Production method of double-component spun-bonded non-woven fabrics

A non-woven fabric, production method technology, applied in textiles and papermaking and other directions, to achieve the effect of soft fiber feel, small fineness, and increased firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A two-component spun-bonded nonwoven fabric and a production method thereof, comprising the following steps:

[0025] (1) The slices of component PE and component PP with a melting point of 145°C were screened at a ratio of 1:1, and then dried and balanced at a vacuum of 45Pa and a temperature of 75°C for 35 hours;

[0026] (2) Heat and melt PE and PP polymers in a screw extruder at a temperature of 150°C. After melting, enter the melt filter to filter out impurities in the melt, and then calculate according to requirements. Enter metering pump and weigh, pressure 10Mpa after filtration, spinning system heat medium temperature 250 DEG C;

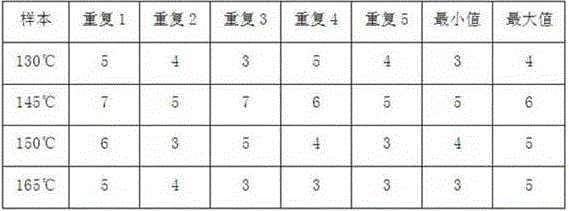

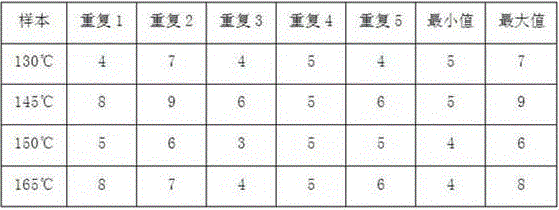

[0027] (3) The melt through the extruder is extruded from the spinning hole into the air, and while the thin stream of melt is cooled in the air, it is stretched at a certain speed to become thinner and longer. At this stage, the polymer melt is refined Simultaneous solidification, the fiber web is initially formed, and the pre-setti...

Embodiment 2

[0036] A two-component spun-bonded nonwoven fabric and a production method thereof, comprising the following steps:

[0037] (1) The slices of component PE and component PP with a melting point of 130°C were screened at a ratio of 1:1, and then dried and balanced at a vacuum of 30Pa and a temperature of 30°C for 15 hours;

[0038] (2) Heat and melt PE and PP polymers in a screw extruder at a temperature of 130°C. After melting, enter the melt filter to filter out impurities in the melt, and then calculate according to requirements. Enter metering pump to weigh, pressure 7Mpa after filtration, spinning system heating medium temperature 150 DEG C;

[0039] (3) The melt through the extruder is extruded from the spinning hole into the air, and while the thin stream of melt is cooled in the air, it is stretched at a certain speed to become thinner and longer. At this stage, the polymer melt is refined Simultaneous solidification, the fiber web is initially formed, and the pre-sett...

Embodiment 3

[0048] A two-component spun-bonded nonwoven fabric and a production method thereof, comprising the following steps:

[0049] (1) The slices of component PE and component PP with a melting point of 165°C were screened at a ratio of 1:1, and then dried and balanced at a vacuum of 75Pa and a temperature of 85°C for 50 hours;

[0050](2) Heat and melt PE and PP polymers in a screw extruder at a temperature of 165°C. After melting, enter the melt filter to filter out impurities in the melt, and then calculate according to requirements. Enter metering pump and weigh, pressure 15Mpa after filtration, spinning system heating medium temperature 320 DEG C;

[0051] (3) The melt through the extruder is extruded from the spinning hole into the air, and while the thin stream of melt is cooled in the air, it is stretched at a certain speed to become thinner and longer. At this stage, the polymer melt is refined Simultaneous solidification, the fiber web is initially formed, and the pre-set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking force | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com