Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Not prone to chromatic aberration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Real stone paint, and preparation method and construction method thereof

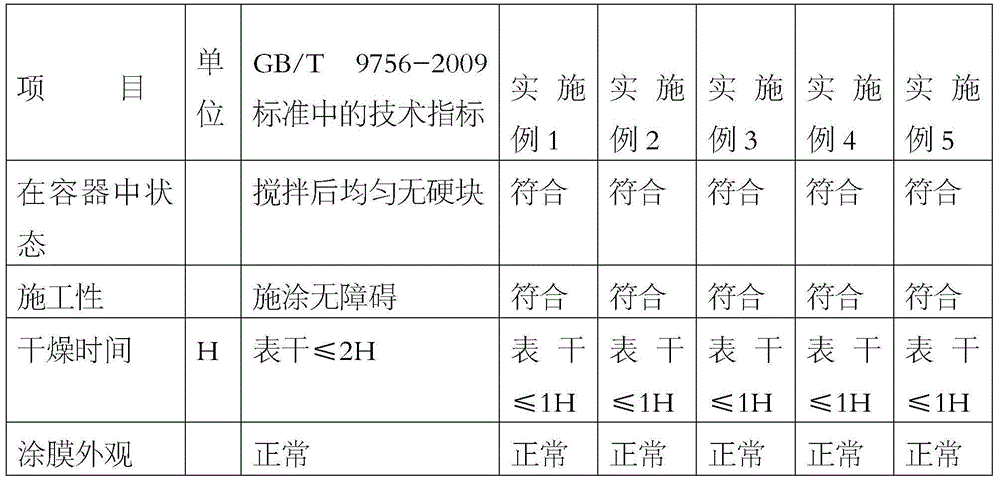

The invention provides a real stone paint. The real stone paint comprises, by weight, 90-130 parts of water, 2-5 parts of hydroxyethyl cellulose, 2-5 parts of a dispersant, 1-3 parts of a wetting agent, 4-8 parts of an antifoaming agent, 2-3 parts of an antiseptic, 100-150 parts of an emulsion, 5-12 parts of a film forming assistant, 1-3 parts of a pH adjusting agent, 5-20 parts of an antifreeze agent and 400-900 parts of a color sand component, wherein the color sand component comprises two or more than two natural stone flours with similar color. The invention further provides a preparation method of the real stone paint. The natural stone flowers with similar color in raw materials are blended in the embodiment of the invention to balance the color difference of all the natural stone flours, so even the color of one of the natural stone flours changes, the color difference of real stone paint products in batches is very small under the contrast of other natural stone flours with similar color, thereby the color difference change of the real stone paint is well controlled.

Owner:DRAGON BRAND COATINGS (BEIJING) CO LTD

Clear glaze and method for manufacturing same

InactiveCN101182238AWide firing temperatureNot prone to chromatic aberrationPotassium feldsparCalcite

The invention discloses a transparent glaze and a preparation method thereof. The weight percentages of ach component of the transparent glaze are 10 percent to 35 percent of potassium feldspar powder, 8 percent to 25 percent of calcite, 8 percent to 10 percent of kaolin, 2 percent to 5 percent of quartz, 9 percent to 15 percent of calcined kaolin, 5 percent to 8 percent of burning talc, 3 percent to 5 percent of alumina, 1 percent to 3 percent of barium carbonate, 3 percent to 10 percent of transparent of fusion cake, 0.15 percent to 0.35 percent of methyl, 0.2 percent to 0.4 percent of tripolyphosphate and 15 percent to 30 percent of water. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is less than 0.15 percent. The technical process of the manufacturing method is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature of ball milled glaze slurry is 1200 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the performance of the glaze material is good; the glaze surface is smooth and is not easy for producing chromatic aberration; the cost can be reduced by about 35 percent.

Owner:霍炳祥

Cover glaze and preparation method thereof

The invention discloses a cover glaze which is characterized in that: the constituents of the cover glaze are as follows by weight percentage: 90-96 percent of matte fusion cake, 4-6 percent of gas knife soil, 0.08-0.2 percent of sodium carboxymethylcellulose, 0.03-0.36 percent of industrial sodium tripolyphosphate, and 0.20-0.26 percent of ceramic dispergator, and water accounting for 20-26 percent of total proportion of the raw materials. The preparation process flows of the cover glaze are as follows: raw material incoming inspection--batching--ball milling--detection--deironing and sieving--decaying--warehousing and being sieved by 250 meshes of deironing oscillating screen. The ball milling time is 7-10 hours, and ball-milling glazeslip specific gravity is 1.4-1.9g / cm<3>, and the fineness is 0.6-1.0mm; the flowing speed of the ball-milling glazeslip is controlled above 55s. The cover glaze has the advantages of transparent and smooth performance, bright color and luster and wide market prospect.

Owner:李建平

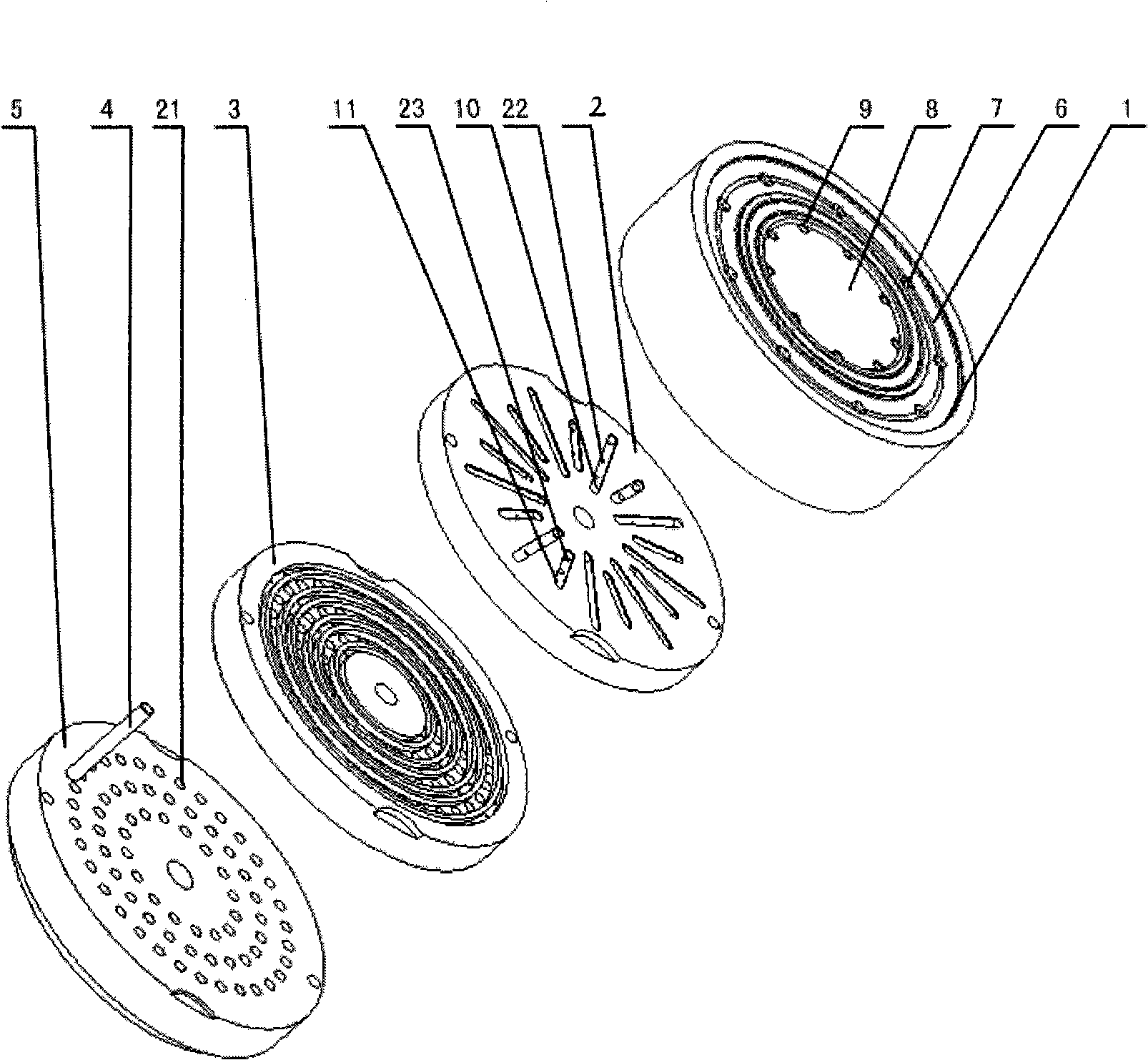

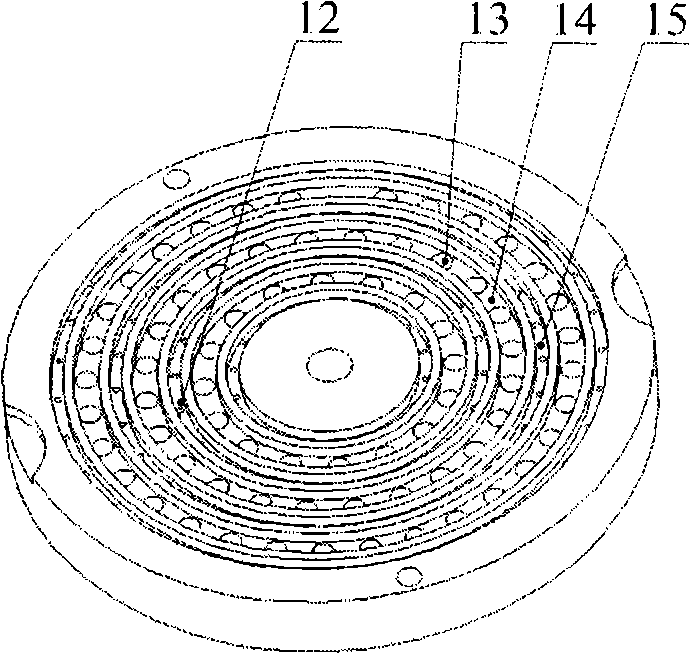

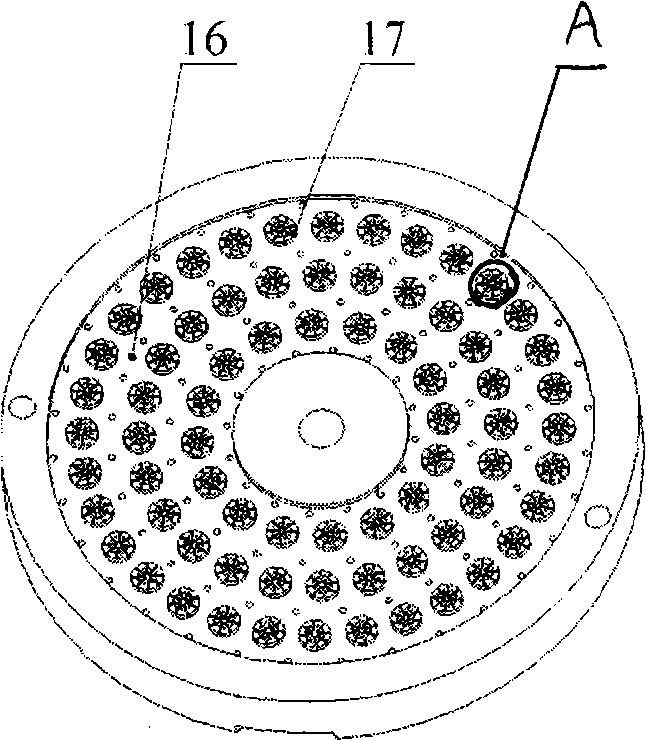

Superfine polyester-nylon composite spinning component

The invention discloses a superfine polyester conjugate spinning component with creative design and simple structure, which comprises a slant hole plate, a radiation plate, a composite plate, a positioning pin and a spinneret plate; the difficulties are as follows: a boss of a discharge surface is provided with a star-shaped structure; the star-shaped structure is provided with a star-shaped diversion trench; the cross section of the bottom of the trench is designed into a rectangle with the chamfer angle of R0.03 to R0.05; the creative and simple design of the star-shaped structure and the chamfer angle at the bottom of the star-shaped diversion trench prevents flowing dead corners produced by fluid turbulent eddies, so that the fluidity of different types of polymer is greatly improved; therefore, the fabric made of the product spun by the spinning component is soft to touch, does not fuzz, has no color difference in dyeing, and very conveniently solves the technical difficulties of the industry which cannot be overcome.

Owner:苏州市吴中喷丝板有限公司

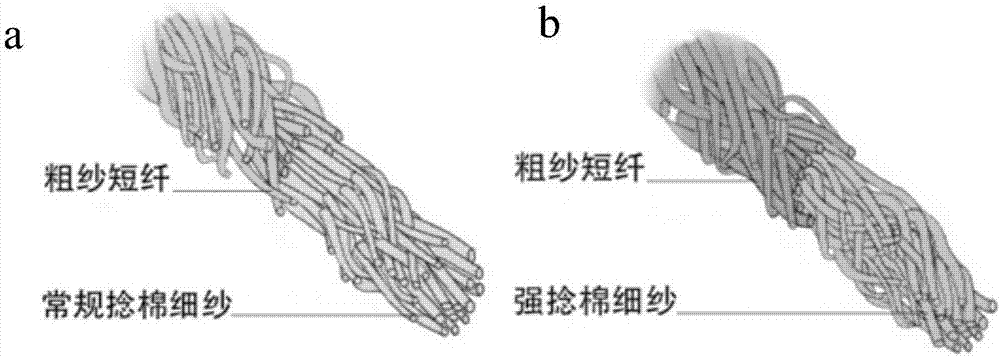

Sirofil pure cotton elastic yarn and manufacturing and application thereof

InactiveCN106917174AComfortable to wearEasy to dressMercerising of yarns/threads/filamentsYarnYarnFiber

The invention relates to a sirofil pure cotton elastic yarn and manufacturing and applications thereof. The pure cotton elastic yarns form a pure cotton coating structure by roving which forms a coating layer and spun yarns which forms a core layer through a sirofil spinning technology. The sirofil pure cotton elastic yarn is obtained by twisting and spinning roving and spun yarns in the same direction on a sirofil spinning frame, and finishing. Pure cotton fibers which do not have elasticity originally have natural elasticity after certain processing procedures and treatment, and the sirofil pure cotton elastic yarns replace conventional spandex elastic core-spun yarns used in an elastic jean fabric, so that technical problems of exposed cores, difficult weaving, and difficult control of breadth caused by using stretch yarns are prevented. The sirofil pure cotton elastic yarns are beneficial for enhancing stiff and smooth property of the elastic jean fabric and do not reduce fabric hand feeling. The invention provides a new yarn raw material for a conventional low-medium elastic jean fabric.

Owner:DONGHUA UNIV

Fancy glaze and method for manufacturing same

The invention discloses a fancy glaze and a preparation method thereof. The weight percentages of each component of the fancy glaze are 18 percent to 38 percent of potassium feldspar, 10 percent to 23 percent of calcite, 4 percent to 7 percent of talc, 3 percent to 7 percent of quartz, 4 percent to 10 percent of zirconium silicate, 2 percent to 5 percent of zinc oxide, 5 percent to 10 percent of alumina, 3 percent to 6 percent of barium carbonate, 6 percent to 10 percent of black mud, 0 percent to 0.3 percent of tripolyphosphate, 6 percent to 20 percent of water, 0 percent to 10 percent of squeegee oil and 0 percent to 10 percent of printing paste. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is 100 percent. The technical process of the method of manufacturing the fancy glaze is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature is 1195 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the glaze surface is smooth; the sintering temperature range is wide; the chromatic aberration can not be produced easily; the finished product rate is high; the cost can be reduced by about 40 percent.

Owner:清远市欧雅陶瓷有限公司

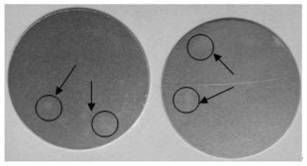

Manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance

ActiveCN108690944AImprove corrosion resistanceImprove surface conditionHot-dipping/immersion processesFurnace typesCorrosionCoating

The invention discloses a manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance. The manufacturing method comprises the following steps: increasing the oxygen partial pressure in an annealing furnace to 30-80 ppm when basic strip steel enters a preheating section of the annealing furnace, wherein the dew point of the preheating furnace is 0-50DEG C, the furnace pressure of the annealing furnace is 300-500 Pa, and the preheating temperature is 500-700 DEG C; controlling the dew point of a soaking section at 30 DEG C below zero to 30 DEG Cafter the basic strip steel enters the soaking section, wherein the hydrogen content in percent by volume is 15-25%; and finally, controlling the cooling speed at 20-100 DEG C / s for cooling, wherein the basic strip steel enters a zinc pot to produce Mg-containing hot dipped steel plates. Mg-enriched ternary eutectic phase sheets in coatings of the steel plates are small in interlayer spacing, relatively short and uniform in distribution, Mg-containing oxides are unlikely produced, and the hot dipped steel plates have high corrosion resistance and good blacken resistance. In a severe environment, the corrosion resistance of the coatings is 2-3 times of that of conventional hot dipped steel plates, or the corrosion resistance is even higher, and the quality of the surface tissues of the coatings is good.

Owner:武汉钢铁有限公司

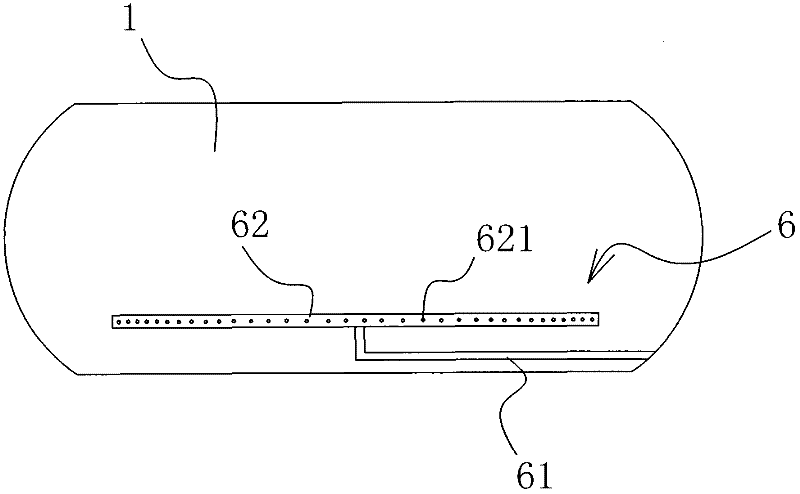

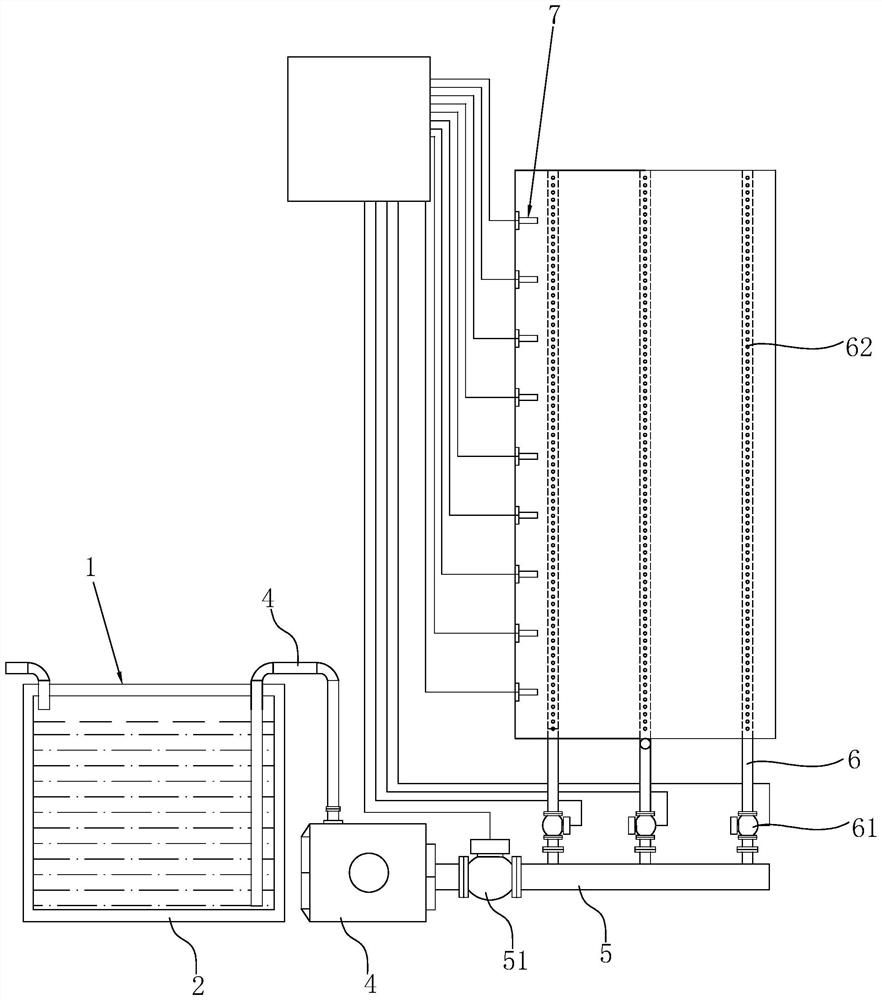

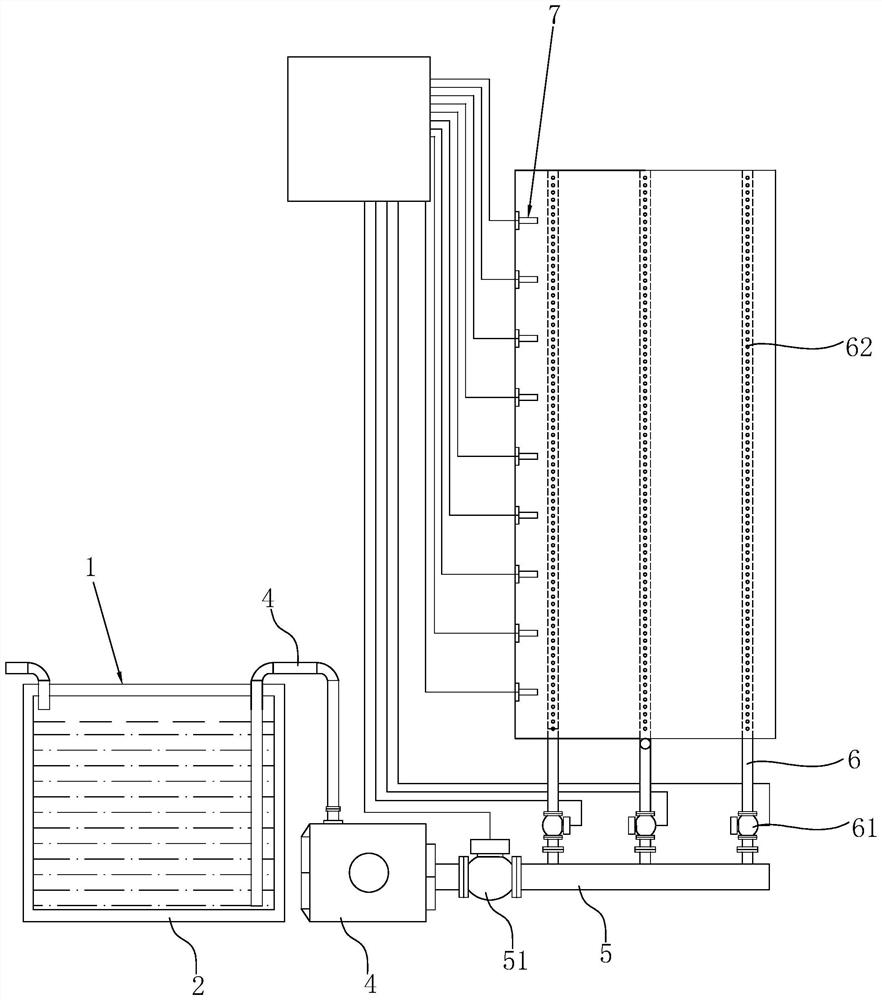

High-temperature high-pressure dyejigger

InactiveCN102493139AReasonable designSimple structureLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsFrequency conversionEngineering

The invention belongs to the technical field of printing and dyeing equipment, in particular to a high-temperature high-pressure dyejigger which solves the technical problems that the prior art is not reasonable enough in design, and the like. The high-temperature and high-pressure dyejigger comprises a pressure container, wherein the side part of the pressure container is provided with a window, and a side cover is arranged at the window; a first roller and a second roller are arranged in the pressure container, wherein a dye vat is arranged below the first roller and the second roller; a steam input mechanism is connected to the pressure container; the first roller and the second roller are respectively connected with a first frequency-conversion drive device and a second frequency-conversion drive device; a vertical tensioning mechanism is arranged between the first roller and the dye vat; and another vertical tensioning mechanism is arranged between the second roller and the dye vat. The high-temperature high-pressure dyejigger disclosed by the invention has the advantages of reasonable design, simple structure, difficulty in generating chromatic aberration, easiness in operation and use, time and labor saving, high working efficiency and capability of effectively ensuring the evenness of fabrics. According to the high-temperature high-pressure dyejigger, pressure balance and temperature evenness in the pressure container can be realized, the dyeing quality is effectively ensured, and the product quality is good.

Owner:骆玛丽

Medical blue laser printing film and preparation method

ActiveCN106965586AImprove adhesion fastnessEliminate electrostatic adsorptionDuplicating/marking methodsConjugated diene hydrocarbon coatingsBatch productionMicrometer

The invention relates to a medical blue laser printing film and a preparation method. The medical blue laser printing film comprises a transparent PET base material, wherein a laser printing coating is arranged on the front surface of the transparent PET base material, and a blue antistatic layer is arranged on the back surface of the PET base material; the preparation method comprises the following steps: step 1, preparing the coating material of the laser printing coating; step 2, coating to form the laser printing coating: performing slope flow extrusion coating, heating with steam, drying, and enabling the drying temperature to reach 100 DEG C or above and the dry basis thickness of the coating to reach 10 micrometers; step 3, preparing the coating material of the blue antistatic layer; step 4, coating to form the blue antistatic layer: performing slope flow extrusion coating, heating with steam, drying, and enabling the drying temperature to reach 100 DEG C or above and the dry basis thickness of the coating to reach 2-2.5 micrometers. The medical blue laser printing film prepared by adopting the preparation method is suitable for high resolution laser printing, anti-adhering, low in friction coefficient, static resistant, high in adhesion capability, good in glossiness, blue and transparent in appearance, acid-base resistant, high in wear resistance, environment-friendly, simple and convenient in manufacturing method, and suitable for batch production.

Owner:江苏耐斯数码科技股份有限公司

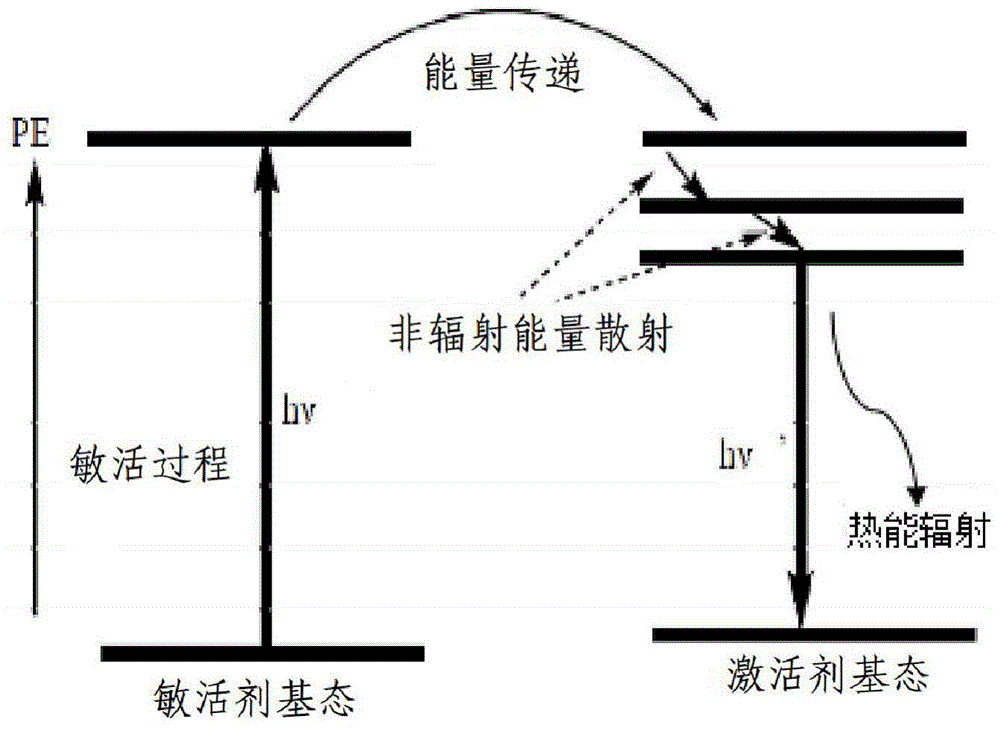

Indoor water-based paint capable of converting light energy into heat energy and preparation method thereof

InactiveCN104087088AEffective absorptionReduce harmRadiation-absorbing paintsWater basedLight energy

The invention relates to an indoor water-based paint capable of converting light energy into heat energy and a preparation method thereof. The indoor water-based paint is prepared from the following raw materials in parts by mass: 20-30 parts of water, 0.1-0.4 part of thickener, 0.05-0.2 part of pH regulator, 0.2-0.4 part of wetting agent, 0.1-0.4 part of dispersing agent, 10-30 parts of nano titanium dioxide, 4-10 parts of nano diatom ooze, 0.3-0.8 part of polyhydroxyphenylbenzoyl resorcinol derivative, 0.1-0.5 part of photostabilizer, 3-20 parts of pigment, 15-30 parts of filler, 9-17 parts of emulsion, 0.1-0.4 part of film-forming assistant, 0.1-0.4 part of bactericidal mold preventive and 0.2-0.5 part of retarder. The indoor water-based paint can effectively absorb high-energy light rays generated by indoor daylight lamps and household appliances, and has the advantages of excellent color retention, excellent adhesive force, excellent flexibility, excellent impact strength, proper hardness, no toxicity, no smell, high safety and environment friendliness.

Owner:SKSHU PAINT

Coarse-pore EVA molded foaming material and preparation method thereof

The invention relates to the field of plastic mold foaming, and provides a coarse-pore EVA molded foaming material for the problem of non-uniform pores of the coarse-pore EVA molded foaming material.The coarse-pore EVA molded foaming material is prepared from the following components in parts by mass: 10 to 20 parts of an ethylene-vinyl acetate copolymer, 55 to 78 parts of high pressure polyethylene, 5 to 10 parts of a high temperature foaming agent, 3 to 10 parts of a medium temperature foaming agent, 0.5 to 1 part of a crosslinker DCP, 0.5 to 1 part of zinc oxide, and 0.3 to 0.8 part of stearic acid. A preparation method of the coarse-pore EVA molded foaming material comprises the following steps: S1, performing mixing to form a mixture; S2, performing one-time opening; S3, performing secondary opening; and S4, performing foaming. By using the high temperature foaming agent and the medium temperature foaming agent, the melting point of the foaming agent is different from the meltingpoints of the ethylene-vinyl acetate copolymer and the high pressure polyethylene, so that the foaming agent is not easily decomposed in the mixing process, and coarse pores of the EVA molded foamingmaterial are more uniform and do not easily have chromatic aberration; and meanwhile, the tensile strength and the anti-seismic property of the EVA molded foaming material are not easily affected.

Owner:广州市欧橡隔热材料有限公司

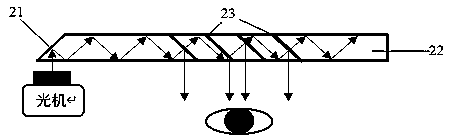

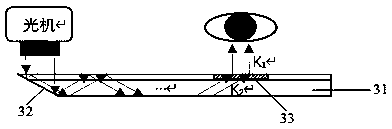

Waveguide display device and augmented reality display equipment

PendingCN111474721AImprove uniformityNot prone to chromatic aberrationOptical elementsPhysicsLight wave

The invention relates to a waveguide display device and augmented reality display equipment. The waveguide display device comprises a waveguide substrate, a geometrical optical input element and a diffractive optical output element, wherein the geometrical optical input element is arranged in the light wave input area of the waveguide substrate and is used for coupling input light waves into the waveguide substrate in a geometrical optical mode; the waveguide substrate is used for transmitting the light waves coupled into the waveguide substrate through the geometrical optical input element tothe diffractive optical output element in a total reflection mode; the diffractive optical output element is arranged in the light wave output area of the waveguide substrate and used for outputtinglight waves transmitted to the diffractive optical output element in a diffractive optical mode.

Owner:谷东科技有限公司

Yarn spinning process of cotton polyester siro-spun AB yarns

InactiveCN105821547AStrong cloth surface hazy feelingImprove visual effectsDrafting machinesCarding machinesPolyesterYarn

The invention relates to the field of spinning and weaving and particularly relates to a yarn spinning process of cotton polyester siro-spun AB yarns. The yarn spinning process comprises the following steps of: (1) prefabricating a blended drawing stripe; (2) a drawing procedure: taking 6 threads of A yarn prefabricated drawing stripes and one thread of B yarn prefabricated drawing stripe and preparing into the blended drawing stripe containing 88% of polyester and 12% of cotton; taking 4 threads of the blended drawing stripes and 4 threads of the B yarn prefabricated drawing stripes, and mixing according to a mutual separation manner to prepare AB yarn stripes, wherein in a drawing process, the back zone drafting multiple is set to be 1.75, the roller gauge length is 12mm*15mm and the vehicle speed is controlled to be 200m / min-220m / min; (3) a roving procedure; and (4) a spinning procedure. Compared with the prior art, the prepared siro-spun AB yarns have a relatively strong cloth hazy feeling and the cloth does not easily have color difference cross lines; prepared cotton polyester siro-spun AB gauze has good visual effect and aesthetic feeling.

Owner:SHANGHAI SHENAN TEXTILE

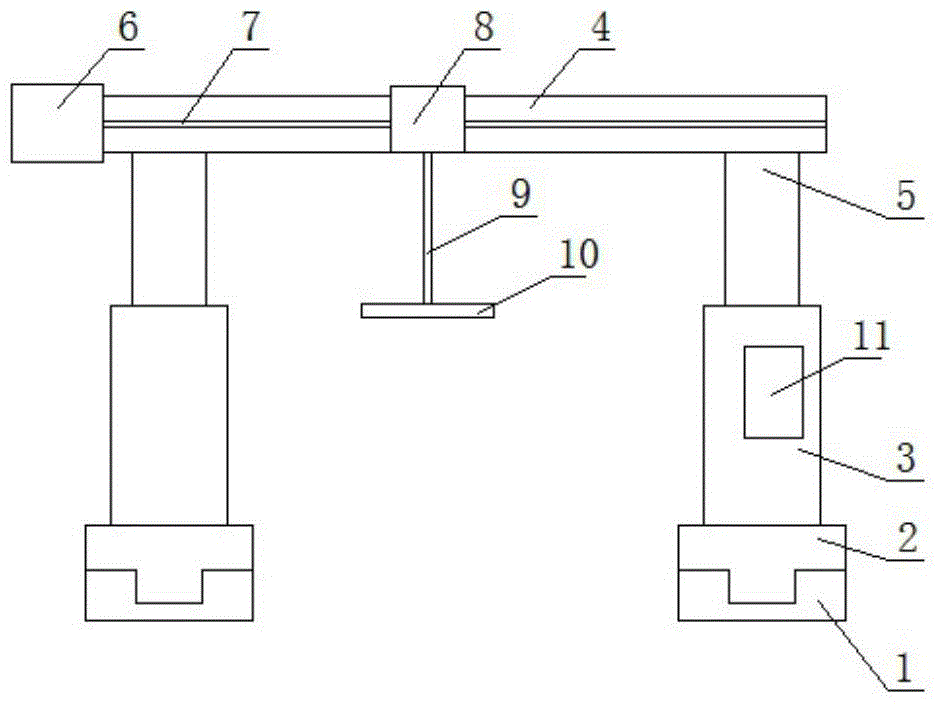

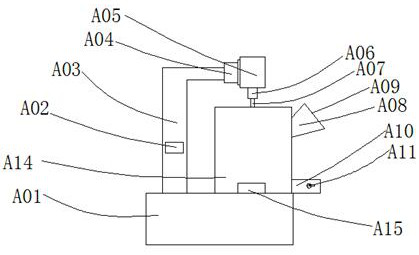

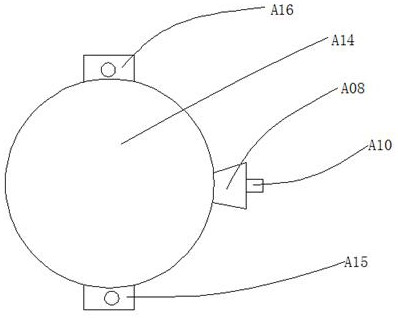

Paint stirring device

InactiveCN104415684AIncrease volumeNot prone to chromatic aberrationRotary stirring mixersHigh densityStructural engineering

The invention discloses a paint stirring device, comprising a track and a sliding base, wherein the sliding base is arranged on the track; a rack is arranged on the base, and comprises a beam and an upright post; a lifting device is arranged on the upright post; the beam is connected with a lifting gear; a fixed block is arranged on the beam; a stirring device is arranged on the fixed block; the fixed block is connected with a screw rod in the beam; a drive device which is connected with the screw rod is arranged at one end of the beam; the stirring device comprises a servo motor and a stirring wheel; the servo motor is connected with the stirring wheel through a connecting rod; and the lifting device, the servo motor and the drive device are electrically connected with a controller arranged at one side of the upright post. According to the paint stirring device, the problems that high-viscosity and high-density materials are large in viscosity and poor in liquidity, and cannot reach the stirring requirements are solved; a paint barrel matched with the paint stirring device is large in volume; the paint stirring device is suitable for mass production; and a color difference cannot occur easily.

Owner:中泰致远(天津)涂料有限公司

Low-temperature pre-treatment method of real silk textile

InactiveCN107641961AHigh color saturationReduce liquidityBiochemical fibre treatmentDry-cleaning apparatus for textilesWarm waterEngineering

The invention discloses a low-temperature pre-treatment method of a real silk textile. The low-temperature pre-treatment method comprises the following steps: (1) carrying out alkali liquid pre-treatment; (2) washing with warm water; (3) washing with cold water; (4) degumming with acidic protease; (5) carrying out counter-current washing in warm water; (6) sizing and airing. According to the low-temperature pre-treatment method disclosed by the invention, efficient degumming of the real silk textile can be realized at relatively low temperature, so that the quality in all aspects of the real silk textile can be improved.

Owner:HUZHOU NANXUN JINJIBAO TEXTILE

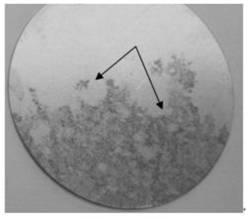

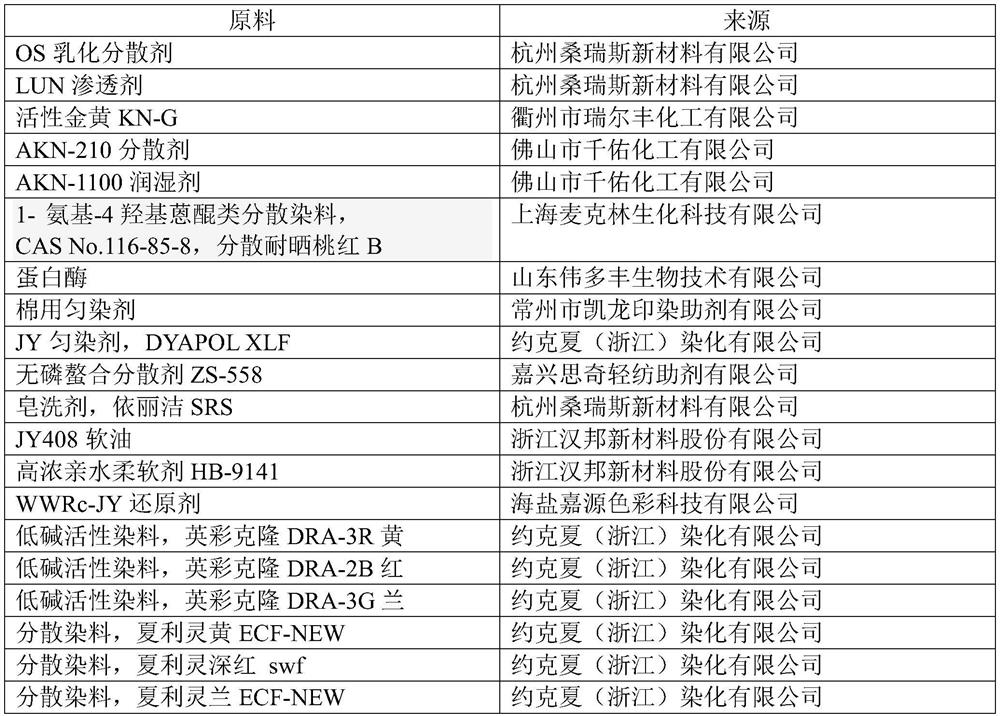

Dyeing and finishing process of cellulose acetate fiber and protein fiber silk fabric

ActiveCN113373705AUniform colorNot prone to chromatic aberrationDyeing processDisperse dyeColour fastness

The invention relates to the technical field of dyeing and finishing, in particular to a dyeing and finishing process of cellulose acetate fiber and protein fiber silk fabric. The dyeing and finishing process of the cellulose acetate fiber and protein fiber silk fabric comprises the following steps that S1, pretreatment is carried out; S2, a two-bath dyeing method is adopted for dyeing, the two-bath dyeing method is divided into two steps, the first step is that the protein fibers are dyed with reactive dye, and the second step is that the cellulose acetate fibers are dyed with disperse dye; S3, softening treatment is carried out; S4, drying treatment is carried out; and S5, shaping treatment is carried out. The cellulose acetate fiber and protein fiber silk fabric obtained through dyeing and finishing is not prone to generating color difference, uniform in color and luster, high in color fastness, not prone to decoloring, soft in hand feeling and comparable with real silk.

Owner:HAIYAN JIAYUAN PRINTING & DYEING

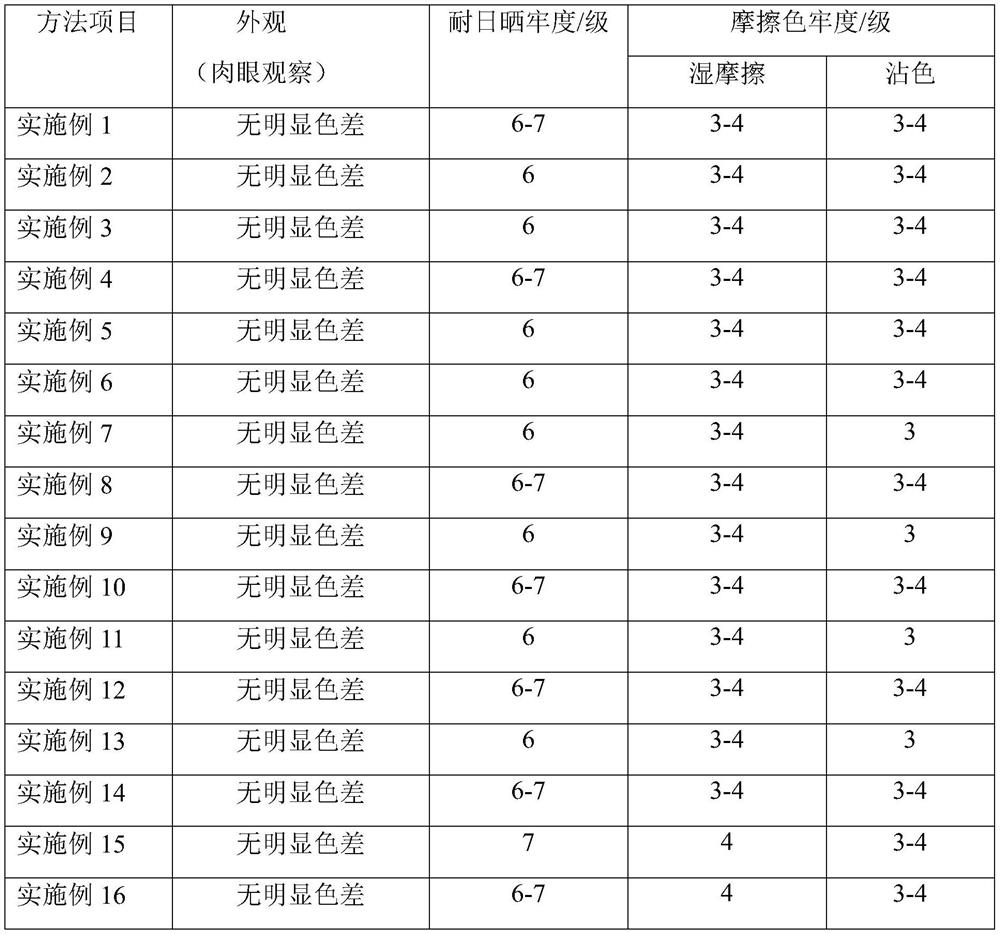

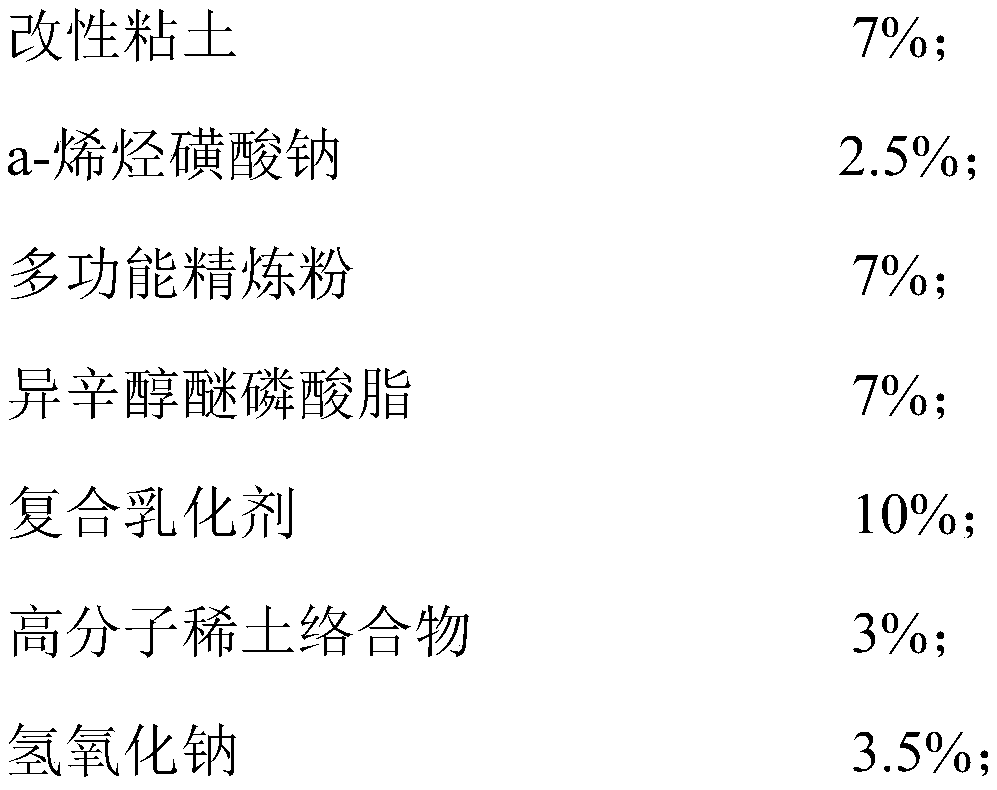

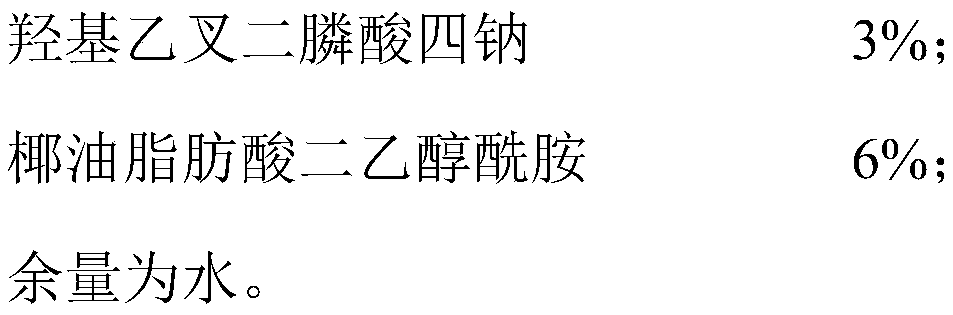

Fabric printing and dyeing pretreatment refining agent and preparing method thereof

The invention relates to the field of textile printing and dyeing technologies, in particular to a fabric printing and dyeing pretreatment refining agent and a preparing method thereof. The fabric printing and dyeing pretreatment refining agent is prepared from, by mass, 5-10% of modified clay and 1-5% of a polymer rare earth complex. The preparing method of the refining agent has the advantage ofbeing simple; the refining agent is used for refining textiles, the cleanliness, whiteness, capillary effect, strength and internal texture of the textiles can be significantly improved, and the refining agent also has an obvious effect of deepening and brightening during dyeing.

Owner:厦门谢田守望新材料有限公司

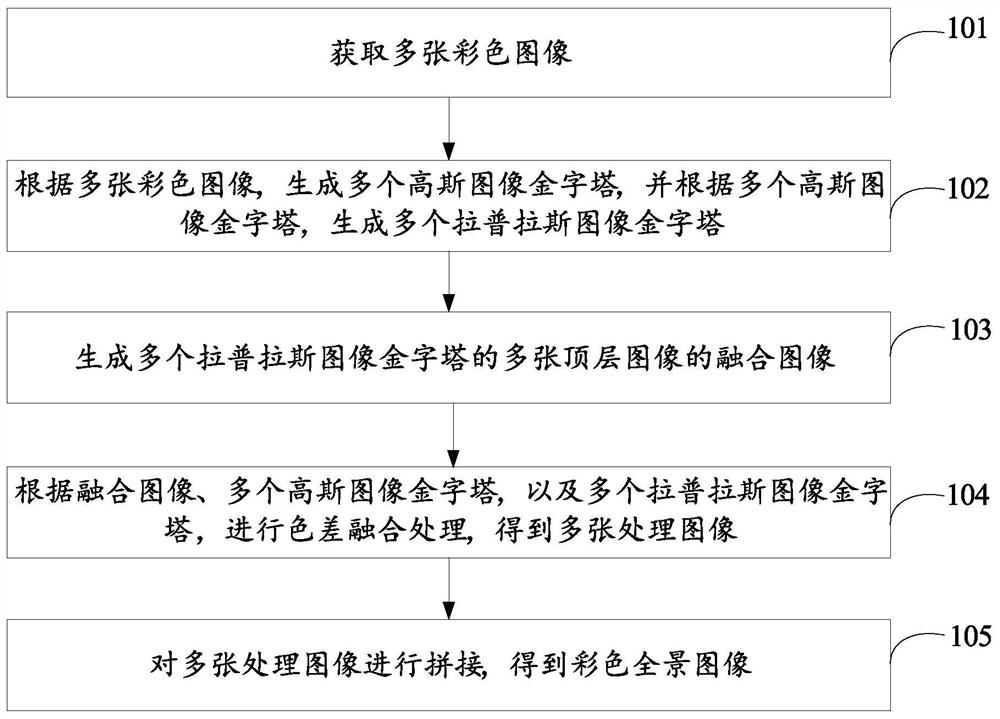

Image processing method and device, computer readable storage medium and electronic equipment

ActiveCN112102171AResolve color brightness differencesNot prone to chromatic aberrationImage enhancementImage analysisColor imageImaging processing

The embodiment of the invention discloses an image processing method and device, a computer readable storage medium and electronic equipment. The method comprises the following steps: acquiring a plurality of color images; generating a plurality of Gaussian image pyramids according to the plurality of color images, and generating a plurality of Laplace image pyramids according to the plurality ofGaussian image pyramids; generating a fused image of a plurality of top-layer images of the plurality of Laplace image pyramids; performing color difference fusion processing according to the fused image, the plurality of Gaussian image pyramids and the plurality of Laplace image pyramids to obtain a plurality of processed images; and splicing the plurality of processed images to obtain a color panoramic image. In the embodiment of the invention, through image color difference fusion based on the Gaussian image pyramid and the Laplace image pyramid, the color difference problem of the color panoramic image can be well solved, and the color panoramic image can meet the actual requirements.

Owner:KE COM (BEIJING) TECHNOLOGY CO LTD

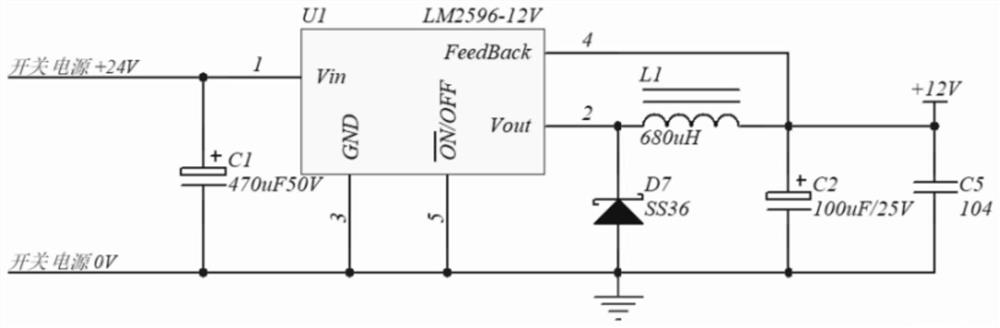

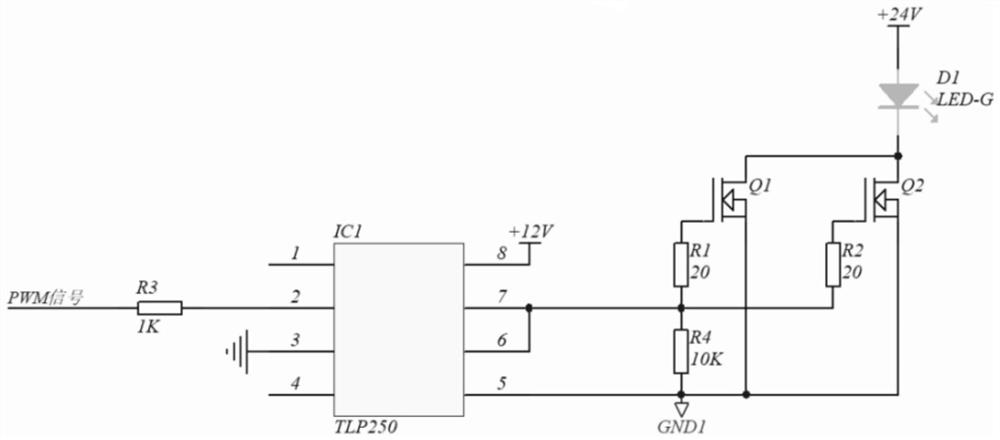

Plant light environment research method based on PWM signal intensity adjustment technology

PendingCN112524503ANot easy to chromatic aberrationNot prone to chromatic aberrationLighting support devicesElectric lightingLight TestingSpectral composition

The invention discloses a plant light environment research method based on a PWM signal intensity adjustment technology, belongs to the field of plant light environment research methods, and providesthe plant light environment research method based on the PWM signal intensity adjustment technology. The method can adjust and control spectral composition, radiation intensity and radiation time within a certain range and can perform intelligent control. Researchers and experiment teaching personnel can adjust and control spectrum composition, illumination intensity of each spectrum section and illumination time length according to own test schemes, and various research and teaching requirements related to plant light environments are met. The device can be widely applied to various laboratories, teaching and scientific research test service platforms and test bases of agricultural disciplines, and light can be mixed through non-directional conduction of the light-guide fiber clusters andthen irradiate out through a protection lens, so that a test light source in the scheme is not easy to generate large chromatic aberration, and the test accuracy is not easy to influence.

Owner:ZHEJIANG UNIV

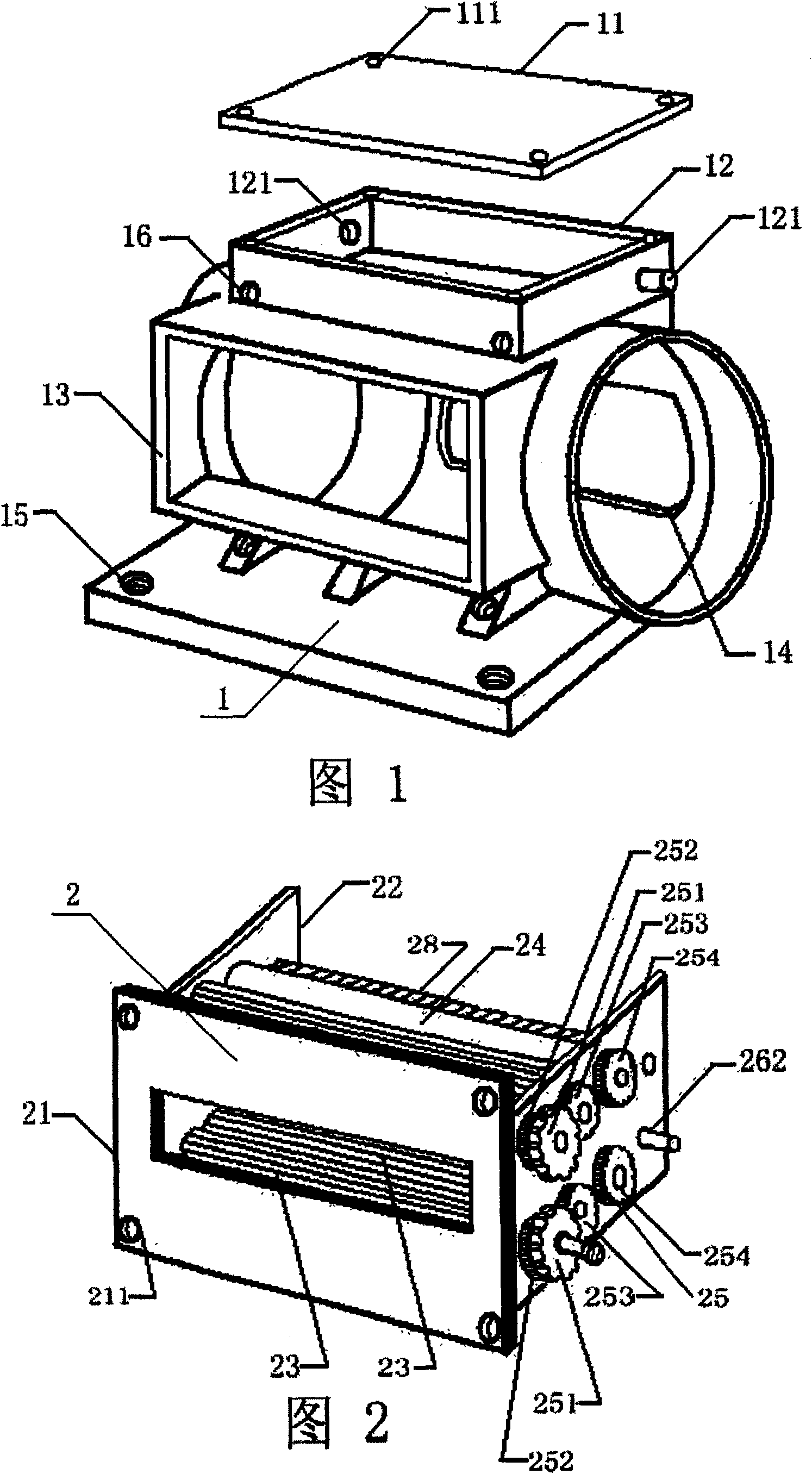

EVA leftover disintegrating machine

ActiveCN100534746CHigh recycling valueReduce pollutionPlastic recyclingGrain treatmentsGrinding wheelScrap

An EVA scrap crushing machine includes a shell, a feeding machine and an abrasive wheel, in which, the shell is set with a feeding port and an exit port, said feeding machine is fixed on the feeding port of the shell, said abrasive wheel includes a carborundum wheel, two end covers fixed at both sides of the shell, a central shaft through and fixed at the center of the two bottoms of the wheel and supported by the end cover and a belt wheel fixed on the central shaft.

Owner:陈荣辉

Production technology of fiber cloth

InactiveCN104862902AImprove color fastnessReduce defective rateLiquid/gas/vapor removalTextile treatment by spraying/projectingFiberPulp and paper industry

The invention discloses a production technology of fiber cloth. The technology comprises four steps, namely, pretreatment, dyeing, water washing and aftertreatment; a dyeing technology comprises steps as follows: cloth is placed on a flat plate machine, colors are sprayed onto the cloth through movement of dyes; after the cloth is heated to a certain temperature, the temperature is kept, the cloth is washed with water, and the dyeing technology is finished. With the adoption of the production technology of the verdant viscose fiber cloth, components of an alkaline agent and the addition manner of the alkaline agent are adjusted, so that the probability of dyeing defects of grey cloth is decreased, and the production quality is improved.

Owner:RUGAO DONGZHAO CLOTHING CO LTD

Method for producing hot-dipped steel sheet excellent in blackening resistance and corrosion resistance

ActiveCN108690944BImprove corrosion resistanceImprove surface conditionHot-dipping/immersion processesFurnace typesHydrogen contentStrip steel

The invention discloses a manufacturing method for hot dipped steel plates excellent in blackening resistance and corrosion resistance. The manufacturing method comprises the following steps: increasing the oxygen partial pressure in an annealing furnace to 30-80 ppm when basic strip steel enters a preheating section of the annealing furnace, wherein the dew point of the preheating furnace is 0-50DEG C, the furnace pressure of the annealing furnace is 300-500 Pa, and the preheating temperature is 500-700 DEG C; controlling the dew point of a soaking section at 30 DEG C below zero to 30 DEG Cafter the basic strip steel enters the soaking section, wherein the hydrogen content in percent by volume is 15-25%; and finally, controlling the cooling speed at 20-100 DEG C / s for cooling, wherein the basic strip steel enters a zinc pot to produce Mg-containing hot dipped steel plates. Mg-enriched ternary eutectic phase sheets in coatings of the steel plates are small in interlayer spacing, relatively short and uniform in distribution, Mg-containing oxides are unlikely produced, and the hot dipped steel plates have high corrosion resistance and good blacken resistance. In a severe environment, the corrosion resistance of the coatings is 2-3 times of that of conventional hot dipped steel plates, or the corrosion resistance is even higher, and the quality of the surface tissues of the coatings is good.

Owner:武汉钢铁有限公司

A kind of dyeing and finishing process of acetate fiber and protein fiber silk fabric

ActiveCN113373705BUniform colorNot prone to chromatic aberrationDyeing processDisperse dyeColour fastness

Owner:HAIYAN JIAYUAN PRINTING & DYEING

Protective film of photosensitive dry film

PendingCN106933038AEasy to separateTransport stablePhotosensitive materials for photomechanical apparatusOptical elementsPolymer sciencePolymer chemistry

The invention relates to a protective film of a photosensitive dry film. The protective film includes a film body, and the film body comprises a matt layer with a matt surface and a glossy layer with a glossy surface. The glossy layer has roughness Ra of 0-0.15 micrometer, surface energy of 0-25 dyne / cm, and a release force of 0-2000g; the matt layer has roughness Ra of greater than micrometer, surface energy of greater than 0-25 dyne / cm, and a release force of greater than 0-2000g. The film body also includes at least one intermediate layer, and the intermediate layer is disposed between the matt layer and the glossy layer to connect the matt layer and the glossy layer. According to the invention, through improvement of the existing technology, the film body has the matt surface and the glossy surface, wherein the glossy surface is compounded with a photosensitive layer, moderate release force ensures that the protective film and the photosensitive layer are attached together, and also guarantees that the protective film is easily separated at a film press link. The matt layer provides appropriate friction force, prevents untidy roll-up caused by interlayer slipping and offset of the dry film layer during roll-up and transportation, and enhances the product quality.

Owner:湖南五江高科技材料有限公司

Image processing method, device, computer-readable storage medium, and electronic device

ActiveCN112102171BResolve color brightness differencesNot prone to chromatic aberrationImage enhancementImage analysisPattern recognitionColor image

The embodiment of the present disclosure discloses an image processing method, device, computer-readable storage medium and electronic equipment. The method comprises: acquiring a plurality of color images; generating a plurality of Gaussian image pyramids according to the plurality of color images, and generating a plurality of Laplacian image pyramids according to the plurality of Gaussian image pyramids; generating a plurality of Laplacian image pyramids The fused image of multiple top-level images; according to the fused image, multiple Gaussian image pyramids, and multiple Laplacian image pyramids, color difference fusion processing is performed to obtain multiple processed images; multiple processed images are stitched to obtain color panoramic image. In the embodiment of the present disclosure, the chromatic aberration problem of the color panoramic image can be better solved through the image color difference fusion based on the Gaussian image pyramid and the Laplacian image pyramid, so that the color panoramic image can meet actual requirements.

Owner:KE COM (BEIJING) TECHNOLOGY CO LTD

Coating stirring equipment for building decoration and use method thereof

InactiveCN113351103AAvoid uneven mixingLower resistanceRotating receptacle mixersTransportation and packagingGlass coverElectric machinery

The invention provides coating stirring equipment for building decoration and a use method thereof. The coating stirring equipment comprises a base, a gear motor and a stirring rod; a supporting frame is arranged on the upper surface of the base, a controller is arranged in the middle of the supporting frame, and a support is arranged at the end, away from the base, of the supporting frame; the gear motor is arranged on the side, away from the supporting frame, of the support, a coupler is arranged at one end of the gear motor, a stirring shaft is arranged at the end, away from the gear motor, of the coupler, the stirring rod is arranged on the surface of the stirring shaft, and a hair brush is arranged on the lower surface of the stirring rod; and a round barrel is arranged on the side, away from the supporting frame, of the base. According to the coating stirring equipment, a water drainage pipe is arranged, a glass cover is opened, hardware products are taken out, a paint spraying chamber is cleaned, the paint spraying chamber and a drying device are arranged in a separated mode, the paint spraying chamber can be directly cleaned, after cleaning is completed, sewage is discharged from the water drainage pipe, and convenience and rapidness are achieved.

Owner:东莞市瑞辉新材料技术有限公司

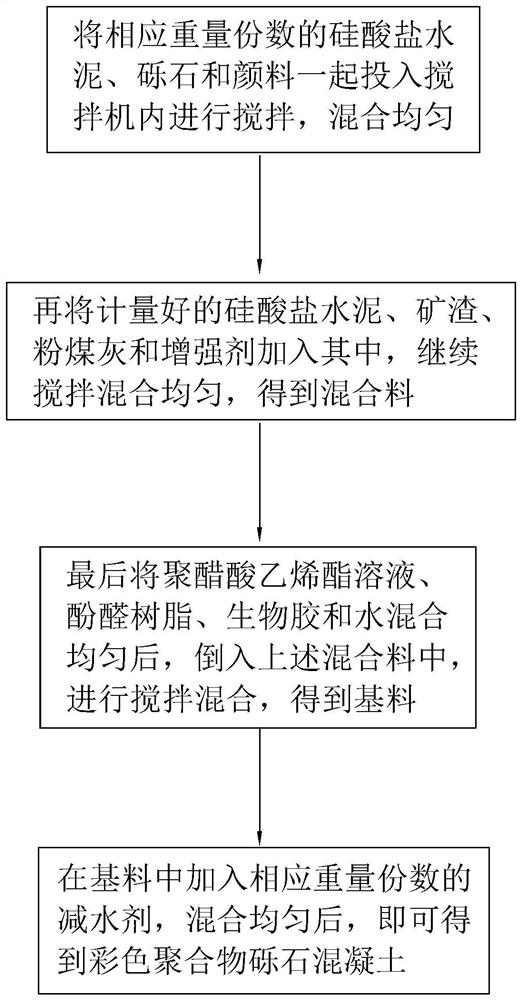

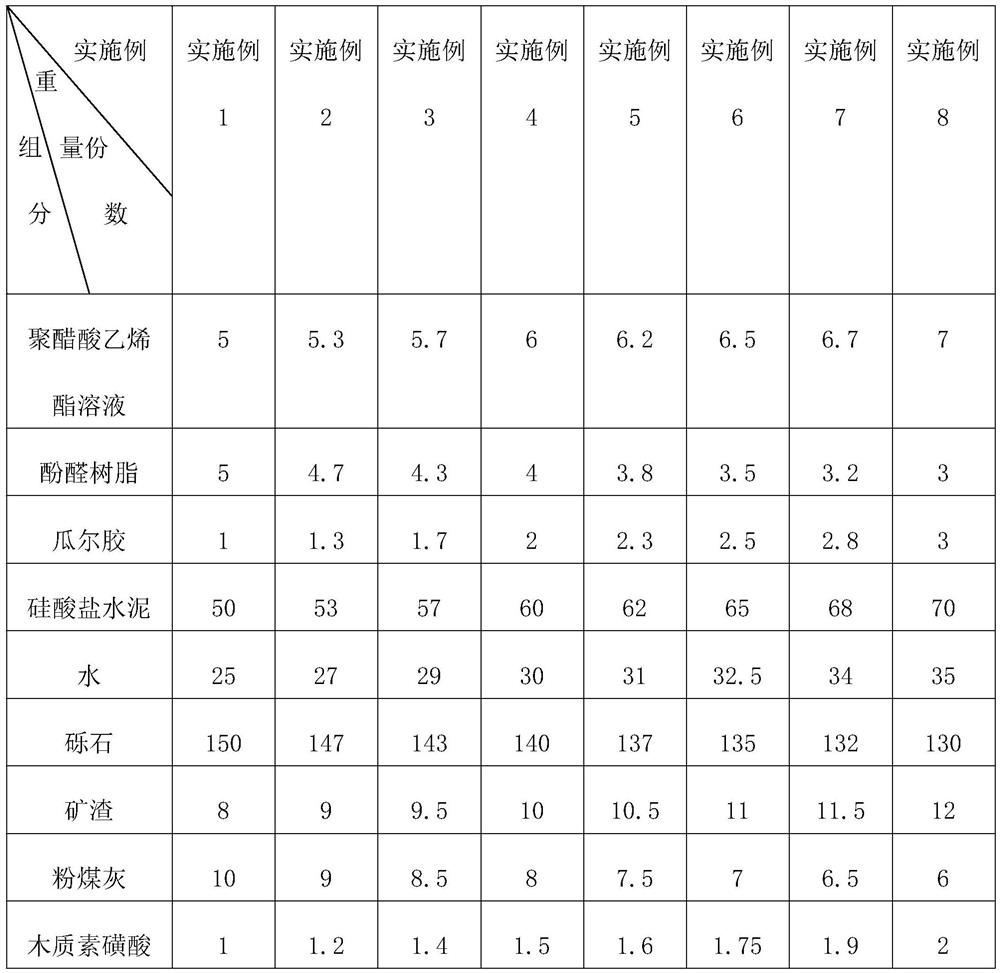

A kind of colored polymer gravel concrete and its preparation method

The invention discloses a colored polymer gravel concrete and a preparation method thereof, relates to the technical field of concrete, and solves the problem that the colored concrete used for pouring construction tends to have large surface color differences, which leads to poor overall application effect. A colored polymer gravel concrete, which comprises the following components in parts by weight: 5-7 parts of polyvinyl acetate solution; 3-5 parts of phenolic resin; 1-3 parts of biological glue; 50-70 parts of Portland cement 25-35 parts of water; 130-150 parts of gravel; 8-12 parts of slag; 6-10 parts of fly ash; 1-2 parts of water reducing agent; 4-6 parts of reinforcing agent; 4-6 parts of pigment. The colored polymer gravel concrete in the present invention has good workability and cohesiveness, and it can be directly laid and used after the preparation is completed. Compared with throwing aggregates on the surface of traditional concrete, it is more scientific, and the surface is not easy to produce larger Chromatic aberration, the overall has a good application effect.

Owner:上海柏芝混凝土搅拌有限公司

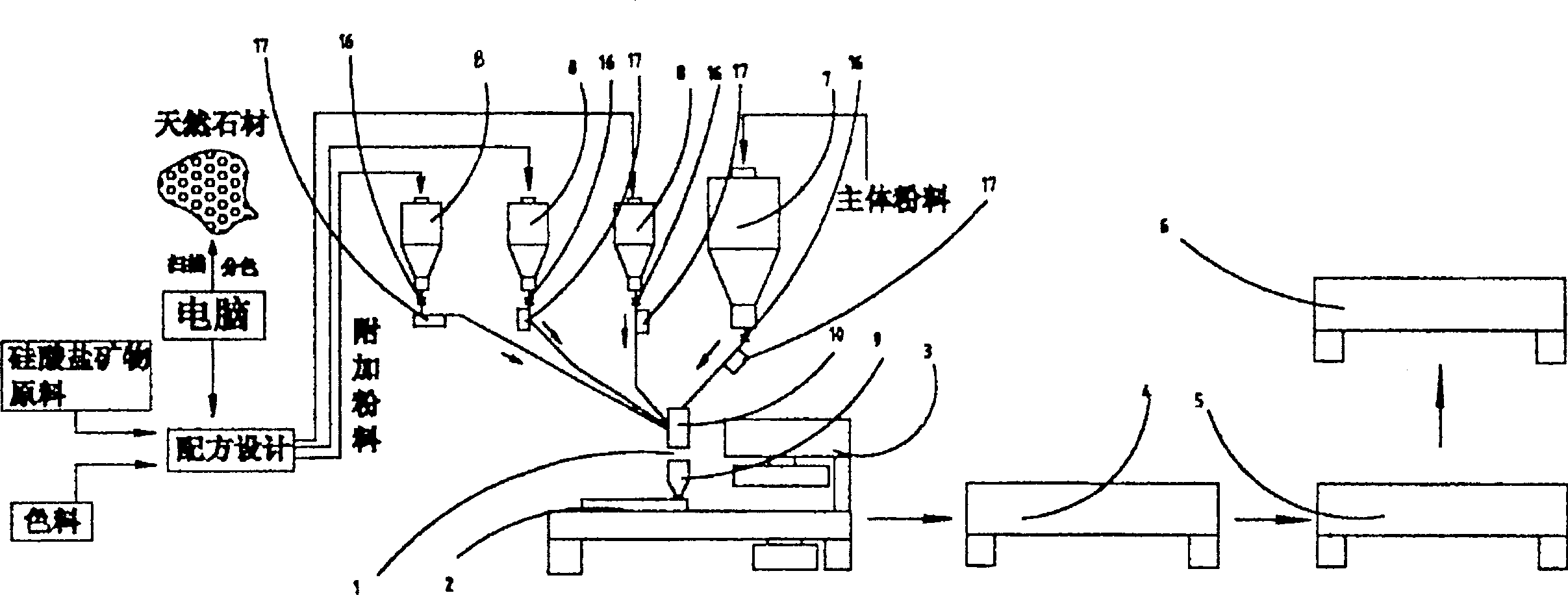

Method and equipment for making magic coloured polished bricks

By use of special blanking mechanism, many colored additional powder materials together with the main powder material are laid down on the blanking mechanism, then they are pushed to a pressing machine under the feeding mechanism to be pressed into blank body which is dried, calcined, polished into glazing brick products. Advantages include pattern close to natural stone, colors possessing obvious boundaries and also color with transition from natural boundary, color difference not easy to be produced in prodn. process, and high prodn. efficiency.

Owner:广东佛陶集团海鸥陶瓷有限公司

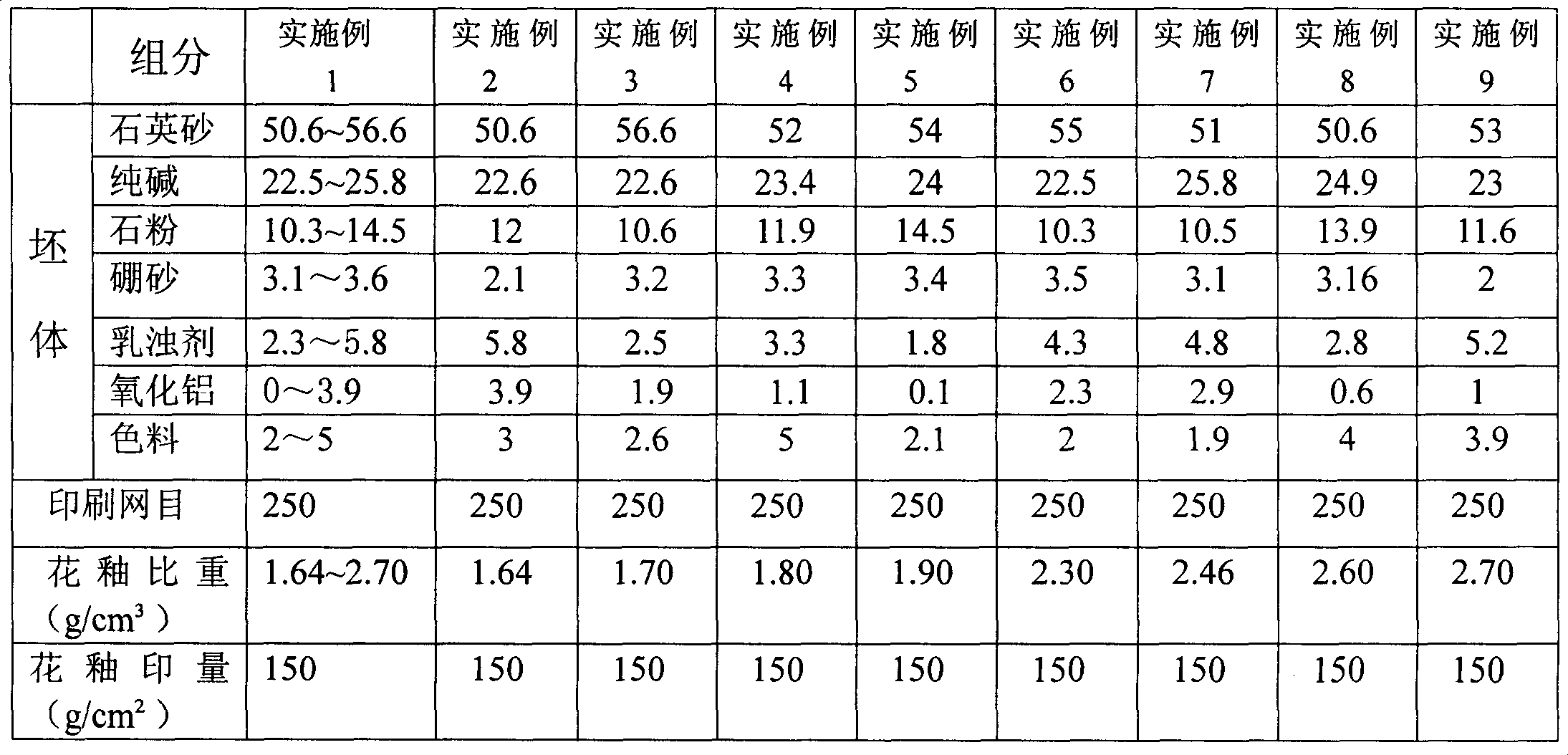

Glass waist-line, flower piece and producing method

This invention relates to a glass corbel and flower piece. According to weight, the key components are: quartz sand 50.6 to 56.6%, sodium carbonate 22.5 to 25.8%, mountain meal 10.3 to 14.5%, borax 3.1 to 3.6%, opacifier 2.3 to 5.8%, alumina 0 to 3.9%, toner 0 to 1.3%; this invention also discloses the manufacturing method. The production process: pattern design ->film out->drying->hunk glass cutting->snippet glass cutting-> printing bottom white-> printing bottom closing glue->incising->planking->burning->edging->sorting->casing; the printing mesh is 250; flower glaze specific gravity is 1.64 to 2.70g / cm3; flower glaze printing quantity: 150g / cm2; this invention can reduce cost about 20%.

Owner:霍镰泉

Fancy glaze and method for manufacturing same

The invention discloses a fancy glaze and a preparation method thereof. The weight percentages of each component of the fancy glaze are 18 percent to 38 percent of potassium feldspar, 10 percent to 23 percent of calcite, 4 percent to 7 percent of talc, 3 percent to 7 percent of quartz, 4 percent to 10 percent of zirconium silicate, 2 percent to 5 percent of zinc oxide, 5 percent to 10 percent of alumina, 3 percent to 6 percent of barium carbonate, 6 percent to 10 percent of black mud, 0 percent to 0.3 percent of tripolyphosphate, 6 percent to 20 percent of water, 0 percent to 10 percent of squeegee oil and 0 percent to 10 percent of printing paste. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is 100 percent. The technical process of the method of manufacturing the fancy glaze is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature is 1195 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the glaze surface is smooth; the sintering temperaturerange is wide; the chromatic aberration can not be produced easily; the finished product rate is high; the cost can be reduced by about 40 percent.

Owner:清远市欧雅陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com