Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

668 results about "Textile yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

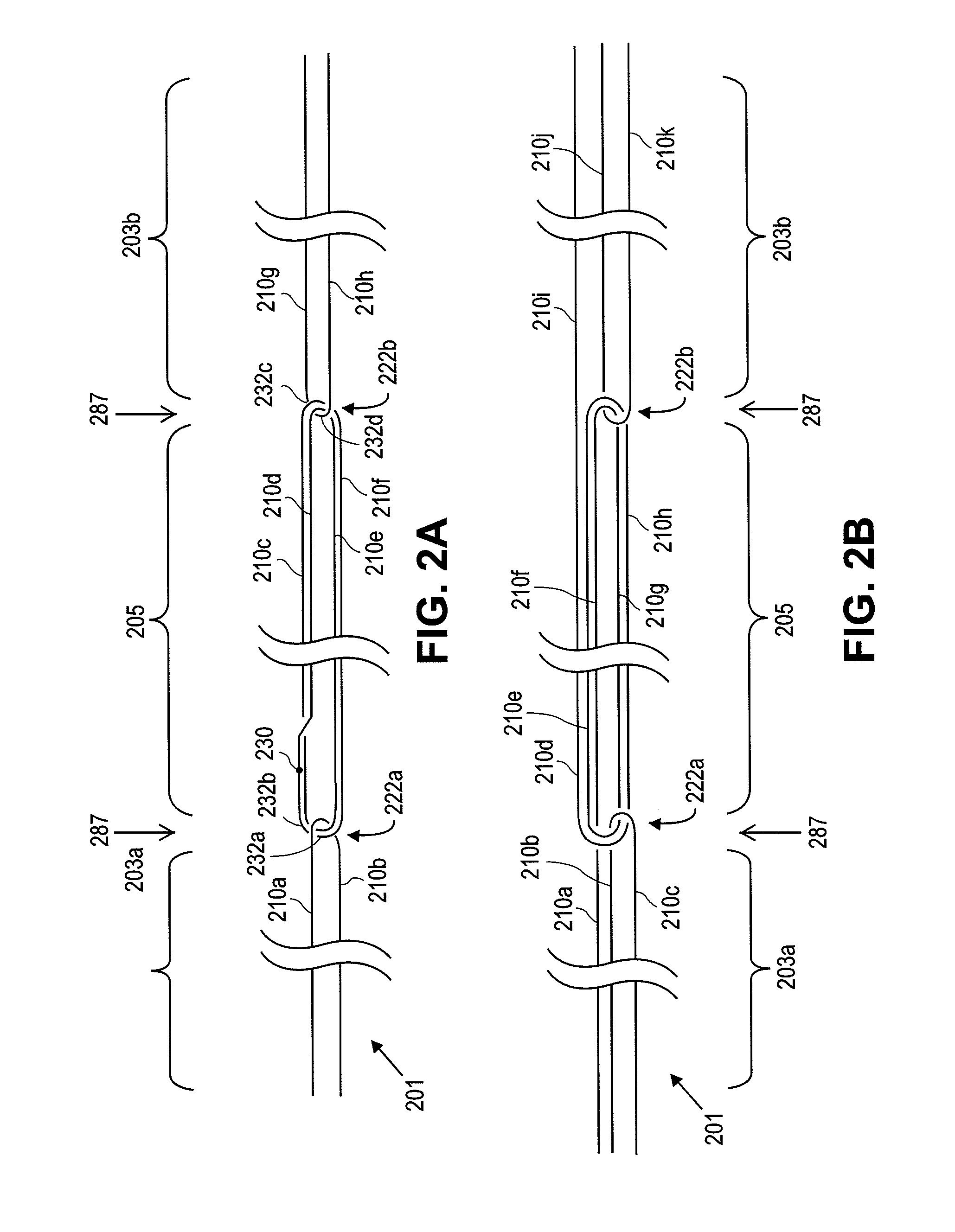

Fabric or garment with integrated flexible information infrastructure

InactiveUS6381482B1Raise the ratioImprove high temperature stabilityWeft knittingOrnamental textile articlesInformation processingEngineering

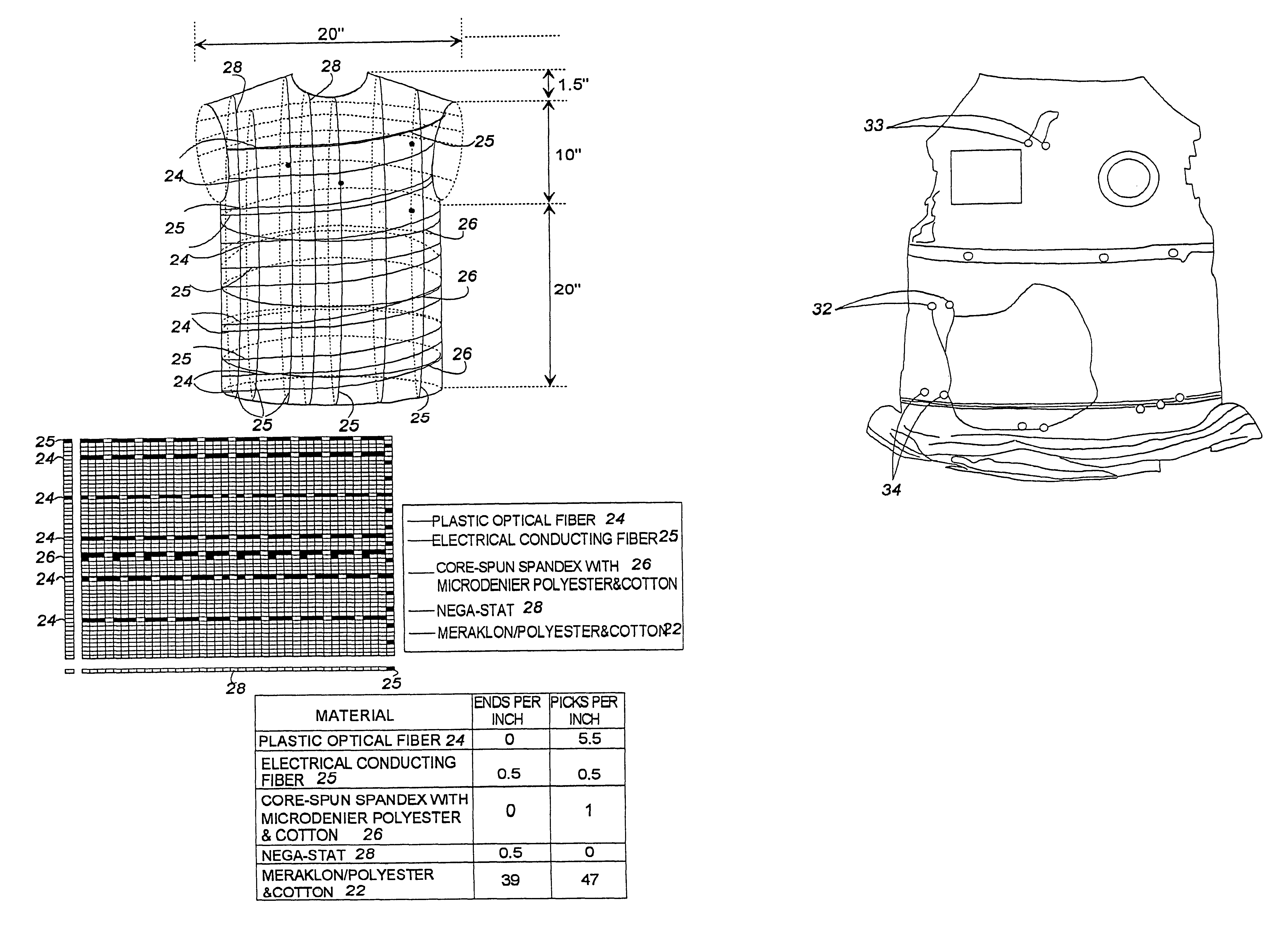

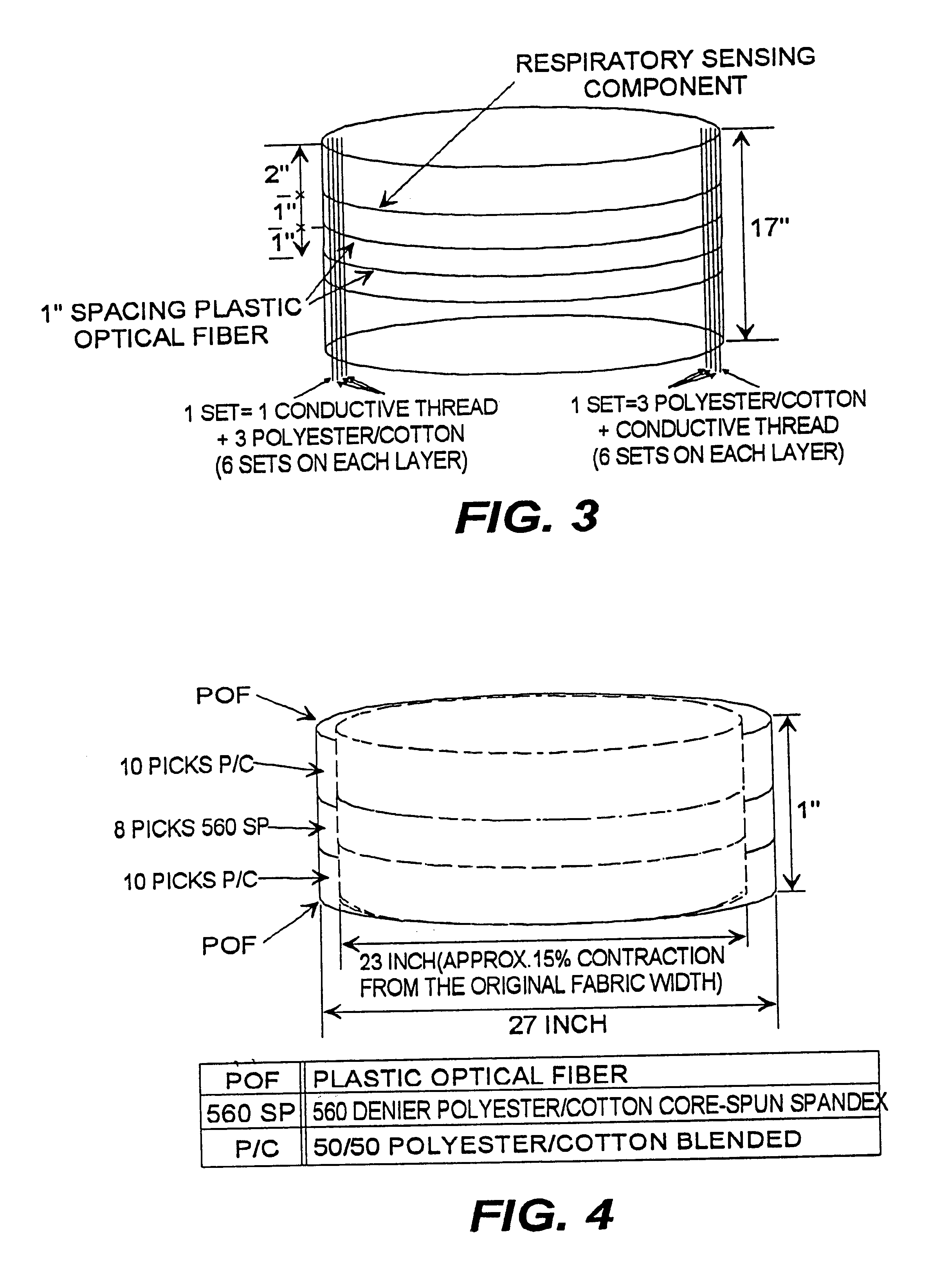

A fabric, in the form of a woven or knitted fabric or garment, including a flexible information infrastructure integrated within the fabric for collecting, processing, transmitting and receiving information concerning-but not limited to-a wearer of the fabric. The fabric allows a new way to customize information processing devices to "fit" the wearer by selecting and plugging in (or removing) chips / sensors from the fabric thus creating a wearable, mobile information infrastructure that can operate in a stand-alone or networked mode. The fabric can be provided with sensors for monitoring physical aspects of the wearer, for example body vital signs, such as heart rate, EKG, pulse, respiration rate, temperature, voice, and allergic reaction, as well as penetration of the fabric. The fabric consists of a base fabric ("comfort component"), and an information infrastructure component which can consist of a penetration detection component, or an electrical conductive component, or both. The preferred penetration detection component is a sheathed optical fiber. The information infrastructure component can include, in addition to an electrically conductive textile yarn, a sensor or a connector for a sensor. A process is provided for making an electrical interconnection between intersecting electrically conductive yarns. Furthermore, a process is established for sheathing the plastic optical fiber and protecting it.

Owner:GEORGIA TECH RES CORP

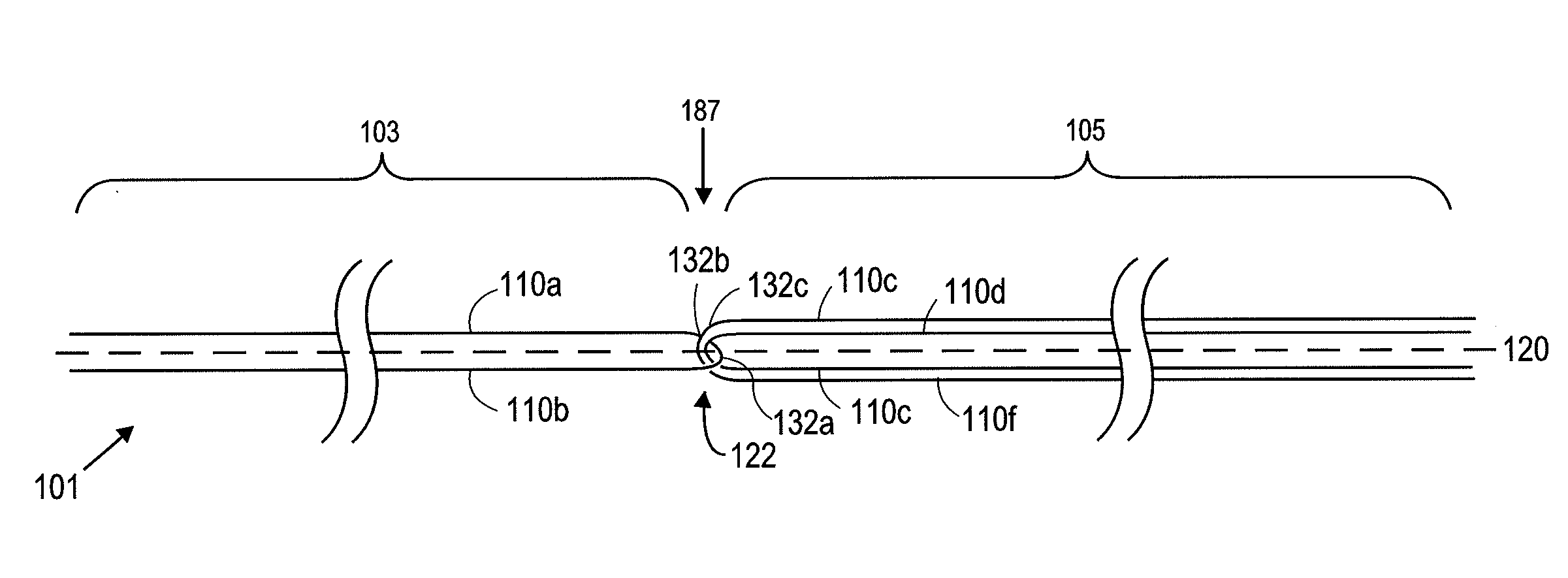

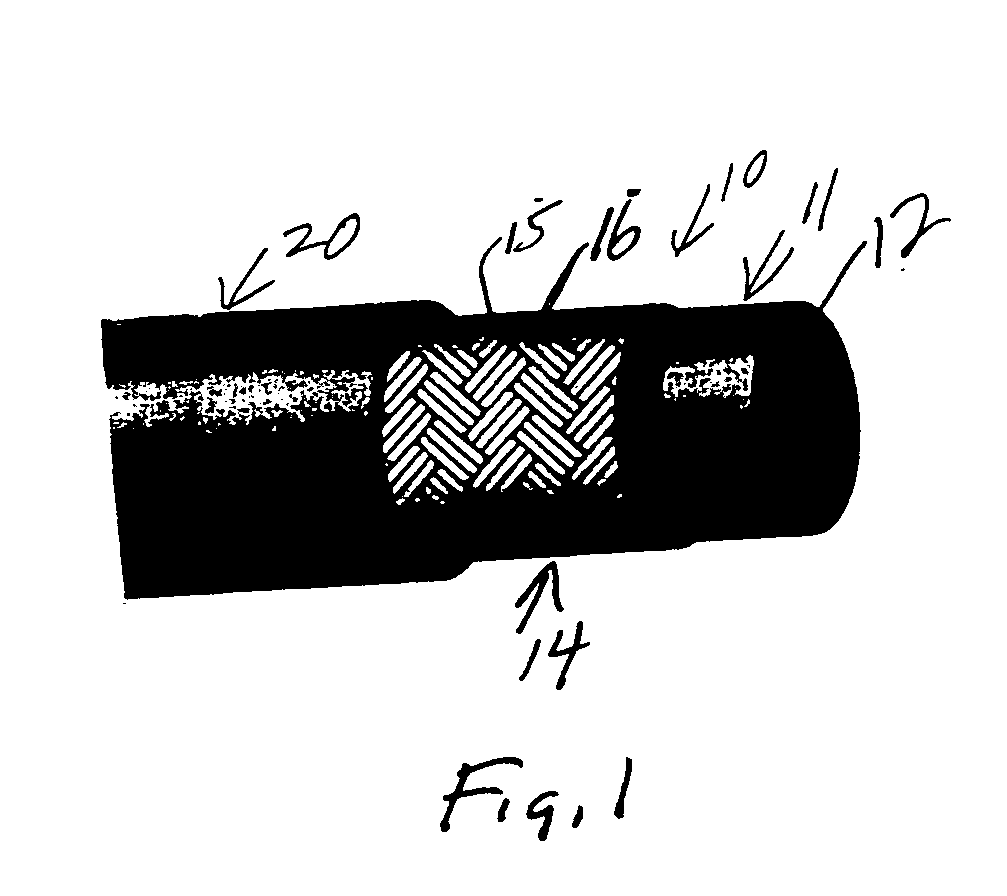

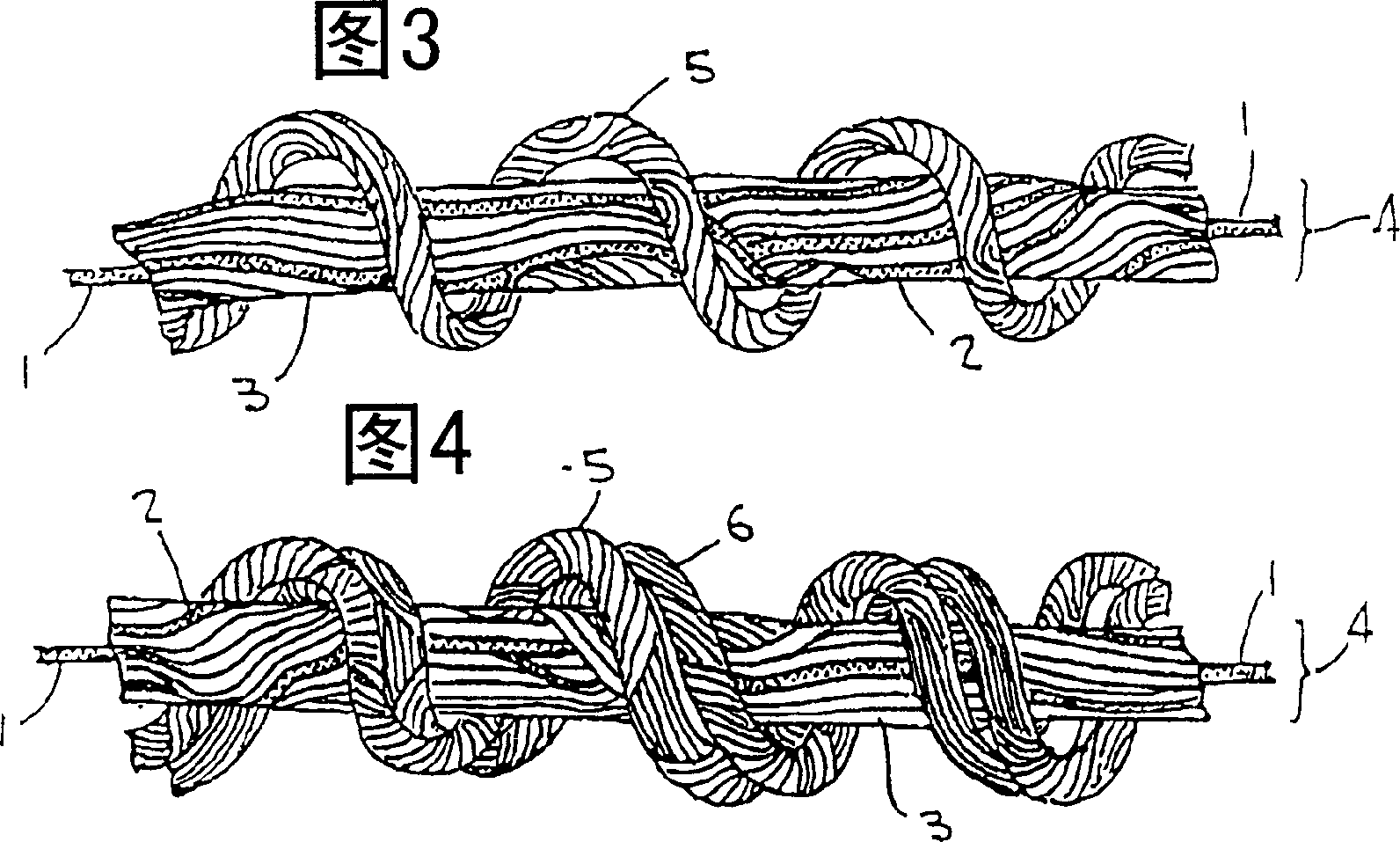

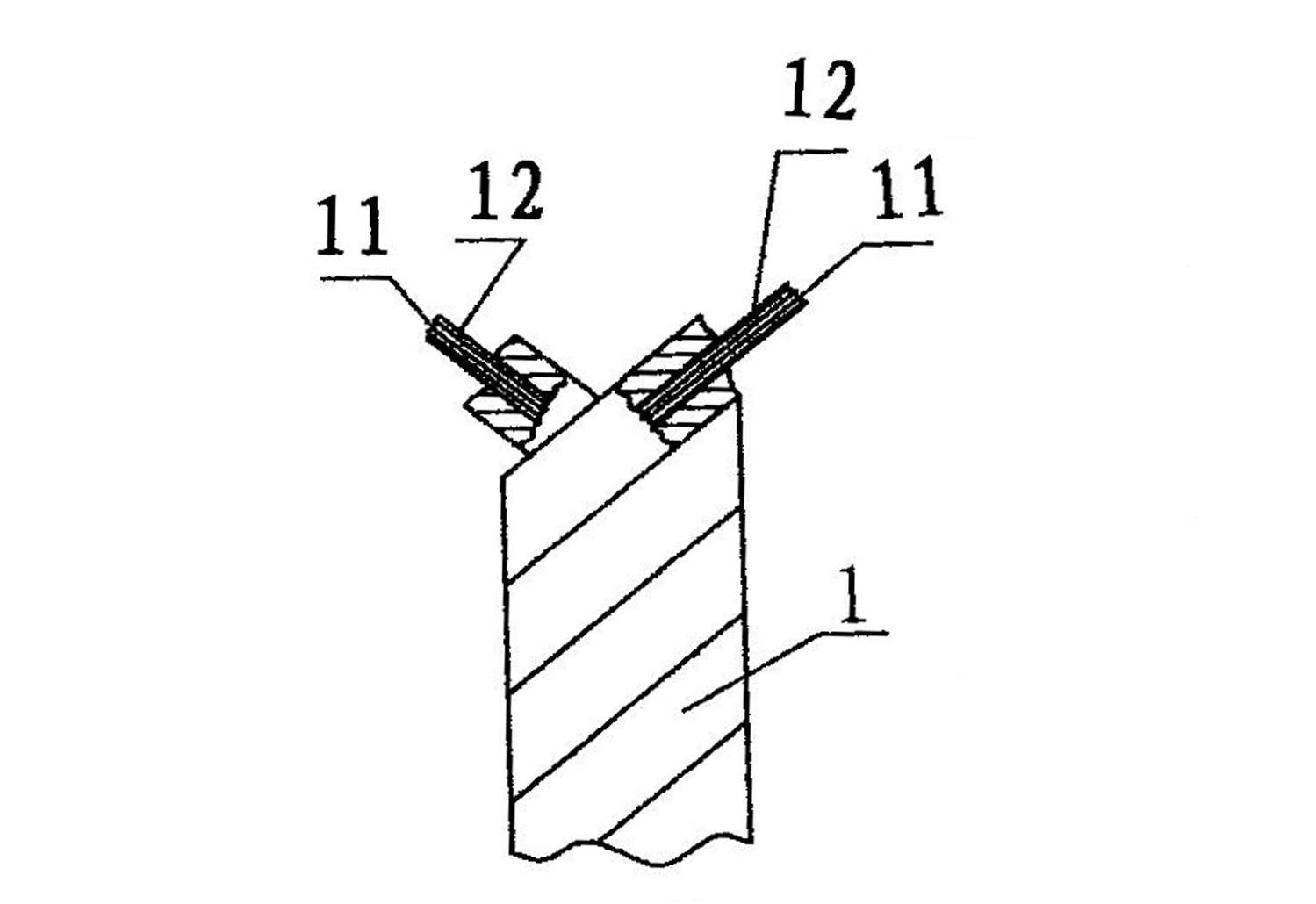

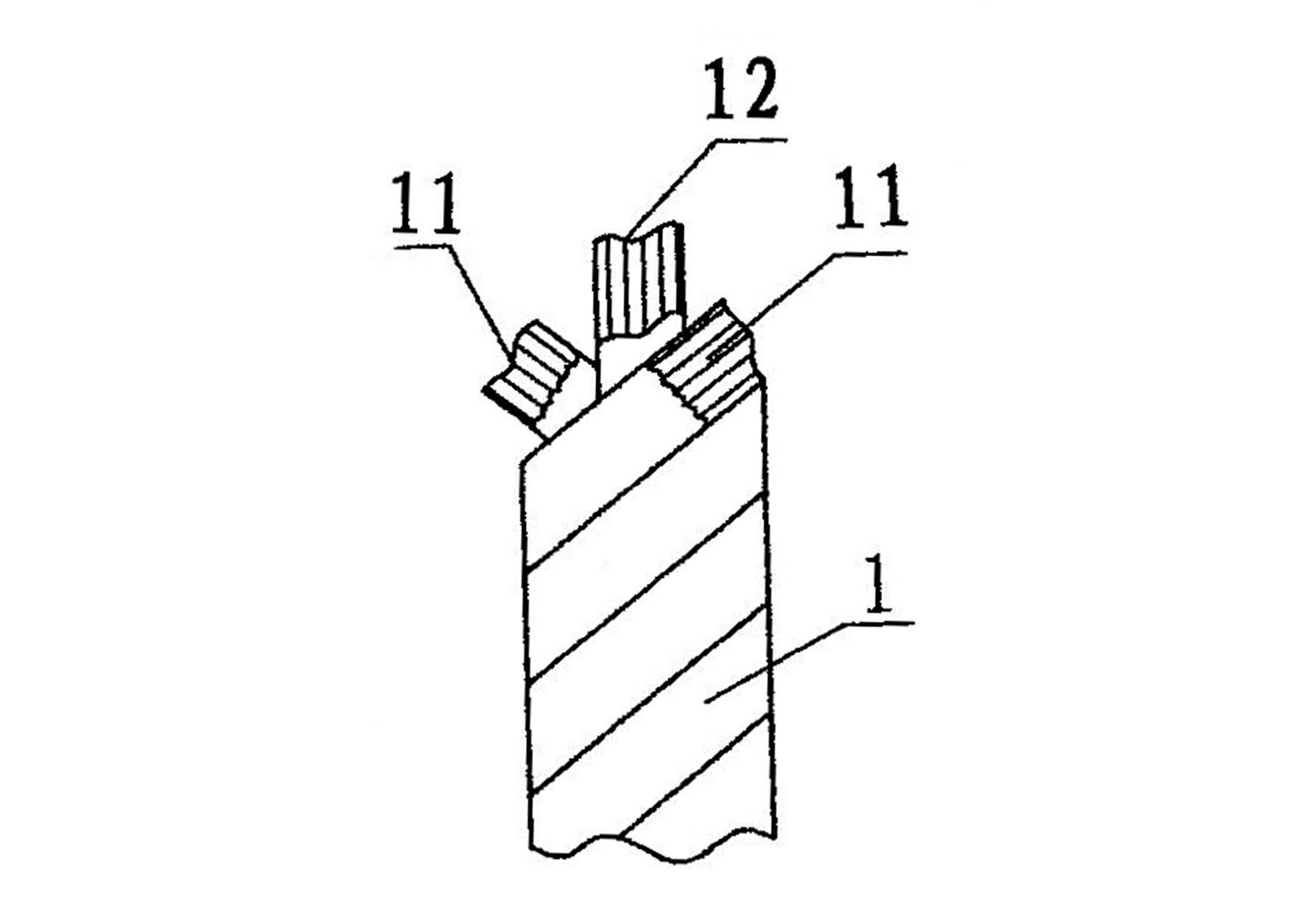

Variable denier yarn and suture

A textile yarn includes a first segment and a second segment. The first segment includes a plurality of first strands and has a substantially constant first denier. The second segment includes a plurality of second strands integrated together and has a substantially constant second denier. There are more second strands in the second segment than first strands in the first segment such that the second denier is greater than the first denier. A first portion of the plurality of second strands is made from a first plurality of yarn elements that extend through the first and second segments. A second portion of the plurality of second strands is made from a second plurality of yarn elements present in the second segment and not the first segment. The yarn elements in the second plurality of yarn elements terminate in a transition zone between the first segment and the second segment.

Owner:SYNTORR

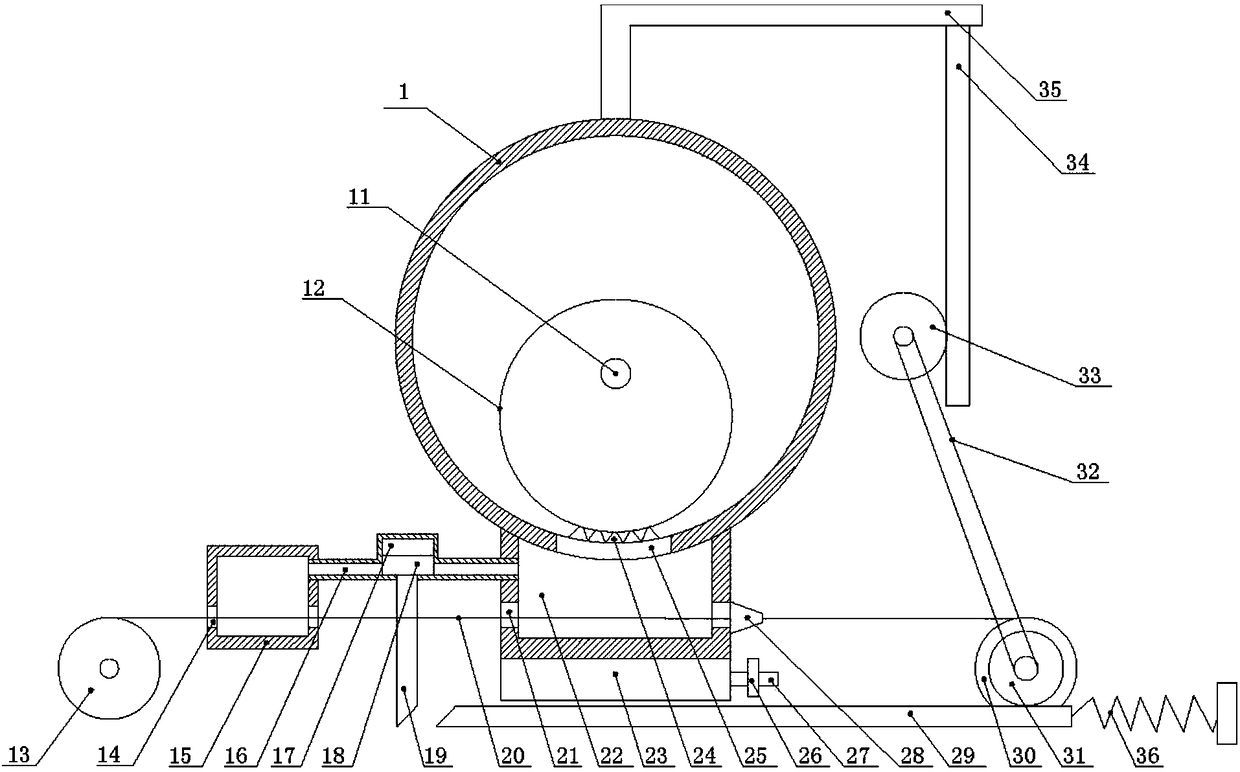

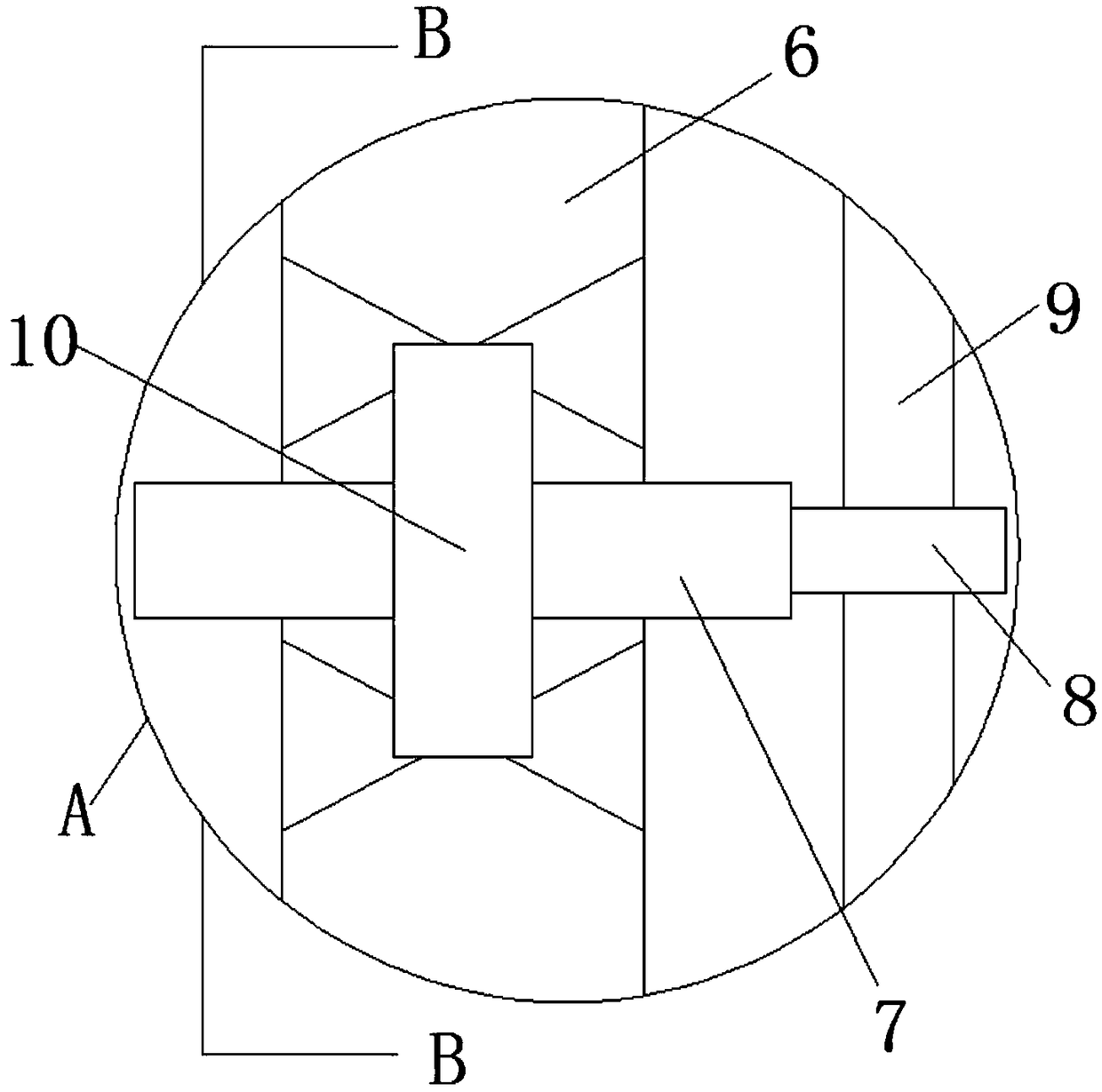

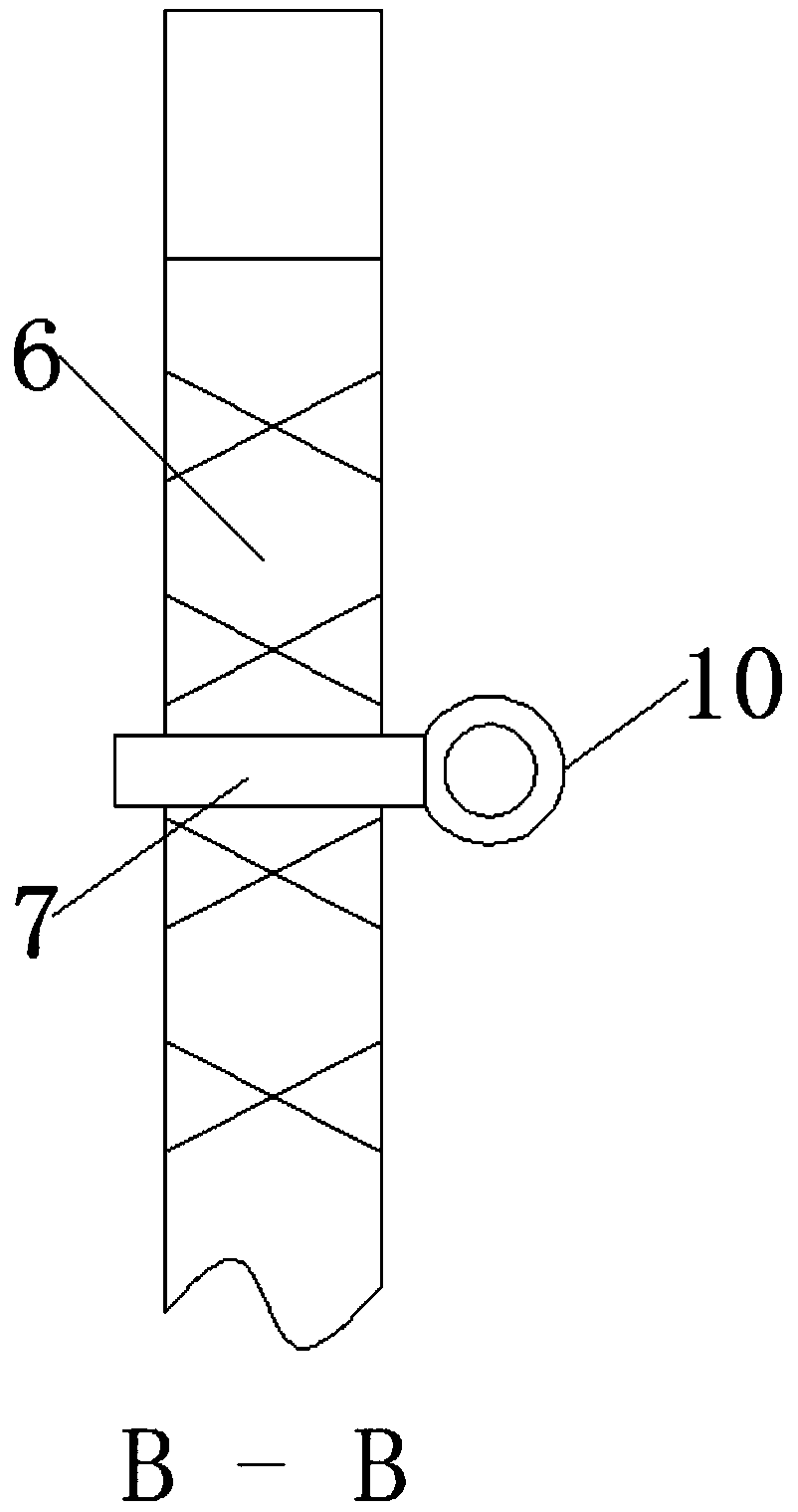

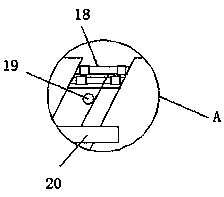

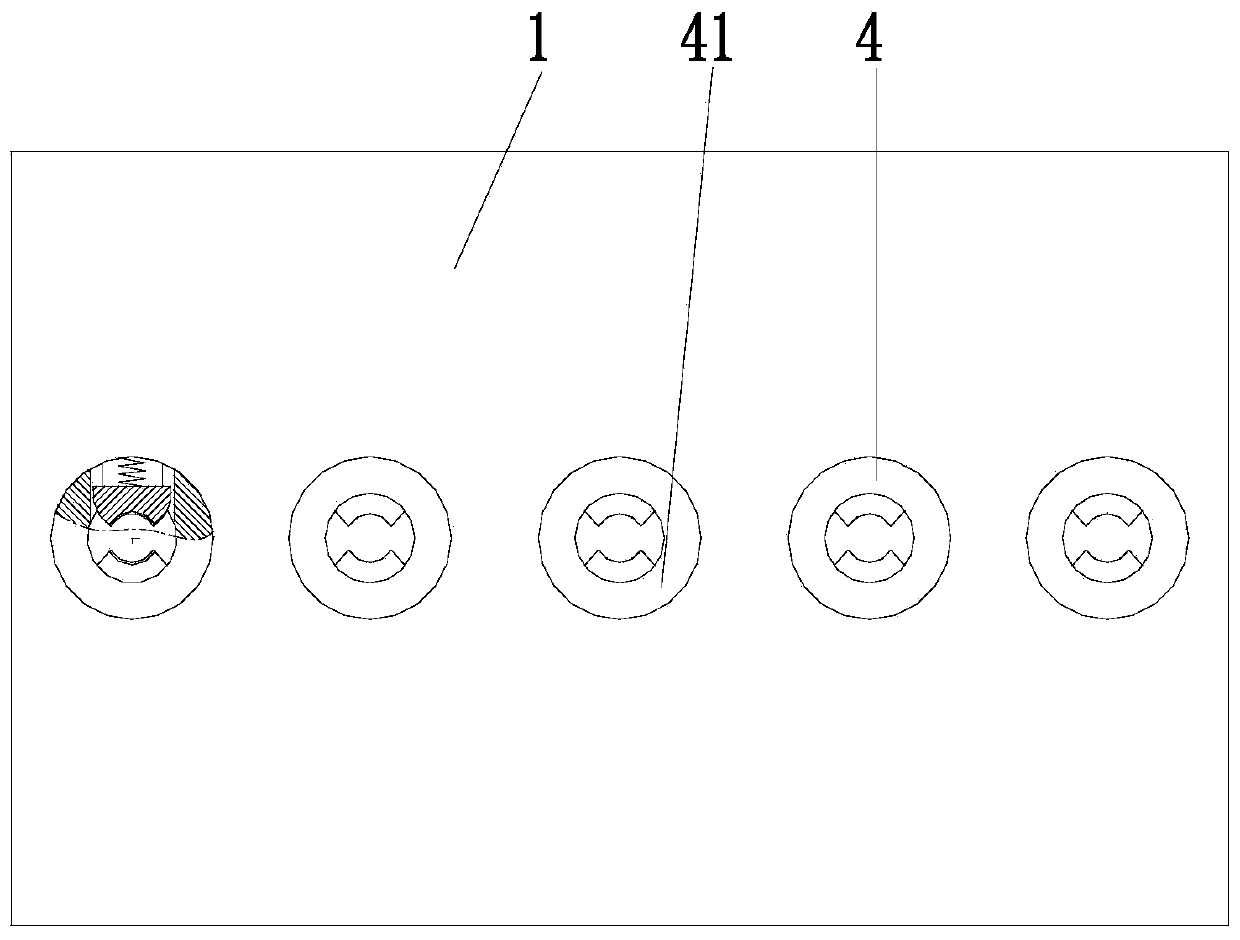

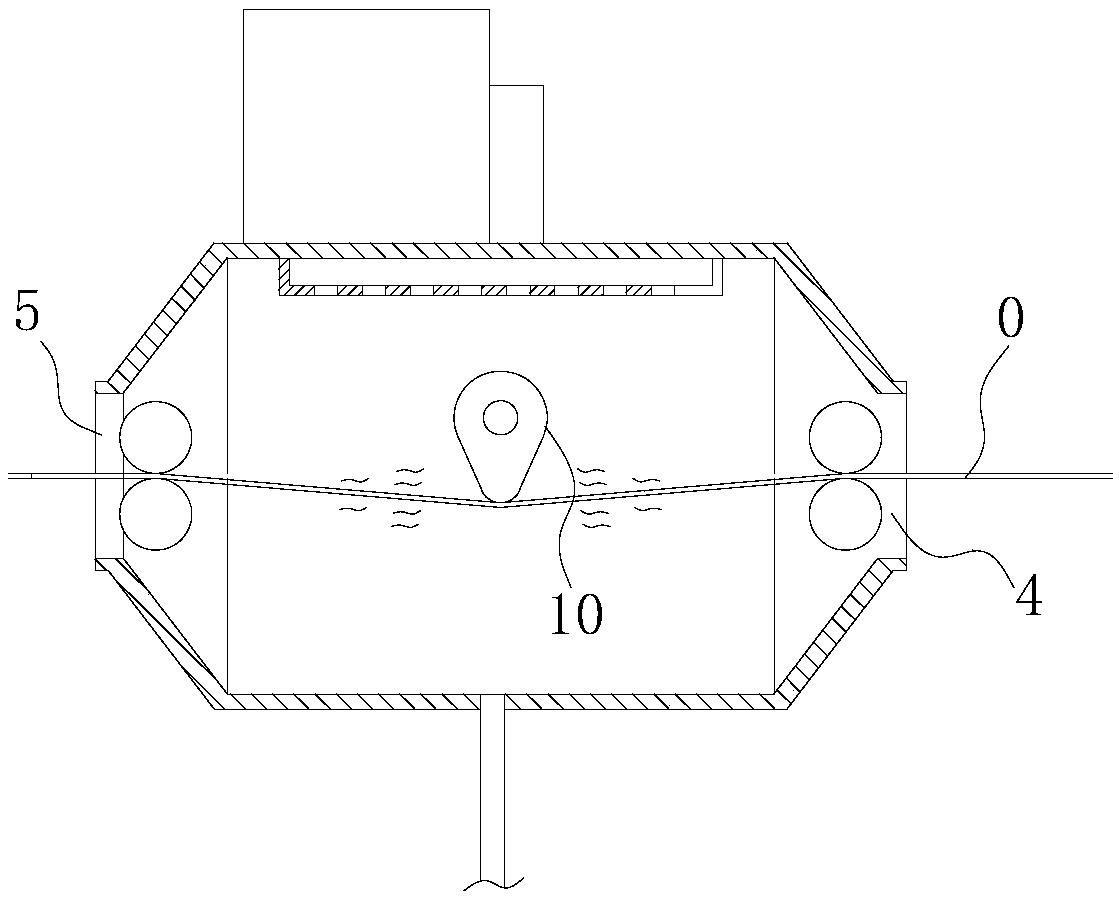

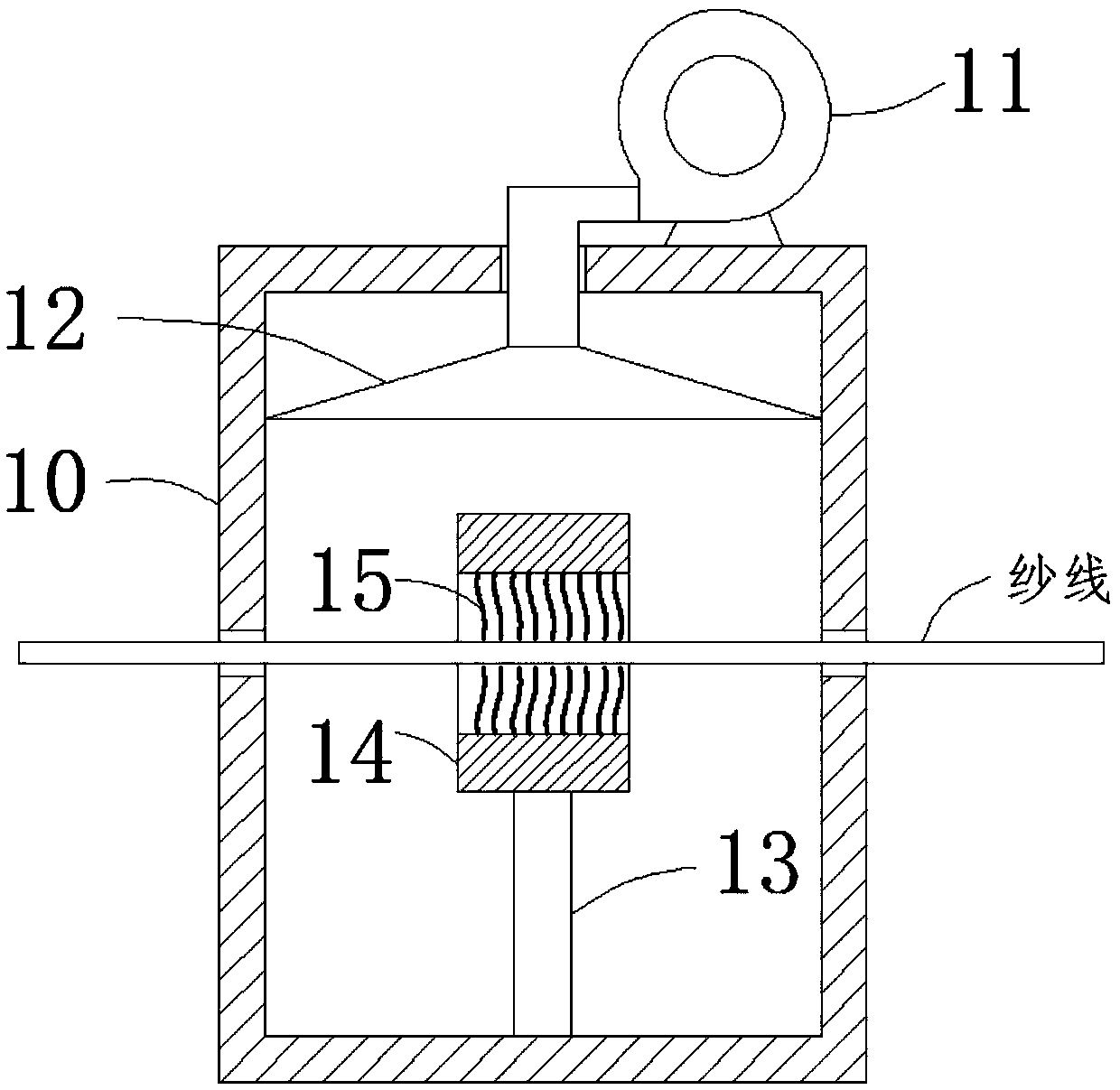

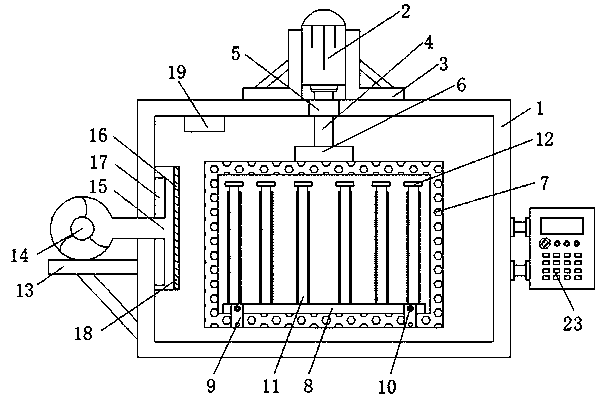

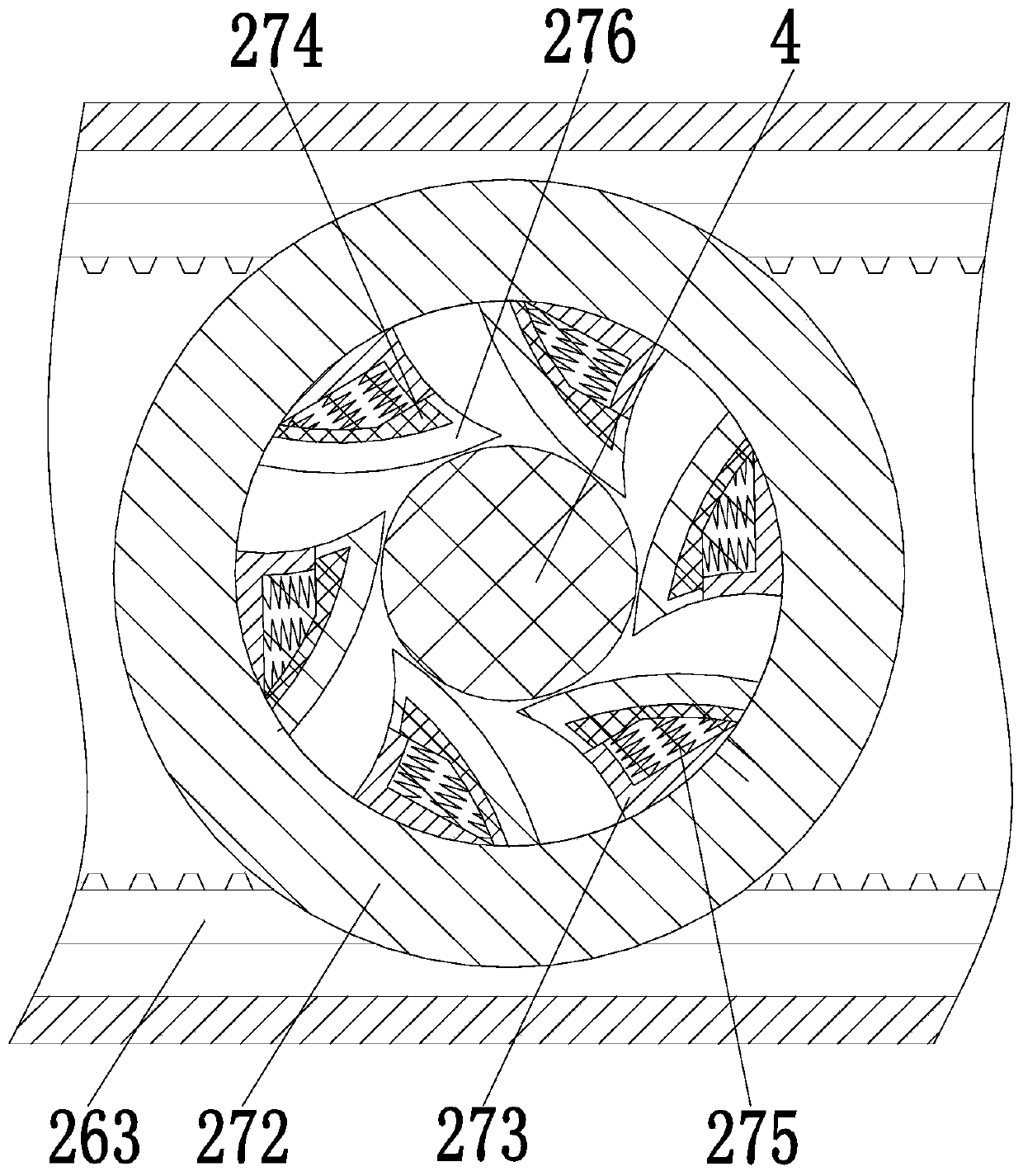

Textile yarn waxing device

The invention relates to the technical field of textile processing, in particular to a textile yarn waxing device. The textile yarn waxing device comprises a rotary drum. A rotary shaft is arranged inthe rotary drum. The rotary shaft is arranged under the axis of the rotary drum and is parallel to the axis of the rotary drum. A wax block is eccentrically arranged on the rotary shaft. A scraper isarranged at the bottom of the rotary drum and can make contact with the wax block. A wax melting box is arranged below the scraper. First through holes allowing yarns to pass through are symmetrically formed in the side walls of the wax melting box. A pay-off roller and a take-up roller are arranged on the two sides of the wax melting box correspondingly. A gear is arranged above the take-up roller. A transmission part is connected between the gear and the take-up roller. A first rack is vertically engaged with one side of the gear. A support is connected with one end of the first rack and connected with the rotary shaft. The problems that in the prior art, yarns are waxed unevenly, and wax blocks are wasted seriously can be solved.

Owner:NINGBO WENZE TEXTILE CO LTD

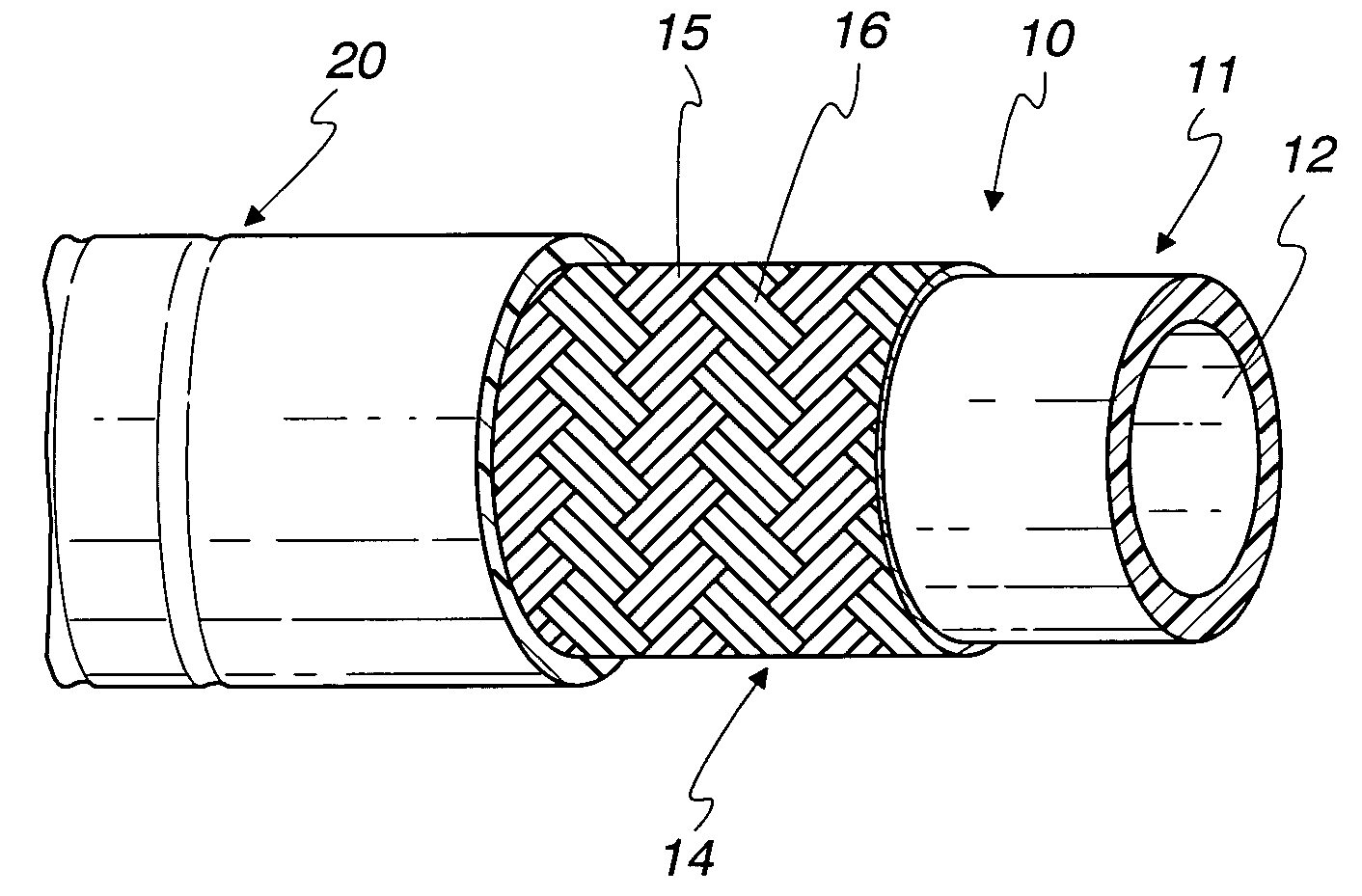

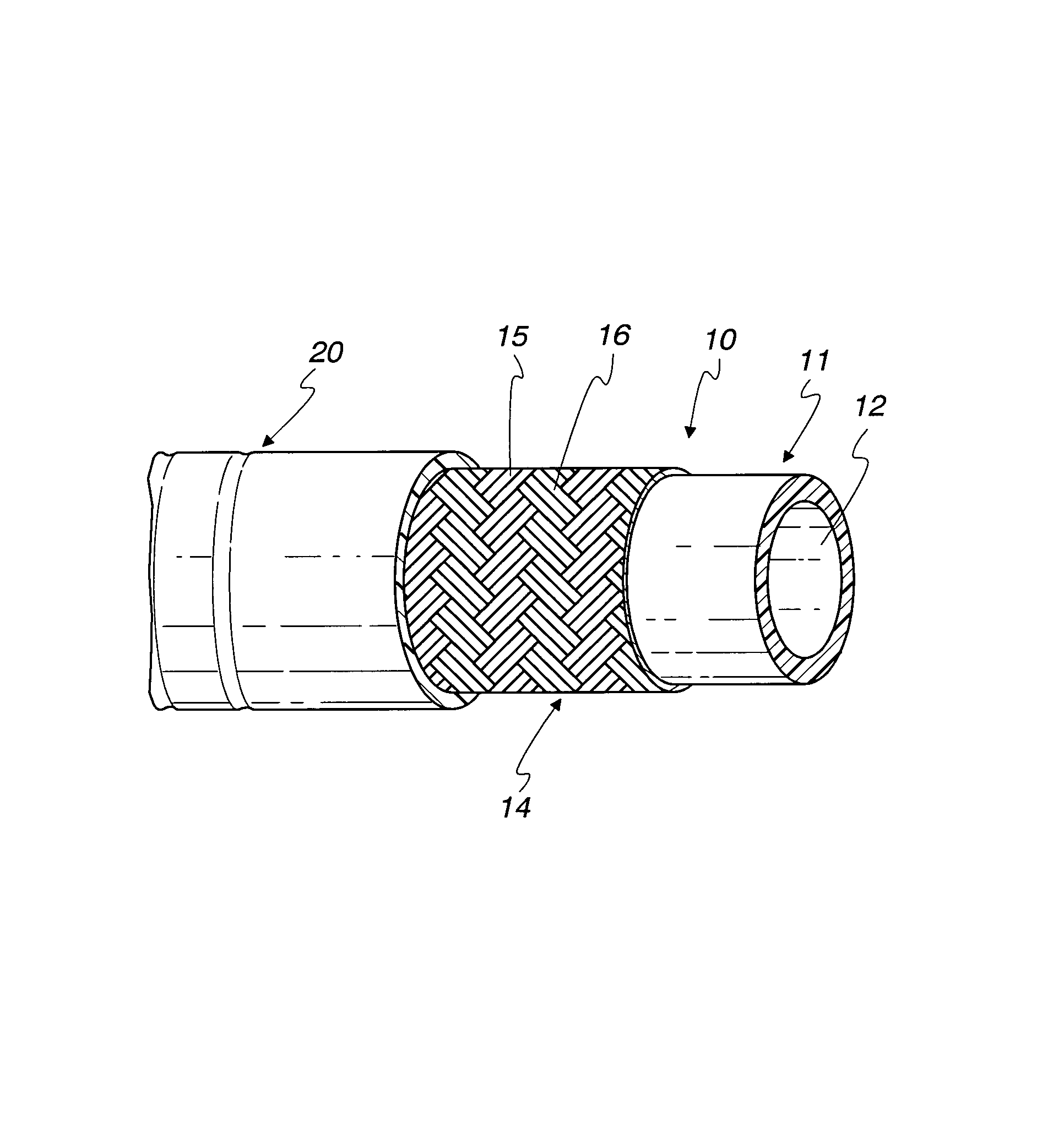

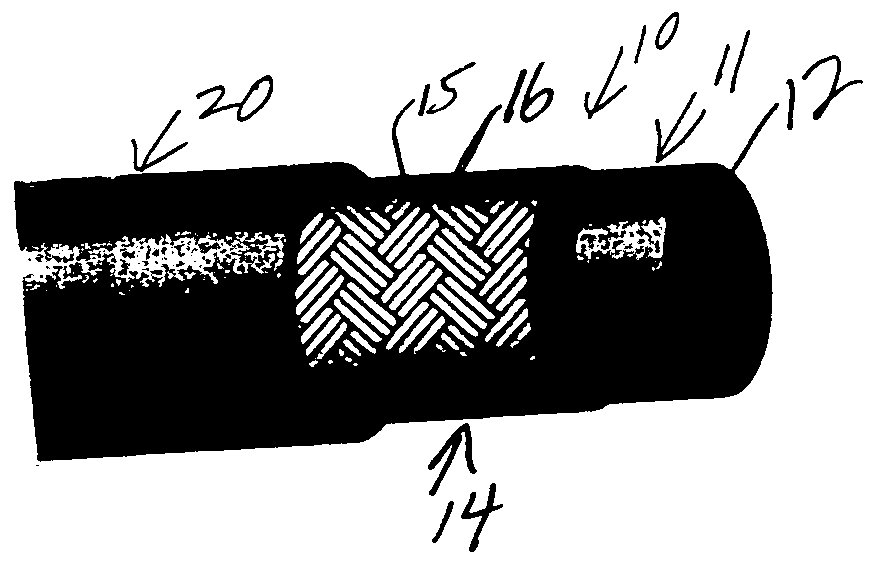

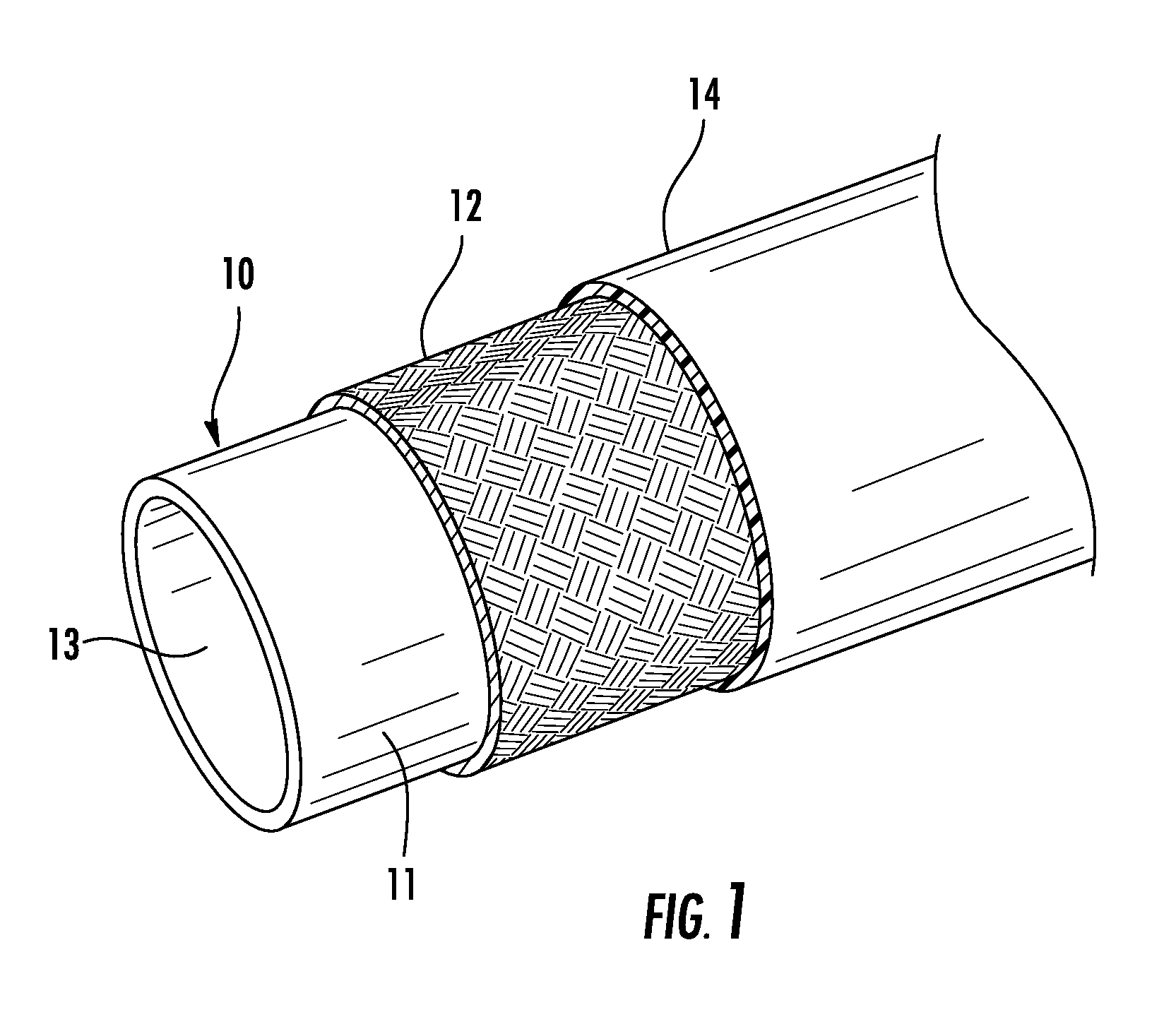

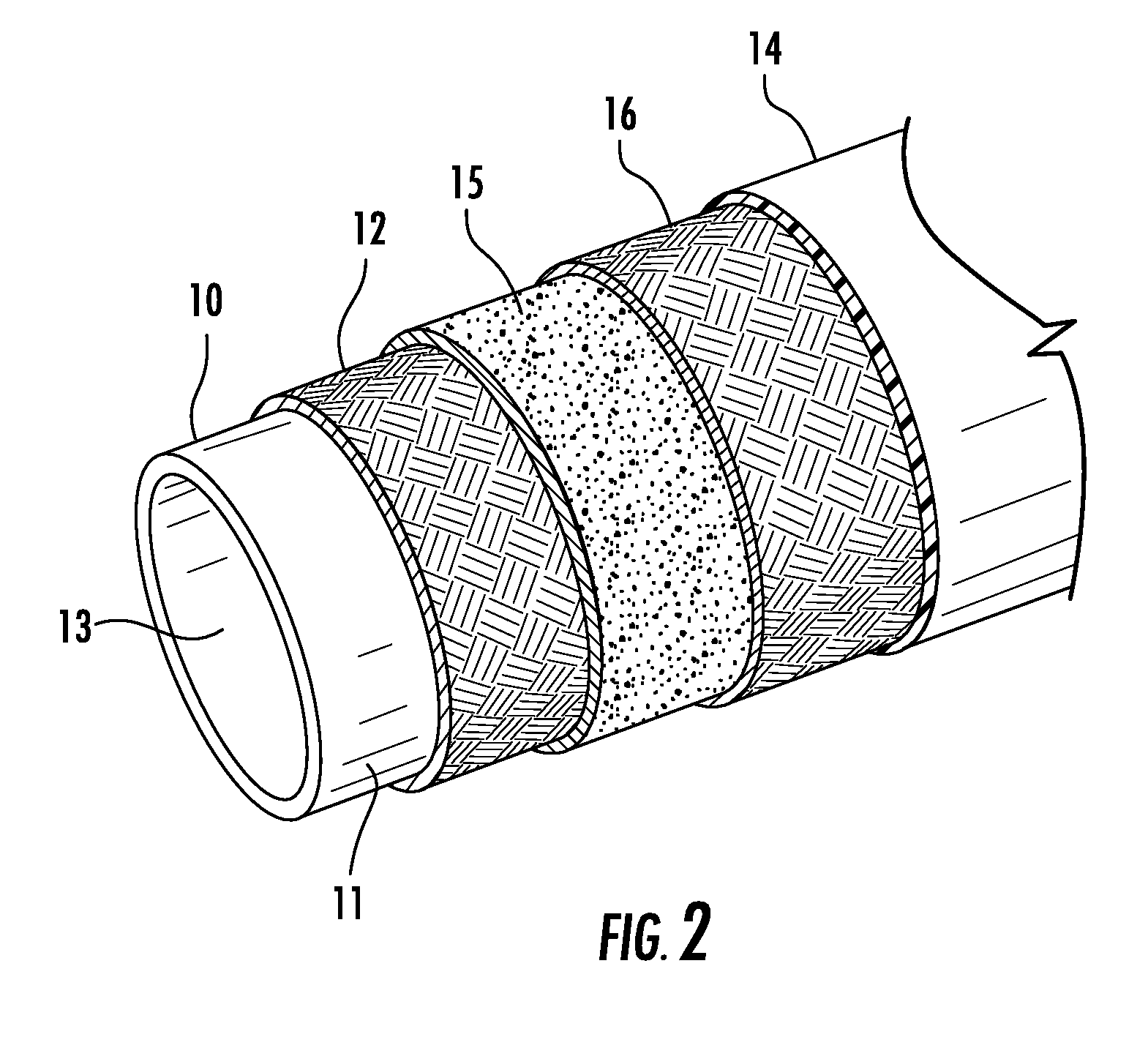

High pressure flexible hose

InactiveUS6978805B2High tensile strengthUniform diameterFlexible pipesRigid pipesTextile fiberMetal fiber

A flexible, thermoplastic hose for high pressure and high velocity flow is provided with a flexible braided reinforcement layer with a static drain therein for conducting static electricity towards a ground. This is achieved by having at least one textile fiber yarn with conductive fibers therein braided with non-conducting textile yarns to form the braided reinforcement layer. The preferred conducting fiber yarn is formed with metal fibers as well as plastic fibers. A method of manufacture of the hose comprises providing electrical conducting yarns and non-conducting yarns in a braiding machine and braiding them about a tube having a hollow bore through which fluid flows. An abrasion resistant outer cover layer of polyurethane is extruded over the braided layer having the drain therein. For higher pressure applications, a second braided reinforcement layer may also be provided over the inner braided layer having the electrically conductive yarns. Several conductive yarns may be used to have spaced electrically conductive yarns, e.g., at 3:00, 6:00, 9:00 and 12:00 in a circular cross-section through the hose.

Owner:DYNAFLEX

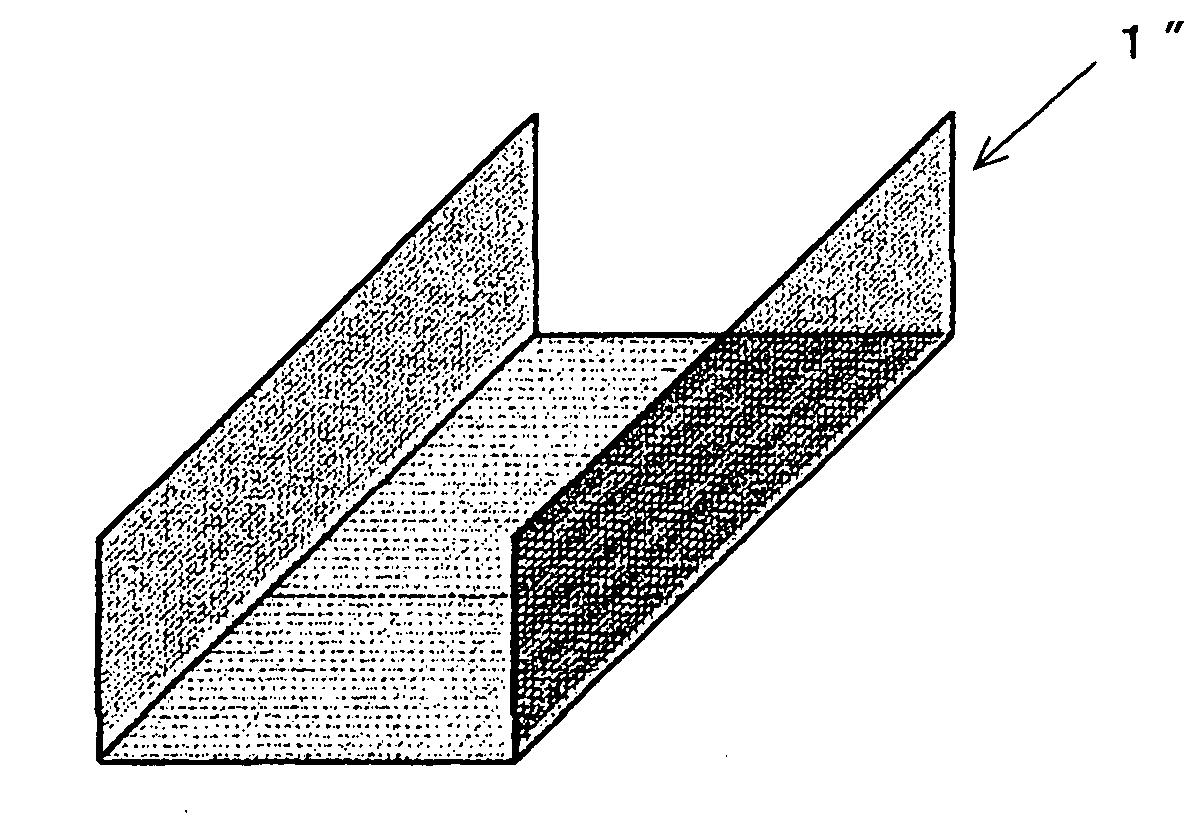

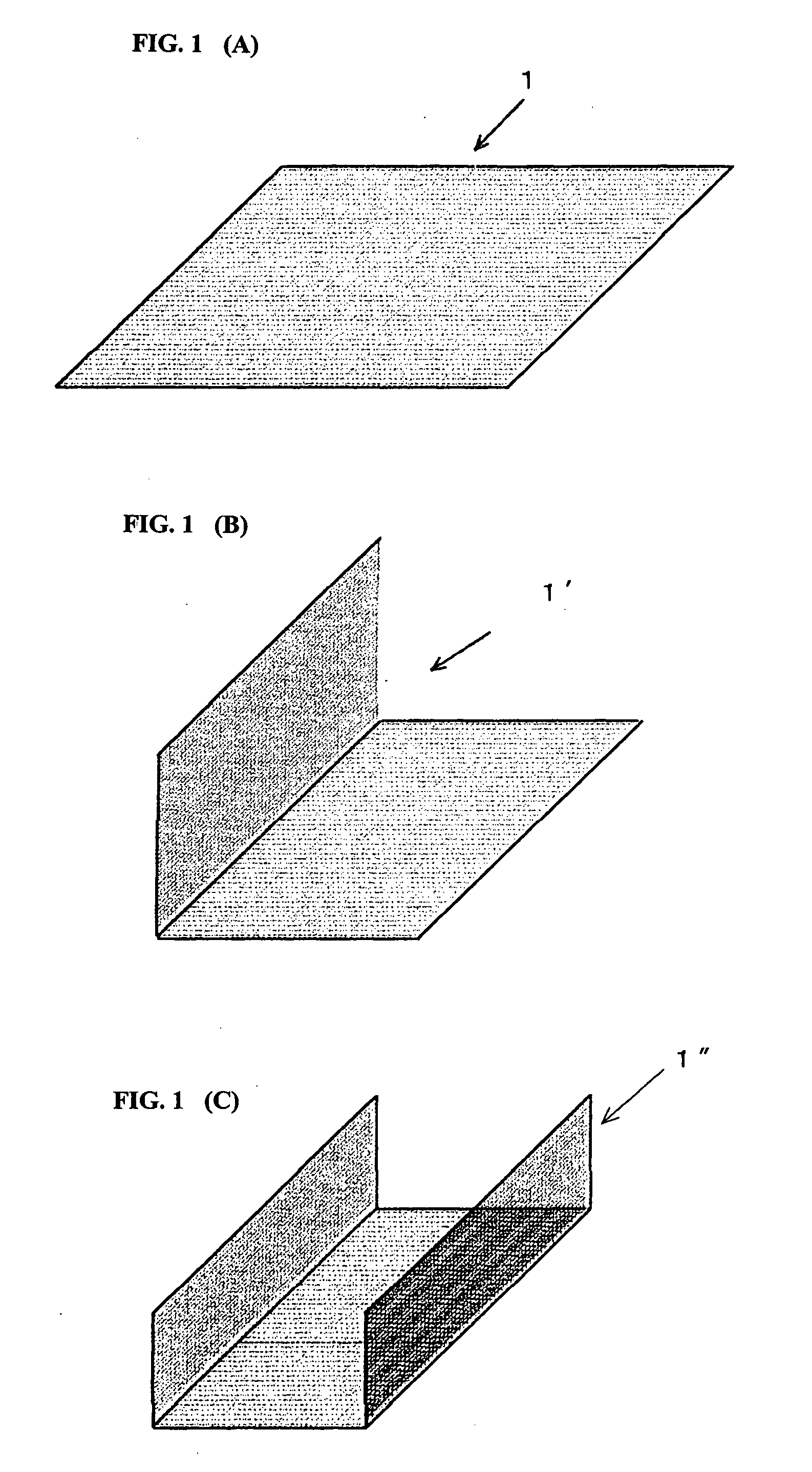

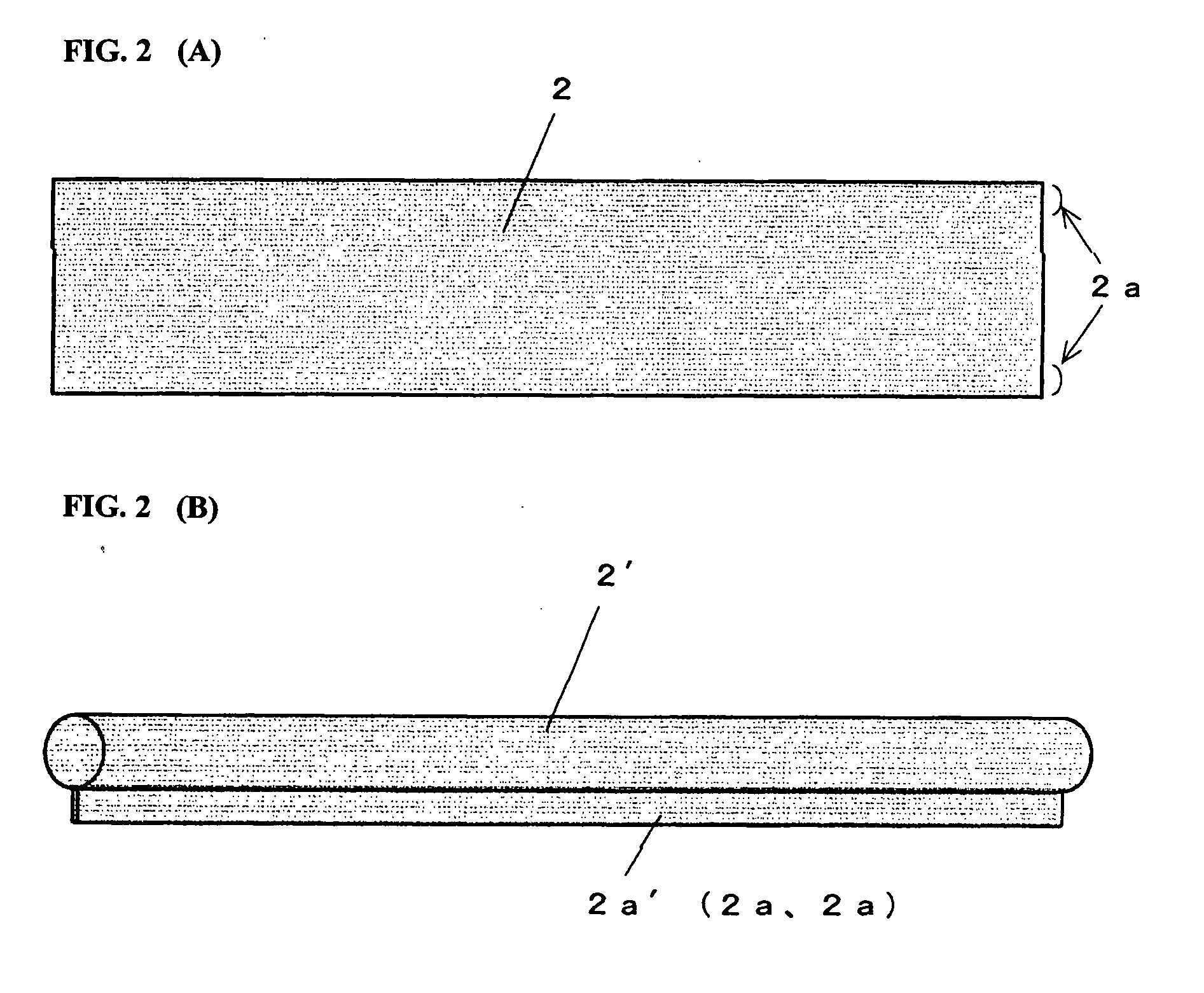

Method of processing woven/knitted fabric and the like composed of thermal fusion bonding yarns

InactiveUS20060081329A1Reduce manufacturing costShort timeLamination ancillary operationsMouldsPolyesterTextile yarn

In a method of processing woven / knitted fabric composed of thermal fusion bonding yarns, woven fabric, knitted fabric, or a braid, which is obtained by weaving or knitting thermal fusion bonding textile yarns such as thermal fusion bonding polyester and the like, is molded by being subjected to heat-processing. The molded product can be remolded by being subjected to heat-processing again. The woven fabric or the knitted fabric is a flat sheet or a three-dimensional woven / knitted fabric. It is also possible to partly overlapping the woven fabric or the knitted fabric on ordinary woven fabric or ordinary knitted fabric and to heat-molding them integrally with each other.

Owner:ORUSEN

High pressure flexible hose

InactiveUS20050051226A1Uniform diameterHigh tensile strengthFlexible pipesRigid pipesTextile fiberMetal fiber

A flexible, thermoplastic hose for high pressure and high velocity flow is provided with a flexible braided reinforcement layer with a static drain therein for conducting static electricity towards a ground. This is achieved by having at least one textile fiber yarn with conductive fibers therein braided with non-conducting textile yarns to form the braided reinforcement layer. The preferred conducting fiber yarn is formed with metal fibers as well as plastic fibers. A method of manufacture of the hose comprises providing electrical conducting yarns and non-conducting yarns in a braiding machine and braiding them about a tube having a hollow bore through which fluid flows. An abrasion resistant outer cover layer of polyurethane is extruded over the braided layer having the drain therein. For higher pressure applications, a second braided reinforcement layer may also be provided over the inner braided layer having the electrically conductive yarns. Several conductive yarns may be used to have spaced electrically conductive yarns, e.g., at 3:00, 6:00, 9:00 and 12:00 in a circular cross-section through the hose.

Owner:DYNAFLEX

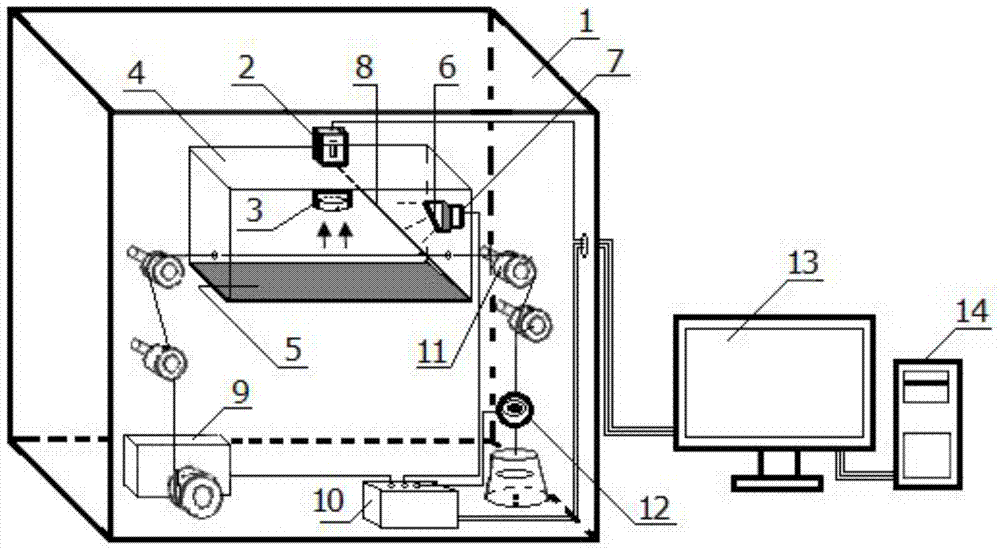

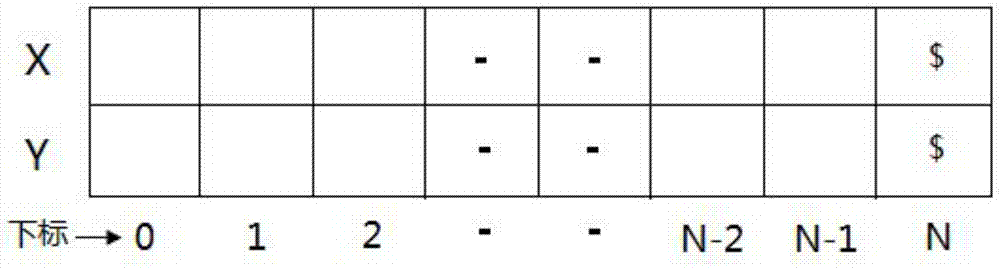

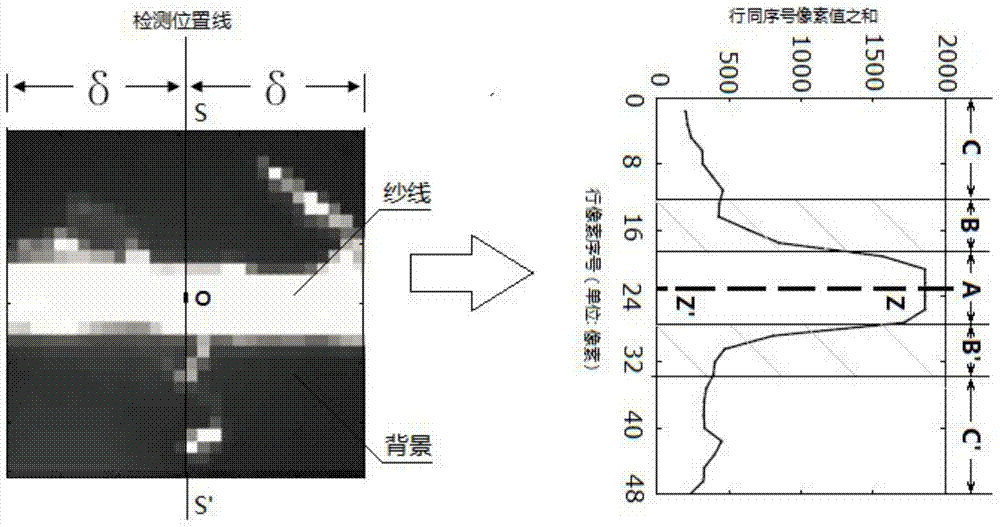

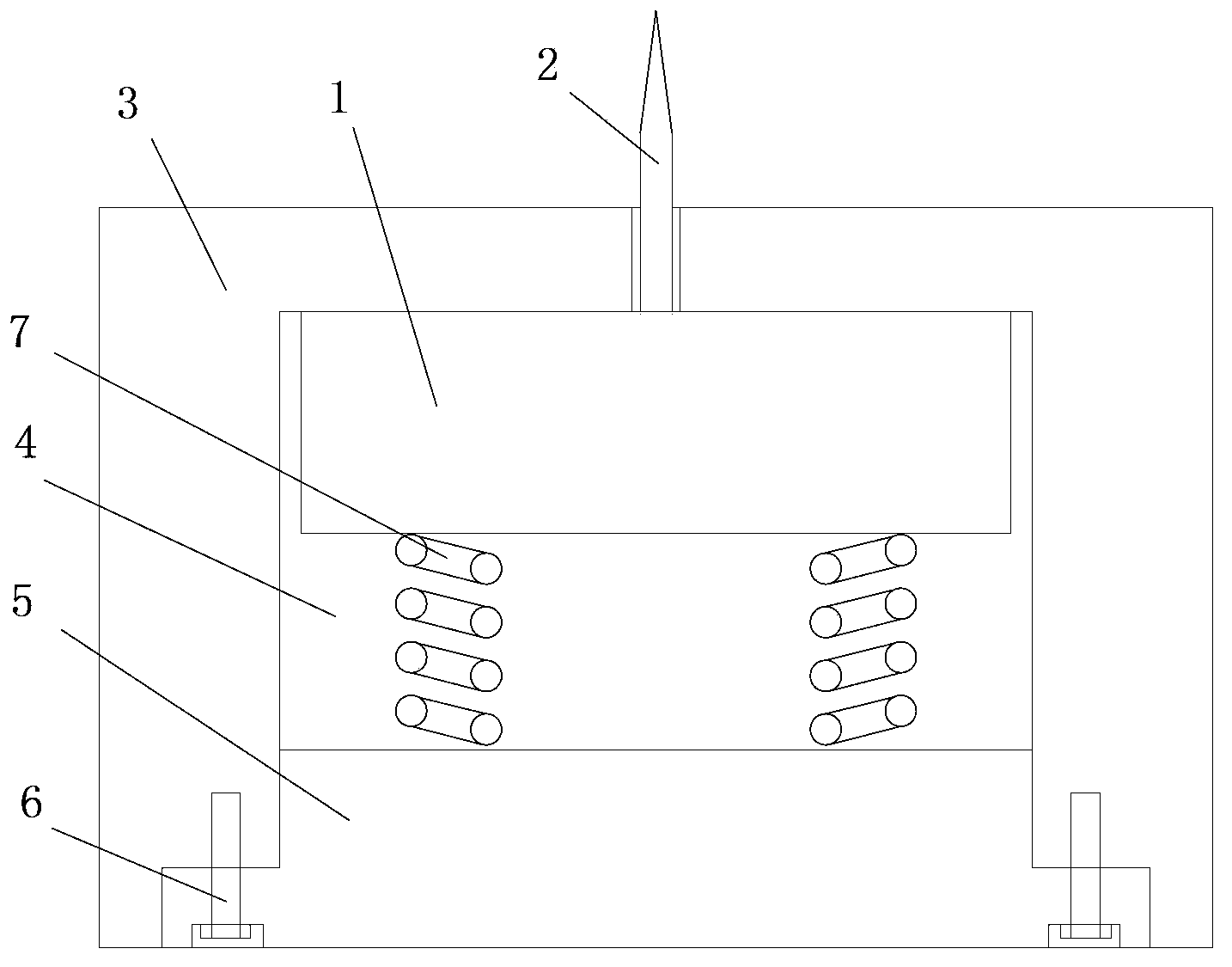

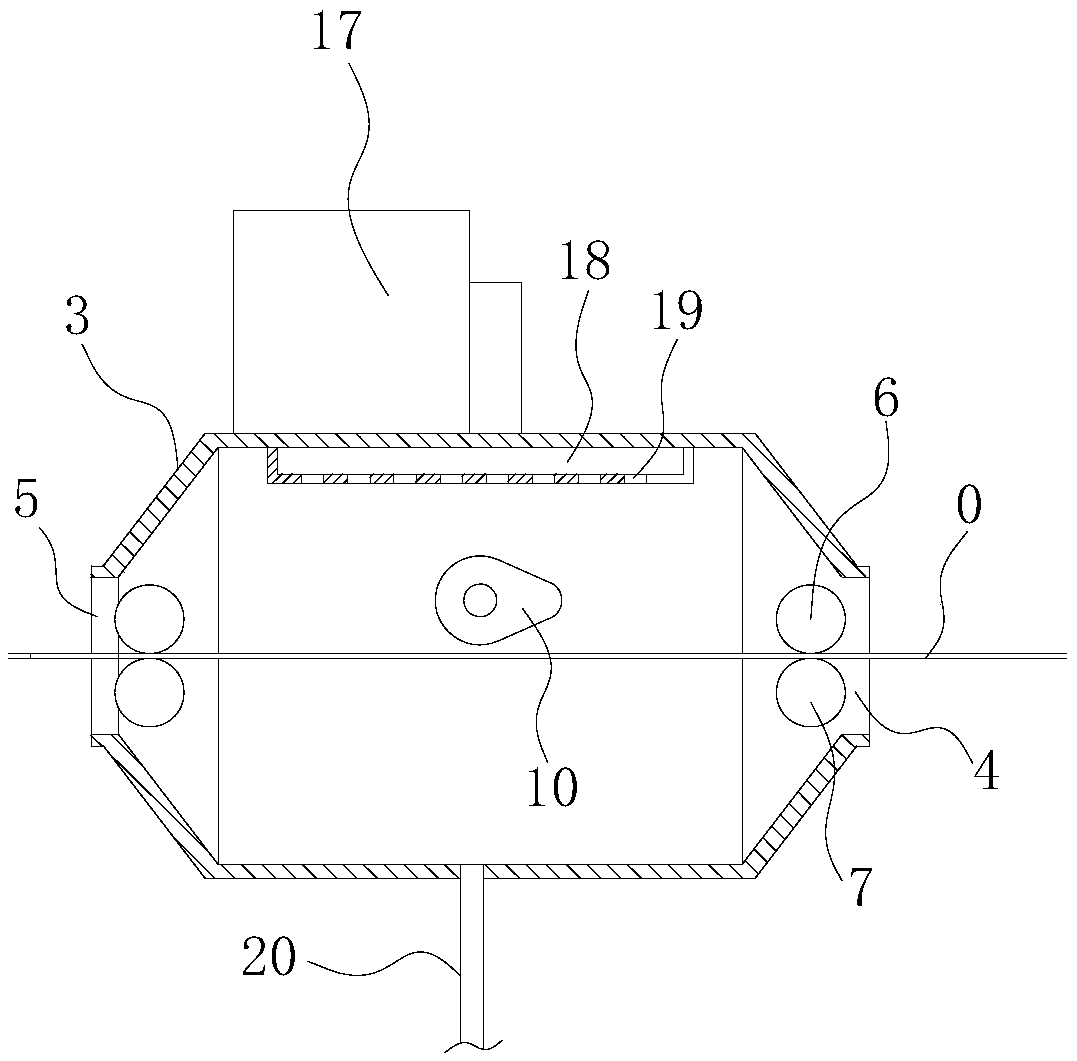

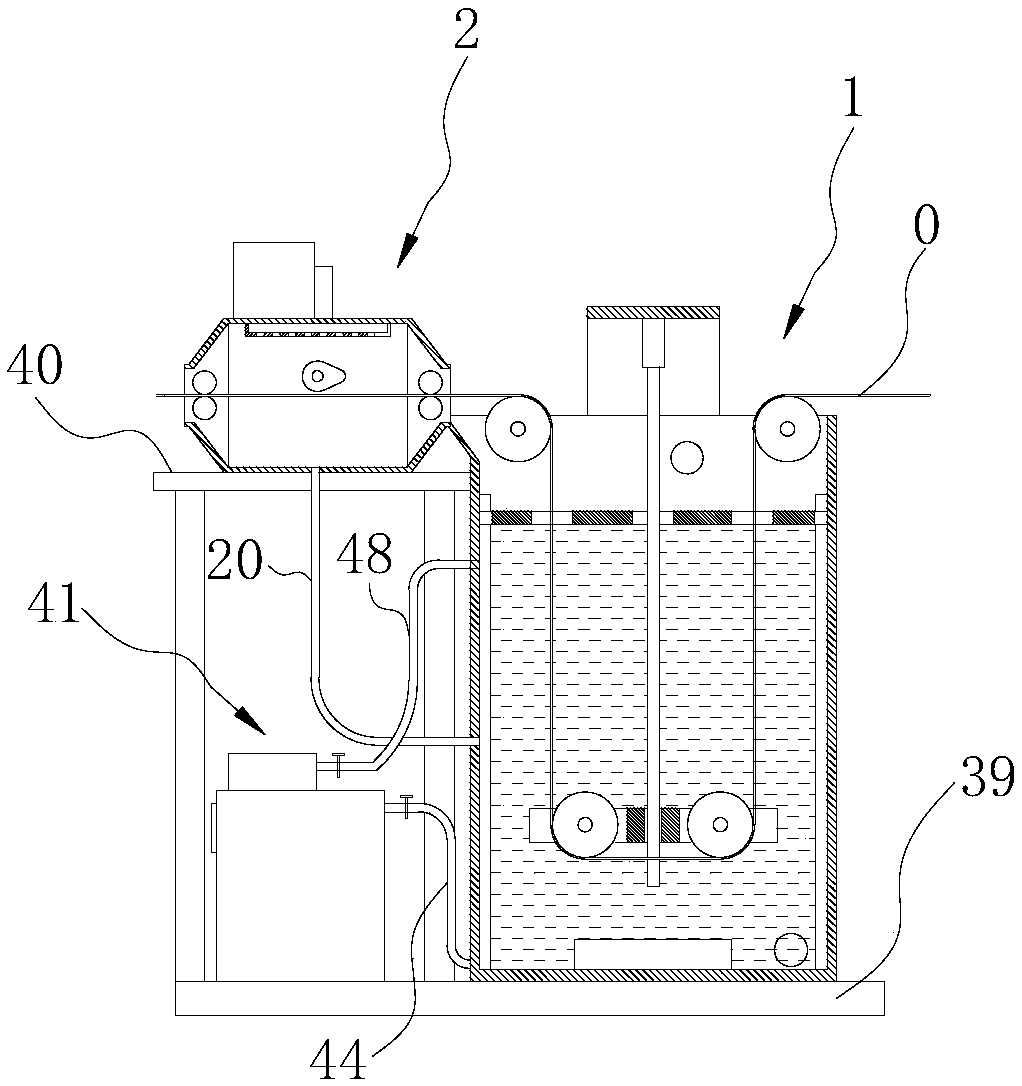

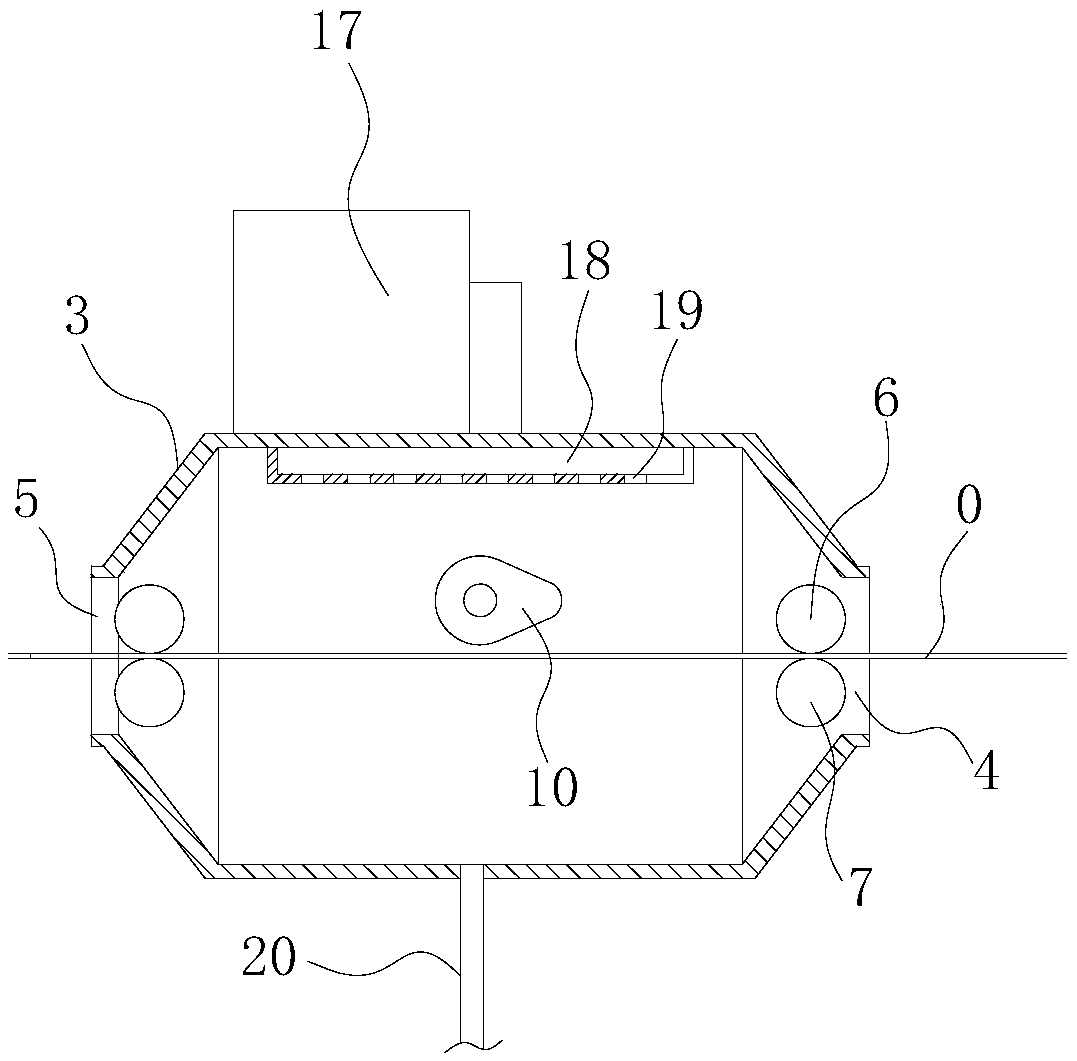

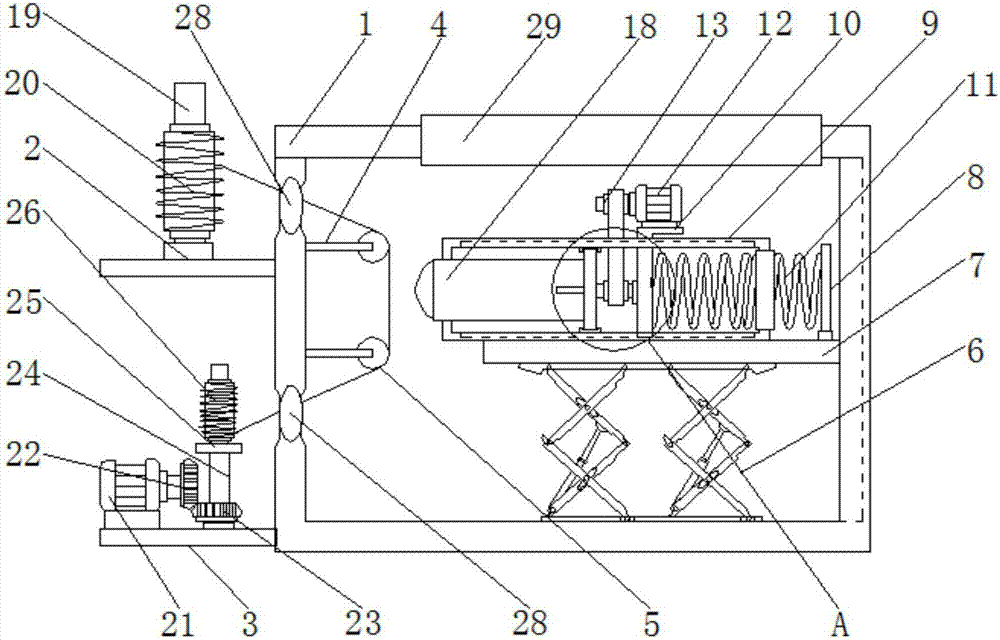

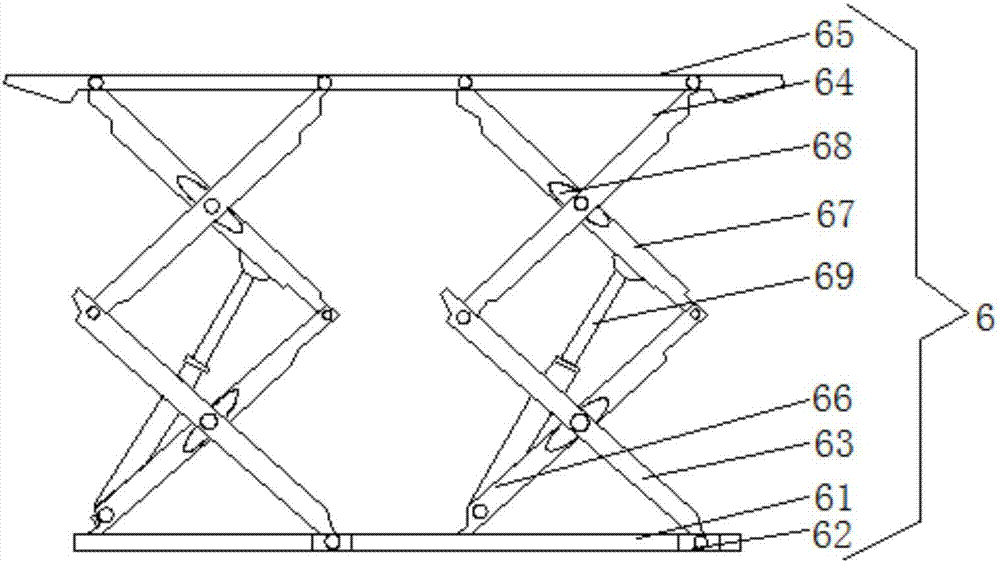

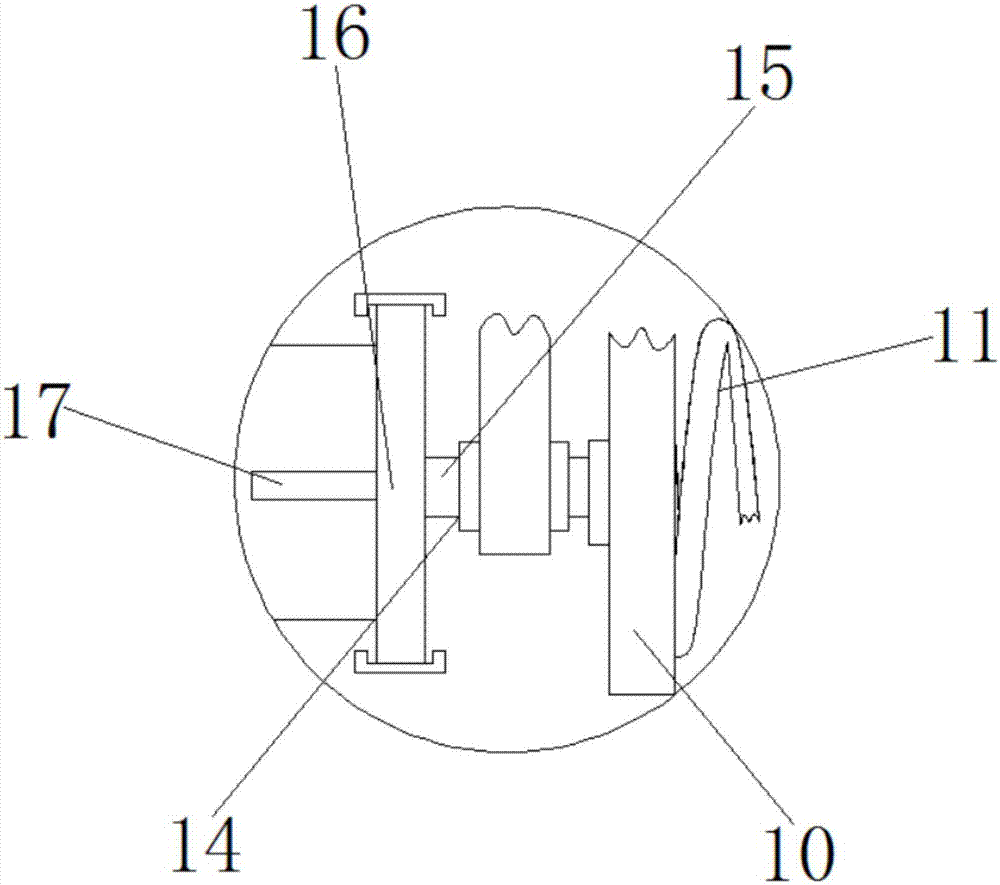

Dynamic textile yarn diameter rapid-measuring device and method

InactiveCN103759662AMeet the test requirementsEliminate reflectionsUsing optical meansBatch processingTextile yarn

The invention relates to a dynamic textile yarn diameter rapid-measuring device and method. The device comprises a box body, a yarn tension controller, a control cabinet, a lighting source, an image acquiring device and a computer. According to the method, a detecting point neighborhood length subimage is captured to serve as a process object, and the subimage is rapidly divided into a yarn body area, a yarn body suspicious area and a background area according to the gray scale projection curve distribution characteristics of the subimage; a classifier is established with the grey scale characteristics of pixels of the yarn body suspicious area and the direction connectivity between the yarn body suspicious area and the yarn body area as the constraint condition, and the classifier is used for classifying the pixels of the yarn body suspicious area to extract a complete yarn body image area; the average value of the diameters of all yarn detecting point axial neighborhood length location points serves as the diameter of the yarn at the detecting point. By establishing a detecting point and image serial number address mapping table, automatic batch processing of image sequences of moving yarn captured continuously is achieved. The dynamic textile yarn diameter rapid-measuring device and method can achieve rapid detection of diameters of all detecting points of yarn with a preset length automatically.

Owner:DONGHUA UNIV

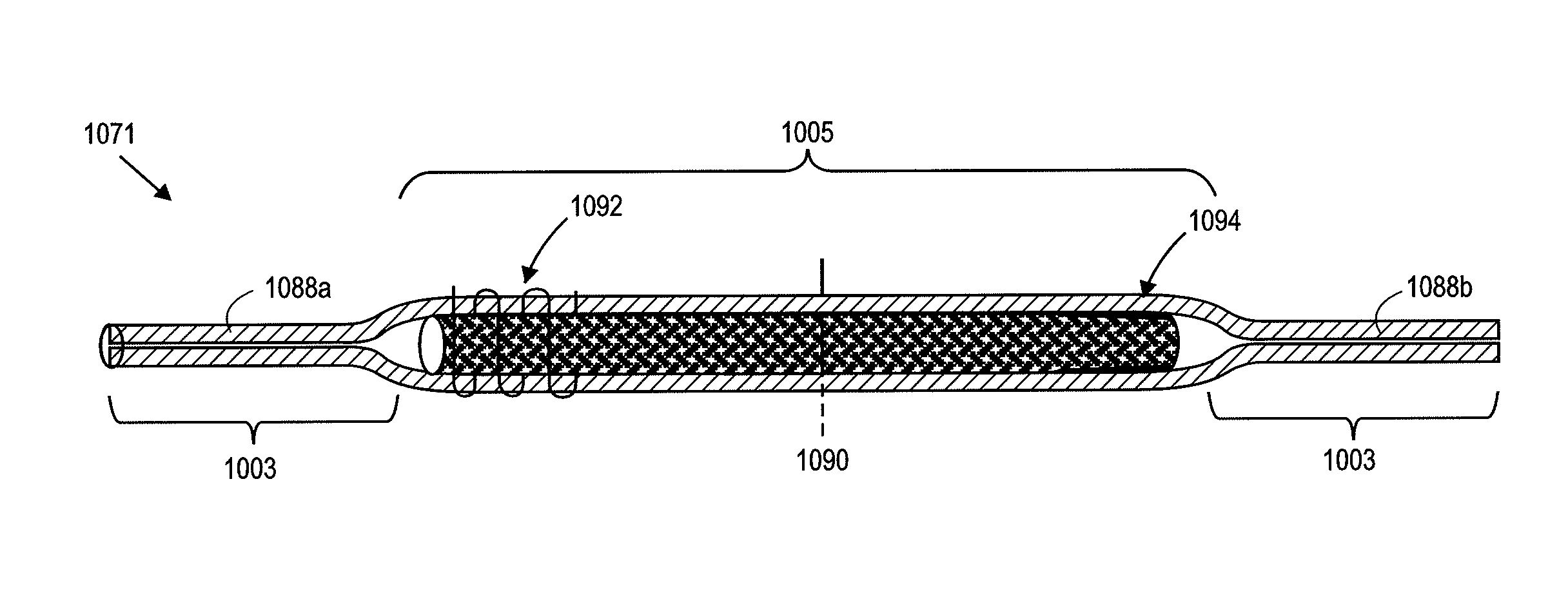

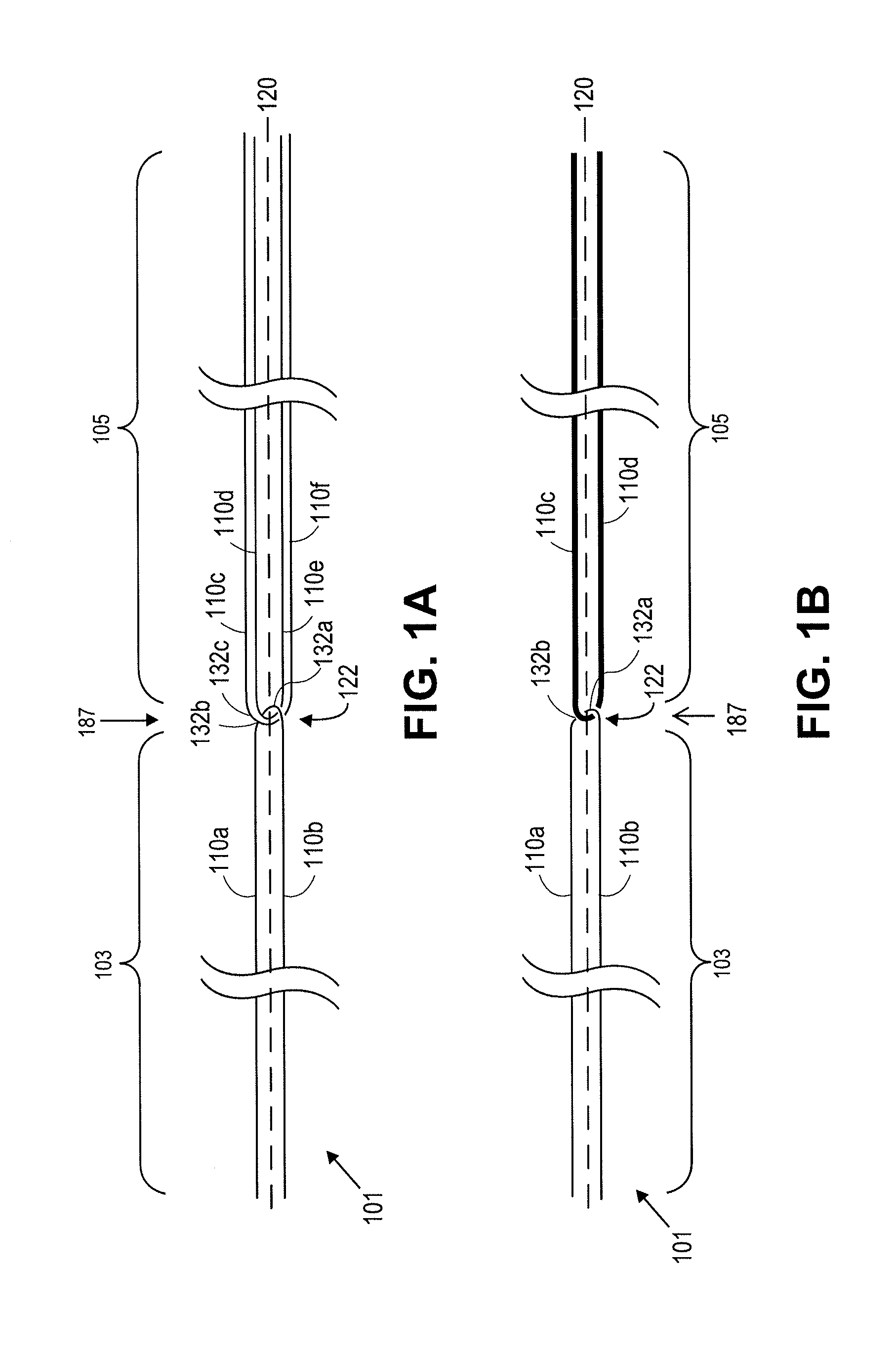

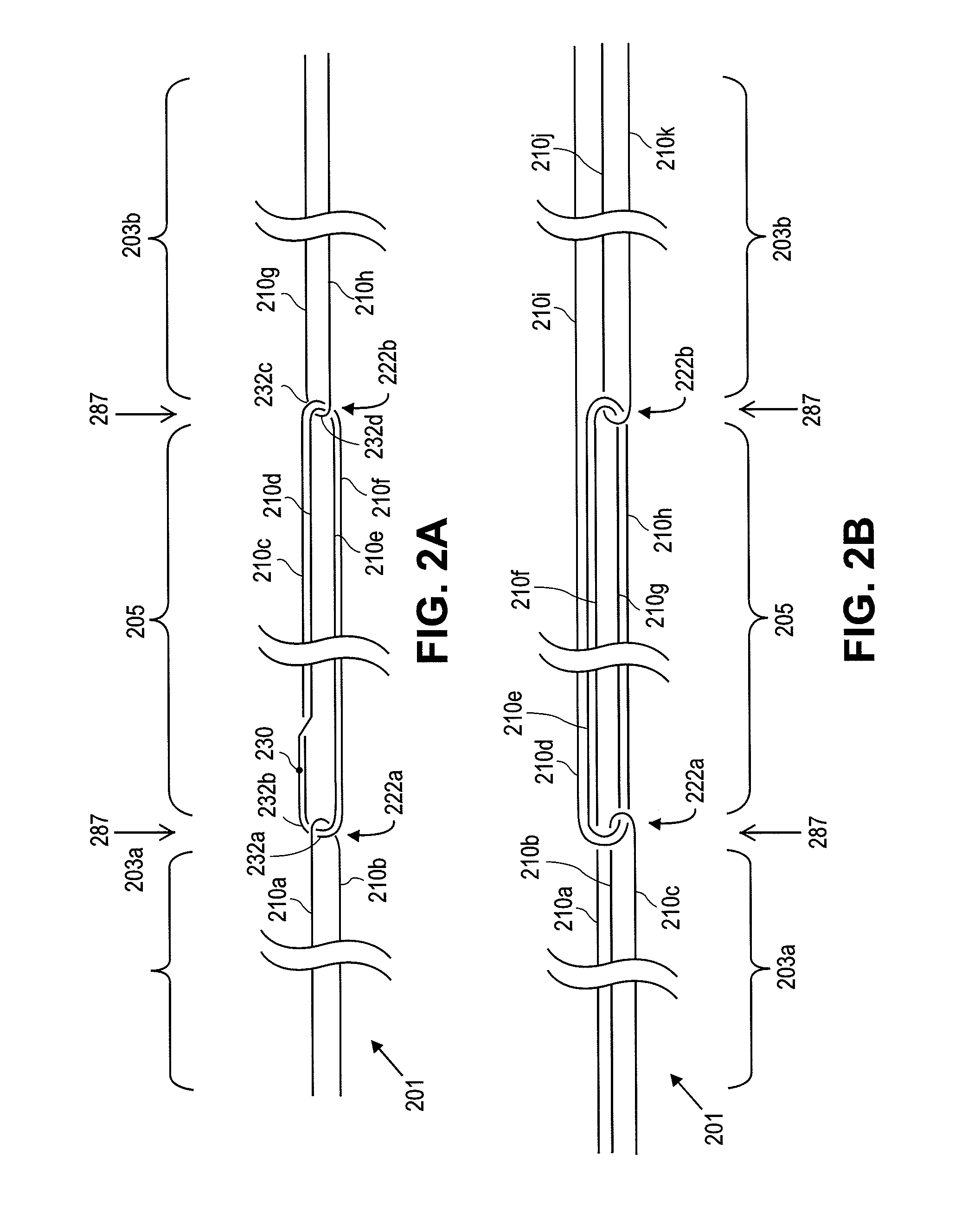

Variable denier yarn and suture

A textile yarn includes a first segment and a second segment. The first segment includes a plurality of first strands and has a substantially constant first denier. The second segment includes a plurality of second strands integrated together and has a substantially constant second denier. There are more second strands in the second segment than first strands in the first segment such that the second denier is greater than the first denier. A first portion of the plurality of second strands is made from a first plurality of yarn elements that extend through the first and second segments. A second portion of the plurality of second strands is made from a second plurality of yarn elements present in the second segment and not the first segment. The yarn elements in the second plurality of yarn elements terminate in a transition zone between the first segment and the second segment.

Owner:SYNTORR

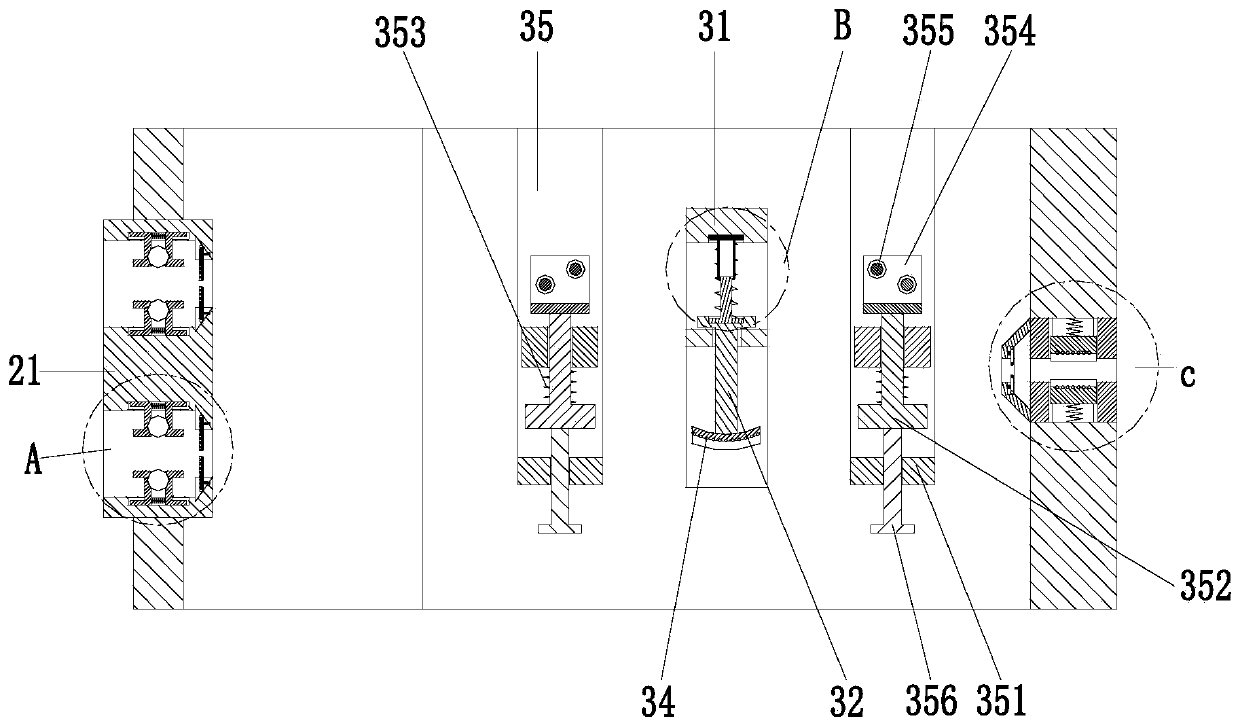

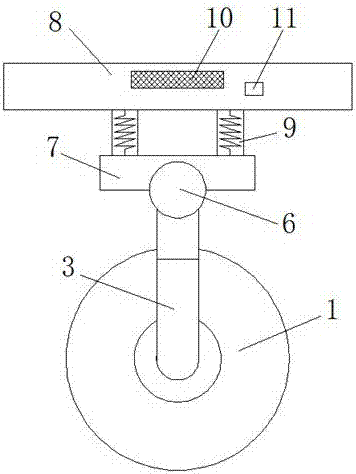

Textile yarn tensioning device

InactiveCN106865353AGuaranteed to proceed normallyModerate tensionFilament handlingDrying machines with progressive movementsTextile yarnEngineering

The invention discloses a textile thread tensioning device, which comprises a support base frame, and a feed roller and a discharge roll are respectively arranged on both sides of the support base frame. The pulley is connected to the discharge roller, and the tensioning frame is fixedly arranged on the supporting base frame. The top of the tensioning frame is provided with a return spring, and the lower part of the return spring is connected with the tensioning wheel. The central shaft of the tensioning wheel is a 360-degree rotating central shaft of the tensioning wheel driven by electric power. The outer sleeve of the central shaft of the tensioning wheel is provided with a sliding sleeve. The sliding sleeve is connected to the adjusting rod through the telescopic bracket flange, and the adjusting rod is set on the tensioning frame. At the bottom of the bottom, the present invention completes the adjustment of the tension wheel to the lower side by shortening the length of the adjustment rod, and improves the tension; Reduce tension to ensure normal spinning.

Owner:YANCHENG DIJIANI CLOTHING

Hybrid high pressure hose

A high pressure hose and method of manufacturing the hose is disclosed. The hose is comprised of an elastomer, thermoset rubber inner tube, reinforced with one or more layers of braided or spiralized high tensile strength wire or high tenacity textile yarn and covered with a highly flexible thermoplastic sheath.

Owner:SCHIEFFER INT L C

Processing technology for smooth and non-shrinkable wool yarns

InactiveCN101812806AGood effectEliminate itchingBiochemical fibre treatmentAnimal fibresEngineeringFatty alcohol

The invention discloses processing technology for smooth and non-shrinkable wool yarns, and belongs to the technical field of performance processing for textile yarns. The processing technology comprises the following steps of: analyzing mechanical and physical properties of wool yarns sold in the market, and humidifying the wool yarns in a yarn processor; performing socking, preprocessing, rinsing, biochemical preparation processing and neutralizing on the wool yarns; and adding a softening and dispersing agent consisting of a silicone softening agent, fatty alcohol-polyoxyethylene ether, amide ether, double-chain esterquat for function processing, drying, and packaging finished products. For the wool yarns processed by the technology, the density and thickness of scales are all reduced, so felt contraction is reduced, and the itchy feeling of the wool is removed on the basis of maintaining the special elasticity and warmness of fibers. Meanwhile, various adverse effects in the spinning process after the wool fibers are subjected to fiber loosening processing in the industry in the prior art are overcome. The wool yarns processed by the technology are smooth, soft, non-shrinkable and non-itchy, and have bright and uniform colors and lasting effect.

Owner:PINDAR INDAL TAIYUAN +1

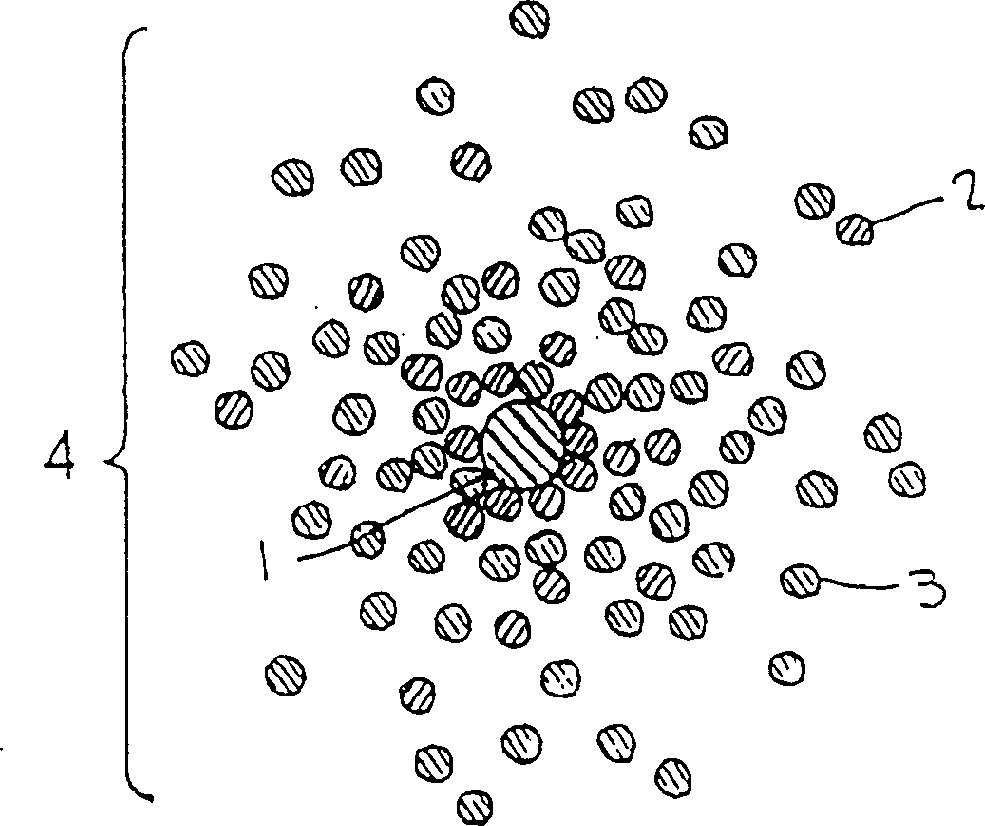

Elastic hydrophobic/hydrophilic composite yarns and moisture management elastic fabric made therefrom

InactiveCN1450217AEasy printing or transfer printingSimple knittingWeft knittingWarp knittingYarnFiber type

A composite textile yarn and a moisture management elastic fabric made therefrom, the yarn comprising an elastic filament and hydrophilic fibers embedded at the yarn center within a matrix of hydrophobic fibers such that the hydrophobic fibers are concentrated at the periphery of the yarn, a transition area between the hydrophobic fibers concentrated about the elastic filament at the yarn center and the peripheral hydrophobic yarns in which both fiber types are present.

Owner:FAYTEX CORP

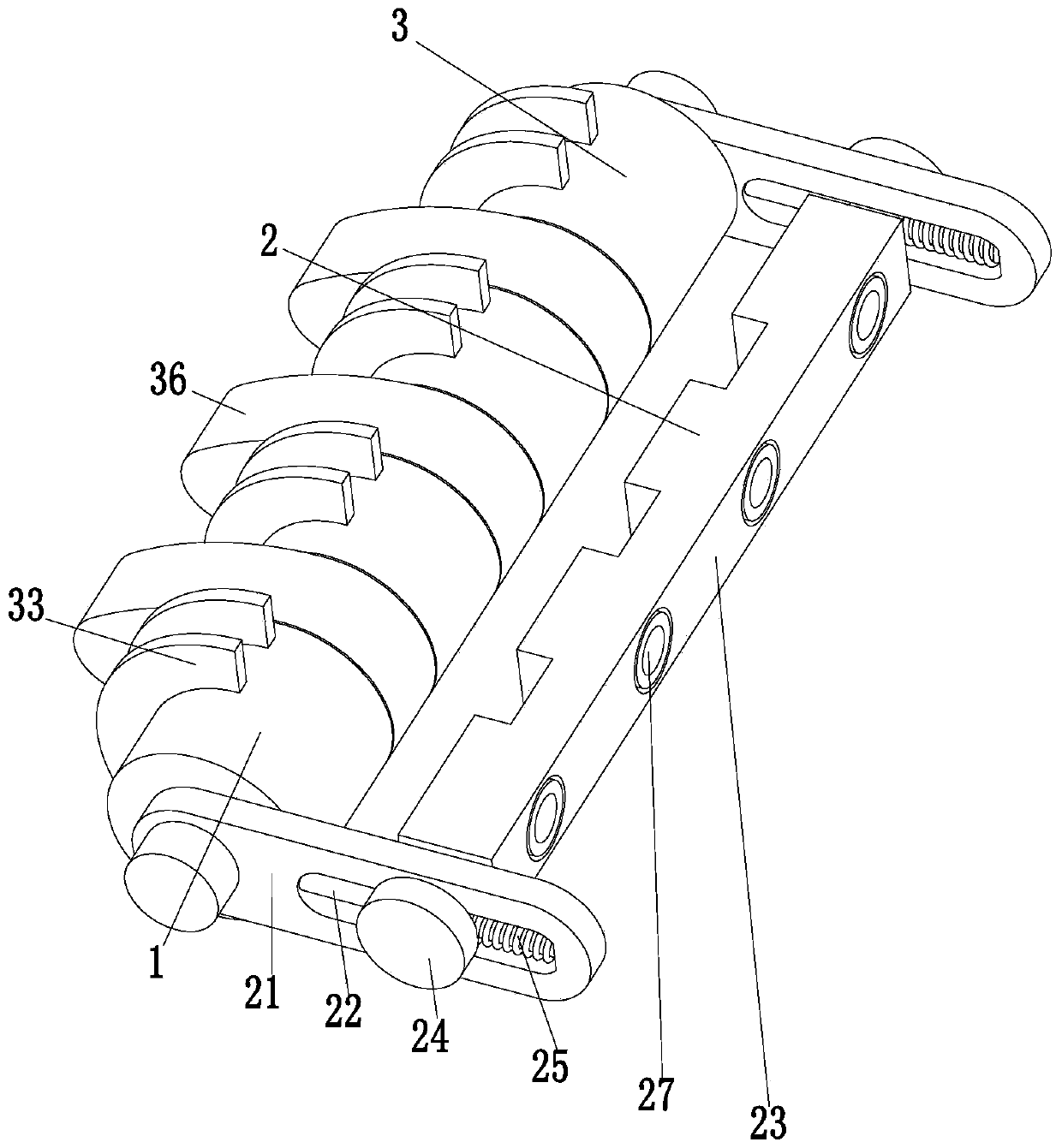

Textile yarn winding device

The invention discloses a textile yarn winding device which comprises a base. Four corners of the lower end of the base are fixedly connected with adjusting mechanisms, the left side of the upper endof the base is rotatably connected with a rotating rod through a first rolling bearing, a reel sleeves the wall of the rotating rod in a fastened manner by a fixing mechanism, the lower end of the rotating rod penetrates the base and extends to the lower portion of the base, the lower end of the rotating rod is fixedly connected with a first bevel gear, the center of the upper end of the base is rotatably connected with a reciprocating lead screw through a second rolling bear, a slider matched with the reciprocating lead screw movably sleeves the wall of the reciprocating lead screw, one sidewall, close to the reel, of the slider is fixedly connected with a connecting block, a through hole is formed in the upper end of the connecting block, a sliding rod is movably arranged in the throughhole, the lower end of the sliding rod is fixedly connected with the base, and the side wall of the front of the slider is fixedly connected with a thread guide. Textile yarns can be effectively wound neatly and uniformly, winding effects are good, and the textile yarns are conveniently used by people during spinning.

Owner:GUIZHOU WANGFENGLIN TEXTILE TECH CO LTD

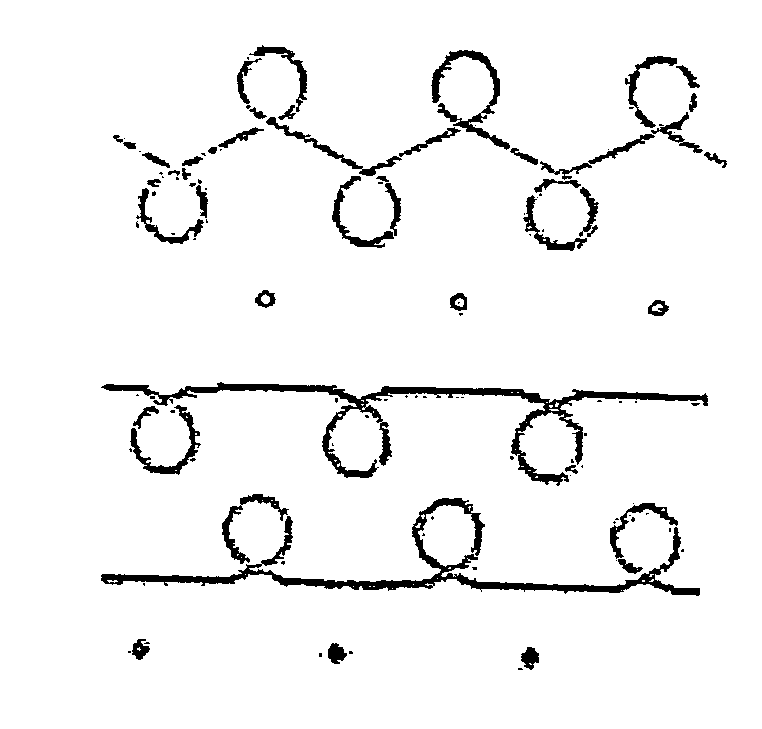

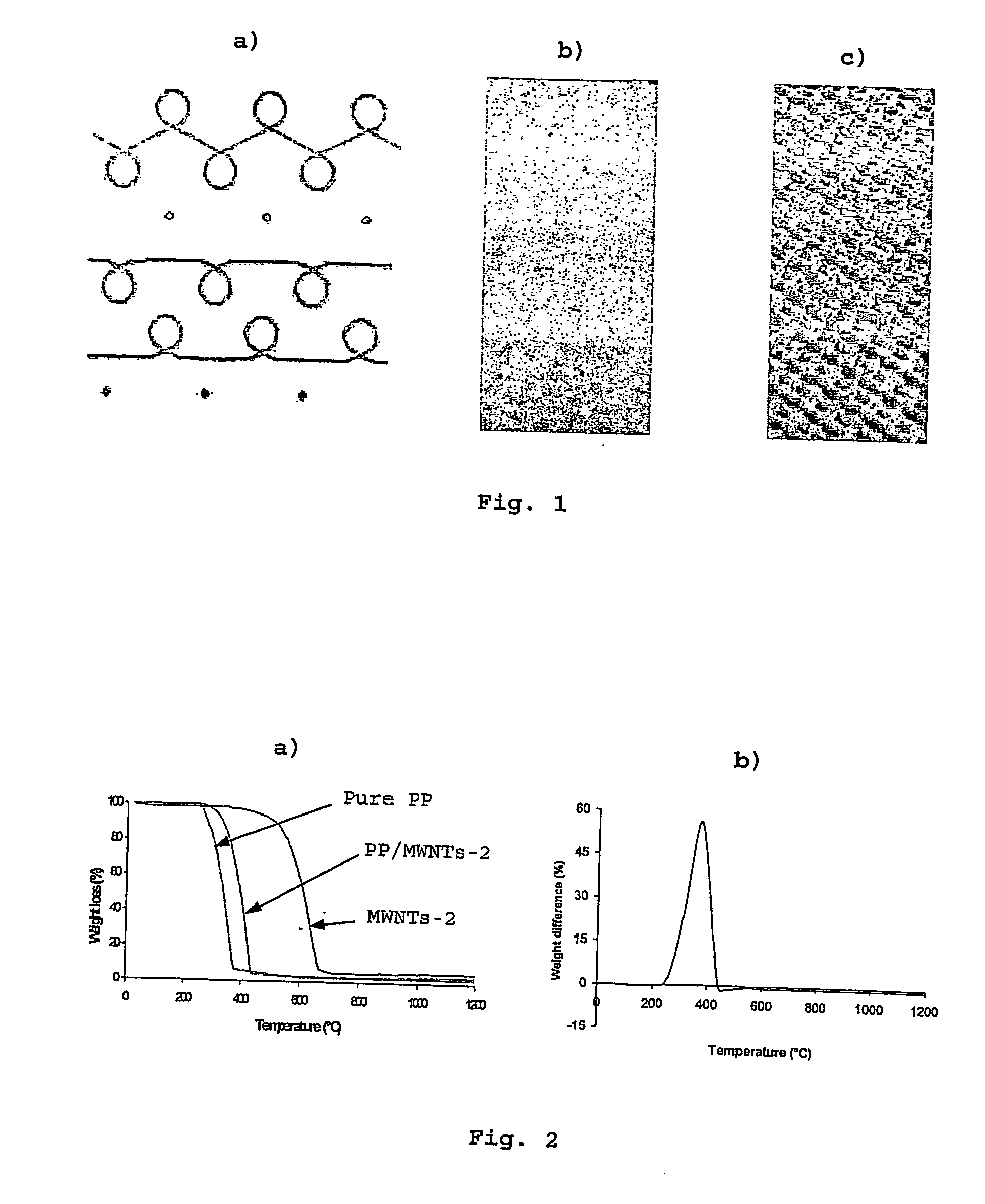

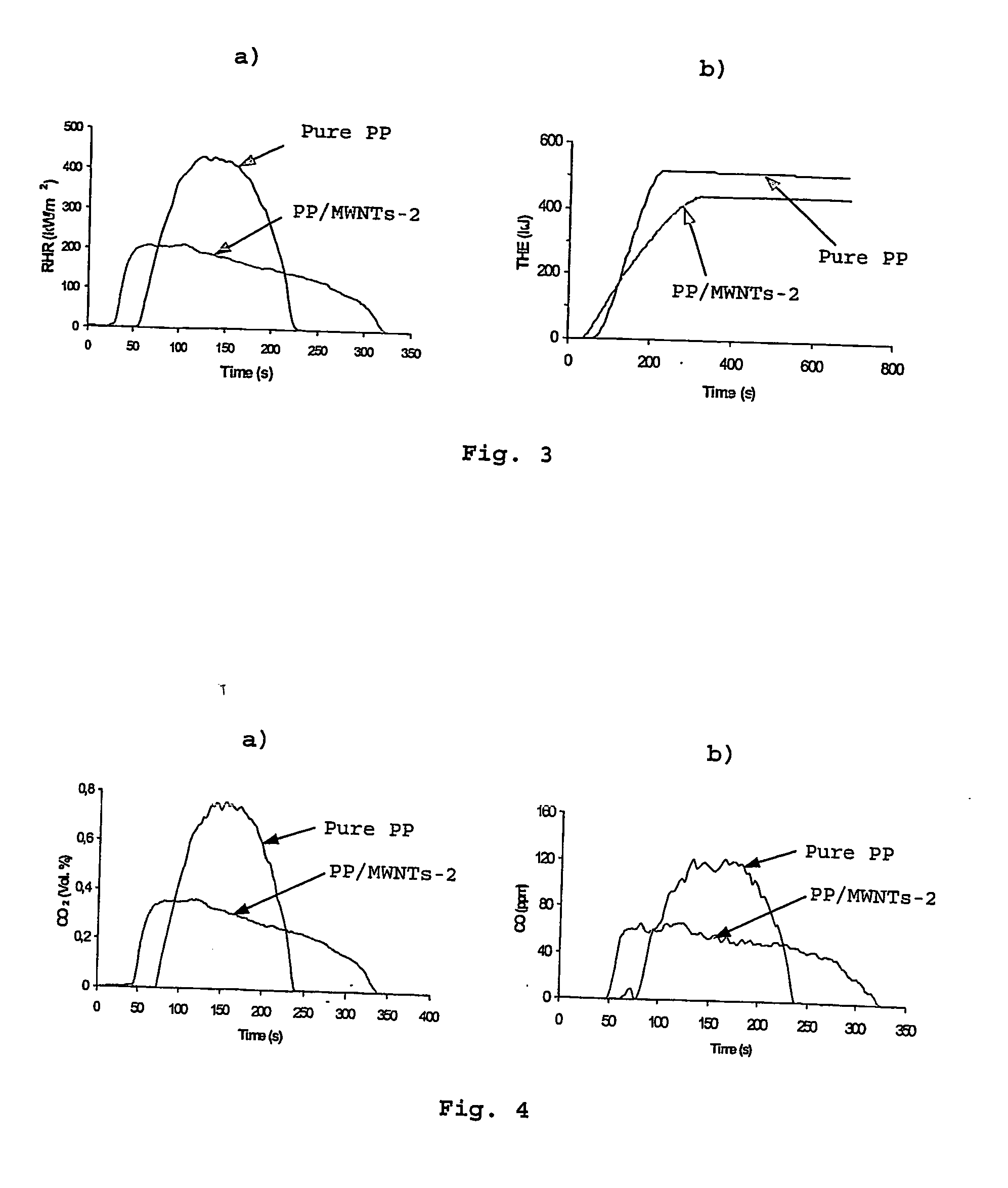

Continuous textile fibers and yarns made from a spinnable nanocomposite

InactiveUS20070031662A1Improve fire stabilityImprove thermal stabilityMaterial nanotechnologyFlame-proof filament manufactureTextile fiberPolymer science

The present invention is related to a multifilament continous textile yarn made by melt spinning of a nanocomposite comprising as components at least one polymer and carbon nanotubes, and to its uses, in particular in the textile industry.

Owner:NANOCYL SA

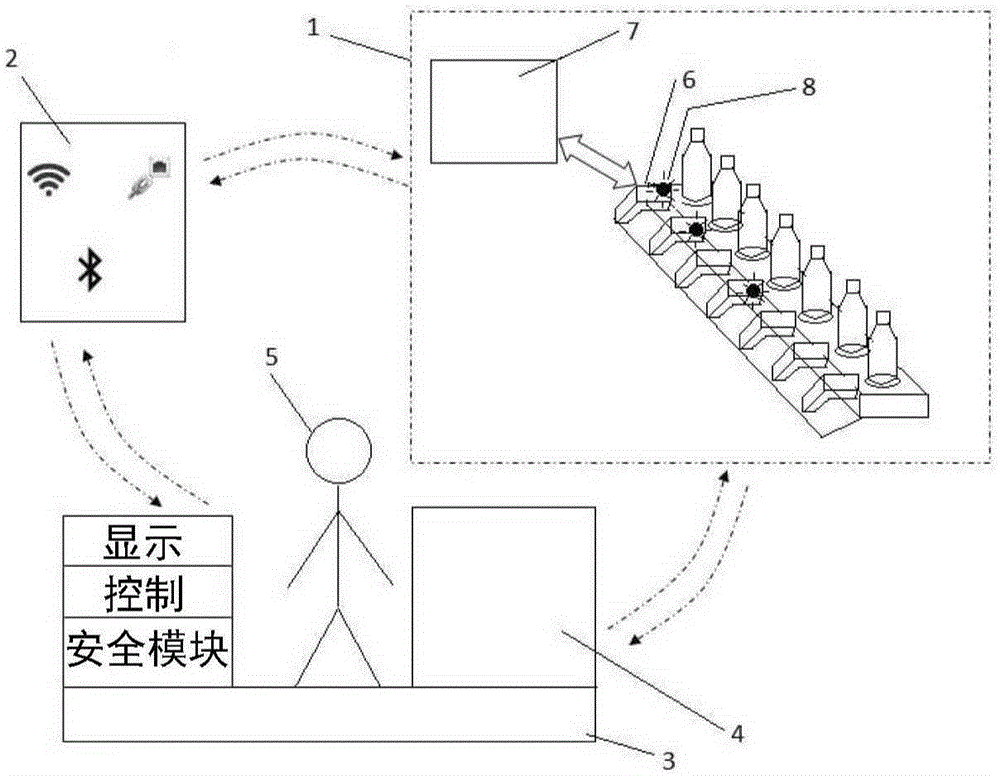

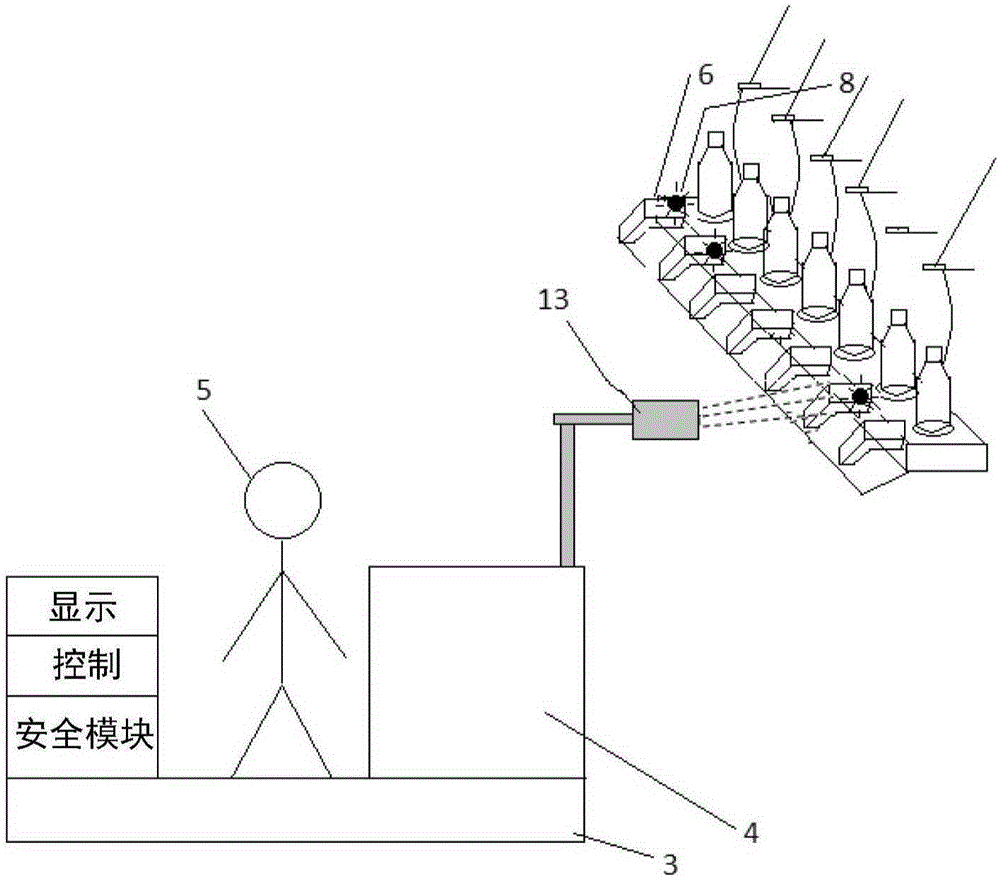

An integrated system and a method for enhancing efficiency and quality in textile yarn manufacturing process

An integrated sensing, control and resurrecting system for yarn breakage and other defects occurrences in a ring spinning machine is provided. Accordingly, a Control system (2) integrating an individual spindle monitoring system (1) and a transportation system (3) is provided. The transportation system can navigate and facilitate movement of work force attending to the yarn breakage and other defects upon detection by the spindle monitoring system, and the information related to yarn breakage occurrence and other defects in the spindles being sensed by the yarn monitoring system and communicated to the transporting system. The transportation system is capable of carrying both personnel and required textile material traversing along the entire longitudinal axis of the ring spinning machine for attending to the yarn breakage and other defects and ensuring quicker restoration of the yarn spinning process of the spindle of the ring spinning machine and also eliminating the production of inferior yarns due to other defects. The transportation system can be effectively used for multiple ring spinning machines for attending to yarn breakage occurrences and other defects.

Owner:PREMIER EVOLVICS PVT LTD

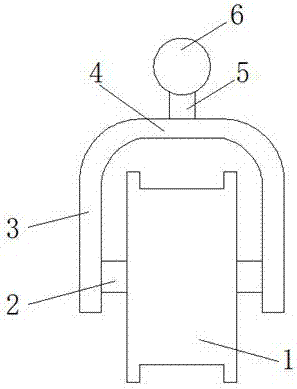

Textile yarn guide seat

InactiveCN104342840AGuaranteed smooth yarn guidanceNo loosenessWeft knittingWarp knittingTextile yarnEngineering

The invention relates to the technical field of textiles, in particular to a textile yarn guide seat. The textile yarn guide seat comprises a positioning plate, a plurality of yarn guide needles fixedly arranged on the upper end face of the positioning plate and a locking structure locking the positioning plate in a positioning seat, wherein the positioning plate is arranged in the positioning seat, and the yarn guide needles on the positioning plate penetrate through the positioning seat to be exposed out of the positioning seat. The positioning plate is locked in the positioning seat through a locking structure, the yarn guide needles extend out of the positioning seat to be used for yarn guide, the positioning plate is firmly limited in the positioning seat and does not loosen, and smooth yarn guide of the yarn guide needles is ensured.

Owner:常州市嘉翔纺织印染有限公司

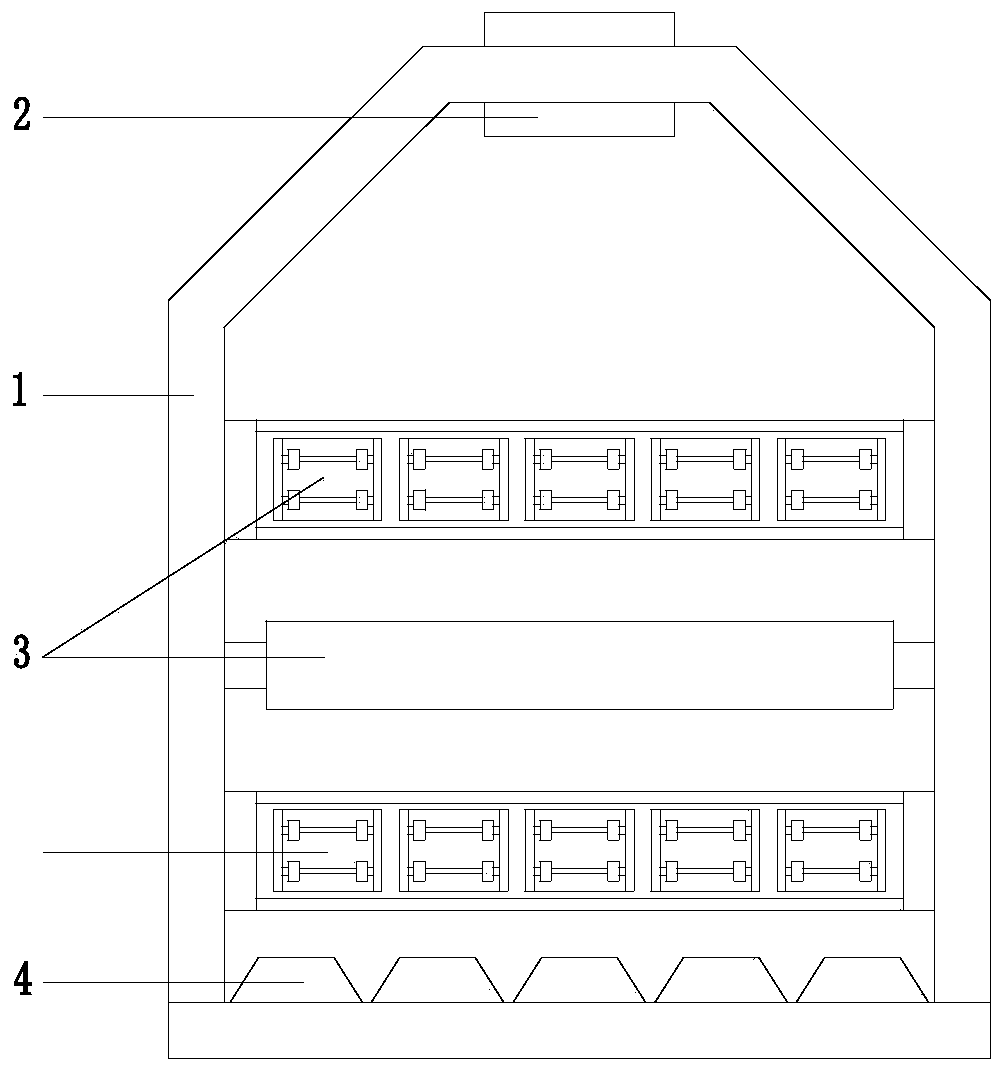

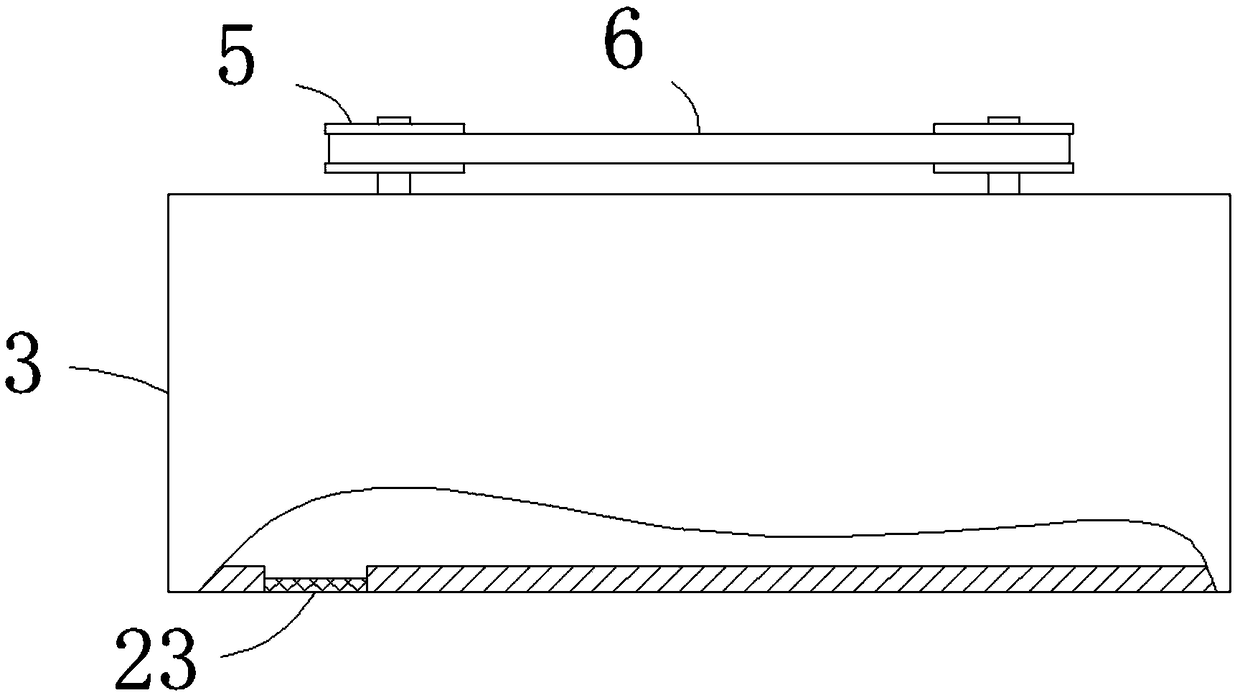

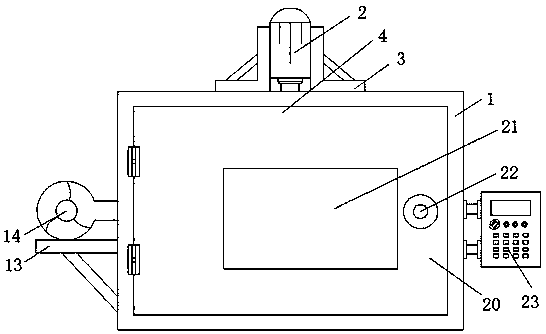

Drying box for spinning

InactiveCN107764014AEasy to dryImprove product qualityMechanical cleaningPressure cleaningTextile yarnEngineering

The invention relates to the technical field of spinning, particularly to a drying box for spinning. The drying box comprises a drying box unit, and an electric heating layer is arranged on the innerwall of the drying box unit; a hollow pipe is arranged in the drying box unit; one end of the hollow pipe is connected with the inner wall of the drying box unit through a connecting rod; the other end of the hollow pipe is connected with an air inlet pipe, and the other end of the hollow pipe communicates with the air inlet pipe; the other end of the air inlet pipe penetrates through a shell of the drying box unit and is connected with a hot air blower; and the hot air blower is fixed to the outer surface of the drying box unit. According to the drying box for spinning provided by the invention, the hollow pipe capable of blowing air to yarns is arranged, a spiral groove is formed in the surface of the hollow pipe, an air outlet is formed in the bottom surface of the groove, and the yarnspassing through the groove can be quickly dried; besides, cleaning devices are arranged in the groove, and impurities on the surfaces of the yarns are removed; and a dust collection pipe and a centrifugal fan are arranged, the yarns are dedusted, and quality of a processed product is higher.

Owner:JIANGSU CHENFEI SPORTS GOODS CO LTD

Biopolymer fiber composite covering yarn structure

The invention discloses a biopolymer fiber composite covering yarn structure and belongs to the technical field of textile yarns. The biopolymer fiber composite covering yarn structure comprises a yarn body, and is characterized in that: the yarn body is formed by combining one or two polylactide filaments and one or two biopolymer staple fiber yarns. The invention has the advantages that: because the yarn body is formed by combining the polylactide filaments and the biopolymer staple fiber yarns, the biopolymer fiber composite covering yarn structure has ideal softness, elasticity, affinity to skin, antibacterial permeability and an excellent environment-friendly effect.

Owner:恒天长江生物材料有限公司

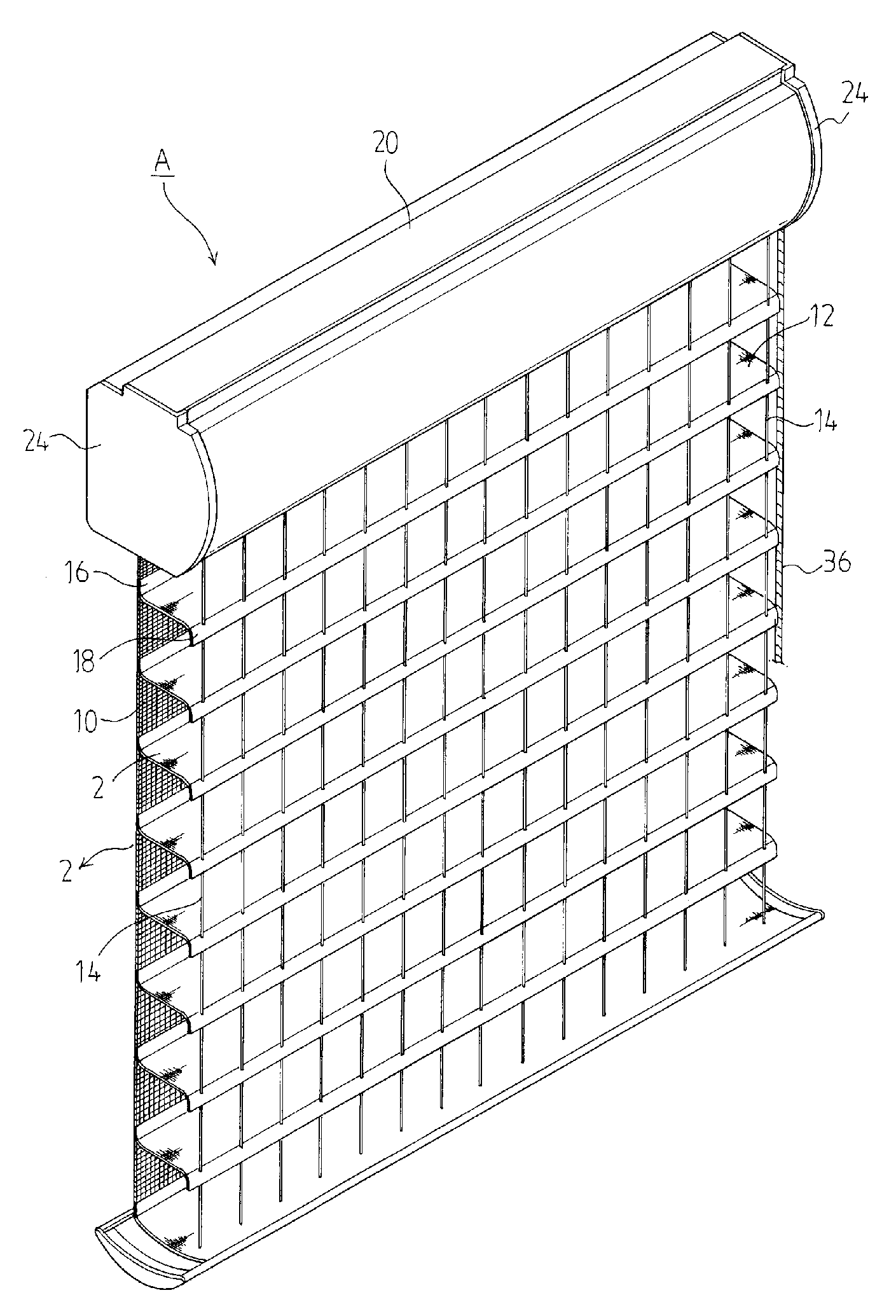

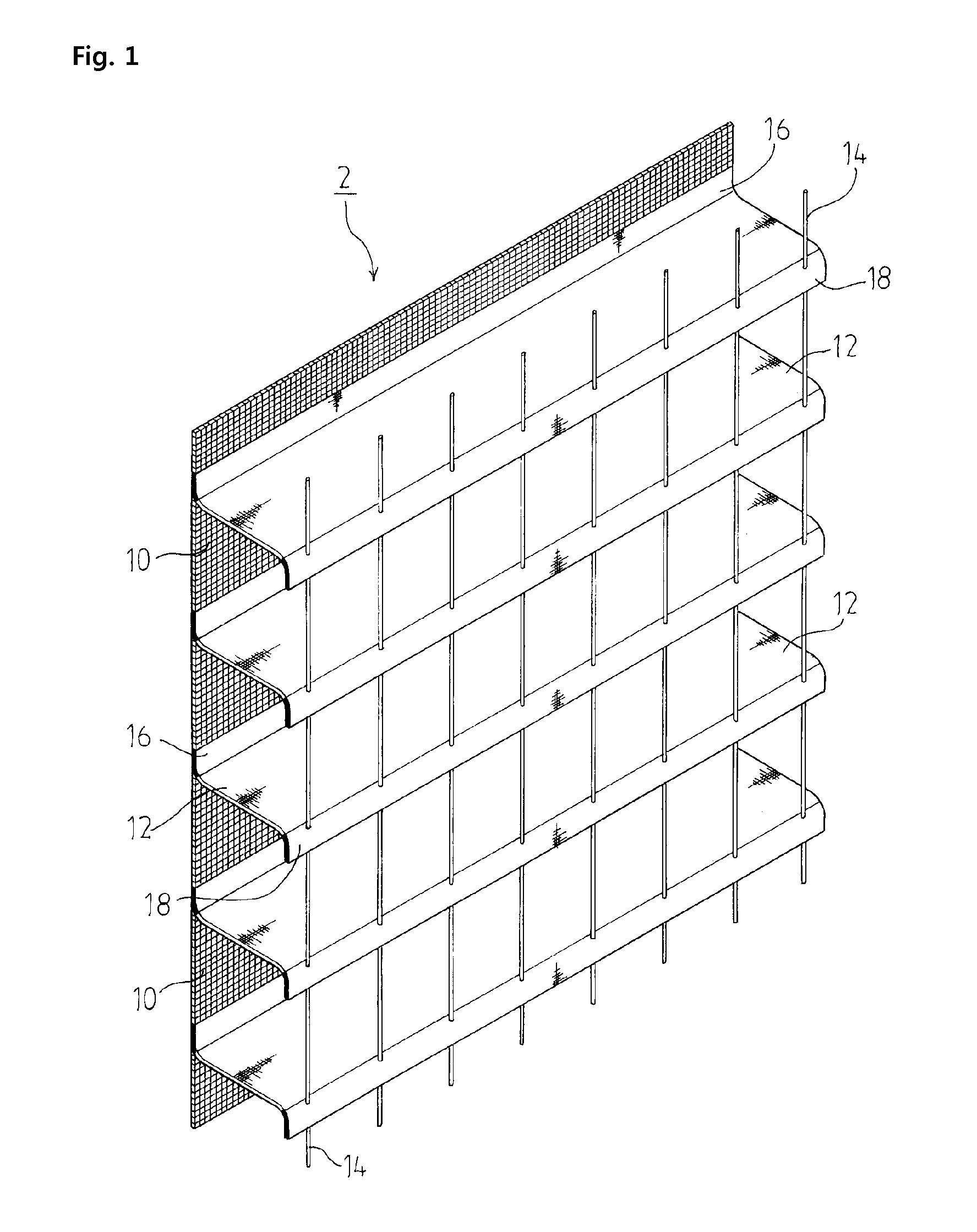

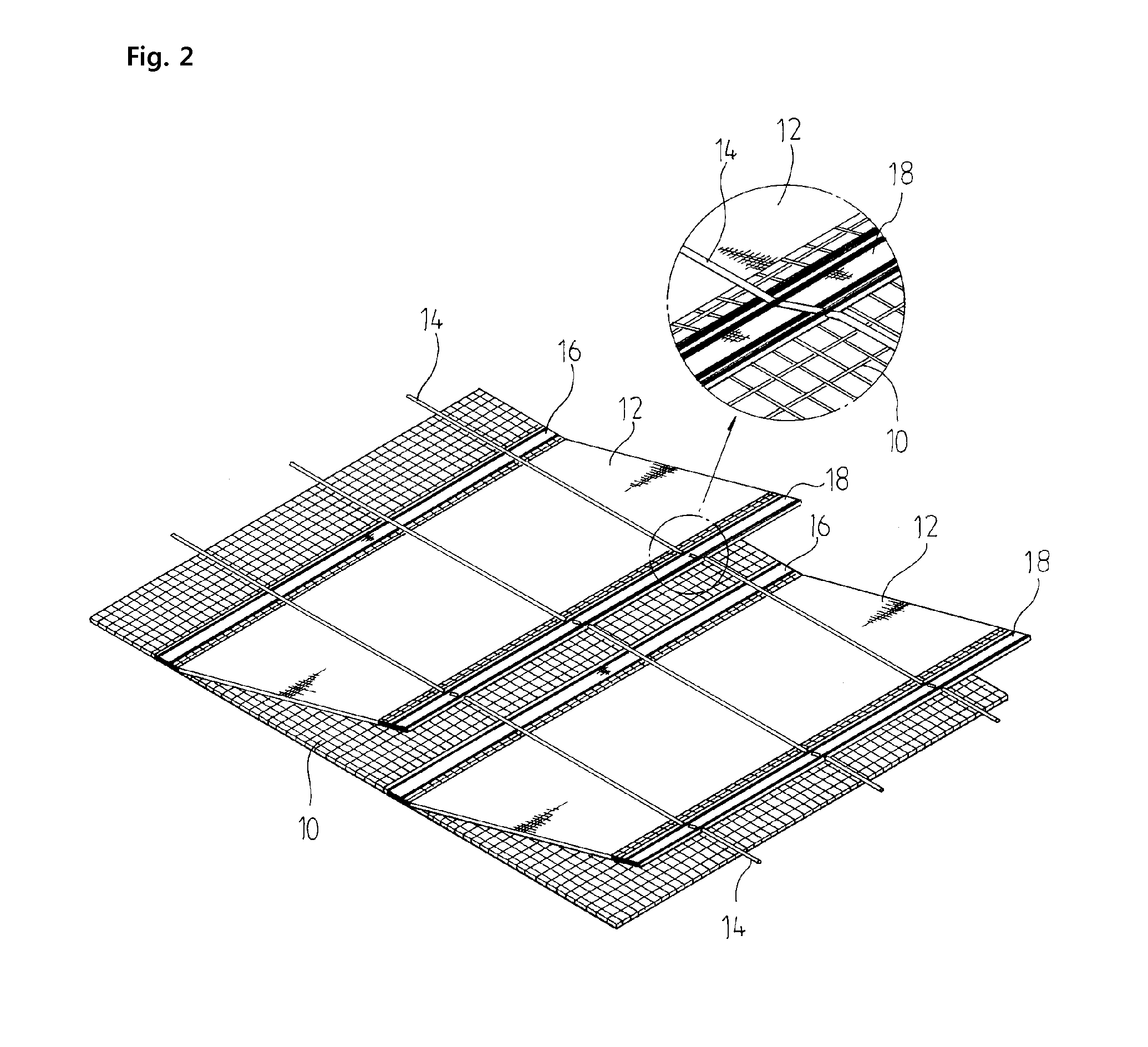

Triple curtain sheet and a window shielding apparatus thereof

InactiveUS20110067821A1Easily control ventilation/floodlighting degreeCurtain suspension devicesLight protection screensTextile yarnEngineering

The present invention relates to a triple curtain sheet for a window shielding apparatus, and wherein when a plurality of blind covers(12) are accumulated on a basic mesh sheet(10), each of upper connecting portions(16) of the plural blind covers(12) opened to a lower side is connected to the basic mesh sheet(10) in crossed-weaving type with textile yarns of the mesh sheet, and a plurality of mutually separated opening / closing-type longitudinal yarns(14) are configured on each lower ream(18) of the blind covers(12) in order to be woven on and combined with textile yarns of the blind covers.

Owner:BYEON TAE WOONG +1

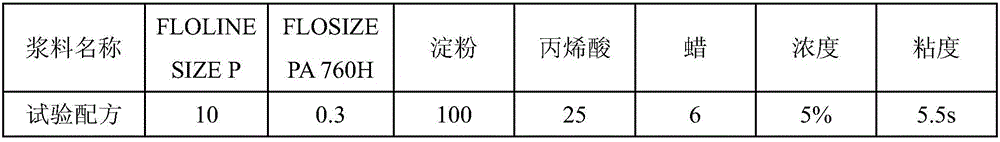

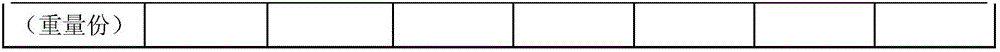

Environment-friendly slurry and sizing process thereof

ActiveCN106245329AGood film formingImprove permeabilityFibre treatmentLiquid/gas/vapor yarns/filaments treatmentEnvironmental resistanceTextile yarn

Belonging to the technical field of textile yarn sizing, the invention in particular relates to an environment-friendly slurry and a sizing process thereof. The environment-friendly slurry includes the following components by weight: 10 parts of FL0LINE SIZE P, 95-105 parts of starch, 22-27 parts of acrylic acid, and 0.2-0.4 part of FLOSIZE PA 760 H. The environment-friendly slurry provided by the invention is conducive to loom moisture regain absorption, the yarn is soft, weaving stop is reduced, the slurry also has good film-forming properties and permeability, can completely replace PVA slurry, and is environment-friendlier. The invention also provides a sizing process of the slurry, and the process consists of: adding the well proportioned components into a mixing bucket in order, performing heating, adding assistants and covering the slurry tightly; then injecting the slurry into a sizing machine size tank, keeping the squeezing roller pressure at 18-21KN, setting the size tank temperature at 90-93DEG C, setting moisture regain at 8.5%, and the sizing machine speed at 55-60m / min, and when the yarn reaches a predetermined length, completing sizing. The slurry provided by the invention is suitable for sizing to all varieties.

Owner:鲁丰织染有限公司

Textile yarn guiding and tensioning device

ActiveCN110294361AEasy to control tensionThere will be no breakageFilament handlingTextile yarnEngineering

The invention provides a textile yarn guiding and tensioning device. The textile yarn guiding and tensioning device comprises a limiting frame, a guide-in device, a tensioning device and output devices. The guide-in device is arranged on the outer wall of the rear end of the limiting frame. The tensioning device is mounted on the middle portion of the limiting frame. The output devices are uniformly arranged on the outer wall of the front end of the limiting frame. Through the textile yarn guiding and tensioning device, the problems that in the existing yarn tensioning process, the tensile force of different thicknesses of yarns is inconvenient to adjust, the yarns are snapped frequently, the production efficiency is affected, the tensioned yarns are inconvenient to wind in the tensioningprocess, the yarns bear too much friction force and are likely to get snapped, and the yarns get loose and the tensioning effect is affected once yarn winding equipment stops operating can be solved.

Owner:SHANDONG HUALUN CHEM FIBER

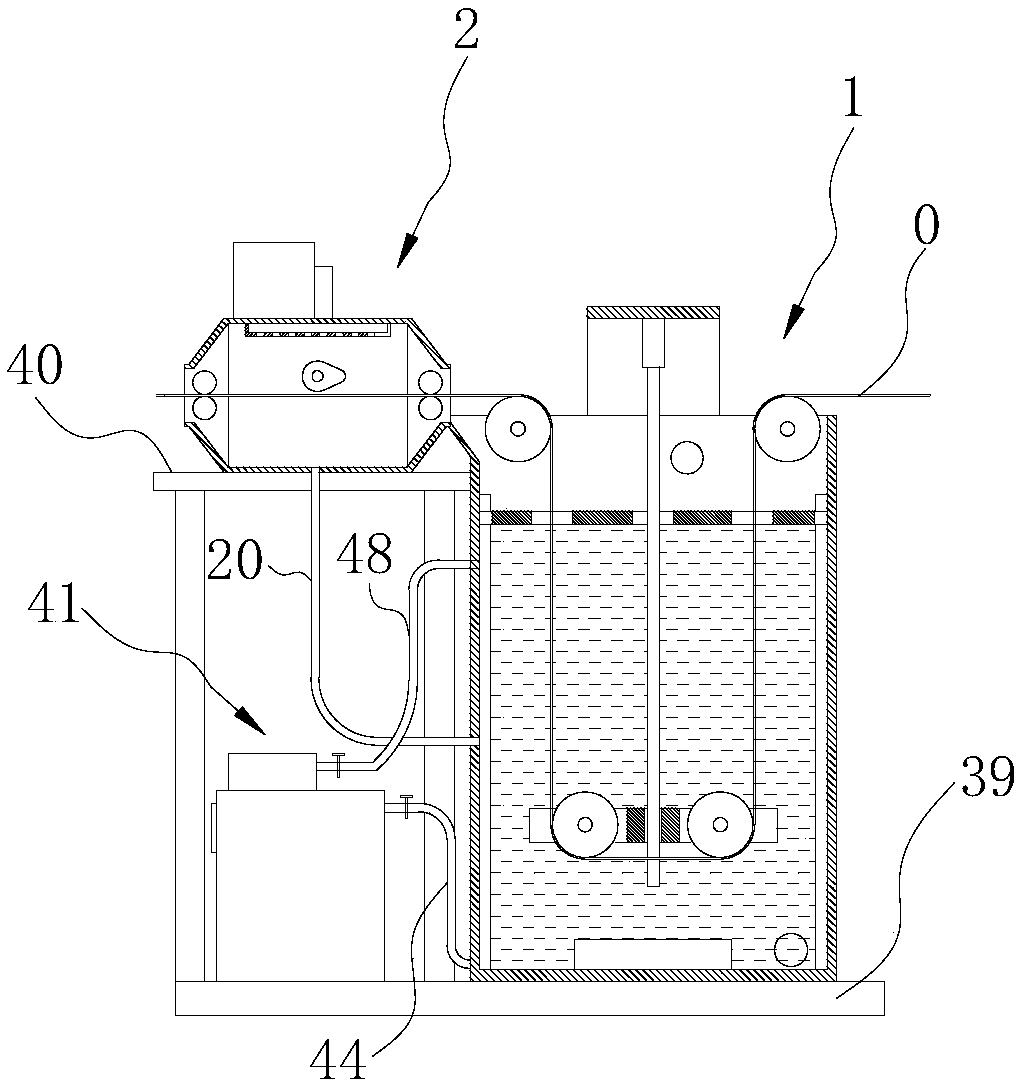

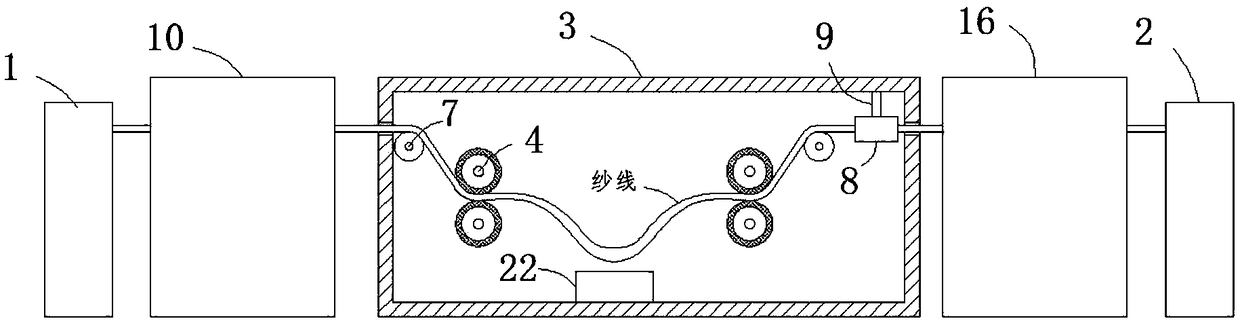

Improved yarn oiling machine

ActiveCN109355839AImprove general performanceImprove versatilityTextile treatment machine arrangementsTextile treatment carriersTextile yarnFuel tank

The invention relates to the technical field of textile yarn processing and aims to provide an improved yarn oiling machine high in universality. The improved yarn oiling machine comprises a dip-dyeing oiling device and a springing-type deoiling device positioned on one side of the dip-dyeing oiling device, and yarn sequentially penetrates the dip-dyeing oiling device and the springing-type deoiling device along the conveying direction; the dip-dyeing oiling device comprises an oil tank with an opening at the top, an outgoing yarn guide roller and an incoming yarn guide roller are arranged left and right sides of the top of the oil tank respectively, and an in-box guide mechanism capable of moving along the up-down direction of the oil tank is arranged in the oil tank; oil is injected in the oil tank, and the yarn sequentially bypasses the upper portion of the incoming yarn guide roller, the lower portion of the in-box guide mechanism and the upper portion of the outgoing yarn guide roller along the conveying direction. The improved yarn oiling machine is suitable for various yarn having different oiling amount needs by changing dip-dyeing stroke of the yarn in oil to change dip-dyeing duration of the yarn, thereby being high in universality.

Owner:纤丝纺特种纤维(苏州)有限公司

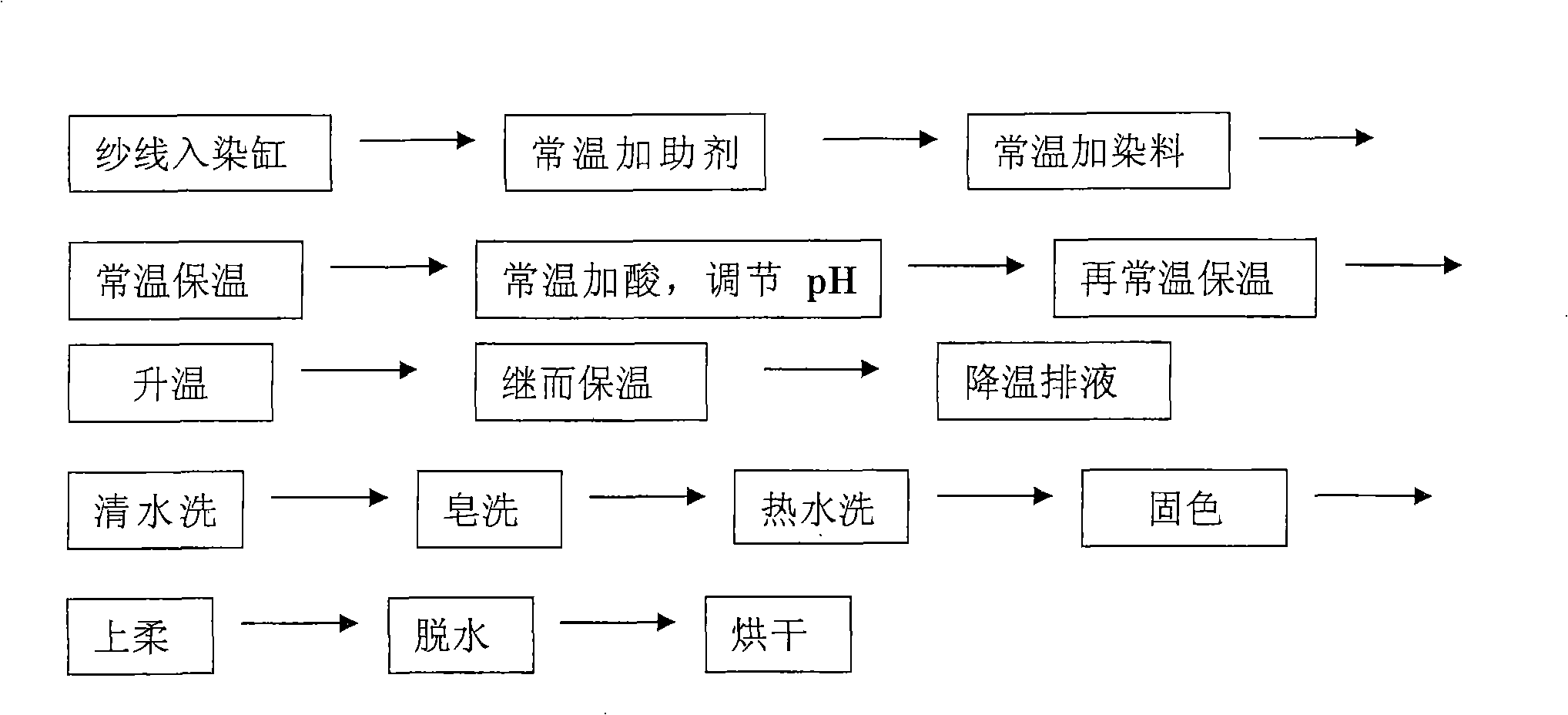

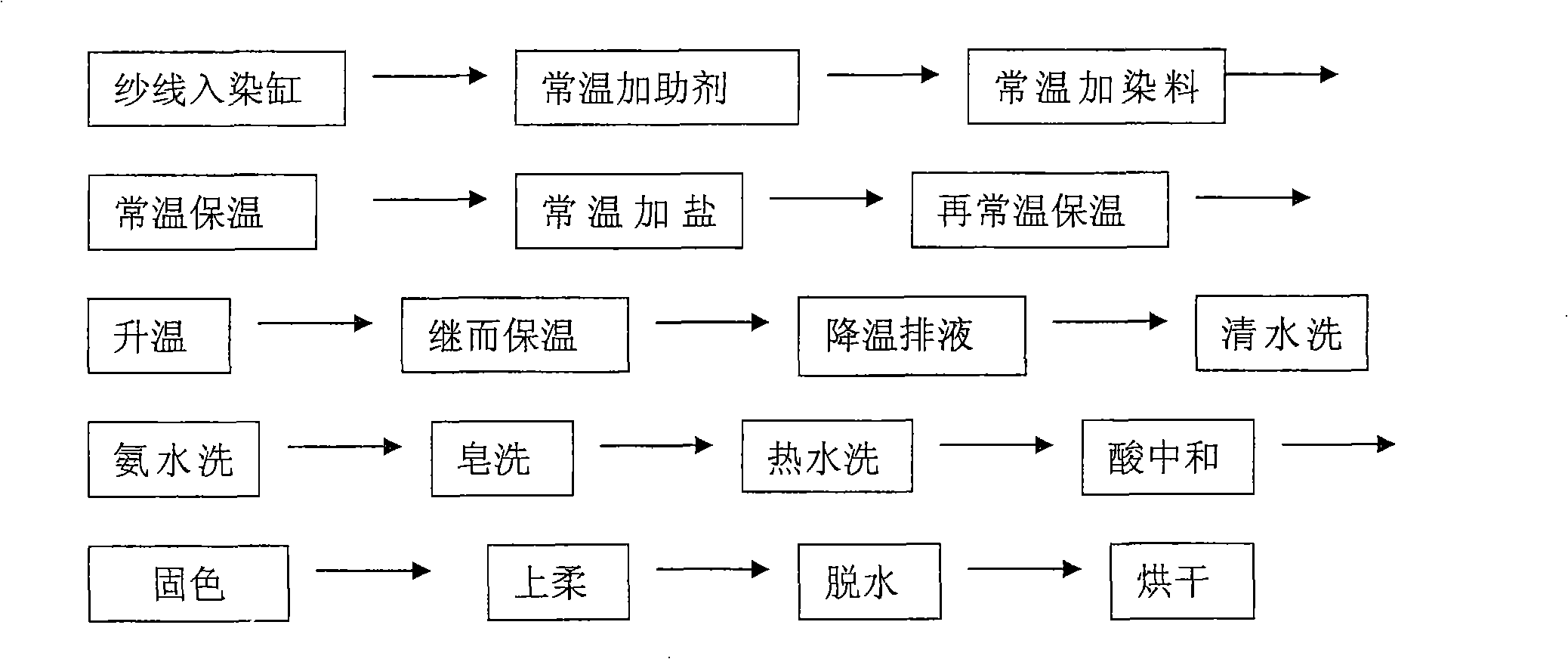

Dyeing technique of silkete unshrinkable wool yarn

The invention relates to a process for dyeing mercerized shrinkproof wool yarn, belonging to the textile yarn dyeing technical field. The process comprises the following steps that: the to-be-dyed mercerized shrinkproof wool yarn which is treated before dyeing is put into a dyeing container; water is added to the dyeing container and the bath ratio is controlled; additives and cotton reactive dyes are added to the dyeing container at the room temperature; the heat of the dyeing container is preserved at the room temperature; salt is added to the dyeing container at the room temperature; then the heat of the dyeing container is preserved at the room temperature; the dyeing container is heated, and the heating speed is controlled; the heat of the dyeing container is preserved; finally, the dyed mercerized shrinkproof wool yarn can be obtained orderly through cooling, liquid discharge, washing through clear water, washing through ammonia water, soaping, washing through hot water, acid neutralization, fixation, softening, dehydration and drying. The process has the advantages that: the dyes used are cotton reactive dyes, which are low in prices and helpful to save cost; the dyes raise the color fastness after dyeing by 1-2 levels, are good in level dyeing property, bright in color and helpful to guarantee product quality; the process is simple, favorable for saving energy and friendly to environment.

Owner:常熟市亨时特染织有限公司

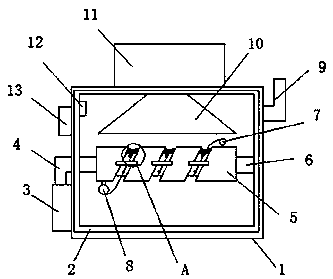

Equipment for uniformly sizing and shaping textile yarn

InactiveCN108642762AImprove sizing effectOptimize sizing and setting effectTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingBristleHeating time

The invention discloses equipment for uniformly sizing and shaping textile yarn, and belongs to the technical field of textile machines. The equipment comprises a yarn unreeling device, a cleaning device, a sizing device, a shaping device and a yarn reeling device; the sizing device comprises a sizing box body, and two stretching double rollers which are symmetric left and right are arranged in aninner cavity of the sizing box body, and are in synchronous transmission through synchronous belt pulleys and a synchronous belt; guide rollers and slurry draining devices are arranged at both outersides of the stretching double rollers, the cleaning device comprises a cleaning box body, a dust collection device, a dust collection hood, a cleaning fixed cover and flexible bristles, and the shaping device comprises a shaping box body; an inner cavity of the shaping box body is provided with shaping adjusting grooves, adjusting screws, guide cylinders and butterfly nuts, and electric heating sheets are arranged at the top, the bottom and the front side wall of the inner cavity of the shaping box body. By means of the equipment for uniformly sizing and shaping the textile yarn, sizing is uniform and sufficient, and the shaping and heating time is adjustable, and the purpose of optimizing the effect of sizing and shaping the yarn is achieved.

Owner:CHANGXING DEHONG MACHINERY CO LTD

Textile yarn oiling machine

The invention relates to the technical field of textile yarn processing and aims to provide a textile yarn oiling machine capable of improving yarn quality. The textile yarn oiling machine comprises adip-dyeing oiling device and a springing-type deoiling device, the springing-type deoiling device comprises a deoiling box, a yarn inlet and a yarn outlet are symmetrically arranged on left and rightsides of the deoiling box and are in the shape of a strip extending along front-rear direction of the deoiling box, a group of yarn conveying rollers driven by a first motor are arranged at each of the yarn inlet and the yarn outlet and composed of an upper roller and a lower roller in up-down arrangement, and a striking roller driven by a second motor for rotary motion is arranged in the deoiling box. By the textile yarn oiling machine, excessive oil after yarn dip-dyeing can be eliminated without causing damage to yarn, and the oil is enabled to seep into yarn fiber deeply, so that qualityof the yarn is improved.

Owner:RUGAO LANTU KNITTING CLOTHING CO LTD

Waxing device for textile processing

ActiveCN107963520ASolve wear and tearSolve the problem of reduced waxing effectFilament handlingWaxTextile yarn

The invention discloses a waxing device for textile processing. The waxing device comprises a body box, and the top and the bottom of the left side of the body box are fixedly connected with a first transverse plate and a second transverse plate respectively. The top and the bottom of one side of the inner wall of the body box are both fixedly connected with support rods, and the bottom of the inner wall of the body box is fixedly connected with a lifting device. The top of the lifting device is fixedly connected with a support plate, and one side of the support plate is connected with one side of the inner wall of the body box through a sliding groove in a sliding mode. One side of the top of the support plate is fixedly connected with a fixed plate, and the top of the support plate is fixedly connected with a wax box. A main plate is connected between the top and the bottom of the inner wall of the wax box through a sliding rail in the sliding mode. The invention relates to the technical field of textile equipment. The waxing device solves the problem that as the current textile yarn waxing machine cannot complexly wind up the waxed yarns after waxing yarns, the yarns are abraded.

Owner:嘉兴久珥科技有限公司

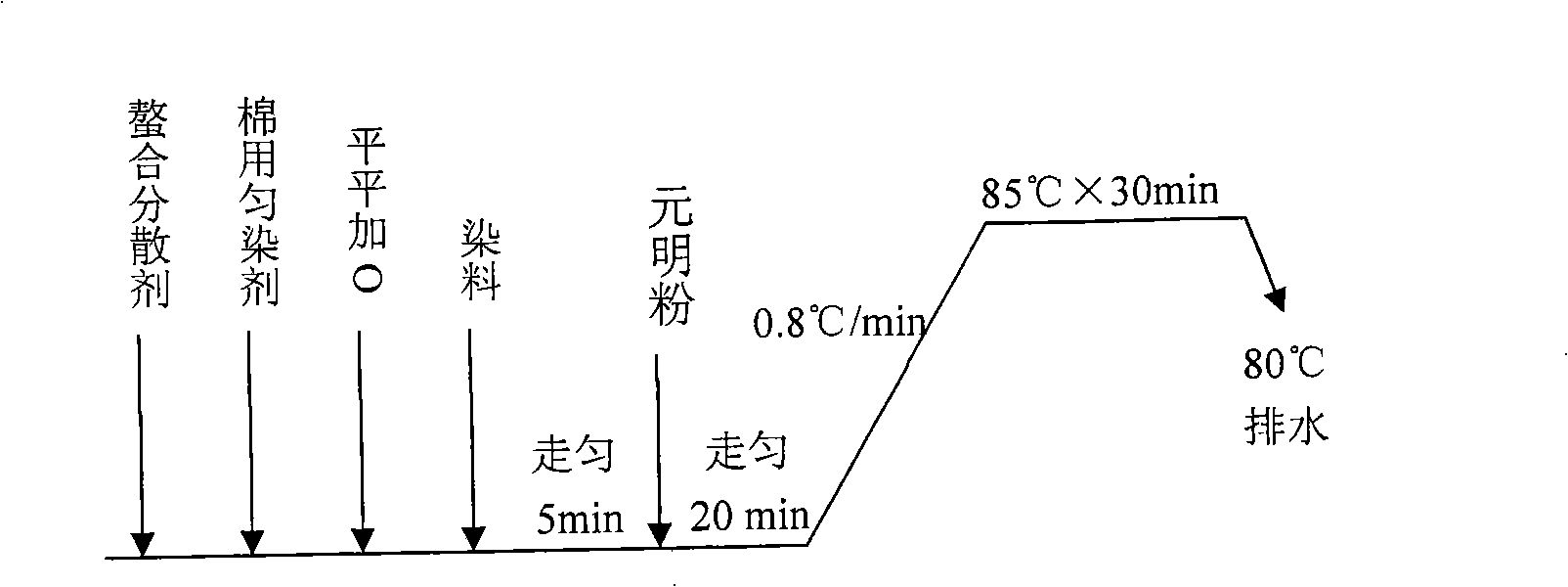

Method for preparing and processing semi-worsted section color slub yarn

The invention relates to the field of textile yarns, in particular to a method for preparing and processing a section color slub yarn, and aims to provide the method for preparing and processing the semi-worsted section color slub yarn that has good comfortableness and a softer hand feeling and enables a fabric style to have an expandable and colorful effect. The method comprises the following steps: step 1, raw material selection: 100 percent of 80S merino wool or 100 percent of 90S mercerized merino wool; step 2, dyeing treatment: proportioning the merino wool or the mercerized merino wool according to a bath ratio of (1:8)-(1:10) at a room temperature and also adding 0.5-1 g / L glacial acetic acid, 0.05-1 g / L Abaige leveling agent B and a reactive dye for the wool from shallow to deep with an adding amount of 0-3 percent, keeping for ten minutes, raising the temperature to 45-55 DEG C by the temperature of 0.8 DEG C per minute, then raising the temperature to 80-90 DEG C by the temperature of 1 DEG C per minute and keeping for 45-60 minutes. Through the method for preparing and processing the semi-worsted section color slub yarn, designed by the invention, a spun yarn fabric strip is strong in irregularity, and rich and outstanding in color, has flowing water-like and corrugated effects, is unique in style and can better meet people's needs.

Owner:浙江中鼎纺织股份有限公司

Textile yarn drying device

InactiveCN107816862ADry evenlyGuaranteed uniformityDrying gas arrangementsDrying chambers/containersThermal energyCoupling

The invention relates to the technical field of textiles, and discloses a yarn drying device for textiles, which includes a body, the top of the body is fixedly connected with a first fixing frame, and one side of the first fixing frame is fixedly connected with a motor. The output shaft of the motor is fixedly connected with a rotating shaft through a coupling, the middle part of the top of the body is inlaid with a bearing, the bottom of the rotating shaft passes through the bearing and extends to the inside of the body, and the bottom of the rotating shaft is fixedly connected with a mounting block . In this textile yarn drying device, the motor works through the rotating shaft to quickly rotate the placement basket, thereby throwing out the moisture inside the yarn on the yarn hanging rod, and at the same time, the blower can blow out the heat inside the heating chamber, and evenly align the yarn The yarn is heated and dried, thereby ensuring the uniformity of yarn drying, improving the utilization rate of heat energy, reducing the waste of heat, thereby saving production costs, and the drying of spinning yarn is relatively uniform, which improves the quality of the product , thereby improving production efficiency.

Owner:宿迁至诚纺织品股份有限公司

All-dimensional rotating guide roller structure for textile machine

The invention discloses an all-dimensional rotating guide roller structure for a textile machine. The all-dimensional rotating guide roller structure comprises a guide roller body. A spherical universal steering structural member is arranged at the top end of a steering lever. The outside of the universal steering structural member is connected with a supporting plate. A bearing plate is horizontally arranged on the upper portion of the supporting plate. The supporting plate and the bearing plate are connected through elastic stretching sensors. An alarm apparatus and a controller are further arranged at the outer side of the bearing plate. The input end and the output end of the controller are connected with the data output ends of the elastic stretching sensors and the control end of the alarm apparatus correspondingly. According to the all-dimensional rotating guide roller structure for the textile machine, the spherical universal steering lever is adopted, so that steering is made convenient and smooth, the working face of a guide roller can make full contact with textile yarns all the time, and measuring is made accurate by matching the sensing ends of the elastic stretching sensors; and moreover, an alarm can be given out in time when silk yarns are excessively stressed, and thus the phenomenon of yarn breaking can be avoided.

Owner:XIANGSHUI BAOJI TEXTILE

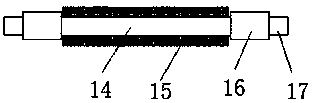

Spinning roller capable of removing burrs on surface of yarn

The invention relates to a spinning roller capable of removing burrs on the surface of a yarn. The spinning roller comprises a round roller, a scraping unit, a cleaning unit and the spinning yarn, wherein the scraping unit is mounted at the right end of the round roller, the cleaning unit is arranged in the round roller, and the spinning yarn is placed on the round roller and the scraping unit. Bysimultaneously performing left-and-right reciprocating scraping on the yarn, the scraping effect is enhanced in a rotating mode, the burrs on the spinning yarn are basically removed, and meanwhile, alarge amount of floating hairs is removed; and the surface of the spinning yarn is cleaned through a brush to remove the floating hairs adhered to the spinning yarn by hooking, so that removal of theburrs on the surface of the yarn is completed through improvement of the roller and one process is omitted.

Owner:佛山维彩纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com