Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176results about How to "Natural texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

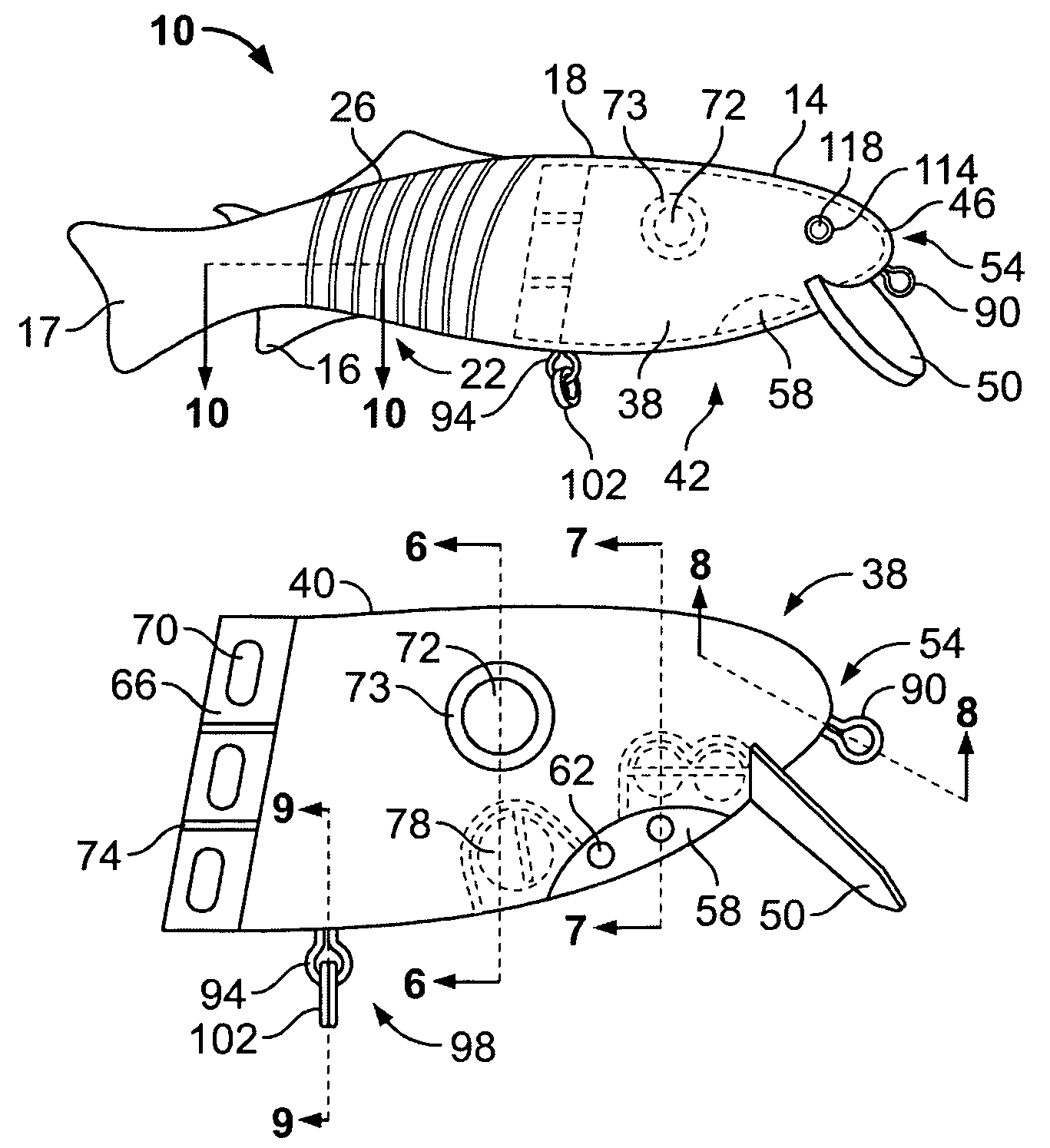

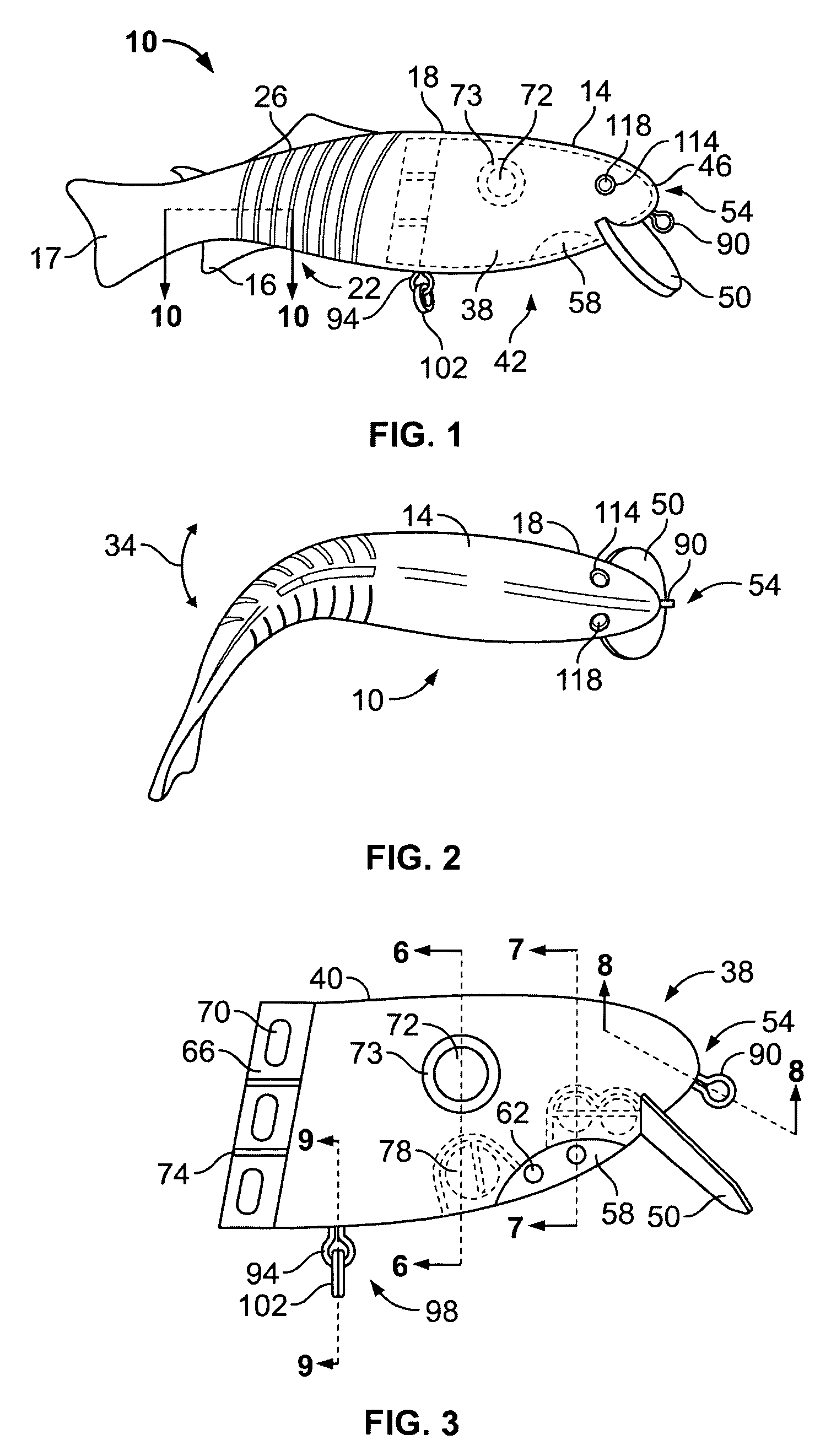

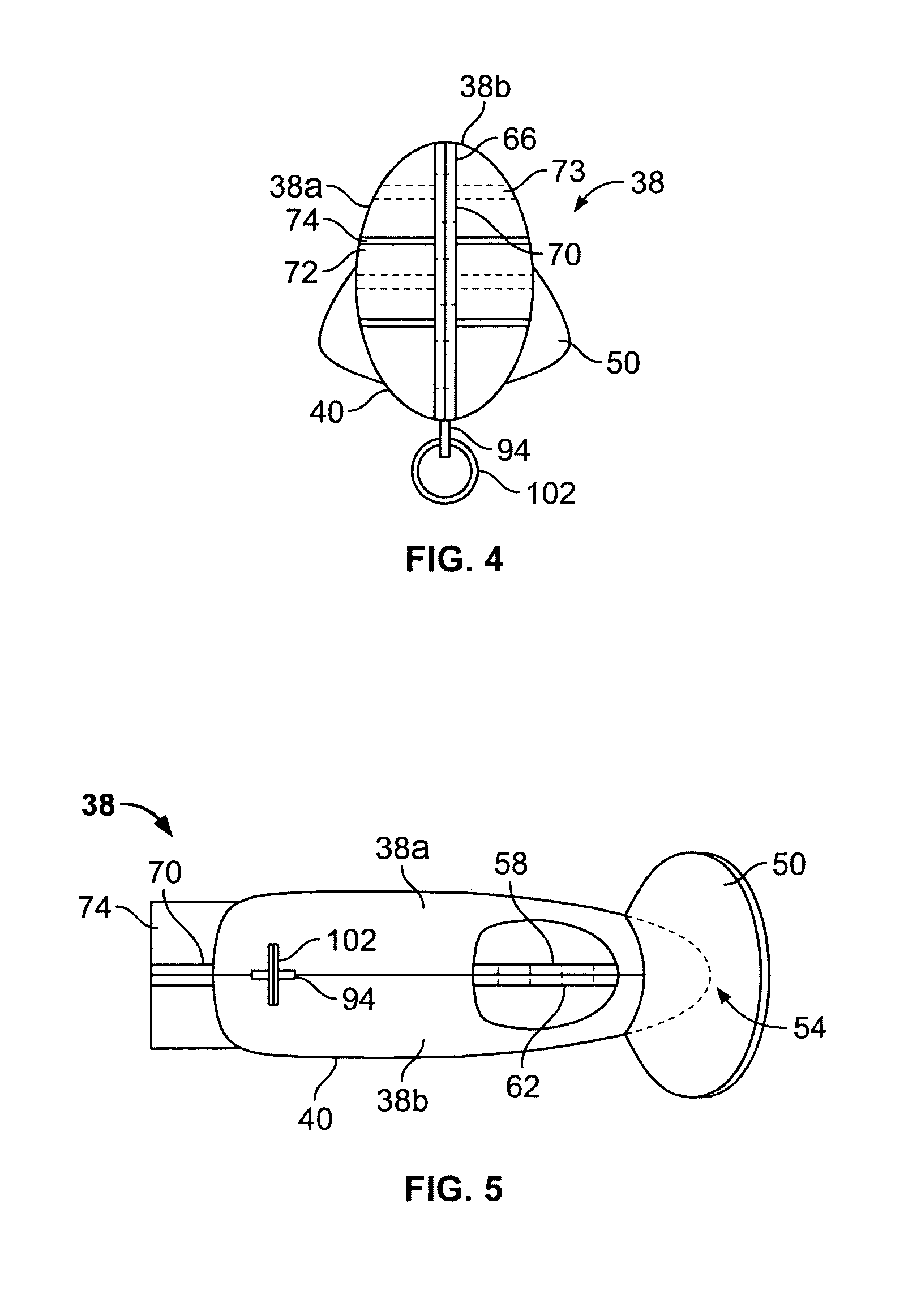

Fishing lure

A lure comprising: a) a hollow body, made of hard plastic, having a shape approximating the front of a natural fish, and including several ribs with through holes; b) several weights, affixed inside the hollow body; c) a resilient skin, having the shape, texture and coloration of the front of a natural fish and an eye sockets, adhered around the hollow body, around the ribs and through the through holes; d) a resilient tail having the shape, texture and coloration of the tail of a natural fish, integral with the resilient skin; the resilient tail including approximately vertical slits; e) a diving bill affixed to the hollow body just below the nose and protruding through the skin; f) a reflective eye attached to the hollow body within the eye socket; g) a line eye hook, affixed to the hollow body at the nose and protruding through the skin; and h) a fish hook eye hook, affixed to the hollow body underneath and protruding through the skin).

Owner:MAK LUKE CHI KWONG

Collagen-base PEG composite fibre and spinning technique thereof

InactiveCN101215733AGive full play to the advantages of biological performanceTechnology transfer is feasibleConnective tissue peptidesFibre typesFiberBiocompatibility Testing

The invention provides a novel collagen protein-based PEG composite fiber and spinning technology, comprises extracting collagen protein, preparing collagen protein-PEG blending spinning original liquid, spinning composite fiber, preparing coagulating liquid and fixing fiber, and carrying out acetalation process of composite fiber and the like, wherein collagen protein is extracted through alkali method or enzymatical method from chrome leather scraps, and can be also extracted from raw hide or heel tendon of healthy animals through enzymatical method. PEG is high molecular polymer which has biocompatibility. Spinning fluid which has certain concentration and viscosity is prepared through mixing collagen protein 100 parts and PEG 5-30 parts according to weight by parts, then composite fiber is prepared through wet spinning, and collagen protein-based composite fiber which is used in fabric needs carrying out acetalization and stretching and the like to improve intensity, swellability, water-absorbing quality and the like of composite fiber. The collagen protein-based PEG composite fiber which is disclosed by the invention can be both used in fabric material and in biological medical material.

Owner:SICHUAN UNIV

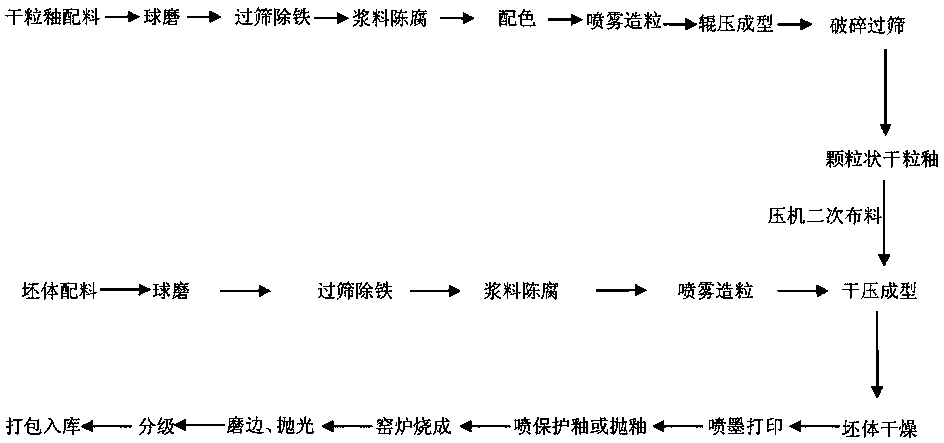

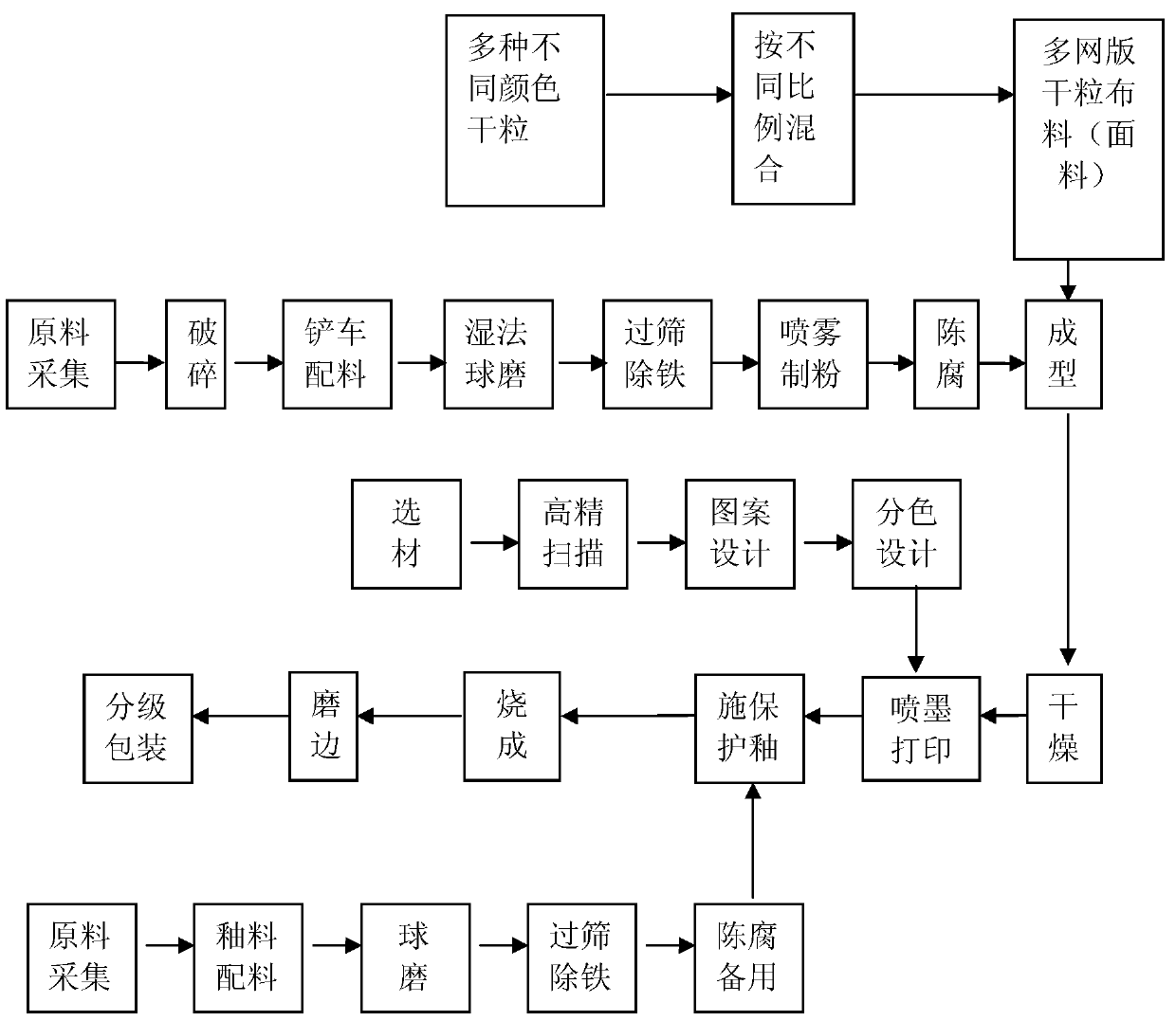

Granular dry grain glaze and granular dry grain glaze cloth imitation stone brick, and production methods thereof

The invention relates to a granular dry grain glaze and a granular dry grain glaze cloth imitation stone brick, and production methods thereof. The production method of the granular dry grain glaze comprises the following steps: squeezing glaze powder out of a blank cake; and breaking the blank cake to obtain the granular dry grain glaze. The granular dry grain glaze can be obtained through the simple method, and the granular dry grain glaze can be used in the production of ceramic bricks to obtain the imitation stone material product having accurate pattern, plentiful layers, natural texture,strong stereo perception and strong granular sensation.

Owner:MONALISA GRP CO LTD

House earth surface sectional material and manufacturing method thereof

InactiveCN101280622AImprove textureGuaranteed structural strengthSynthetic resin layered productsFlooringFoaming agentAdhesive

The invention relates to a sectional material for houses and floors, which comprises two layers of different materials which contain synthetic resin. The ratios of main components of the inner layer material of the sectional material by weight are 100 portions of PVC, 0.8 to 1 portion of foaming agent, 5 to 6 portions of composite stabilizing agent and 7 to 9 portions of regulator; the ratios of the main components of the outer layer material by weight are PVC, plant material, composite stabilizing agent, pigment and adhesive; the two layer materials are pressed, molded and processed to become the sectional material. By adopting the ratios and the processing method provided by the invention, the sectional material produced has a color and a texture which are similar to the wood and a relatively high structural intensity, meanwhile the application of plant materials, such as wood powder, etc., are reduced in the production, thereby protecting the environment.

Owner:莱芜白斗新型建材有限公司

Dry grain glaze fabric stone imitating brick and preparing method thereof

ActiveCN107756608AThree-dimensionalRich layersNatural patternsCeramic shaping apparatusBrickMaterials science

The invention relates to a dry grain glaze fabric stone imitating brick and a preparing method thereof. The preparing method of the dry grain glaze fabric stone imitating brick includes the followingsteps that firstly, colored dry grain glaze is distributed on a blank in a layered manner according to a designed pattern; secondly, after glaze distributing is conducted, a raw brick is pressed; thirdly, after the raw brick is dried, an inkjet machine is used for jet printing of the design pattern; and fourthly, the obtained blank is fired. By means of the dry grain glaze fabric stone imitating brick and the preparing method thereof, a stone imitating effect that the pattern is changed randomly and is vivid and rich in layer, the texture is natural, and the third dimension and granular sensation are high can be achieved.

Owner:MONALISA GRP CO LTD

Collagen - Na-MMT complex fiber, and spinning technological process thereof

InactiveCN101503834AStrong interactionImprove mechanical propertiesMonocomponent protein artificial filamentArtificial filament washing/dryingInorganic saltsFiber

The invention discloses novel collagen composite fiber mainly comprising collagen and a small amount of Na-MMT, and a spinning technical method thereof. The proportion of collagen and Na-MMT in the composite fiber counted in portion by dry weight is 10,000:1-100. The main preparation method of the composite fiber comprises: stirring and mixing 15 to 50 weight percent collagen solution and 0.1 to 2 weight percent Na-MMT solution according to a set proportion under a water bath condition between 50 and 80 DEG C; carrying out hot filtration at a temperature between 50 and 80 DEG C after the solutions are evenly mixed; obtaining spinning solution used to imitate collagen-Na-MMT composite fiber after defoaming; extruding the spinning solution through a spinneret under the action of gas pressure at a temperature between 50 and 80 DEG C; and entering inorganic salt coagulation bath to prepare the collagen-Na-MMT composite fiber through solidification. In addition, the intensity, swelling capacity, water absorption, and the like of textile composite fiber can be improved through post treatments such as acetalation and oiling. The collagen-Na-MMT composite fiber can be used for textile materials and biomedical materials.

Owner:SICHUAN UNIV

Multi-purpose gelatin fiber and preparation method thereof

InactiveCN101643947AImprove thermal stabilityHigh strengthWigsArtificial filament washing/dryingPolymer scienceEmulsion

The invention relates to a multi-purpose gelatin fiber and a preparation method thereof, in particular to the preparation of amphipathy polymer and emulsion thereof, the preparation of spinning solution, fiber spinning, after-treating of the fiber and the like, wherein firstly free radical polymerization or polyurethane prepolymer is adopted for compounding amphipathy polymer which is prepared into emulsion in water, and then the emulsion is added into a gelatin solution to prepare spinning solution with certain viscosity; the spinning solution is prepared in to fiber by a wet spinning; and finally in order to increase the intensity of the fiber, the fiber is needed to be post-treated. The gelatin fiber and the preparation method thereof belong to the textile industry technical field; andthe formed fiber can be used for clothing material, biology medical material and hairpiece products.

Owner:UNIV OF SCI & TECH OF CHINA

Production of ceramic tiles with simulated wood grains

InactiveCN1490139AHigh degree of simulationVivid textureAuxillary shaping apparatusCeramic tilesSolid wood

A technology for producing the ceramic tiles which has the simulative wood grain from top to bottom includes such steps as preparing raw material, vacuumizing, harmonizing colours, preparing wood grain, rolling for shaping, punching, calcining, and grinding-polishing. Its advantages are high lifelike degree, and high anti-leakage effect.

Owner:李桂容

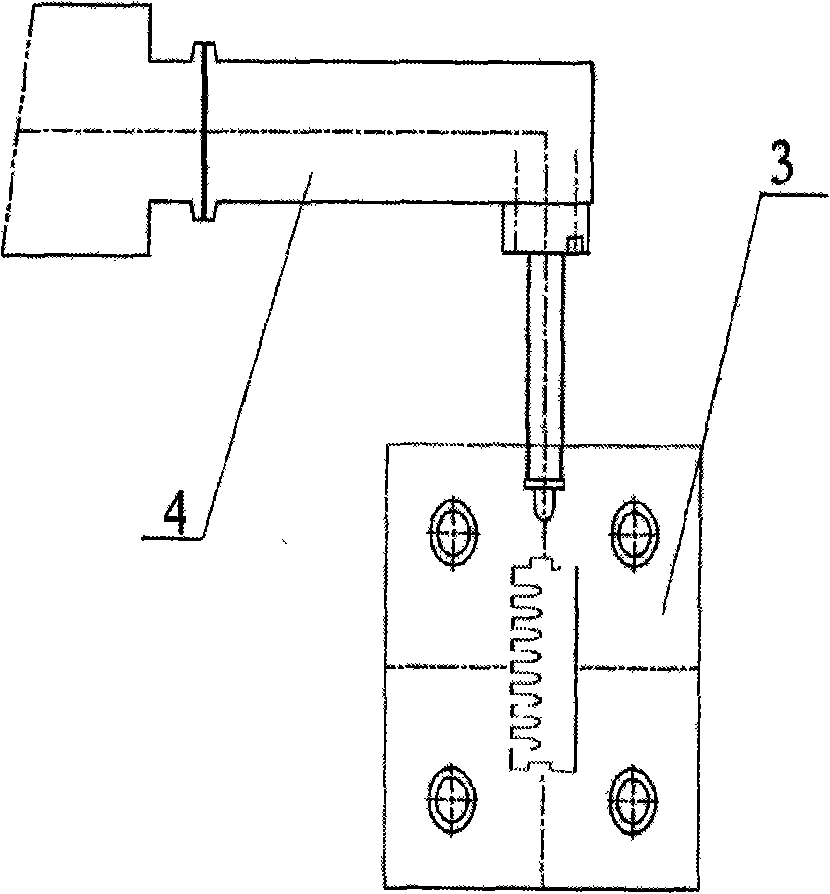

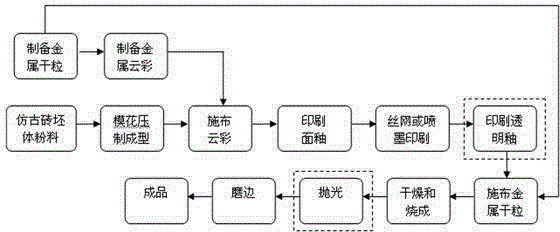

Furnace-transmuted archaized brick and production method thereof

ActiveCN104405101ASolve the decorativeSolve the problem that the level is not rich enoughCovering/liningsBrickMetal particle

The invention relates to a furnace-transmuted archaized brick and a production method thereof. A furnace transmutation effect and an archaized brick are ingeniously combined in a decoration effect, matte glazes of multiple archaized color systems such as yellow, coffee and dark red are printed on the surface of a ceramic tile in a large scale to form the peculiar primitive charm and classical style of the archaized brick, dry metal particles matched with a mold pattern are printed on the surface of the ceramic tile, and a complex color developing effect is achieved by oxide in the dry metal particles under the influence of glaze bodies and a firing atmosphere at high temperature, so that the produced archaized brick is endowed with impressive metal corrosion appearance and bitterness, and is extremely decorative and artistic, the natural and imposing classical style caters to the mindset of admiring and returning to the nature of modern people, and the problems of undiversified decoration methods and undiversified layers of the archaized brick are solved.

Owner:HANGZHOU NABEL CERAMIC

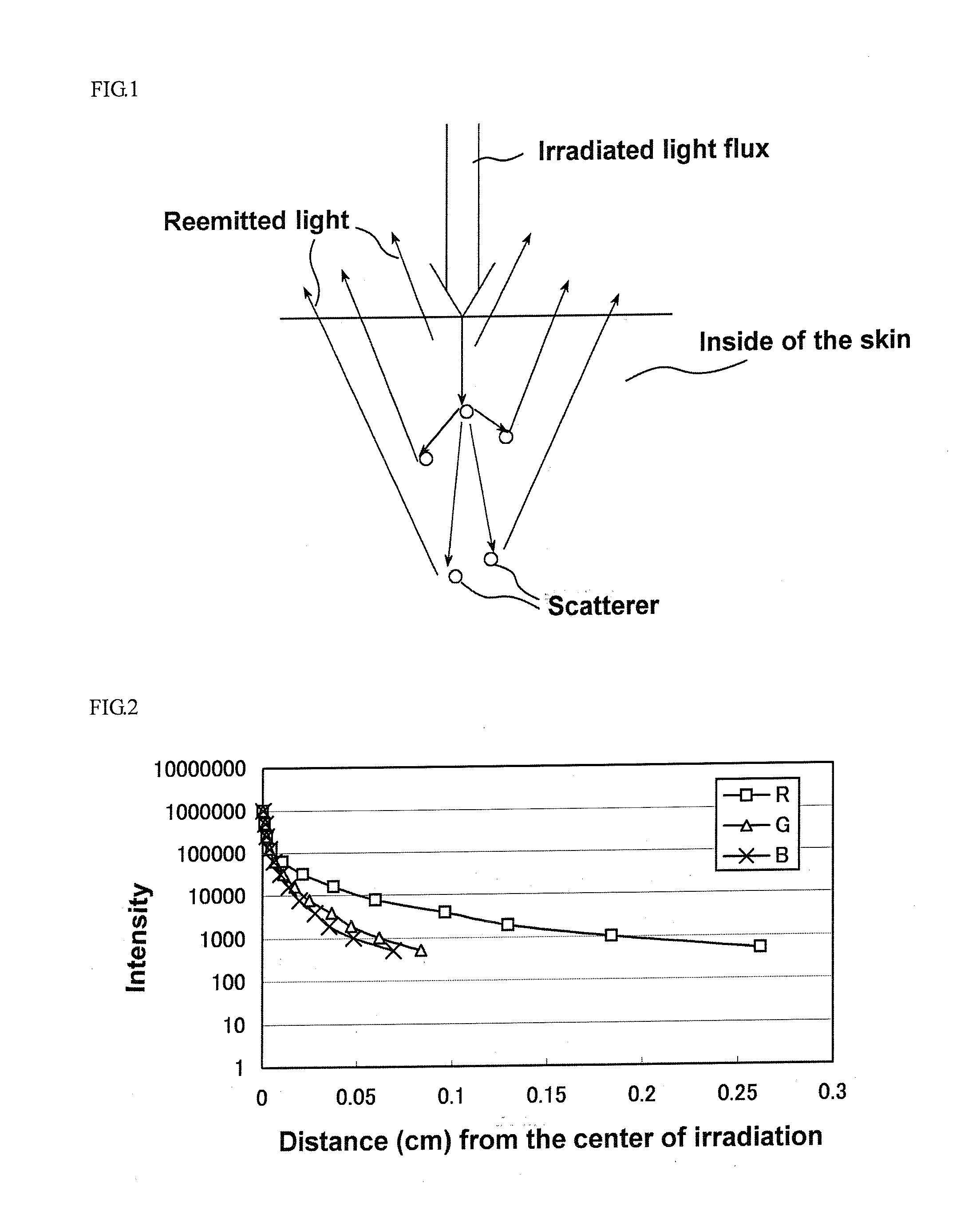

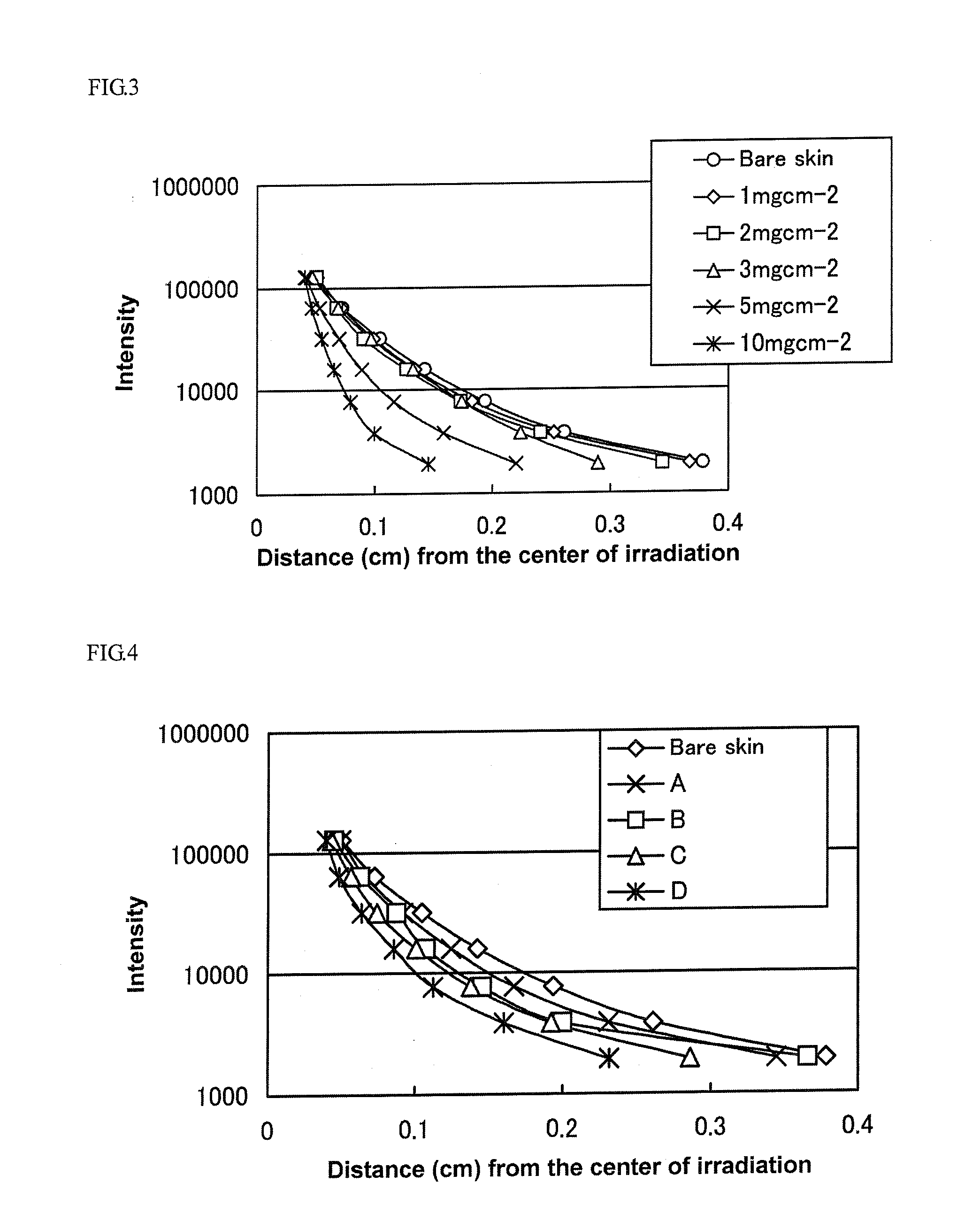

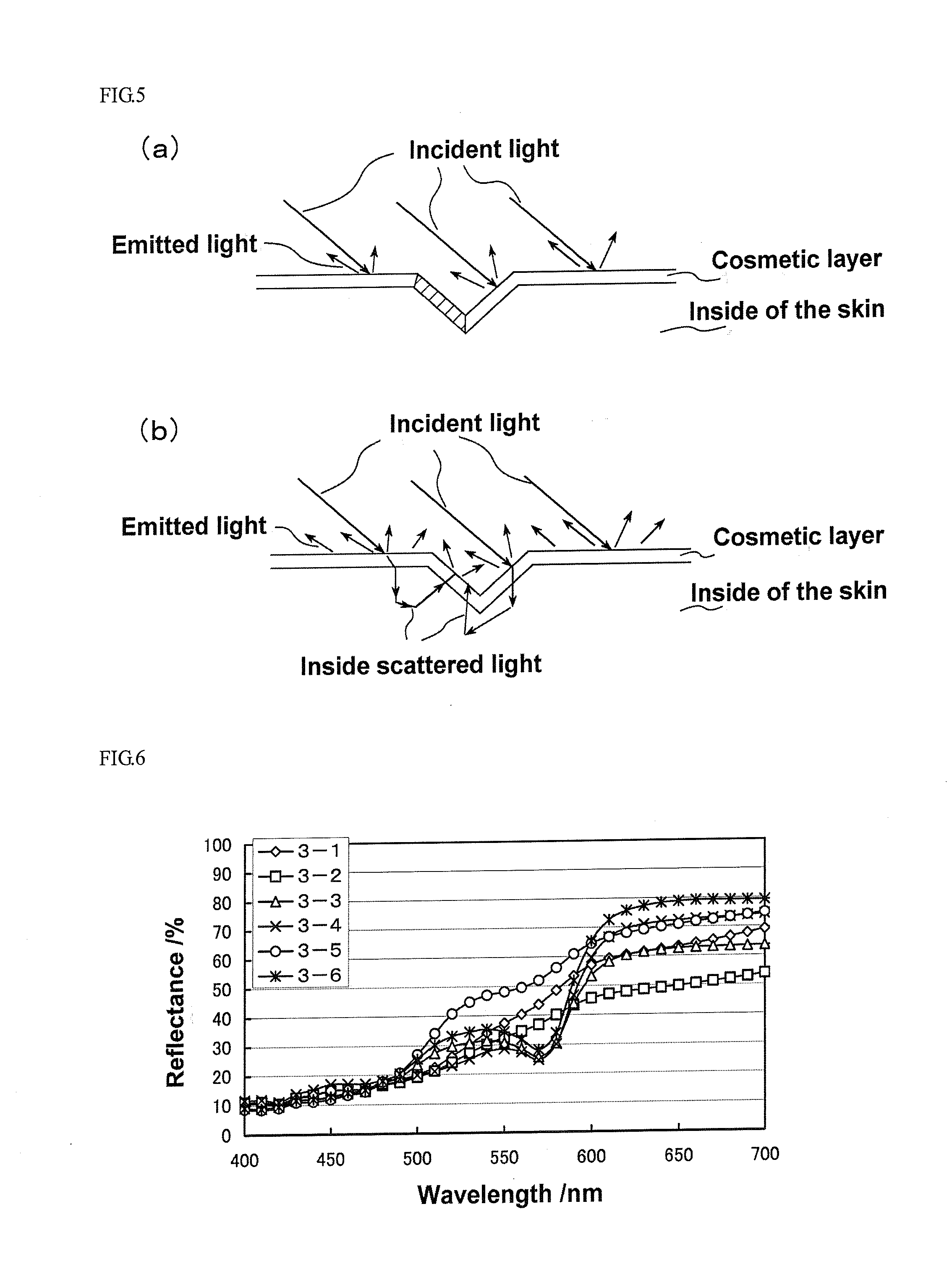

Colorant Composition For Skin Cosmetics, Foundation Containing The Same, And Method Of Makeup Application

InactiveUS20090060856A1Natural textureHigh refractive indexCosmetic preparationsMake-upPolymer scienceColored white

The object of the invention is to provide a colorant composition for skin cosmetics, that can provide a natural texture while retaining hiding power, a foundation containing the same, and a method of makeup application. A colorant composition for skin cosmetics of the present invention is characterized in that the colorant composition, which contains nonwhite coloring materials, does not contain a high refractive index white pigment, and when the spectral reflectance of the colorant composition is measured under the below-described measurement conditions, the minimum spectral reflectance on the white ground in the wavelength range of 630-700 nm is 75% or higher, and the Y value on the white ground is in the range of 25-65 (Measurement conditions) A colorant composition is dispersed in nitrocellulose lacquer, the concentration of the colorant composition is adjusted so that the spectral reflectance on the white ground of a black and white hiding test paper at the wavelength of 400 nm is 10±2%, a black and white hiding test paper is coated with an applicator having a 0.101 mm clearance, and the spectral reflectance is measured with a spectrocolorimeter.

Owner:SHISEIDO CO LTD

Polyvinyl chloride (PVC) decorative molded door panel and machining method thereof

InactiveCN102619444AStrong three-dimensional sensePollution-free environmentWood working apparatusFlat articlesFiberPolyvinyl chloride

The invention relates to a molded door panel and a machining method thereof. A polyvinyl chloride (PVC) decorative molded door panel comprises a panel and PVC skin, wherein the panel is a concave-convex compression-molded fiberboard; the PVC skin is coated on the panel; and the panel is 2 to 4 mm thick. The machining method comprises the following steps of: spraying suction glue onto the surface of the molded door panel with a thickness of 2 to 4 mm, arranging the molded door panel on a template, placing the template into a work chamber of a laminating machine, coating the cropped PVC skin onto the molded door panel, and performing vacuum suction to completely adhere the PVC skin to the molded door panel. The PVC decorative molded door panel is manufactured by adopting the concave-convex compression-molded fiberboard, and the concave-convex surface of the concave-convex compression-molded fiberboard is not implemented by a carving and milling method, so that fibrous dust pollution is avoided, production cost is lowered, the surface of the panel has strong stereoscopic sensation, and textures on the surface of the panel are natural, attractive and elegant.

Owner:ZHEJIANG KAIYANG DOORS

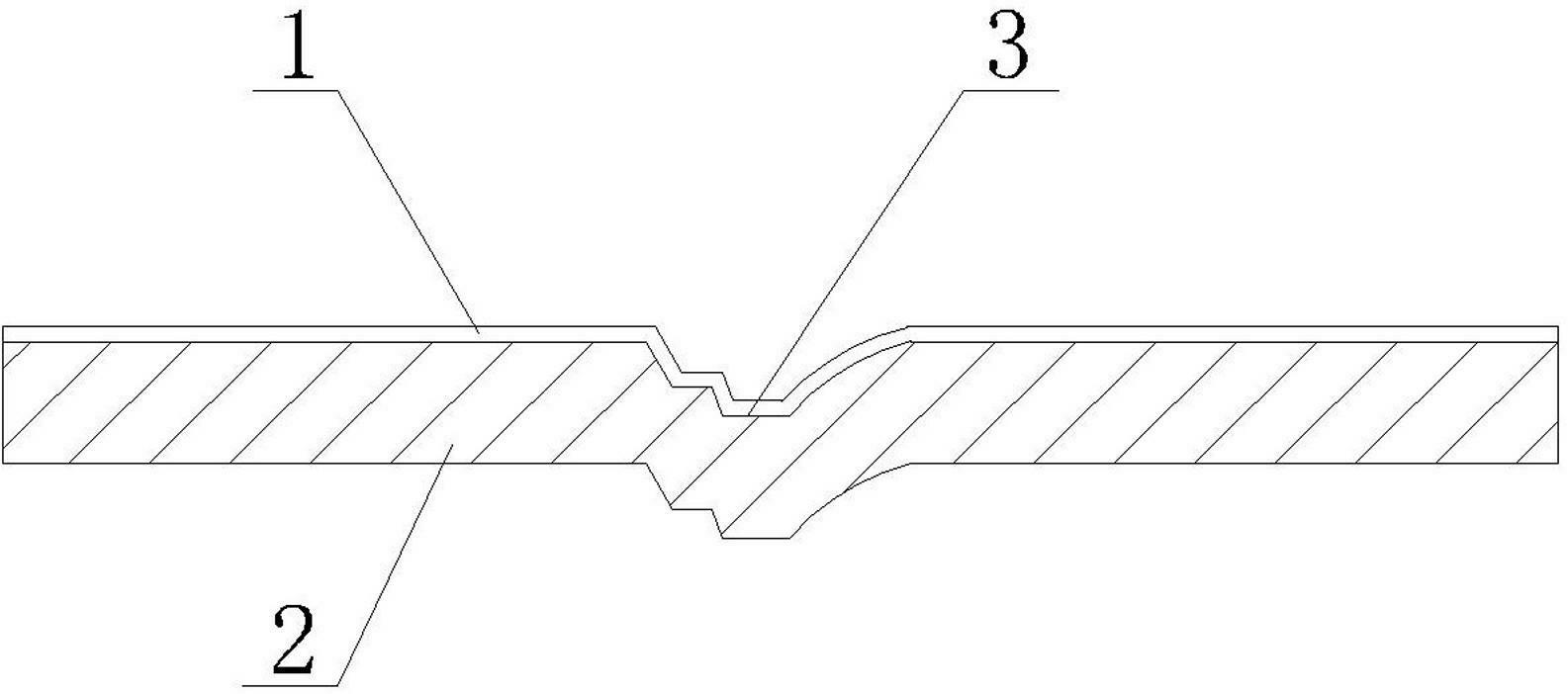

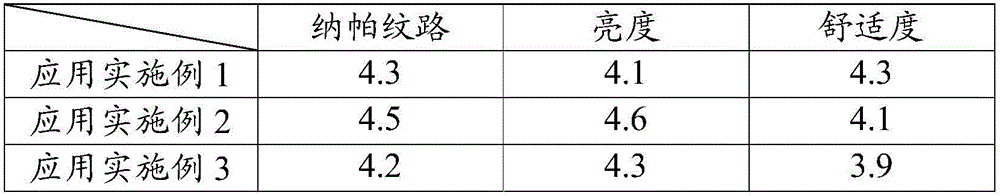

Nappa leather coating composition and coating technology thereof

ActiveCN105860839AImprove comfortIncrease brightnessWax coatingsPolyurea/polyurethane coatingsSlurrySurface grinding

The invention discloses a nappa leather coating composition and a coating technology thereof. The nappa leather coating composition comprises scraping-touchup slurry, base sealing slurry, base slurry, isolation slurry, surface slurry and bright slurry; and the coating technology comprises the steps of crust milling, toggling, mending of blemishes, surface grinding, dust removal, base sealing, first ironing, base slurry brushing, pressing of coarse needle lines, base slurry spraying, spraying of an isolation layer, pressing of nappa lines, second milling, first vibration staking, second ironing, surface slurry spraying, spraying of a bright layer and third ironing. The nappa leather coating composition disclosed by the invention is used for processing common leather into high-grade nappa leather so that the nappa leather has natural lines and comfortable handfeel, and the leather grade is promoted.

Owner:河南中牛实业有限公司

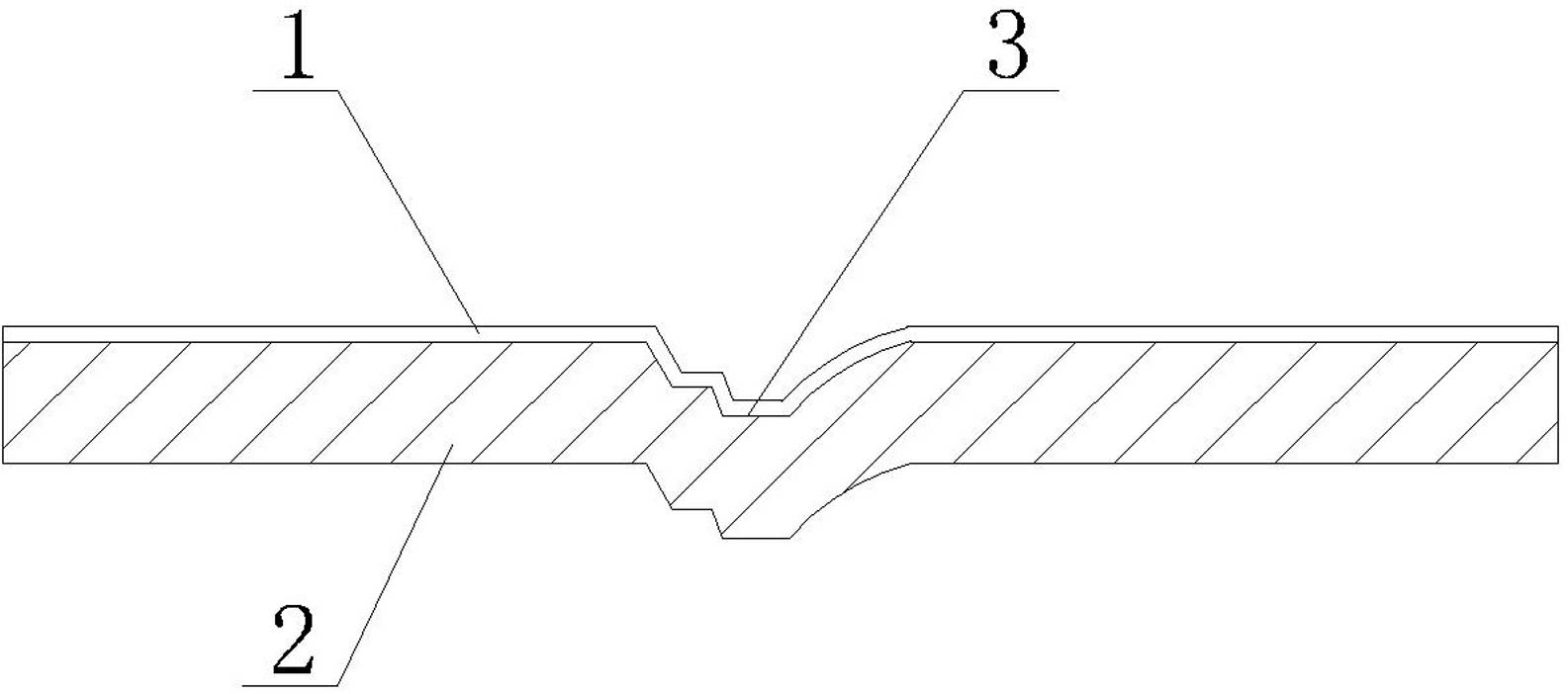

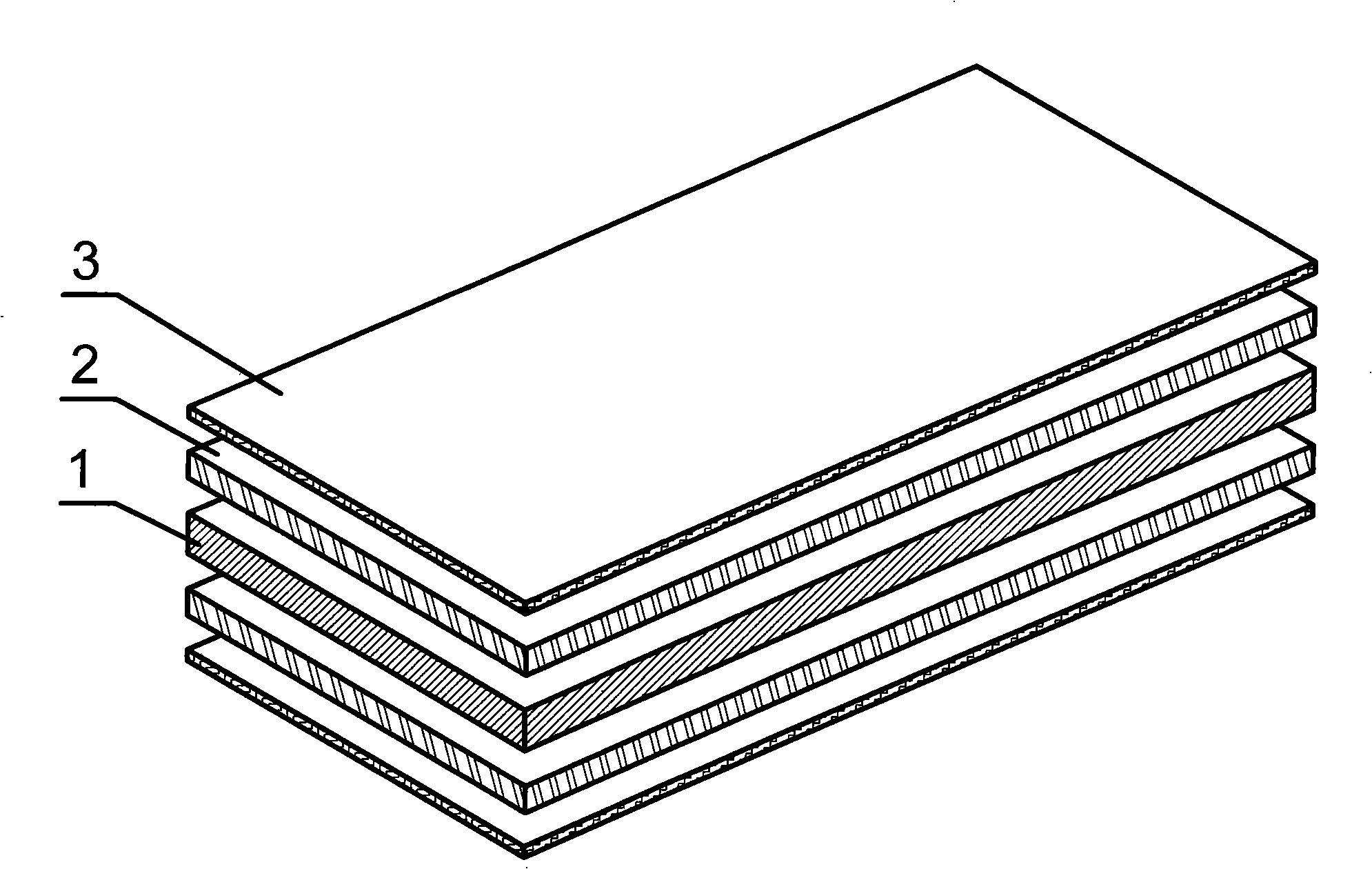

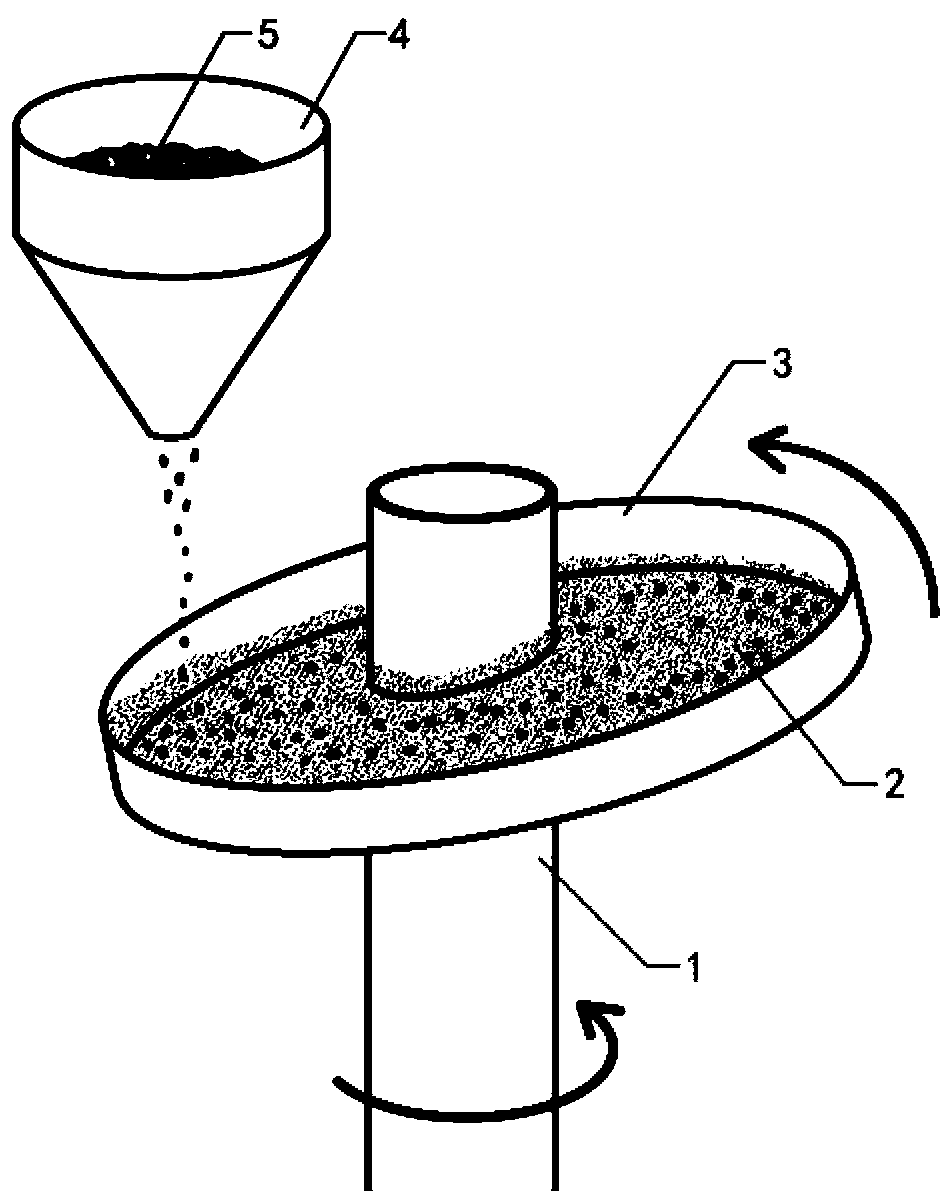

Solid wooden composite door and method for making the same

InactiveCN101343975AVarious shapesReduce consumptionDecorative surface effectsLayered productsNatural resourceSolid wood

The invention discloses a solid wood composite door and a manufacturing method thereof. The solid wood composite door comprises a door framework (1), mould boards (2) symmetrically arranged on the bottom surface and the surface of the door framework (1), and decorative boards (3) arranged on the mould boards (2); compared with the traditional solid wood door, the invention has the advantages that the consumption of wood is reduced, precious natural resources are saved, the manufacture cost is reduced, the phenomenon of contortion or deformation or rip is not easy to occur during the use of the solid wood composite door, the texture of the solid wood composite door is natural and artistic, the hardness degree of the painting surface is high, the wear resistance and the anti-yellowing property are good, the adhesive force of oil paint is strong, the transparency of the painting surface is high, and the environmental protection performance is good.

Owner:湖州世友门业有限公司

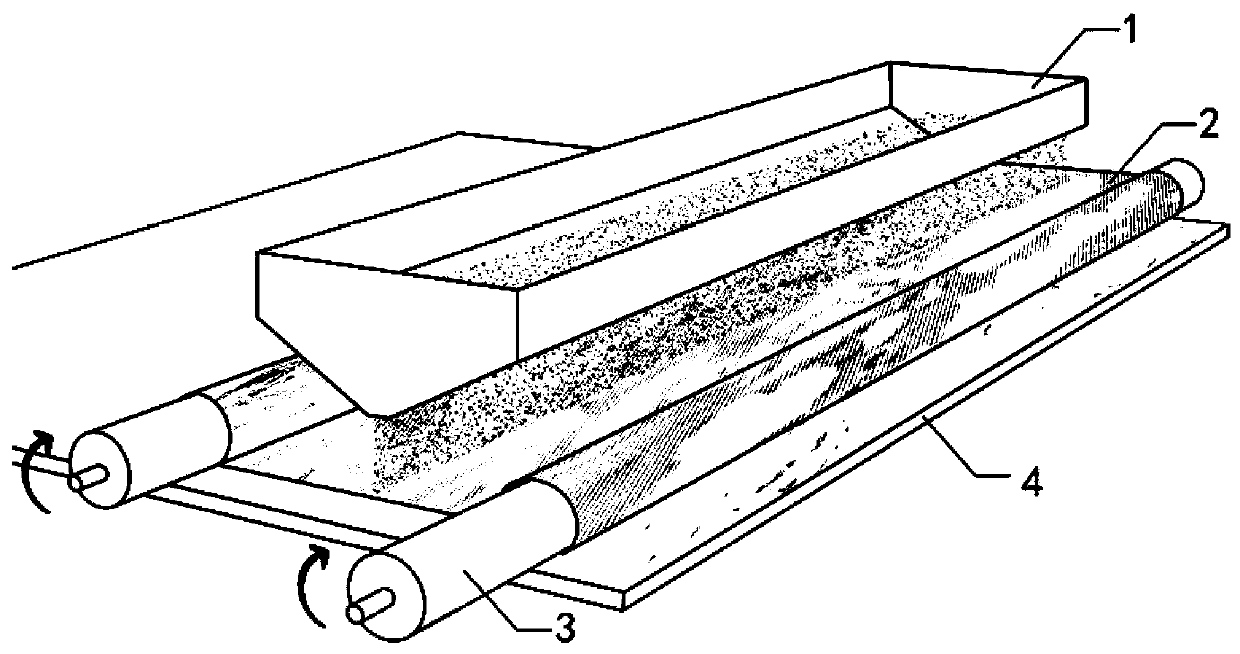

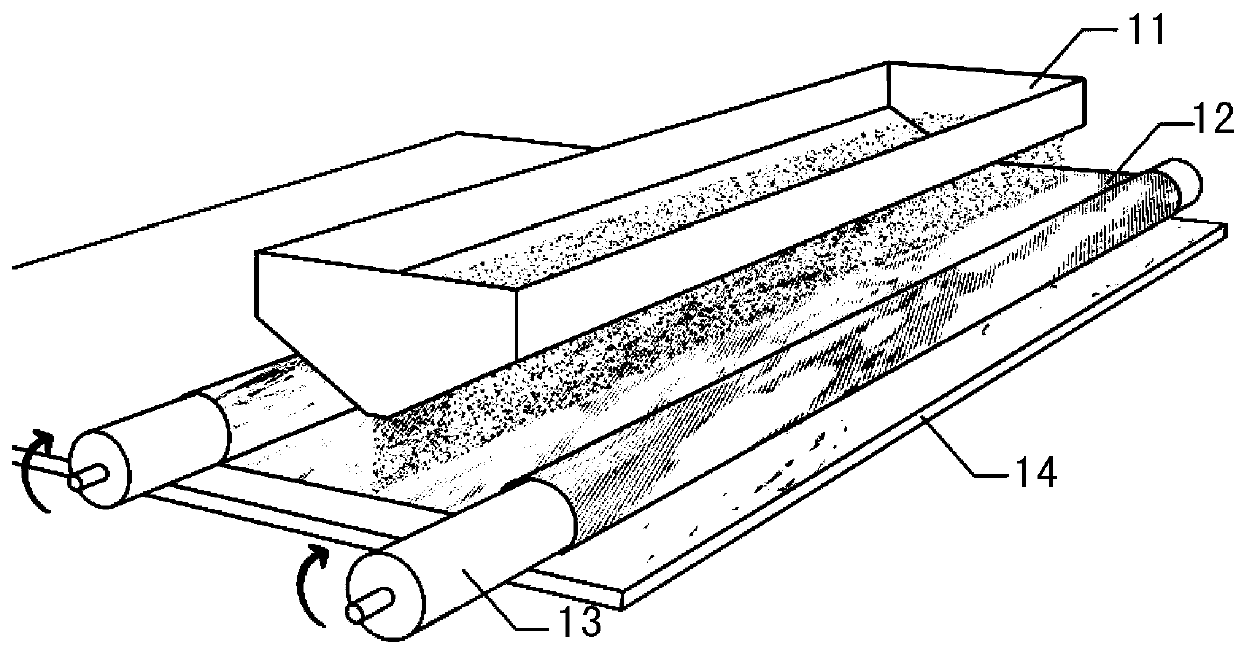

Method for manufacturing sandrock effect imitating nucleated glass composite board

The invention discloses a distribution device for a microcrystalline glass composite board simulating sandstone effect and a process method. The process method is characterized in that a surface layer is prepared by mixing microcrystalline fusion cake granules with two or more colors and meshes according to a definite proportion, the mixed fusion cake granules fall on a large belt according to a proportion through an engraving roller, and the large belt distributes the fusion cake granules on the surface of a blank evenly. The fusion cake granules are sintered in a roller kiln by a ceramic sintering process, edged and polished. The method for distributing the microcrystalline glass ceramic composite board based on the prior microcrystalline glass ceramic composite board realizes the stone effect of natural sandstone with clear texture by using the roller to engrave and distribute, and has transparent aesthetic feeling of microcrystalline glass and good stereoscopic decorative effect.

Owner:萧华

Travertine-like arabesquitic vat and production technology thereof

The invention discloses a travertine-like arabesquitic vat. The forming material of the travertine-like arabesquitic vat mainly comprises a solid material, a blended solution and staple, wherein the solid material comprises the following components in percentage by weight: 30-45% of rapid-hardening sulphoaluminate cement, 45-65% of fine river sand, 1-3% of titanium dioxide, 1-3% of yellow powder and 0.01-0.15% of red powder; the blended solution comprises the following components in percentage by weight: 99-99.9% of water and 0.01-0.1% of polyacrylamide; and the staple is glass fiber of which the length is 5-10cm. The invention also discloses a production technology for the travertine-like arabesquitic vat, which comprises the following steps of: burdening, mixing, cleaning a mold, installing a material mold, installing the staple, demolding, nursing, trimming, repairing, brushing to be smooth, applying a surface coating and the like. The travertine-like arabesquitic vat disclosed by the invention has the advantages of clear and natural texture, good product intensity, light weight, hard surface layer, abrasion resistance, small possibility of delaminating and falling powder, low cost and good decoration effect, is convenient to produce on a large scale and is easy for stable control of product chromatic aberration, natural travertine in the natural world can be prevented from being mined on a large scale, and mine waste can be utilized to protect the ecological environment.

Owner:泉州市嘉利来石材工艺有限公司

Microlite PVC foam floor

The invention relates to a microlite PVC (Poly Vinyl Chloride) foam floor and belongs to the technical field of chemical building materials. The microlite PVC foam floor is prepared from the following raw materials in parts by weight: 100-150 parts of PVC, 200-300 parts of microlite powder, 0.5-0.7 part of stabilizer, 0.6-1.0 part of foaming agent, 0.2-0.3 part of plasticizer, 0.5-0.7 part of lubricant and 0.5-0.7 part of flame retardant. The microlite PVC foam floor is extrusion-molded by using a plastic extruding machine; the obtained microlite PVC foam floor is low in density, wear-resistant, impact-resistant, high in elastic strength, natural in texture, and beautiful and elegant; the microlite PVC foam floor is also environment-friendly, non-toxic, tasteless and formaldehyde-free; the microlite PVC foam floor is further waterproof, damp-proof, skid-proof, wear-resistant, corrosion-resistant, fire-resistant, and recyclable.

Owner:HENAN LEISEN IND

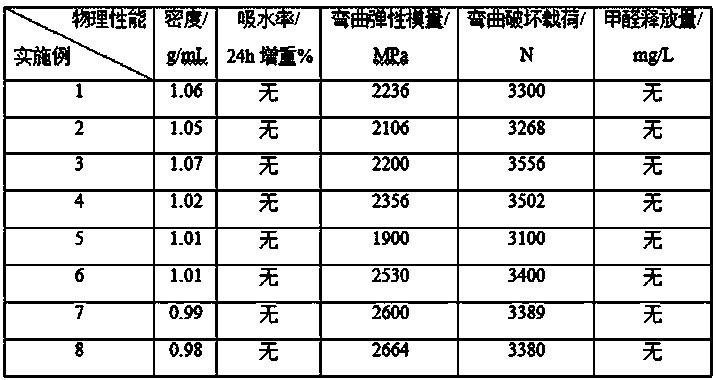

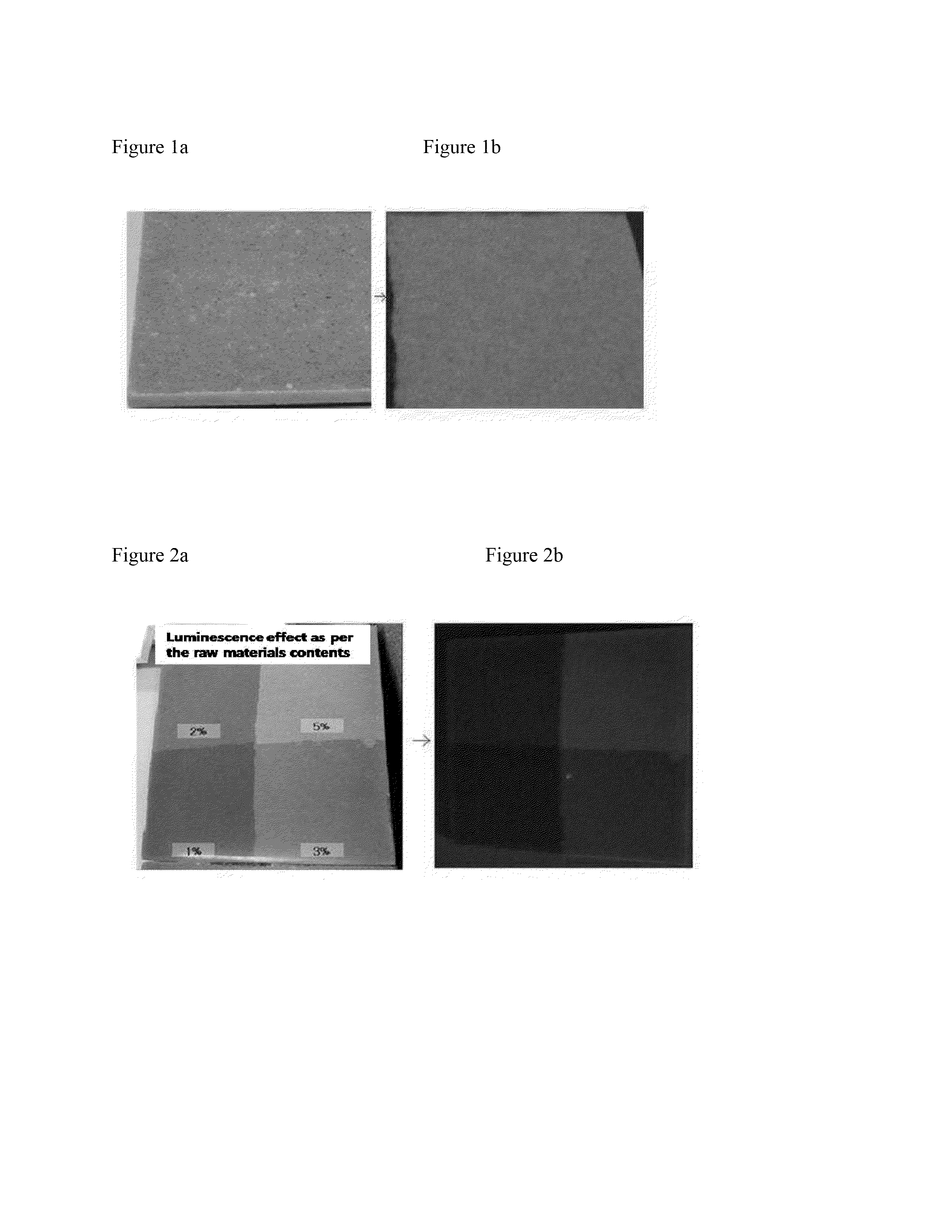

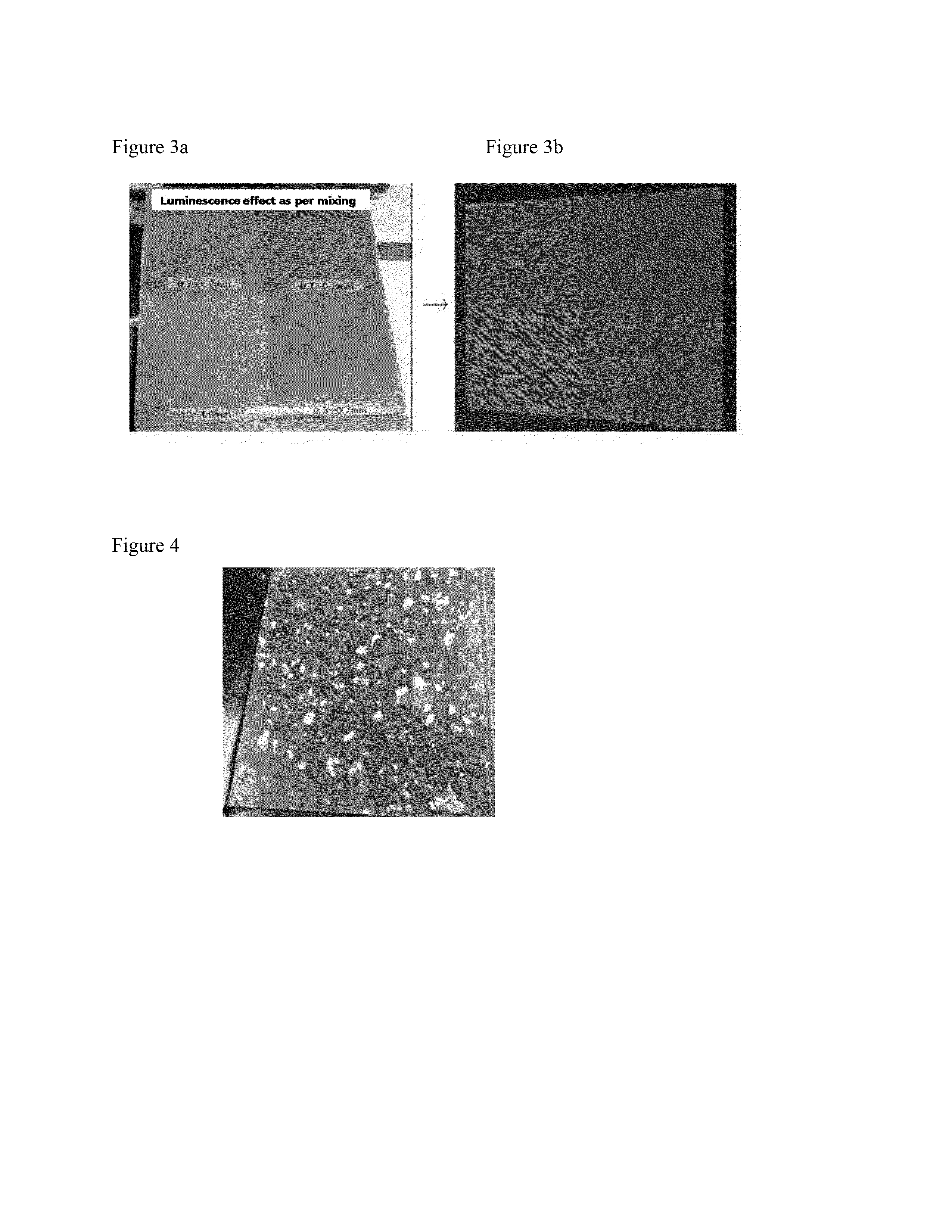

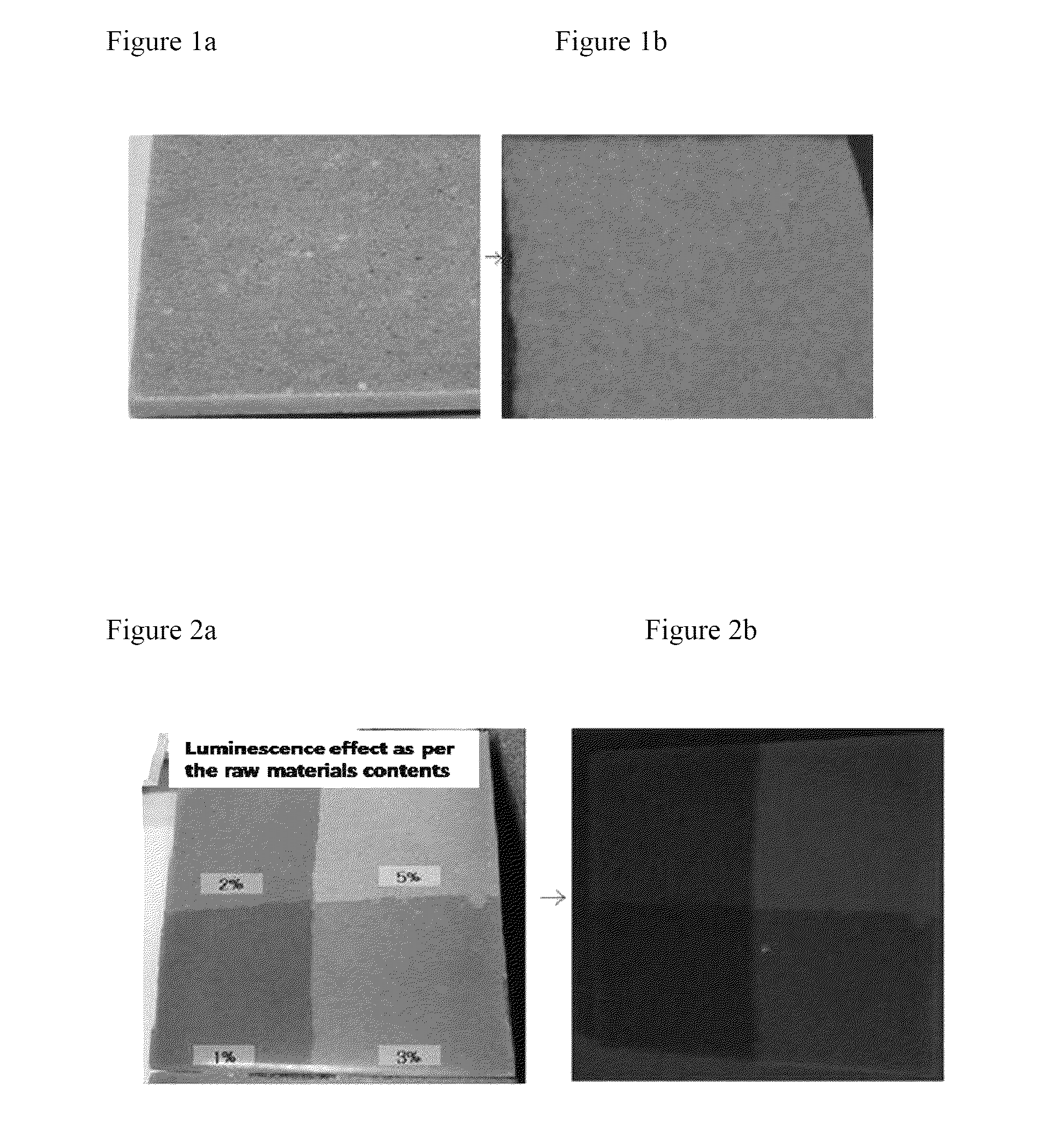

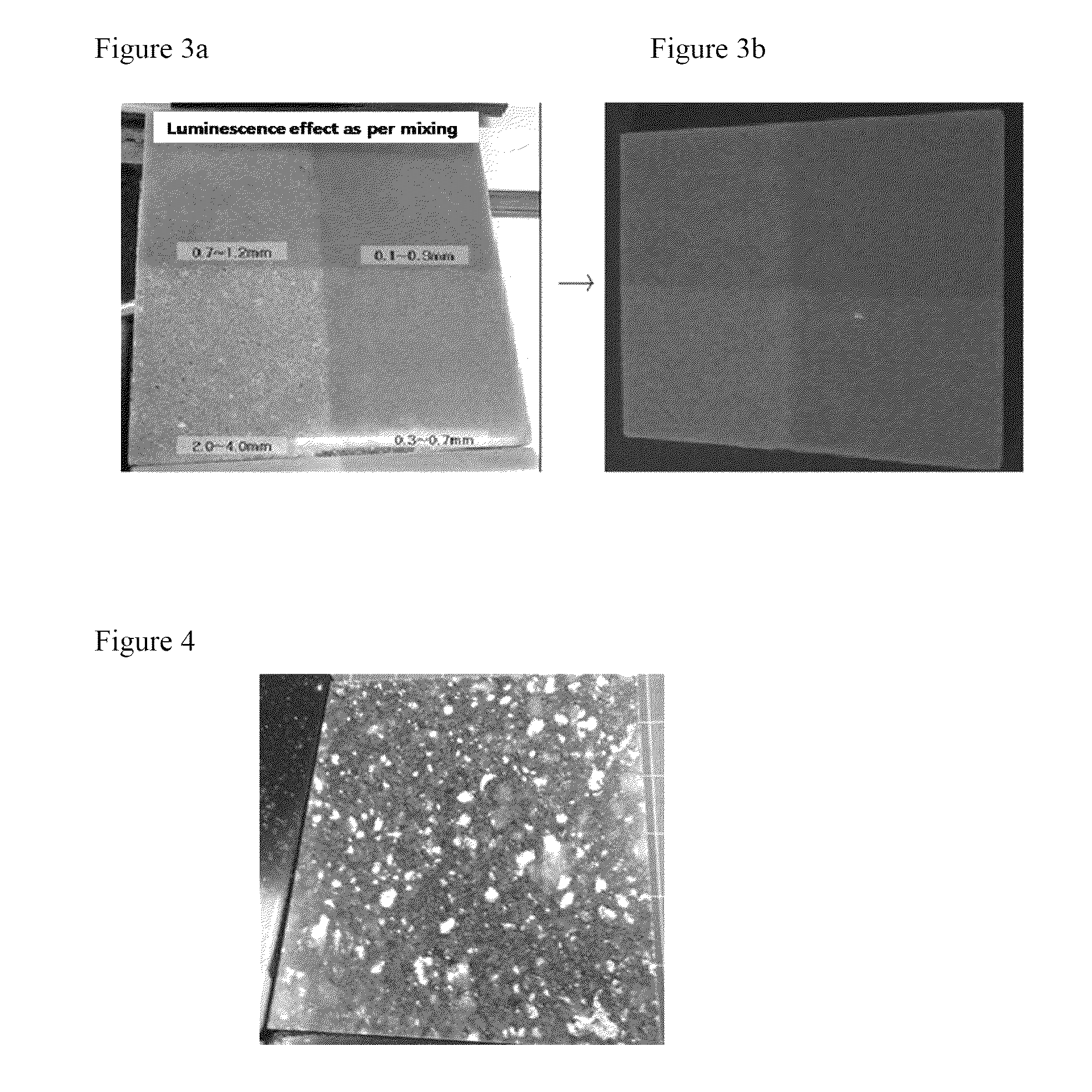

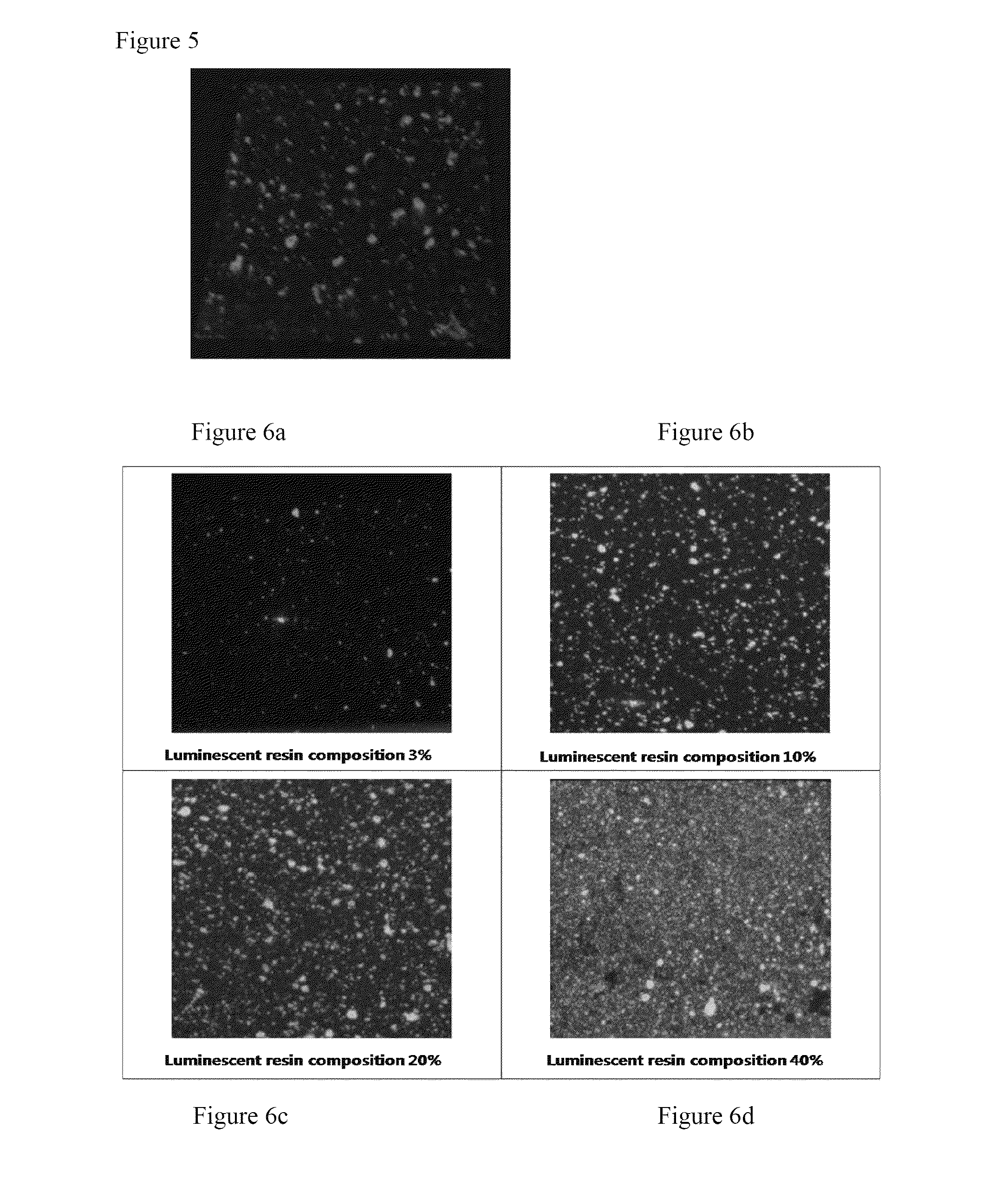

Artificial Marble Having Natural Textures and Luminescent Patterns and Method of Preparing the Same

ActiveUS20130168607A1Bright enoughNatural textureNatural patternsLight effect designsInorganic pigmentsUnsaturated polyester

An artificial marble includes unsaturated polyester resin (A), compound including silica (B), and luminescent pigment (C). An artificial marble according to a second embodiment includes about 70 to about 95% by weight of a non-luminescent base material (I) comprising unsaturated polyester resin (A), compound including silica (B), and organic / inorganic pigment (C) and about 5 to about 30% by weight of a luminescent amorphous pattern part (II) comprising unsaturated polyester resin (A), compound including silica (B), and luminescent pigment (D). An artificial marble according to a third embodiment includes unsaturated polyester resin (A), compound including silica (B), and amorphous luminescent chip (C).

Owner:LOTTE ADVANCED MATERIALS CO LTD

Anti-caster surface laminate

InactiveUS20060234009A1Superior caster resistanceImprove impact resistanceCovering/liningsSynthetic resin layered productsEngineeringSynthetic resin

Disclosed herein are a caster-resistant surface laminate using a synthetic resin and a flooring comprising the surface laminate. The surface laminate utilizes buffering properties of a synthetic resin layer, thus minimizing damage to the surface of the flooring. The surface laminate uses a resin selected from PVC, PE, PET, PETG, PCTG and PU in order to enhance the caster resistance, impact resistance and water resistance. As a result, the surface laminate has improved physical properties without occurrence of damage, such as hollowing and breakage, caused by external impacts, as compared to conventional surface laminates. In addition, the caster-resistant surface laminate attains interior decorative effects by coloration of the synthetic resin layer.

Owner:LG CHEM LTD

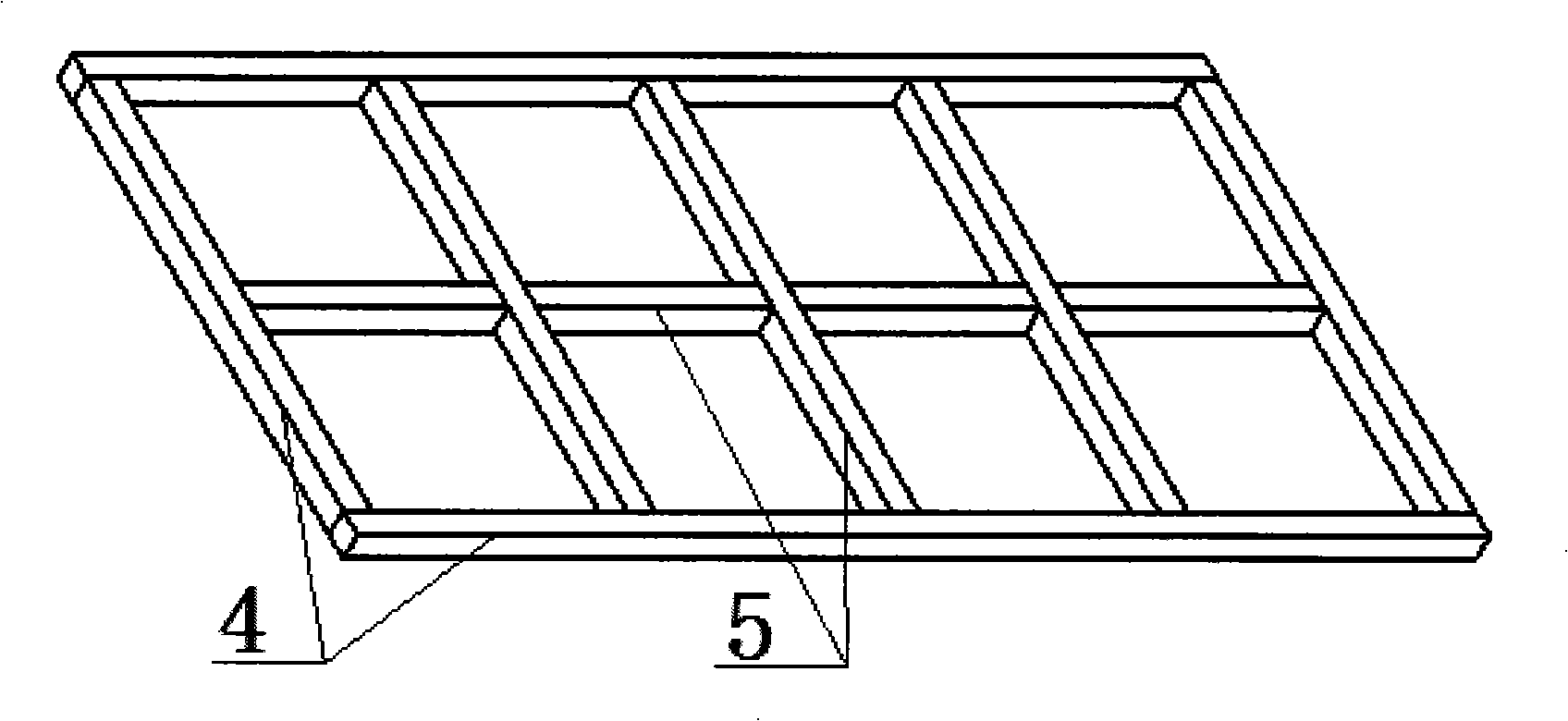

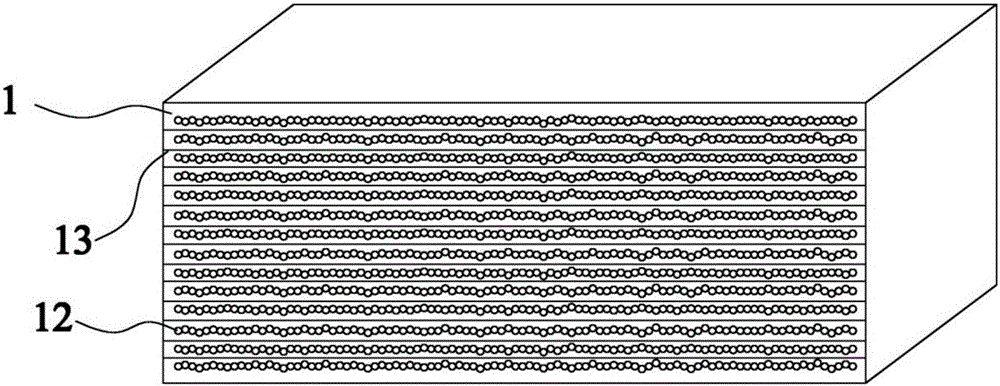

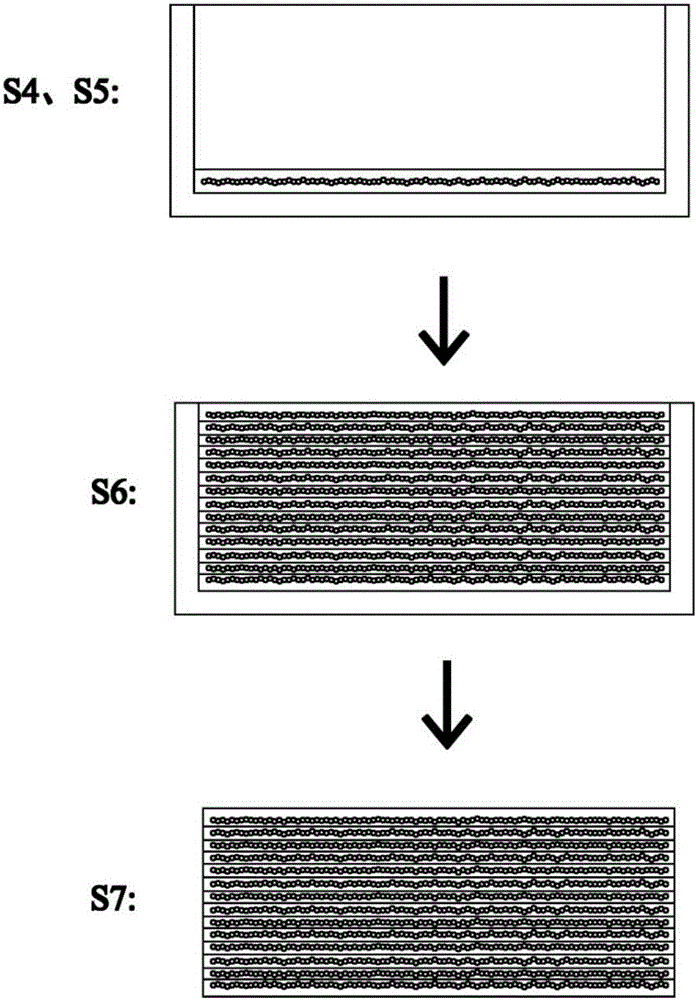

Light-transmitting concrete slab with wire drawing effect and manufacturing method thereof

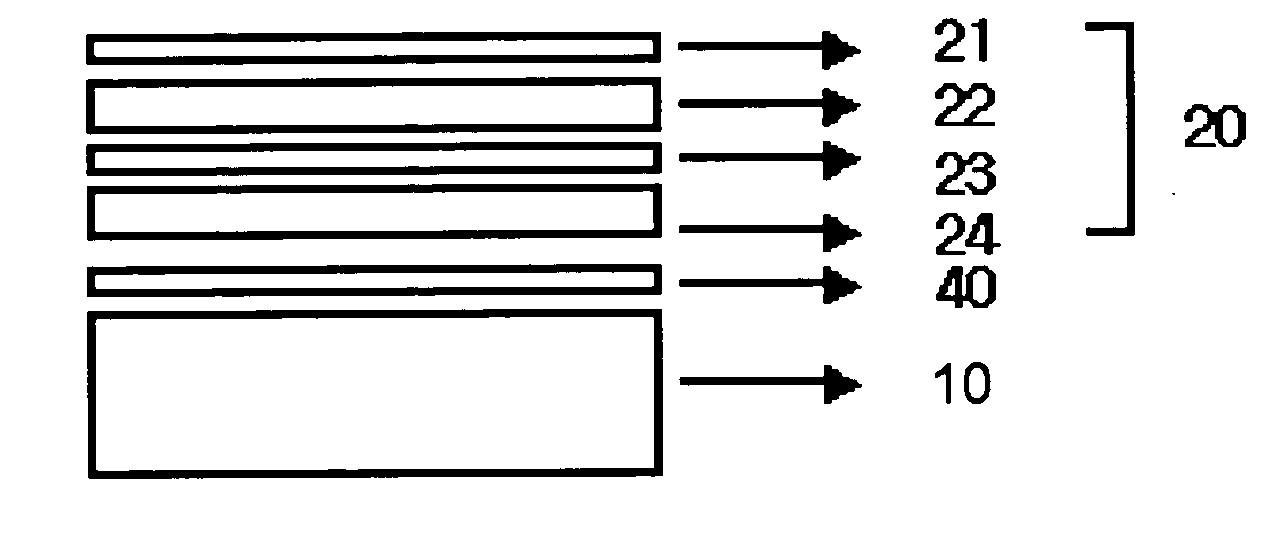

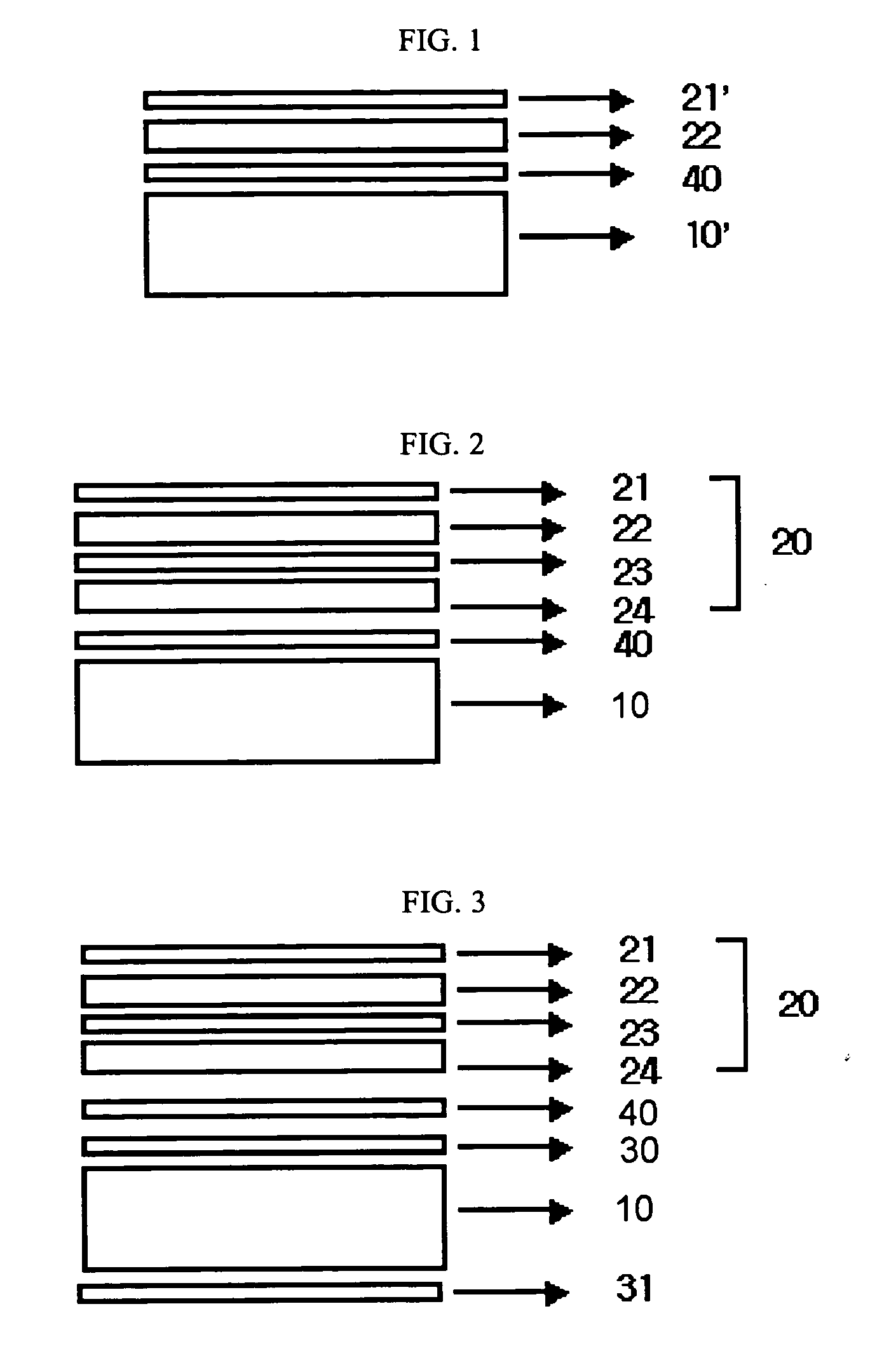

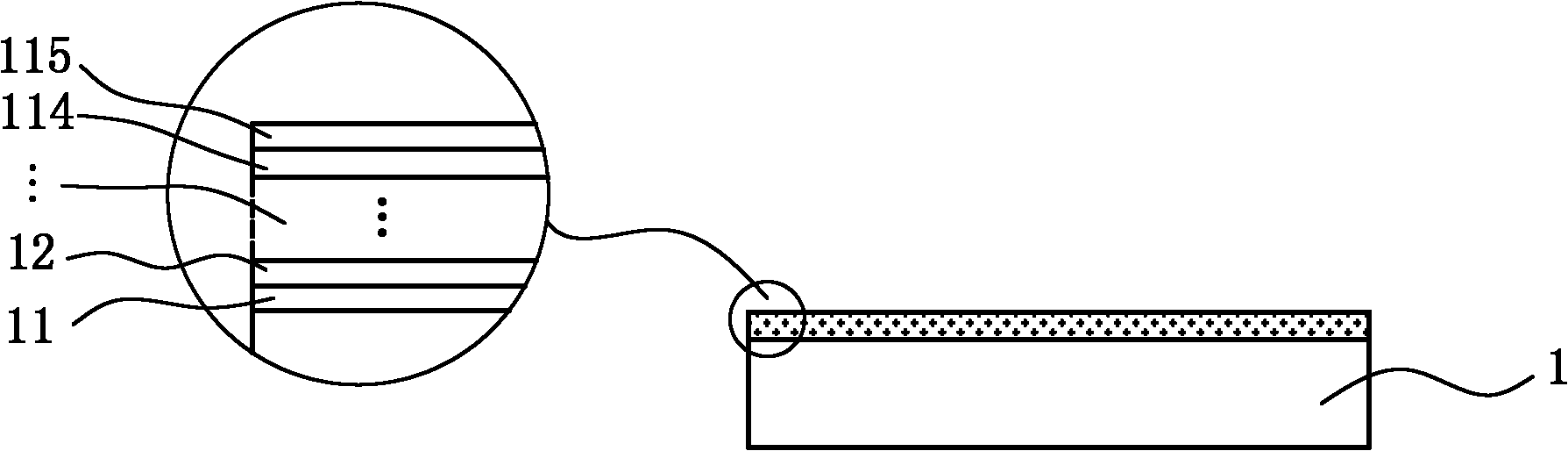

ActiveCN105971194AIncrease productivityHigh strengthConstruction materialCeramic shaping apparatusFiberglass meshGlass fiber

The invention provides a light-transmitting concrete slab with a wire drawing effect and a manufacturing method thereof. The light-transmitting concrete slab comprises a cement mortar gel material and multiple light-guide fiber cloth layers and multiple fiberglass mesh cloth layers which are wrapped and fixed into the cement mortar gel material, wherein the light-guide fiber cloth layers and the fiberglass mesh cloth layers are alternately stacked and arranged in the cement mortar gel material, and one fiberglass mesh cloth layer is arranged between every two adjacent light-guide fiber cloth layers; each light-guide fiber cloth layer comprises multiple light-guide fibers which are sequentially arranged on the same plane, and each light-guide fiber is coatedwith a coupling agent coating layer. According to the light-transmitting concrete slab provided by the invention, the attractiveness of a product is enhanced, and the strength of the product is greatly increased.

Owner:广州固恒建材科技有限公司

Non-cyanide gold imitation electro plating method of flowers and plants

A non-cyanogen golden electroplating on the surface of flower, tree leaf, or beetle, includes such steps as preparing golden electroplating liquid from copper sulfate, zinc sulfate, stannous chloride, potassium pyrophosphate, potassium sodium tartrate, potassium citrate and aminotriacetic acid, washing, roughening, sensitizing, activating, reducing, chemically plating copper, polishing, electroplating golden layer, passivating and coating protective film.

Owner:CHOW TAI SENG JEWELRY CO LTD

Corundum surface floor and production process thereof

ActiveCN101922227AGuaranteed aestheticsNot easy to fall offWood veneer joiningFlooringSurface finishHardness

The invention discloses a corundum surface KINGHARD floor and a production process thereof. The floor comprises a substrate (1), the surface of the substrate (1) is provided with a corundum surface finish coat layer (115), 14 coatings are also arranged below the corundum surface finish coat layer (115), and 15 varnishing processes are adopted in the process of the floor. The corundum surface floor has high surface rigidity, favorable wear resistance, coating adhesiveness and combinability of the coatings and the floor and high transparency, does not deform easily when the floor bears the pressure of heavy objects, protects the floor from contacting moisture, and avoids drastic expansion or shrinkage, prevents worm biting, and can display natural grain of woods and maintain the aesthetic feeling of the floor; the coatings do not have obvious change when the coatings are used for a long period of time, even if heavy furniture or tables and chairs are hauled on the floor, the phenomenon of scratches, whitening or falling seldom occurs to wood floors, and the coatings do not fall easily due to elongated service time.

Owner:ZHEJIANG JIAYE FLOORING CO LTD

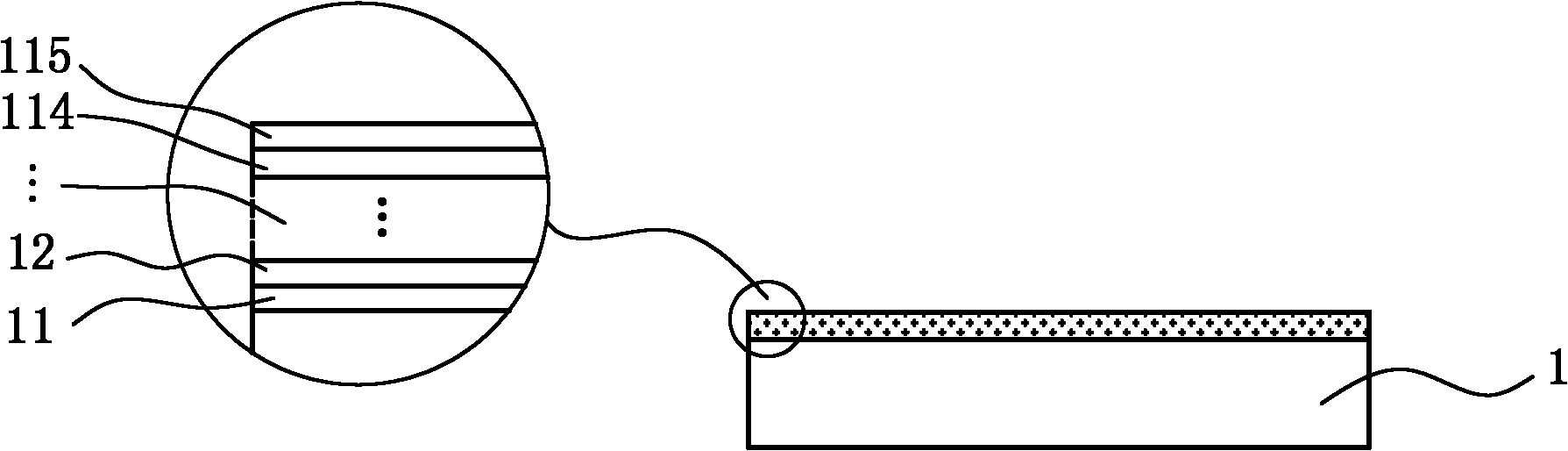

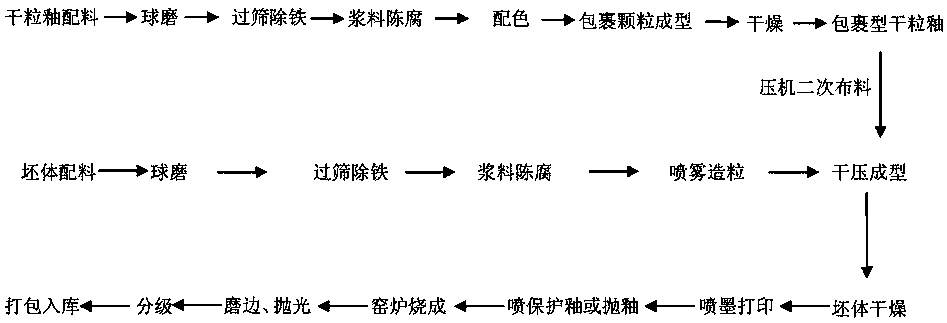

Wrapping type dry granular glaze, wrapping type dry granular glaze cloth ashlar brick and preparation method of wrapping type dry granular size

The invention relates to a wrapping type dry granular glaze, a wrapping type dry granular glaze cloth ashlar brick and a preparation method of the wrapping type dry granular size. The preparation method of the wrapping type dry granular glaze comprises dropwise adding glaze slurry into a rotating disc containing glaze powder so that through the rotating disc, glaze drops can be wrapped with the glaze power to form wrapping type granules, and drying the wrapping type granules to obtain the wrapping type dry granular glaze. The preparation method of the wrapping type dry granular glaze can obtain the wrapping type dry granular glaze through simple processes; the wrapping type dry granular glaze can be applied to preparing ceramic bricks to produce ashlar products vivid in pattern, rich in sense of depth, natural in texture and high in third dimension and granular sensation.

Owner:MONALISA GRP CO LTD

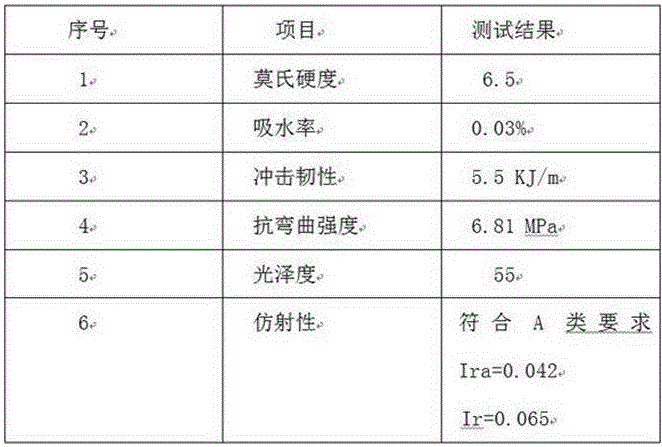

Quartz-stone board and preparation method thereof

The invention relates to a quartz-stone board and a preparation method thereof. The preparation method comprises the following steps: (1) designing a pre-pressing die, namely, arranging a bulge on a pre-pressing plate, and extending the bulge to the side edge of the pre-pressing plate to form a splicing station, so as to obtain the pre-pressing die; (2) mixing unsaturated resin, a curing agent, a coupling agent, quartz sand, quartz powder and a toner mixture to obtain a plurality of mixture groups with different color, and then rolling one group to obtain wet materials; (3) pre-pressing the wet materials through the pre-pressing die, and forming concave grooves in the surfaces of the wet materials, then removing the pre-pressing die, and filling the concave grooves with the rest mixture groups and color paste; (4) performing the subsequent forming processes to obtain the quartz-stone board. According to the method, the position of the splicing station can be flexibly designed according to the requirement of actual engineering, so that the quartz-stone boards can be spliced at random; the textures on the spliced boards are continuous and in natural transition; in addition, the preparation process is stable, and batch production can be achieved.

Owner:OPPEIN HOME GRP

Imitative natural fish-belly whitish color quartz stone board and preparation method thereof

InactiveCN106630743AWith texture effectImprove pass rateFlat articlesSocial benefitsTitanium phosphate

The invention relates to an imitative natural fish-belly whitish color quartz stone board and a preparation method thereof and belongs to the technical field of imitative quartz stone board production. According to the technical scheme, the imitative natural fish-belly whitish color quartz stone board is prepared from, by weight, 50-55 parts of 40-120-mesh quartz sand, 30-35 parts of 325-mesh quartz powder, 10-12 parts of adhesive, 3-5 parts of 800-mesh filler, 0.5-1 part of color paste pigment and 0.2 part of dioctyl titanium phosphate amine, the adhesive is prepared from, by weight, 65-70 parts of unsaturated resin, 25-30 parts of styrene, 5-10 parts of hydroxy o-dimethylamine and 1-3 parts of beta-plasticizer. The imitative natural fish-belly whitish color quartz stone board has the advantages that the quartz stone board has a natural fish-belly whitish color texture effect, is high in pass percent and has very high economic and social benefits, and produced products are clear and natural in texture, low in cost and high in pass percent.

Owner:唐山金信人造板业有限公司

Flame-retardant and Corrosion-resistant Fiber Bamboo Substrate and Preparation Method thereof

ActiveUS20150128827A1Increase profitImprove breathabilityLayered productsWood treatment detailsFiberFire retardant

A preparation method for a flame-retardant and corrosion-resistant fiber bamboo substrate comprises the following steps of: 1) cutting raw bamboo into bamboo filaments; 2) flame-retardant treatment: soaking the bamboo filaments prepared in Step 1) in aqueous solution of a flame retardant; 3) drying: drying the flame-retardant treated bamboo filaments at 55° C. to 65° C.; 4) carbonized pyrolysis: feeding the dried bamboo filaments into a carbonized pyrolysis kiln; and 5) sequentially gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain a bamboo substrate.

Owner:WUXI BODA BAMBOO & WOOD INDAL

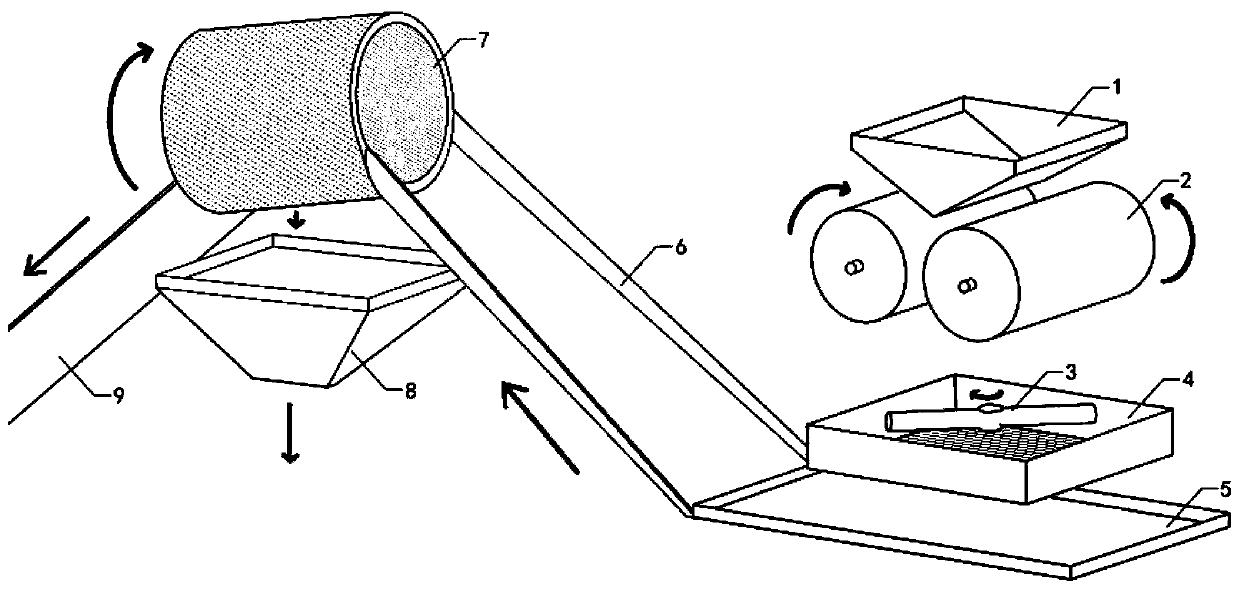

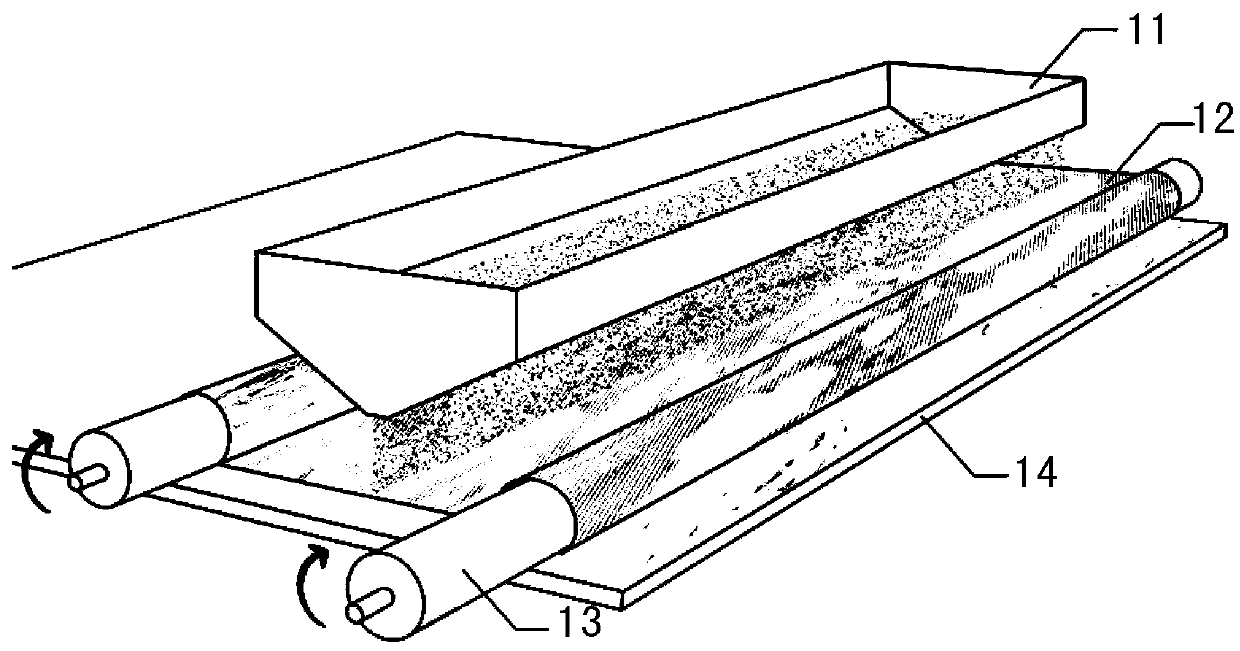

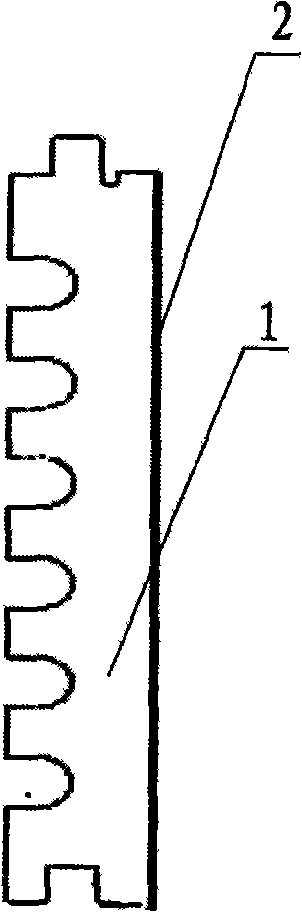

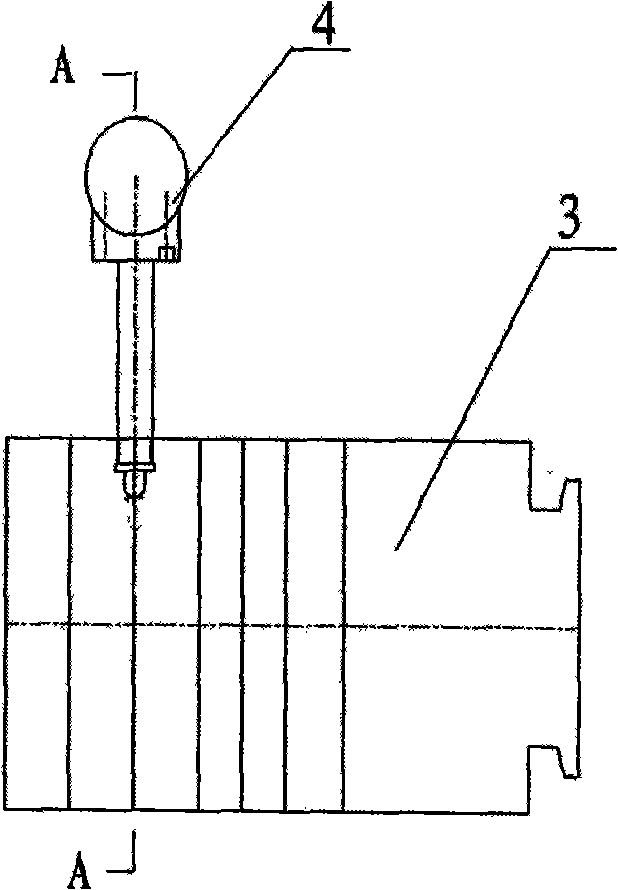

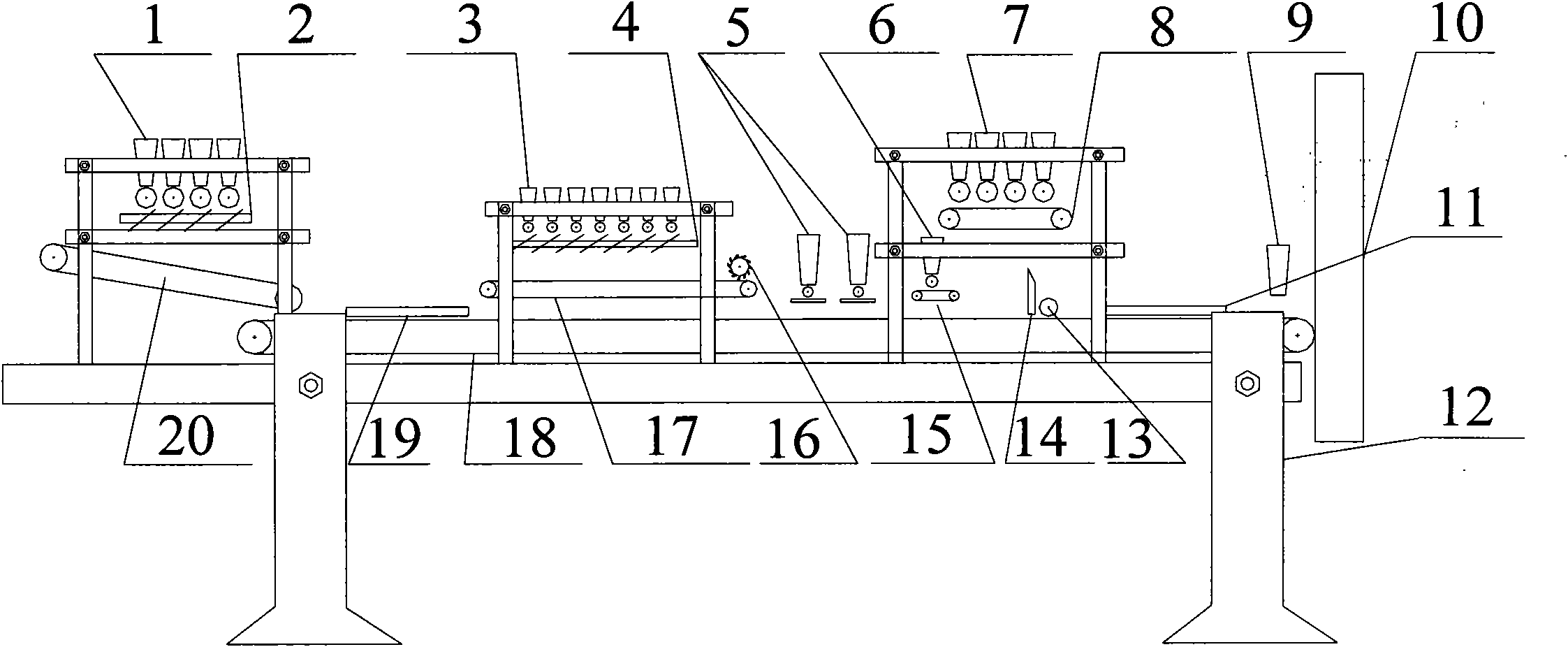

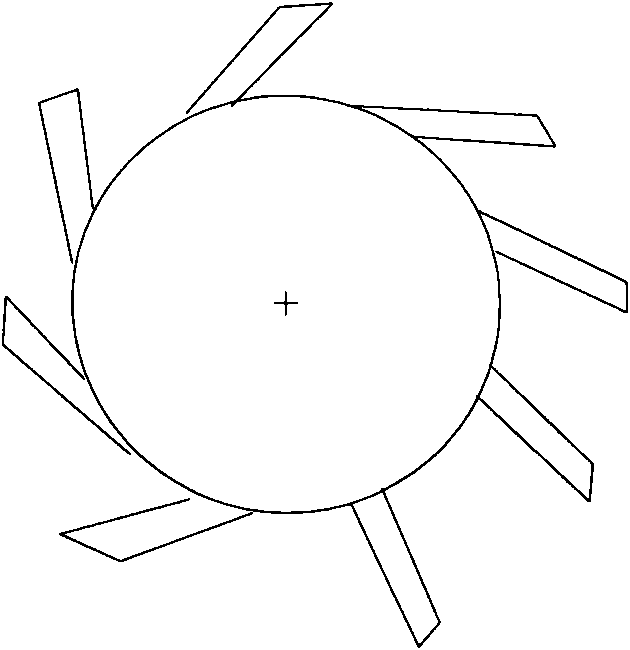

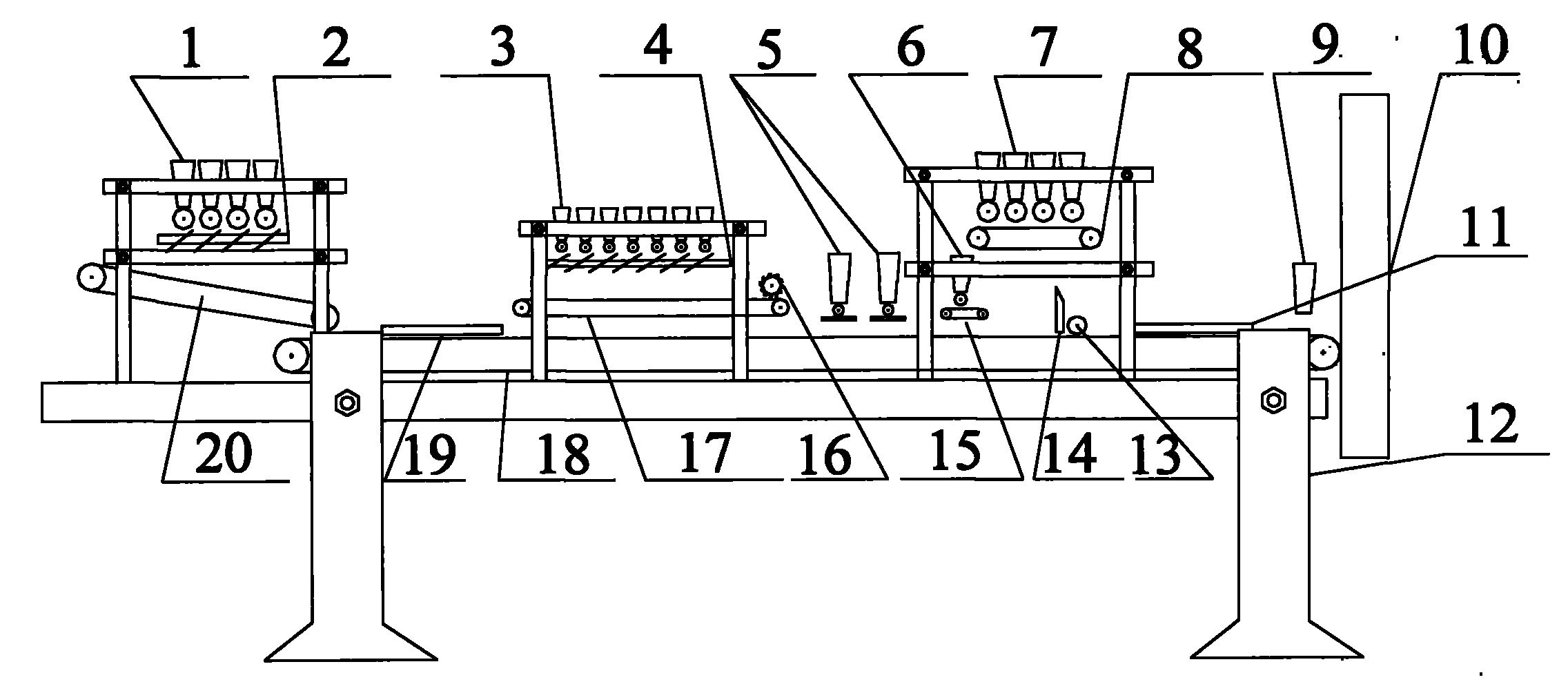

Process for distributing ceramic micro-powder bricks

InactiveCN102120336ARich in colorNatural textureFeeding arrangmentsShaping conveyorsClear LayerBrick

The invention discloses a process for distributing ceramic micro-powder bricks. The method comprises steps as follows: (1) a plurality of components are tiled on a first inclined belt in a plurality of layers on a first work station and then turned over to a large circulating belt through the first inclined belt, thus a plurality of extruded draping material layers are formed on the large circulating belt; (2) a moving grid moves and extrudes the draping material layer which is turned over on the large circulating belt to form a bent profiled texture layer; (3) a plurality of components are tiled on a second cloth belt in a second work station, and a cutter cuts the plurality of components which are tiled on the second cloth belt into pellets, and smashes the pellets on the profiled texture layer on the large circulating belt; and (4) a line material is tiled on a blank gap in a line work station, a component layer is tiled on a feeding work station, and a bottom component is tiled after the component layer is scraped by a scraping mechanism and fed into a press to form. Compared with the prior art, the distributing equipment for the ceramic micro-powder bricks can be used for producing products which have the advantages of rich color, clear layer and natural texture, and have the characteristics of natural shell stone.

Owner:霍镰泉

Processing method of broken leather

ActiveCN105500803ANatural textureHigh economic added valueLamination ancillary operationsLaminationKnurlingAdditional values

The invention relates to the technical field of leather processing, in particular to a processing method of broken leather. The processing method comprises steps as follows: (1) material selection; (2) coating and filling of resin; (3) burnishing and compacting; (4) blade coating of patching paste; (5) calendaring; (6) first roller coating of covering resin; (7) pressing by a sand board; (8) second roller coating of the covering resin; (9) film attaching; (10) knurling; (11) spraying of a feeling agent, and preparation of a finished product leather. Wastes are processed into top layer leather, the utilization rate of the leather is high, the quality of the prepared finished product leather is close to the top layer leather, the grain side and the texture are natural, the leather can be used for pairing of shoes and applied as fabric of children's shoes, and the additional value of the finished product leather is substantially increased.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

Shape and color protection method for paeonia lactiflora

InactiveCN106538514AStrong anti-mildew abilityLong storage timeDead plant preservationCitric acidPaeonia lactiflora

The invention discloses a method for preparing dehydrated dried paeonia lactiflora. The method comprises the following steps: sieving cottonseed meal through a sieve with the mesh size in a range of 60-250 mesh to obtain fine cottonseed meal, sieving corncob powder through a sieve with the mesh size in a range of 60-250 mesh to obtain fine corncob powder, uniformly mixing the fine cottonseed meal with the fine corncob powder, and performing heating and drying at 40-90 DEG C to obtain a dehydrating matrix; providing integrated paeonia lactiflora which are uniform in size and are bright-colored and glossy; performing trimming to the selected integrated paeonia lactiflora; soaking the trimmed integrated paeonia lactiflora in a citric acid solution with the mass concentration being 0.5-2.5% for 5-20 min for color protection; and embedding the obtained in the dehydrating matrix for dehydration, wherein during embedding, the temperature of the dehydrating matrix is no less than 40 DEG C, and the dehydrating time is 4-20 h, and after dehydration is completed, removing the dehydrating matrix to obtain the dehydrated dried paeonia lactiflora. The dried paeonia lactiflora prepared through the method has a good shape and color protection effect.

Owner:刘炳瑞

Method for preparing purple sand slime containing tourmaline iron sand

The invention provides a method for preparing purple sand slime containing tourmaline iron sand. Ore and raw tourmaline scattered in a soft clay ore bed are artificially selected, purple sand ore is stacked in the open air in winter and summer for natural weathering, the weathered raw ore is aired, dried, ground by means of a hard stone mill and smashed into 60-mesh fine powder, 80-mesh fine powder and 120-mesh fine powder, and after the tourmaline ore is smashed and ground and ore powder is screened out by a 140-mesh sieve, water is added, the materials are mixed, evenly stirred and sealed for ageing; vacuum pugging, clay strip pressing, sealing and ageing are repeated for 3-5 times, and the purple sand slime containing the tourmaline iron sand is prepared. The slime prepared through the method is original, pure, free of chemical raw materials and artificial pigment and not likely to crack when purple sand ceramic products are fired, and the manufactured purple sand ceramic products are natural, environmentally friendly, good in quality, natural in texture, fine and smooth in hand feeling, good in light transparency and water color and good in color generation. Meanwhile, the purple sand slime has the effects of improving water quality and promoting blood microcirculation.

Owner:宜兴市帛玉碧砂艺术品有限公司

Artificial marble having natural textures and luminescent patterns and method of preparing the same

ActiveUS8999199B2Bright enoughNatural textureNatural patternsSpecial tyresPolymer sciencePolyester resin

An artificial marble includes unsaturated polyester resin (A), compound including silica (B), and luminescent pigment (C). An artificial marble according to a second embodiment includes about 70 to about 95% by weight of a non-luminescent base material (I) comprising unsaturated polyester resin (A), compound including silica (B), and organic / inorganic pigment (C) and about 5 to about 30% by weight of a luminescent amorphous pattern part (II) comprising unsaturated polyester resin (A), compound including silica (B), and luminescent pigment (D). An artificial marble according to a third embodiment includes unsaturated polyester resin (A), compound including silica (B), and amorphous luminescent chip (C).

Owner:LOTTE ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com