Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

693 results about "Acid dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An acid dye is a dye that is typically applied to a textile at low pH. They are mainly used to dye wool, not cotton fabrics. Some acid dyes are used as food colorants.

Wet method transfer printing method for natural fiber and polyamide fibre

InactiveCN101105006AHigh color yieldReduce consumptionTransfer printing processDyeing processPolyamidePrinting ink

The invention provides a wet-method transfer printing process of natural fiber and nylon, which mainly comprises the following steps: (1) selecting acidic printing ink or active printing ink; (2) printing: printing the surface of PET or BOPP film with the selected printing ink to obtain a transfer printed film; (3) transfer printing: treating natural fiber and nylon with a soaking liquid, subjecting the transfer printed film and printed fabric simultaneously to the compression by a rolling machine; and (4) oven-drying: oven-drying the fabric after the transfer printing is completed and baking to allow color fixation. The invention has the advantages of high transfer printing rate, high color yield of fabric, bright color, good color fastness, less pollution, reduced water consumption, simple process, high production efficiency, low cost, and success in non-paper transfer printing.

Owner:常州涵源新印花有限公司

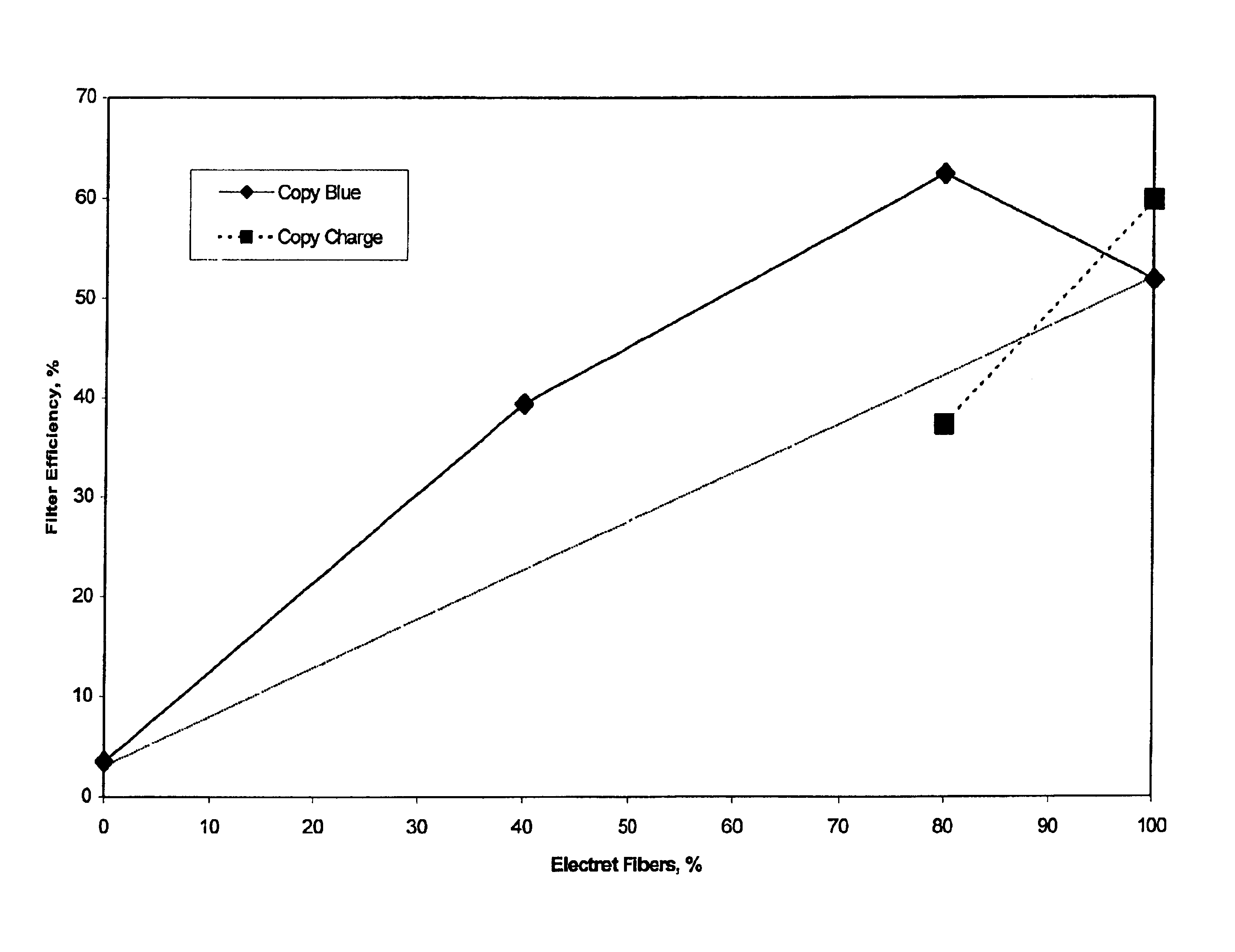

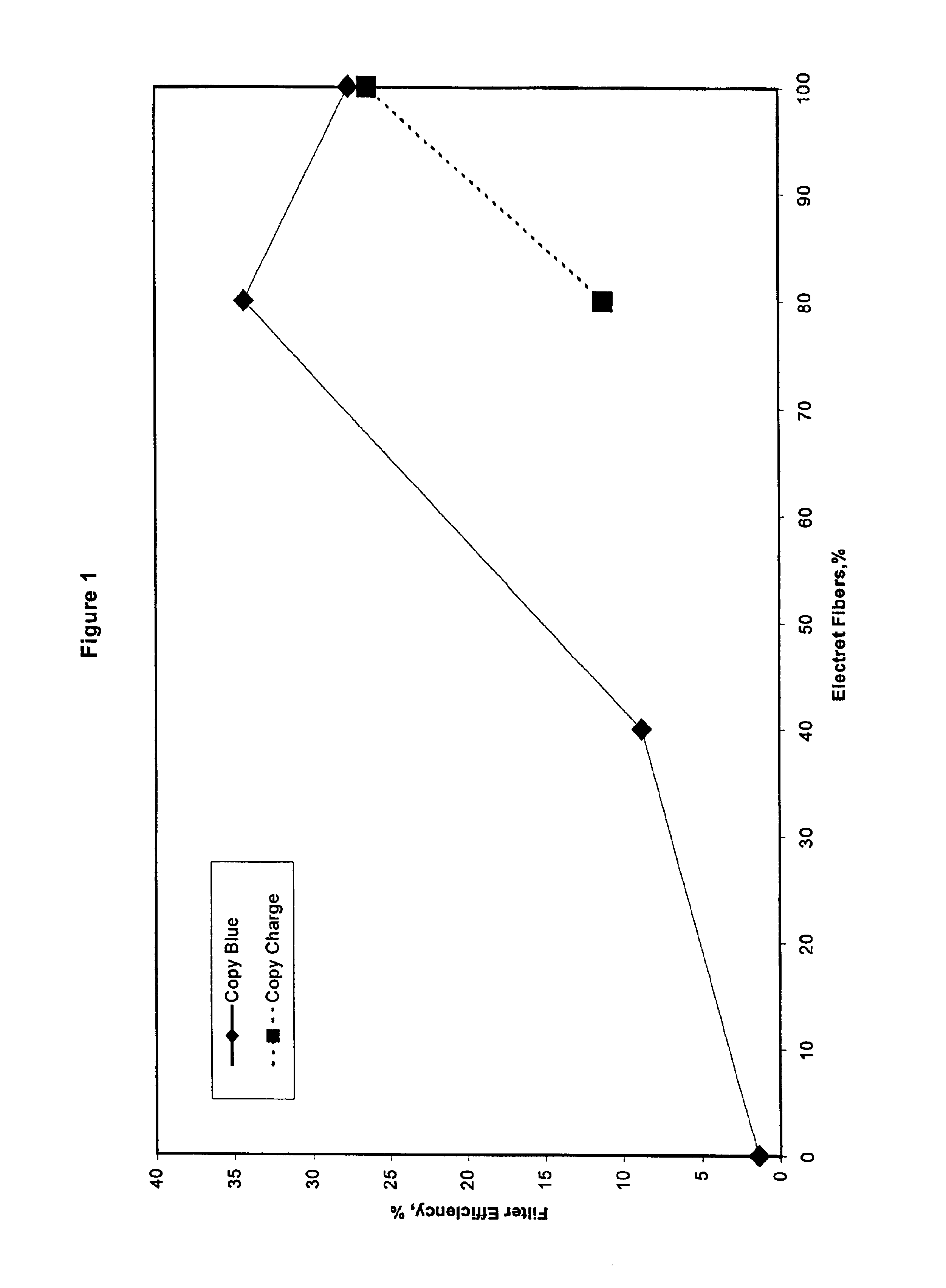

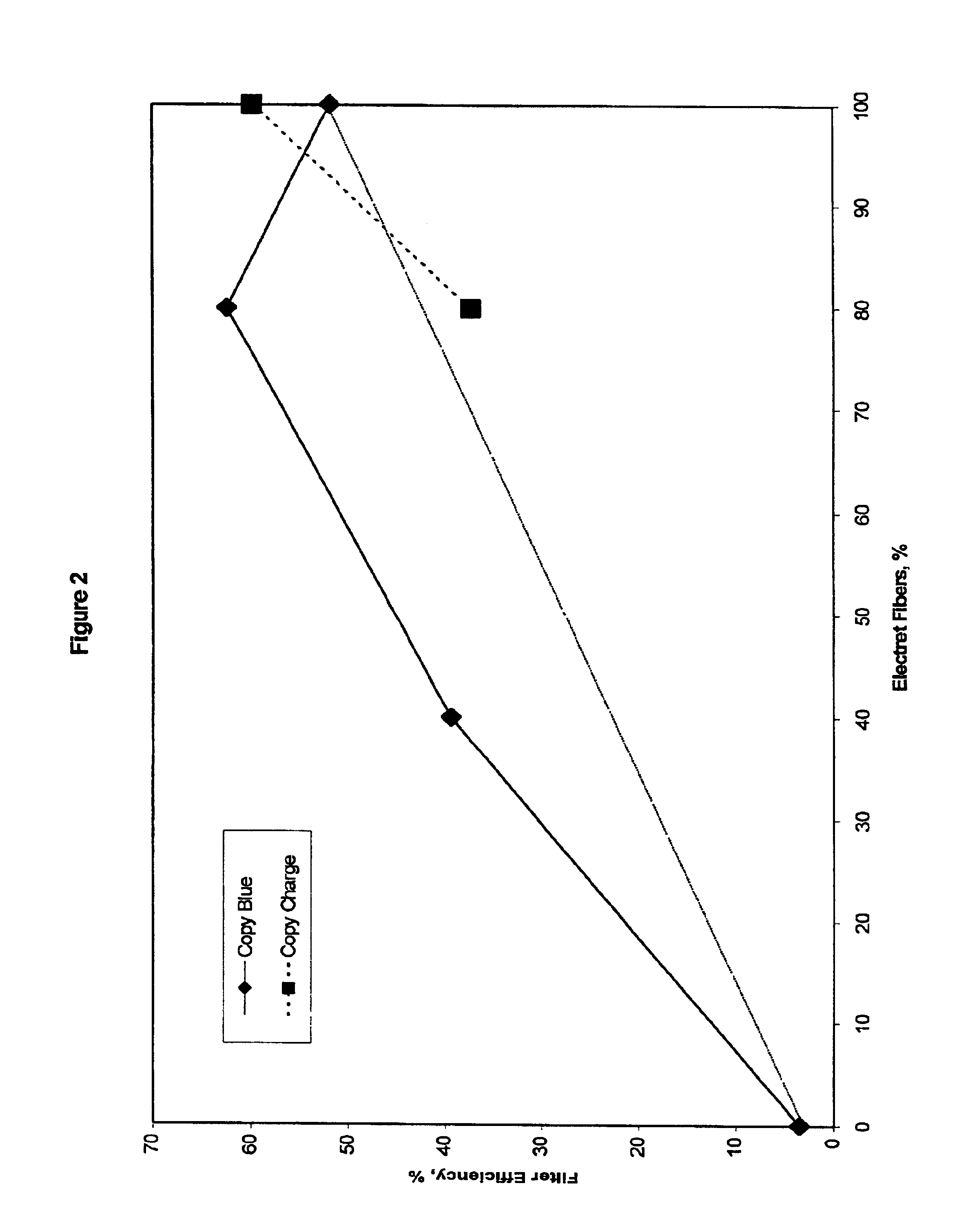

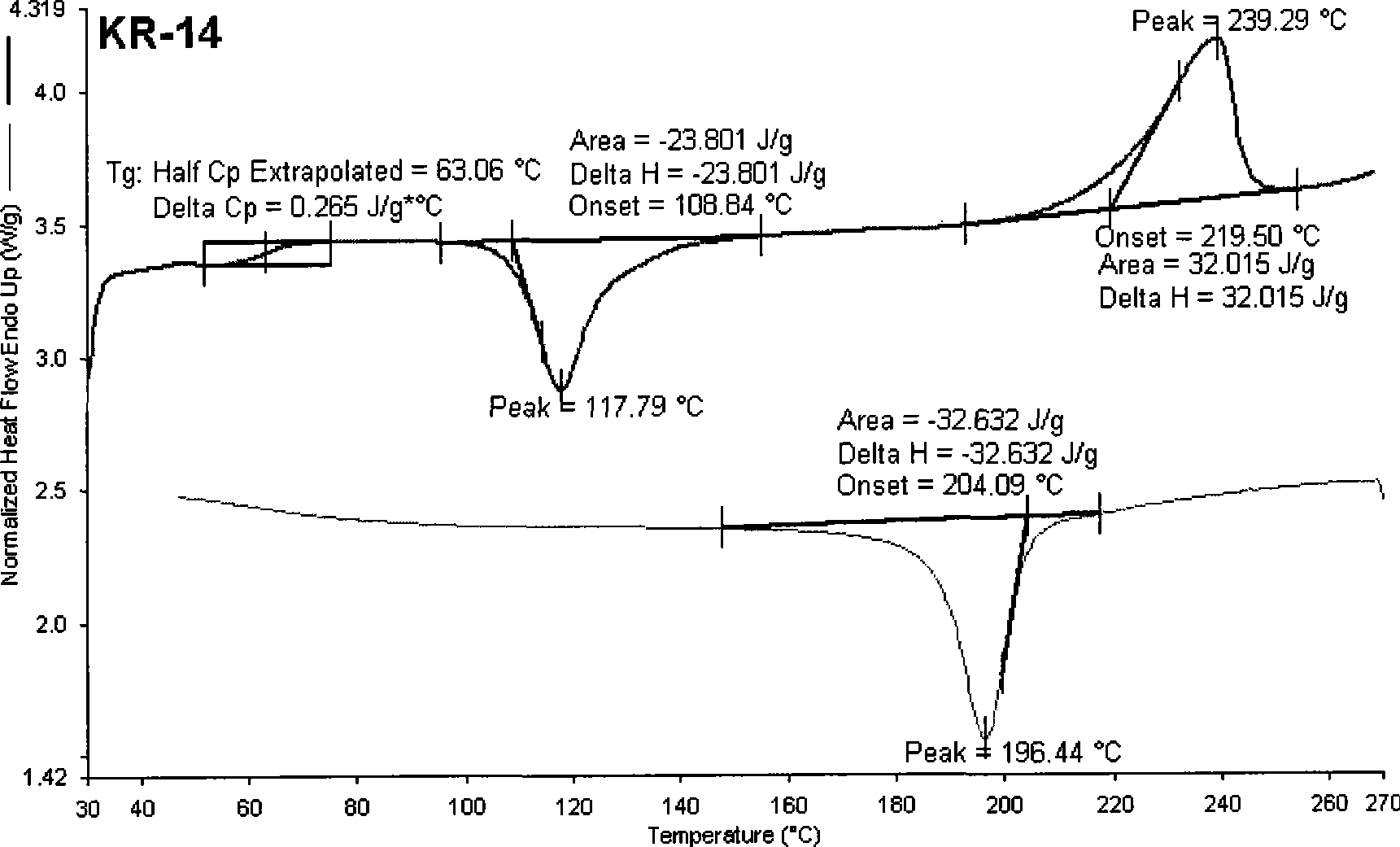

Nonwoven blend with electret fiber

InactiveUS6926961B2Inorganic material magnetismLoose filtering material filtersFiberAmmonium compounds

Owner:INVISTA NORTH AMERICA S A R L

Acid dye composition

An acid dye compound is prepared by taking weak acid dye, natural assistant and stabilizer as raw material and mixing to obtain final product. It has higher absorptive rate, better biological degradability and washing fastness.

Owner:DALIAN UNIV OF TECH

Continuous pad dyeing method of polyamide fibers and blended fabrics thereof

InactiveCN101446048ADeep color yieldGuaranteed color yieldDyeing processLiquid/gas/vapor textile treatmentAfter treatmentPre treatment

The invention provides a continuous pad dyeing method of polyamide fibers and blended fabrics thereof, and the method comprises: the polyamide fibers or the blended fabrics thereof are dyed after pre-treatment, and the dyeing is the single pad dyeing of acid dyes or the sequential pad dyeing of the acid dyes and active dyes. The pad dyeing of the acid dyes has steps as follows: the polyamide fibers or the blended fabrics thereof after treatment are immersed in dyeing liquid, the acid dyes are hot rolled at 60-85 DEG C, color fixing liquid is padded after drying, the color fixing liquid is further padded after steaming and washing, and then washing and drying are carried out. The continuous pad dyeing method has the beneficial effects that the continuous pad dyeing method selects the hot rolling to lead the color yield of the polyamide fibers to be deeper and combines the dual-color-fixing process to ensure the color yield and the color fastness of the fabrics, thereby leading the fabrics to have good using value and meeting the needs of medium and high-grade fabrics.

Owner:SHANGYU XINSHENG CHEM IND

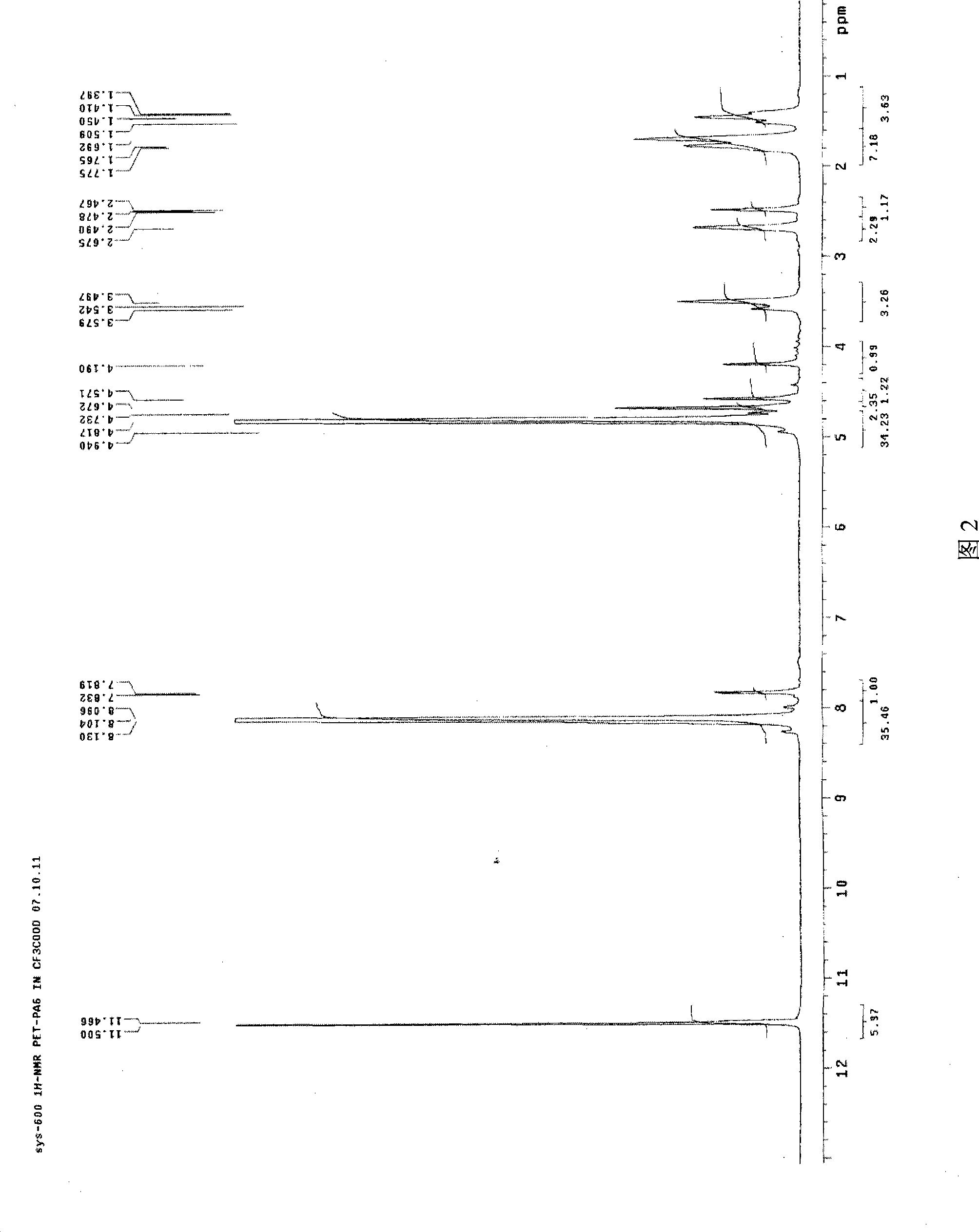

Acidic dyeable polyester and method for preparing acidic dyeable polyester and fiber thereof

ActiveCN101450990AUniform dyeingAffinityMonocomponent copolyesters artificial filamentDyeing processFiberFormate

The invention relates to acidic dyeable polyester and a method for preparing acidic dyeable polyester chip and fiber. The method comprises the steps of performing transesterification or esterification to p-phenyl dimethyl formate or p-phenyl dicarboxylic acid and glycol, adding polyamide such as nylon 6 and / or nylon 66 during polyester polymerization so as to prepare polyester chip, drying the polyester chip and using a conventional spinning machine to spin so as to prepare the polyester fiber used for the dyeing of acid dye. The polyester fiber thoroughly solves the problem that polyester and polyamide are not compatible, ensures uniform dyeing of acid dye, and enables spinning workstage to proceed smoothly. In addition, as the preparation of the polymer adopts a process similar to polyester polymerization for polymerization on a common polyester polymerization device, the method is simple to operate, easy to perform industrial production and low in cost.

Owner:CHINESE TEXTILE ACAD

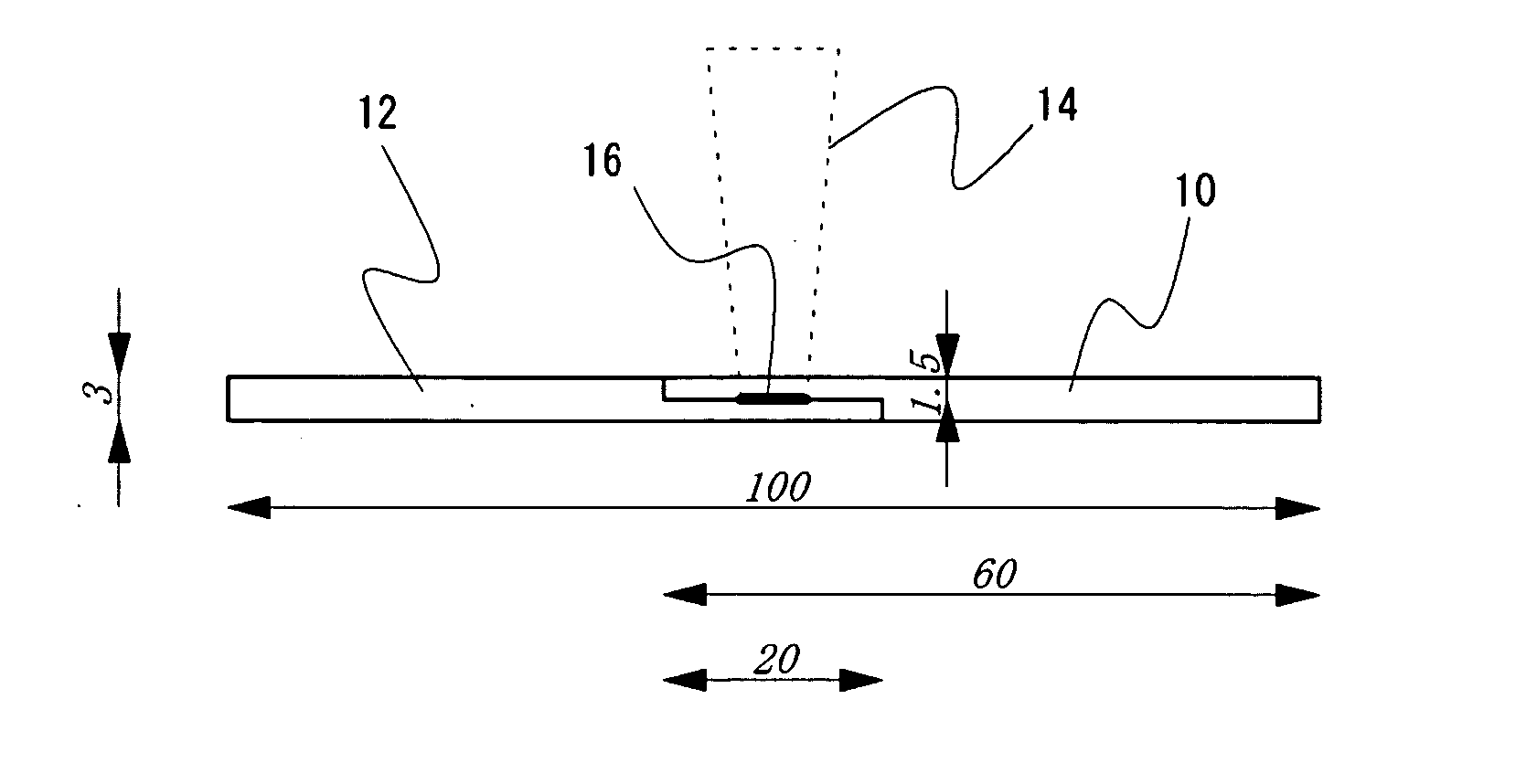

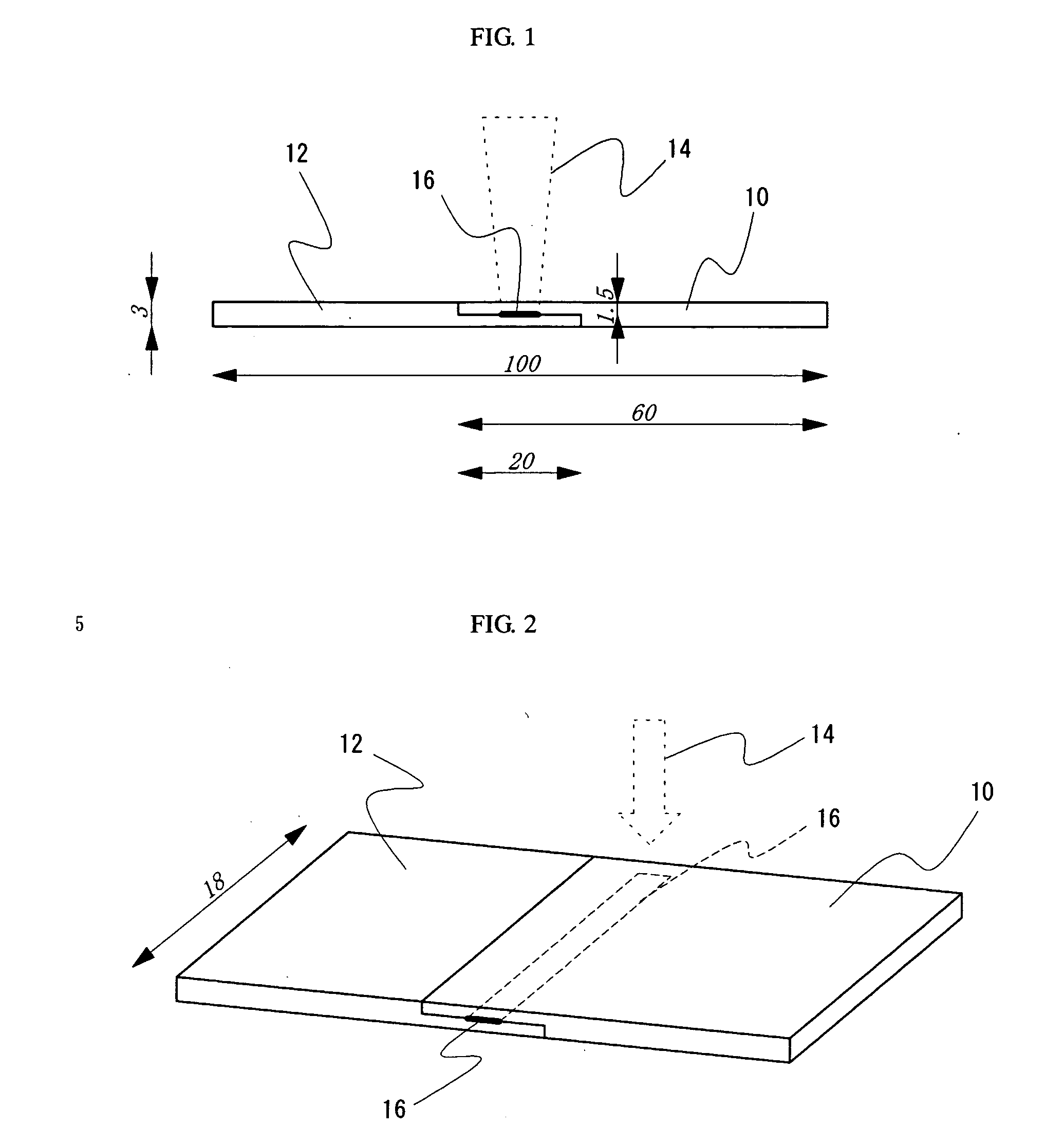

Laser ray transmitting colored thermoplastic resin composition and method of laser welding

InactiveUS20050003301A1High fastnessGood anti-migration propertyPhotomechanical apparatusPhotosensitive material auxillary/base layersOptoelectronicsIrradiation laser

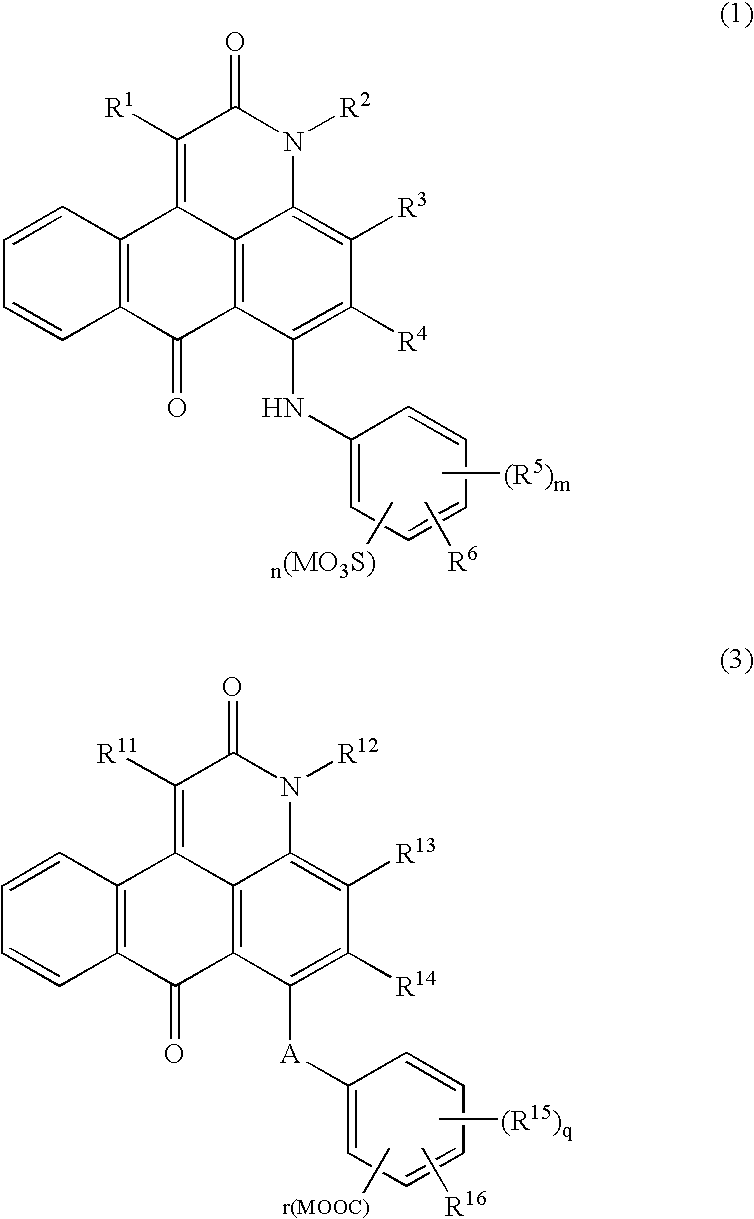

A laser ray transmitting colored thermoplastic resin composition containing an anthrapyridone acid dye represented by formula (1) or (3); method of laser welding wherein a contact portion of a laser ray transmitting material of the laser ray transmitting colored thermoplastic resin composition and a laser absorbent material is welded by irradiating laser ray so that the laser ray transmits the laser ray transmitting material and is absorbed in the laser absorbent material with the laser ray transmitting material and the laser absorbent material in contact with each other.

Owner:ORIENT CHEM INDS

Polyolefin functional master batch, preparation method thereof and use thereof

ActiveCN101812160AAntibacterialAntistaticConjugated synthetic polymer artificial filamentsDisperse dyePolymer science

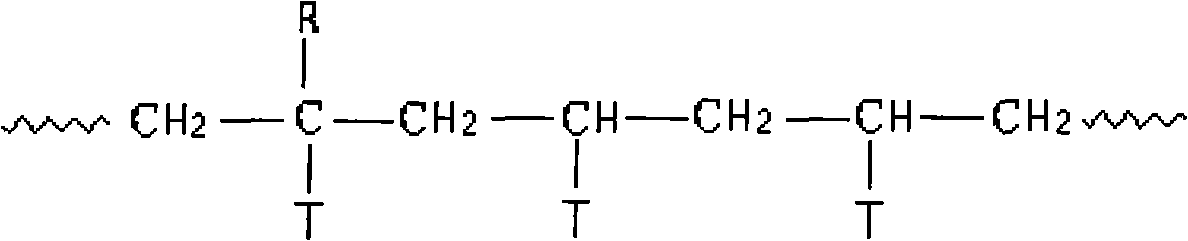

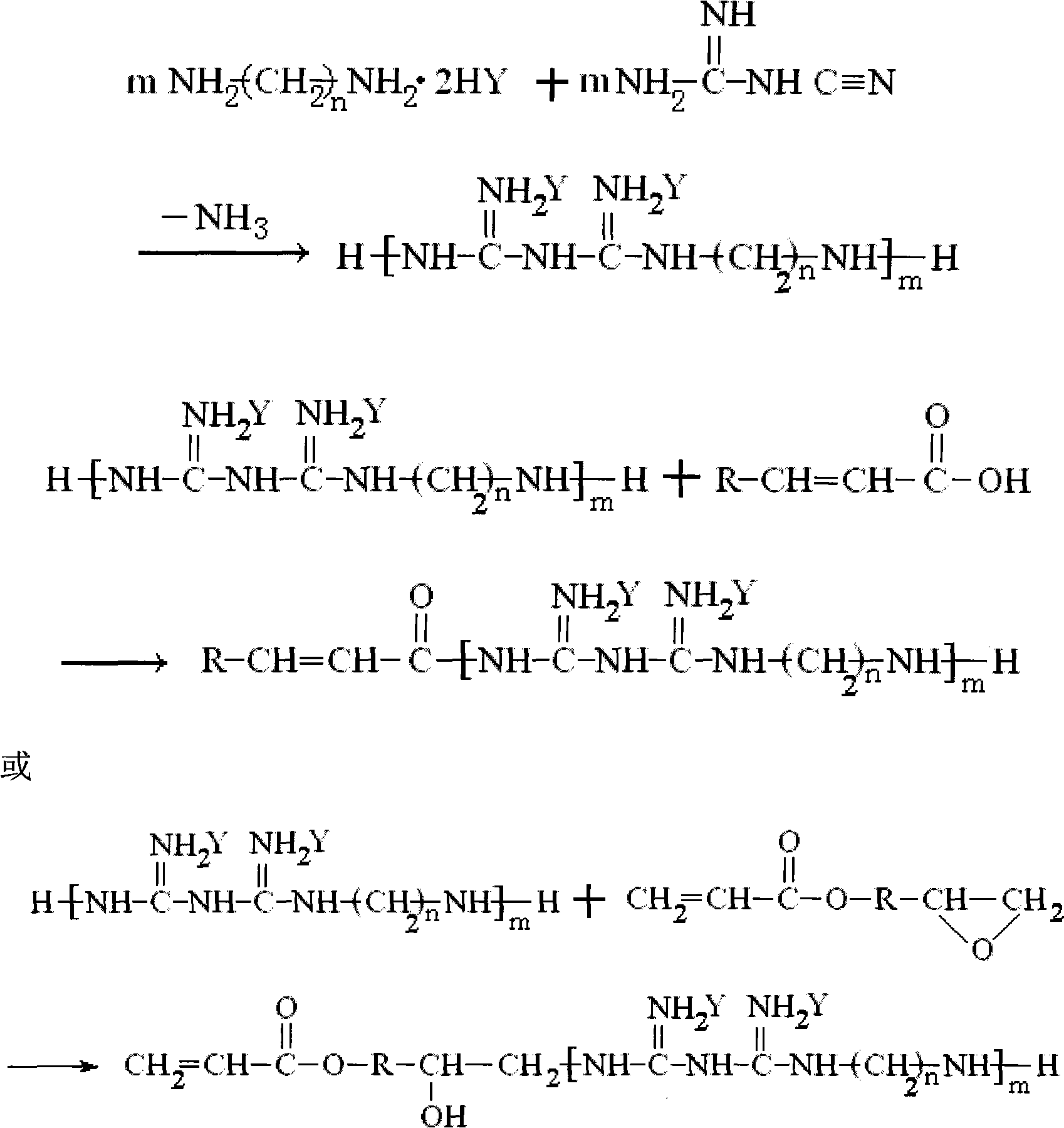

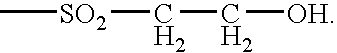

The invention relates to a polyolefin functional master batch, a preparation method thereof and use thereof. The functional master batch is prepared by blending a polyolefine resin, a guazatine oligomer, an olefin monomer, an initiator and the like and by a method of solvent graft, solid phase graft or melt graft and has a structural formula below, wherein in the formula, R represents the guazatine oligomer grafted to molecular chains of the polyolefin, and T may be hydrogen, chlorine, methyl, or phenyl. Compared with the prior art, by blending the functional master batch prepared by the invention with the corresponding polyolefin, various products, including fibers, thin films, water pipes and other plastic products, which have high antimicrobial performance and long-lasting effect and is safe and nontoxic to human bodies can be manufactured; and meanwhile, the acidic dye and disperse dye uptake of polyolefin fibers can be improved greatly, and the surface polarity, antistatic performance and paint film adhesion of polyolefin materials can be improved.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

Laundry Treatment Composition

InactiveUS20080096789A1Detergent dyesOrganic/inorganic per-compounds compounding agentsLaundryAcid dye

Owner:CONOPCO INC D B A UNILEVER

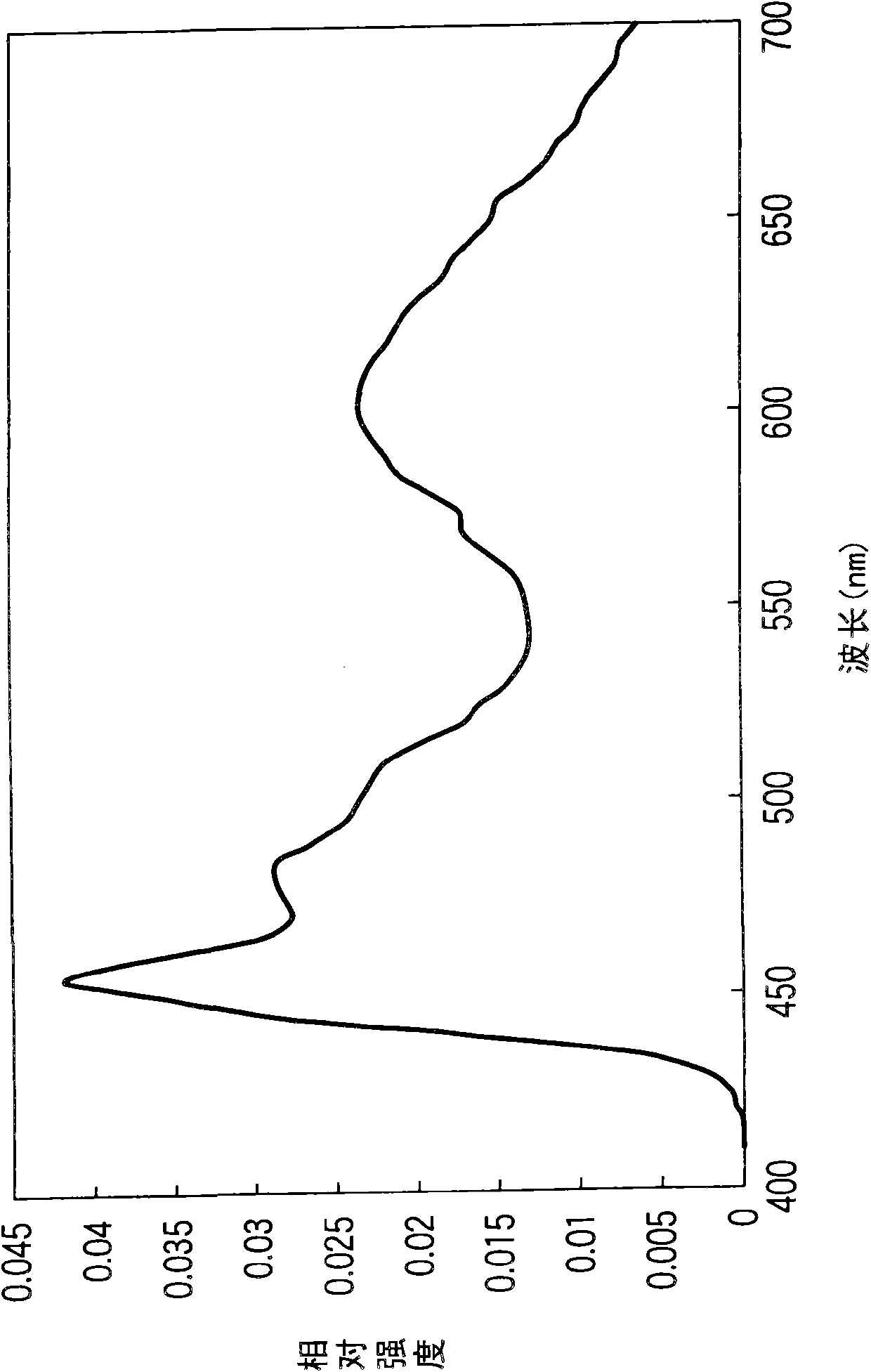

Blue colored composition for color filter, color filter and color display

The invention provides a blue colored composition for a color filter, a color filter and a color display, which are used during the manufacture of color filters of high color characteristic, heat resistance, light resistance and solvent resistance.The blue colored composition for color filters comprises a binder resin and a colorant.The colorant comprises a blue pigment and a salt forming product.The salt forming product is formed by a xanthene series acid dye and a compound with cationic groups.

Owner:TOYO INK SC HOLD CO LTD

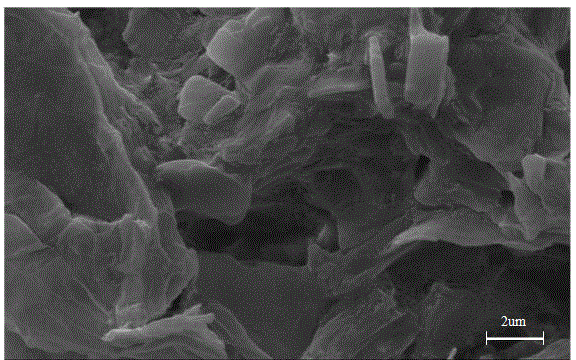

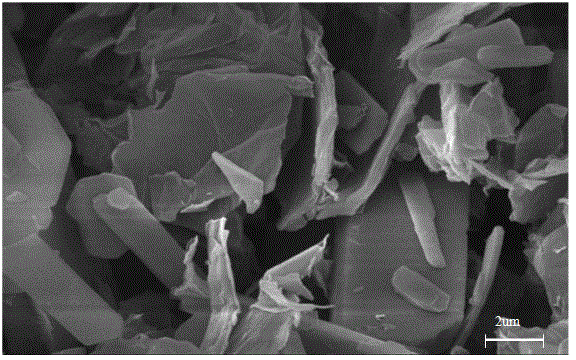

Modified graphene adsorbent as well as preparation method and application thereof

ActiveCN103949218AReduce agglomerationHigh specific surface areaOther chemical processesMultistage water/sewage treatmentPolyacrylamideAluminium

The invention discloses a modified graphene adsorbent as well as a preparation method and application thereof. The preparation method of the modified graphene adsorbent comprises the following steps: carrying out ultrasonic dispersion on oxidized graphene, adding hydroxyl aluminum and a surfactant, stirring fully, then adding a reducing agent, fully reacting so as to obtain a black flocculent precipitate, carrying out suction filtration on black flocculent precipitate, washing and drying, thereby obtaining the modified graphene adsorbent, wherein the surfactant comprises more than one of polyacrylamide, cetyl trimethyl ammonium bromide or sodium dodecyl benzene sulfonate. The modified graphene adsorbent has the characteristics of being simple, easily available, high in adsorption amount, high in removing rate and the like, and can be used for treating wastewater, especially acid dye wastewater; adopted raw materials are low in price and available; the preparation method is simple, is free from pollution, is low in cost, and is easy for industrialization.

Owner:SOUTH CHINA UNIV OF TECH

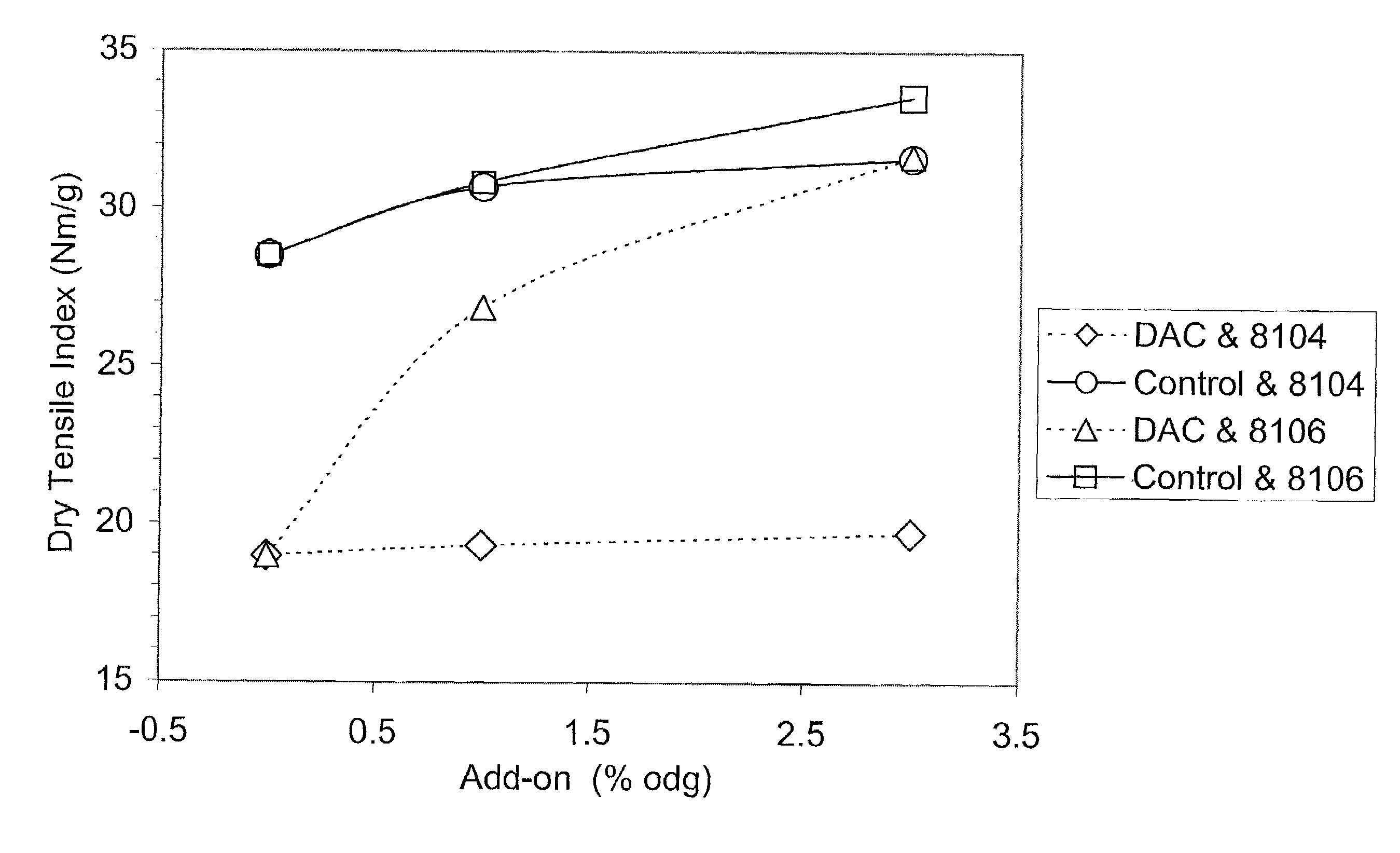

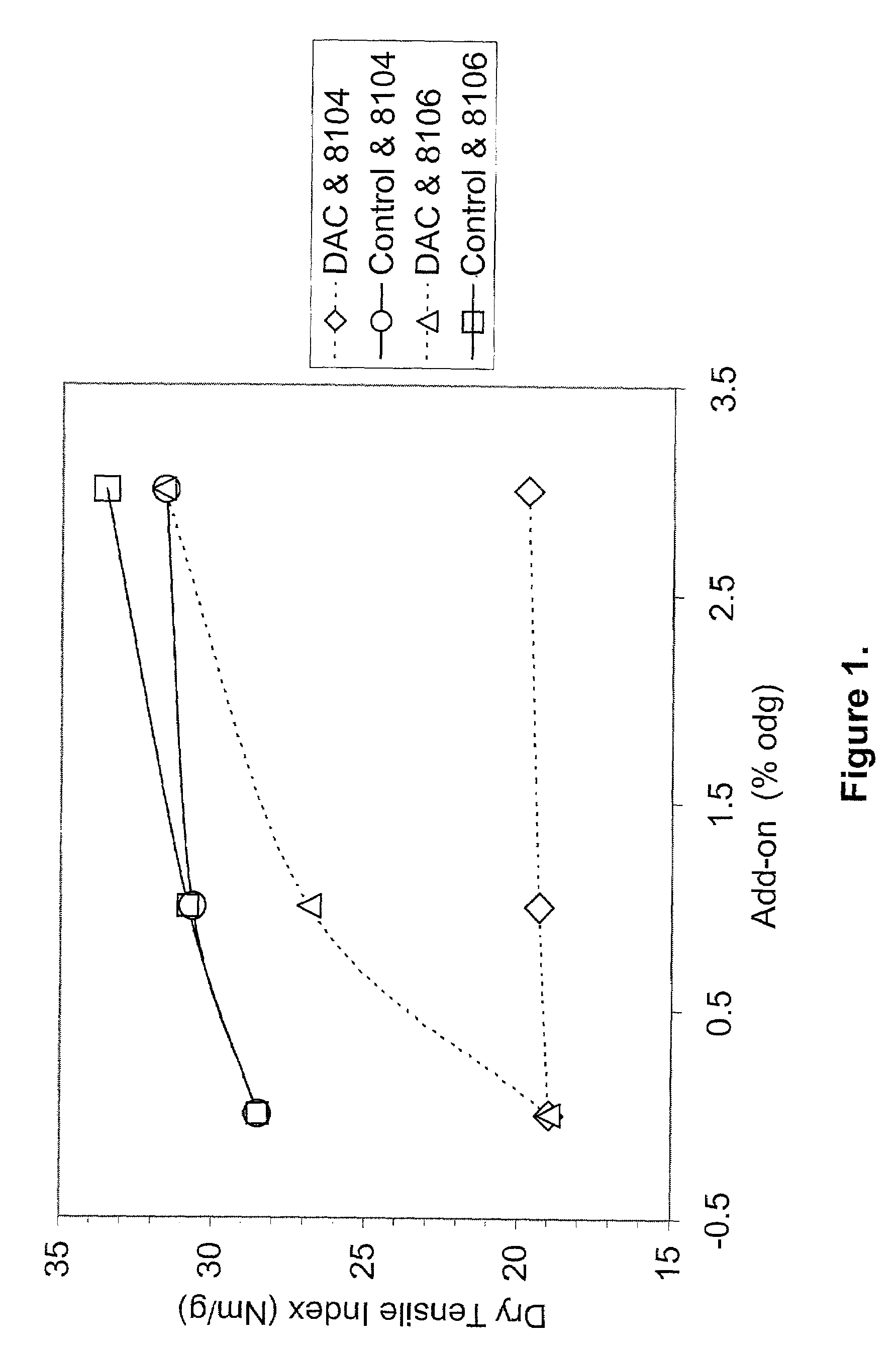

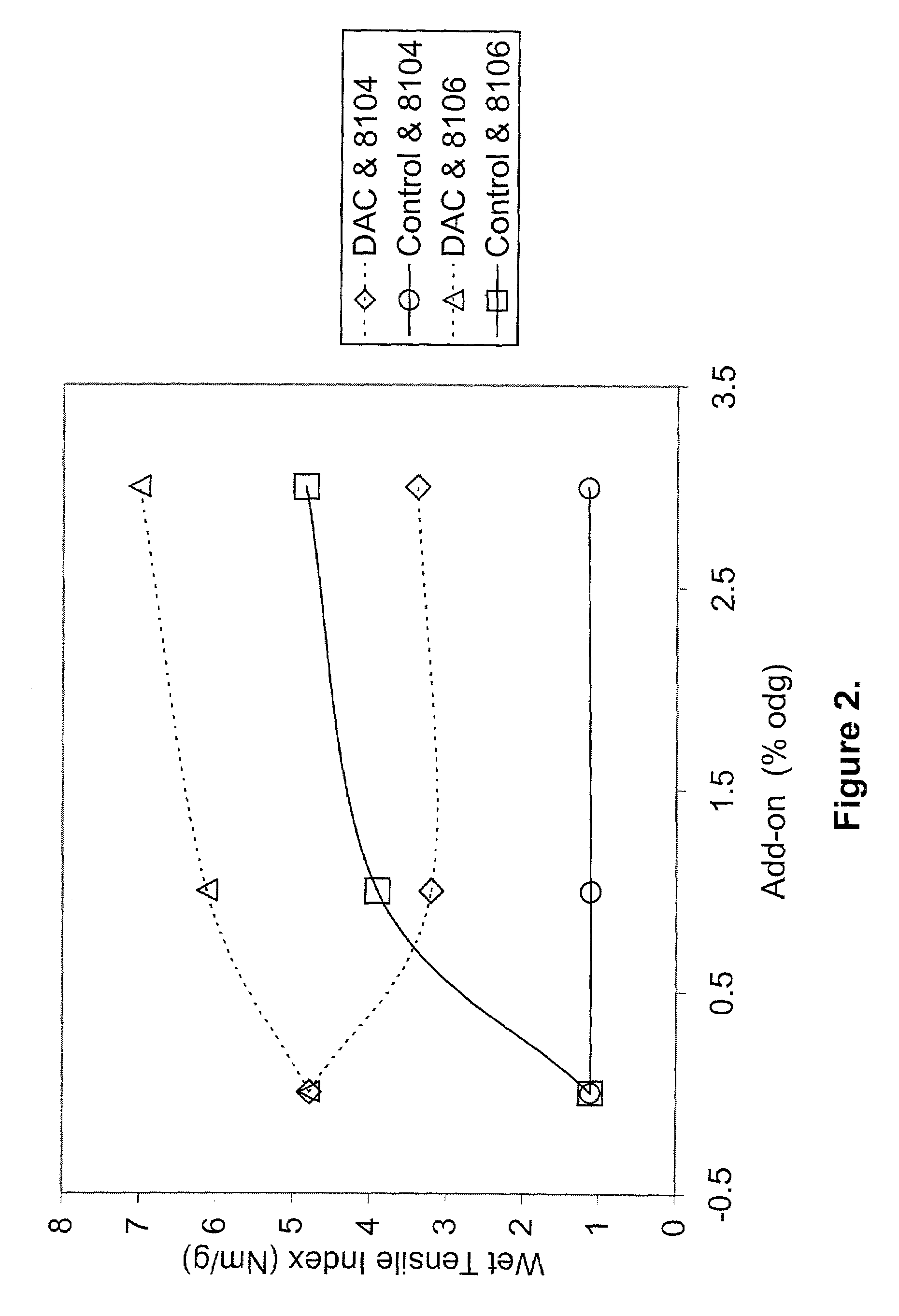

Polyvinylamine treatments to improve dyeing of cellulosic materials

InactiveUS7214633B2Improve wet strengthEasy to dyeDecorative surface effectsFibre treatmentCellulosePolymer interaction

Textile materials, including paper webs, treated with a polyvinylamine polymer and a second agent that interacts with the polyvinylamine polymer is disclosed. The second agent added with the polyvinylamine polymer can be, for instance, a polymeric anionic reactive compound or a polymeric aldehyde-functional compound. When incorporated into a paper web, the combination of the polyvinylamine polymer and the second agent provide improved strength properties, such as wet strength properties. In an alternative embodiment, the polyvinylamine polymer and the second polymer can be applied to a textile material for increasing the affinity of the textile material for acid dyes.

Owner:KIMBERLY-CLARK WORLDWIDE INC

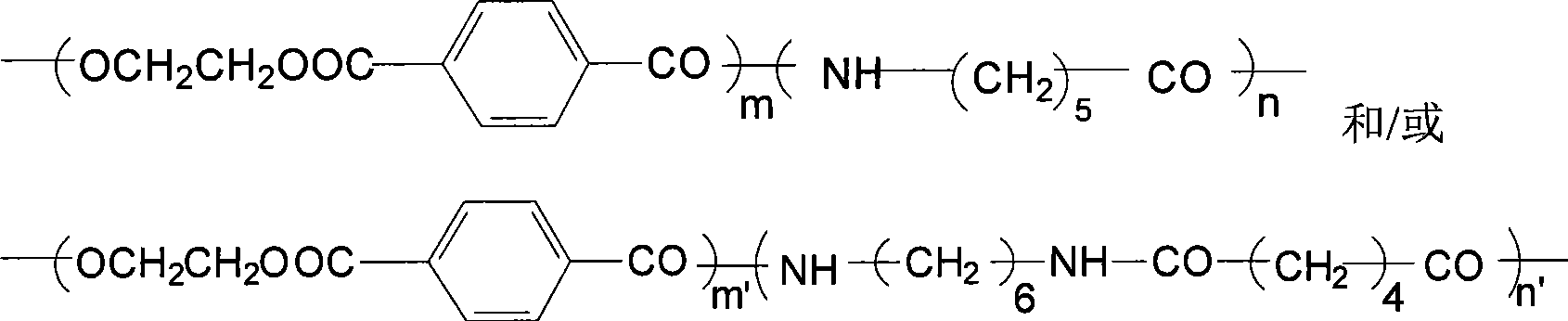

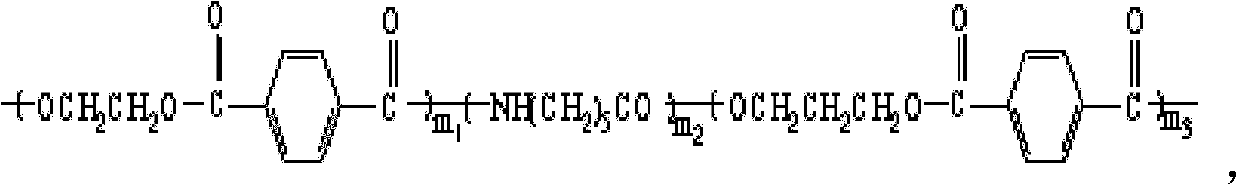

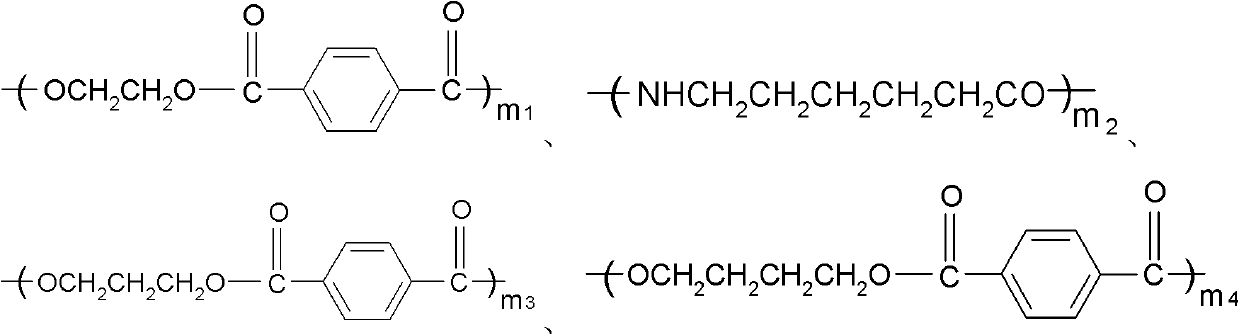

Modified polyester complex fiber and preparation method thereof

ActiveCN101906678AUniform dyeingEvenly distributed sequenceArtificial filament heat treatmentDyeing processDisperse dyeAcid dye

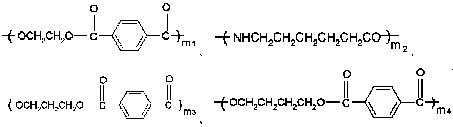

The invention provides a modified polyester complex fiber. The complex fiber is prepared by compounding modified polyester and thermoplastic resin, wherein the modified polyester accounts for 10 to 90 percent of the total weight of the complex fiber, and the thermoplastic resin accounts for 10 to 90 percent of the total weight of the complex fiber; and the modified polyester structure comprises structural units shown in the specifications, wherein m1 is more than 1 and less than 160, m2 is more than 1 and less than 70, m3 is more than or equal to 0 and less than 20, and m4 is more than or equal to 0 and less than 20. The complex fiber can be dyed at normal temperature and normal pressure by using acid dye and disperse dye, and has the advantages of high color fastness, high elasticity and comfortable handfeel.

Owner:CHINESE TEXTILE ACAD

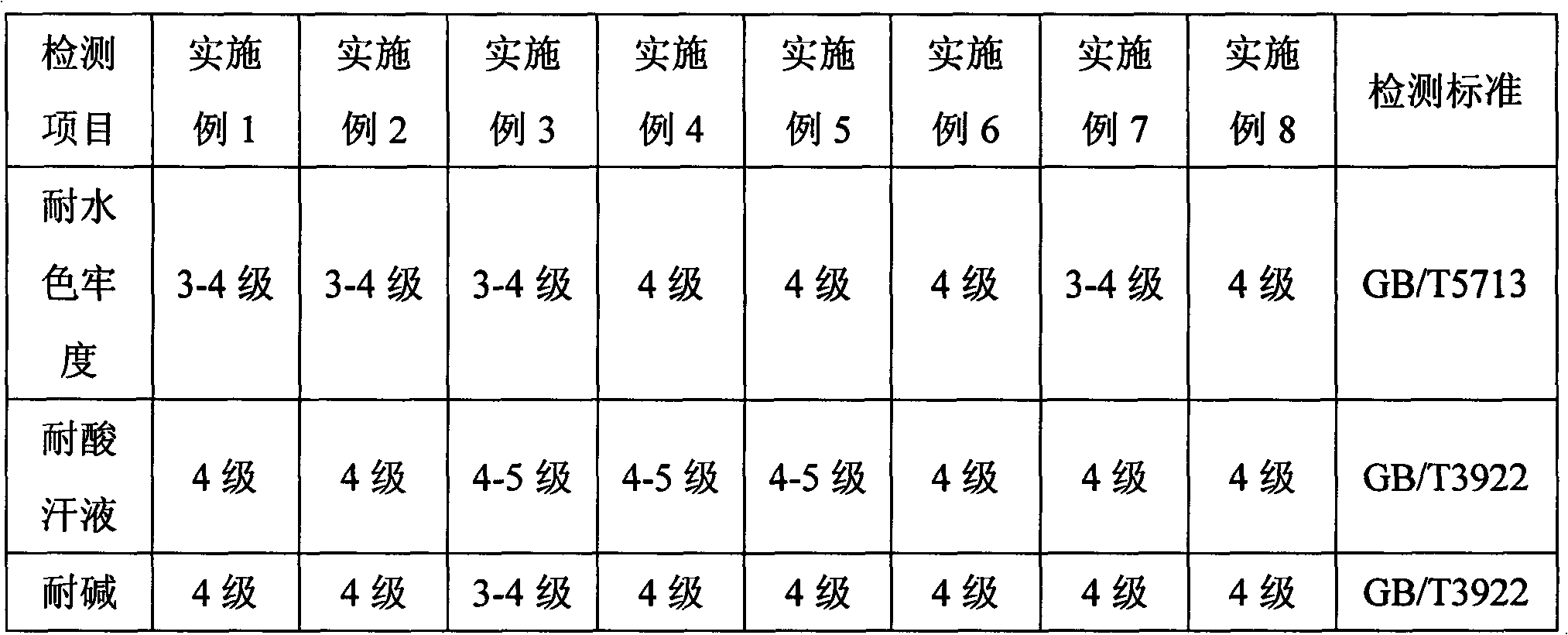

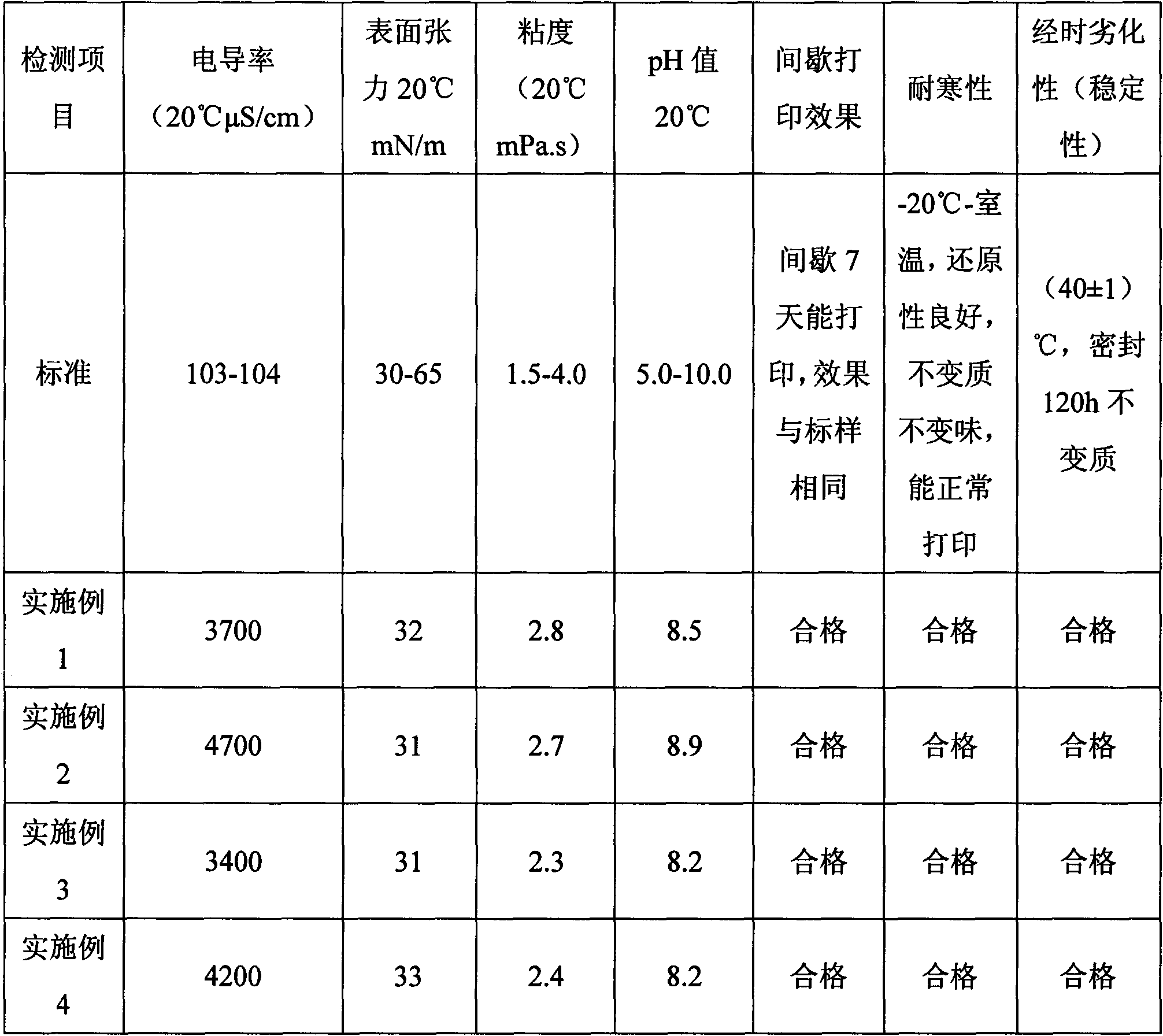

Textile inkjet printing acid dye ink and production method thereof

The invention discloses textile inkjet printing acid dye ink comprising the following components in percentage by weight: 0.5-10 percent of acid dye, 0.5-10 percent of viscosity modifier, 5.0-20 percent of humectant, 0.2-5 percent of osmotic agent, 0.1-2 percent of pH control agent, 0.1-1 percent of disinfectant and the balance of deionized water. The invention also discloses a production method of the textile inkjet printing acid dye ink, comprising the following steps of: (1) mixing the acid dye, the viscosity modifier, the humectant, the osmotic agent, the pH control agent, the disinfectant and the deionized water for 2 hours in the rotation speed of 100-300 revolutions per second at the temperature of 40-60 DEG C; and (2) cooling the mixture to normal temperature and sequentially filtering the mixture by micropore filters with pore diameters of 0.45 micrometer and 0.20 micrometer. The textile inkjet printing acid dye ink can be used for the inkjet printing of true silk, wool, chinlon, leather, and the like.

Owner:HONGSAM DIGITAL SCI & TECH

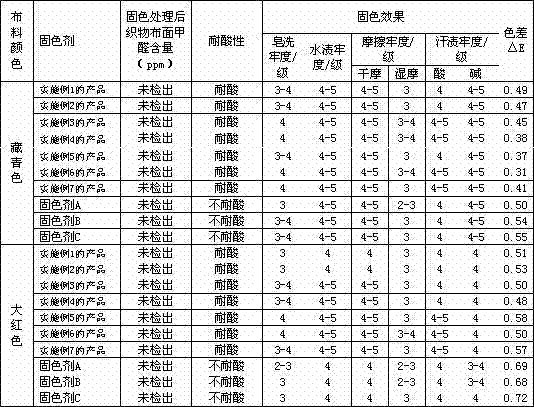

Acid reaction resistant chinlon fixer and application thereof

The invention discloses an acid reaction resistant chinlon fixer. Currently, most chinlon fixer products on the market are not resistant to acid; during a fixation treatment, when the fixer encounters strong acid or concentrated organic acid, a large sum of white precipitates will be produced; and fixer spot is easily generated in the fixation process, leading to generation of inferior-quality products or even waste products. The acid reaction resistant chinlon fixer provided by the invention is prepared by the following method comprising the following steps: subjecting a phenolic compound and two aromatic sulfonic acid compounds to a condensation reaction with formaldehyde in the presence of a complex catalyst; and then adding epichlorohydrin and a modifier to the above reaction system for modification; and finally, adjusting pH value of the modified multielement copolymer aromatic sulfonic acid formaldehyde condensation substance to 2-4 with strong acid or concentrated acid, so as to obtain the acid reaction resistant chinlon fixer. The acid reaction resistant chinlon fixer provided by the invention has acid resistance obviously better than that of a general commercial chinlon fixer, and solves the problem of hard fixation and poor washing fastness of chinlon fabric dyed by acid dyeing.

Owner:传化智联股份有限公司 +1

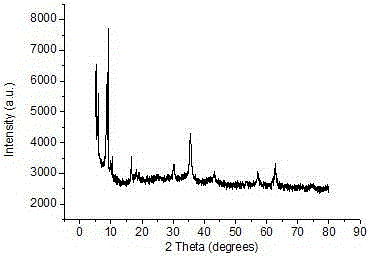

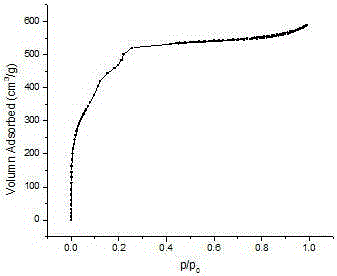

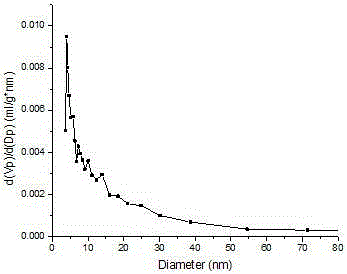

Preparation method and application of Fe3O4/MIL-101(Cr)

ActiveCN105195096AStable and controllable qualityGood dispersionOther chemical processesAlkali metal oxides/hydroxidesSynthesis methodsNitrogen

The invention relates to the technical field of magnetic metal organic framework materials, in particular to a preparation method and application of Fe3O4 / MIL-101(Cr). The method includes the steps of preparing MIL-101(Cr) material through a hydrothermal method to serve as a template, and generating Fe3O4 particles in situ in holes of MIL-101(Cr) through a reduction co-precipitation method under the ultrasonic conduction and in a nitrogen protection state. The Fe3O4 / MIL-101(Cr) composite obtained through the method is strong in magnetism, large in surface area, shortened in synthesis time, controllable in synthesis condition, novel in synthesis method, simple and easy to repeat, stable and controllable in prepared material quality, and capable of being synthesized in batches. The Fe3O4 / MIL-101(Cr) composite is good in effect and can be repeatedly used six times or more when used for adsorbing and removing acid dyes in environmental water.

Owner:SHENYANG PHARMA UNIVERSITY

Pretreatment agents for acidic hair dyes

InactiveUS20040045099A1Good effectImprove abilitiesCosmetic preparationsHair removalHair dyesCationic polymerization

Pretreatment agents for hair colorings with acid dye comprising at least one cationic polymer selected from the group consisting of polymers having amino groups and polymers having quaternary ammonium groups. The pretreatment agents for hair colorings with acid dye are used for improving coloring ability and color fastness of hair colorings with acid dye.

Owner:MANDOM CORP

Low temperature dyeing method for wool fibre

The invention discloses a method for dyeing wool fibers at low temperature, which is characterized by comprising the following steps: increasing one or more than one Gemini cationic surfactant in the process of the prior wool acid dye dyeing or wool active dye dyeing, and then dyeing at specified temperature, wherein usually, the added weight of the Gemini cationic surfactant is 0.1 to 1.0 percent of that of the wool fibers, and the dyeing time is 40 to 90 minutes at a temperature of between 75 and 85 DEG C. The method can improve dyeing quality of the wool fibers and simultaneously reduce energy consumption in the dying process.

Owner:ZHANGJIAGANG CHENCHEN TEXTILE

Log dyeing method

InactiveCN1672886ARetain structurePreserve textureWood treatment detailsPressure impregnationRoom temperatureVolumetric Mass Density

The log dyeing method is one circular hot pressing dyeing and normal temperature and pressure dyeing method on log with water content not higher than 8 % and in proper length. The log dyeing process includes the following steps: compounding acid dye aqua; soaking at room temperature for 120-480 min; dyeing at 25-120 deg.c and 10-15 Mpa under stirring for 30-60 min; lowering to room temperature; dyeing at 25-120 deg.c and 10-15 Mpa under stirring for 30-60 min; and so on until reaching the total dyeing time of 600-900 min; washing with water; drying at 25-120 deg.c to water content not higher than 8 %; and discharging. The log dyeing maintains the natural grains of log, raises the density of timber, homogenizes the color of timber, and raises the value of timber.

Owner:高凯

Polyester fabric capable of acidic dyeing and method for making same

InactiveCN1632195AImprove mechanical propertiesGood acid dyeabilityDyeing processMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to an acid dyeable polyester fiber and a preparation method thereof. Combining polyamide and polyethylene-methacrylate to form polyester acid-dyeable composite additives, adding them to polyester compounds, and blending and spinning to obtain acid-dyeable polyester fibers. Due to the addition of the composite additive, especially the introduction of polyethylene-methacrylate, the compatibility of polyester and polyamide has been improved, and the polyester fiber has better acid dyeability and good mechanical properties. .

Owner:上海丝绸集团股份有限公司

Preparation method of adsorbent for acid dye wastewater treatment

ActiveCN102671631AImprove adsorption capacityImprove film formationOther chemical processesWaste water treatment from textile industryCross-linkSorbent

The invention relates to the field of functional materials, particularly a preparation method of an adsorbent for acid dye wastewater treatment. The invention mainly solves the technical problem that dyeing wastewater can not be easily decolorized, can not achieve the discharge standard and the like in the prior art. The preparation method comprises the following steps: putting 8-10g of beta-cyclodextrin into 1-2g of citric acid monohydrate, and adding 1g of PEG-400 and 0.25g of sodium dihydrogen phosphate to obtain a beta-cyclodextrin polymer by polymerization; adding a silane coupling agent into a chitosan solution; and cross-linking the beta-cyclodextrin polymer with the chitosan to obtain a beta-cyclodextrin-chitosan porous membrane, wherein the mol ratio of the chitosan to the beta-cyclodextrin polymer is 1:3..

Owner:SAINTYEAR HLDG GROUP

Method of low-temperature dyeing for wool

The invention relates to a method of low-temperature dyeing for wool, which is characterized by comprising the following steps: adding fully-dissolved acidic dye for wool, acetum with the concentration of 99% and Univadine in an ultrasonic oscillator, and adding distilled water according to the bath ratio of 1:20-80; wetting wool fiber in the distilled water under the temperature of 40 DEG C, wiping, pouring into the ultrasonic oscillator, boosting the temperature at 40-60 DEG C at the speed of 1 DEG C / min, and dyeing for 45-60min, wherein the ultrasonic frequency is 20-50kHz, and the ultrasonic strength is 0.08-1.0W / cm<2> in the dyeing process; taking the wool fiber out after dyeing, washing by cold water and parching. The invention belongs to low-temperature dyeing, does not need additional heat energy in dye bath, can use no or less aid, and is favor of environment protection.

Owner:JIANGNAN UNIV

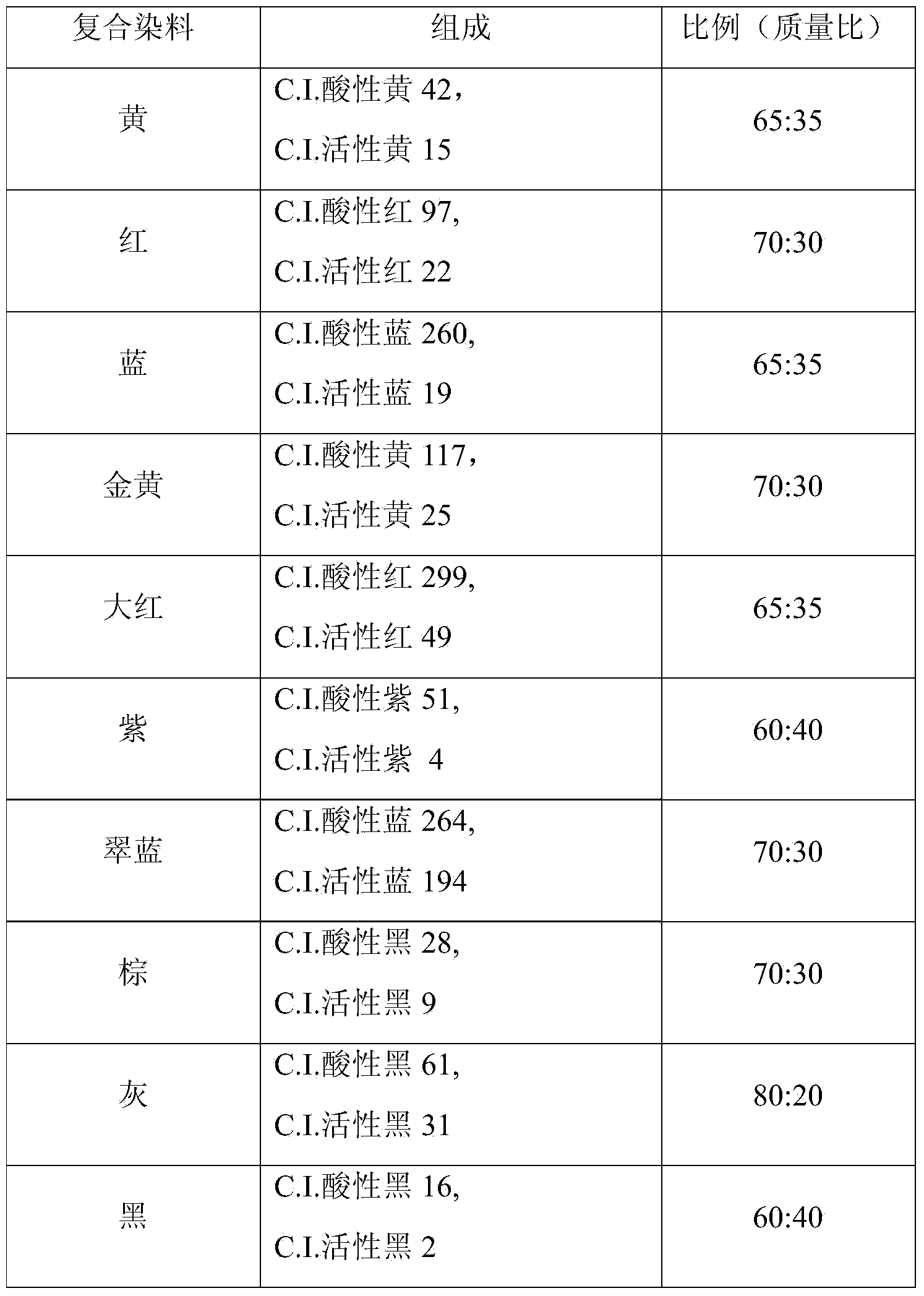

Nylon sea-island microfiber leather fabric composite dye and application thereof

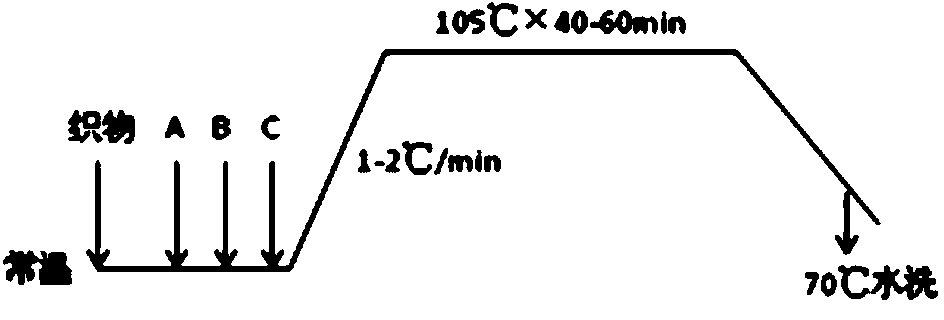

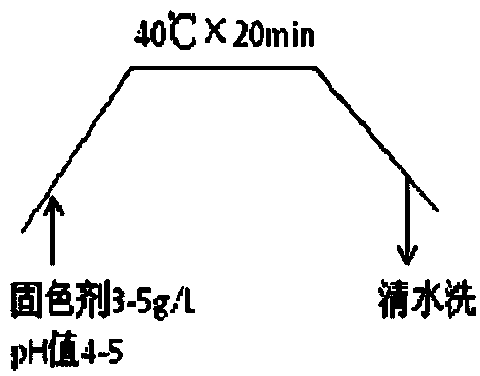

ActiveCN103525123AConsistent dyeingApplicable dyeingOrganic dyesDyeing processAcid dyeIncrease temperature

The invention relates to nylon sea-island microfiber leather fabric composite dye and application thereof. The dye is formed by combining acid dye and active dye. The application is as follows: at normal temperature, sequentially adding an acid level dyeing penetrating agent and composite dye to a dye bath, regulating pH value to 5-6, soaking a fabric in the dye bath, increasing temperature to 105-110 DEG C, preserving for 40-60min, and completely washing at 70-80 DEG C to obtain the dyed fabric; soaking the dyed fabric in a fixation bath, increasing temperature to 40-50 DEG C, preserving for 20-30min and washing. The composite dye formed by combining the acid dye and the active dye, is free from components violating against national technical standard for safety, can consistently dye poly urethane (PU) and nylon superfine fiber, and in particular can dye nylon microfiber leather. The composite dye is complete in chromatography, good in compatibility, synchronous to dye and easy to control quality.

Owner:DONGHUA UNIV +1

Rotary drum dyeing method for fractionally dyeing superfine fiber synthetic leathers with multi-component dyes

InactiveCN101798736AFixedSolve the problem of race infectionDyeing processLiquid/gas/vapor textile treatmentDisperse dyeNonwoven fabric

The invention discloses a rotary drum dyeing method for fractionally dyeing superfine fiber synthetic leathers with multi-component dyes. The most common rotary drum equipment used in the natural leather processing process is adopted in the method. The method comprises the following steps of: adding a low temperature disperse dye to color polyurethane component in the superfine fiber synthetic leathers; lowering the pH value of dyeing solution to 5.5; adding a weak acid dye in the solution to color superfine fiber nonwoven fabric component in the superfine fiber synthetic leathers; lowering the pH value of the dyeing solution to 4.0; adding polycationic color fixing agent to fix the color; washing the leathers with water once after the completion; replacing the original dyeing solution with new dyeing solution; adding a neutral dye for dyeing; and washing the leathers with water once after dyeing. The disperse dye and the weak acid dye selected in the invention color the polyurethane component and the superfine fiber nonwoven fabric component in the superfine fiber synthetic leathers desirably; the neutral dye added in the final step enables evener and thicker color on the surface of the superfine fiber synthetic leathers; and thus the problem of dyeing difference between the two components in the superfine fiber synthetic leathers is solved.

Owner:浙江温州轻工研究院

Method for dyeing and finishing polyester and nylon composite filament corduroy

InactiveCN102605584ADamage intensityHigh strengthSolvent-treatmentFibre typesDisperse dyeNylon material

The invention discloses a method for dyeing and finishing polyester and nylon composite filament corduroy, which comprises the following processes: checking a gray fabric; sewing the gray fabric; pre-shrinking in full width; splitting; pre-shaping; dyeing; soft finishing shaping; and packaging an end product, wherein a full width water washing machine is used for performing the process of pre-shrinking in full width; the process of splitting is performed according to a thermal treatment method and an alkali treatment method; during the process of pre-shaping, the temperature is 195 DEG C-200 DEG C and an assembly line turning speed is 30m / min-35m / min; dye liquor in the process of dyeing is aqueous solution of disperse dye or mixed aqueous solution of disperse dye and acidic dye; and the process of the soft finishing shaping is as follows: the corduroy passes through a material chute containing 10-15g / l softening agent aqueous solution, and then the corduroy is dried and shaped at high temperature, wherein the drying temperature is 165 DEG C-175 DEG C, the assembly line turning speed is 30m / min-35m / min and the softening agent is an organic silicon softening agent. The end product prepared according to the method provided by the invention has the advantages of high strength, full and mild velvet feeling, excellent shape-keeping property, convenience in washing and finishing, uniform dyeing effect, and capability of obtaining specific gigging effects such as frostwork or polyester peach skin, and the like.

Owner:杭州天宇印染有限公司

Wet transfer printing dye intaglio printing ink and preparation thereof

InactiveCN101348633ASimple manufacturing processShorten production timeTransfer printing processInksPrinting inkSolvent

The invention discloses dye intaglio printing ink for transfer printing by the wet method, comprising the following compositions in weight percentage: 1 to 60 percent of dye, 1 to 20 percent of a bonding material and 20 to 98 percent of a solvent. The invention also discloses a method for preparing dye intaglio printing ink for transfer printing by the wet method . The method comprises three steps, namely dissolving of the dye, filtering of solution and preparing the printing ink. The dye intaglio printing ink for transfer printing by the wet method has the advantages that the manufacturing process of the printing ink is simplified greatly, the manufacturing time of the printing ink is shortened; the hydrolyzation of the dye and the deterioration of the remaining printing ink are avoided, and the printing ink can be used for a plurality of times; the printing ink has good printing adaptability to various common plastic membranes; the gravure printing ink has high quality, an active dye or an acid dye or a positive ion dye printed on the plastic membrane or the paper of a coating separating agent has excellent dissolving performance in the wet state, and the dye intaglio printing ink is suitable for transfer printing process by the wet method.

Owner:刘静

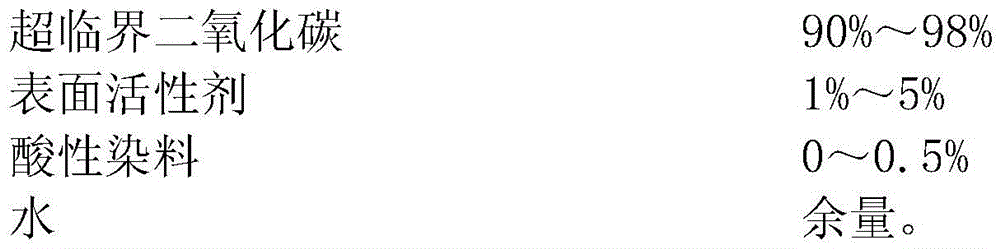

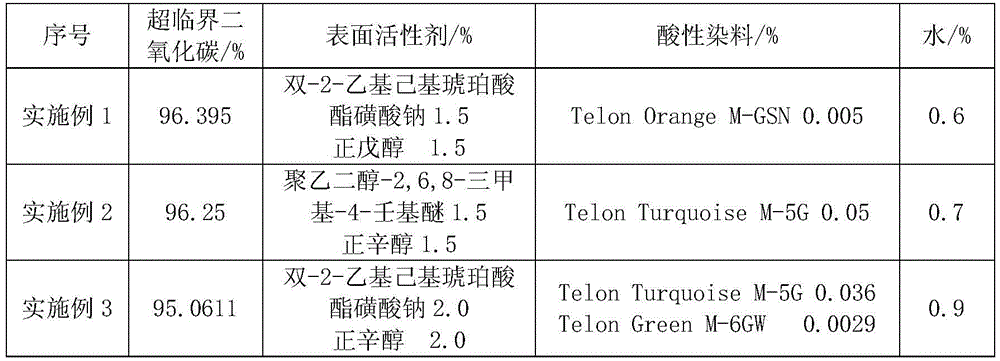

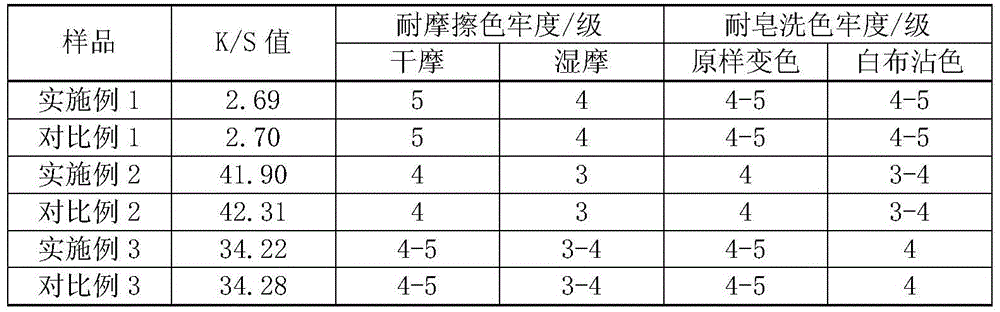

Reverse micelle system and application thereof in acid dye dyeing

InactiveCN105484071AMake up for the inability to dissolve polar substancesReduce dosageDyeing processOrganic solventSolvent

The invention discloses a reverse micelle system and an application thereof in acid dye dyeing. The reverse micelle system is characterized by comprising the following components in percentage by weight: 90%-98% of supercritical carbon dioxide, 1%-5% of a surfactant, 0-0.5% of an acid dye and the balance of water. Supercritical carbon dioxide dyeing is organically combined with reverse micelle dyeing; the supercritical carbon dioxide is taken as a non-polar organic solvent in reverse micelle dyeing due to the fact that the supercritical carbon dioxide is nontoxic, tasteless and not easy to combust and is an environment-friendly chemical solvent; in addition, the system only contains very little water of a reverse micelle-coated soluble dye; the amount of water can be greatly reduced; meanwhile, the carbon dioxide is recovered in the form of gas under the supercritical condition; the non-polar organic solvent, the surfactant and water can be easily separated; and recovery and cyclic utilization are achieved.

Owner:中国纺织科学研究院江南分院 +1

Dyeing process for viscose/brocade blended silks by active/acid dye-bath method

The invention relates to a dyeing process for viscose / brocade blended silks by an active / acid dye-bath method. The dyeing process is characterized in that the optimal dyeing process with mixed dyes is determined by researching pH, an alkaline agent, an electrolyte, a curing agent, temperature at the early period of dyeing and different heat-holding times, so that better homochromatism is obtained for the viscose / brocade fibers in one-bath dyeing, and higher dye-uptake rate and soaping fastness are obtained.

Owner:WUXI DONGXIN WEAVING

Environmental protection type dye printing paste without steaming and washing

ActiveCN101105004AEliminate steaming and washing processSolve the feelDyeing processDisperse dyeAs Directed

The invention discloses an environment-friendly steam- / wash-free dye printing paste, which is implemented by re-formulating monomer components partially in the prior binder. The steam- / wash-free binder can meet the requirement of random combination with acidic dyes, active dyes and disperse dyes; and is suitable for both manual and mechanical printing. The product printed with the blend of synthetic steam- / wash-free binder has bright color, clear pattern, high color yield, uniform printing block, good flowability, and soft touch. The invention is suitable for various printing processes such as direct printing, discharge printing and burnt-out printing, and is also used for printing various textile fabrics after mixing with other dyes. The invention simplifies the printing process, solves the environmental problem of the prior printing process, and avoids the environmental pollution of waste water.

Owner:丁志平

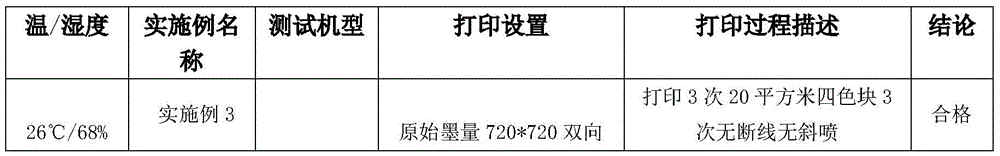

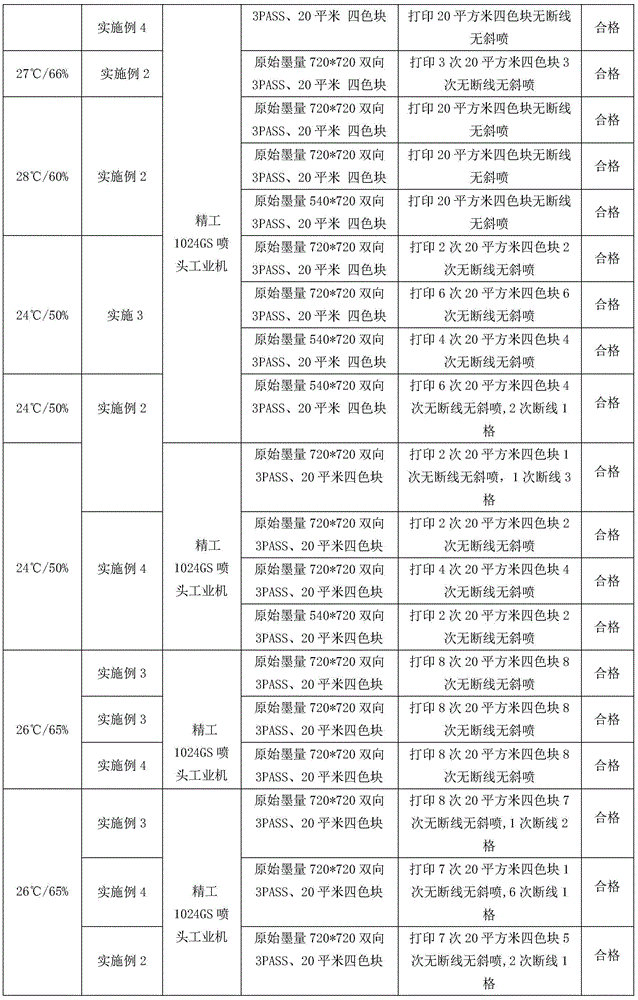

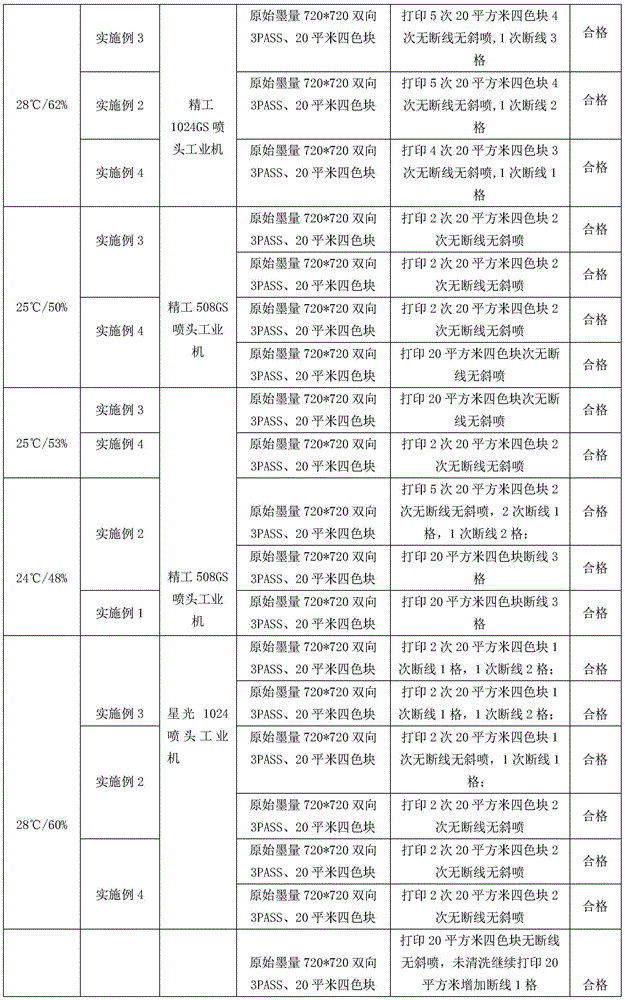

Inkjet printing acidic ink suitable for industrial nozzles and preparation method thereof

The invention discloses inkjet printing acidic ink suitable for industrial nozzles and a preparation method thereof. The ink comprises an acidic dye, a solubilizer, a surfactant, an organic solvent, a moisturizer, water and the like. The solubilizer is at least one selected from polyether polyol, caprolactam, and an ethylene oxide-epoxypropane copolymer; the surfactant includes at least two selected from EH-6, EH-9 and the like; the moisturizer is an amino acid moisturizer; and a defoamer is at least one selected from SUFYNOL DF-110D, BYK-094 and 104E. By means of the solubilizer, solubility of the acidic dye in the ink is effectively increased and flowability and jet-ability of the ink in an ink path and the nozzle are improved. The surfactant combination having low contact angle and low dynamic surface tension enables the ink to have better flatting and wetting properties. The combination of the solubilizer, the surfactant and the moisturizer enables the ink to have better universality and to be smoother, so that the ink is suitable for the industrial nozzles.

Owner:深圳市墨库图文技术有限公司

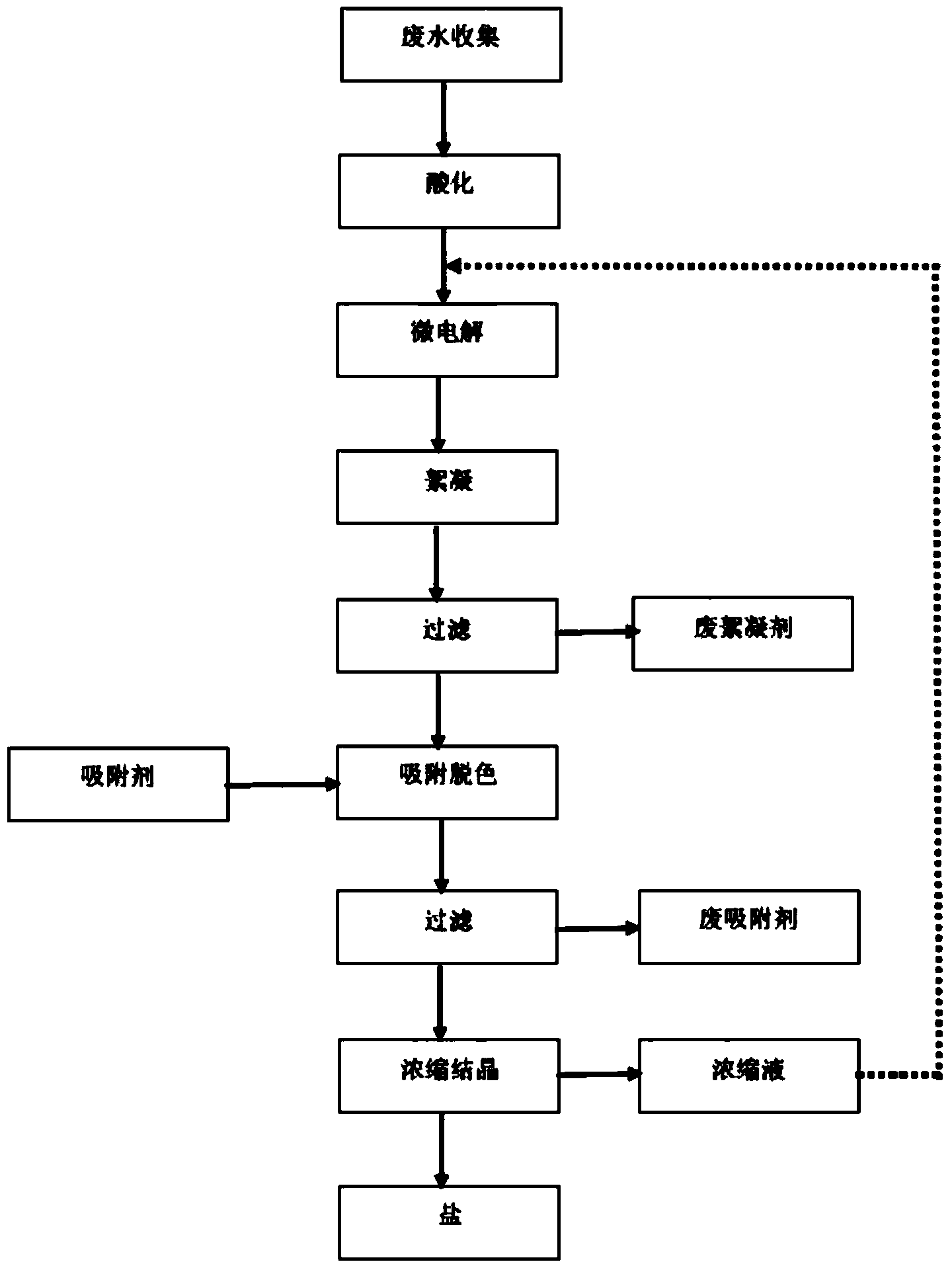

Treatment method of acid dye mother liquor wastewater

InactiveCN103755088AImprove qualityReduce processing costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationFlocculationWastewater

The invention discloses a treatment method of acid dye mother liquor wastewater. According to the treatment method, the collected acid dye mother liquor wastewater is subjected to acidification, microelectrolysis, flocculation, concentration and crystallization and separation, thereby obtaining high-quality sodium salt damp products, and the sodium salt damp products can be recycled to industrial production after being dried, and distilled water and cooled water can be recycled to production, and the collected heat energy also can serve as production energy sources to use. The treatment method reduces the treatment cost of wastewater, and is an environment-friendly and economical treatment method.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com