32) being rotatably mounted around a rotation axis (L) that extends through said support surface (34), such that the support surface (34) is rotatable relative to the heat dissipating portion (54) of the heater (50).

Owner:ASM IP HLDG BV

High temperature vacuum chuck assembly

ActiveUS20090179365A1Avoid overall overheatingSleeve/socket jointsMuffle furnacesEngineeringElectrical connector

A vacuum chuck and a process chamber equipped with the same are provided. The vacuum chuck assembly comprises a support body, a plurality of protrusions, a plurality of channels, at least one support member supporting the support body, at least one resilient member coupled with the support member, a hollow shaft supporting the support body, at least one electrical connector disposed through the hollow shaft, and an air-cooling apparatus. The support body has a support surface for holding a substrate (such as a wafer) thereon. The protrusions are formed on and project from the support surface for creating a gap between the substrate and the support surface. The channels are formed on the support surface for generating reduced pressure in the gap. The air-cooling apparatus is used for providing air cooling in the vicinity of the electrical connector.

Owner:APPLIED MATERIALS INC

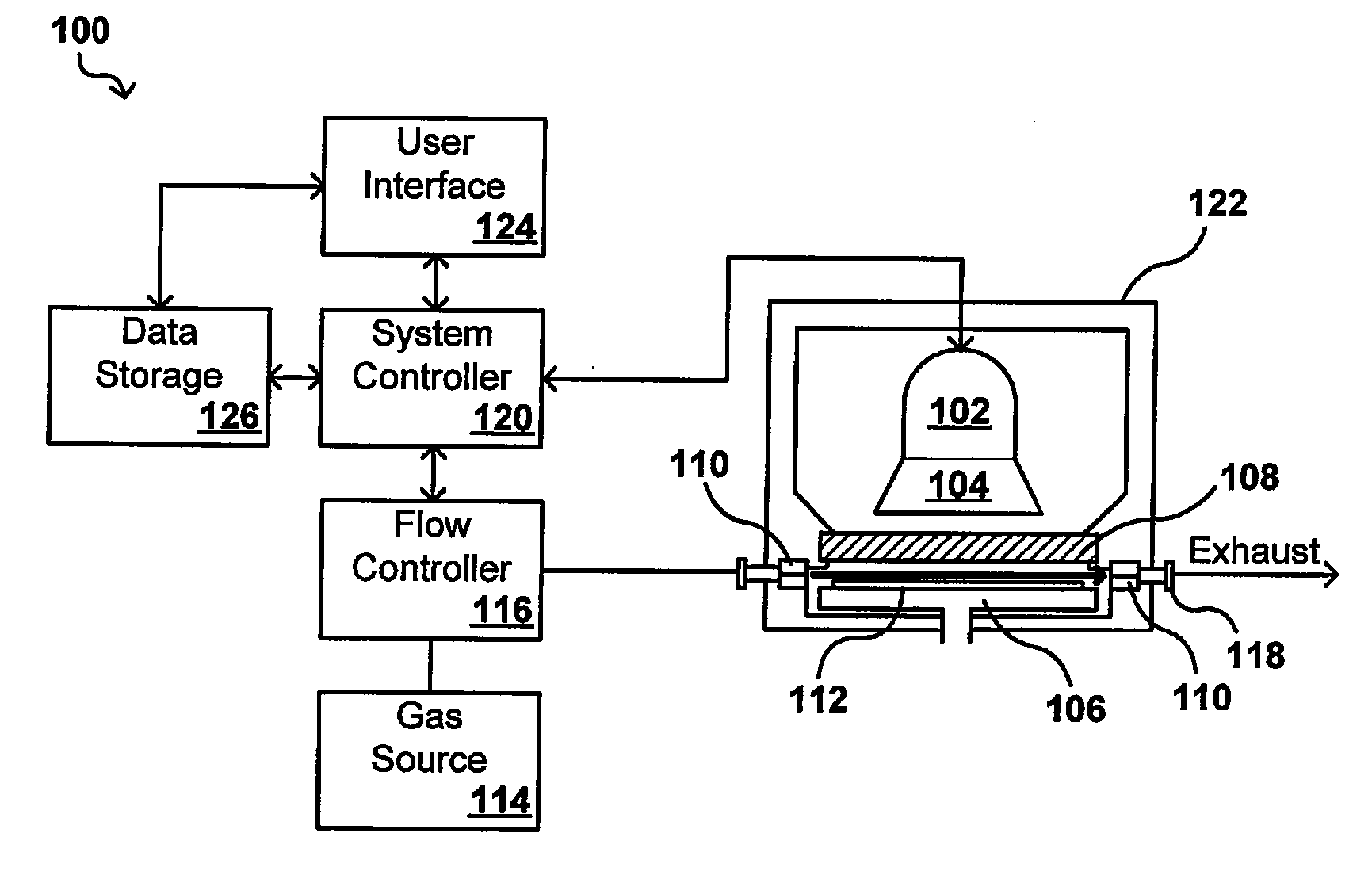

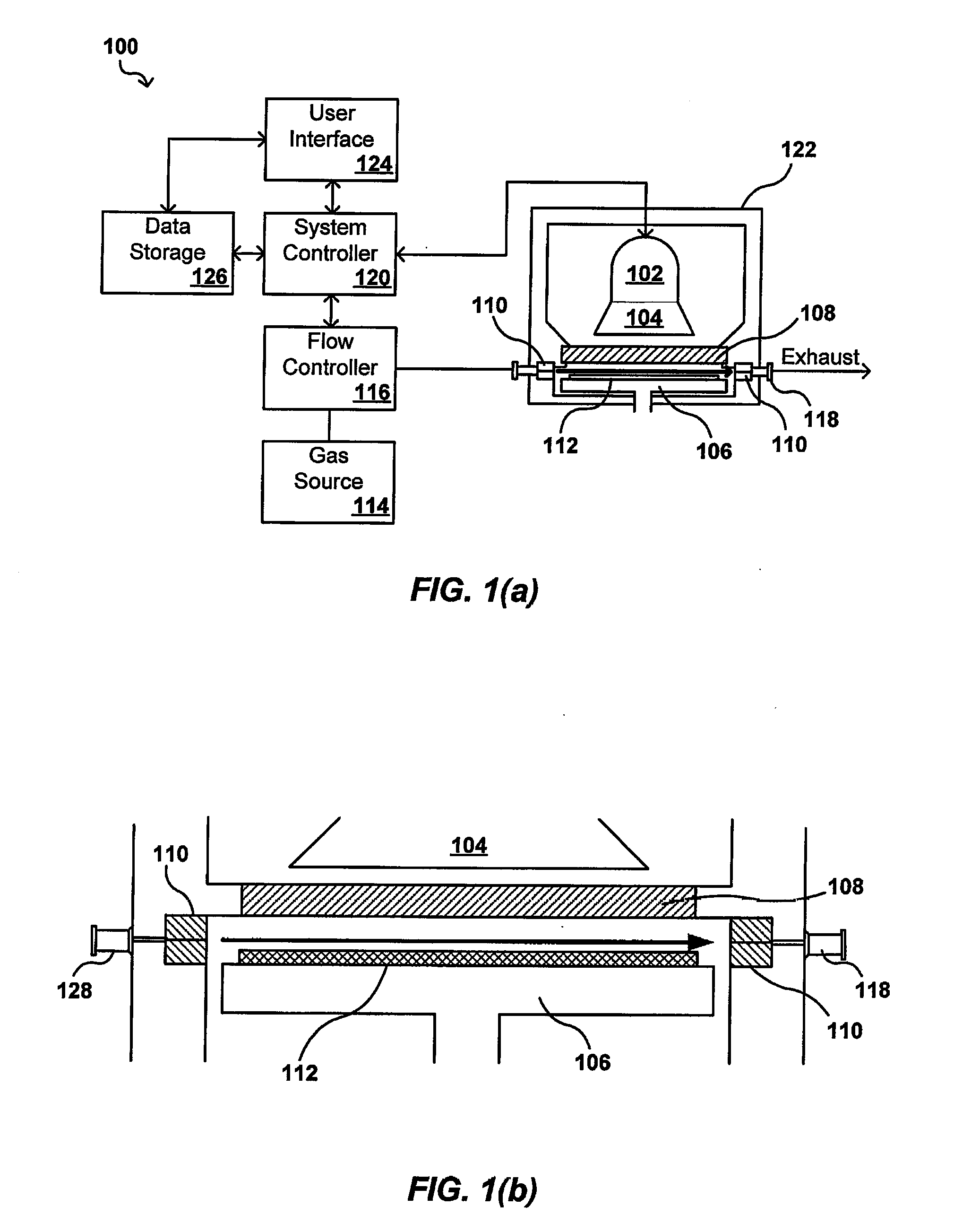

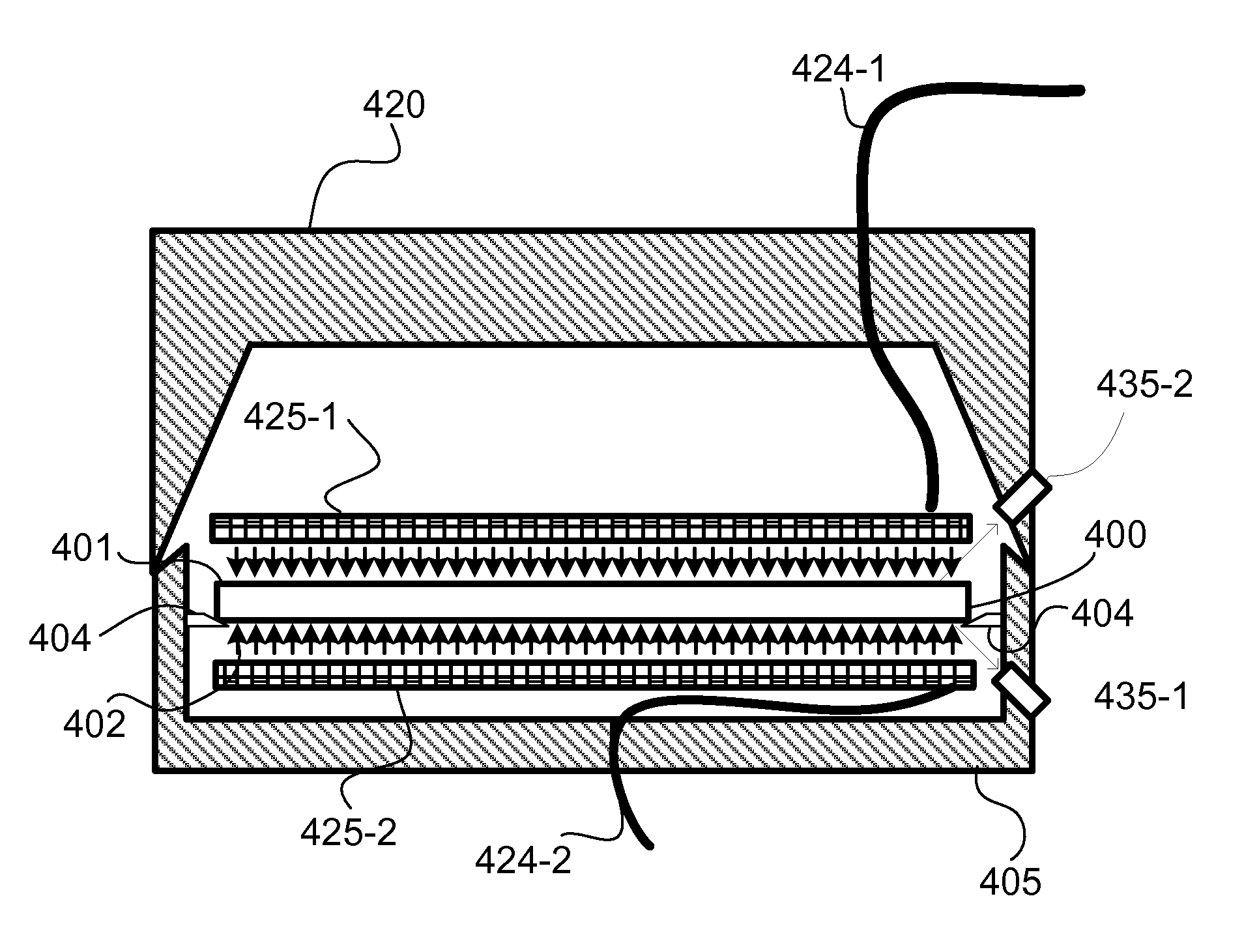

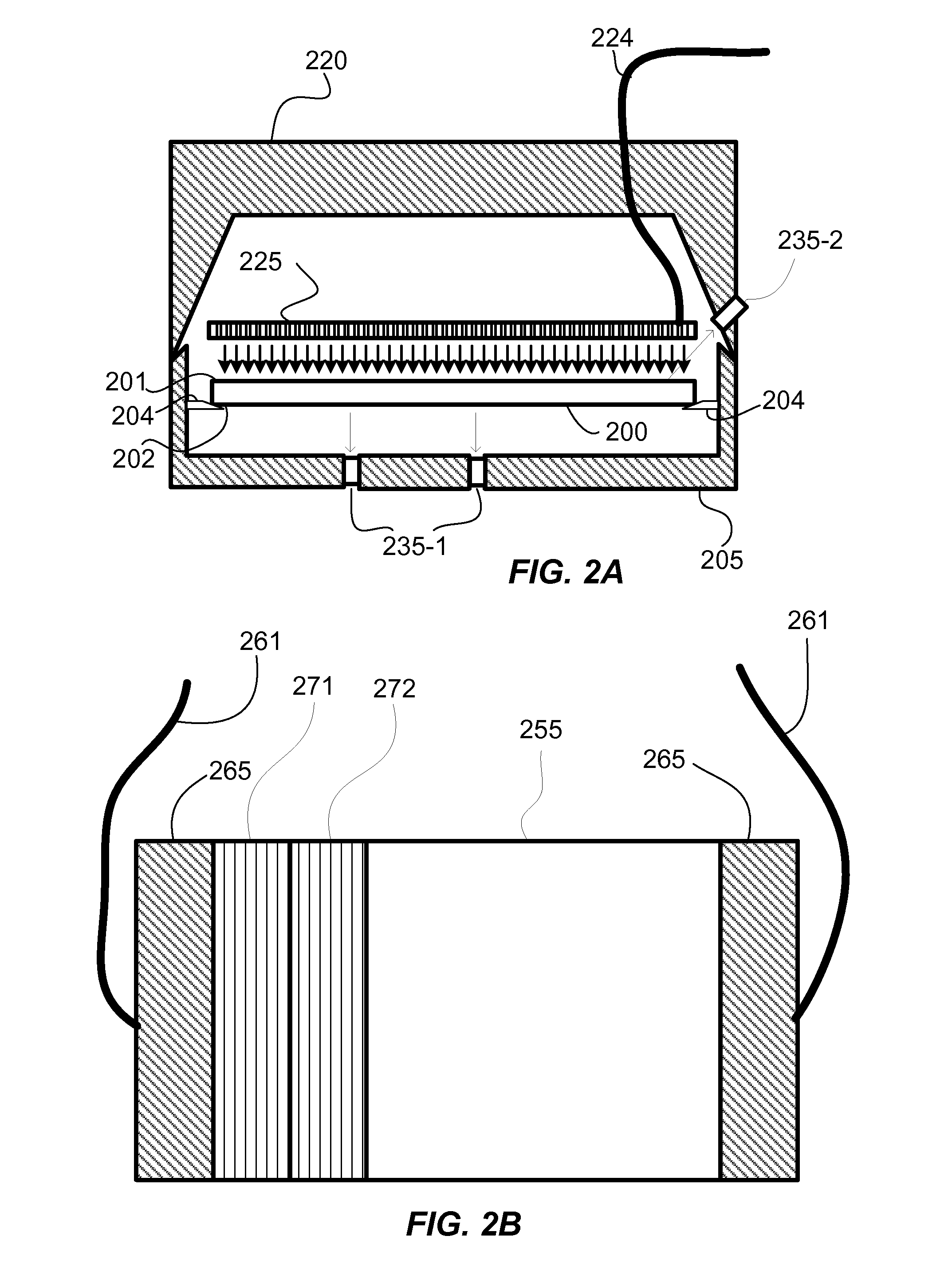

LED substrate processing

ActiveUS8404499B2Improve efficiencyFast response timeSemiconductor/solid-state device testing/measurementMuffle furnacesLong pulseLight-emitting diode

Embodiments of the present invention pertain to substrate processing equipment and methods incorporating light emitting diodes (LEDs) for thermally processing substrates. Such light sources offer a variety of advantages including higher efficiency and more rapid response times. Pulse widths are selectable down to under a millisecond but can be for long pulses up to and exceeding a second. LEDs are preferable to tungsten-halogen lamps even in circumstances that allow longer processing times, since LEDs produce light with greater than 50% efficiency and tungsten-halogen lamps operate with less than 5% efficiency.

Owner:APPLIED MATERIALS INC

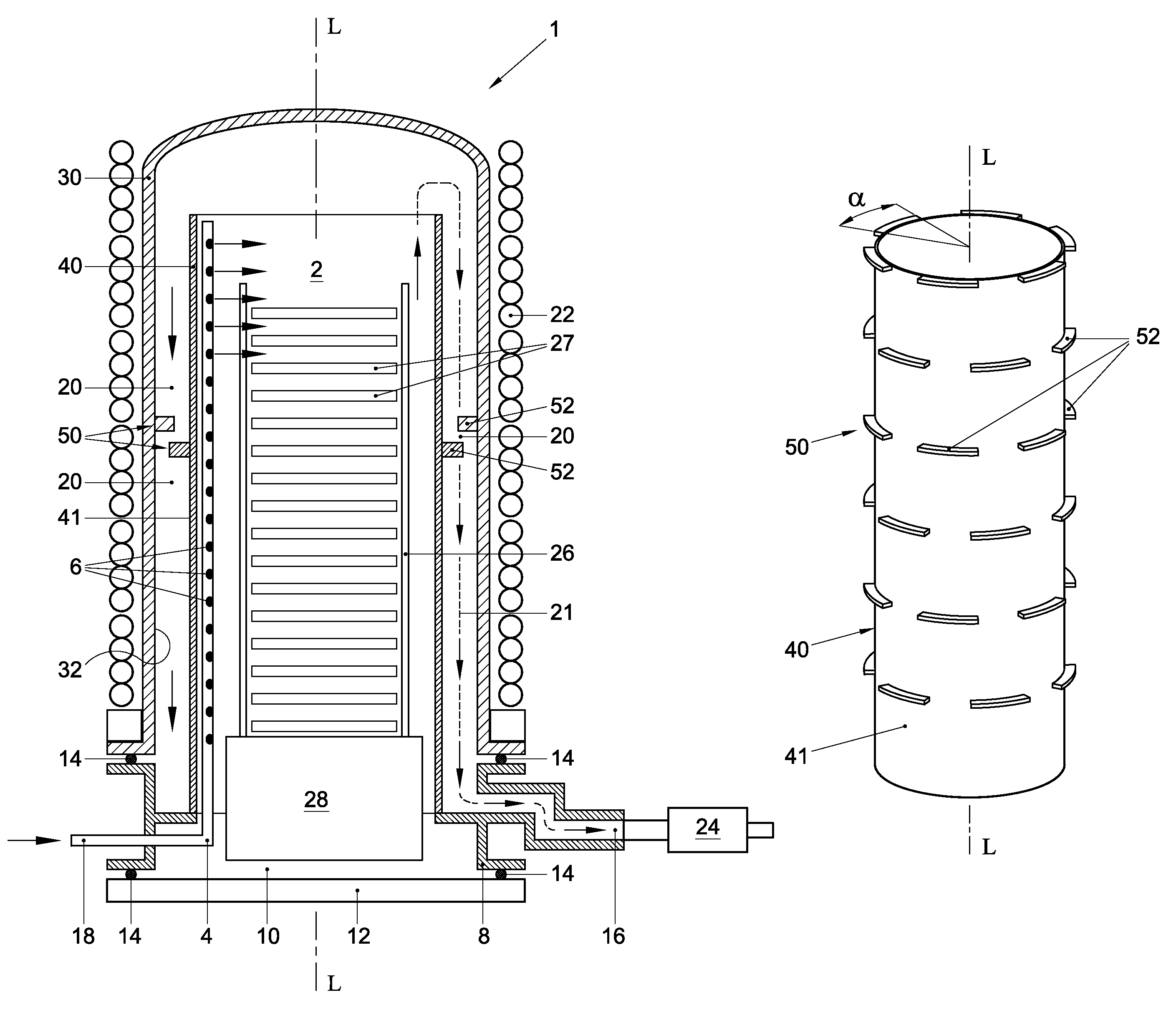

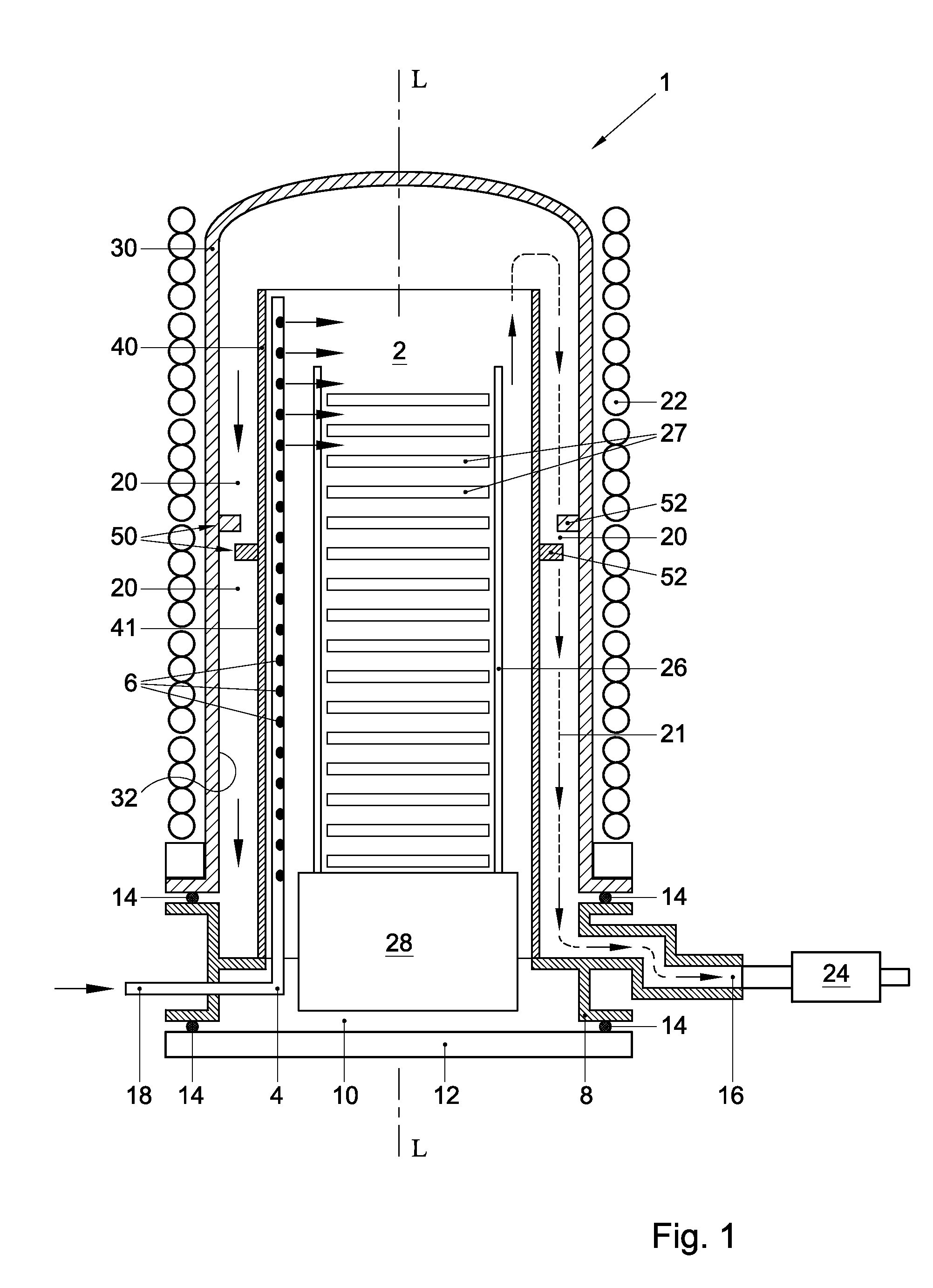

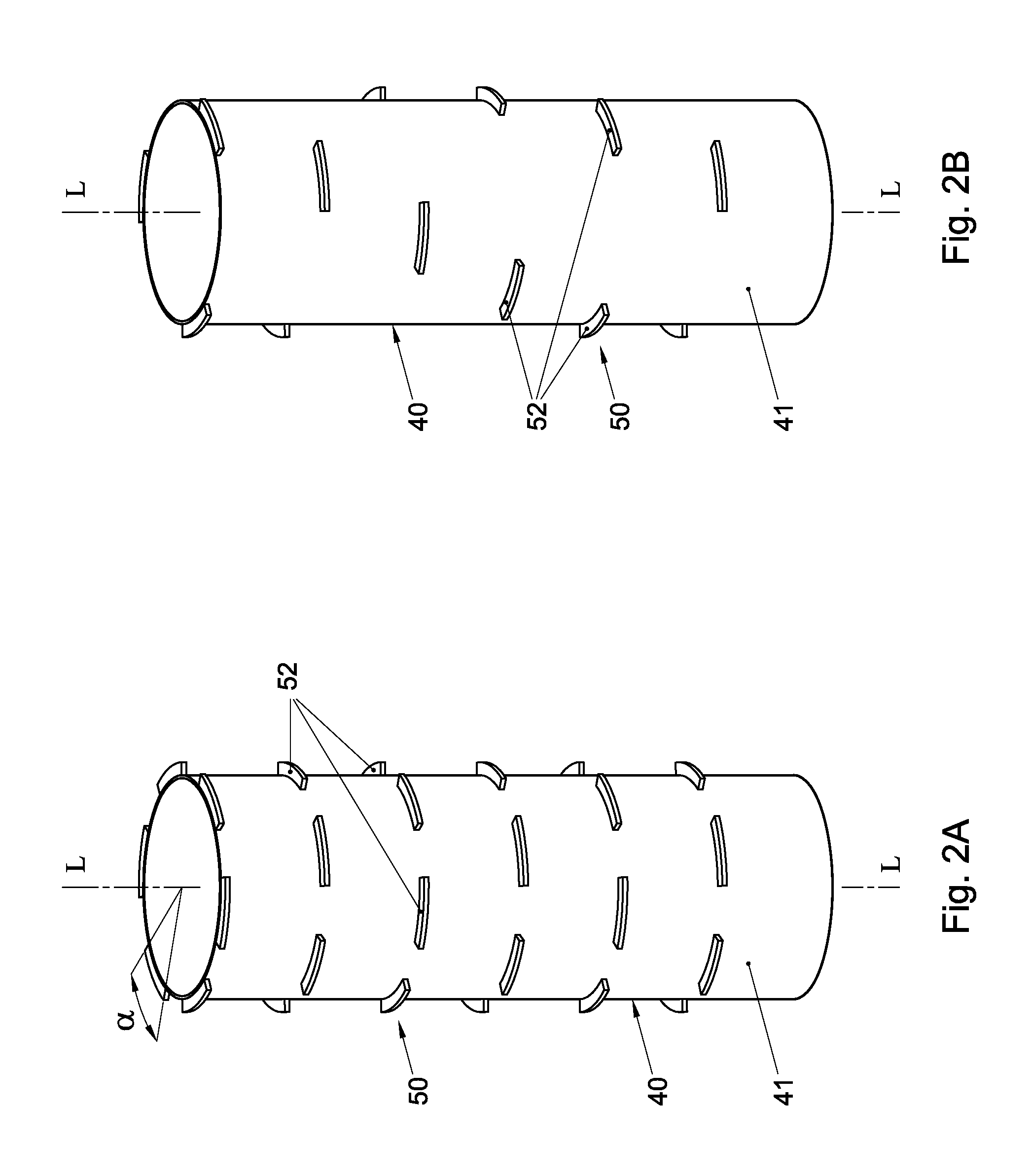

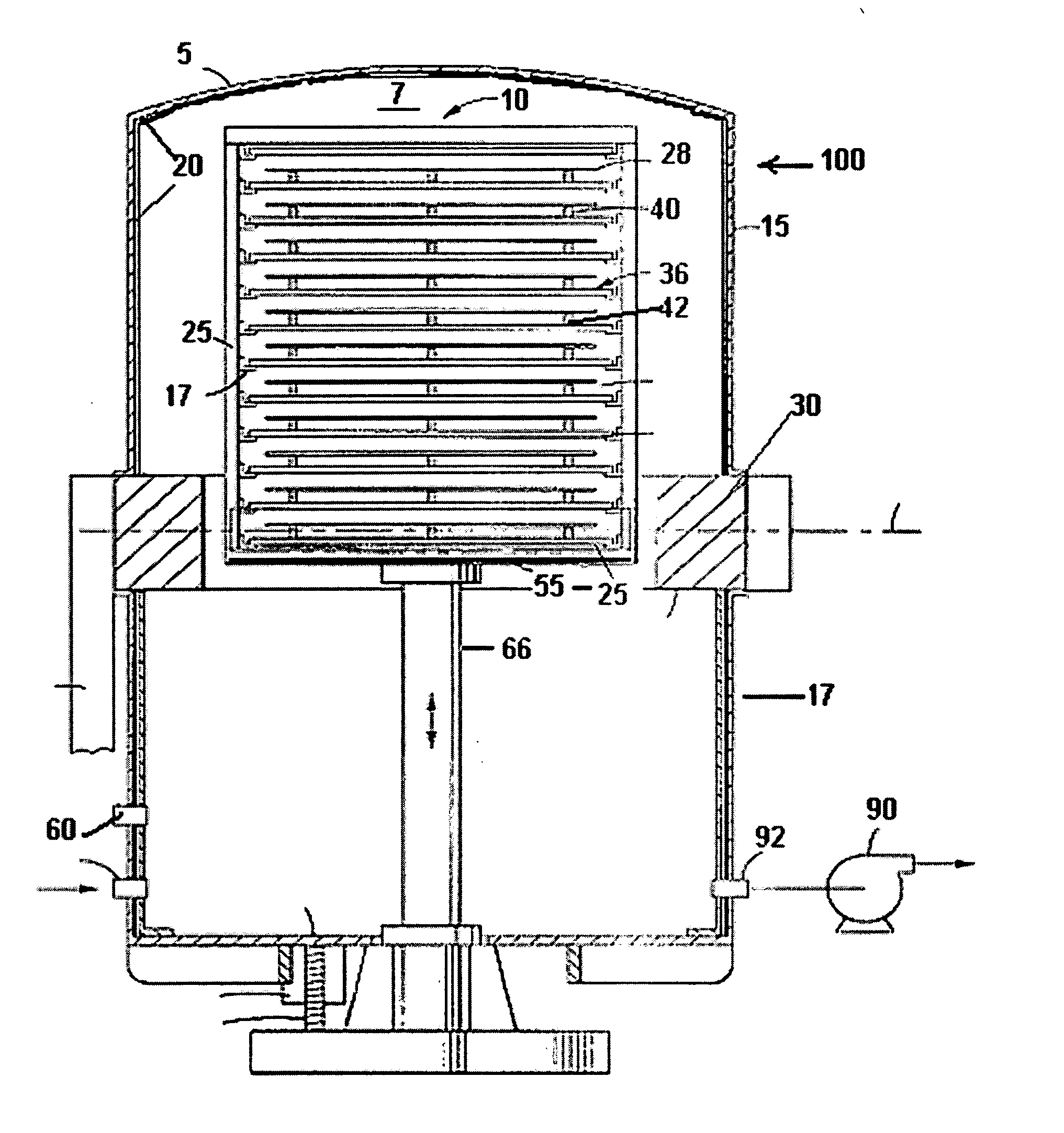

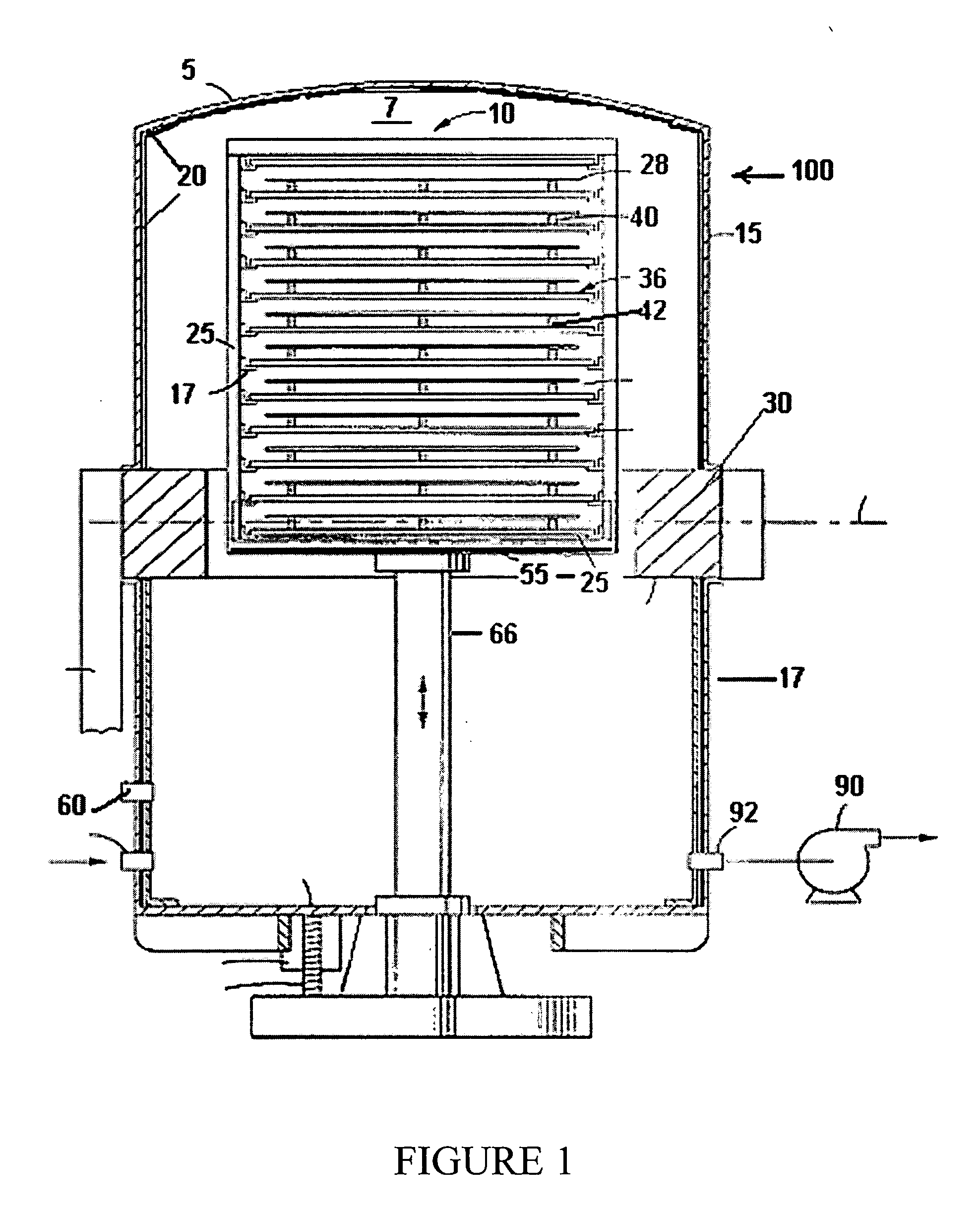

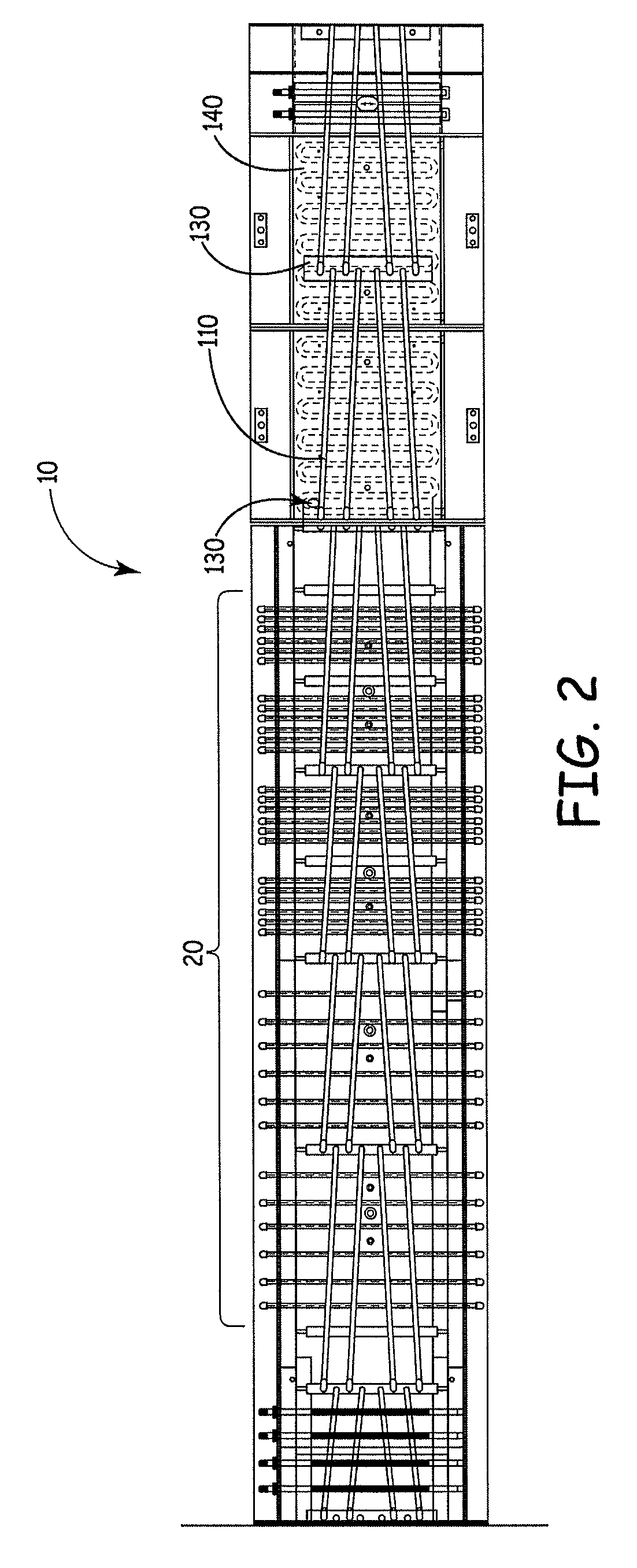

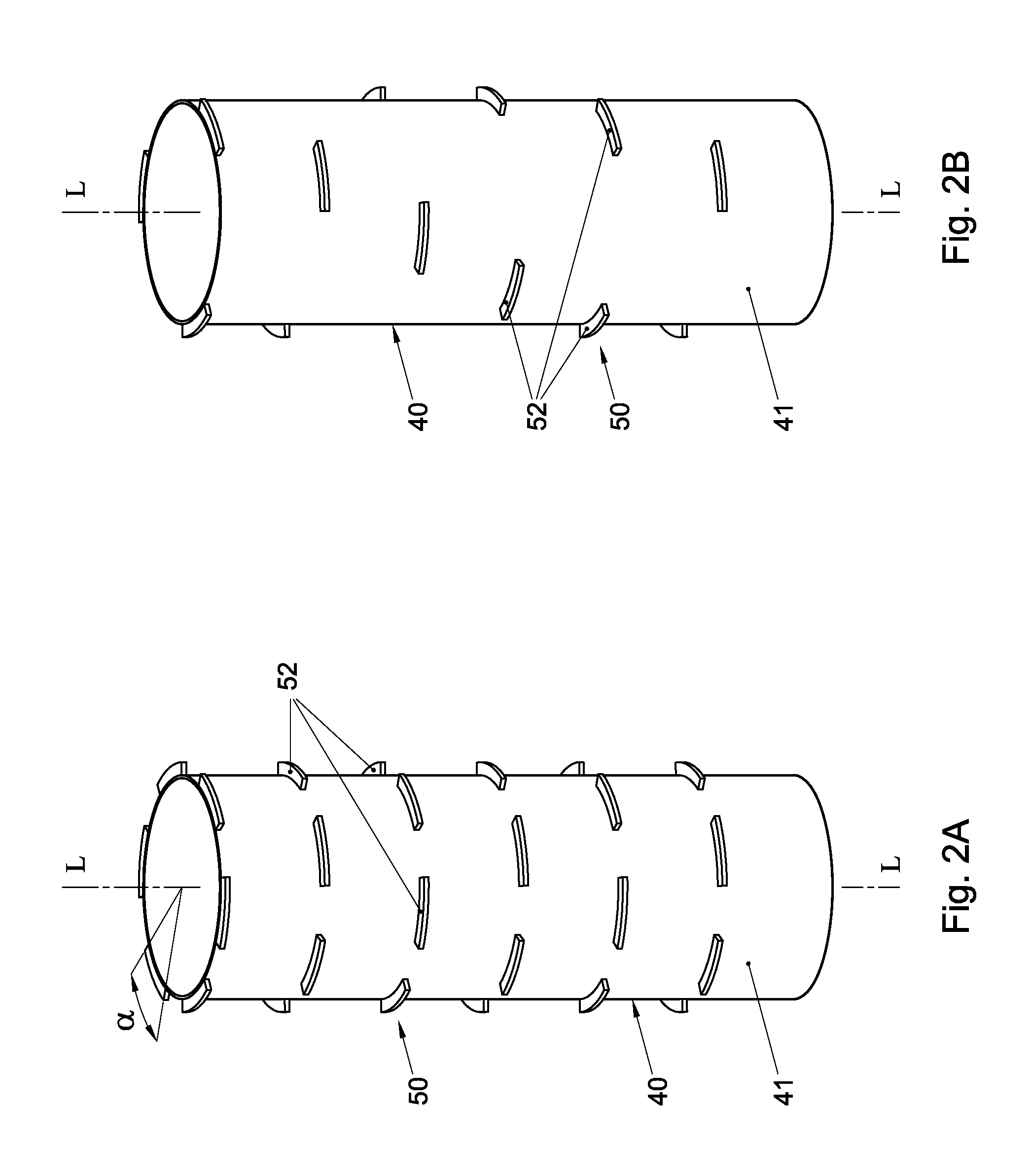

Thermal processing furnace and liner for the same

ActiveUS8398773B2Easy to transportMinimized in sizeDomestic stoves or rangesRotary drum furnacesEngineeringReaction tube

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

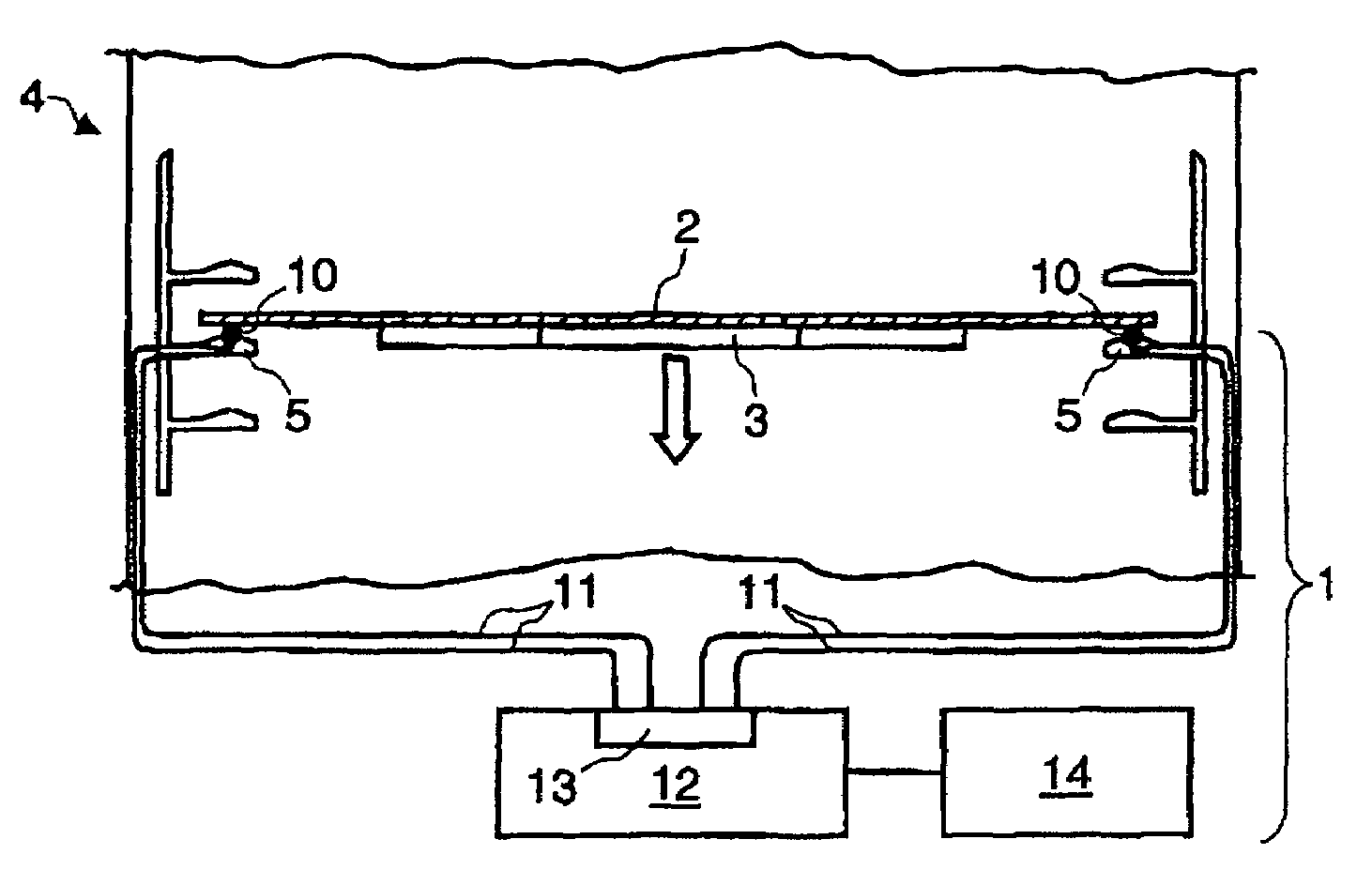

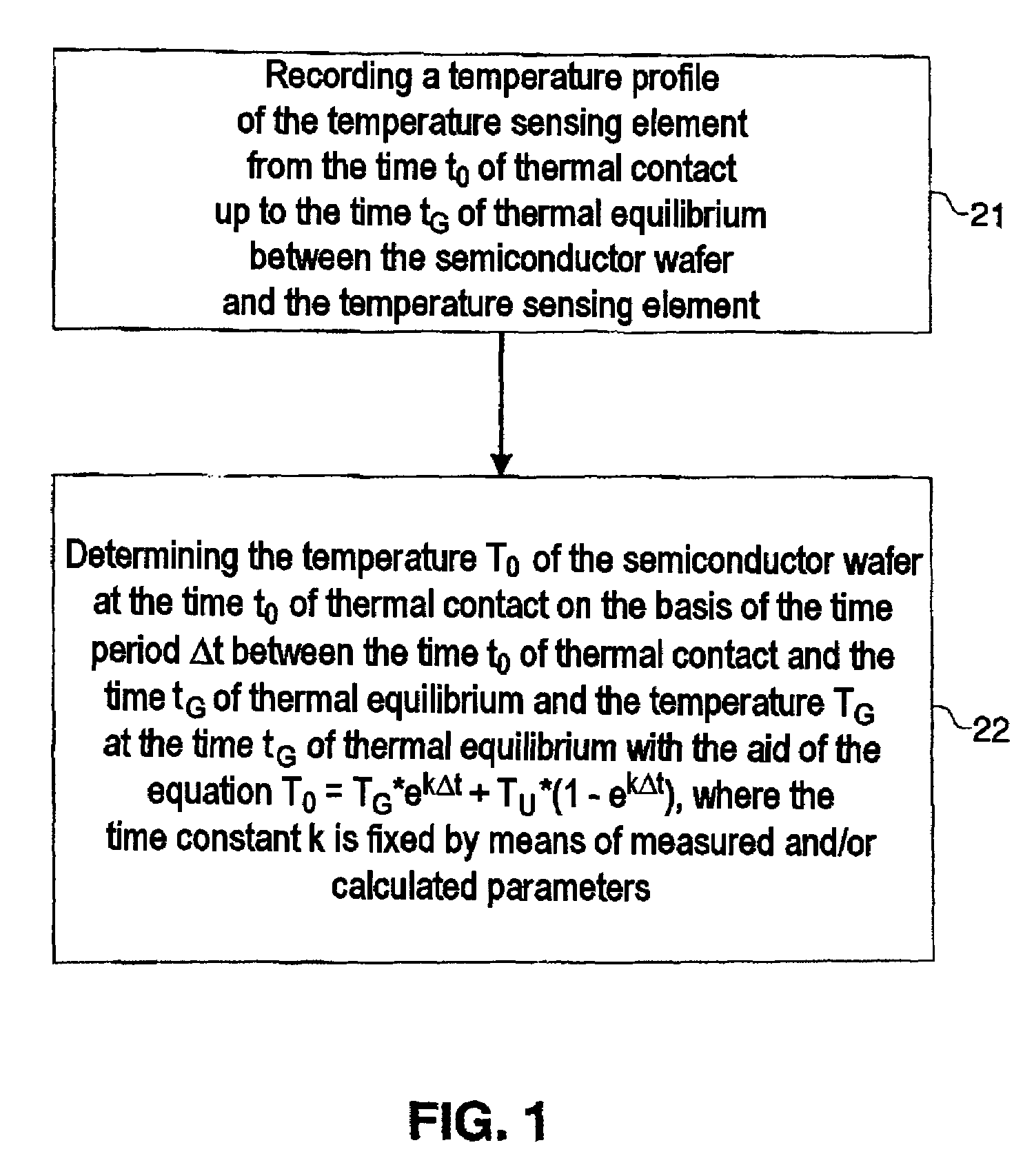

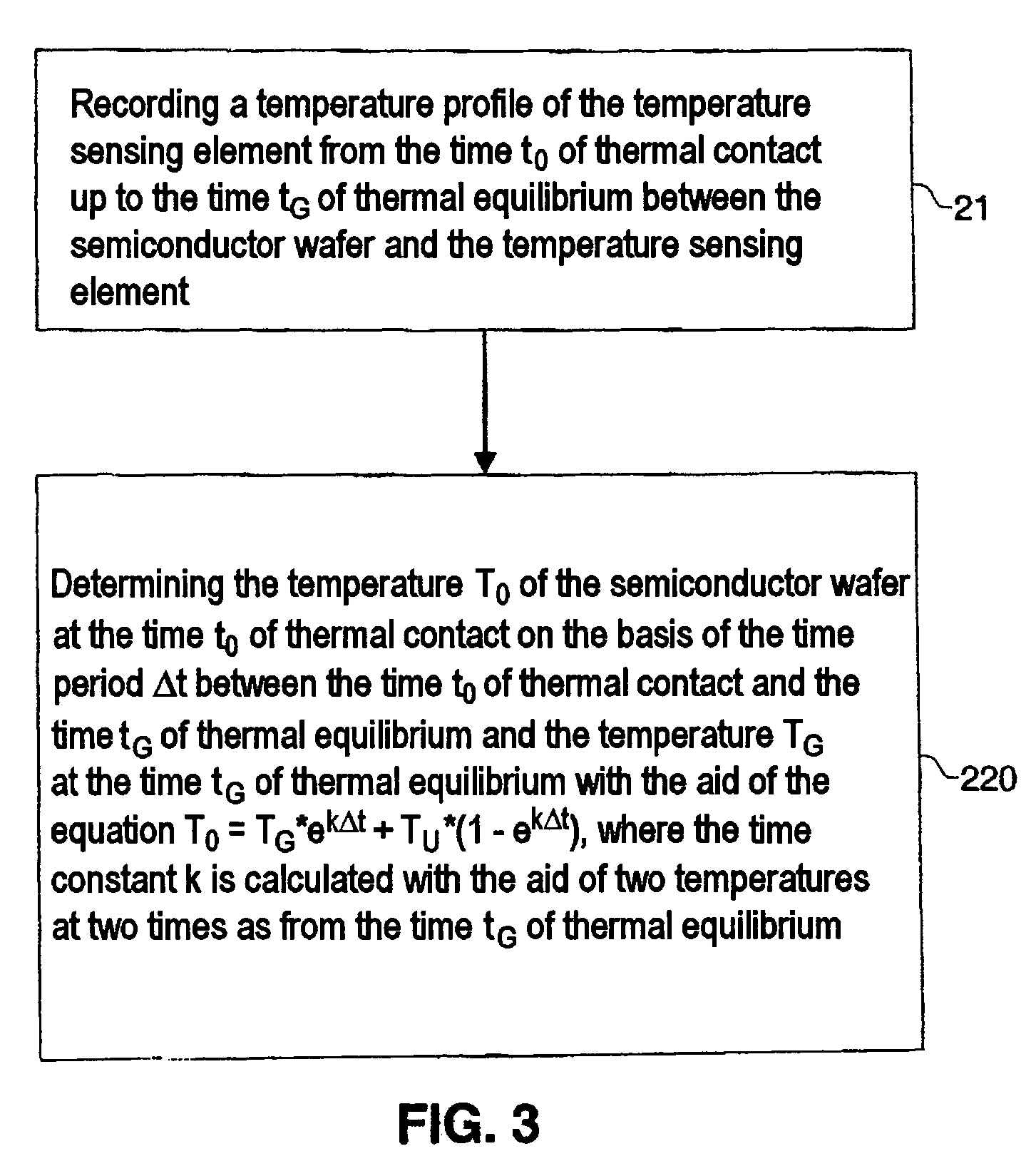

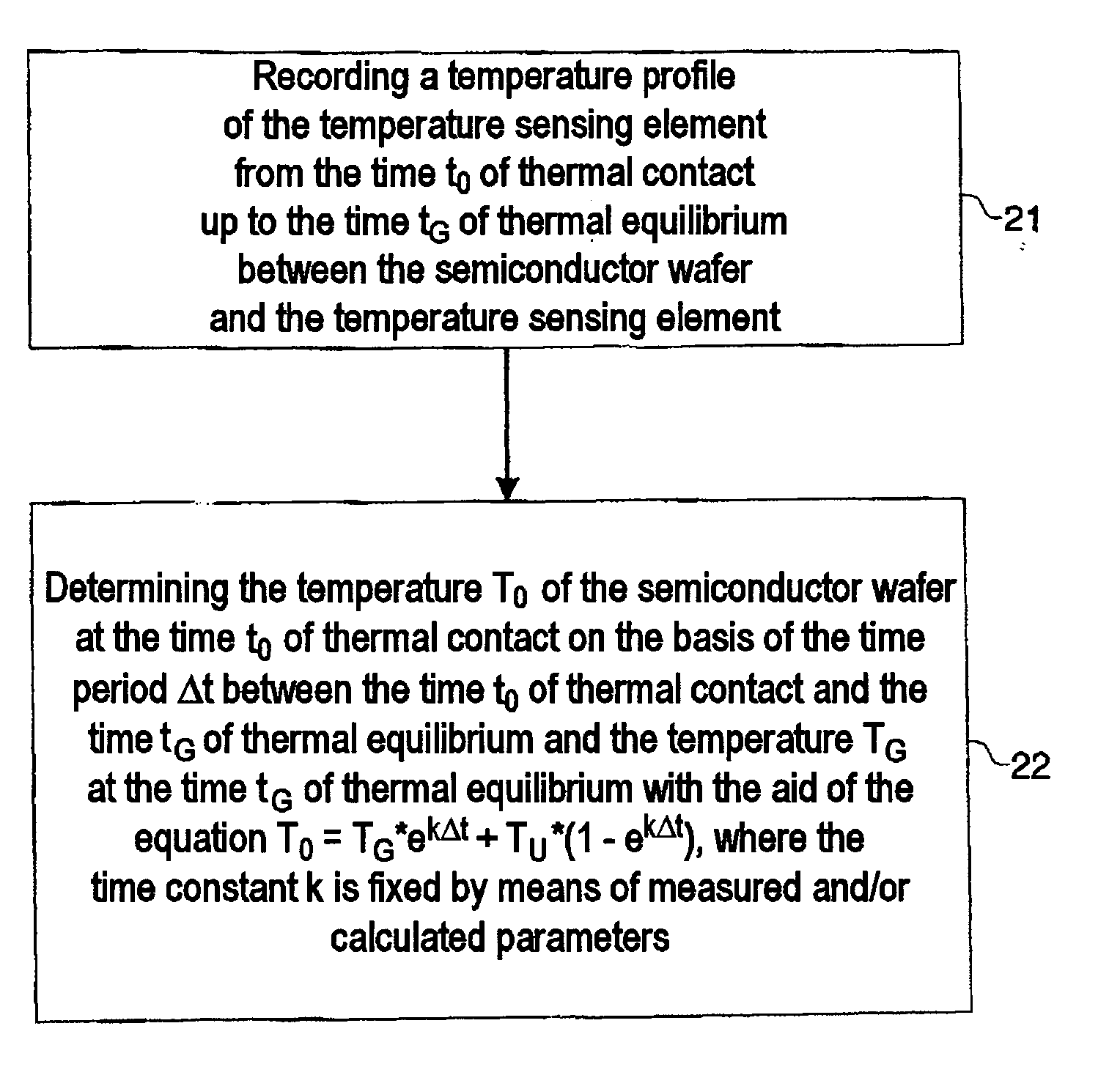

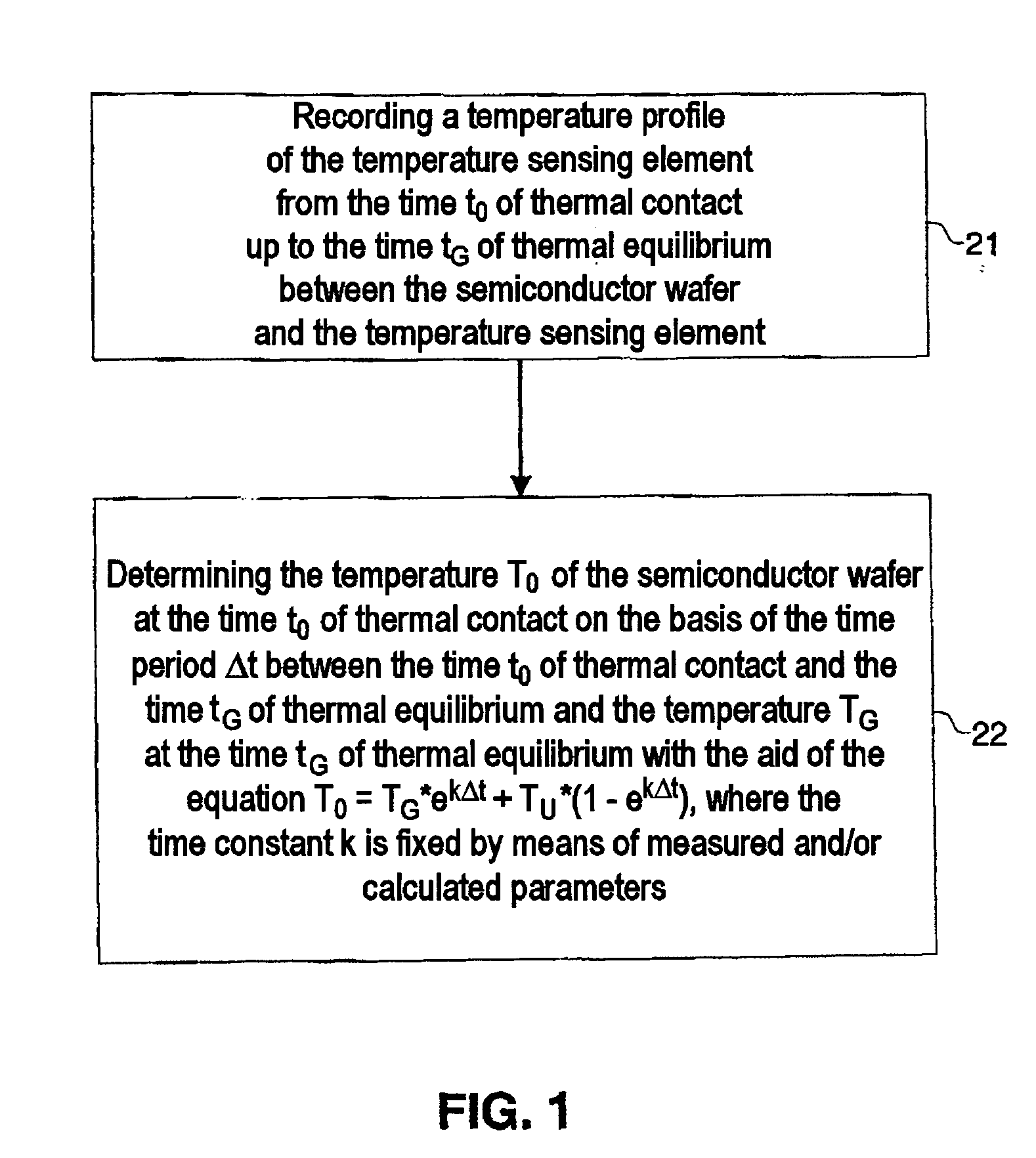

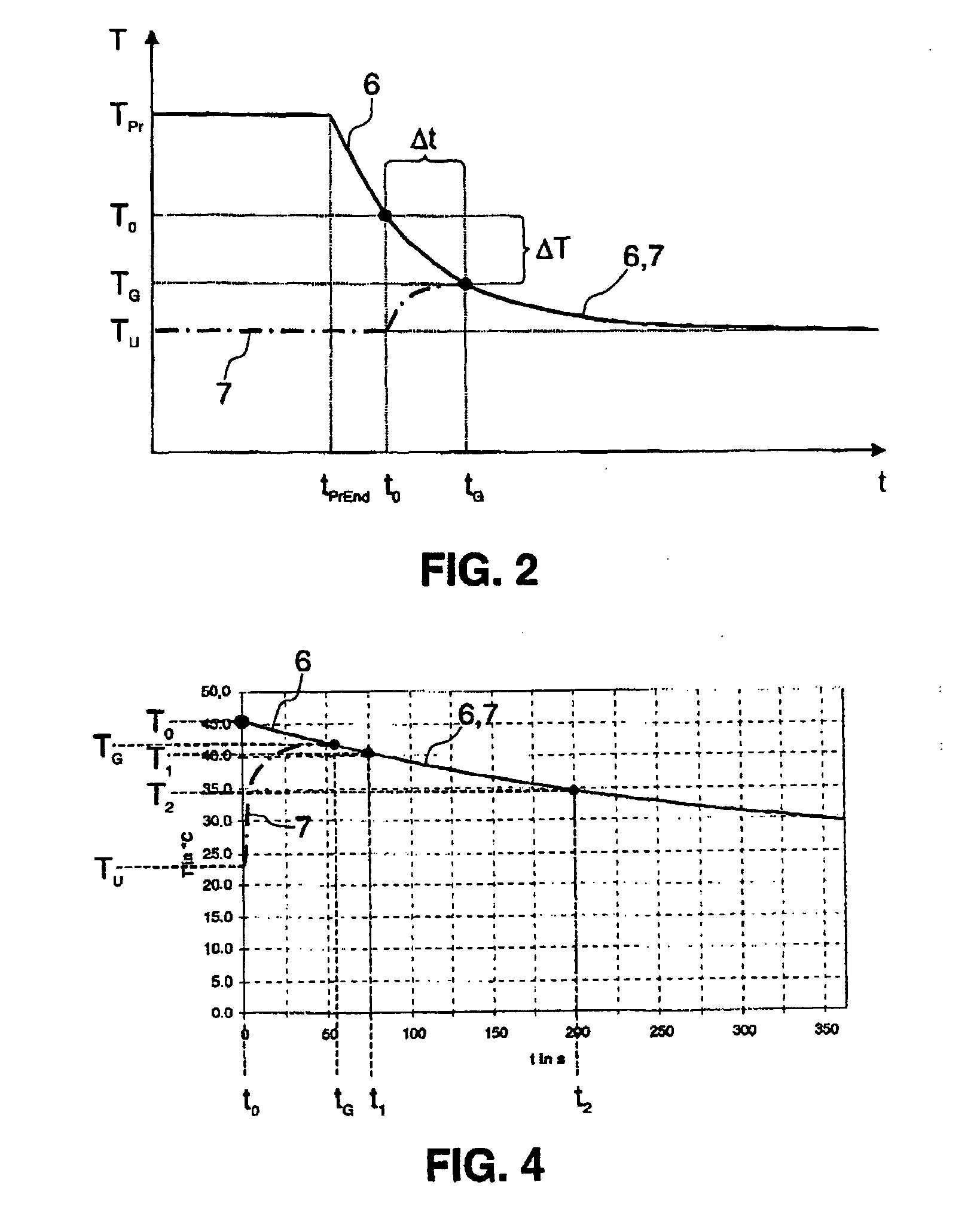

System and method for determining the temperature of a semiconductor wafer

InactiveUS7274867B2High precisionImprove convenienceDrying solid materials with heatSemiconductor/solid-state device testing/measurementTime segmentBack calculation

A system and method for determining the temperature of a semiconductor wafer at the time of thermal contact of the semiconductor wafer with a temperature sensing element. According to the invention, a temperature profile of the temperature sensing element is recorded from the time of thermal contact up to the time of thermal equilibrium between the semiconductor wafer and the temperature sensing element and the temperature of the semiconductor wafer at the time of thermal contact is determined on the basis of a time period between the time of thermal contact and the time of thermal equilibrium and the temperature TG of the semiconductor wafer reached at the time tG of thermal equilibrium is determined by back calculation with the aid of an equation derived from Newton's law of cooling.

Owner:POLARIS INNOVATIONS LTD

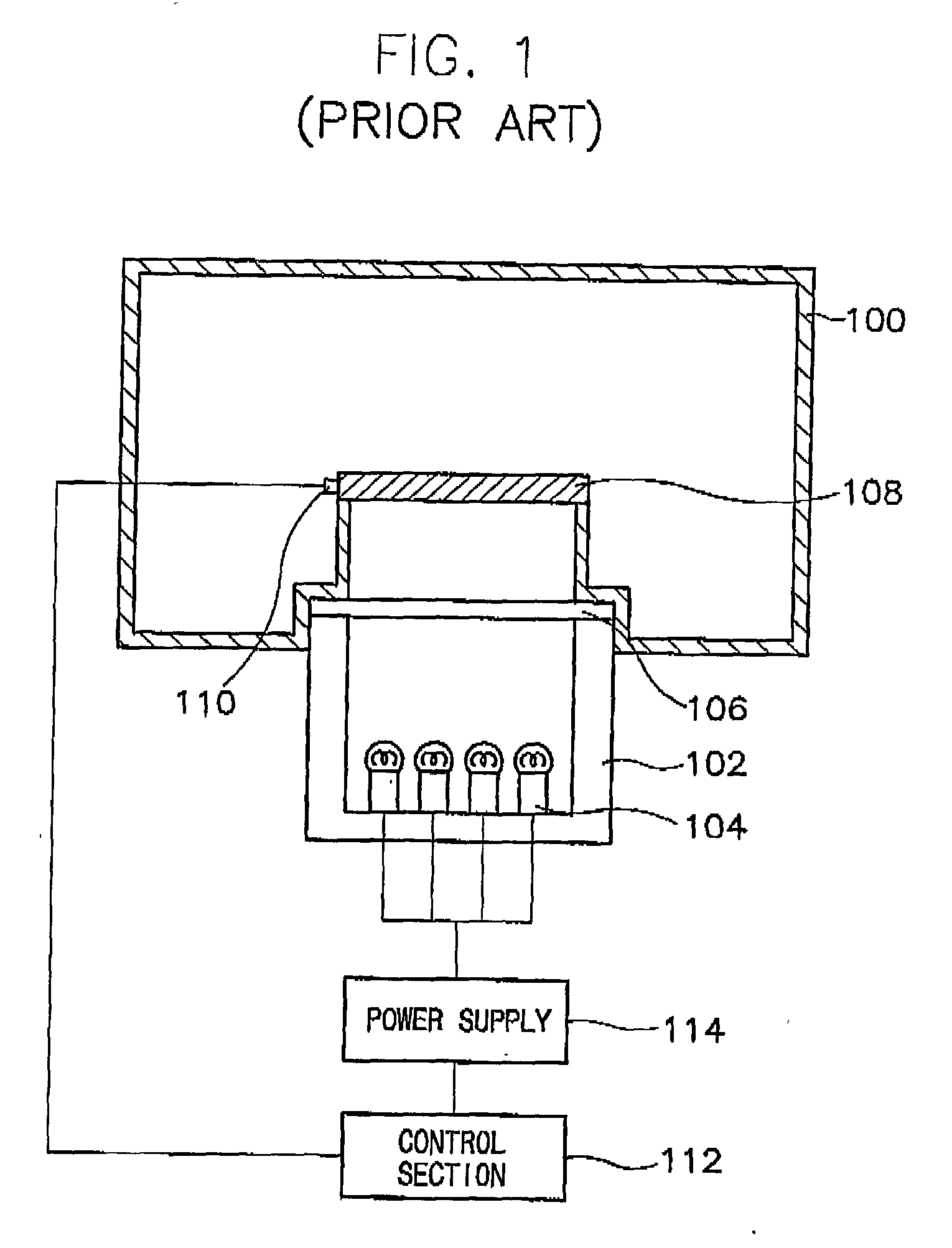

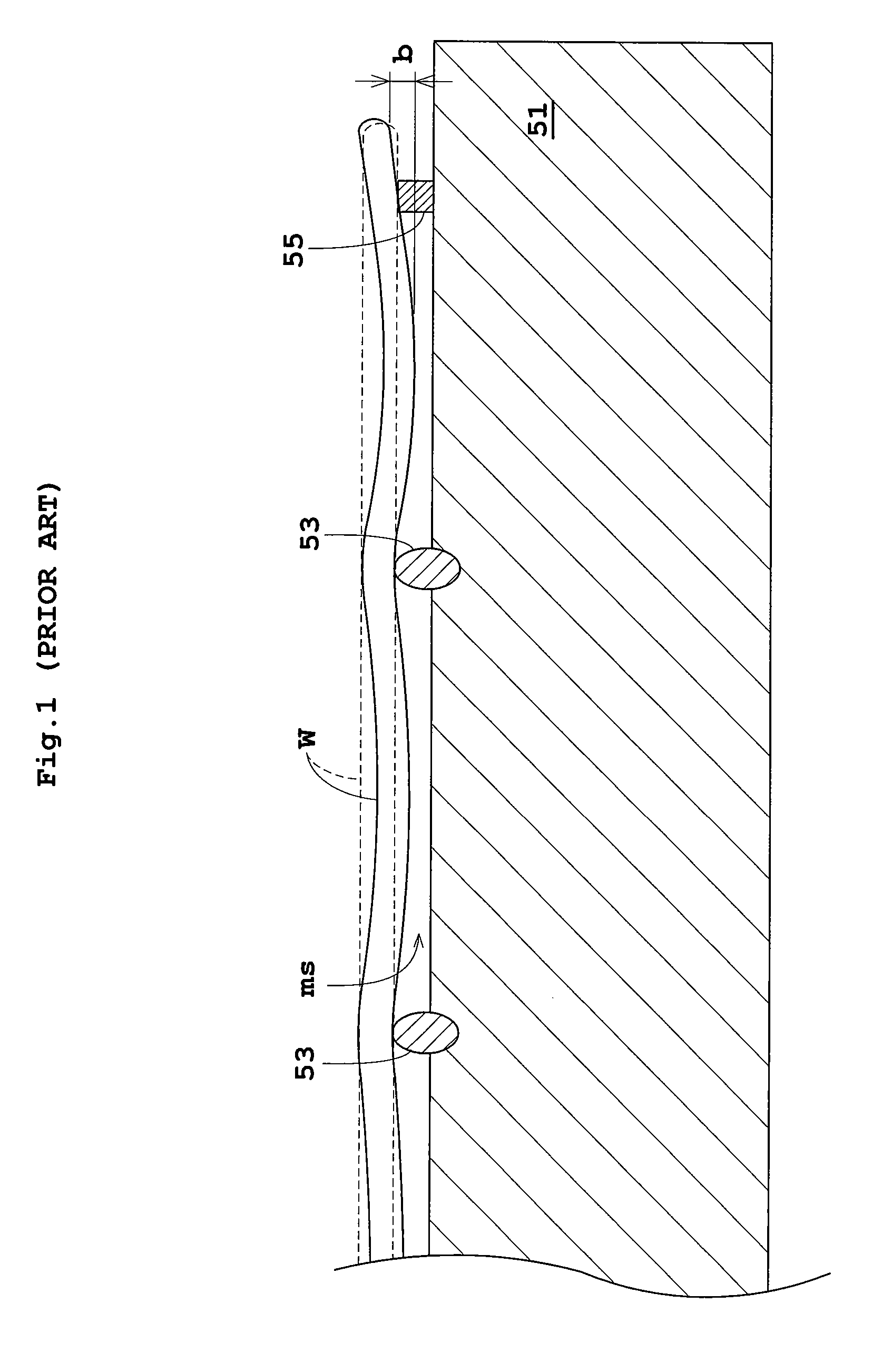

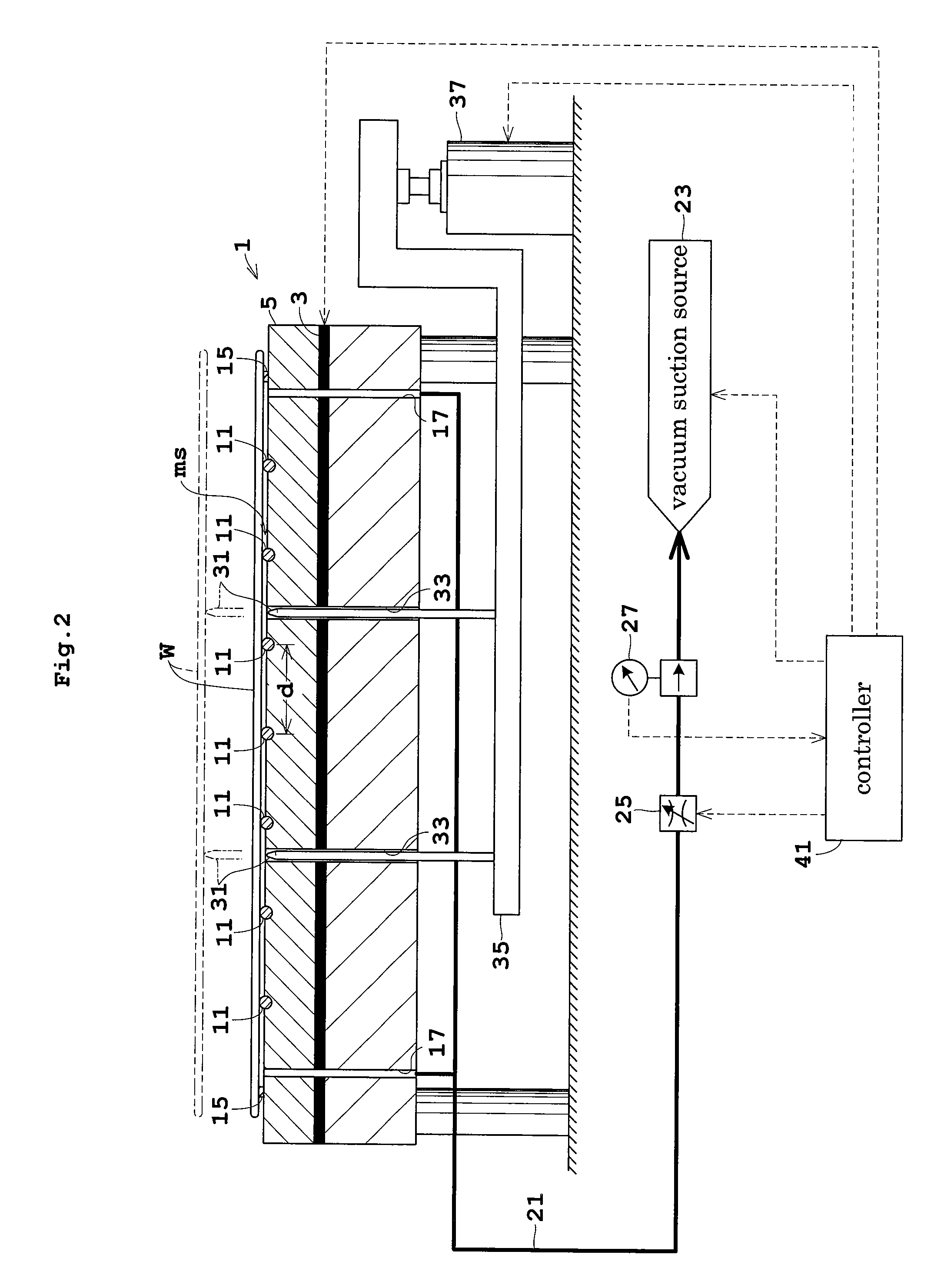

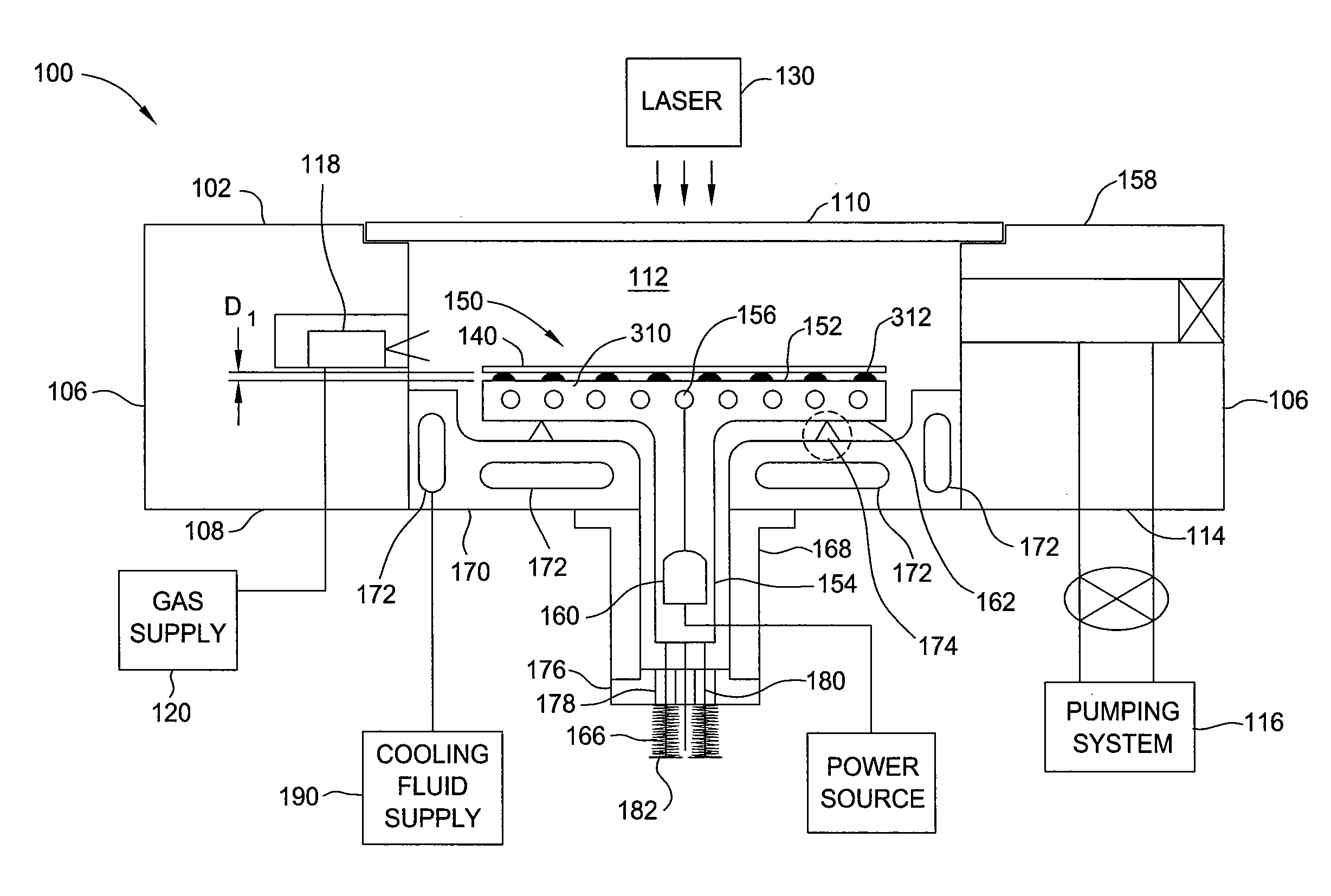

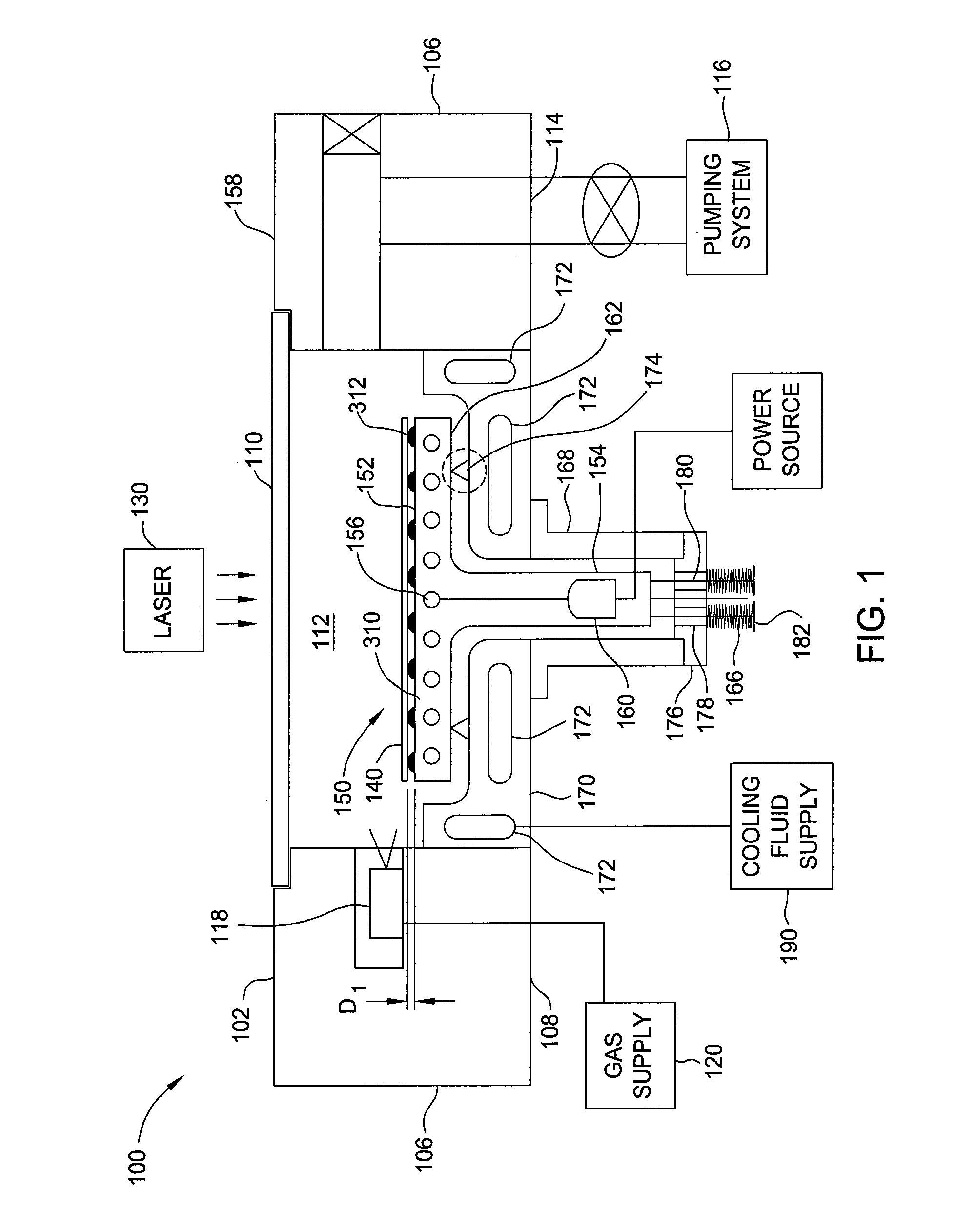

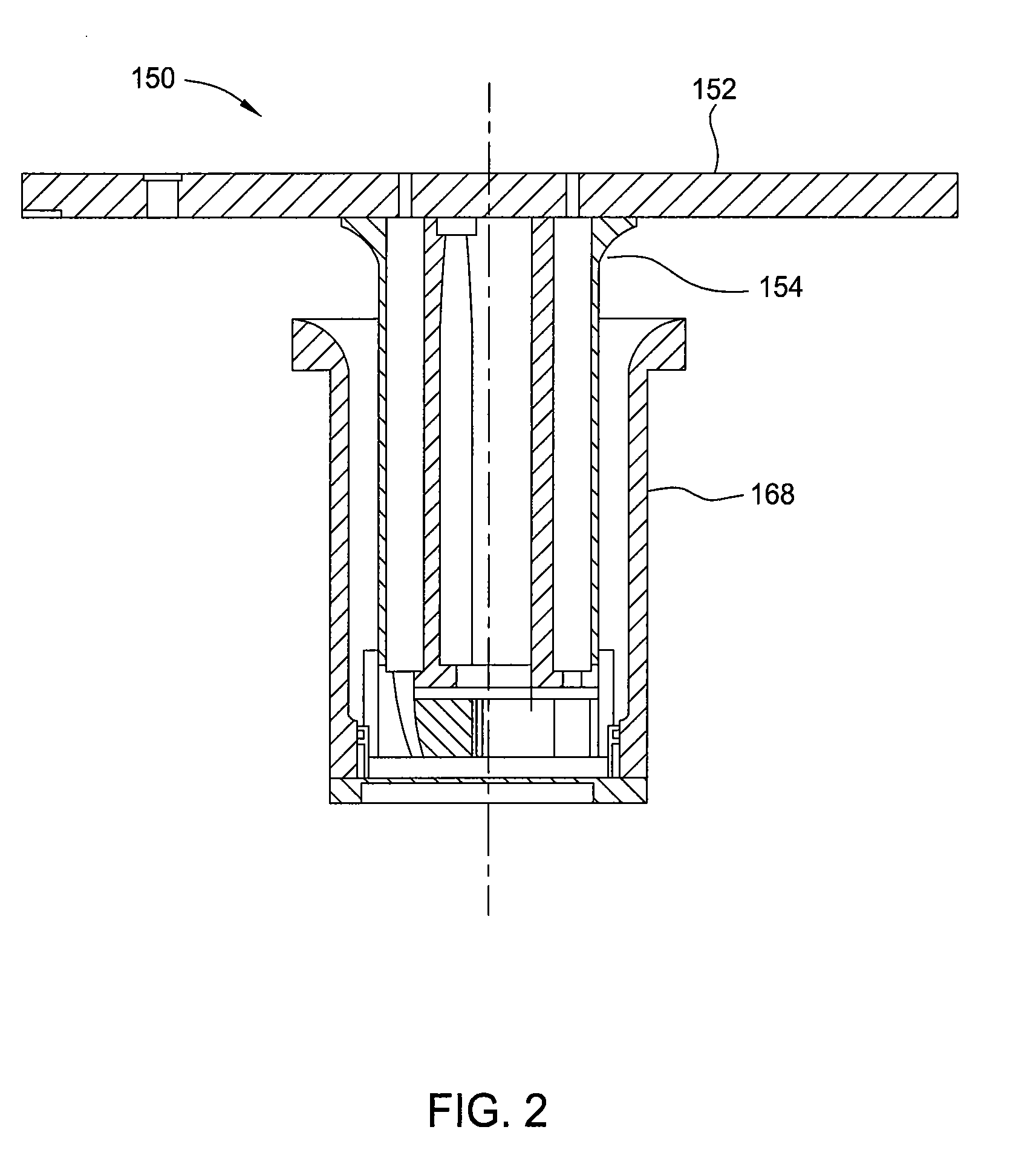

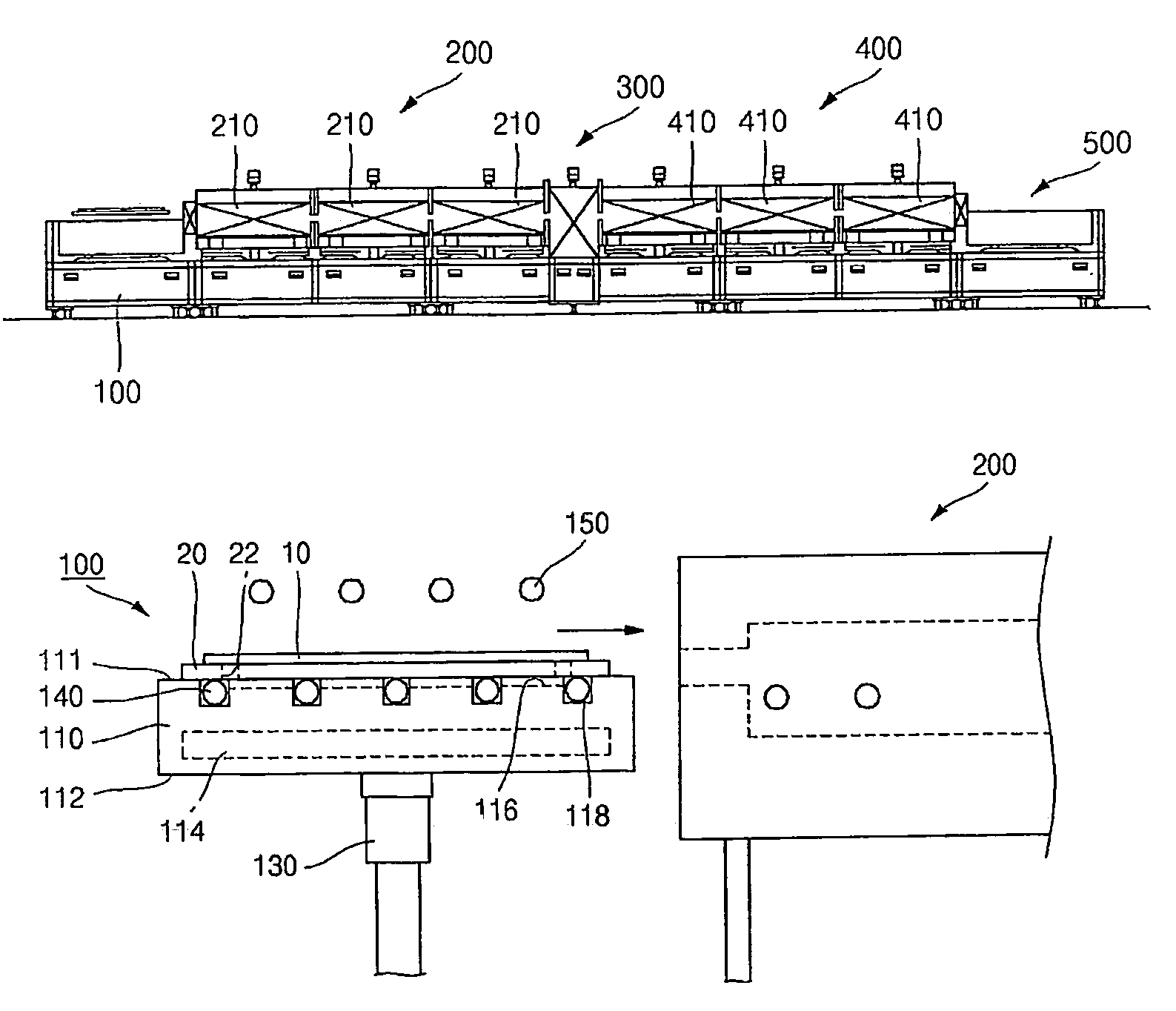

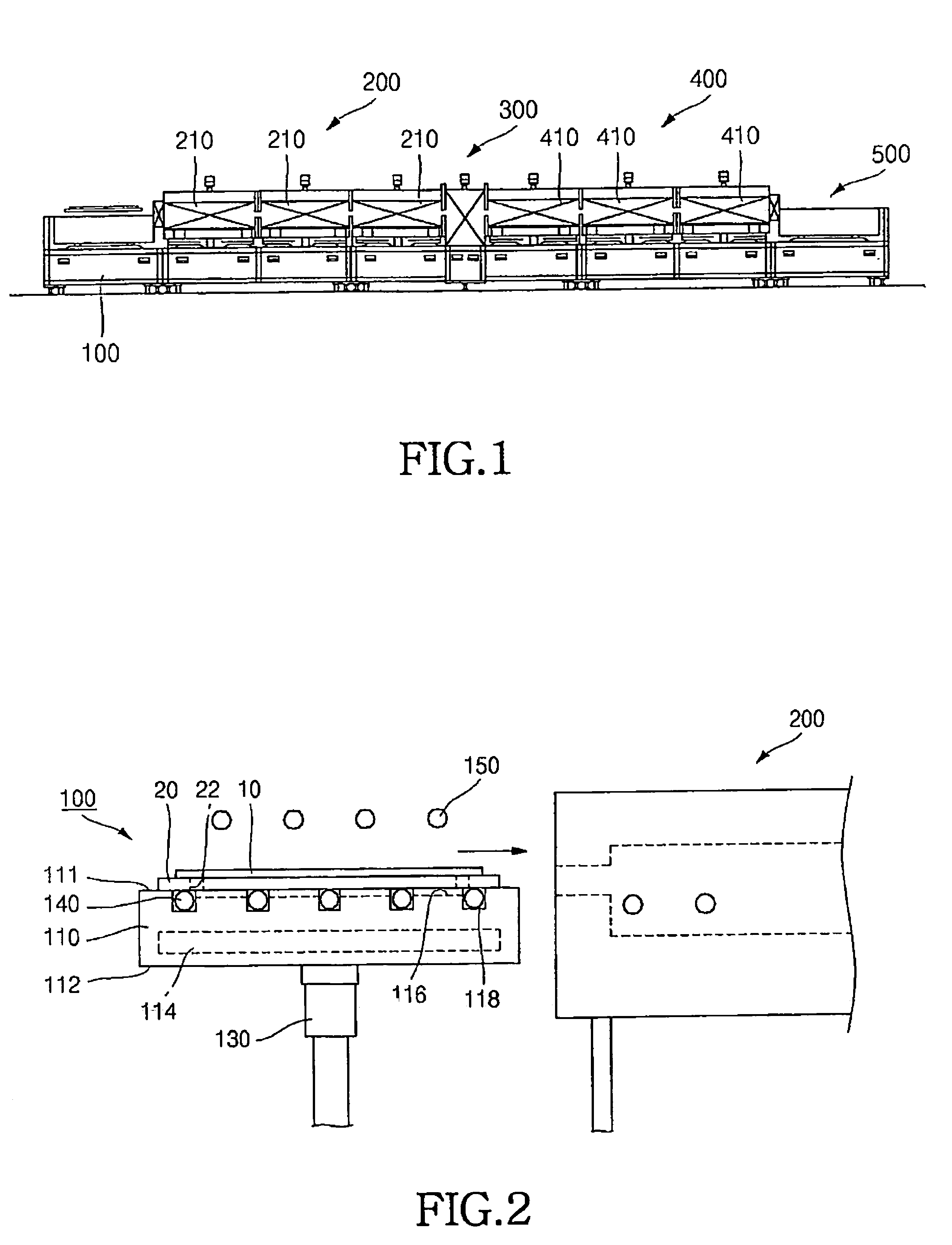

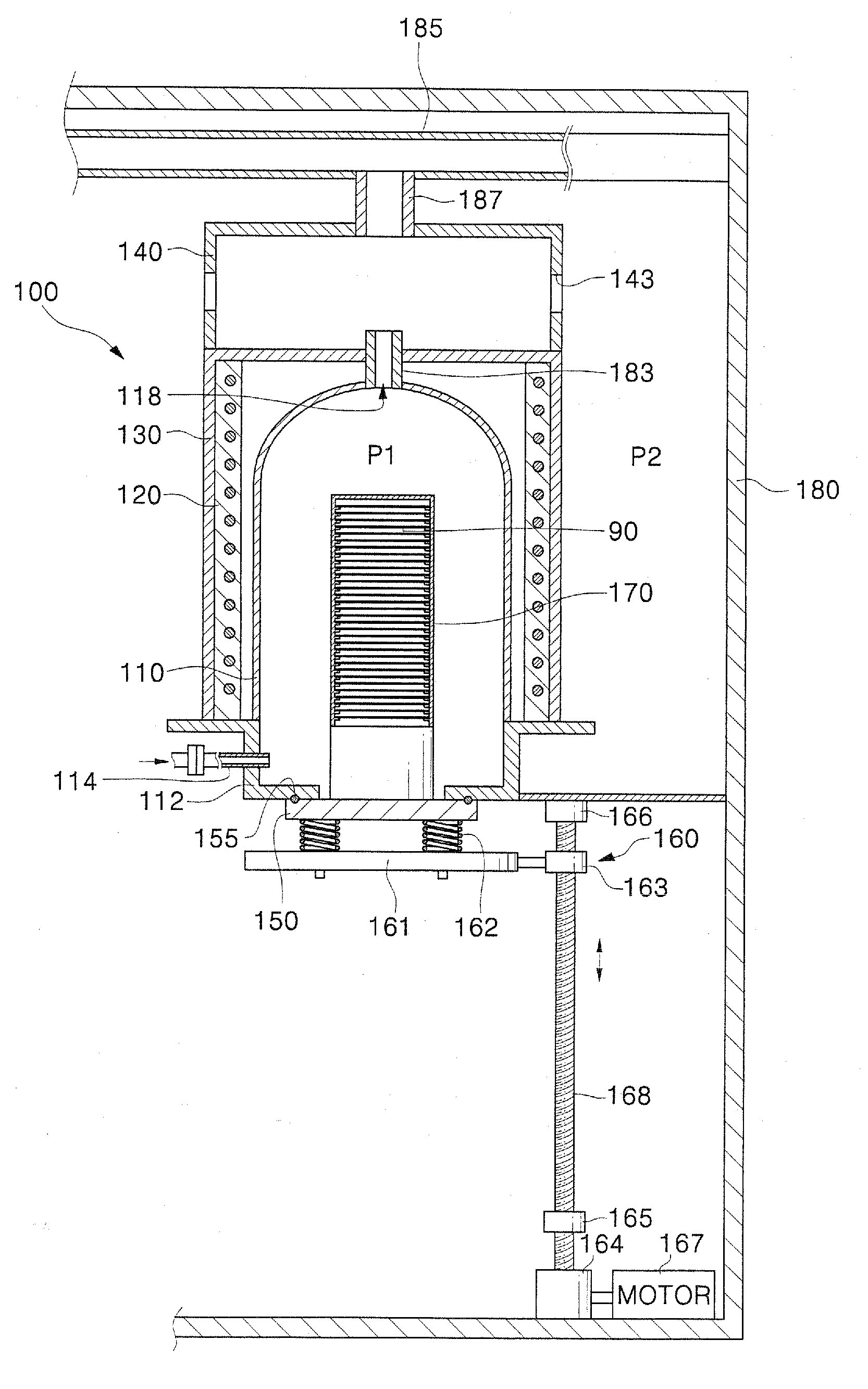

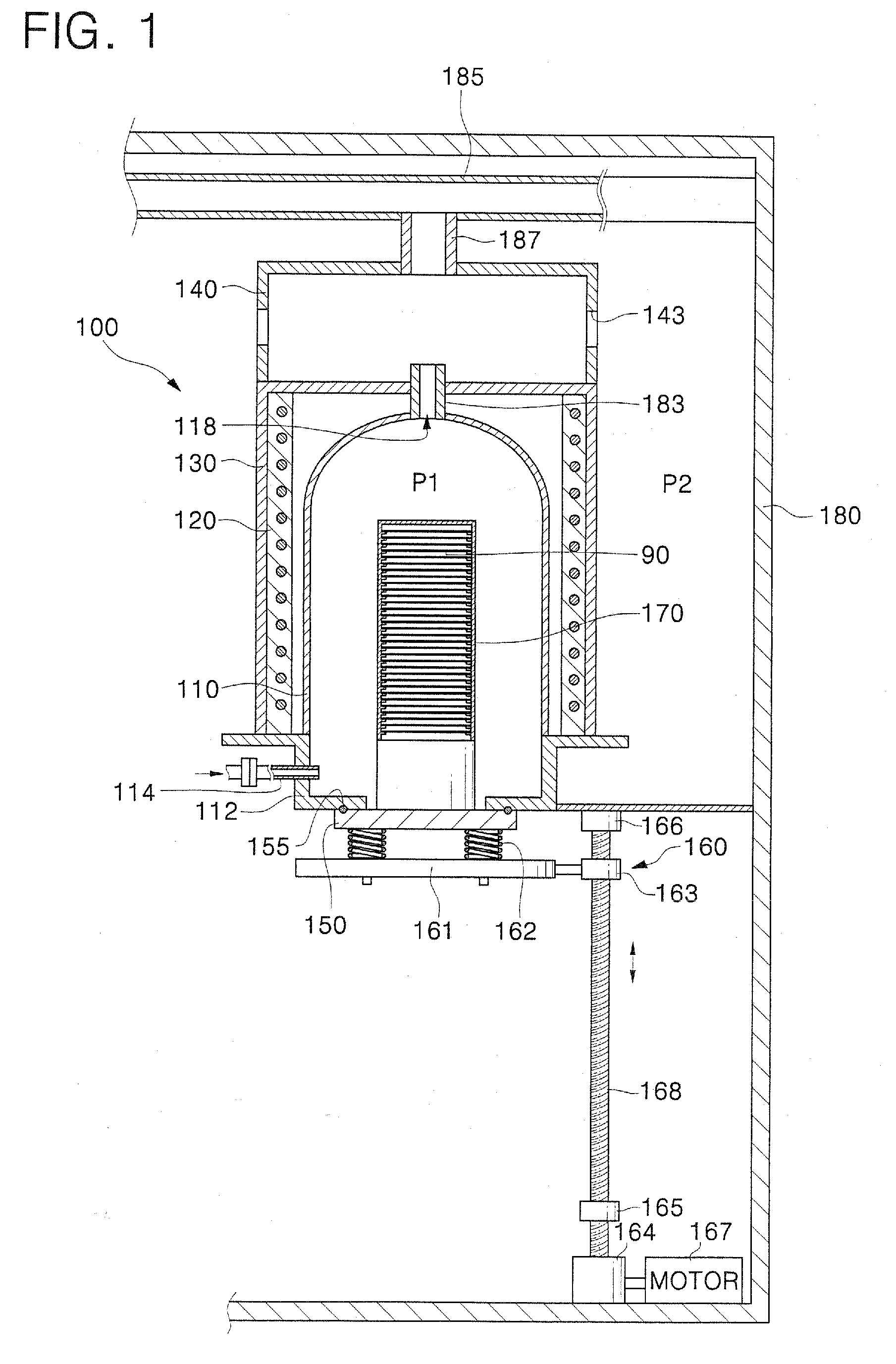

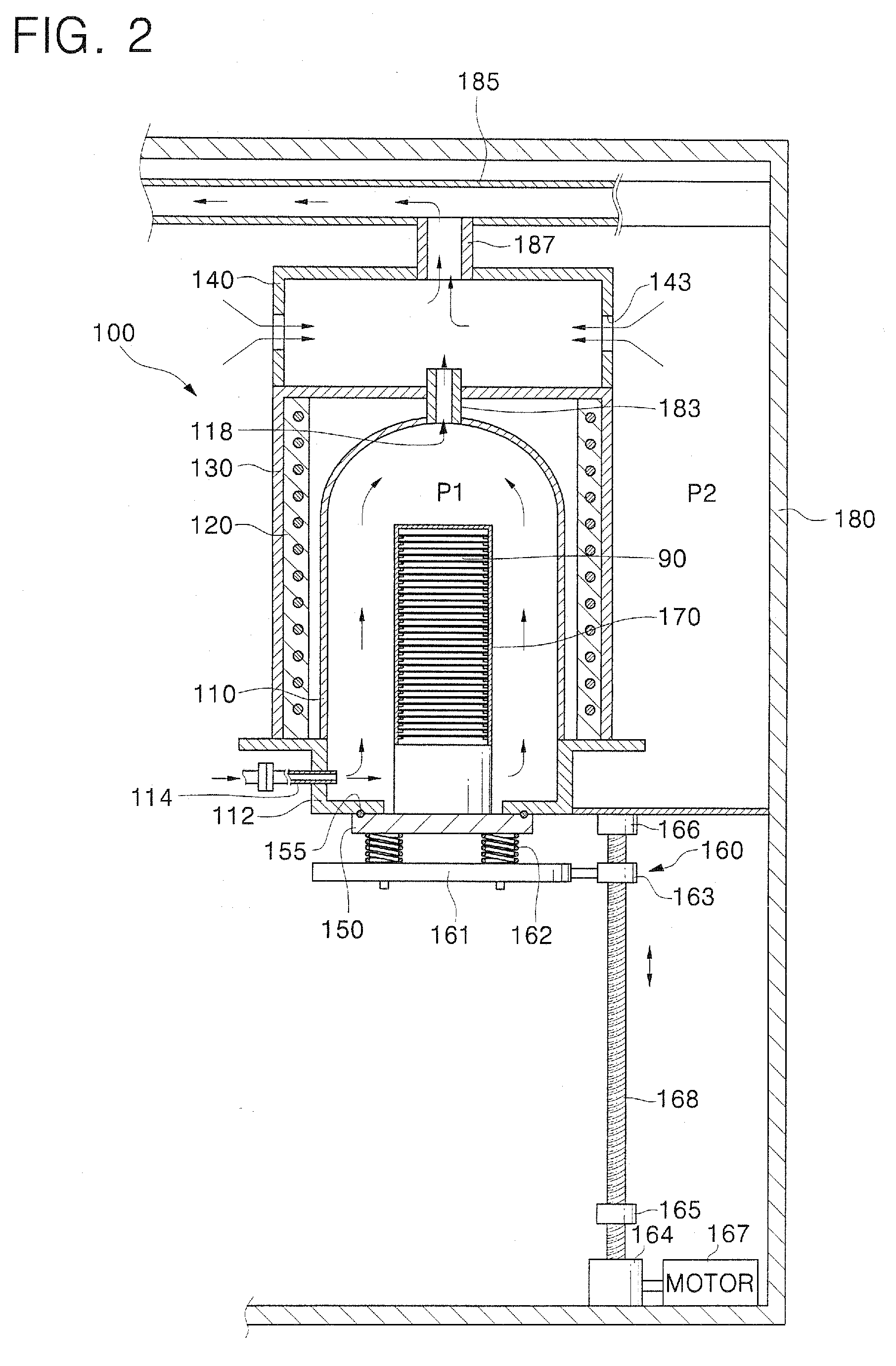

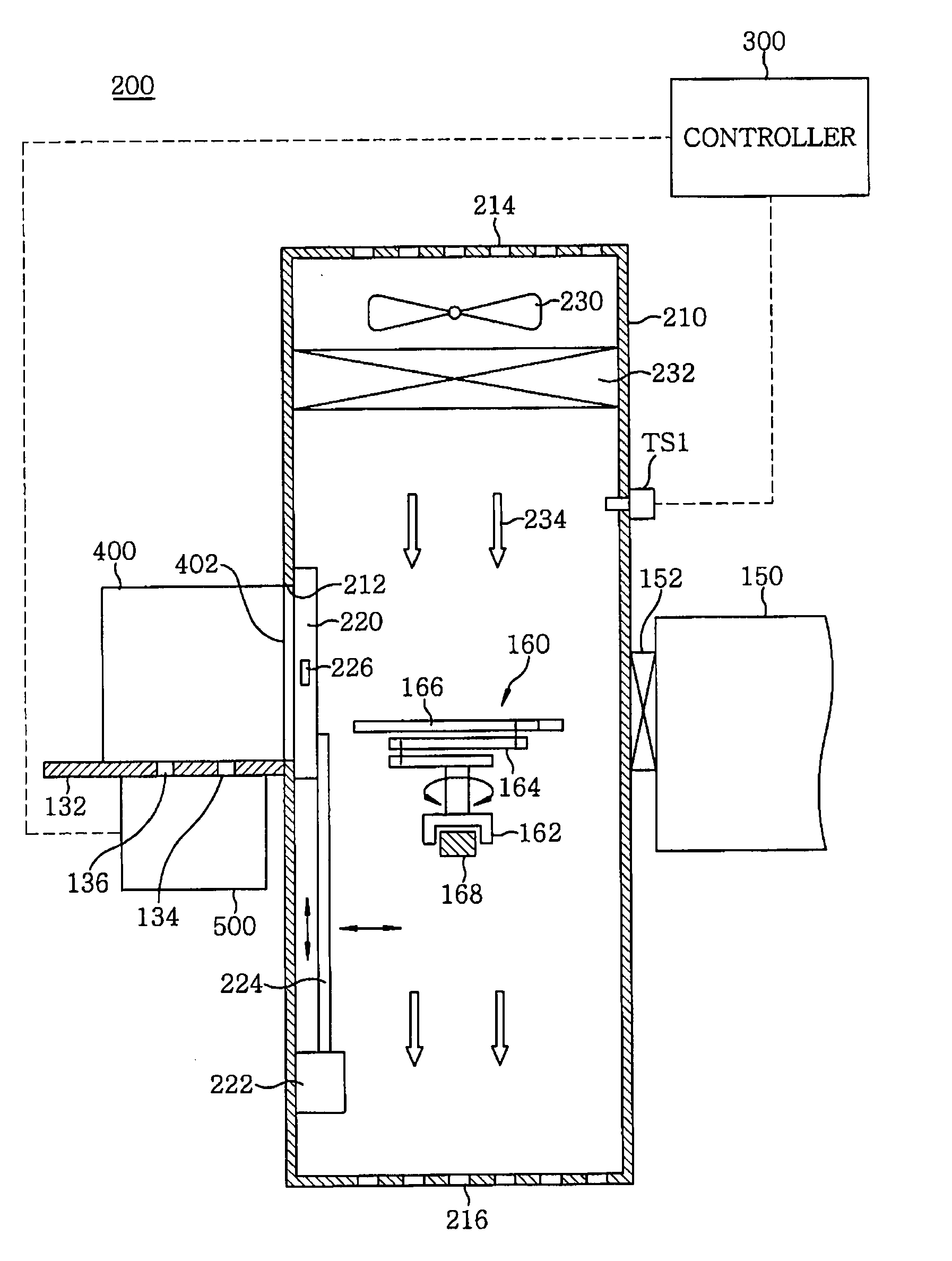

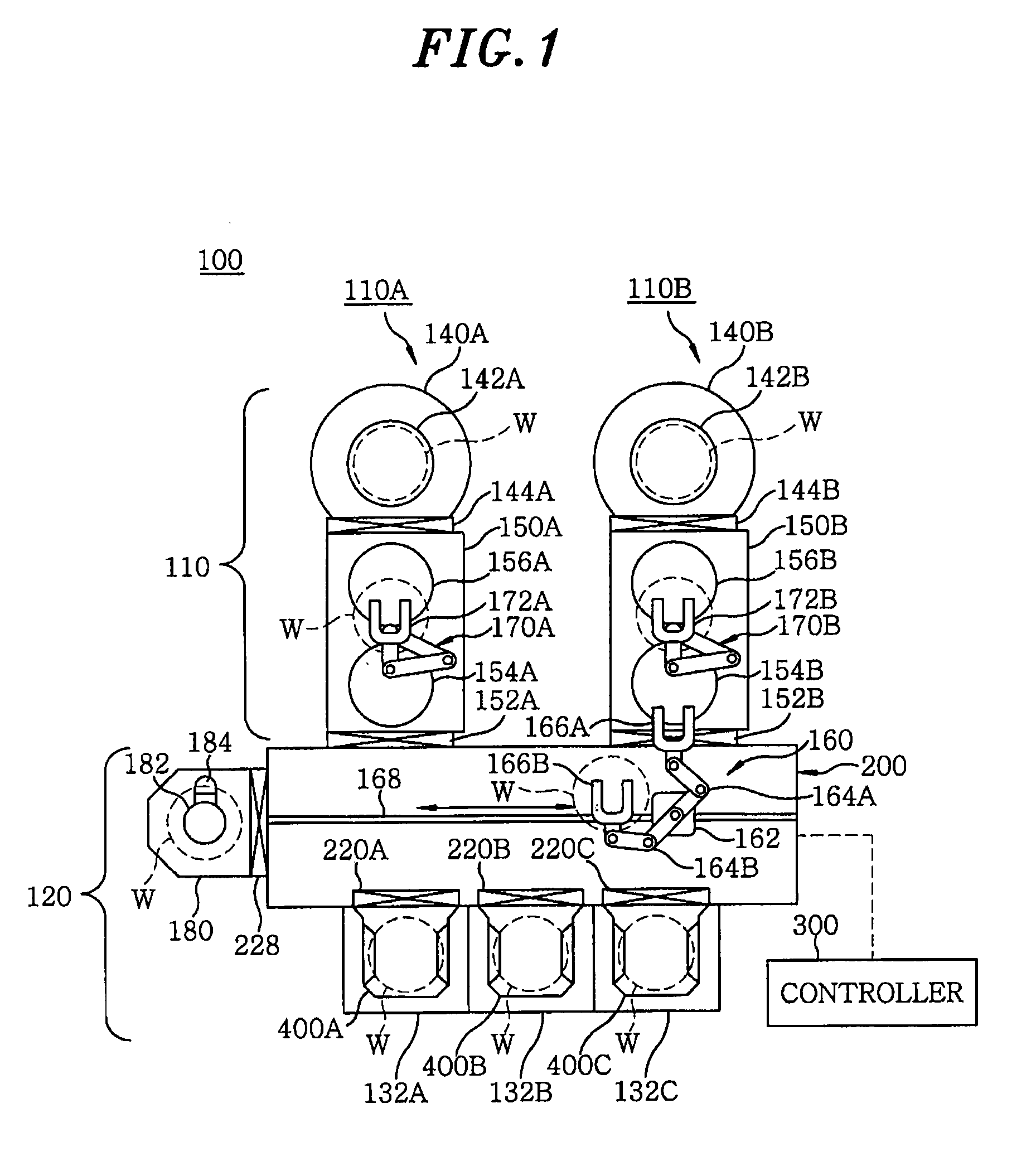

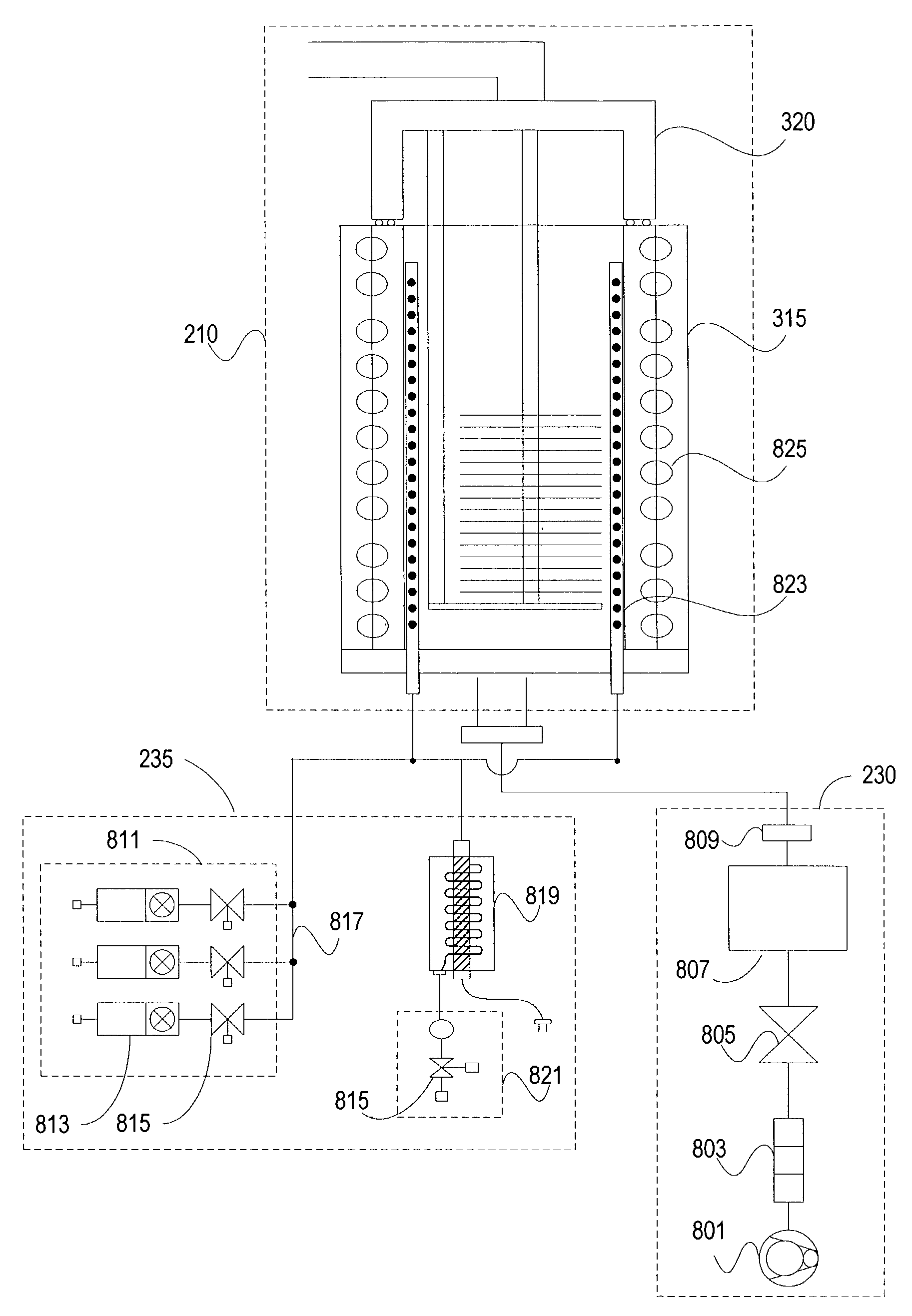

System for heat treatment of semiconductor device

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

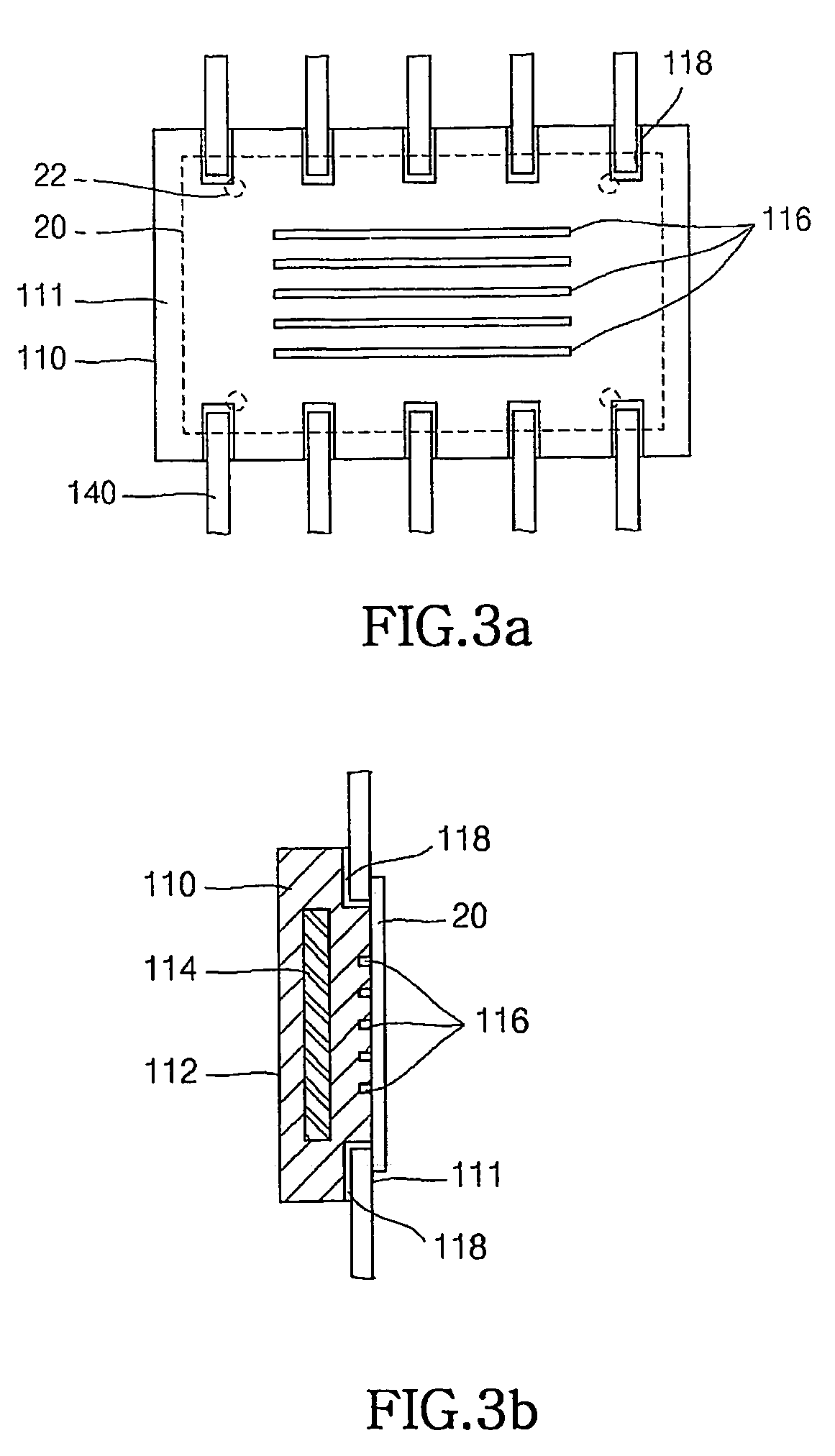

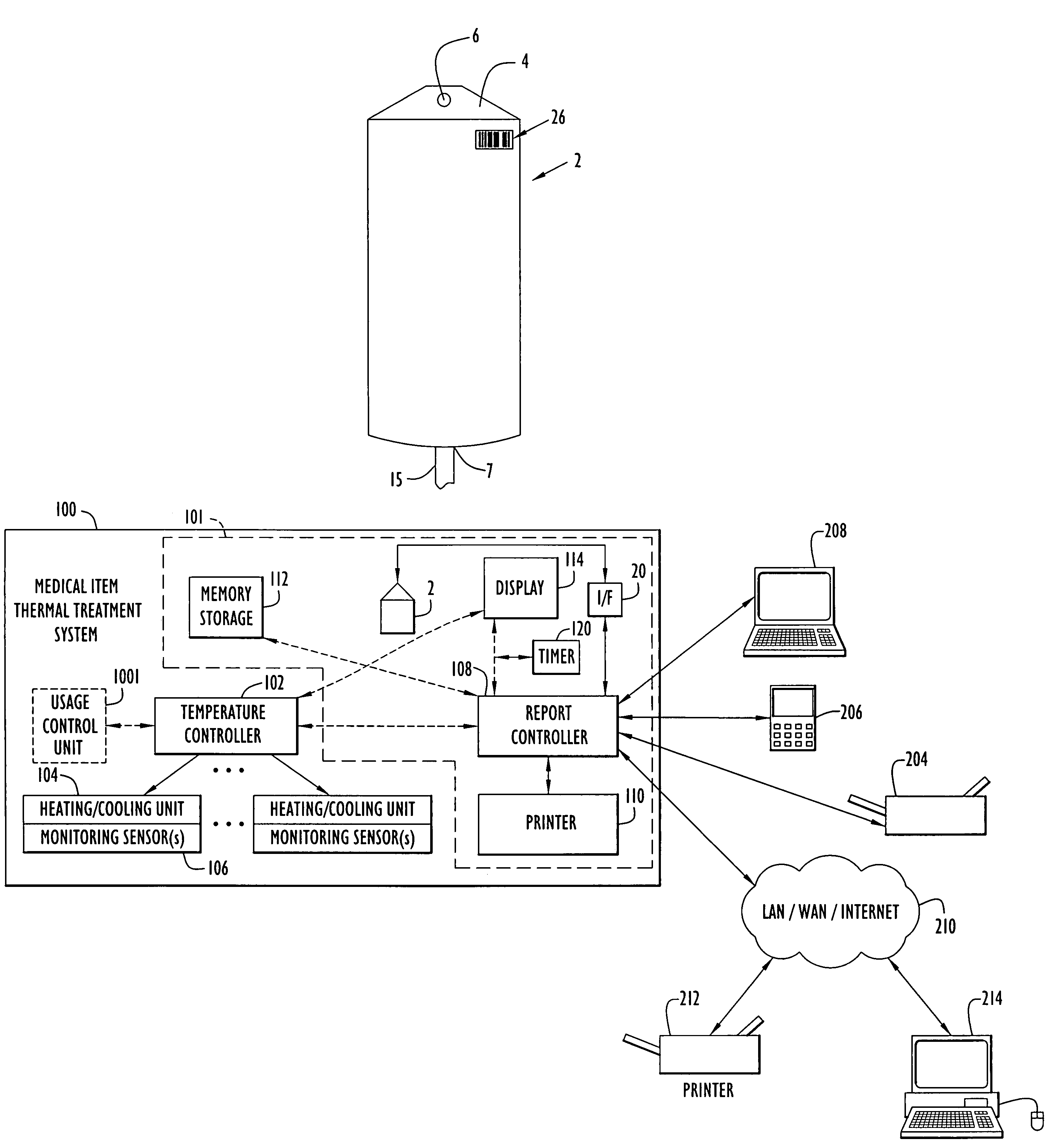

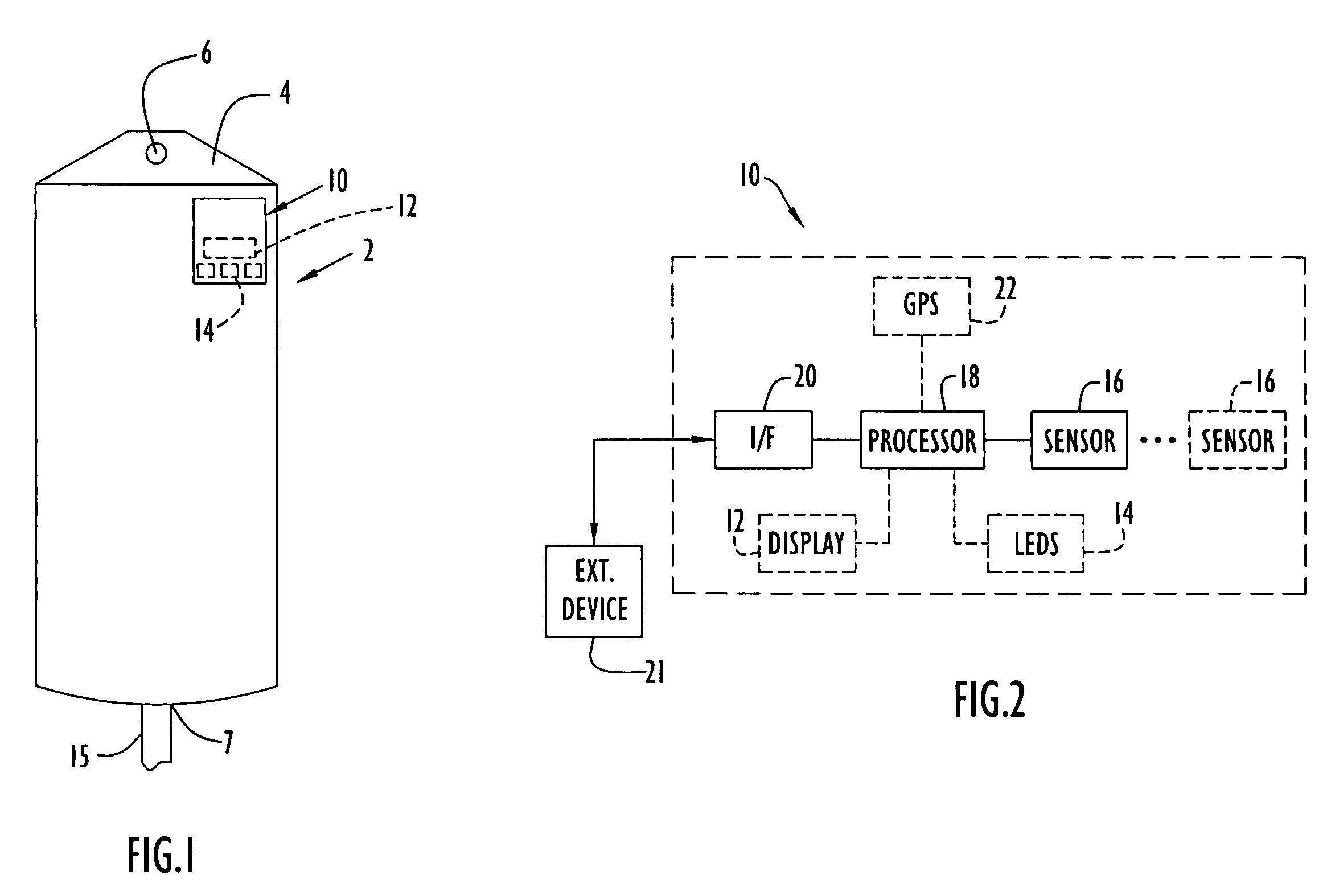

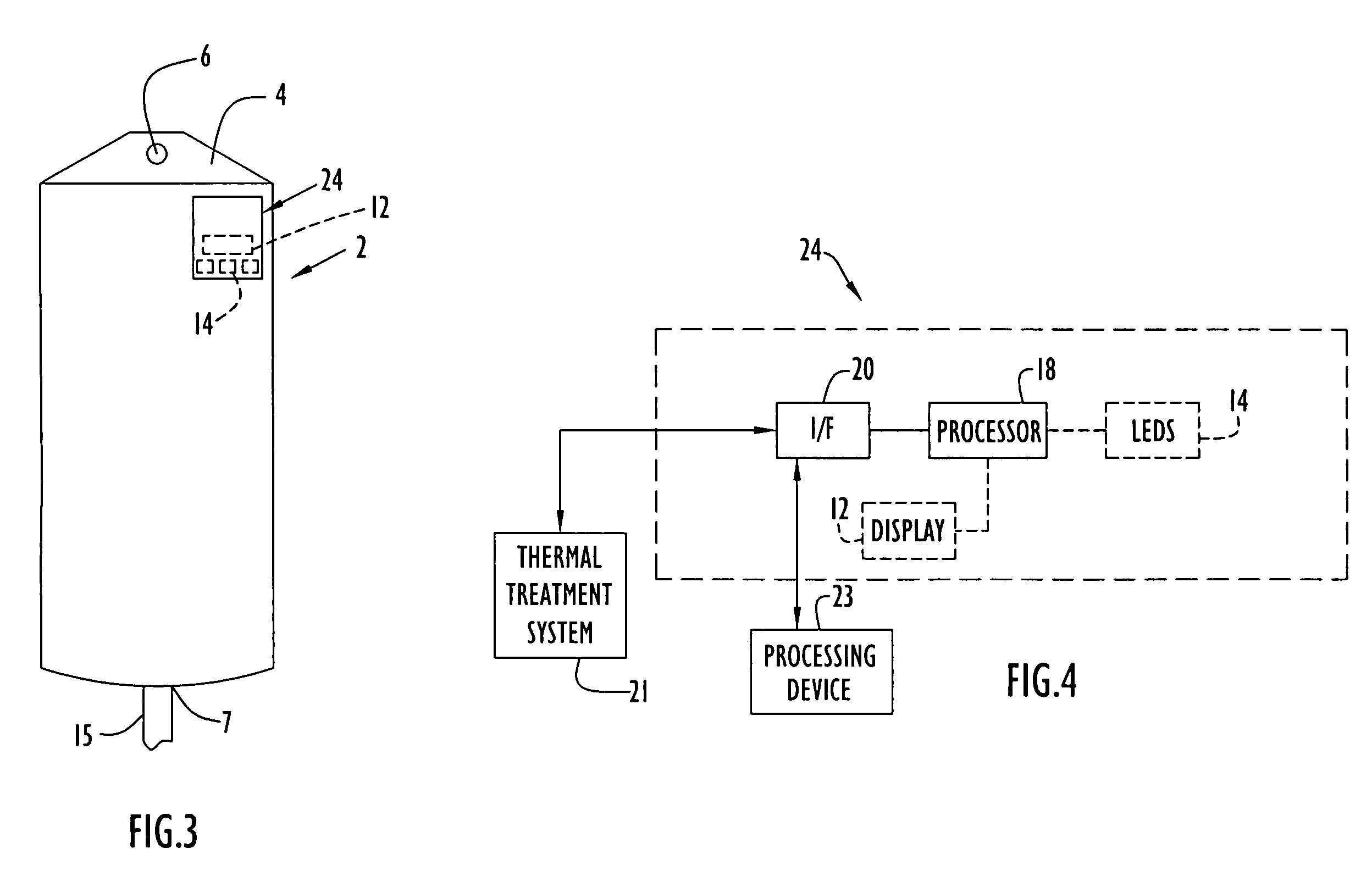

Medical item thermal treatment systems and method of monitoring medical items for compliance with prescribed requirements

Various present invention devices enable adherence to requirements for medical items. A medical item of the present invention includes a monitoring or data recording device to monitor and / or record medical solution conditions. The device may further include indicators to indicate compliance of the medical solution with prescribed requirements (e.g., manufacturer, medical standard or regulation, etc.). The medical item may alternatively include a barcode or transponder to uniquely identify the medical item to a thermal treatment system measuring and storing conditions in a central database. The present invention further includes various thermal treatment systems that monitor medical items for prescribed requirements and display the monitored parameters to medical personnel. In addition, the present invention may place time stamp information on medical items to enable determination by medical personnel of compliance with prescribed requirements.

Owner:PATENTED MEDICAL SOLUTIONS LLC

Heat treatment equipment

InactiveUS7850449B2Growth inhibitionReduce processing stepsMuffle furnacesBaking ovenProcess engineeringPressure controlled ventilation

In an embodiment, heat treatment equipment comprises a process tube, an exhaust duct connected to the process tube, and, during operation, exhausting gases present within the process tube. The heat treatment equipment also comprises a hollow pressure control member interposed between the process tube and the exhaust duct, the pressure control member being operatively connected to the process tube and the exhaust duct respectively, and including one or a number of openings. Negative pressure is avoided in the process tube during heat treatment processes so that unwanted gas and impurities cannot enter the process tube from outside.

Owner:SAMSUNG ELECTRONICS CO LTD

System and method for determining the temperature of a semiconductor wafer

InactiveUS20050042778A1High precisionImprove convenienceDrying solid materials with heatSemiconductor/solid-state device testing/measurementBack calculationThermal contact

A system and method for determining the temperature of a semiconductor wafer at the time of thermal contact of the semiconductor wafer with a temperature sensing element. According to the invention, a temperature profile of the temperature sensing element is recorded from the time of thermal contact up to the time of thermal equilibrium between the semiconductor wafer and the temperature sensing element and the temperature of the semiconductor wafer at the time of thermal contact is determined on the basis of a time period between the time of thermal contact and the time of thermal equilibrium and the temperature TG of the semiconductor wafer reached at the time tG of thermal equilibrium is determined by back calculation with the aid of an equation derived from Newton's law of cooling.

Owner:POLARIS INNOVATIONS LTD

Photoirradiation thermal processing apparatus and thermal processing susceptor employed therefor

ActiveUS7062161B2Avoid crackingAvoid actionLiquid surface applicatorsDrying solid materials with heatSusceptorEngineering

A susceptor is formed with a cavity having a tapered surface and a receiving surface. The gradient α of the tapered surface with respect to the receiving surface is set to at least 5° and less than 30°, so that a semiconductor wafer received by the susceptor can be located on the receiving surface through the tapered surface while the semiconductor wafer can be protected against excess stress also when the surface of the wafer abruptly thermally expands due to flashlight irradiation and can be prevented from cracking in thermal processing. Thus provided are a thermal processing susceptor and a thermal processing apparatus capable of preventing a substrate from cracking in thermal processing.

Owner:DAINIPPON SCREEN MTG CO LTD

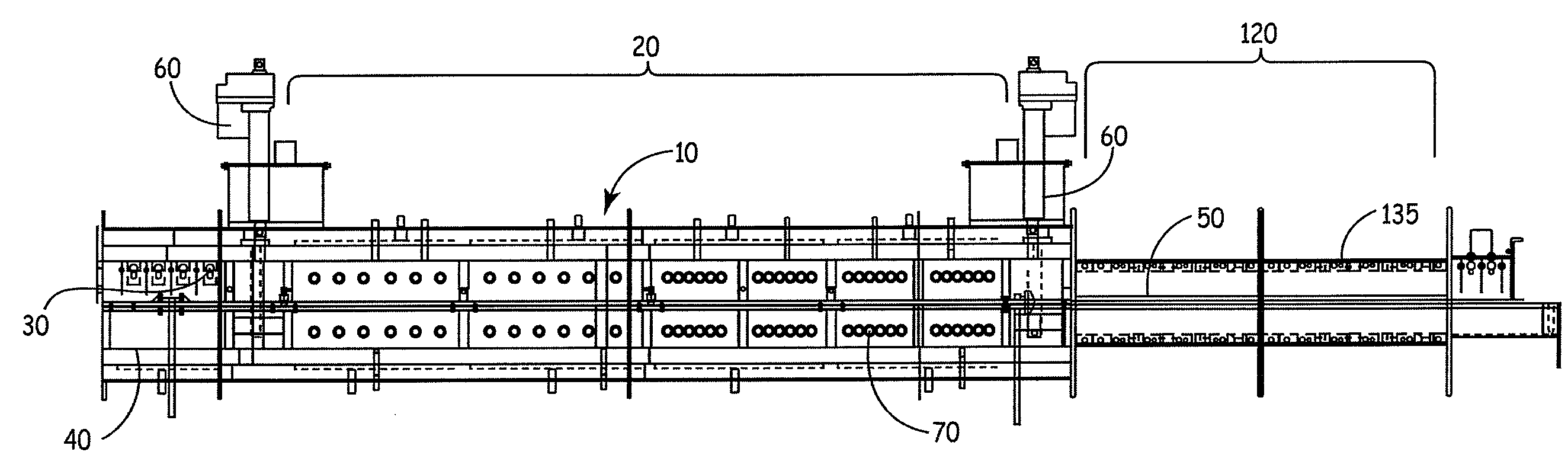

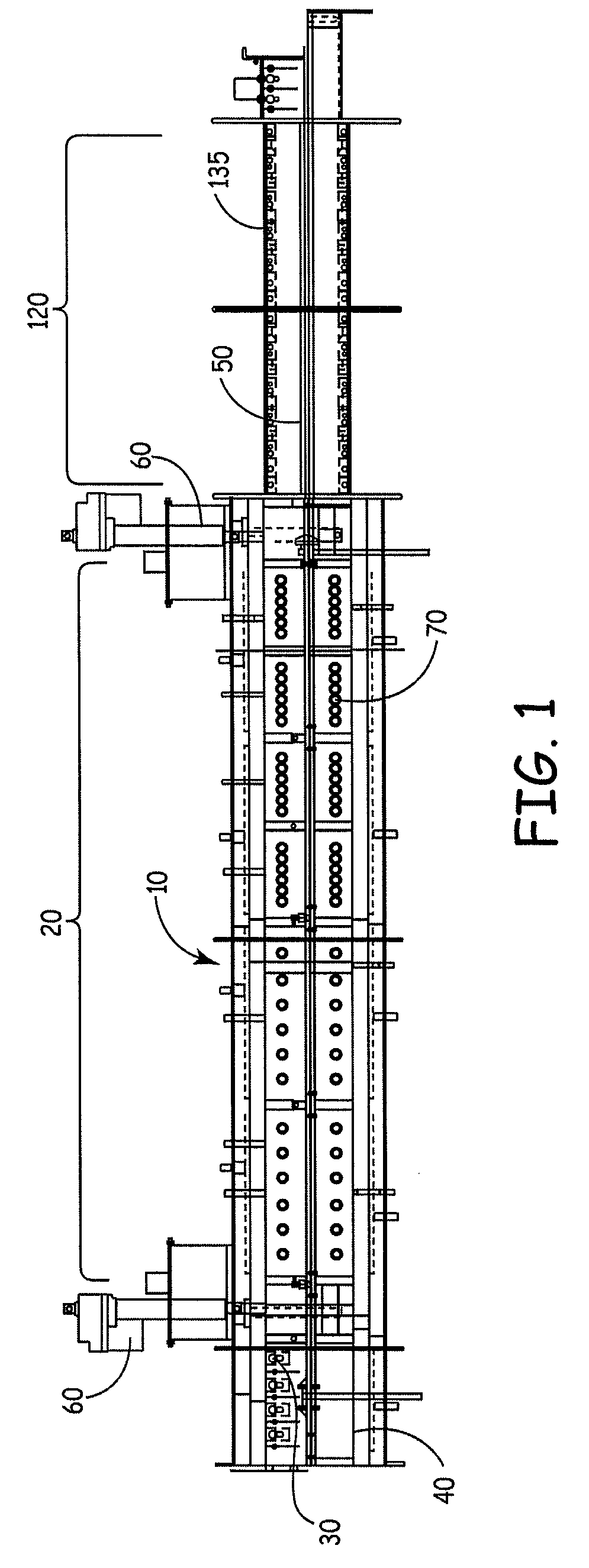

LED heat lamp arrays for CVD heating

Owner:ASM AMERICA INC

Substrate processing apparatus and particle adhesion preventing method

ActiveUS20100111648A1Avoid stickingSecure performanceElectric discharge tubesTemperatue controlTemperature controlParticle adhesion

Owner:TOKYO ELECTRON LTD

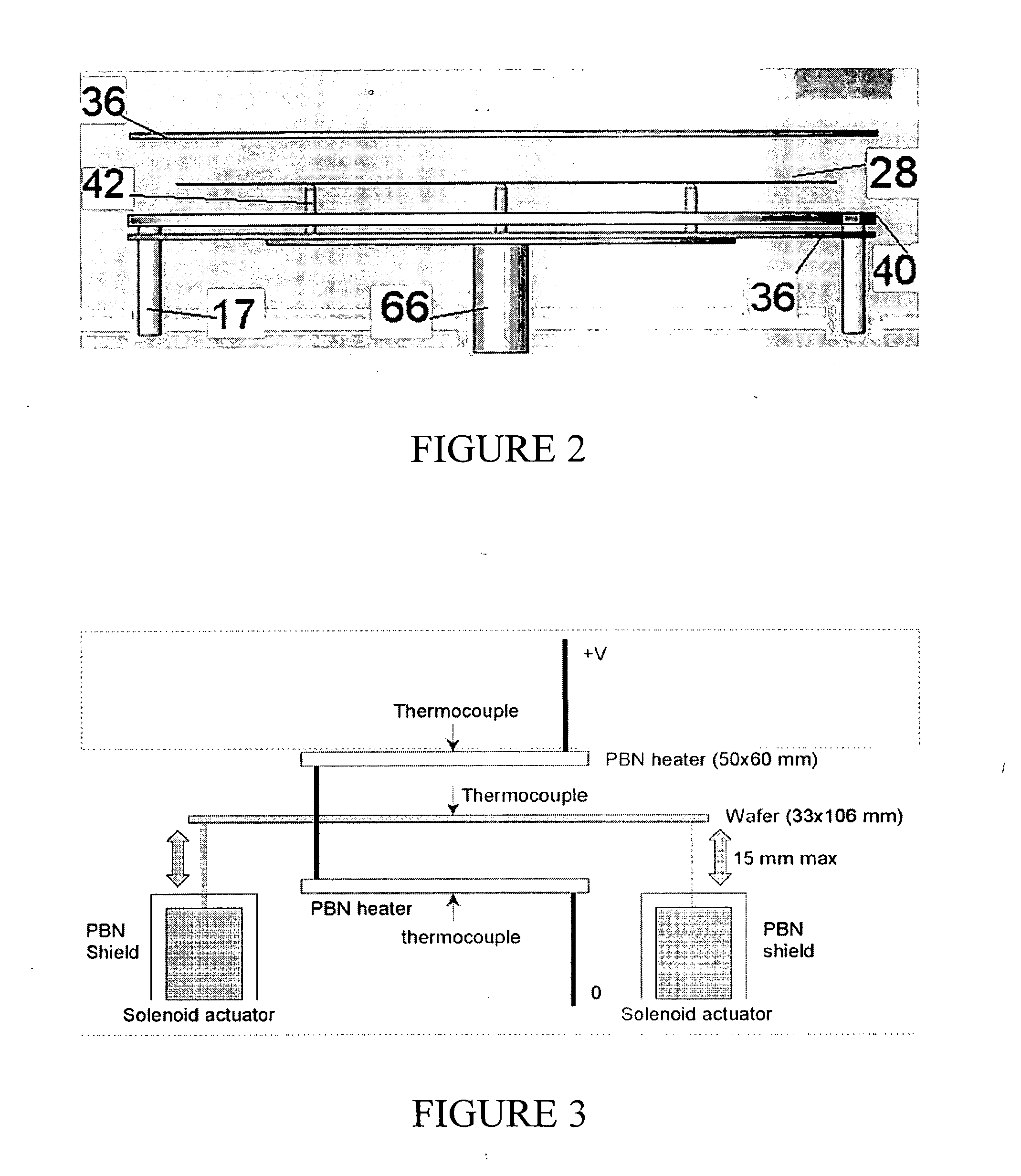

Fast heating and cooling wafer handling assembly and method of manufacturing thereof

InactiveUS20060127067A1Muffle furnacesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceThermal control

A thermal control device for wafer processing which comprises a) a platform for placement of an object of various sizes to be heated, b) at least a shaft extending substantially transverse to the platform; and c) a plurality of resistance heating elements patterned in a plurality of circuits defining at least one zone for independent controlled heating of objects of varying sizes on the platform.

Owner:GENERAL ELECTRIC CO

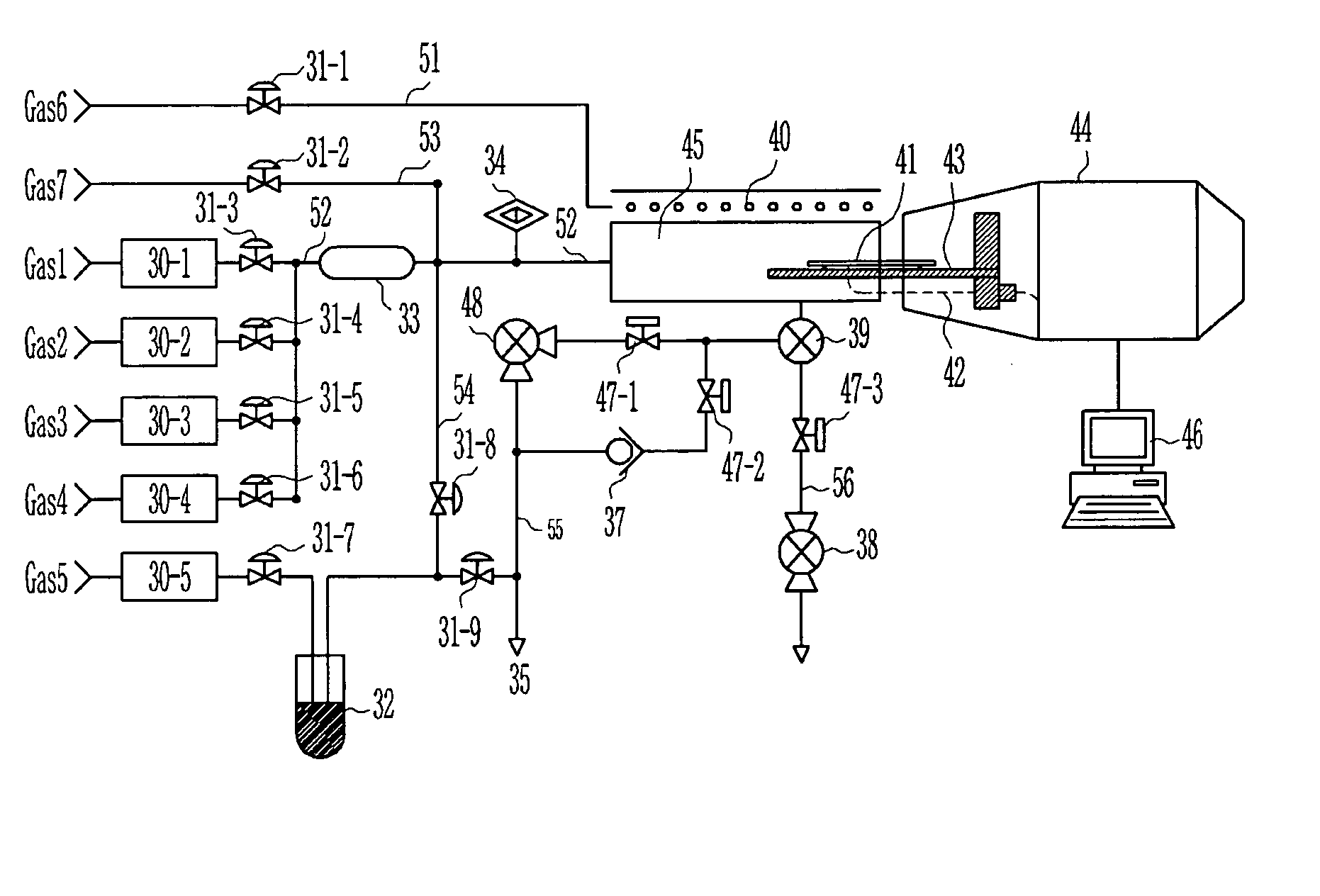

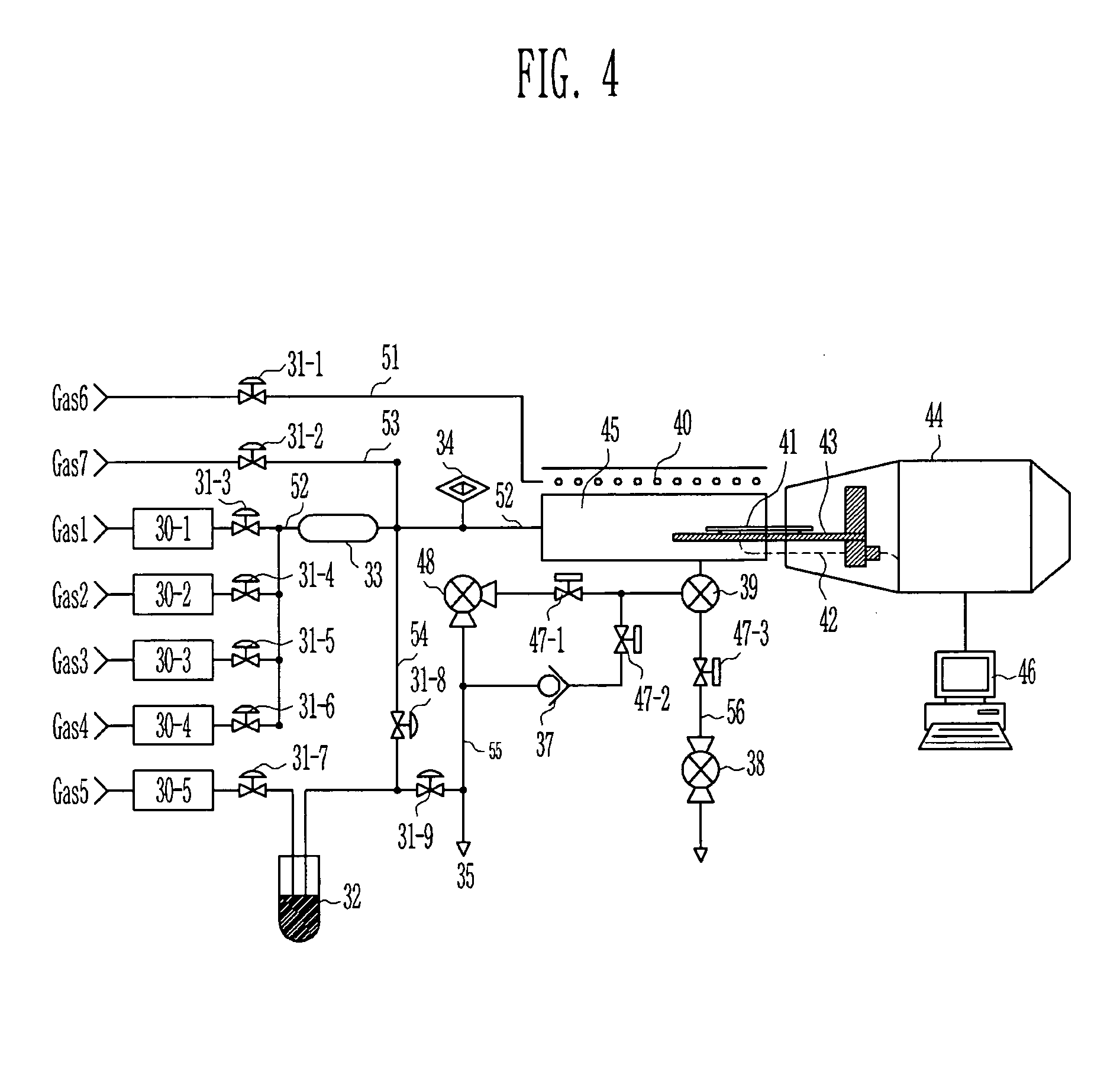

Radical assisted oxidation apparatus

InactiveUS20050115946A1Muffle furnacesSemiconductor/solid-state device manufacturingEngineeringProduct gas

Provided is a radical assisted oxidation apparatus comprising a gas supply system, a radical source, a growth chamber, a load lock chamber, and a vacuum system, whereby it is possible to manufacture a high quality oxide film at a low temperature and improve a low frequency noise (1 / f).

Owner:ELECTRONICS & TELECOMM RES INST

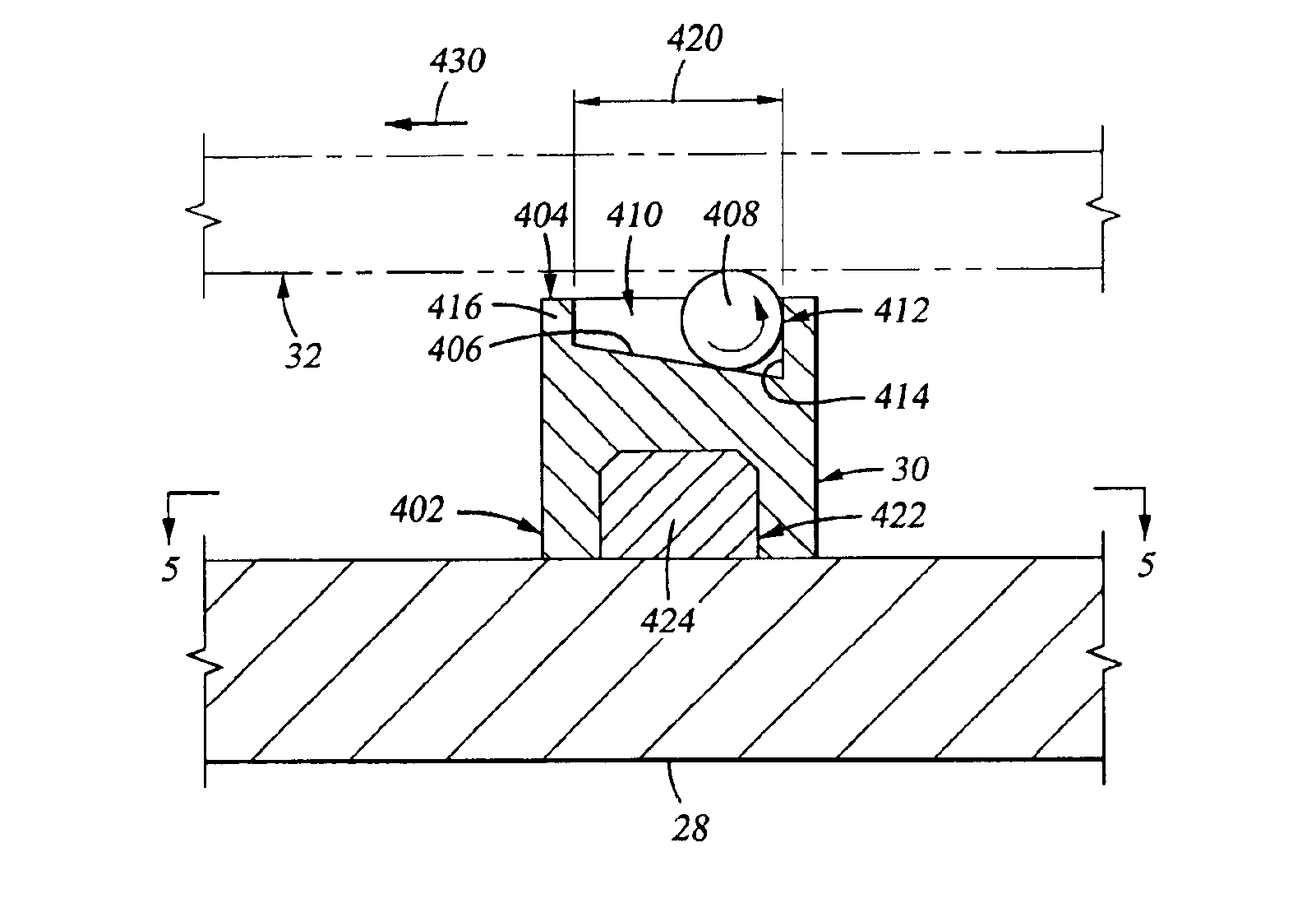

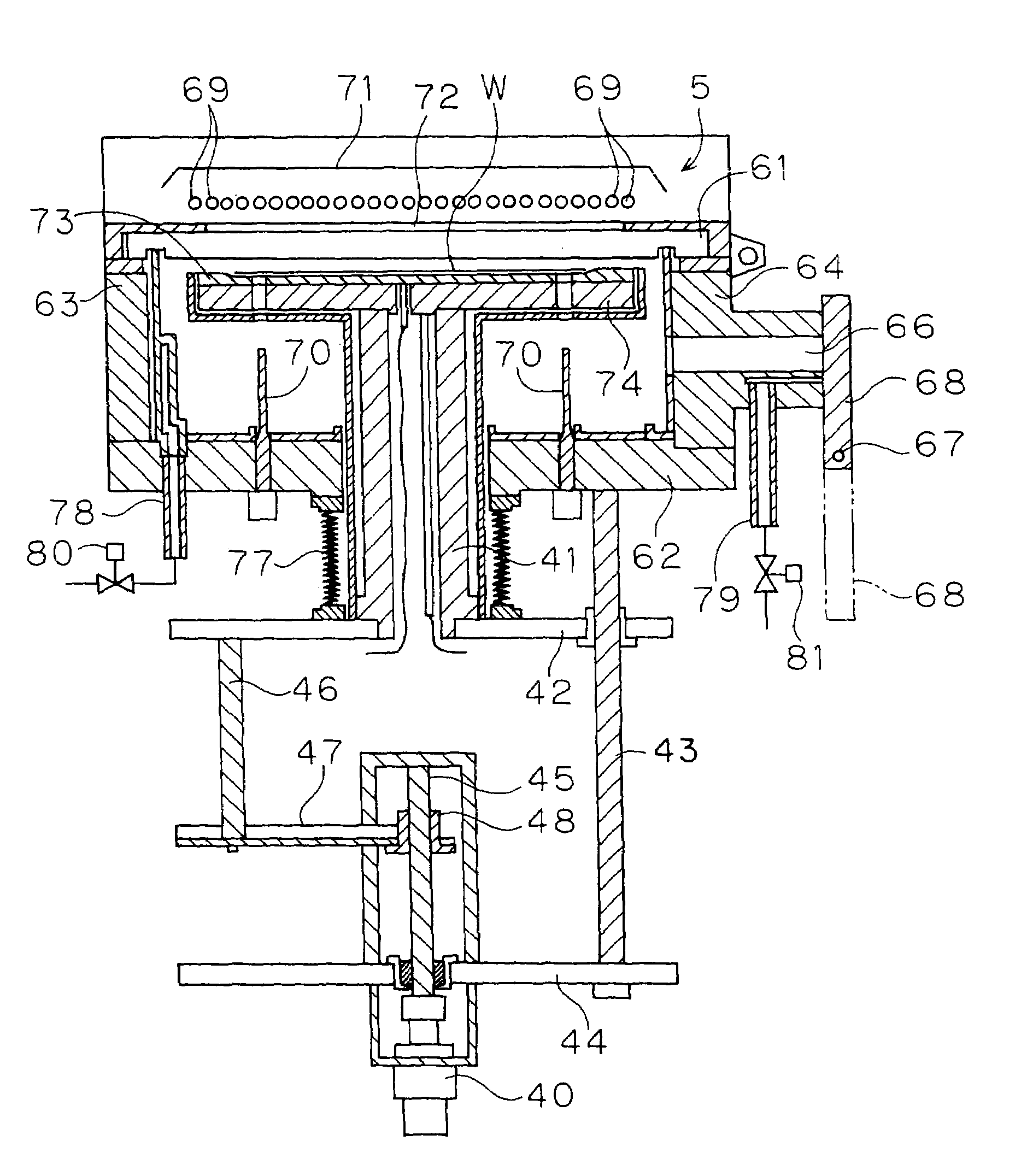

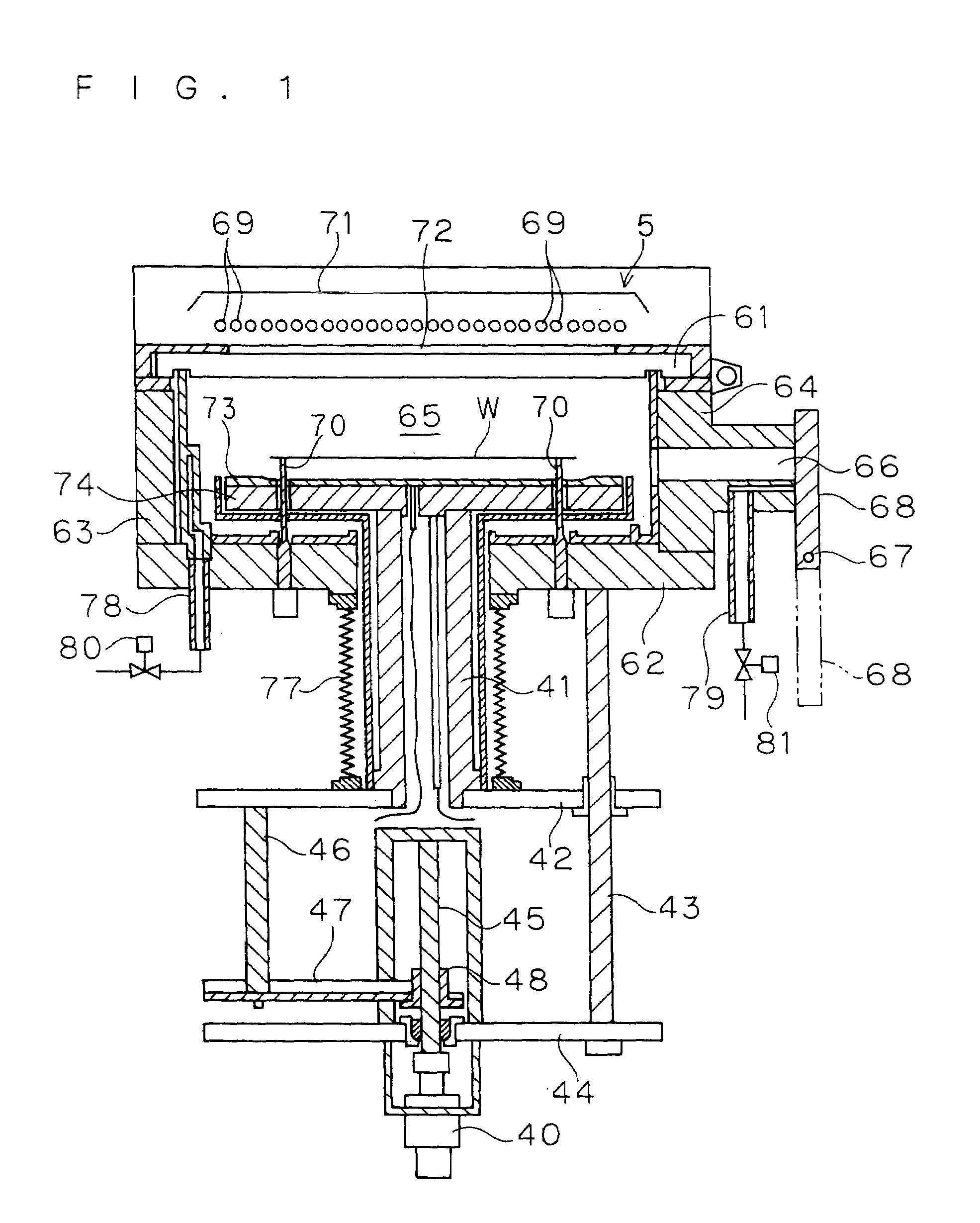

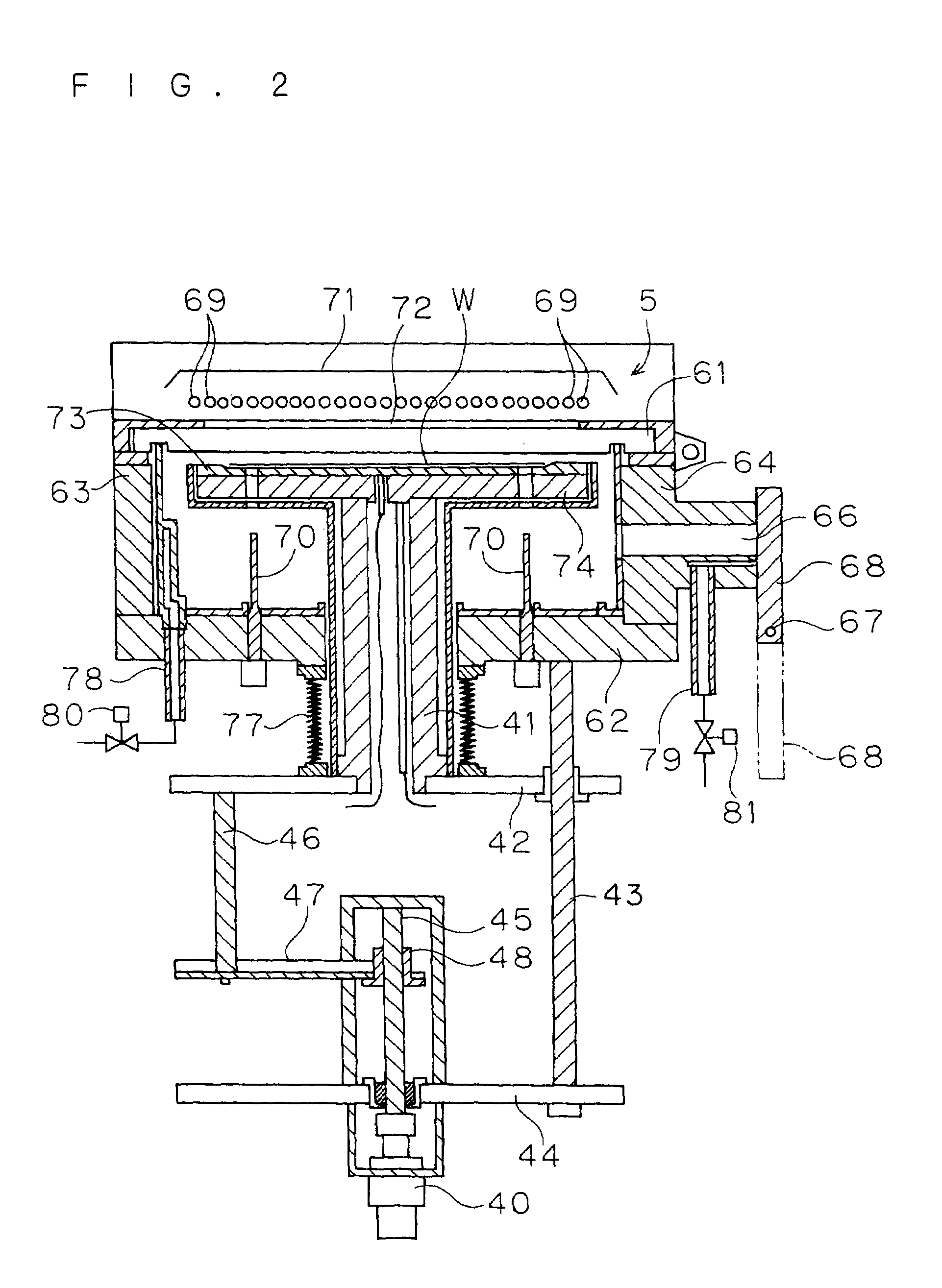

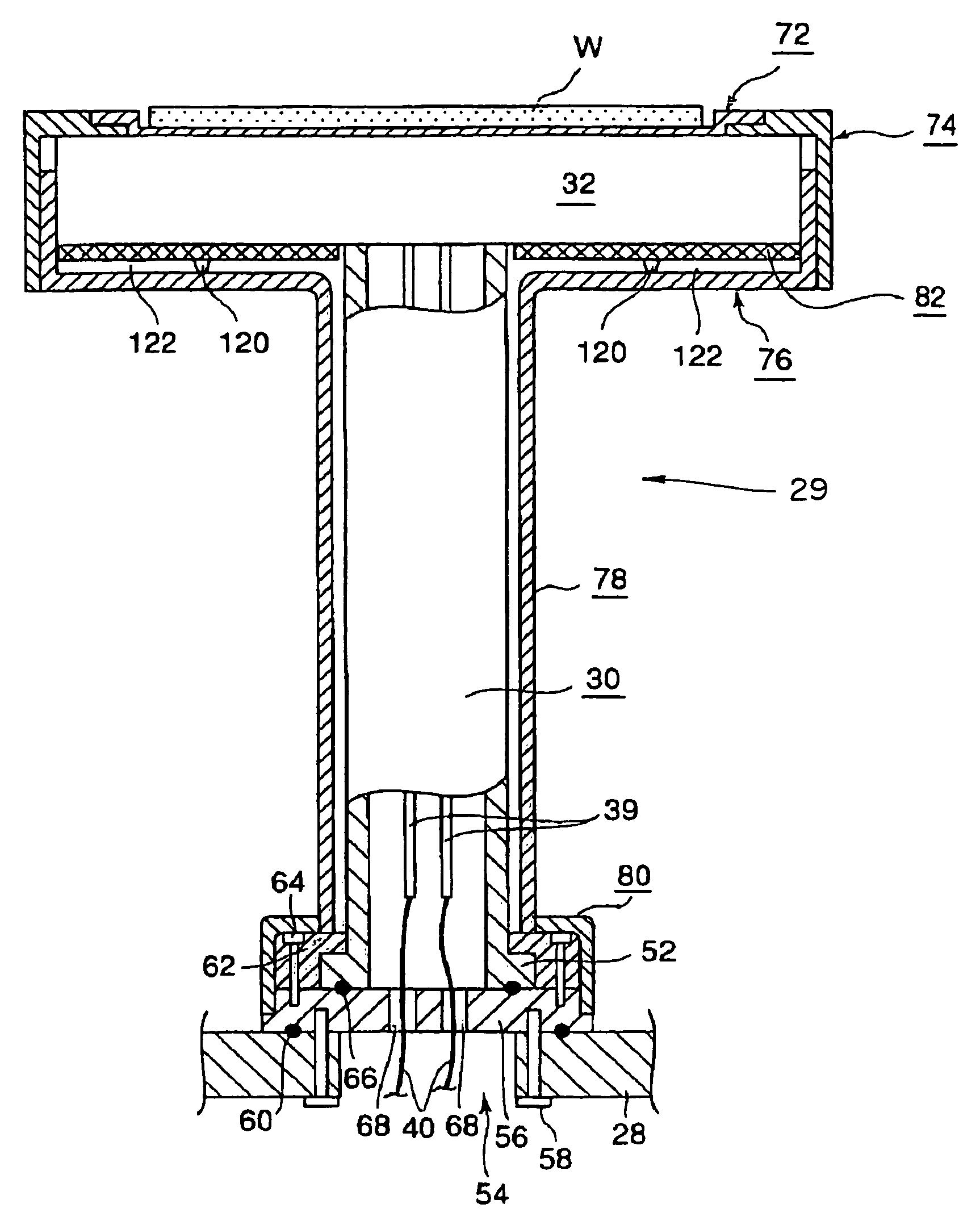

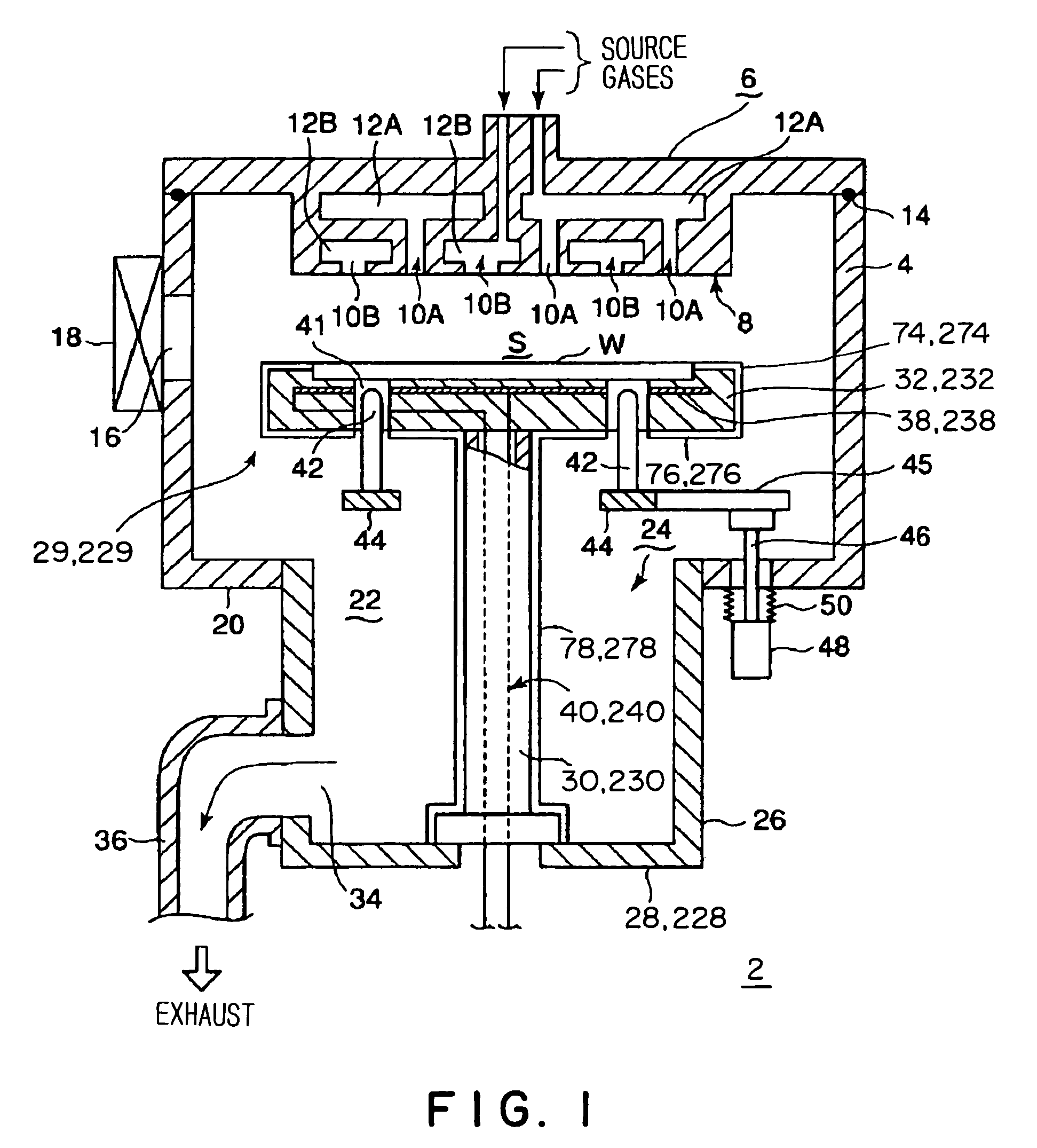

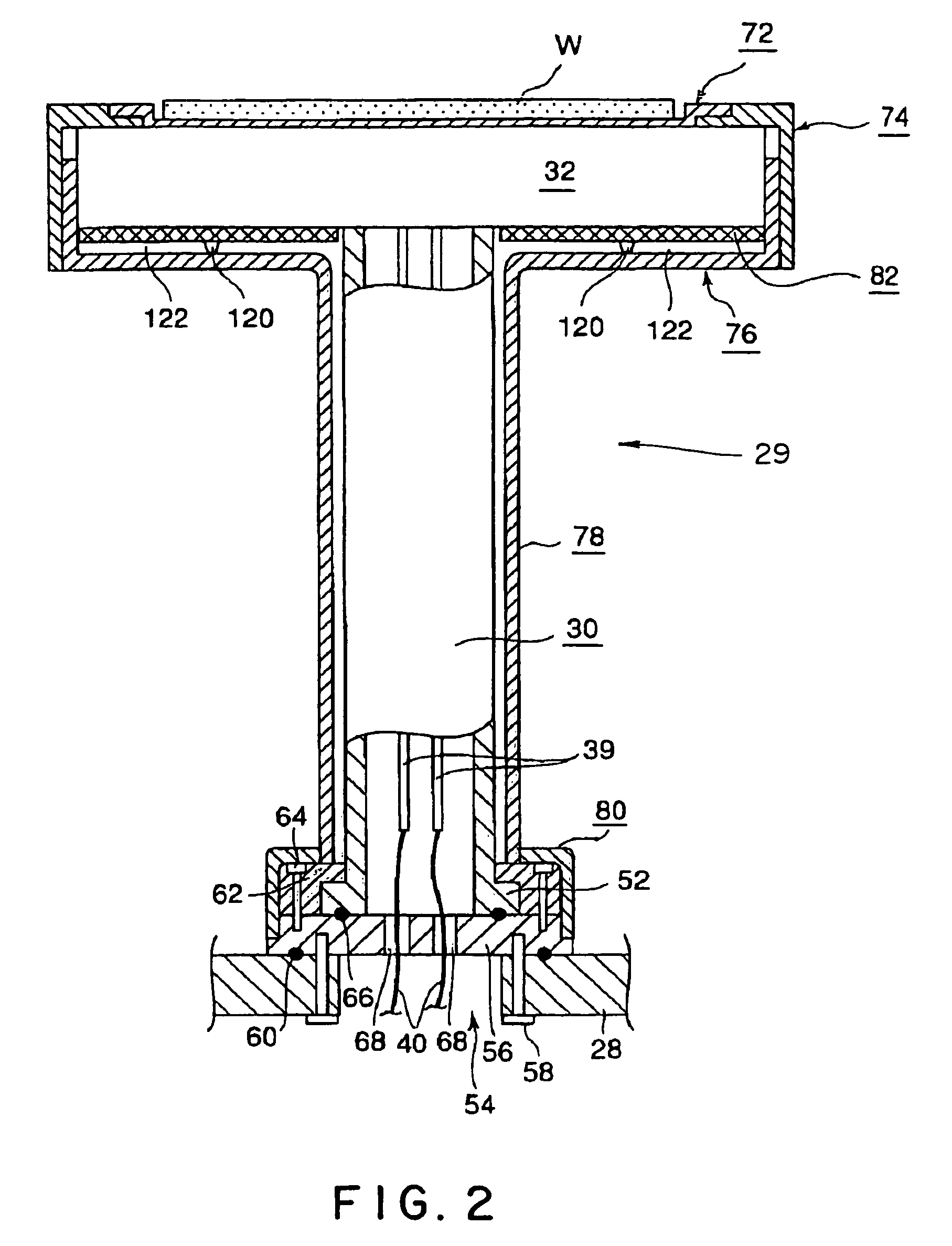

Loading table and heat treating apparatus having the loading table

ActiveUS7718930B2Thermal diffusionPrevent heat from spreadingDrying solid materials with heatMuffle furnacesEngineeringContamination

A thermal processing system has a processing vessel 4, a support post 30 stood on the bottom wall of the processing vessel 4, and a support table 32 internally provided with a heating means 38 and supported on the support post 30. A workpiece W is placed on the upper surface of the support table 32 and is subjected to a predetermined thermal process. The upper, the side and the lower surface of the support table 32 are covered with heat-resistant covering members 72, 74 and 76 to prevent the thermal diffusion of metal atoms causative of contamination from the support table 32. thus, various types of contamination, such as metal and organic contamination, can be prevented.

Owner:TOKYO ELECTRON LTD

Radiant shield

InactiveUS20080314892A1Thermometer detailsDrying solid materials with heatTemperature controlMetallurgy

A radiant shield and a furnace employing a radiant shield for controlled heating and treatment of material using infrared radiation. The furnace is capable of improved temperature control where material treated by the furnace may interfere with the quality of a measured temperature signal and temperature control based on that signal.

Owner:DESPATCH INDS

Thermal processing furnace and liner for the same

ActiveUS20120186573A1Easy to transportReduce decreaseDomestic stoves or rangesRotary drum furnacesEngineeringBell jar

A thermal processing furnace, comprising:a generally bell jar-shaped outer reaction tube having a central axis; andan open-ended inner reaction tube for accommodating a wafer boat holding a plurality of substrates, which inner reaction tube is substantially coaxially disposed within the outer reaction tube, thereby defining a gas passage between an outer wall of the inner reaction tube and an inner wall of the outer reaction tube,wherein at least one of the outer wall of the inner reaction tube and the inner wall of the outer reaction tube is provided with a flow deflector that protrudes radially from the respective wall into the gas passage.

Owner:ASM INTERNATIONAL

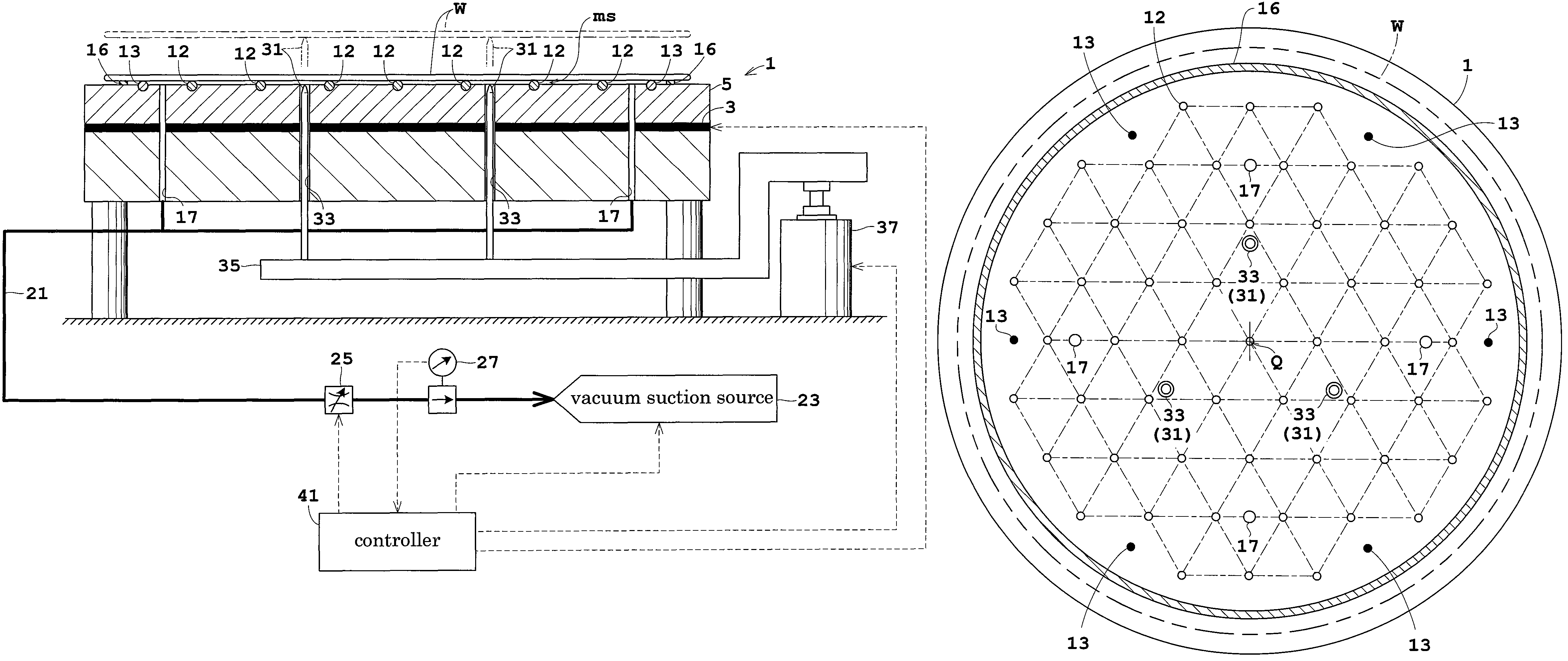

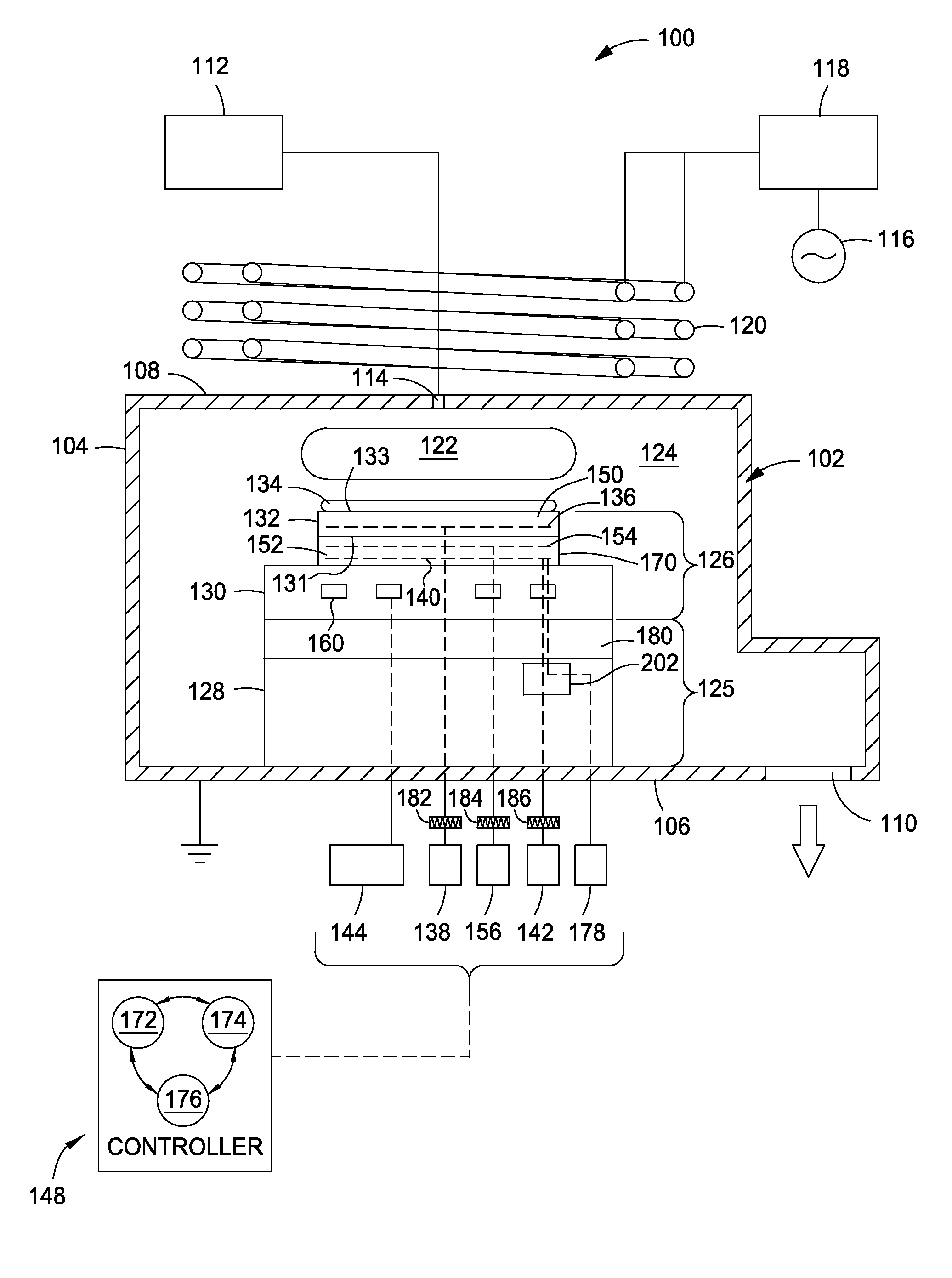

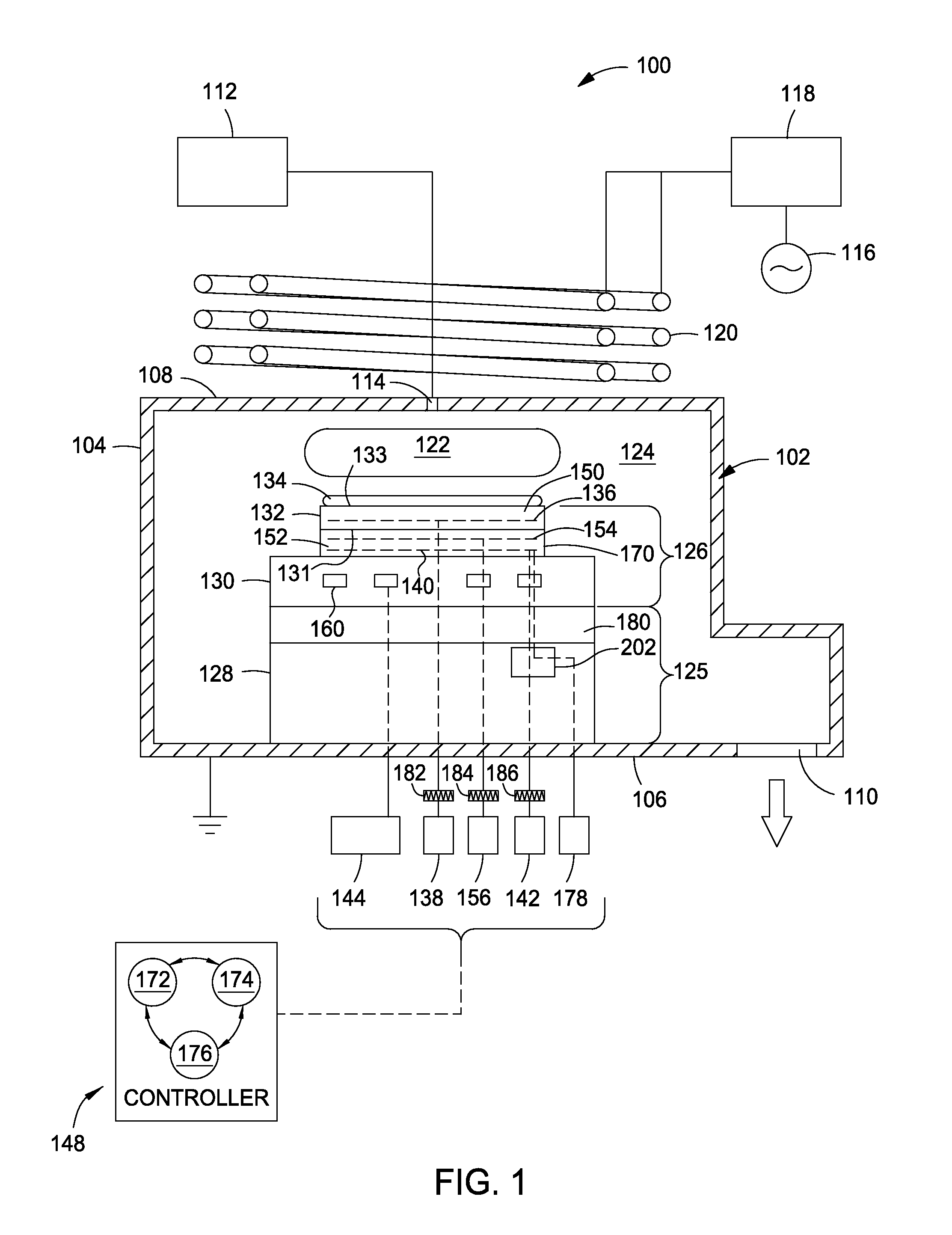

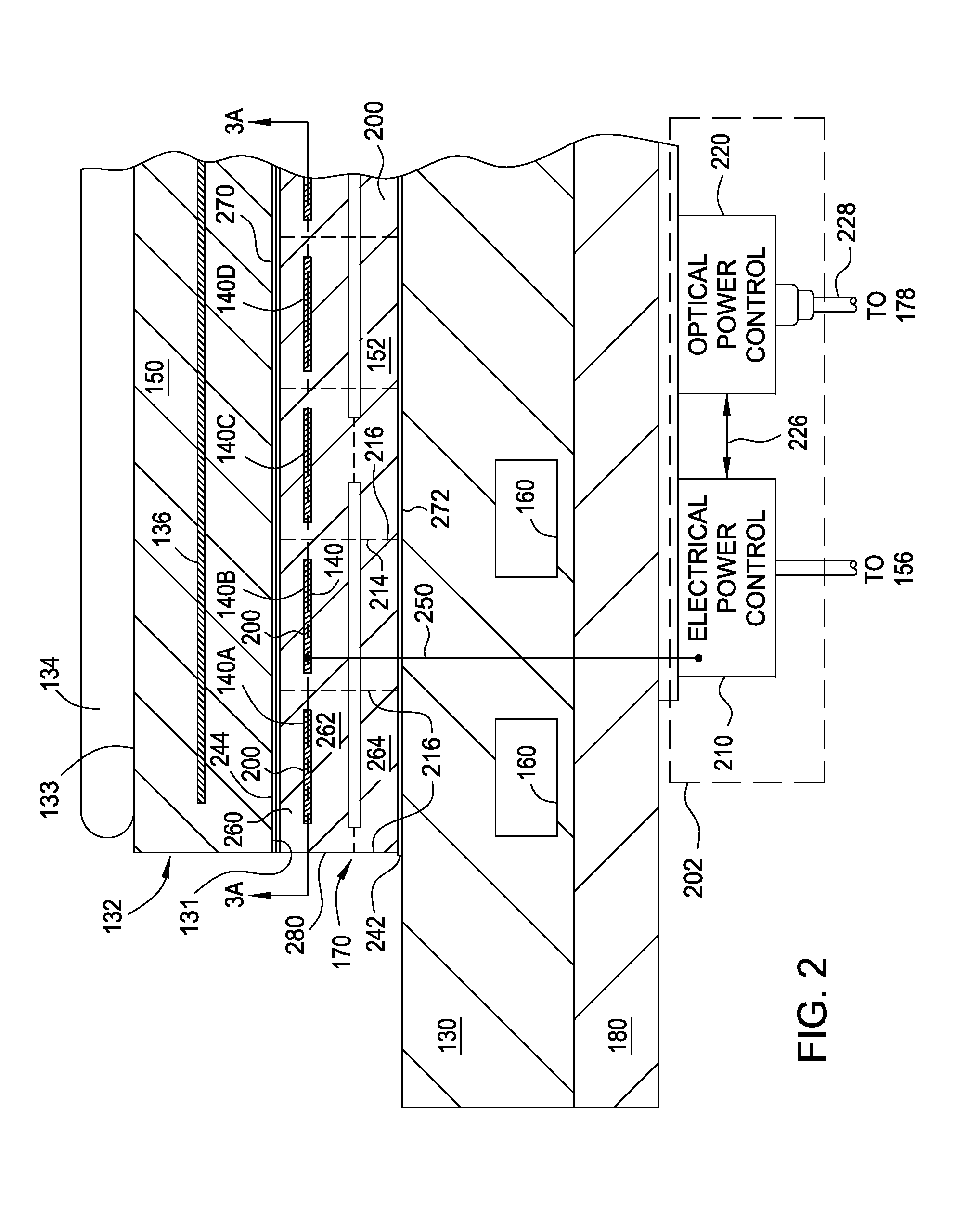

Pixilated temperature controlled substrate support assembly

ActiveUS20150228513A1Charge supportsBaking ovenElectrical resistance and conductanceTemperature control

Implementations described herein provide a pixilated substrate support assembly which enables both lateral and azimuthal tuning of the heat transfer between an electrostatic chuck and a heating assembly. The pixilated substrate support assembly comprises an upper surface and a lower surface; one or more main resistive heaters disposed in the pixilated substrate support; and a plurality of pixel heaters in column with the main resistive heaters and disposed in the substrate support. A quantity of the pixel heaters is an order of magnitude greater than a quantity of the main resistive heaters and the pixel heaters are independently controllable relative to each other as well as the main resistive heater.

Owner:APPLIED MATERIALS INC

Rapid conductive cooling using a secondary process plane

A method and apparatus for thermally processing a substrate is described. The apparatus includes a substrate support configured to move linearly and / or rotationally by a magnetic drive. The substrate support is also configured to receive a radiant heat source to provide heating region in a portion of the chamber. An active cooling region comprising a cooling plate is disposed opposite the heating region. The substrate may move between the two regions to facilitate rapidly controlled heating and cooling of the substrate.

Owner:APPLIED MATERIALS INC

Vacuum thermal annealer

A vacuum thermal annealing device is provided having a temperature control for use with various materials, such as semiconductor substrates. A vacuum is used to remove air and outgas residual materials. Heated gas is injected planar to a substrate as pressure is quickly raised. Concurrent with the heated gas flow, a chamber wall heater is turned on and maintains a temperature for a proper annealing time. Upon completion of the annealing process, the chamber wall heater shuts down and air is forced around the chamber wall heater. Additionally, cool gas replaces the heated gas to cool the substrate.

Owner:STEED TECH

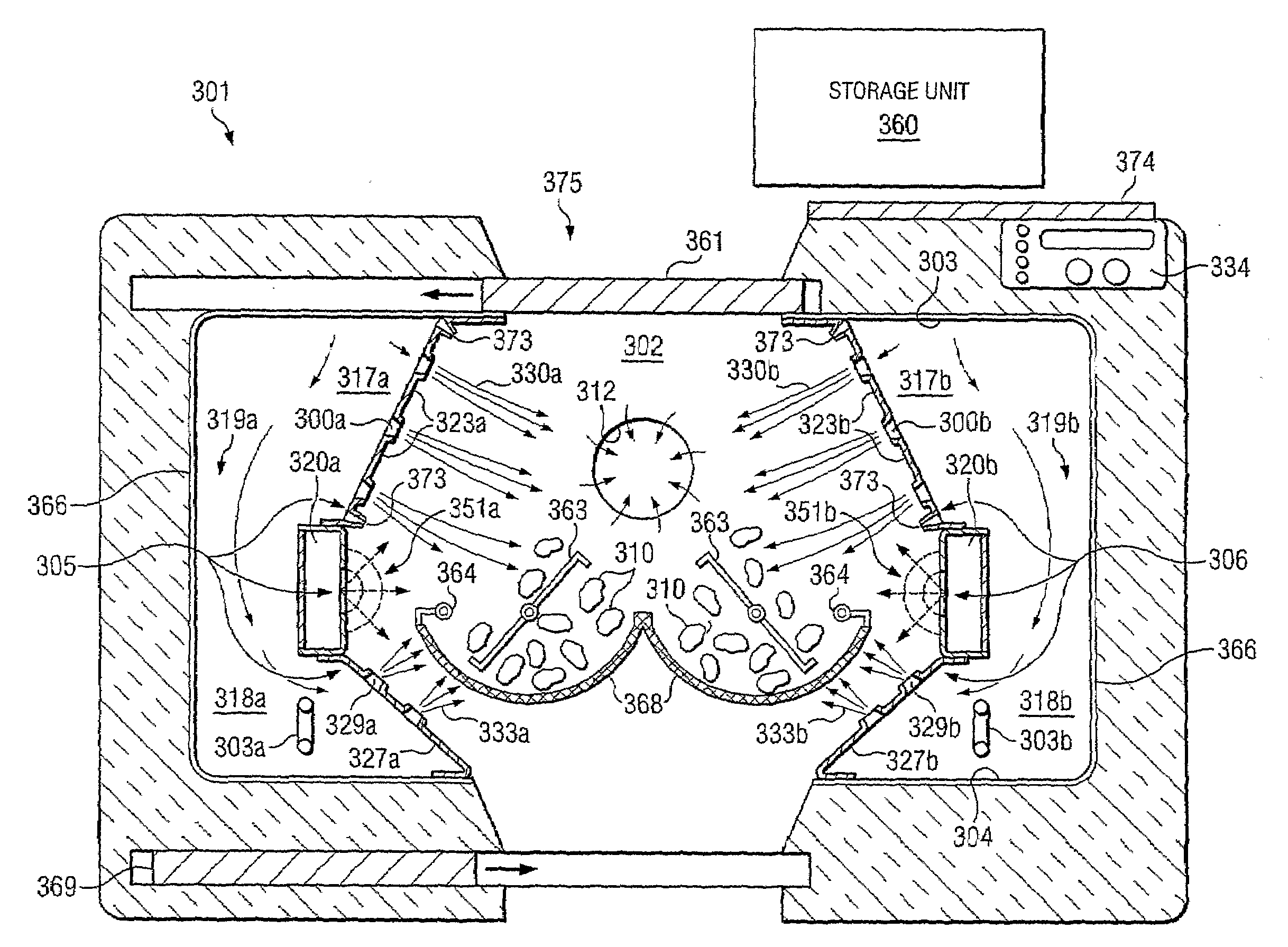

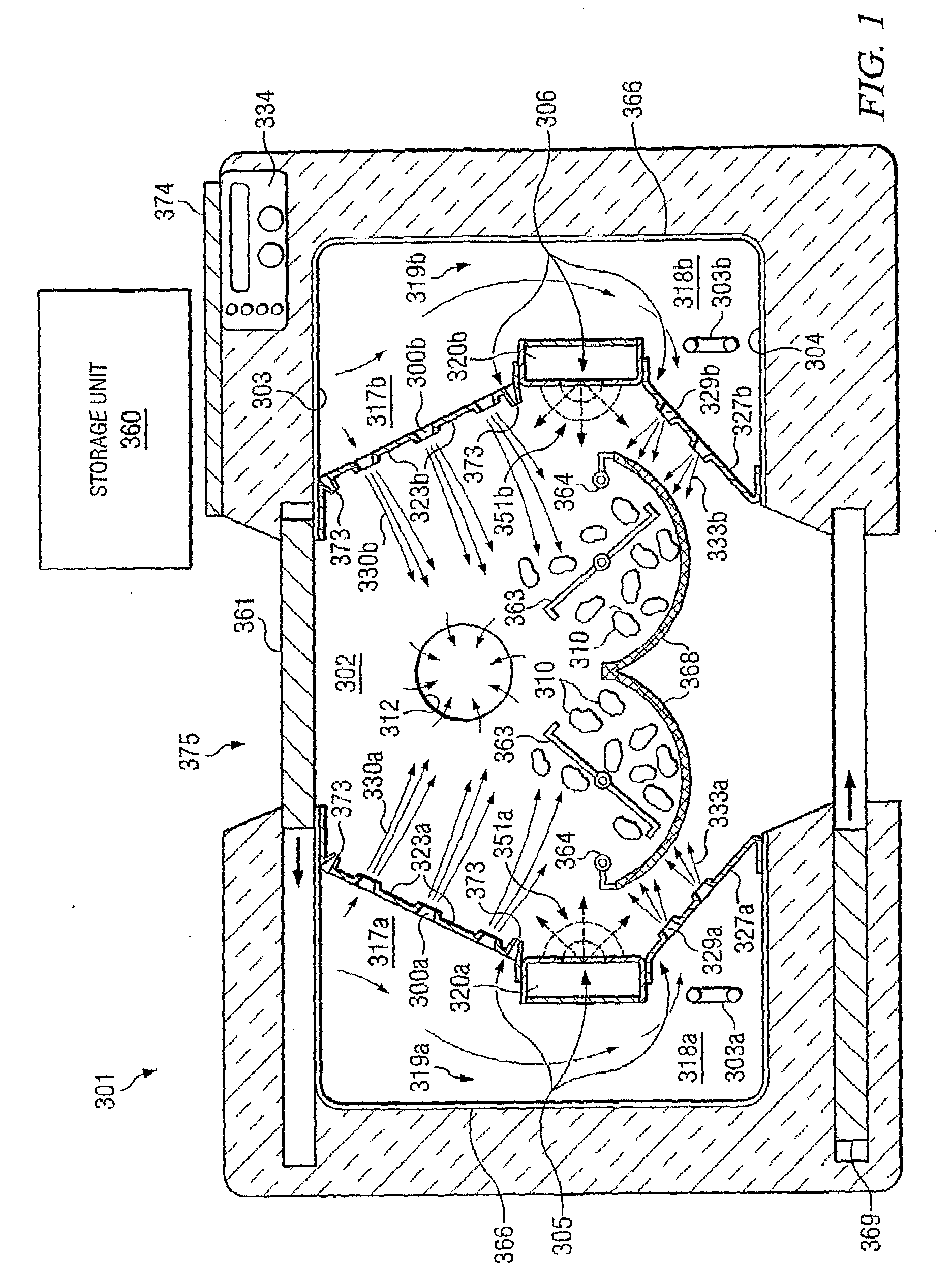

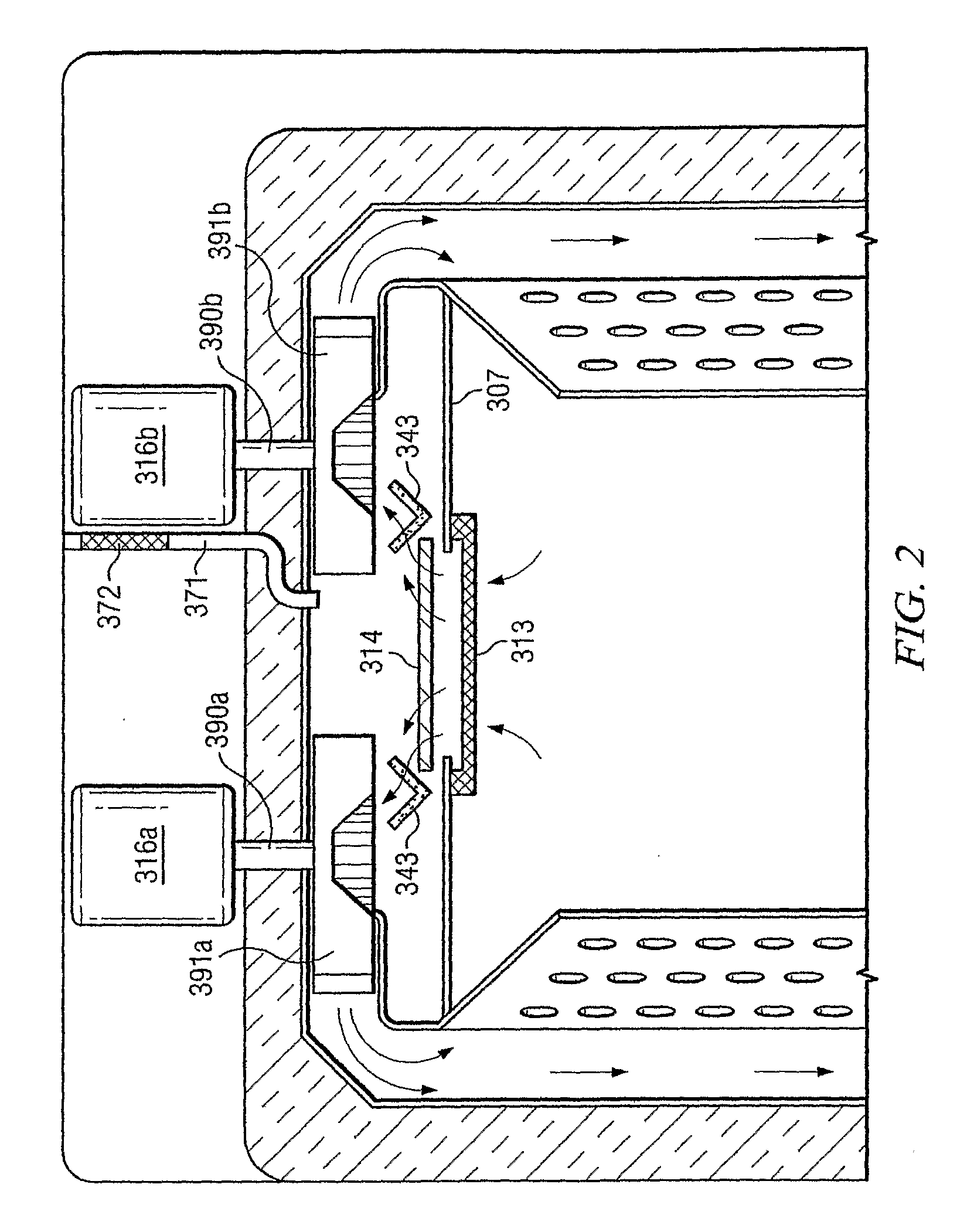

Air Fryer

InactiveUS20080206420A1Improve heat transfer performanceProvide taste and texture and appearance characteristicDomestic stoves or rangesElectrical heating fuelProduct gasProcess engineering

An accelerated cooking air fryer is disclosed comprising a cavity, controller, thermal heating source, blower assembly, gas directing means and a vent assembly. Hot gas is circulated by the blower motor assembly into the air fryer cavity where the hot air is directed in a manner wherein a conflicting, colliding turbulent gas flow is directed at a food product providing for the accelerated cooking of the food product.

Owner:TURBOCHEF TECH INC

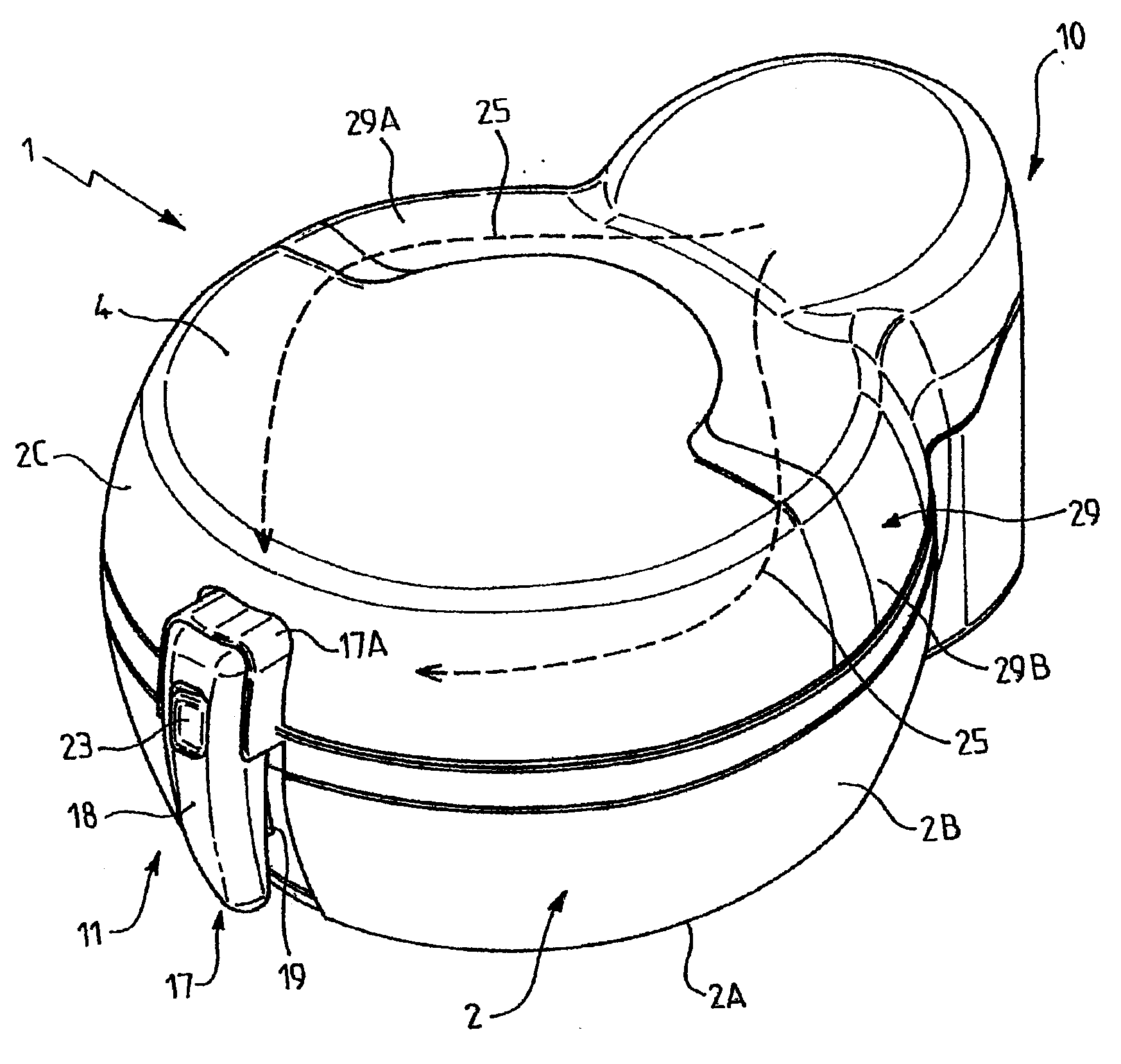

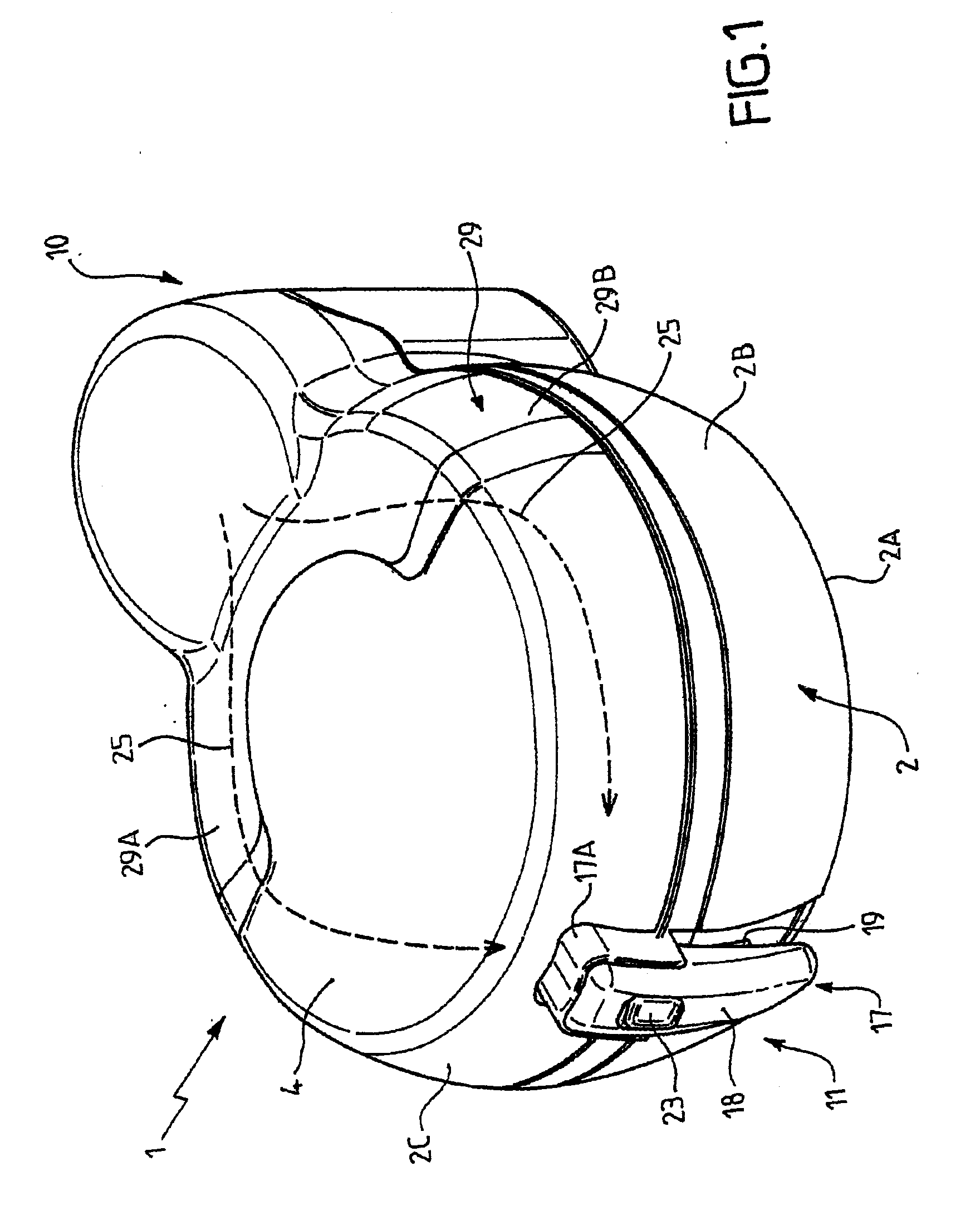

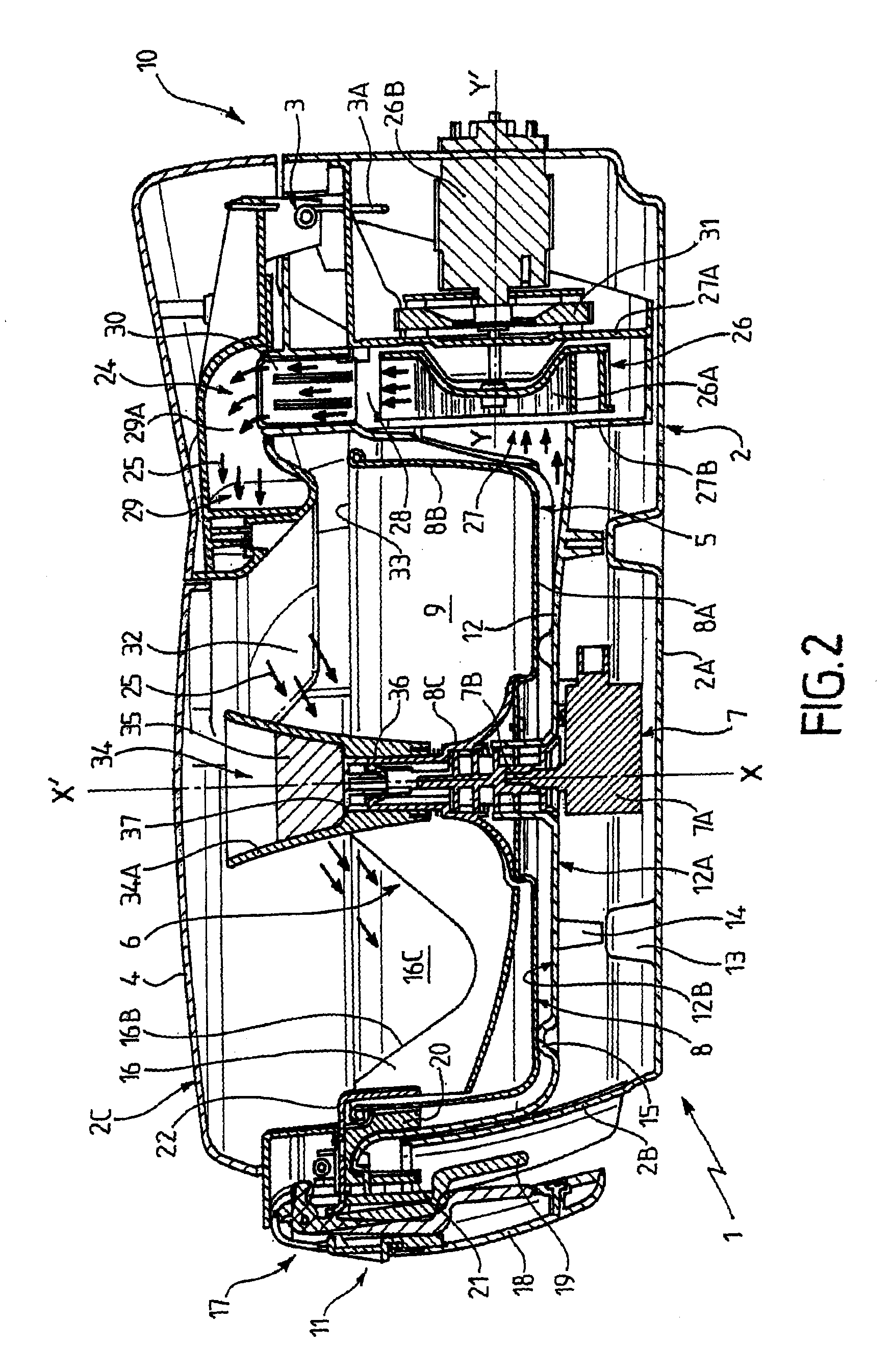

Fryer with Automatic Coating of Fat

ActiveUS20080213447A1Easy to useEasy maintenanceMilk preservationRoasting apparatusEngineeringFood products

Owner:SEB SA

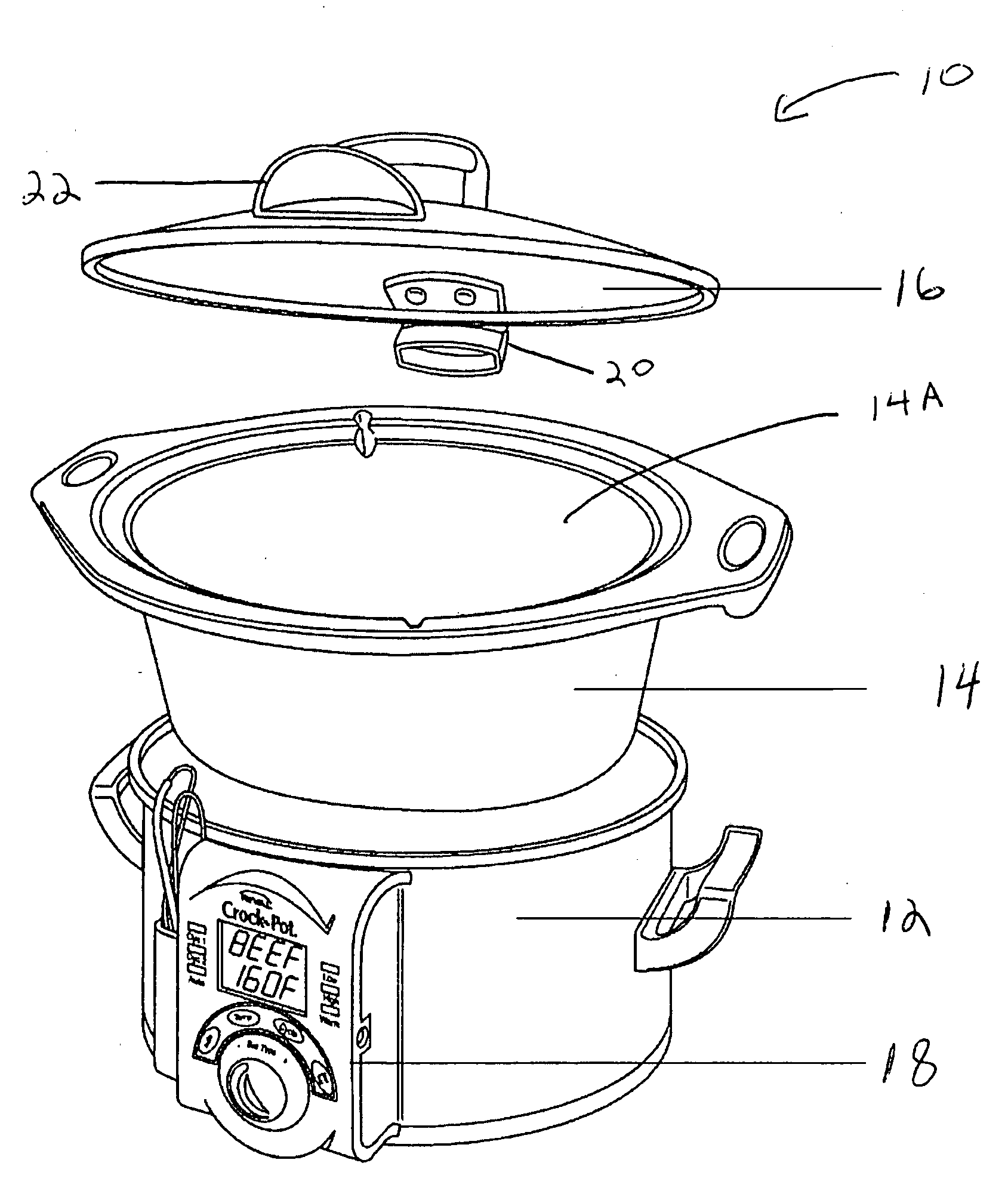

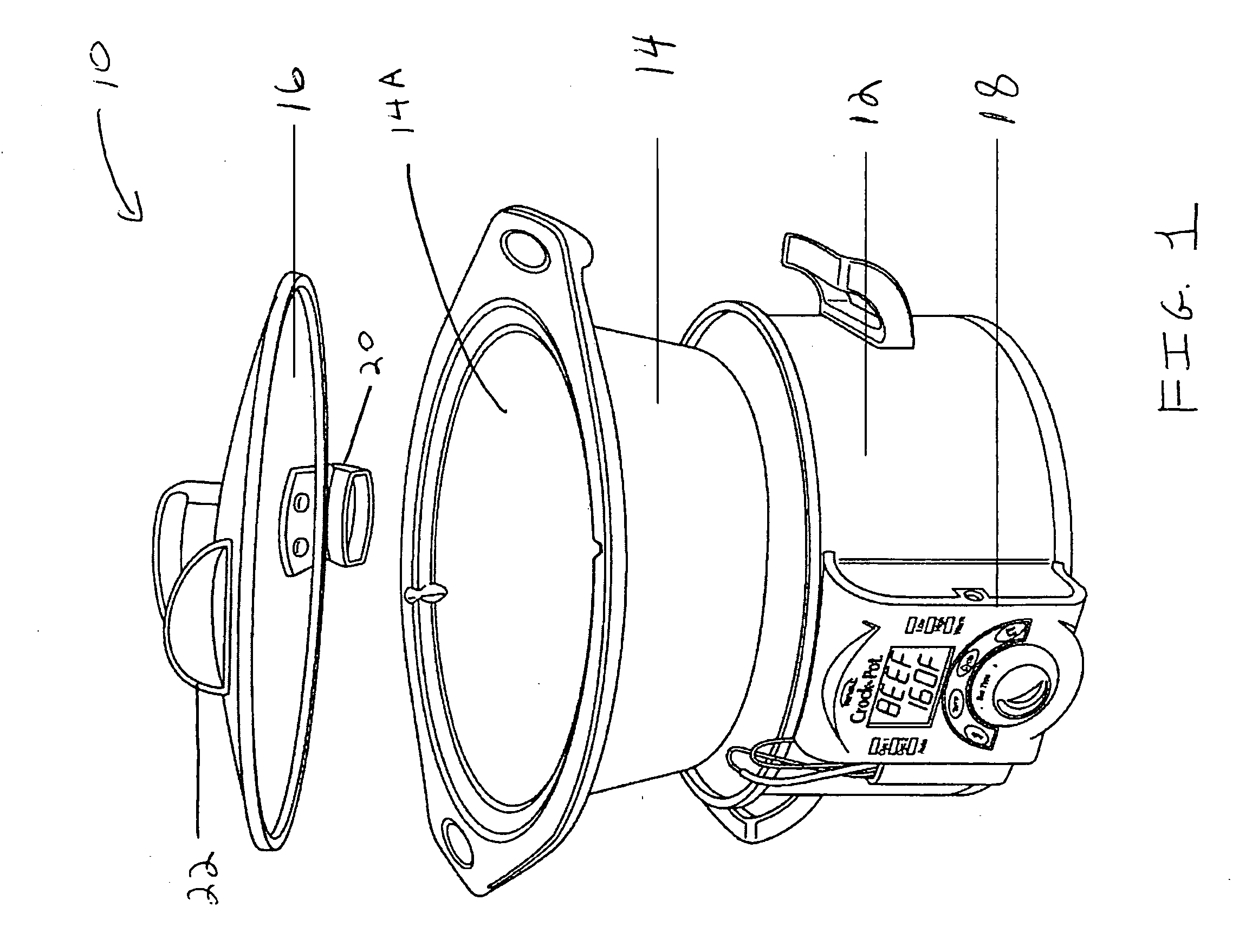

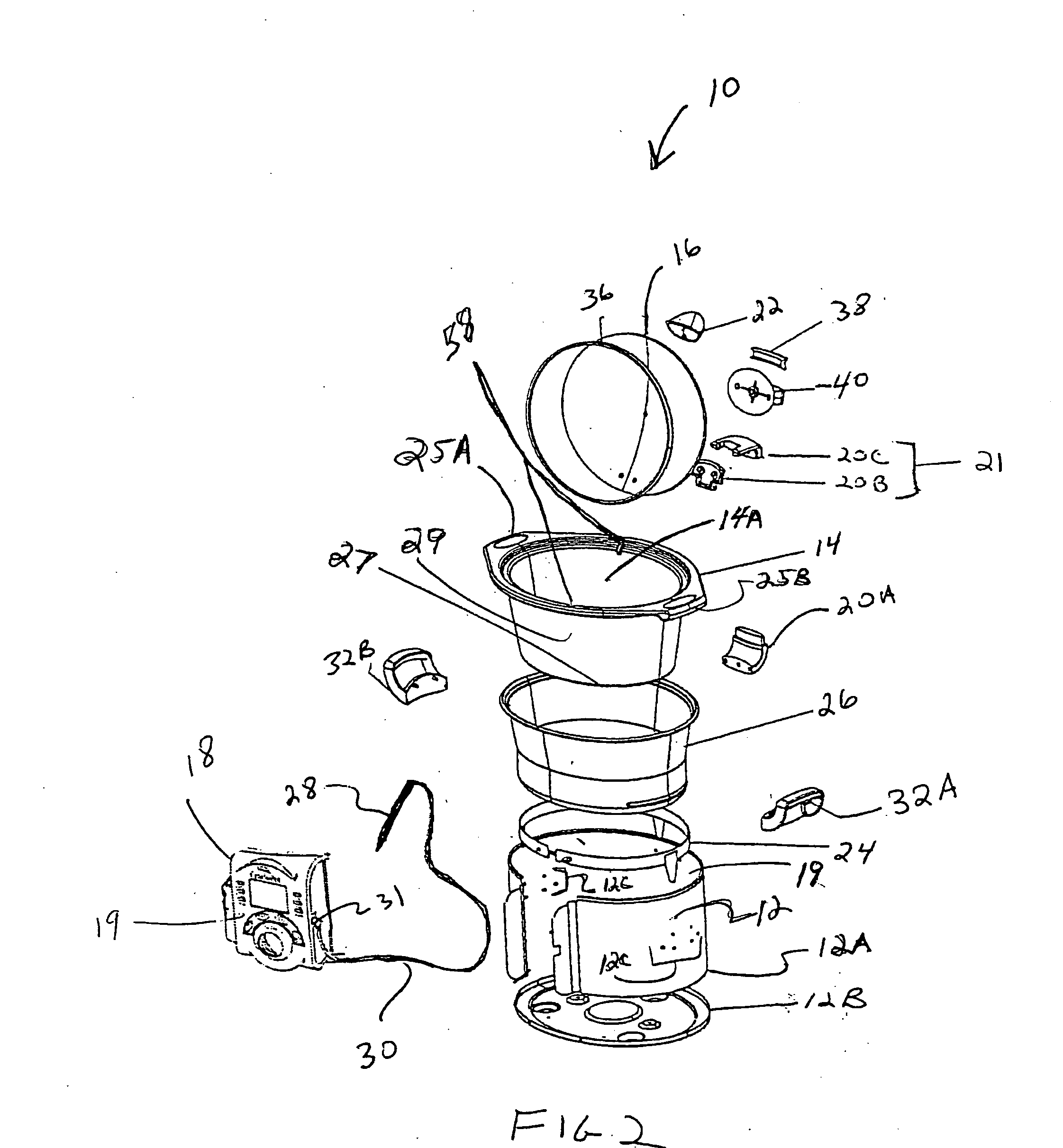

Cooking apparatus with temperature probe and hinged lid

InactiveUS20080083730A1Readily apparentBoiling over preventionCooking-vessel lids/coversThermal probeEngineering

The invention pertains to a multi-functional cooker having a thermal probe operatively connected to a controller for controlling a heating element in response to a real-time temperature reading from the probe. By controlling the level of heat provided by the heating element in response to real-time temperature readings, optimal comestible flavor may be achieved. The multi-functional cooker also includes a hinged lid for directing fluid on an inner surface of the lid into a cooking vessel of the invention upon opening of the lid.

Owner:SUNBEAN PROD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com