Defining and displaying device of fiber machine

A display device and mechanical technology, which is applied in the directions of weaving auxiliary equipment, looms, warping machines, etc., to achieve the effect of simplifying the structure, reducing the processing and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

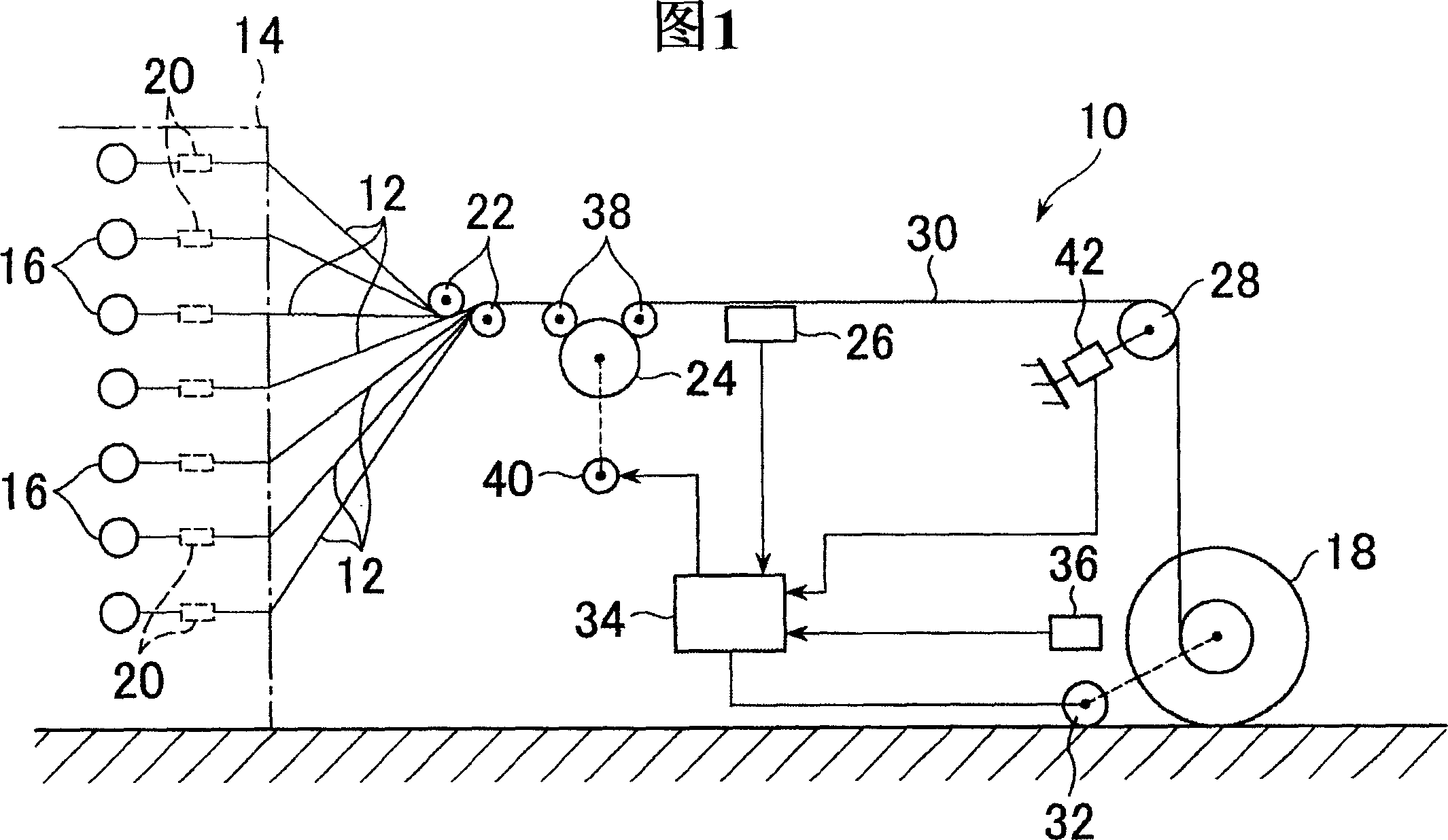

[0024] Referring to Fig. 1, a textile machine 10 serves as a warp winding device. The plurality of yarn feeders 16 around which the warp yarn 12 is respectively wound around the creel 14 are arranged in parallel in a plurality of rows along three-dimensional directions such as the up-down direction, the left-right direction, and the front-rear direction. The warp winding device 10 is a winding device for winding the warp yarns 12 drawn out from the respective yarn feeders 16 placed on the roving creel 14 in a sheet form to a winding shaft 18 .

[0025] These warp yarns 12 wound on the yarn feeder 16 are drawn out from the roving creel 14 through the tensioner 20 provided by each roving frame 1 yarn feeder, and then passed through a pair of guide rollers 22 to gather into a sheet. shape, also through take-up roller 24, warp yarn sensor 26 and tension roller 28 are drawn out simultaneously, thereby these many warp yarns 12 are juxtaposed into sheet shape and are wound on the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com