Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Hexagonal pyramid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

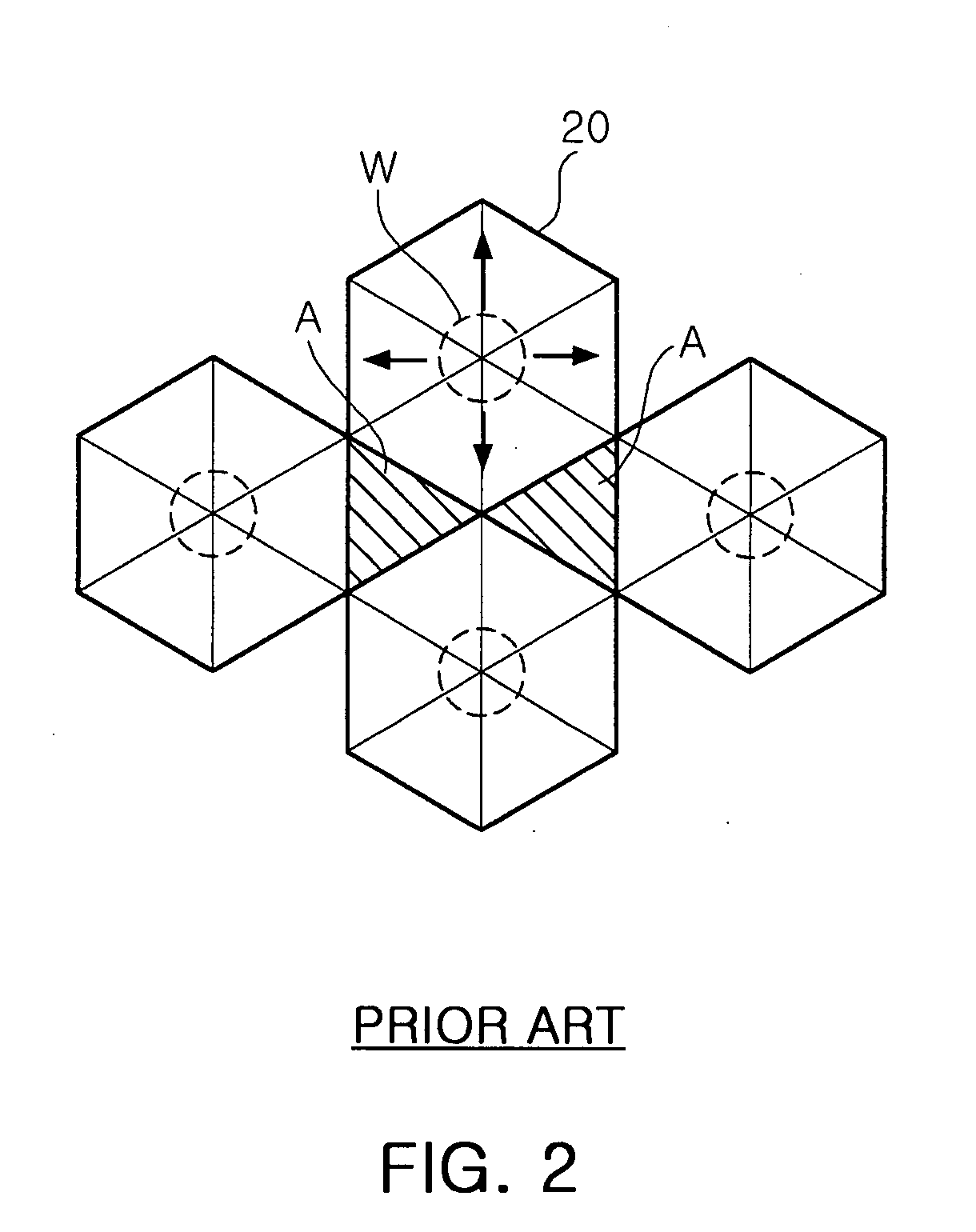

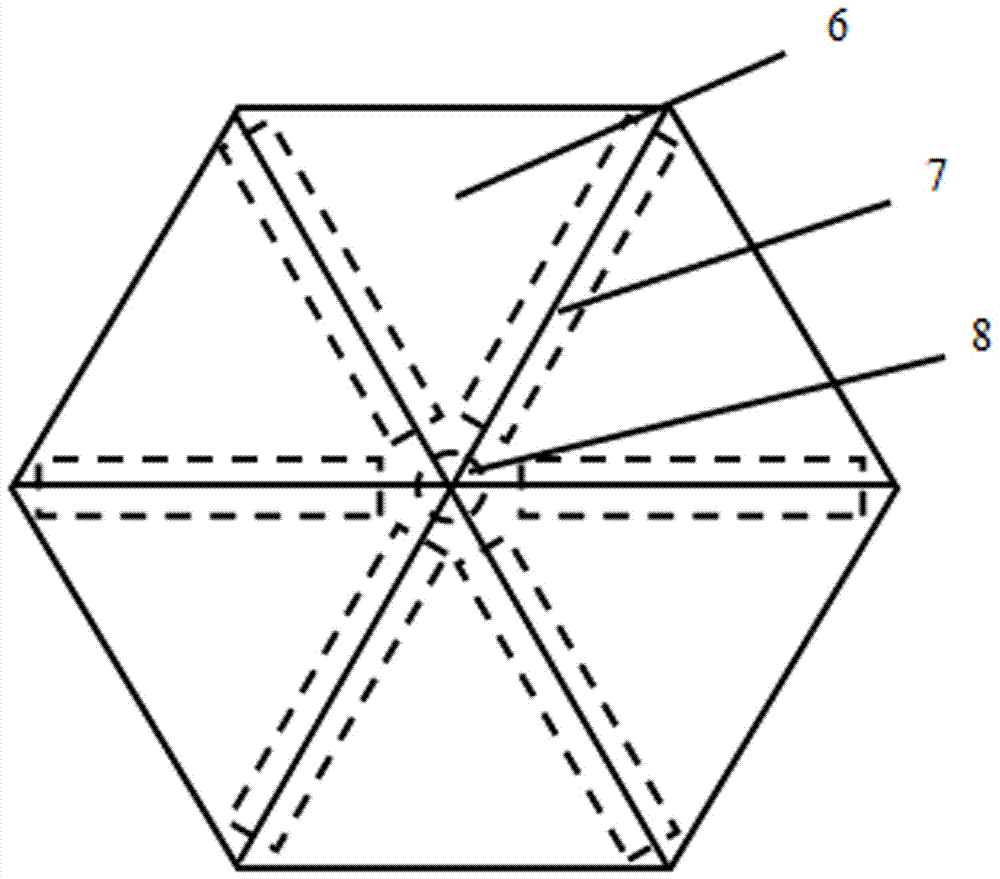

In geometry, a hexagonal pyramid is a pyramid with a hexagonal base upon which are erected six isosceles triangular faces that meet at a point (the apex). Like any pyramid, it is self-dual. A right hexagonal pyramid with a regular hexagon base has C₆ᵥ symmetry.

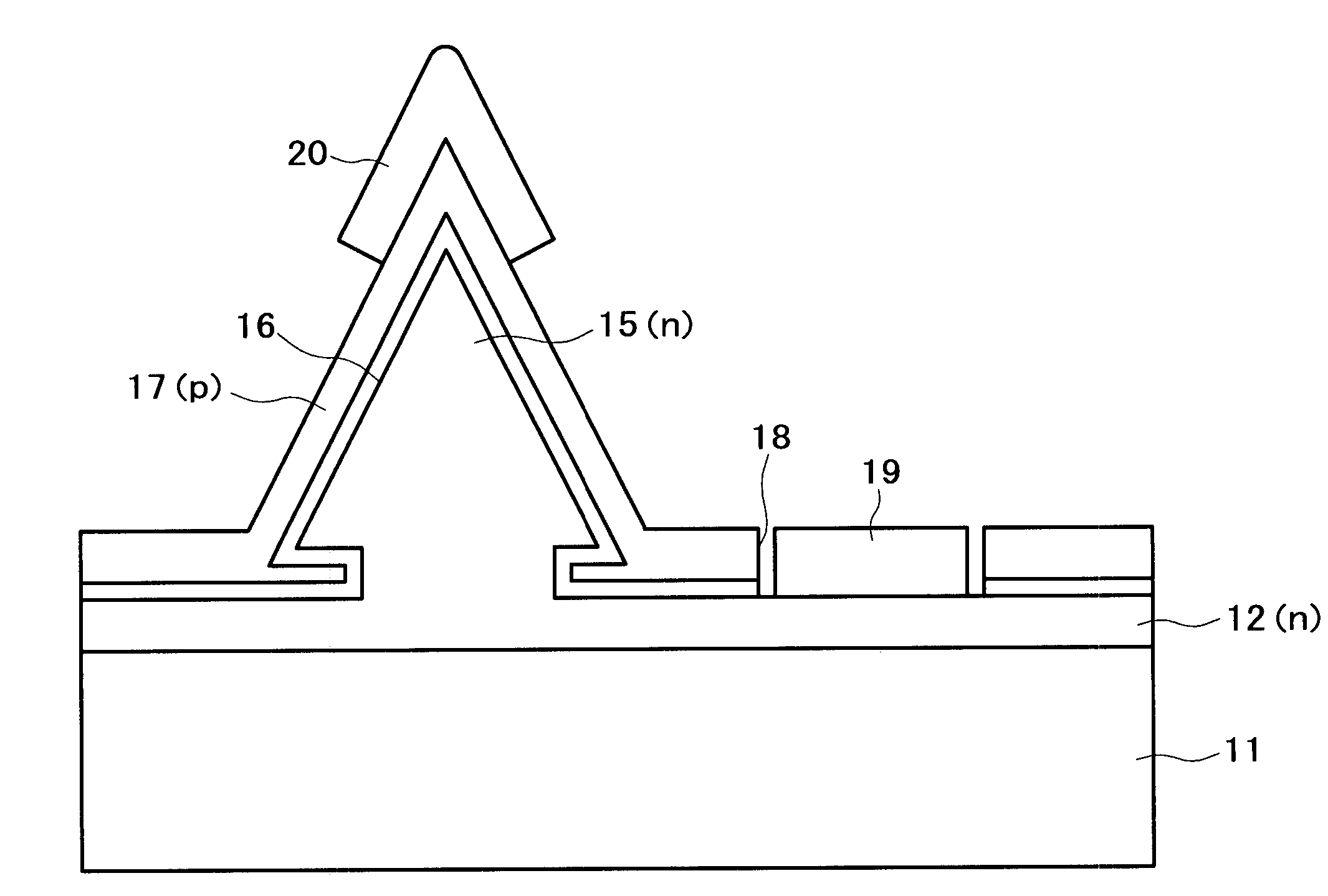

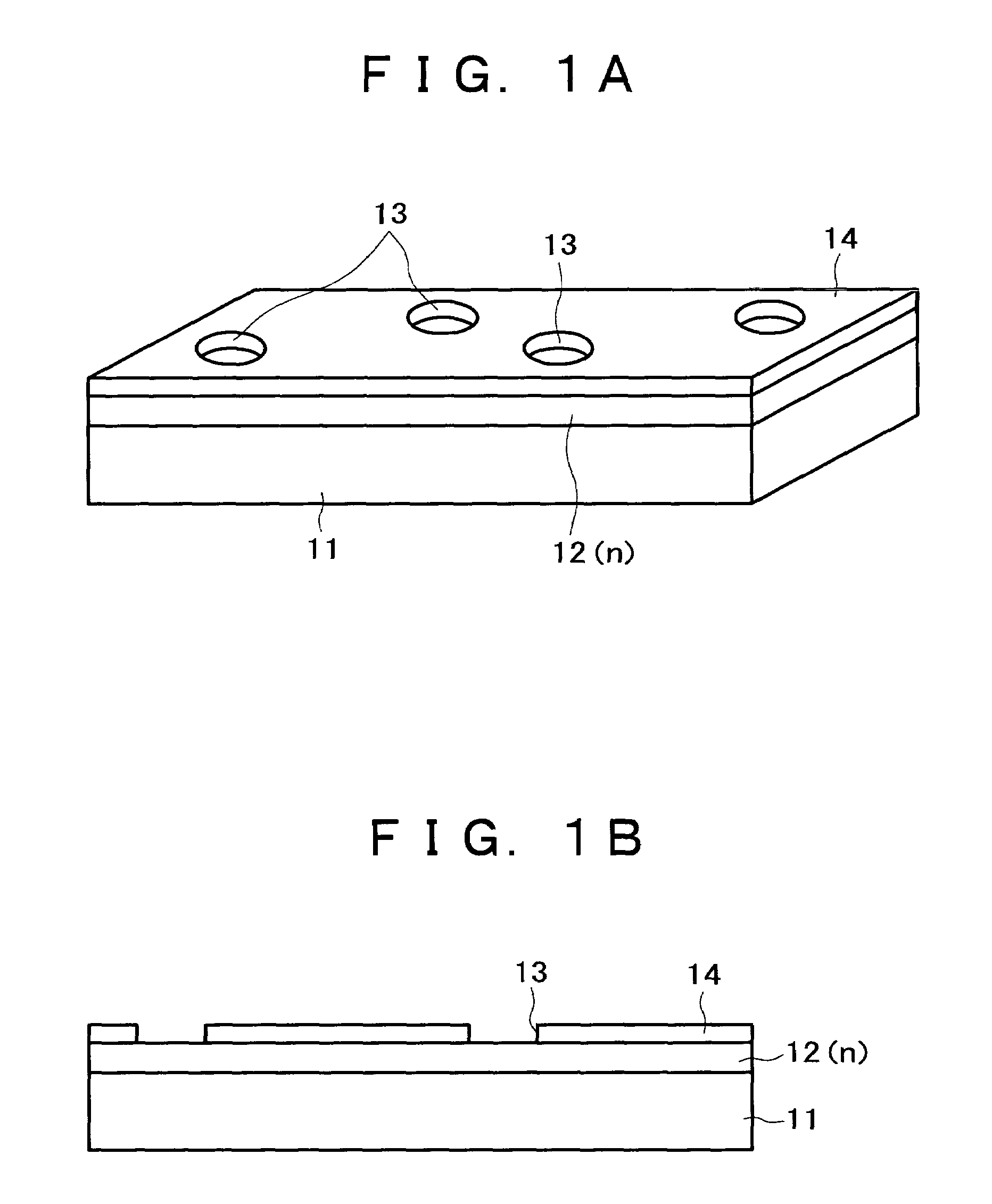

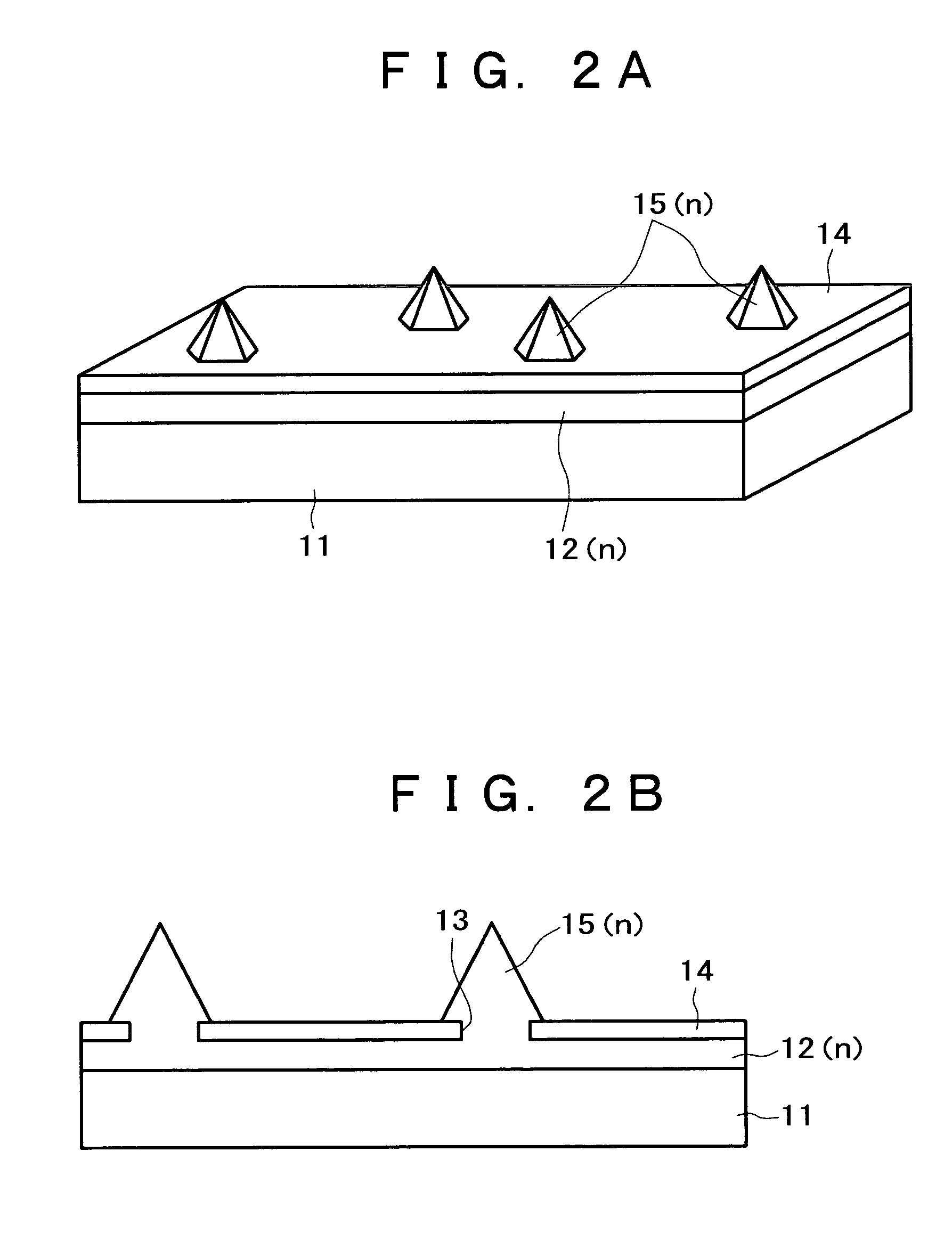

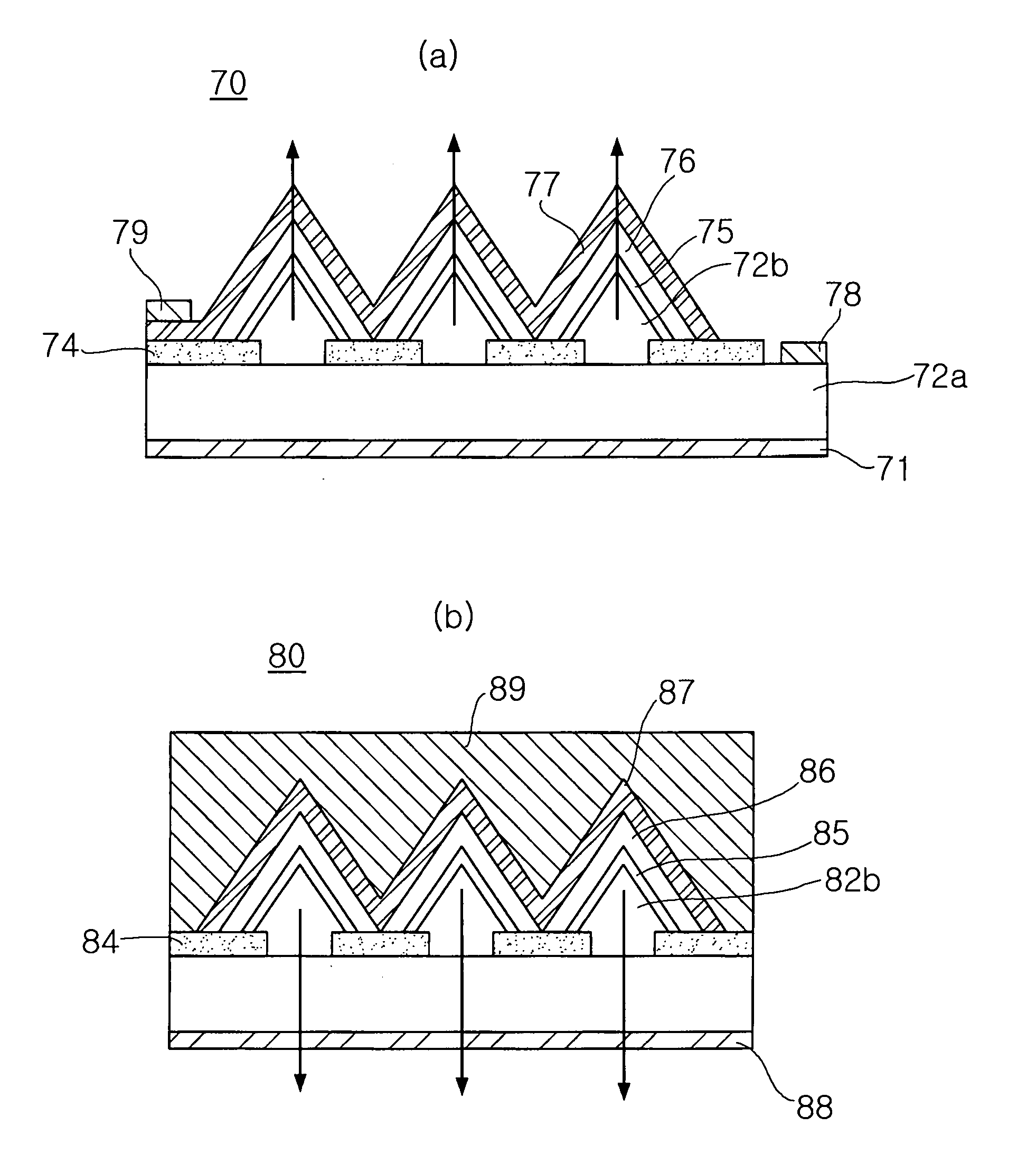

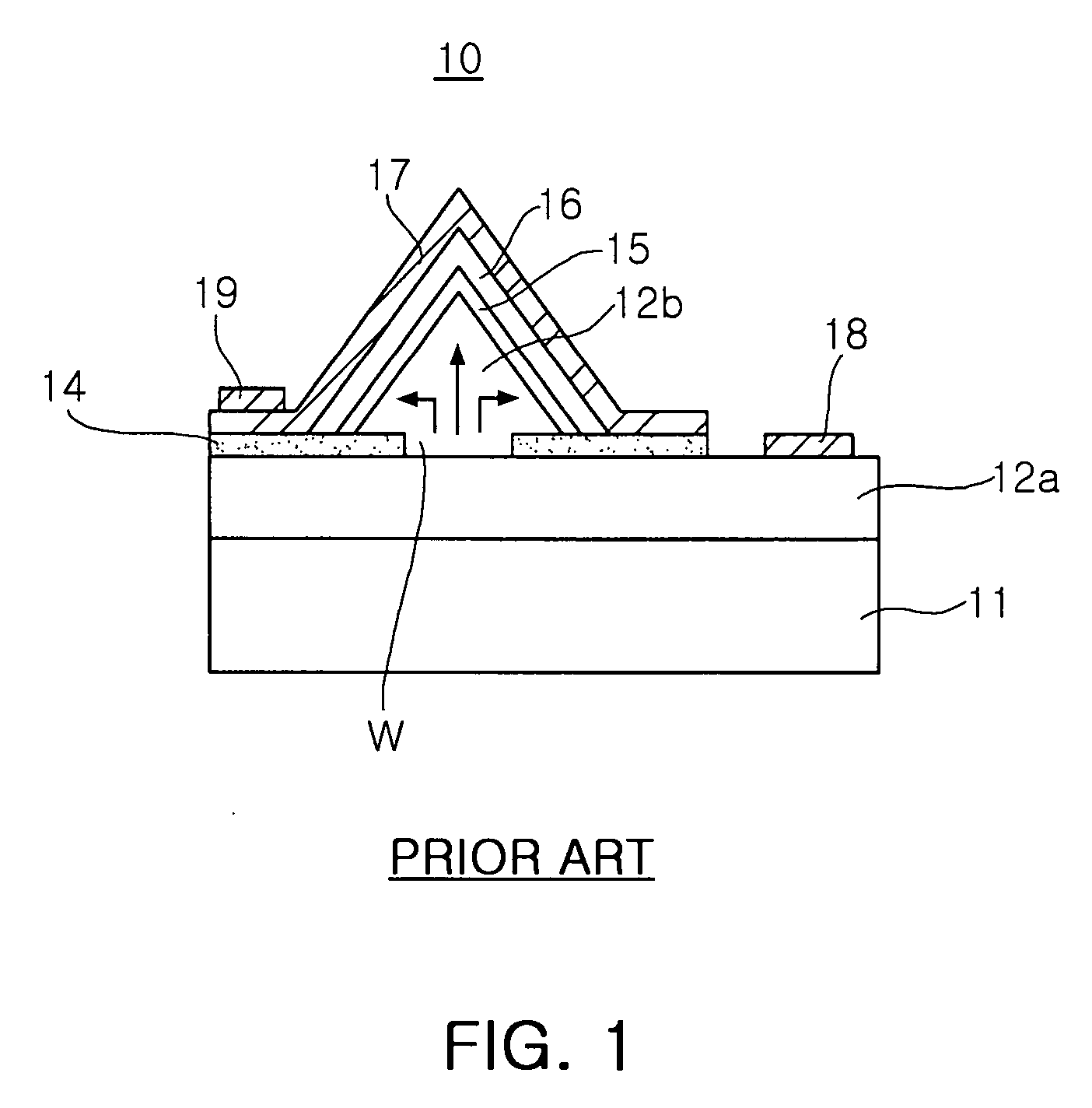

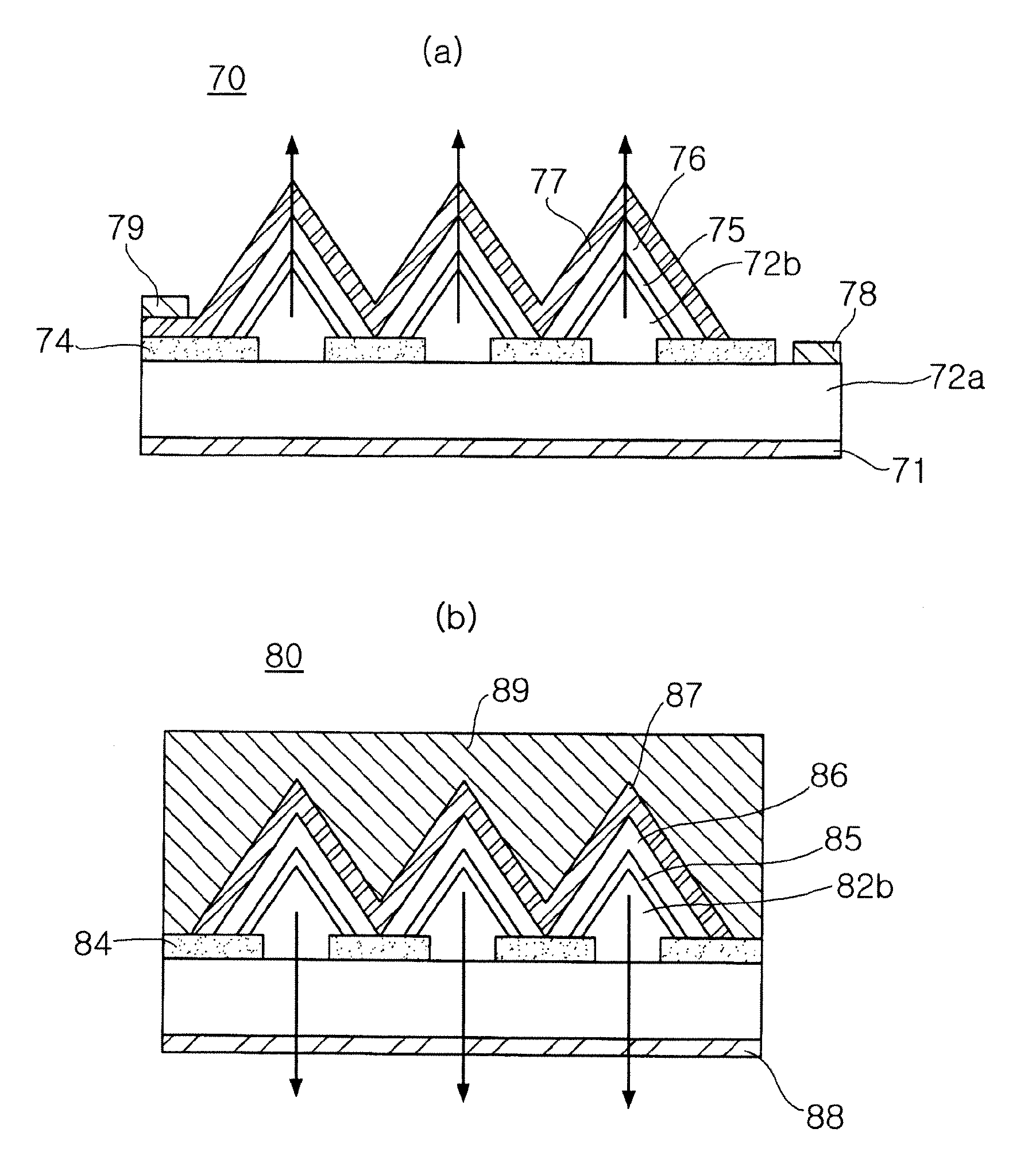

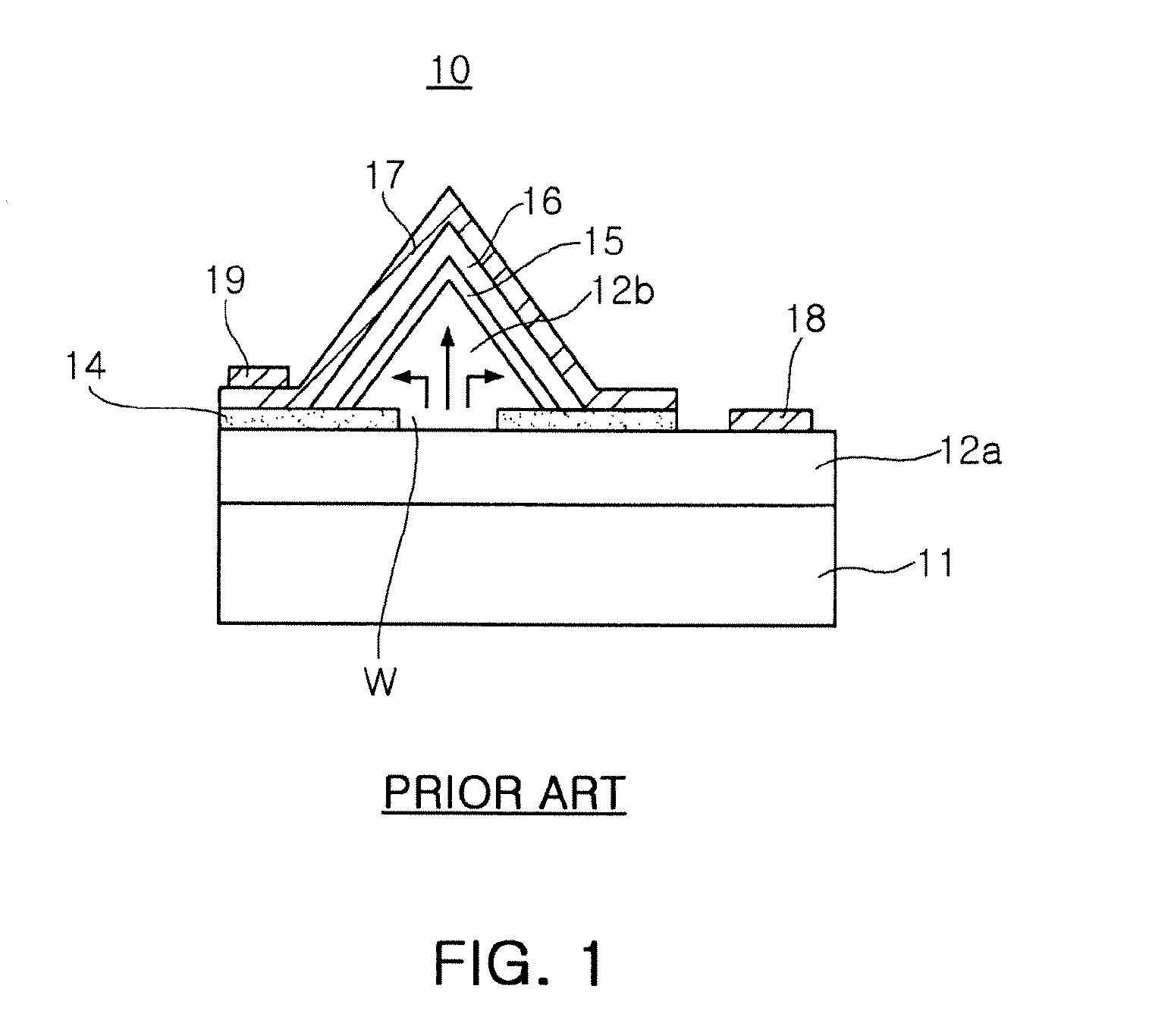

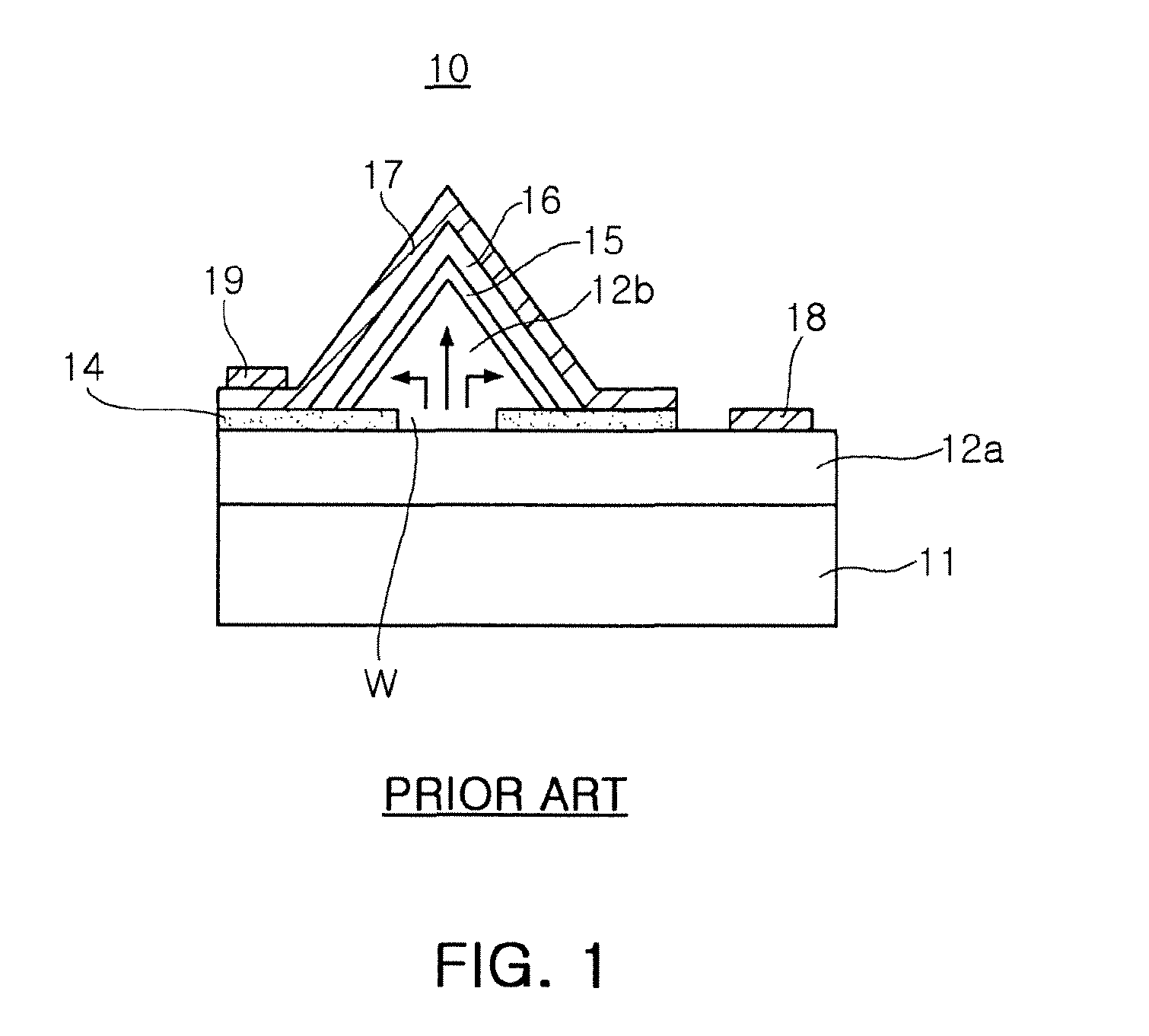

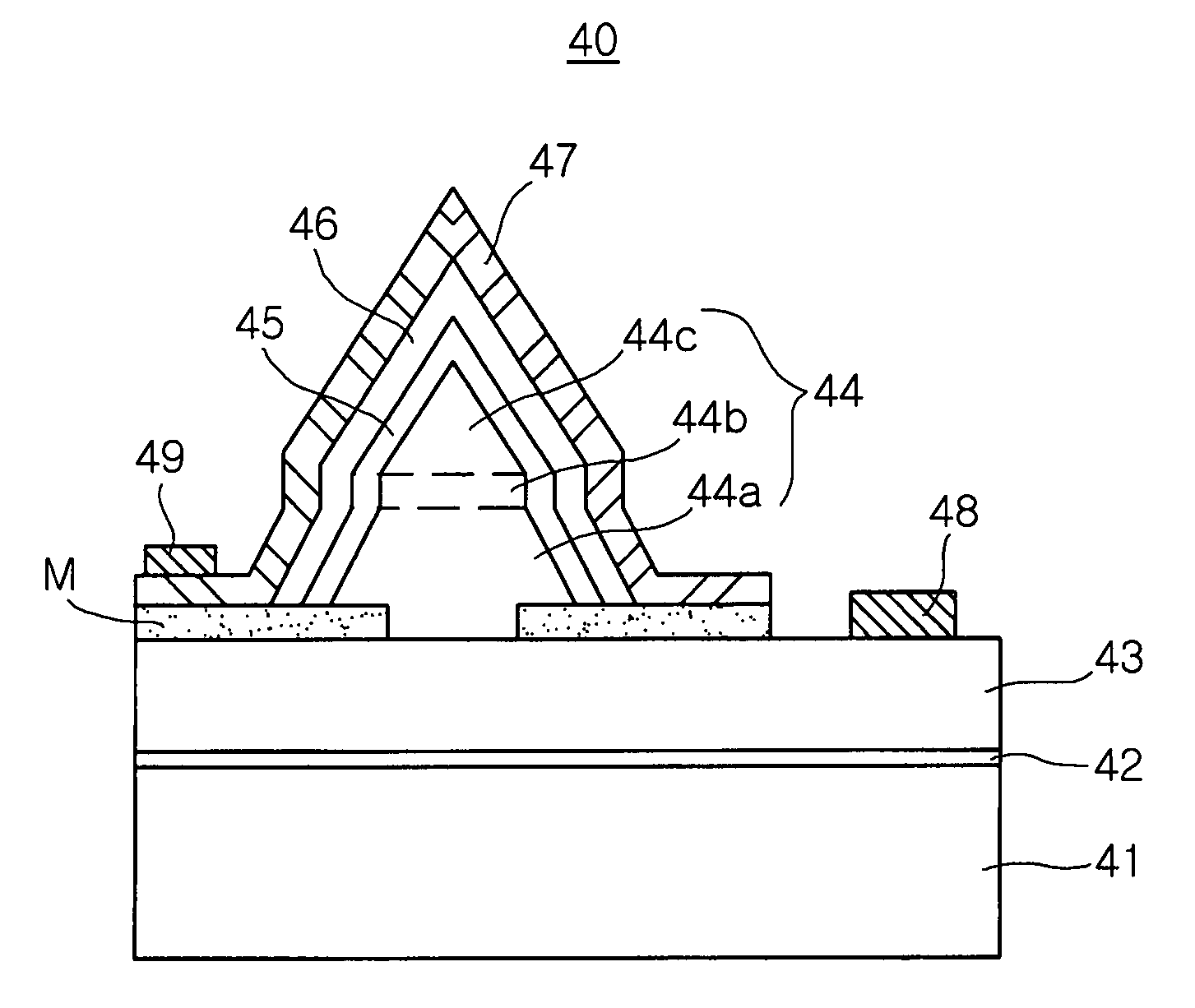

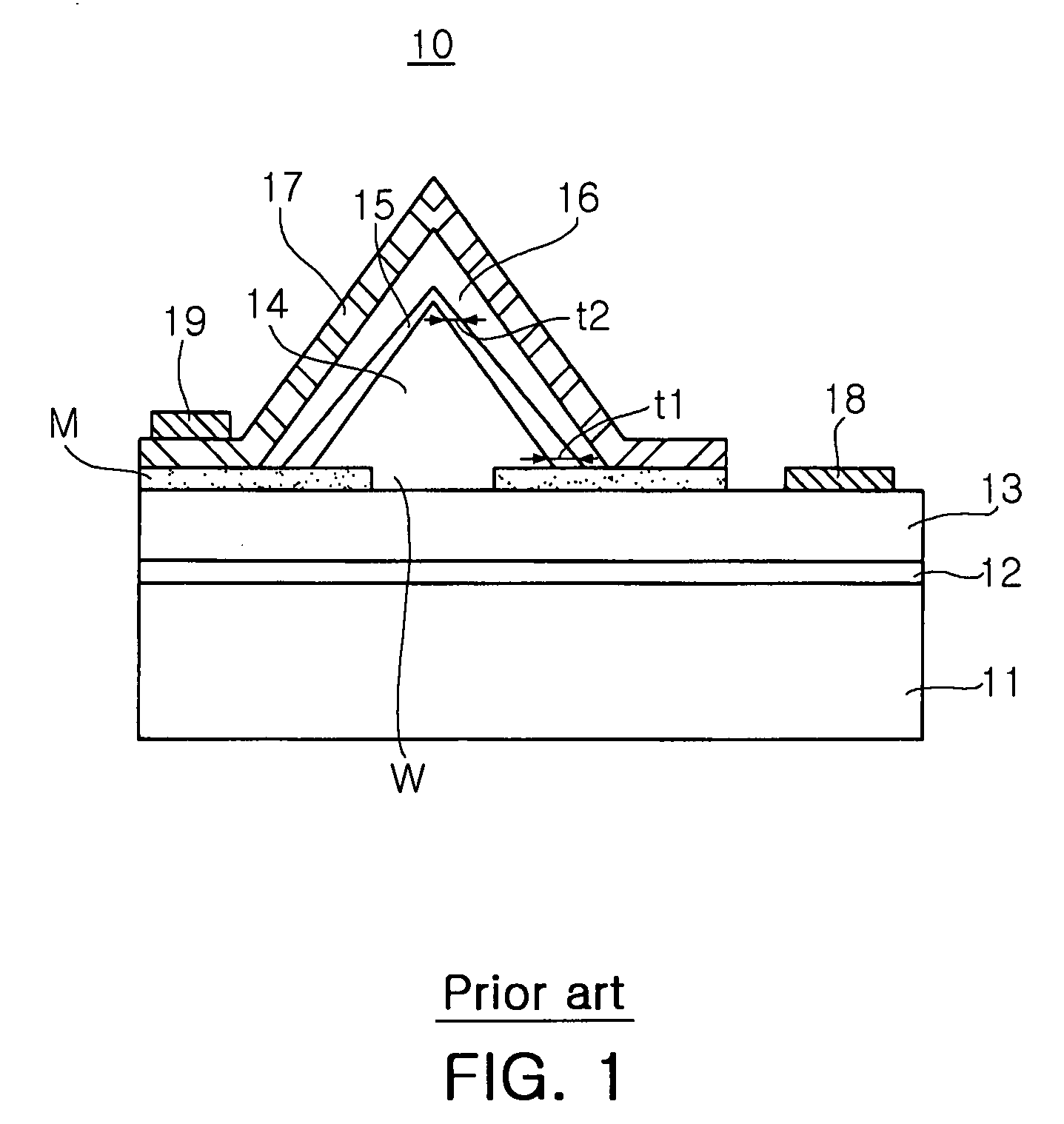

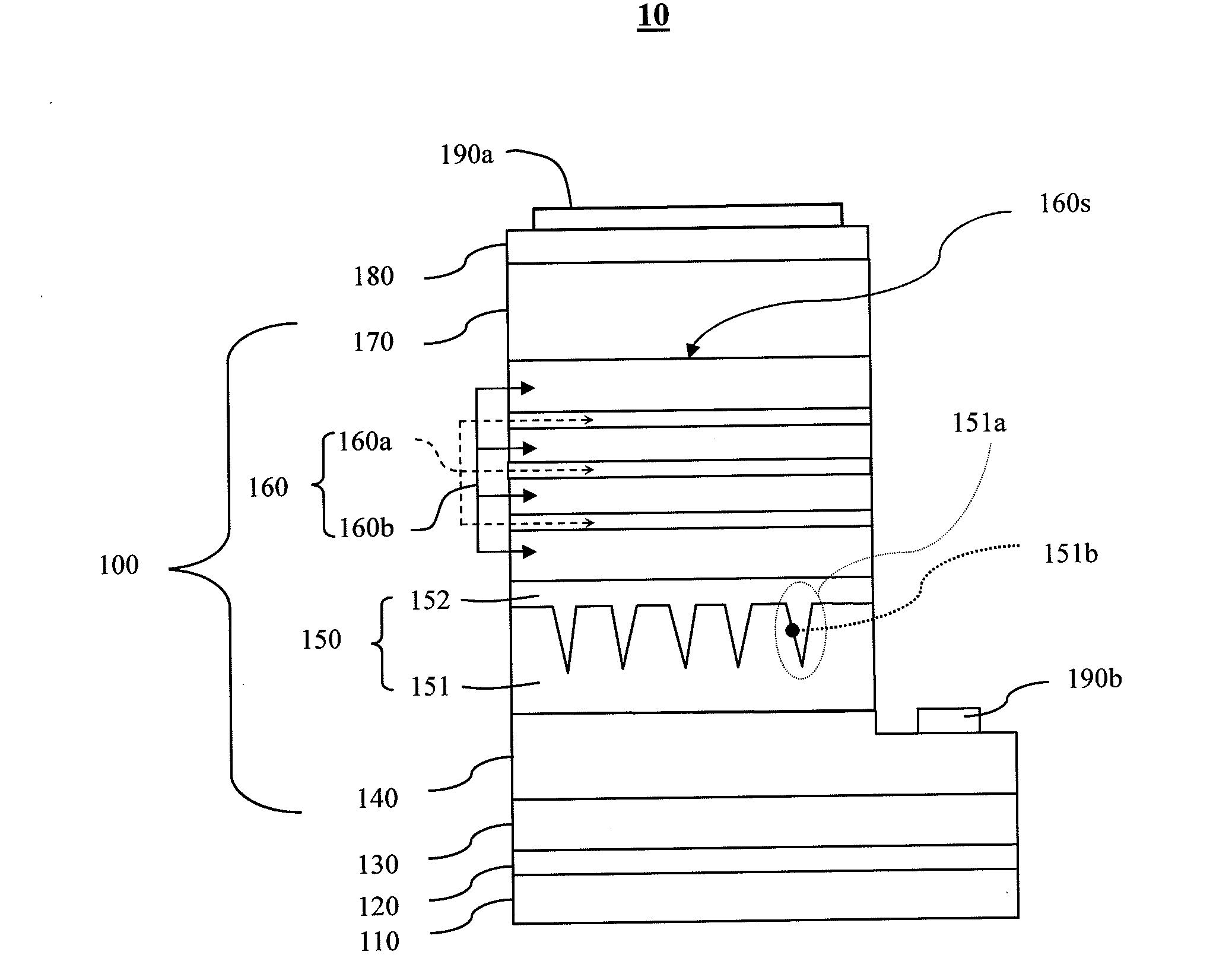

Semiconductor light emitting device integral type semiconductor light emitting unit image display unit and illuminating unit

ActiveUS7002182B2Easily light emittingImprove luminous efficiencySolid-state devicesSemiconductor devicesActive layerLight emitting device

A semiconductor light emitting device with improved luminous efficiency is provided. An underlying n-type GaN layer is grown on a sapphire substrate, and a growth mask made from SiO2 film or the like is formed on the underlying n-type GaN layer. An n-type GaN layer having a hexagonal pyramid shape is selectively grown on a portion, exposed from an opening of the growth mask, of the underlying n-type GaN layer. The growth mask is removed by etching, and then an active layer and a p-type GaN layer are sequentially grown on the entire substrate so as to cover the hexagonal pyramid shaped n-type GaN layer, to form a light emitting device. An n-side electrode and a p-side electrode are then formed.

Owner:SAMSUNG ELECTRONICS CO LTD

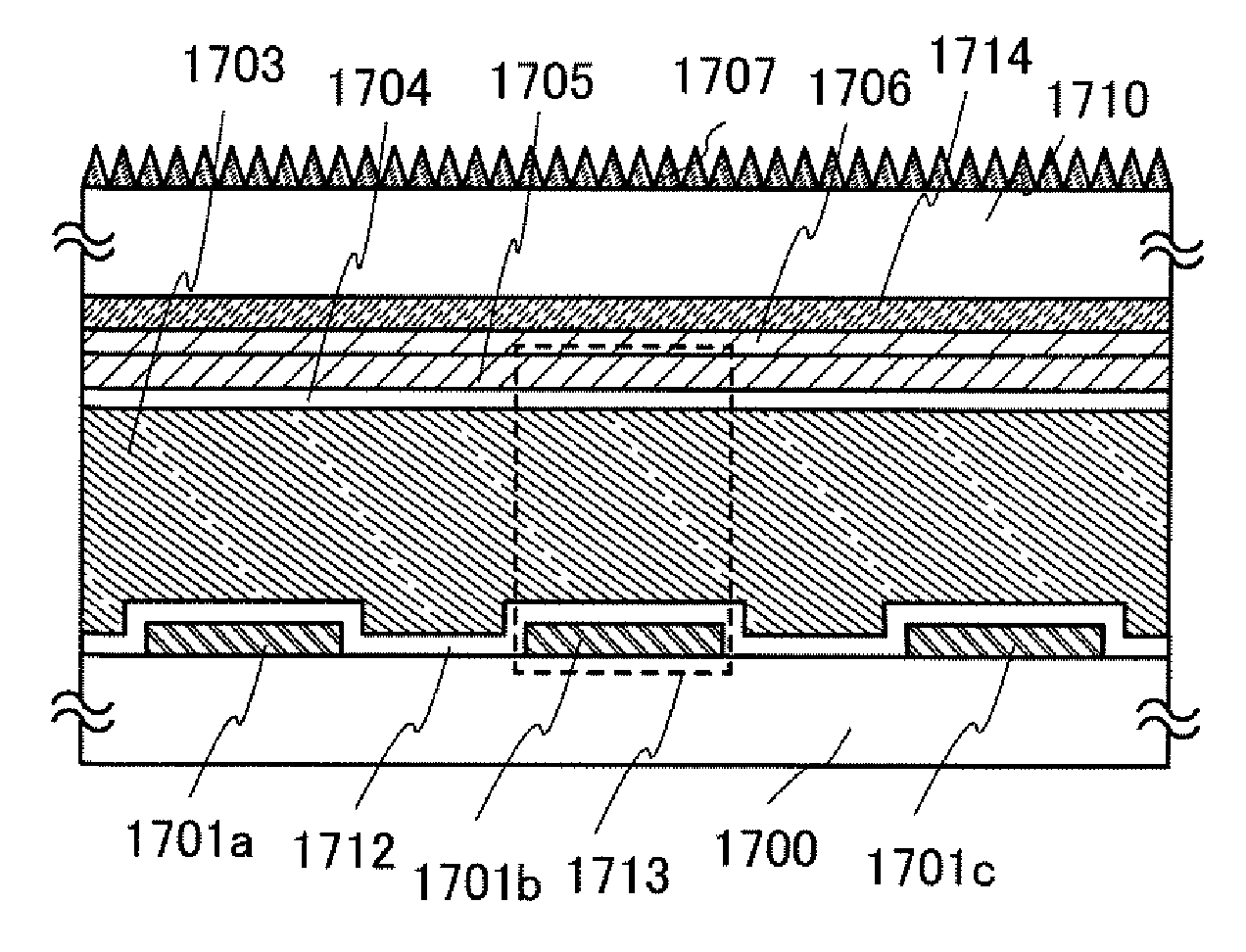

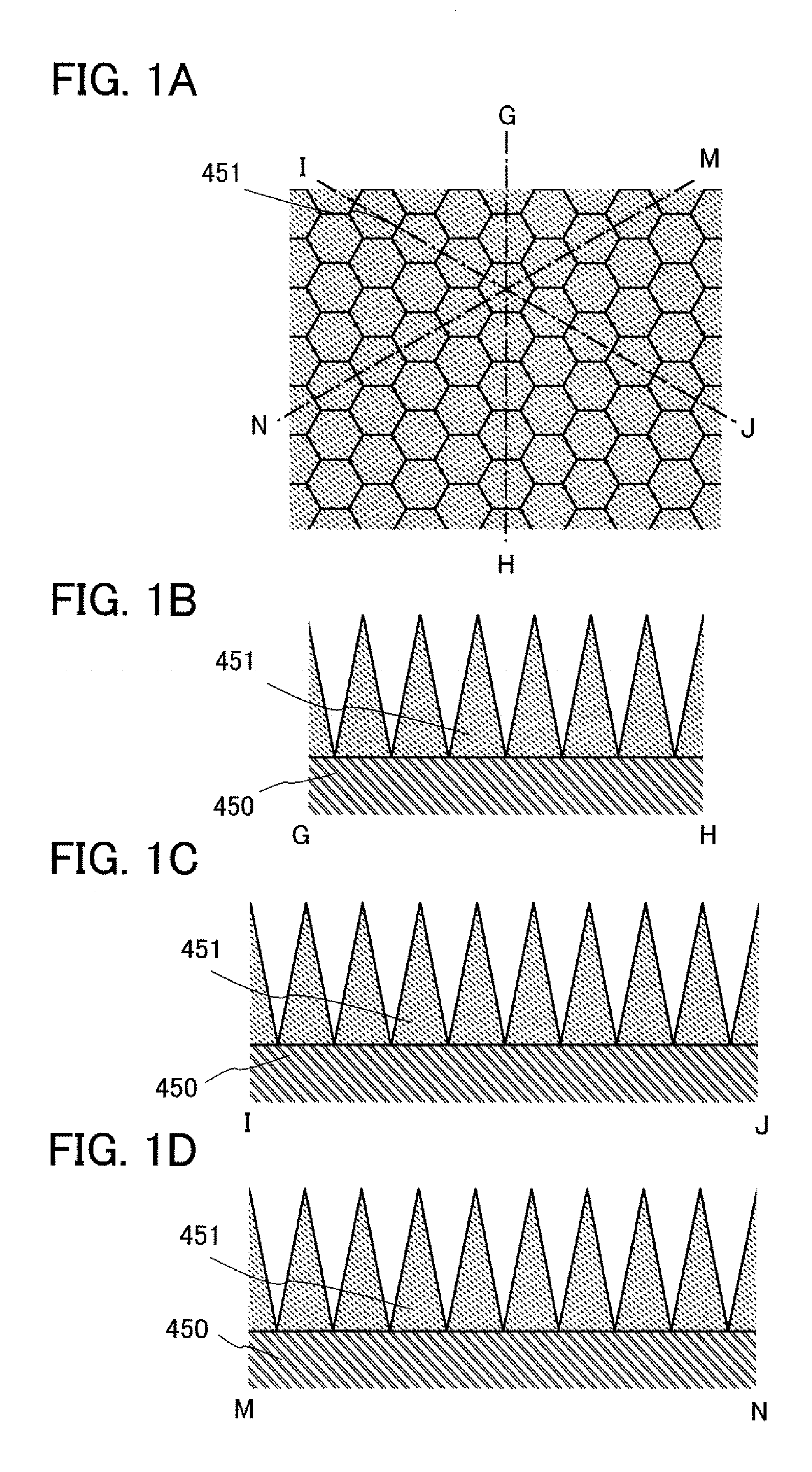

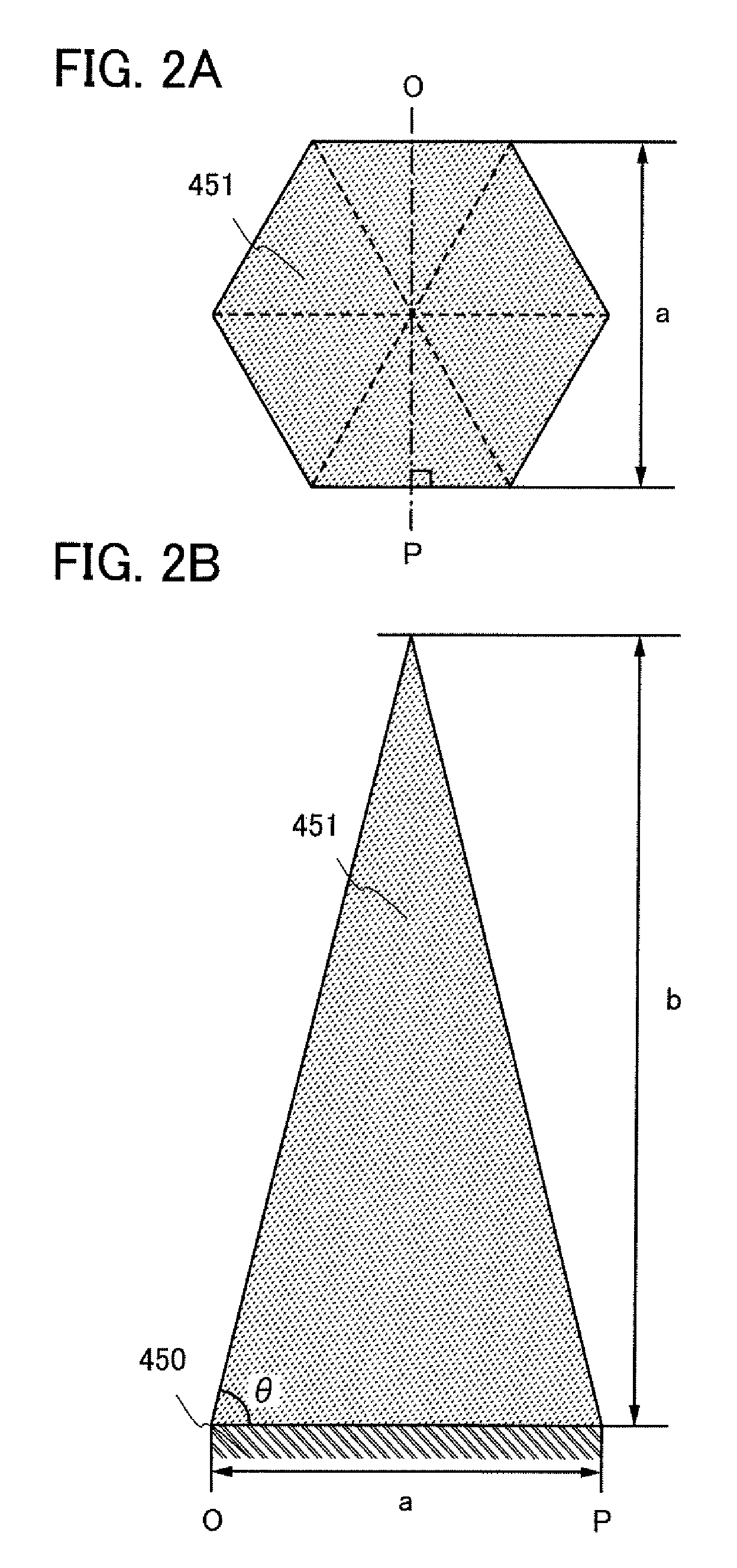

Anti-reflection film and display device

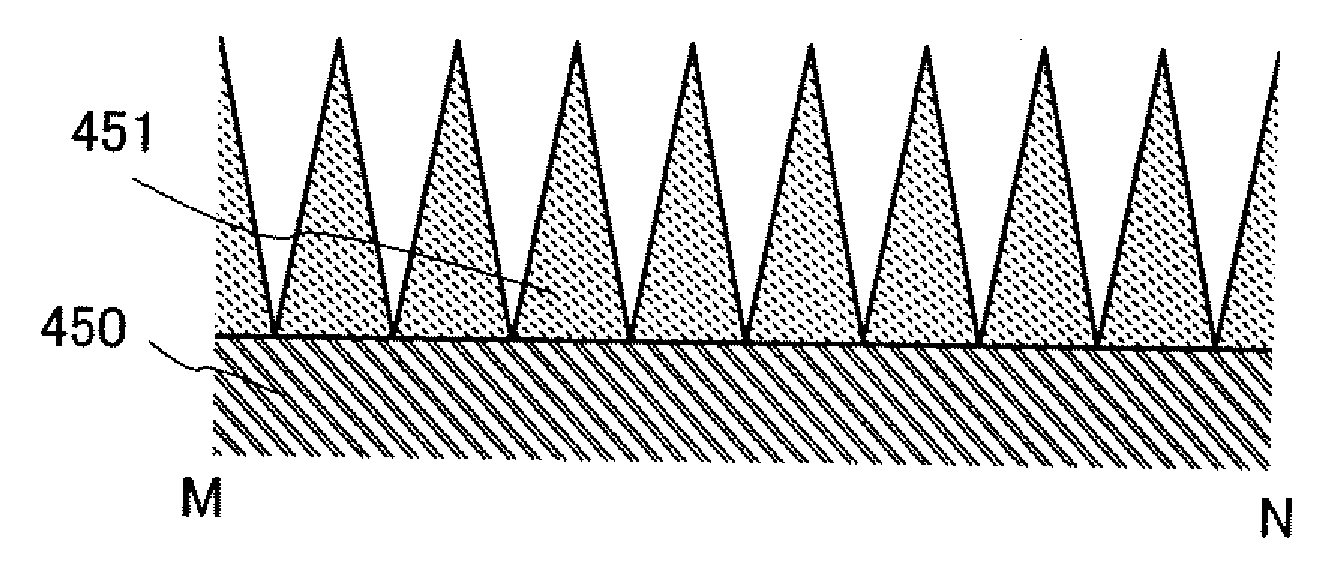

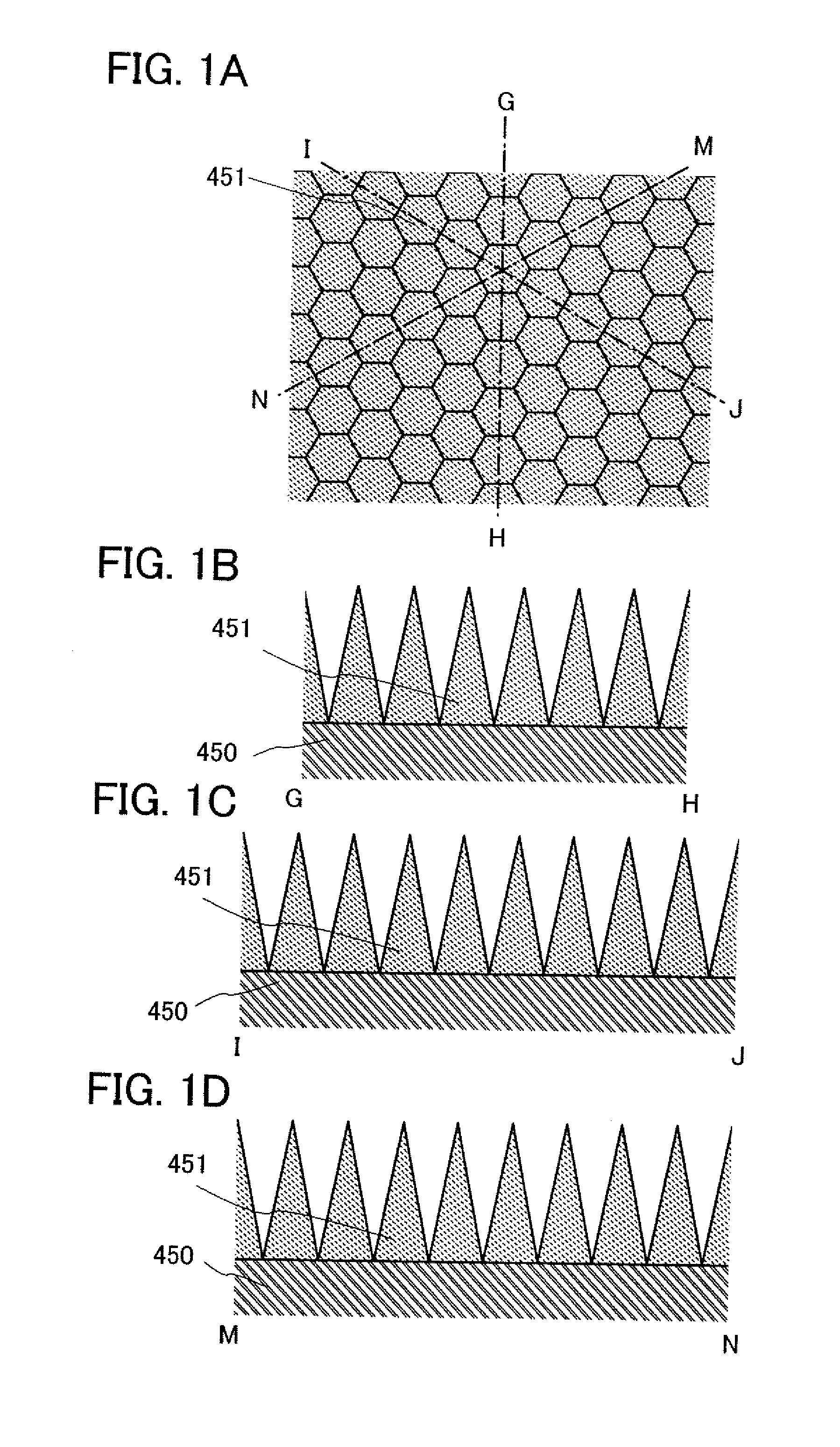

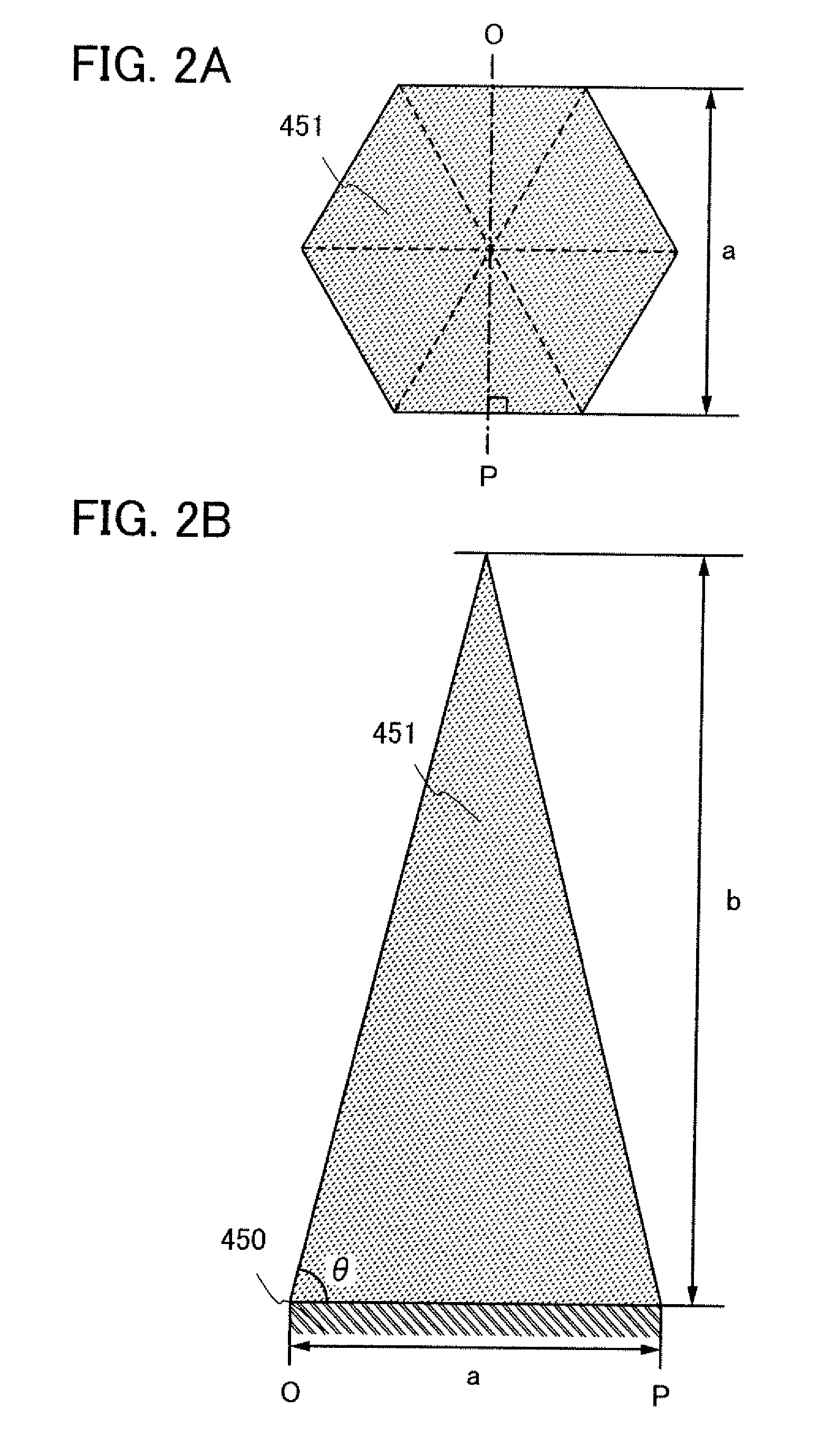

InactiveUS20080130122A1Reduce reflectionImprove visibilityRecord information storageMagnetic recordingVisibilityDisplay device

An object is to provide an anti-reflection film which has an anti-reflection function capable of further reducing reflection of incident light from external, and has excellent visibility, and a display device having the anti-reflection film. A plurality of adjacent hexagonal pyramidal projections is geometrically provided, so that reflection of light is prevented. A refractive index is changed from a display screen surface side to the outside (the air side) because of a physical form that is a hexagonal pyramid. The plurality of hexagonal pyramidal projections can be provided without gaps therebetween and each of six side surfaces thereof is provided at an different angle from a base; thus, light can be sufficiently scattered in many directions.

Owner:SEMICON ENERGY LAB CO LTD

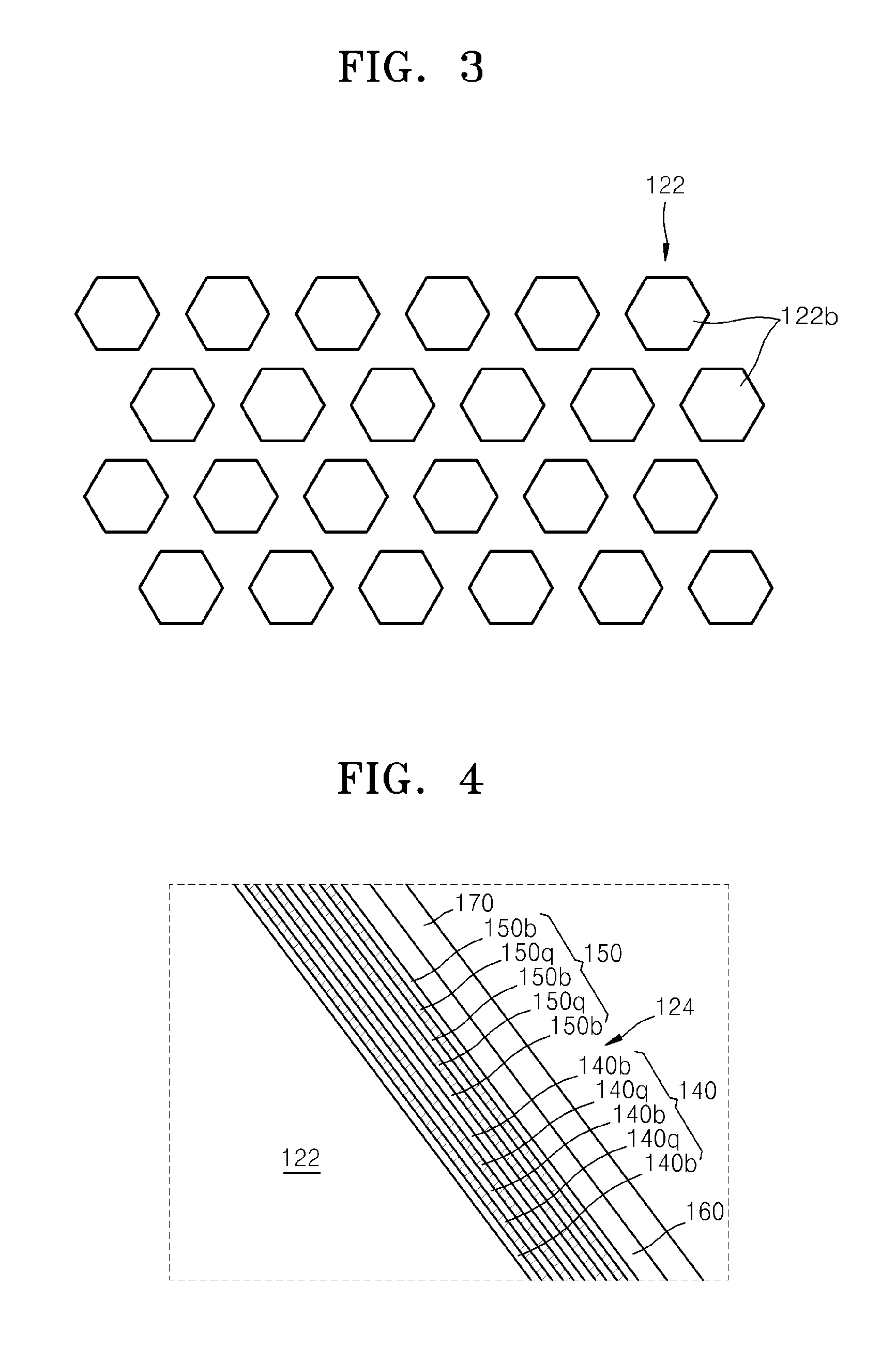

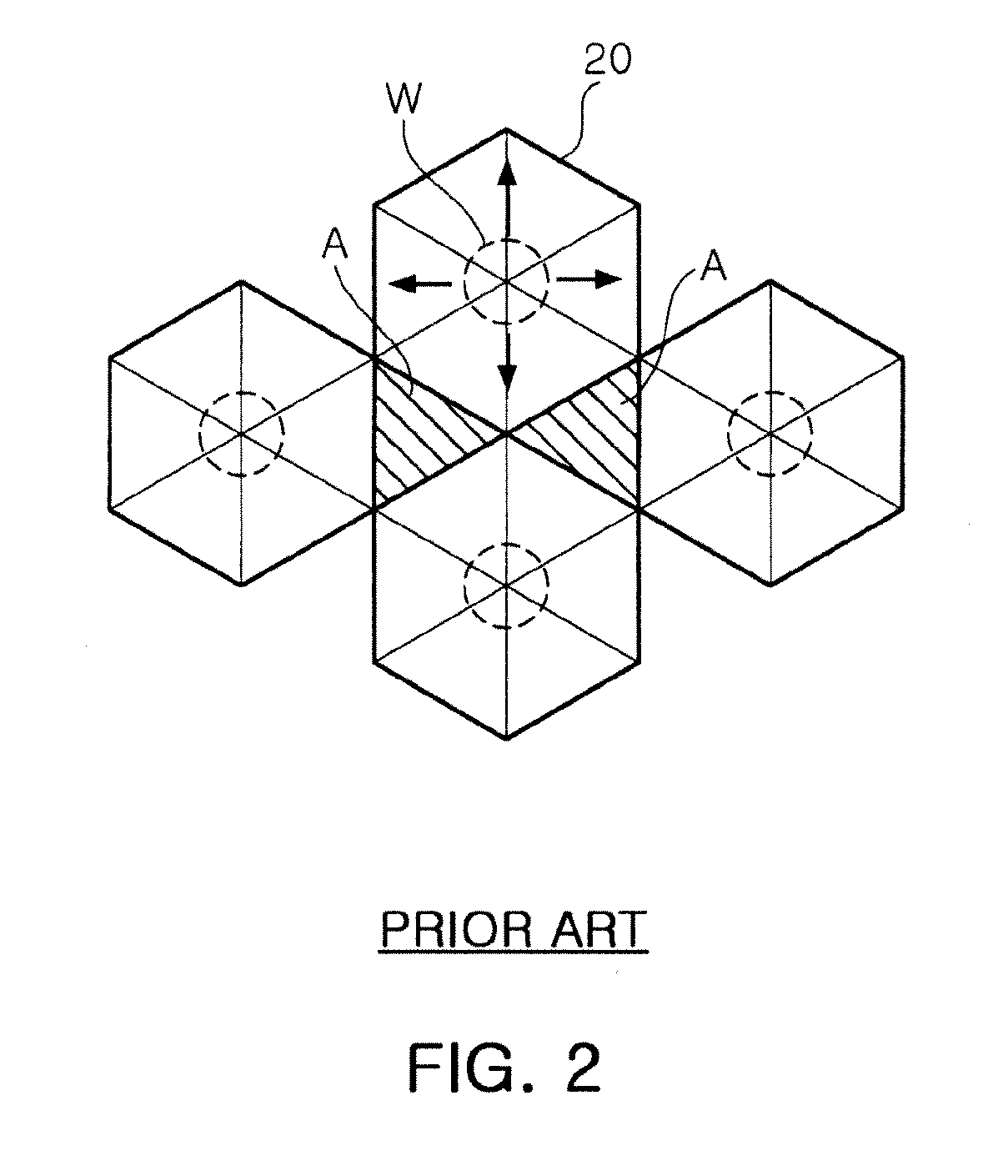

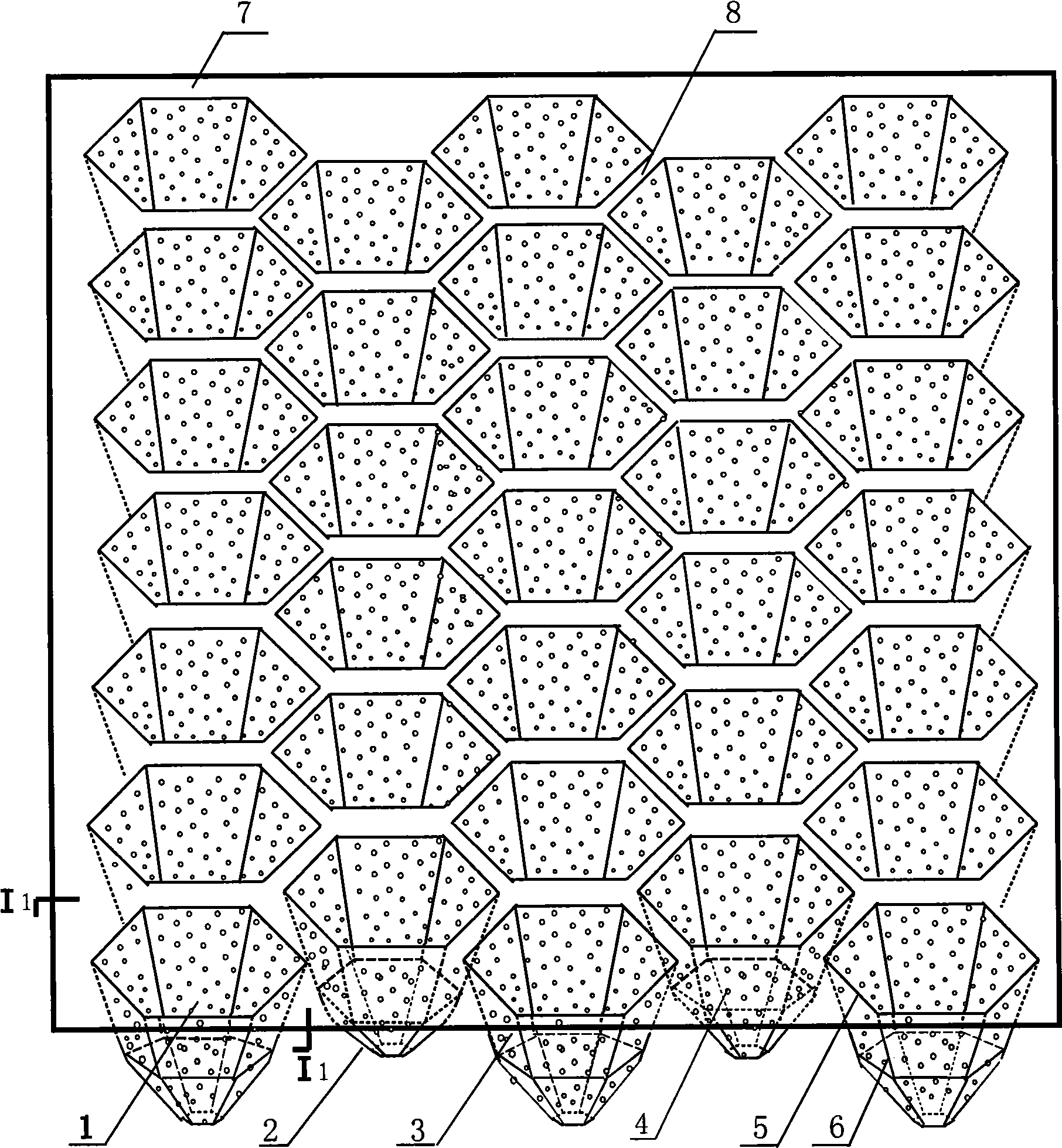

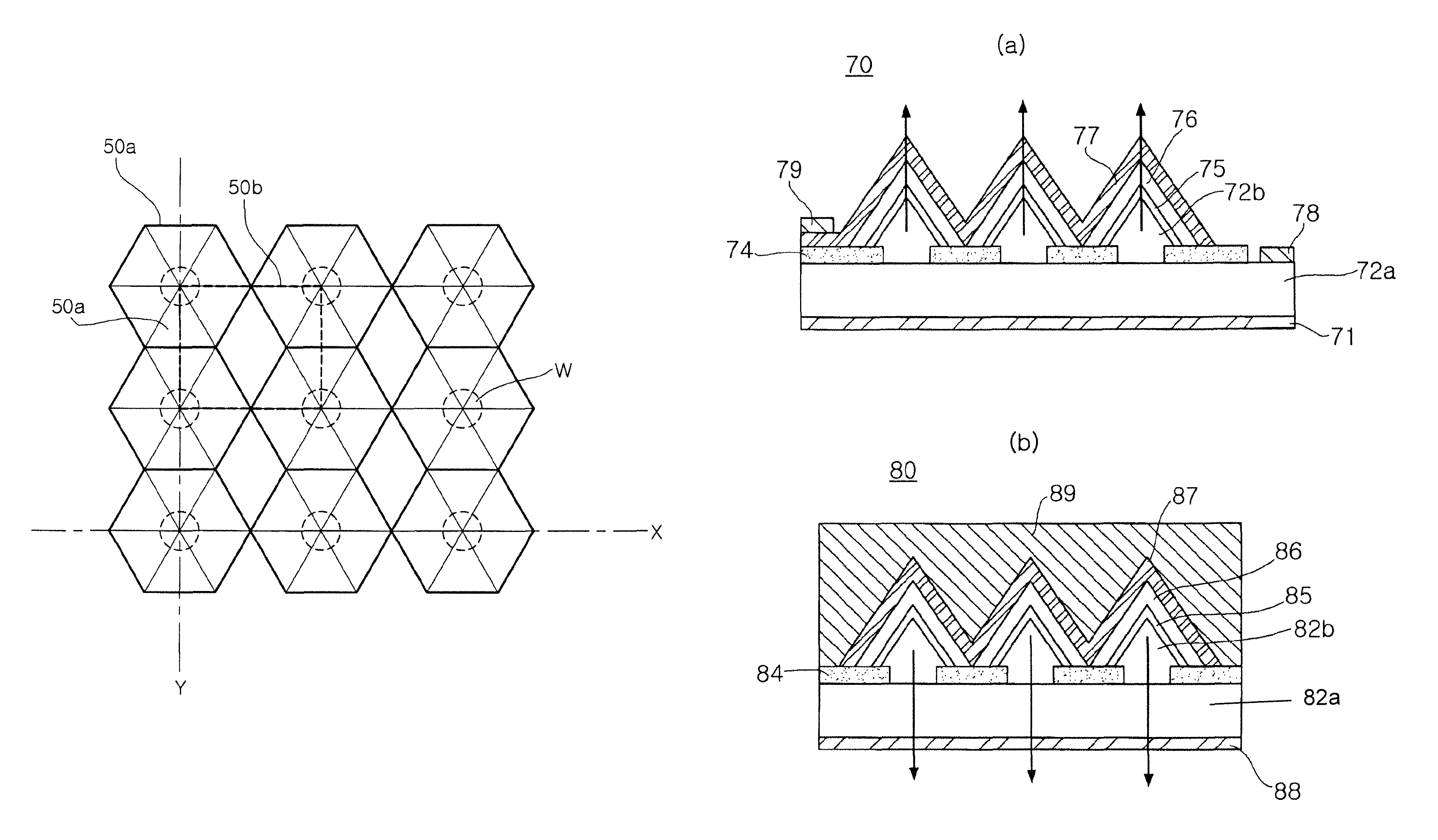

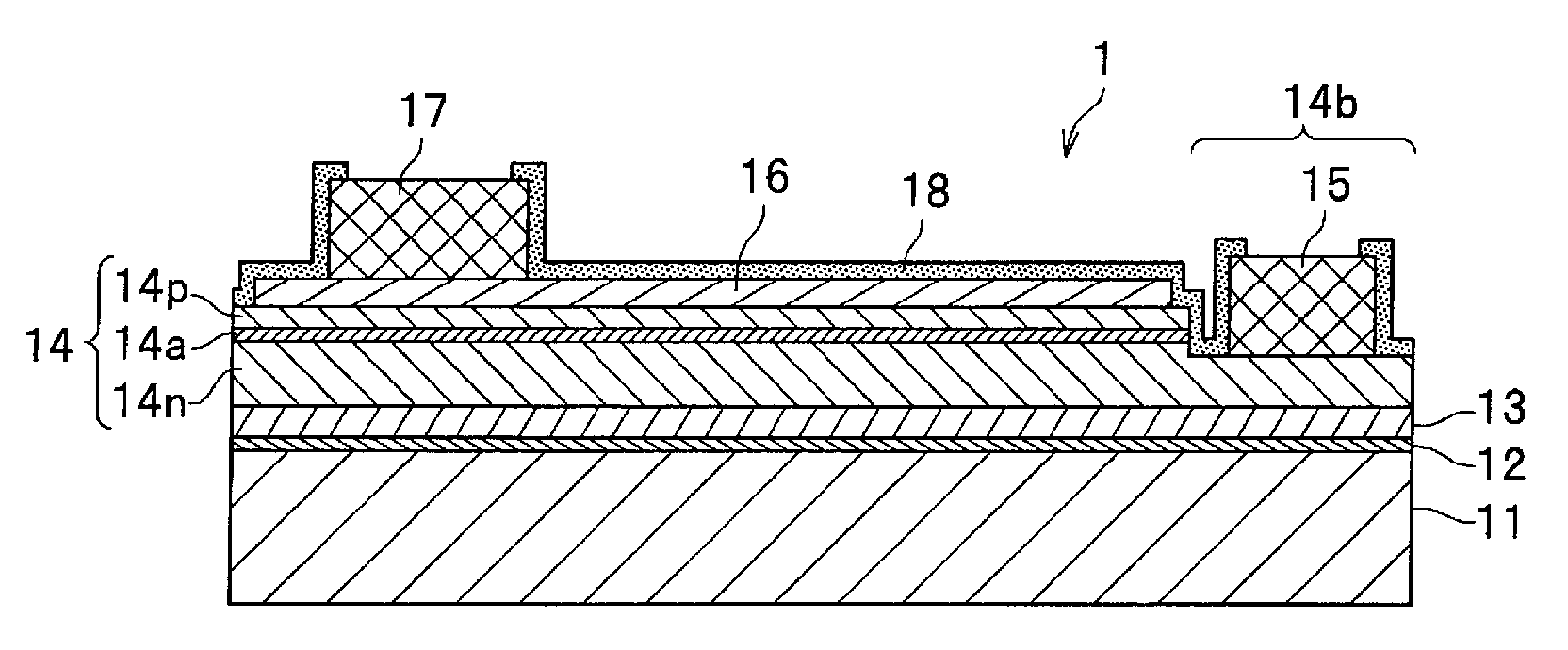

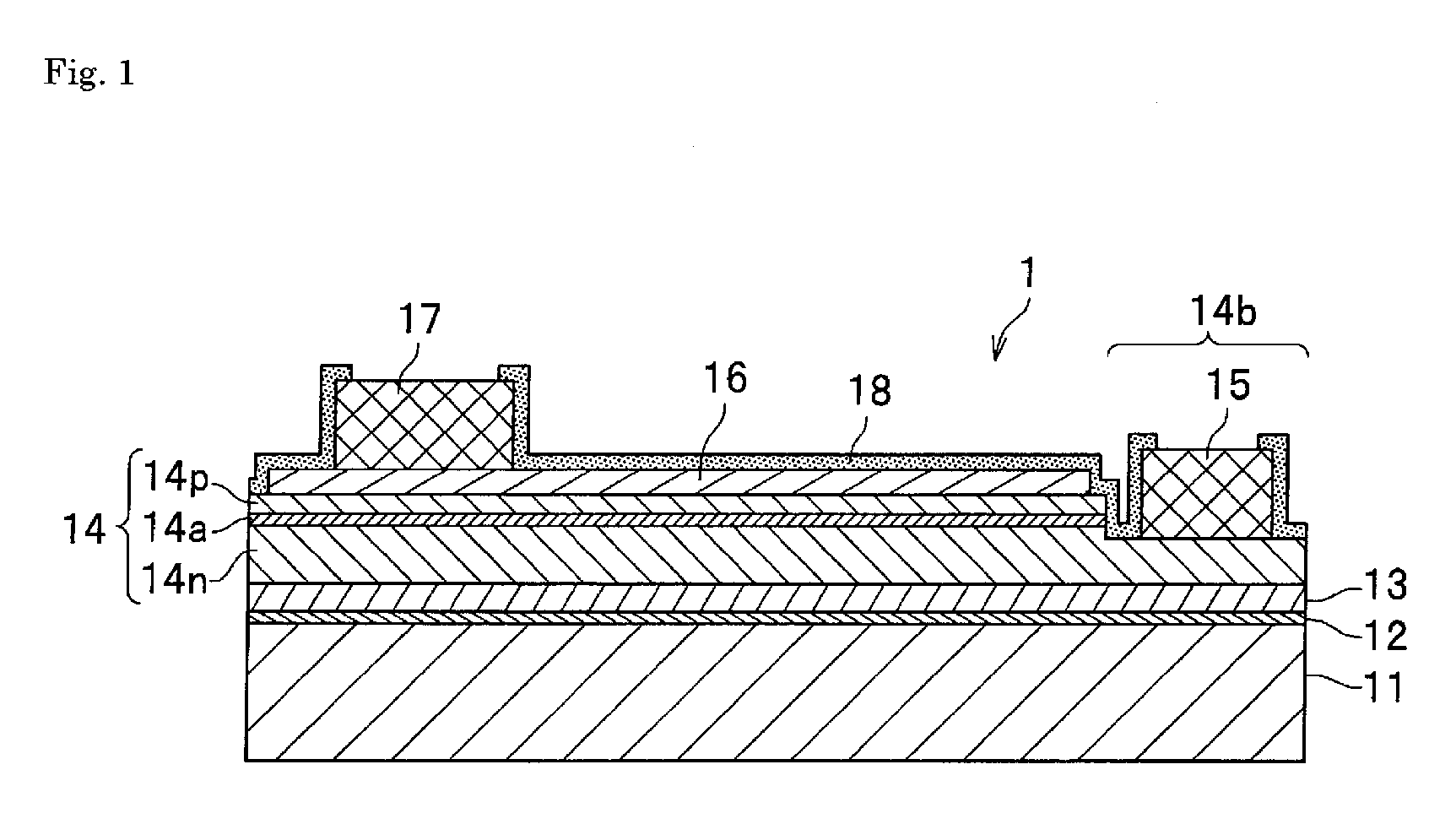

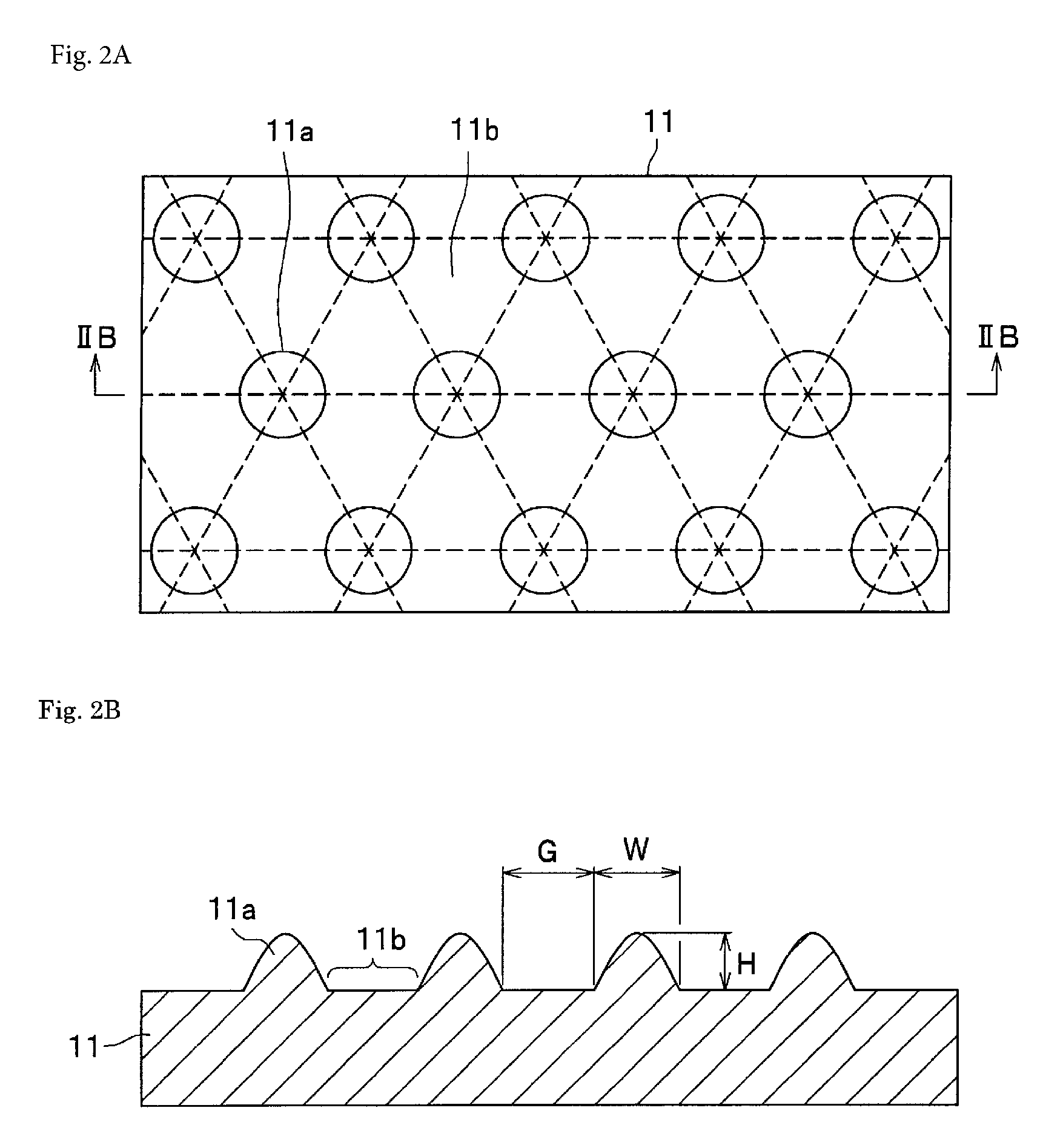

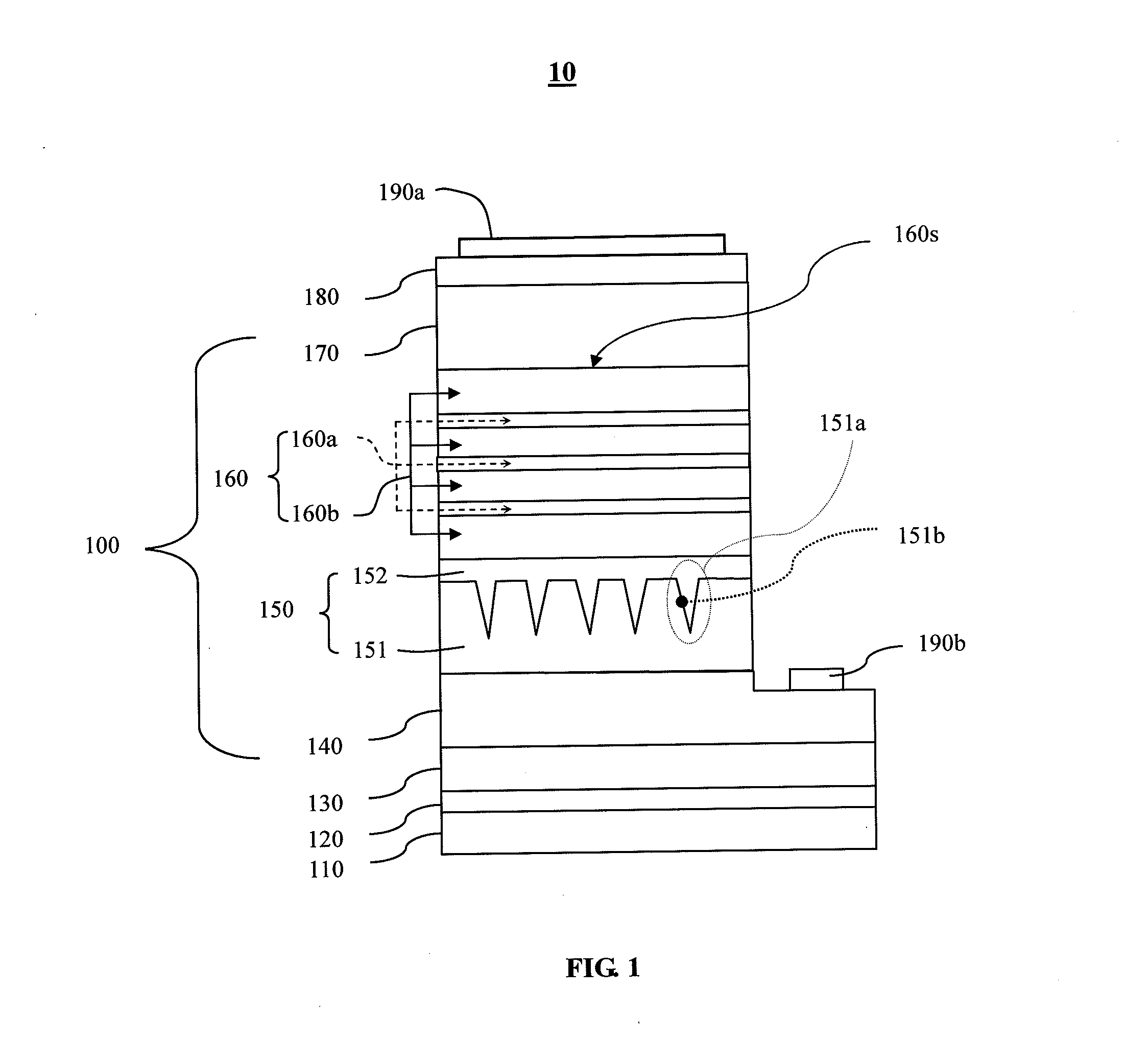

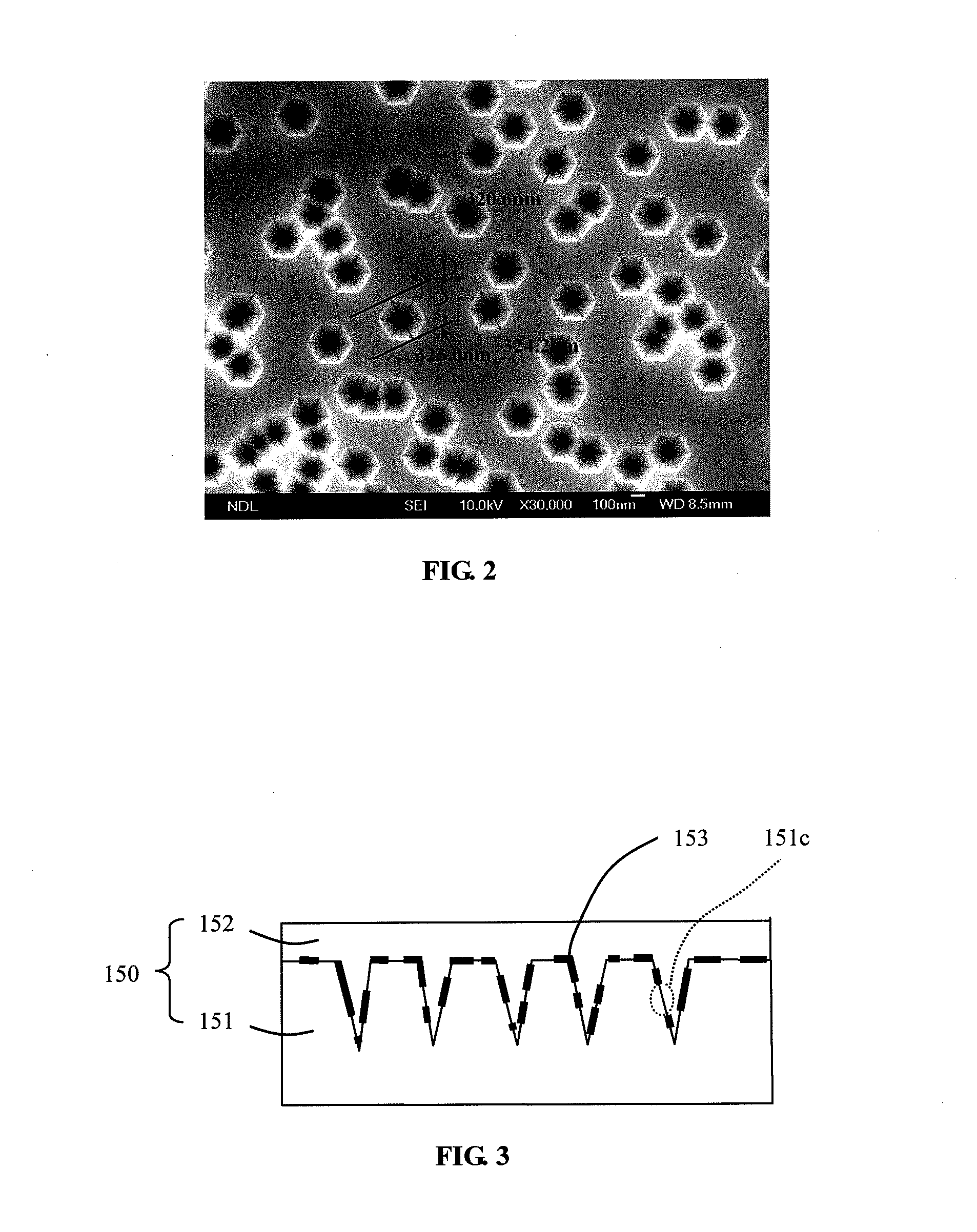

Nitride semiconductor light emitting device array

InactiveUS20080012030A1Maximize the light emitting areaConvenient ArrangementSemiconductor devicesActive layerDielectric layer

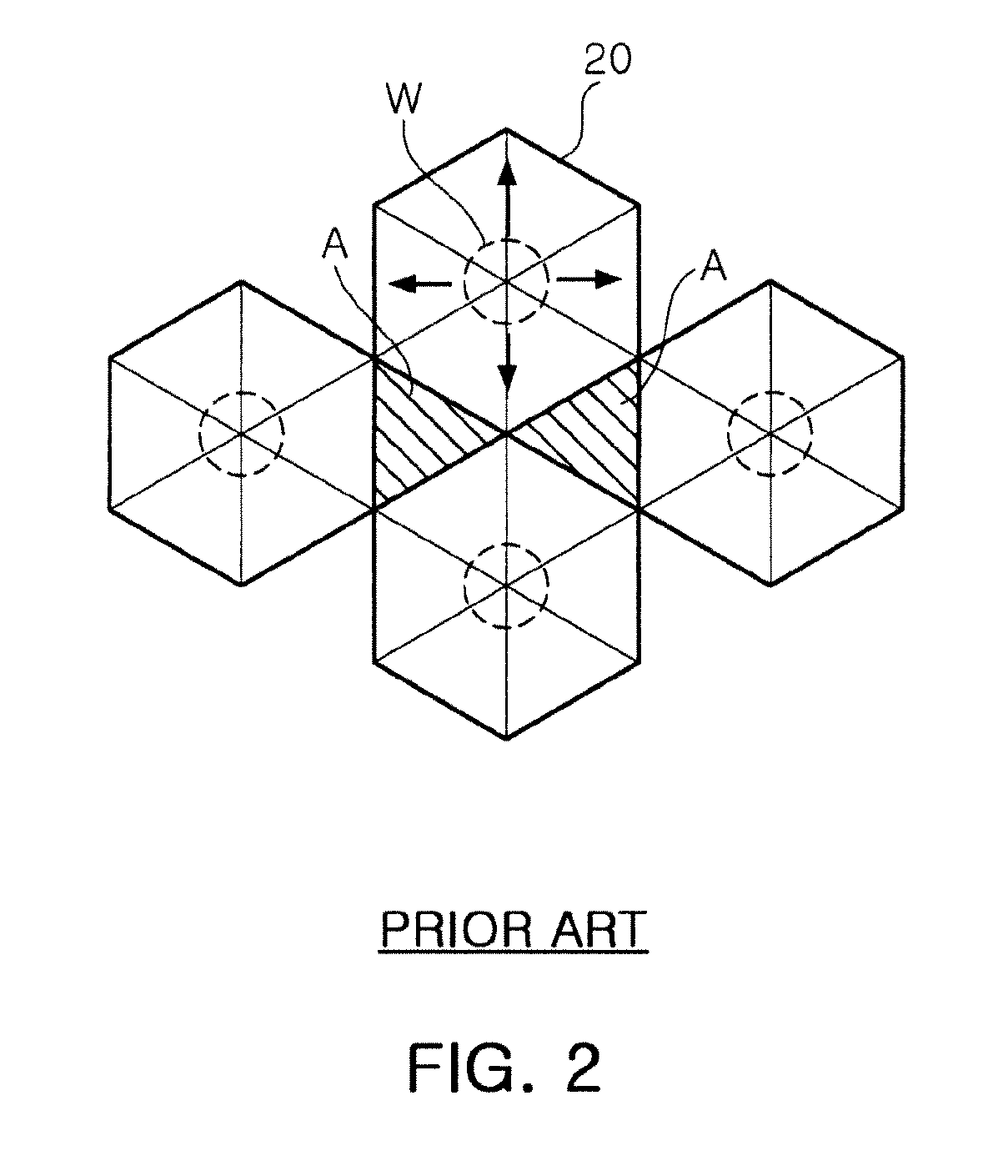

A nitride semiconductor light emitting device array, which includes a dielectric layer formed on a first conductivity lower nitride semiconductor layer, having a plurality of windows. Each of a plurality of hexagonal pyramid light emission structures is grown from a surface of the first conductivity lower nitride semiconductor layer exposed through each of the windows and onto a peripheral area of the window of the dielectric layer. Each of the hexagonal pyramid light emission structures includes a first conductivity upper nitride semiconductor layer, an active layer and a second conductivity nitride semiconductor layer formed in their order. The windows are disposed in such a triangular arrangement that side surfaces of the adjacent hexagonal pyramid light emission structures face each other. Also, a distance between bases of the adjacent hexagonal pyramid light emission structures is less than 0.3 times an interval between centers of the windows of the adjacent hexagonal pyramid light emission structures.

Owner:SAMSUNG ELECTRONICS CO LTD

Plasma display panel and field emission display

InactiveUS20080129188A1Effective dispersionHigh definitionNanostructure manufactureSustain/scan electrodesField emission displayDisplay device

To provide a plasma display panel and a field emission display having an anti-reflection function which can further reduce reflection of incident light from an external source. By providing an anti-reflection layer which geometrically includes a plurality of adjacent hexagonal pyramid-shaped projections, reflection of light is prevented. The reflective index changes from a surface side of display screen to an out side (an atmosphere side) due to a physical shape of a hexagonal pyramid. The plurality of hexagonal pyramid-shaped projections can be provided densely without any space remaining, and six surfaces of side of the hexagonal pyramid-shaped projection are each provided at different angles to a base surface. Therefore, light ray can be effectively scattered in many directions.

Owner:SEMICON ENERGY LAB CO LTD

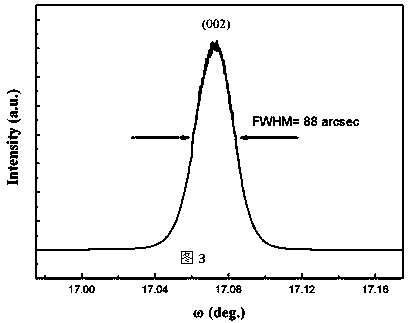

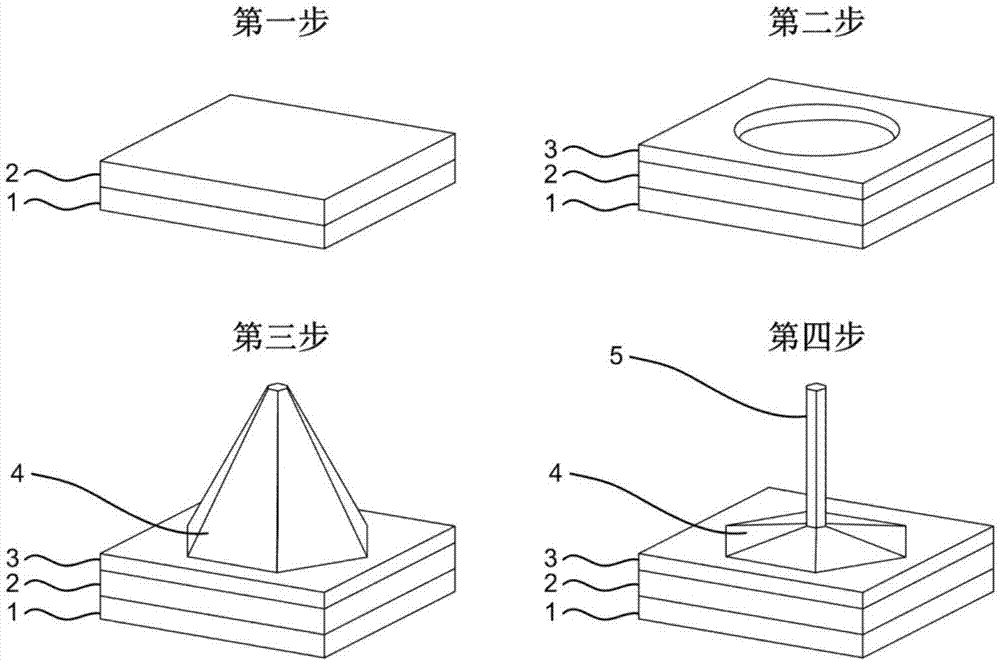

Gallium nitride homoepitaxy method based on in situ etching

ActiveCN103614769AQuality improvementEfficient removalSemiconductor/solid-state device manufacturingFrom chemically reactive gasesMicro structureEffective solution

The invention discloses a gallium nitride homoepitaxy method based on in situ etching. The method comprises the following steps: 1) selecting a gallium nitride substrate and transferring the substrate into an MOCVD system; 2) conducting fast etching on the substrate for a short time; 3) conducting long-time slow etching after the fast etching to form hexagonal pyramid micro structures on the substrate surface; 4) laterally growing to merge the hexagonal pyramid micro structures; and 5) continuing to grow a high-quality GaN epitaxial layer on the merged film. The invention has the following advantages: through the control of components of in situ etching gas, impurities on the surface of the substrate are removed, while the hexagonal pyramid micro structures are formed on the surface of the substrate; and the micro structures are merged in a lateral epitaxial stage, so as to reduce the dislocation density of the epitaxial layer and finally obtain the gallium nitride epitaxial thin film with high quality. Formation of hexagonal pyramid micro structures on the surface of the substrate does not need additional process equipment; the method is economical, simple and practicable; and the epitaxial material has good performance. Therefore, the method provided by the invention is an effective solution for realizing high-quality and low-cost growth of GaN epitaxial thin film.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

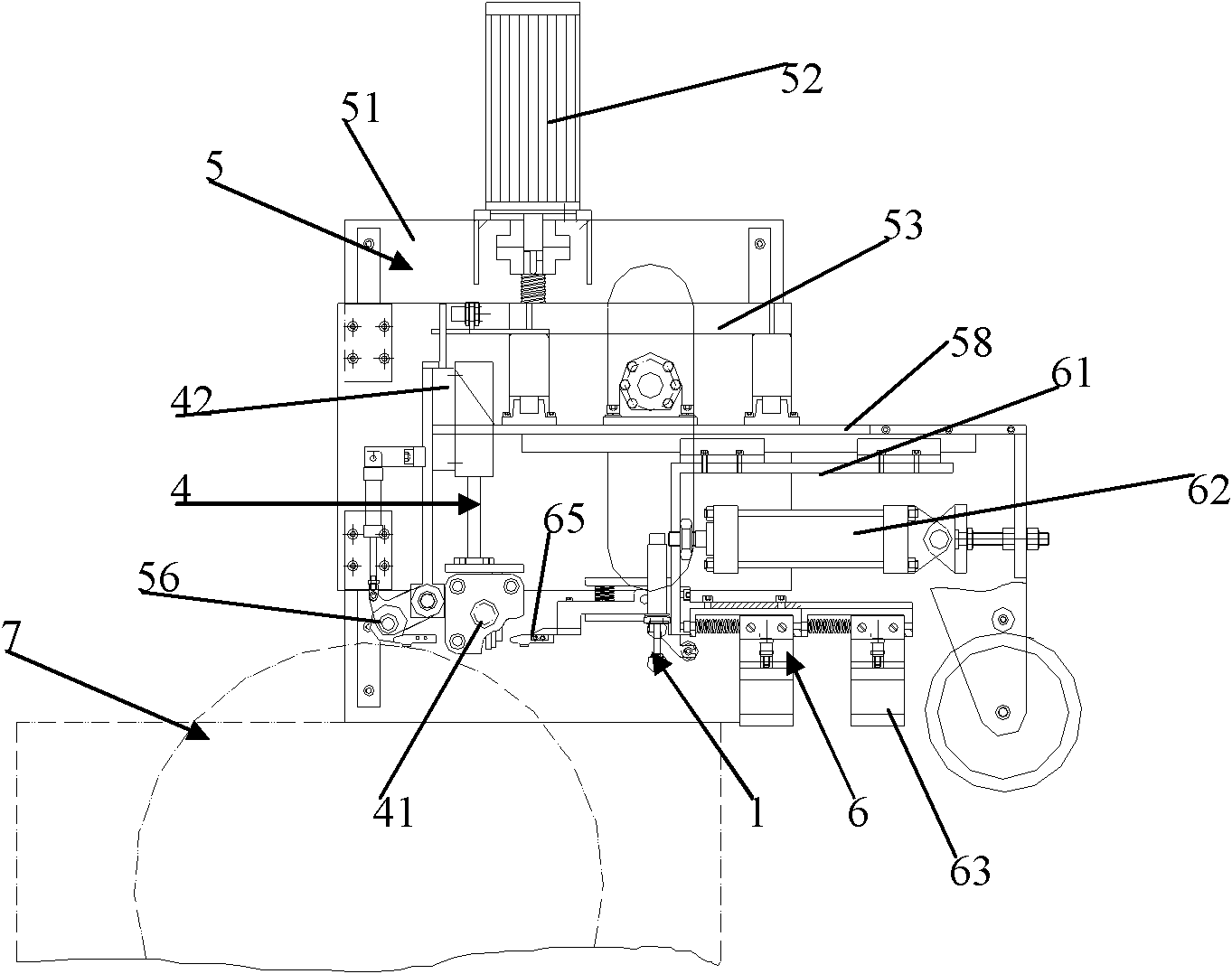

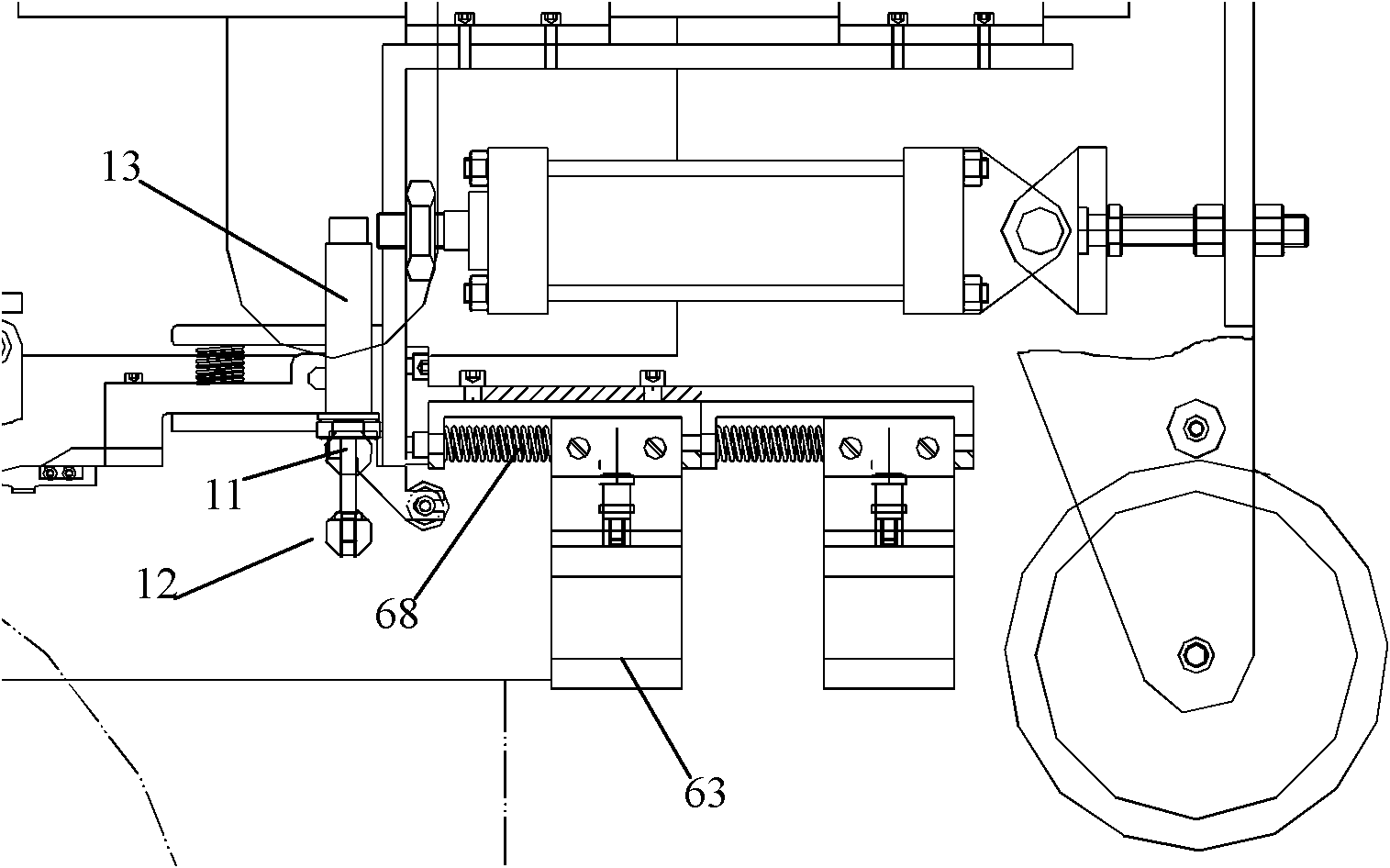

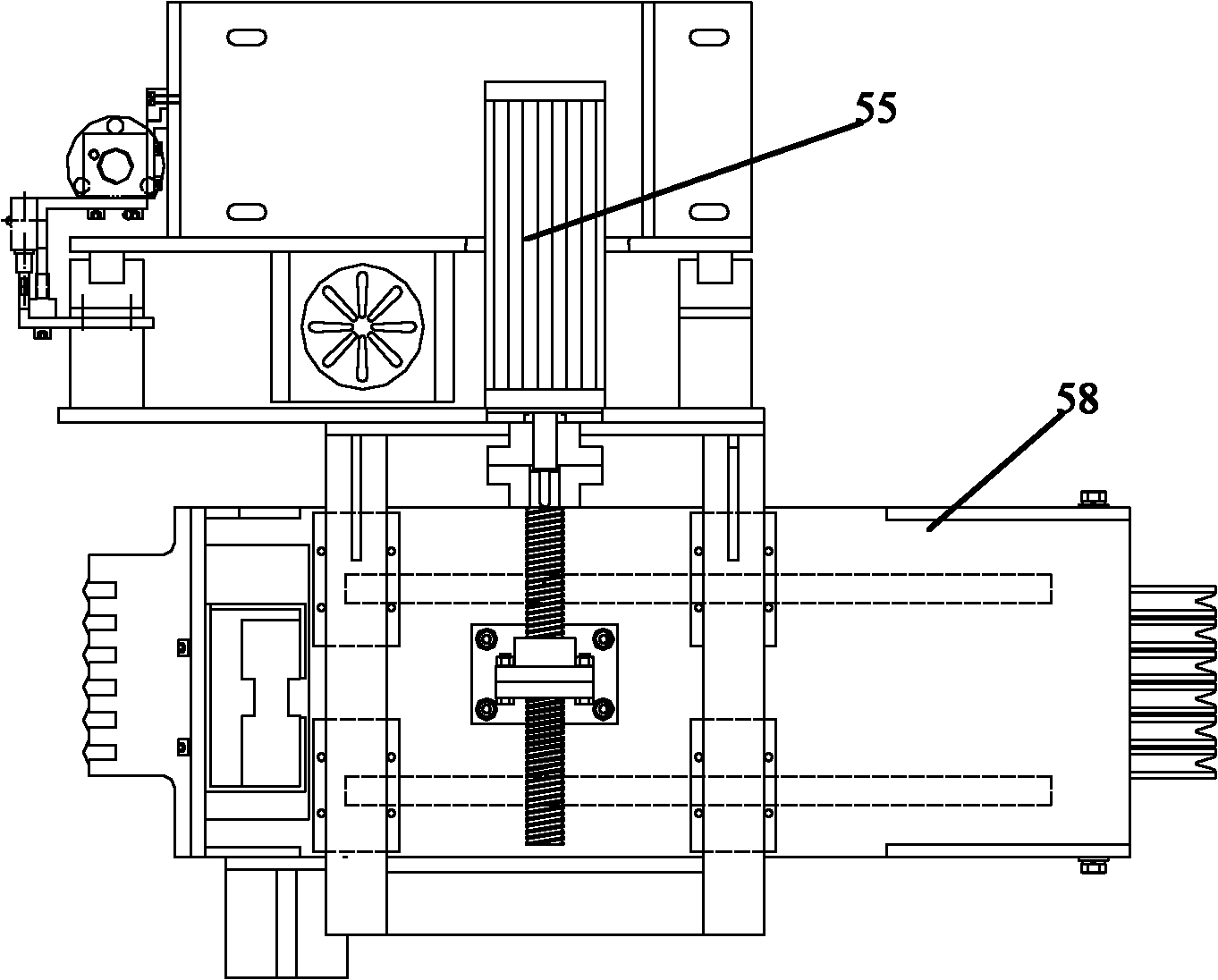

Radial tire bead ring winding machine with six stations

The invention discloses a radial tire bead ring winding machine with six stations, comprising a wire arraying device, a wire feeding device, a wire cutting device and a winding device, wherein the winding device comprises a stand, a sliding shaft driving motor, a sliding shaft, a main shaft, a main shaft driving motor and a speed reducer; a main connecting disk is installed on the main shaft; a plurality of fixed linear rails in an outward radiating form from the center are uniformly distributed on the end face of the main connecting disk; an umbrella stand seat is installed on a sliding block of the linear rail; a hexagonal pyramid-shaped movable umbrella stand is arranged fixedly at the end part of the sliding shaft; a winding module is detachably and fixedly arranged on the umbrella stand seat; and a plurality of wire winding grooves are uniformly distributed along the circumference direction of a cambered surface on the winding module. According to the radial tire bead ring winding machine with six stations disclosed by the invention, six wire winding grooves are arranged on the winding module, thus the bead rings can be wound in the six stations simultaneously, the production efficiency is improved by at least more than 50% compared with two-ring and four-ring winding, bead rings with different diameters can be effectively wound by controlling the positions of the movable umbrella stand and the umbrella stand seat, and the diameter range of the bead rings is 13-25cun.

Owner:TIANJIN SAIXIANG TECH

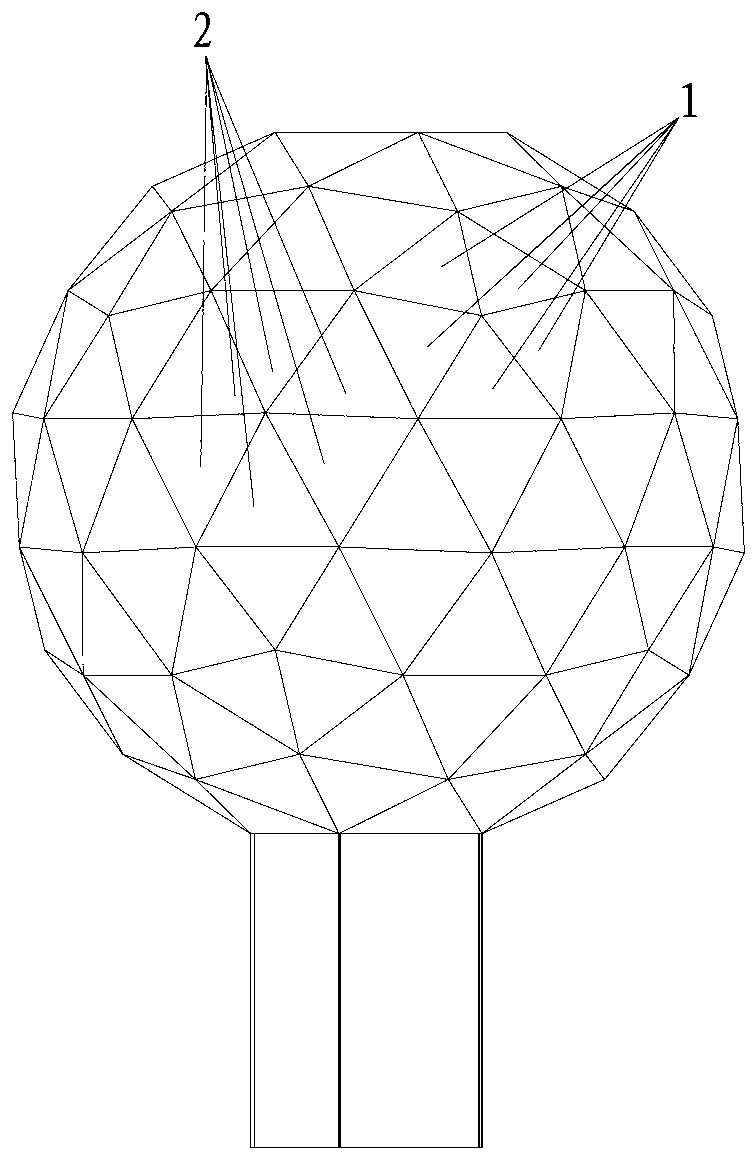

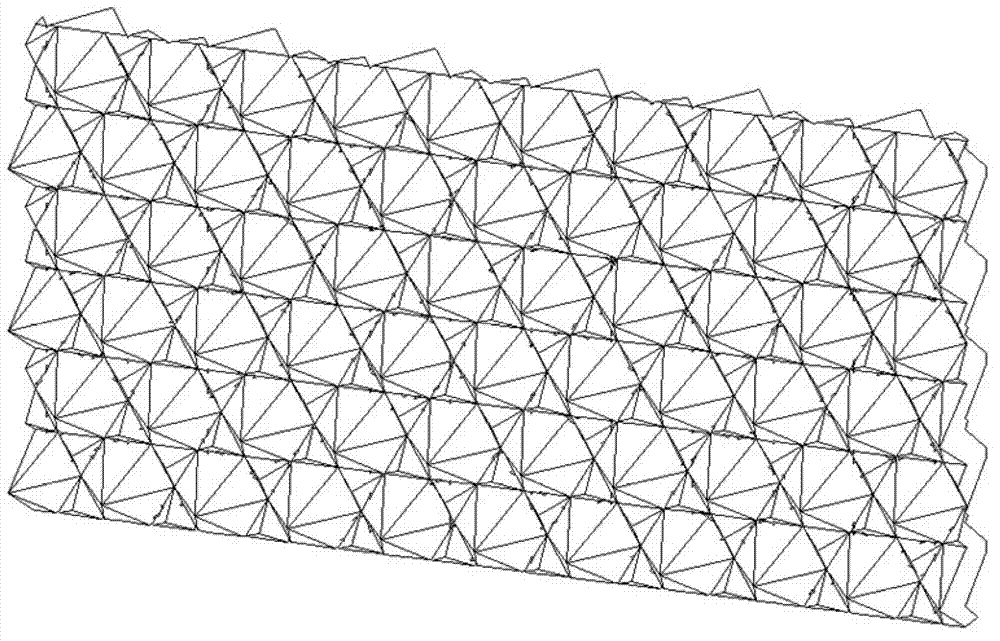

Spherical display screen and manufacturing method thereof

InactiveCN103310709AComplete specificationsSimple structureIdentification meansSpherical shapedDistortion

The invention discloses a spherical display screen and a manufacturing method thereof. The method comprises the following steps: according to the Euler's formula in space, obtaining 12 pentagons and 20 hexagons which can form a 32-face body inscribed in a spherical surface; then causing one points on the spherical surfaces corresponding to the pentagons and the hexagons to be connected with the end points of corresponding pentagons and hexagons to form pentagonal pyramids and hexagonal pyramids; according to the side faces of the pentagonal pyramids and the hexagonal pyramids, manufacturing pentagonal display modules and hexagonal display modules; finally assembling 12 pentagonal display modules and 20 hexagonal display modules into a spherical screen similar with a sphere. Therefore, when the display modules are designed, at most 32 display modules are designed, the product-design period is greatly shortened, and a lot of design labor resources are reduced. In the spherical display screen manufactured with the method, glowing pixel points can be uniformly arranged on each triangular side face of the pentagonal display modules and the hexagonal display modules. The spherical display screen has the advantages of simple structure, good pictures of displayed images and small distortion.

Owner:UNILUMIN GRP

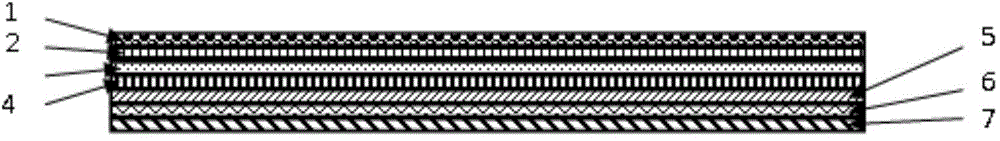

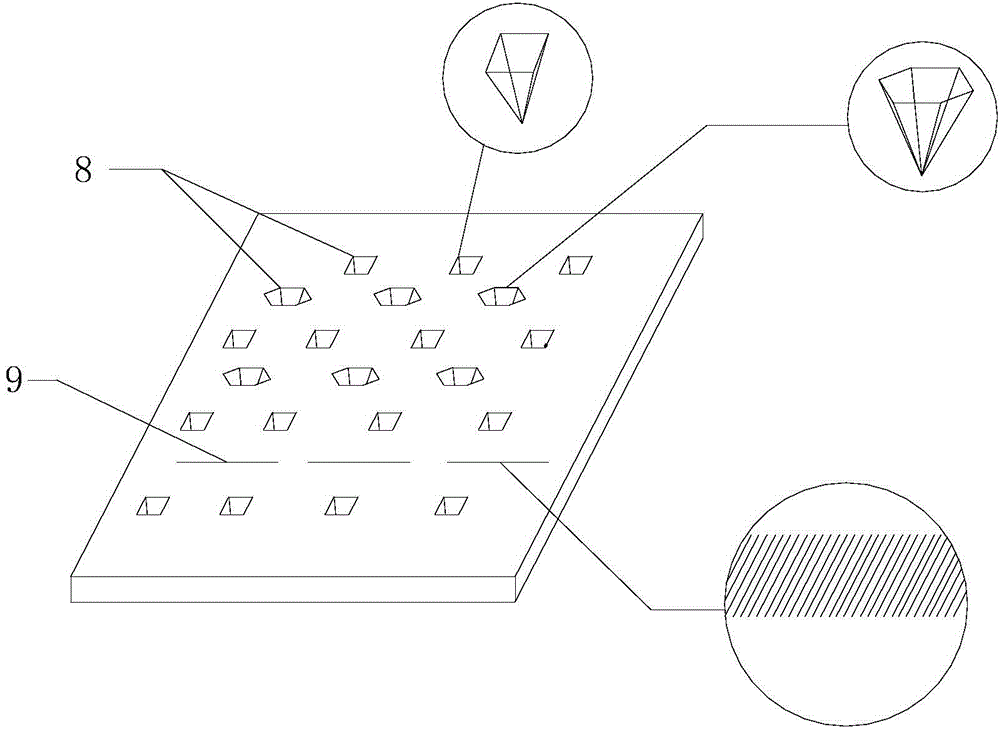

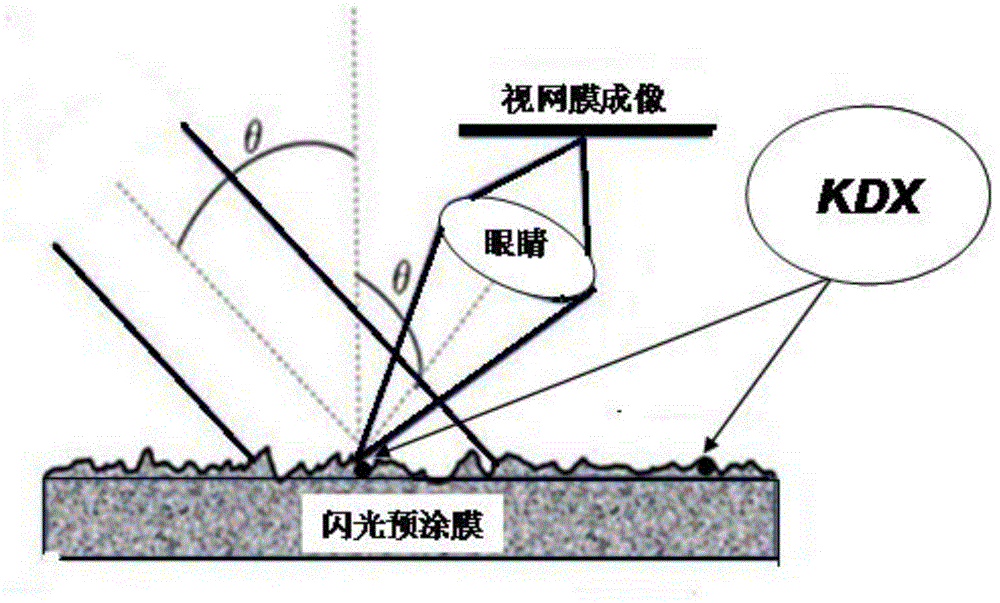

Metallic surface glittering effect simulated pre-coated film for packaging and manufacturing method of metallic surface glittering effect simulated pre-coated film

ActiveCN104553217AHas multiple anti-counterfeiting effectsReduce pinholesFlexible coversWrappersGratingMetal sheet

The invention discloses a metallic surface glittering effect simulated pre-coated film for packaging and a manufacturing method of the metallic surface glittering effect simulated pre-coated film. The metallic surface glittering effect simulated pre-coated film sequentially comprises a printing or coating color layer, an aluminum coated layer, an enhanced aluminum-coated resin layer, a molding resin layer, a film layer, a base coating layer and a hot melt adhesive layer, wherein a glittering pattern with pyramid nicks and an anti-counterfeiting encryption image having the laser holographic effect and with grating nicks are arranged on the molding resin layer, the pyramid nicks are shaped like a rectangular pyramid, a hexagonal pyramid or rectangular pyramid and hexagonal pyramid mixed nicks, the depth of each pyramid nick is 10-20 microns, and the depth of the grating nick is below 1 micron. The metallic surface glittering effect simulated pre-coated film is mainly characterized of having the granular glittering effect, being provided with the glittering point combined pattern designed by computer software, having an anti-counterfeiting function, and being environmentally-friendly, and can be applied to laminated films of stationery, clothes, furniture decoration, package of luxuries, substitute metal sheets and the like.

Owner:张家港保税区康得菲尔实业有限公司

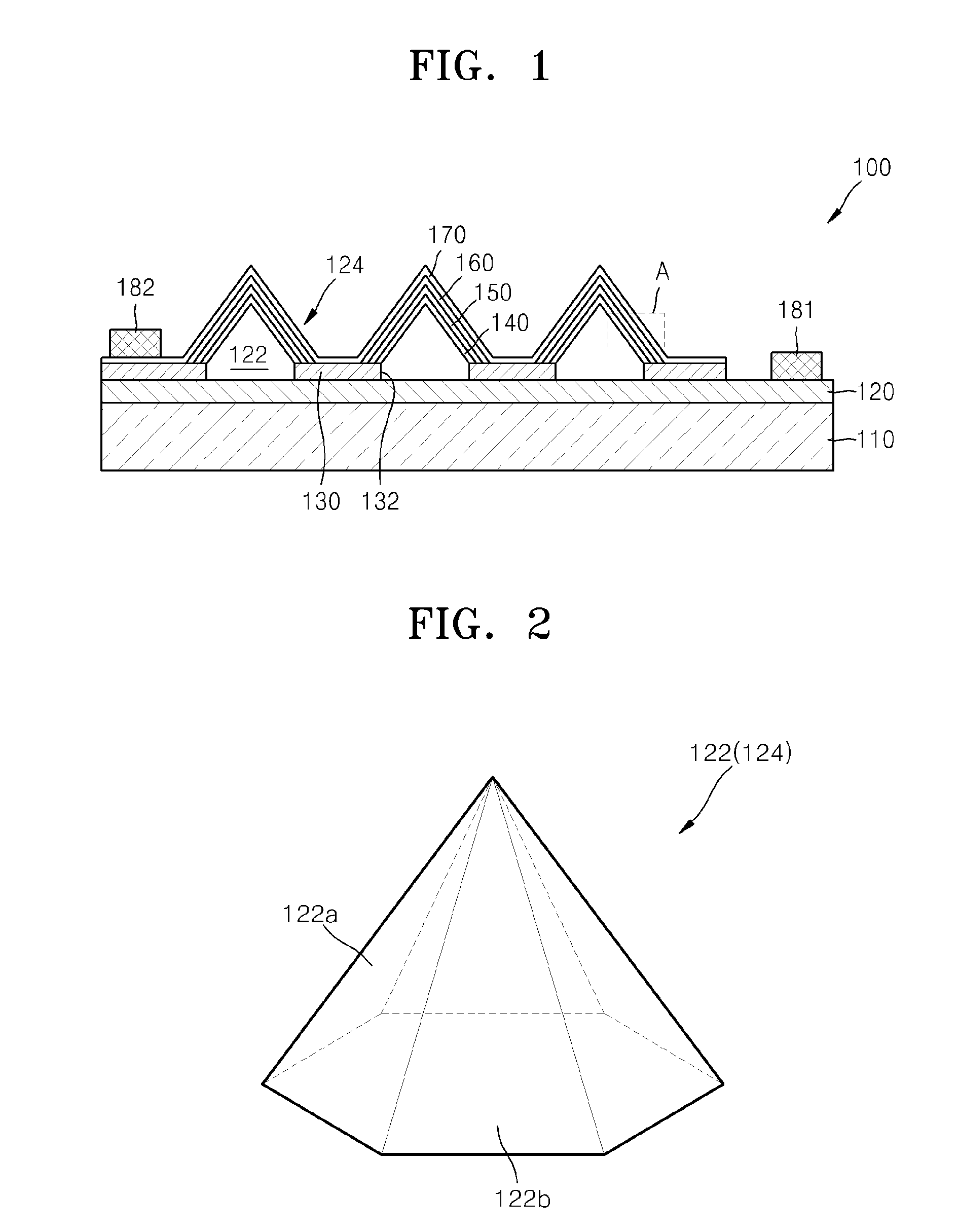

White light emitting diode

InactiveUS20130248817A1Improve internal quantum efficiencyImprove external quantum efficiencyNanotechnologySemiconductor devicesElectrical conductorPhosphor

According to example embodiments, a white light-emitting diode may be configured to emit white light without a phosphor. According to example embodiments, a white light-emitting diode may include a first semiconductor layer that includes a plurality of hexagonal-pyramid shape nanostructures that protrude upwards from an upper surface of the first semiconductor layer, at least two multi-quantum well layers that are sequentially stacked on the hexagonal-pyramid shape nanostructures; and a second semiconductor layer on the multi-quantum well layers. The at least two multi-quantum well layers may be configured to generate lights having different wavelengths, and white light may be generated by mixing the lights having different wavelengths.

Owner:SAMSUNG ELECTRONICS CO LTD

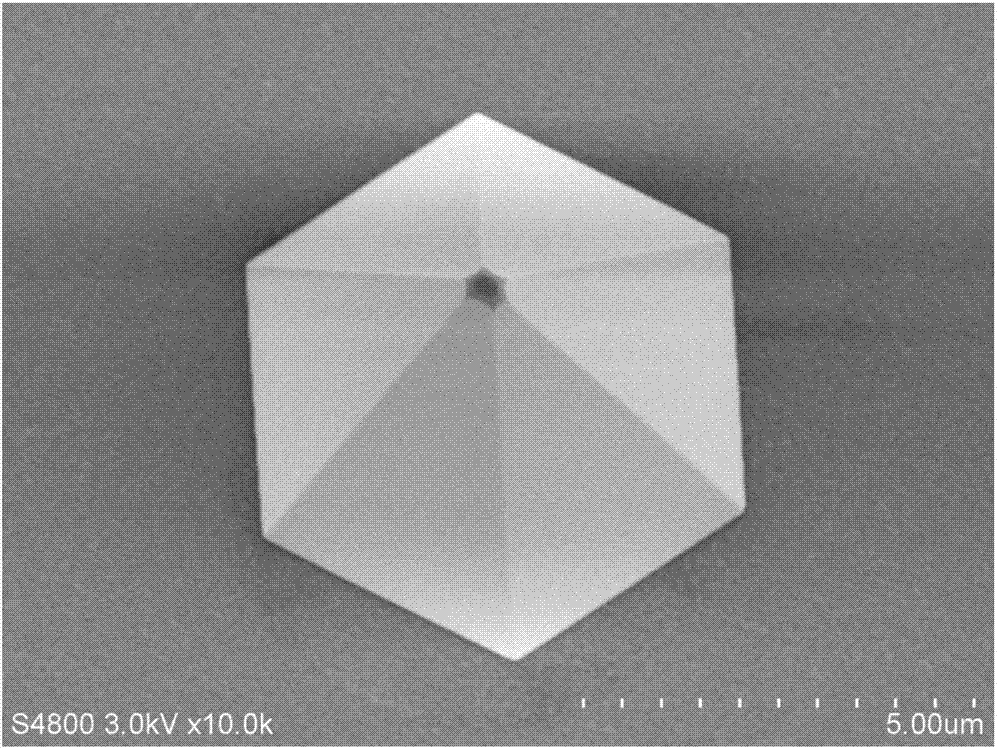

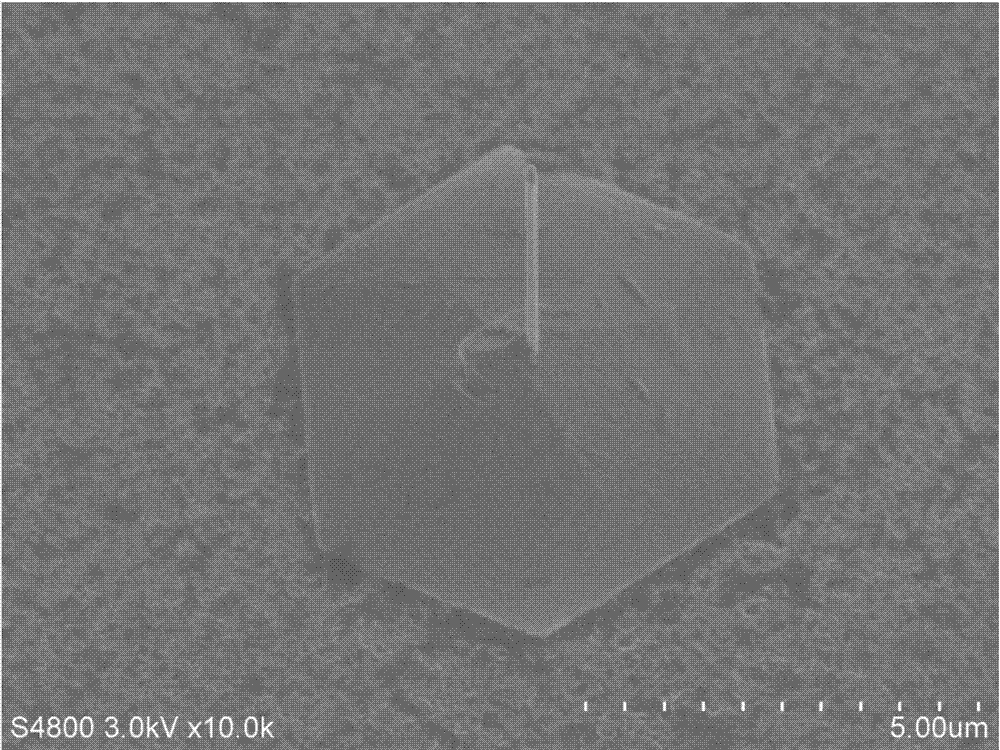

GaN nanowire and preparation method thereof

The invention discloses a GaN nanowire and a preparation method thereof. The preparation method of the GaN nanowire comprises the steps of forming a III-nitride film on a substrate in a epitaxial growth mode through MOCVD, preparing a graphical masking film on an epitaxial wafer, growing a GaN hexagonal pyramid microstructure on the graphical epitaxial wafer based on an MOCD selective area growing method, then etching the side face {1-101} of the GaN hexagonal pyramid microstructure off through an alkaline solution etching method, finally preparing the GaN nanowire, wherein the side face of the GaN nanowire is a {1-100} face, and the top face of the GaN nanowire is a {1-101} face. The GaN nanowire and the preparation method of the GaN nanowire have the advantages that the process is simple, and the diameter, height and position of the nanowire are controllable. In addition, the GaN nanowire can be used for manufacturing a GaN nanodevice with high performance.

Owner:SUN YAT SEN UNIV

Nitride semiconductor light emitting device array

InactiveUS20110198625A1Maximize the light emitting areaConvenient ArrangementSemiconductor devicesActive layerDielectric layer

A nitride semiconductor light emitting device array, which includes a dielectric layer formed on a first conductivity lower nitride semiconductor layer, having a plurality of windows. Each of a plurality of hexagonal pyramid light emission structures is grown from a surface of the first conductivity lower nitride semiconductor layer exposed through each of the windows and onto a peripheral area of the window of the dielectric layer. Each of the hexagonal pyramid light emission structures includes a first conductivity upper nitride semiconductor layer, an active layer and a second conductivity nitride semiconductor layer formed in their order. The windows are disposed in such a triangular arrangement that side surfaces of the adjacent hexagonal pyramid light emission structures face each other. Also, a distance between bases of the adjacent hexagonal pyramid light emission structures is less than 0.3 times an interval between centers of the windows of the adjacent hexagonal pyramid light emission structures.

Owner:SAMSUNG ELECTRONICS CO LTD

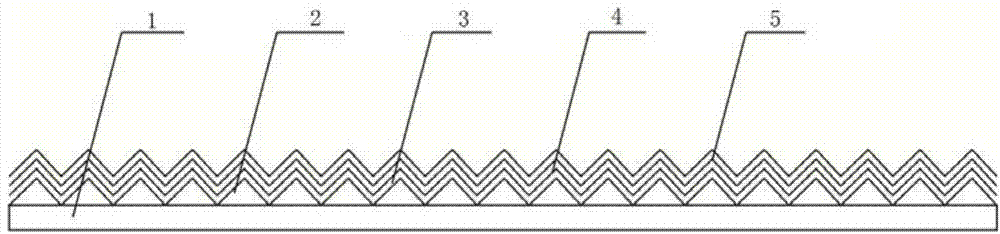

Micro cone tower array heat exchanging plate and manufacture method thereof

InactiveCN103047893ALarge specific surface areaVarious shapesSemiconductor/solid-state device detailsSolid-state devicesMilling cutterEngineering

The invention discloses a micro cone tower array heat exchanging plate and a manufacture method thereof and belongs to the field of heat dissipation. A multi-height micro cone tower array structure is respectively arranged on two sides of the heat exchanging plate. The structures are formed by mixing regular triangular pyramid linear arrays and regular hexagonal pyramid linear arrays with two heights or formed by mixing multi-height linear or circumference arrays of pyramids and conoids. A notch milling cutter with a V-shaped cutting tip or a diamond grinding wheel is used for milling or grinding a thin plate, a V-shaped groove array in the first direction is machined on one side of the thin plate during machining, then the thin plate rotates an angle theta sequentially to machine the rest V-shaped groove arrays respectively, and the other side of the thin plate is machined through the same method. By means of the heat exchanging plate, specific surface area of the thin plate can be increased, concave joints in V-shaped grooves are favorable for core forming, runners formed by the multi-height micro cone tower array structures are favorable for complicating a fluid flowing condition, and a heat transferring effect of the heat exchanging plate is improved.

Owner:SOUTH CHINA UNIV OF TECH

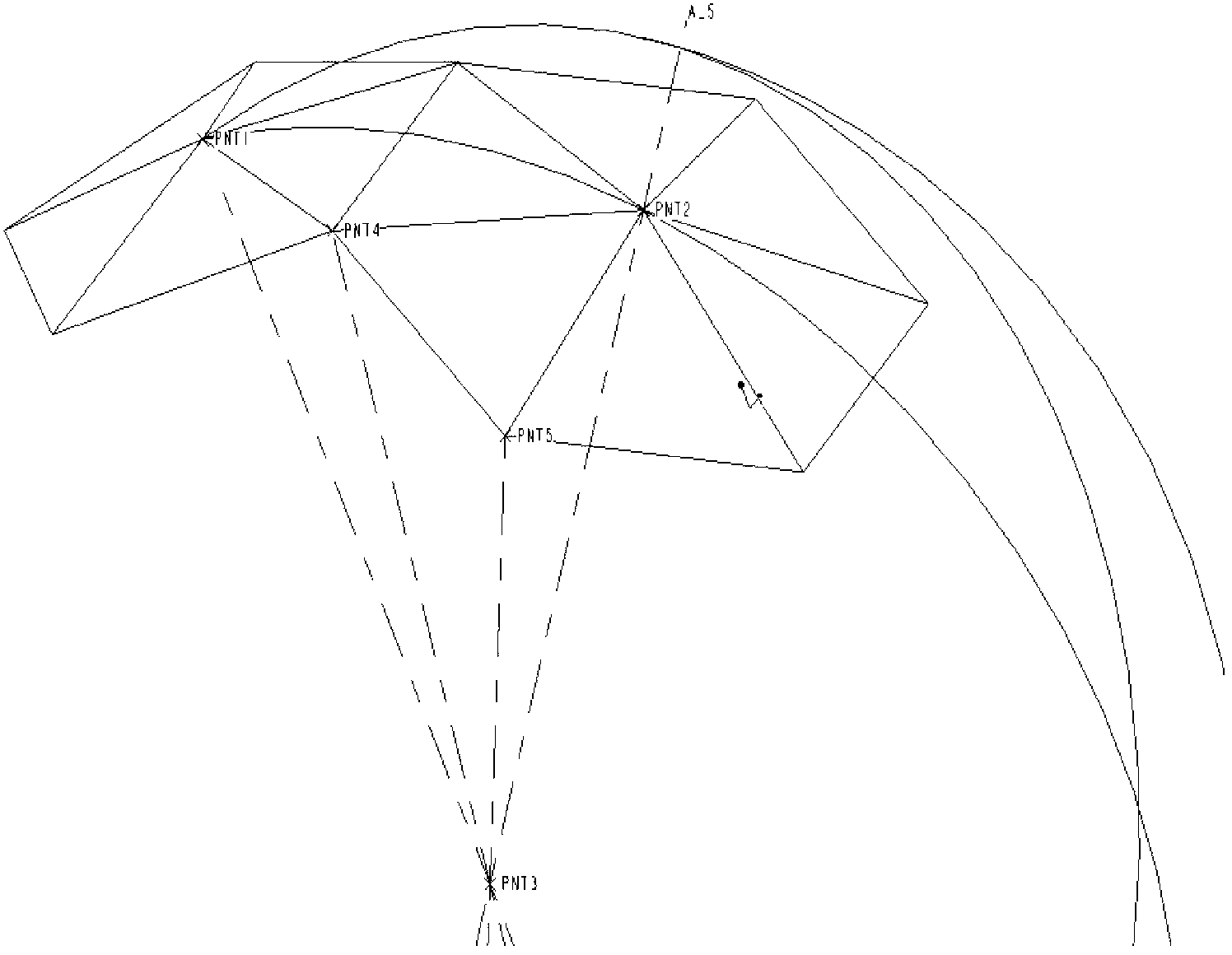

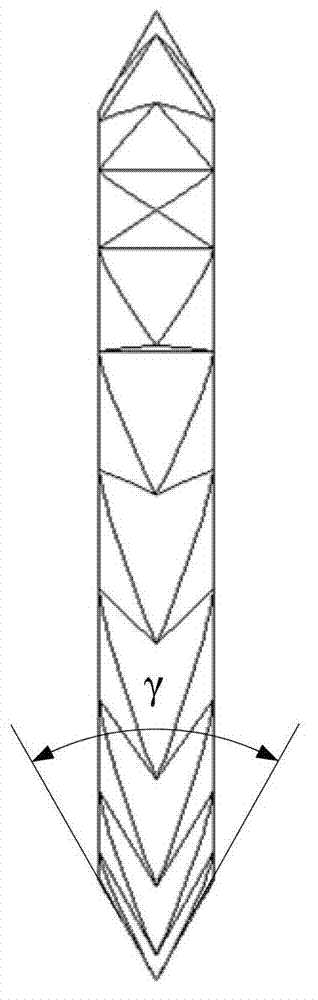

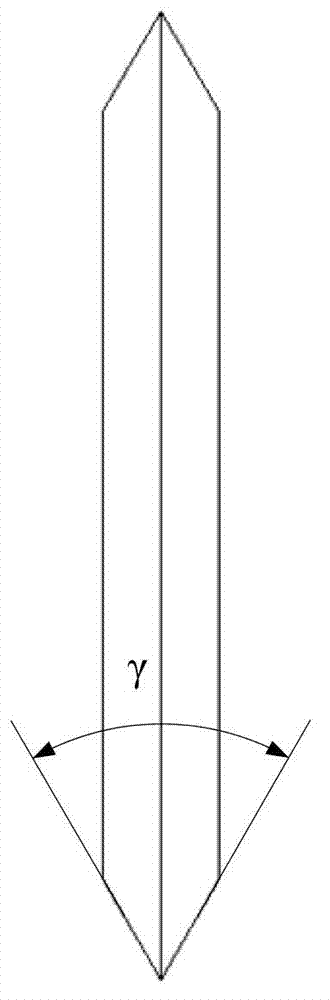

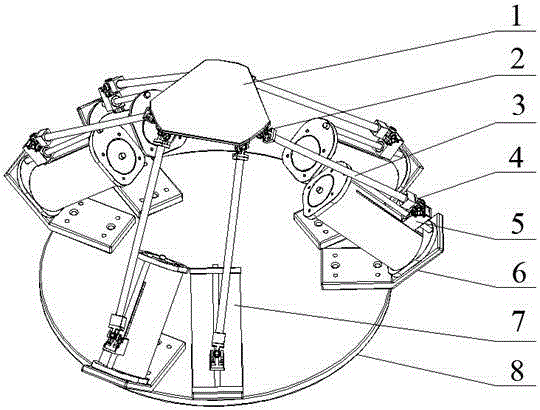

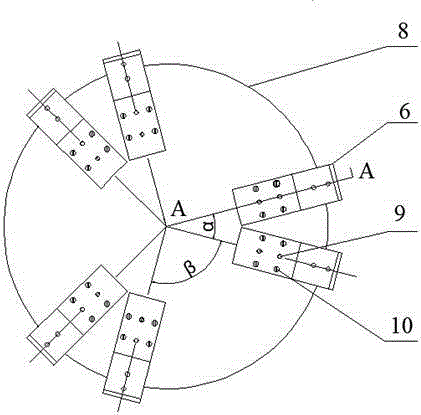

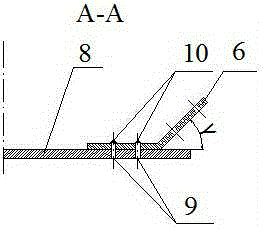

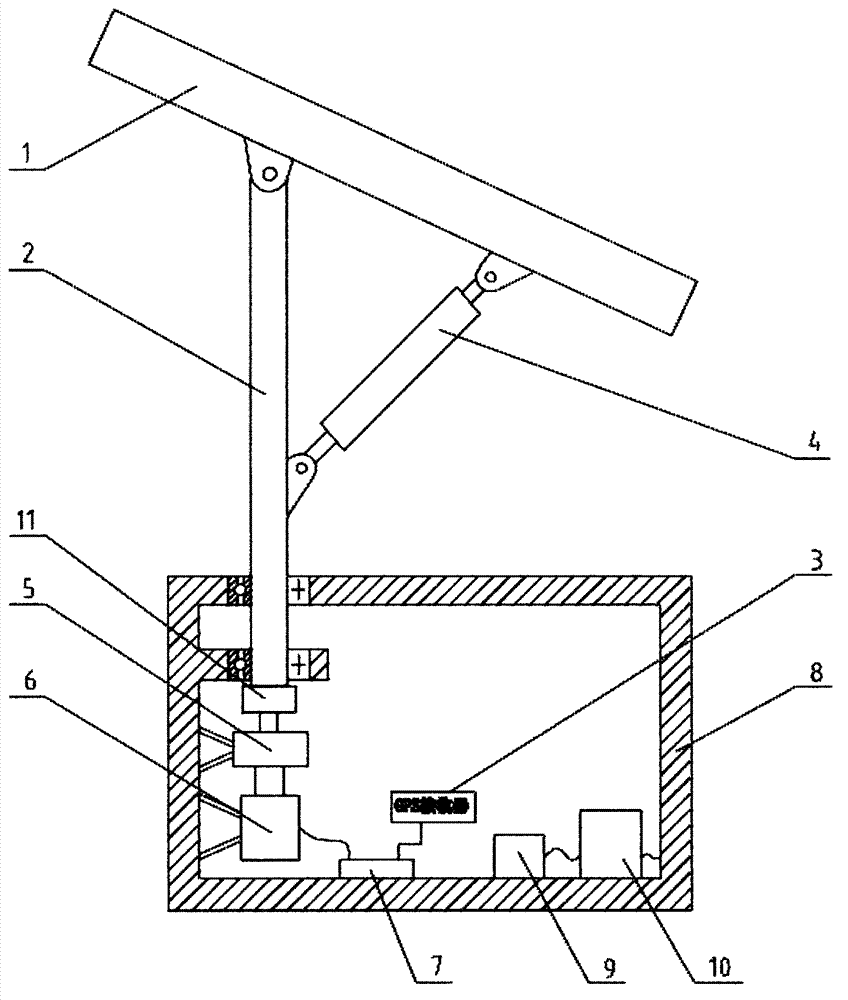

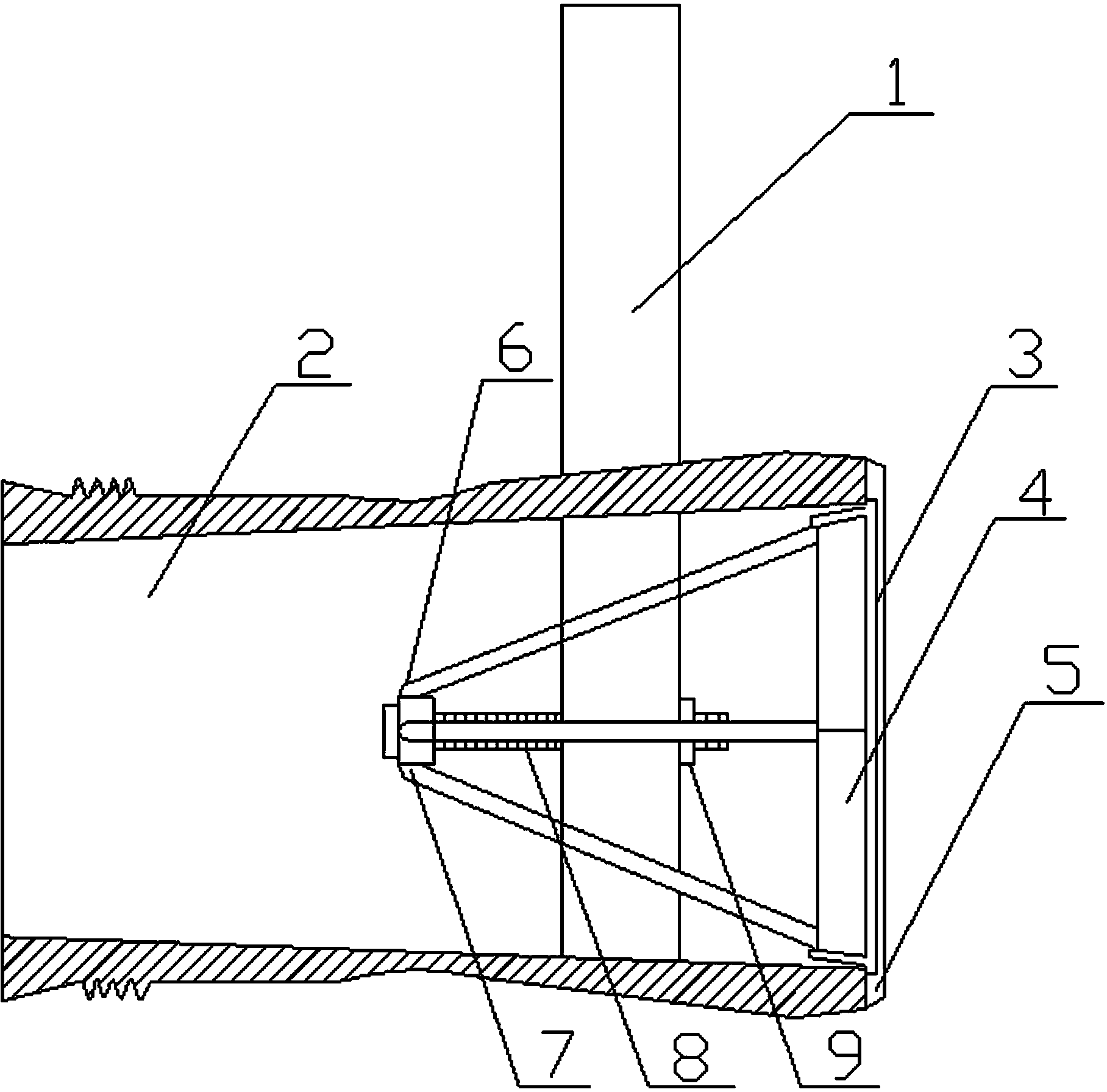

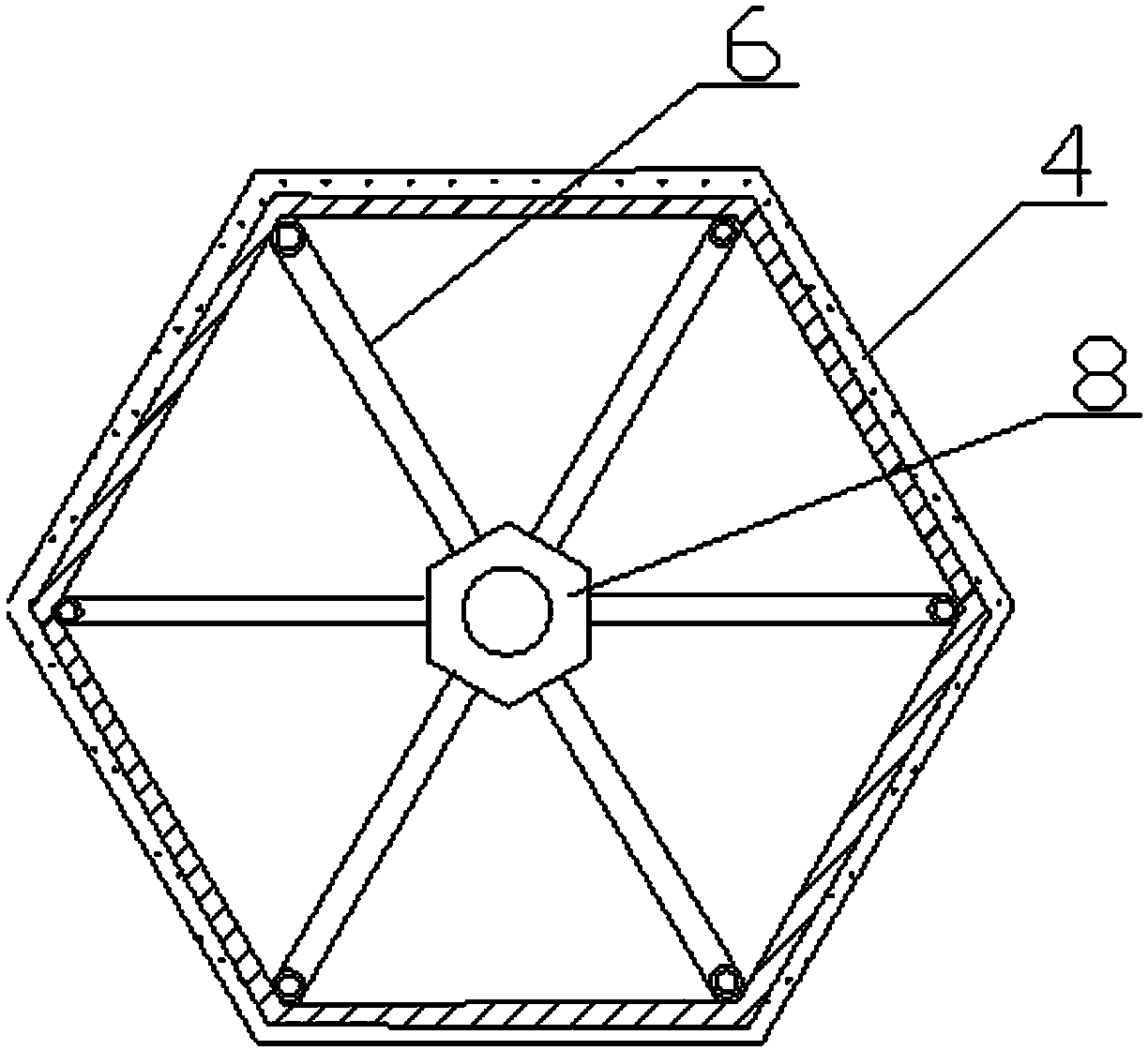

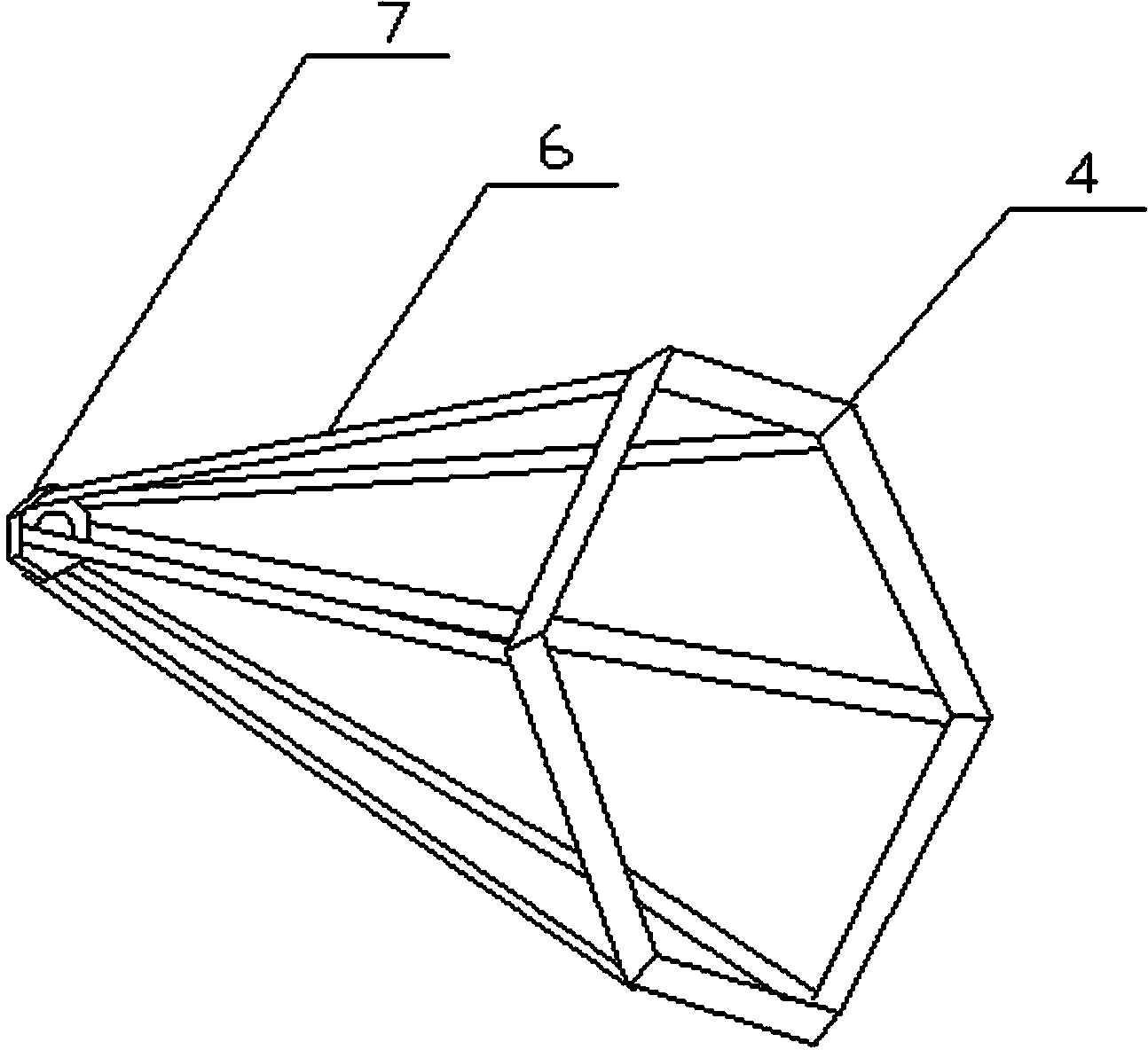

Hexagonal pyramid type six-freedom-degree parallel mechanism

InactiveCN105171728AGood turning effectHigh speedProgramme-controlled manipulatorDegrees of freedomLinear motor

The invention relates to a motion simulation device, in particular to a hexagonal pyramid type six-freedom-degree parallel mechanism. The hexagonal pyramid type six-freedom-degree parallel mechanism is formed by connecting a load platform (1), a mechanism base (8) and six sets of branch chains in parallel. Each branch chain set is composed of a hook joint (2), a connecting rod (3), a three-freedom-degree hinge (4) and a linear motor (7), wherein one end of the connecting rod (3) is connected with the load platform (1) through the hook joint (2), and the other end of the connecting rod (3) is connected with a wedge-shaped sliding block (16) of the linear motor (7) through the three-freedom-degree hinge (4). The linear motors (7) drive the connecting rods (3) through the wedge-shaped sliding blocks (16) to drive the load platform (1) to be in linkage. The hexagonal pyramid type six-freedom-degree parallel mechanism has the beneficial effects of being high in speed, precision and response speed and the like. The maximum rotating angle theta of the load platform (1) can reach 51 degrees, and automobile six-freedom-degree vibration simulation under the cross-country road situation is achieved.

Owner:YANCHENG INST OF TECH +1

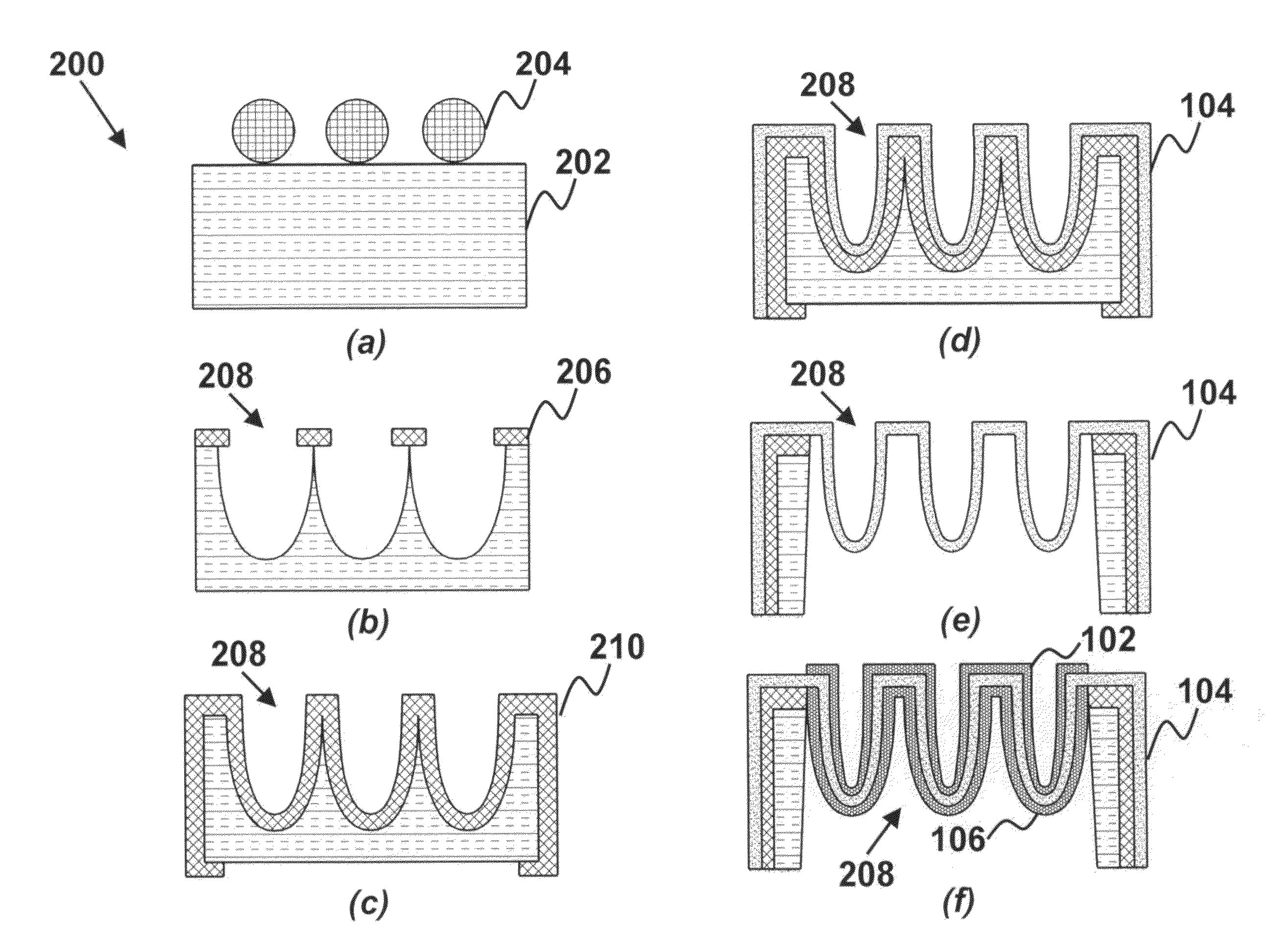

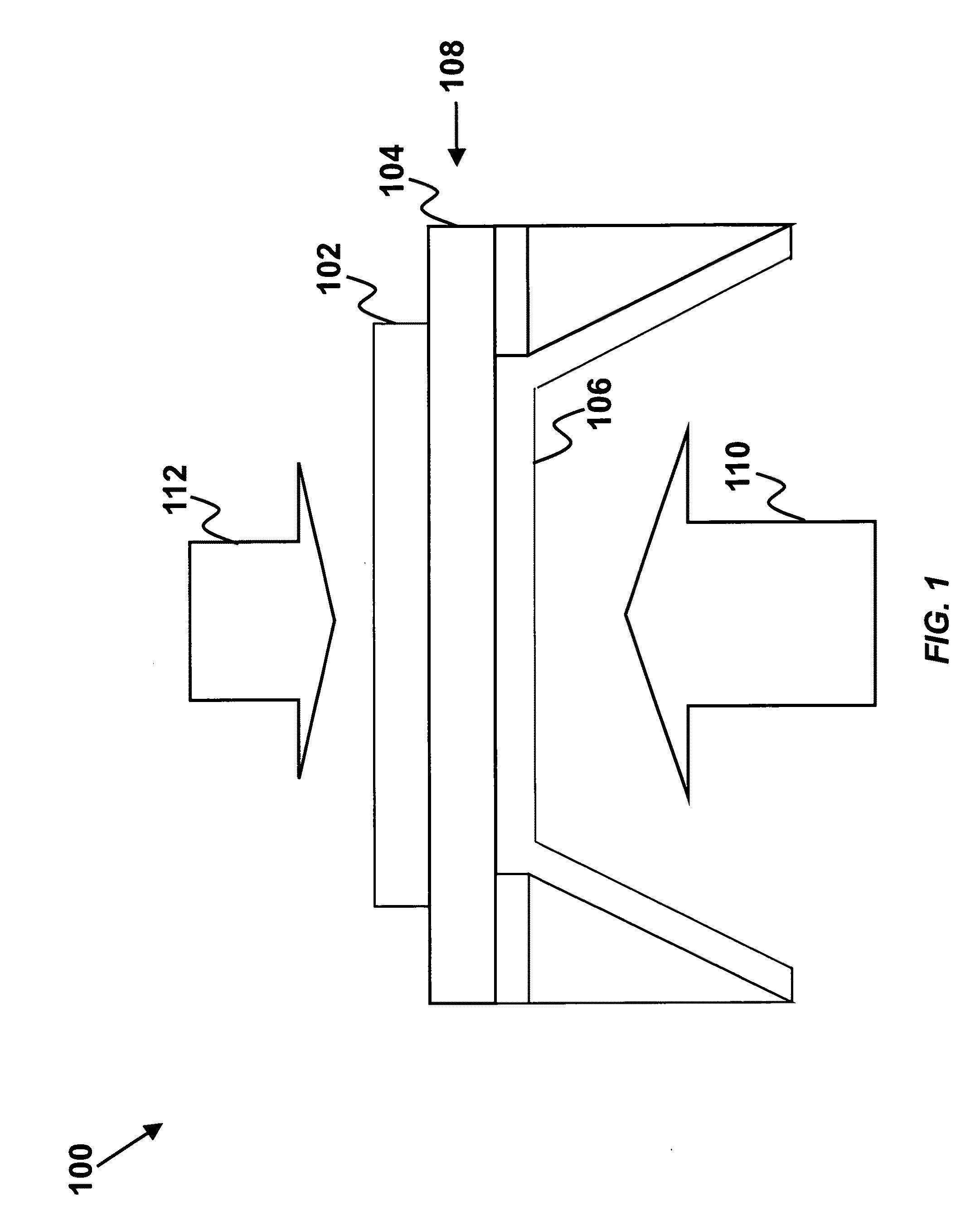

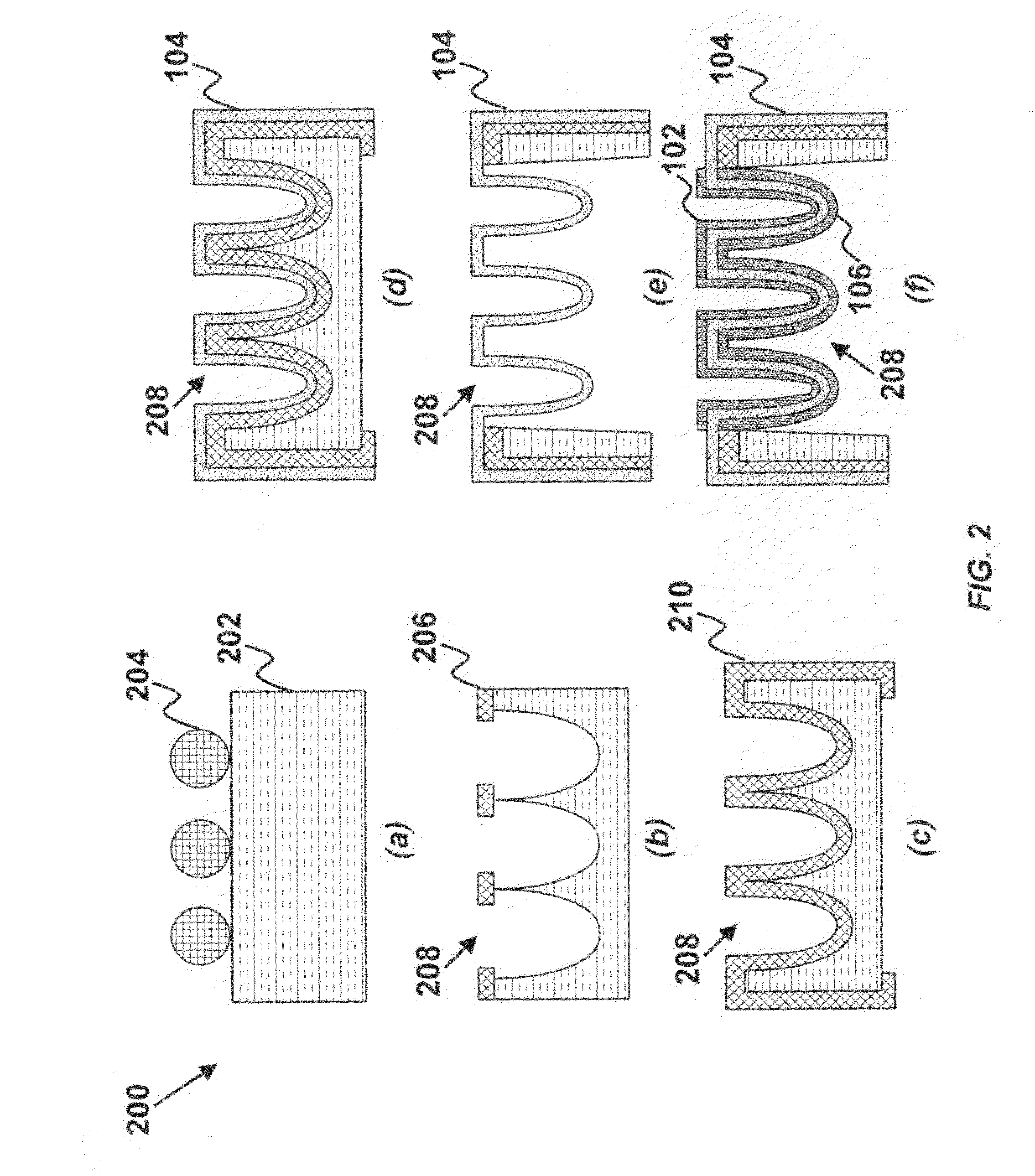

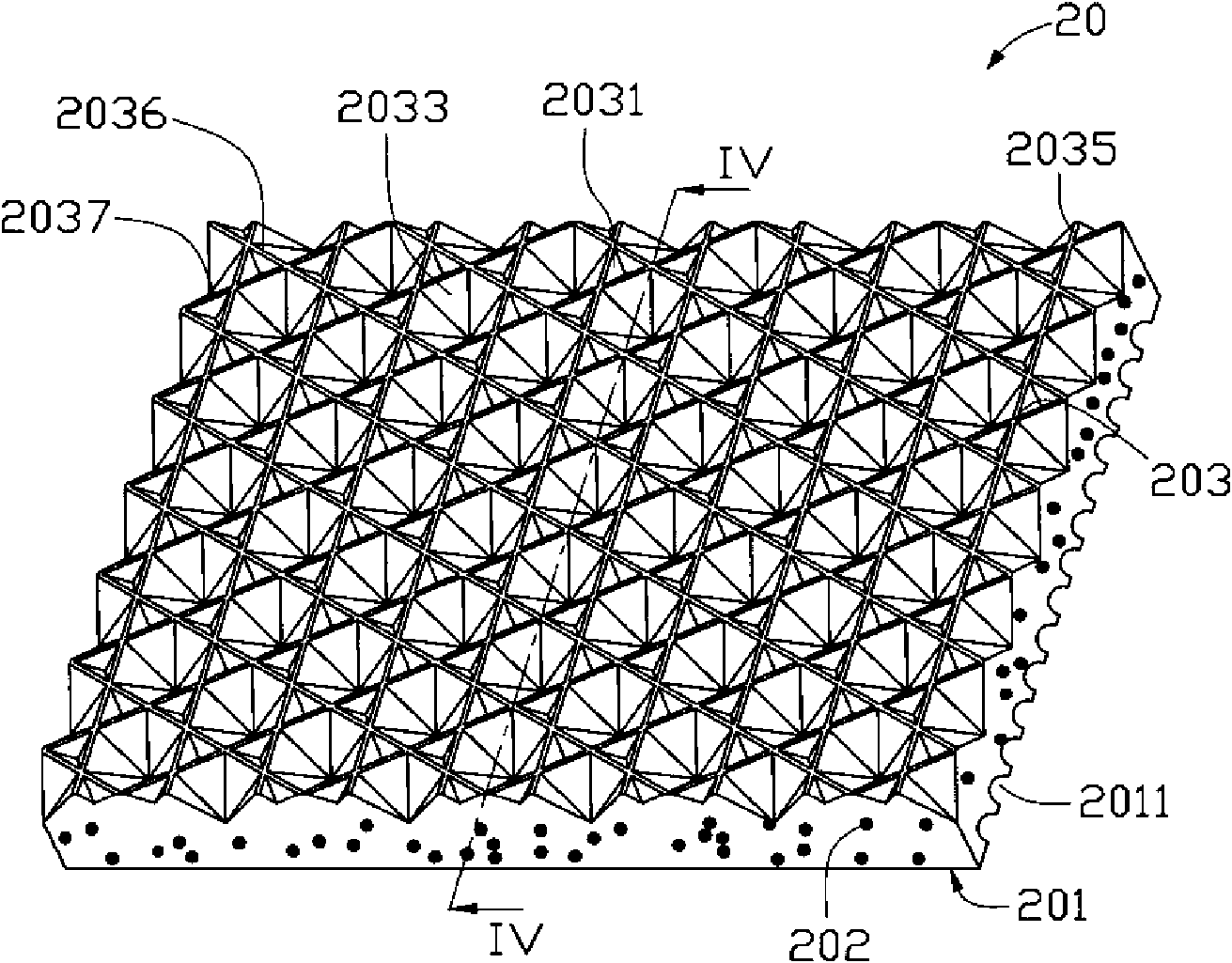

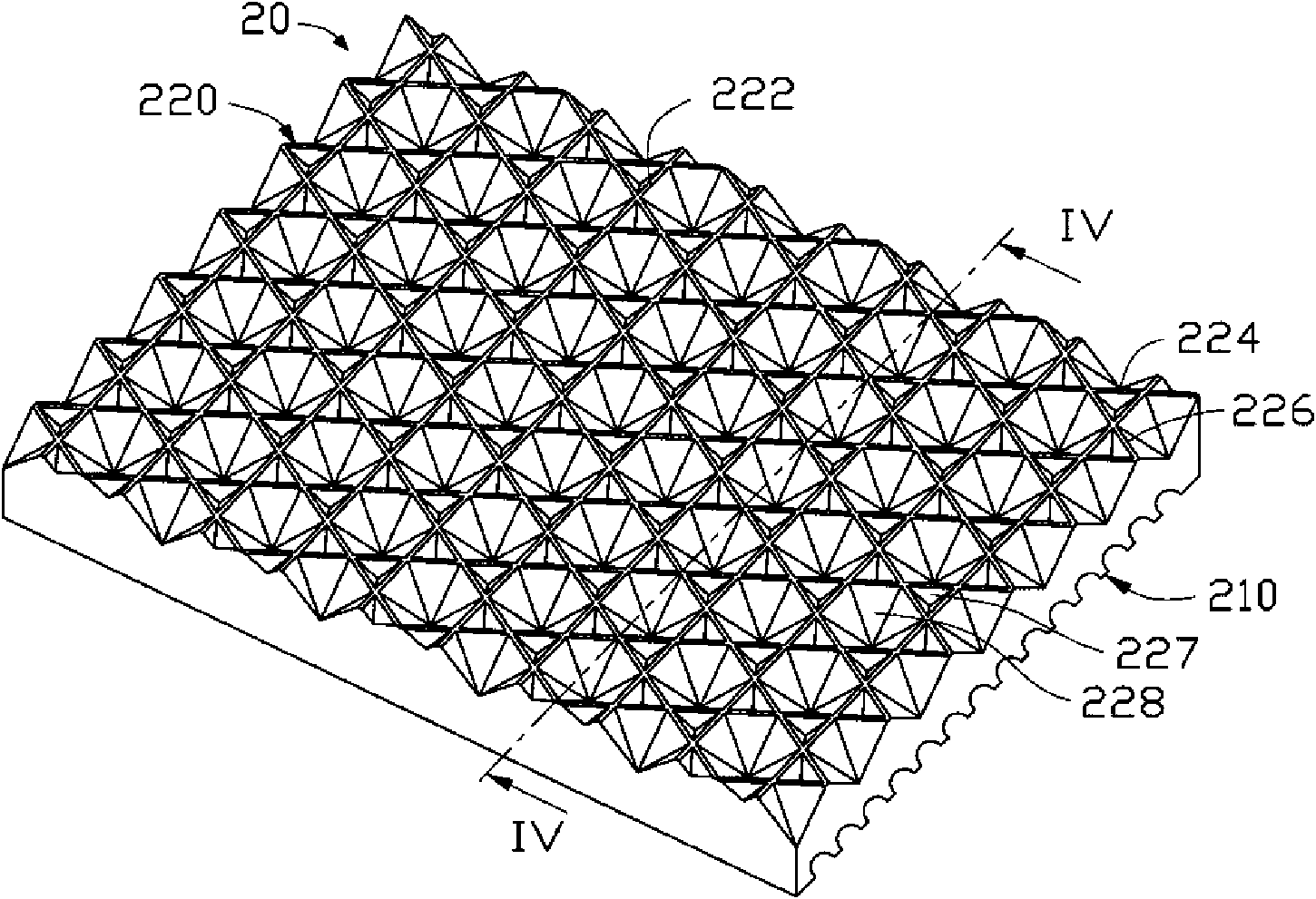

Nano-patterned electrolytes in solid oxide fuel cells

InactiveUS20110076589A1Final product manufactureActive material electrodesFuel cellsPorous electrode

A nano-patterned membrane electrode assembly (MEA) is provided, which includes an electrolyte membrane layer having a three-dimensional close-packed array of hexagonal-pyramids, a first porous electrode layer, disposed on a top surface of the electrolyte membrane layer that conforms to a top surface-shape of the three-dimensional close-packed array of hexagonal-pyramids, and a second porous electrode layer disposed on a bottom surface of said electrolyte membrane layer that conforms to a bottom surface-shape of the three-dimensional close-packed array of hexagonal-pyramids, where a freestanding nano-patterned MEA is provided.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

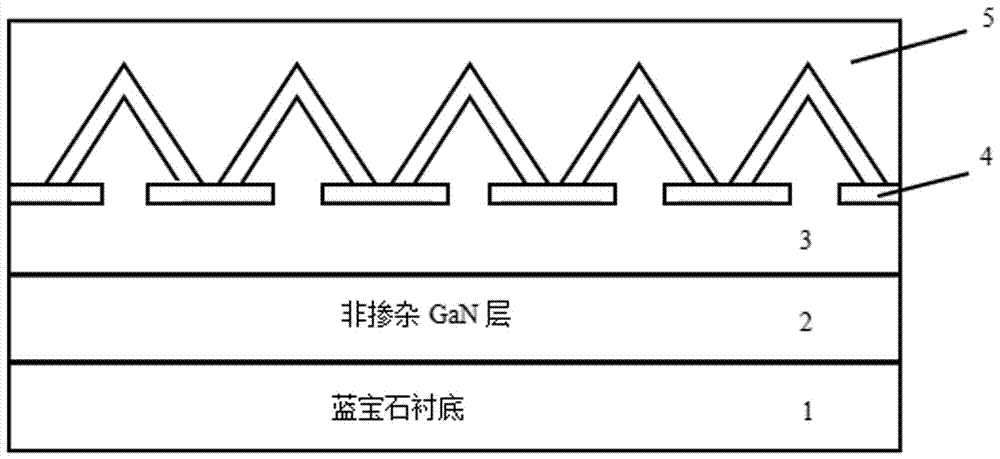

GaN hexagonal-pyramid array-based LED epitaxial structure and preparation method therefor

The invention relates to the field of a semiconductor, and discloses an LED epitaxial structure. The LED epitaxial structure comprises a substrate, a nucleating layer, a non-doped GaN layer, an n type GaN layer and a porous SiN<x> layer on the n type GaN layer, and also comprises an n type GaN hexagonal-pyramid array formed in the holes of the porous SiN<x> layer, and quantum dots on the peak of the hexagonal pyramid, quantum lines on the six ridges and a multi-quantum-well layer on six semi-polar (10-11) crystal surfaces, and a p type GaN filling layer at the tail part; and the GaN hexagonal pyramid and the quantum dots / lines / well layer at different positions thereon form the three-dimensional core-shell structure. The structure is large in light emitting area and high in light extracting efficiency; in addition, due to influences of different In contents and polarization effects and other factors, the light emitting wavelengths of the quantum dots / lines / well structures are also different; through reasonable control, white light emission can be realized; in the preparation method of the GaN hexagonal pyramid array, substrate patterning is not needed, so that the technological process is simple; and meanwhile, the grown GaN crystals are high in quality, so that the luminous efficiency of the LED can be improved effectively.

Owner:TAIYUAN UNIV OF TECH

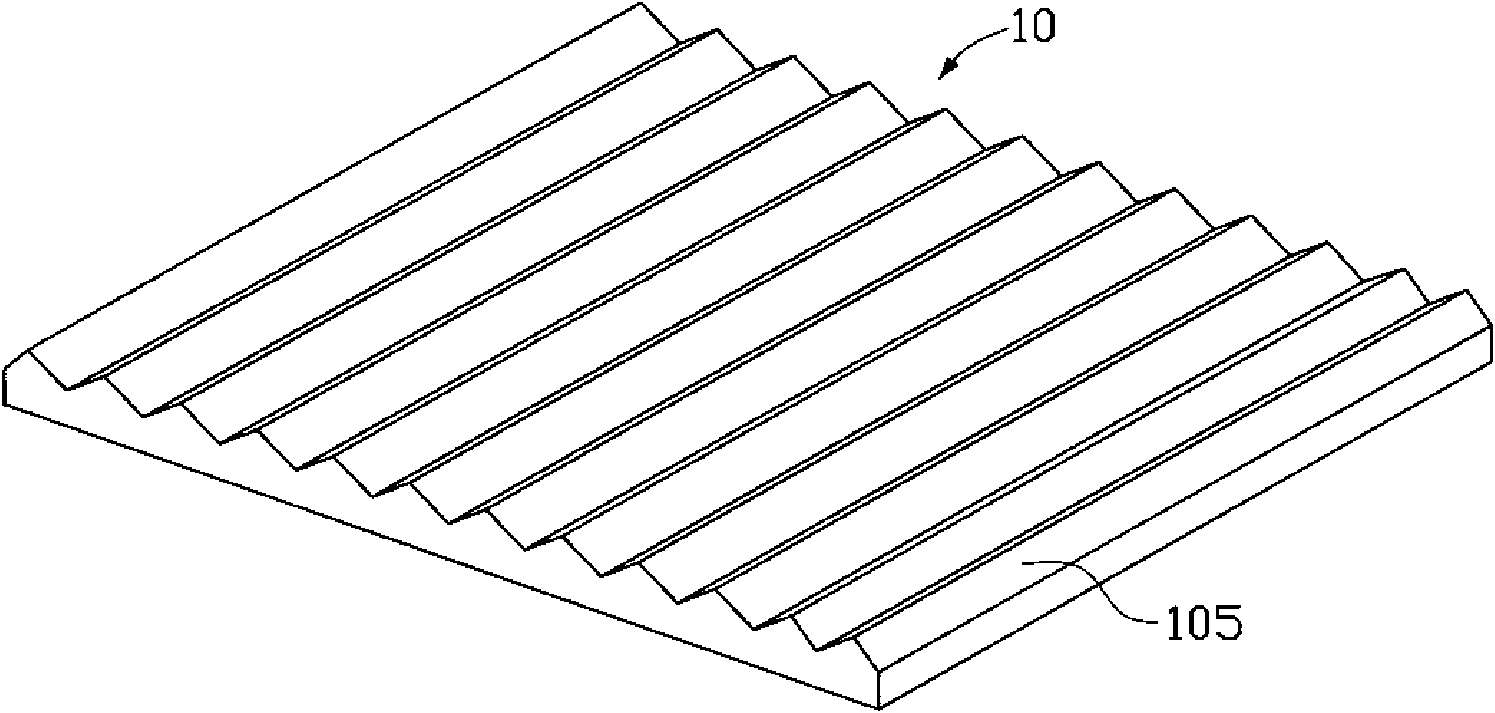

Backlight module and diffusion plate thereof

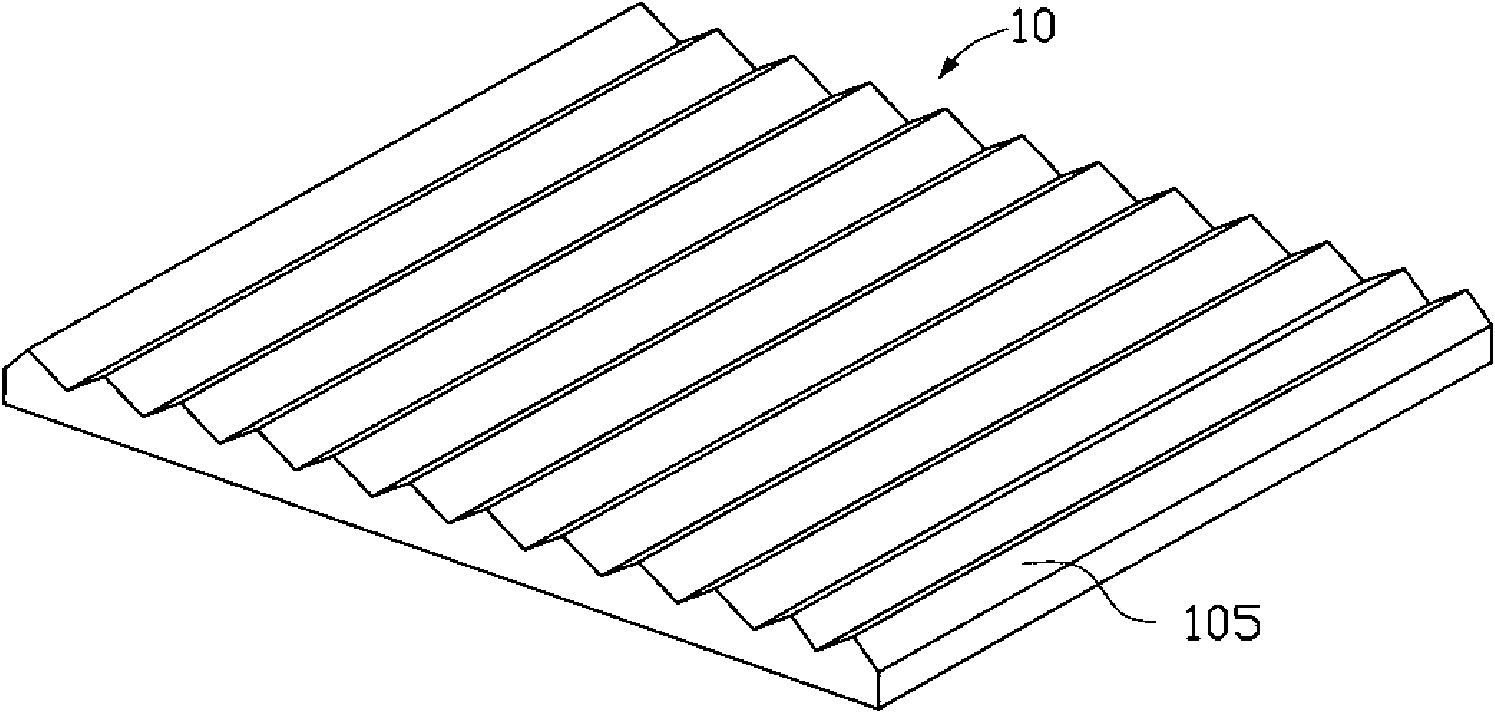

ActiveCN101625481AImprove light uniformityIncrease profitDiffusing elementsNon-linear opticsDiffusionLight emission

A backlight module comprises a frame, a light source and a diffusion plate; wherein, the light source is positioned in the frame; the diffusion plate is positioned above the light source and comprises a body; the body is made of transparent materials in which scattering particles are dispersed and comprises a first surface and a second surface opposite to the first surface; the first surface is provided with a plurality of mutually parallel long strip arc grooves; the second surface is provided with a plurality of triangular pyramid shaped grooves and hexagonal pyramid shaped grooves; each triangular pyramid shaped groove is enclosed by three adjacent hexagonal pyramid shaped grooves. The invention also provides the diffusion plate adopted by the backlight module. The backlight module has the advantages of improving effective utilization ratio of light and enjoying uniformity of light emission.

Owner:深圳市诚誉兴光电有限公司

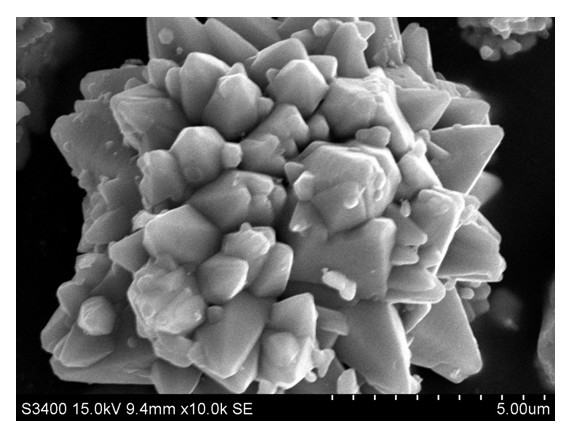

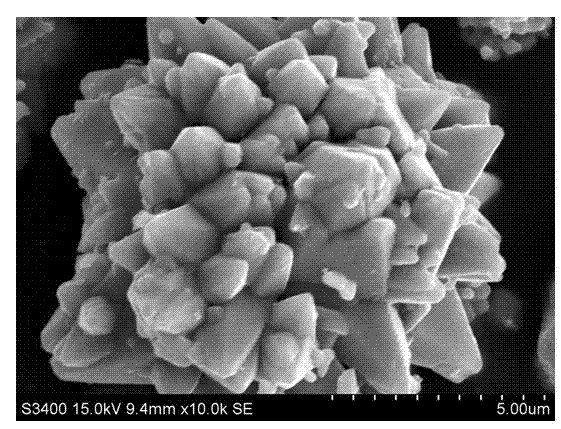

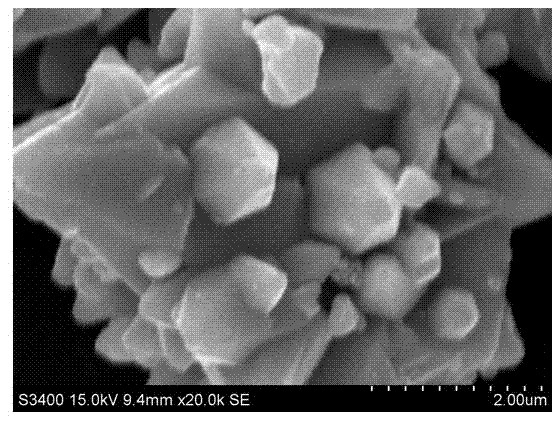

Method for preparing hexagonal pyramid-like zinc oxide by low temperature combustion synthesis method

InactiveCN102180513AGood dispersionShape is easy to controlZinc oxides/hydroxidesNanotechnologySynthesis methodsSolar battery

The invention relates to a method for preparing hexagonal pyramid-like zinc oxide by a low temperature combustion synthesis method and belongs to the field of synthesis of new materials. The method comprises the following steps: on the basis of low temperature combustion synthesis, taking zinc nitrate as a zinc source, and adding ammonium acetate and ammonium nitrate as ancillary reactive materials; mixing the zinc nitrate, the ammonium acetate and the ammonium nitrate according to the mol ratio (1:3 to 7:0.1-1.5); adding deionized water to be grinded into a colloidal substance; the mol ratiobetween the added deionized water and the ammonium acetate is 1:1; ultrasonically dispersing the colloidal substance for 5 minutes with an ultrasonic processor with power of 150 W and frequency of 20kHz, and then putting the colloidal substance into a muffle furnace for combustion synthesis at the temperature of 550-650 DEG C; and grinding and annealing the obtained powder for 3 hours at the temperature of 400-700 DEG C, namely, obtaining the hexagonal pyramid-like zinc oxide. The method can achieve the purpose of controllably preparing the hexagonal pyramid-like zinc oxide, is simple, convenient and rapid in process and less in energy consumption and is suitable for large-scale industrial production, and the obtained zinc oxide powder is widely used for various fields such as microelectronic devices, solar batteries, optical devices, etc.

Owner:舟山市质量技术监督检测院

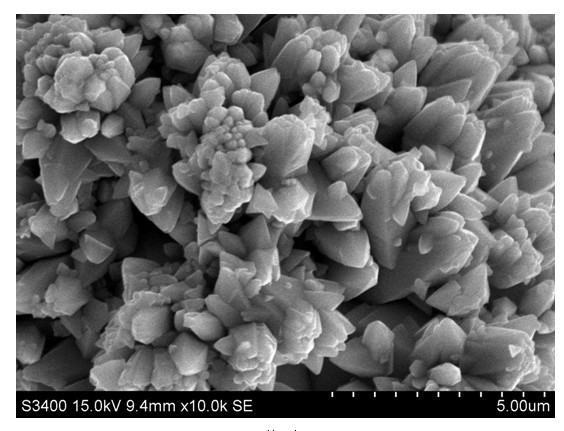

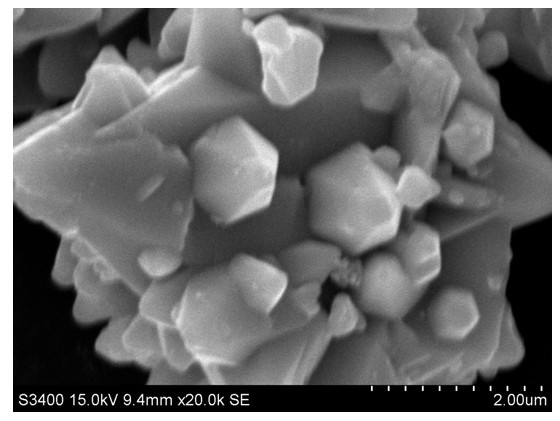

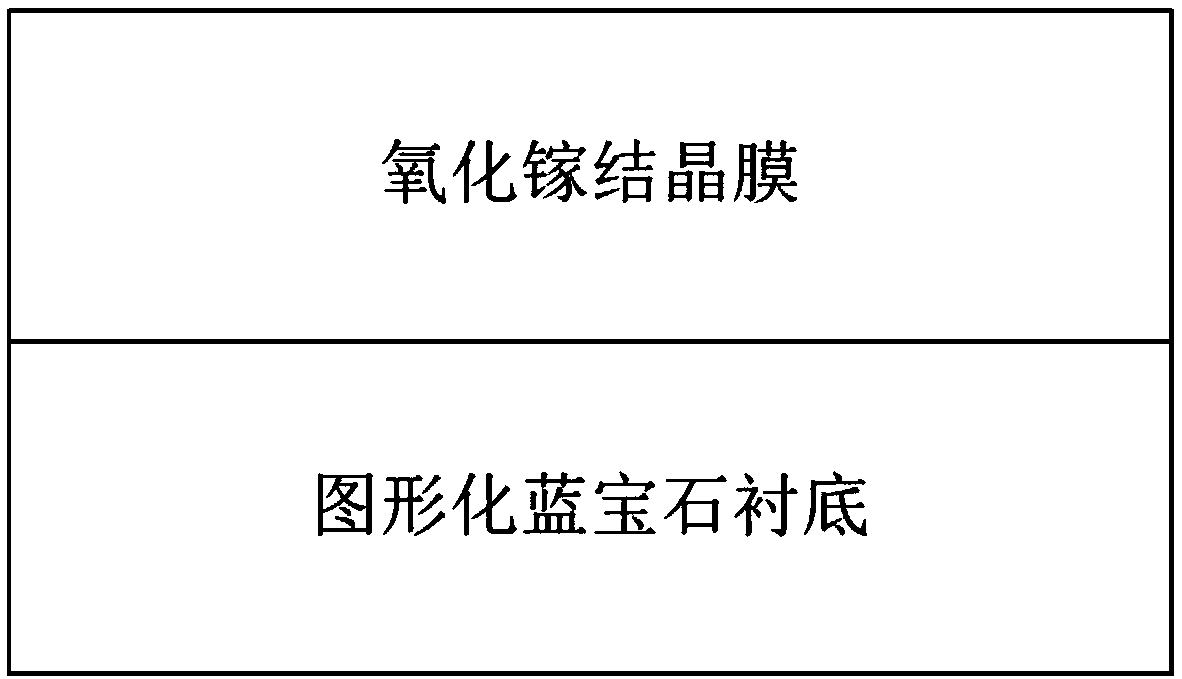

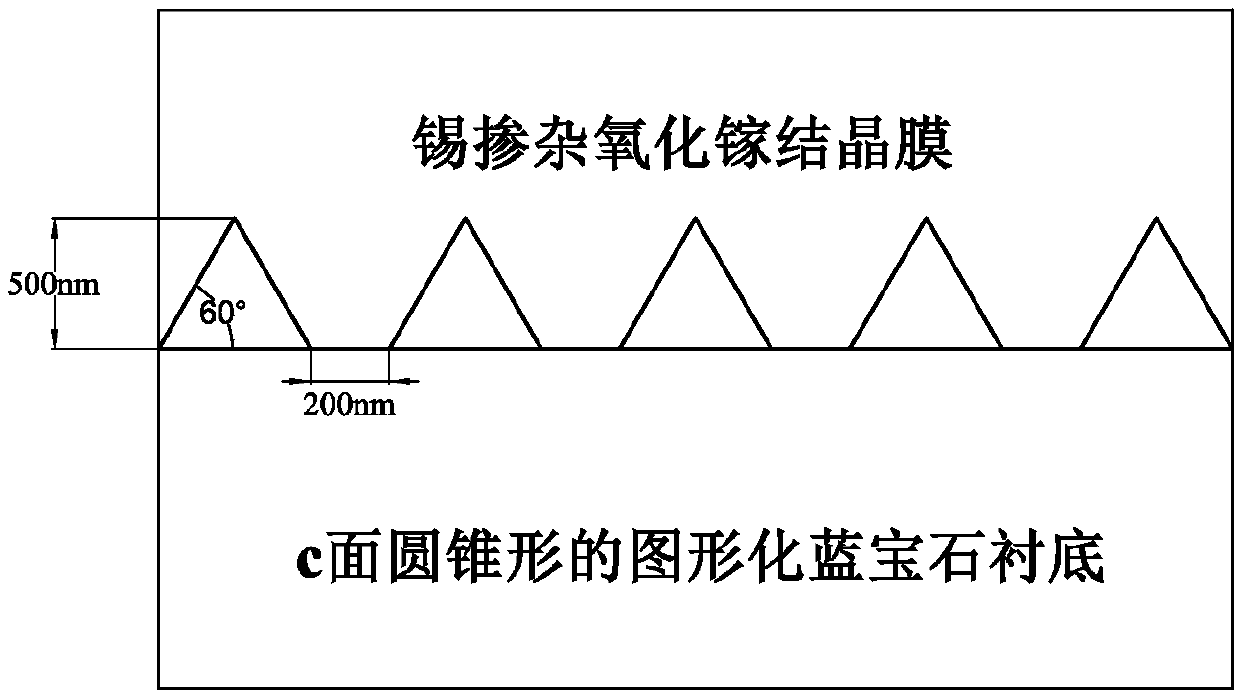

Gallium oxide semiconductor laminated structure and preparation method thereof

ActiveCN109659411AImprove growth advantageInhibition formationSemiconductor devicesMicrometerSemiconductor

The invention provides a gallium oxide semiconductor laminated structure. The gallium oxide semiconductor laminated structure comprises a patterned sapphire substrate and a gallium oxide crystal filmgrown on the patterned sapphire substrate. The gallium oxide is pure-phase or pure-phase gallium oxide. An actual surface and a c crystal face of the patterned sapphire substrate have a deviation angle of 0-10 degrees, and the thickness of the patterned sapphire substrate is 400 micrometers to 2 millimeters. The graphical sapphire substrate is in one of a groove shape, a hexagon shape, a trilateral shape, a hemisphere shape, a cone shape, a pyramid shape, a circular truncated cone shape, a hexagonal pyramid shape, a triangular pyramid shape or a triangular truncated cone shape or more, and theheight of the graphical structure is 100 nanometers to 2 micrometers. According to the invention, the problem that a mixed phase is easily generated in the process of growing a phase or phase galliumoxide on a heterogeneous substrate is solved, and pure-phase gallium oxide or pure-phase gallium oxide can be obtained on the heterogeneous substrate.

Owner:上海您惦半导体科技有限公司

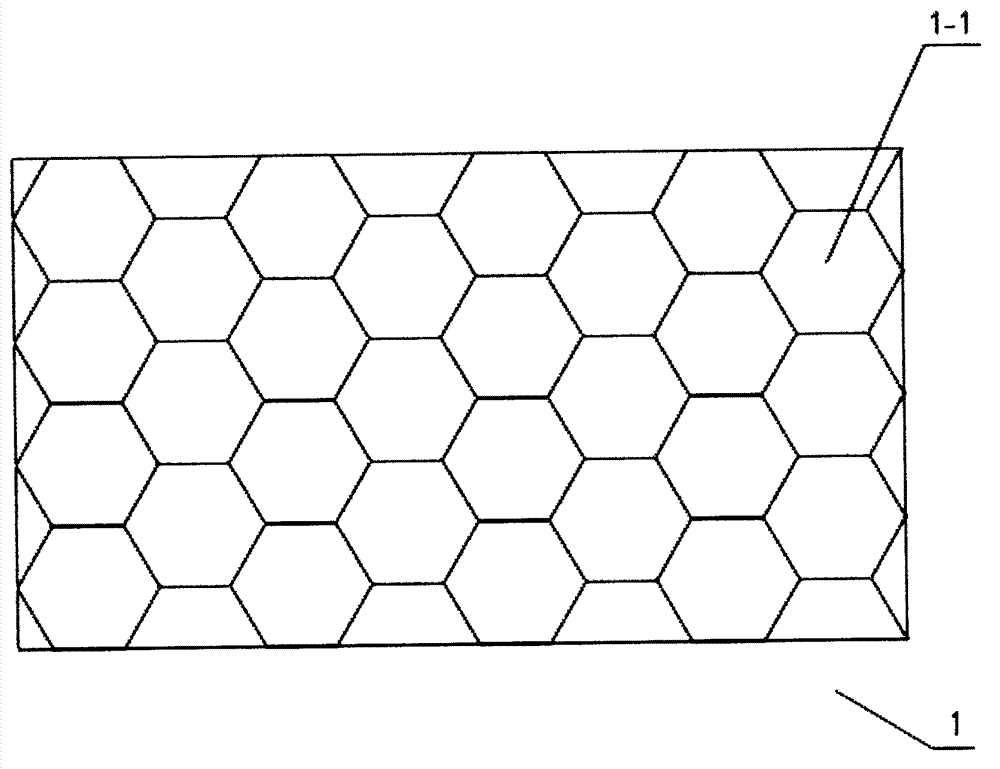

Honeycomb type solar energy collecting device

InactiveCN103034245AImprove utilization efficiencyIncrease light receiving areaPhotovoltaic supportsBatteries circuit arrangementsHoneycombAngle alpha

The invention discloses a honeycomb type solar energy collecting device which comprises a solar energy lighting plate, a connecting shaft, a supporting frame, a sun following control device and a driving device. The sun following control device is capable of enabling the solar energy lighting plate to face the sun, and the driving device drives the connecting shaft to rotate. The solar energy lighting plate is formed by a plurality of lighting bodies in a three-dimensional arrangement mode, and the cross section of each lighting body is a regular hexagon. The lighting bodies are formed by regular six pyramid bodies and the opening formed upwardly and regular hexagonal pyramid bodies on bottom in a connecting mode. The column length L1 of each regular six pyramid body is 1.15 times to 1.5 times of the side length L2 of the regular hexagon, two opposite cylinder surfaces of each regular six pyramid body are respectively a photovoltaic cell piece and a high-reflection lens. Six sides of each regular hexagonal pyramid body are high-reflection lenses, an inclined angle alpha is formed between one pyramidal surface and one opposite cylinder surface of each regular six pyramid body, and the alpha is 109 degrees. An inclined angle between two opposite pyramidal surfaces of each regular hexagonal pyramid body is 142 degrees. The honeycomb type solar energy collecting device is capable of always enabling the lighting plate to face the sun at a certain angle, and improving solar energy utilization rate to the maximum.

Owner:张卫平

Method for preparing hexagonal pyramid-like zinc oxide by low temperature combustion synthesis method

InactiveCN102180513BGood dispersionShape is easy to controlZinc oxides/hydroxidesNanotechnologySolar batteryZinc nitrate

The invention relates to a method for preparing hexagonal pyramid-like zinc oxide by a low temperature combustion synthesis method and belongs to the field of synthesis of new materials. The method comprises the following steps: on the basis of low temperature combustion synthesis, taking zinc nitrate as a zinc source, and adding ammonium acetate and ammonium nitrate as ancillary reactive materials; mixing the zinc nitrate, the ammonium acetate and the ammonium nitrate according to the mol ratio (1:3 to 7:0.1-1.5); adding deionized water to be grinded into a colloidal substance; the mol ratio between the added deionized water and the ammonium acetate is 1:1; ultrasonically dispersing the colloidal substance for 5 minutes with an ultrasonic processor with power of 150 W and frequency of 20 kHz, and then putting the colloidal substance into a muffle furnace for combustion synthesis at the temperature of 550-650 DEG C; and grinding and annealing the obtained powder for 3 hours at the temperature of 400-700 DEG C, namely, obtaining the hexagonal pyramid-like zinc oxide. The method can achieve the purpose of controllably preparing the hexagonal pyramid-like zinc oxide, is simple, convenient and rapid in process and less in energy consumption and is suitable for large-scale industrial production, and the obtained zinc oxide powder is widely used for various fields such as microelectronic devices, solar batteries, optical devices, etc.

Owner:舟山市质量技术监督检测院

Tunnel reflecting material and preparation method thereof

ActiveCN104847376ASimple processing technologyReduce manufacturing costCovering/liningsUnderground chambersProtection layerEnergy conservation

The invention discloses a tunnel reflecting material and a preparation method thereof. The tunnel reflecting material comprises a baseplate, triangular pyramid, hexagonal pyramid or octagonal pyramid protrusions are arranged on one side face of the baseplate, the side face of the baseplate and the surfaces of the protrusions are sprayed with a color layer, the surface of the color layer is sprayed with a reflecting layer, and the surface of the reflecting layer is sprayed with a transparent protection layer. The tunnel reflecting material is simple in processing process, low in manufacture cost, long in service life and energy saving and mainly applied to tunnels, roads and places with the requirement on improvement of reflecting effect and illumination brightness.

Owner:SICHUAN JIEBANG SCI & TECH CO LTD

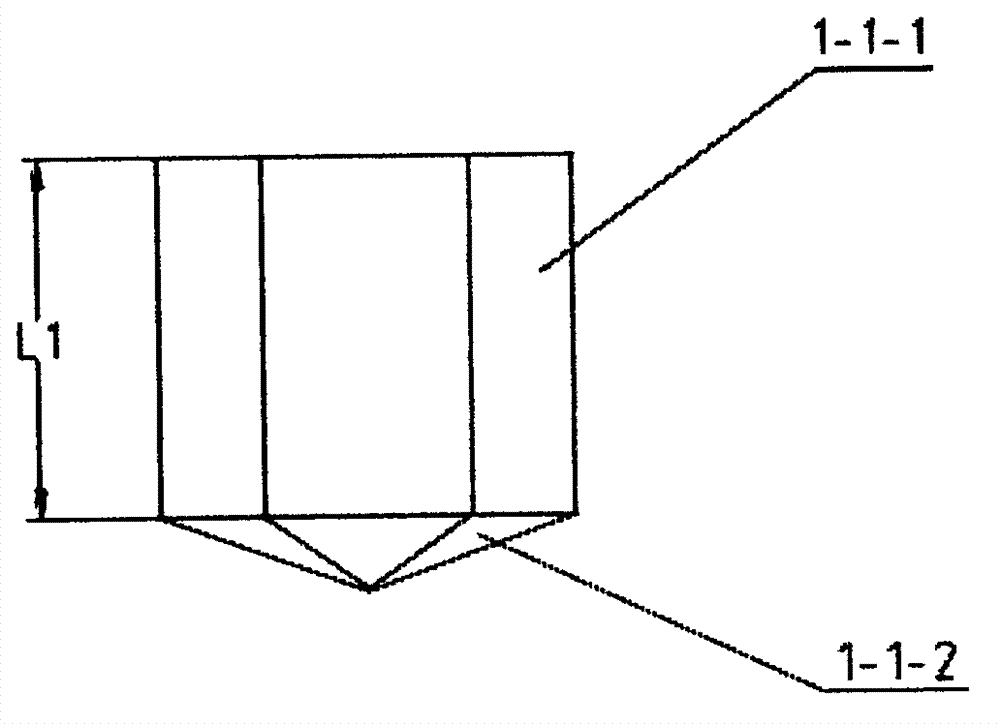

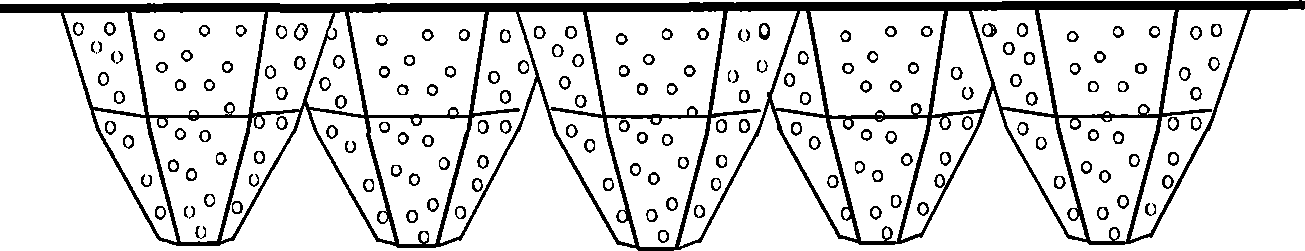

Stoup body seedling cultivation disk with micropore and hexagonal pyramid bottom

InactiveCN101485267AIncrease supplyMeet growth nutrient needsCultivating equipmentsBody shapeNetwork structure

The invention relates to a micropore hexagonal pyramid bottom bowl body seedling culture tray for crop seedling culture. A plurality of micropore hexagonal pyramid bottom bowl bodies sharing the same shape are closely arranged in the form of a matrix on a plane; and the periphery of the tray is reinforced by a tray frame. The tray face is a network structure formed by a plurality of open-ended hexagons; the bowl mouth is hexagonal; a plurality of micropores are arranged on the bowl wall and bowl bottom; the upper part of the bowl body is hexagonal prismoid-shaped; the lower part of the bowl body has a plurality of shapes such as a hexagonal prismoid cone, a sharp hexagonal pyramid, a truncated cone, a circular cone, a sharp circular cone, and the like; each bowl body shape can be one product. The tray can contain a great amount of soil; the micropores on the bowl wall enable the water fertilizer in the seedbed to infiltrate into the bowl body and be absorbed by seedlings during seedling raising, thereby enlarging the nutrient supply amount, reaching the aim of raising the big and strong seedlings, and facilitating the production and income improvement. The tray is suitable for seedling culture of various crops and is applied to soft and hard soil. The tray which has good agricultural performance can be easily pressed into the soil and save time and labor. The bottom of the tray is not easily broken and the tray is durable. As the tray is made by plastics, the tray has simple processing and lower cost.

Owner:杨庚 +1

Nitride semiconductor light emitting device array

InactiveUS8587005B2Maximize the light emitting areaConvenient ArrangementSemiconductor devicesActive layerDielectric layer

A nitride semiconductor light emitting device array, which includes a dielectric layer formed on a first conductivity lower nitride semiconductor layer, having a plurality of windows. Each of a plurality of hexagonal pyramid light emission structures is grown from a surface of the first conductivity lower nitride semiconductor layer exposed through each of the windows and onto a peripheral area of the window of the dielectric layer. Each of the hexagonal pyramid light emission structures includes a first conductivity upper nitride semiconductor layer, an active layer and a second conductivity nitride semiconductor layer formed in their order. The windows are disposed in such a triangular arrangement that side surfaces of the adjacent hexagonal pyramid light emission structures face each other. Also, a distance between bases of the adjacent hexagonal pyramid light emission structures is less than 0.3 times an interval between centers of the windows of the adjacent hexagonal pyramid light emission structures.

Owner:SAMSUNG ELECTRONICS CO LTD

Backlight module and optical plate thereof

InactiveCN101625434AIncrease profitReduce or even avoid afterimageOptical light guidesNon-linear opticsEngineeringLight emission

An optical plate comprises a transparent body which comprises a first surface and a second surface opposite to the first surface; wherein, the first surface is provided with a plurality of mutually parallel long strip arc grooves; the second surface is provided with a plurality of triangular pyramid shaped grooves and hexagonal pyramid shaped grooves; each triangular pyramid shaped groove is enclosed by three adjacent hexagonal pyramid shaped grooves. A backlight module has the advantages of improving effective utilization ratio of light and enjoying uniformity of light emission. The invention also provides the backlight module adopting the optical plate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Selective growth method, nitride semiconductor light emitting device and manufacturing method of the same

ActiveUS20080035951A1Relieve pressureGood effectPolycrystalline material growthSemiconductor/solid-state device manufacturingStress relievingCrystal plane

A method for selectively growing a nitride semiconductor, in which a mask is formed, with an opening formed therein, on a nitride semiconductor layer. A nitride semiconductor crystal is selectively grown on a portion of the nitride semiconductor layer exposed through the opening in the mask, the nitride semiconductor crystal shaped as a hexagonal pyramid and having crystal planes inclined with respect to a top surface of the nitride semiconductor. Here, the nitride semiconductor crystal has at least one intermediate stress-relieving area having crystal planes inclined at a greater angle than those of upper and lower areas of the nitride semiconductor crystal, the intermediate stress-relieving area relieving stress which occurs from continuity in the inclined crystal planes.

Owner:SAMSUNG ELECTRONICS CO LTD

Nitride semiconductor device and method for producing the same

ActiveUS9515219B2Large thicknessReduce layeringSemiconductor/solid-state device manufacturingSemiconductor devicesCrystal structureFrustum

A method for producing a nitride semiconductor device. The method comprises providing a substrate made of a material other than a nitride semiconductor. The material has a hexagonal crystal structure. An upper face of the substrate has at least one flat section. The method further comprises growing a first nitride semiconductor layer on the upper face of the substrate. The first nitride semiconductor layer is made of monocrystalline AlN. The first nitride semiconductor layer has an upper face that is a +c plane. The first nitride semiconductor layer has a thickness in a range of 10 nm to 100 nm. The method further comprises growing a second nitride semiconductor layer on the upper face of the first nitride semiconductor layer. The second nitride semiconductor layer is made of InXAlYGa1-X-YN (0≦X, 0≦Y, X+Y<1). In an initial stage of growing the second nitride semiconductor layer, micronuclei are formed in multiple locations on the upper face of the first nitride semiconductor layer such that a plurality of upside-down hexagonal pyramid-shaped or upside-down hexagonal frustum-shaped recesses separate the micronuclei above the at least one flat section of the upper face of the substrate. After the initial stage of growing, further growth is performed to reduce a size of the recesses until the recesses are substantially eliminated. The further growth is performed such that the recesses are substantially eliminated before a thickness of the second nitride semiconductor layer grows to 800 nm. The second nitride semiconductor layer is grown to have an upper face with at least one flat section.

Owner:NICHIA CORP

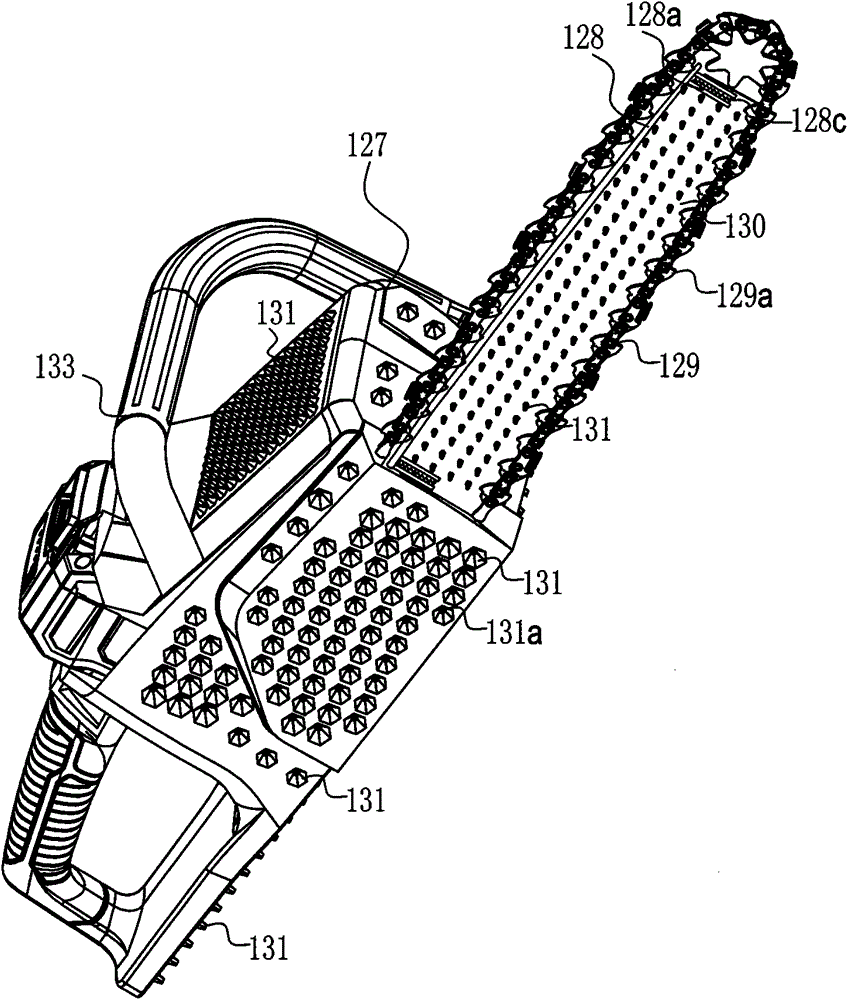

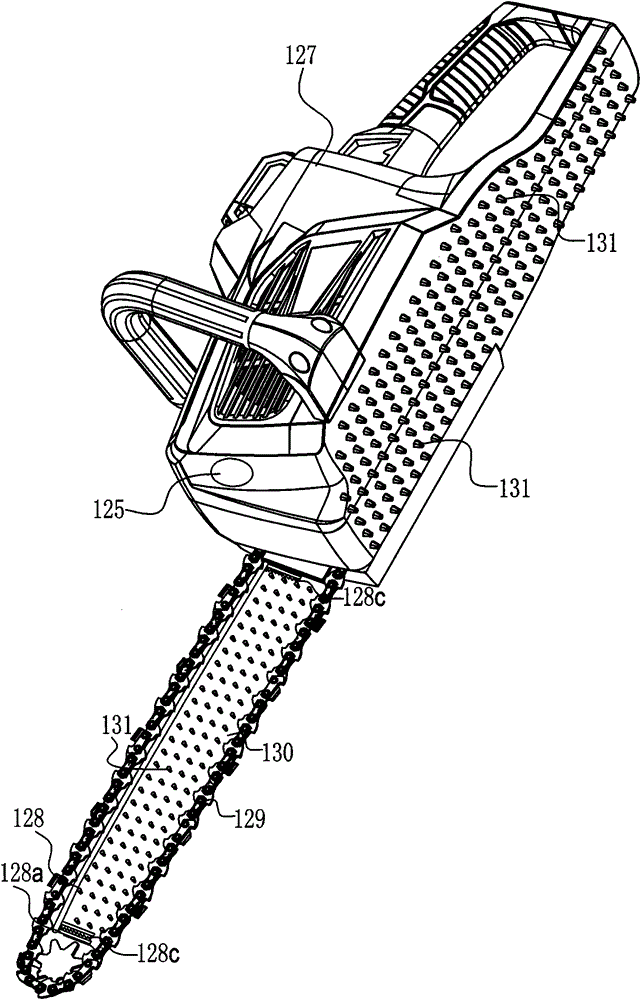

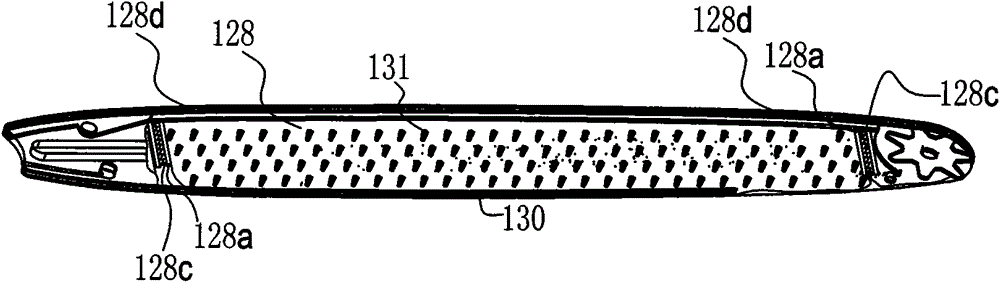

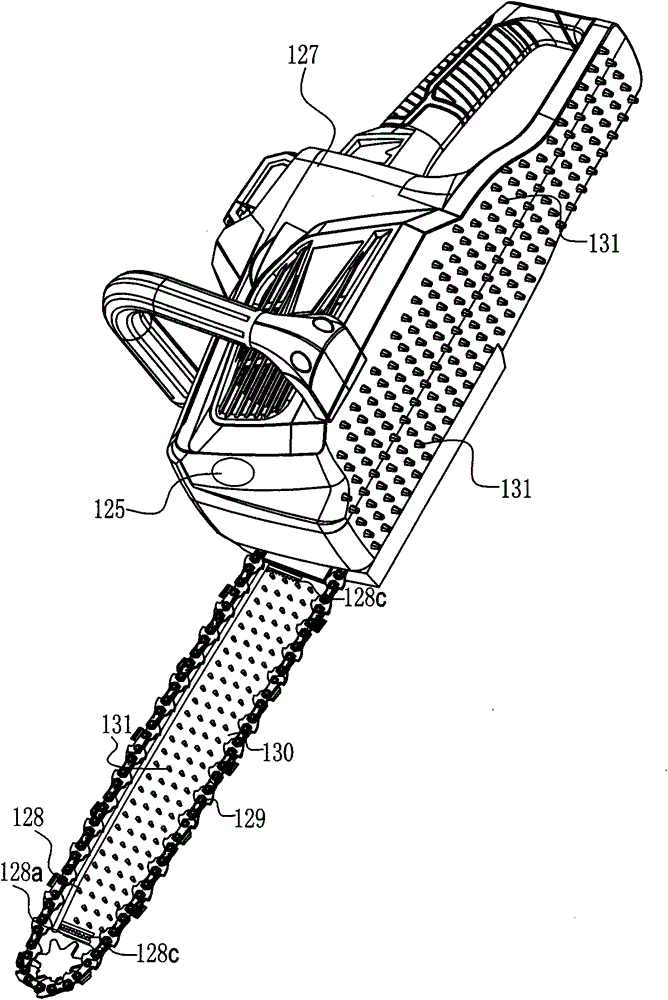

Lithium-ion chain saw containing cubic parabola for reducing impact

The invention provides a lithium-ion chain saw containing a cubic parabola for reducing impact. The lithium-ion chain saw comprises a machine body (127) with a wedge, a machine cover (127a) with the wedge, and a following chain saw bracket (128) with the wedge and the cubic parabola; the wedges are hollow hexagonal pyramid bodies (131) with small through holes (131a) formed in the top parts; a sound absorbing piece (131c) is adhered on the bottom surface of each hollow hexagonal pyramid body with the small through holes; a plurality of micro pores (131f) in the sound absorbing pieces are respectively corresponding to the small through holes, and thereby, a muffling and noise reducing cavity is formed; with the adoption of the muffling and noise reducing cavity, noise flowing into the micro pores is compressed into a muffling cavity of each hollow hexagonal pyramid body to be expanded and then is discharged through small through holes; a vibration absorbing handle (133) is arranged at the outer part of the machine body; a foam polyurethane pipe sleeves a hollow plastic pipe by the method of extending a compressed air gun in a gap between the plastic pipe and the foam polyurethane pipe to feed as blowing; the curvature of the cubic parabola at point (0, 0) is known as zero, the same to the curvature of a straight line; a function bracket strip (128d) containing the cubic parabola of the following chain saw bracket is manufactured through spring steel plates by normalizing heat treatment.

Owner:NINGBO DAYE GARDEN EQUIP

Light-emitting diode with strain-relaxed layer

ActiveUS20120305888A1Semiconductor/solid-state device manufacturingSemiconductor devicesActive layerLight-emitting diode

Disclosed is a light-emitting diode (LED) and the method to form the LED. The LED comprises: a first conductivity type semiconductor layer; a strain-relaxed layer over the first conductivity type semiconductor layer, the strain-relaxed layer comprising: a strain-absorbed layer over the first conductivity type semiconductor layer, the strain-absorbed layer containing a plurality of cavities in a substantial hexagonal-pyramid form; and a surface-smoothing layer on the strain-absorbed layer filling the cavities; an active layer over the strain-relaxed layer; and a second conductivity type semiconductor layer over the active layer.

Owner:EPISTAR CORP

Lithium electric chain saw provided with logarithmic spiral for steady regulation

ActiveCN104094781AEasy to operate in batchesReduce shockCuttersCutting implementsNoise reductionFuselage

A lithium electric chain saw provided with a logarithmic spiral for steady regulation comprises a body (127) provided with wedges, a cover (127a) provided with the wedges, a follow-up chain saw stent (128) provided with the wedges and a cubic parabola, wherein each wedge is a hollow hexagonal pyramid (131) with a small through hole (131a) in the top; a sound-absorbing piece (131c) is pasted on the bottom face of the hollow hexagonal pyramid with the small through hole of each wedge; multiple pores (131f) are formed in the sound-absorbing pieces and are in one to one correspondence with the small holes to form sound-absorbing chambers through which noise enters the pores to be compressed into the hollow hexagonal pyramids, and sound-absorbing noise reduction chambers through which noise is expanded and then escapes from the small through holes; a damping handle (133) is arranged outside the body, a foamed polyurethane pipe sleeves a hollow plastic pipe, and the method of sleeving the foamed polyurethane pipe is that a pneumatic gun nozzle with compressed air extends into a pipe gap between the plastic pipe and the foamed polyurethane pipe, and blowing and sleeving are performed simultaneously. As generally known, the curvature of the cubic parabola at the point (0, 0) and the curvature of the line are both zero, and a material of a function stent bar (128d) provided with the cubic parabola of the follow-up chain saw stent adopts a steel spring plate, and is subjected to normalization heat processing.

Owner:NINGBO DAYE GARDEN EQUIP

Novel erhu tuner

InactiveCN103413543ASimple structureEasy tuning operationStringed musical instrumentsEngineeringHexagonal pyramid

The invention discloses a novel erhu tuner. The novel erhu tuner is fixed to a rod in a neck in a sound box, is a regular hexagonal pyramid, and comprises a regular hexagonal metal ring, six metal bars fixed to six corners of the regular hexagonal metal ring and a nut I fixedly connected with the other end of each metal bar. The regular hexagonal metal ring abuts on the inner side of the end portion of the sound box; fur covers the end portion, provided with the regular hexagonal metal ring, of the erhu sound box in a fixed mode. The novel tuner is connected with and fixed to a nut II on the neck in a threaded mode through a bolt penetrating through the neck. The novel erhu tuner has the advantages of being simple in structure, convenient to tune, and capable of achieving the best tone after being adjusted on the premise that the fur does not need to cover the erhu tuner again although the fur is very soft and collapses.

Owner:刘森石

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com