Modified polyester complex fiber and preparation method thereof

A composite fiber and modified polyester technology, applied in the field of polyester composite fibers, can solve the problems of dyeing process, dye selection limitation, dye usage limitation, inability to continuous production, etc., to improve hand comfort, reduce dyeing cost, The effect of not easy to color difference

Active Publication Date: 2010-12-08

CHINESE TEXTILE ACAD

View PDF8 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for ordinary polyester, due to its structural characteristics, it is difficult to achieve normal pressure dyeing, and high temperature and high pressure dyeing cannot be continuously produced industrially.

For example, Chinese patent application CN200810242976.4 discloses a new type of double-color side-by-side composite polyester fiber, which is a new type of double-color side-by-side composite fiber of ordinary semi-dull PBT and PET polyester. Its cross section is peanut-shaped, and the composite fiber can only Dyeing with disperse dyes under normal pressure, the use of dyes is limited, especially after blending with wool, etc., the dyeing process and the choice of dyes are limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Login to View More

Abstract

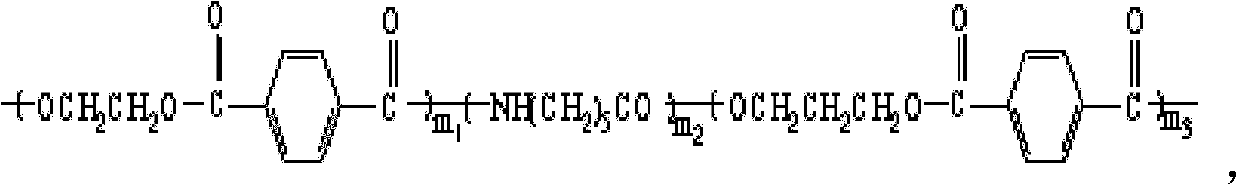

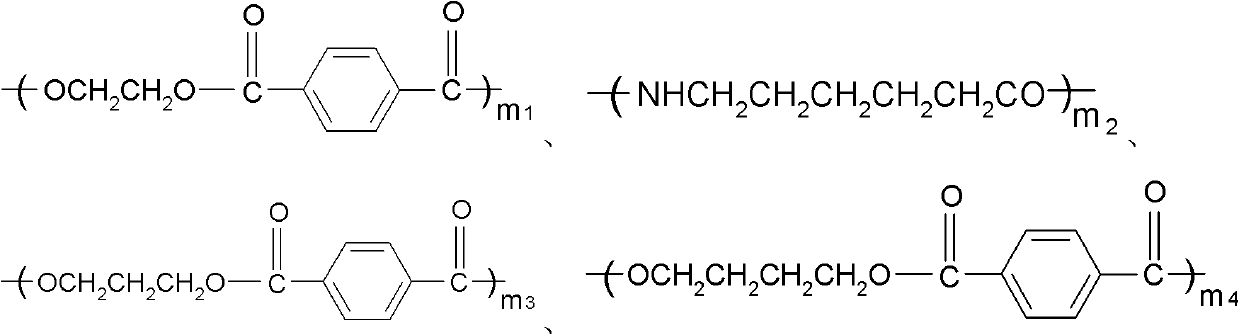

The invention provides a modified polyester complex fiber. The complex fiber is prepared by compounding modified polyester and thermoplastic resin, wherein the modified polyester accounts for 10 to 90 percent of the total weight of the complex fiber, and the thermoplastic resin accounts for 10 to 90 percent of the total weight of the complex fiber; and the modified polyester structure comprises structural units shown in the specifications, wherein m1 is more than 1 and less than 160, m2 is more than 1 and less than 70, m3 is more than or equal to 0 and less than 20, and m4 is more than or equal to 0 and less than 20. The complex fiber can be dyed at normal temperature and normal pressure by using acid dye and disperse dye, and has the advantages of high color fastness, high elasticity and comfortable handfeel.

Description

technical field The invention relates to a polyester composite fiber, in particular to a modified polyester composite fiber and a preparation method thereof. Background technique Polyester fiber is widely used in various fields due to its excellent mechanical, physical and chemical properties. With the development of the polyester industry, our life has become rich and colorful. The development of many new polyester modified varieties has greatly enriched the diversity of the fabric market. In recent years, with the gradual acceleration of my country's economic development, and The integration of the world trend has made great progress in my country's polyester industry, and the chemical fiber market has followed the world trend. Each fiber has its advantages and disadvantages, and in life, what people pursue is not only the mechanical properties of the fabric, but also a variety of colors to increase its beauty. But for ordinary polyester, due to its structural characteri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01F8/14D01F8/12D01D5/34D01D5/32D01D5/28D01D5/12D01D10/02D02G1/00D02G1/20D06P3/24D06P3/26

Inventor 吴鹏飞崔宁刘伯林黄庆李杰史贤宁崔华帅

Owner CHINESE TEXTILE ACAD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com