Apparatus used for generating thread yarn coil

A technology of rope yarn and yarn roll, applied in the directions of transportation and packaging, liquid/gas/vapor yarn/filament processing, textile and papermaking, etc., can solve problems such as unfavorable production speed, improve expected service life, and maximize stability , the effect of high winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

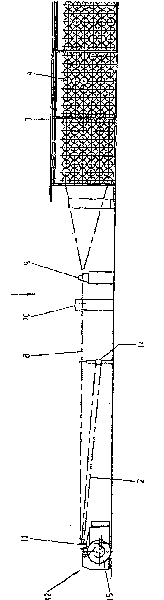

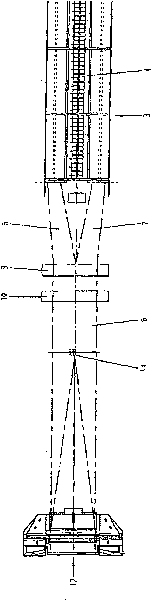

[0024] figure 1 A device 1 for producing a skein roll from a skein is shown.

[0025] The device 1 has a creel 3 in which a plurality of yarn bobbins 4 are arranged. Draw yarn from each bobbin. The yarn bobbins are arranged on both sides of the center plane 5 so that two yarn sheets 6 , 7 are drawn out of the creel 3 . For example, when a corresponding number of yarn bobbins 4 are present, 300-500 yarns can be withdrawn from the creel 3 by the order of magnitude.

[0026] The two parts, the yarn sheets 6 , 7 , are combined to form a yarn sheet 8 and passed through a pretreatment device 9 in which the yarn sheets 8 can be sucked off, for example. Such a pretreatment mechanism 9 is optional.

[0027] The yarn sheet 8 is then passed through the warp part reed 10 . This part warp reed 10 is also optional, that is to say it can be omitted.

[0028] The yarn sheet 8 is then guided to a steering mechanism 11 arranged in the region of the warping machine 12, in combination with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com