Method for preparing high-modulus carbon fiber by adopting precursor drawing technology

A carbon fiber and fiber technology, which is applied in the field of preparing high-strength and high-modulus carbon fiber, can solve the problems of affecting the mechanical properties of fibers, the method of physically stretching the fiber properties of the original silk fiber, and the cumbersome processing of equipment, etc. Oxidation and carbonization efficiency, effect of reducing fiber microscopic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

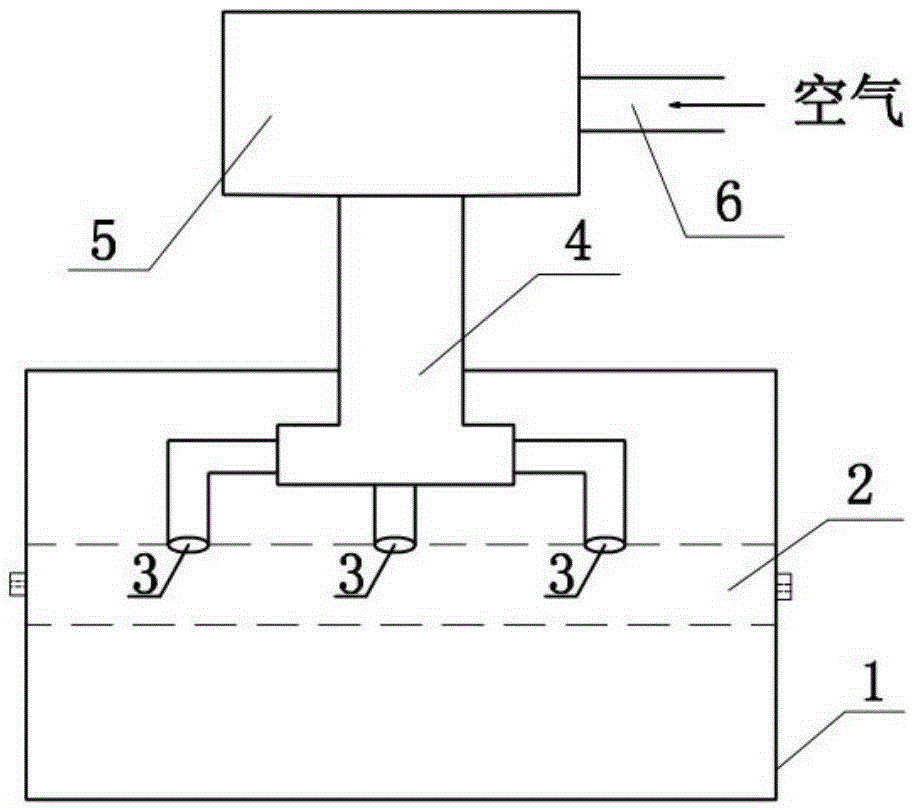

Image

Examples

Embodiment 1

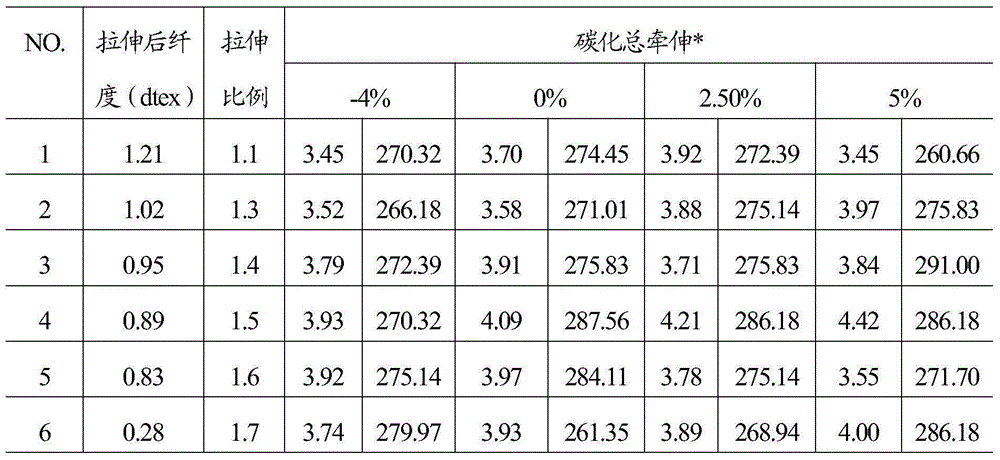

[0105] Embodiment 1: Adopt the method of the present invention to produce high-strength high-modulus carbon fiber

[0106] The implementation steps of this embodiment are as follows:

[0107] A. Preparation of spinning solution and wet spinning

[0108] It will be produced by Northwest Research Institute of Chemical Industry and sold under the trade name PAN-P1 with a weight average molecular weight of 3×10 5 The above polyacrylonitrile polymer was dissolved in dimethyl sulfoxide solvent to obtain a solution containing 95.2% by weight of polyacrylonitrile and 1.0% of unsaturated carboxylic acid comonomer, and the solution was placed under pressure 3.2kPa to remove the monomer contained in it and the entrained air bubbles, so that the spinning solution is clear and free of air bubbles. Then use a candle wick filter sold by Shanghai Runlan Filtration Equipment Co., Ltd. under the trade name RH-ZS candle filter to filter, and use the method described in the specification to mea...

Embodiment 2

[0120] Embodiment 2: adopt the inventive method to produce high strength high modulus carbon fiber

[0121] The implementation steps of this embodiment are as follows:

[0122] A. Preparation of spinning solution and wet spinning

[0123] The weight average molecular weight to be sold by Beijing Chemical Co., Ltd. under the trade name acrylonitrile is 3×10 5 The above polyacrylonitrile polymer was dissolved in dimethyl sulfoxide solvent to obtain a solution containing 95.5% by weight polyacrylonitrile and 0.5% unsaturated carboxylic acid comonomer, and the solution was placed under pressure 3.8kPa to remove the monomers contained in it and the entrained air bubbles, so that the spinning solution is clear and free of air bubbles, and then use the candles sold by Shanghai Si Filter Environmental Protection Equipment Co., Ltd. under the trade name Si Filter SL-ACF filter Cartridge filter is filtered, adopts the method described in specification to measure, and the viscosity of ...

Embodiment 3

[0135] Embodiment 3: Adopt the method of the present invention to produce high-strength high-modulus carbon fiber

[0136] The implementation steps of this embodiment are as follows:

[0137] A. Preparation of spinning solution and wet spinning

[0138] To be sold under the trade name Acrylonitrile by Shanghai Jinjinle Industrial Co., Ltd. has a weight average molecular weight of 3×10 5 The above polyacrylonitrile polymer was dissolved in dimethyl sulfoxide solvent to obtain a solution containing 95.8% by weight of polyacrylonitrile and 2.1% of unsaturated carboxylic acid comonomer, and the solution was placed under pressure 3.0kPa to remove the monomers contained in it and the entrained air bubbles to achieve the degree of clarity and no air bubbles in the spinning solution, and then use the candle wick sold by Shanghai Jiayu Filtration Equipment Co., Ltd. under the trade name ZL series candle type airtight filter Type filter to filter, using the method described in the ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com