Dyeing process for silk and pashm blended yarn

A silk cashmere and blended yarn technology, applied in the field of textile yarn dyeing, can solve the problems of resource waste, yarn fluffing, and difficulty in guaranteeing yarn quality, and achieve the goals of reducing sewage discharge, increasing breaking strength, and saving dye costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

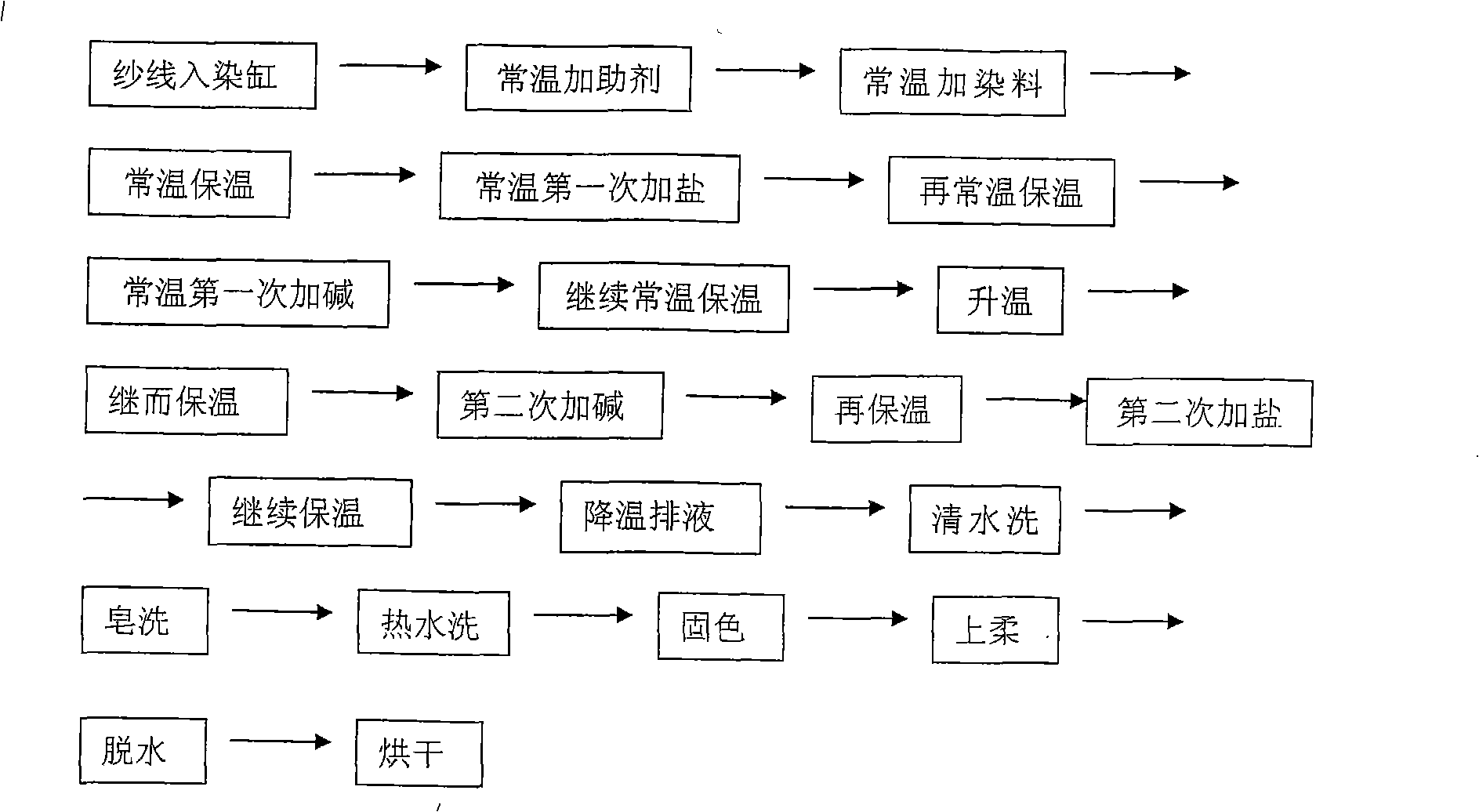

Method used

Image

Examples

Embodiment 1

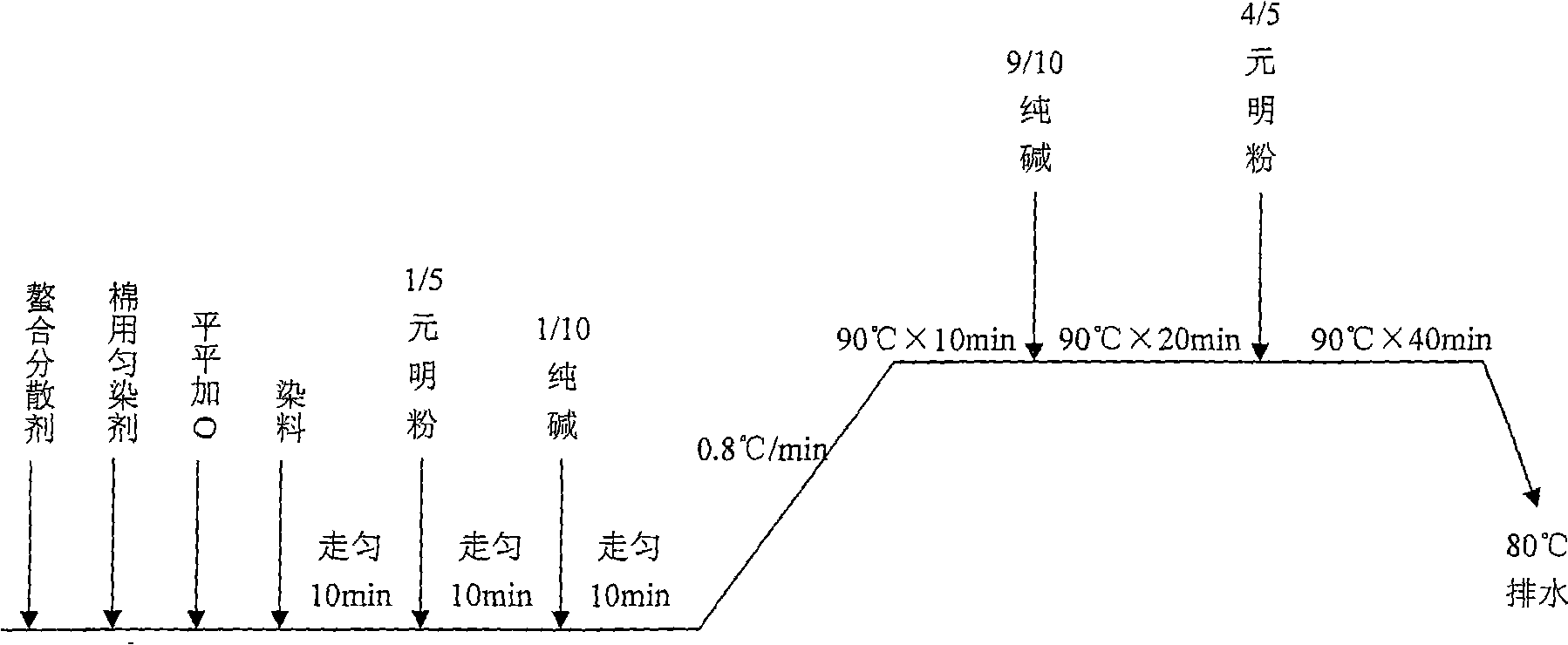

[0023] It is 60S / 2 (two-ply, 45% cashmere, 55% silk) with specification, and quantity is 100Kg, and dyeing color and luster is blue silk and cashmere blended package yarn as example.

[0024] Please refer to figure 2 with image 3 . Firstly, loosen the commercially available 60S / 2 silk cashmere blended package yarn. The loose tube referred to here refers to the dyeing tube that rewinds the silk cashmere blended yarn previously placed on the paper bobbin with a yarn rewinding device to enter the dyeing vat. On the tube, preferably but not limited to, the yarn weight of each dyed bobbin is 0.8Kg, and the winding density is 0.38g / cm 3 , and then put the dyeing bobbin on the sarong, and lock the top lock.

[0025] Put the dyed bobbin wrapped with silk and cashmere blended yarn in the sarong into a semi-filled dyeing vat such as that produced by Hong Kong Lixin Co., Ltd., and fill the dyeing vat with water. The liquor ratio is 1:8, that is, 1Kg of yarn is mixed with 8Kg water,...

Embodiment 2

[0027] It is 60S / 2 (two-ply, 45% cashmere, 55% silk) with specification, and quantity is 60Kg, and dyeing color and luster is dark green silk cashmere blended bobbin yarn as example.

[0028] Please refer to figure 2 with Figure 4 . Firstly, loosen the commercially available 60S / 2 silk cashmere blended package yarn. The loose tube referred to here refers to the dyeing tube that rewinds the silk cashmere blended yarn previously placed on the paper bobbin with a yarn rewinding device to enter the dyeing vat. On the tube, preferably but not limited to, the yarn weight of each dyed bobbin is 0.9Kg, and the winding density is 0.39g / cm 3 , and then put the dyeing bobbin on the sarong, and lock the top lock.

[0029] Put the dyeing bobbin wrapped with silk and cashmere blended yarn in the sarong into a half-filled dyeing vat such as that produced by Hong Kong Lixin Co., Ltd., and fill the dyeing vat with water. The liquor ratio is 1:9.5, that is, 1Kg of yarn is mixed with 9.5Kg ...

Embodiment 3

[0031] Be 60S / 2 (two-ply, 15% cashmere, 85% silk) with specification, quantity is 600Kg, dyeing color and luster is the silk cashmere blended cheese of dark gray as example.

[0032] Please refer to figure 2 with Figure 5 . Firstly, loosen the commercially available 60S / 2 silk cashmere blended package yarn. The loose tube referred to here refers to the dyeing tube that rewinds the silk cashmere blended yarn previously placed on the paper bobbin with a yarn rewinding device to enter the dyeing vat. On the tube, preferably but not limited to, the yarn weight of each dyed bobbin is 1.0Kg, and the winding density is 0.40g / cm 3 , and then put the dyeing bobbin on the sarong, and lock the top lock.

[0033] Put the dyeing bobbin wrapped with silk and cashmere blended yarn in the sarong into a half-filled dyeing vat such as that produced by Hong Kong Lixin Co., Ltd., and fill the dyeing vat with water. The liquor ratio is 1:7, that is, 1Kg of yarn is mixed with 7Kg of water. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com