Corundum surface floor and production process thereof

A production process, corundum surface technology, applied to floors, manufacturing tools, wood processing appliances, etc., can solve problems such as poor scratch resistance, shrinkage or swelling of wooden floors, and discounted aesthetics of wooden floors, etc., to achieve coating Good adhesion, avoid expansion or shrinkage, maintain aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

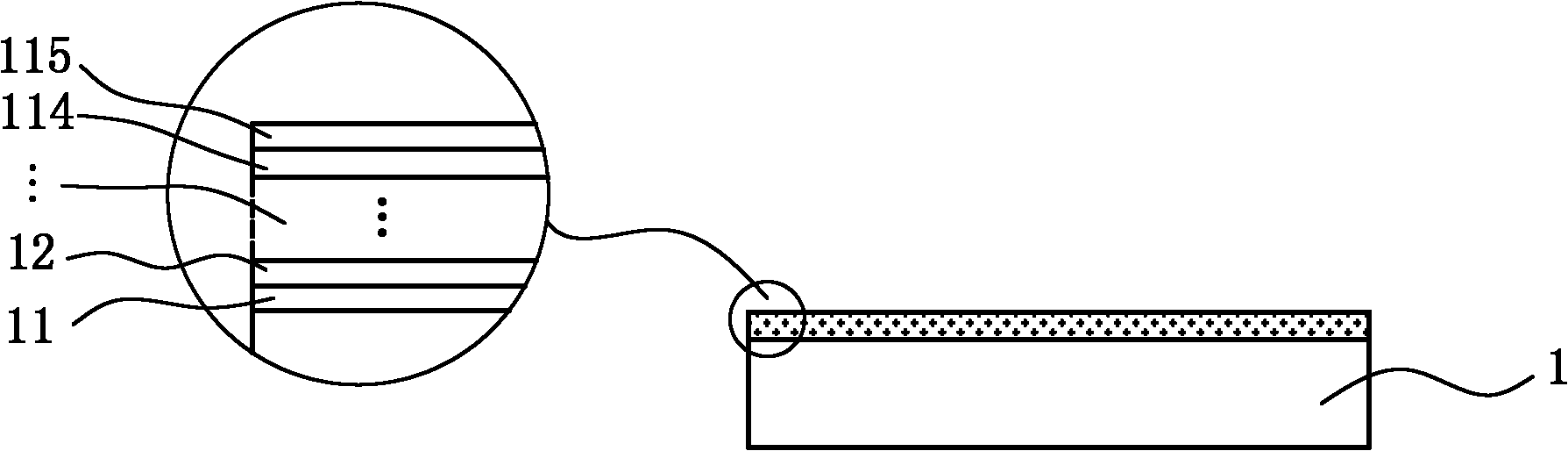

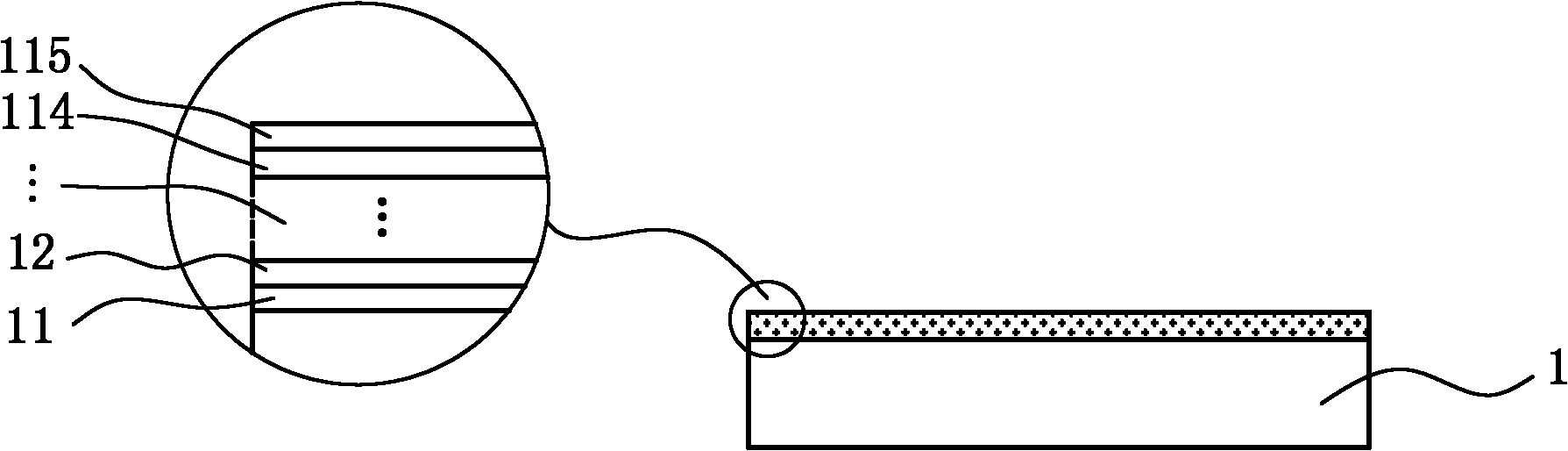

[0076] Example: Corundum flooring, as attached figure 1 As shown, including the substrate 1, the surface of the substrate 1 is coated with fifteen layers of coatings, which are in order from bottom to top: high penetration adhesive layer 11, high toughness paint layer 12, first high transparent paint layer 13, first corundum Top paint layer 14, second highly transparent paint layer 15, high elastic paint layer 16, third high transparent paint layer 17, second corundum top paint layer 18, first high transparent resin layer 19, second high transparent resin layer 110 , the third highly transparent resin layer 111 , the fourth highly transparent resin layer 112 , the first precision touch-up layer 113 , the second precision touch-up layer 114 and the corundum top coat layer 115 .

[0077] The models used in the above fifteen coatings are as follows from bottom to top:

[0078] (1), the adhesive agent that high penetration adhesive agent layer 11 adopts is the adhesive agent that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com