High-lightness and high-brightness black masterbatch and preparation method thereof

A bright black and high-gloss technology, which is applied in the field of plastic coloring, can solve the problems that cannot meet the technical and cost requirements, it is difficult to increase the carbon black content, and it is difficult to increase the blackness, etc., so as to improve the service life, high carbon black content, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

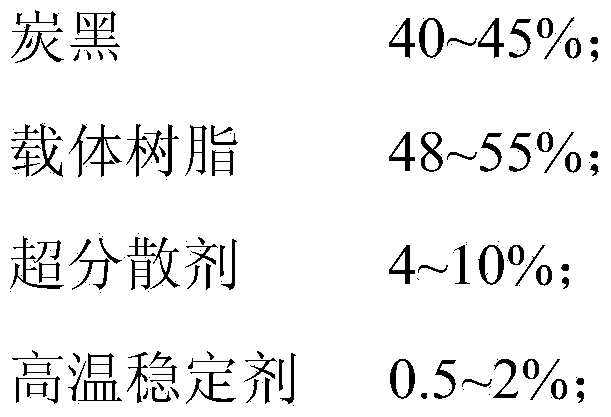

[0026] A high-gloss high-brightness black masterbatch, the weight percentage of each component is:

[0027]

[0028] The carrier resin is AS; the hyperdispersant is ethylene bis stearic acid amide; the high temperature stabilizer is polyester wax, specifically CERALENE693 polyester wax product of EuroCeras company;

[0029] The preparation method of the above-mentioned high-gloss high-brightness black masterbatch includes the following steps: preparing each raw material component according to the components and percentages in the formula, adding all the raw material components into a low-speed mixer for pre-mixing treatment for 5 minutes; Press the internal mixer, pressurize the internal mixer at 8kg pressure and 120°C for 12min; slice the material obtained by the pressurized internal mixing, put it into a twin-roll extruder for extrusion molding, control the roller surface temperature to 100°C, and the material temperature to be 180°C; crush the extruded material, and then...

Embodiment 2

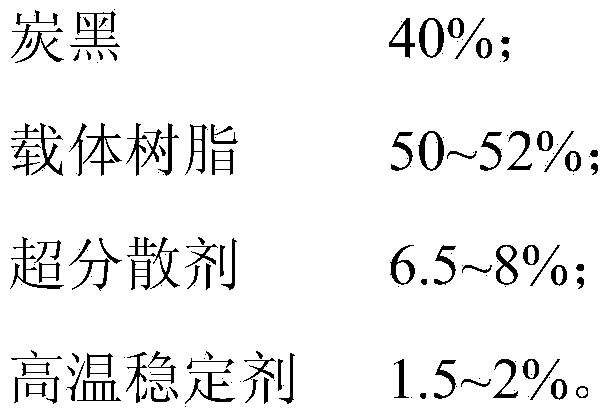

[0032] A high-gloss high-brightness black masterbatch, the weight percentage of each component is:

[0033]

[0034] The carrier resin is PS; the hyperdispersant is ethylene bis stearic acid amide; the high temperature stabilizer is polyester wax, specifically the CERALENE693 polyester wax product of EuroCeras company;

[0035] The preparation method of the above-mentioned high-gloss high-gloss black masterbatch includes the following steps: preparing each raw material component according to the components and percentages in the formula, adding all the raw material components into a low-speed mixer for pre-mixing treatment for 4 minutes; Press the internal mixer, pressurize the internal mixer at 9kg pressure and 100°C for 13min; slice the material obtained by the pressurized internal mixing, put it into a twin-roll extruder for extrusion molding, control the roller surface temperature to 90°C, and the material temperature to be 160°C; crush the extruded material, and then m...

Embodiment 3

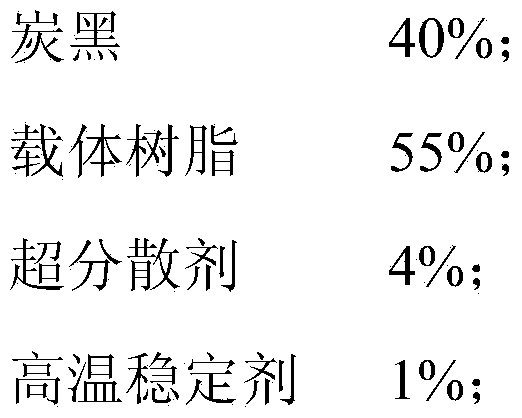

[0038] A high-gloss high-brightness black masterbatch, the weight percentage of each component is:

[0039]

[0040] The carrier resin is PE; the hyperdispersant is ethylene bis stearic acid amide; the high temperature stabilizer is polyester wax, specifically the CERALENE693 polyester wax product of EuroCeras company;

[0041] The preparation method of the above-mentioned high-gloss high-brightness black masterbatch includes the following steps: preparing each raw material component according to the components and percentages in the formula, adding all the raw material components into a low-speed mixer for pre-mixing treatment for 5 minutes; Press the internal mixer, pressurize the internal mixer under 10kg pressure and 120°C for 15min; slice the material obtained by the pressurized internal mixing, put it into a twin-roll extruder for extrusion molding, control the roller surface temperature to 100°C, and the material temperature to 180°C; crush the extruded material, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com