Uniform cloth dye smearing device for textile printing and dyeing

A technology for textile printing, dyeing, and fabrics, which is applied to the field of fabric dye smearing devices, can solve the problems of easy residual dye, low quality, poor dyeing effect, etc., and achieves the effect of high dyeing quality and guaranteed dyeing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

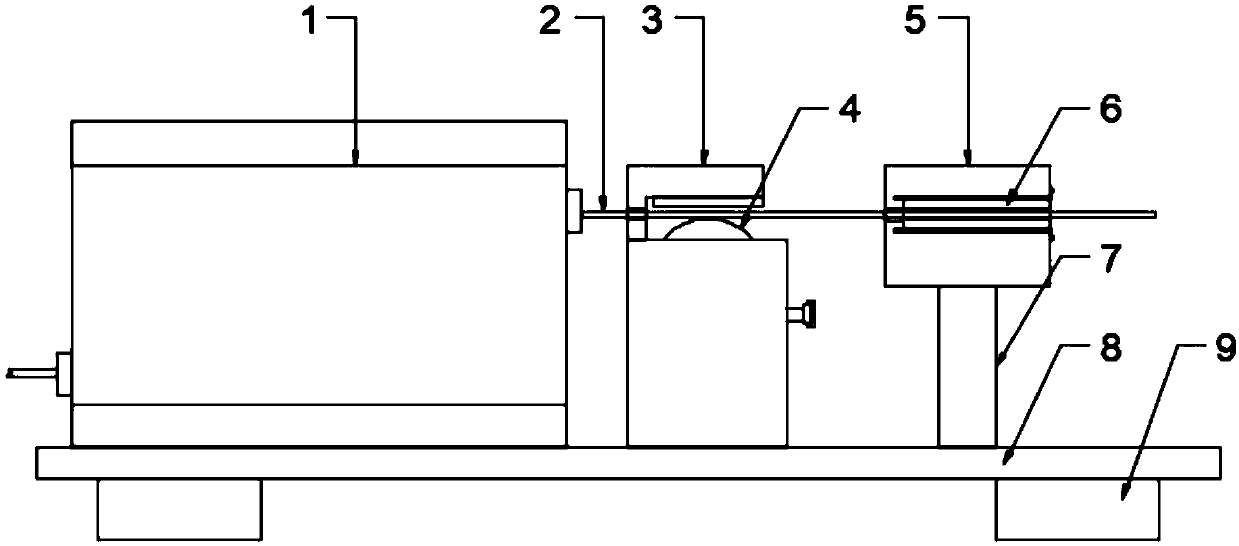

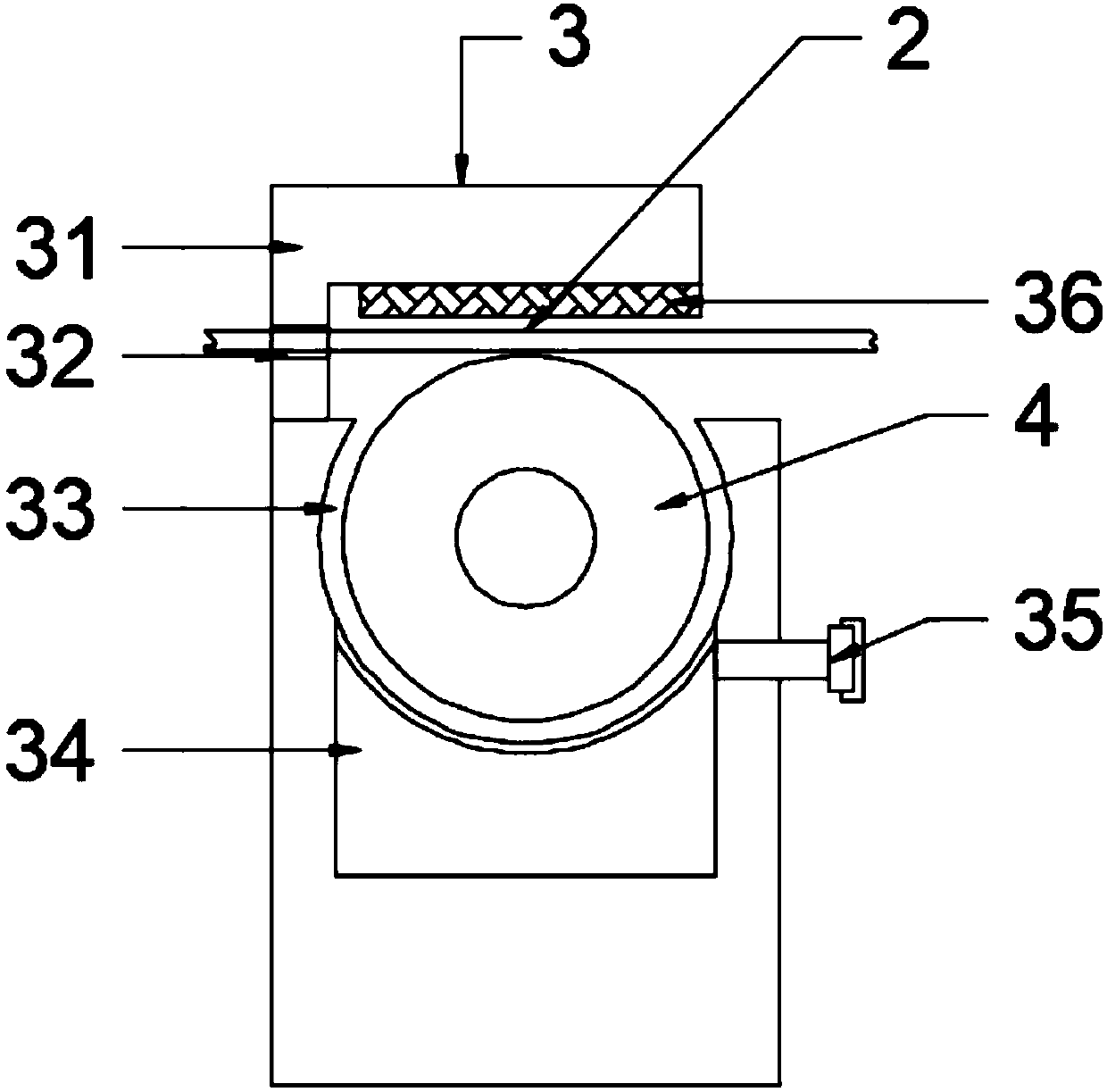

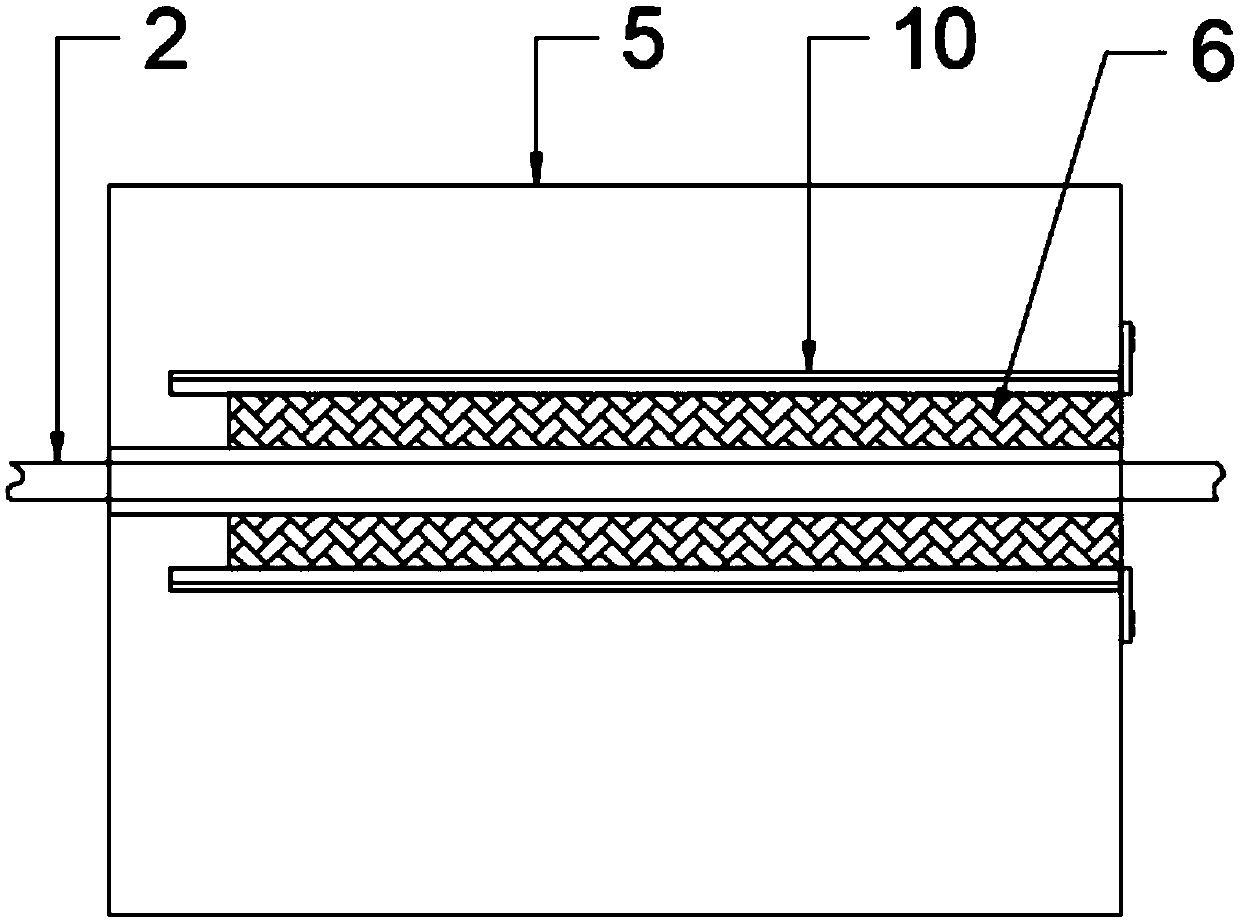

[0025] see Figure 1-4 , a cloth dye leveling device for textile printing and dyeing, comprising a secondary dyeing leveling device 3 and a leveling device 5, the secondary dyeing leveling device 3 is equipped with a secondary dyeing roller 4, and the secondary dyeing leveling The lower end of the device 3 is fixed on the base plate 8, and two dismountable sponges 6 are symmetrically installed on the smoothing device 5, and the lower end of the smoothing device 5 is fixed on the base plate 8 through the supporting legs 7.

[0026] Further, the lower end of the base plate 8 is provided with four support pads 9 distributed in a rectangular array, and the left side of the upper end of the base plate 8 is fixed with a dyeing box 1, (the dyeing box 1 is the prior art and is not what this technical solution will solve. This will not be described in detail), the inside of the dyeing box 1 is interspersed with cloth 2 .

[0027] Further, the upper end of the secondary dyeing and smoo...

Embodiment 2

[0030] see Figure 2-5 , a cloth dye leveling device for textile printing and dyeing, comprising a secondary dyeing leveling device 3 and a leveling device 5, the secondary dyeing leveling device 3 is equipped with a secondary dyeing roller 4, and the secondary dyeing leveling The lower end of the device 3 is fixed on the base plate 8, and two dismountable sponges 6 are symmetrically installed on the smoothing device 5, and the lower end of the smoothing device 5 is fixed on the base plate 8 through the supporting legs 7.

[0031] Further, the lower end of the base plate 8 is provided with four support pads 9 distributed in a rectangular array, and the left side of the upper end of the base plate 8 is fixed with a dyeing box 1, (the dyeing box 1 is the prior art and is not what this technical solution will solve. This will not be described in detail), the inside of the dyeing box 1 is interspersed with cloth 2 .

[0032] Further, the upper end of the secondary dyeing and smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com