Thermal-radiating material and fire-resisting material using same

A technology of refractory materials and heat radiation, applied in the field of refractory materials, can solve the problems of short life (the coating will not work after only a few months, the coating is easy to age, the furnace radiation is strengthened and the heating is weakened, etc., and the heat loss can be reduced. , Improve thermal efficiency, improve the effect of high emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

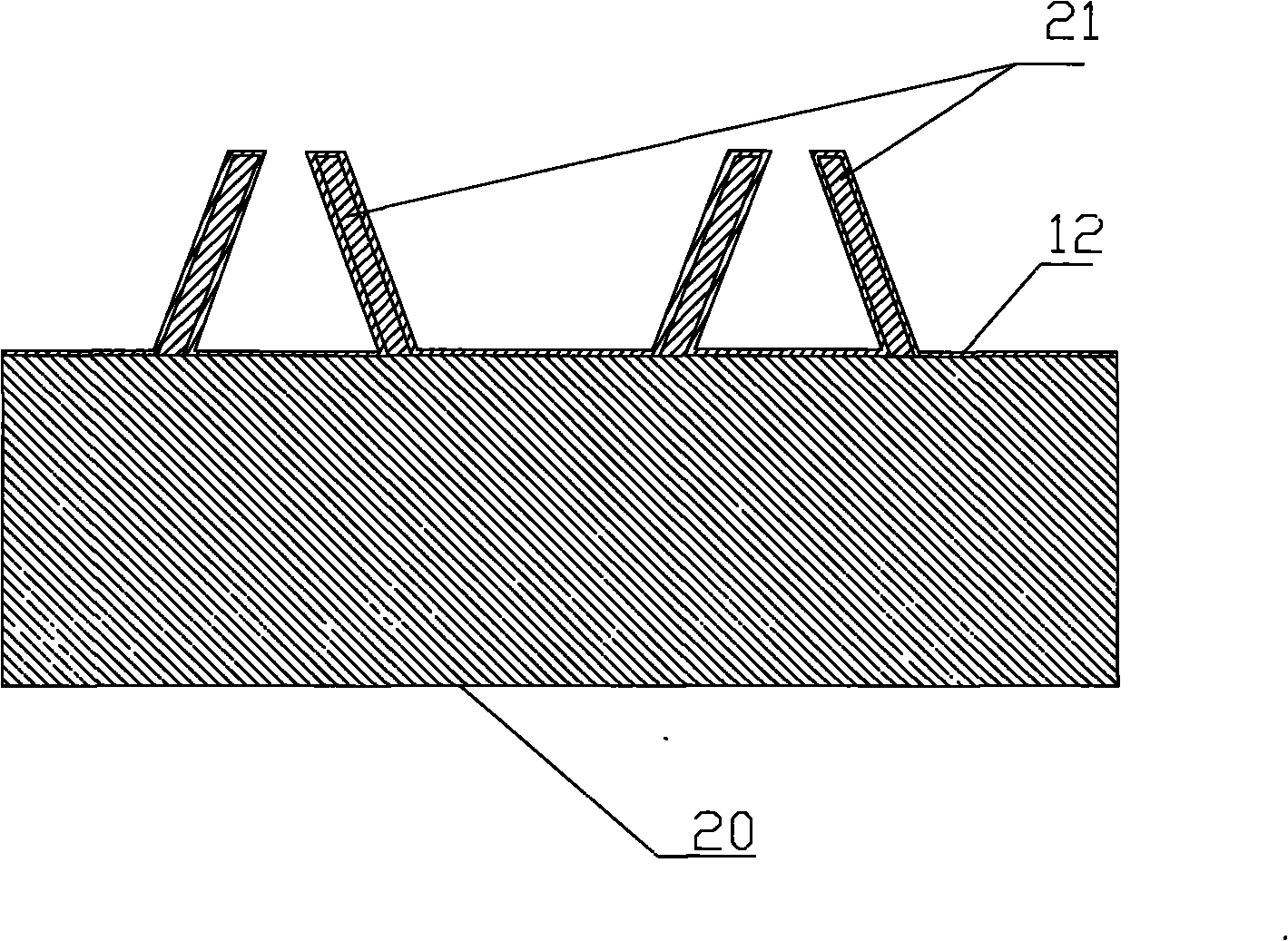

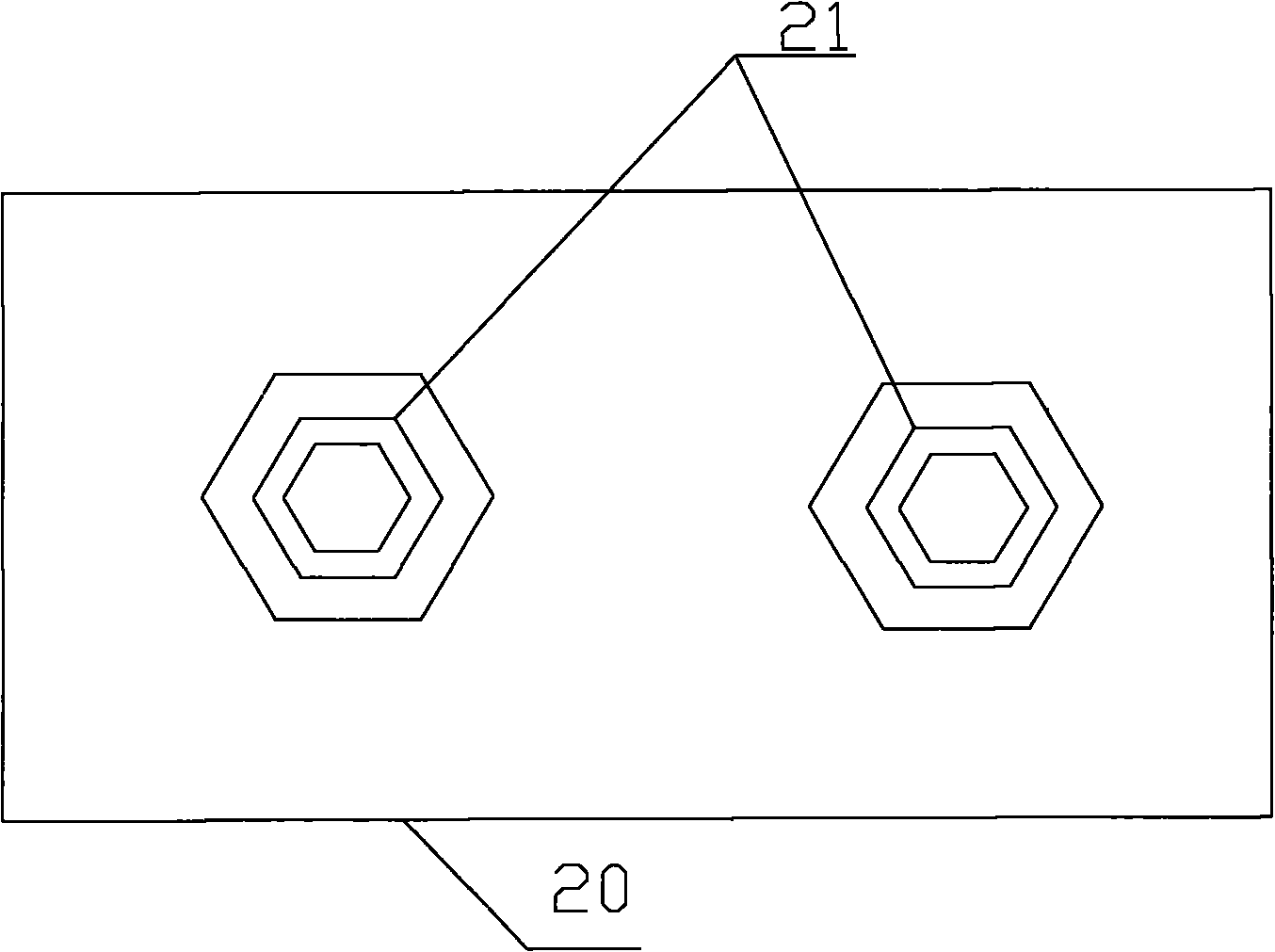

[0098] The furnace heat radiation element 21 can be arranged on the refractory material in the furnace, such as refractory bricks, and the shape of the furnace heat radiation element can be eight-sided cone, six-sided cone, cone, cone or cylinder. Alternatively, the structure of the furnace heat radiation element adopts the form of a cavity, that is, an octagonal cone, a hexagonal cone, a cone or a cylindrical cavity is arranged inside the body of the refractory brick.

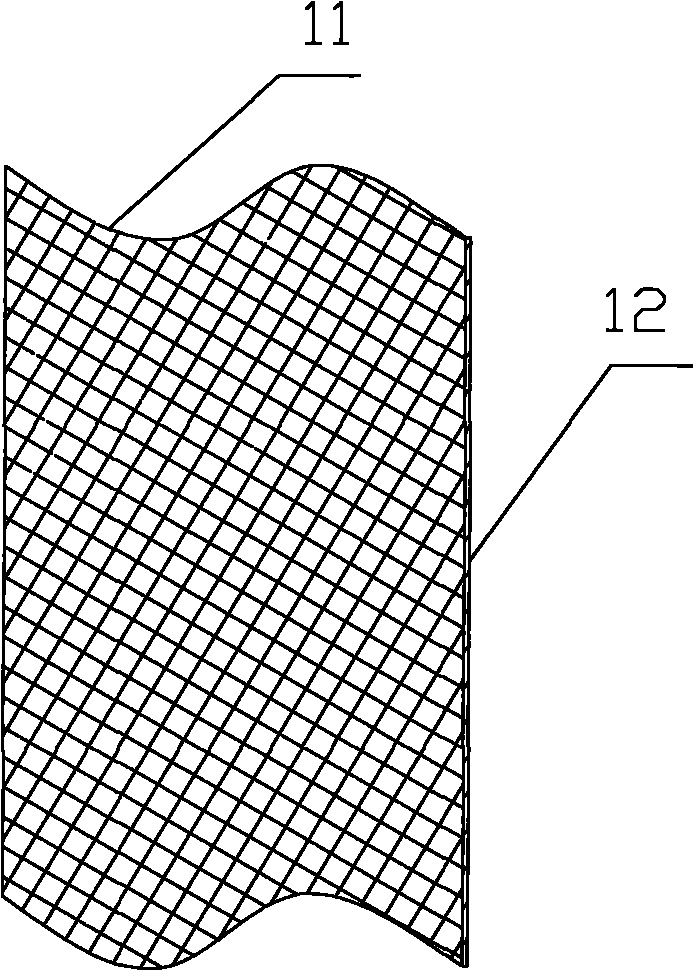

[0099] like figure 2 and 3 As shown, the furnace heat radiation element 21 adopts a hollow hexagonal pyramid structure, and the furnace heat radiation element 21 is arranged on the upper plane of the refractory brick 20 . The furnace heat radiation element 21 is surrounded by six side walls, and a bottom surface may also be provided at the bottom of the furnace heat radiation element 21 . The furnace heat radiation element 11 has an inner wall and an outer wall, which can effectively increase the heat trans...

Embodiment 2

[0104] The heat radiation material 12 is coated on the inner surface of the furnace heat radiation element 31, and the thermal emissivity of the heat radiation material 12 is 0.95, and the heat radiation material 12 is fixed on the inner wall of the furnace or the inner wall of the furnace heat radiation element 31 by special bonding technology The heat radiation material 12 can be sprayed with multiple layers on the entire inner wall of the furnace and the inner wall of the heat radiation element 31 of the furnace.

[0105] For the structural form of the furnace heat radiation element 21 and the furnace heat radiation element 41 of the preferred embodiment 1 and the preferred embodiment 2, it has a high heat emissivity in the normal direction, and the inner walls of the furnace heat radiation elements 21 and 41 absorb the diffuse heat in the furnace. At the same time, it continuously emits heat rays with the same high emissivity, and directly shoots to the heated object. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com