Pulp axis take-off device of warp rebeaming machine

A pulp shaft and unwinding technology, which is applied in the field of parallel shaft machine pulp shaft unwinding device, can solve the problems of uneven tightness of the weaving shaft roll layer, unstable performance of the magnetic powder brake, uneven tension, etc., and achieve the effect of consistent tightness of the roll layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

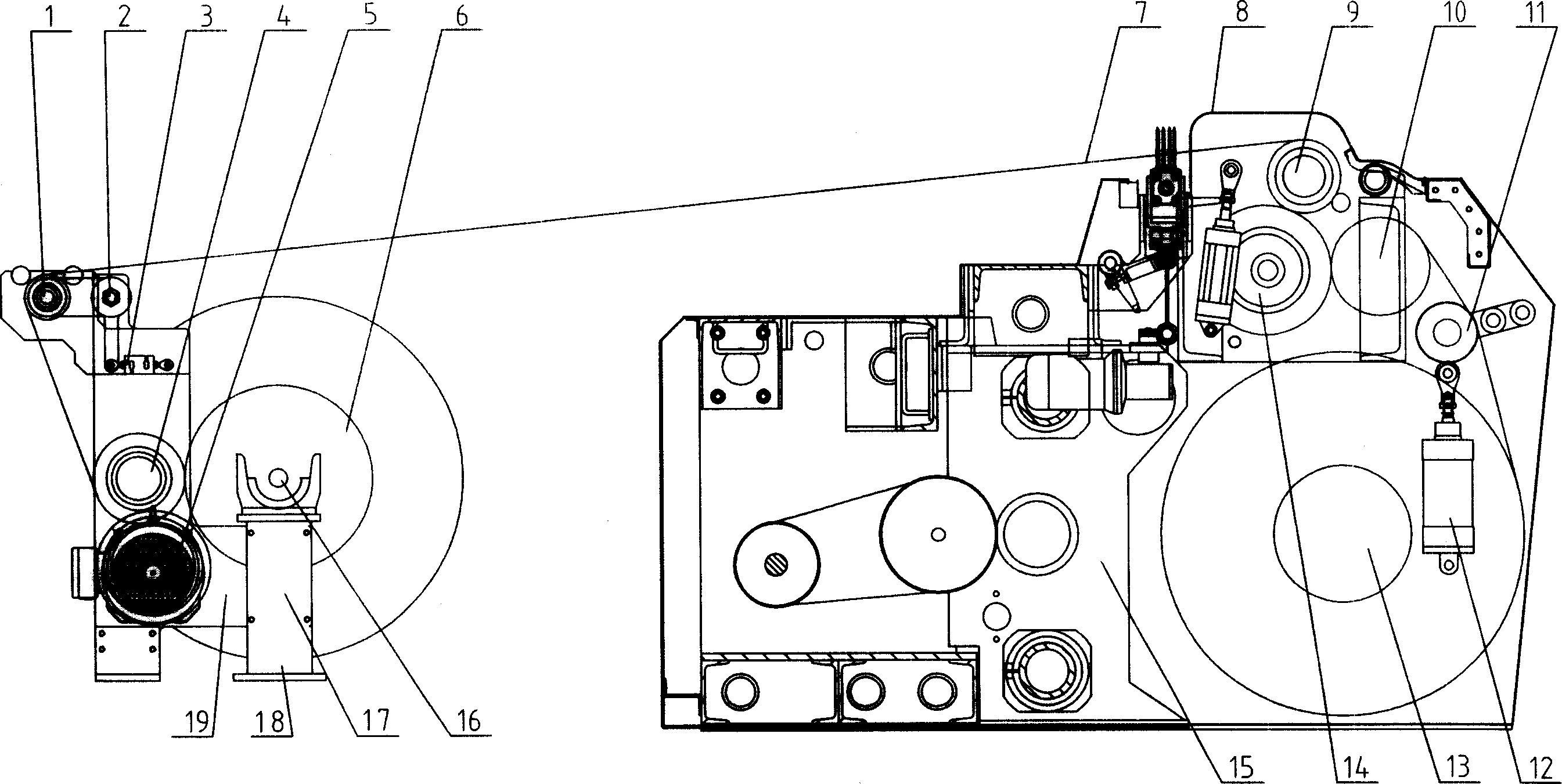

[0009] In the accompanying drawings, the present invention consists of an unwinding creel 18 and a head 15. Unwinding shaft frame 18 comprises bracket 17, paddle shaft 16, paddle shaft gear 6, intermediate gear 4, tension roller 1, support shaft 2, paddle shaft 16 is arranged on support 17, and one end of paddle shaft 16 is provided with paddle shaft gear 6 , the intermediate gear 4 meshes with the paddle shaft gear 6 and is arranged on the upper left side of the bracket 17, the motor reducer 5 is also arranged on the lower left side of the bracket 17, and the output shaft gear of the motor reducer 5 meshes with the intermediate gear 4 , the support shaft 2 is arranged on the upper left side of the bracket 17, the tension roller 1 is arranged on the support shaft 2 through the force arm, one end of the sensor force arm 19 is arranged on the support shaft 2, and the other end is connected with one end of the tension sensor 3, The other end of the tension sensor 3 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com