A high shrinkage side by side type composite filament and a method for manufacturing the same

A composite fiber and manufacturing method technology, applied in fiber processing, fiber chemical characteristics, conjugated synthetic polymer rayon, etc., can solve the problems of lack of shrinkage, complicated process, increase manufacturing cost, etc., and achieve omission of false twisting process. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

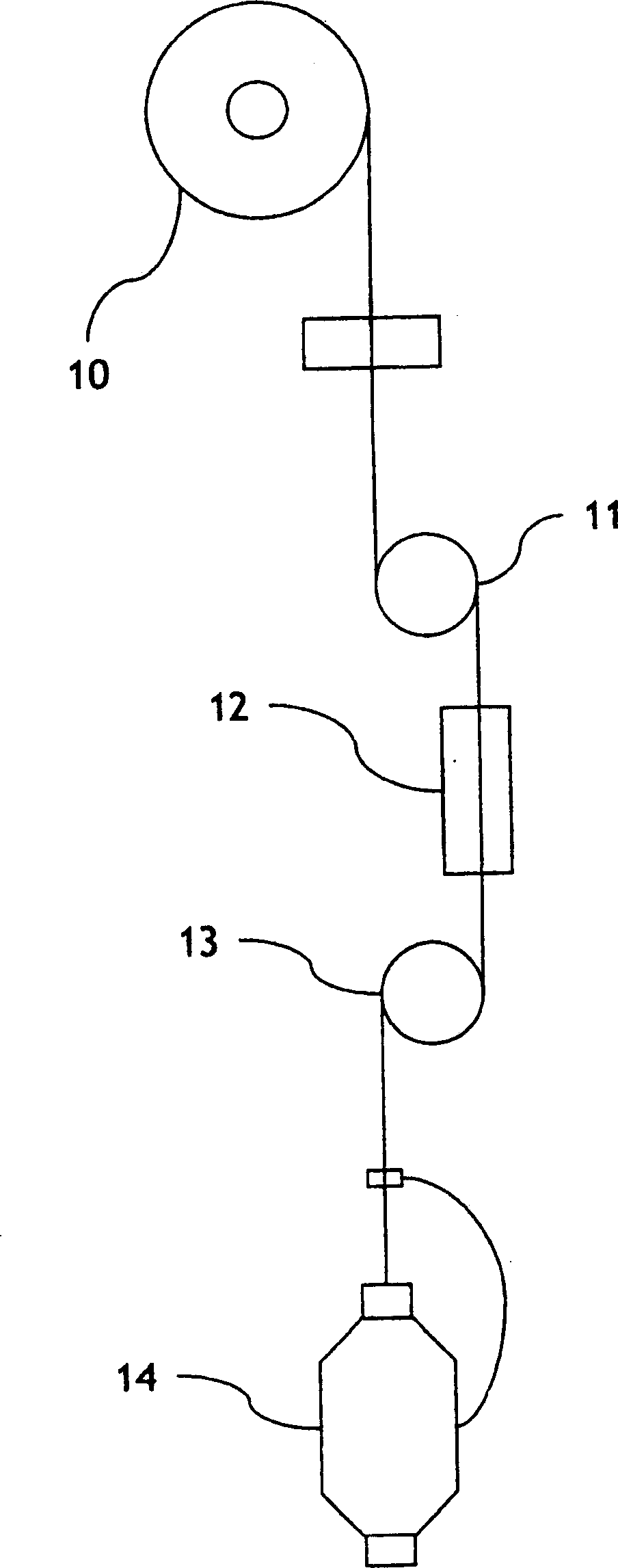

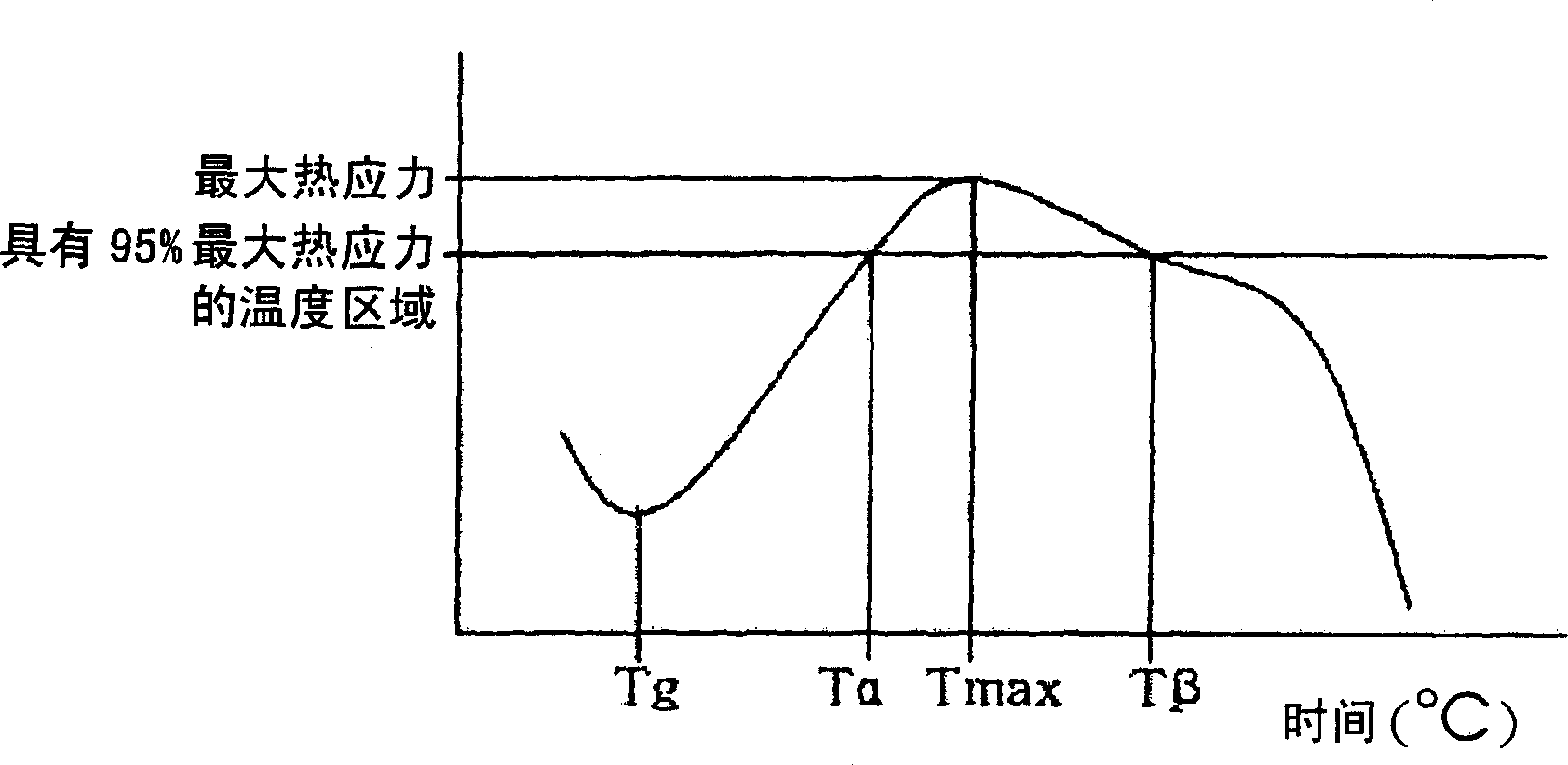

[0083] A polyethylene terephthalate with a number average molecular weight (Mn) of 15,000 and a polyethylene terephthalate with a number average molecular weight (Mn) of 25,000 are placed side by side at a speed of 3,000m / min and a temperature of 285°C type for composite spinning. exist figure 2 In the spinning and heat treatment process shown, the resulting material was drawn and heat treated at a spinning speed of 650 m / min and a spinning ratio of 1.68 to produce side-by-side bonded (composite) fibers with 100 denier / 24 fibers. The spinning and heat treatment temperature (hot plate temperature) is set at 132°C so that the composite fiber can satisfy the following physical properties:

[0084] Maximum thermal stress per denier: 0.21 g / denier

[0085] The temperature at which the maximum thermal stress occurs (Tmax): 155°C

[0086] Temperature region exhibiting 95% of maximum thermal stress (Tmax, 95%): 122 to 228°C

[0087] Next, a five-filament satin having a warp densi...

Embodiment 2

[0089]Polyethylene terephthalate having a number average molecular weight (Mn) of 12,000 and polyethylene terephthalate having a number average molecular weight (Mn) of 25,000 are placed side by side at a speed of 3,000 m / min and a temperature of 285°C type for composite spinning. in such as figure 2 In the spinning and heat treatment process shown, the obtained material was drawn and heat treated at a spinning speed of 650 m / min and a spinning ratio of 1.68 to prepare side-by-side composite fibers having 100 denier / 24 fibers. The spinning and heat treatment temperature (hot plate temperature) is set to 140°C so that the composite fiber can satisfy the following physical properties:

[0090] Maximum thermal stress per denier: 0.31 g / denier

[0091] The temperature (Tmax) showing the maximum thermal stress: 165°C

[0092] Temperature region exhibiting 95% of maximum thermal stress (Tmax, 95%): 122 to 228°C

[0093] Next, a five-filament satin having a warp density of 190 y...

Embodiment 3

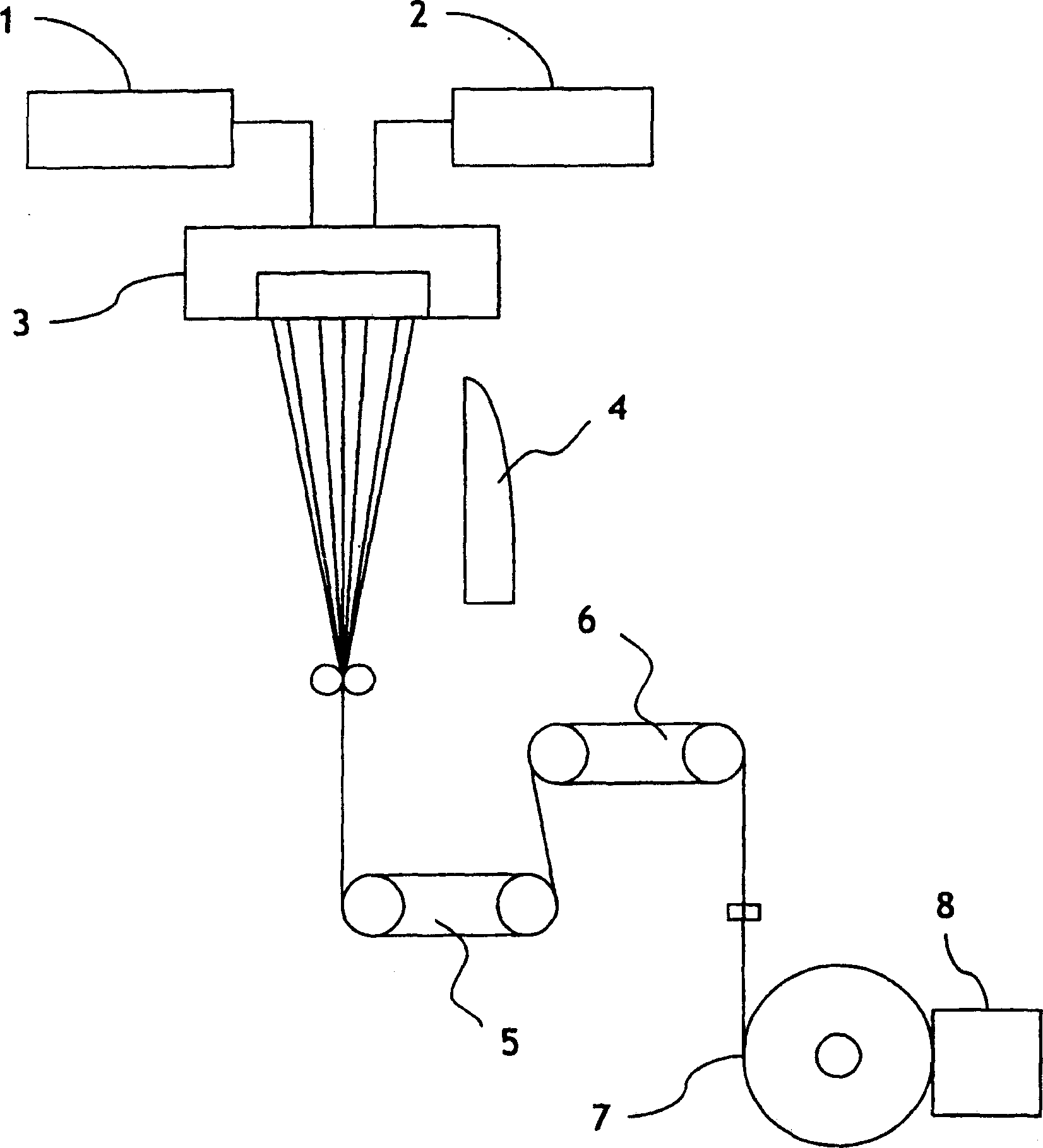

[0095] Polyethylene terephthalate having a number average molecular weight (Mn) of 16,000 and polyethylene terephthalate having a number average molecular weight (Mn) of 28,000 were composite-spun in a side-by-side type at a temperature of 290°C. The obtained material is in the figure 1 Drawing and heat treatment were carried out in the continuous drawing and baking process shown to produce side-by-side composite fibers having 100 denier / 24 fibers. The first godet temperature was set to 82°C, and its speed was set to 1,800 m / min. The speed of the second godet wheel is set to 4,815m / min, the speed of the take-up drum is set to 4,800m / min, and the temperature of the second godet wheel is set to 163°C so that the composite fiber can meet the following physical properties :

[0096] Maximum thermal stress per denier: 0.16 g / denier

[0097] The temperature (Tmax) showing the maximum thermal stress: 175°C

[0098] Temperature region exhibiting 95% of maximum thermal stress (Tmax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com