Black dye mixer and preparation method and application thereof

A technology of black dyes and mixtures, applied in the field of dyes, can solve problems such as natural environmental pollution, unsuitable environmental protection requirements, human and other biological hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

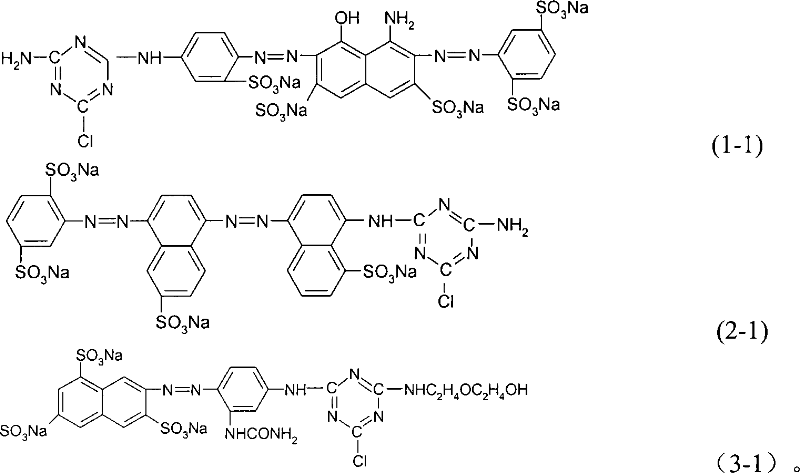

Image

Examples

Embodiment 1

[0065] Embodiment 1: Raw material production

[0066] Dissolve 0.1mol aniline-2.5-disulfonic acid in water and beat for 30 minutes, cool down to 0-5°C with ice, add appropriate amount of hydrochloric acid and stir for 10 minutes, then add 30% sodium nitrite solution for diazotization reaction for 2 hours (keep T=0-5°C throughout the whole process, and the amount of hydrochloric acid and sodium nitrite should be sufficient), and the obtained diazonium salt carries out acidic coupling reaction with H acid under the conditions of T≤10°C and pH≤25 hour (acid couple), add 0.1mol cyanuric chloride to an appropriate amount of water / ice mixture and make a slurry for 45 minutes, then add 0.1mol meta-bis (PH=5.5-6.0) that has been fully dissolved to it for 1 hour Carry out the first condensation reaction, control T=5-10°C, PH=3.5-4.0, add ice to cool down to 0-5°C after reacting for 4 hours, add appropriate amount of hydrochloric acid and stir for 10 minutes, then add 30% sodium nitrite...

Embodiment 2

[0068] Embodiment 2: Raw material production

[0069] Dissolve 0.1mol aniline-2.5-disulfonic acid in water and beat for 30 minutes, cool down to 0-5°C with ice, add appropriate amount of hydrochloric acid and stir for 10 minutes, then add 30% sodium nitrite solution for diazotization reaction for 2 hours (keep T=0-5°C throughout the whole process, and the amount of hydrochloric acid and sodium nitrite should be sufficient), and the obtained diazonium salt carries out acidic coupling reaction with H acid under the conditions of T≤10°C and pH≤25 hour (acid couple), add 0.1mol cyanuric chloride to an appropriate amount of water / ice mixture and make a slurry for 45 minutes, then add 0.1mol meta-bis (PH=5.5-6.0) that has been fully dissolved to it for 1 hour Carry out the first condensation reaction, control T=5-10°C, PH=3.5-4.0, add ice to cool down to 0-5°C after reacting for 4 hours, add appropriate amount of hydrochloric acid and stir for 10 minutes, then add 30% sodium nitrite...

Embodiment 3

[0071] Embodiment 3: Raw material production

[0072] Dissolve 0.1mol aniline-2.4-disulfonic acid in water and beat for 30 minutes, cool down to 0-5°C with ice, add appropriate amount of hydrochloric acid and stir for 10 minutes, then add 30% sodium nitrite solution for diazotization reaction for 2 hours (keep T=0-5°C throughout the whole process, and the amount of hydrochloric acid and sodium nitrite should be sufficient), and the obtained diazonium salt is acidicly coupled with 0.1mol H acid under the conditions of T≤10°C and pH≤2 React for 5 hours (acid couple), add 0.1mol cyanuric chloride to an appropriate amount of water / ice mixture for beating for 45 minutes, and then fully dissolve 0.1mol metabis (PH=5.5-6.0) for 1 hour Add it for the first condensation reaction, control T=5-10°C, PH=3.5-4.0, add ice to cool down to 0-5°C after reacting for 4 hours, add appropriate amount of hydrochloric acid and stir for 10 minutes, then add 30% of Sodium nitrate solution was subject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com