Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133results about "Beaming machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

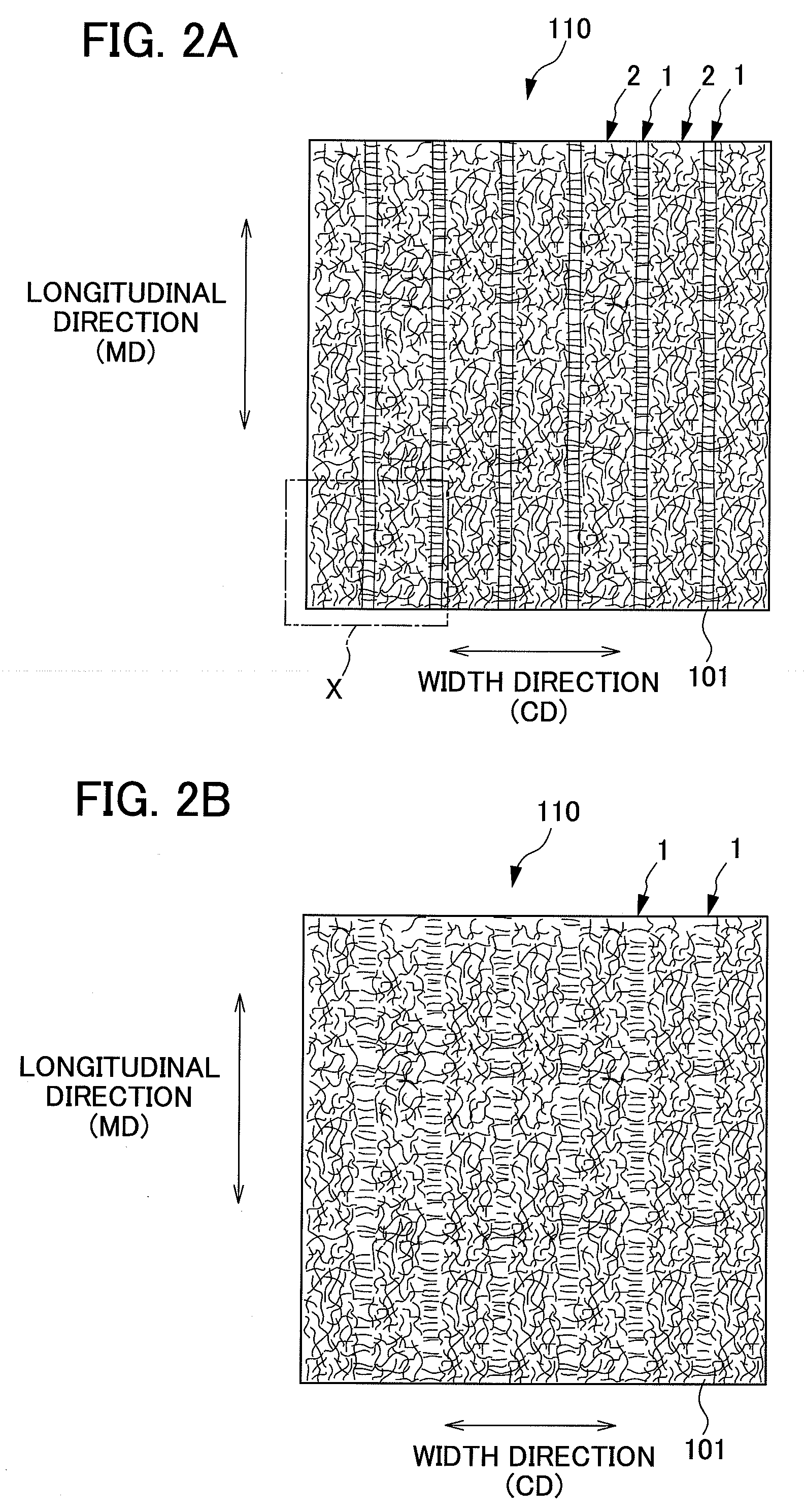

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

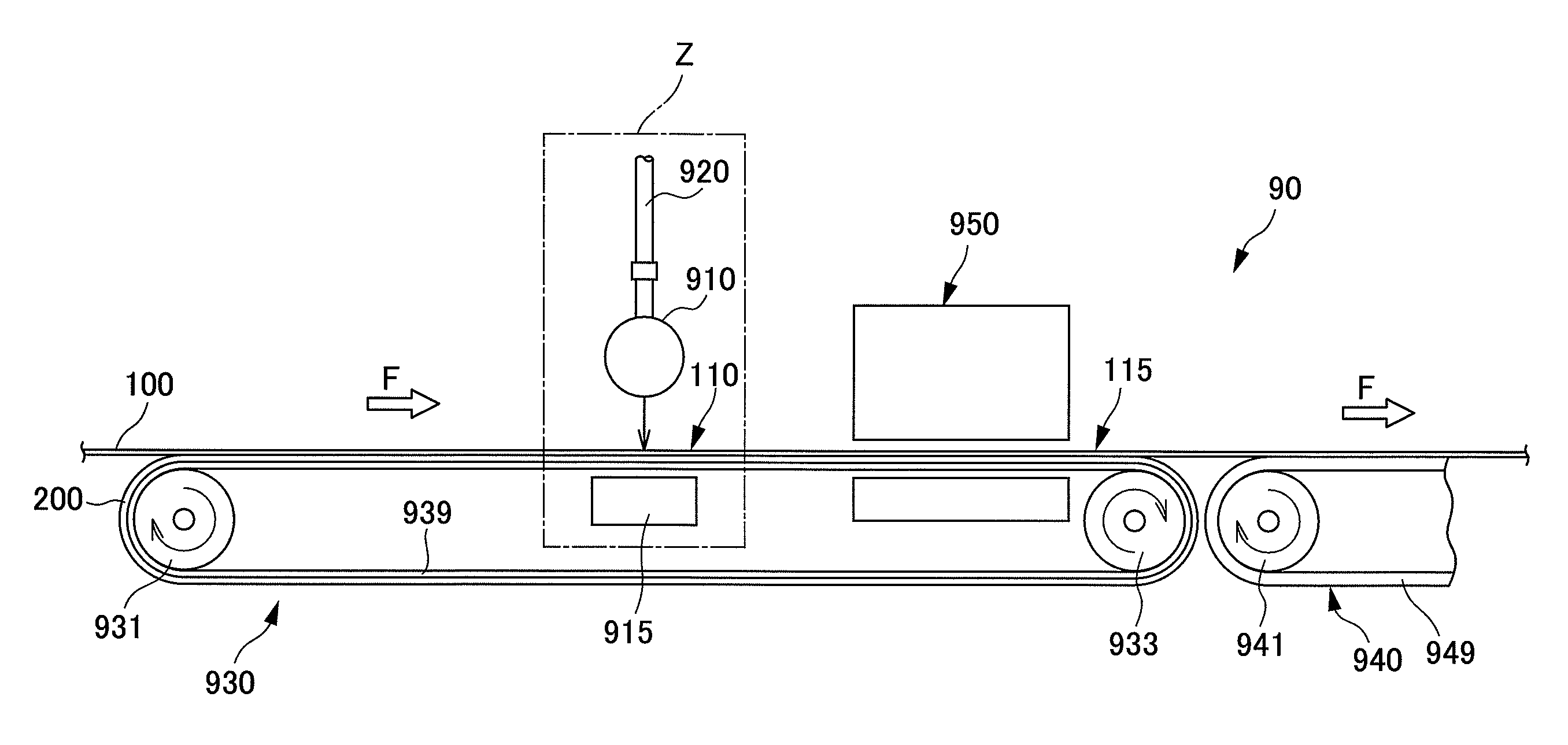

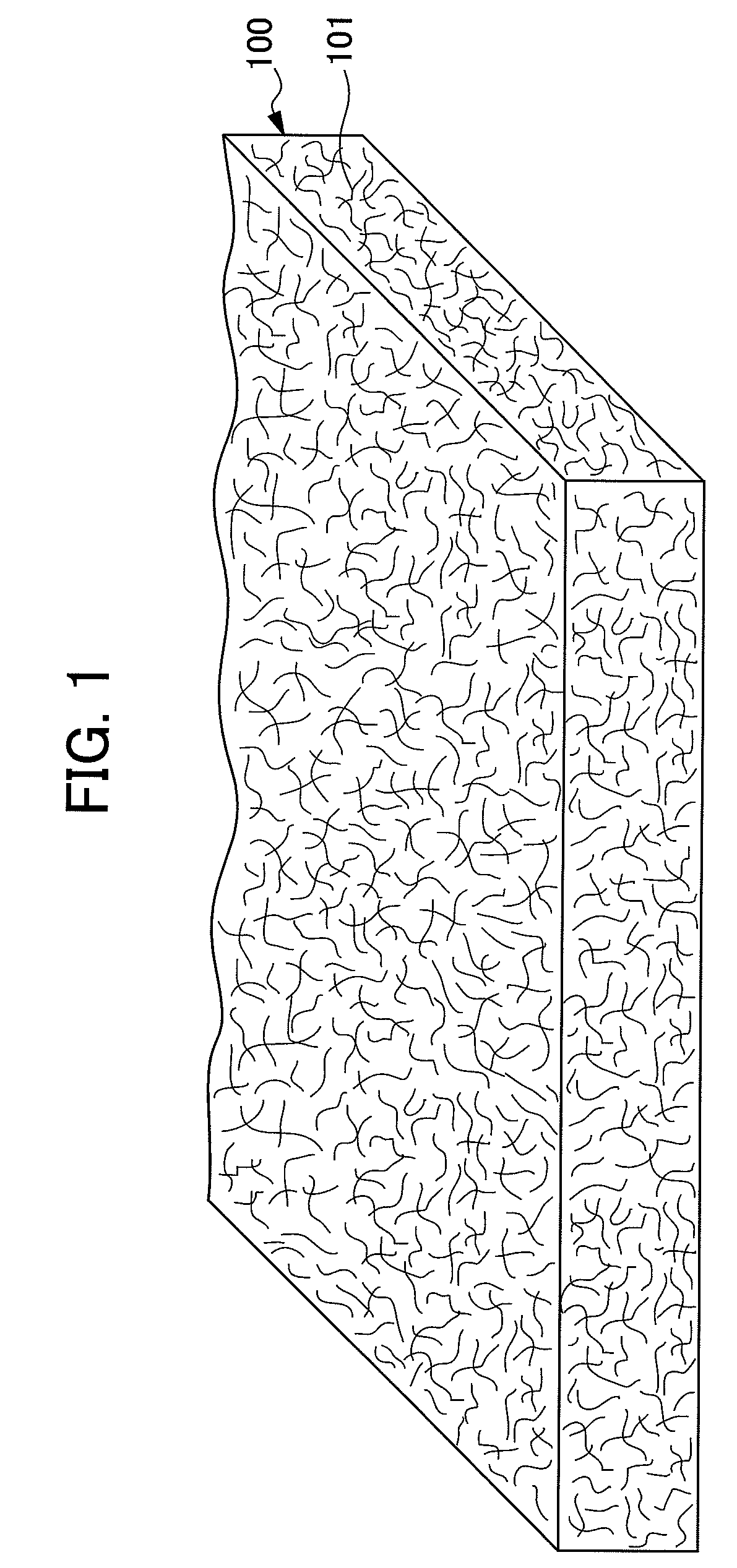

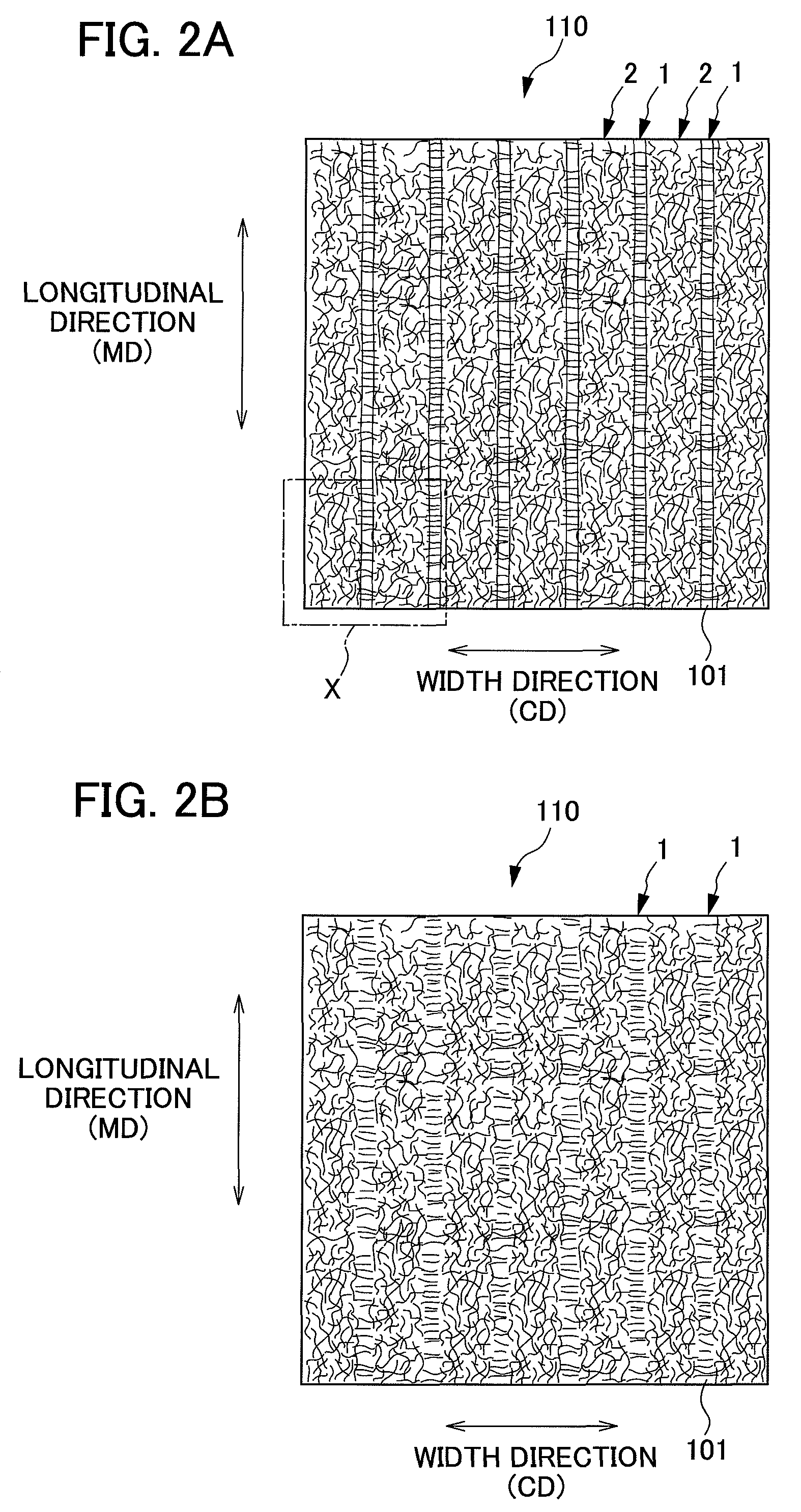

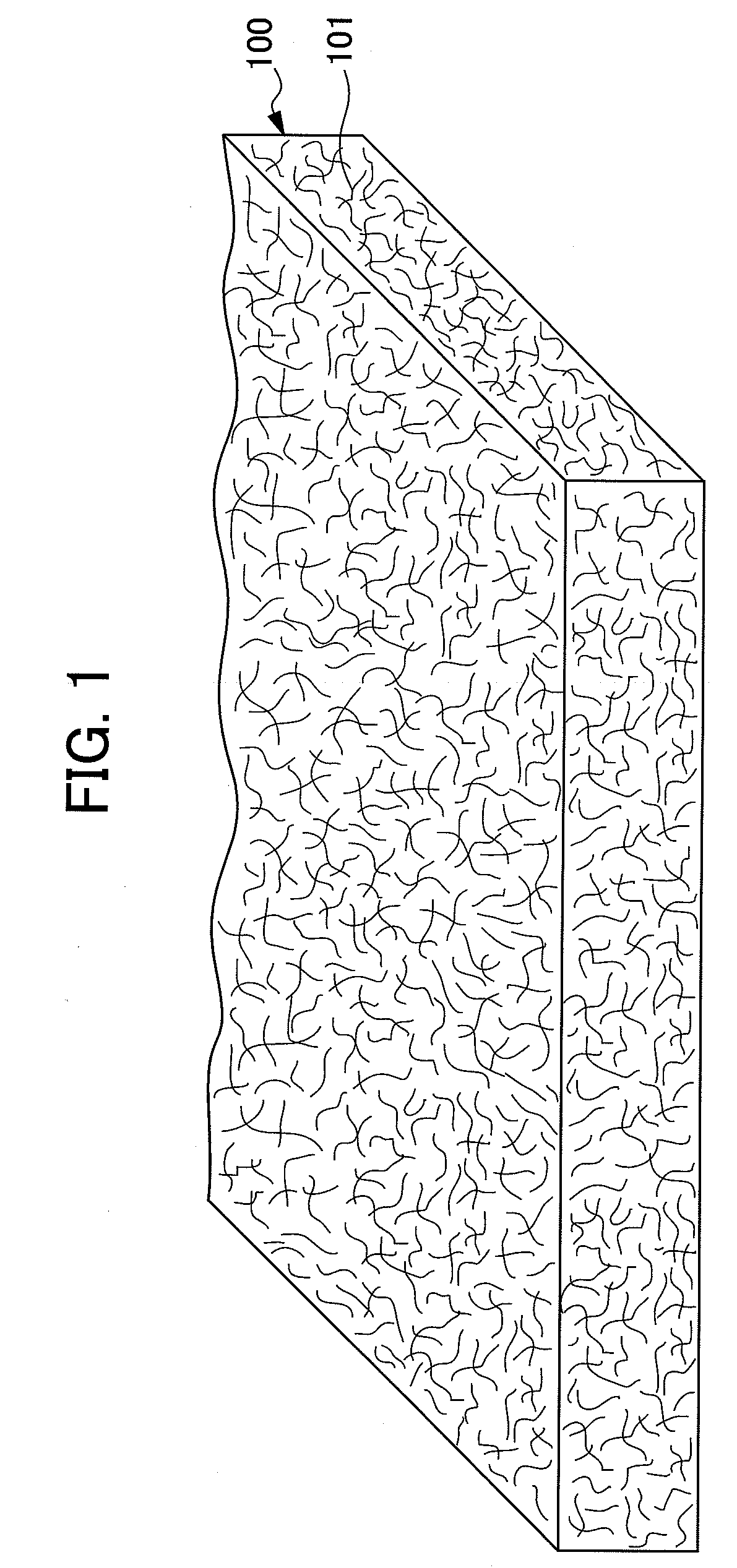

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

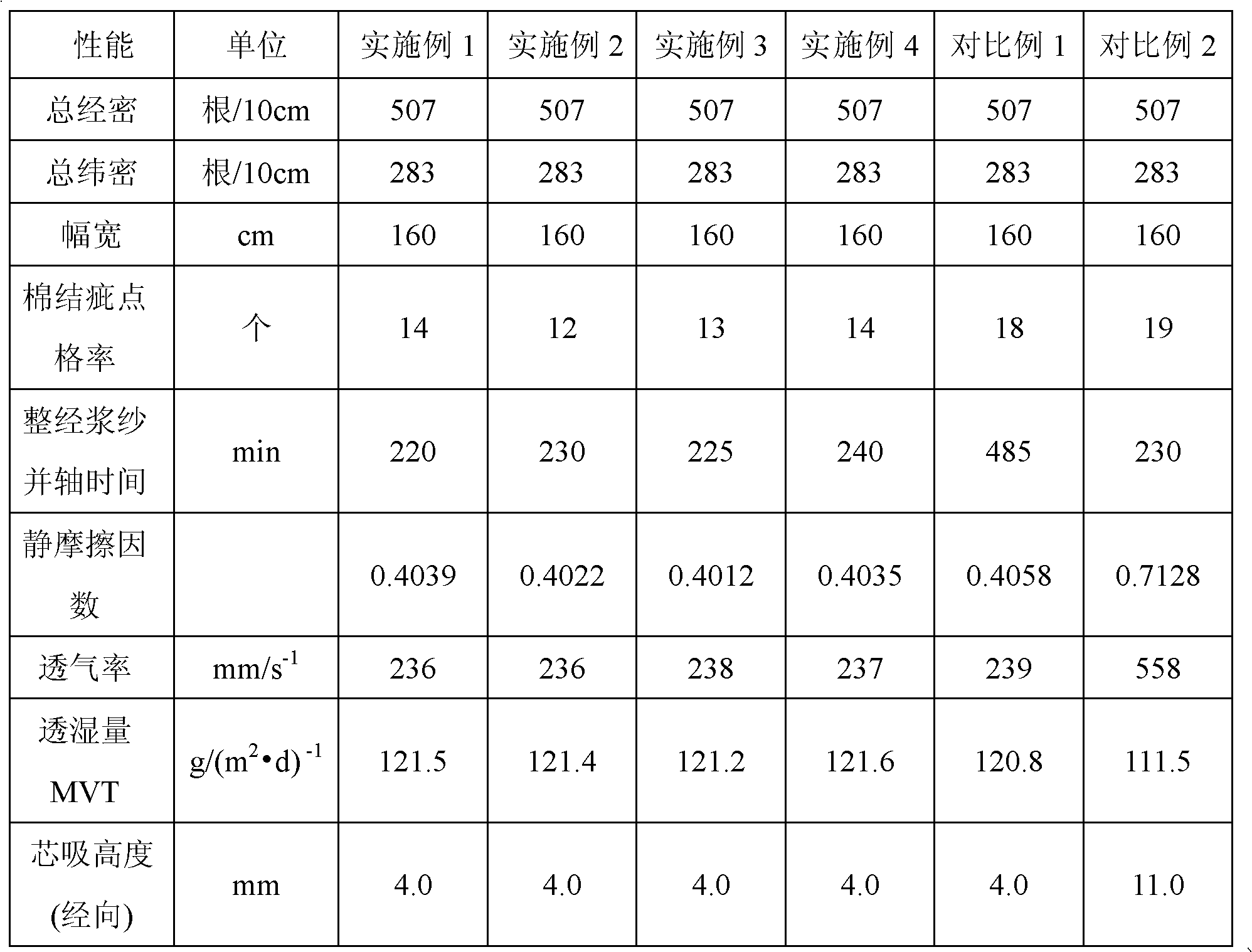

Sizing process of fine denier circular hole bright polyamide multifilament

InactiveCN102828369AReduce incidenceImprove flatnessLiquid/gas/vapor removalBeaming machinesPolyamideEngineering

The invention discloses a sizing process of a fine denier circular hole bright polyamide multifilament. By adjusting the technological parameters of four procedures such as warping, sizing, re-beaming and weaving, a good size film is formed on the surface of the fine denier circular hole polyamide filament and is convenient for weaving, the production efficiency is above 95% and a series of problems such as low weaving efficiency of multifilament woolen fabrics of fine denier circular hole bright polyamide multifilament series are solved.

Owner:WUJIANG FUHUA WEAVING

Method Of Sizing Of Fibers And Articles Manufactured From The Same

The method includes the steps of functionalizing a polyaryletherketone (PAEK) polymer, and blending the PAEK polymer with water to form a sizing composition. The method may further include the step of applying the sizing composition to a fiber. The method may further include the step of heating the fibers, coated with sizing composition, for example to between 300C-400C. In some methods, the functionalized PAEK polymer comprises functionalized polyetherketoneketone (PEKK). In yet other methods, the functionalized PAEK polymer comprises sulfonated PEKK (sPEKK).

Owner:OXFORD PERFORMANCE MATERIALS

PTT (poly(trimethylene terephthalate)) memory fabric production process

InactiveCN101736487ASoft touchShinyWarping machinesHeating/cooling textile fabricsFiberPolyethylene terephthalate

The invention relates to a PTT (poly(trimethylene terephthalate)) memory fabric, in particular to a PTT memory fabric production process. The production process comprises the following steps of: batch warping, starching, shaft combining, leasing, looming healding, weaving, pretreatment of dying and finishing, alkali quantity decreasing, dying, waterproof processing and thermal forming. The fabric has unique memory function and comfortable hand feel, the performance of smoothing by touching the fabric enables the product to achieve an effect of totally ironing free, and favorable draping effect and recovery capability enable the fabric to become one of fashionable functional fabrics. Fibers of the fabric are completely biodegradable under certain condition and the fabric is an environmental-protection and green product.

Owner:杭州宏峰纺织集团有限公司

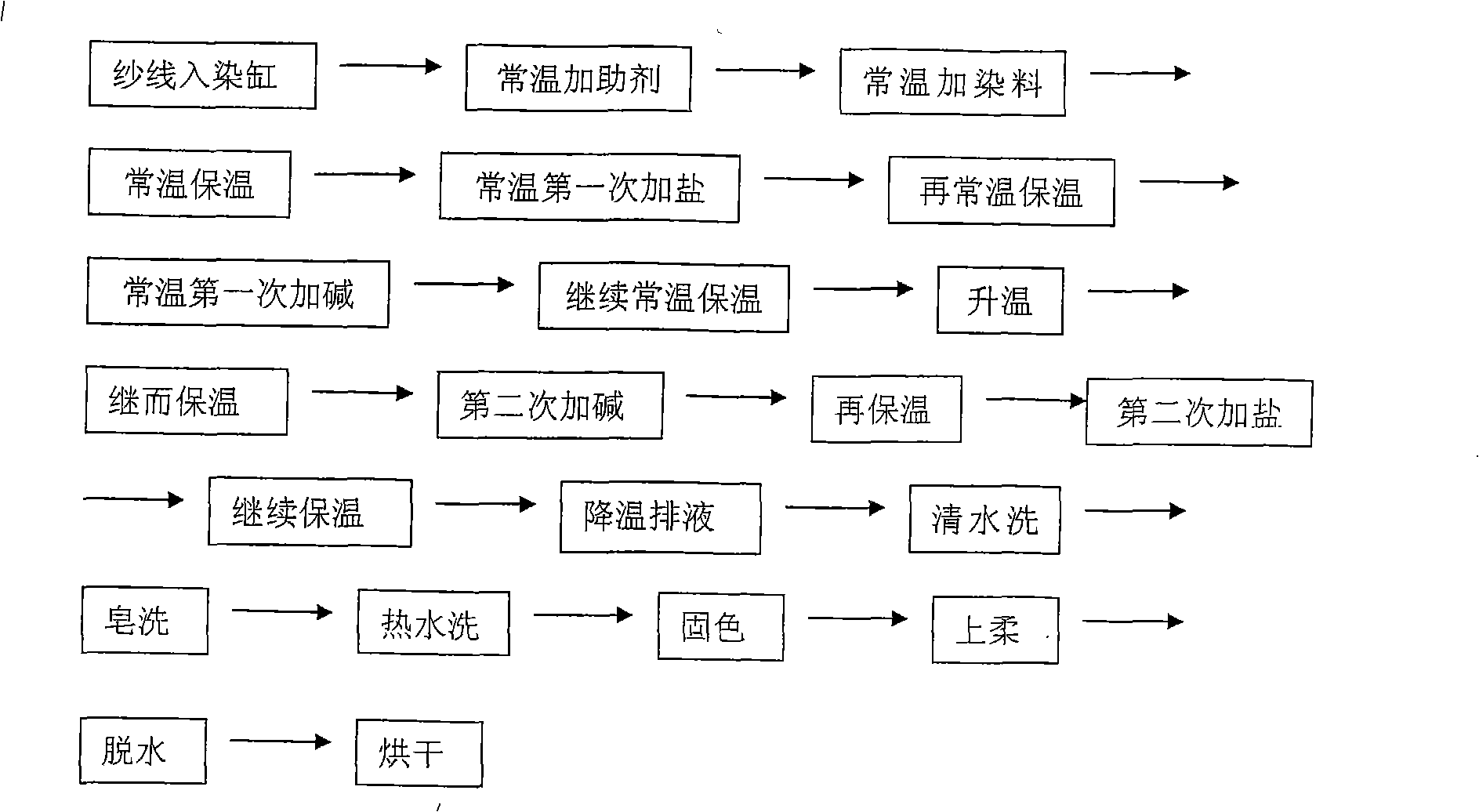

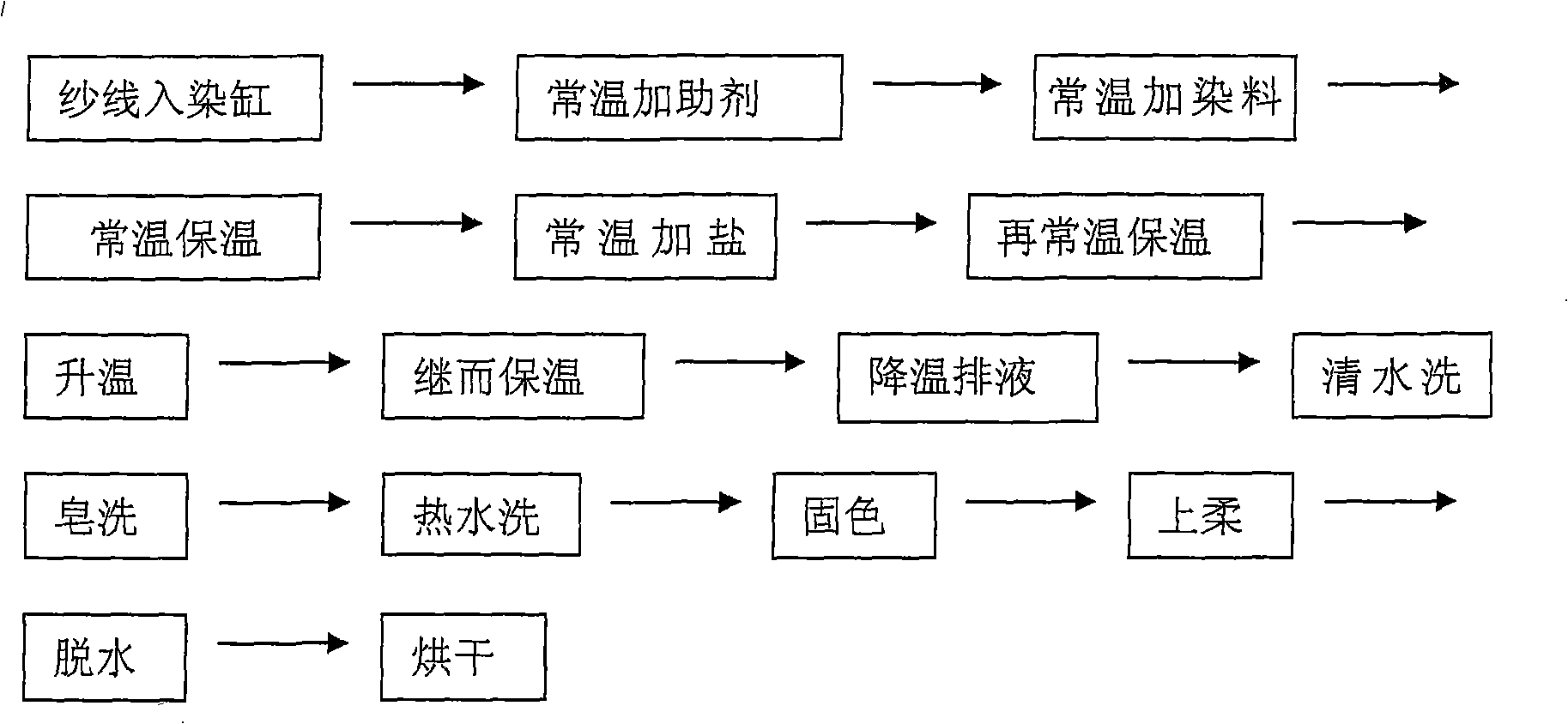

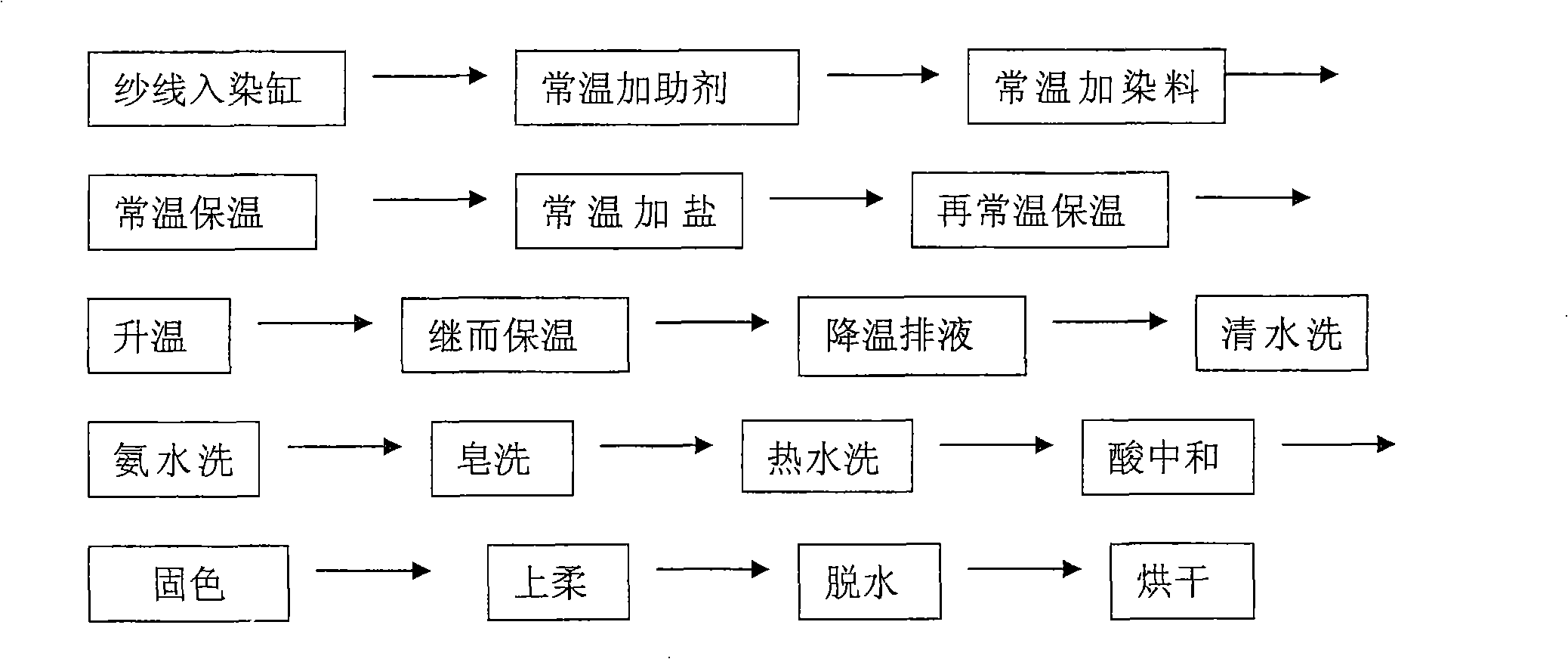

Dyeing process for silk and pashm blended yarn

InactiveCN101289812ALow costEmission reductionBeaming machinesDyeing processColour fastnessBreaking strength

The invention provides a process for dyeing silk-cashmere blended yarns, belonging to the weaving yarn dyeing technical field. The process comprises the following steps that: silk-cashmere blended yarns ready to be dyed are put in a dye vat, water is added in the dye vat, and the bath ratio is controlled; at the normal temperature, auxiliary agent and dyes are added in the dye vat; the dye vat is kept warmth at the normal temperature; at the normal temperature, salt is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; alkali is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; the dye vat is heated, and the temperature-rise speed is controlled; the dye vat is kept warmth; alkali is added in the dye vat for the second time; the dye vat is kept warmth again; salt is added in the dye vat for the second time; the dye vat is kept warmth again; finally after sequent steps of temperature drop and liquid discharging, fresh water washing, soap washing, hot water washing, color fixation, upper flexibility, dewatering and drying, dyed silk-cashmere blended yarns are obtained. The process has the advantages of high color fastness, good level-dyeing property, good homochromaatism, high breaking strength, bright color, filled yarns, uneasy teasing, time conservation, low dye cost, simple processing step, energy consumption reduction, low sewage discharge and environment protection.

Owner:常熟市亨时特染织有限公司

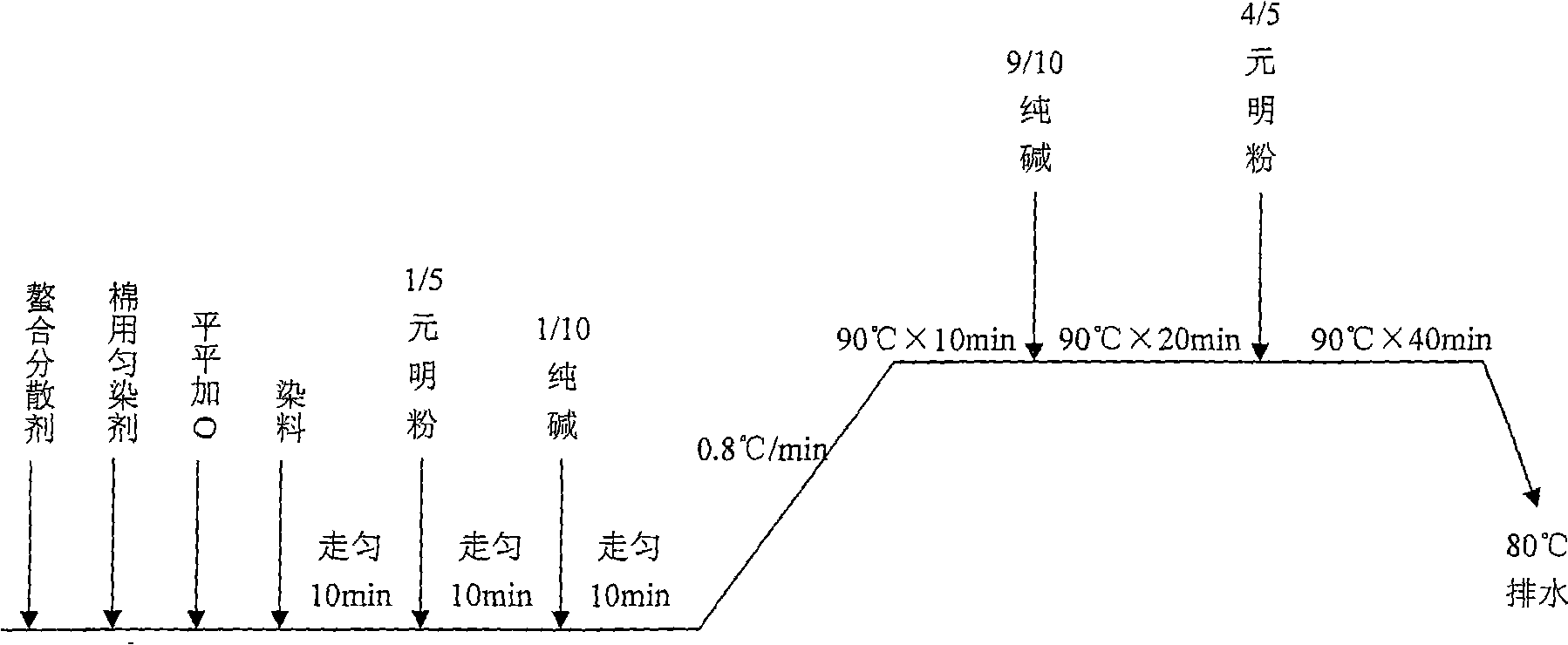

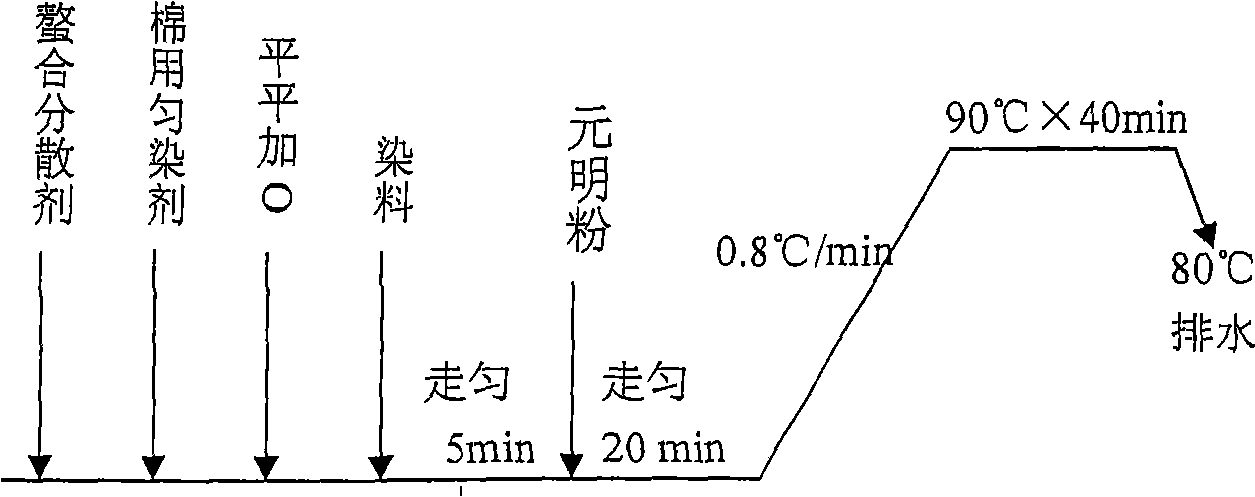

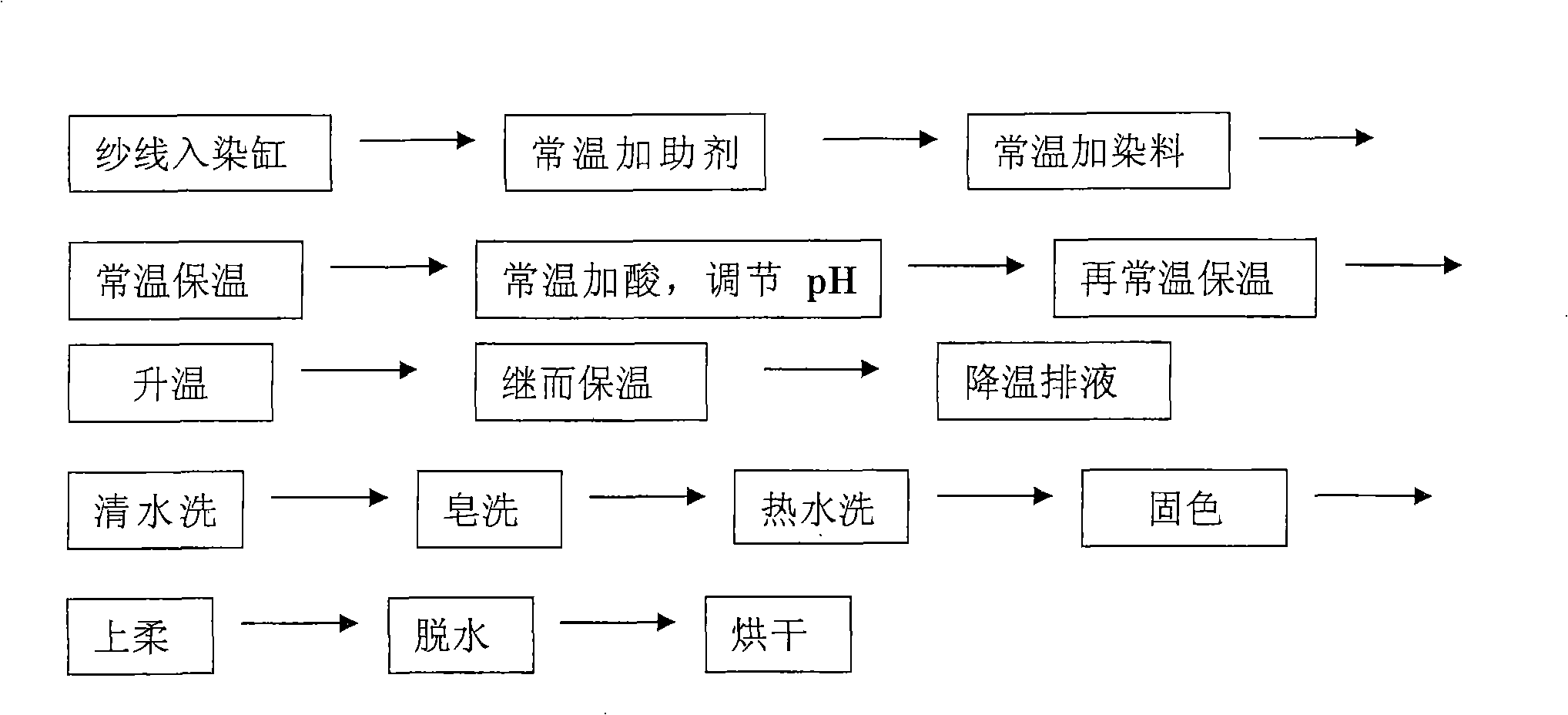

Dyeing process for spun silk

InactiveCN101289810ABe friendlyHigh color fastnessBeaming machinesDyeing processBreaking strengthColour fastness

The invention provides a process for dyeing spun silks, belonging to the weaving yarn dyeing technical field. The process comprises the following steps that: spun silk yarns which are ready to be dyed and undergo the pre-dyeing treatment are put in a dye vat, water is added in the dye vat, and the bath ratio is controlled; at the normal temperature, auxiliary agent and cotton-used reactive dyes are added in the dye vat; the dye vat is kept warmth at the normal temperature; at the normal temperature, salt is added in the dye vat; the dye vat is kept warmth at the normal temperature again; the dye vat is heated, and the temperature-rise speed is controlled; the dye vat is kept warmth; finally after sequential steps of temperature drop and liquid discharging, fresh water washing, soap washing, hot water washing, color fixation, upper flexibility, dewatering and drying, dyed spun silk yarns are obtained. The process has the advantages of improving the color fastness of dyed spun silk yarns by one or two levels, having good level-dyeing property, improving the color yield by 20 percent and improving the breaking strength by 5 to 10 percent; because alkali is not used for the color fixation, the process has the advantages of simple process, unnecessary following acid neutralization step, energy conservation and low dyeing cost; because alkalization and acid neutralization steps are not necessary, the process is environment friendly.

Owner:常熟市亨时特染织有限公司

Cashmere silk woollen cloth and production process thereof

InactiveCN105192957AImprove wear resistanceStrong and goodSucessive textile treatmentsBeaming machinesFiberCombing

The invention discloses cashmere silk woollen cloth and a production process thereof. The cashmere silk woollen cloth comprises the following raw materials in percentage by weight: 70% of 110 SW Australian wool, 14% of 1.5 D terylene, 10% of 4 cashmere, 5% of mulberry silk and 1% of 3D conductive fiber, and adopts the following process: dyeing process, spinning process, weaving process and finishing process, wherein the spinning process comprises the step of wool blending: firstly conducting wool blending by adopting silk and wool, combing, then blending with cashmere, and blending with conductive fiber strips at last needling, and comprises the following process flows: wool preparation, twice wool blending, second needling, combing, third needling, and last needling; the finishing process comprises the following process flows: singeing, first boiling, scouring, second boiling, water absorption, drying, in-process inspection, deep reparation, in-process inspection, rolling and softening, in-process inspection, decatizing, KD pot decatizing and finished product obtaining.

Owner:JIANGSU JIANLU WOOLEN

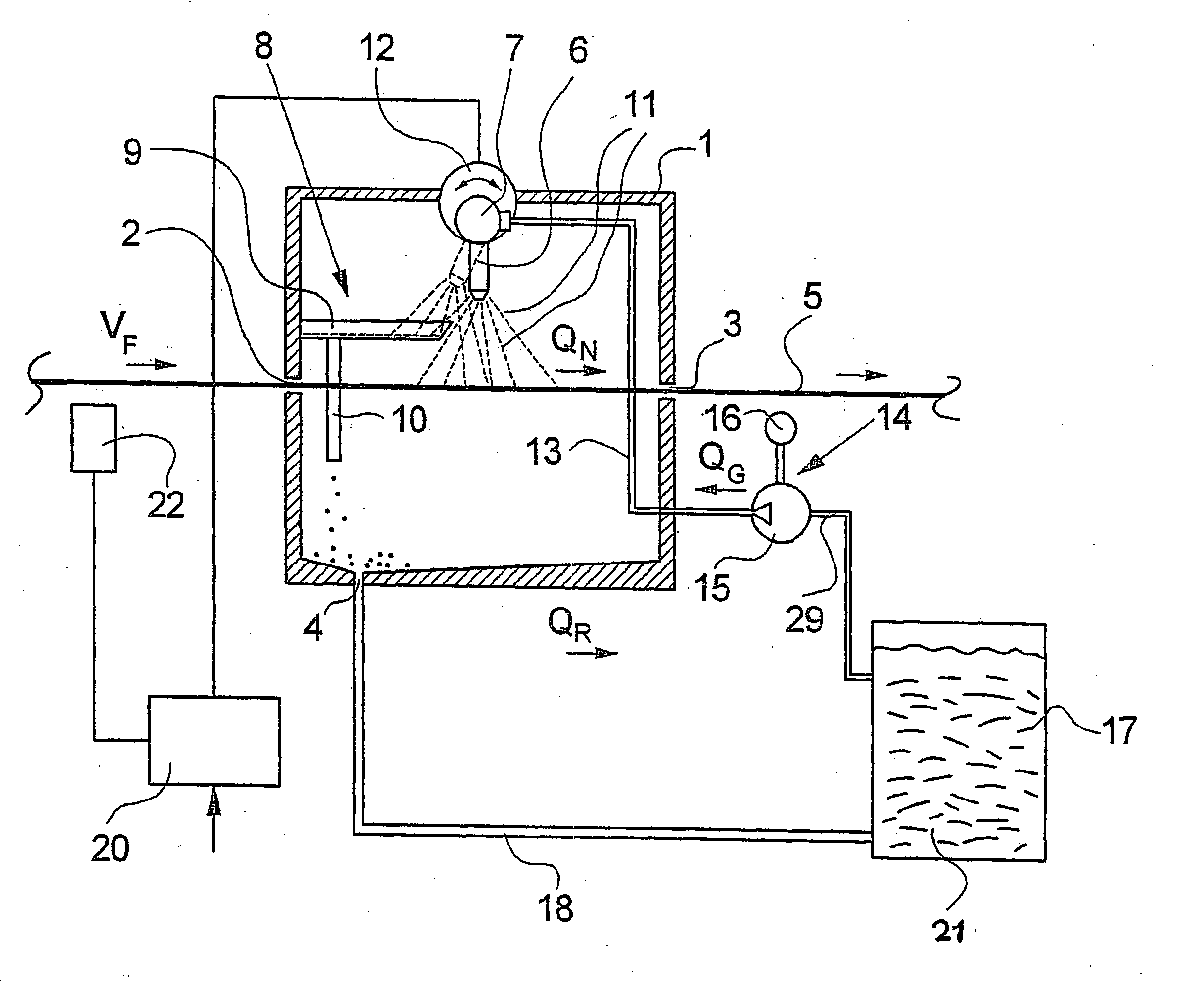

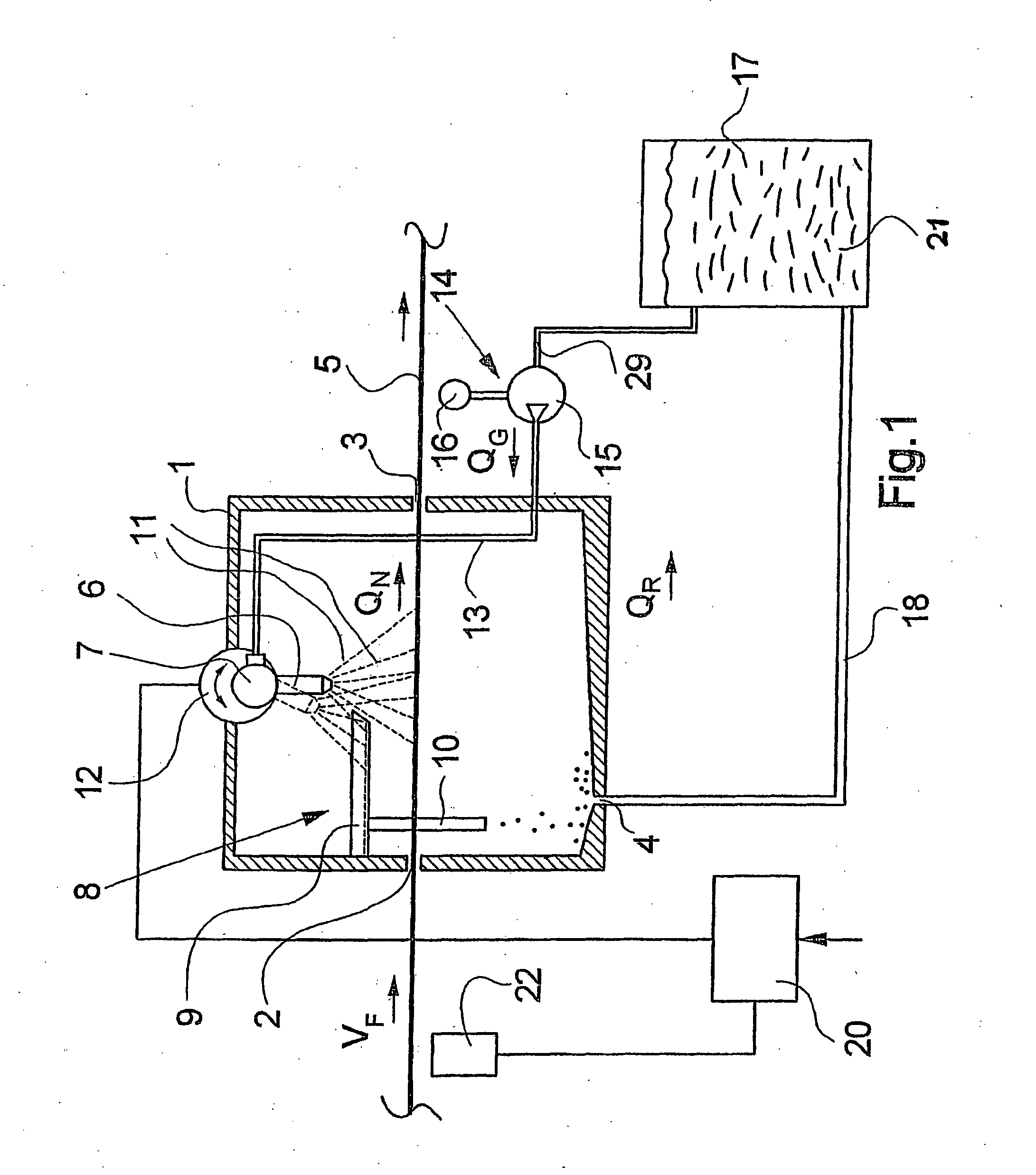

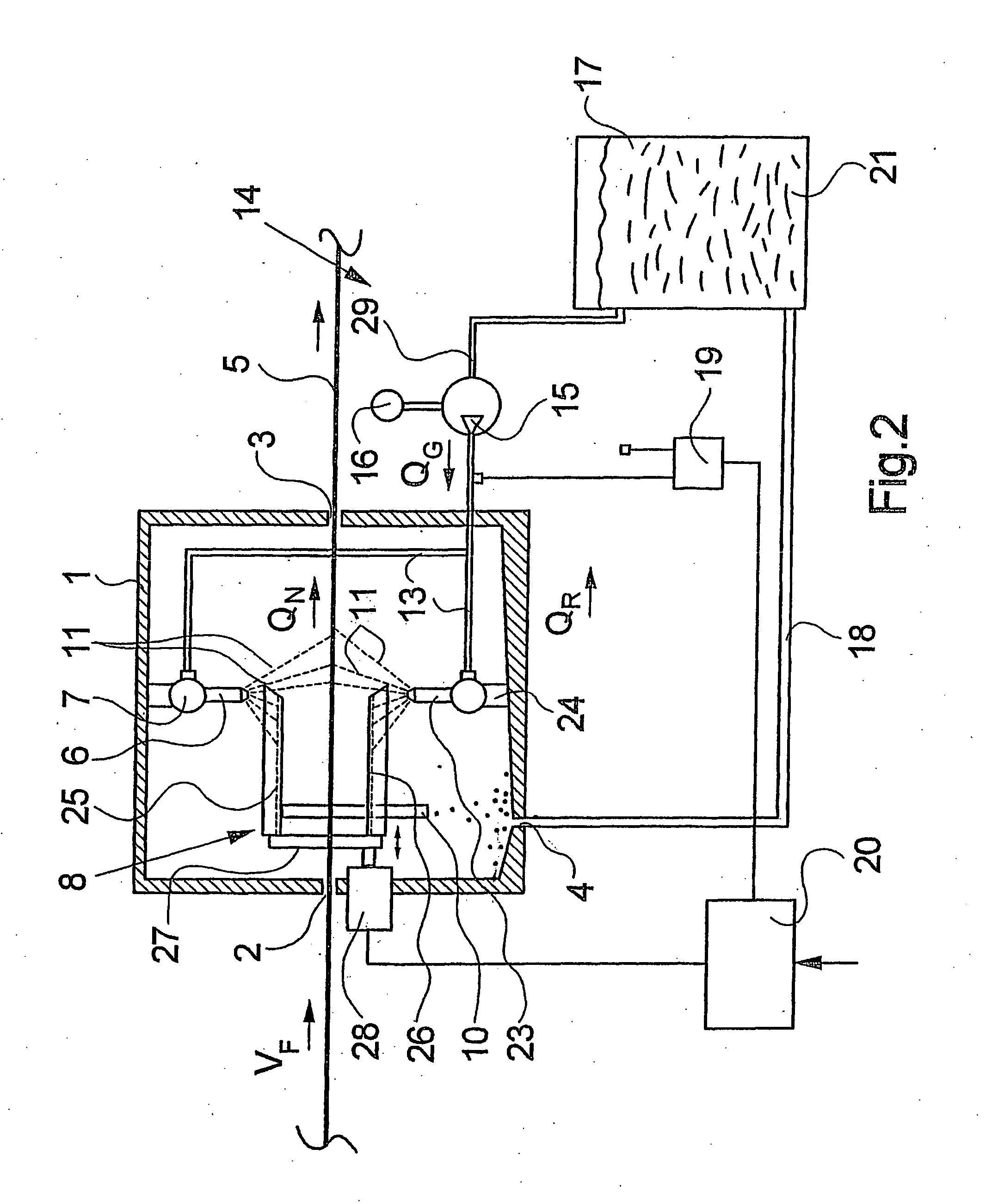

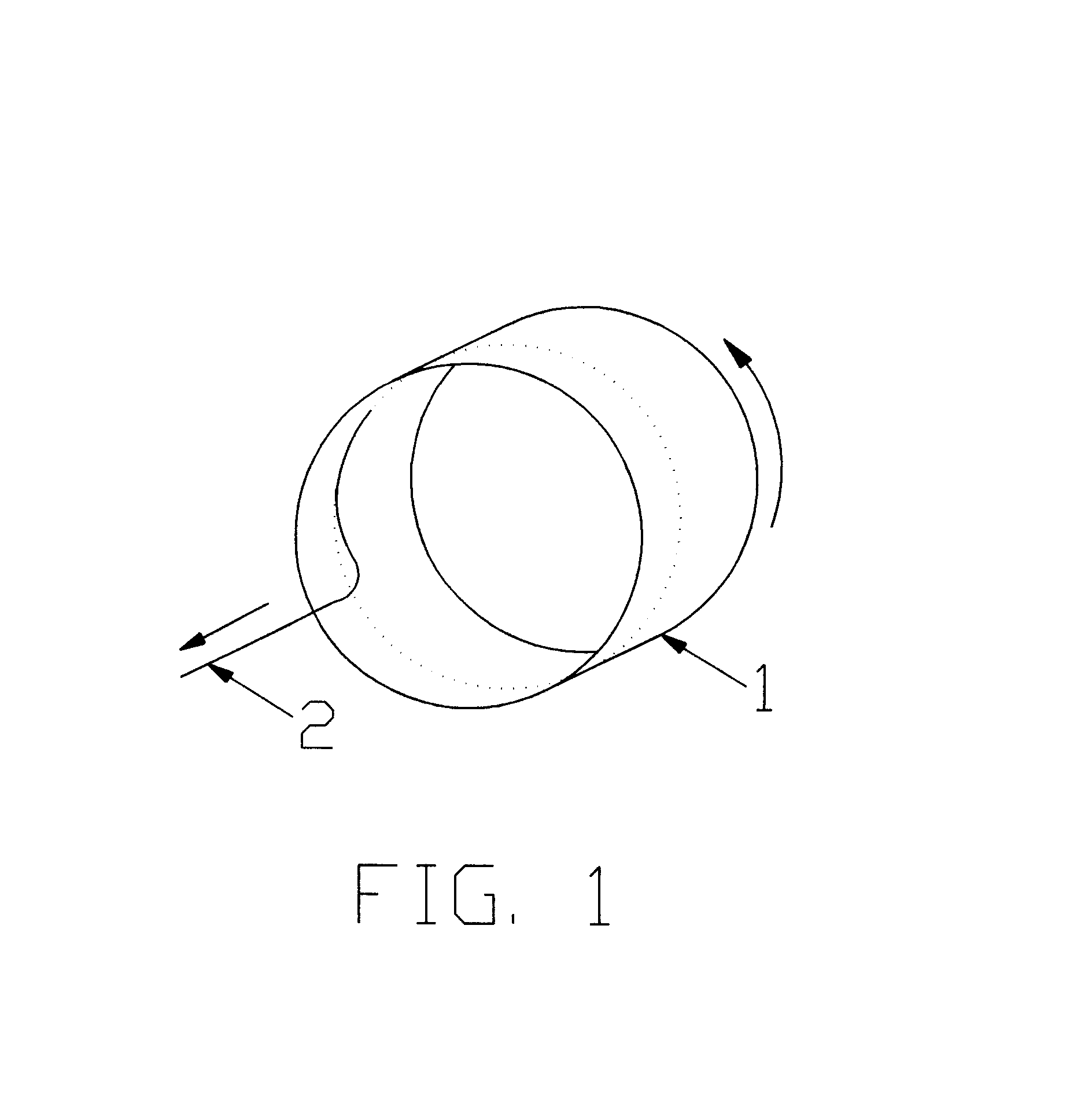

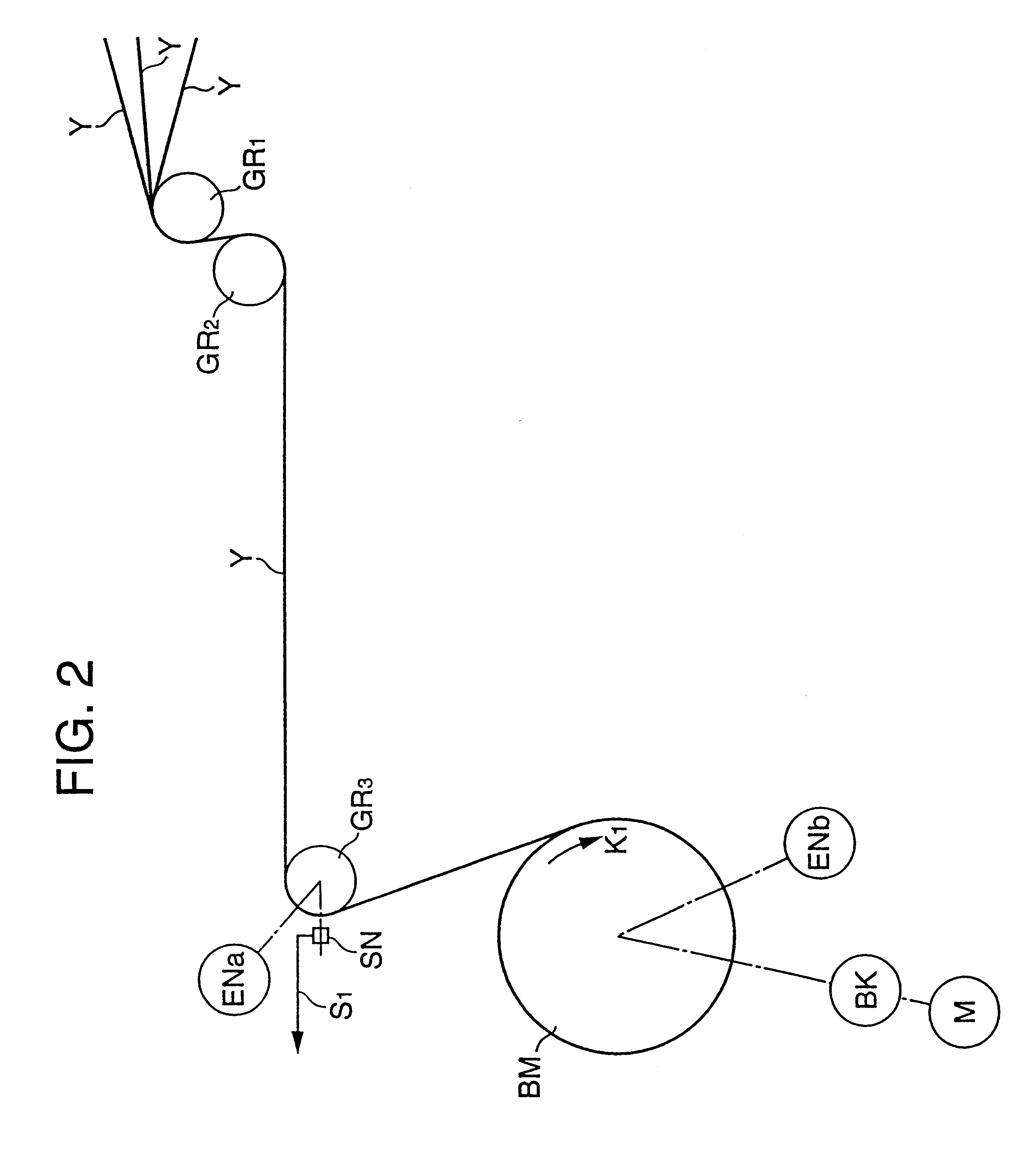

Method and apparatus for wetting a running filament strand

InactiveUS20050015951A1Guaranteed uptimeDegree of shielding is lessenedFilament handlingBeaming machinesEngineeringNozzle

A method and an apparatus for wetting an advancing filament bundle. A fluid is applied by means of a nozzle in the form of a fluid spray jet to the filament bundle advancing in spaced relationship with the nozzle. A portion of the spray jet is shielded before impacting upon the filament bundle, so that the application of fluid to the filament bundle is determined by the degree of shielding of the spray jet. With that, the invention is adapted for finely adjusting the fluid application to the filament bundle.

Owner:SAURER GMBH & CO KG

Sizing technology for dope dyed polyester low stretch yarn

ActiveCN103205832AImprove smoothnessGood extensibilitySucessive textile treatmentsLiquid/gas/vapor removalYarnPolyester

The invention discloses a sizing technology for dope dyed polyester low stretch yarn. The sizing technology includes four work processes including warping, sizing, waxing and warp beam combining. The waxing process is added on the basis of the sizing process, so that smoothness of warp is greatly improved, frictional coefficient of low stretch yarn is reduced, and opening is enabled to be clearer and smoother. During sizing, since the dope dyed polyester low stretch yarn is poor in tensile property, a negative stretching method is utilized to facilitate the improvement of the tensile property of the sized warp, sizing rate is increased at the same time, abrasive resistance of the warp is strengthened, and broken warp is reduced.

Owner:浙江长兴艺柯纺织有限公司

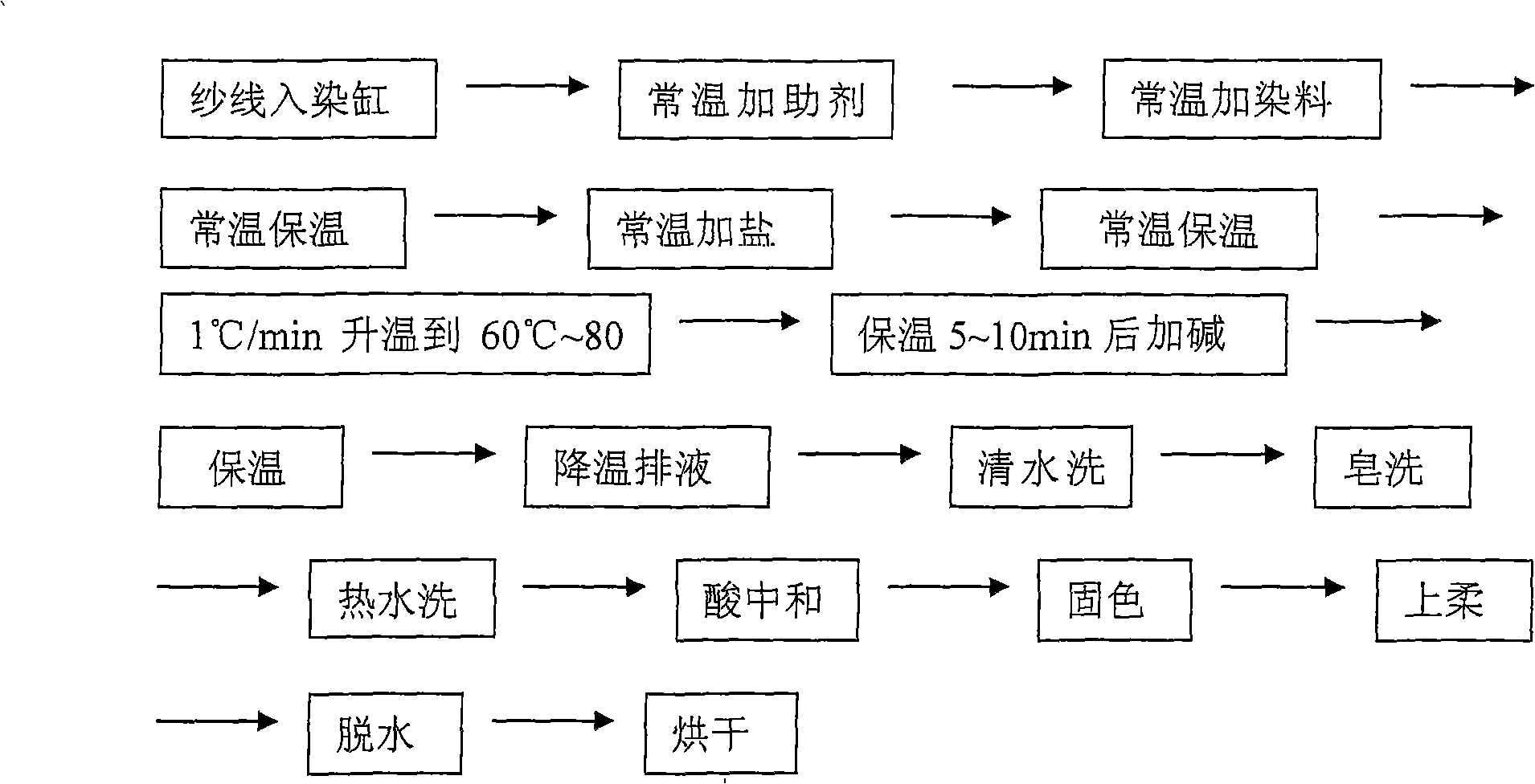

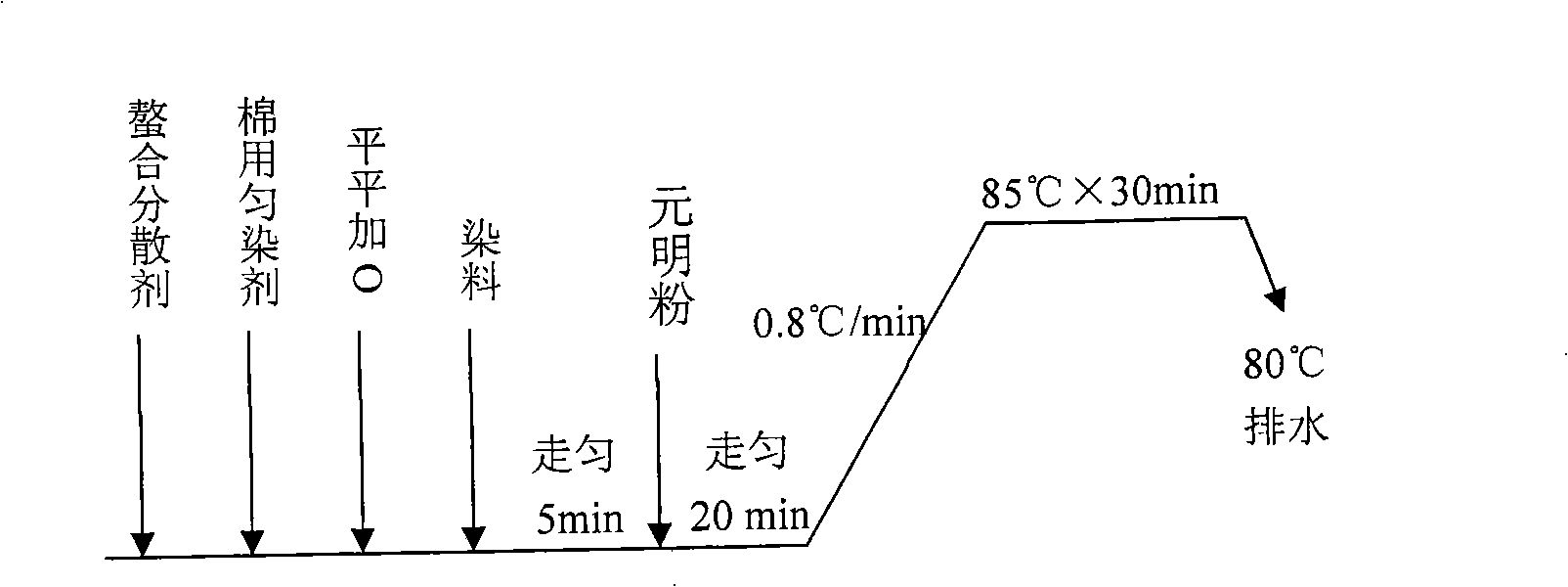

Dyeing technique of silkete unshrinkable wool yarn

The invention relates to a process for dyeing mercerized shrinkproof wool yarn, belonging to the textile yarn dyeing technical field. The process comprises the following steps that: the to-be-dyed mercerized shrinkproof wool yarn which is treated before dyeing is put into a dyeing container; water is added to the dyeing container and the bath ratio is controlled; additives and cotton reactive dyes are added to the dyeing container at the room temperature; the heat of the dyeing container is preserved at the room temperature; salt is added to the dyeing container at the room temperature; then the heat of the dyeing container is preserved at the room temperature; the dyeing container is heated, and the heating speed is controlled; the heat of the dyeing container is preserved; finally, the dyed mercerized shrinkproof wool yarn can be obtained orderly through cooling, liquid discharge, washing through clear water, washing through ammonia water, soaping, washing through hot water, acid neutralization, fixation, softening, dehydration and drying. The process has the advantages that: the dyes used are cotton reactive dyes, which are low in prices and helpful to save cost; the dyes raise the color fastness after dyeing by 1-2 levels, are good in level dyeing property, bright in color and helpful to guarantee product quality; the process is simple, favorable for saving energy and friendly to environment.

Owner:常熟市亨时特染织有限公司

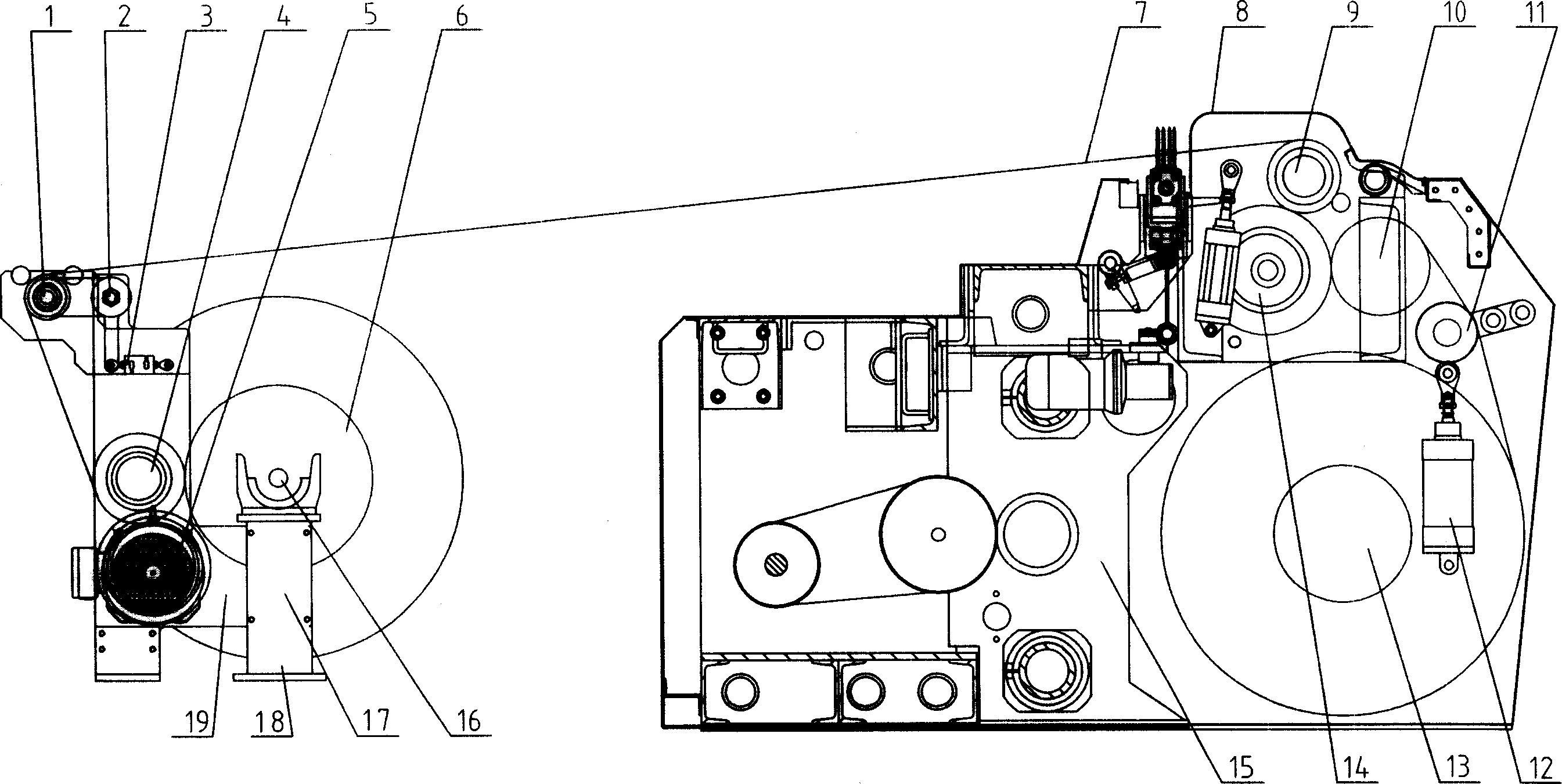

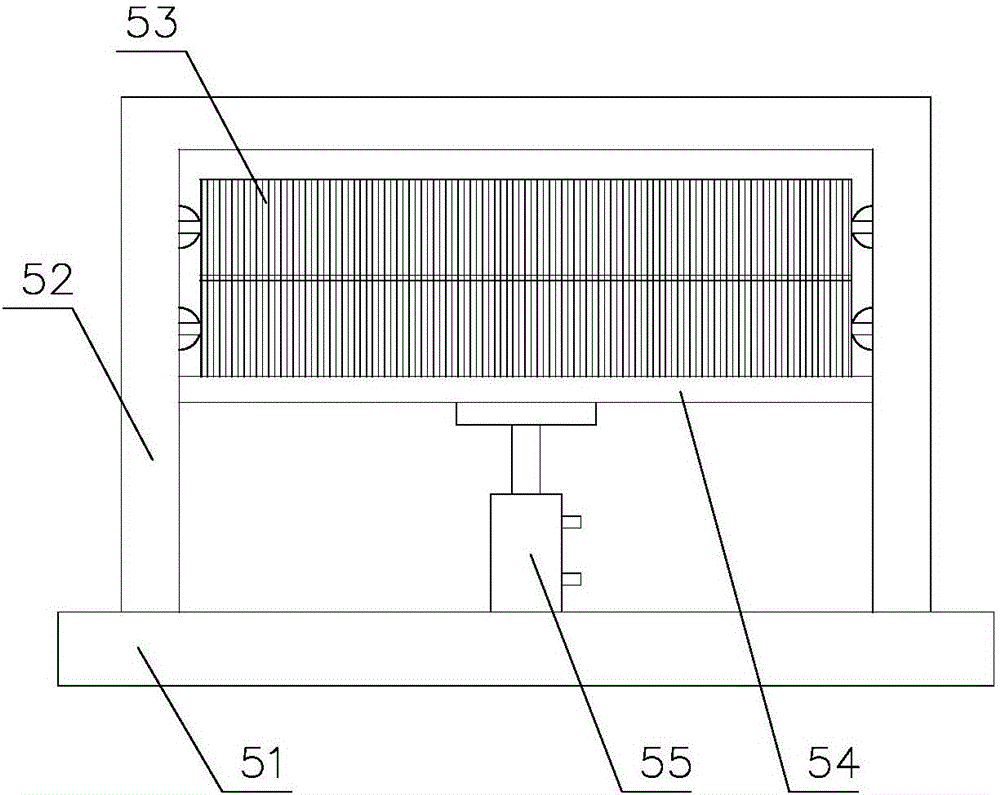

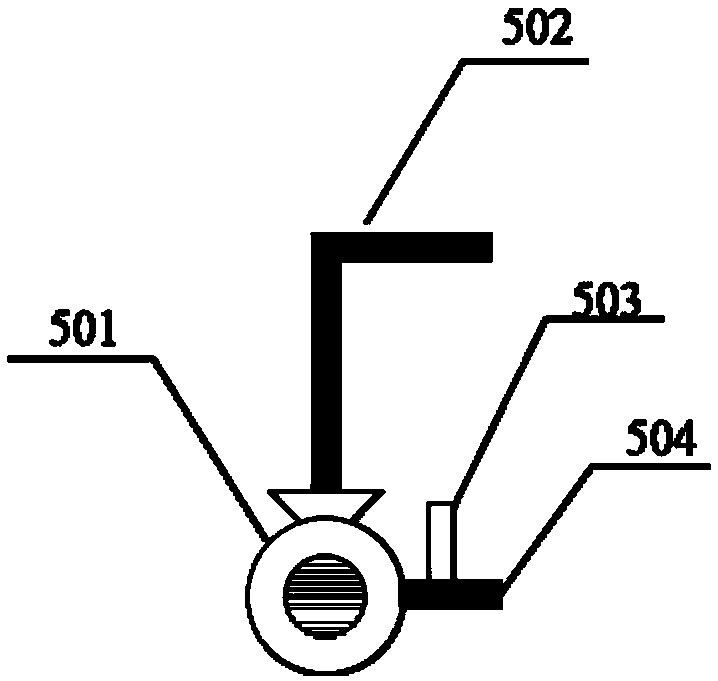

Pulp axis take-off device of warp rebeaming machine

The invention discloses a shaft reel off device of assembling machine, comprising a reel off shaft support and a machine head, wherein the reel off shaft support comprises a support, a shaft, a shaft gear, a middle gear, a tension roller via an arm is arranged on the support shaft, a support shaft, a tension sensor, a sensor arm, and motor reducer. One end of the sensor arm is arranged on the support shaft, while another end is connected with one end of the tension sensor, and another end of the sensor is arranged on the support, the motor reducer is arranged side under the middle gear while the output gear is meshed with the middle gear. The invention can hold constant tension in the reel process, to make constant force of reeled layer.

Owner:YANCHENG TEXTILE MASCH CO LTD

Method for setting offset set value of warp take-up device and warp take-up device

InactiveCN1576417AHigh precisionImprove qualityFilament handlingWarping machinesConductor CoilMechanical engineering

Owner:TSUDAKOMA KOGYO KK

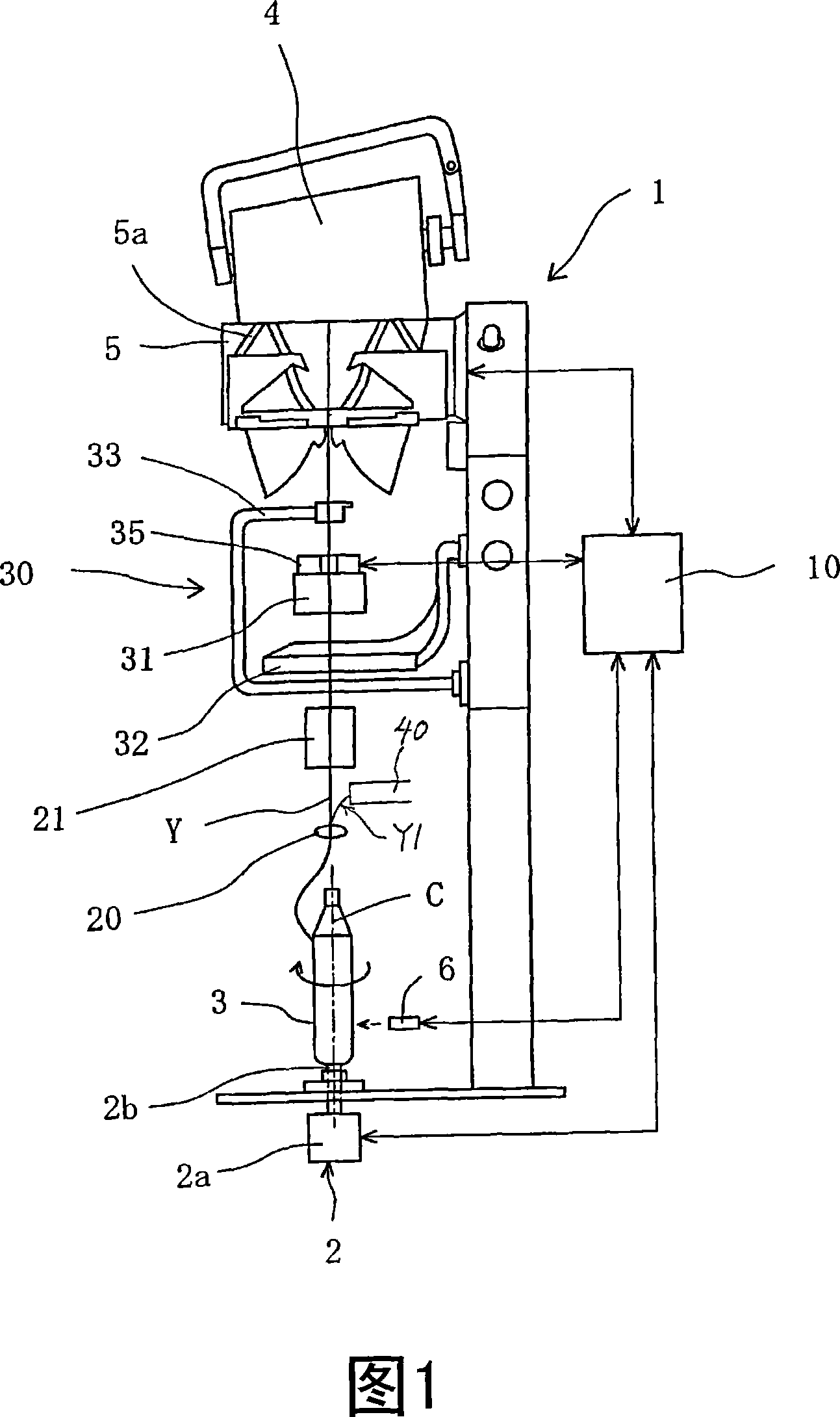

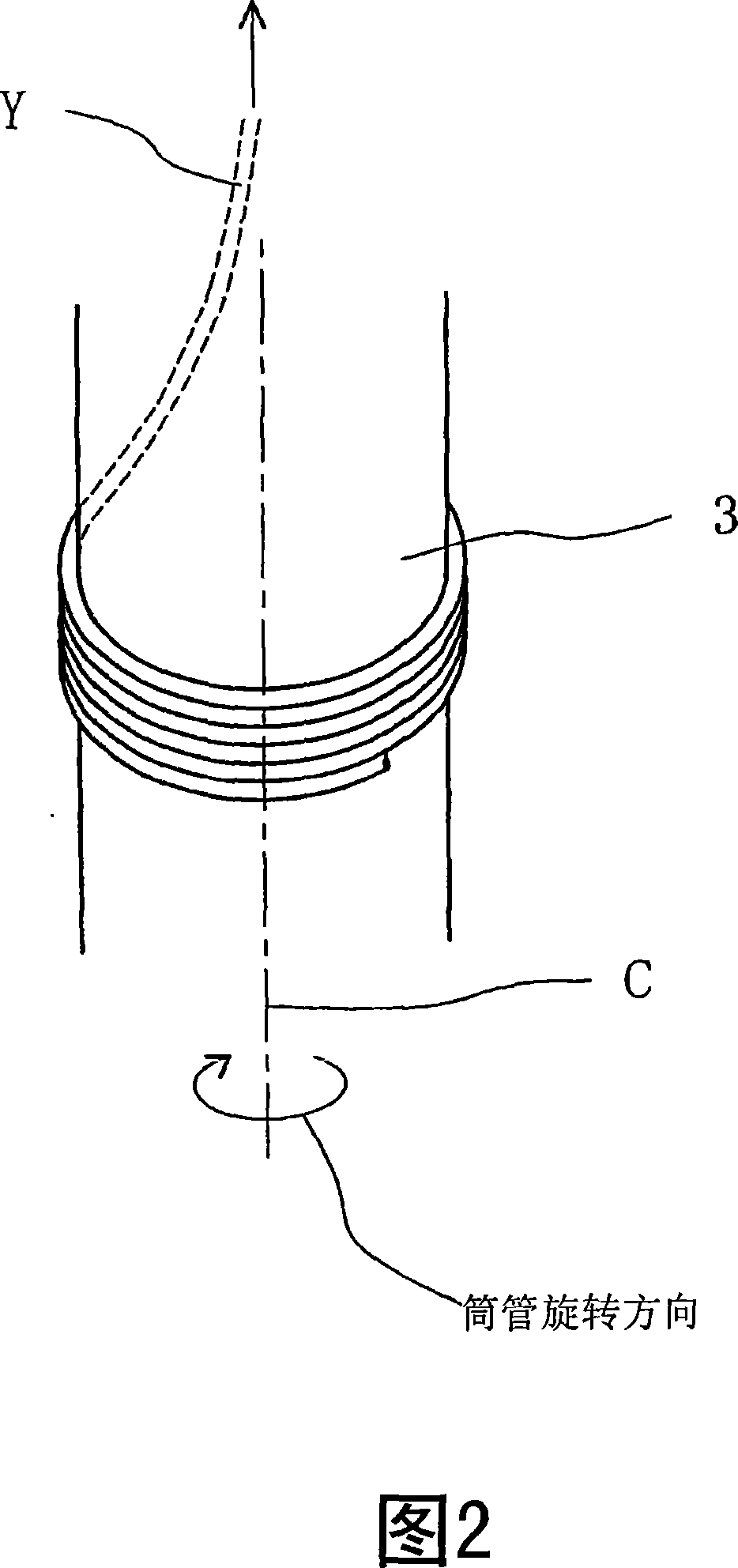

Automatic winder

InactiveCN101058377AReduce tension changesEliminate decapitationFilament handlingBeaming machinesYarnBobbin

The present invention provides an automatic winder capable of suppressing sloughing and fluffing even when used with yarn supply bobbins for various counts and types of yarn, including fine count yarns. The automatic winder unwinds a yarn Y from a yarn supply bobbin 3, and winds the yarn onto a package 4. The automatic winder includes rotational drive means 2 for rotationally driving the yarn supply bobbin 3 about its central axis C in the yarn unwinding direction to positively unwind the yarn Y.

Owner:MURATA MASCH LTD

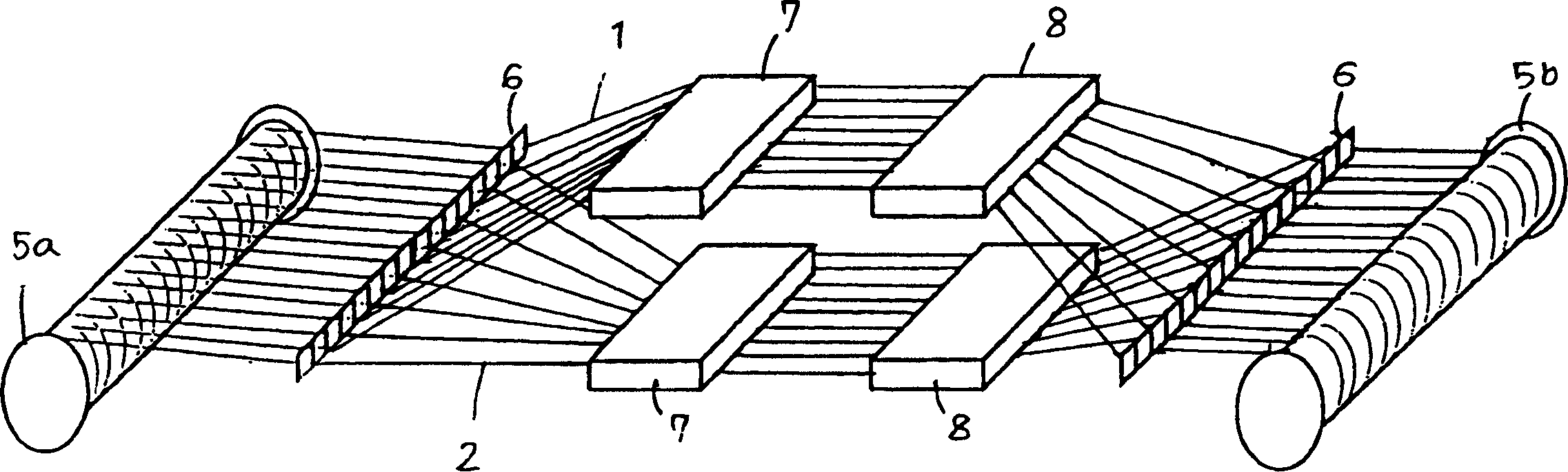

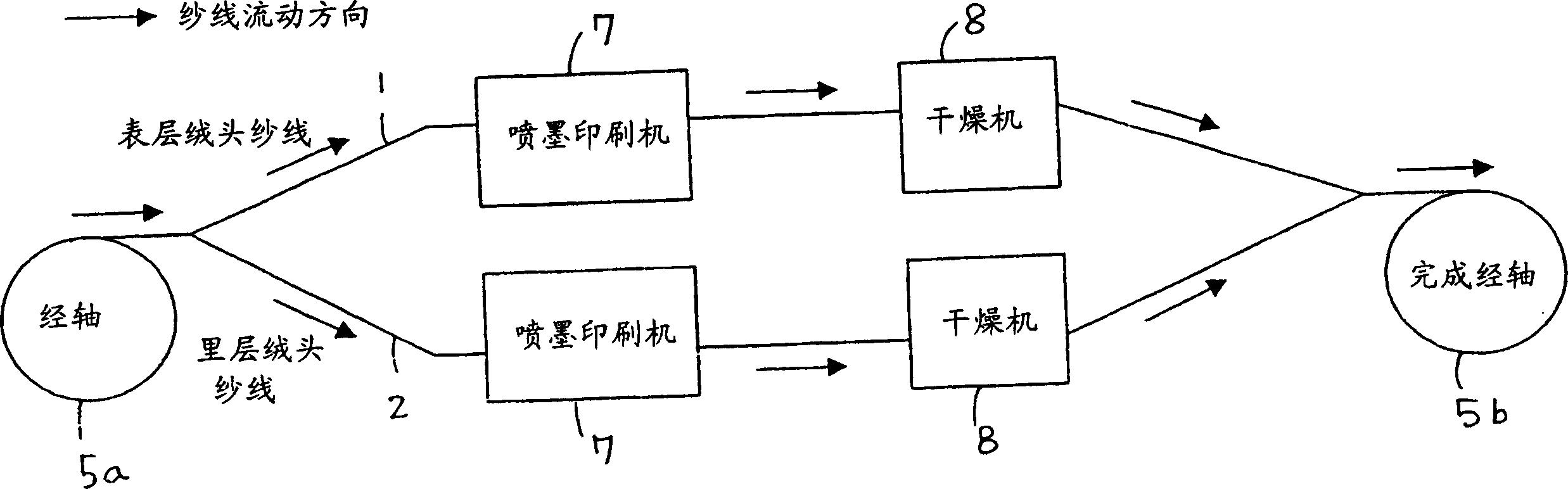

Dyeing processing method for textile

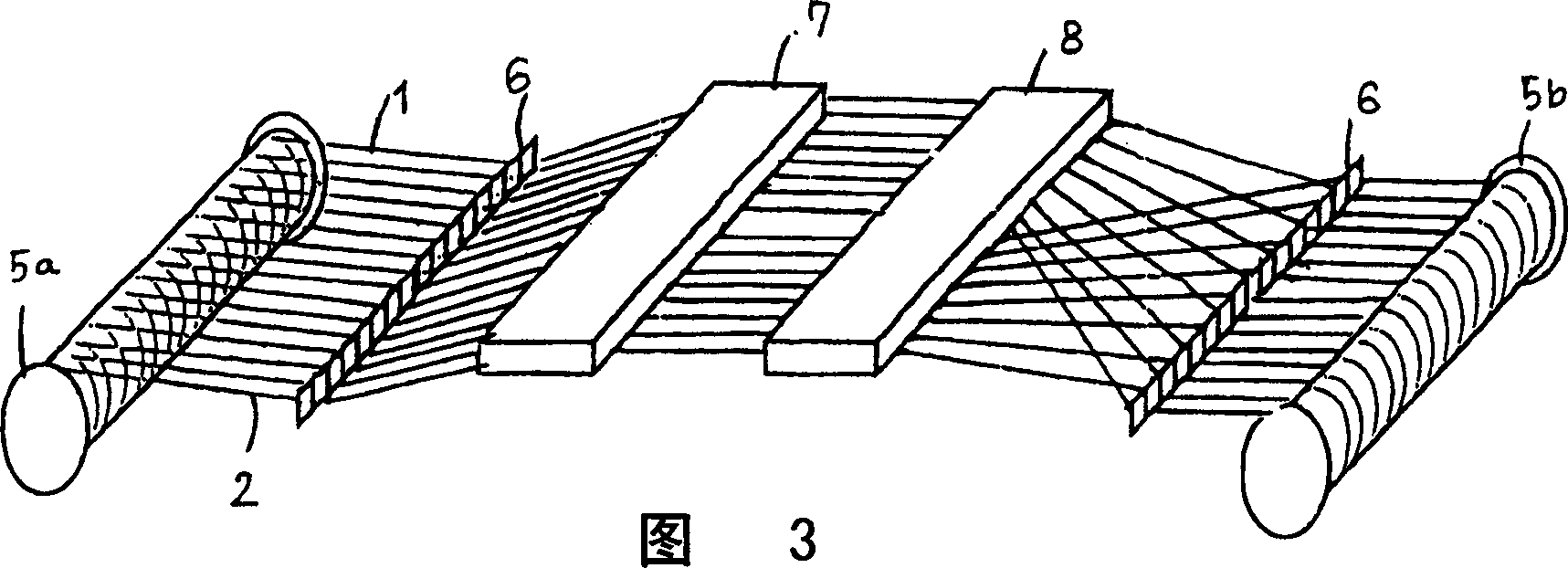

InactiveCN1461848ANot easy to cause displacementShift does not produceWarping machinesBeaming machinesYarnEngineering

The invention provides a method for dye-processing a fabric, not exhibiting discrepancy in patterns between the surface side and back surface side. This method for dye-processing the fabric comprises separating warp yarns wound on a same beam 5a into surface pile warp yarns 1 and back surface pile warp yarns 2 in sheet states, dyeing for forming the same pattern as the pattern expressed on the surface of the fabric, and then winding on a finish beam 5b. Since the pile warp yarns 1, 2 are drawn out under a fixed tension and transported at a same speed, the dyed patterns of the surface pile warp yarns and the back surface pile yarns do not get discrepancy. Therefore, the patterns expressed on the surface and back surface of the pile fabric are made so as not to form the discrepancy between the surface and the back surface.

Owner:INAOKA INDAL

Process for making a warp beam of untwisted fiberglass strands

InactiveUS20020129474A1Improve warping and processImprove consistencyFilament handlingWarping machinesFiberGlass fiber

Owner:DIELECTRIC SOLUTIONS

Slasher capable of realizing automatic pattern arrangement and automatic pattern arranging method

ActiveCN103046266AWith automatic flower arrangement functionImprove accuracyBeaming machinesTextile treatment carriersData processing systemYarn

The invention discloses a slasher capable of realizing automatic pattern arrangement and an automatic pattern arranging method. The slasher comprises a yarn distributing device and a headstock winding device, wherein the yarn distributing device is arranged in front of the headstock winding device, a compression roller device, an automatic pattern arranging device and an expansion reed are arranged between the yarn distributing device and the headstock winding device and are sequentially arranged along moving direction of yarns, and the automatic pattern arranging device is connected with a data processing system. By the aid of the automatic pattern arranging method, automatic pattern arranging function of the slasher is realized, thus labor force is saved, accuracy rating of sizing pattern arrangement is greatly increased, and producing efficiency and utilization rate of an automatic warp drafting machine during drafting process are greatly improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Warping device

The invention relates to a warping device (1), which has a winding carrier, a rotation drive (8) that rotationally drives the winding carrier, a bearing unit (11) for the winding carrier and a threadband guiding device moved along the winding carrier. For the purpose that the production time can be short in the process of producing warp threads by the warping device, the warping device is designed in the following way: the winding carrier is designed into a yarn beam (2) which can be detachably connected with the rotation drive (8) and bearing unit (11) and has at least one yarn beam plate (24).

Owner:KARL MAYER STOLL R&D GMBH

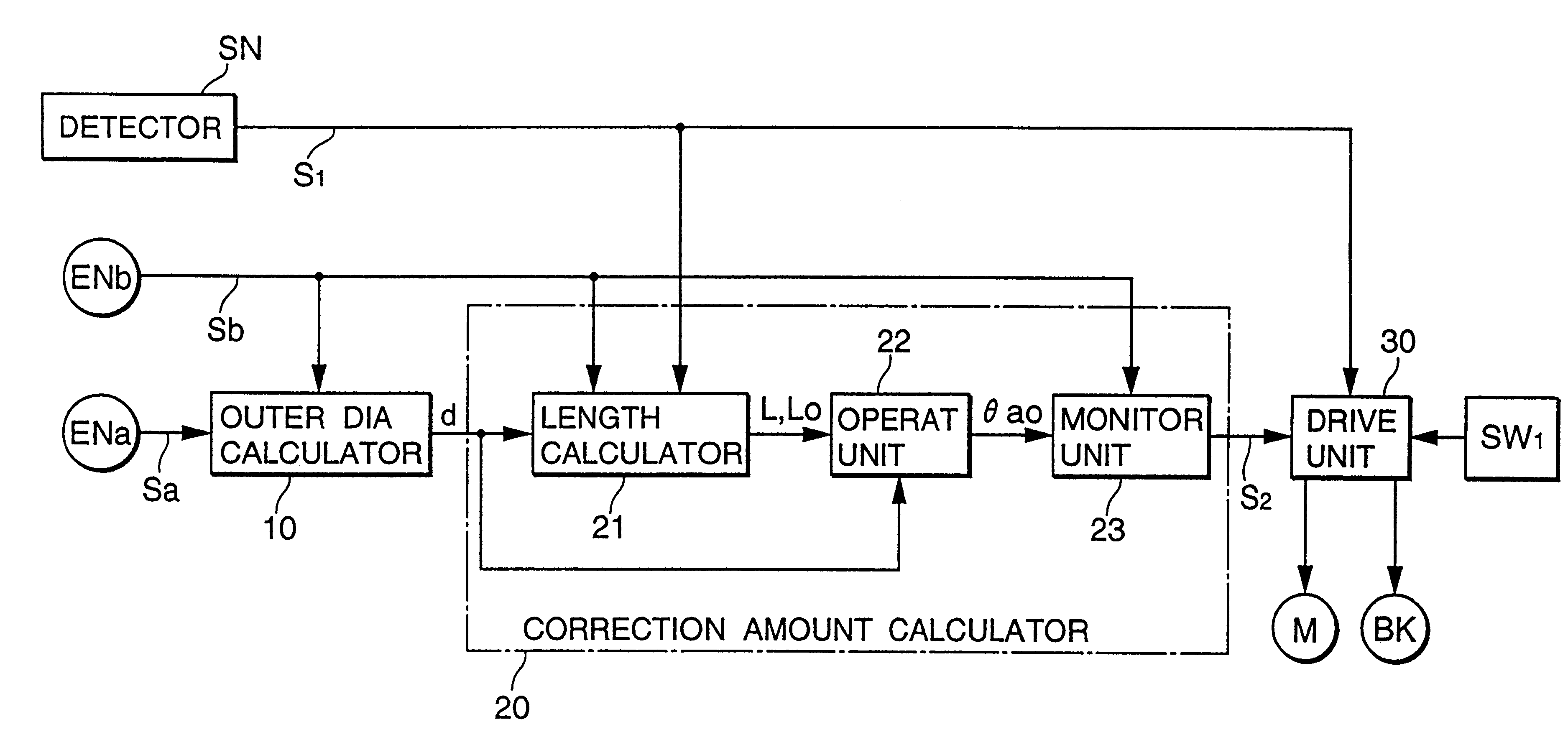

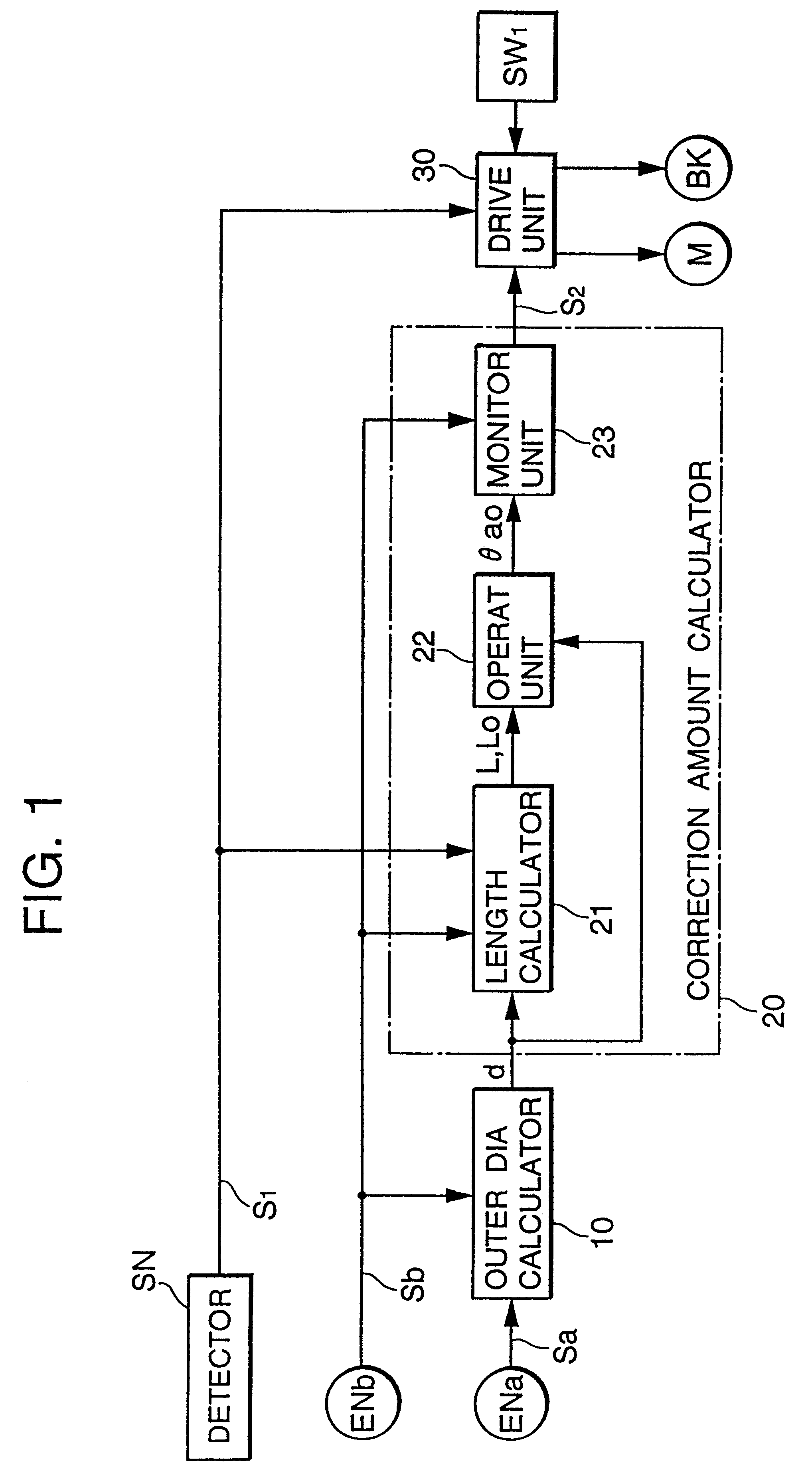

Warp repair assisting apparatus for warper

An outermost diameter calculation unit for calculating an outermost diameter d of a take-up beam and a correction amount calculation unit in a warp repair assisting apparatus are combined. The correction amount calculation unit calculates a corrected rotation amount thetaao in the forward direction of the take-up beam necessary to position an abnormal portion of warps at a specified operation position on the take-up beam. A driving unit moves the abnormal portion to the operation position by rotating the take-up beam in the forward direction by an amount corresponding to the corrected rotation amount thetaao. Therefore, the abnormal portion of the warps can be easily repaired.

Owner:TSUDAKOMA KOGYO KK

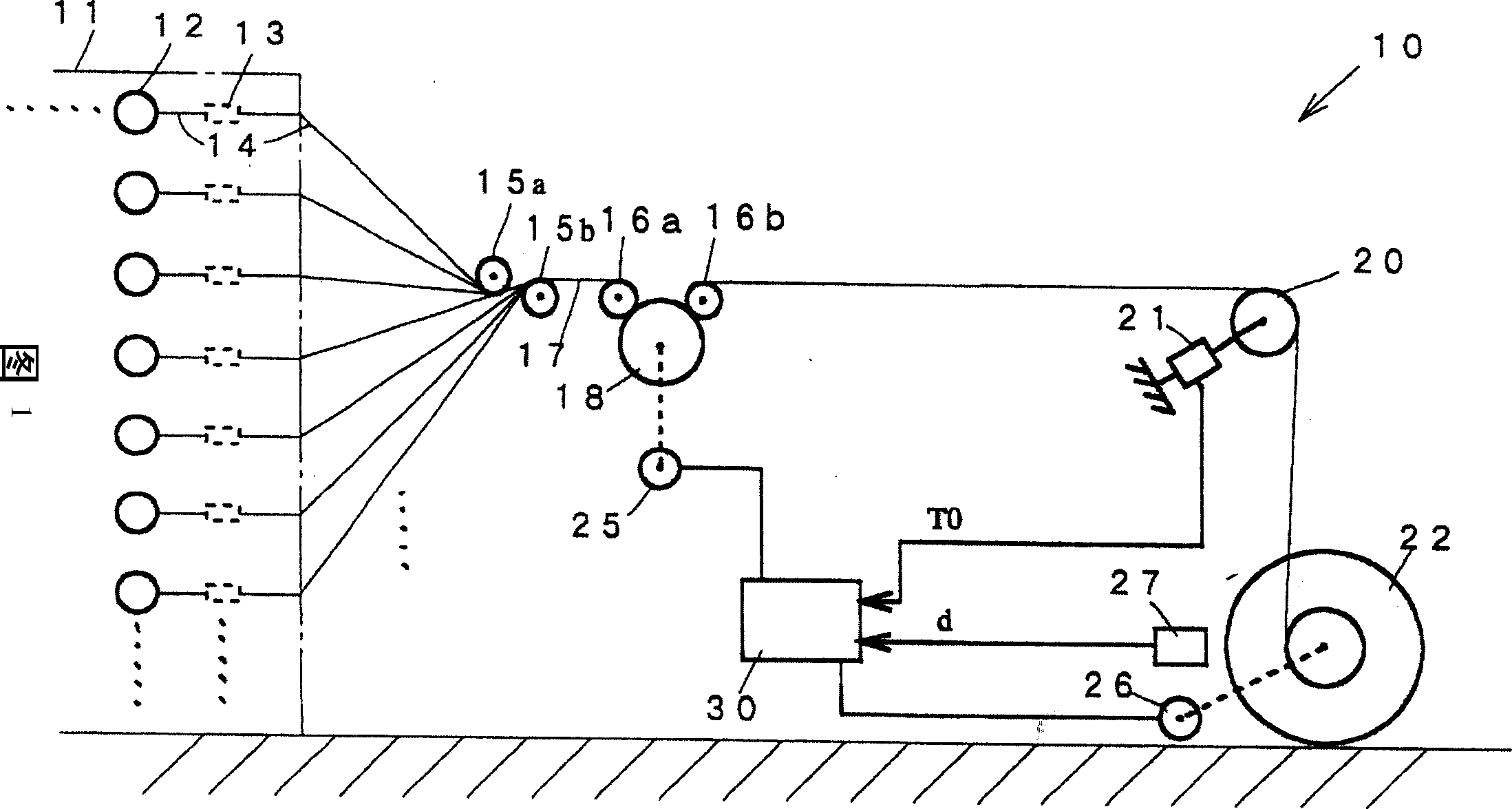

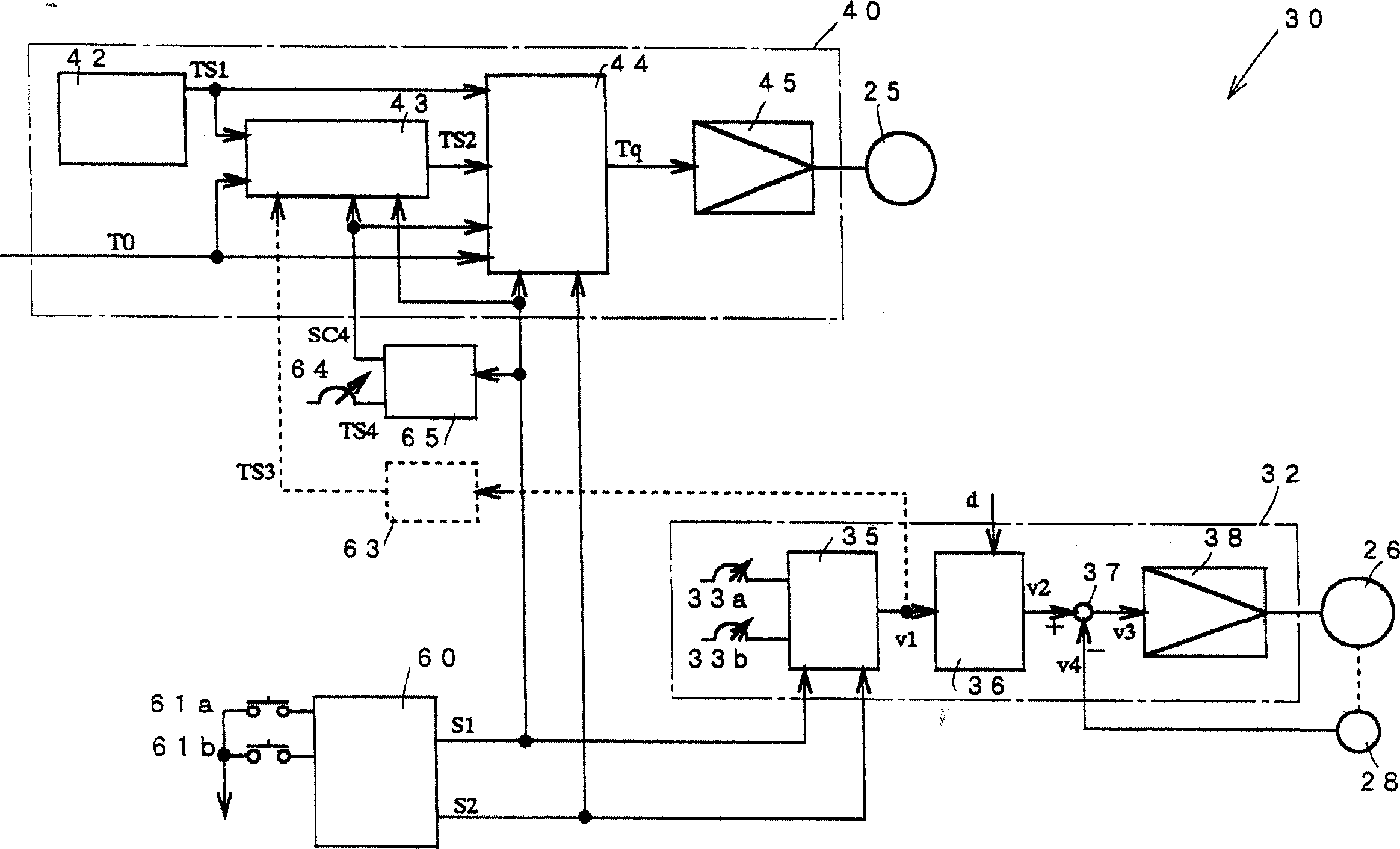

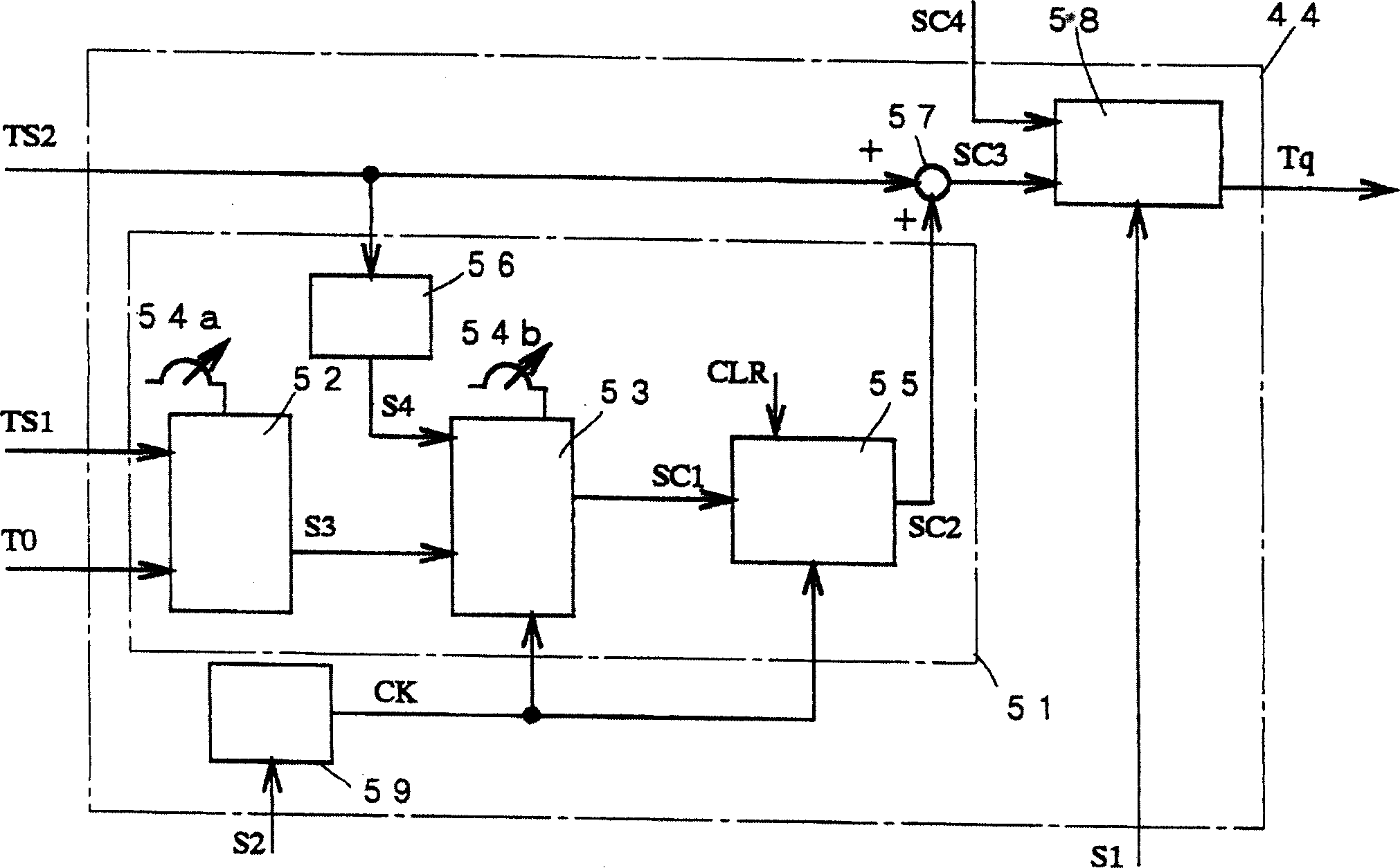

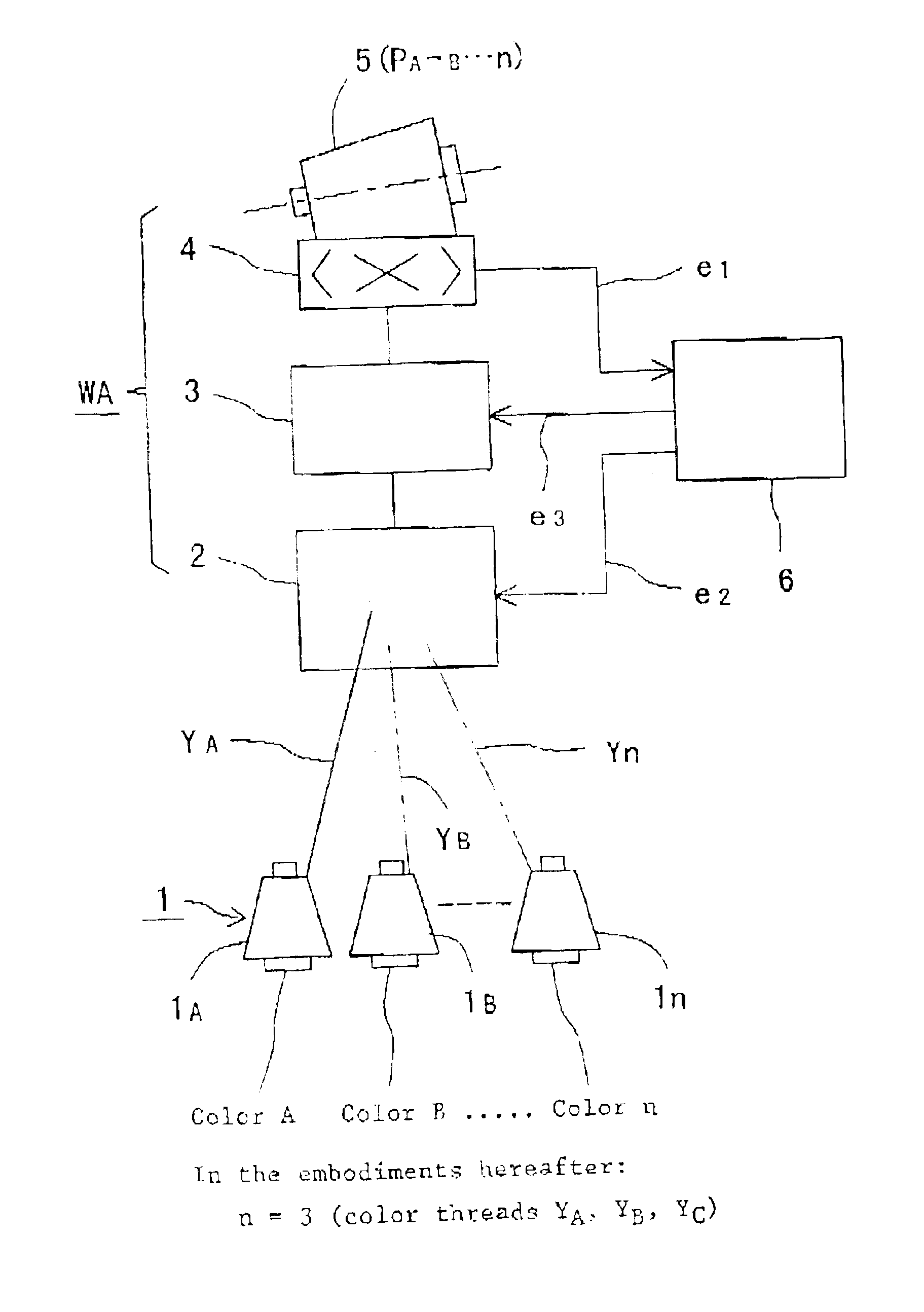

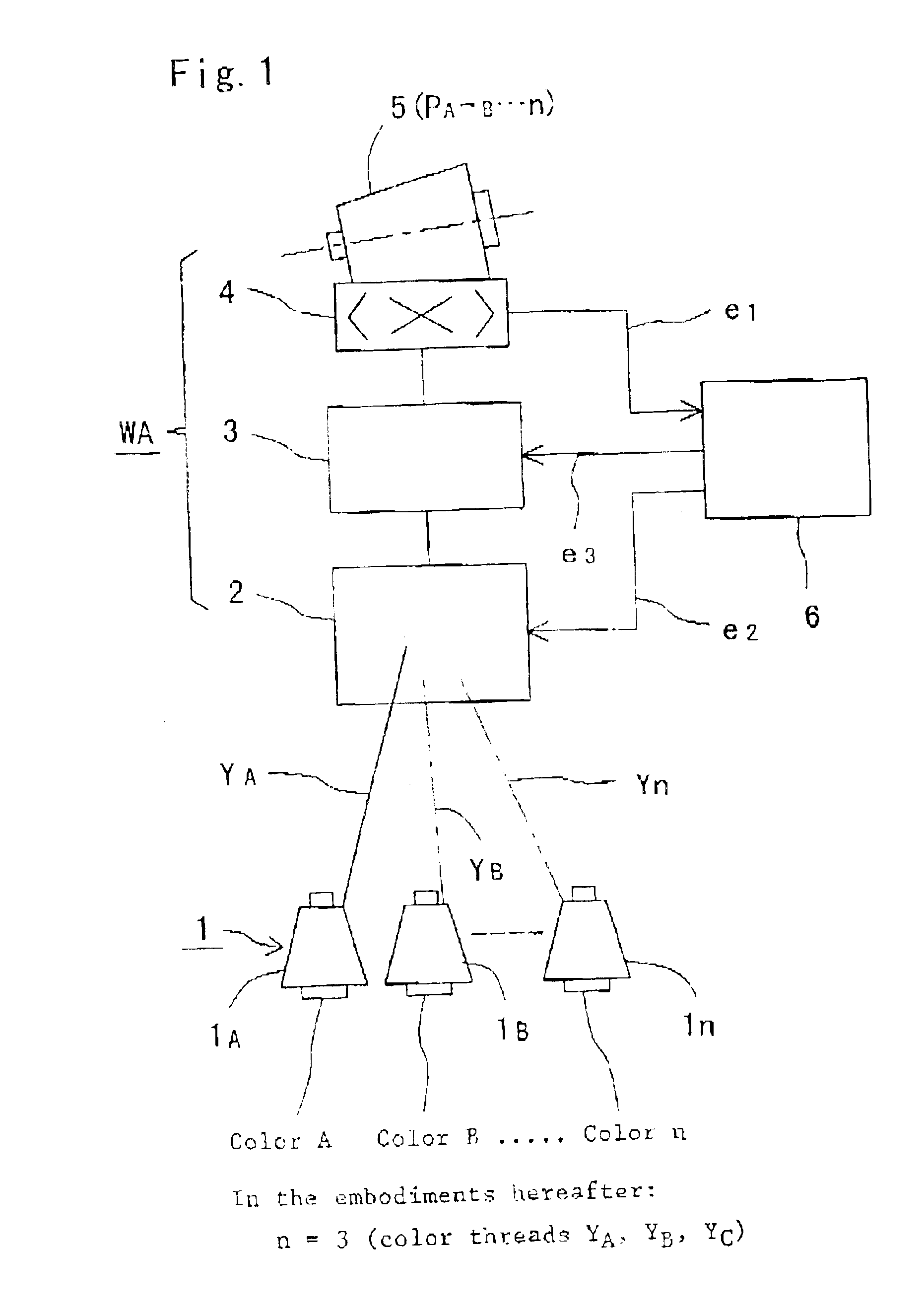

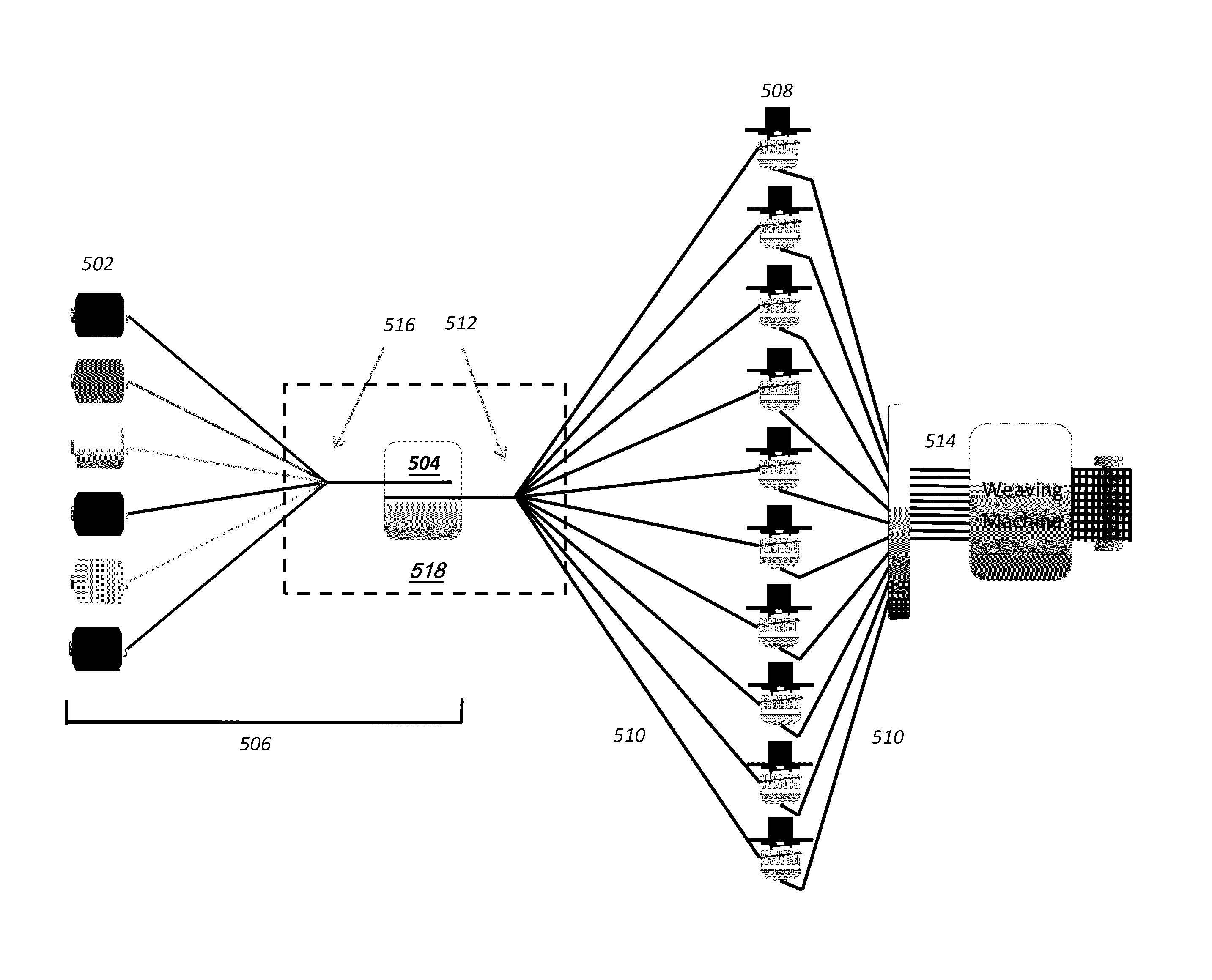

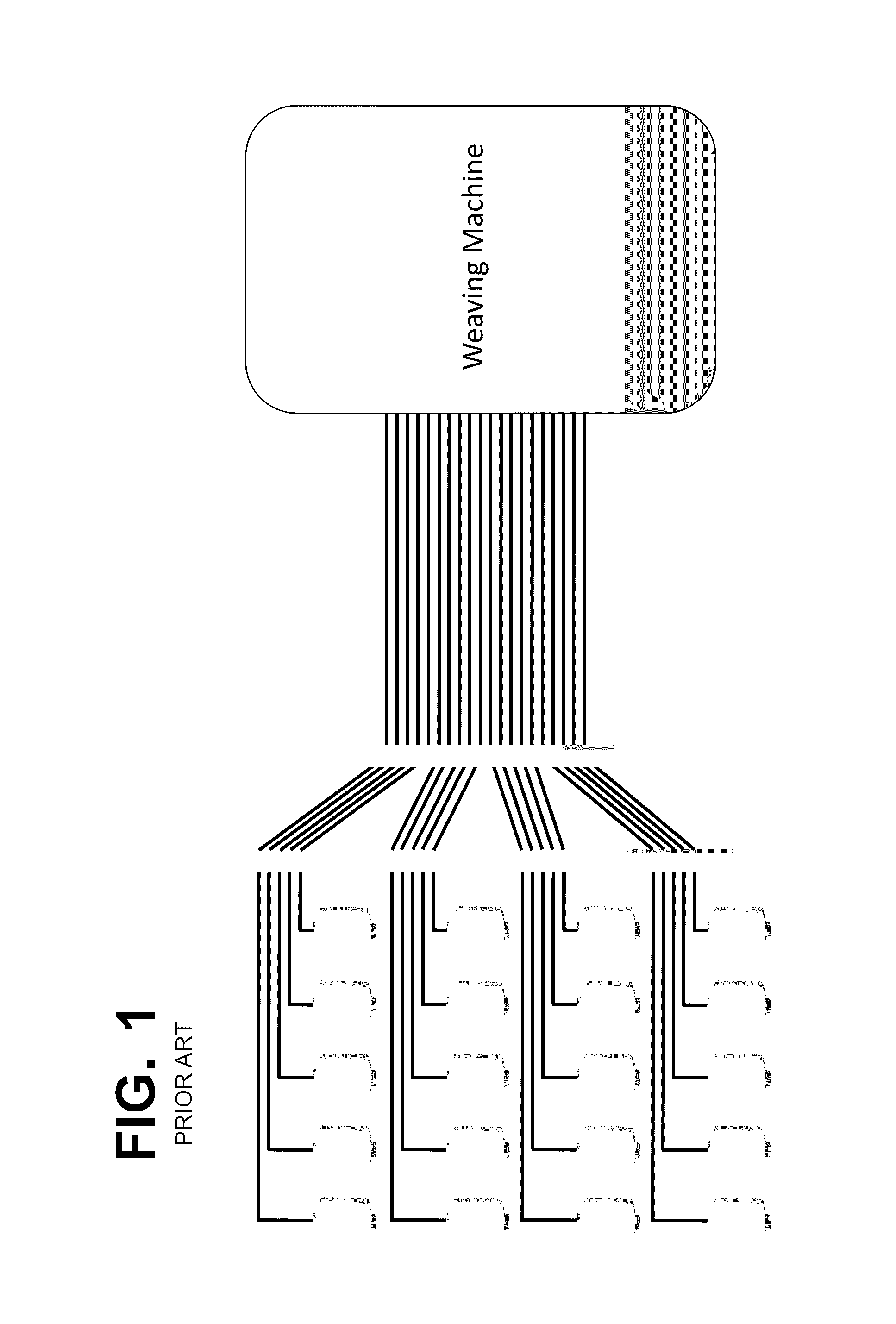

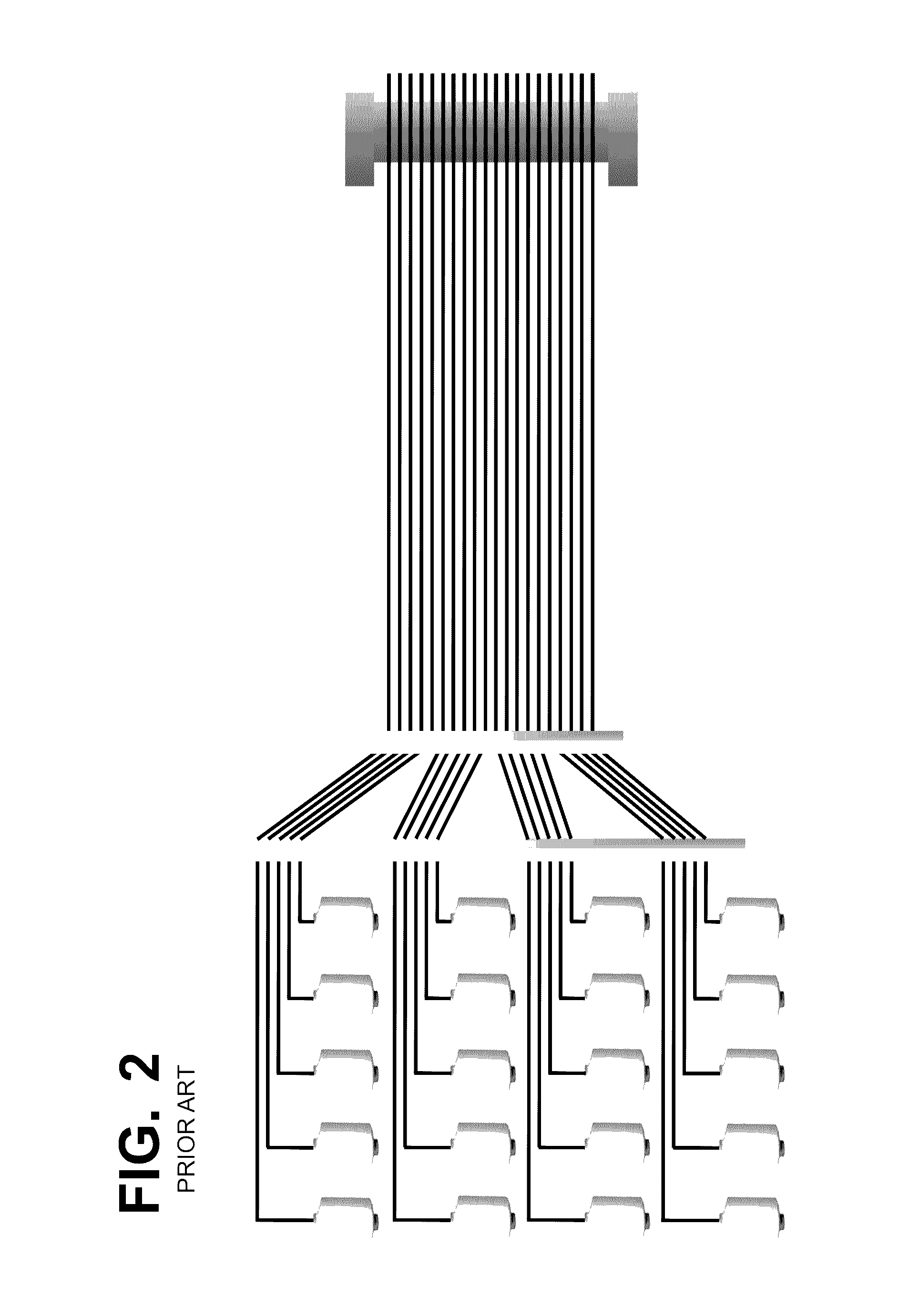

Weaving system for woven fabrics of various kinds in small lots

InactiveUS6845550B2Prevents waste generationAvoid generatingLoomsFilament handlingContinuous operationMechanical engineering

The present invention provides a weaving system for woven fabrics of various kinds in small lots, capable of weaving woven fabrics of various kinds in small lots in a continuous operation by an existing weaving machine while preventing generation of waste to the minimum degree. A weaving system for woven fabrics of various kinds in small lots, comprises the steps of successively selecting a plurality of kinds of threads according to a preliminarily designed design pattern, producing a thread supplying package for the warp by jointing per a predetermined thread supply amount, warping a plurality of the thread supplying packages for the warp so as to provide a warp beam, and organizing a weft to the warp supplied from the warp beam for forming different design patterns of a plurality of kinds continuously each with a warp thread jointing area disposed therebetween in the weaving direction.

Owner:MURATA MASCH LTD

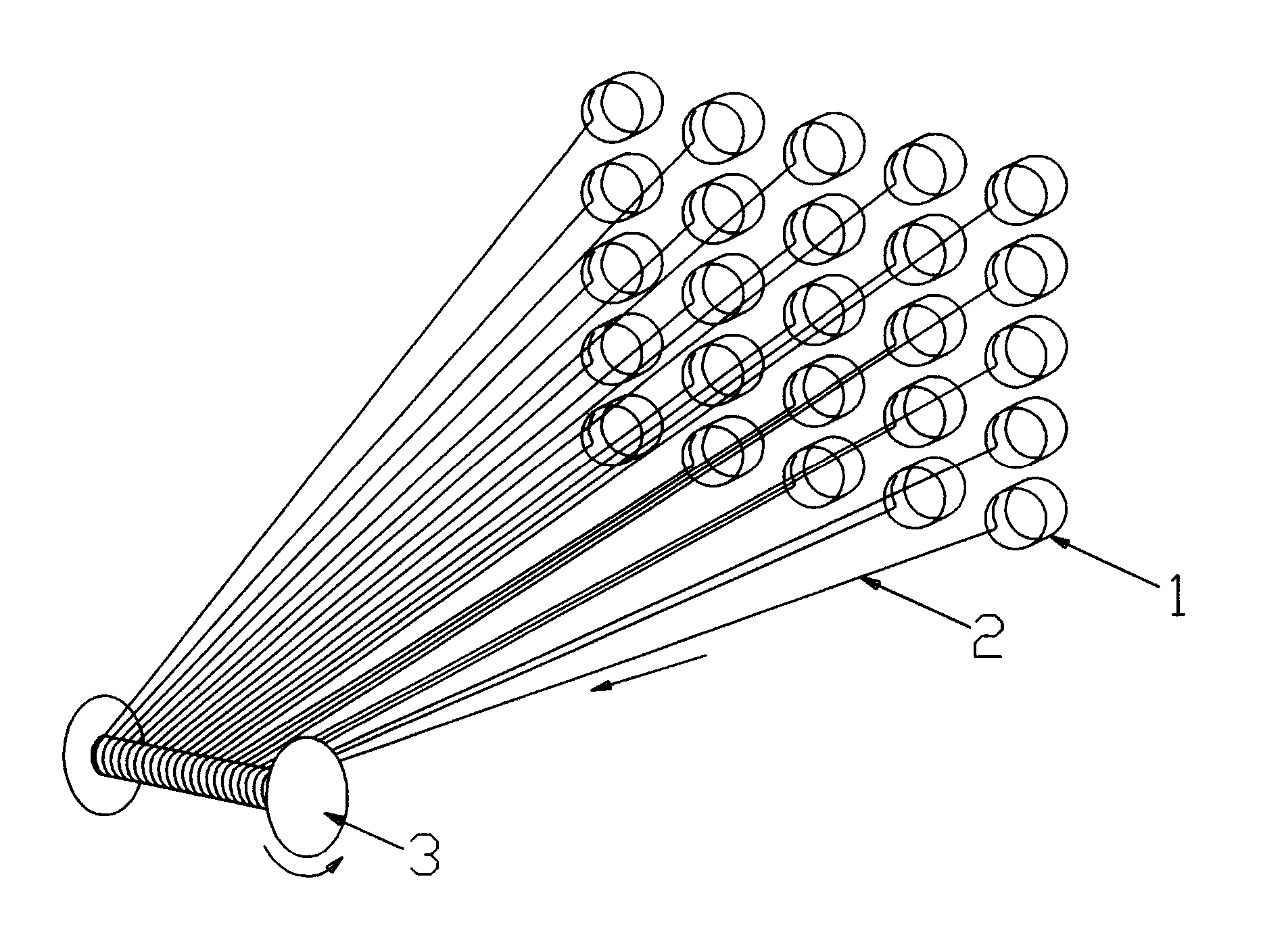

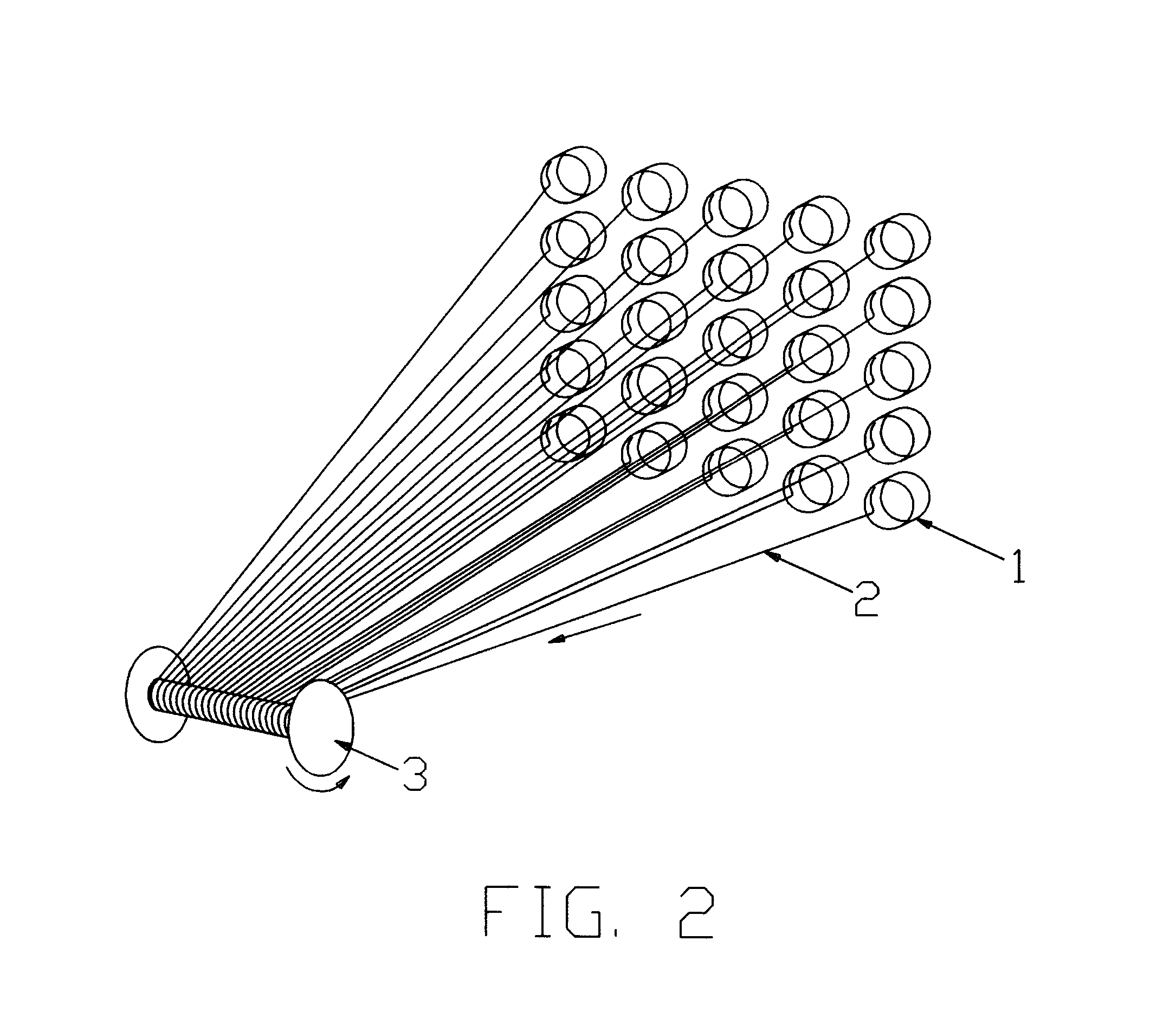

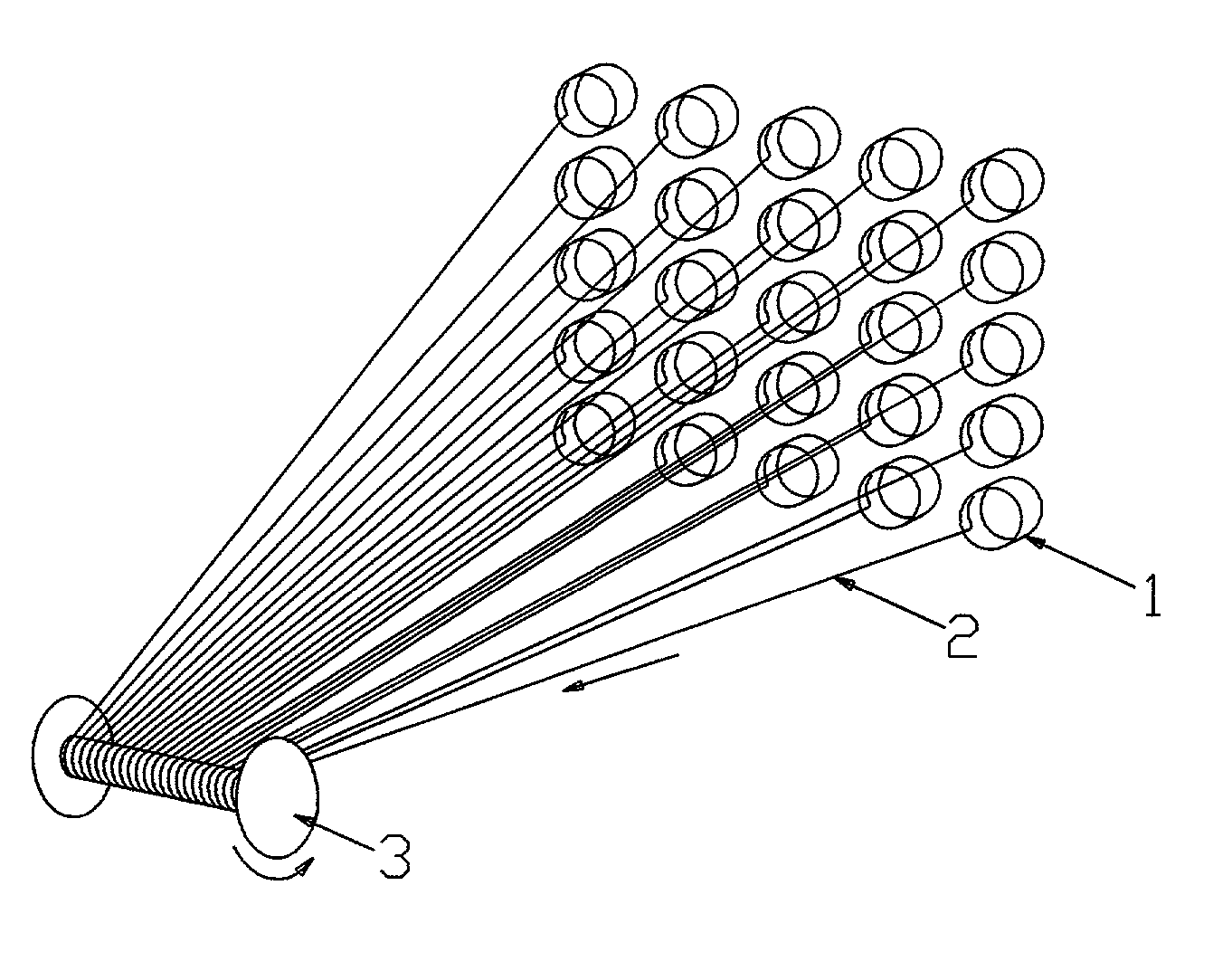

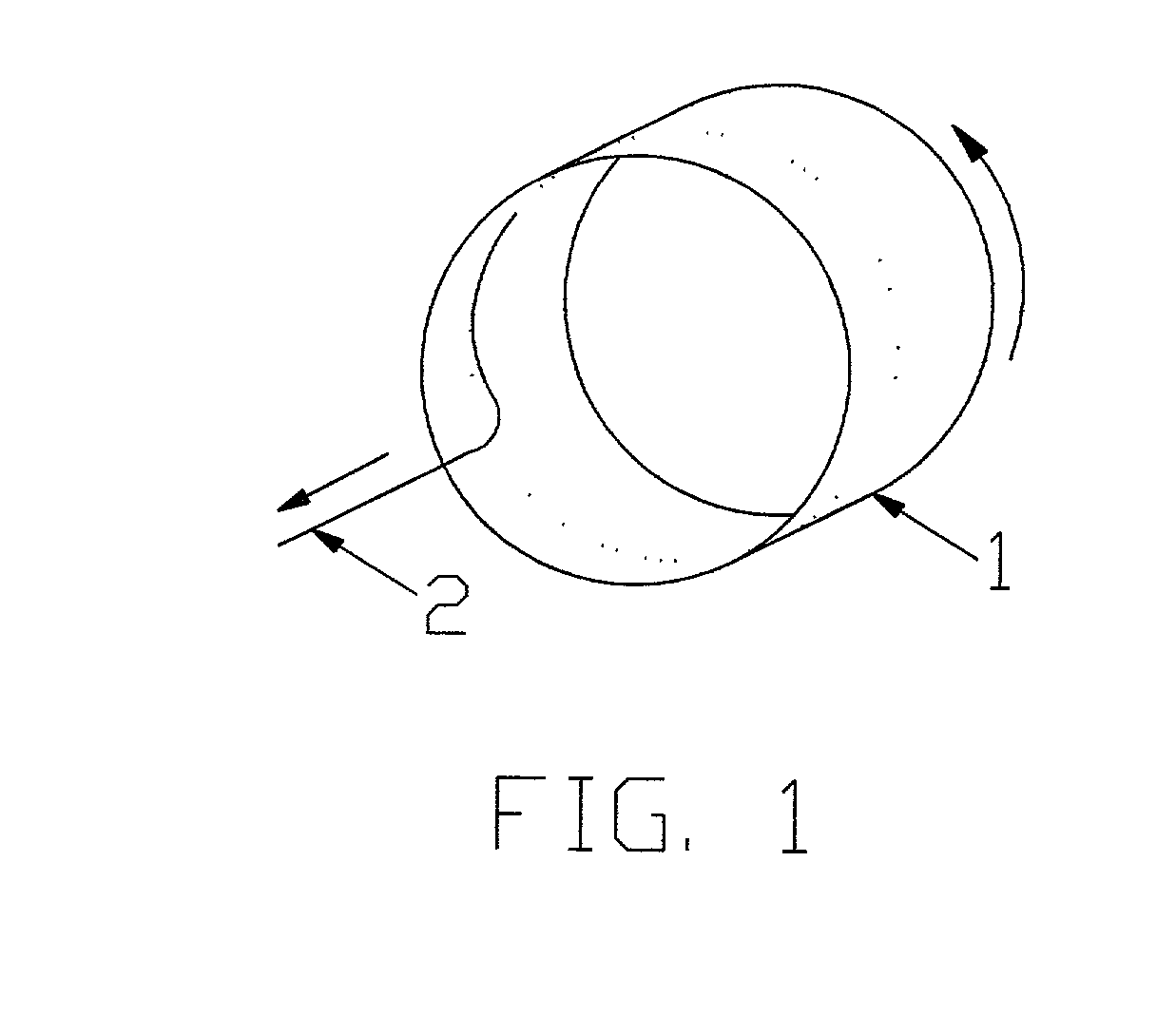

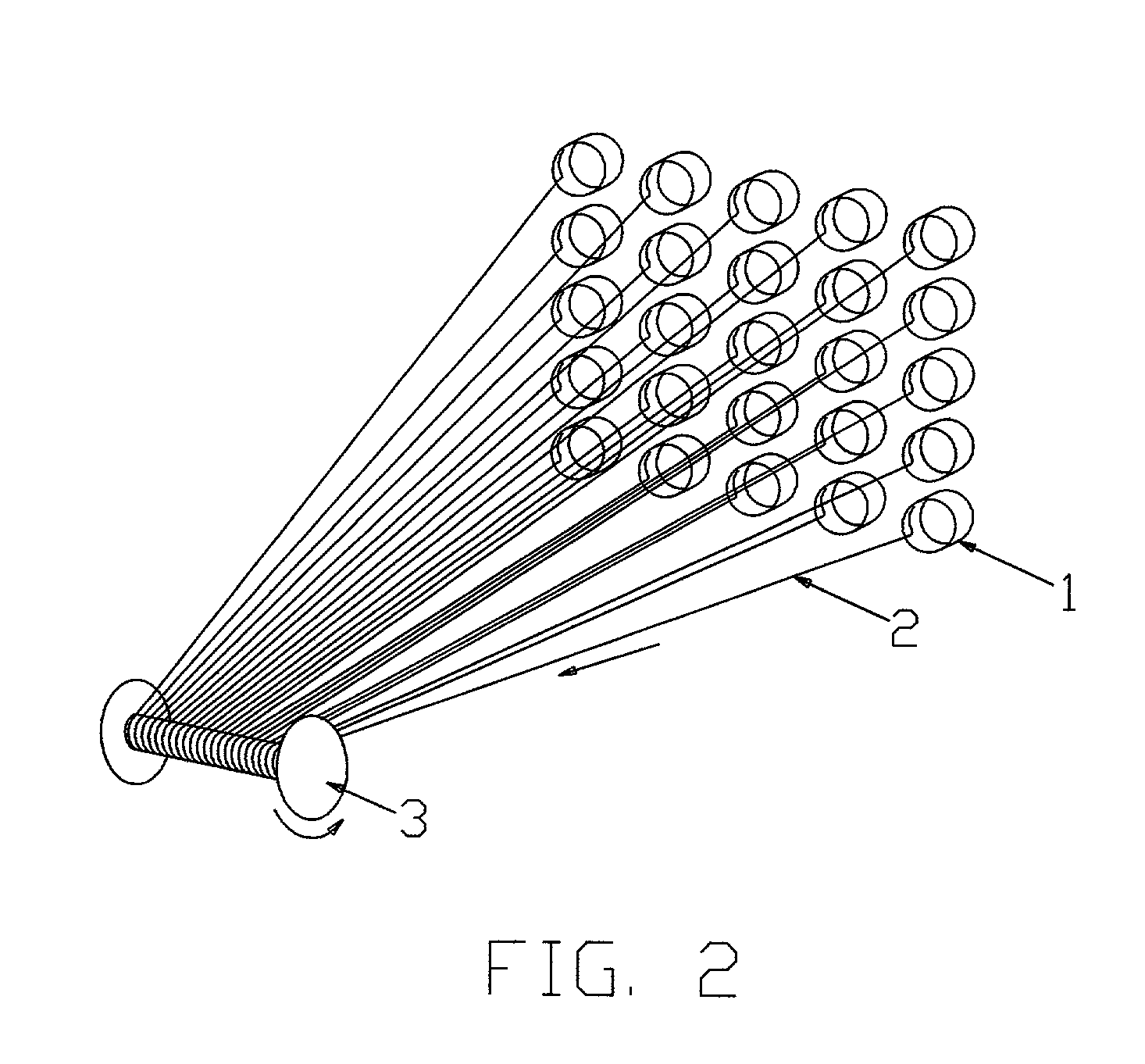

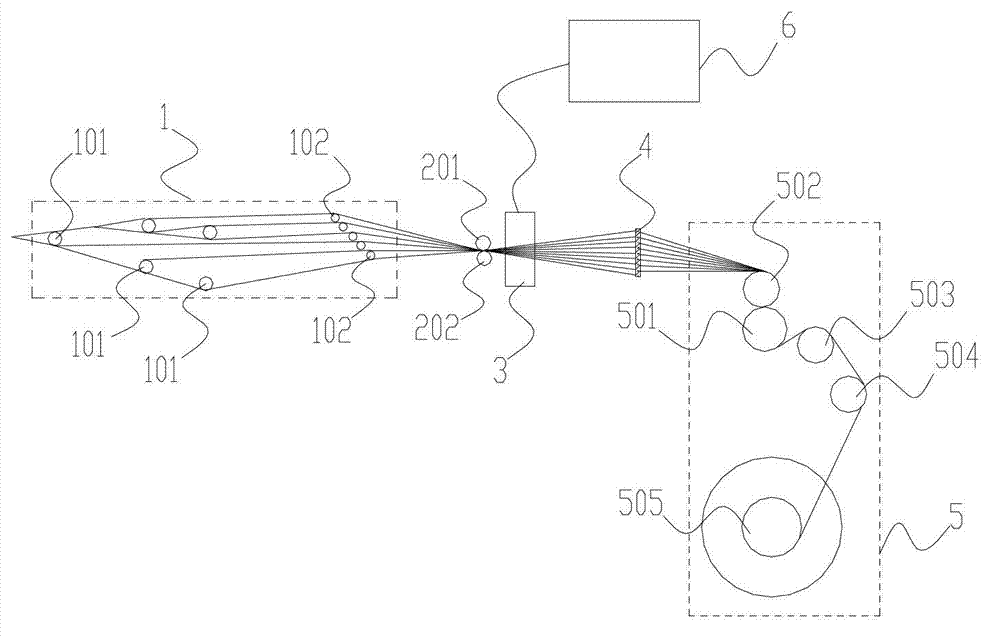

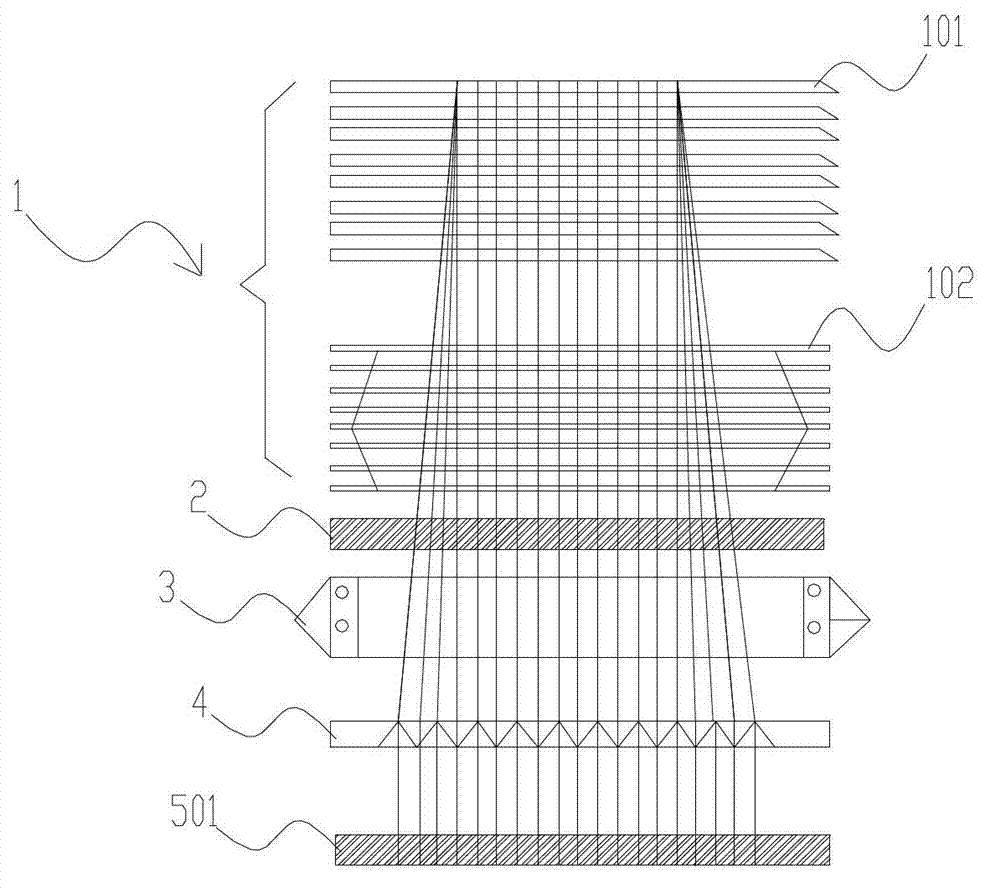

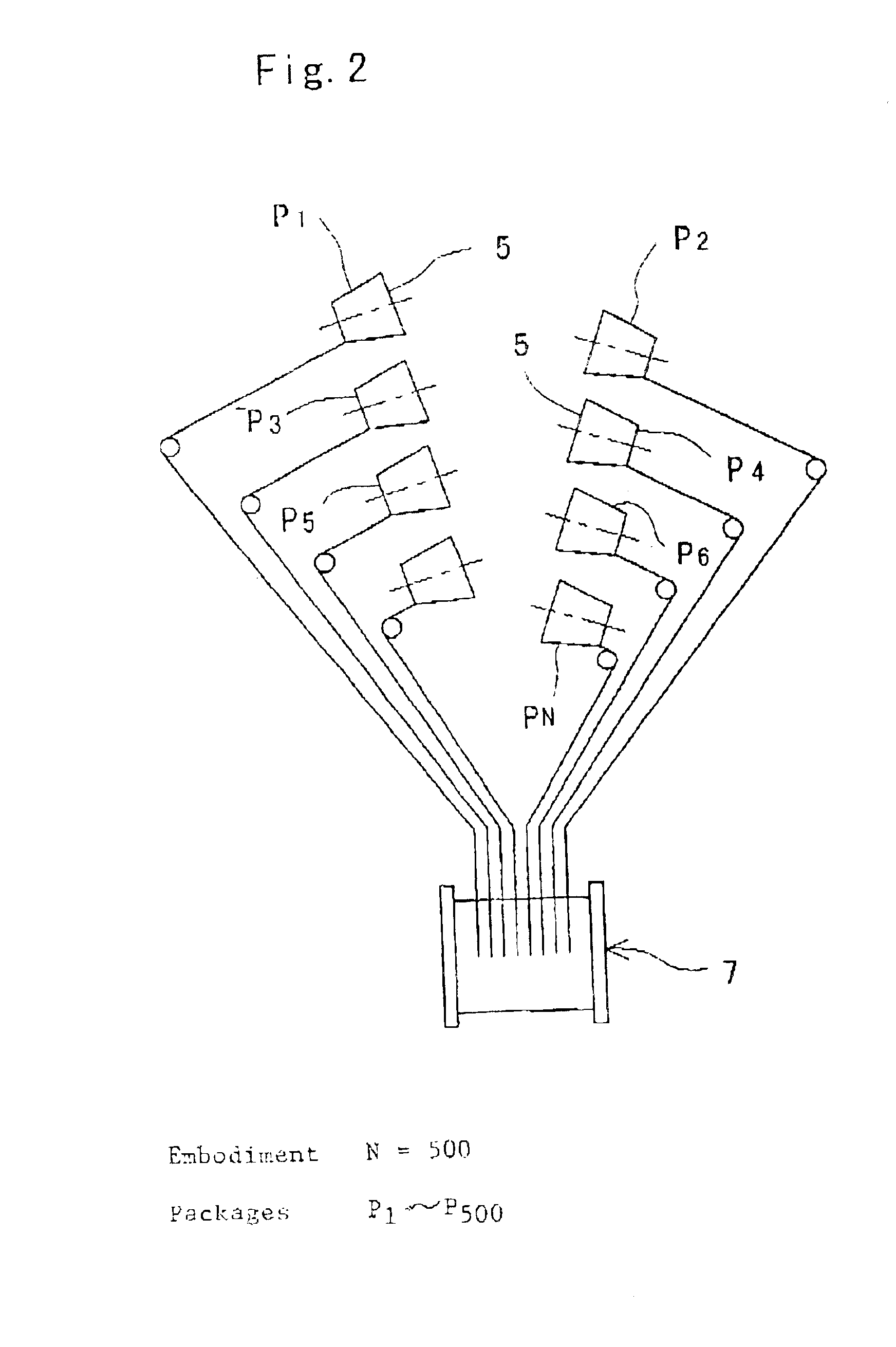

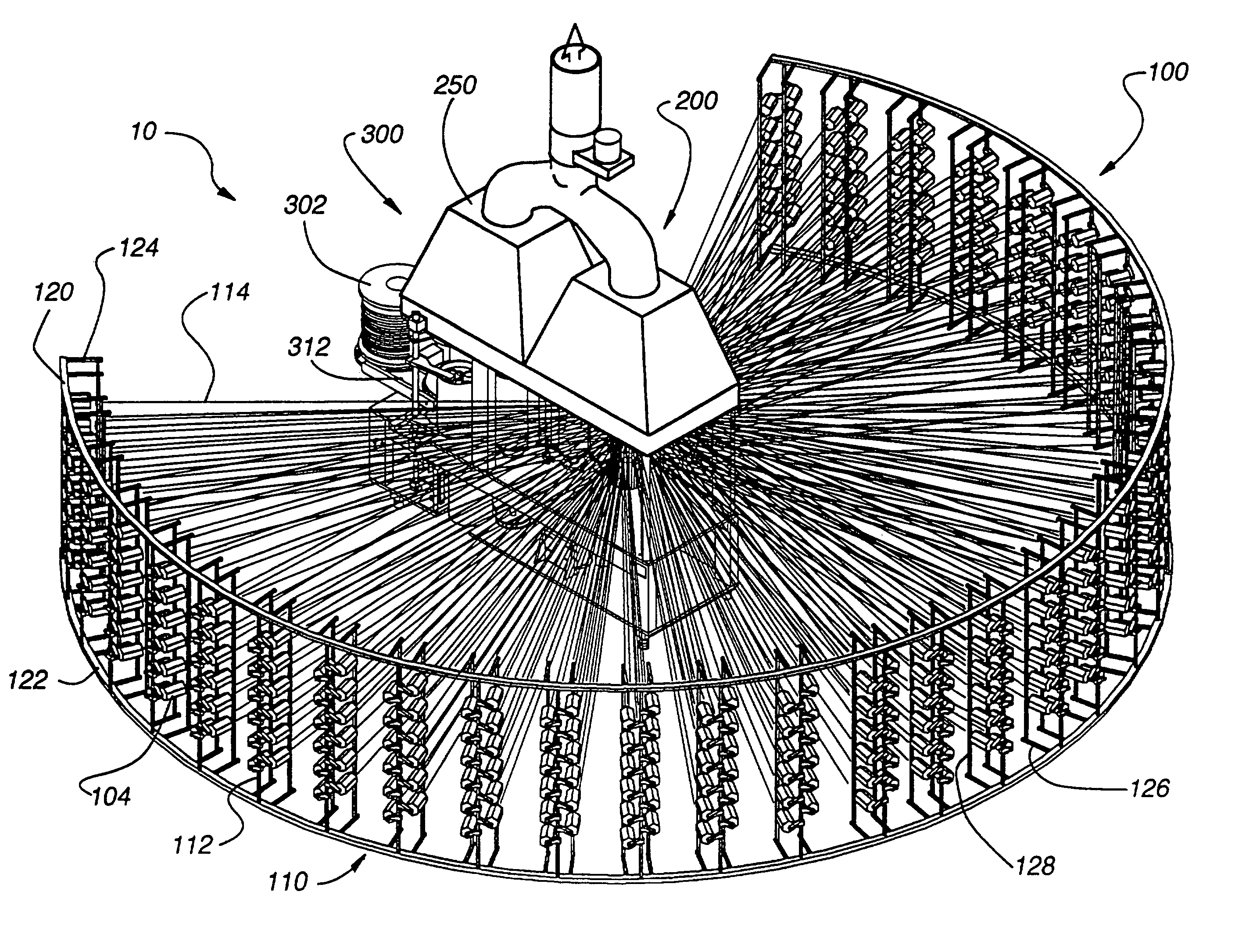

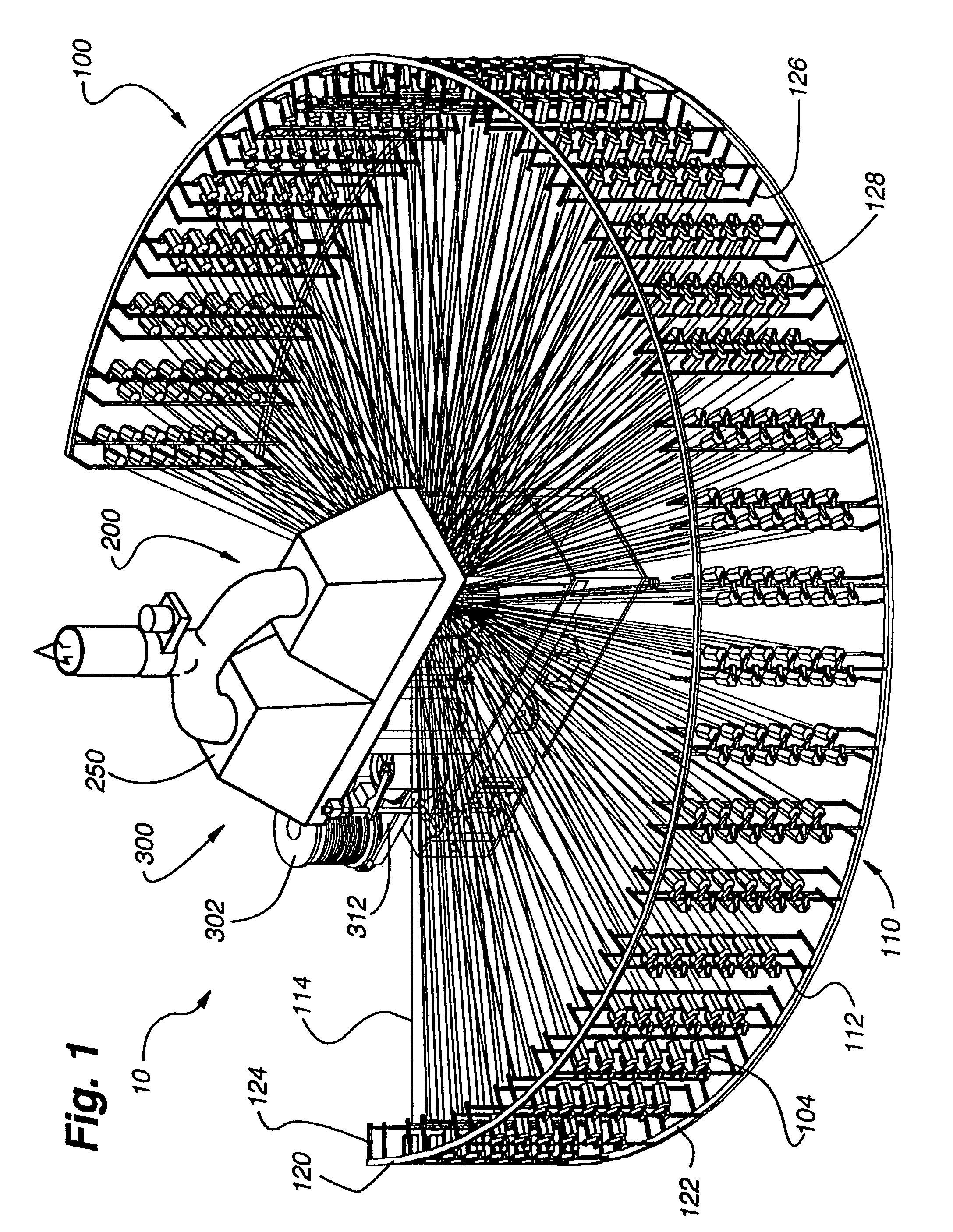

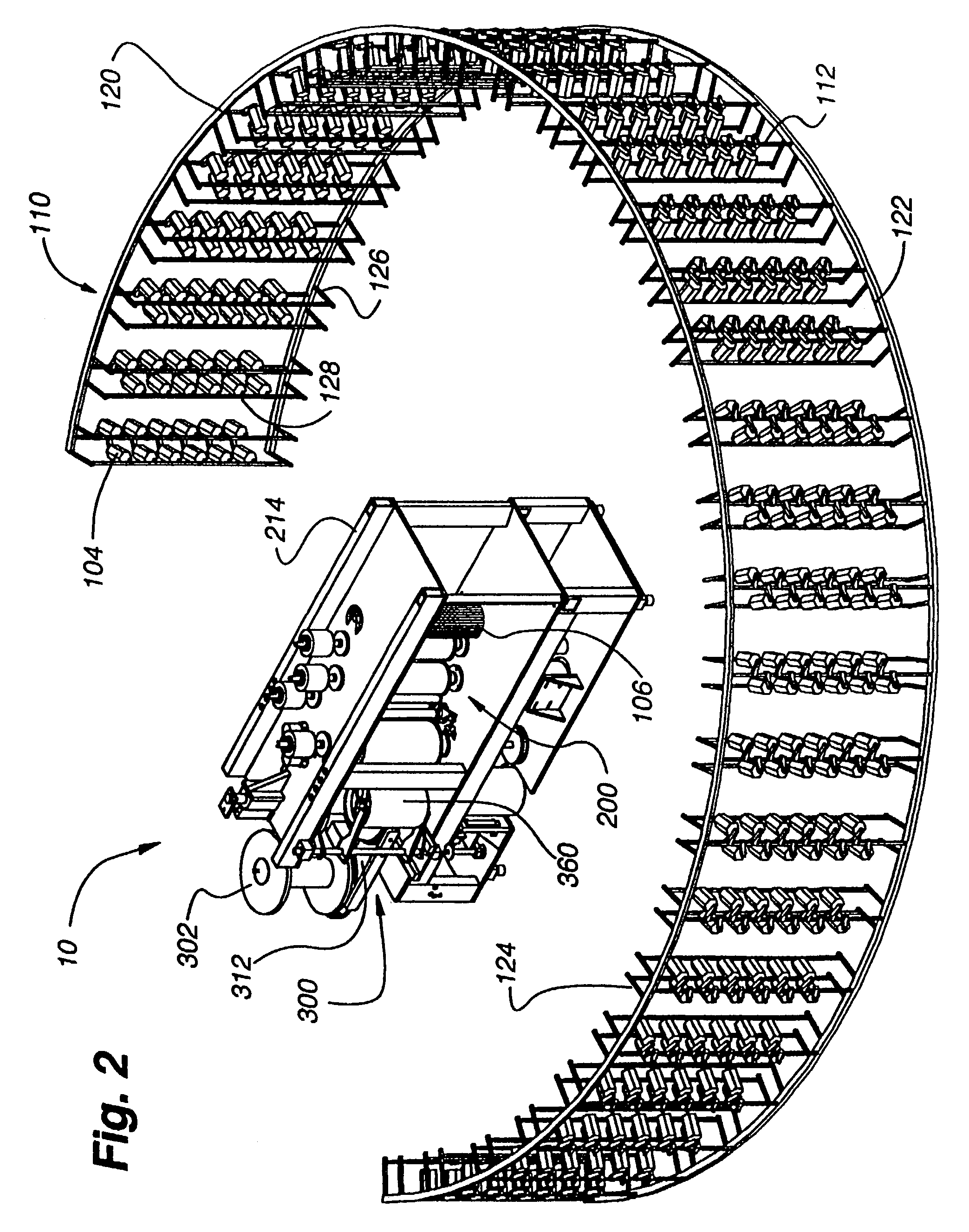

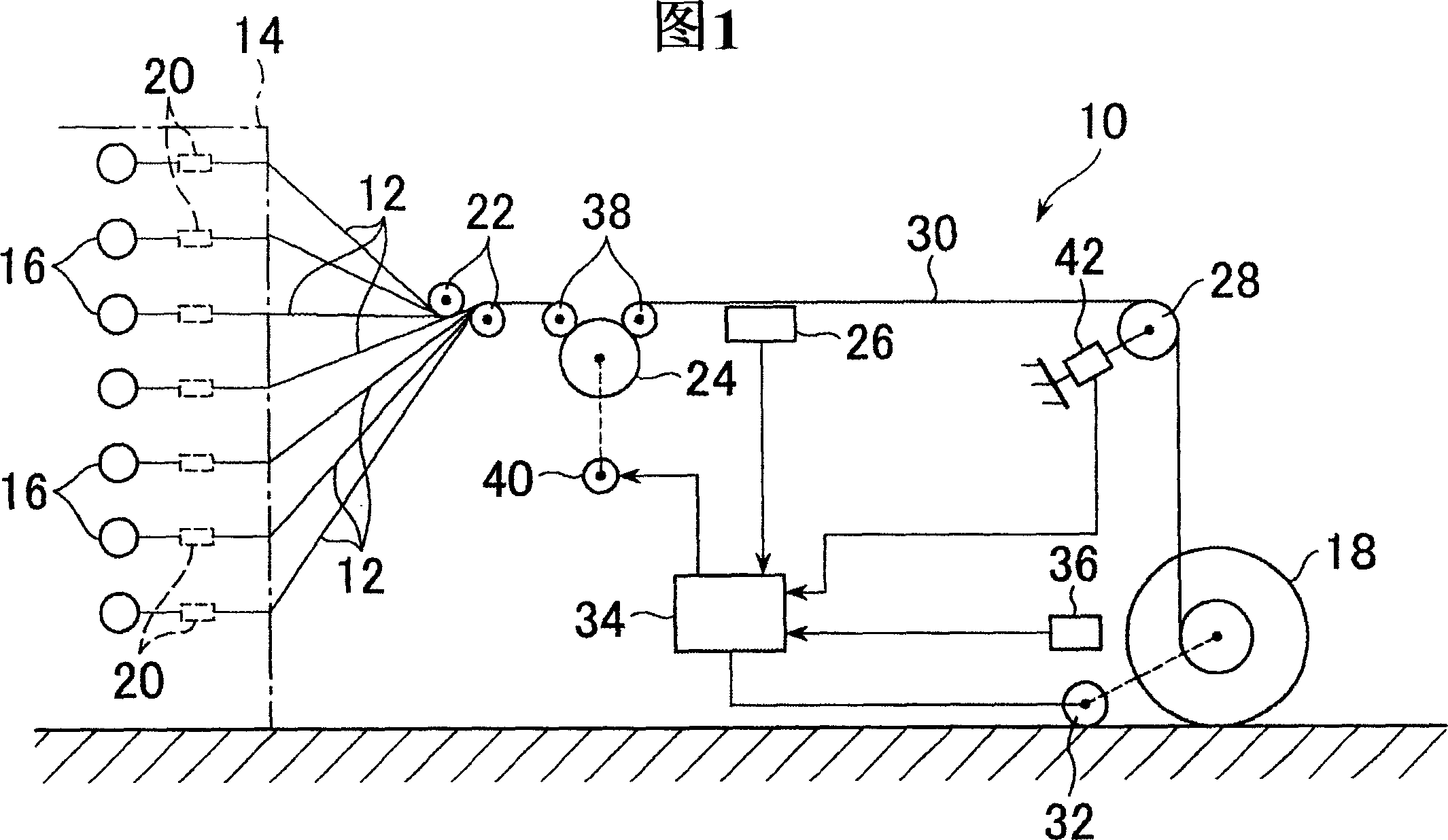

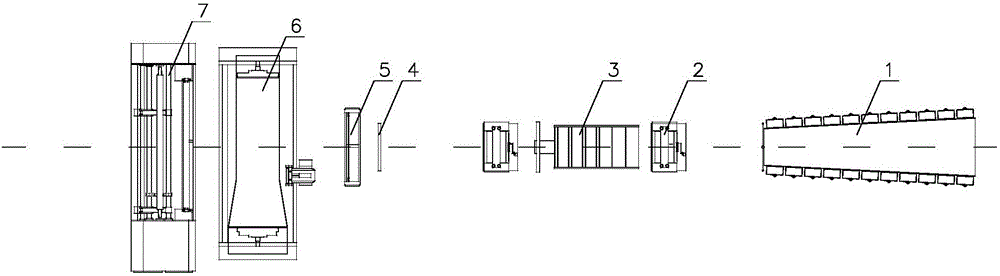

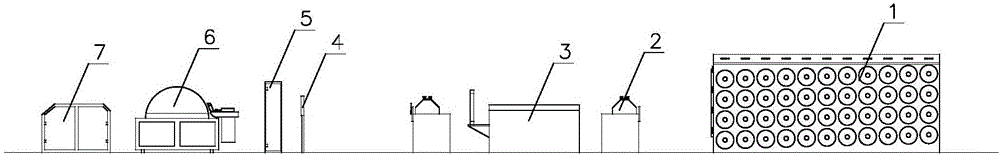

Beam winding apparatus

An apparatus and method for winding a sheet of aligned parallel yarns onto a beam is described. The beam winder utilizes a circularly arced yarn spool rack that feeds each yarn to an alignment comb through associated guide tubes. The distance between each spool of yarn and the alignment comb is substantially the same for all spools of yarn, thereby equalizing the force necessary to pull them to the comb. Next, the aligned sheet of material is preshrunk using heated rollers and wound onto a beam. Multiple speed controlled stepper motors are utilized to maintain a constant low level of tension in the sheet during the shrinking process. After shrinkage, the tension level of the yarn sheet is increased as it is wrapped onto the beam. A turntable that supports two or more beams is provided to facilitate the rapid switching of beams once one beam has become full.

Owner:HUNTER DOUGLAS INC

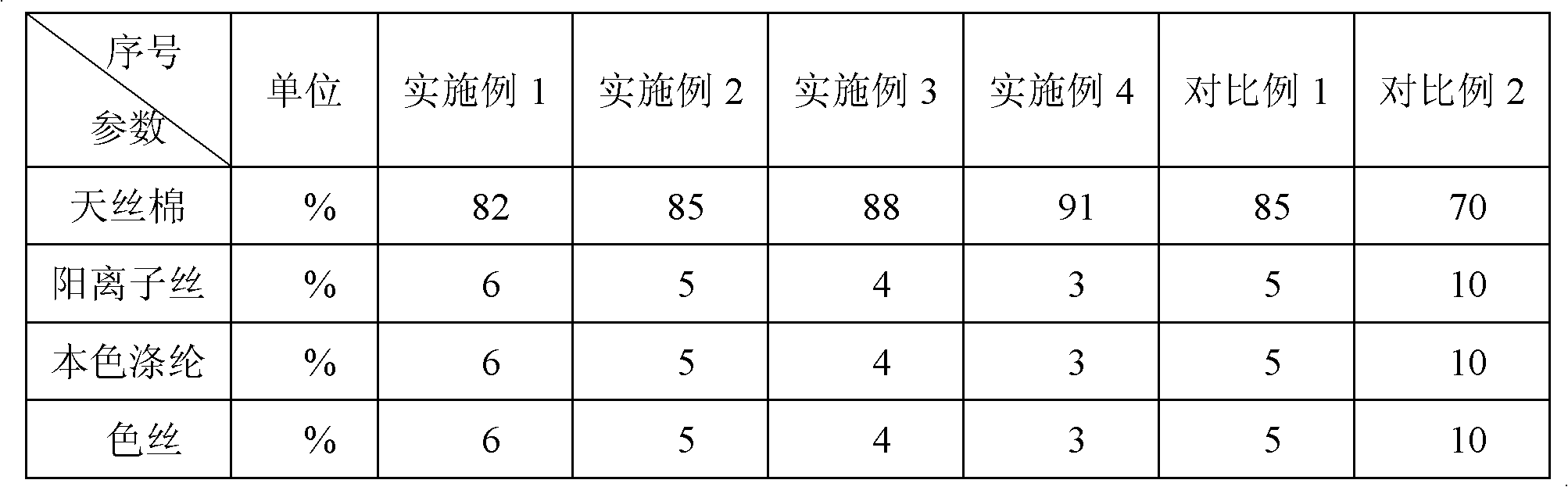

Multi-component warp imitated yarn-dyed fabric and preparation method thereof

The invention relates to a multi-component warp imitated yarn-dyed fabric and a preparation method thereof, and belongs to the field of textiles. The fabric is characterized by being prepared by overdying four raw materials such as 80 to 90 percent of tencel, 2 to 7 percent of natural color polyester, 2 to 7 percent of cationic yarns and 2 to 7 percent of dyed yarns. A warping step in the preparation method is performed by two short fiber warping machines, and the tencel, the natural color polyester, the cationic yarns and the dyed yarns are subjected to warp sizing and warp rebeaming by the same double size box independent size supply machine in a warp sizing and warp rebeaming step. The problem that the multi-component warp imitated yarn-dyed fabric is small in production lot and long in period because warping, warp sizing and warp rebeaming cannot be performed by the short fiber warping machines and the double size box warp sizing machine at one time is solved.

Owner:ZIBO YINSHILAI TEXTILE

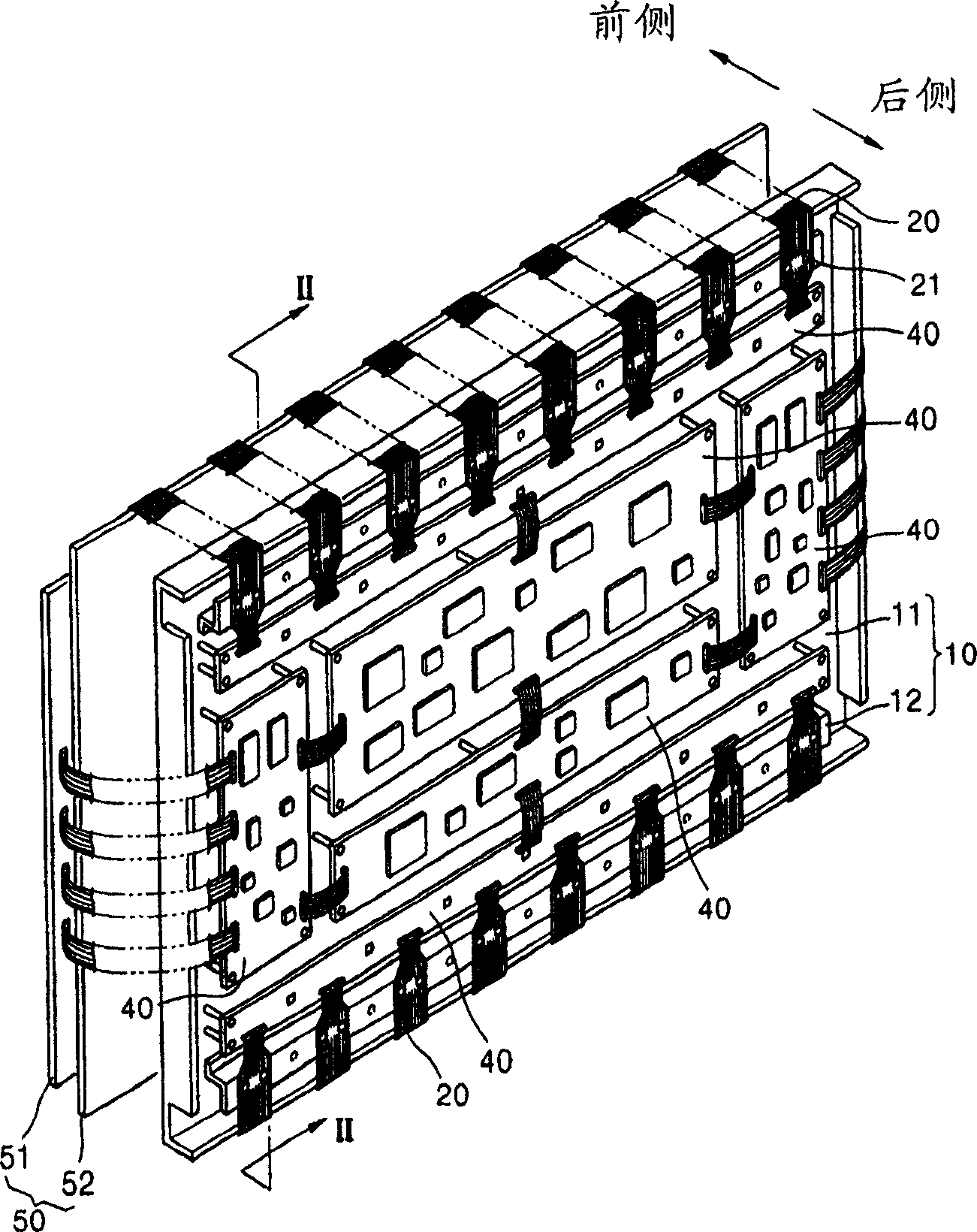

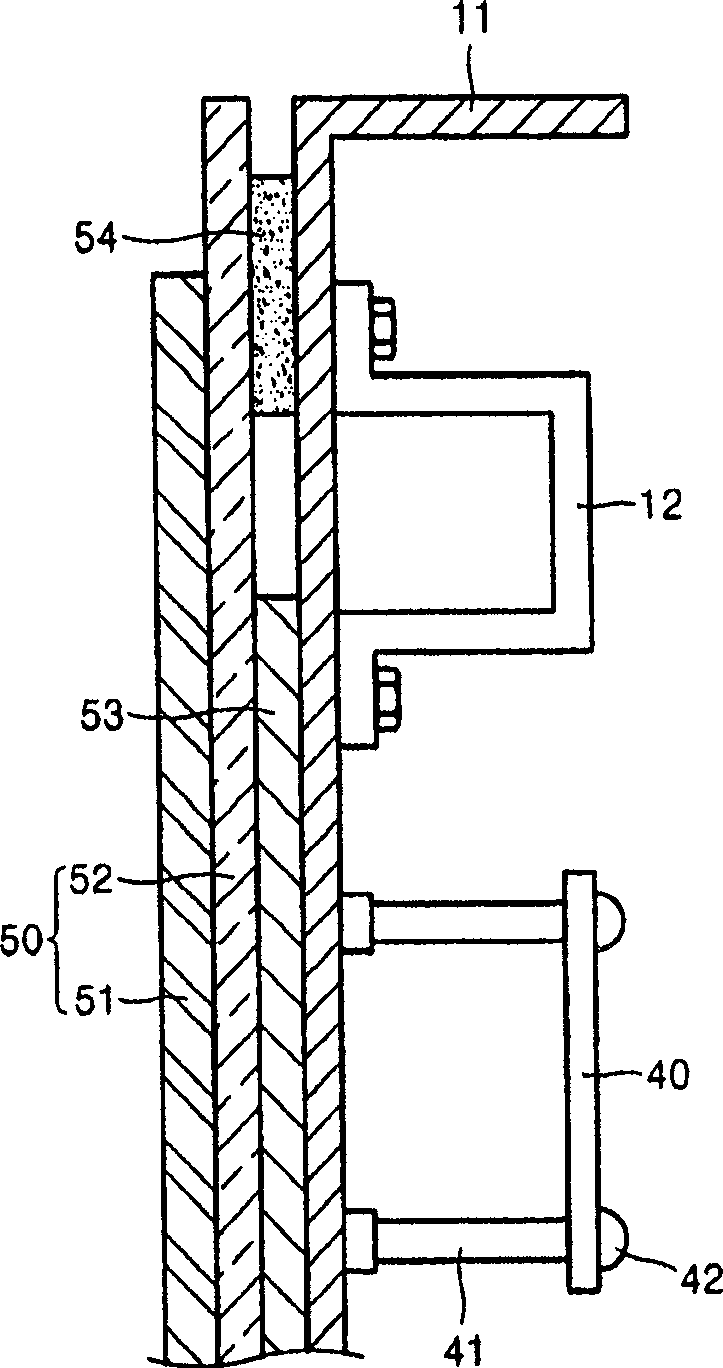

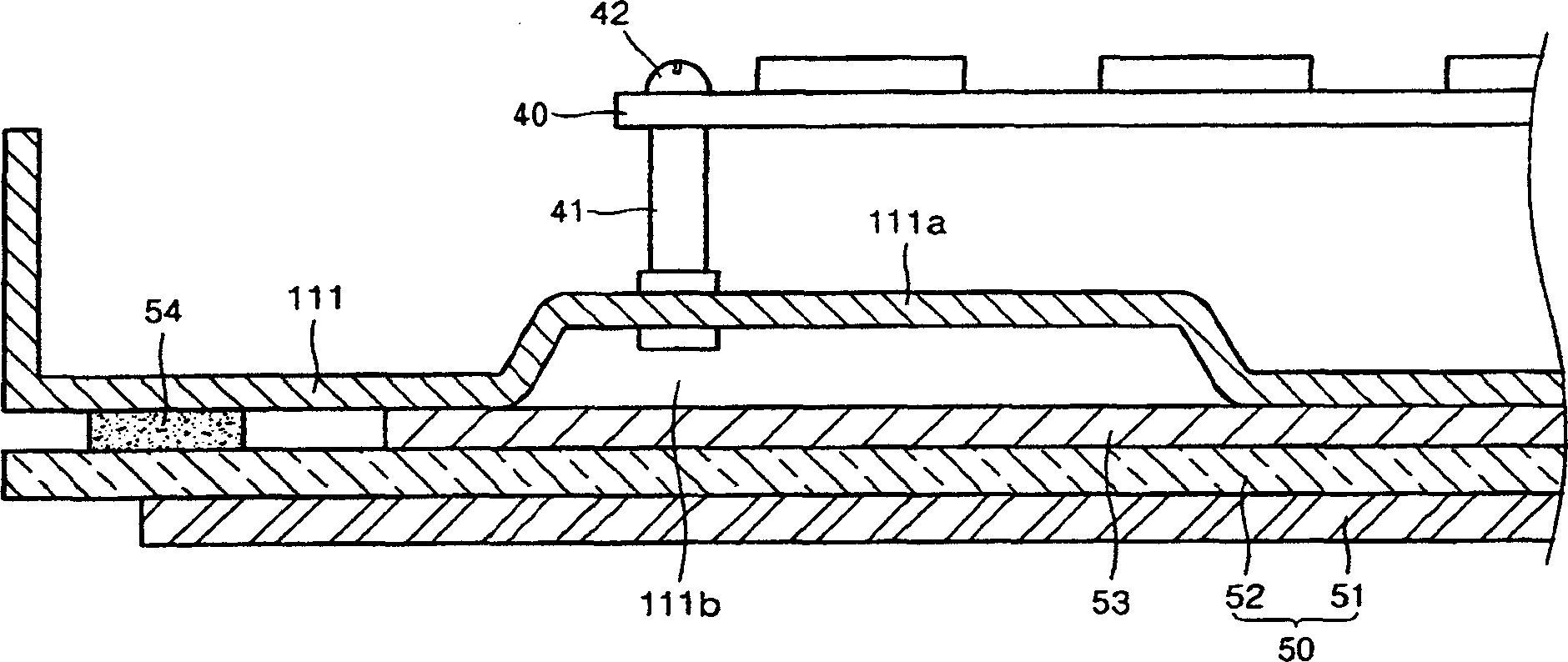

Display module

InactiveCN1808528ADigital data processing detailsCircuit arrangements on support structuresComputer moduleEngineering

A display module, used for, e.g., a plasma display panel, is disclosed. In one embodiment, the display module includes a display panel, a drive circuit board driving the display panel, and a chassis base supporting the display panel and the drive circuit board. A curved portion is formed on the chassis base with a predetermined width, a boss is installed on an upper surface of the curved portion, and the drive circuit board is installed on the top of the boss. According to embodiments of the present invention, the strength of the chassis base constituting the display module is reinforced, without requiring a separate reinforcement member, and simultaneously the heat and noise generated by the display panel and the drive circuit board during operation can be appropriately dissipated and prevented.

Owner:SAMSUNG SDI CO LTD

Apparatus used for generating thread yarn coil

Disclosed is an apparatus (1) used for generating thread yarn coil. The apparatus (1) has a bobbin cradle (3), a thread yarn forming mechanism (4) used for extracting yarns from the bobbin cradle (3) and combining them into thread yarns (2), and a coiling mechanism (12); wherein a large number of yarn cylinders (4) are disposed inside the bobbin cradle (3). For achieving high production speed, the coiling mechanism (12) is provided with a warper beam; a cross mechanism having a thread yarn guiding member is disposed adjacent to the warper beam, wherein the thread yarn guiding member is used for guiding the thread yarns (2).

Owner:KARL MAYER TEXTILMASCHFAB GMBH

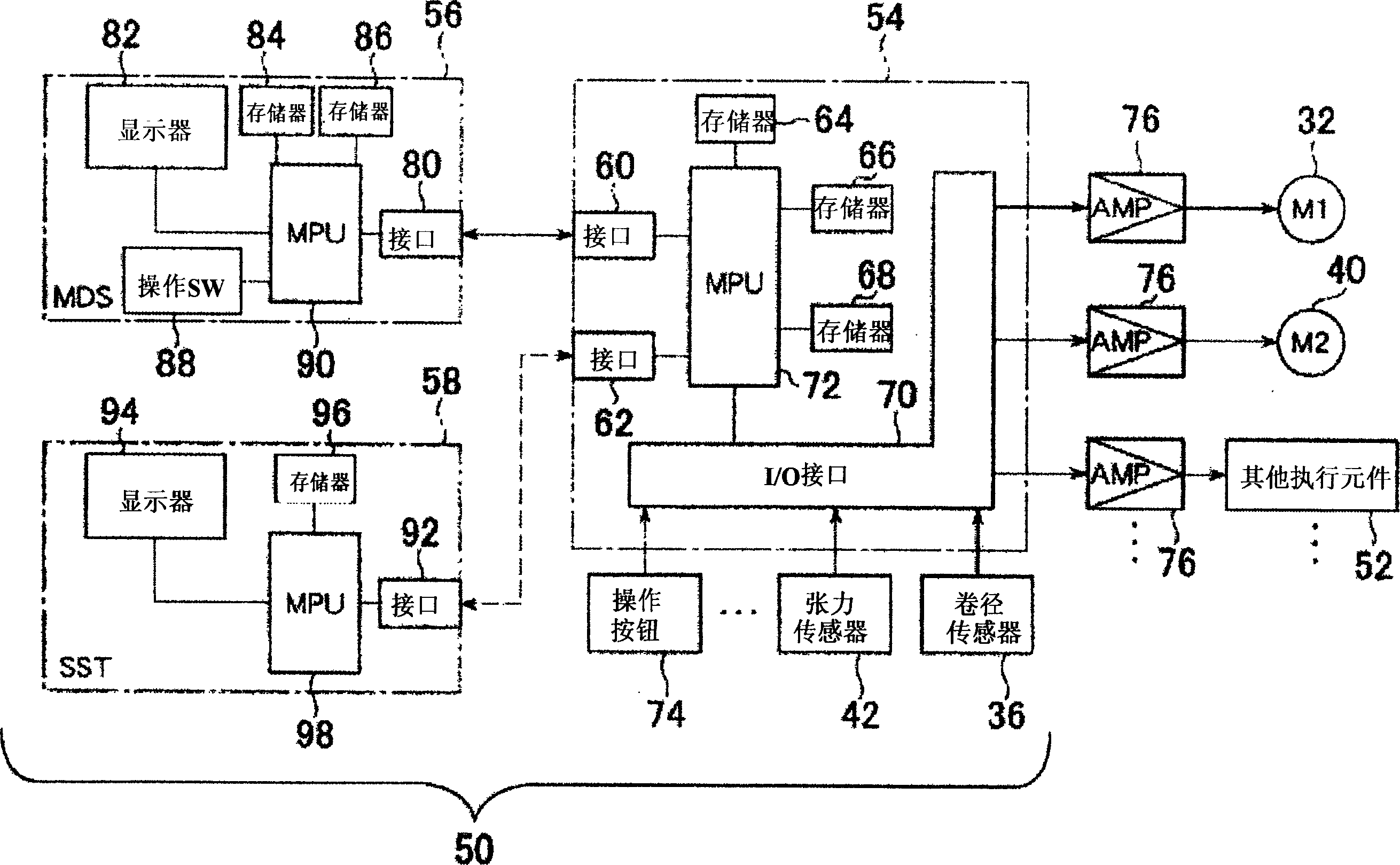

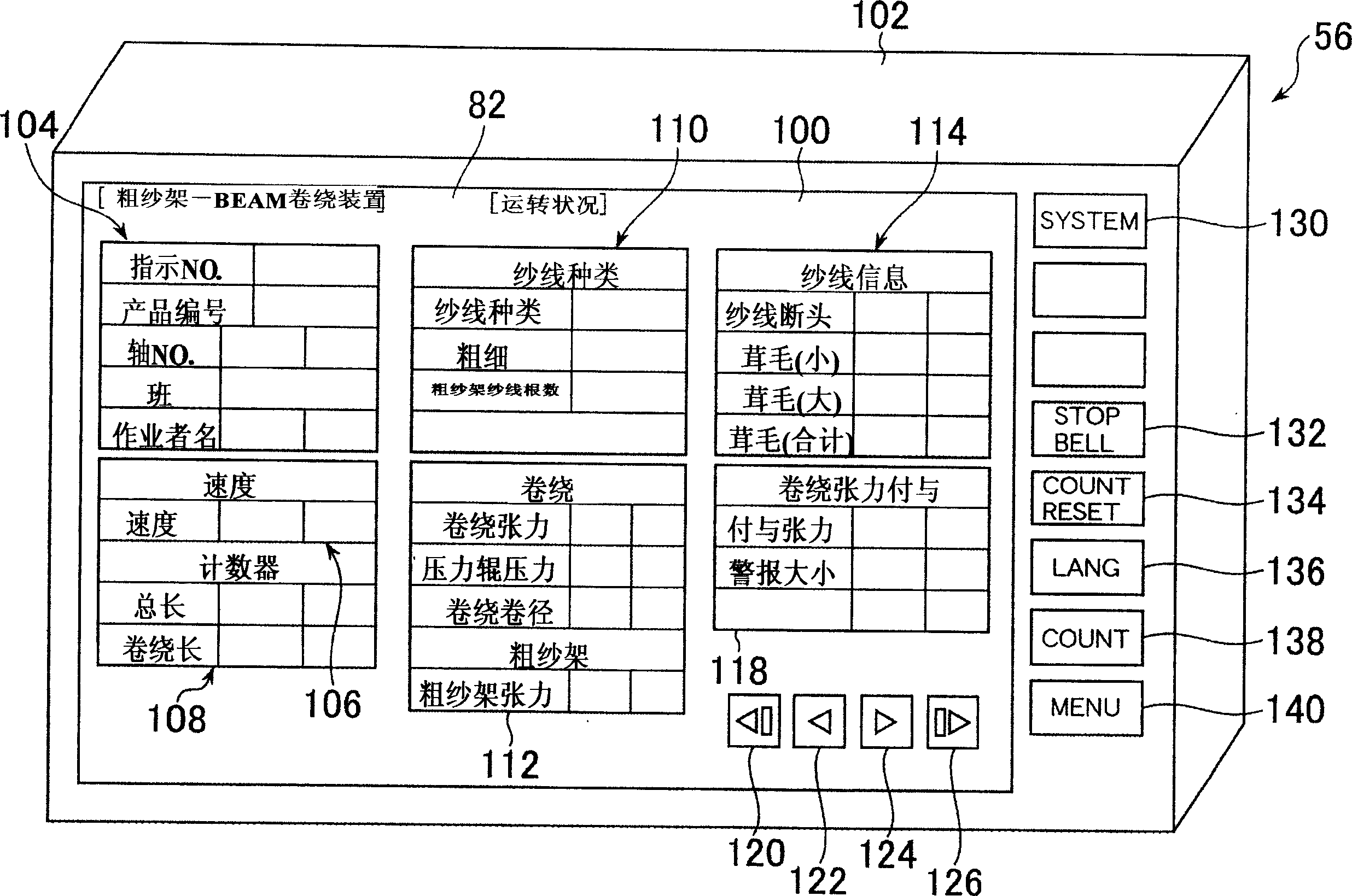

Defining and displaying device of fiber machine

The object of the present invention is to reduce costs related to spare parts which a user has so as to deal with part troubles. Besides an ordinary setter comprising a first indicator and a first input unit, the setting display device for a textile machine is also equipped with an emergency setter furnished with a second indicator and a second input unit having a restricted display amount of information per screen in comparison with the ordinary setter. The emergency setter is used when the ordinary setter malfunctions. The emergency setter enables input information by the second input unit to be outputted to a controller. The controller pre-stores a program for dealing with the emergency setter, which renews and sends display information that is display information related to input demand information for display item information, data information, and an operator, and is displayed by a string or a numerical value according to input information from the emergency setter.

Owner:TSUDAKOMA KOGYO KK

Slitting, dividing and warping device

InactiveCN106676705ARealize regulationAchieve constantWarping machinesBeaming machinesYarnDrive wheel

The invention relates to a slitting, dividing and warping device which comprises a creel, a yarn guide mechanism, a dividing mechanism, a staggered mechanism, a host and a reverse shaft which are sequentially arranged. The yarn guide mechanism comprises two yarn guide units and a tension adjustment unit, each yarn guide unit comprises a base, at least two yarn guide rollers and a reciprocating mechanism, the yarn guide rollers are parallel to each other and perpendicular to a straight line of the host and the creel, and each reciprocating mechanism comprises a motor, a driving wheel, a driving shaft, a driving frame and a thread plate. The slitting, dividing and warping device integrates a dividing procedure and a slitting procedure, so that a plurality of master silk strands can be directly drawn and subsequently slit on the device, tension in the procedures is adjusted and kept constant by the aid of the yarn guide mechanism and the dividing mechanism, the problem of tension matching of previous and subsequent procedures is solved, and normal operation of the whole processing procedure is ensured.

Owner:邱俪勇 +2

Systems and methods for manufacturing textiles

An apparatus for manufacturing textiles includes a creel having mounted thereon a plurality of regenerating yarn packages and a yarn extension device having a first plurality of inputs each coupled to a strand of yarn from one of the plurality of yarn packages, a second plurality of inputs each coupled to a strand of yarn from one of the plurality of regenerating yarn packages, and a yarn joining device operative to join a first strand of yarn from one of the first plurality of inputs to a second strand of yarn from one of the second plurality of inputs to create a joined strand of yarn.

Owner:GROSSMAN JONATHAN

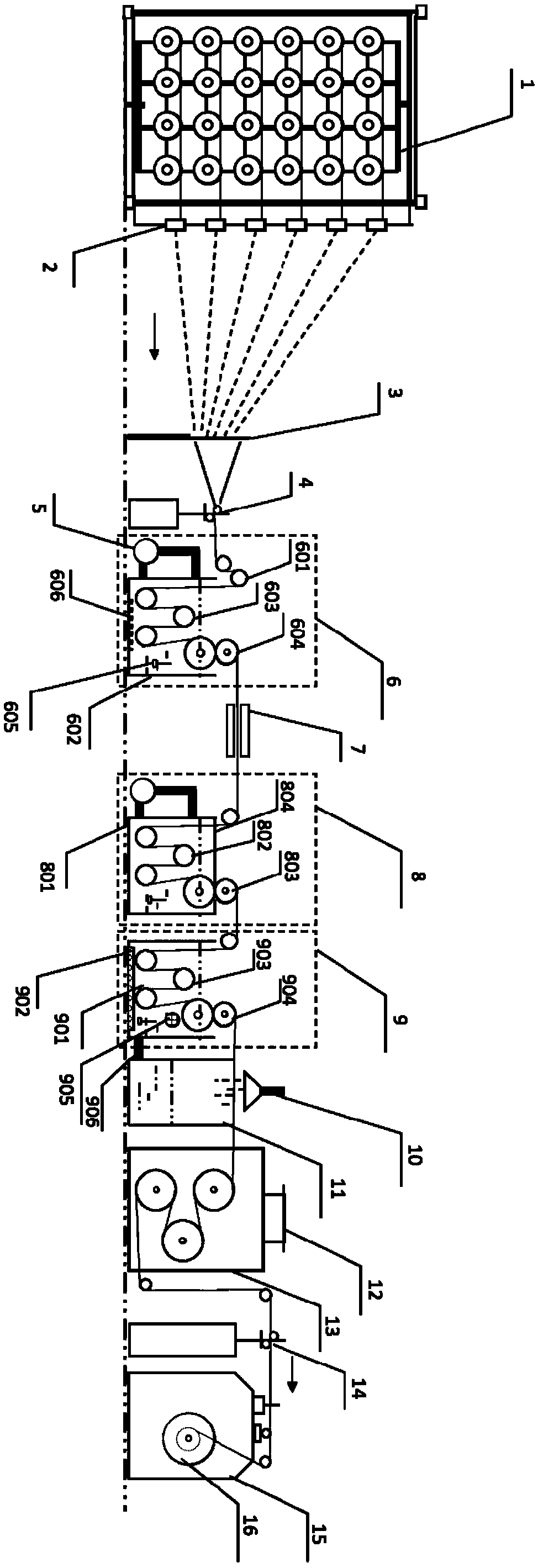

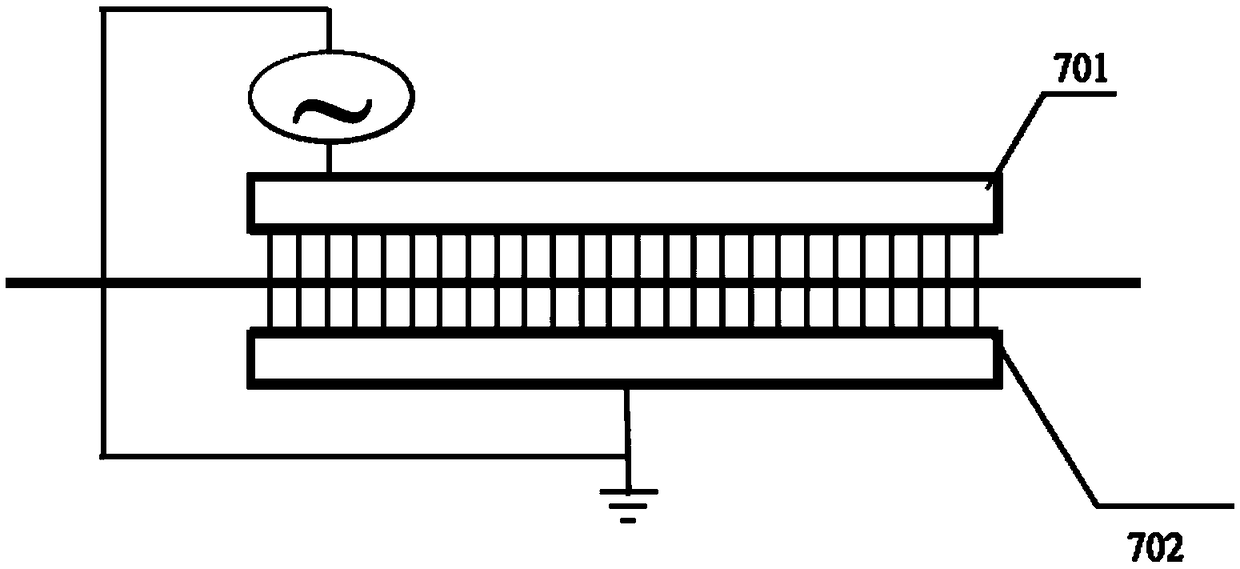

Surface polymerization and continuous treatment warping machine for composite conductive yarns

ActiveCN108754738AImprove conductivityImprove stabilityPhysical treatmentTextile treatment machine partsConductive polymerEngineering

The invention discloses a surface polymerization and continuous treatment warping machine for composite conductive yarns, and belongs to the technical field of warping equipment of textile machinery.The warping machine comprises a yarn unwinding device, a liquid circulating system, a rinsing device, a normal-temperature and normal-pressure plasma treatment device, a dipping device, a polymerization device, a cleaning device, a drying device, a headstock and the like. Multiple processing procedures such as bathing, dipping and polymerization drying are integrated on the surface polymerizationand continuous treatment warping machine, conductive polymers are polymerized on the surfaces of the yarns, in a warping process, the yarns have conductive performance, integration and continuity of preparation and warping processes of the composite conductive yarns are realized, and with the aid of the liquid circulating system, the purposes of saving resources, protecting the environment and thelike are achieved.

Owner:JIANGNAN UNIV

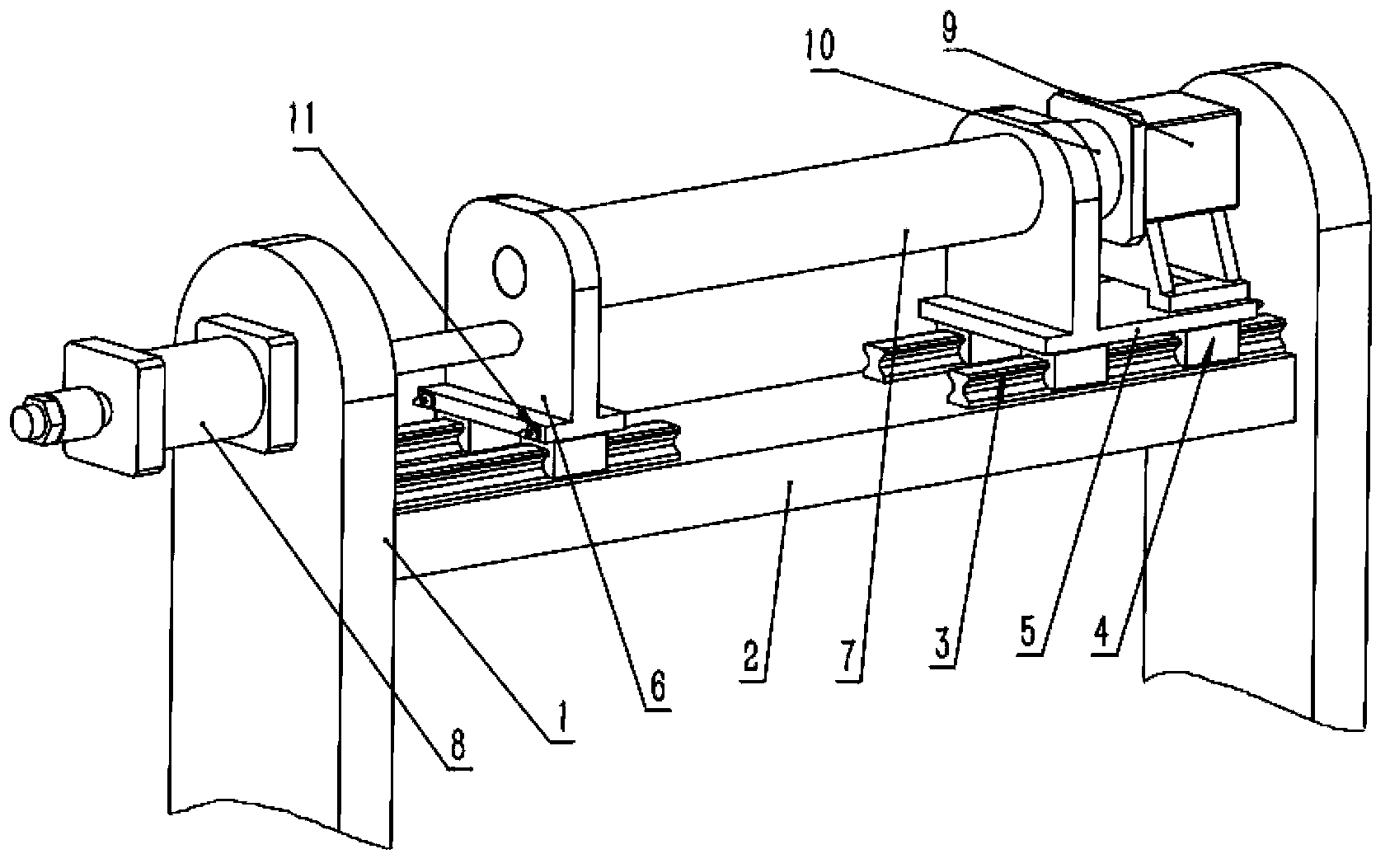

Left-right swing device for yarn guide roll

InactiveCN103374775AAchieve left and right swingEvenly arrangedBeaming machinesOther manufacturing equipments/toolsYarnDrive shaft

A left-right swing device for a yarn guide roll comprises two symmetrical support columns (1). Two ends of a crossbeam (2) are fixed on the two symmetrical support columns (1). Multiple groups of guide rails (3) are fixed at each of the two ends of the crossbeam (2). Sliders (4) are sleeved on the guide rails. A left support (6) and a right support (5) are fixed on the sliders (4). Two ends of the yarn guide roll (7) are fixed on the left support (6) and the right support (5) respectively. The right end of the yarn guide roll (7) is connected with a rotary shaft of a motor (9) through a coupler (10). The motor is fixed on the right support (5). A piston rod of an air cylinder (8) is connected to the left support (6) in a threaded manner. The air cylinder (8) is fixed on the left support column (1). By the left-right swing device, left-right swing of the yarn guide roll can be achieved, even warp arrangement on a driving shaft can be achieved when warp density is low, single yarn is even in tension, and high-quality driving shaft can be provided.

Owner:吴江红蔷薇纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com