Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Good same color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing process for viscose/brocade blended silks by active/acid dye-bath method

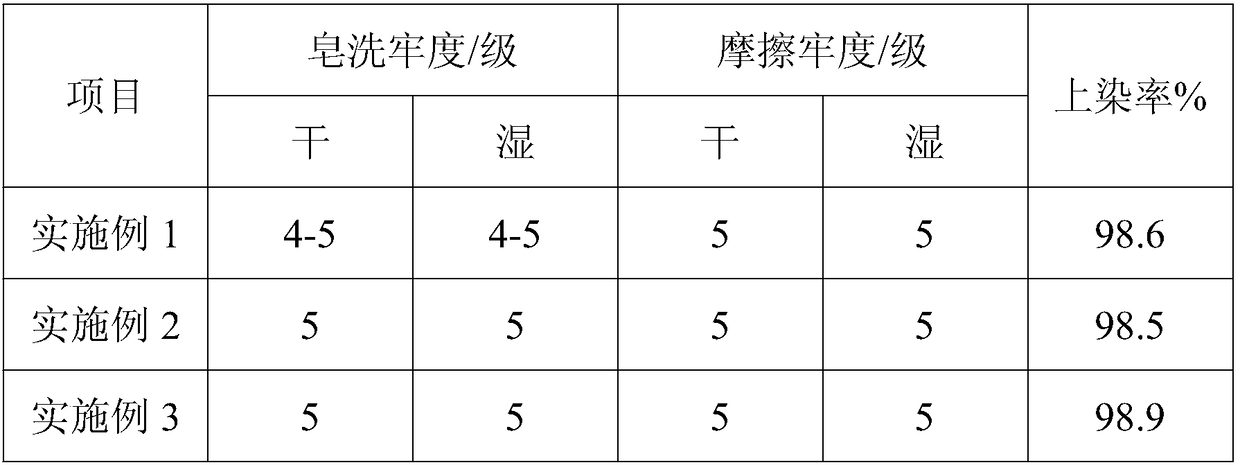

The invention relates to a dyeing process for viscose / brocade blended silks by an active / acid dye-bath method. The dyeing process is characterized in that the optimal dyeing process with mixed dyes is determined by researching pH, an alkaline agent, an electrolyte, a curing agent, temperature at the early period of dyeing and different heat-holding times, so that better homochromatism is obtained for the viscose / brocade fibers in one-bath dyeing, and higher dye-uptake rate and soaping fastness are obtained.

Owner:WUXI DONGXIN WEAVING

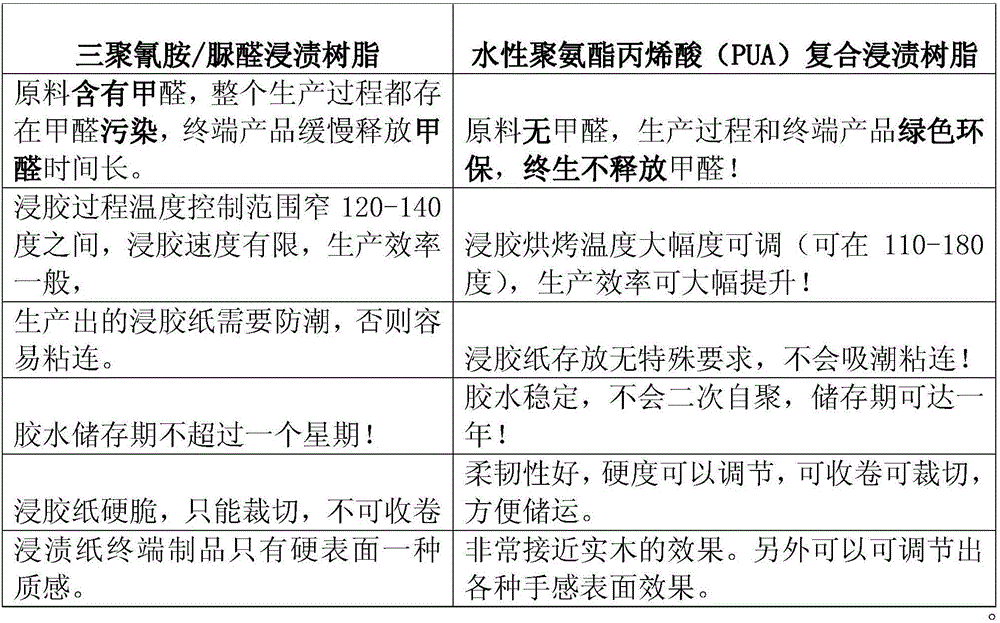

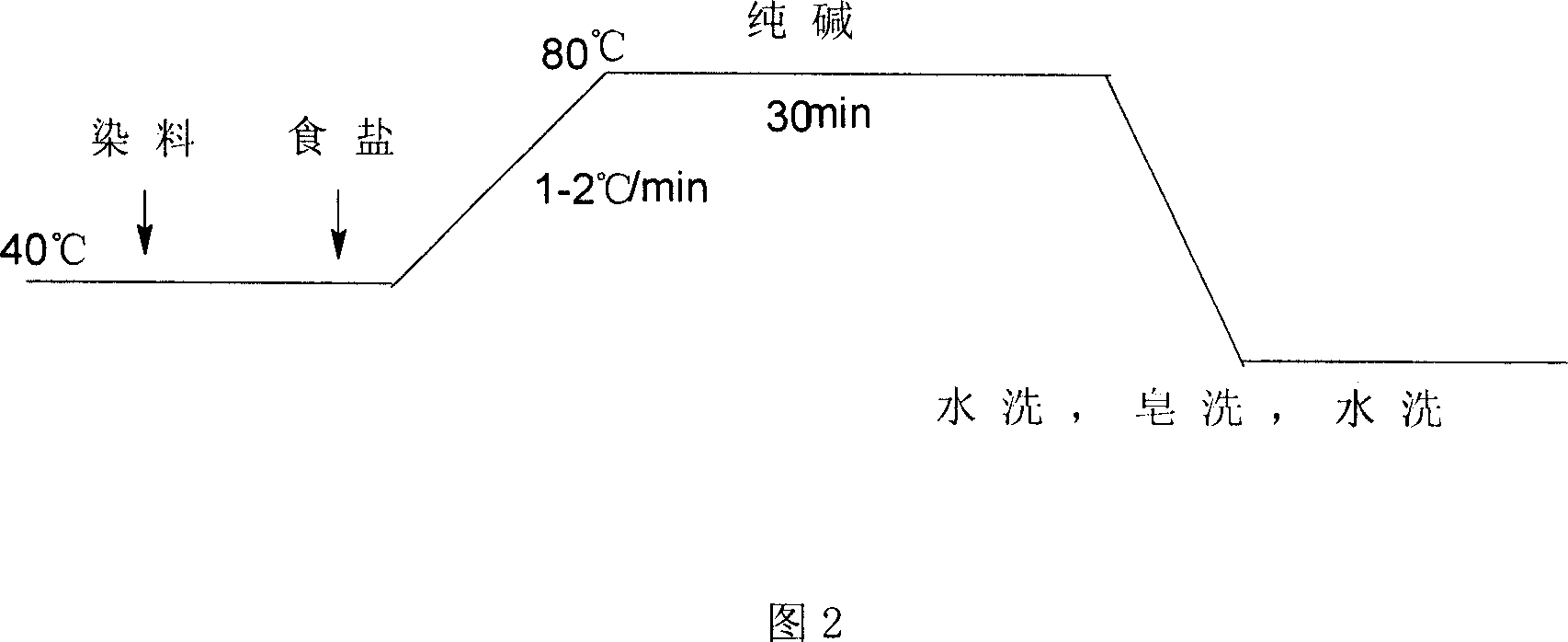

Dyeing process for silk and pashm blended yarn

InactiveCN101289812ALow costEmission reductionBeaming machinesDyeing processColour fastnessBreaking strength

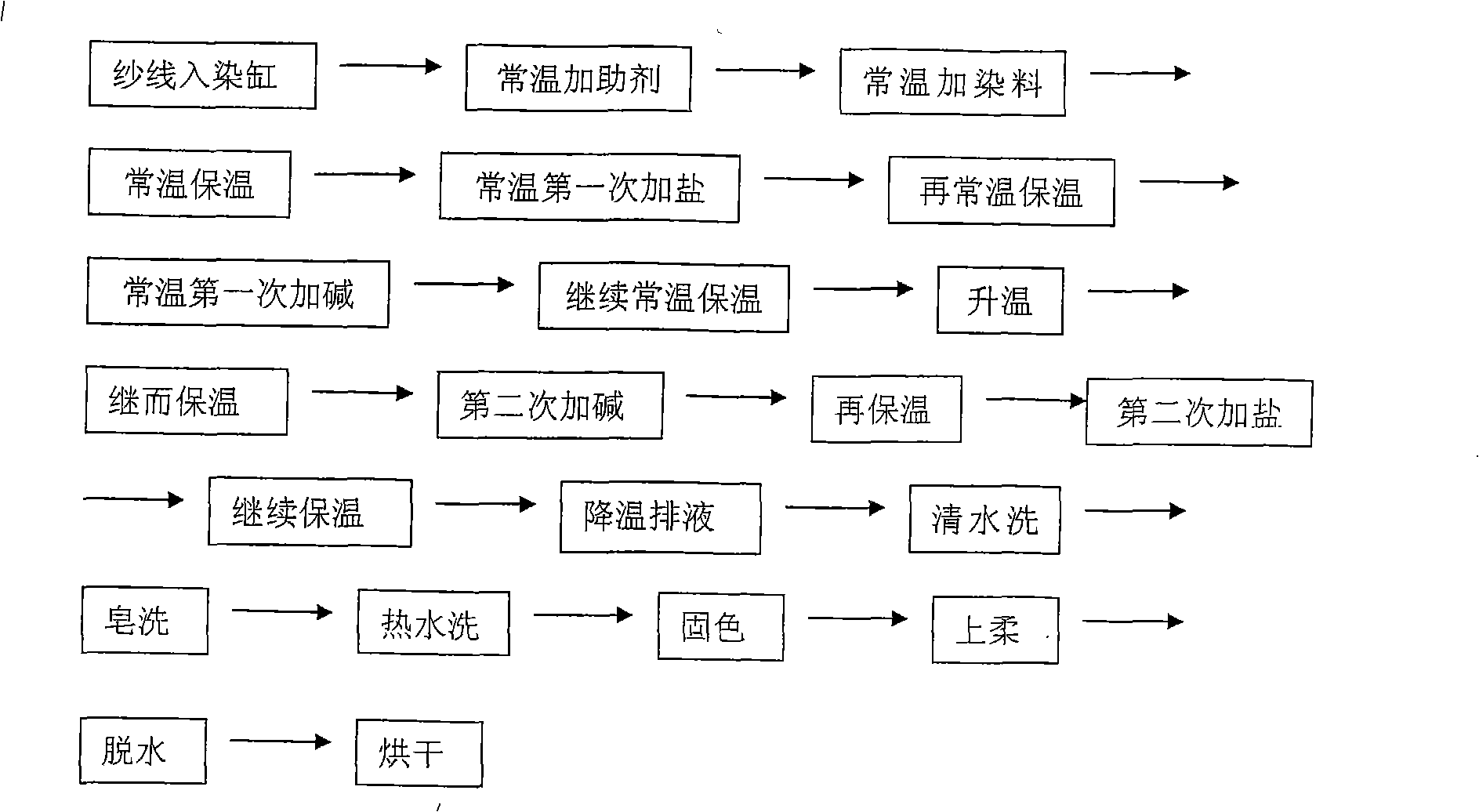

The invention provides a process for dyeing silk-cashmere blended yarns, belonging to the weaving yarn dyeing technical field. The process comprises the following steps that: silk-cashmere blended yarns ready to be dyed are put in a dye vat, water is added in the dye vat, and the bath ratio is controlled; at the normal temperature, auxiliary agent and dyes are added in the dye vat; the dye vat is kept warmth at the normal temperature; at the normal temperature, salt is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; alkali is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; the dye vat is heated, and the temperature-rise speed is controlled; the dye vat is kept warmth; alkali is added in the dye vat for the second time; the dye vat is kept warmth again; salt is added in the dye vat for the second time; the dye vat is kept warmth again; finally after sequent steps of temperature drop and liquid discharging, fresh water washing, soap washing, hot water washing, color fixation, upper flexibility, dewatering and drying, dyed silk-cashmere blended yarns are obtained. The process has the advantages of high color fastness, good level-dyeing property, good homochromaatism, high breaking strength, bright color, filled yarns, uneasy teasing, time conservation, low dye cost, simple processing step, energy consumption reduction, low sewage discharge and environment protection.

Owner:常熟市亨时特染织有限公司

Energy and water saving dyeing method for seamless underwear

ActiveCN102561070AReduce residual rateHigh whitenessBiochemical fibre treatmentBleaching apparatusWater savingOxygen

The invention relates to an energy and water saving dyeing method for a seamless underwear. A seamless weft knitting weaving technology is used for achieving one-off weaving forming of the seamless underwear. The dyeing and finishing process of the seamless underwear after being woven includes oxygen bleaching by the liquor ratio of 1: 8-10, dyeing by the liquor ratio of 1: 12-15 and soaping by the liquor ratio of 1: 8-10. By means of the energy-saving dyeing and finishing technology of non-caustic-soda oxygen bleaching process, one-bath one-step dyeing process and biological enzyme soaping process, one-time accurate dyeing is achieved, one-bath one-step completion is achieved, processing time is shortened, and sewage discharge and treatment are reduced.

Owner:GUANGDONG RUIYUAN TECH

Dyeing and finishing process of coffee-yarn blended and knitted fabric

ActiveCN104727163ARealize medium and dark double dyeing processAccelerated adsorption and dispersionFibre treatmentDyeing processColour fastnessYarn

The invention discloses a dyeing and finishing process of a coffee-yarn blended and knitted fabric. The dyeing and finishing process is characterized by comprising the following steps: preparing grey fabric, pretreating, dyeing, soaping, softening and carrying out after finishing, wherein a mild pre-treatment degreasing process is adopted; and an active double-dyeing process of firstly dyeing, dispersing and dyeing is adopted to dye, so that the difficulty in dying with the same color of the blended and knitted fibers is solved; through control on a finishing agent and the amount of the finishing agent in the after finishing process of the coffee-yarn blended and knitted fabric, the problems of same color and different colors in the dyeing process of the coffee-yarn blended and knitted fabric are solved; good air permeability and relatively good rubbing fastness are obtained; and meanwhile, a plurality of efficacies that the coffee-yarn blended and knitted fabric is capable of absorbing stink, removing an odor, storing heat, keeping warm, absorbing moisture and drying quickly in an far infrared manner are taken into account.

Owner:浙江七色彩虹科技有限公司

Polyester/sorona mixed fabric disperse dye one-bath process dyeing method

InactiveCN103215831AImprove qualityShade stabilityDry-cleaning apparatus for textilesDyeing processDisperse dyeColour fastness

The invention relates to a polyester / sorona mixed fabric disperse dye one-bath process dyeing method. According to the determined optimal dyeing process of polyester / sorona mixed fabric, the dye dosage is greater than or equal to 2% (owf), the pH value is 5.5, the dyeing time is 50 minutes, the dyeing temperature is 110 DEG C, and the carrier dosage is 1.5g / L. The result indicates that the dyeing method can obtain a product with stable color light, good homochromatism and high color fastness; and the process is simple, the time is short, and the production cost is low.

Owner:JIANGYIN POLYTECHNIC COLLEGE

Fiber pervasion swelling agent and method for dyeing the same

ActiveCN101349009AUniform dyeingGood same colorFibre treatmentDyeing processDiacetone alcoholEthyl salicylate

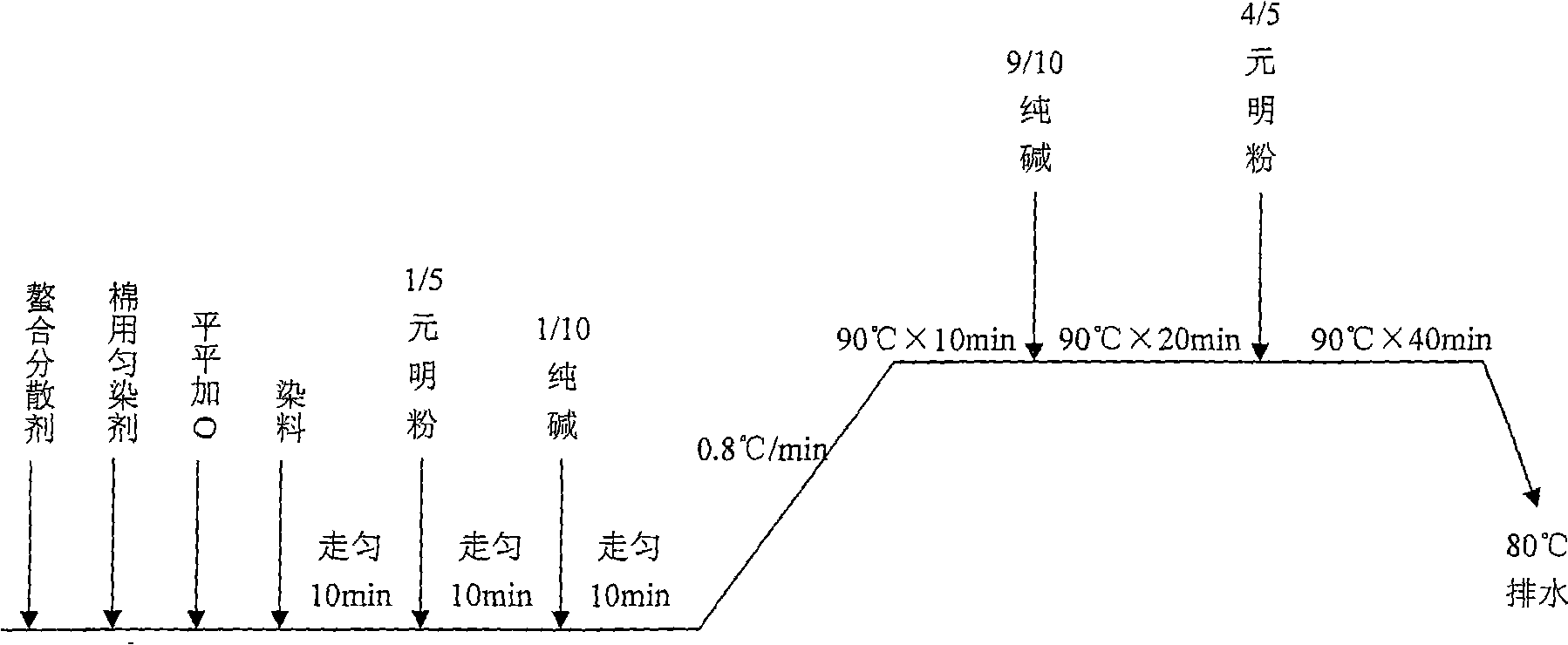

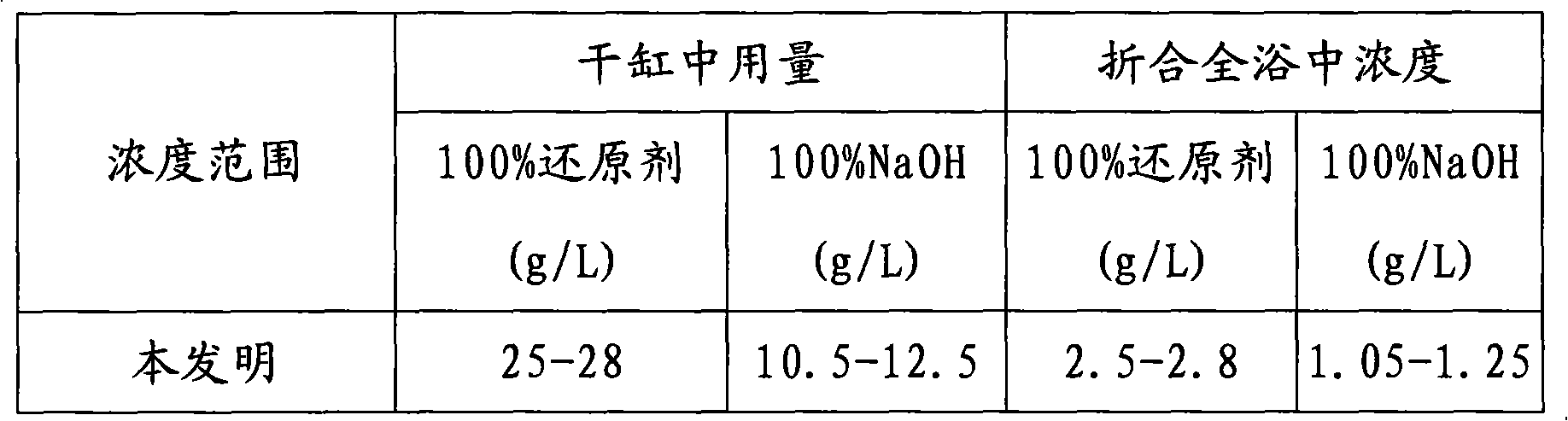

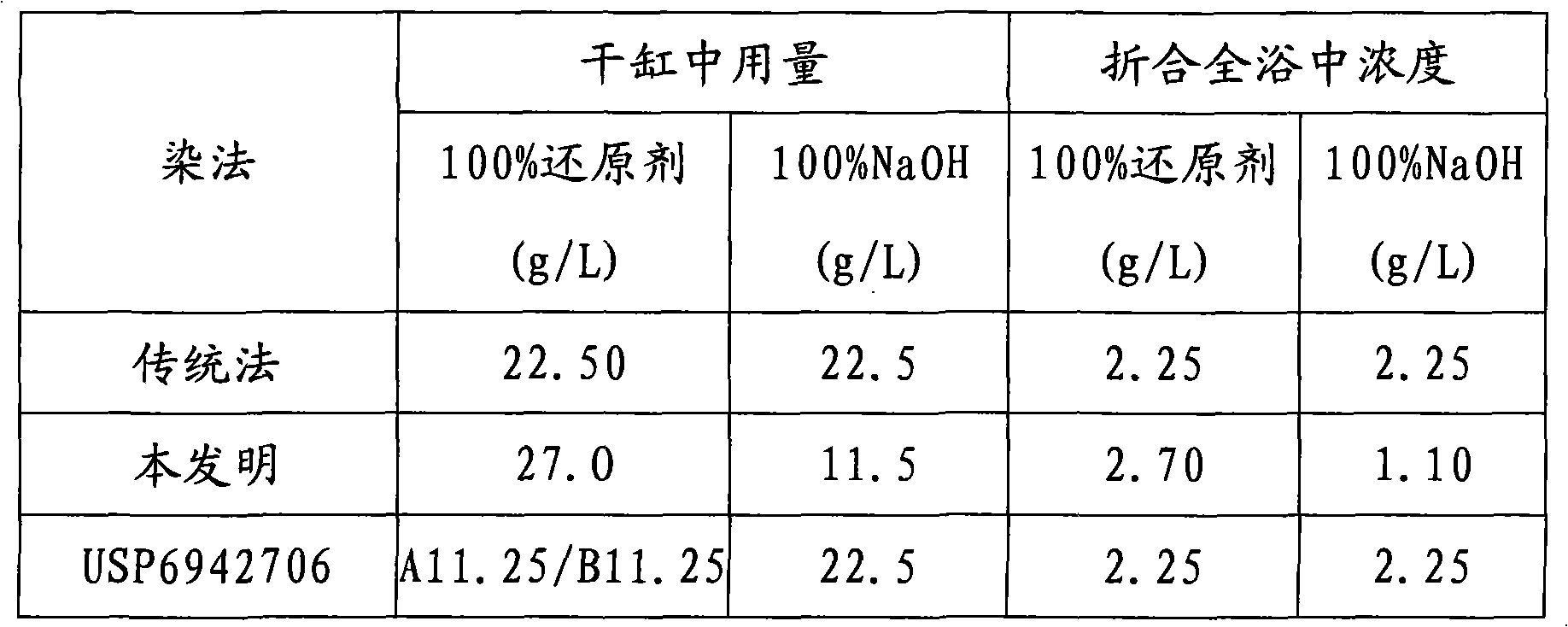

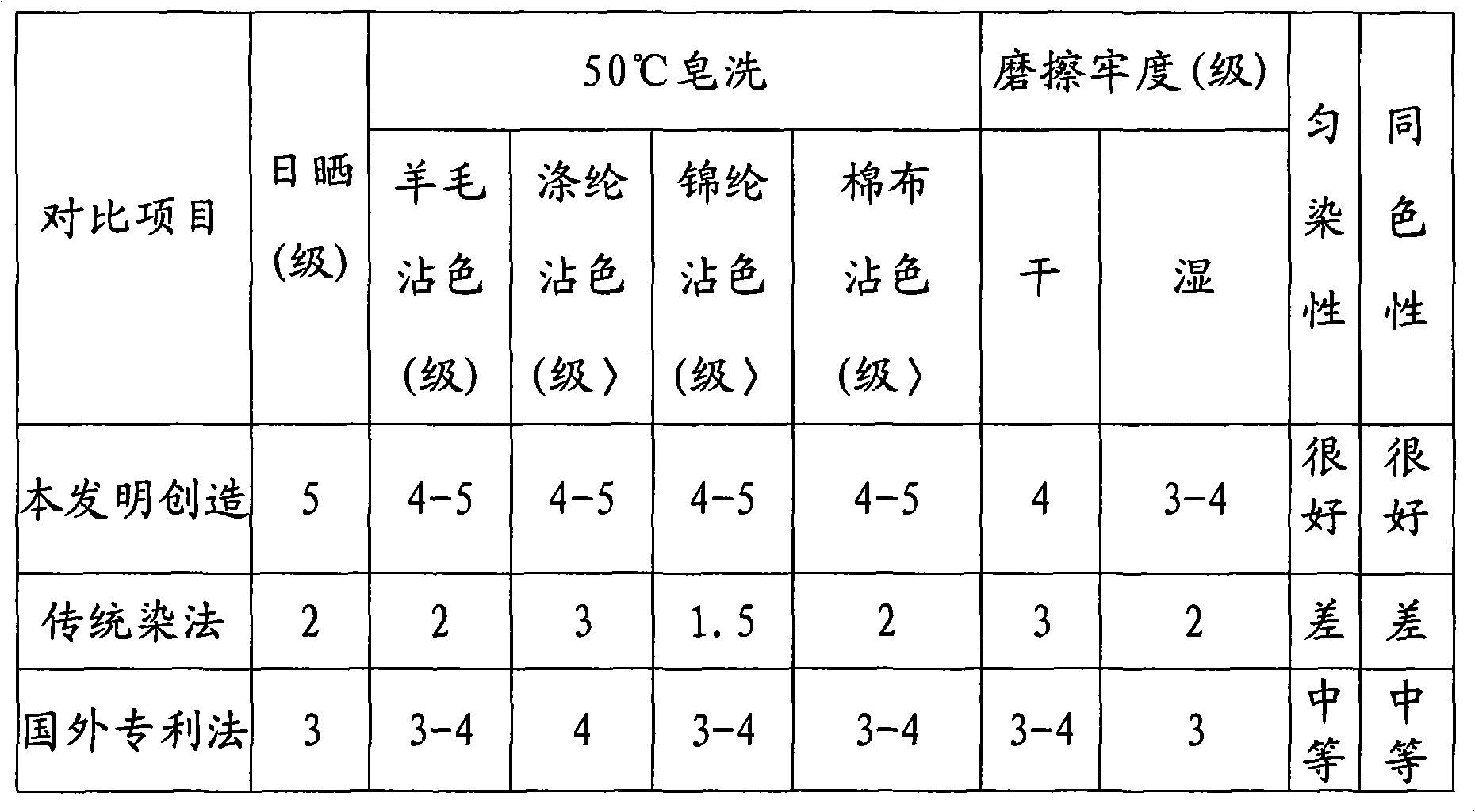

The invention discloses a fiber penetrating swelling agent which comprises the compositions in weight portion: 0.00016 to 0.0006 portion of laurocapram, 1 to 5 portions of N-methyl pyrrolidone, 5 to 10 portions of diacetone alcohol, 5 to 15 portions of ethyl salicylate, and 5 to 10 portions of isopropyl salicylate. The invention also discloses a method for dyeing by the fiber penetrating swelling agent, comprising the following steps that: a reducing agent and sodium hydrate are used for reducing the dye by a vatting method; the weight ratio of a reducing solution to the dye is 37.5: 0.8 to 2.0; a leveling agent and the fiber penetrating swelling agent are added to dye or a buffering agent is added to adjust the pH value and is dyed by vat acid, the temperature is reduced and the mixture is washed; the mixture is subjected to oxidizing to develop color, fixing, reducing temperature and washing; the fresh water bath is performed, the fiber penetrating swelling agent is reduced and washed, and the temperature is reduced and the fiber penetrating swelling agent is produced. The fiber penetrating swelling agent ensures that the dye insoluble in water is effectively moistened and penetrated, and the fiber crystallizing area is effectively swelled to receive the dye; the fiber penetrating swelling agent ensures that a suspended solid is dyed evenly, has good homochromatism, improves the degree of dyeing, and solves the 'white core' problem of fiber.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

Seamless knitting anti-electromagnetic radiation clothing and manufacturing method thereof

The invention relates to seamless knitting anti-electromagnetic radiation clothing and a manufacturing method thereof. The seamless knitting anti-electromagnetic radiation clothing consists of two layers of fabrics which are outer knitting fabric and inner shielding fabric. The outer knitting fabric comprises the following fiber compositions by weight percentage: 80-90 percent of chinlon 6 stretch yarns, 5-10 percent of chinlon 66 stretch yarns and 5-10 percent of spandex elastic fiber yarns; and the inner knitting fabric comprises the following fiber compositions by weight percentage: 50-55 percent of chinlon 6 stretch yarns and 45-50 percent of silver metal conductive fiber yarns; and after assistants such as 3 percent of leveling agents, 4 percent of detergents, 4 percent of creasing agents, 2 percent of penetrants and 0.5 percent of ammonium sulfate are added, an appropriate amount of dyes is added again. The seamless knitting anti-electromagnetic radiation clothing has the advantages of anti-electromagnetic radiation and good shielding effect and is comfortable to wear.

Owner:GUANGDONG RUIYUAN TECH

Dyeing and finishing technology of Lyocell and cotton and spun silk blended fabric

InactiveCN102926236ASolve the consistency of dyeing the same colorThe dyeing process is reasonableDry-cleaning apparatus for textilesBleaching apparatusEngineeringLyocell

The invention relates to a blended fabric dyeing and finishing technology, and particularly relates to a dyeing and finishing technology of a Lyocell and cotton and spun silk blended fabric. The invention aims at providing a dyeing condition capable of well coordinating Lyocell and cotton and spun silk to produce a high-quality product. The dyeing and finishing technology of the Lyocell and cotton and spun silk blended fabric comprises the processes of pretreatment, dyeing and the like; the pretreatment process comprises desizing and bleaching, wherein the desizing is performed by an enzyme-oxygen cold batch technology, and desizing enzyme, a chelating dispersant, a dewaxing agent and a refining agent are added in the desizing process; and 100% hydrogen peroxide and a stabilizer are added in the bleaching process. Through the invention, the problems of difficult color register and long technological flow are successfully solved; and through the method, the dyeing flow of the fabric is more reasonable, the production is clean and environment-friendly, and the product quality is stable.

Owner:HUAFANG

Dyeing and finishing process for suede fabric

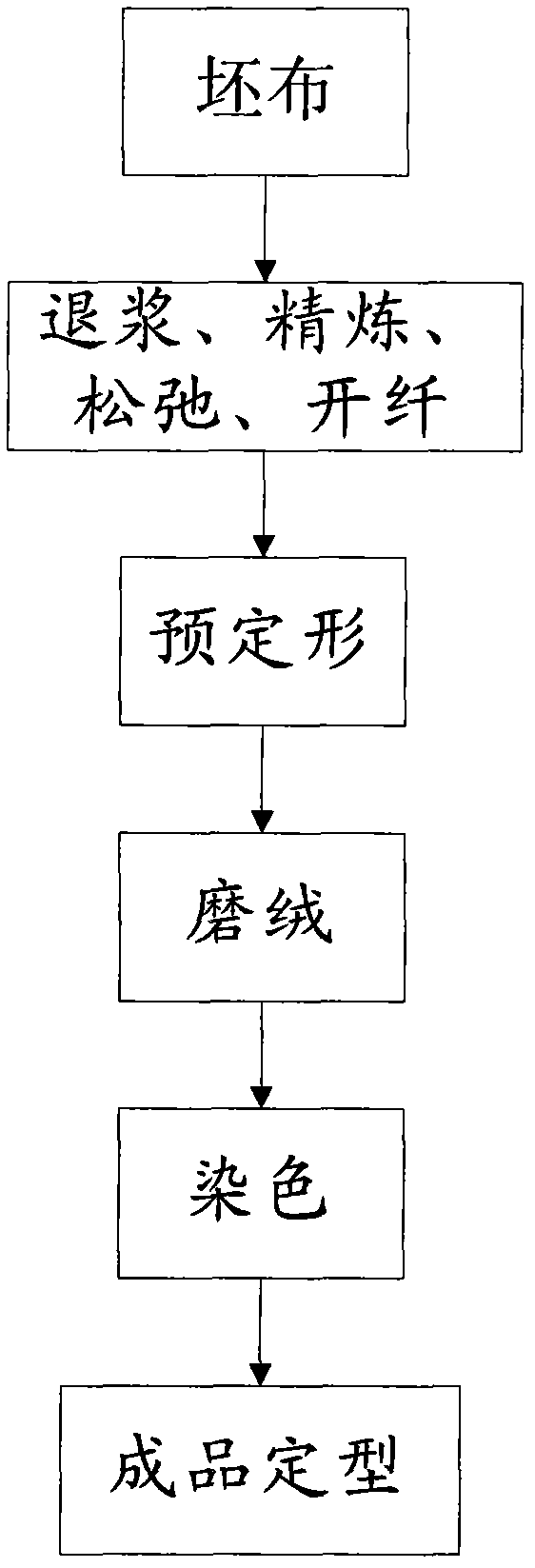

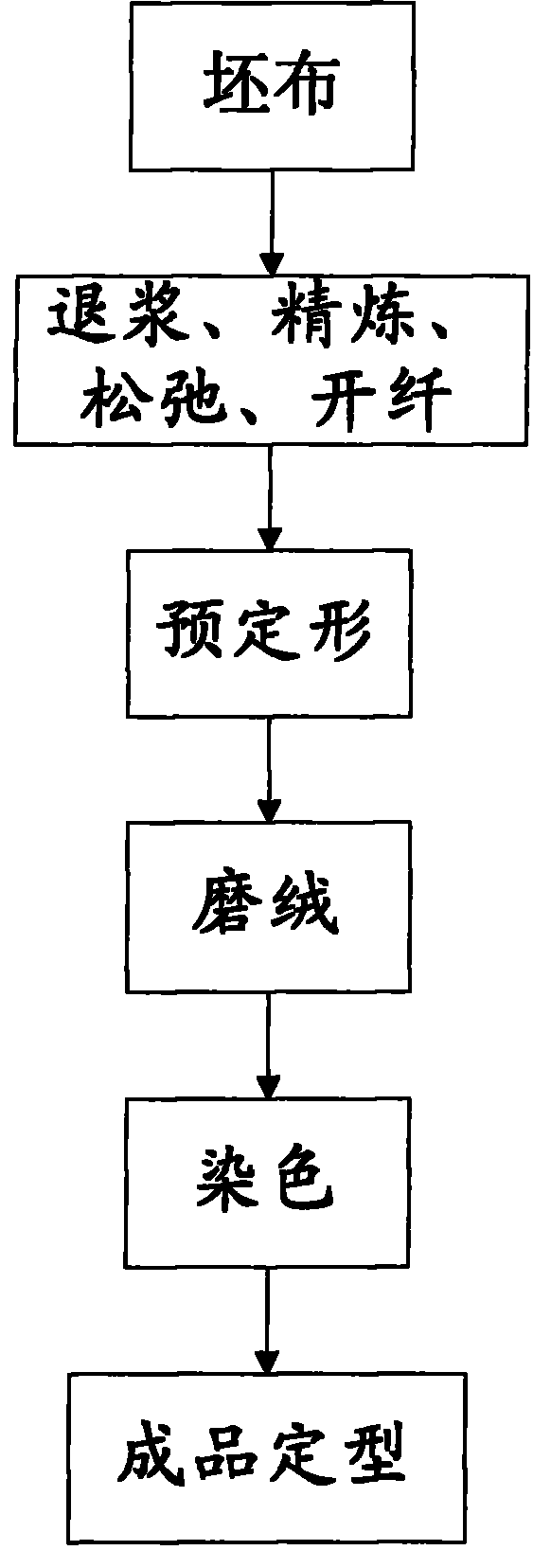

InactiveCN102465460AImprove recycling efficiencyMeet the requirements of rapid responseDyeing processEngineeringDye penetration

The invention discloses a dyeing and finishing process for a suede fabric. The dyeing and finishing process comprises the following steps of: desizing, refining, slackening, splitting, presetting, sueding, dyeing a gray fabric; and forming a finished product, wherein the gray fabric is dyed by adopting a supercritical fluid dyeing means in the dyeing step, the dyeing temperature is 90-115 DEG C, the dyeing pressure is 18-25MPa, and the dyeing time is 15-45min. According to the dyeing and finishing process disclosed by the invention, time, labor and energy sources are saved; the environment is protected; and the dyed and finished product has the characteristics of high dyeing firmness, dyeing penetration and isochromatic property.

Owner:CHANGSHU ZHUOHUI TEXTILE

Dyeing method for hybrid loose fibers

InactiveCN102965978AShorten the processing flowGood same colorBleaching apparatusDyeing processYarnVinyl sulfone

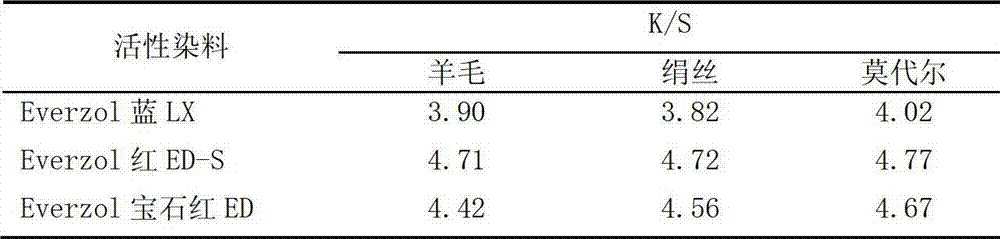

The invention relates to a dyeing method for hybrid loose fibers and particularly relates to a method for co-bath dyeing of the hybrid loose fibers including wool fibers, spun silk fibers and regenerated cellulose fibers in a same cylinder, which belongs to the field of fabric dyeing. According to the technical scheme, the dyeing method comprises the step of performing pretreatment on the hybrid loose fibers subjected to co-bath in the same cylinder, wherein the pretreatment comprises the procedures of performing reduction bleaching on the fibers by sodium hydrosulfite and oxidation bleaching on the fibers by hydrogen peroxide, and then performing once same-color dyeing on the hybrid loose fibers through co-bath in the same cylinder by vinyl sulfone reactive dyes or reactive dyes containing vinyl sulfone groups. The dyeing method is used for dyeing the three loose fibers in the same dyeing cylinder by the reactive dyes, fulfills the aim of dyeing the three fibers, and changes the conventional processing mode of dyeing the three loose fibers for three times independently in the current spinning processing of colored blended yarns, thus greatly reducing the processing flow of the colored blended yarns, lowering the production costs of the colored blended yarns, achieving remarkable effects of energy conservation and emission reduction, and ensuring good homochromatism of the three fibers.

Owner:SUZHOU UNIV +1

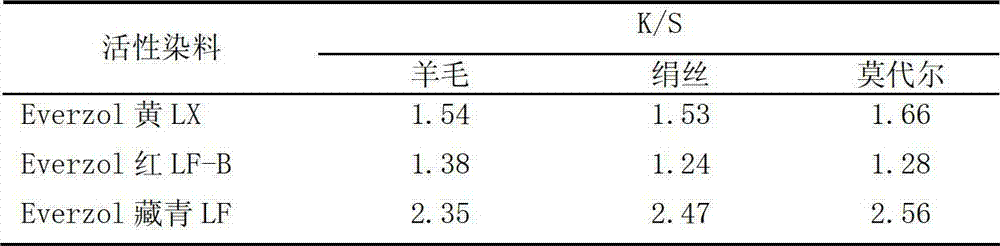

Novel aqueous polyurethane-acrylate composite impregnating resin and preparation method thereof

The invention relates to novel aqueous polyurethane-acrylate composite impregnating resin and a preparation method thereof and aims to enable resin prepared by the method provided by the invention to simultaneously have the advantages of aqueous polyurethane and water-based acrylic acid, and become aqueous polyurethane-acrylate (PUA) composite resin. The technical scheme is that the novel aqueous polyurethane-acrylate composite impregnating resin is prepared from the following components: an acrylate monomer, dimethylolpropionic acid (DMPA) and the like; the preparation method of the novel aqueous polyurethane-acrylate composite impregnating resin comprises the following steps: firstly, preparing a polyurethane prepolymer; secondly, preparing an aqueous polyurethane-acrylate monomer mixed emulsion; thirdly, adding 20 percent of the mixed emulsion obtained by preparation in a reactor, adding remaining deionized water, improving the temperature to be 80 DEG C, and adding potassium peroxodisulfate serving as an oxidant for initiating; at the moment, paying attention to controlling temperature mutation; after clear blue light appears in the emulsion, keeping the reaction temperature unchanged, and dropwise adding remaining mixed emulsion and sodium hydrogen carbonate serving as a buffering agent.

Owner:HANGZHOU TIANYUAN CHENGDA DECORATIVE MATERIAL

Method for improving level-dyeing property of chitin/cotton fiber mixed fabrics

This invention discloses one process method to improve crust or cotton mixture dying property, which comprises the following steps: adopting anode ion etherifying agent, alkaline agent and other assistant agent before mixture fabric dying. This invention adopts cation crust or cotton mixture fabric for pre-process for dying, which improves the cotton fiber direct property and reduce dying rate difference on curst fiber and mixture fabric even dying.

Owner:QINGDAO UNIV

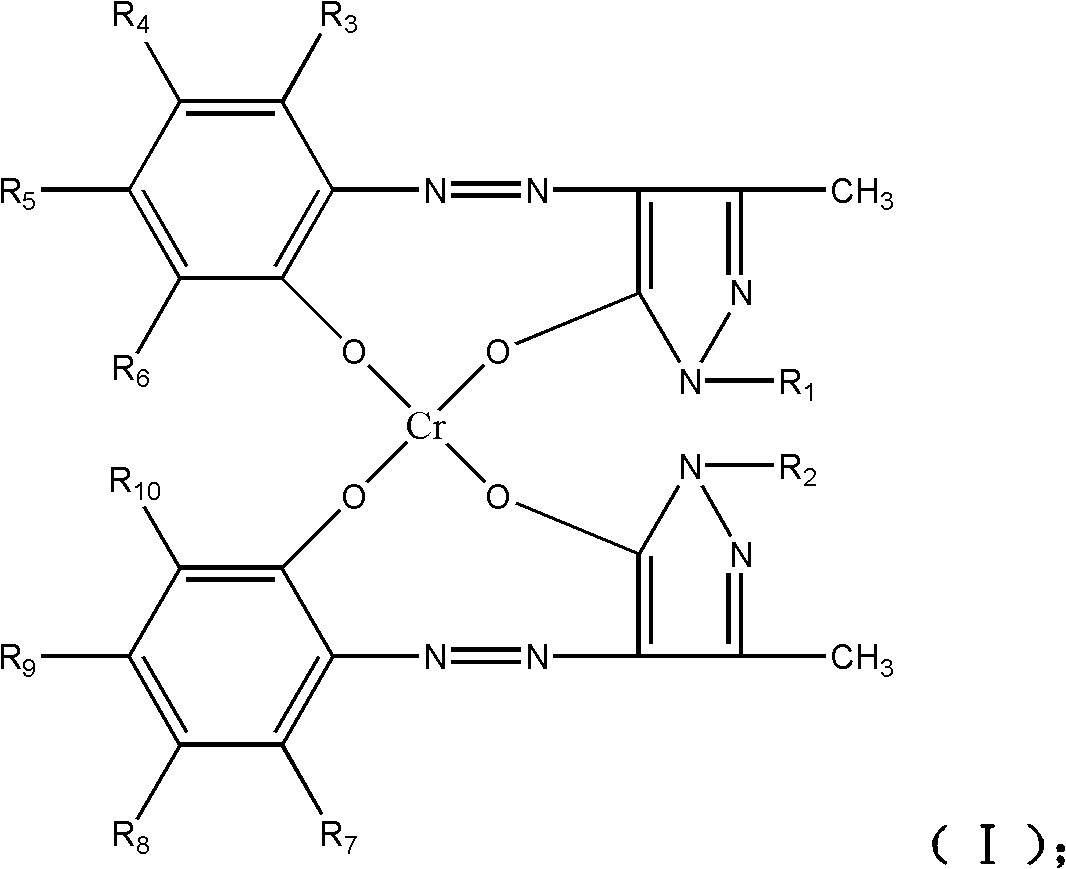

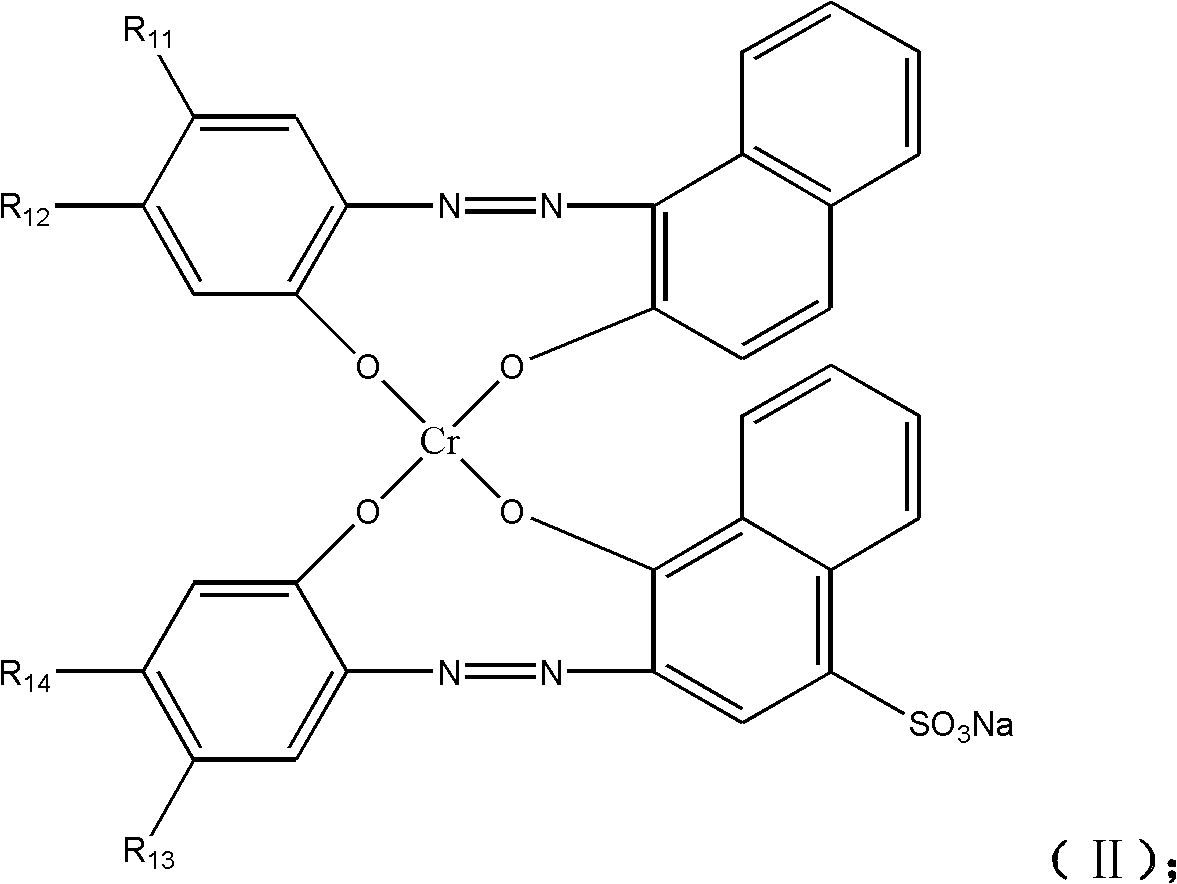

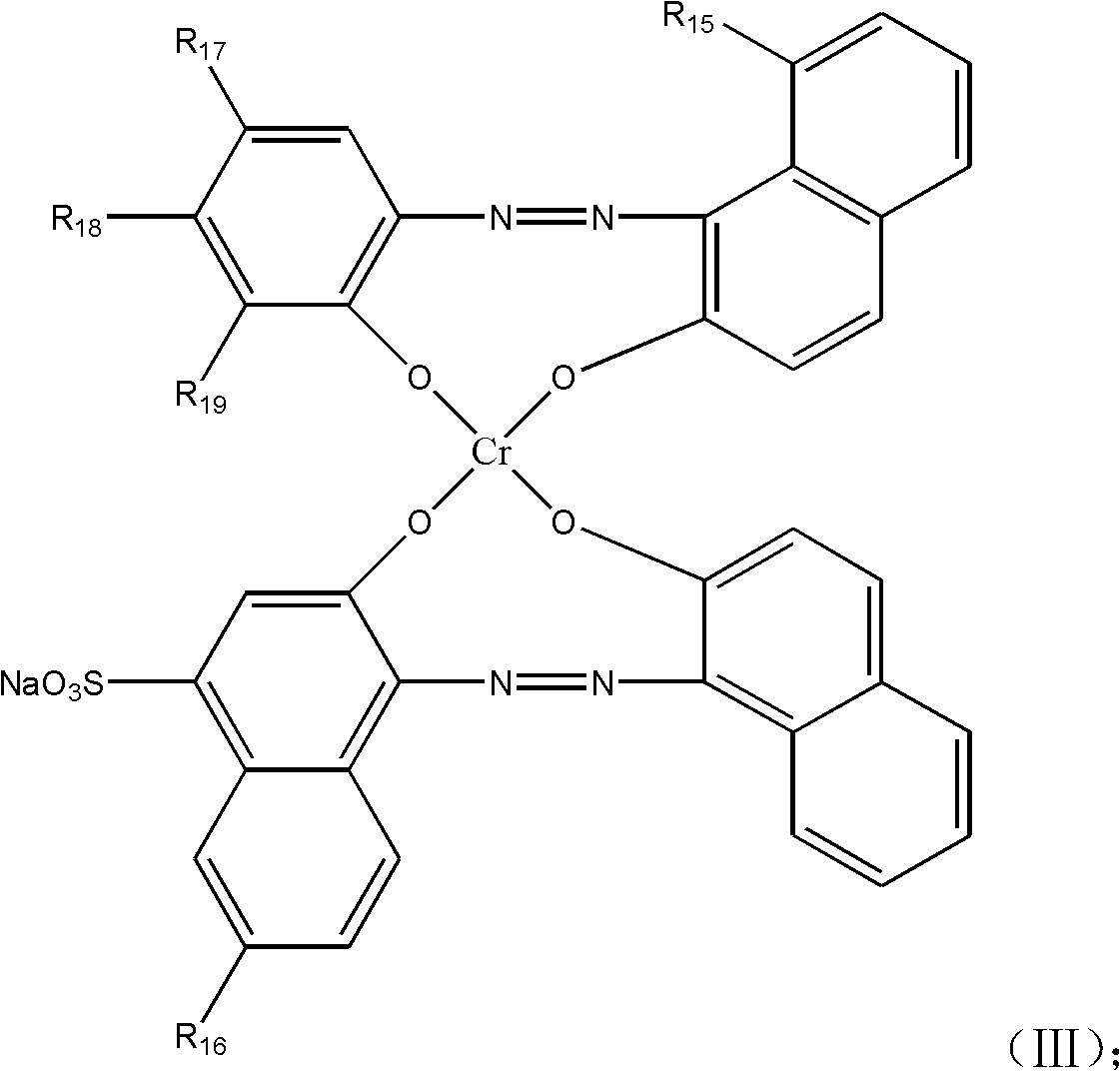

Neutral dye composition

InactiveCN102634235AGood same colorGood compatibilityOrganic dyesDyeing processPerspirationColor tone

The invention discloses a neutral dye composition which consists of a dye component and an auxiliary component. In the dye composition, three dyes are mixed in compatibility, and each of the three dyes is asymmetric 1:2 metal complex. The composition has better isochromatic property in dyeing wool, chinlon and chinlon-spandex blend fiber to obtain better color tone, better wet fastness, water logging fastness of level 5, rubbing fastness of level 5, light fastness of level 6, perspiration (alkali) of level 4-5, perspiration (acid) of level 4-5, consistent dyeing curve, high dyeing rate and good isochromatic property; and the composition can be widely applied to the dip dyeing for continuous dyeing.

Owner:河北永泰柯瑞特化工有限公司

A kind of 3D technology paper and its production method and production equipment

ActiveCN104562848BHigh hardnessImprove wear resistanceNon-fibrous pulp additionPaper/cardboardCross-linkAcrylic resin

The invention provides 3D science paper as well as a production method and production equipment thereof. The 3D science paper is prepared by soaking printing decorative paper serving as a raw material into glue with high transparency, wherein the glue comprises the following components in percentage by weight: 20-30% of polyurethane, 30-50% of acrylic resin, 1-3% of a cross-linking agent, 1-3% of a curing agent, 3-5% of a permeating agent, 1% of a flatting agent and the balance of water. The 3D science paper has an extremely good homochromatic effect, does not have chromatic aberration, is high in hardness, scratch-resistant, wear-proof and good in toughness, can be bent for 180 degrees without cracking, and is favorable for packaging. Moreover, the raw materials, aids, resin and the like in the production process of the product are water-soluble, so the 3D science paper is nontoxic and environmentally friendly.

Owner:HANGZHOU TALENT DECORATION PAPER

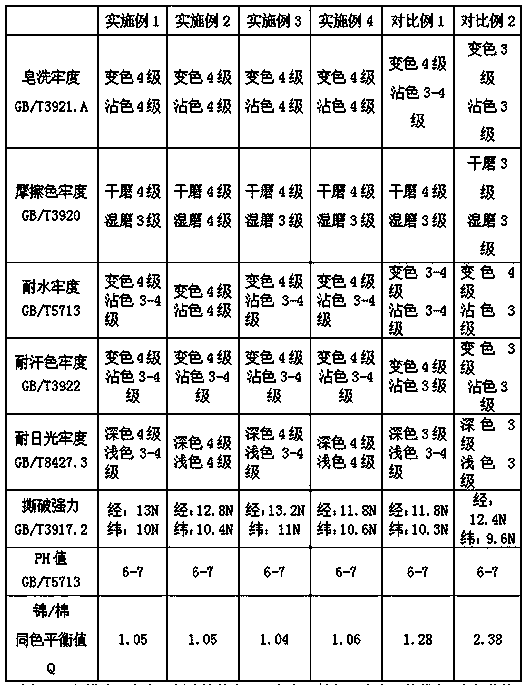

One-bath and one-step dyeing preparation method of brocade/cotton blended fabric acid dyes

The invention relates to a one-bath and one-step dyeing preparation method of brocade / cotton blended fabric acid dyes. The method includes the steps: mixing and reacting a brocade / cotton blended fabric and fiber modifying agents with quaternary ammonium groups, adding alkali solution to continue to react mixture, taking out the fabric, washing the taken fabric by the aid of water, treating the washed fabric by the aid of acid solution, and washing and drying the fabric to obtain a modified brocade / cotton blended fabric; mixing the modified brocade / cotton blended fabric, acid dyes and levelingagents, adding pH (potential of hydrogen) conditioning agents to adjust pH of dye bath to reach 3-5, performing one-bath and one-step dyeing, discharging liquid, and performing washing, color fixing and drying on the modified brocade / cotton blended fabric to obtain the dyed brocade / cotton blended fabric. A dyeing process is simple to operate, high in efficiency, high in device adaptability and lowin cost, the dyed blended fabric is good in union color property, bright in color and excellent in washing fastness and rubbing fastness, and the method has far-reaching influence on development of brocade / cotton blended fabric dyeing techniques.

Owner:DONGHUA UNIV +1

Environmentally friendly dye composition

Owner:FOSHAN SHIRUI LEADING MATERIAL RES INST GENERAL PARTNERSHIP

Homochromatic dyeing process of wool/silk blended fabric

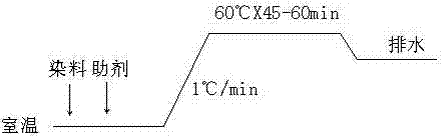

The invention provides a homochromatic dyeing process of wool / silk blended fabric, which comprises the following steps: A)washing fabric; B)dyeing: placing the washed fabric in a dyeing machine, adding 1-2%owf leveling agent, adding 1-3%owf vinyl sulfone double-reactive-group dye for dyeing, wherein bath ratio is 1: 10-30, controlling the pH value at 5-7 during a dyeing process; wherein the dyeing temperature is 80-90 DEG C, and the dyeing time is 80-100 minutes; C)fixing color: washing water with temperature of 50 DEG C on the dyed fabric, adding 3-5%owf fixing agent, immersing for 30-50 minutes under normal temperature; and D)drying. The homochromatic dyeing process has the advantages of good homochromatic property of blended fabric and good color fasteness, the fastness of soaping and dry friction can reach more than grade four, moisture friction fastness can reach more than grade 3, and the discharge capacity of the dyeing waste water can be greatly reduced.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

One-bath dyeing process of brocade cotton fabric

The invention relates to one-bath dyeing process of brocade cotton fabric. The process comprises the following steps: putting the brocade cotton fabric subjected to cold-dwell desizing treatment intoa dye vat, wherein a bath ratio is 1 to (5-10), adding Anoky NC type reactive dye, and sequentially adding anhydrous sodium sulphate and an alkaline agent after the reactive dye is uniformly dissolved, slowly heating up to 98-100 DEG C and carrying out heat preservation for 50-60min, then cooling and draining, sequentially washing and soaping, then washing again, and discharging the fabric. The reactive dye used in the process contains a quaternary ammonium pyridine formic acid active group, and the pH value of a dyeing bath gradually changes from alkalinity to acidity as the rise of temperature, and the dye-uptake of the dye changes along with the change of the pH; when being alkaline, the dye bath reacts with a hydroxyl group in cotton fibers, so that a covalent bond with a firm structure is formed, and cotton dyeing is further realized; when being gradually turned to be acid, the dye bath reacts with an amino group in chinlon, so that a covalent bond with a firm structure is formed,and chinlon dyeing is further realized; therefore, the brocade cotton fabric is not only good in color and cloth surface effect, but also has the fastness which is in line with customer requirements.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

Blend dyeing method of cotton-real-silk fabric

InactiveCN103103827AGood same colorLong-lasting color adhesionDyeing processWoven fabricsWater bathsSodium bicarbonate

The invention discloses a blend dyeing method of a cotton-real-silk fabric. The blend dyeing method comprises the following steps: based on adopting real-silk fiber yarns as warp yarns and adopting cotton fiber yarns as weft yarns, interleaving the warps and the wefts to obtain a cotton-real-silk blended fabric; adding reactive dye, sodium sulfate and sodium bicarbonate to a water bath with water; uniformly stirring; adding the cotton-real-silk blended fabric; dyeing for a certain time; adding alkali to the water bath to adjust the pH (Potential Of Hydrogen) to 8 to 10; and adding a dye-fixing agent to obtain the dyed cotton-real-silk blended fabric. According to the mode mentioned above, the blend dyeing method of the cotton-real-silk fabric, provided by the invention, has the advantages that high homochromatism is ensured by dyeing through the dye, the color can be attached for a long time, and the dye can be applied to the cotton fibers due to the sodium sulfate; the adopted method is few in processes and convenient in operation; the dyeing quality is effectively improved; and the method can be massively popularized and applied.

Owner:WUJIANG MAIDAO TEXTILE

Decoration method for silkworm chrysalis protein and acrylon graft copolymerization fabrics

The invention relates to a dyeing method for silkworm chrysalis protein and propylene graft copolymerization fiber, and its characteristic: adopting positive ion dye to dye them on the condition of adding DCP level dyeing agent, where the components of the level dyeing agent: C12-C18 alkyl dimethyl benzyl ammonium chloride, fatty alcohol polyoxyethylene (20-35), sorbitol fatty acid ester (C11H23COOC6H8(OH)5) and water. Before dyeing, it uses oxydol to bleach the fiber. The dyeing method is simple and the finished product has good homochromy and chroma.

Owner:上海丝绸集团股份有限公司

Method of producing cotton fiber product having smooth surfaces and cotton-regenerated cellulose compound yarn or fabric

Manufactures cotton fibers and fabrics containing cotton fibers with a glossy surface, soft touch, and excellent dyeability. Or when dyeing yarn or cloth containing both cotton fibers and regenerated cellulose fibers, the uniformity (same color) of the degree of dyeing between cotton fibers and cellulose fibers can be improved without impairing the hand feeling , and impart sufficient dyeability. Through the aqueous solution of potassium hydroxide whose surface tension is less than 75dyn / cm2, the yarn or cloth is treated under the condition of no tension until the static friction coefficient of the cotton fiber surface is 50-75% of the unprocessed product. Or process under tension until the coefficient of static friction is 40-65% of the unprocessed product.

Owner:SEIREN CO LTD

Seamless knitting anti-electromagnetic radiation clothing and manufacturing method thereof

The invention relates to seamless knitting anti-electromagnetic radiation clothing and a manufacturing method thereof. The seamless knitting anti-electromagnetic radiation clothing consists of two layers of fabrics which are outer knitting fabric and inner shielding fabric. The outer knitting fabric comprises the following fiber compositions by weight percentage: 80-90 percent of chinlon 6 stretch yarns, 5-10 percent of chinlon 66 stretch yarns and 5-10 percent of spandex elastic fiber yarns; and the inner knitting fabric comprises the following fiber compositions by weight percentage: 50-55 percent of chinlon 6 stretch yarns and 45-50 percent of silver metal conductive fiber yarns; and after assistants such as 3 percent of leveling agents, 4 percent of detergents, 4 percent of creasing agents, 2 percent of penetrants and 0.5 percent of ammonium sulfate are added, an appropriate amount of dyes is added again. The seamless knitting anti-electromagnetic radiation clothing has the advantages of anti-electromagnetic radiation and good shielding effect and is comfortable to wear.

Owner:GUANGDONG RUIYUAN TECH

Wool and silk blended fabric dyeing method

The invention discloses a wool and silk blended fabric dyeing method which comprises the following steps of: dyeing a wool and silk blended fabric, alum and alizarine in a water bath kettle at 20-40 DEG C, adding sodium sulfate and sodium bicarbonate to the water bath kettle for dyeing continuously; dyeing the dyed wool and silk blended fabric, which is taken out of the water bath kettle before, in another water bath kettle at 90-95 DEG C with acid red and anhydrous sodium sulfate, cooling the wool and silk blended fabric, and adding sodium carbonate to the water bath kettle for fixation of the wool and silk blended fabric, thus obtaining a red wool and silk blended fabric which is taken out of the water bath kettle. In the mode, the wool and silk blended fabric dyeing method adopts a homochromy dyeing technology to dye the wool and silk blended fabric, and thus the blended fabric has a high homochromy property and is hardly damaged; the dye is firmly attached to the blended fabric, and thus the blended fabric is not discolored under exposure to the sun; and a small quantity of wastewater and scraps are generated in the preparation process, and thus the pollution to water quality and environment is greatly alleviated.

Owner:WUJIANG MAIDAO TEXTILE

A kind of method for the same color dyeing of polyester-cotton fabric with indigo dye

The invention discloses a union dyeing method of a polyester-cotton fabric with indigo dye. The polyester-cotton fabric is dyed through the indigo dye in a two-bath two-step dyeing manner. The method including following steps: adding the indigo dye, sodium hydrosulfite and sodium hydroxide to a dye bath, increasing a temperature to 40-80 DEG C and maintaining the temperature for 10-50 min to enable the indigo dye to be reduced, adding a carrier and sodium chloride, putting the polyester-cotton fabric into the dye bath, increasing the temperature to 80-100 DEG C and maintaining the temperature for 20-90 min, adding the indigo dye, the sodium hydrosulfite and the sodium hydroxide to another dye bath, increasing the temperature to 40-80 DEG C and maintaining the temperature for 10-50 min to enable the indigo dye to be reduced, putting the dyed polyester-cotton fabric into the dye bath, increasing the temperature to 20-60 DEG C and maintaining the temperature for 30-60 min, and finally carrying out a water-washing process, a soaping process, a water-washing process and a drying process, or a drying process by air, to the dyed fabric. By means of the two-bath two-step dyeing method, the polyester-cotton fabric is dyed so that polyester and cotton fabric have a relative good identical color ability and a satisfactory dyeing depth can be achieved. The method is simple and feasible.

Owner:HENAN INST OF ENG

Homochromatic dyeing process for chitin-containing viscose-fiber fabric

ActiveCN106087489AAvoid high levels of adsorptionGood dyeing reproducibilityDyeing processOrganic baseSolvent

The invention discloses a homochromatic dyeing process for a chitin-containing viscose-fiber fabric. The method comprises the following steps: (S1) carrying out pretreatment: submerging the chitin-containing viscose-fiber fabric into isopropyl alcohol, adding a sodium hydroxide solution, carrying out uniform stirring, then, adding an etherifying agent CTA, carrying out a reaction with stirring, pumping off a solvent, carrying out water washing, and carrying out baking; (S2) carrying out reactive dyeing: submerging the fabric into a reactive dye dyeing solution, heating the reactive dye dyeing solution to a primary dyeing temperature, adding an organic solvent B, heating the solution to a dyeing temperature, then, adding organic base and sodium carbonate according to the volume of the reactive dye dyeing solution, then, cooling the solution to a color fixation temperature, carrying out heat preservation, cooling the solution to room temperature; (S3) carrying out aftertreatment: washing the fabric by water, carrying out soaping, carrying out water washing again, and carrying out air-drying. According to the homochromatic dyeing process for the chitin-containing viscose-fiber fabric, the defect that the dyeing rate of chitin viscose fibers is relatively high can be overcome, a uniform and consistent dyeing effect is obtained, and the homochromatic dyeing process has the advantages of high color fastness and simple process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Dyeing and finishing technology of Lyocell and cotton and spun silk blended fabric

InactiveCN102926236BSolve the consistency of dyeing the same colorThe dyeing process is reasonableDry-cleaning apparatus for textilesBleaching apparatusFiberEngineering

The invention relates to a blended fabric dyeing and finishing technology, and particularly relates to a dyeing and finishing technology of a Lyocell and cotton and spun silk blended fabric. The invention aims at providing a dyeing condition capable of well coordinating Lyocell and cotton and spun silk to produce a high-quality product. The dyeing and finishing technology of the Lyocell and cotton and spun silk blended fabric comprises the processes of pretreatment, dyeing and the like; the pretreatment process comprises desizing and bleaching, wherein the desizing is performed by an enzyme-oxygen cold batch technology, and desizing enzyme, a chelating dispersant, a dewaxing agent and a refining agent are added in the desizing process; and 100% hydrogen peroxide and a stabilizer are added in the bleaching process. Through the invention, the problems of difficult color register and long technological flow are successfully solved; and through the method, the dyeing flow of the fabric is more reasonable, the production is clean and environment-friendly, and the product quality is stable.

Owner:HUAFANG

Dyeing method of cotton viscose ramie blended fabric

InactiveCN102392370ABright colorGood same colorTextile storage in wounded formDyeing processEngineeringViscose fiber

The invention discloses a dyeing method of a cotton viscose ramie blended fabric, which can enable the cotton viscose ramie blended fabric to obtain good homochromatic effect and beautiful color. The method comprises the following steps of: (1) first, boiling and blanching or boiling off the cotton viscose ramie blended fabric; (2) drying the boiled and blanched cotton viscose ramie blended fabric; (3) carrying out cold pad batch dyeing on the dried cotton viscose ramie blended fabric, wherein a dyeing liquid is obtained by mixing a reactive dye and an alkali auxiliary mixed solution according to a volume ratio of 4:1 in the dyeing process; padding the cotton viscose ramie blended fabric in the dyeing liquid for 3-6 seconds; winding the padded cotton viscose ramie blended fabric by using a winding frame; sealing and packaging the cotton viscose ramie blended fabric on the winding frame by using a sealing material after the winding is finished; and then placing the sealed and packaged cotton viscose ramie blended fabric in a constant temperature environment for 12-16 hours, wherein the temperature of the constant temperature environment is one of 25-30 DEG C; and keeping the winding frame to rotate at a constant speed, wherein the rotation speed is 4-6 rpm; and (4) taking the cotton viscose ramie blended fabric out of water and neutralizing the cotton viscose ramie blended fabric.

Owner:杭州天宇印染有限公司

Dyeing method of wool-silk blended fabric

The invention discloses a dyeing method of a wool-silk blended fabric. The dyeing method comprises the following steps: sequentially adding sodium chloride, dye leveler, acidic condense dye and metal complex dye based on 1: 2 to a constant-temperature water bath and uniformly stirring; adding the wool-silk blended fabric to the constant-temperature water bath, and dyeing, wherein the setting temperature of the constant-temperature water bath is 30 to 40 DEG C; raising the temperature of the solution in the constant-temperature water bath to reach 97 DEG C; and continuously dyeing to obtain the dyed wool-silk blended fabric. According to the mode mentioned above, the dyeing method of the wool-silk blended fabric has the advantages that the wool-silk blended fabric is dyed by homochromy dyeing technology, so that the blended fabric is high in homochromatism and is nearly not damaged; the dye is firmly attached on the blended fabric and cannot be decoloured after placing under the blazing sun; and little wastewater and waste are generated during preparation, so that the pollution to the water and the environment can be greatly reduced.

Owner:WUJIANG MAIDAO TEXTILE

Dyeing and finishing process of celery fiber cotton blended fabric

InactiveCN112458766AStrong damageGood same colorSynthetic fibresDyeing processPolymer scienceCarding

The invention discloses a dyeing and finishing processing technology of a celery fiber cotton blended fabric. The fabric is formed by blending and weaving celery fibers and cotton fibers, the weight percentage of the two fiber components is 40% of celery fibers and 60% of cotton fibers, and the main body length range of the celery fibers is 40-70mm; the dyeing and finishing process mainly comprises the steps of weaving, scouring, bleaching, dyeing and finishing; and the weaving process mainly comprises the steps of opening picking, cotton carding, drawing, roving, spinning, spooling, warping,slashing and weaving. The dyed celery fibers and cotton fibers are good in homochromatism, so that the strength damage of the fabric is reduced.

Owner:淮南秋涵服饰有限公司

A kind of homochromatic dyeing process of viscose fiber fabric containing chitin

ActiveCN106087489BAvoid high levels of adsorptionGood dyeing reproducibilityDyeing processOrganic baseSolvent

The invention discloses a homochromatic dyeing process for a chitin-containing viscose-fiber fabric. The method comprises the following steps: (S1) carrying out pretreatment: submerging the chitin-containing viscose-fiber fabric into isopropyl alcohol, adding a sodium hydroxide solution, carrying out uniform stirring, then, adding an etherifying agent CTA, carrying out a reaction with stirring, pumping off a solvent, carrying out water washing, and carrying out baking; (S2) carrying out reactive dyeing: submerging the fabric into a reactive dye dyeing solution, heating the reactive dye dyeing solution to a primary dyeing temperature, adding an organic solvent B, heating the solution to a dyeing temperature, then, adding organic base and sodium carbonate according to the volume of the reactive dye dyeing solution, then, cooling the solution to a color fixation temperature, carrying out heat preservation, cooling the solution to room temperature; (S3) carrying out aftertreatment: washing the fabric by water, carrying out soaping, carrying out water washing again, and carrying out air-drying. According to the homochromatic dyeing process for the chitin-containing viscose-fiber fabric, the defect that the dyeing rate of chitin viscose fibers is relatively high can be overcome, a uniform and consistent dyeing effect is obtained, and the homochromatic dyeing process has the advantages of high color fastness and simple process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com