Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Efficient heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

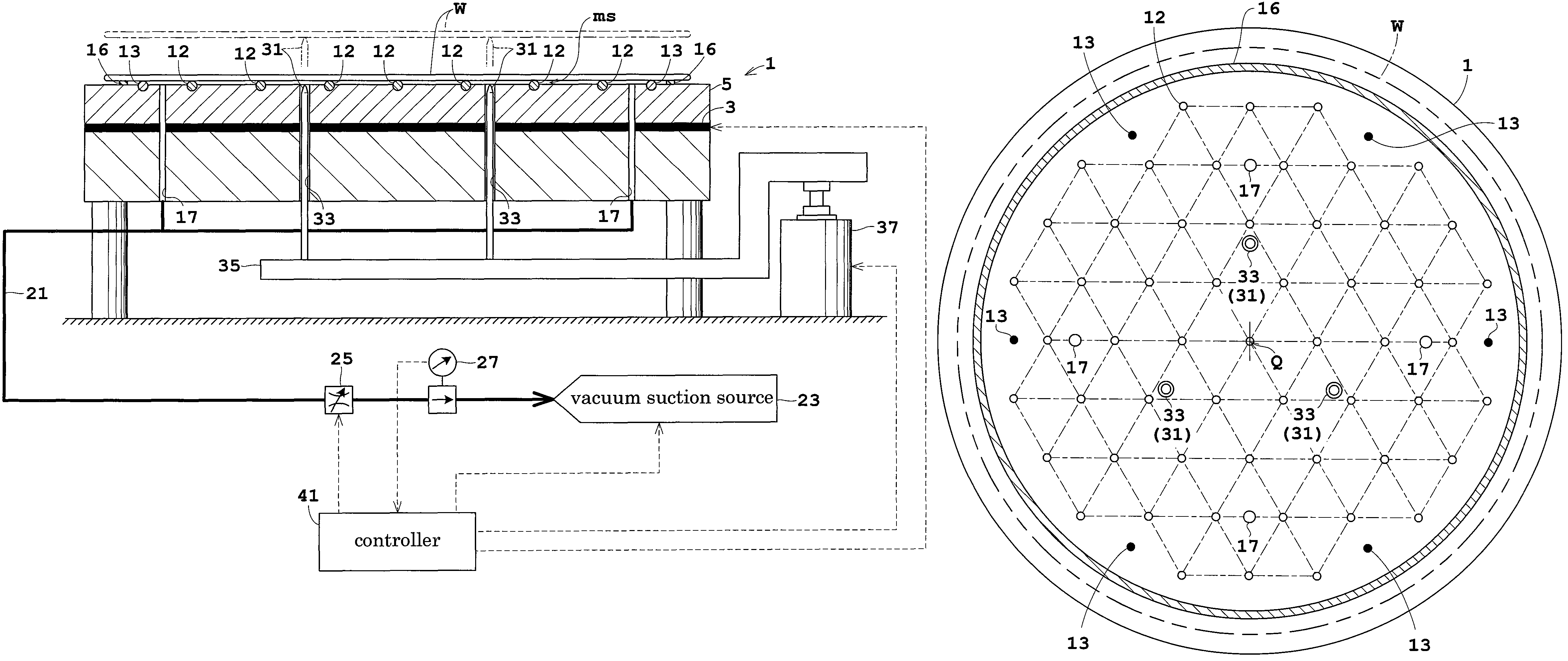

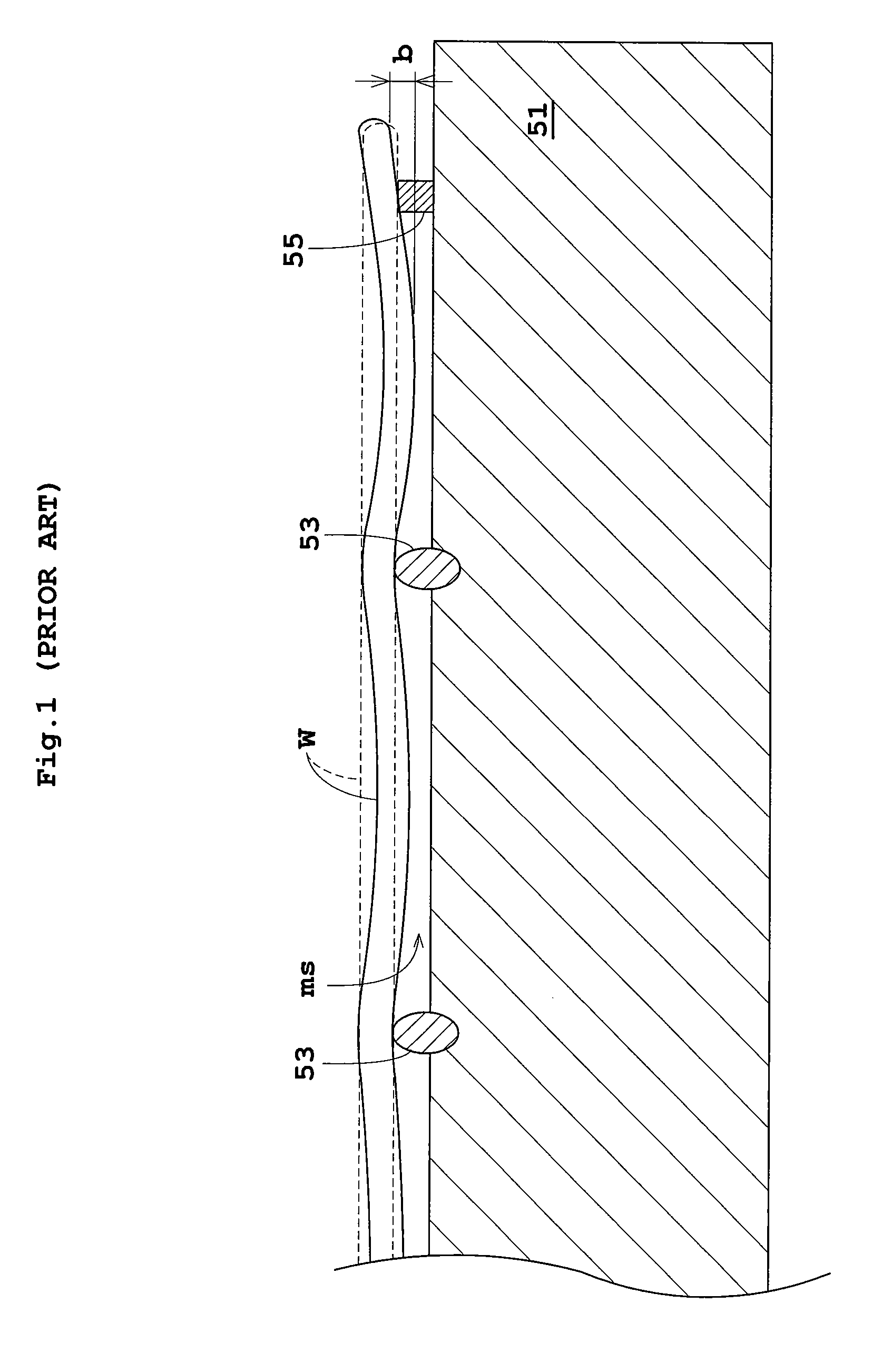

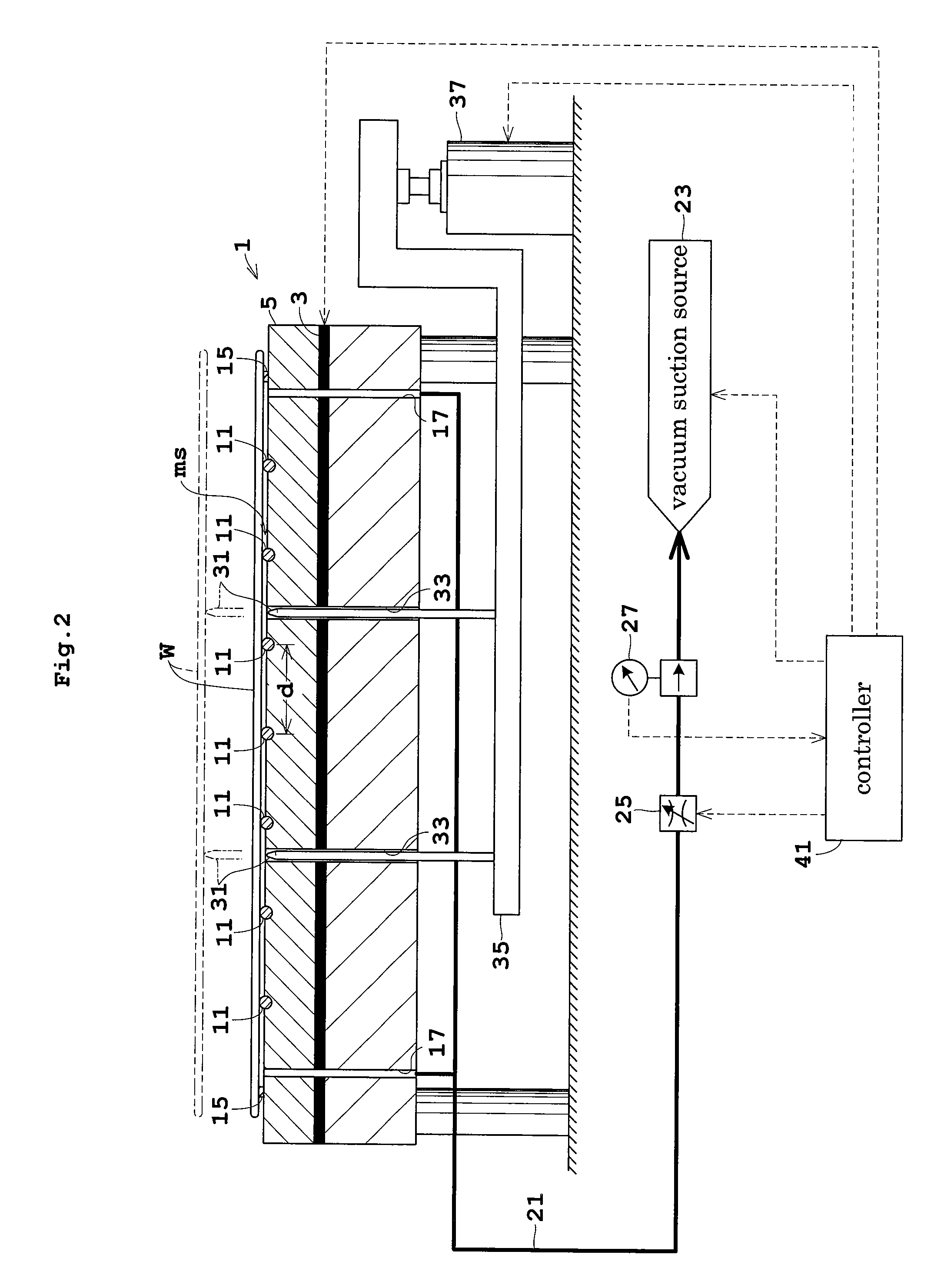

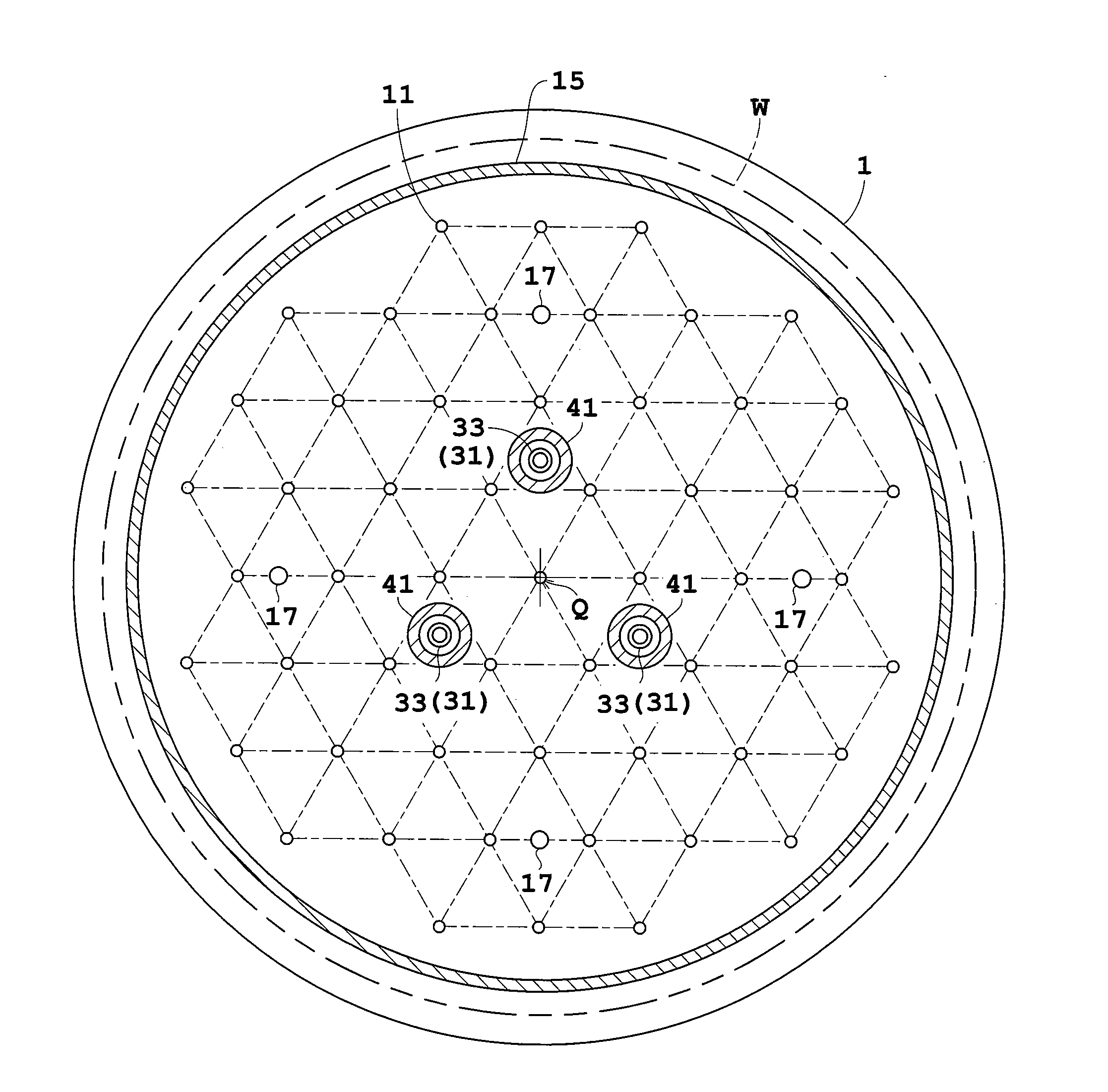

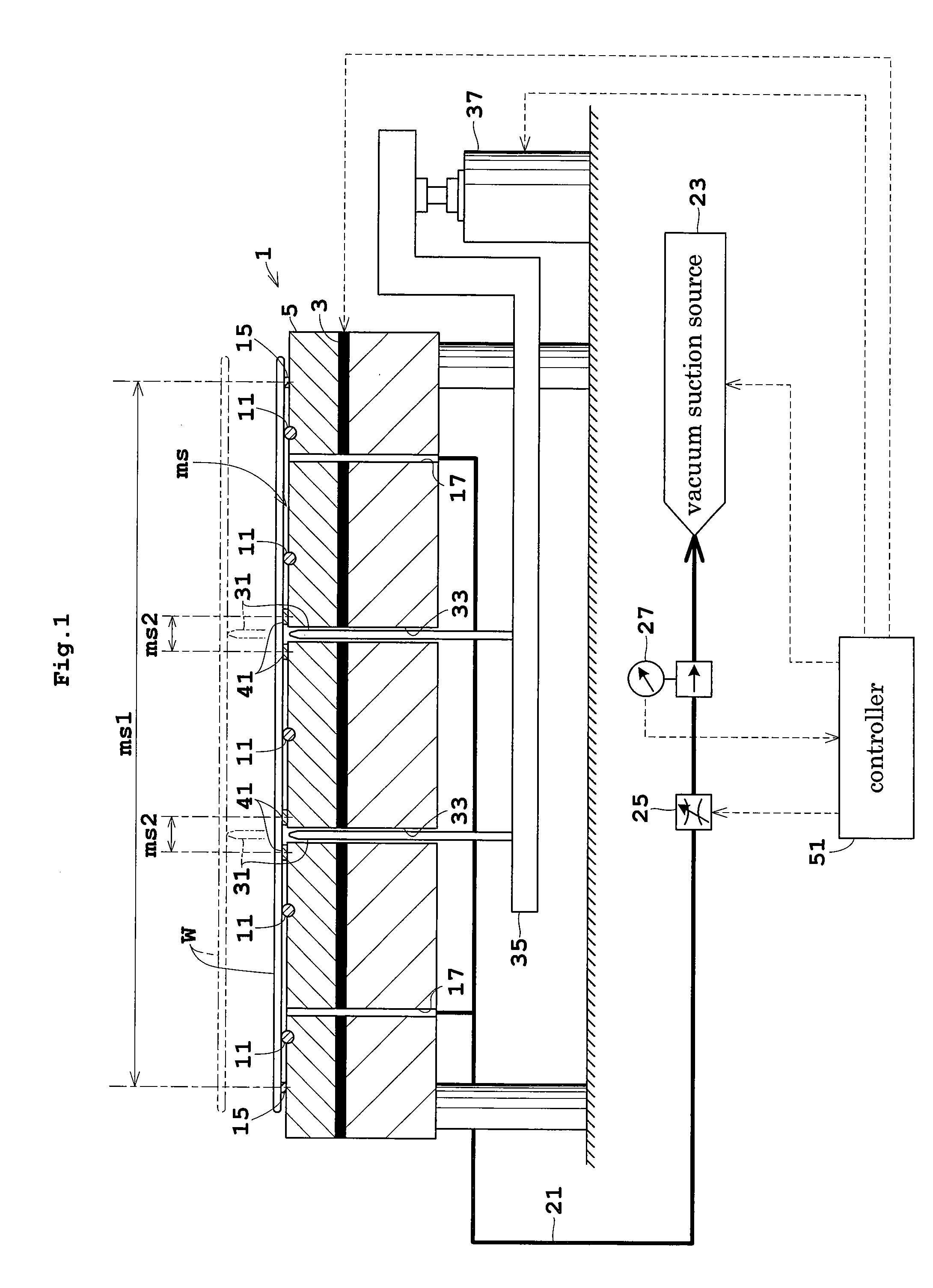

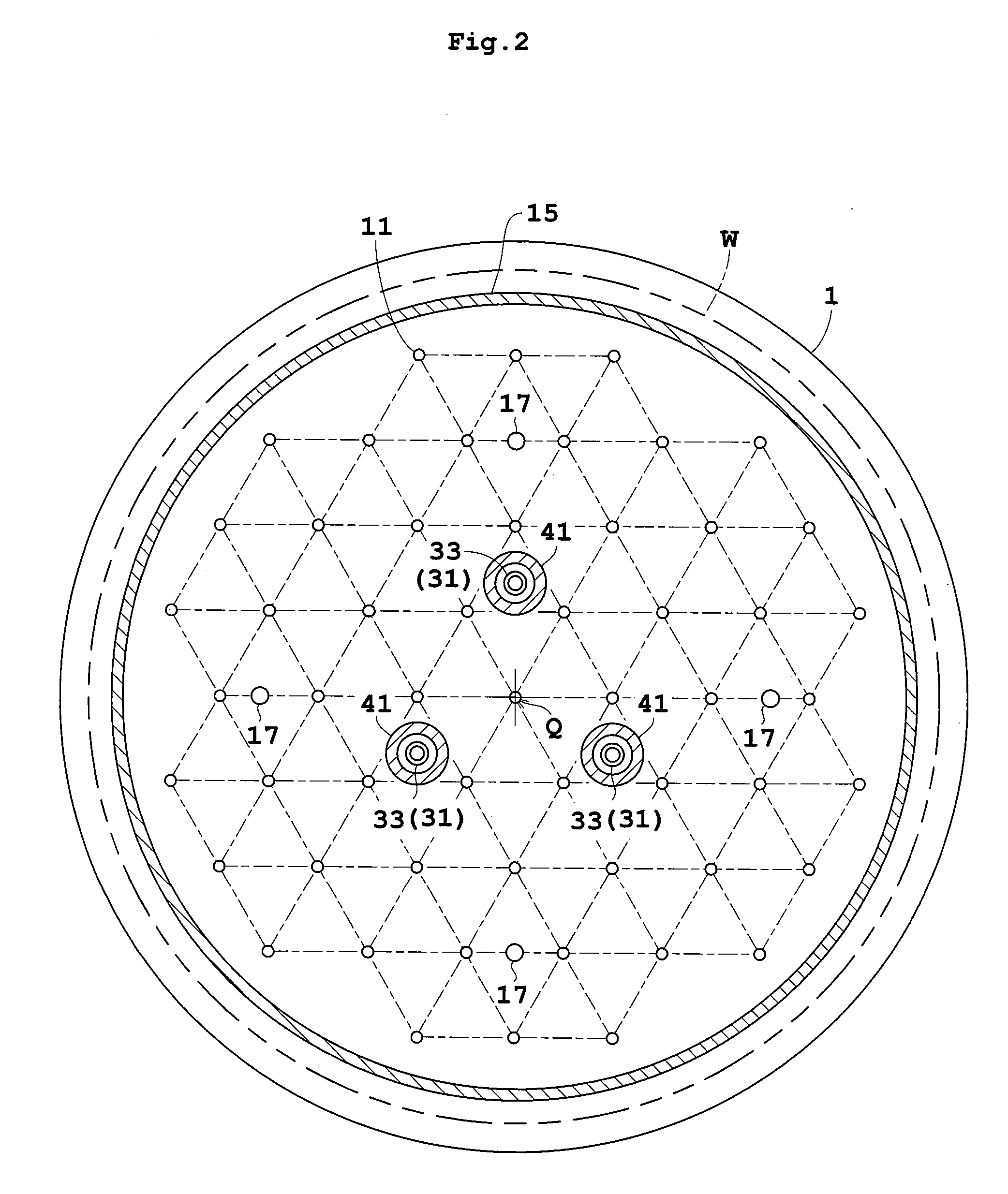

Substrate heat treatment apparatus

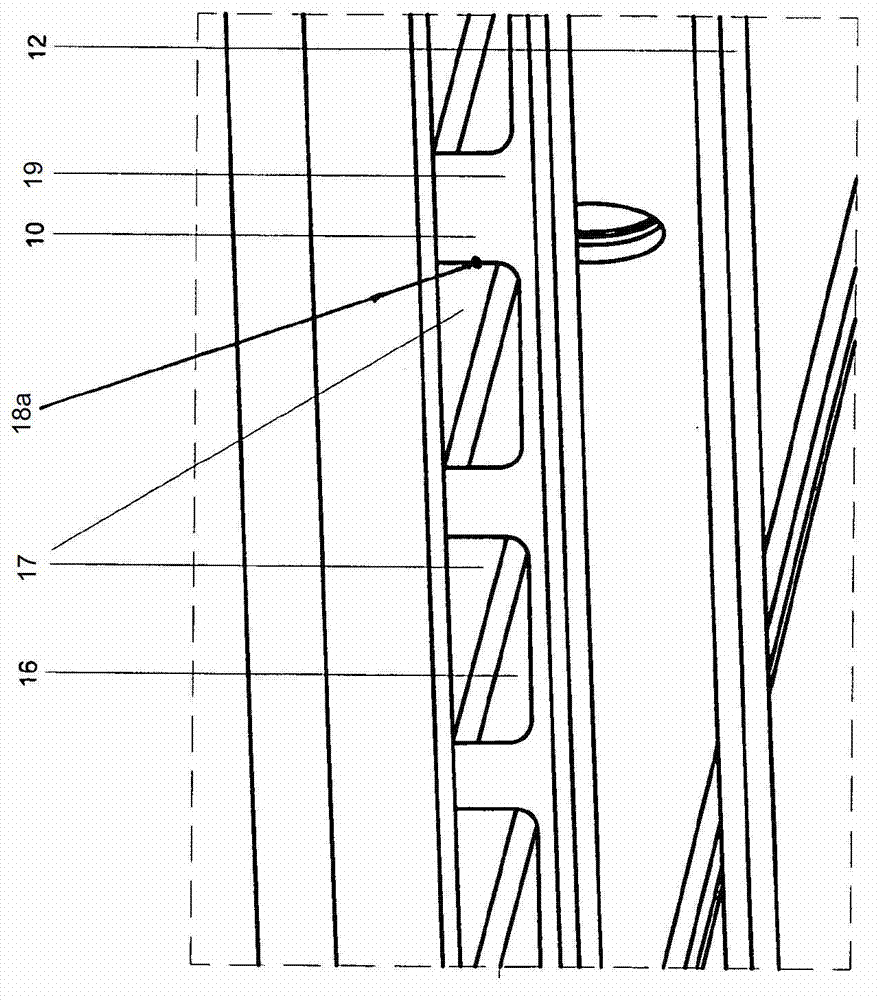

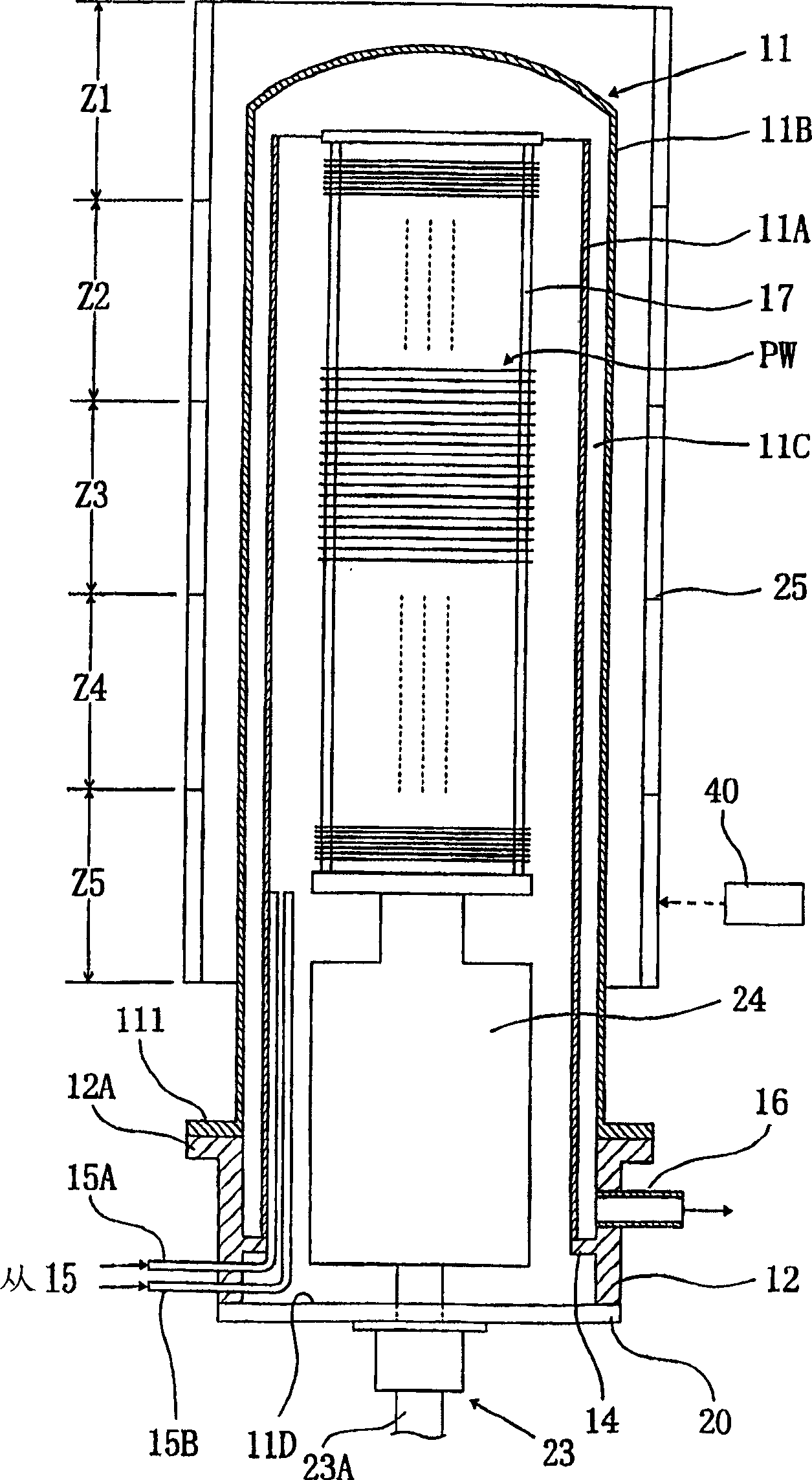

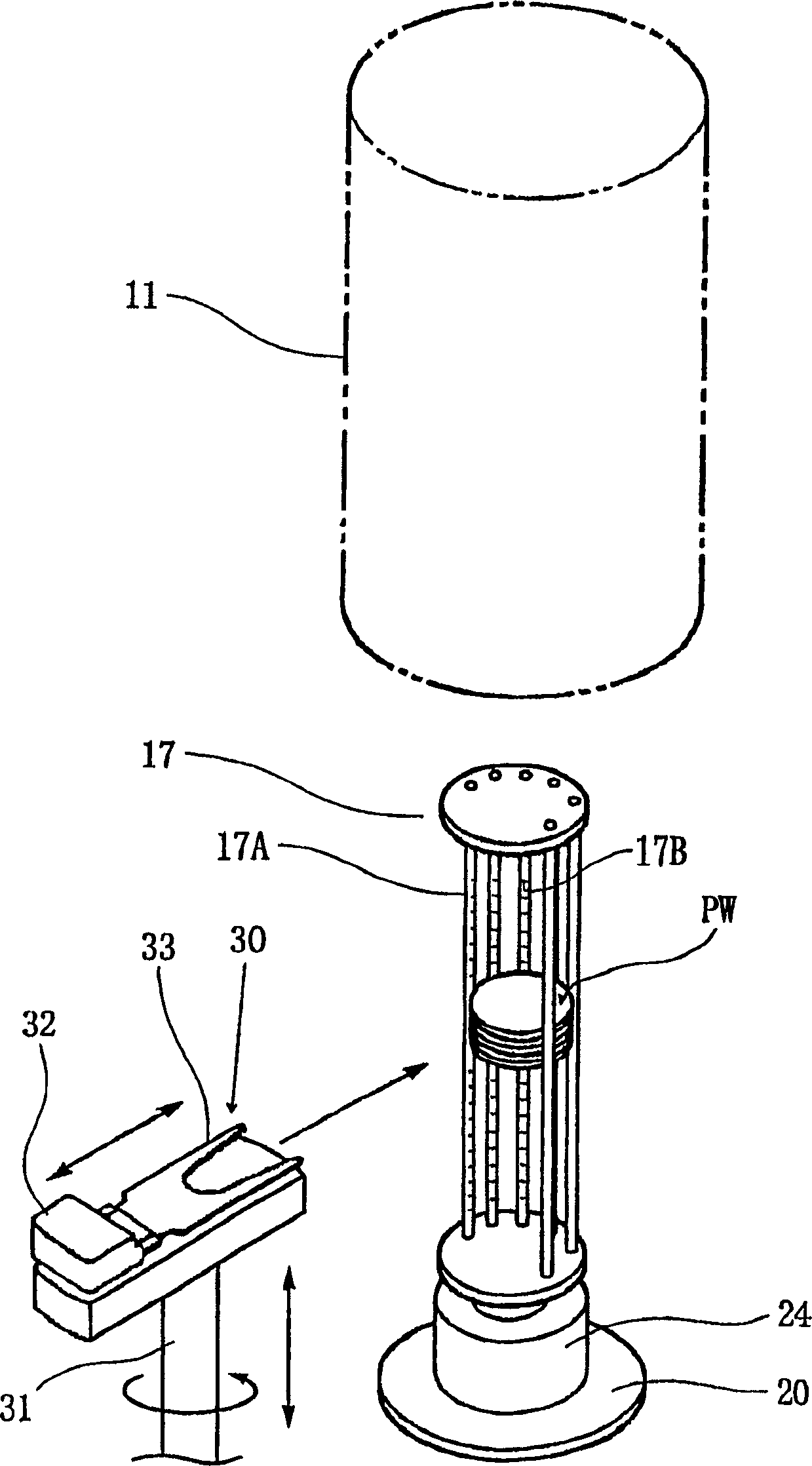

ActiveUS8003919B2Efficient heat treatmentEfficiently inhibiting sagging of a substrateMuffle furnacesCharge supportsIsoetes triquetraEngineering

Owner:DAINIPPON SCREEN MTG CO LTD

Substrate heat treatment apparatus

ActiveUS20070128889A1Efficient heat treatmentRealized easily and properlyMuffle furnacesSemiconductor/solid-state device manufacturingExhaust gasHeat treating

Owner:DAINIPPON SCREEN MTG CO LTD

Method for producing perovskite-type composite oxide

InactiveUS20050249653A1Efficient heat treatmentImprove securityInternal combustion piston enginesMercury oxidesComposite oxideOxide

To provide a highly safe and hygienic method for industrially efficiently producing a perovskite-type composite oxide at low temperatures in heat treatment, in which the resulting perovskite-type composite oxide can maintain the catalytic activity of a noble metal at a high level over a long time, in a method for producing a perovskite-type composite oxide, a perovskite-type composite oxide is produced by mixing organometal salts of all elementary components constituting the perovskite-type composite oxide to prepare a precursor of the perovskite-type composite oxide, or mixing one or more organometal salts of part of the elementary components constituting the perovskite-type composite oxide with the other elementary components prepared as alkoxides of the respective elements, a coprecipitate of salts of the respective elements or a citrate complex of the respective elements to prepare a precursor of the perovskite-type composite oxide, and heat-treating the precursor of the perovskite-type composite oxide.

Owner:DAIHATSU MOTOR CO LTD +1

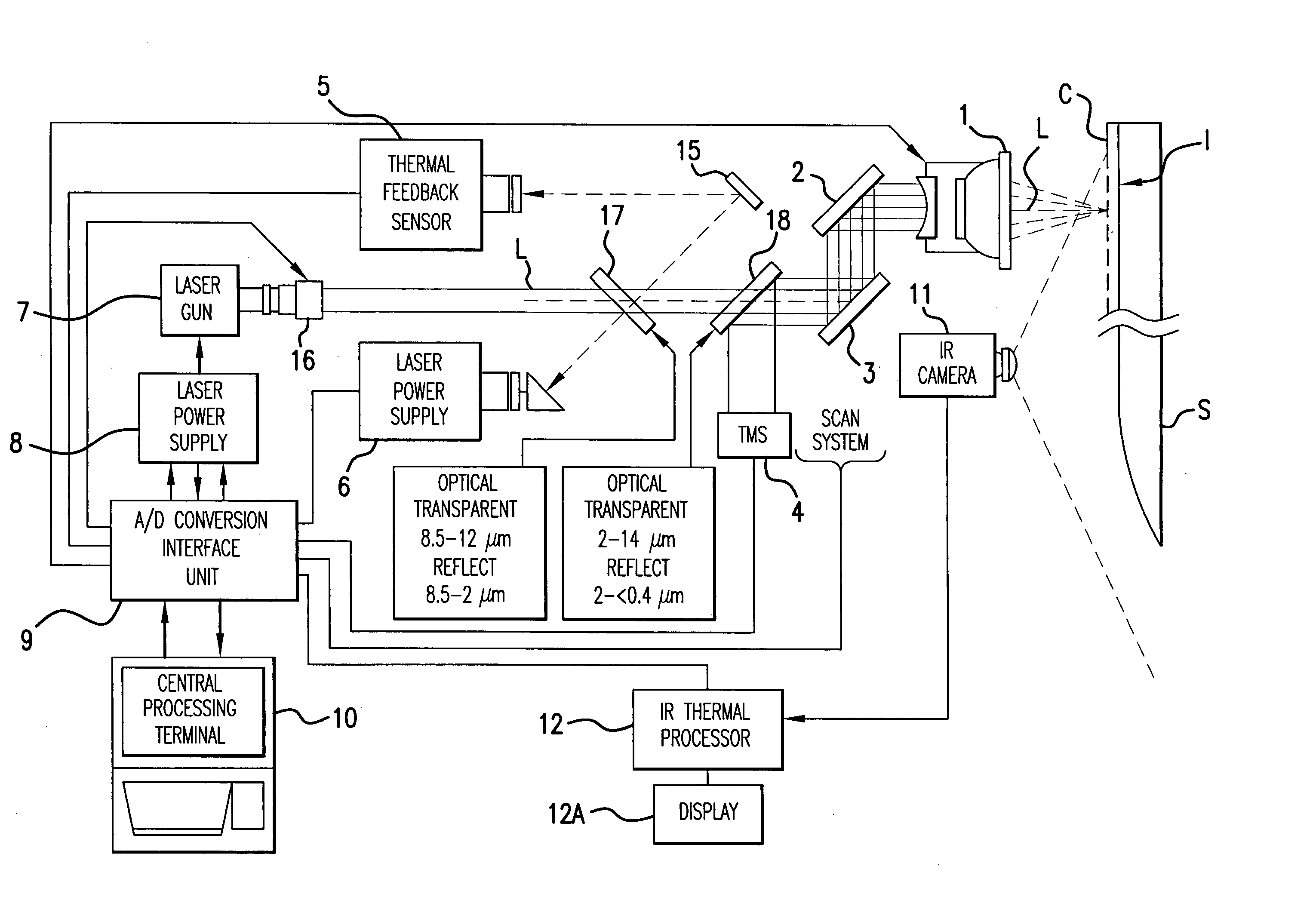

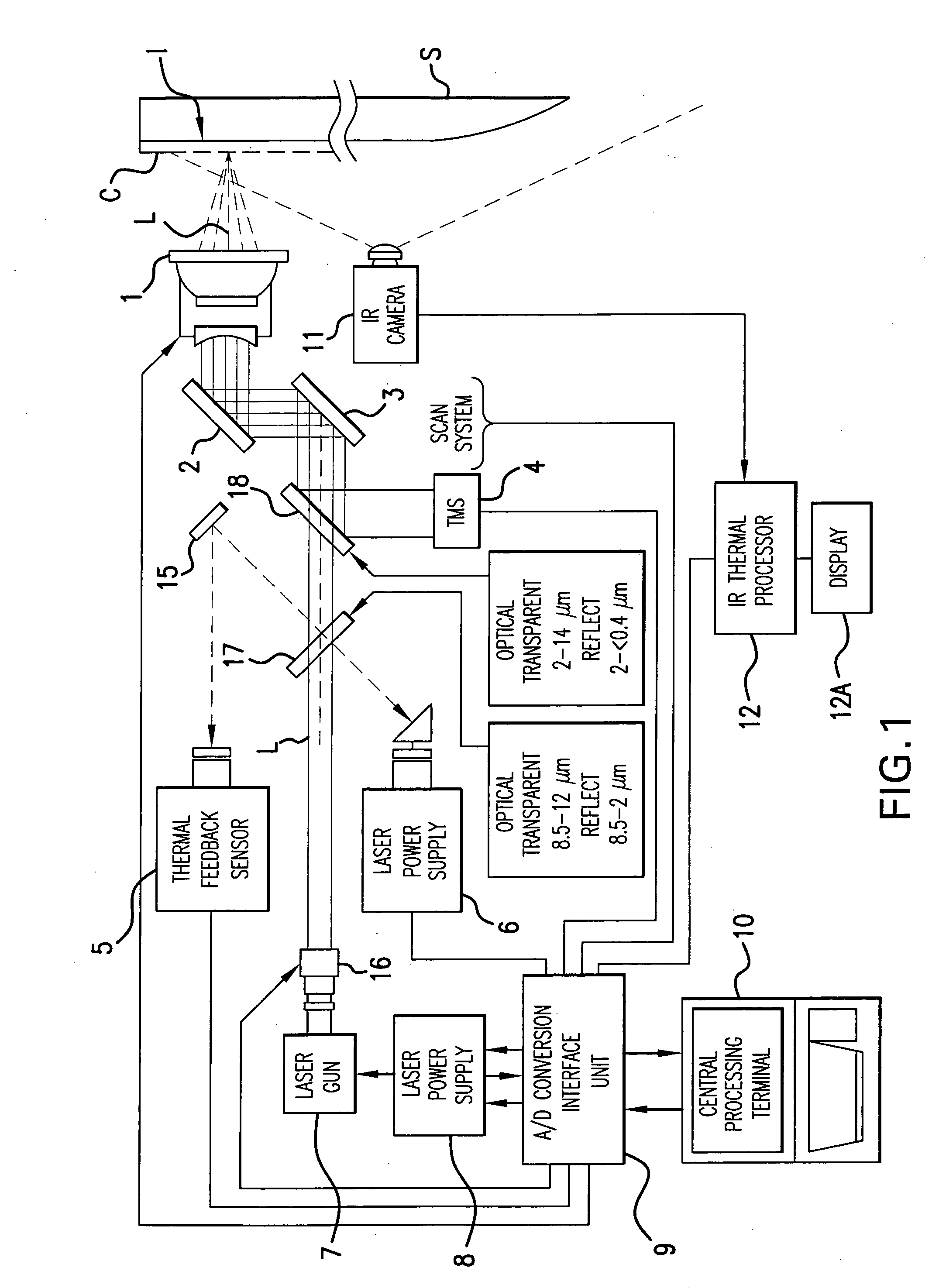

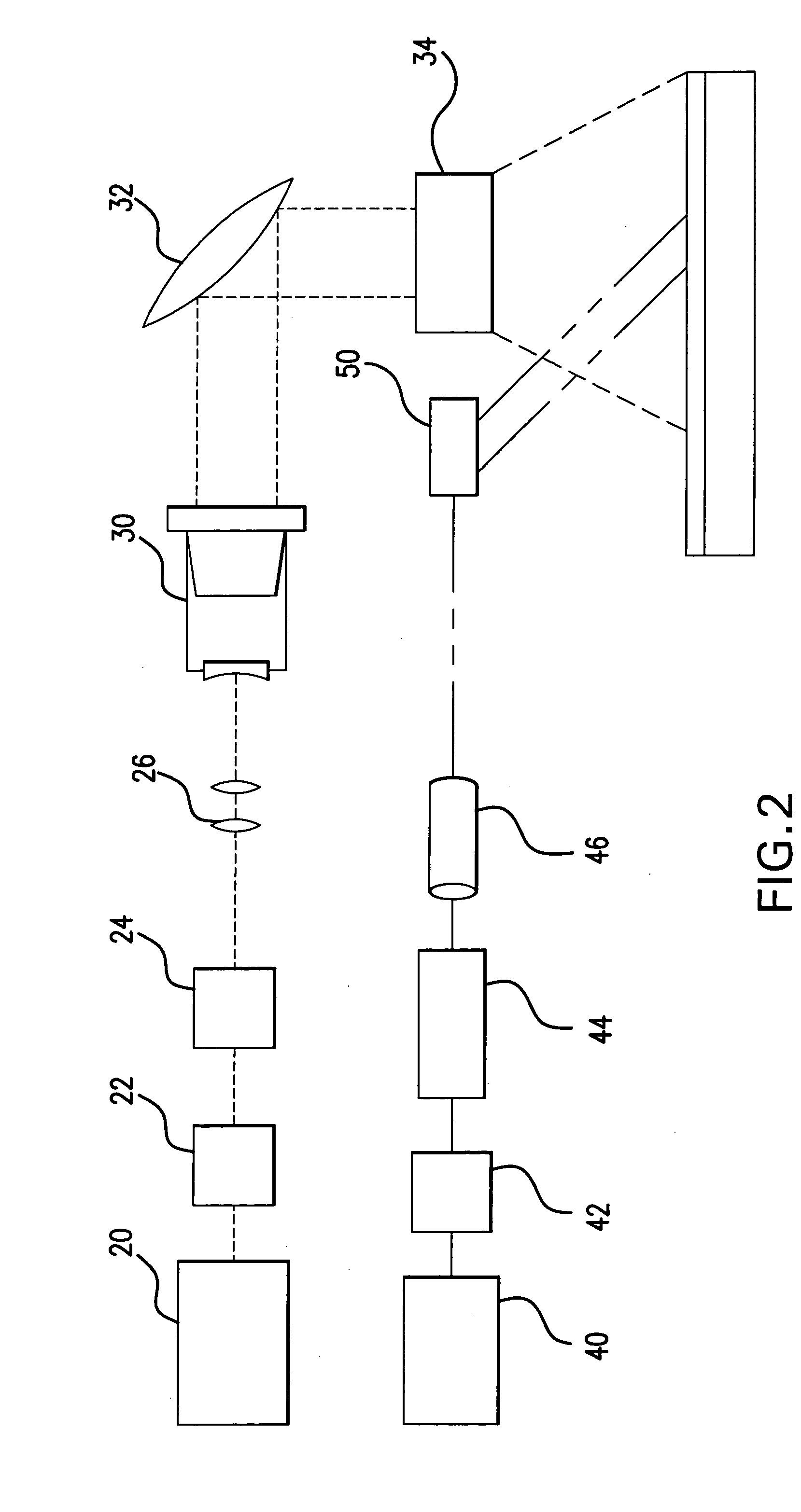

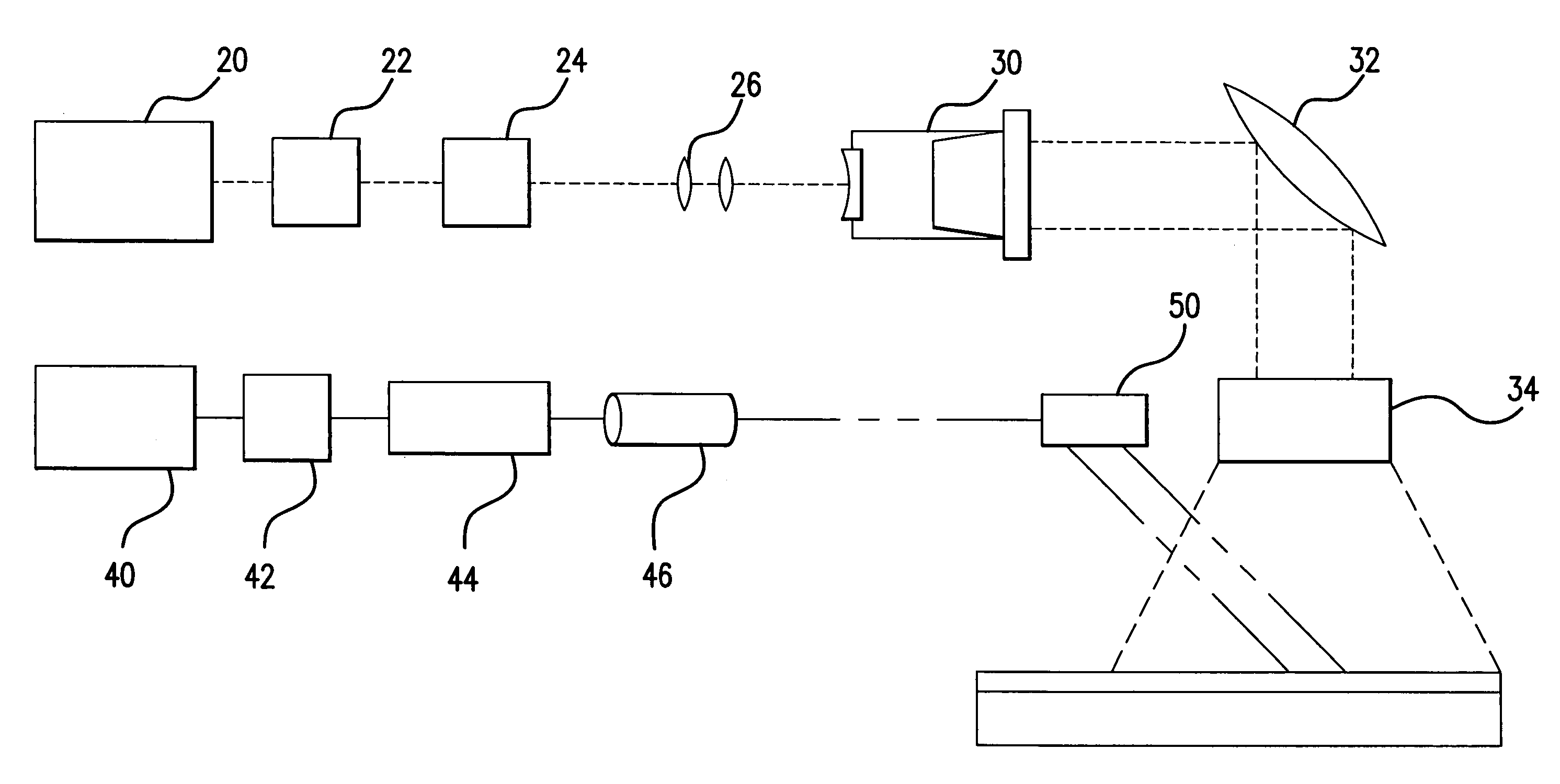

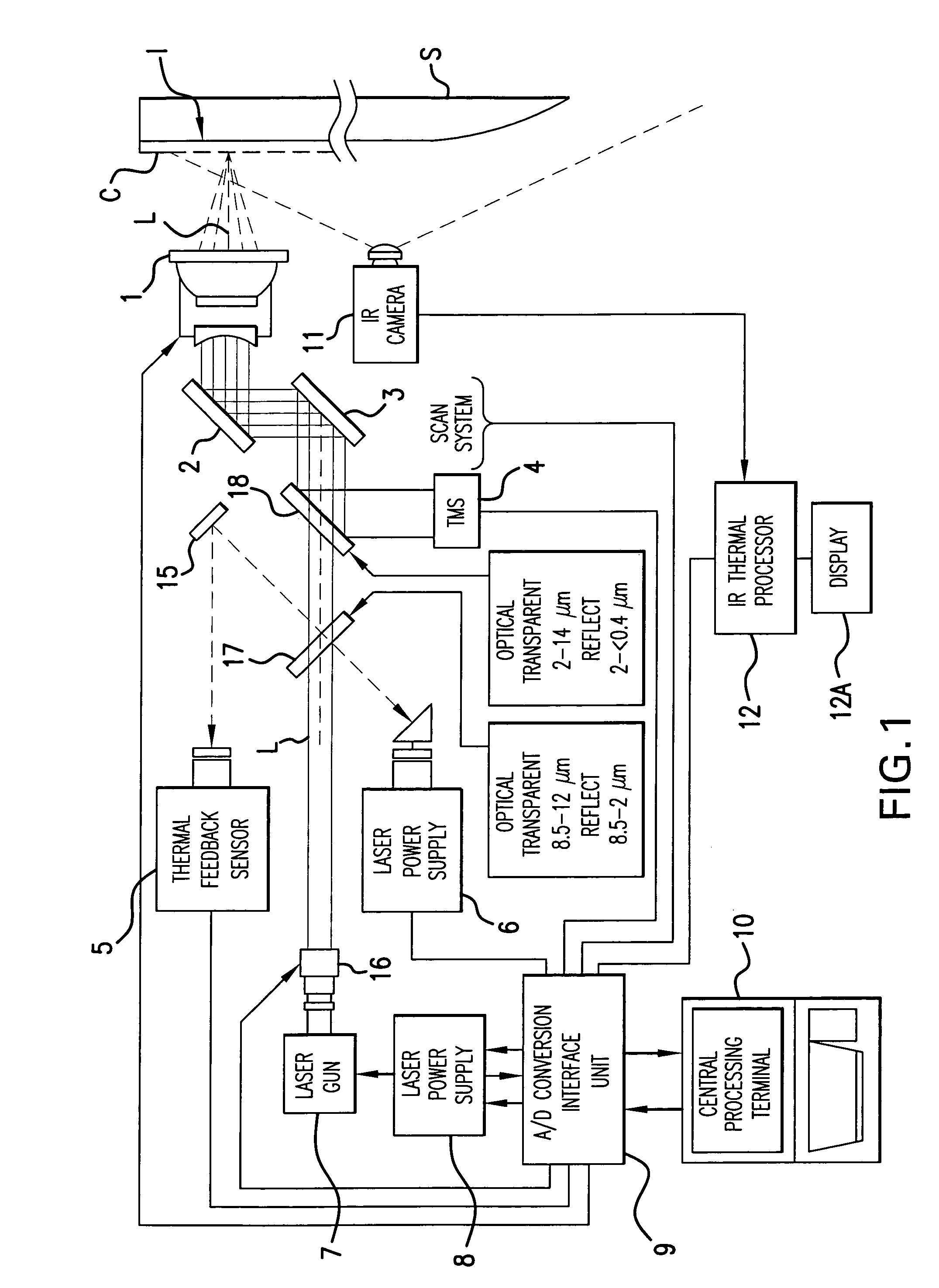

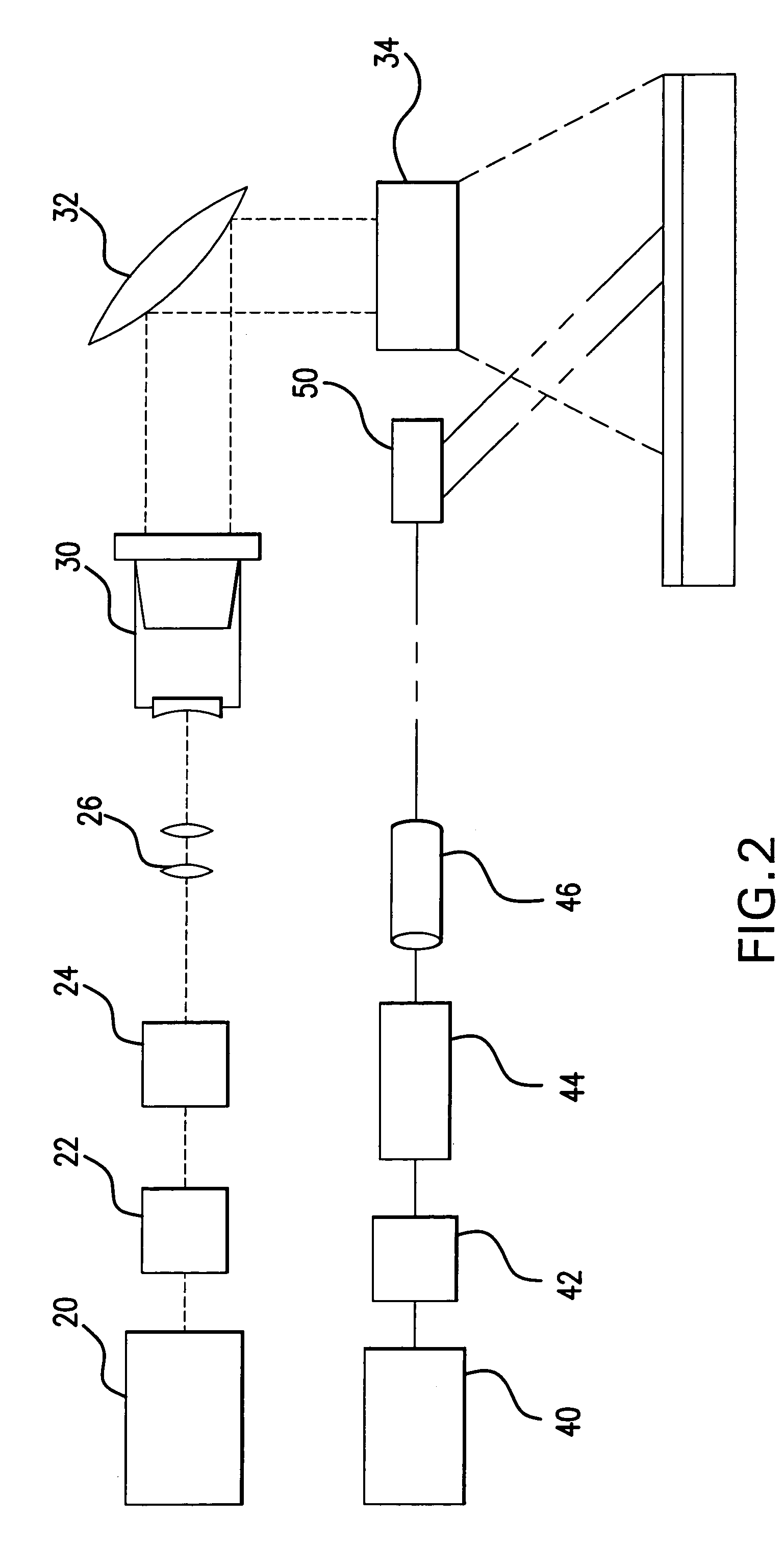

Dual laser coating apparatus and process

ActiveUS20050266168A1Good for absorptionSufficient powerPretreated surfacesLiquid spraying apparatusSpectral linePowder coating

An apparatus for applying and fusing a powder coating to substrates of various composition uses two lasers to accurately heat the coating to the optimum temperature. A second laser has less power and heats a smaller area than the first laser. Temperature control is enhanced by the ability to superheterodyne two lasers at separate frequencies. This allows for better absorption of certain materials being fused by the laser. Another common problem associated with laser processing occurs as the polymer heats up. During the heating process the spectral lines are Doppler broadened and slightly shifted. This can affect the absorption of a laser of a fixed wavelength. With the present invention, the optimum laser frequency can be turned to a more optimum frequency for absorption still with sufficient power for fast efficient thermal processing.

Owner:PHOTOFUSION TECH

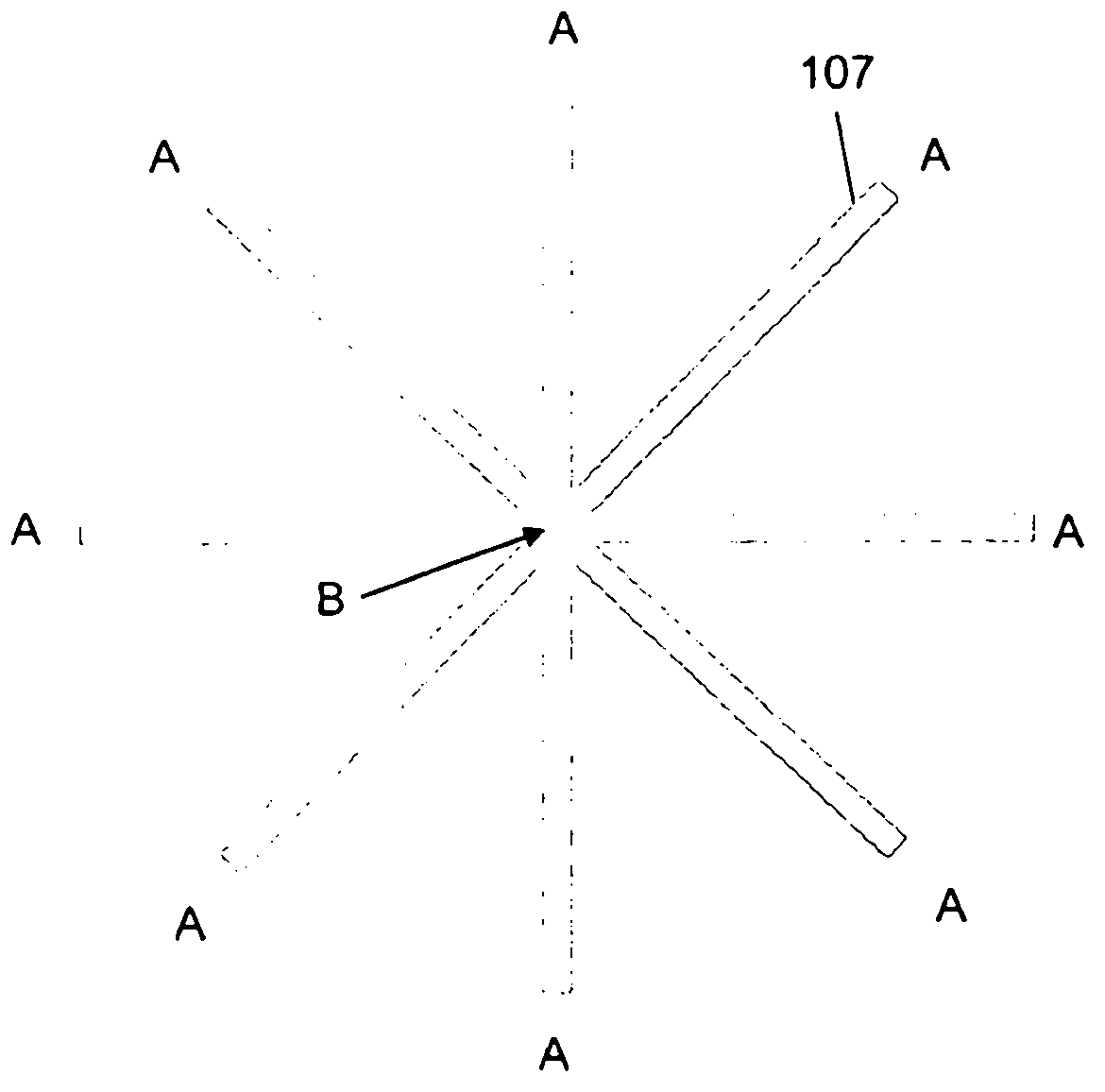

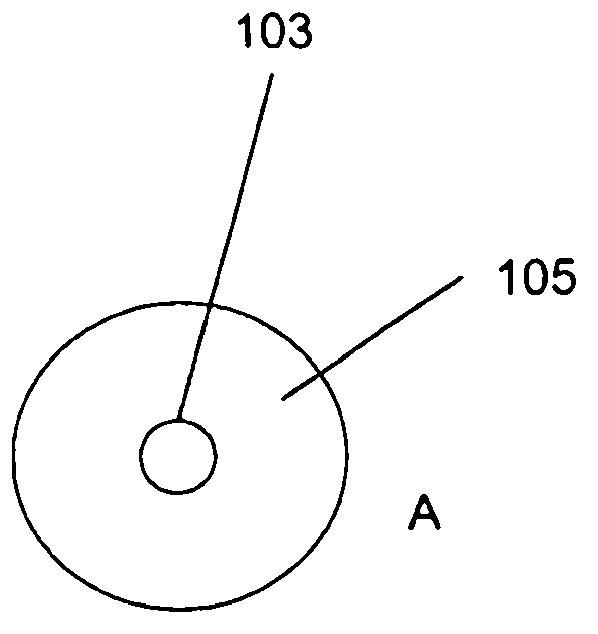

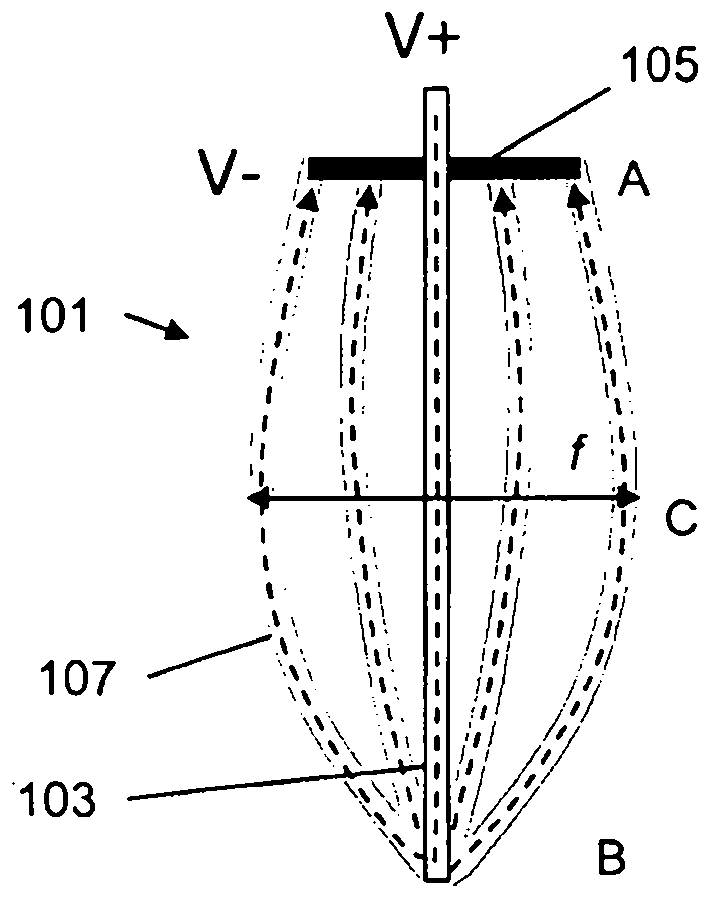

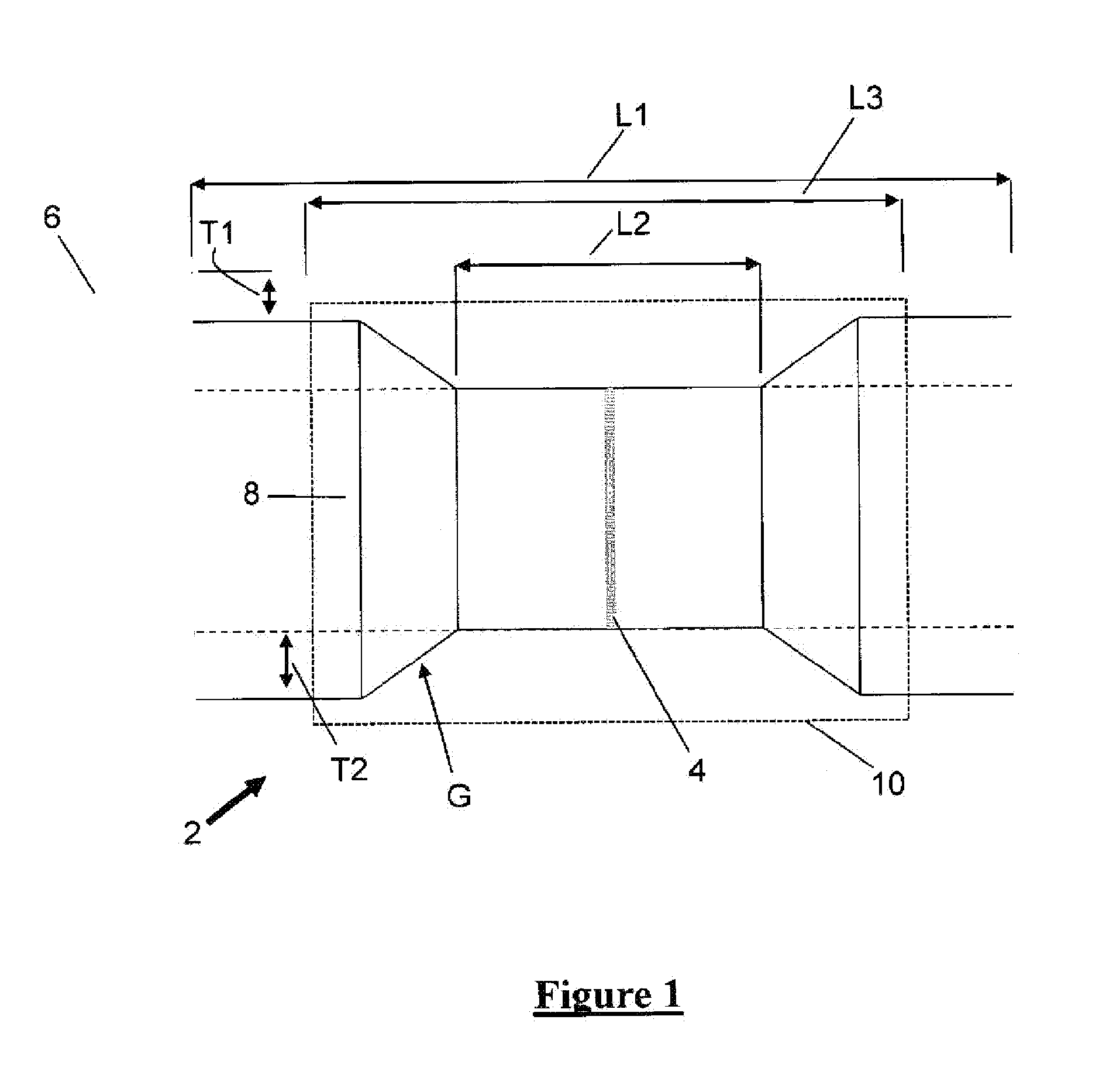

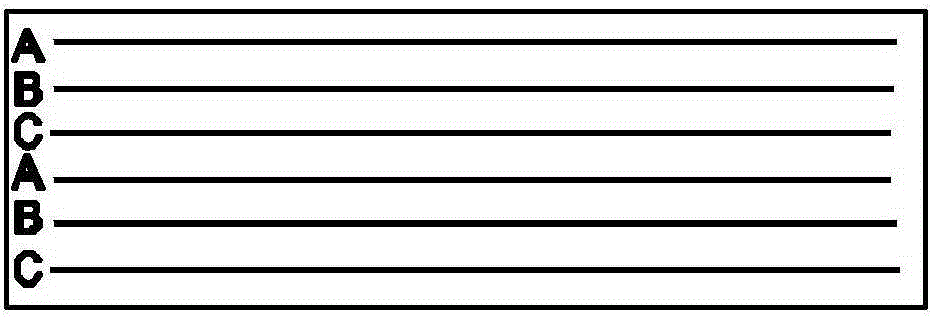

A shaped heater for an aerosol generating system

ActiveCN102781266AEfficient heatingEfficient heat treatmentOhmic-resistance heating circuitsTobacco treatmentElectricityEngineering

There is provided a heater (101) for heating an aerosol-forming substrate. The heater comprises a plurality of elongate heating elements (107) arranged in an elongate array. The elongate array has a support end with a first dimension, a heating end with a second dimension and a middle portion with a third dimension. The array is arranged to heat the substrate to form an aerosol. The third dimension is greater than the first dimension and greater than the second dimension. There is also provided an electrically heated aerosol generating system including such a heater.

Owner:PHILIP MORRIS PROD SA

Method for producing perovskite-type composite oxide

InactiveUS7381394B2Highly hygienicImprove securityInternal combustion piston enginesMercury oxidesCITRATE ESTERComposite oxide

Methods of producing a safe and hygienic method for industrially and efficiently producing a perovskite-type composite oxide are provided that can maintain the catalytic activity of a noble metal at a high level. Methods include preparing a precursor of the perovskite-type composite oxide by mixing organometal salts of elementary components of the perovskite-type composite oxide and heat treating the precursor. The precursor may be prepared by mixing all elementary components constituting the perovskite-type composite oxide, or by mixing one or more organometal salts of part of the elementary components with the other elementary components prepared as alkoxides, a coprecipitate of salts, or a citrate complex of the respective elements.

Owner:DAIHATSU MOTOR CO LTD +1

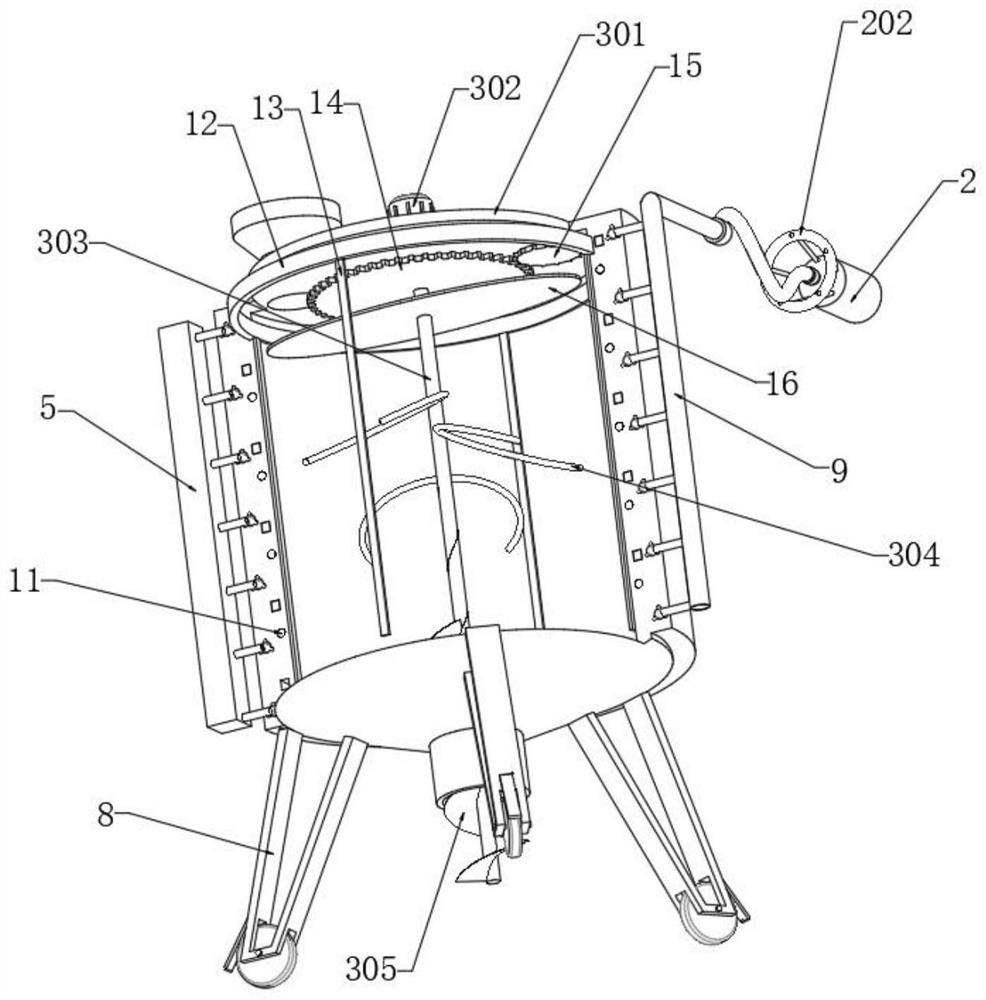

Manufacturing method for quick-release type hoisting connection ring body

InactiveCN101264564ASave raw materialsHigh strengthMetal-working apparatusMetal fibersUltimate tensile strength

The invention relates to a manufacturing method of a fast-unloading hoisting connection ring, which comprises the following steps: blanking materials are processed by a 20 CrMaTi bar material saw; the bar materials are hammered into materials of different diameters when heated to 900 DEG C to 1150 DEG C; then the bar materials are bent into a form similar to the shape of a connecting ring; the forging blanks are forged into die forgings and forging stress is removed through annealing; when the forging blanks are molded, the waste selvages are cut off and the shape is elaborately modified; a permanent seat with the same radian as the ring body is adopted for the bent die forgings; two chain joints with the same radian as the ring body are arranged at both ends; one end of the chain joint is arranged on the permanent seat and the other end is connected with a handle; the die forgings are put on the permanent seat after forging, and then the chain joints at both ends are moved to bend the bar materials into the form similar to the ring body. The manufacturing method of the fast-unloading hoisting connection ring has the advantages that unevenness of the two ends of the materials is avoided to prevent deficiency in the forging process which further influences the quality of the ring body; the direction of the metal fiber is consistent with the direction of the connecting ring, thus enhancing the intensity and toughness of the ring body.

Owner:上海鸿安港口设备附件厂

Dual laser coating apparatus and process

ActiveUS7661387B2Promote absorptionEasy temperature controlPretreated surfacesLiquid spraying apparatusTemperature controlLaser coating

An apparatus for applying and fusing a powder coating to substrates of various composition uses two lasers to accurately heat the coating to the optimum temperature. A second laser has less power and heats a smaller area than the first laser. Temperature control is enhanced by the ability to superheterodyne two lasers at separate frequencies. This allows for better absorption of certain materials being fused by the laser. Another common problem associated with laser processing occurs as the polymer heats up. During the heating process the spectral lines are Doppler broadened and slightly shifted. This can affect the absorption of a laser of a fixed wavelength. With the present invention, the optimum laser frequency can be turned to a more optimum frequency for absorption still with sufficient power for fast efficient thermal processing.

Owner:PHOTOFUSION TECH

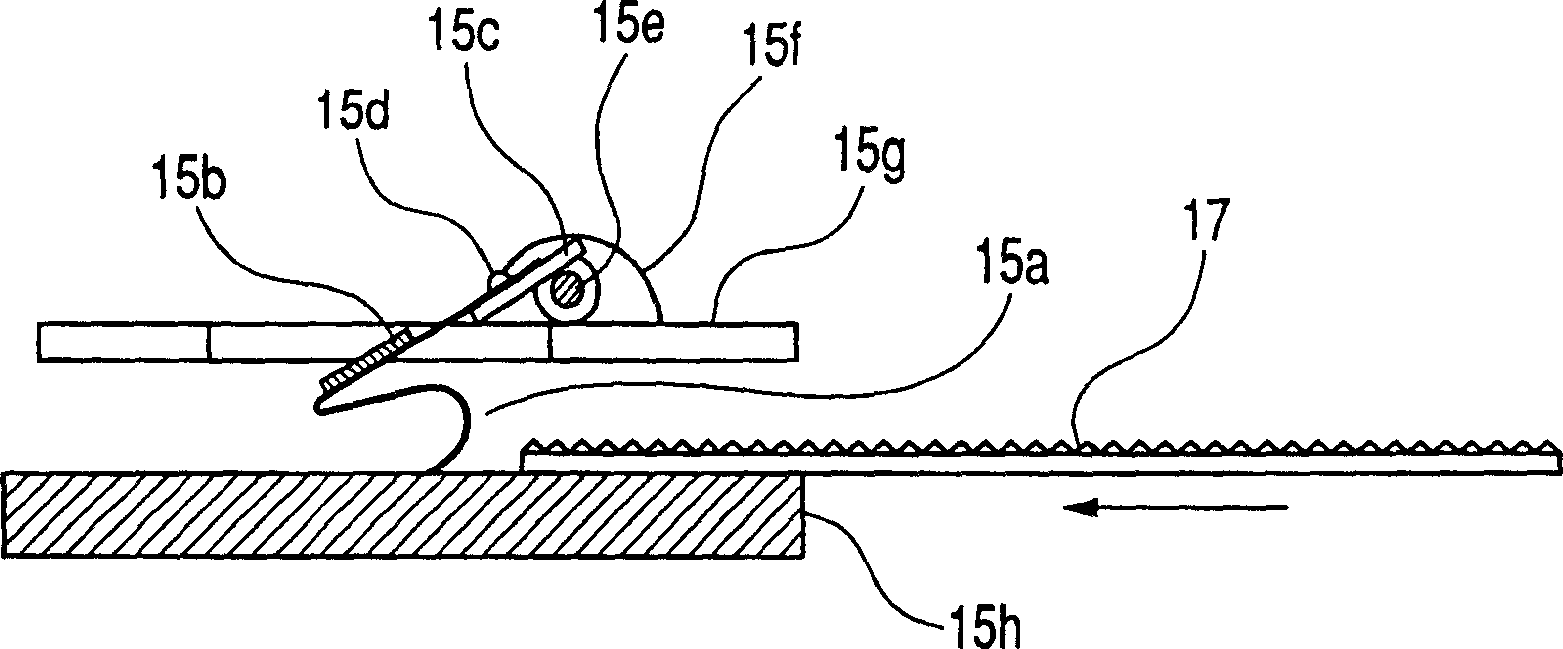

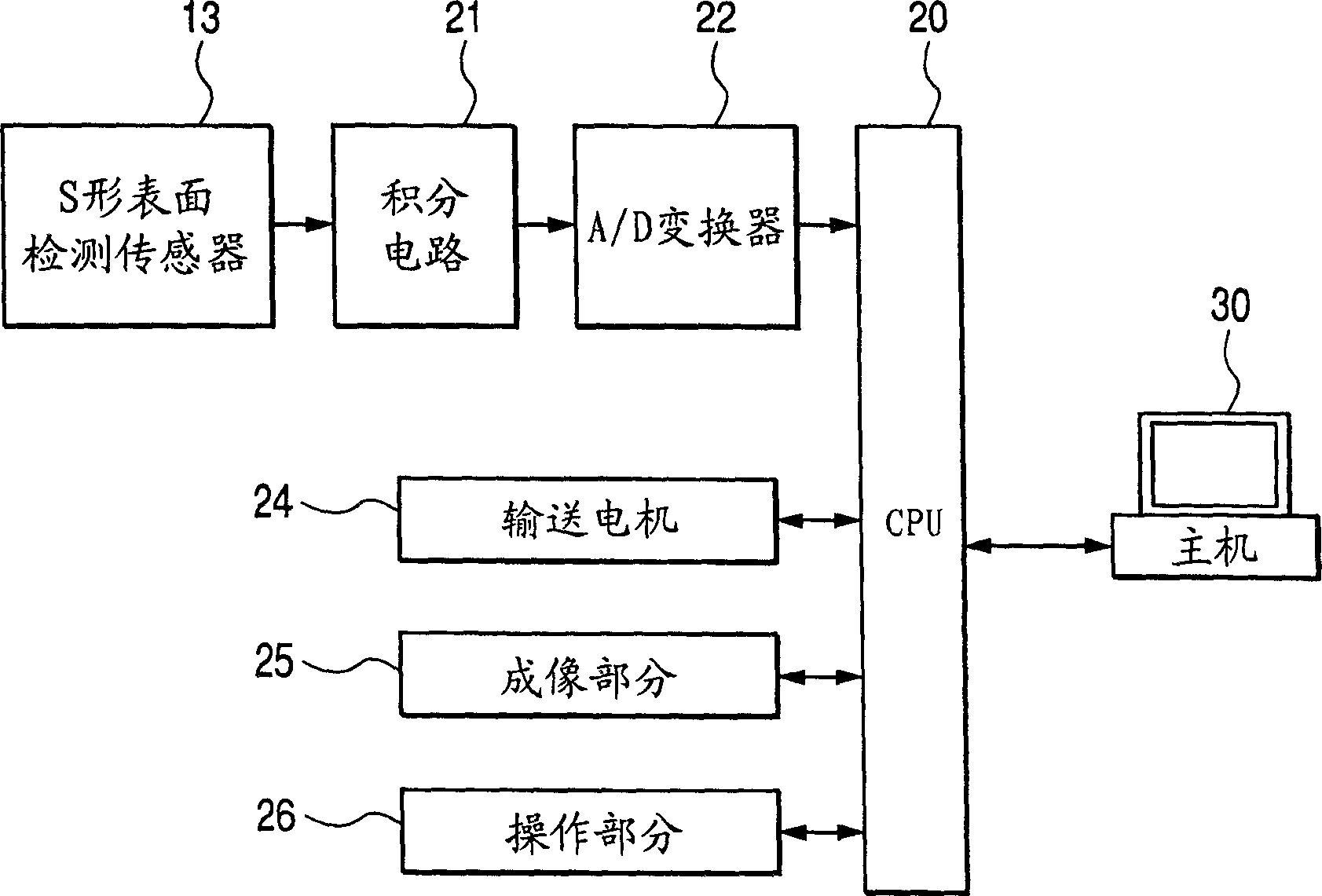

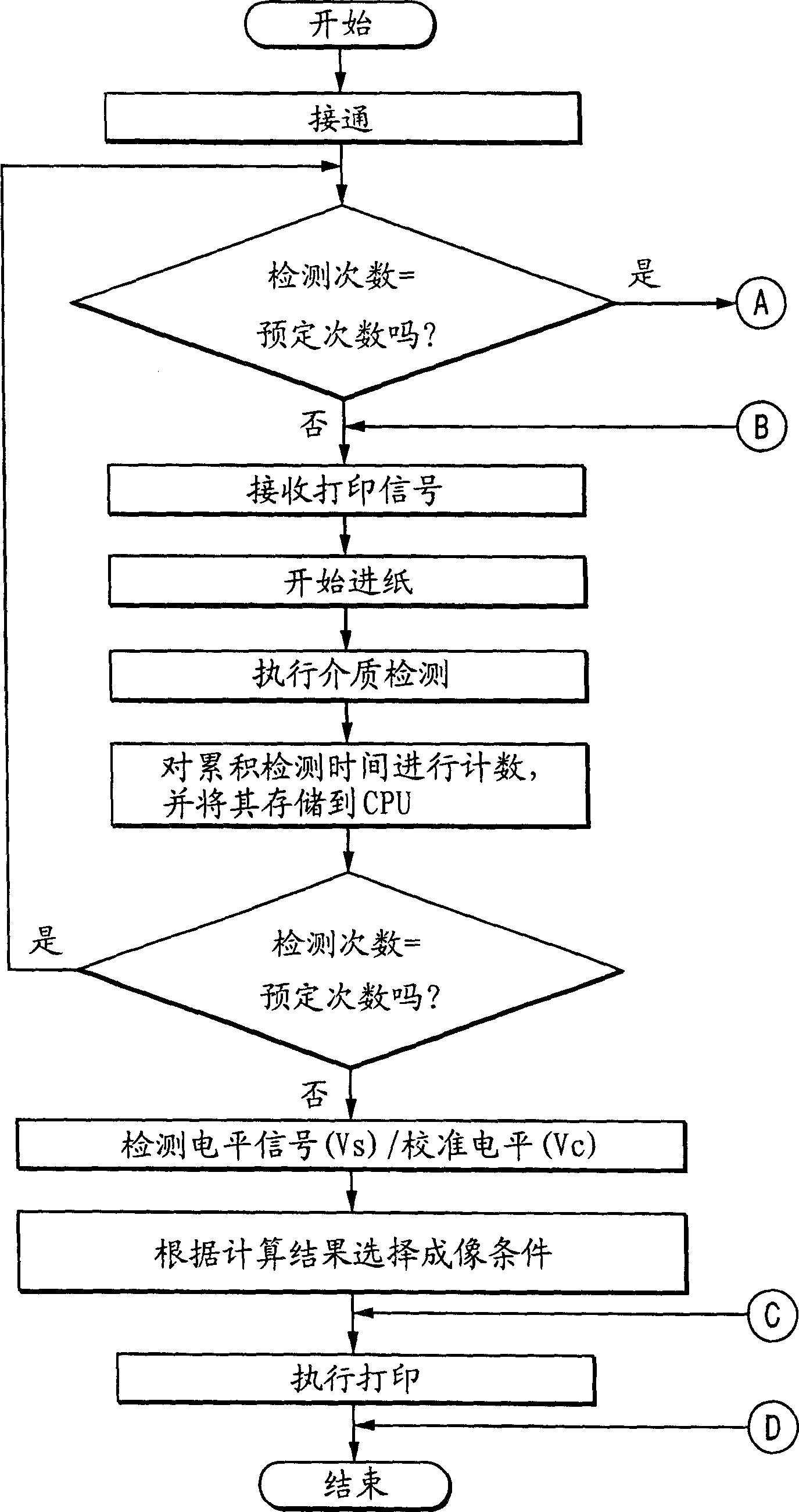

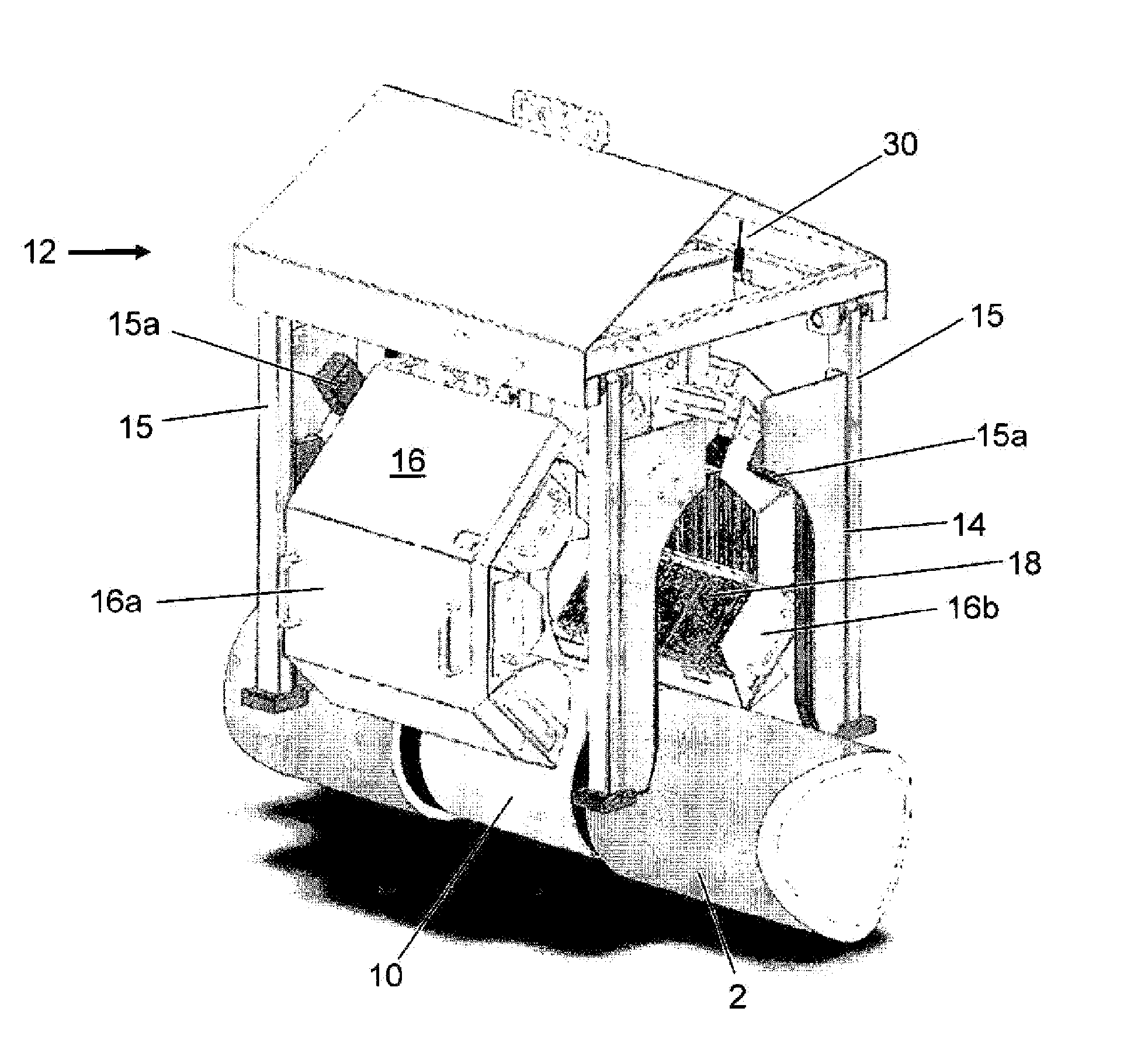

Sheet material identification apparatus and image forming apparatus therewith

InactiveCN1727201AEfficient heat treatmentEnhance the imageOther printing apparatusOffice printingSurface roughnessEngineering

The sheet material identification apparatus, includes a sensor adapted to bring a probe having a built-in piezoelectric element into contact with a surface of sheet material being conveyed, and thereby to generate electric detection signals corresponding with irregularities of the sheet material surface; an identification part adapted to identify types of sheet material based on detection signals outputted from the above described sensor; and a correct part adapted to correct fluctuations in detection features of the above described sensor based on detection output of the above described sensor at the time when the above described sensor has detected correction sheet material having a predetermined surface roughness. The appratus prevents misdetection during use for a long period of sheet material identification apparatus that does not require any type-of-paper selection setting operation by a user and can implement good heat treating, fixing and image forming efficiently even if sheets of paper having various kinds of surface roughness.

Owner:CANON KK

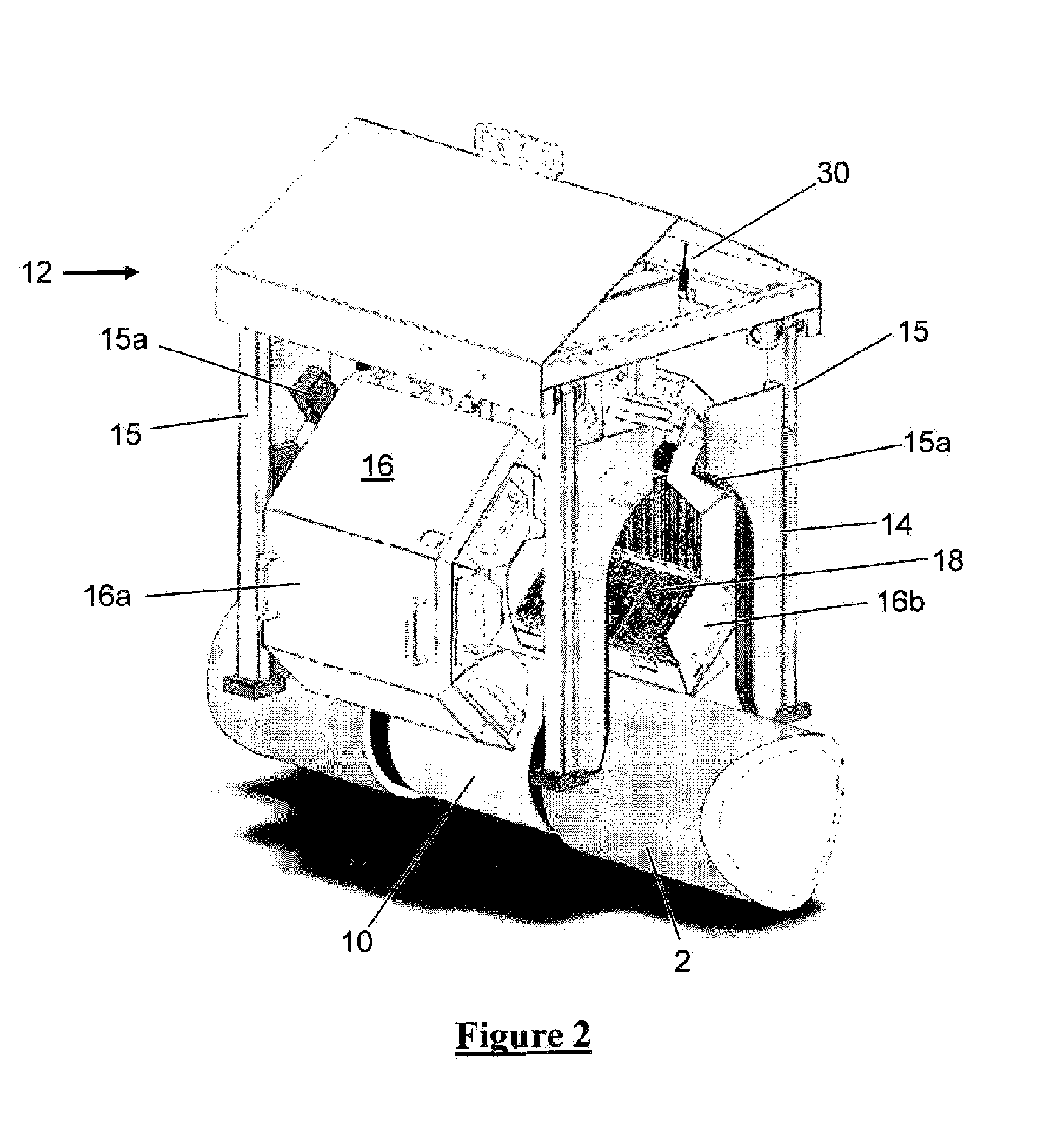

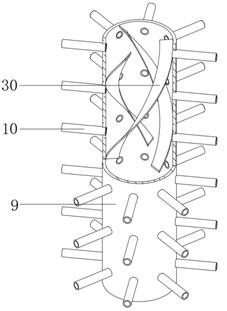

Apparatus and method for heating heat-shrinkable pipe sleeves

InactiveUS20120037297A1For quick replacementEasy to controlDrying solid materials with heatLaminationThermodynamicsMechanics

The present invention provides a method of applying a heat-shrinkable sleeve to a portion of a pipe, the method including the following steps:providing a pipe,arranging a heat-shrinkable sleeve around a portion of the pipe,arranging a heat-delivery apparatus around the pipe in the region of the sleeve, the heat-delivery apparatus including at least three heater devices arranged at different positions along the axis of the pipe, such thata first heater device is positioned closer to the centre of the sleeve, in the axial direction, than second and third heater devices,the second heater device is positioned in the region of a first end of the sleeve, and the third heater device is positioned in the region of a second end of the sleeve opposite to the first end, andindividually controlling each of the first, second and third heater devices to apply heat to the heat-shrinkable sleevewherein each heater device is in the form of an infrared heater device.

Owner:SAIPEM SPA

Inorganic solid electrolyte and lithium cell component

InactiveUS20060147806A1Improve ionic conductivityMaintain good propertiesElectrolytic capacitorsPhosphorus sulfur/selenium/tellurium compoundsMetallic lithiumPhysical chemistry

A sulfide-based inorganic solid electrolyte that suppresses the reaction between silicon sulfide and metallic lithium even when the electrolyte is in contact with metallic lithium, a method of forming the electrolyte, and a lithium battery's member and lithium secondary battery both incorporating the electrolyte. The electrolyte comprises Li, P, and S without containing Si. It is desirable that the oxygen content vary gradually from the electrolyte to the lithium-containing material at the boundary zone between the two members when analyzed by using an XPS having an analyzing chamber capable of maintaining a super-high vacuum less than 1.33×10−9 hPa and that the oxygen-containing layer on the surface of the lithium-containing material be removed nearly completely. The electrolyte can be formed such that at least part of the forming step is performed concurrently with the step for etching the surface of the substrate by irradiating the surface with inert-gas ions.

Owner:SUMITOMO ELECTRIC IND LTD

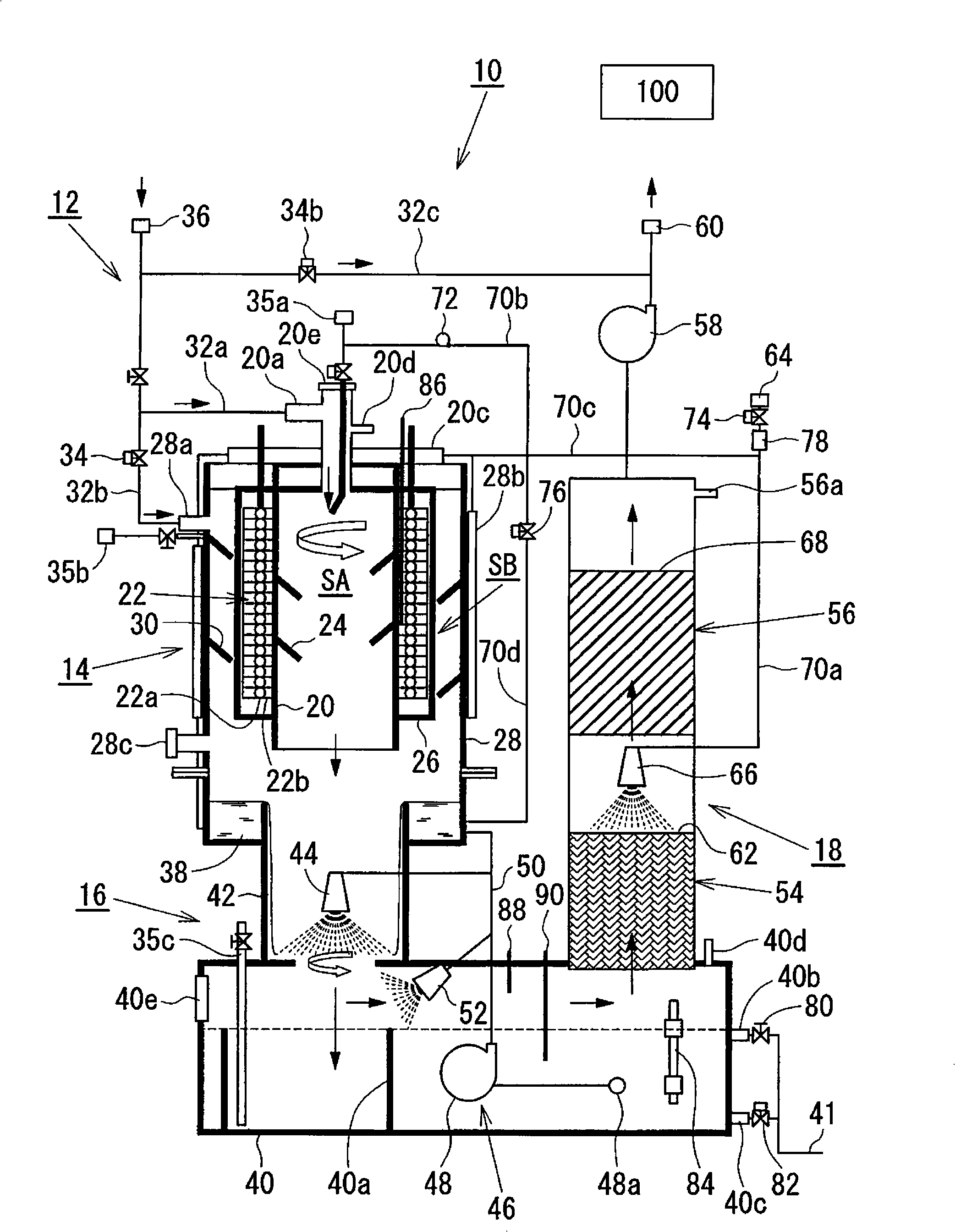

Water gas treatment device

InactiveCN101332405AExcellent temperature correction capabilityAvoid warmingFinal product manufactureDispersed particle separationHeating timeDecomposition

The invention provides a waste gas treating apparatus for effectively executing heat treatment for waste gas containing warm gas. The waste gas is introduced from a waste gas introducing section (12) into a heating treatment section (14). The waste gas is pyrolyzed mainly by radiation heat heated with an electromagnetic induction heating unit (22) and coming from a circular cylinder tube (20), in process of one-way pass from its base end section to end section in a circular cylinder tube of the heating treatment section. At this time, heating time for waste gas is adequately secured because waste gas becomes rotational flow via a commutation unit (24) to pass through the circular cylinder tube (20). As a result, even in condition that introduced waste gas from the waste gas introducing section (12) rapidly increases, desired capacity of decomposition is secured. In addition, power and gas generated by heating waste gas is cooled and decomposed in a water treating section (16) to remove residual mist in a final treating section (18).

Owner:NISSEI SANGYO

Production technology for anti-loosening double-segment wire screw

The invention discloses a production technology for an anti-loosening double-segment wire screw. The production technology includes the following steps that S1, in wiredrawing, a low-carbon steel wireis machined through a steel wire rod wiredrawing machine to have a needed diameter; S2, in balling, the low-carbon steel wire after wiredrawing is subjected to balling treatment through a balling furnace; S3, in blanking, the low-carbon steel wire is selected and cut into a steel wire segment with a fixed length; S4, in heading, a heading machine is adopted for machining one end of the steel wiresegment into a screw head through a die; S5, in tail pointing, a tail pointing machine is adopted for machining the other end of the steel wire segment into a double-segment wire; S6, in thread rolling, a thread rolling machine is adopted for machining the periphery of the steel wire segment into threads; S7, heat treatment is performed, wherein normalizing and quenching operation is sequentiallyoperated on the screw, wherein normalizing temperature is 600-650 DEG C, and quenching temperature is 760-780 DEG C; S8, galvanizing is performed. The machining technology for the screw is simple, ascrew formed through machining in an early period can be effectively subjected to heat treatment, in this way, the overall performance of the screw is greatly improved, high surface strength and rigidity of the screw are realized, and the quality of the screw is guaranteed.

Owner:浙江俊荣五金工业有限公司

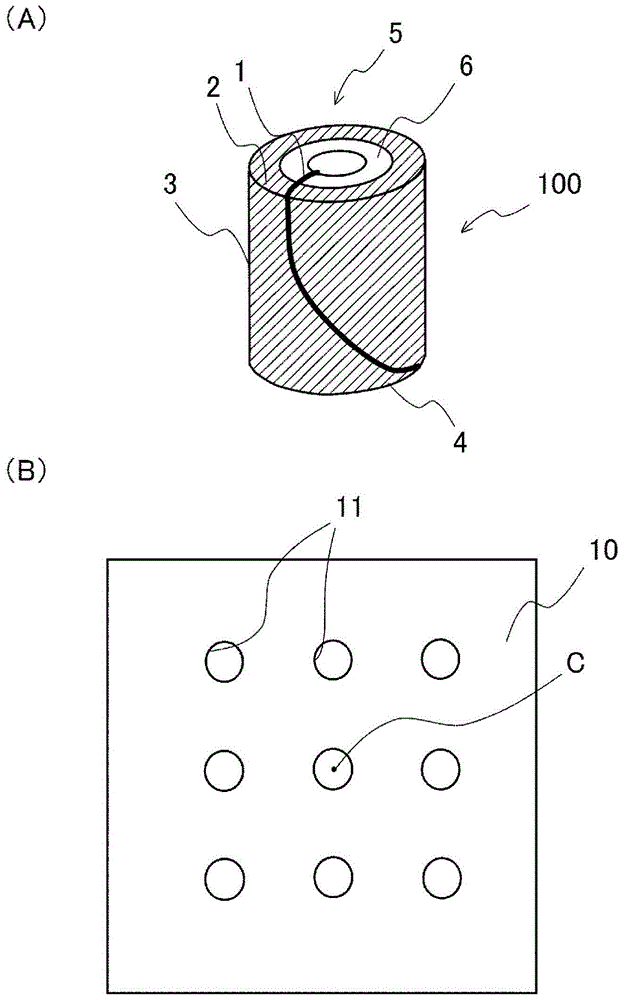

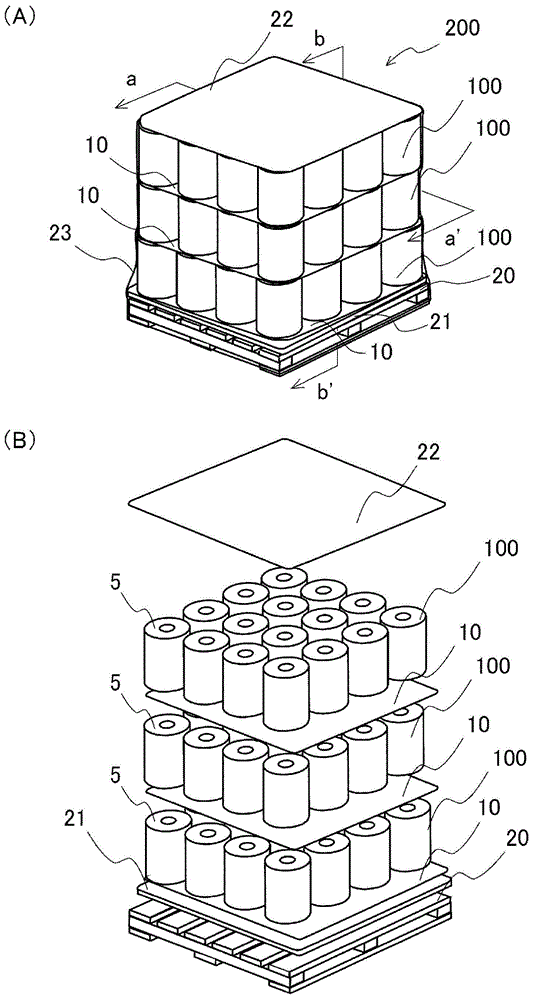

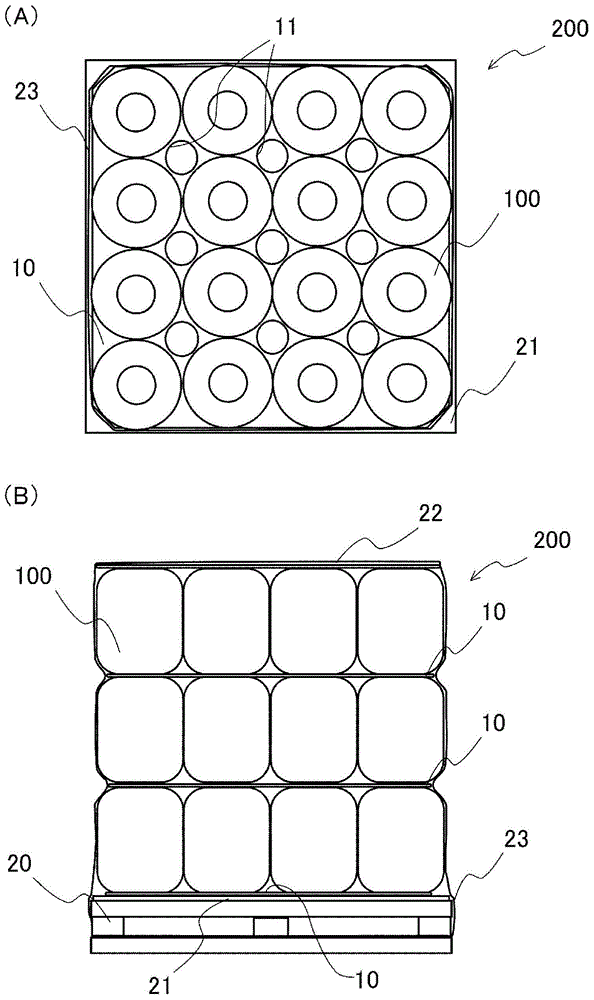

Glass roving package

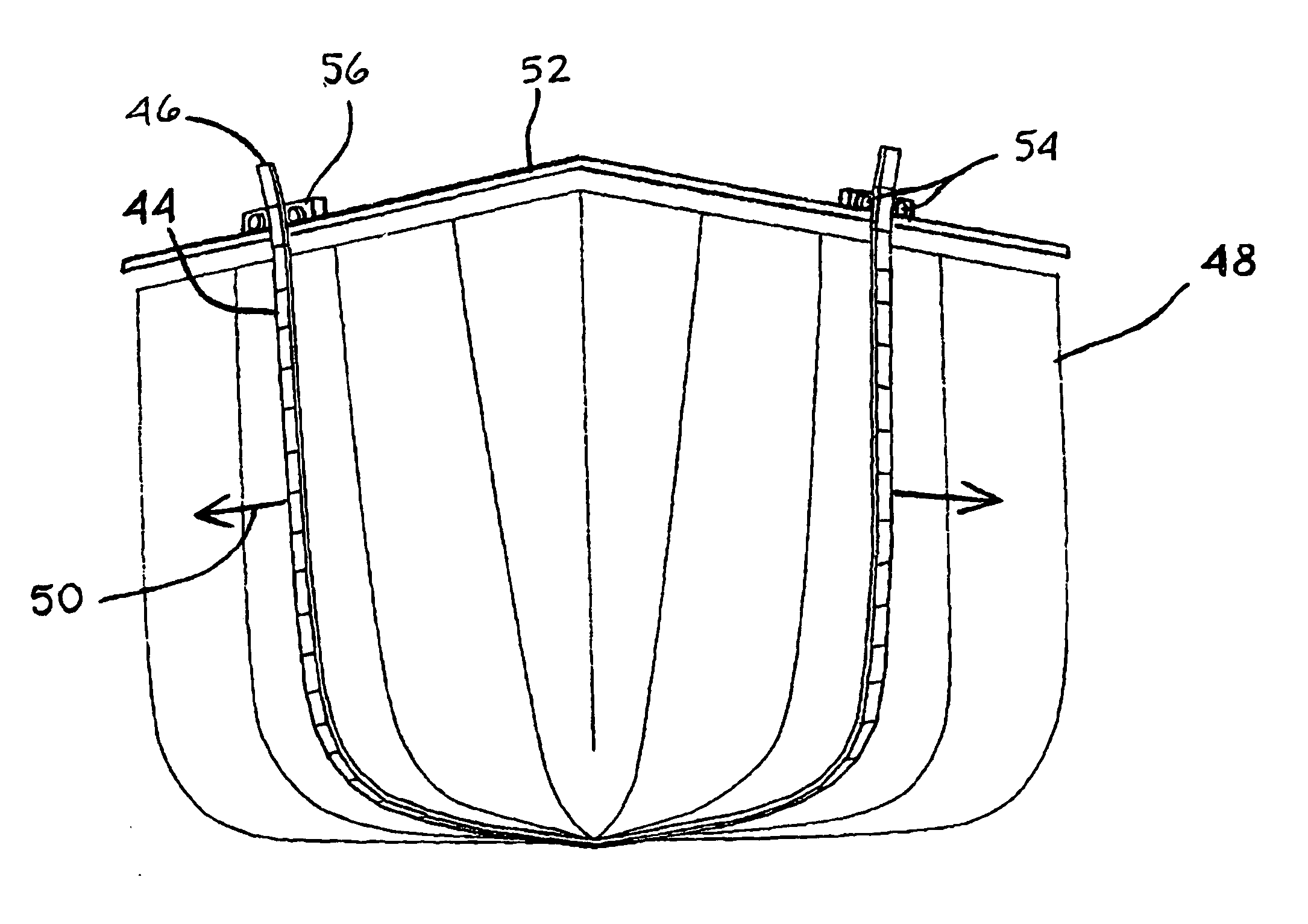

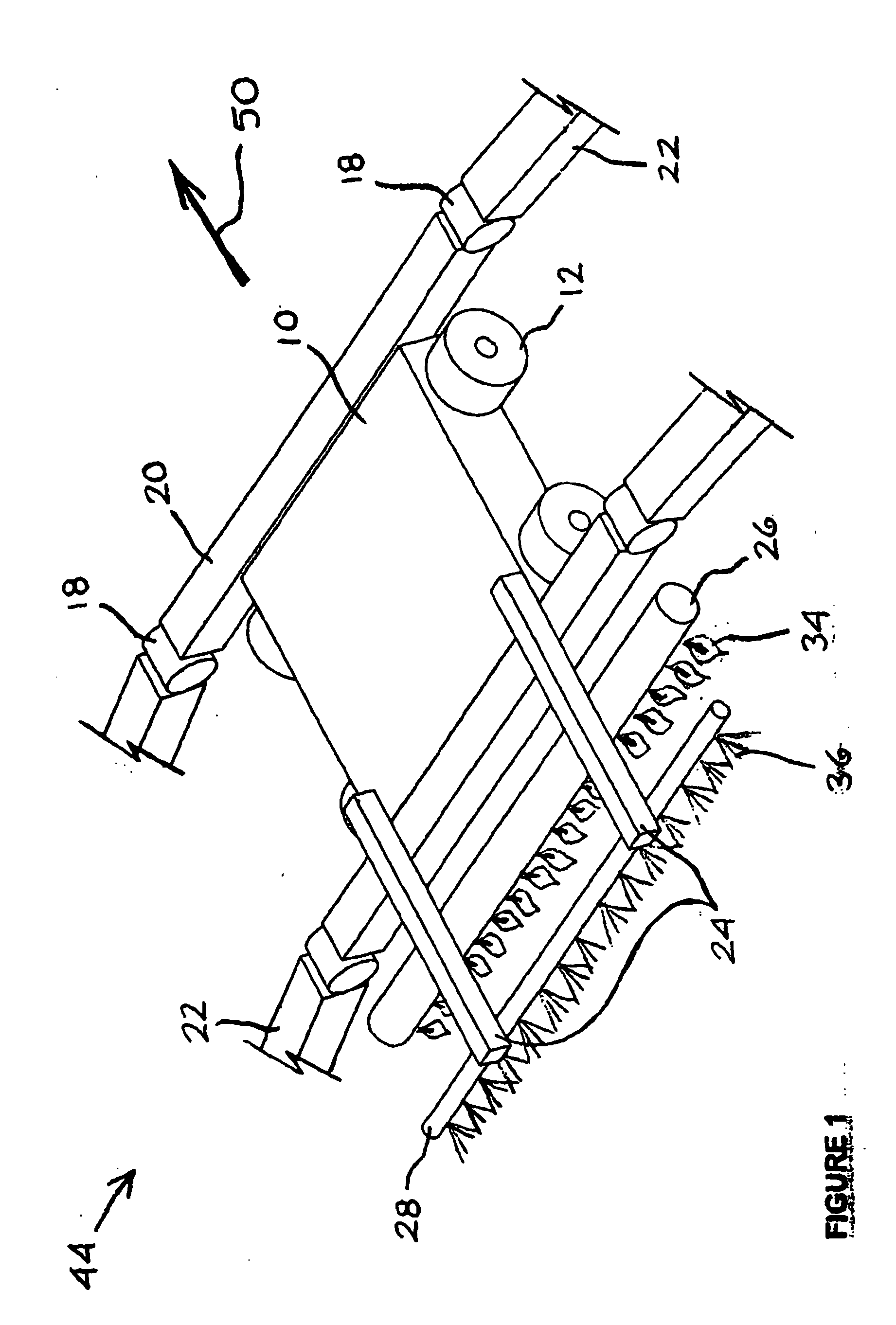

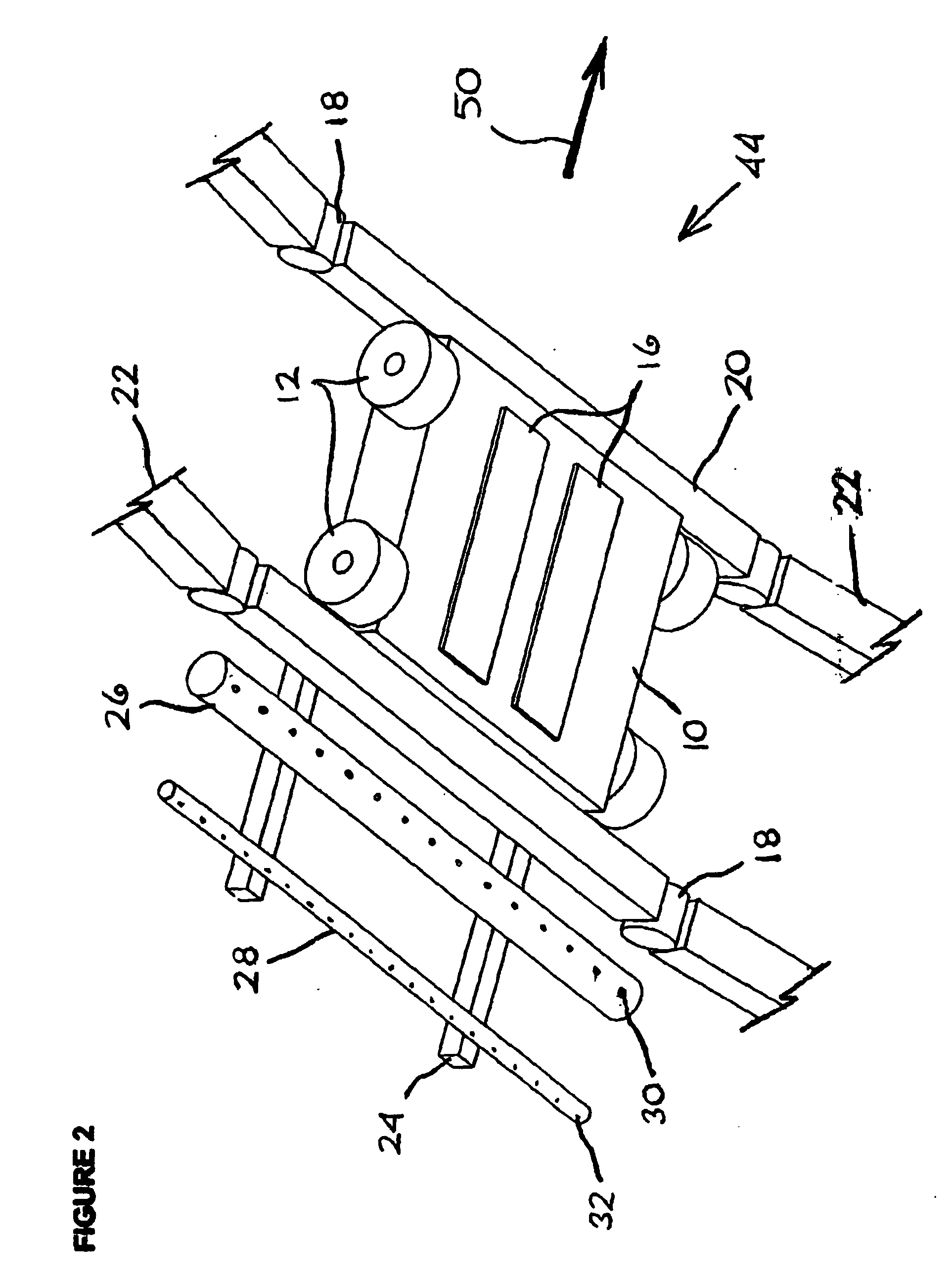

ActiveCN104105646AEfficient heat treatmentEqual heat treatmentContainers for annular articlesContainers with multiple articlesGlass fiberEngineering

Provided is a glass roving package (200) with which it is possible to prevent shifting and collapse of glass roving packages (200) during package transport using a simple structure and which makes it possible to simplify glass roving (100) packing and unpacking work and reduce glass roving package (200) packing costs. A glass roving package (200) in which multiple glass rovings (100) are stacked on multiple glass rovings (100) that are disposed in rows on a base (20) and the periphery thereof is wrapped with a packaging material, wherein an anti-positional shifting sheet (10), which prevents positional shifting of upper level glass rovings (100) during package transport, is placed between glass rovings (100) of a lower level and glass rovings (100) of an upper level.

Owner:NIPPON ELECTRIC GLASS CO LTD

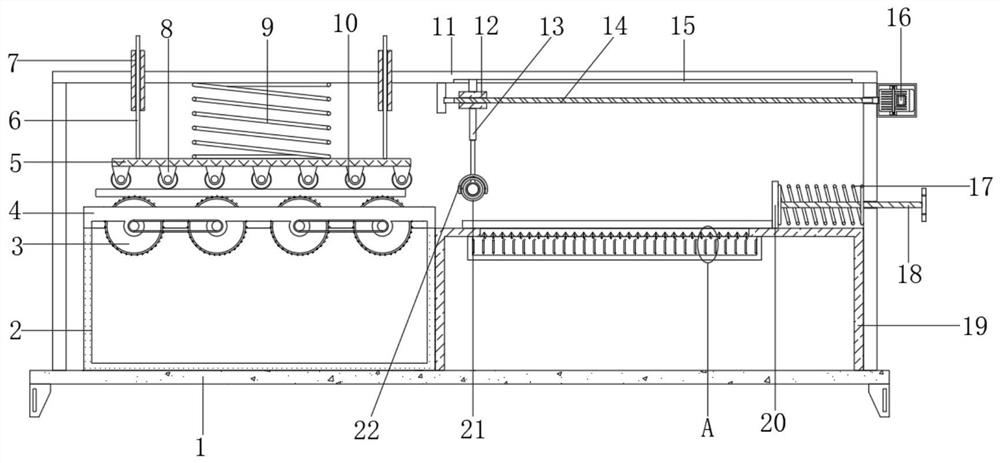

Plate gluing and pressing device for furniture processing

InactiveCN112405731AIncrease ShengjiaoImprove gluing effectPlywood pressesPretreated surfacesAdhesive glueStructural engineering

The invention belongs to the technical field of furniture processing, and particularly relates to a plate gluing and pressing device for furniture processing. In order to solve the problems that mostof traditional furniture plate gluing devices are simple in structure and low in subsequent glue drying efficiency, the following scheme is provided. The plate gluing and pressing device comprises a base and a top plate, a glue box is fixed to one end of the outer wall of the top of the base through bolts, a first mounting frame is fixed to the outer wall of the top of the glue box through bolts,the first mounting frame is rotationally connected with gluing rollers distributed at equal intervals through bearings, and protruding strips annularly distributed at equal intervals are fixedly installed on the circumferential outer walls of the gluing rollers. According to the plate gluing and pressing device, through an arranged abutting mechanism, a compression spring, a mounting plate and anabutting roller can be used for effectively abutting against a plate, and the transmission effect of the gluing rollers on the plate is improved; and through an arranged second heating wire, the innerwall of a rotating pressing roller can be heated, the plate can be conveniently heated in the pressing process, and the drying rate of glue is increased.

Owner:李家臣

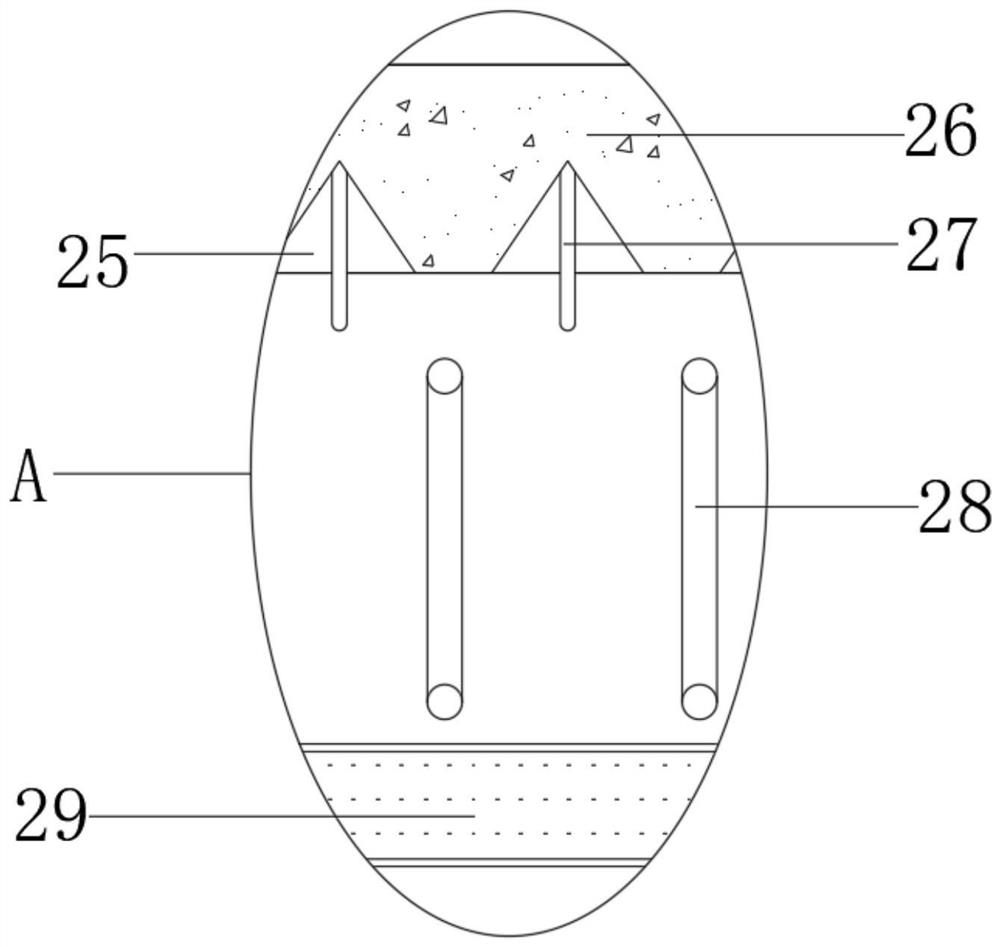

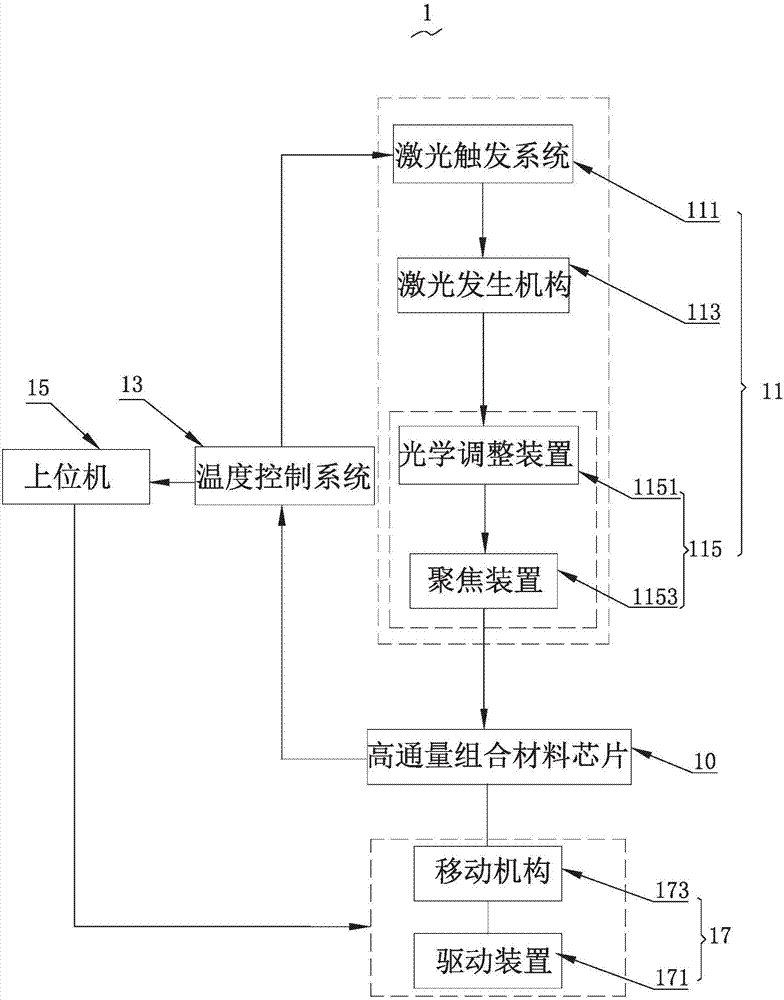

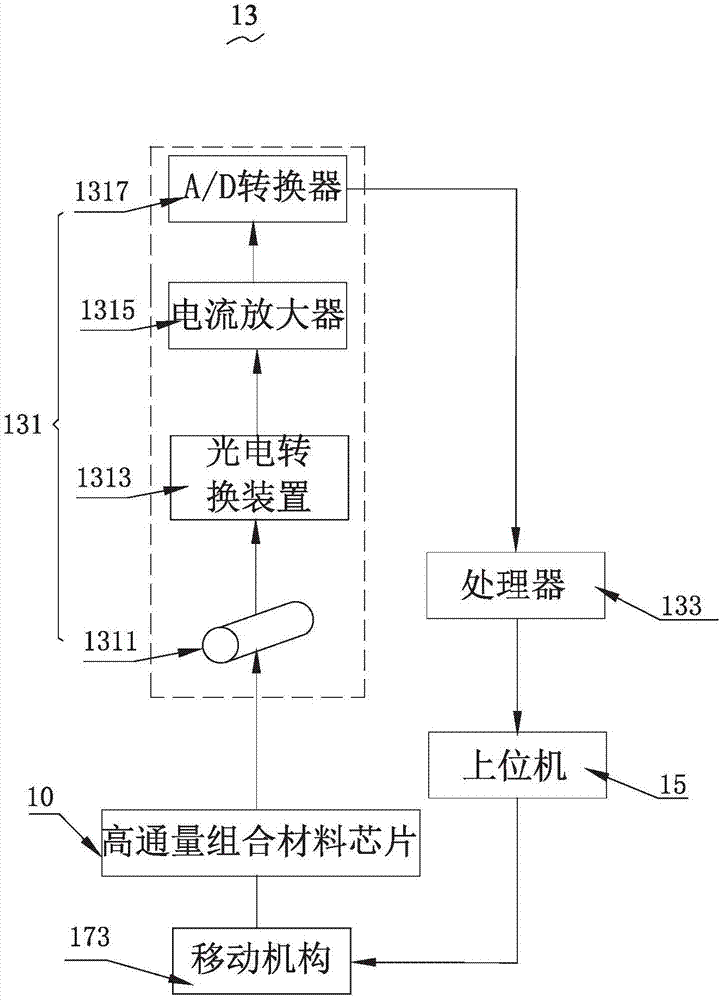

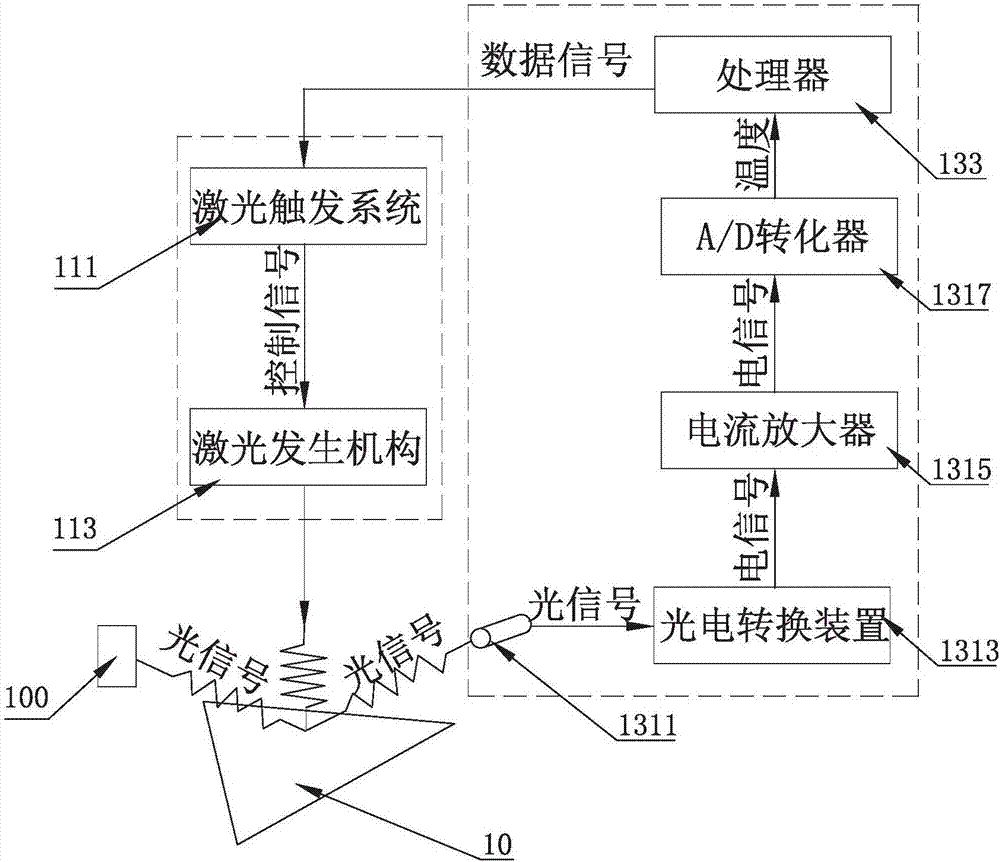

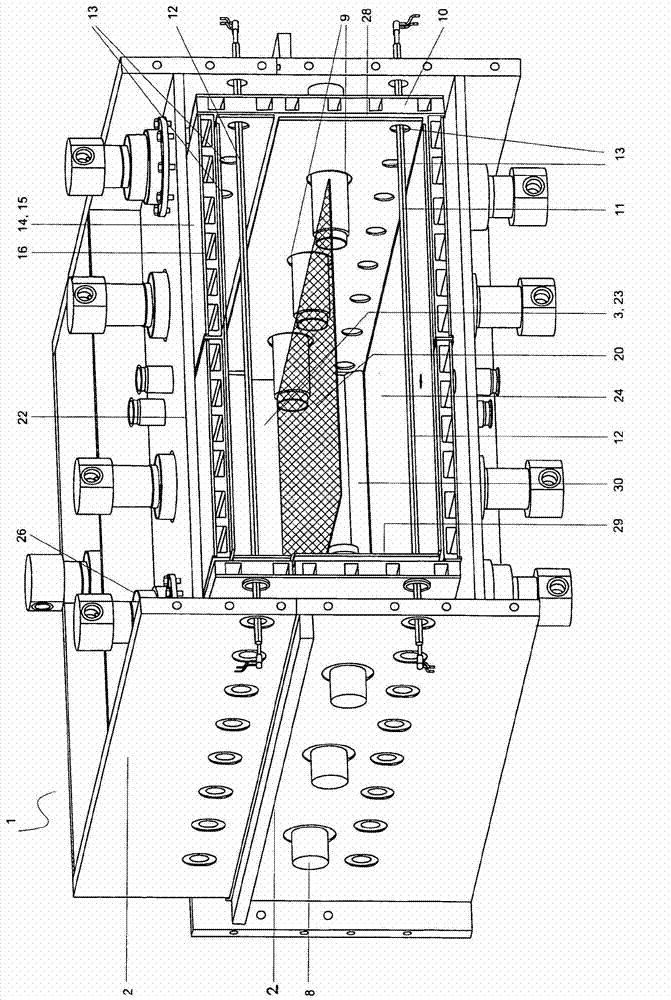

High-flux combined material heat treatment system and heat treatment and detecting method thereof

ActiveCN106992131AGuaranteed consistent temperatureEnsure that all micro-area samples reach the same temperatureSemiconductor/solid-state device manufacturingThermometer applicationsTemperature controlHigh flux

The invention relates to a high-flux combined material heat treatment system which is used for performing heat treatment on a high-flux combined material chip. The system comprises a power-adjustable laser heating system and a temperature control system. The temperature control system detects temperature of a micro-area sample and performs operational analysis for acquiring a data signal. The laser heating system adjusts heating power according to the data signal so that consistent temperature increase amplitude of each micro-area sample at each time is realized. When phase change of the micro-area sample occurs, the temperature control system records phase change temperature and simultaneously makes the laser heating system stop heating to the micro-area sample. The invention further relates to a heat treatment and detecting method which utilizes the high-flux combined material heat treatment system. The high-flux combined material heat treatment system can perform stable and accurate heat treatment on the micro-area sample, thereby ensuring stable quality of the micro-area sample in heating at each time.

Owner:成都芯曌科技有限公司

Substrate supporting/transferring tray

InactiveCN101061578AEfficient heat treatmentSemiconductor/solid-state device manufacturingOptoelectronicsMaterials science

To provide a substrate supporting / transferring tray, which can be placed on a substrate supporting part arranged in a treatment chamber wherein heat treatment is performed to a substrate, especially on a substrate supporting part having a built-in heating means for heating the substrate, and on an upper side of which, the substrate is placed. At the time of heat-treating the substrate, the substrate can be more uniformly heated, and when the heat treatment is completed, the tray can be easily removed from the substrate supporting part without waiting for the temperature of the substrate to be reduced, and can transfer the substrate to other parts from the treatment chamber wherein the heat treatment is performed. The substrate supporting / transferring tray, which has the disc-shaped substrate supporting part on an upper plane side, and is provided with a cylindrical side wall part extending from a periphery of the disc-shaped substrate supporting part to a lower side, and an annular part extending from a lower end side of the cylindrical side wall part to an outer side in a diameter direction.

Owner:CANON ANELVA CORP

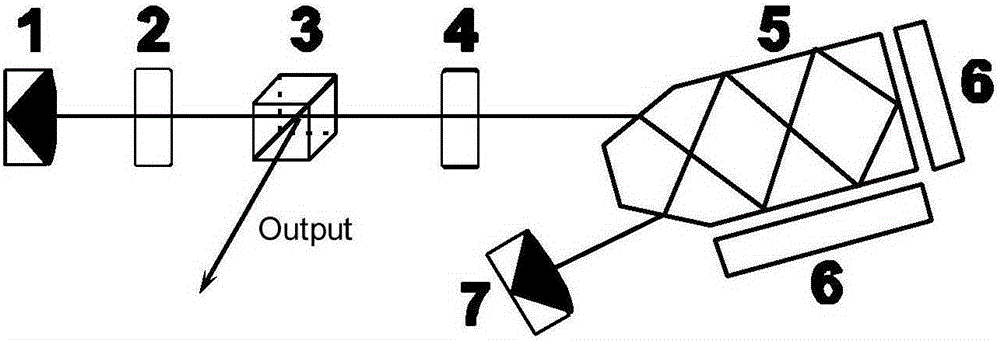

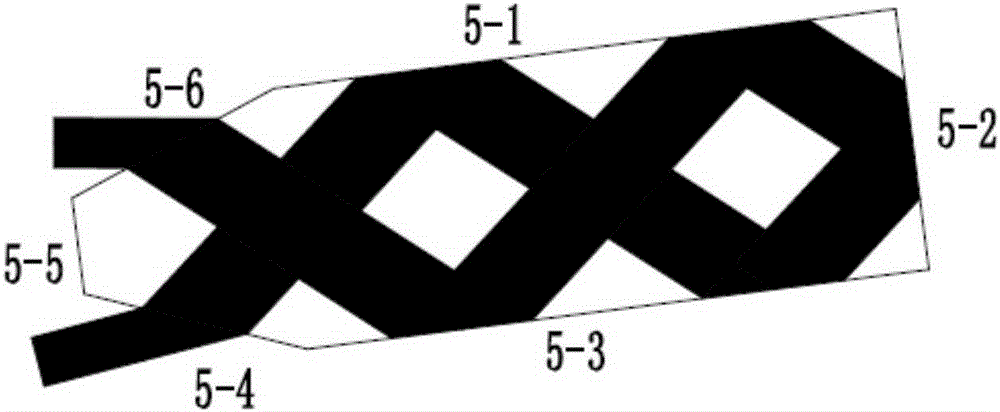

Wide temperature range laser based on hexagon plate strip structure

InactiveCN105281189AAvoid refrigerationFully absorbedOptical resonator shape and constructionActive medium materialIsosceles trapezoidResonant cavity

A wide temperature range laser based on hexagon plate strip structure comprises a large power laser diode light source, two orthogonally placed porro prisms, a laser gain medium, a polarization beam splitter, 0.57 wave sheet and 1 / 4 wave sheet, wherein the laser gain medium is a hexagon plate strip structure formed by a rectangle together with an isosceles trapezoid; the large power laser diode light source comprises a plurality of conduction-cooled laser diode arrays; the orthogonally placed porro prisms, the laser gain medium, the polarization beam splitter, the 0.57 wave sheet and the 1 / 4 wave sheet are used to construct a resonant cavity for producing laser; and the 0.57 wave sheet and the 1 / 4 wave sheet are zero-order wave sheets outputting laser with corresponding wavelengths. According to the invention, the structure is compact; the performance is stable; and the wide temperature range laser can work stably under the condition of no cooling with the temperature range of minus 30 to plus 70 DEG C.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

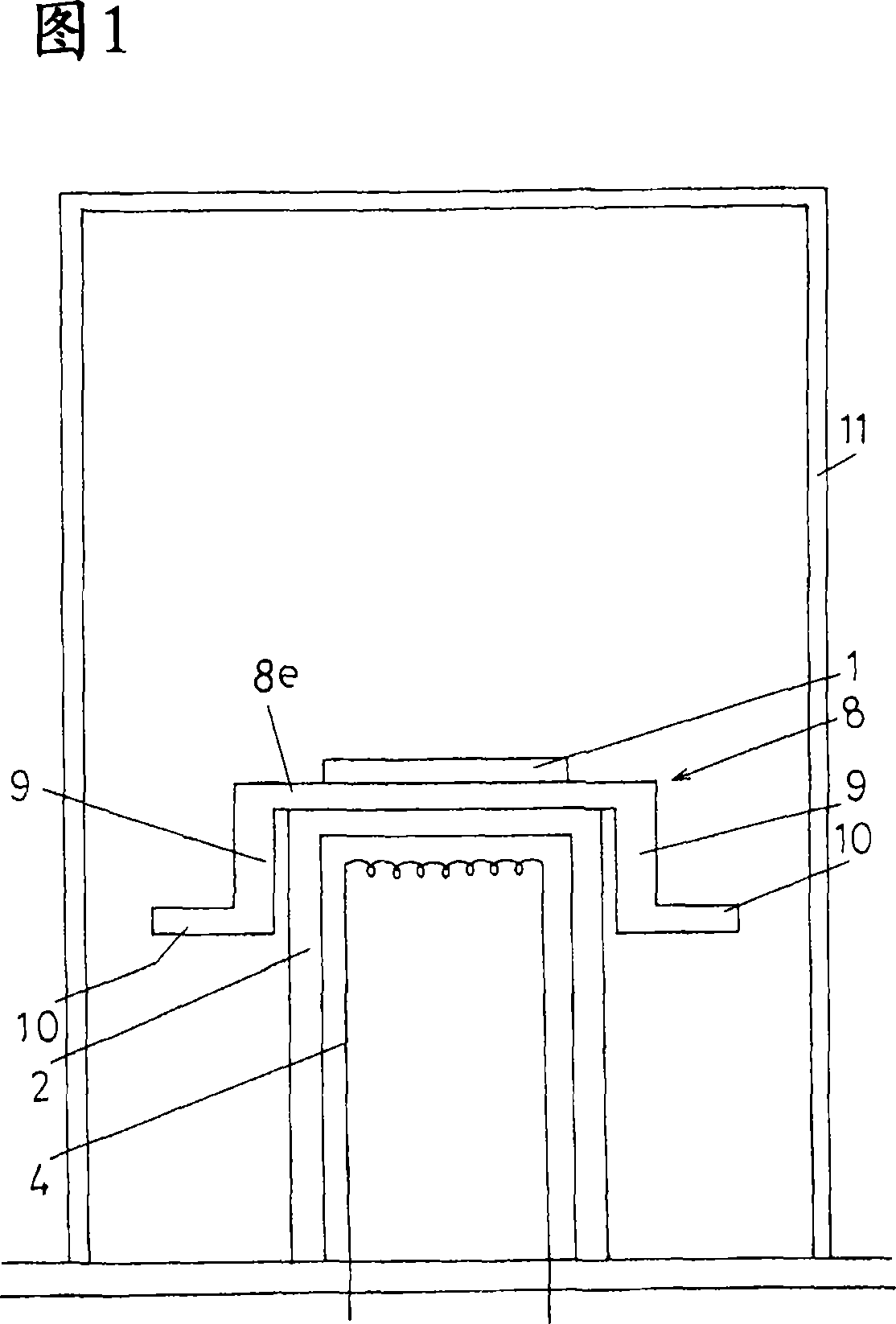

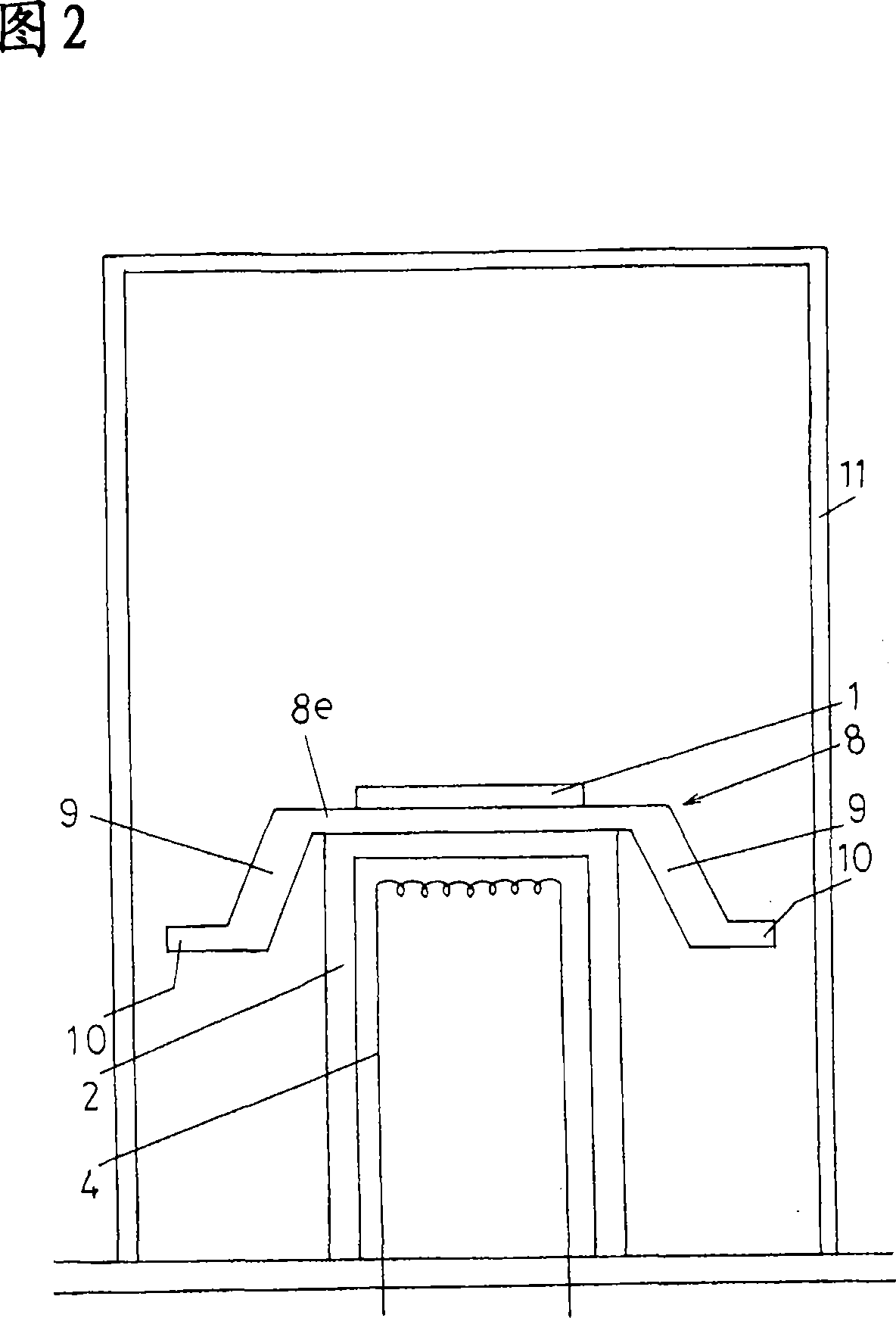

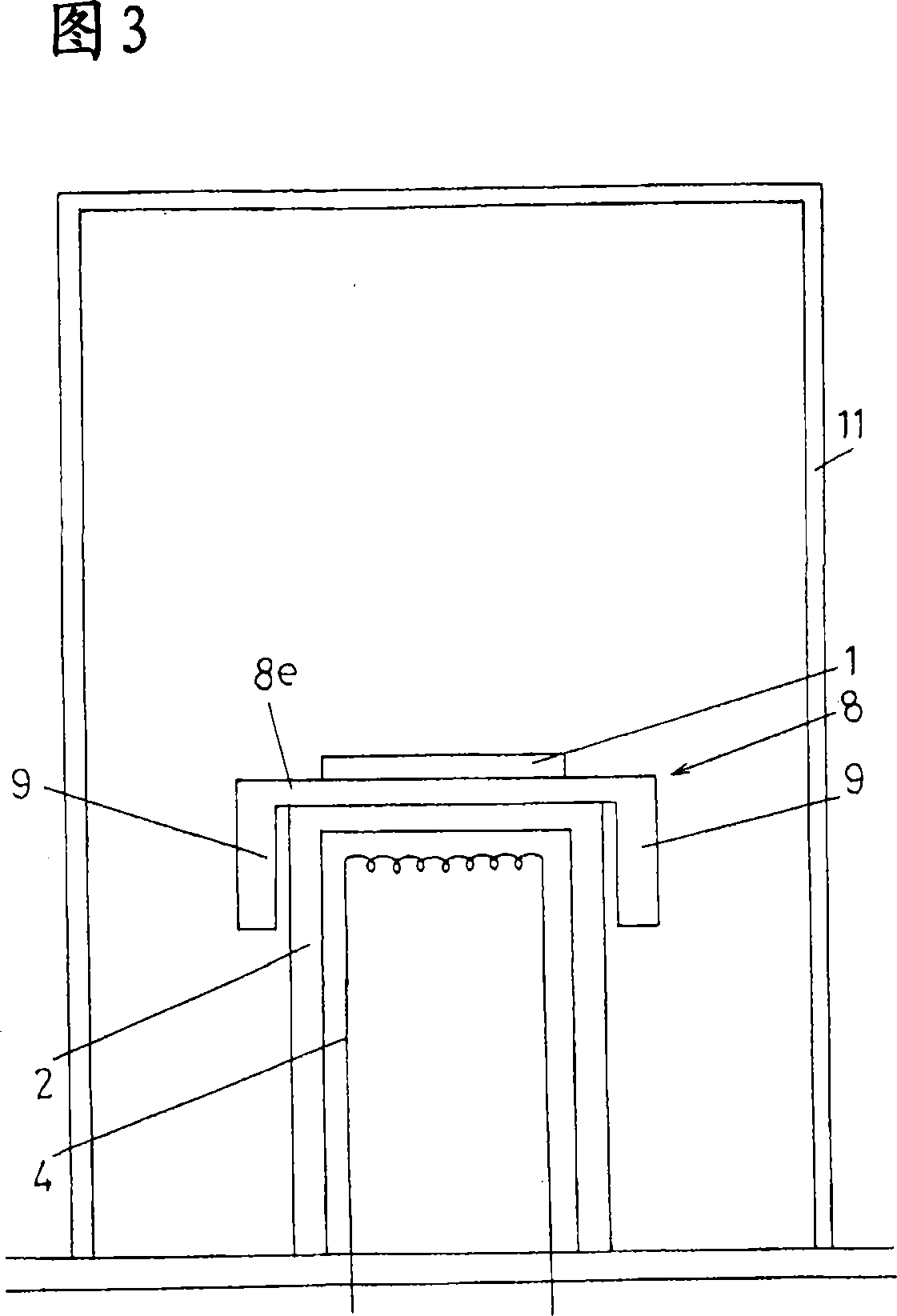

Device for thermally treating substrates

InactiveCN102859646ASimplify production operationsLow costSemiconductor/solid-state device manufacturingElectric heating for furnacesEngineeringHeat treated

The invention relates to an inner heat treatment chamber (3) for thermally processing a substrate (20), comprising walls (10) that surround an inner space (24) of the inner heat treatment chamber (3), a storage unit (8) for storing the substrate (20) during the thermal processing and an energy source (11) for introducing energy into the inner space (24) of the inner heat treatment chamber (3), wherein at least a part of the inner sides of the walls (10) is designed to reflect power introduced by the energy source (11). The at least one part of the inner sides of the walls (10) is made of a material that reflects at least infrared radiation to a high degree. The invention further relates to an inner heat treatment chamber (3) for thermally processing a substrate (20), comprising walls (10) that surround an inner space (24) of the inner heat treatment chamber (3), a storage unit (8) for storing the substrates (20) during the thermal processing and an energy source (11) for introducing energy into the inner space (24) of the inner heat treatment chamber, wherein a cooling device (14) is provided for cooling the walls (10).

Owner:LEYBOLD OPTICS +1

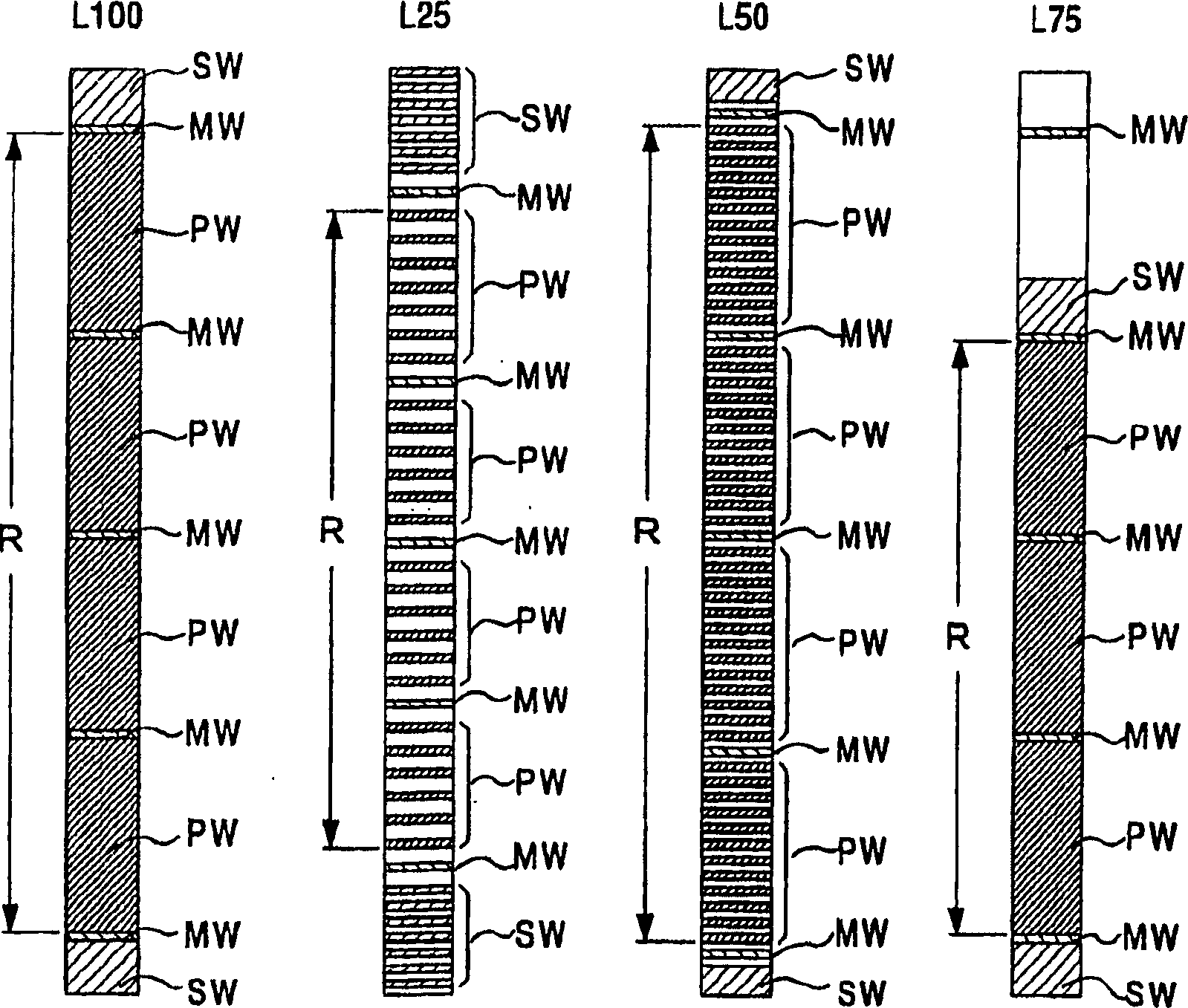

Method and device for heat treatment

InactiveCN1565050AEfficient heat treatmentReduce in quantitySemiconductor/solid-state device manufacturingControl devices for furnacesDistribution patternComputer science

A thermal processing method selects a batch size range including the number of workpieces to be processed from a plurality of batch size ranges including batch size ranges in which reference numbers smaller than the holding capacity of a workpiece holder are maximums. The workpieces are distributed in the workpiece holder on the basis of the workpiece distribution pattern determined corresponding to the specified batch size range. Processing conditions of the thermal process are determined according to the workpiece distribution pattern. A thermal processing apparatus comprises a controller capable of carrying out the thermal processing method.

Owner:TOKYO ELECTRON LTD

Skinned structures of air hardenable or liquid quench hardenable steel plate and methods of constructing thereof

InactiveUS20050224129A1Efficient heat treatmentSufficient hardening and thus strengthWelding/cutting auxillary devicesAuxillary welding devicesMaterials scienceSteel plates

The present invention provides skinned structures of air or liquid quench hardenable steel plates or sheets, and methods of constructing such structures. The present invention also provides hardened skinned structures made from a plurality of air or liquid quench hardenable steel plates or sheets that are made by such methods.

Owner:RAOS DAVOR JACK

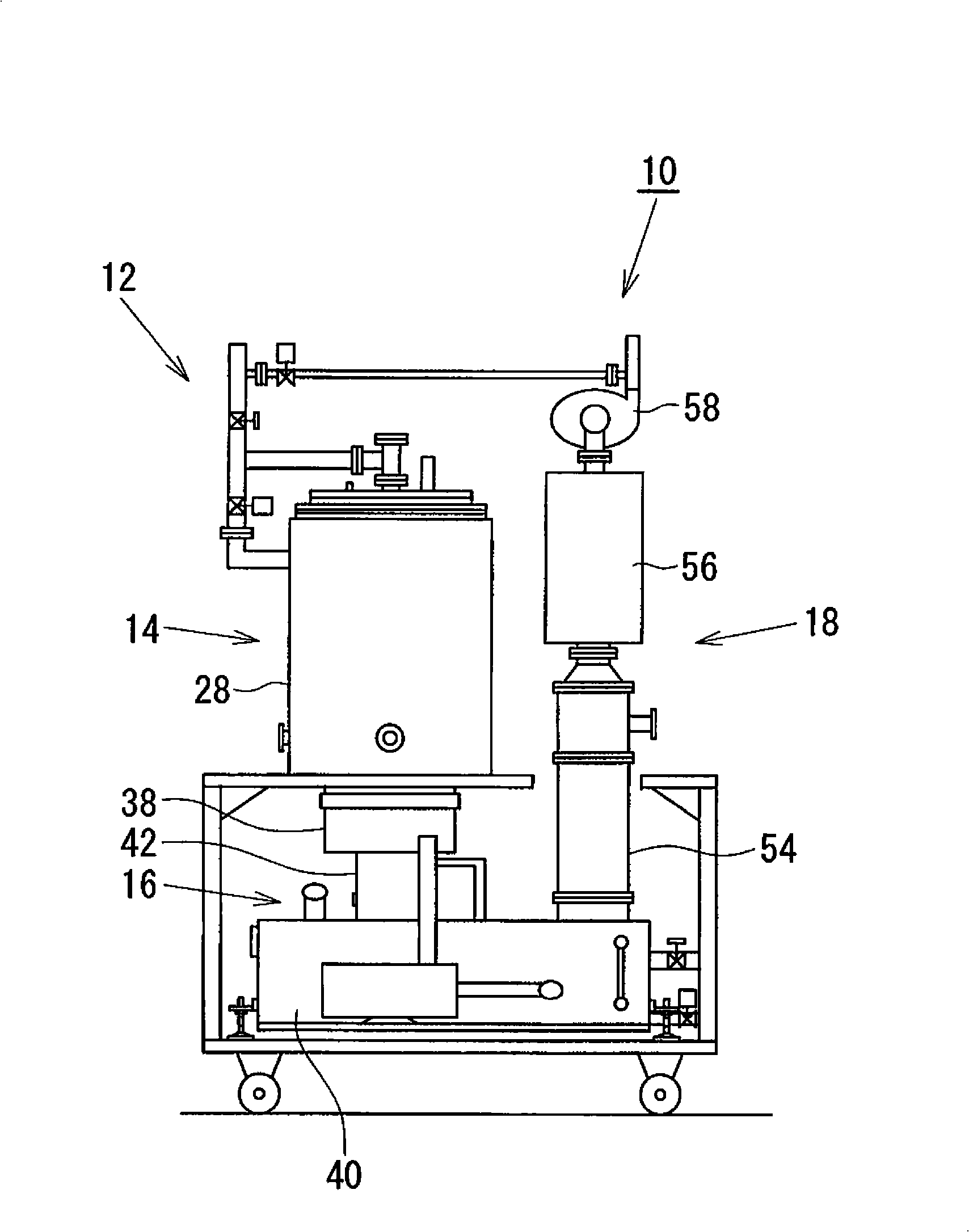

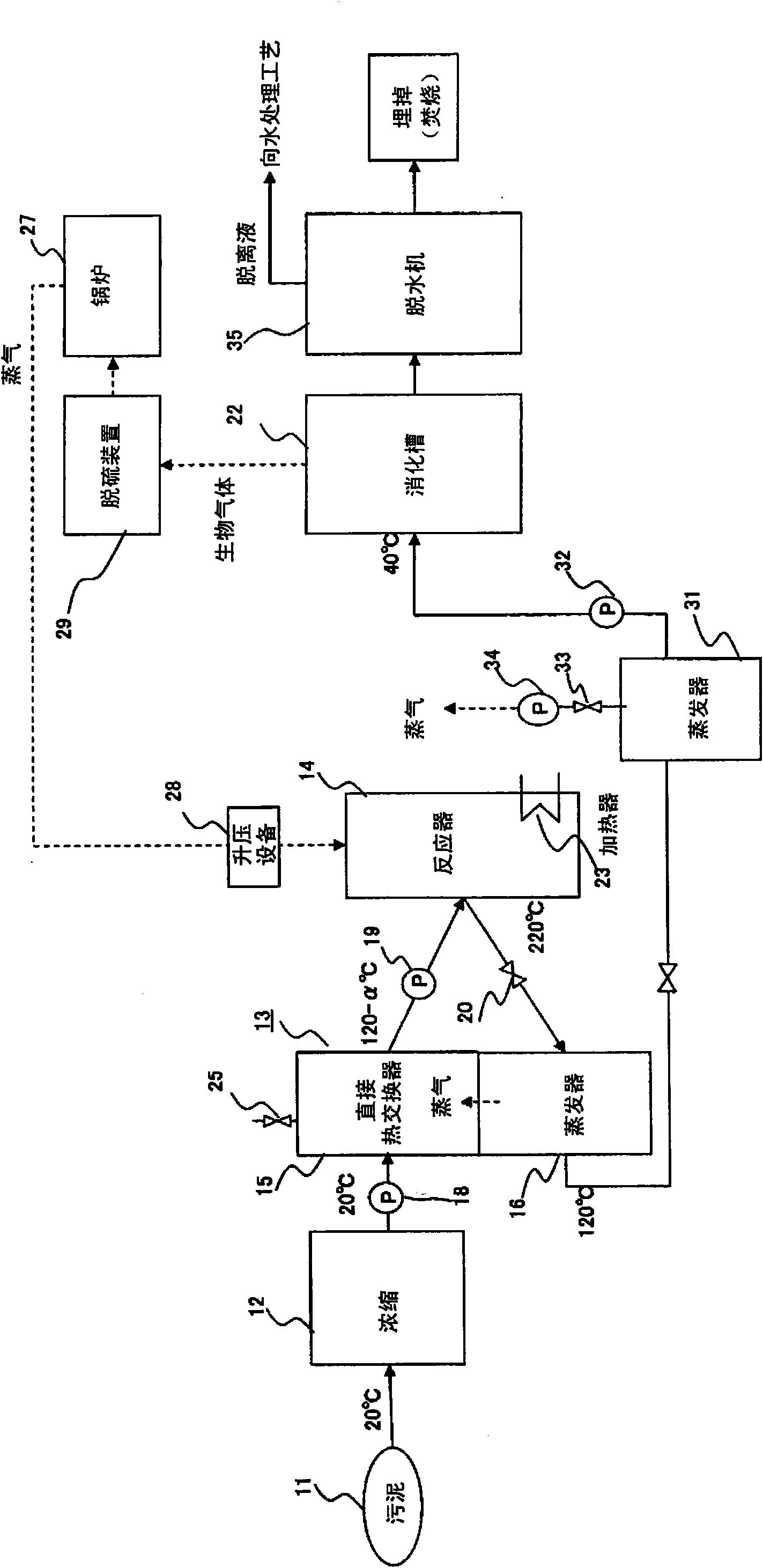

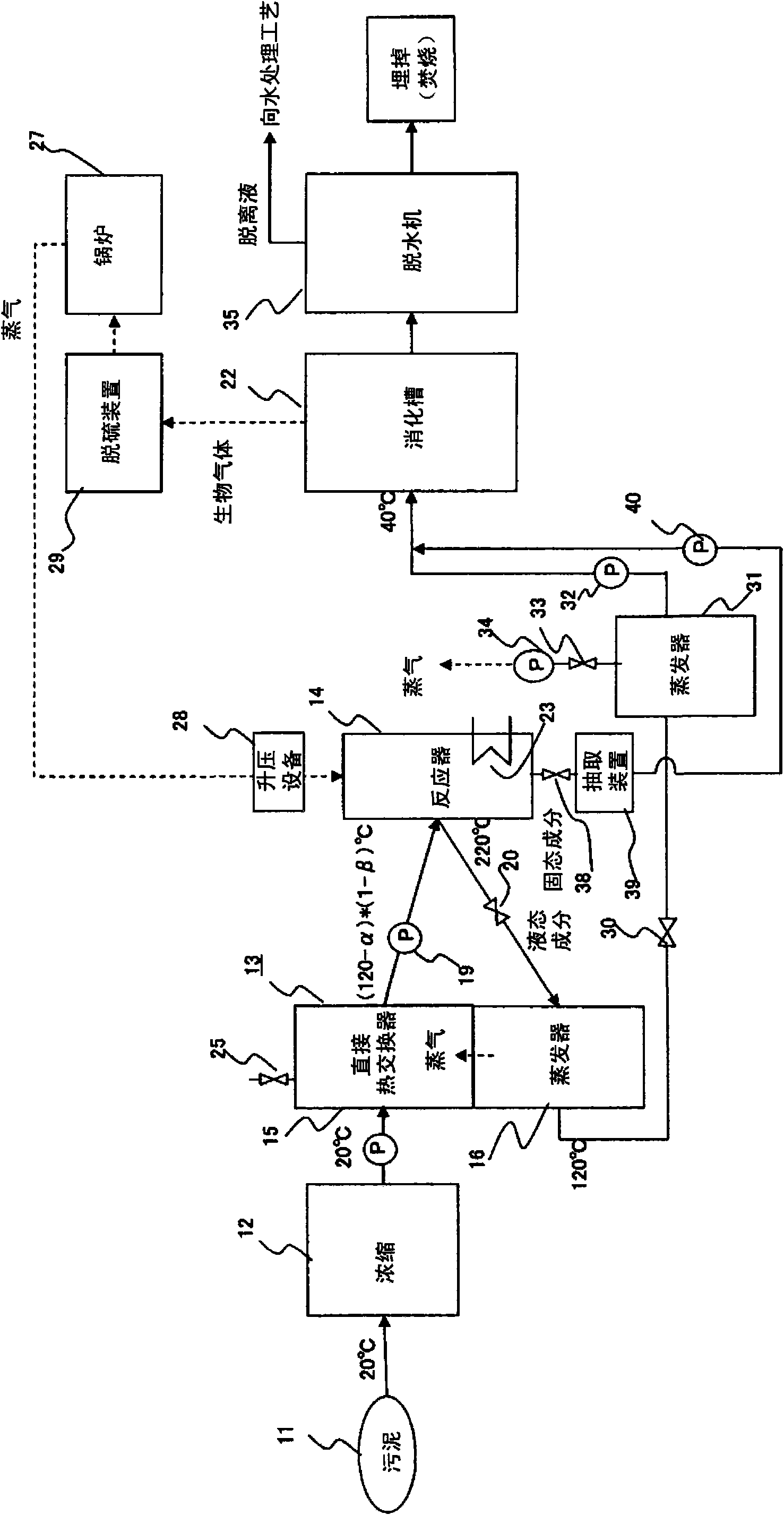

Sludge treating system

InactiveCN101835715ASimple structureNot easy to drop in heat exchange efficiencyWater treatment parameter controlSludge treatment by de-watering/drying/thickeningNuclear engineeringEvaporator

Sludge can be effectively heat-treated with neither the drop of heat-treatment efficiency due to the adhesion of a sludge component to a heat transfer face nor the clogging of a passage with the sludge. The sludge is subjected to a heat-treatment by heating it by a reactor (14) under a predetermined pressure. Before this heat-treatment by the reactor (14), the sludge is preheated by a preheating device (13). This preheating device (13) is constituted by integrating a direct heat exchanger portion (15) connected to a feed passage of the sludge to the reactor (14) and an evaporator portion (16) connected to a discharge passage of the heat-treated sludge from the reactor (14). These portions are held therein at a pressure lower than that in the reactor (14). The sludge, which is introduced into the direct heat exchanger portion (15) but before heat-treated, is preheated by making direct contact with the steam which is produced from the heat-treated sludge introduced from the discharge passage into the evaporator portion (16).

Owner:KK TOSHIBA

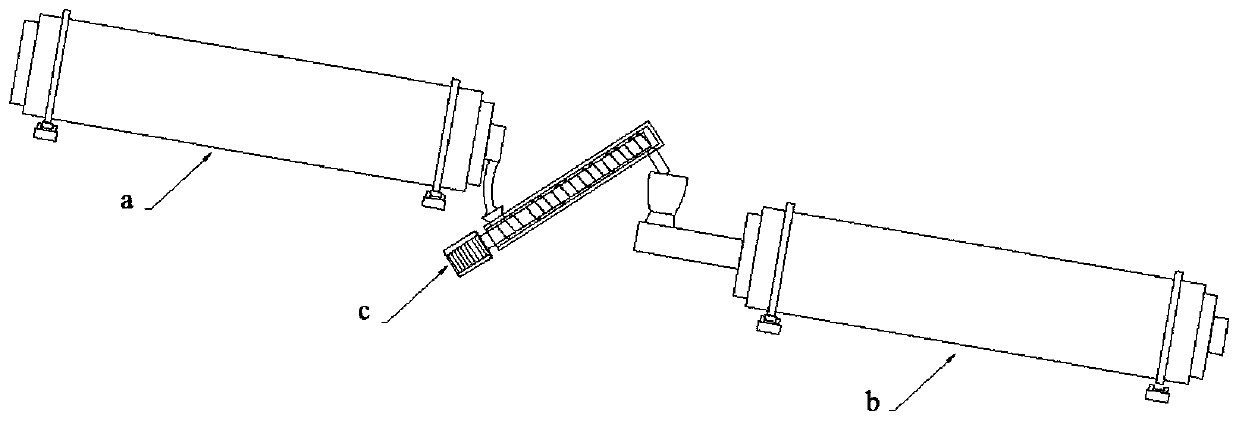

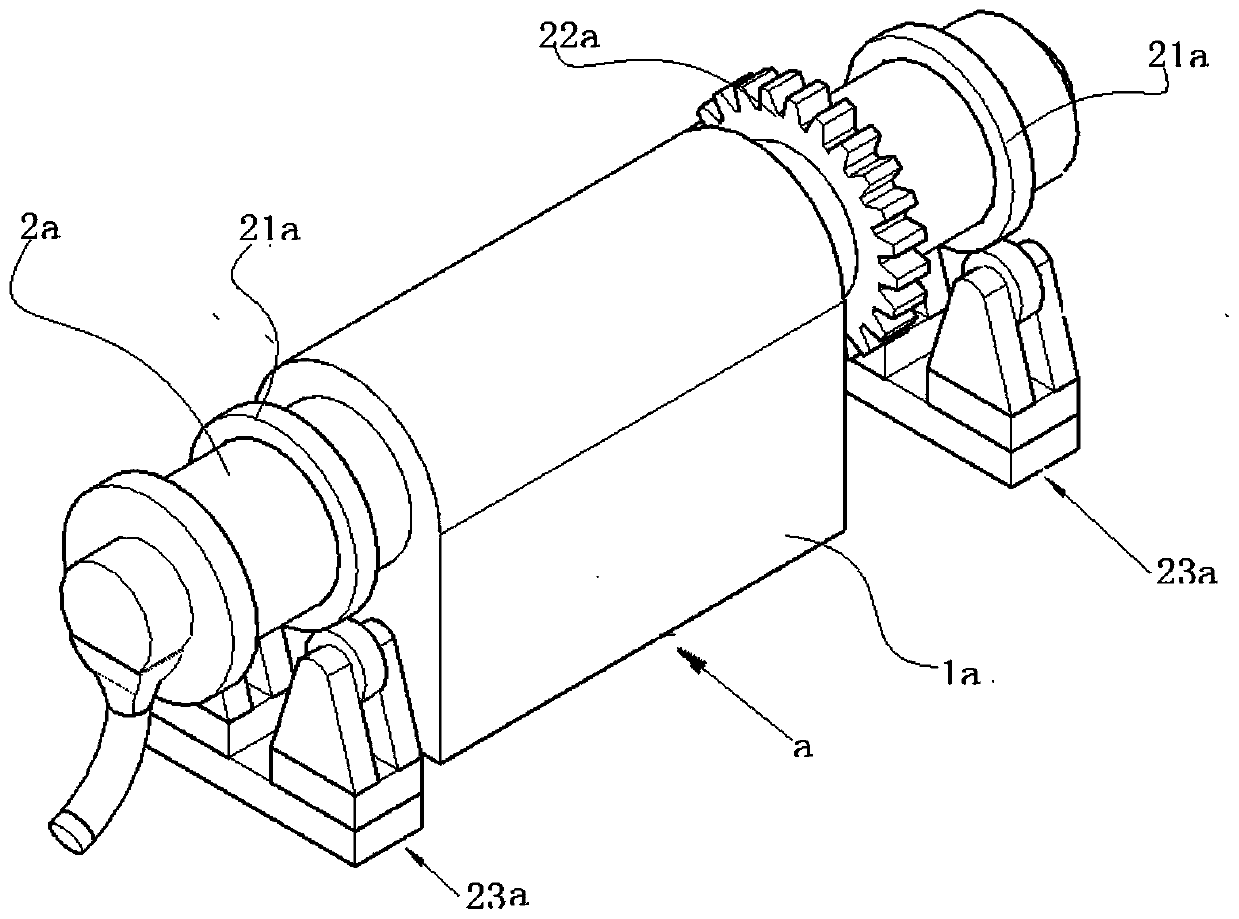

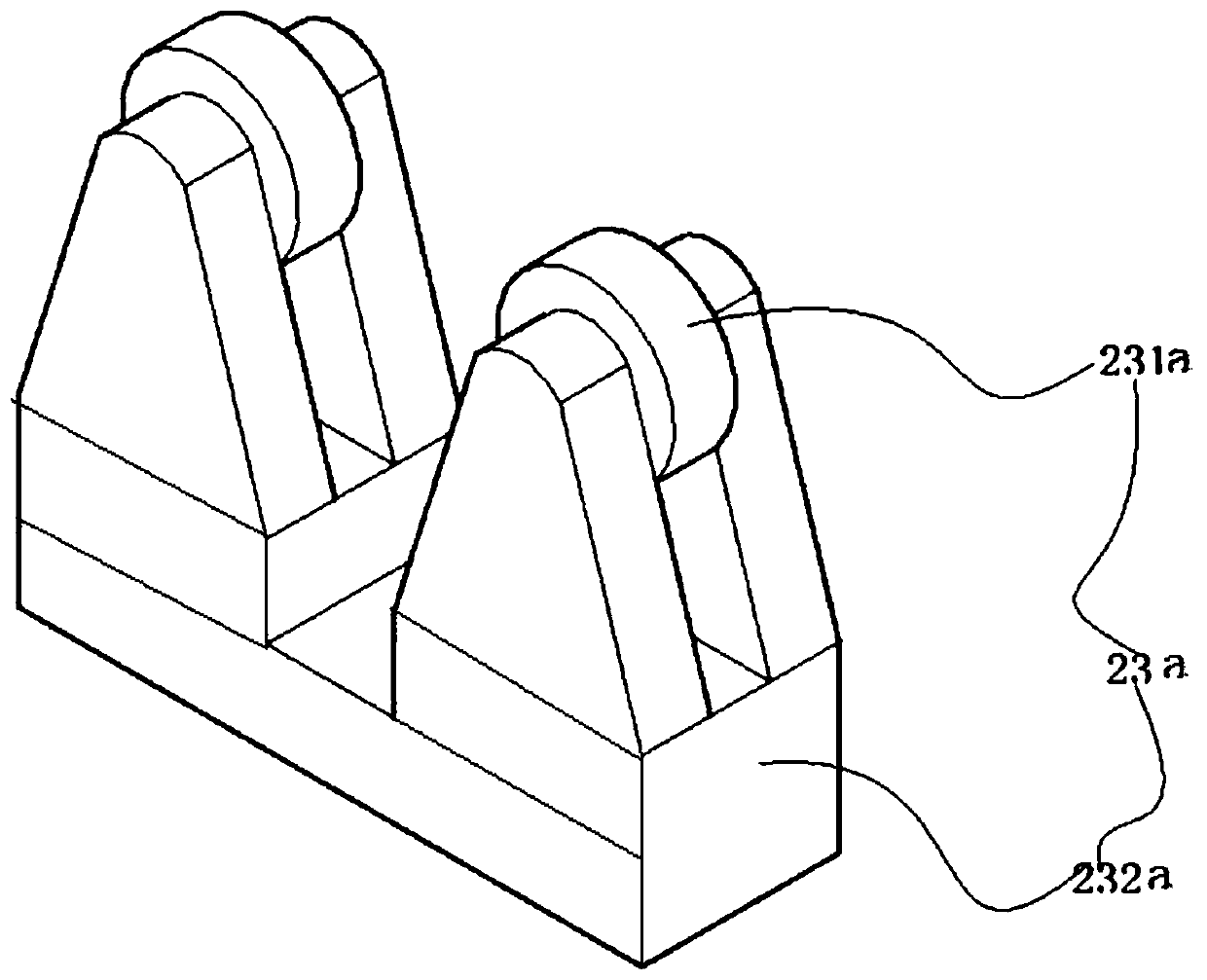

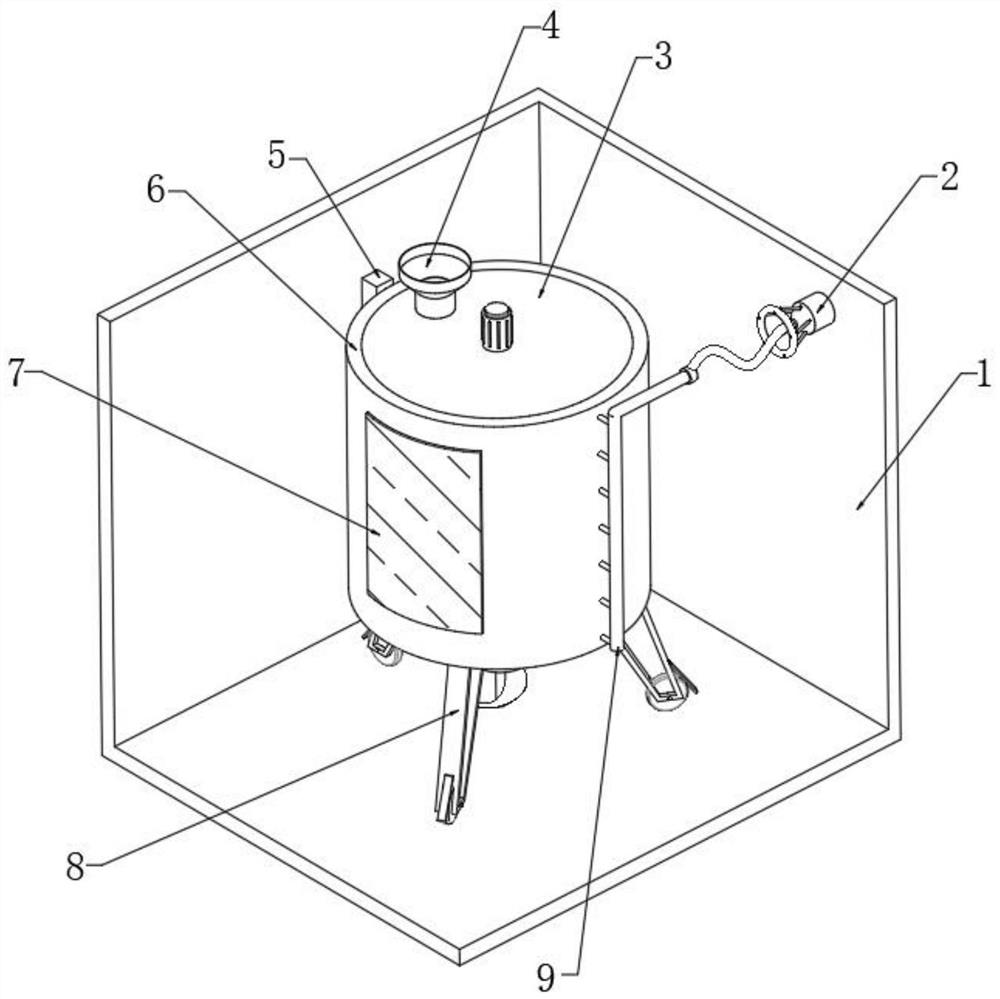

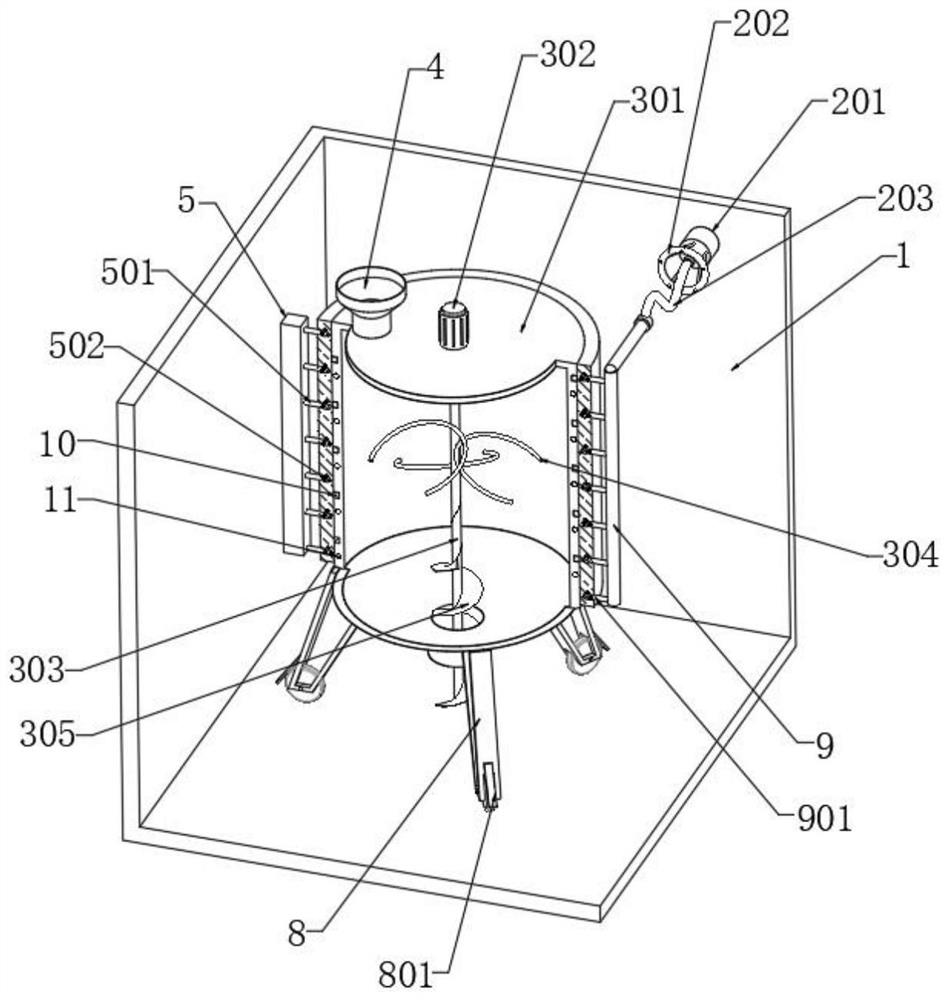

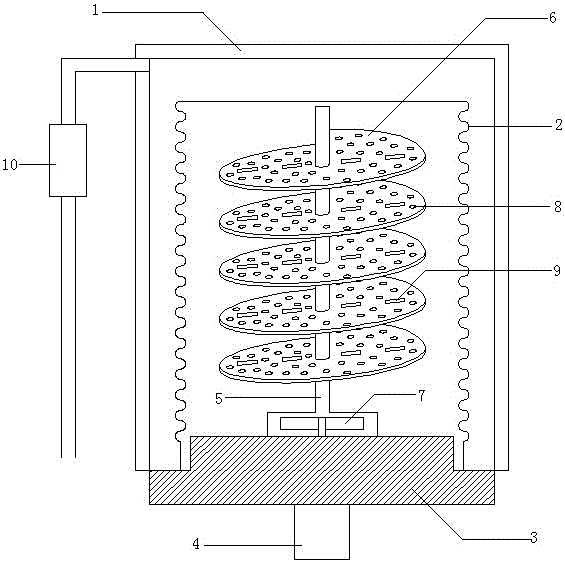

Sludge drying-carbonization combined heat treatment equipment

PendingCN110606645ASpeed up entryEasy dischargeSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention discloses sludge drying-carbonization combined heat treatment equipment which comprises a drying furnace and a carbonization furnace. The discharging end of the drying furnace is communicated with the feeding end of the carbonization furnace through a spiral feeder. Materials are dried by the drying furnace and then are fed to the carbonization furnace for carbonization treatment through the spiral feeder. The materials are crushed in the drying furnace by designing a class I material crushing cutter and a class II material crushing cutter. The carbonization furnace comprises aninner furnace body and an outer furnace body, and the inner furnace body is rotatably connected into the outer furnace body. A first material shoveling plate and a plurality of second material shoveling plates are designed in the carbonization furnace, so that mixing and crushing of materials are increased. By adopting the sludge heat treatment equipment formed by the drying furnace and the carbonization furnace disclosed by the invention, sludge can be effectively dried and carbonized, and the heat treatment effect is remarkably improved.

Owner:HEFEI BAIHE ENVIRONMENTAL PROTECTION TECH CO LTD

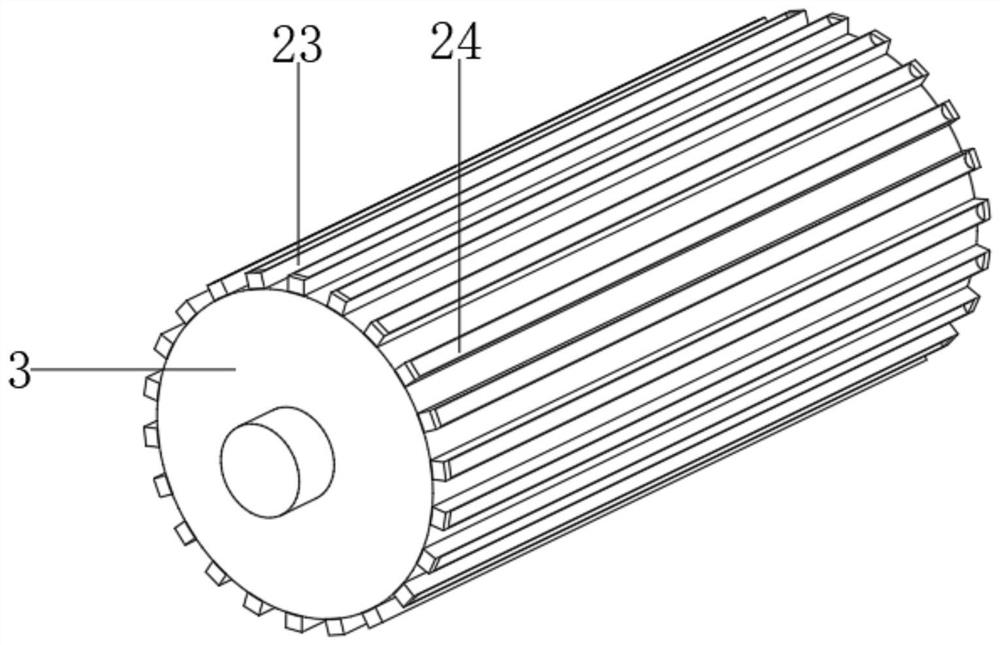

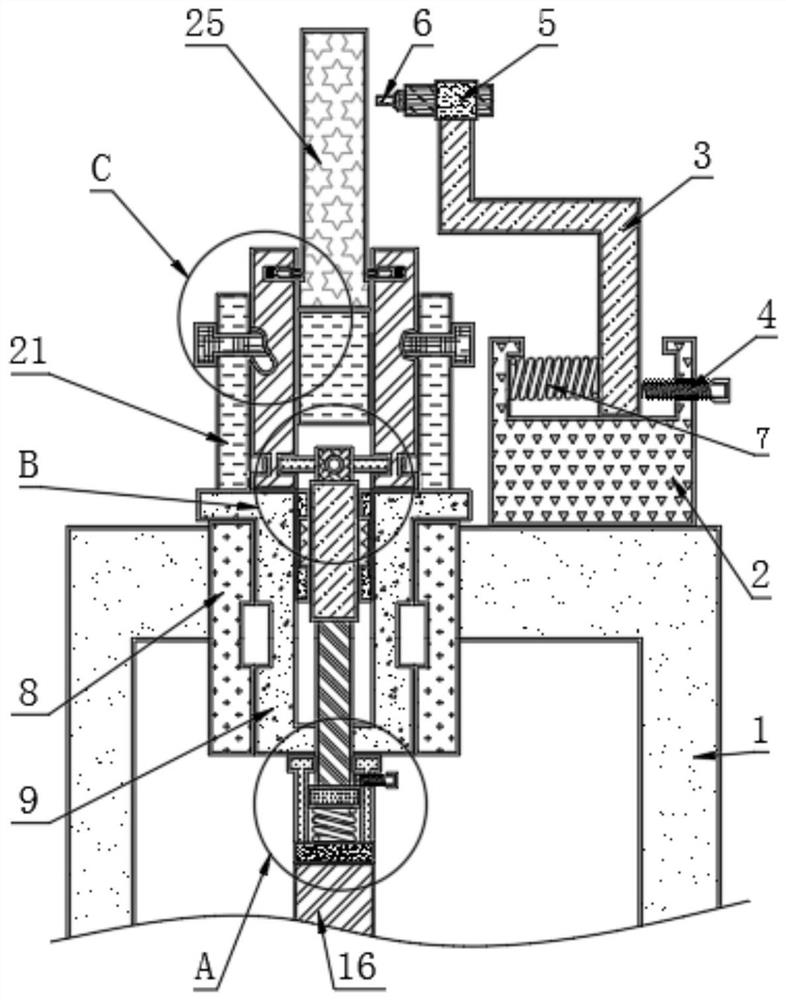

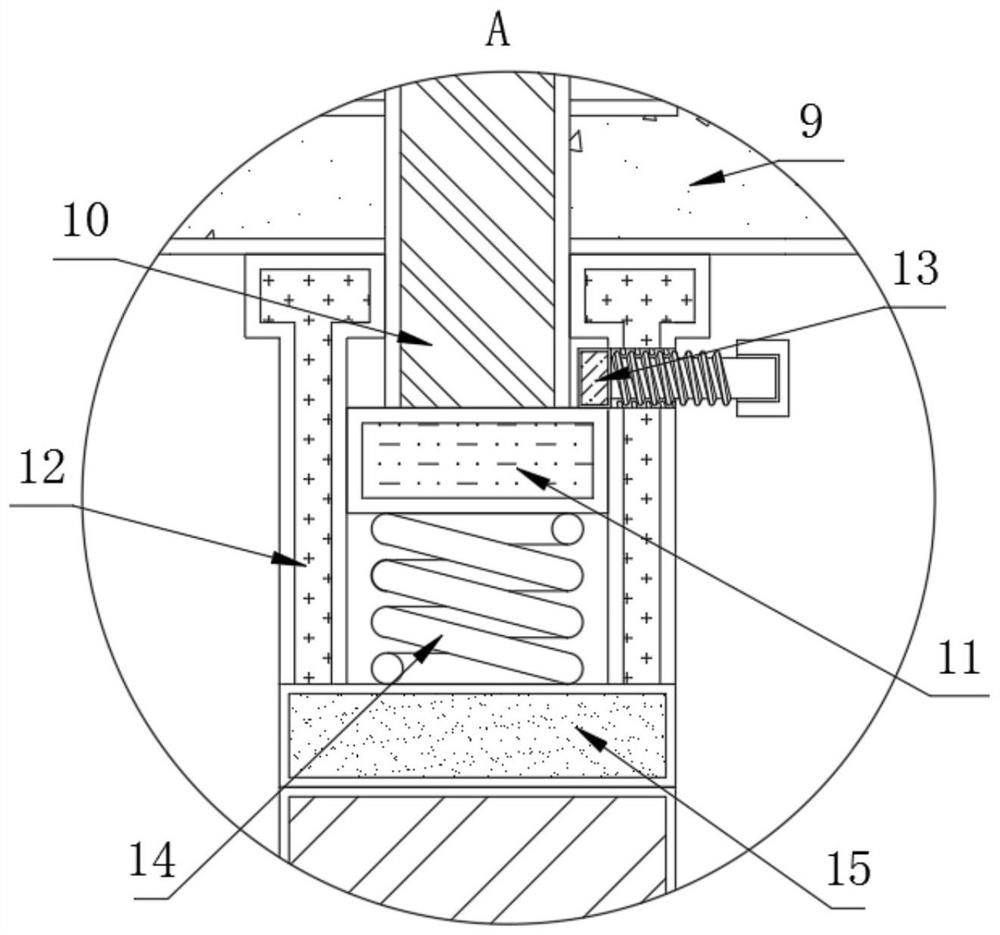

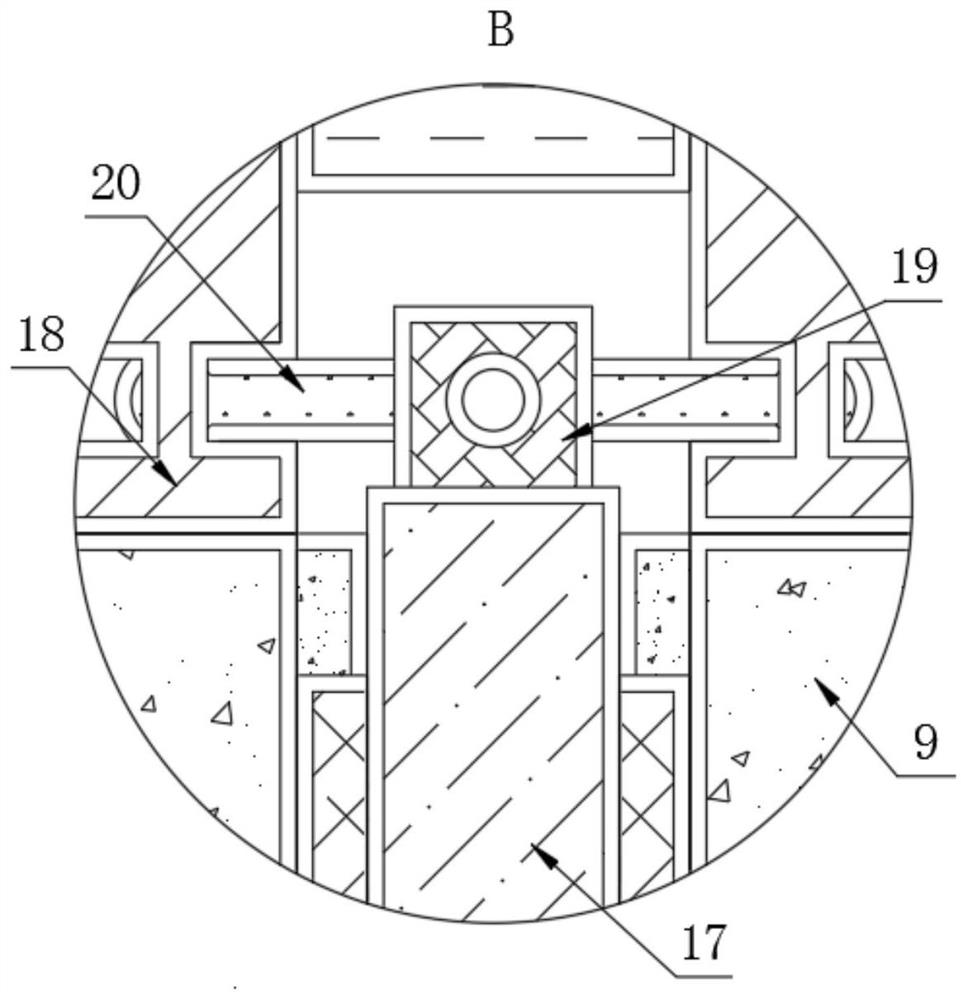

High-frequency welding device capable of achieving efficient heat treatment and preventing cylindrical piece from moving

InactiveCN113351978AEfficient heat treatmentEfficient and uniform heat treatmentWelding/cutting auxillary devicesHigh frequency current welding apparatusDrive shaftEngineering

The invention relates to the field of high-frequency welding machines, and discloses a high-frequency welding device capable of achieving efficient heat treatment and preventing a cylindrical piece from moving. A rotary displacement column is fixedly connected to a spring rod through the side face of a spring groove, the other end of the spring rod is fixedly connected to a clamping block, the middle of the clamping block is fixedly connected to a round rod, the clamping block is rotationally connected to a clamping wheel through the round rod, and the upper end of a bearing block is fixedly connected to a cylindrical workpiece. According to the high-frequency welding device capable of achieving efficient heat treatment and preventing the cylindrical piece from moving, the lower side of a clamping plate rotationally connected to the clamping wheel is clamped with the upper end of a protruding part at the bottom of the cylindrical workpiece at the moment, so that the cylindrical workpiece is limited to move in the vertical direction, the rotary displacement column moves downwards to drive a horizontal rod and a moving seat to move downwards, the moving seat pushes a driven shaft to move downwards, the driven shaft pushes the sliding block to move downwards so that the right side of the top of the sliding block can descend to the lower side of a limiting block, the clamping wheel buffers radial vibration of the cylindrical workpiece in real time through the spring rod, and the purpose of preventing the cylindrical workpiece from moving in the heat treatment process is achieved.

Owner:欧阳南庆

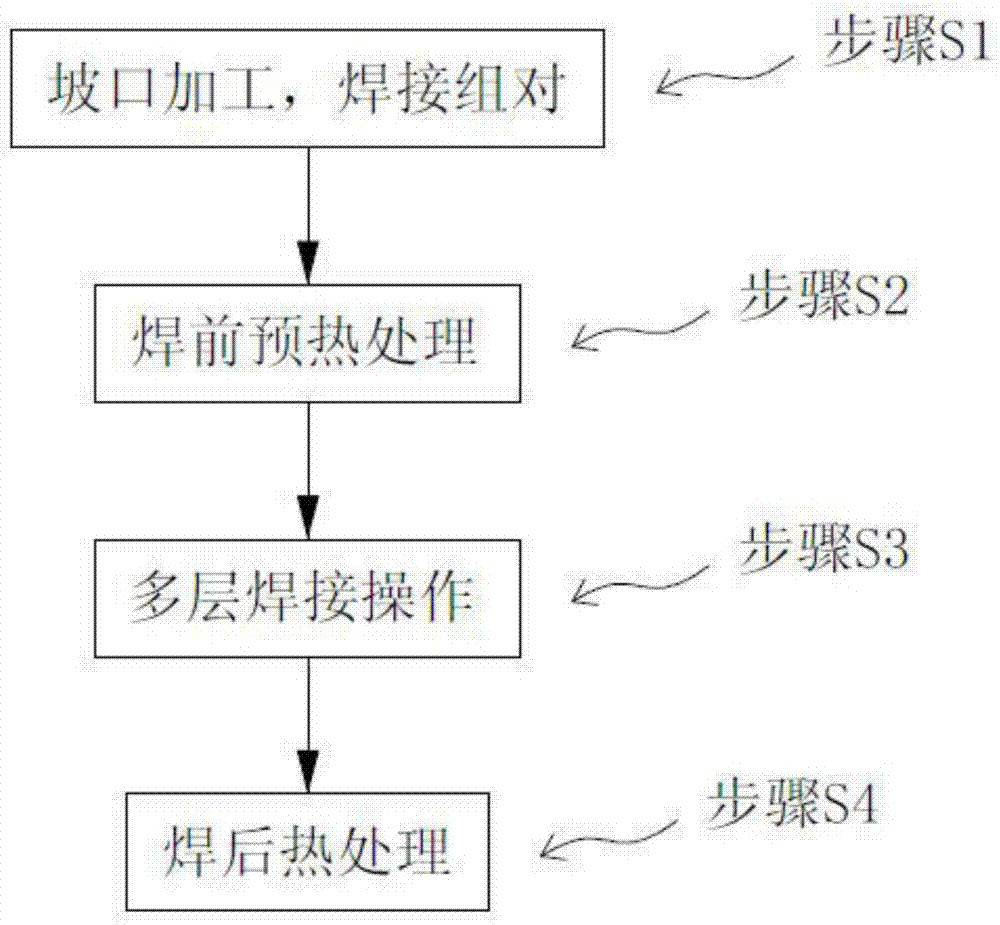

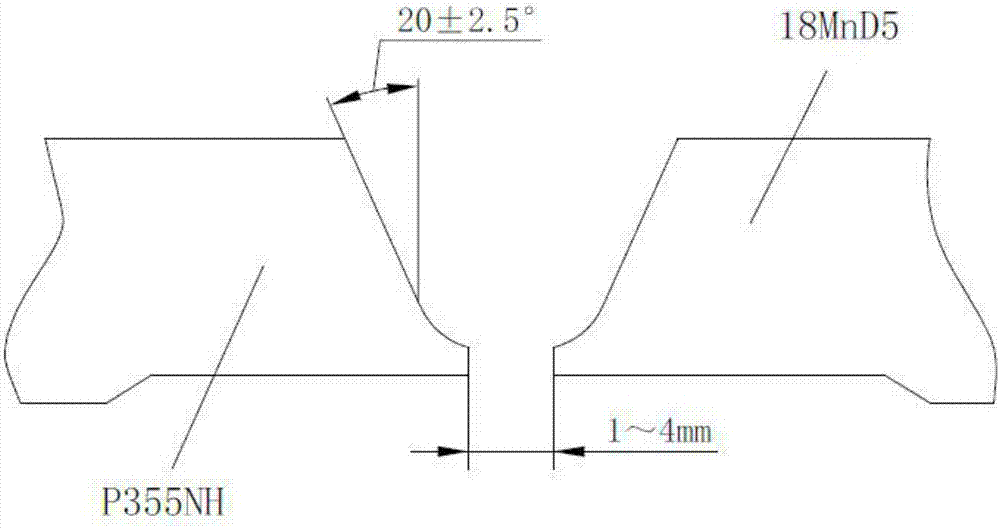

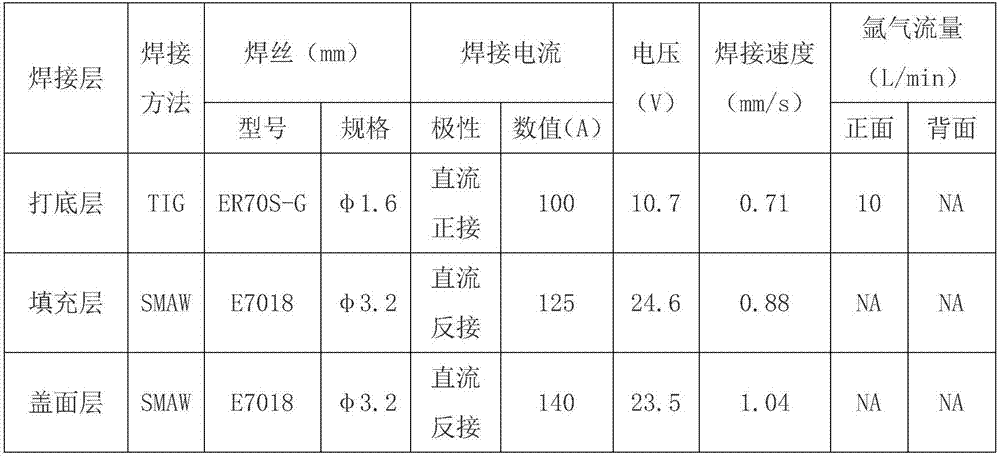

Welding method for P355NH and 18MnD5 dissimilar steel

InactiveCN107498143AControl cooling rateReduced tendency to crackArc welding apparatusBrittle fractureHeat treated

The invention belongs to the technical field of welding of dissimilar steel, particularly relates to a welding method for P355NH and 18MnD5 dissimilar steel, and discloses a welding method for P355NH and 18MnD5 dissimilar steel in order to solve the problem that welding cracks and brittle fracture are likely to be produced in a welding joint area of P355NH and 18MnD5 when the P355NH and the 18MnD5 are welded. The method comprises the steps that 1, edge preparation and welding assembling are carried out on P355NH and 18MnD5 dissimilar steel base metal to be welded; 2, preweld preheat treatment is carried out on the P355NH and 18MnD5 dissimilar steel base metal to be welded; 3, multi-layer welding operation is carried out on the P355NH and 18MnD5 dissimilar steel base metal, wherein the multi-layer welding operation sequentially comprises base coat welding, filling layer welding and cover face layer welding; and 4, a P355NH and 18MnD5 dissimilar steel welding joint obtained after welding is subjected to postweld heat treatment. In the welding method, the parameters in the welding operation process are selected and controlled, so that welding for P355NH and 18MnD5 dissimilar steel is completed, and the welding joint with the excellent welding performance is obtained.

Owner:CHINA NUCLEAR IND 23 CONSTR

Flour storage system for food processing factory

ActiveCN113859789AEfficient storageRapid coolingClimate change adaptationLarge containersAir cleaningProcess engineering

The invention discloses a flour storage system for a food processing factory, and relates to the technical field of flour storage. The flour storage system comprises a storage chamber, a storage mechanism is arranged inside the storage chamber, an air purification mechanism is arranged on one side of the storage chamber, the storage mechanism comprises a storage tank arranged inside the storage chamber, a spiral installing cavity is formed in the inner wall of the storage tank, and a spiral heating wire is fixedly installed inside the spiral installing cavity. According to the flour storage system, by means of the arranged air purification mechanism, after the storage tank is dried, a valve body can be opened, so that air continuously enters an annular cavity in an outer sleeve layer, rapid cooling treatment of the storage tank is achieved, flour can be rapidly stored after drying is facilitated, meanwhile, when the air purification mechanism normally operates, the valve body is closed, the air in the storage chamber is sent to the outside through an air exhaust ring pipe and an exhaust cylinder, air exchange in the storage chamber is achieved, and the cleanliness of the air in the storage chamber is guaranteed.

Owner:东莞市国丰粮油有限公司

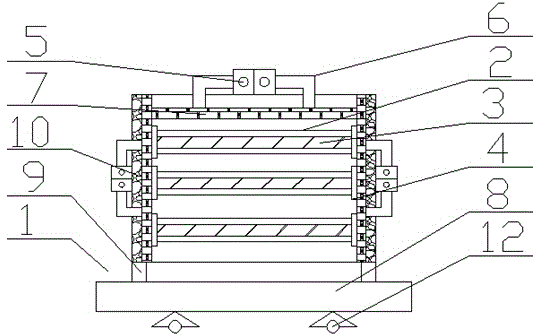

Cover type annealing furnace

InactiveCN106119478AEfficient heat treatmentReduce consumptionFurnace typesHeat treatment furnacesImpellerMaterials science

The invention provides a cover type annealing furnace. The cover type annealing furnace comprises an annealing furnace outer cover, an annealing furnace inner cover, a furnace table base, a furnace table fan, a material column and a tray; the annealing furnace outer cover and the annealing furnace inner cover are both mounted at the top of the furnace table base; the furnace table fan is mounted at the bottom of the furnace table base; an output shaft of the furnace table fan penetrates through the furnace table base to fix with a fan impeller; the material column is a hollow column, and is vertically fixed on the furnace table base; the fan impeller is covered in the material column; the tray is annularly wound on the side wall of the material column, and is communicated with the material column; through holes are uniformly formed in the surface of the tray; and a positioning buckle is vertically upwards arranged in the radial direction. The cover type annealing furnace has a more excellent insulation effect, effectively heats castings, facilitates reduction of the heat consumption, and reduces the treatment cost.

Owner:YANCHENG SHENGAO HEAT TREATMENT CO LTD

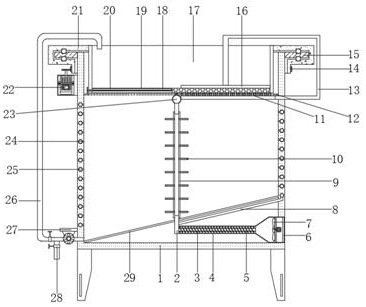

Drying and sterilizing device for edible fungi

InactiveCN104814115AReasonable structural designGood sterilization effectFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationEngineeringEdible fungus

The present invention discloses a drying and sterilizing device for edible fungi and the device comprises a main body which includes a base, multiple support frames and a transparent window. Multiple support frames are arranged within the main body and have hollow structures; one heating layer is arranged in the support frame; an insulating layer is arranged on the inner wall of the main body; a layer of gas pre-distributors cover the surface of the insulating layer; two fans are arranged on the upper part of the main body; the gas pre-distributors are arranged at the top position within the main body; the base is arranged below the main body; a supporting device is arranged between the main body and the base; and universal wheels are arranged at the bottom of the base. The drying and sterilizing device for edible fungi has reasonable structure and good sterilizing effect, is convenient to use, etc.

Owner:DONGZHI COUNTY XINGNONG MUSHROOM PROCESSING

Wheat drying device for agricultural product processing

ActiveCN111854396AUniform drying treatmentImprove uniformityDrying gas arrangementsDrying chambers/containersAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural product processing, particularly relates to a wheat drying device for agricultural product processing, and aims at solving the problems that most traditional wheat drying devices are simple in structure and general in drying uniformity. The wheat drying device comprises a drying box with supporting legs welded to the four corners of theouter wall of the bottom, a rotary net barrel is arranged at the top end of the drying box, the rotary net barrel is provided with three to four falling openings, a material guiding inclined plate isobliquely welded to the bottom end of the drying box, a horizontally-arranged drying barrel is fixedly installed at the end, close to the rotary net barrel, of the drying box, a fixed air conveying pipe is welded to the middle end of the material guiding inclined plate, and the opposite sides of the fixed air conveying pipe and the drying barrel are rotationally connected with the same rotating air barrel through sealing bearings. According to the wheat drying device, by arranging arc-shaped air baffles which are annularly distributed at equal intervals, the arc-shaped air baffles can be blownby hot air in the ventilation process, so that the rotating air barrel rotates, and the drying uniformity of wheat is further improved.

Owner:萧县华野农业科技有限公司

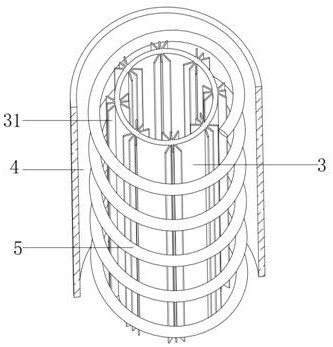

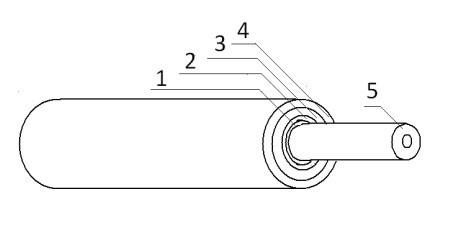

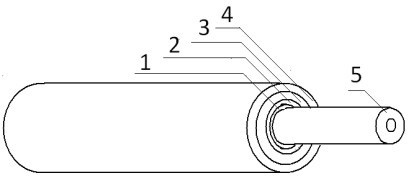

Device and method for chemical fiber rope heat-treatment

ActiveCN102383327AHigh strengthHigh elongation at breakRope making machinesYarnContinuous production

The invention discloses a device and a method for chemical fiber rope heat-treatment, wherein the device comprises a tubular heater and a movable hollow sleeve. The method comprises the following steps: the hollow sleeve which is matched with a chemical fiber rope penetrates the tubular heater, the tubular heater is heated, and the chemical fiber rope passes through the inner chamber of the hollow sleeve at the speed of 0.1 to 2.0 m / s. In continuous production, the invention can carry out safe, controllable and efficient heat treatment to the chemical fiber rope and can eliminate the tension in fibers and plied yarns.

Owner:SHANDONG OCEAN PIONEER NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com