Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Small denier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

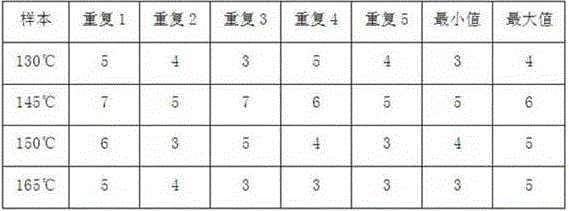

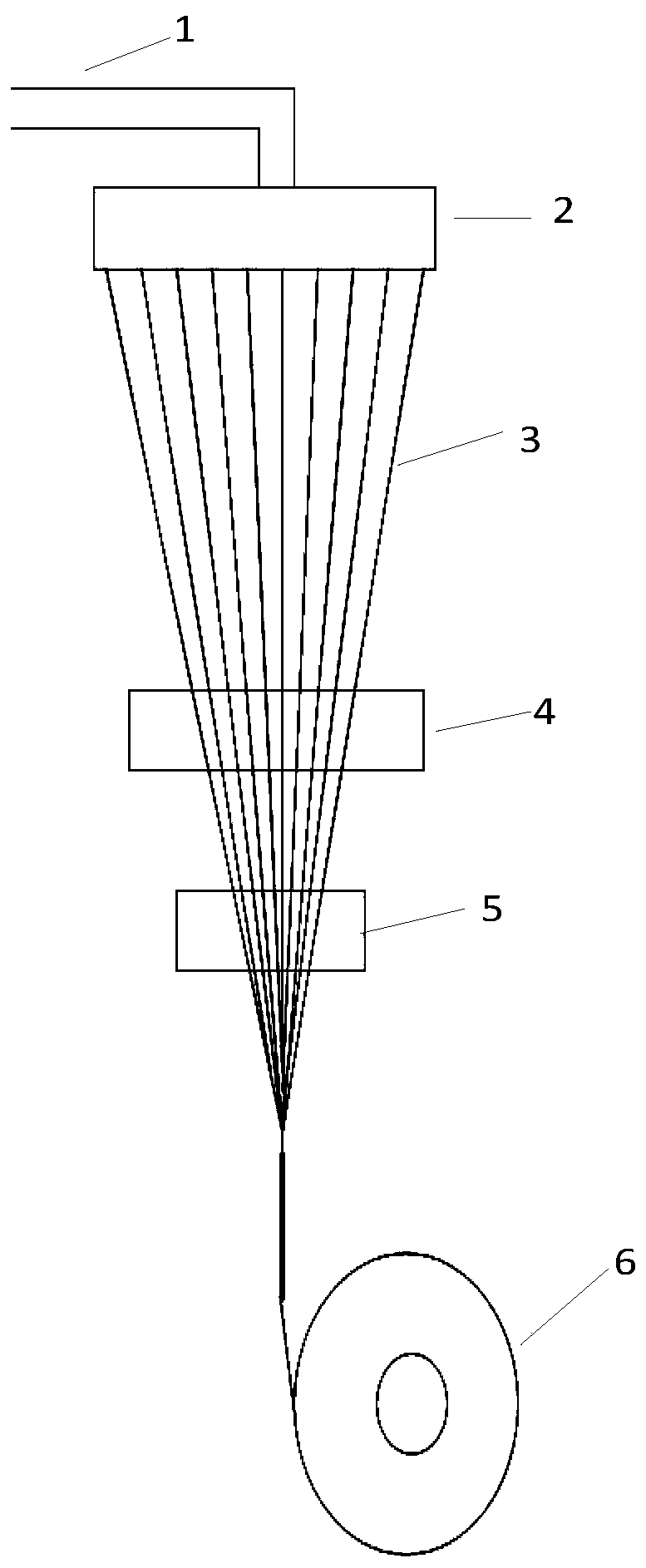

Cellulose fiber, preparation method thereof and equipment

ActiveCN102477591AHigh strengthSmall denierArtificial filaments from cellulose solutionsArtificial thread manufacturing machinesPolymer scienceSpinning

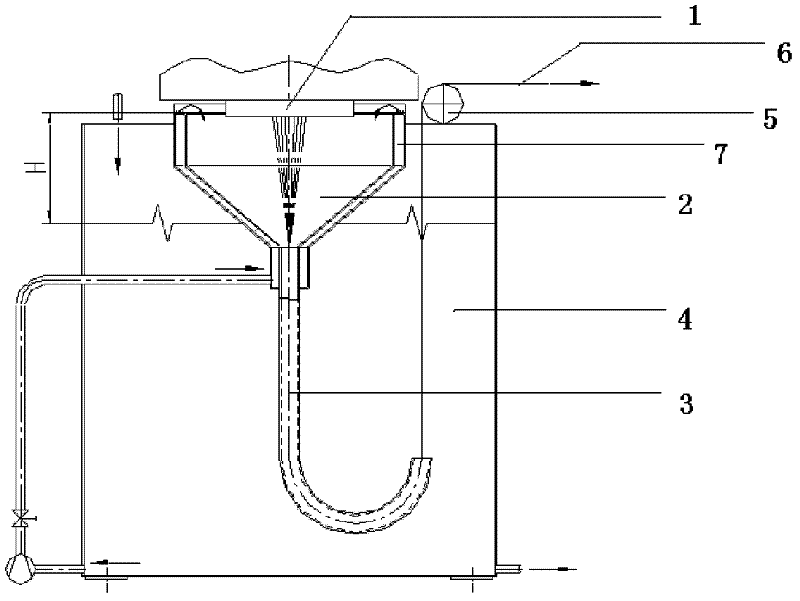

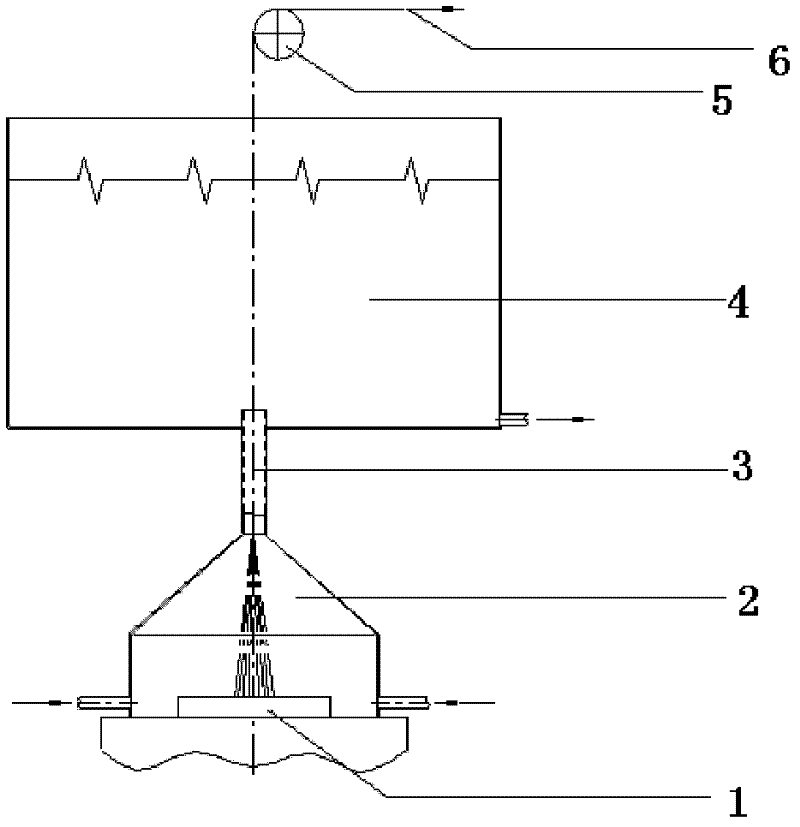

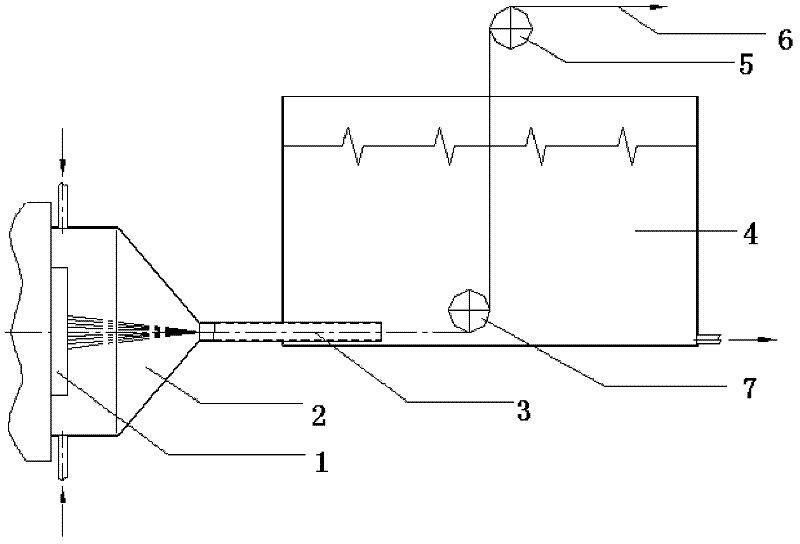

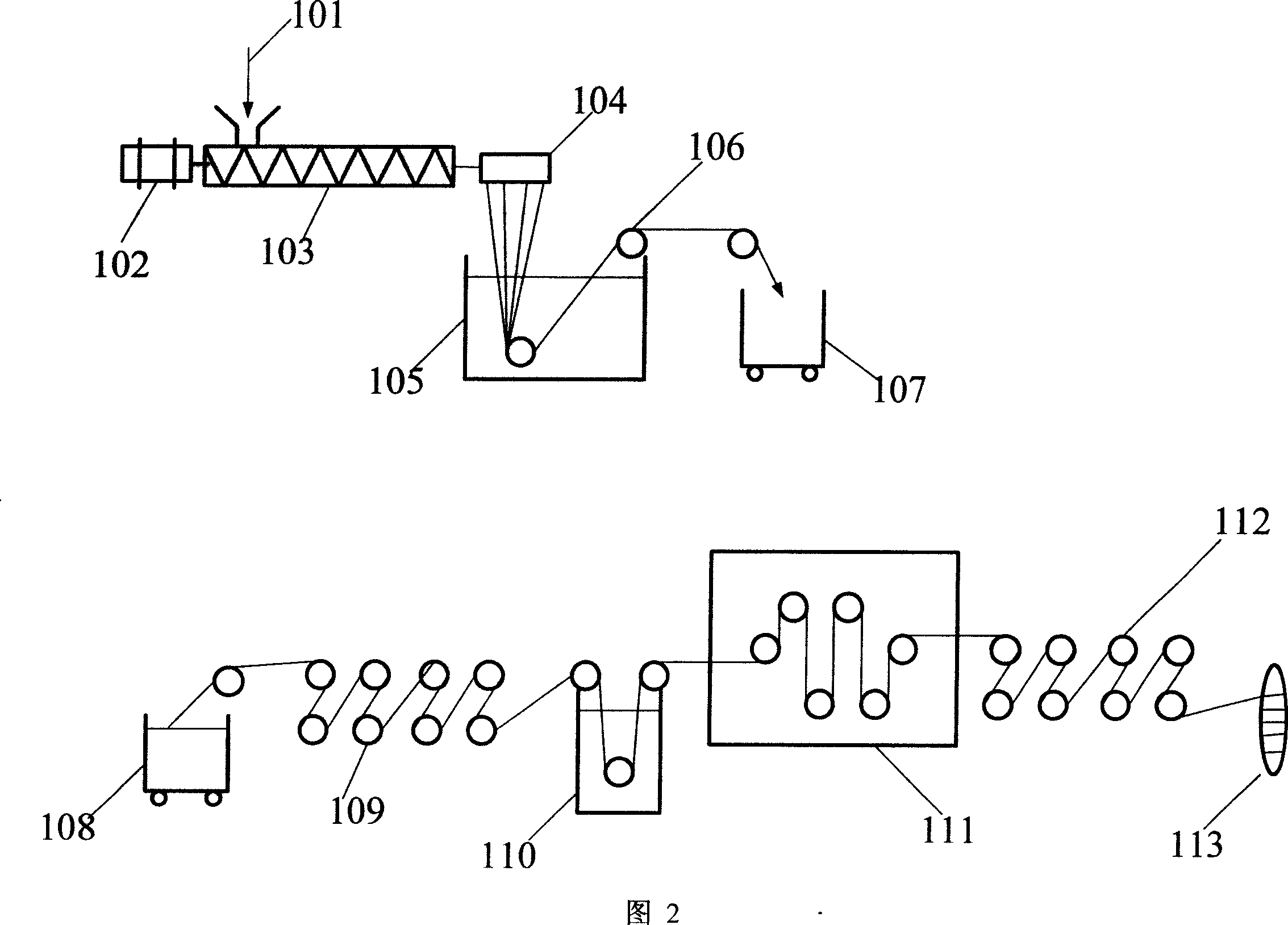

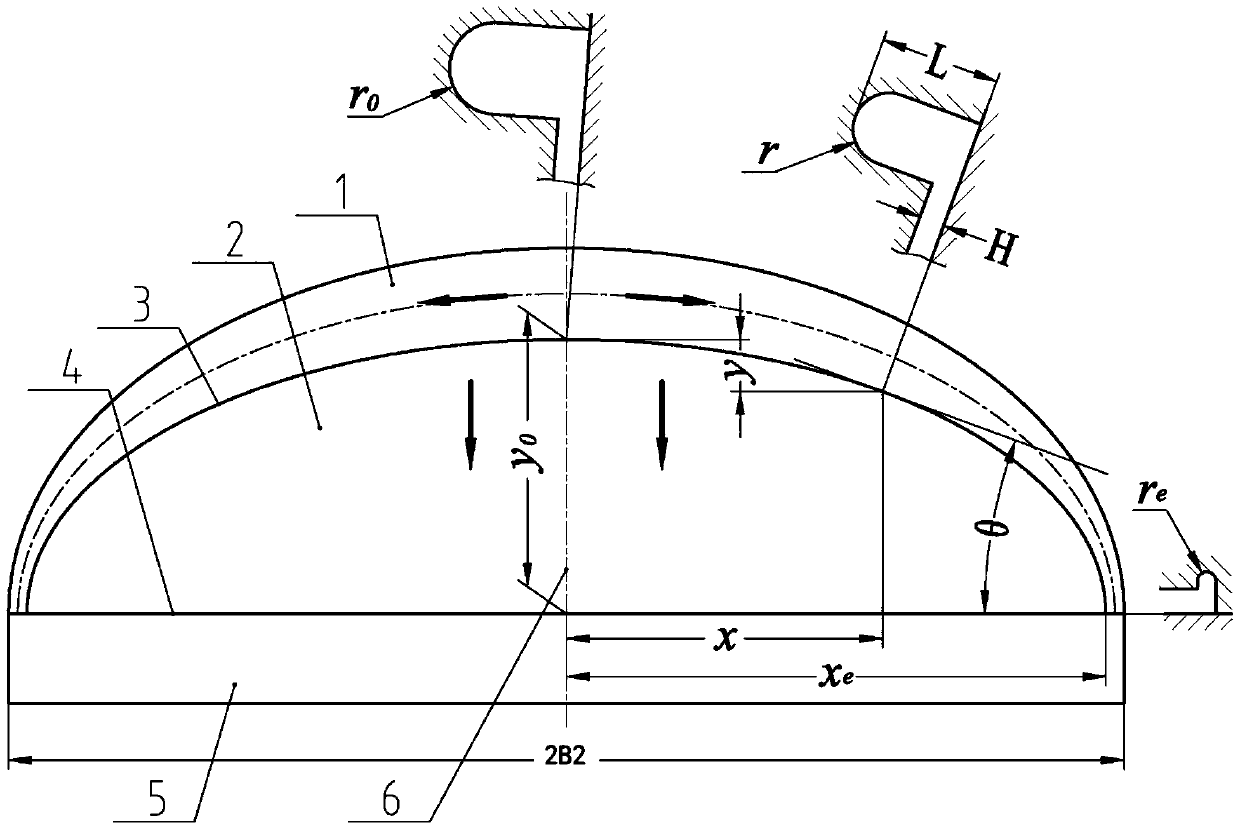

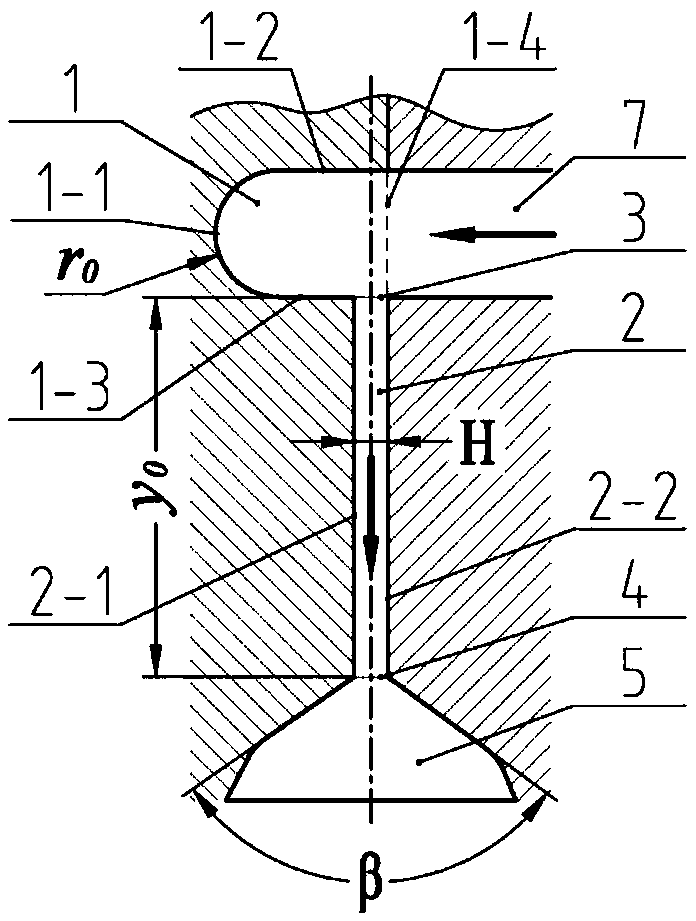

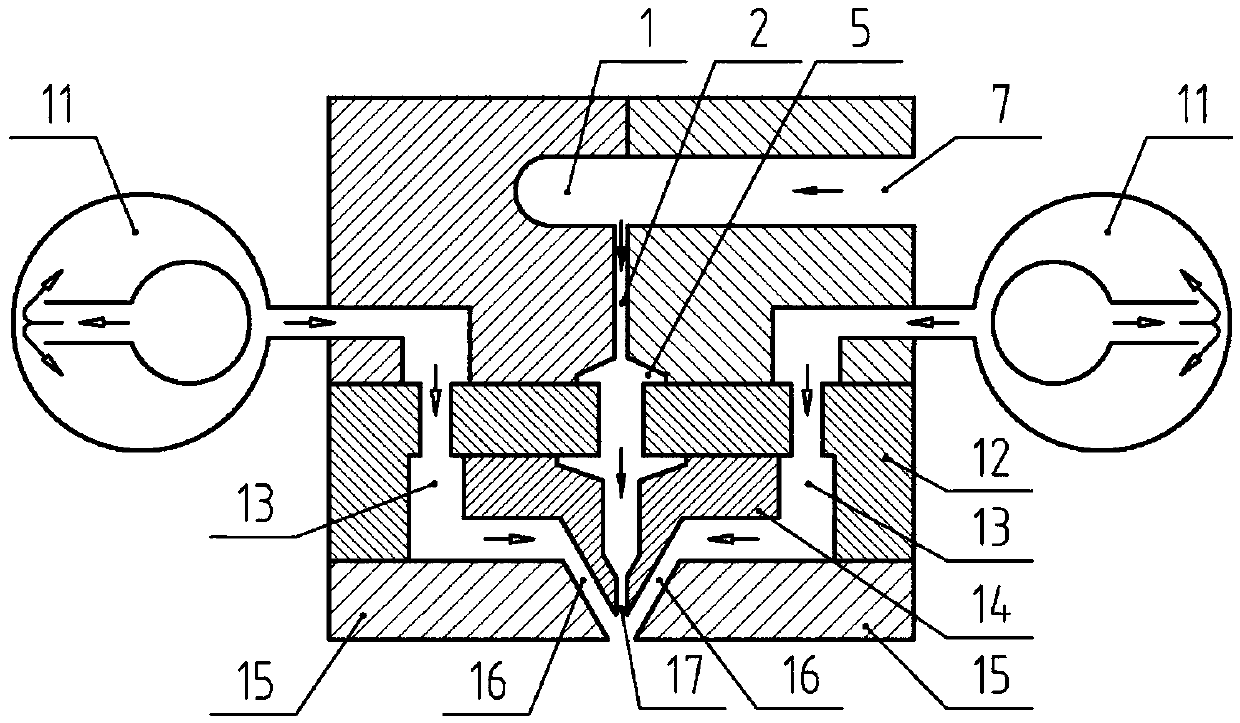

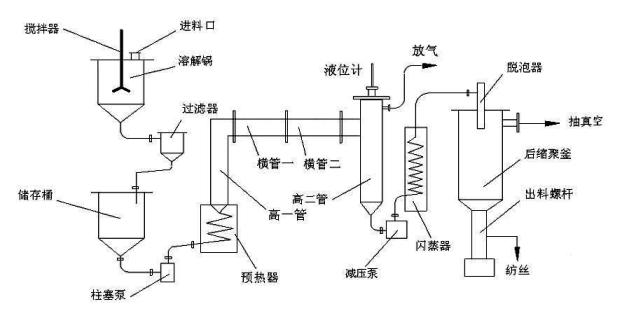

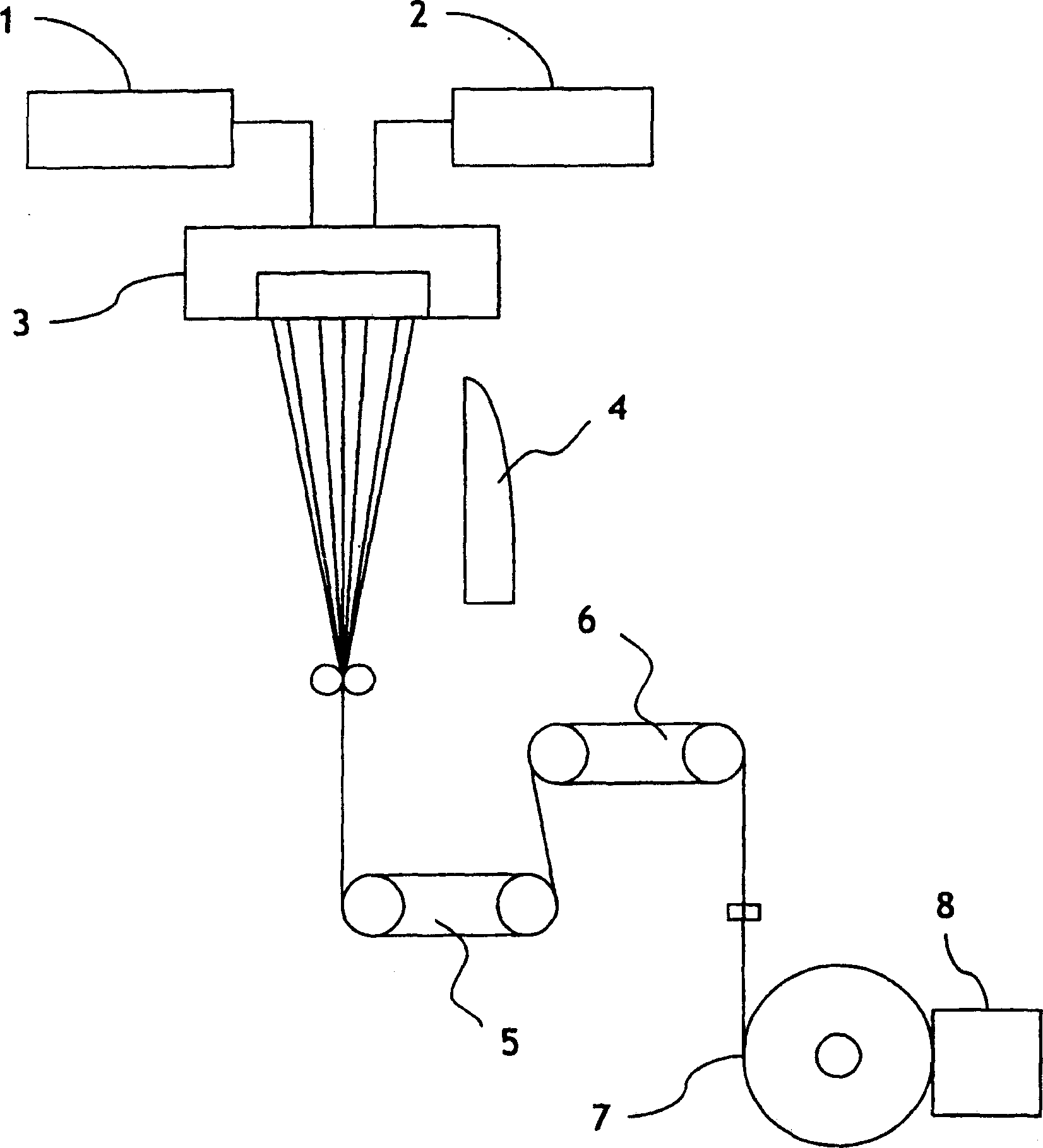

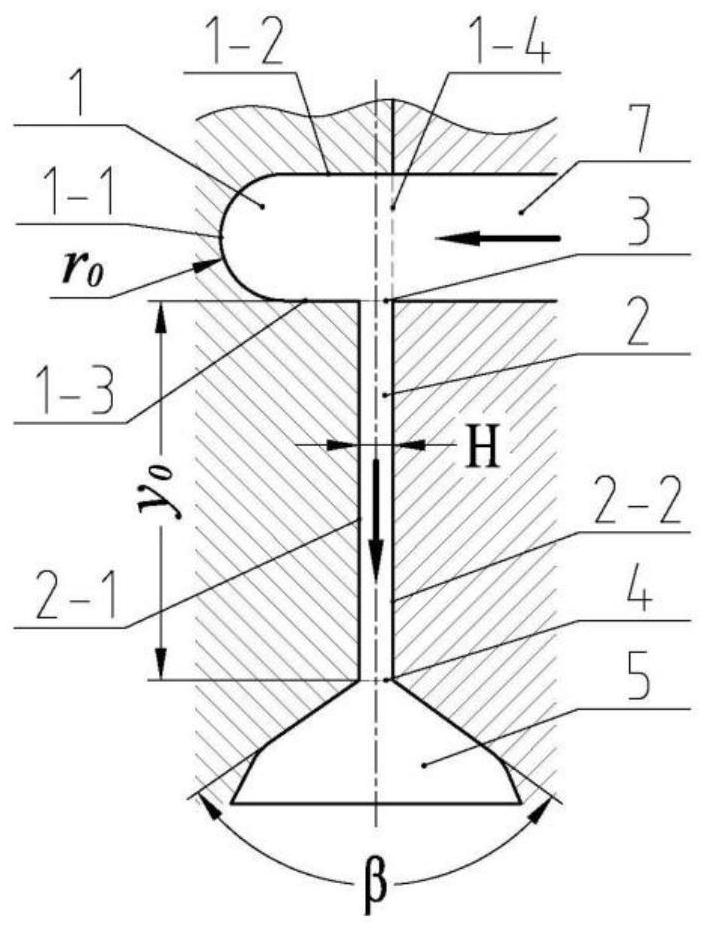

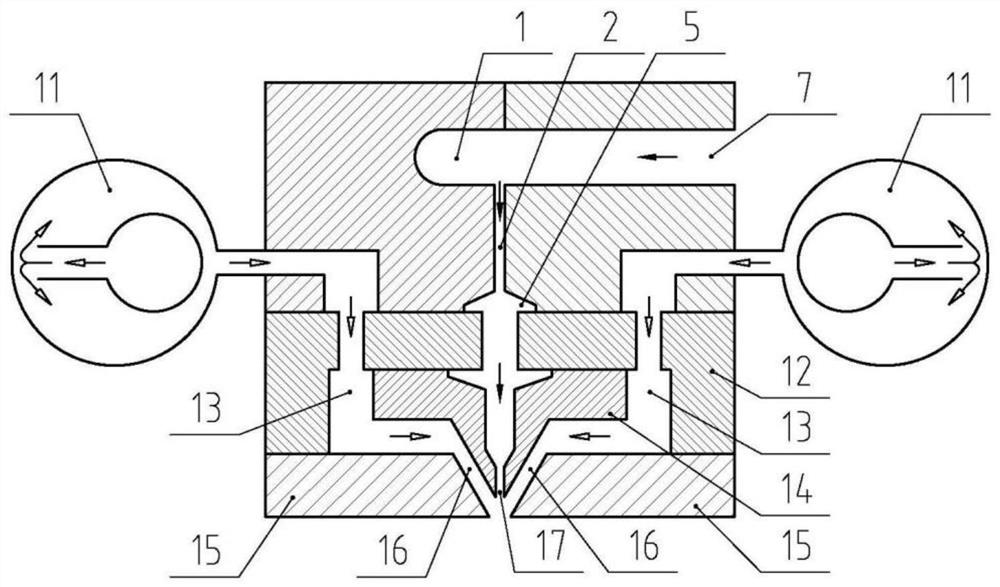

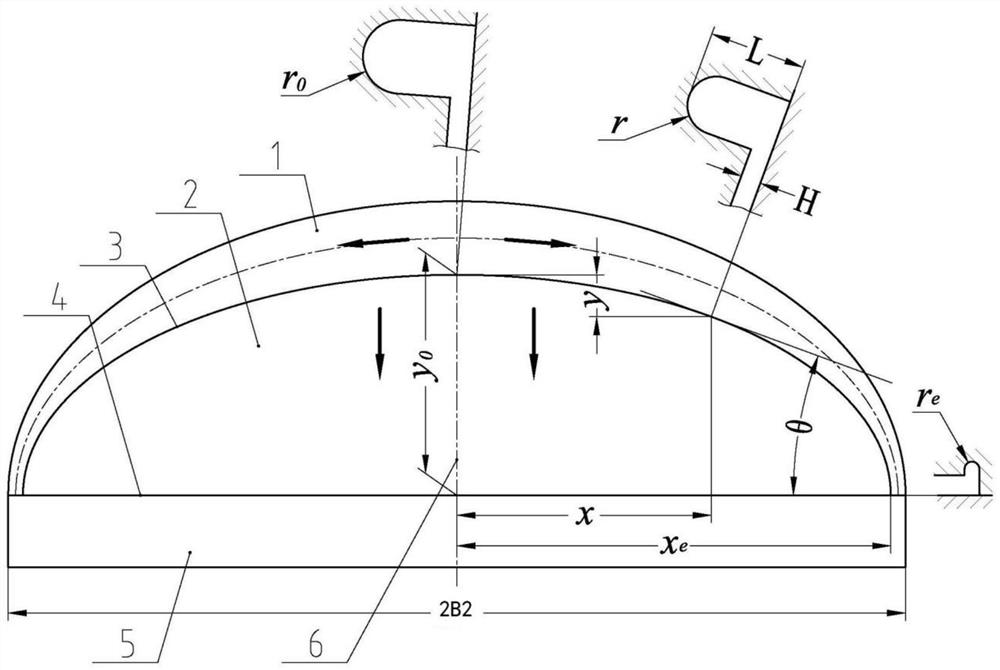

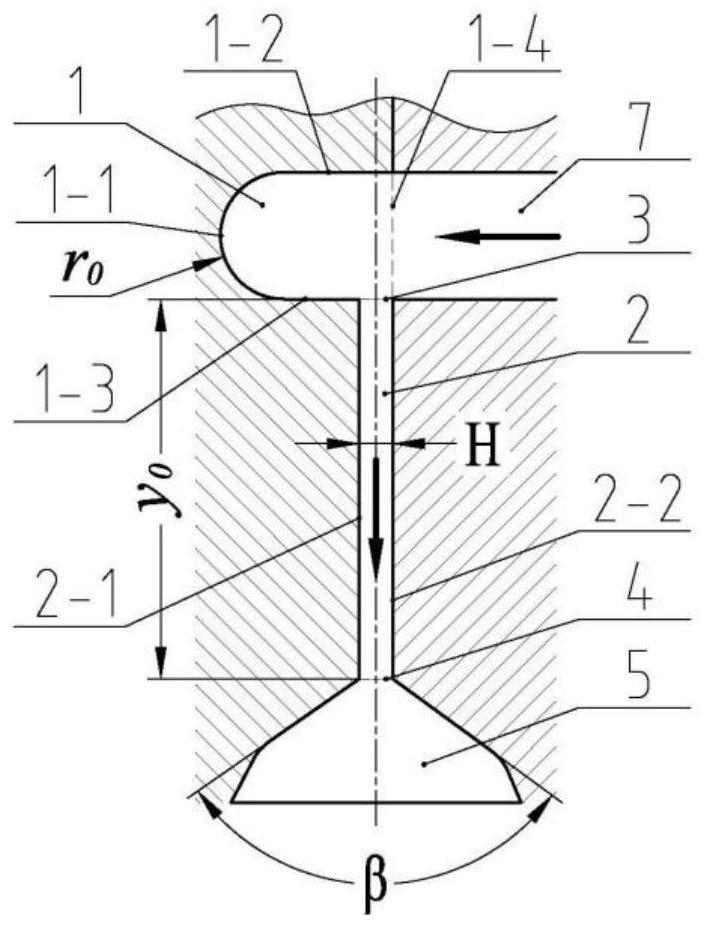

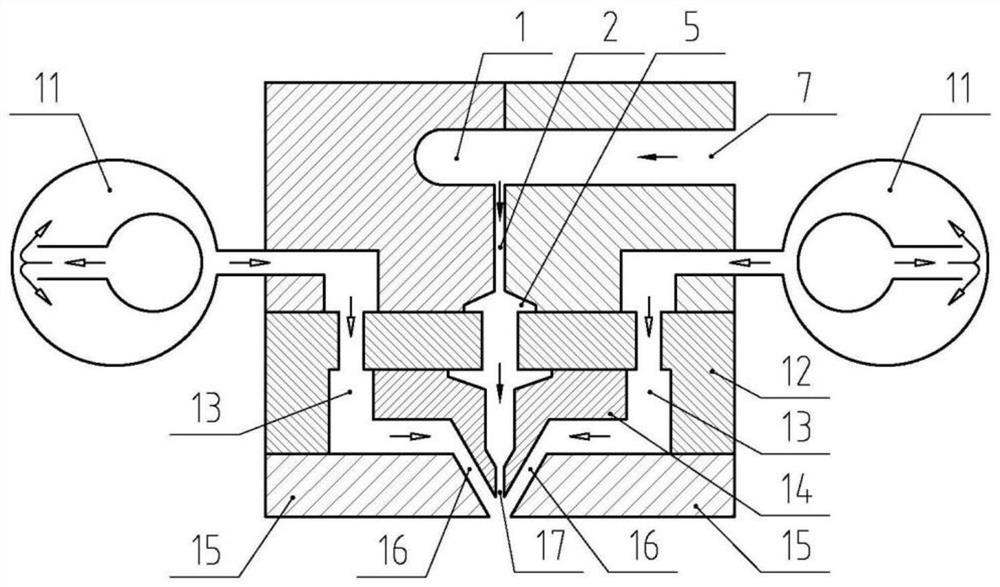

The invention relates to the field of chemical fibers, in particular to a cellulous fiber, a preparation method thereof and equipment. The cellulose fiber mainly comprises cellulous, is prepared by the solidifying liquid co-current drawing and spinning technology, and meets the following conditions that the tension breakage strength of the fiber is higher than or equal to 2.0cN / dtex, the fineness of the fiber is equal to or smaller than 1.67dtex, the content of S elements in the fiber is smaller than or equal to 100ppm, the fibrillation index (F.I.) of the fiber is smaller than or equal to 2. In addition, the cellulose fiber is free of chemical compositions relevant to fibrillation treatment resistance. The invention further relates to the preparation method of the cellulous fiber and the equipment. The cellulose fiber is high in strength, low in fineness and free of fibrillation tendency, the preparation method is simple, and is easy to control and applicable to large-scale industrialized production, and the equipment is simple in structure, skillful in design and stable in condition.

Owner:CHINESE TEXTILE ACAD

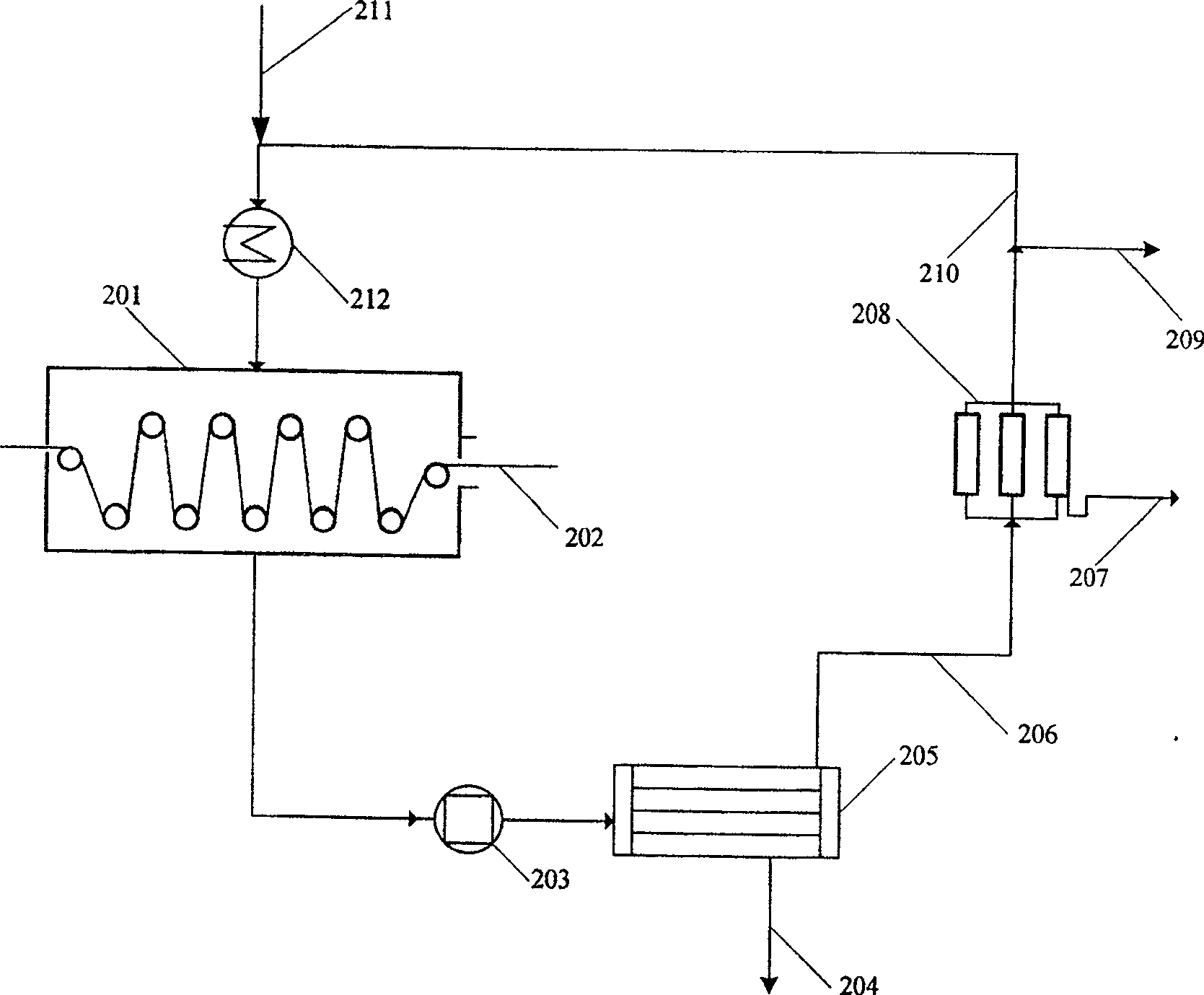

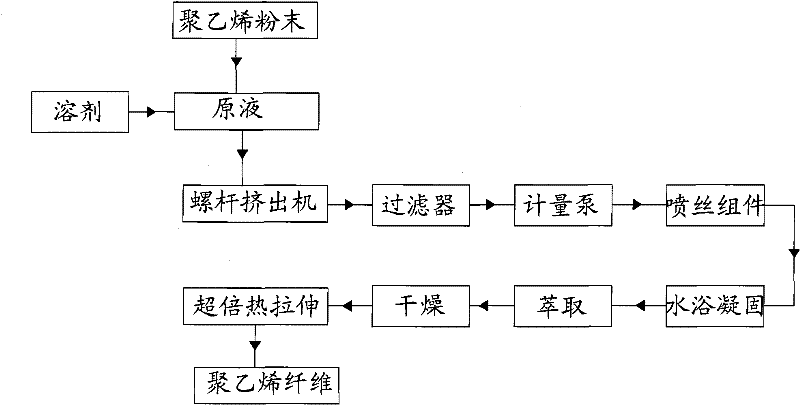

Extraction and desiccation method in preparing process of polyvinyl fibre with super high molecular weight

ActiveCN101012577AReduce oil contentHigh strengthArtificial filament washing/dryingMonocomponent polyolefin artificial filamentFiberPolymer science

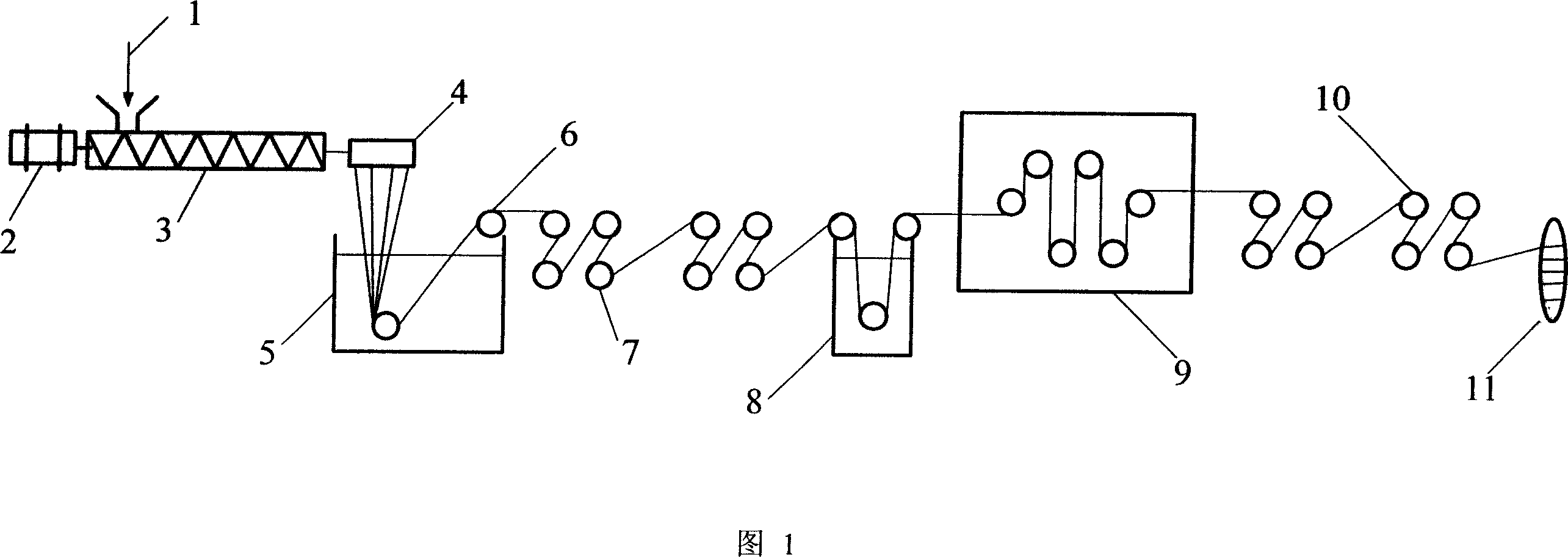

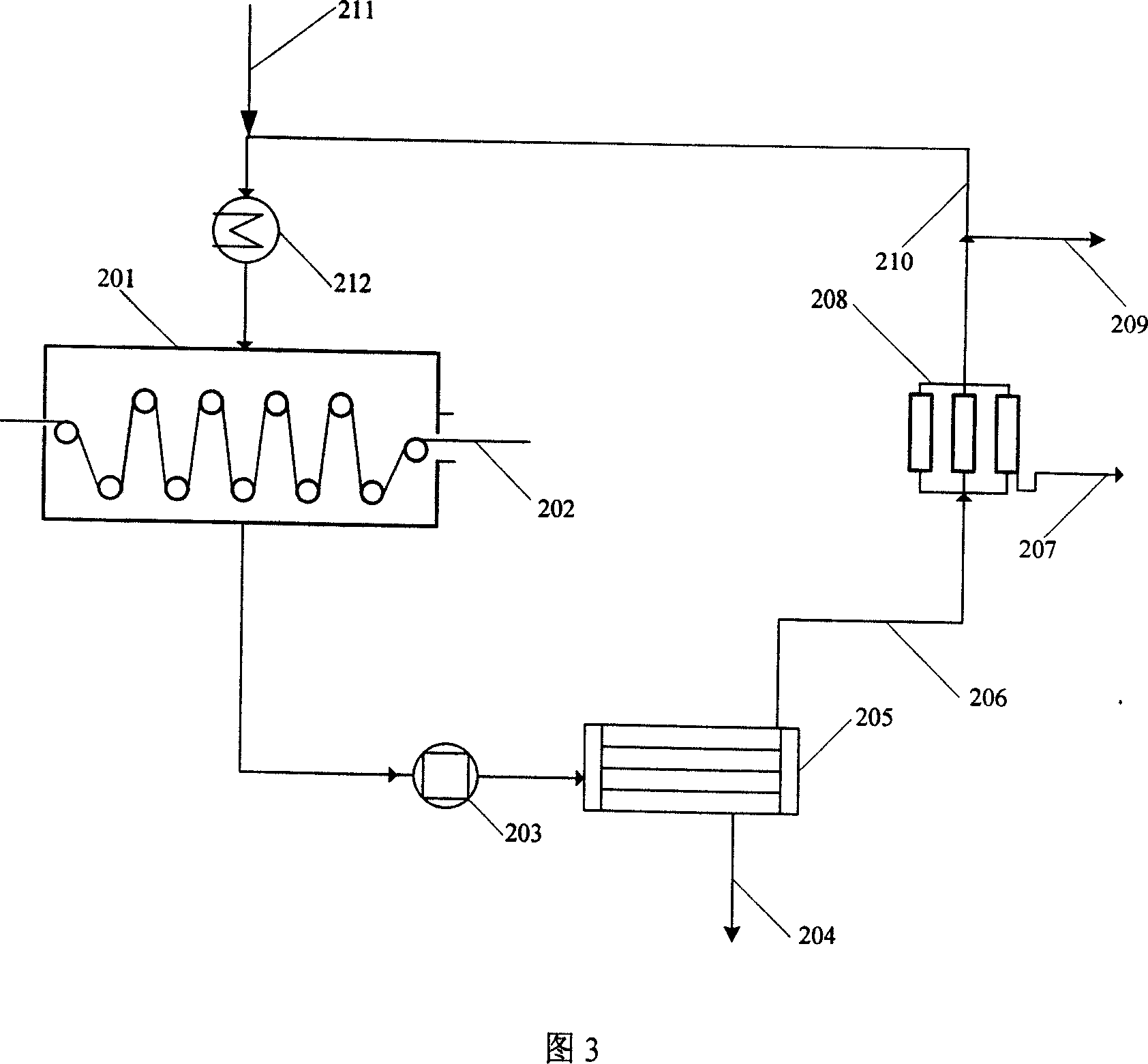

The invention relates to extracting and drying methods in the process for preparing uhmwpe fiber, belonging to the field for polymers preparing technology. The method comprises that the uhmwpe powder, assistant and solvent is solidified by extruding after they are mixed in uniformity and solved sufficiently; the solvent is eliminated in extracting process and the extraction agent is eliminated by drying technology; the final product is formed by heat drawing. It is characterized in that because dichloromethane is used as the extraction agent, there is good safety, low boiling point and it is eliminated easily. Because countercurrent extraction operation is adopted in the extracting process and there is no ultrasonic wave, it is provided with low drying temperature, simple technology, high intensity of fiber product, high modulus and low oil percentage of fiber.

Owner:安徽威亚新材料技术有限公司

Solidification method for preparing para-aramid by adopting dry jet-wet spinning

InactiveCN104451935AIncrease productivityIncrease production speedArtificial filament washing/dryingWet spinning methodsUltimate tensile strengthAramid

The invention provides a solidification method for preparing para-aramid by adopting dry jet-wet spinning. The method is characterized by comprising the following specific steps: extruding a PPTA-H2SO4 spinning solution from a spinneret plate; enabling liquid flow extruded from the spinneret plate to vertically pass through an air layer and feeding to a solidification bath; leading out through a godet wheel, so as to obtain a nascent fiber; and washing, winding and drying, so as to obtain a para-aramid fiber precursor, wherein the solidification bath is sulfuric acid solution and is formed by sulfuric acid and water; the mass fraction of the solidification bath is 2.0%-15.0%; and the temperature of the solidification bath is 1-12 DEG C. The fineness of the fiber can be significantly reduced under the condition of the solidification bath; the strength of the para-aramid fiber is improved; the apparent defects of the fiber can be reduced; and the fiber quality is improved, thus the stability of a spinning process and the quality of a fiber product can be effectively improved.

Owner:DONGHUA UNIV

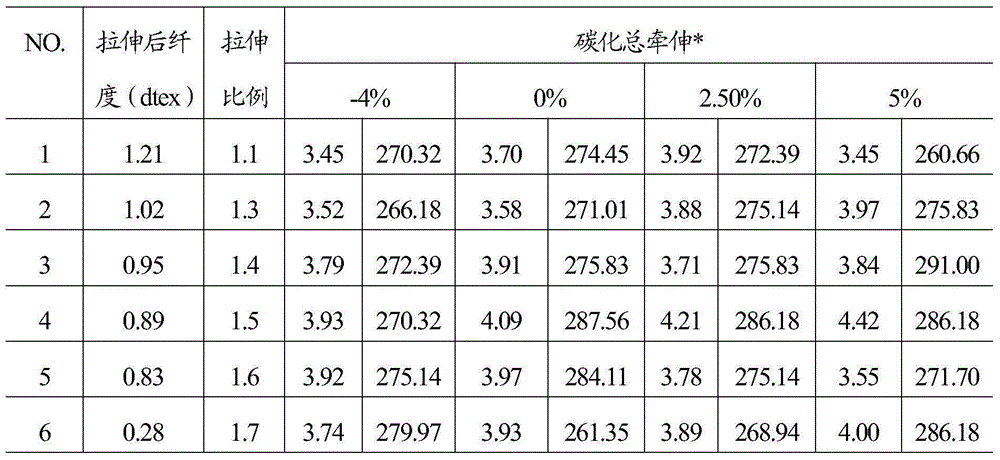

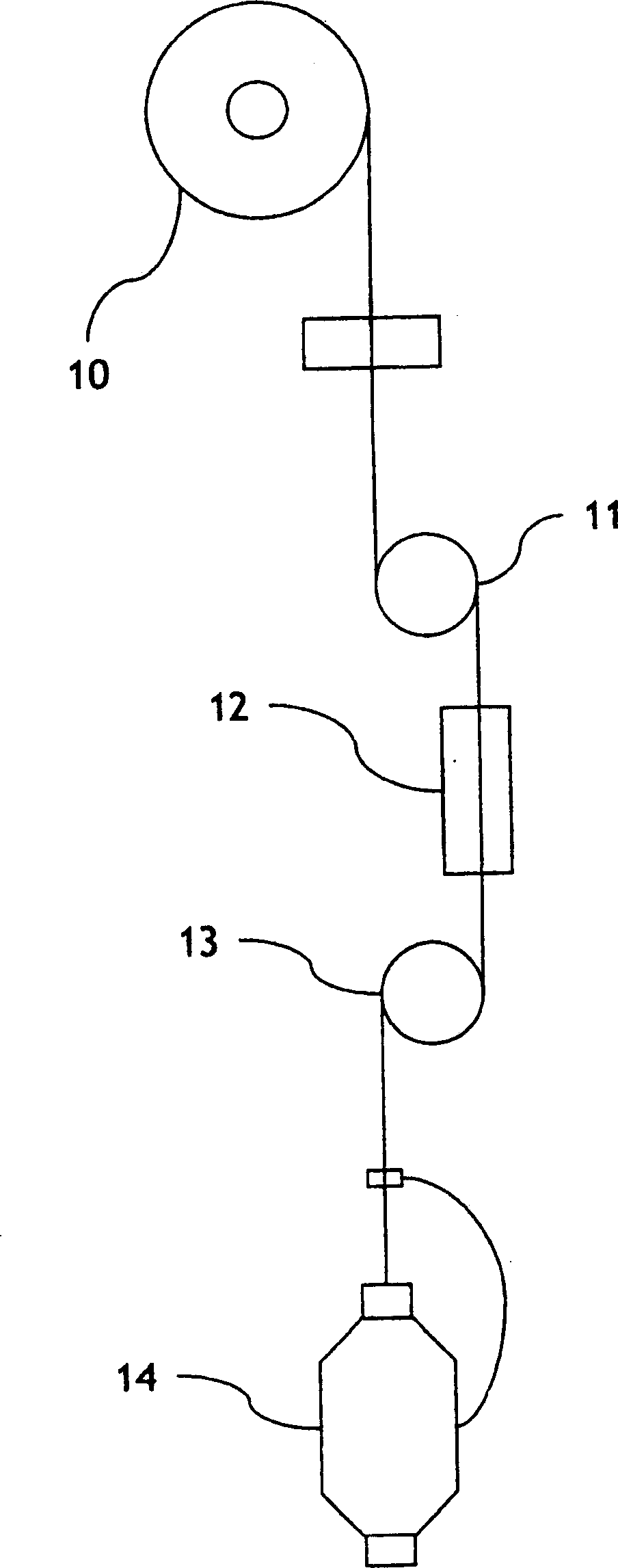

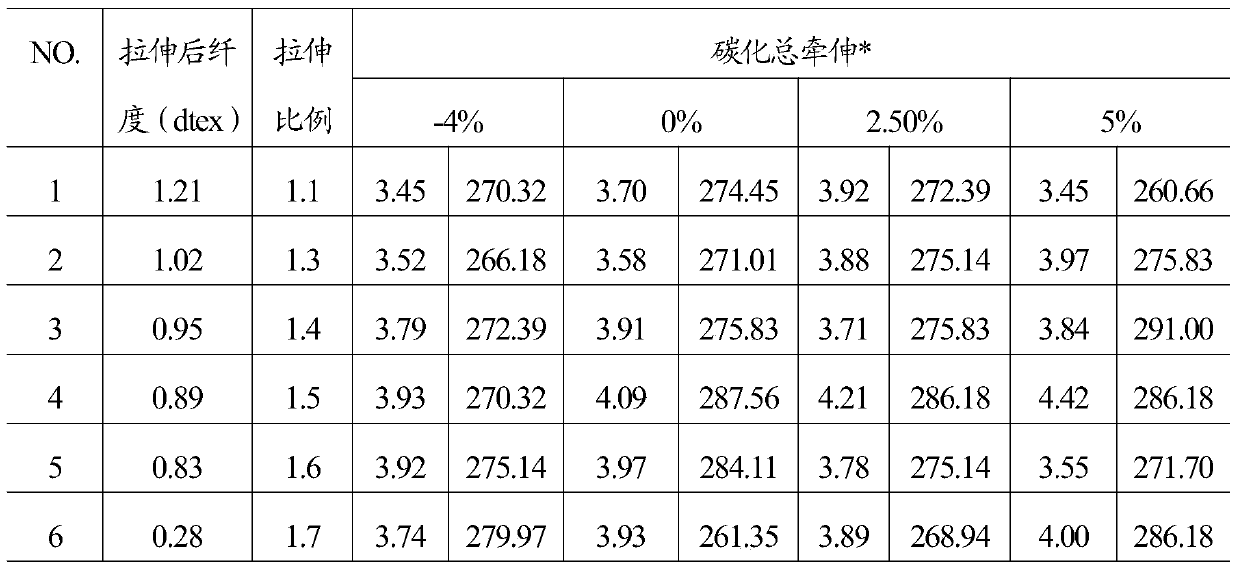

Method for preparing high-modulus carbon fiber by adopting precursor drawing technology

InactiveCN105200566AReduce microstructural defectsImprove mechanical propertiesArtificial filament chemical after-treatmentVitrificationCarbon fibers

The invention relates to a method for producing a high-modulus carbon fiber by adopting a precursor drawing technology. The method comprises the following steps: preparing a spinning solution, carrying out the wet-method spinning, solidifying a nascent fiber, drawing in steam, stretching a precursor to precursor fiber, pre-oxidizing the fiber, and carbonizing the fiber. By adopting the method, the defect of a micro structure in the fiber precursor preparation process can be effectively reduced, compared with the process which does not utilize the process, the orientation degree of the pre-oxidized fiber is further improved, and the mechanical performance of the carbonized fiber is remarkably improved; since the fiber is re-stretched at a temperature above a vitrification temperature, the fiber fineness is reduced, the specific surface area is increased in the high-temperature treatment process, and the thermal treatment efficiency is effectively improved; by virtue of the process, the fiber quality is obviously improved.

Owner:THE NORTHWEST RES INST OF CHEM IND

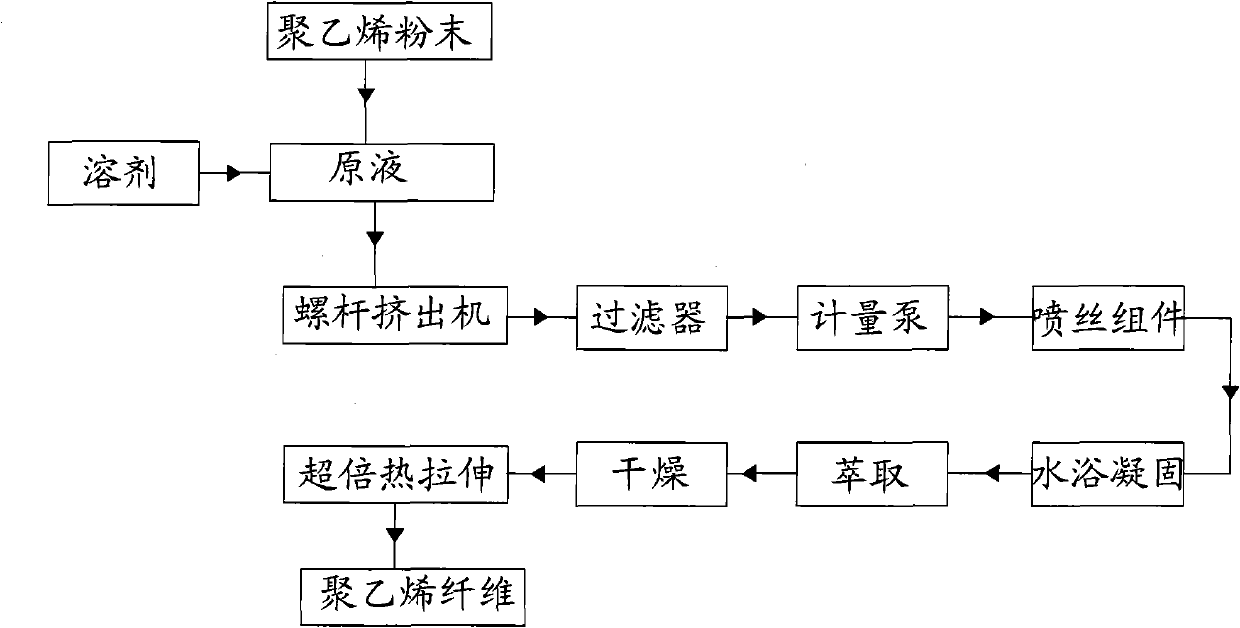

Preparation method of ultrahigh molecular weight polyethylene fiber

ActiveCN101768786AReduced breaking strengthReduce dosageWet spinning methodsMonocomponent polyolefin artificial filamentUltra-high-molecular-weight polyethyleneFiber

The invention relates to a method of preparing ultrahigh molecular weight polyethylene fiber through gel spinning method. The method comprises the following steps: (1) preparing gel protofilament of ultrahigh molecular weight polyethylene; and (2) processing the gel protofilament through extracting, drying and hot drawing to obtain the ultrahigh molecular weight polyethylene fiber. The method is characterized in that the method also comprises the step of pre-drawing the gel protofilament obtained in the step (1) before the step (2), wherein the pre-drawing time is 2.2-24 times and the total hot drawing time in the step (2) is 30-45 times. The method of the invention can be used to obtain ultrahigh molecular weight polyethylene fiber product with low size and high breaking strength and the production cost is low.

Owner:CHANGSHU SUPERFIBER

Superfine dacron low stretch yarn and preparation method thereof

ActiveCN107988649AEasy to spreadImprove fiber qualityFibre typesMonocomponent copolyesters artificial filamentPolyesterYarn

The invention relates to a superfine dacron low stretch yarn and a preparation method thereof. Modified polyester fusant is subjected to metering, extrusion, cooling, oiling and winding to prepare POYyarns; the POY yarns are subjected to yarn guide tube passing, networking, heating stretching, false twisting, heat setting and winding formation to prepare DTY yarns, i.e., the superfine dacron lowstretch yarn is obtained. During cooling, the longitudinal height is kept unchanged; the cross section area of a slow cooling chamber is increased; meanwhile, the slow cooling chamber maintains the plate surface temperature of a spinneret plate in a heat insulation mode; an oil agent for oiling contains crown ether; the content of the crown ether is 67.30 to 85.58 weight percent; the dihydric alcohol chain segment with branched chain is introduced into modified polyester; the prepared superfine dacron low stretch yarn has the filament number being smaller than 0.3dtex; the crimp shrinkage is 8.0+ / -1.0 percent; the crimp stability is greater than or equal to 75 percent. The method is simple and reasonable; the prepared superfine dacron low stretch yarn has the advantage of low fiber number.

Owner:JIANGSU HENGLI CHEM FIBER

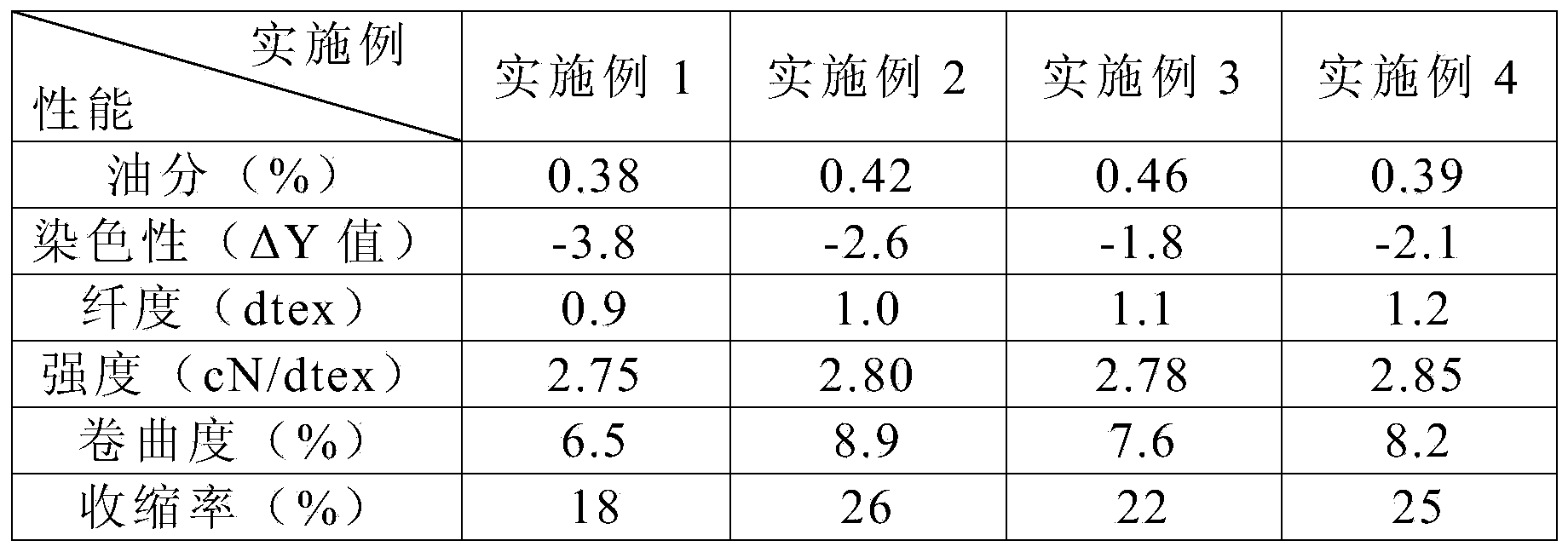

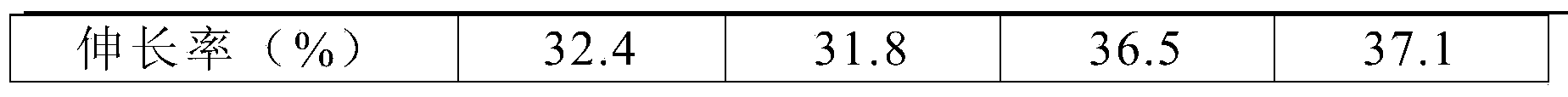

High-shrinkage superfine acrylic fiber and preparation method thereof

ActiveCN103882546ASmall denierImprove shrinkageArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentPolymer scienceShrinkage rate

The invention relates to a high-shrinkage superfine acrylic fiber and a preparation method thereof. The high-shrinkage superfine acrylic fiber consists of 91-94 percent of acrylonitrile and 6-9 percent of vinyl acetate, wherein the fineness is 0.8-1.2dtex, and the shrinkage rate is 18-30 percent. The preparation method comprises the following steps: performing spinning forming, washing, drafting, oiling, drying, setting and performing high-shrinkage treatment. The prepared vivid cashmere-imitated high-shrinkage superfine acrylic fiber has excellent performances on strength, elongation, shrinkage rate, dyeing property, elasticity, glossiness, gas permeability and the like.

Owner:NINGBO ZHONGXIN ACRYLIC FIBERS

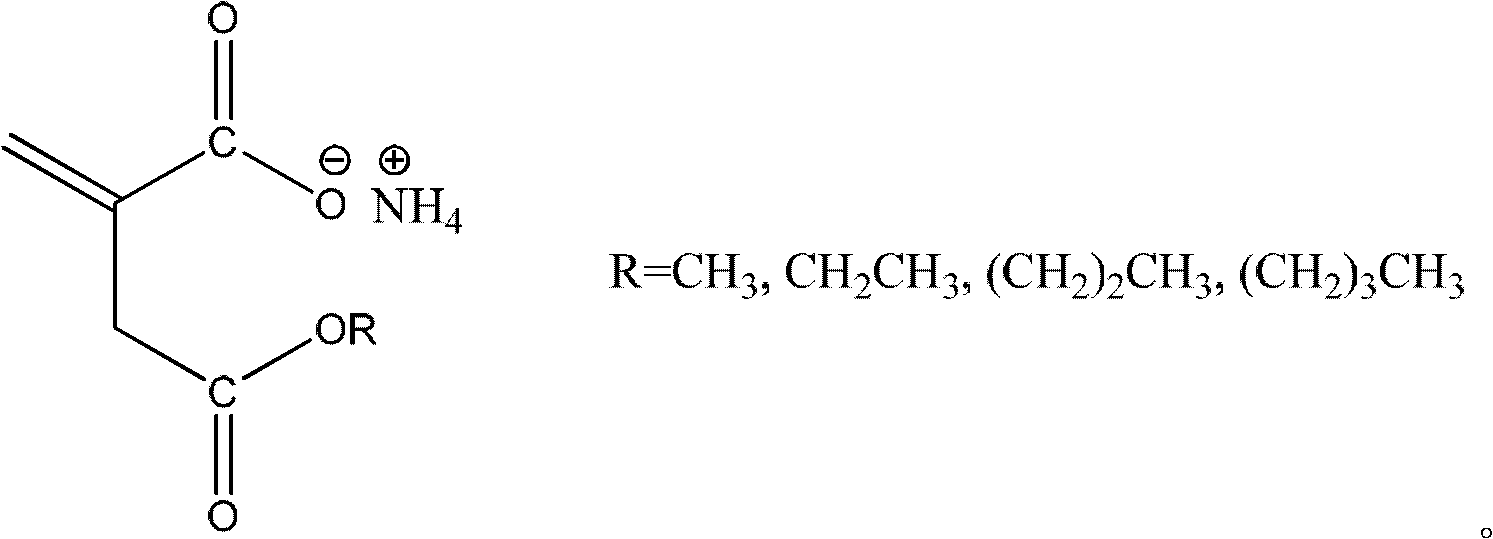

Preparation method of binary polyacrylonitrile carbon fiber precursor

InactiveCN103614800AReduce dosageImprove structural regularityFibre typesArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a preparation method of a binary polyacrylonitrile carbon fiber precursor. The method comprises the following steps: mixing acrylonitrile, a second comonomer beta-itaconic acid ester amide and a solvent in the presence of nitrogen, and adding an initiator; reacting for 22-38 hours under the condition of 35-75 DEG C, so as to obtain an acrylonitrile polymer; then filtering, taking off and defoaming, so as to prepare a spinning solution; spinning the spinning solution by virtue of a dry-jet wet process, stretching, oiling, drying, densifying, drawing by hot steam, and thermoforming, so as to obtain the binary polyacrylonitrile carbon fiber precursor. By adopting the preparation method, double functional group beta-itaconic acid ester amide is adopted as a comonomer, and a polyacrylonitrile macromolecule for the carbon fiber precursor is prepared by binary copolymerization and substituted ternary copolymerization. Thus, the dosage of the comonomer is reduced, meanwhile, the structural regularity of the polyacrylonitrile macromolecule is improved, and the prepared carbon fiber precursor is even in structure, small in fineness and high in strength.

Owner:DONGHUA UNIV

Method for preparing carbon fiber precursor by polymerization from mixed solvent

InactiveCN104695036ANarrow molecular weight distributionReduce dosageWet spinning methodsMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

The invention relates to a method for preparing a carbon fiber precursor by polymerization from a mixed solvent. The method for preparing the carbon fiber precursor by polymerization from the mixed solvent comprises the following steps: (1) initiating copolymerization on acrylonitrile, 3-carboxyl-3 butylene amide and itaconic acid diester at the temperature of 50-80 DEG C while dimethyl sulfoxide / deionized water or N,N-dimethyl formamide / deionized water is taken as the solvent and azodiisobutyronitrile is taken as an initiating agent; and (2) dissolving an acrylonitrile polymer obtained in the step (1), defoaming, filtering, carrying out dry jet wet spinning, drawing, oiling, compacting by drying, drawing in superheated steam, and carrying out heat setting, so that the carbon fiber precursor is obtained. The method for preparing the carbon fiber precursor by the polymerization from the mixed solvent has the advantages that the characteristic that the chain transfer constant of the deionized water is zero is utilized, the molecular weight of the polymer is regulated and controlled by regulating the ratio of the deionized water to the organic solvent, the molecular weight of the prepared polymer is more than 1.5 times of the molecular weight of the polymer obtained by the polymerization from the traditional solvent, and the prepared carbon fiber precursor is uniform in structure, low in fineness and high in strength; meanwhile, water is adopted for substituting part of the organic solvent, the environment protection can be facilitated, and the production cost is effectively reduced.

Owner:JIANGNAN UNIV

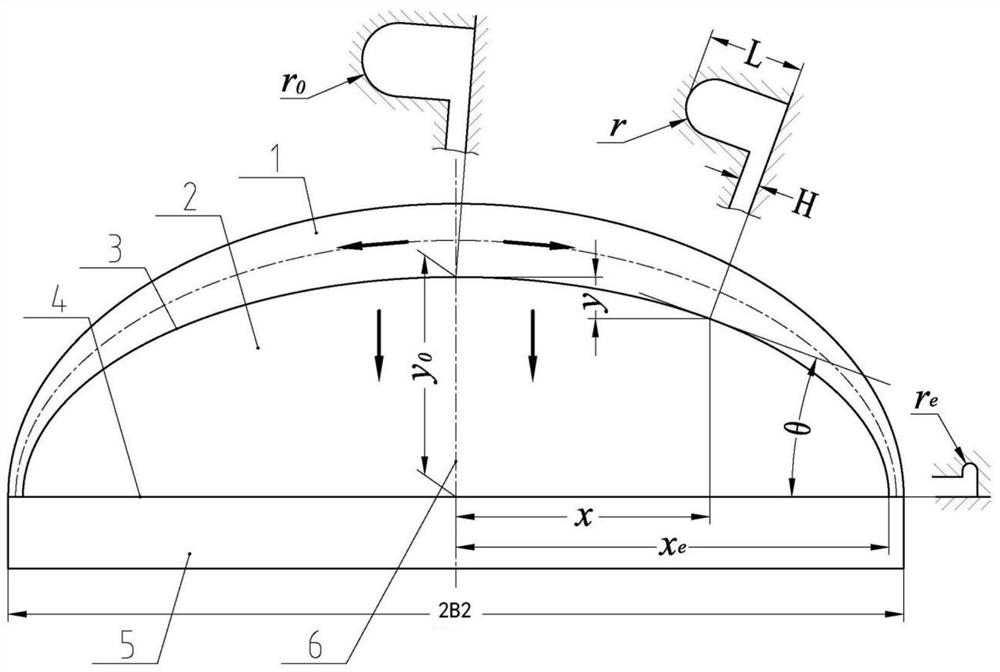

Clothes-hanger shaped spinning die head runner structure for uniform melt distribution

PendingCN110644062AReduce the amount of processingReduced processing performanceSpinnerette packsMelt spinning methodsFiberPolymer science

The invention provides a clothes-hanger shaped spinning die head runner structure for uniform melt distribution and a clothes-hanger shaped spinning die head with the die head runner structure. The structure is characterized in that firstly, the flow rate of high polymer melt in the breadth direction of a slit runner outlet is equal everywhere; secondly, the pressure drop of the high polymer meltflowing from a feeding port to the slit runner outlet is equal everywhere in the breadth direction; thirdly, the staying time of the high polymer melt in the whole spinning die head runner structure is short and equal everywhere at the slit runner outlet along the in the breadth direction. The equalities in three aspects have unique advantages in production of high polymers with poor thermal stability or with dependency of the rheological property on time. By adoption of the clothes-hanger shaped spinning die head runner structure, stable and uniform products can be prepared, such as ultrafinenanofibers and related products thereof. A wide application range is realized, and a great spinning performance aiming at high polymers which can be hardly processed and utilized by conventional spinning equipment is achieved.

Owner:北京钧毅微纳新材科技有限公司

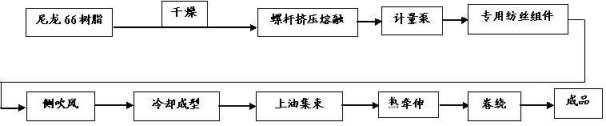

Nylon 66 resin, nylon 66 filament and preparation method thereof

InactiveCN102181052ASmall denierImprove mechanical propertiesMelt spinning methodsMonocomponent polyamides artificial filamentNylon 66Additional values

The invention belongs to the field of spinning materials, and provides a nylon 66 resin. The nylon 66 resin is prepared by polymerization and post condensation polymerization reaction after nylon 66 salt melt and a compound of a first main group metal are mixed, wherein based on the weight of the nylon 66 salt, the weight of the compound of the first main group metal is 0.03 to 1.0 percent. The invention also provides a nylon 66 filament prepared from the nylon 66 resin. The nylon 66 filament is obtained by melt spinning of the nylon 66 resin. The fine denier or superfine denier nylon 66 filament with fineness of about 0.30 to 1.0dtex can be obtained by using the nylon 66 resin and a preparation method, the strength and the breaking elongation of the fibers meet the requirements of post weaving, the blank of producing the fine denier / superfine denier nylon 66 filament by adopting the conventional high-speed spinning method at home and abroad is filled, and the technological content and the additional value of the nylon 66 fiber product are promoted.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for preparing binary polyacrylonitrile-based carbon fiber protofilament

InactiveCN102605476AReduce dosageImprove structural regularityArtificial filament washing/dryingArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a method for preparing a binary polyacrylonitrile-based carbon fiber protofilament. The method comprises the following steps of: (1) performing copolymerization reaction on acrylonitrile and beta-ammonium itaconate for 10 to 30 hours at the temperature of between 50 and 70 DEG C by using dimethyl sulfoxide as a solvent and using azodiisobutyronitrile as an initiator, filtering, removing residual monomers, and defoaming to obtain a spinning solution; and (2) sequentially performing dry-spray wet spinning, drawing, oiling, drying densification, hot steam drawing and heat setting on the spinning solution, and thus obtaining the carbon fiber protofilament. By the method, the consumption of copolymerization monomers is reduced, and the structural regularity of polyacrylonitrile macromolecules is improved; and the prepared carbon fiber protofilament is uniform in structure, low in fineness and high in strength, and is suitable for preparing high-performance carbon fibers.

Owner:DONGHUA UNIV

Fine denier yarn leather base fabric and preparation method thereof

InactiveCN102168336ABroaden your optionsSmall denierLiquid/gas/vapor open-width material treatmentBiochemical fibre treatmentAmylasePolymer science

The invention discloses a fine denier yarn leather base fabric and a preparation method thereof. In the leather base fabric, fine denier yarn grey cloth is weaved by using fine denier yarns warps and wefts, and the leather base fabric with the thickness below 0.15mm is prepared by dyeing and finishing the grey cloth. The preparation method comprises the following steps of: (1) desizing, scouring and dyeing by adopting a full width jig dyeing machine, wherein the temperature for desizing, scouring and dyeing is 90+ / -2 DEG C, and the velocity for desizing, scouring and dyeing is 95+ / -2m / min; (2) selecting a desizing mode: bio-enyzme desizing is adopted, wherein a bio-enzyme preparation is intermediate temperature alpha-amylase, the proportion of the substances in desizing is as follows: 2 to 10g of intermediate temperature alpha-amylase and 2 to 10g of salt are contained in water per liter; (3) raising: raising is realized by an imported raising machine the model of which is 92067-R2094; and (4) shaping the finished product: the shaping temperature is controlled within a range from 180 to 185 DEG C, and the shaping time is controlled within a range from 35 to 45 seconds.

Owner:淮安富泰革基布有限公司

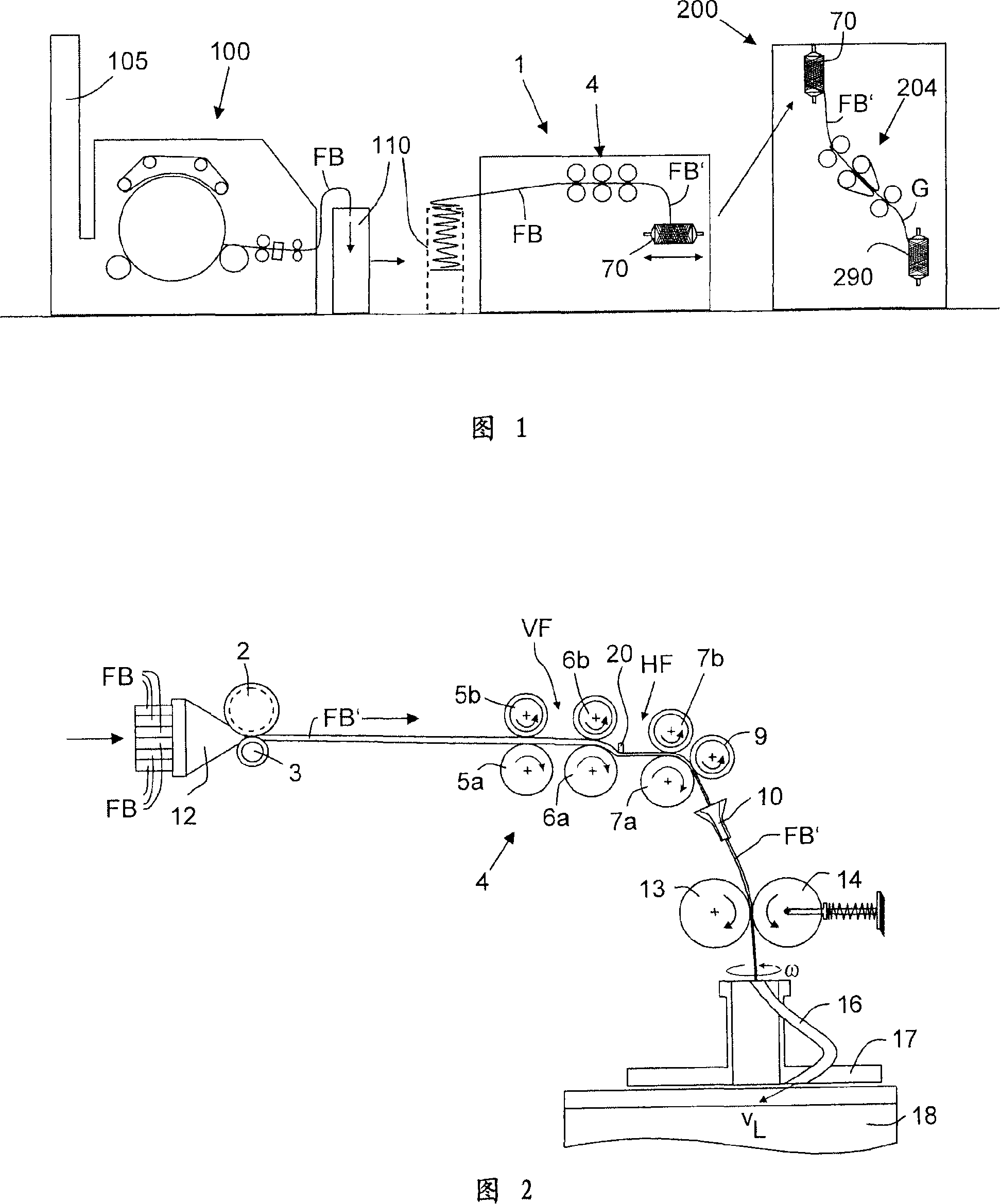

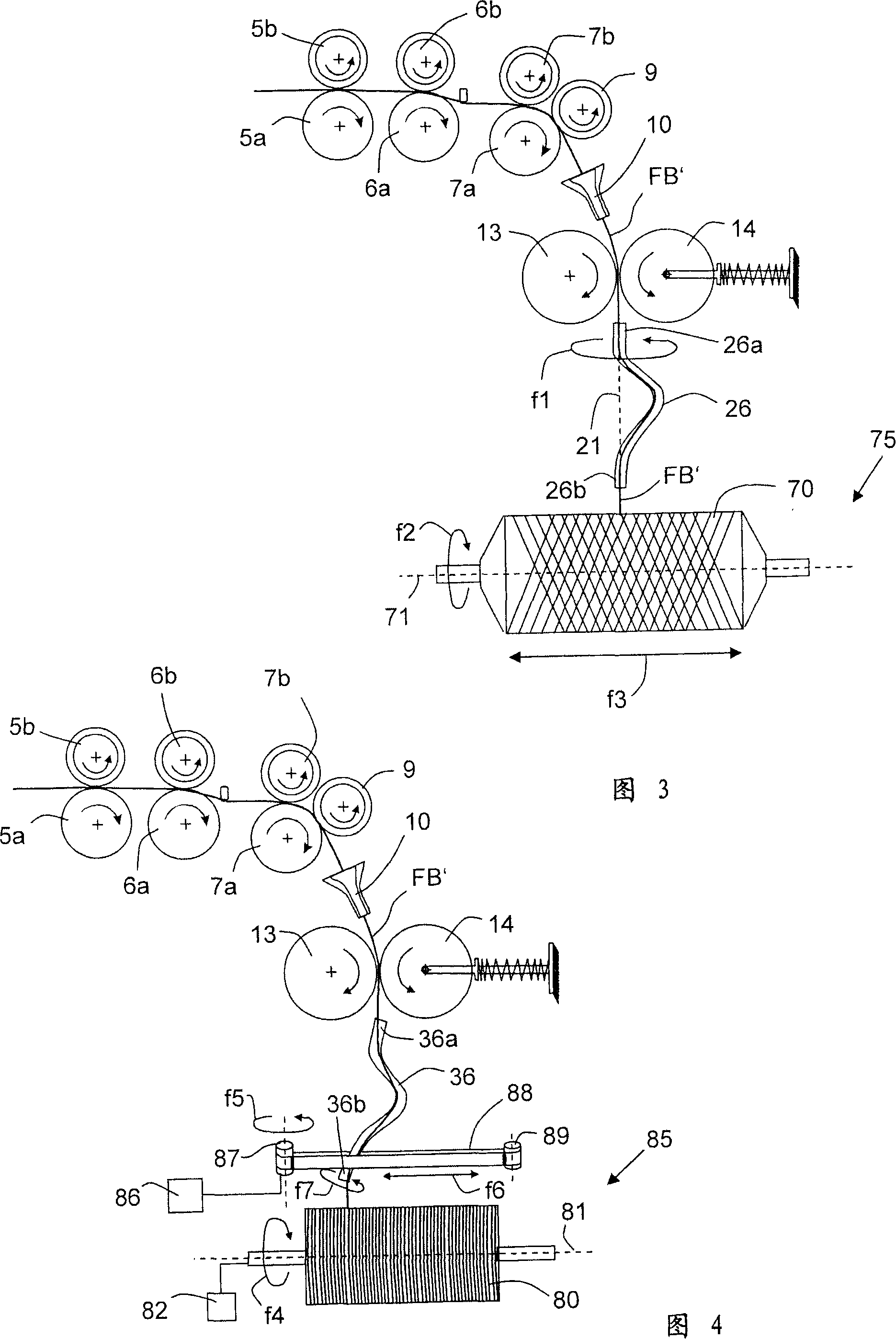

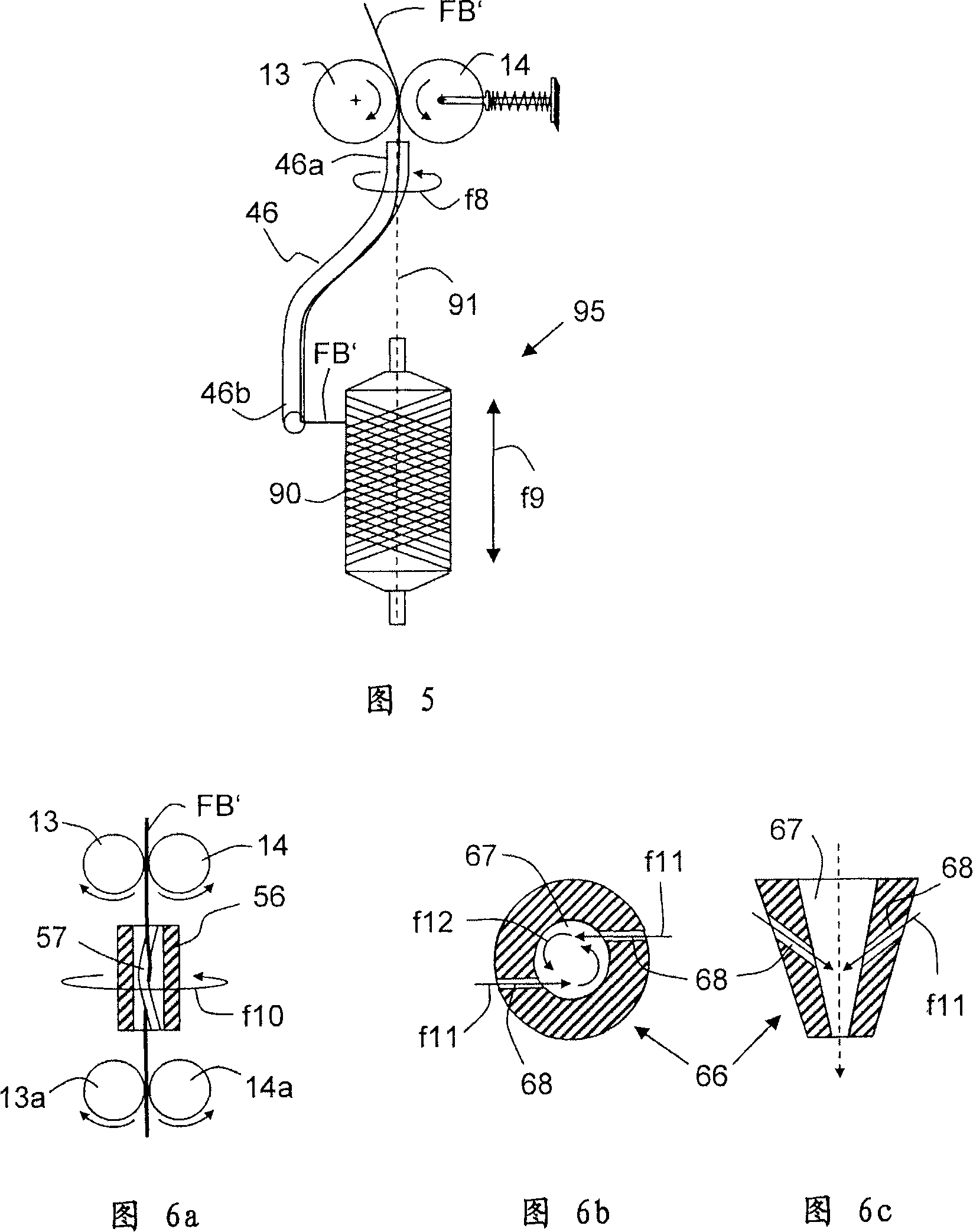

Flyerless spinning method and device with a drawing unit

InactiveCN101133197ASmall denierFor the highest demands in terms of titerDrafting machinesYarnEngineering

The invention concerns a spinning method without recourse to a flyer, for the direct spinning of sliver and also concerns an apparatus with a draft system in accord with the principal concepts of the independent claims. Various attempts have been made known, of directly spinning fiber on a ring spinning machine. In the case of spinning methods of this type, it is possible to eliminate the use of the flyer so that costs and space can be saved. It is particularly well known, that sliver with a band fineness of ca. 5 ktex in connection with a first draft system, which is normally a component of a draw frame, can be stored in a can. These cans are then brought to a movable creel, on which they are pulled away and fed into respectively one spinning position of a ring spinning machine. Since on the said creel, distortions of the sliver can occur, at this location no bands of less than 3.5 ktex are allowed. Since the distortion at the ring spinning machine is machine-limited, it is possible with this known method, to spin chiefly only rough ring yarn. This method has not been particularly well accepted due to: difficult access for maintenance, necessary space for the cans and the said distortion. One achieves finer yarns normally by the interposition of a flyer, by means of which a fiber with a band weight, for example, of 5 ktex is drawn to a pre-yarn with a roving of 200-1200 tex and wound onto a spool, in order that this can then be delivered to a ring spinning machine.

Owner:RIETER INGOLSTADT SPINNEREI

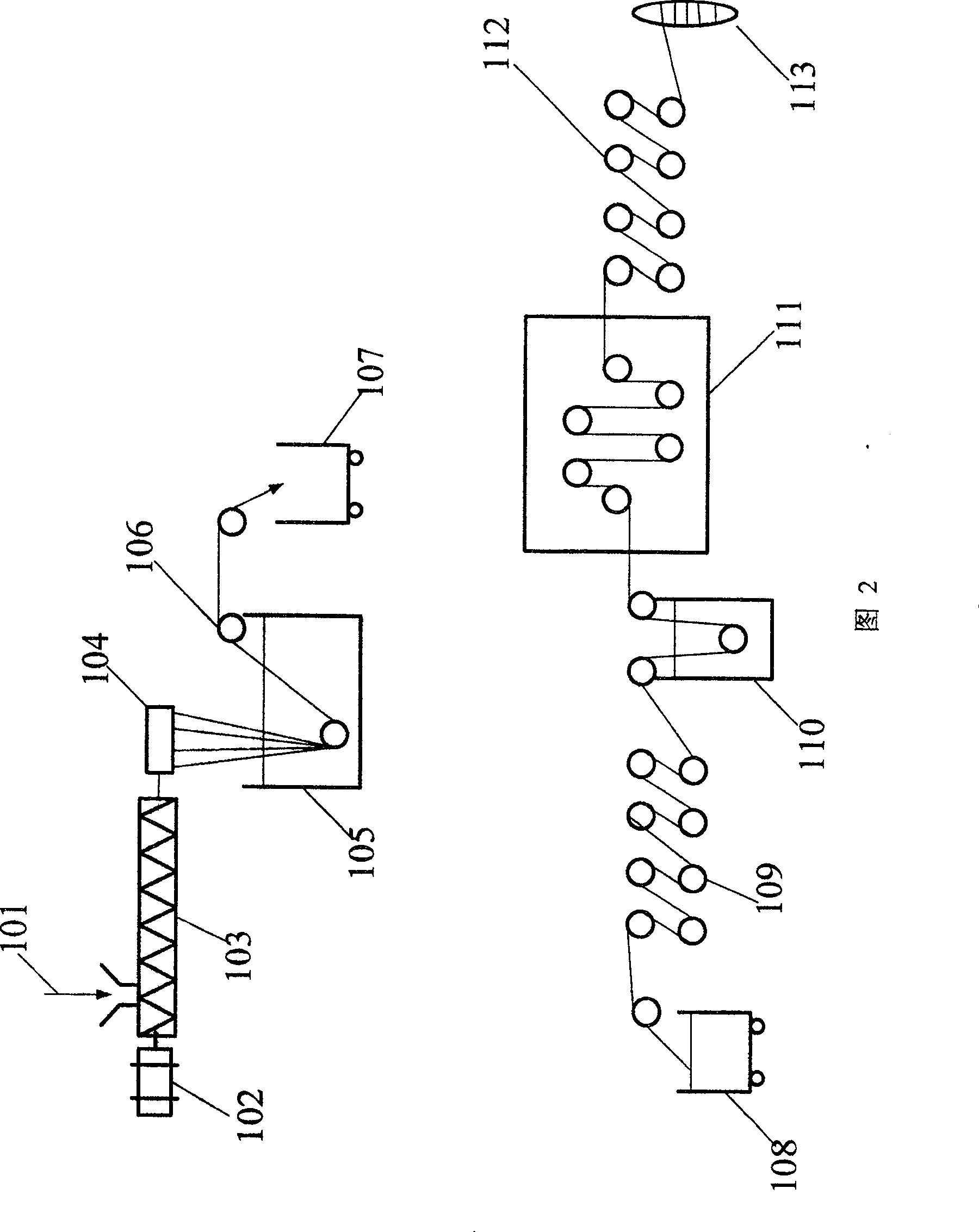

Production method of double-component spun-bonded non-woven fabrics

The invention provides a production method of double-component spun-bonded non-woven fabrics. Double-component PP / PE filaments are adopted and are processed through slicing, filtration, hot air drying, heating and melting, positive pressure stretching, slitting and package and other processes, fiber filaments are externally loose and curled and are internally tightened and straight after deformation and have fluffy and stereochemical structures. Compared with common filaments, the original high strength, abrasion resistance and other excellent properties of fibers are kept, the structures and morphology similar to silk fiber flocculi are obtained, especially the filaments have excellent elasticity, few hairiness, good anti-pilling properties and high in firmness, web forming is uniform, gram weight can be up to 9 G, the width can be up to 3.2 M, and the pulling strength is longitudinally greater than 18 N and is transversely greater than 9 N.

Owner:漳州市鼎鑫电子科技有限公司

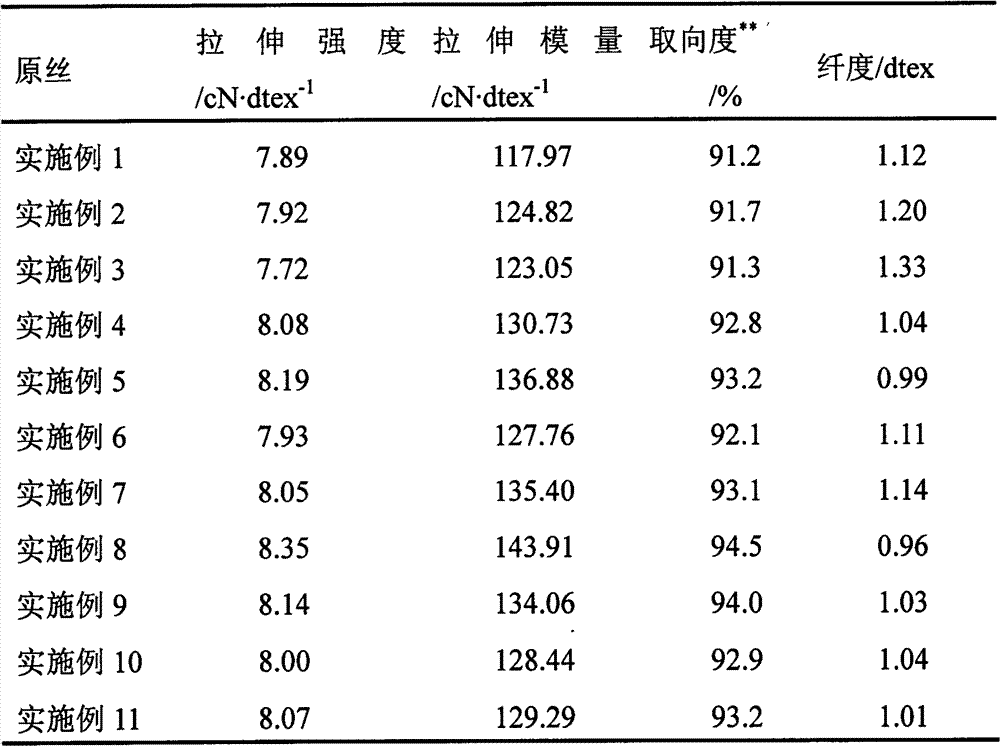

Preparation method of high-performance polyacrylonitrile-based carbon fiber precursor

InactiveCN102277645BGood orientationIncrease spinning speedArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentOrganic solventPolymer science

The invention relates to a preparation method of a high-performance polyacrylonitrile-based carbon fiber precursor. The method provided by the invention comprises the following steps of: (1) dissolving less high-performance polyacrylonitrile resin into a diluted polyacrylonitrile solution; (2) dissolving certain amount of polyacrylonitrile with conventional molecular weight into the diluted polyacrylonitrile solution with super-high molecular weight to obtain a polyacrylonitrile spinning solution; (3) obtaining a polyacrylonitrile carbon fiber precursor through utilizing a dry-wet spinning method; and (4) washing the primary precursor by water, stretching, carrying out a second-grade stretching by hot water, drying and densifying, and stretching by saturated steam to obtain the high-performance polyacrylonitrile-based carbon fiber precursor. Compared with the prior art, the method provided by the invention can prepare the good-quality polyacrylonitrile-based carbon fiber precursor with high strength, high modulus, high orientation degree and small fineness.

Owner:SHANGHAI JIAOTONG UNIV

Superfine polyester low elastic yarn and preparation method thereof

ActiveCN107988649BSimple manufacturing methodSmall denierFibre typesMonocomponent copolyesters artificial filamentPolyesterPolymer science

The invention relates to a superfine dacron low stretch yarn and a preparation method thereof. Modified polyester fusant is subjected to metering, extrusion, cooling, oiling and winding to prepare POYyarns; the POY yarns are subjected to yarn guide tube passing, networking, heating stretching, false twisting, heat setting and winding formation to prepare DTY yarns, i.e., the superfine dacron lowstretch yarn is obtained. During cooling, the longitudinal height is kept unchanged; the cross section area of a slow cooling chamber is increased; meanwhile, the slow cooling chamber maintains the plate surface temperature of a spinneret plate in a heat insulation mode; an oil agent for oiling contains crown ether; the content of the crown ether is 67.30 to 85.58 weight percent; the dihydric alcohol chain segment with branched chain is introduced into modified polyester; the prepared superfine dacron low stretch yarn has the filament number being smaller than 0.3dtex; the crimp shrinkage is 8.0+ / -1.0 percent; the crimp stability is greater than or equal to 75 percent. The method is simple and reasonable; the prepared superfine dacron low stretch yarn has the advantage of low fiber number.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing high-strength polyacrylonitrile-based precursor for carbon fiber

ActiveCN101724922BEffective filteringGuaranteed neatnessArtificial filament washing/dryingArtificial filament heat treatmentCarbon fibersAcrylonitrile

The invention discloses a method for preparing a high-strength polyacrylonitrile-based carbon fiber precursor. The method comprises the steps of: using azodiisobutyronitrile to trigger acrylonitrile and a comonomer to perform homogeneous solution polymerization in dimethyl sulfoxide to obtain spinning solution, and controlling the temperature of the spinning solution to be between 40 and 70 DEG C and the solid content to be between 18 and 24 percent; performing monomer removal on the spinning solution under the pressure of between -60 and -78KPa, and performing deaeration treatment under the pressure of between -78 and -97KPa; then extruding the spinning solution into a spin duct in a coagulation bath with a temperature of between 35 and 65 DEG C and a dimethyl sulfoxide concentration of between 50 and 70 percent for molding through a spinneret, and obtaining PAN-based as-spun fiber through 45 to 75 percent of minus stretch in the coagulation bath; then molding and stretching through a secondary coagulation bath, a third coagulation bath, a fourth coagulation bath and a fifth coagulation bath; and obtaining the high-strength polyacrylonitrile-based carbon fiber precursor through solvent removal by water scrubbing, hot water stretch, oiling, drying and densification, steam stretch, and hot air setting. The tensile strength of the high-strength polyacrylonitrile-based carbon fiber precursor reaches 10.2cN / dtex.

Owner:ZHONGFU SHENYING CARBON FIBER

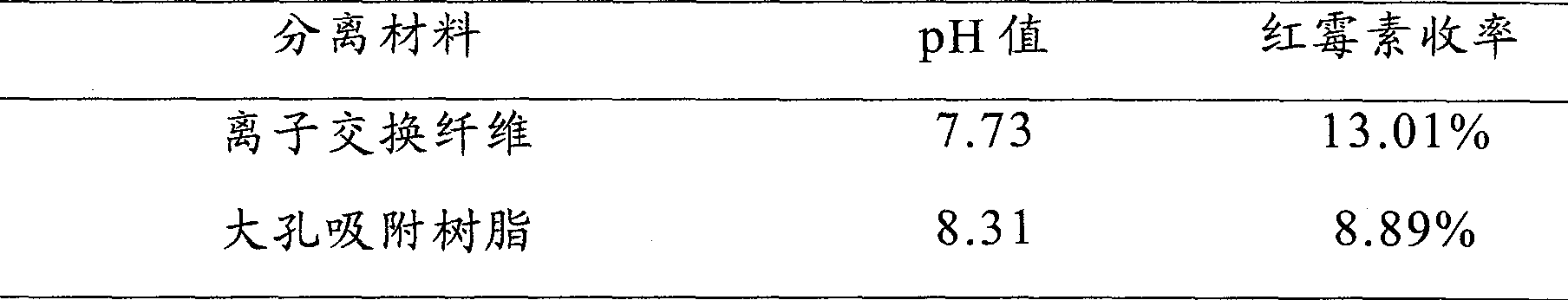

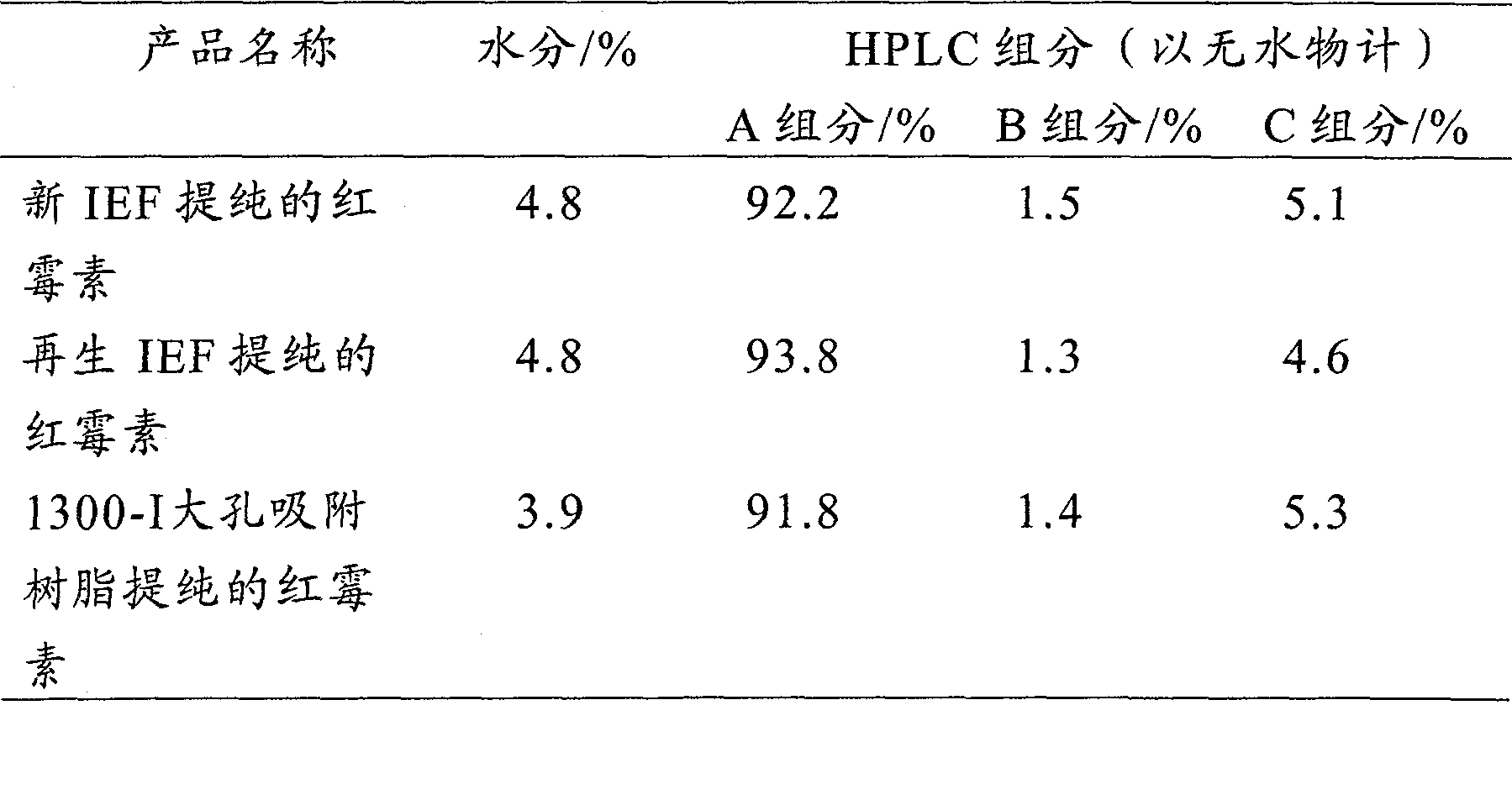

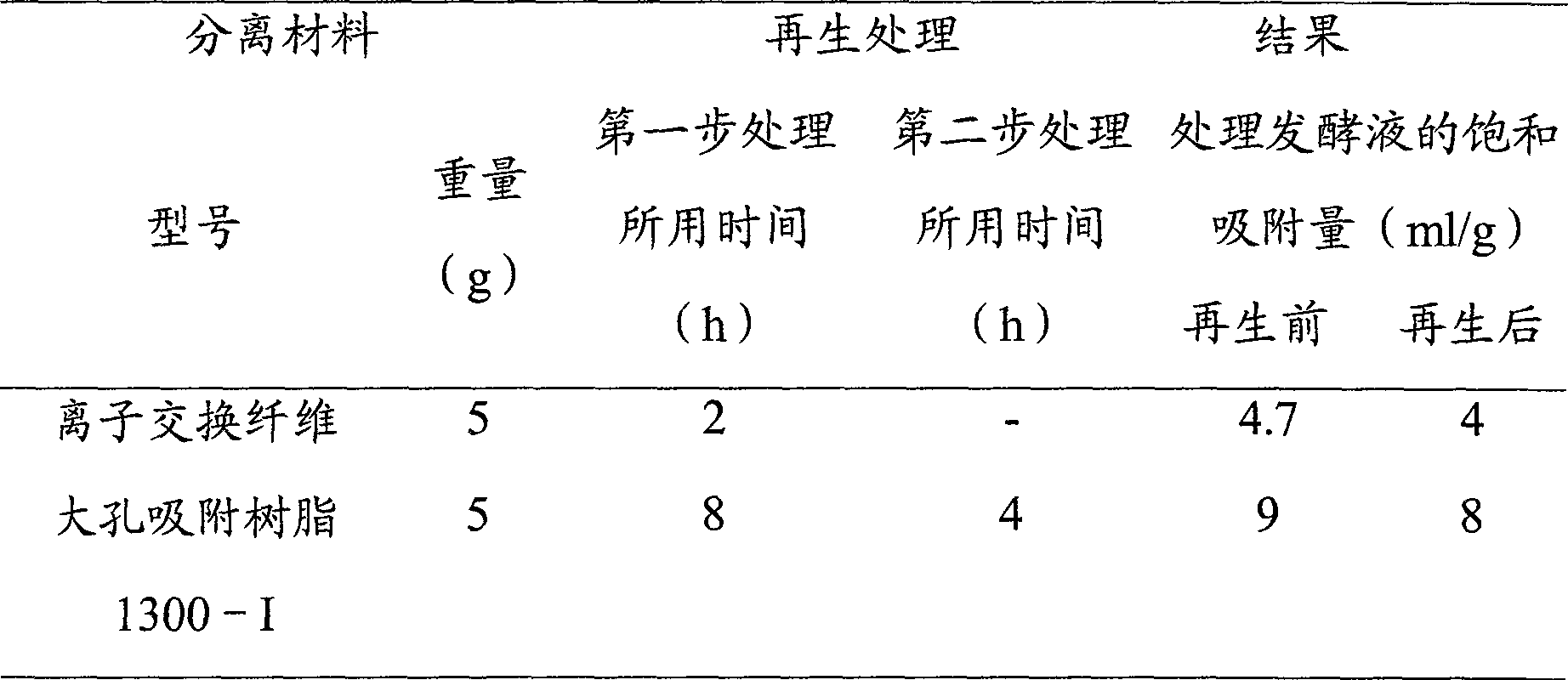

Method for separating and purifying erythromycin

ActiveCN100537587CSmall denierDiffusion pathway is shortSugar derivativesSugar derivatives preparationRegenerative processDesorption

The invention discloses a new method for separating and purifying erythromycin from liquid containing erythromycin by adopting ion exchange fiber with synthetic fiber as the skeleton. The method of the present invention utilizes its special fibrous physical form to make it have a larger contact area with erythromycin, has less resistance to fluids, and utilizes the functional group of ion-exchange fibers to make the adsorption and desorption speed faster, which is faster than the existing The macroporous adsorption resin is easy and thorough in elution, fast in regeneration speed and strong in affinity, achieving the purpose of separation and purification. The application of the method of the invention also solves the problem that the regeneration process is difficult after the macroporous resin absorbs erythromycin, thereby reducing the cost.

Owner:桂林正翰科技开发有限责任公司

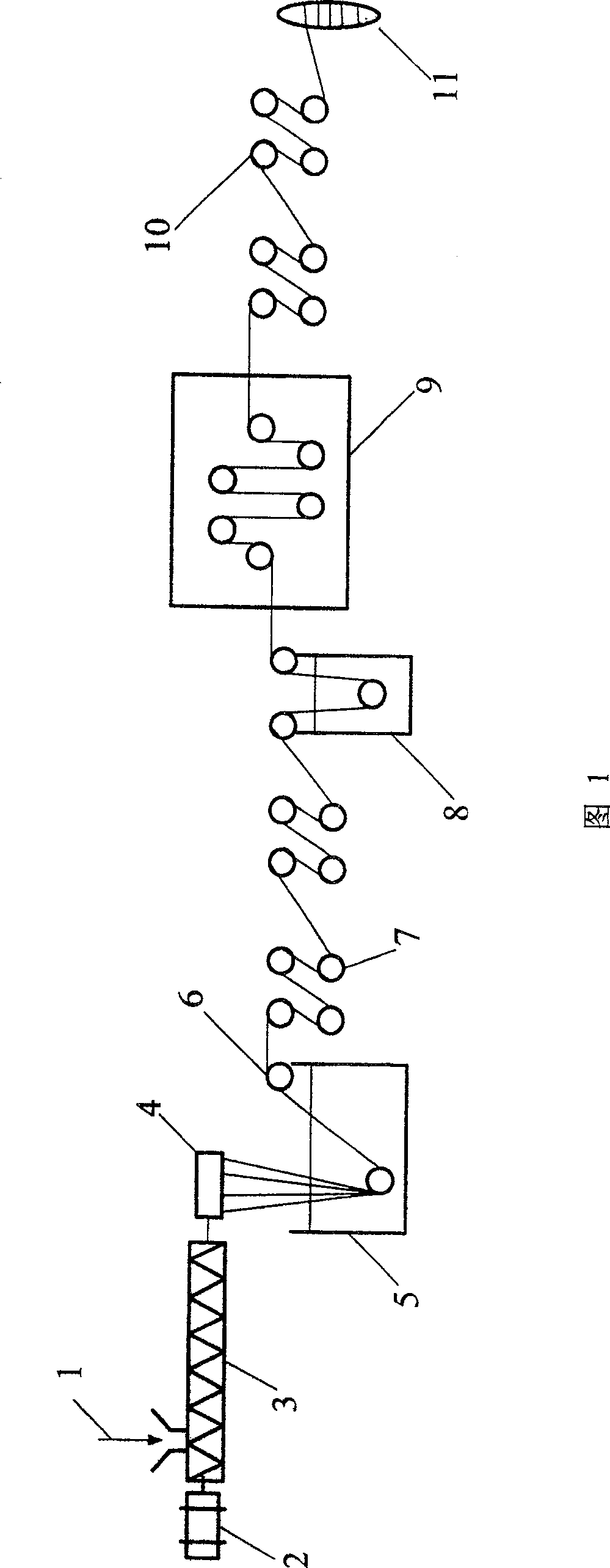

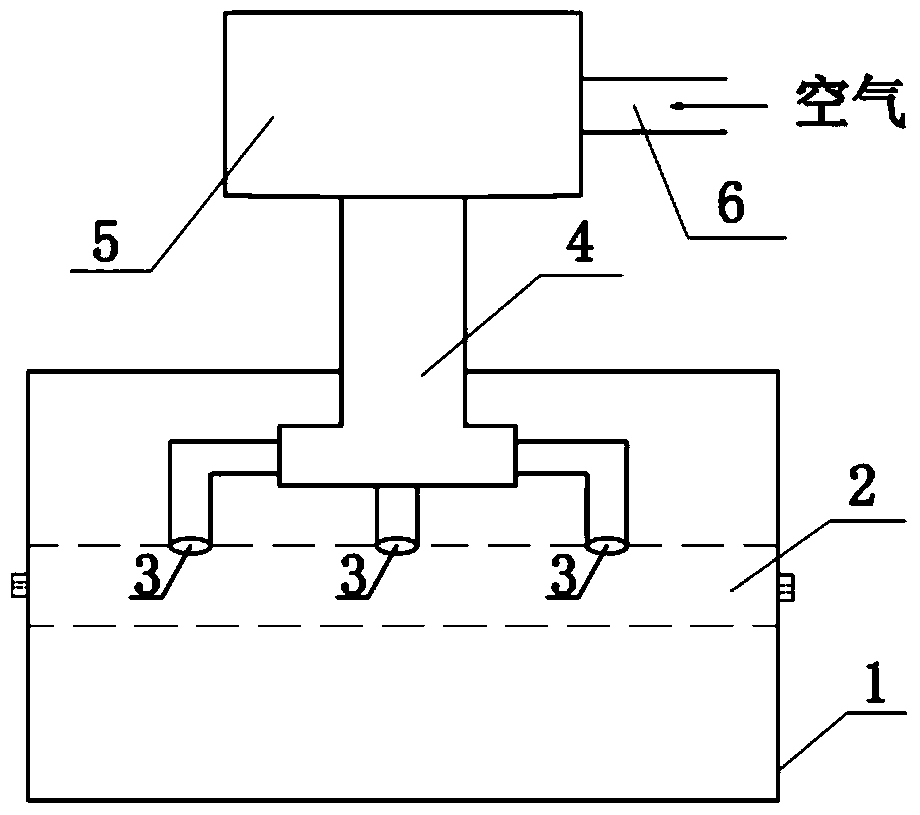

Production method and production device for superfine-denier POY (polyester pre-oriented yarn) product

PendingCN110735197ASmall denierReduce heat dissipationArtificial thread manufacturing machinesMelt spinning methodsPolyesterPolymer science

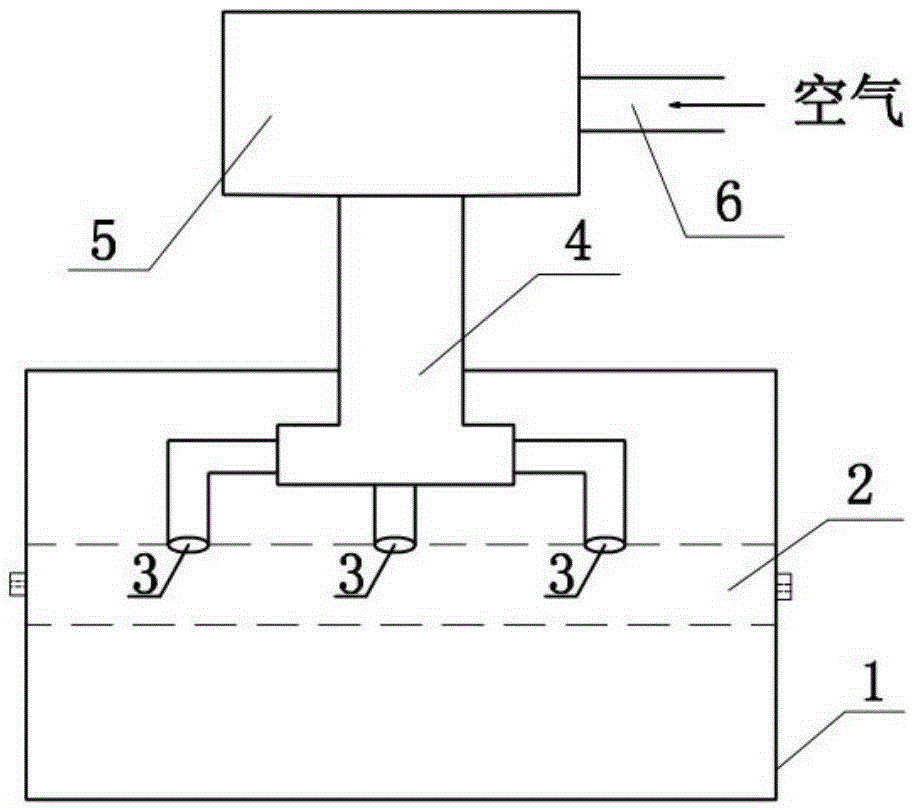

A production method for a superfine-denier POY (polyester pre-oriented yarn) product includes: adding a heat-insulating material layer to a gap between a spinning cabinet and an annular blowing cabinet, mounting an air tube central insertion plate into an annular blowing tube, and distributing through holes in the air tube central insertion plate; taking semi-matte polyester melt as a raw material, feeding the semi-matte polyester melt with the initial temperature of 276 DEG C through a melt delivery pipe into a melt cooler after pressurization by a booster pump, cooling the melt by the melt cooler, and feeding the melt into the spinning cabinet with the temperature of 288 DEG C; filtering the melt in a spinning component after metering, extruding the melt by a spinneret plate, performingcooling and curing by the annular blowing cabinet with the air temperature of 22 DEG C and the air pressure of 13Pa to obtain nascent fibers; oiling the nascent fibers by an oil nozzle, performing pre-netting, and finally performing package formation by a wings winding head. The invention further provides a production device for the superfine-denier POY product. By the production method and the production device, the denier of the POY product can be lower than 60 dtex, and the denier per filament can be lower than 0.7 dtex.

Owner:新凤鸣集团股份有限公司 +1

A high shrinkage side by side type composite filament and a method for manufacturing the same

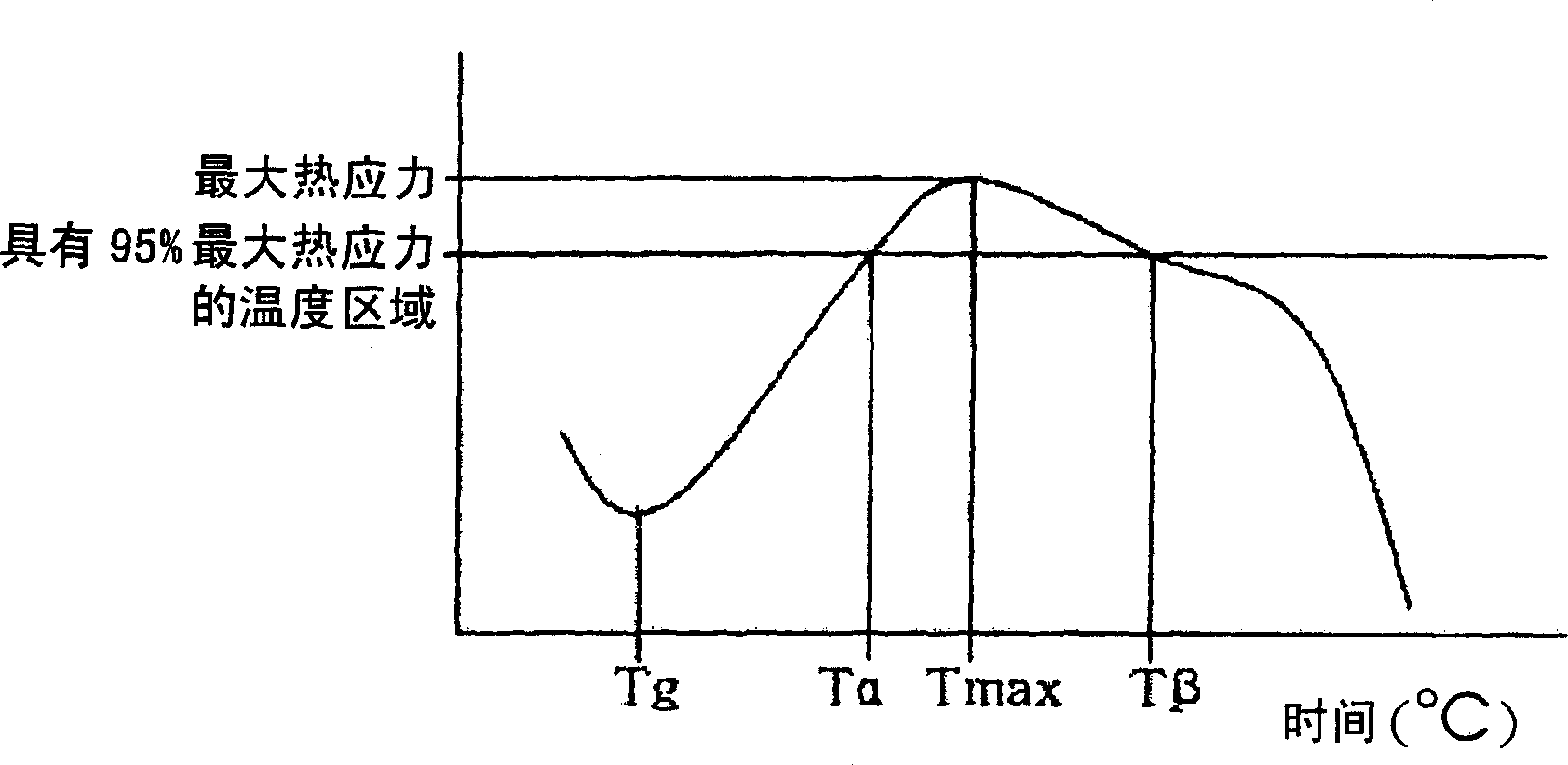

InactiveCN1717510AImprove shrinkageSmall denierFilament/thread formingMonocomponent synthetic polymer artificial filamentMaterials scienceHeat treated

The present invention relates to a high shrinkage side-by-side type composite filament, wherein two kinds of thermoplastic polymers are arranged side by side type and a boiling water shrinkage (Sr2) measured by the method (initial load = notified denier x 1 / 10g, static load = notified denier x 20 / 10g) of clause 5.10 of JIS L 1090 is 20 to 75% of a boiling water shrinkage (Sr1) measured by the method (initial load = notified denier x 1 / 30g, static load = notified denier x 40 / 30g) of clause 7.15 of JIS L 1013. The side-by-side type composite filament. is made of two kinds of thermoplastic polymers having a number average molecular weight difference (Mn) of 5,000 to 15,000 upon spinning and the composite filament is drawn and heat-treated so as to satisfy the following physical properties: Temperature area exhibiting 95% of maximum thermal stress (Tmax, 95%): 120 to 230 DEG C Range of maximum thermal stress per denier : 0.1 to 0.4g / denier.

Owner:KOLON IND INC

A kind of composite floc and its preparation method and application

ActiveCN110644143BNon-toxic and harmlessIncrease elasticitySpinnerette packsMelt spinning methodsPolymer scienceMelt blowing

The invention belongs to the technical field of melt-blowing and particularly relates to a composite wadding sheet and a preparation method and application thereof. The composite wadding sheet comprises a melt-blown fiber layer consisting melt-blown fiber and staple fiber; the diameter of the melt-blown fiber ranges from 200 nanometer and 2000 nanometer, and the mass percent content of the melt-blown fiber within the range of the diameter is greater than or equal to 80%. The composite wadding sheet has excellent resilience rate and voidage, its filtering effect, heat insulation, flame resistance, oil absorbency and noise reduction effect is increased by 10-60% as compared with that of the wadding sheet prepared of the general melt-blown fiber, and besides, the composite wadding sheet is poisonless and harmless.

Owner:北京钧毅微纳新材科技有限公司

Preparation method for polyacrylonitrile-based carbon fiber protofilament

InactiveCN101643943BGood orientationHigh strengthArtificial filament washing/dryingFilament/thread formingOrganic solventUltimate tensile strength

The invention relates to a preparation method for a polyacrylonitrile-based carbon fiber protofilament, comprising the following steps: firstly, polyacrylonitrile / organic solvent spinning solution is prepared; secondly, after defoaming, filter and metering, the spinning solution forms a spinning solution trickle by being extruded through a spinneret, and enters a coagulation bath to be shaped by coagulation through an air layer; and thirdly, air stretching, washing, prestretching, main stretching, dry collapse and steam stretching are carried out. The invention efficiently enhances the draft ratio of a strand silk during spinning, and can carry out scale production on the prior spinning plant, therefore, the prepared protofilament has uniform structure, little fibrousness and high strength.

Owner:DONGHUA UNIV

A kind of melt blown fiber and its preparation method and application

ActiveCN110644140BNon-toxic and harmlessImprove oil absorption capacityNon-woven fabricsFiberPolymer science

The invention belongs to the technical field of fibers, and particularly relates to a melt-blown fiber, a preparation method thereof and an application of the fiber. The diameter of the melt-blown fiber is 200-2000 nanometers, and the weight percentage content of the melt-blown fiber within the range of the diameter is larger than or equal to 80%. A melt-blown fiber mesh is prepared from the melt-blown fiber, the filtering effect, thermal insulation, oil absorbency and the sound absorption effect of the melt-blown fiber and the prepared melt-blown fiber mesh are improved by 10-60% as comparedwith those of a common melt-blown fiber and a common melt-blown fiber mesh, and the melt-blown fiber and the melt-blown fiber mesh have the advantages of poisonless and harmless properties and the like.

Owner:北京钧毅微纳新材科技有限公司

Extraction and desiccation method in preparing process of polyvinyl fibre with super high molecular weight

ActiveCN100494523CSafe to useLow boiling pointArtificial filament washing/dryingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to extracting and drying methods in the process for preparing uhmwpe fiber, belonging to the field for polymers preparing technology. The method comprises that the uhmwpe powder, assistant and solvent is solidified by extruding after they are mixed in uniformity and solved sufficiently; the solvent is eliminated in extracting process and the extraction agent is eliminated by drying technology; the final product is formed by heat drawing. It is characterized in that because dichloromethane is used as the extraction agent, there is good safety, low boiling point and it is eliminated easily. Because countercurrent extraction operation is adopted in the extracting process and there is no ultrasonic wave, it is provided with low drying temperature, simple technology, high intensity of fiber product, high modulus and low oil percentage of fiber.

Owner:安徽威亚新材料技术有限公司

Preparation method of ultrahigh molecular weight polyethylene fiber

ActiveCN101768786BWill not damage the structureLess quantityWet spinning methodsMonocomponent polyolefin artificial filamentFiberBreaking strength

Owner:CHANGSHU SUPERFIBER

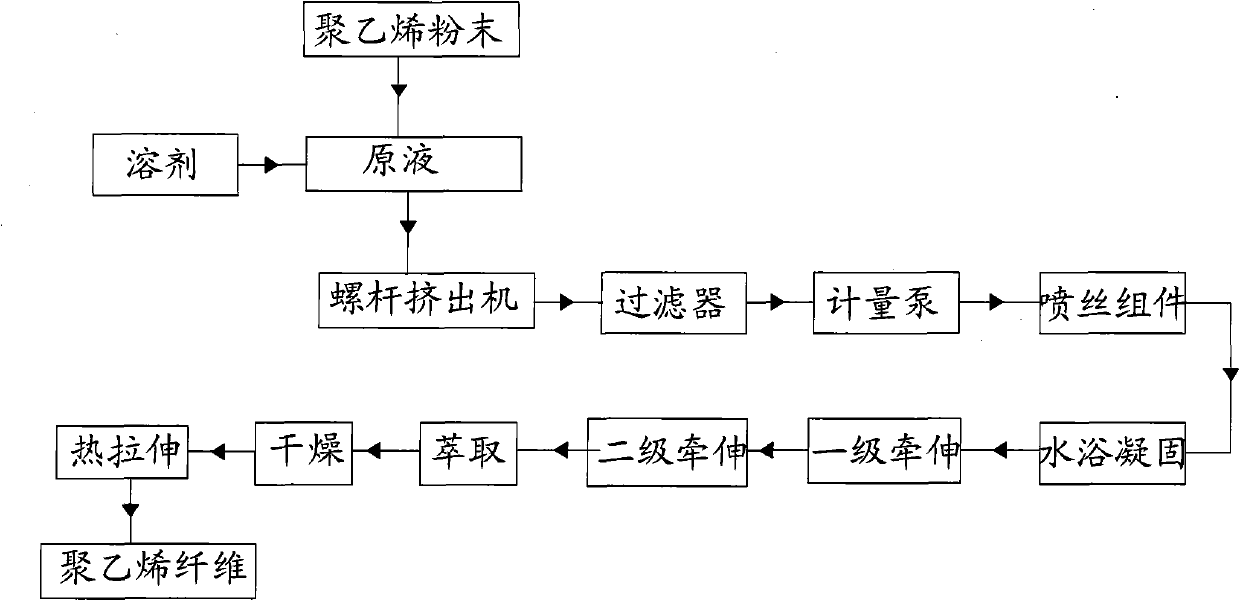

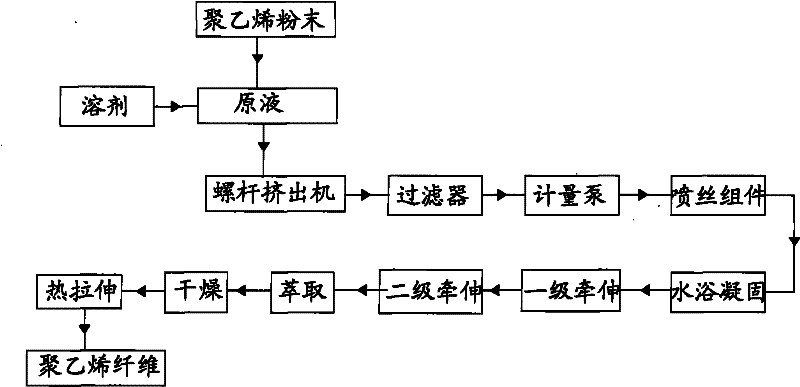

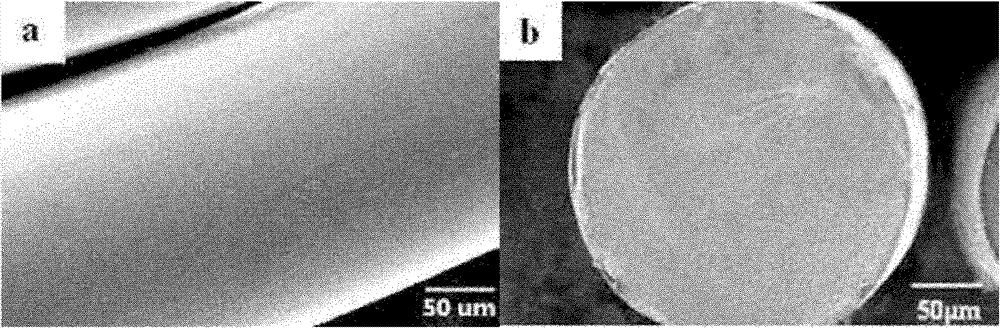

Preparation method of ultrahigh-molecular-weight polyethylene fine denier fibers

ActiveCN102199798BShrink evenlyHigh strengthMonocomponent polyolefin artificial filamentStretch-spinning methodsFiberPolymer science

The invention relates to a method for preparing ultrahigh-molecular-weight polyethylene fine denier fibers by a jelly spinning process, which comprises: (1) preparing jelly protofilaments of ultrahigh-molecular-weight polyethylene; and (2) subjecting the jelly protofilaments to pre-stretching, extraction, drying and hot stretching to obtain ultrahigh-molecular-weight polyethylene fine denier fibers, wherein the pre-stretching is performed for many times till the jelly protofilaments are stretched by 15 to 35 times totally, the many times of stretching are all performed in a stretching medium at 30 to 50 DEG C, the stretching medium is air, water or oil, and the jelly protofilaments are hotly stretched by 35 to 50 times totally. And after the step (1) and before the step (2), the method also comprises a step of standing the jelly protofilaments at a constant temperature of 20 to 40 DEG C and a constant humidity of 30 to 60 percent for 48 to 72 hours. When the method is used, low-titre and high-breaking-strength ultrahigh-molecular-weight polyethylene fine denier fiber products can be obtained, and the production cost is low.

Owner:CHANGSHU SUPERFIBER

Method for preparing polyacrylonitrile-based carbon fiber precursors without skin-core structure

InactiveCN102154723BSmall denierGood orientationMonocomponent synthetic polymer artificial filamentSpinning solutions preparationAlcoholOrganic solvent

The invention provides a method for preparing polyacrylonitrile-based carbon fiber precursors without a skin-core structure and belongs to the technical field of carbon fiber precursors. The method comprises the followings steps of: evenly mixing water or alcohol compounds and an organic solvent, adding polyacrylonitrile resin in the mixed solution, performing the heated swelling dissolution treatment, and filtering the mixed solution to obtain polyacrylonitrile spinning solution; and ageing the polyacrylonitrile spinning solution, performing spraying and extrusion to obtain primary precursors, and performing water-washing stretching, second-level hot water stretching, drying densification and saturated steam stretching of the primary precursors in sequence to obtain the polyacrylonitrile-based carbon fiber precursors. By the method, the good-quality polyacrylonitrile-based carbon fiber precursors having the advantages of no skin-core structure, less defects, small fiber number and high strength can be mass produced in large scale in the conventional industrialized spinning equipment, and the production cost can be effectively lowered.

Owner:SHANGHAI JIAOTONG UNIV

A method for preparing high-strength and high-modulus carbon fiber by using raw fiber drawing technology

InactiveCN105200566BReduce microstructural defectsImprove mechanical propertiesArtificial filament chemical after-treatmentPolymer scienceCarbon fibers

The invention relates to a method for producing high-strength and high-modulus carbon fibers by using the raw fiber drawing technology. Fiber, fiber pre-oxidation and carbonization and other steps. The invention can effectively reduce the defects of the microstructure in the preparation process of the fiber and the original fiber. Compared with the fiber without the application of the process, the orientation degree of the fiber used for pre-oxidation is further improved, and the mechanical properties of the fiber after carbonization are significantly improved; The above drawing again reduces the fiber fineness, increases the specific surface area during the high temperature treatment, and effectively improves the heat treatment efficiency; through the process of the present invention, the fiber quality is significantly improved.

Owner:THE NORTHWEST RES INST OF CHEM IND

A kind of preparation method of binary polyacrylonitrile-based carbon fiber precursor

InactiveCN103614800BReduce dosageImprove structural regularityFibre typesArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a preparation method of a binary polyacrylonitrile carbon fiber precursor. The method comprises the following steps: mixing acrylonitrile, a second comonomer beta-itaconic acid ester amide and a solvent in the presence of nitrogen, and adding an initiator; reacting for 22-38 hours under the condition of 35-75 DEG C, so as to obtain an acrylonitrile polymer; then filtering, taking off and defoaming, so as to prepare a spinning solution; spinning the spinning solution by virtue of a dry-jet wet process, stretching, oiling, drying, densifying, drawing by hot steam, and thermoforming, so as to obtain the binary polyacrylonitrile carbon fiber precursor. By adopting the preparation method, double functional group beta-itaconic acid ester amide is adopted as a comonomer, and a polyacrylonitrile macromolecule for the carbon fiber precursor is prepared by binary copolymerization and substituted ternary copolymerization. Thus, the dosage of the comonomer is reduced, meanwhile, the structural regularity of the polyacrylonitrile macromolecule is improved, and the prepared carbon fiber precursor is even in structure, small in fineness and high in strength.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com