Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

908results about How to "Three-dimensional" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

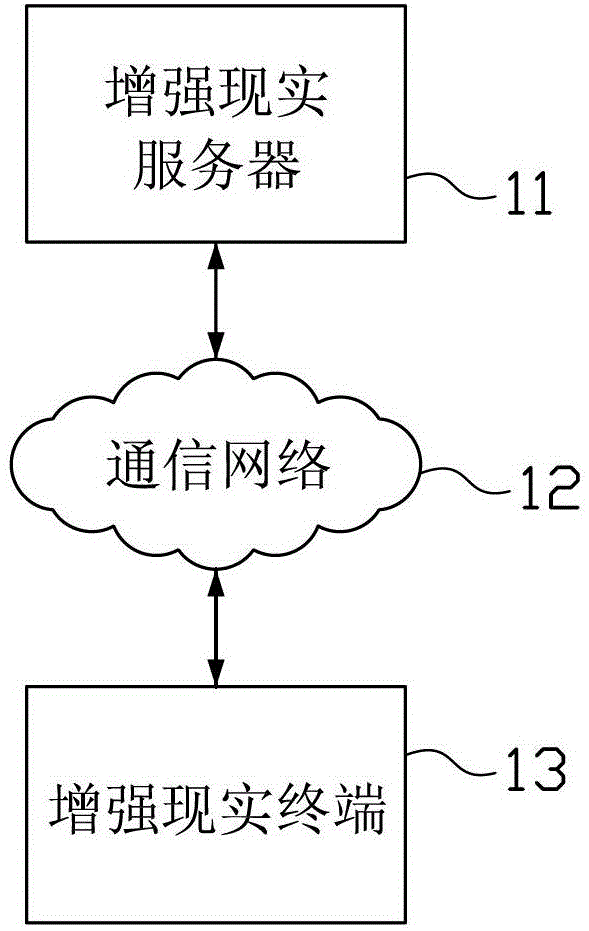

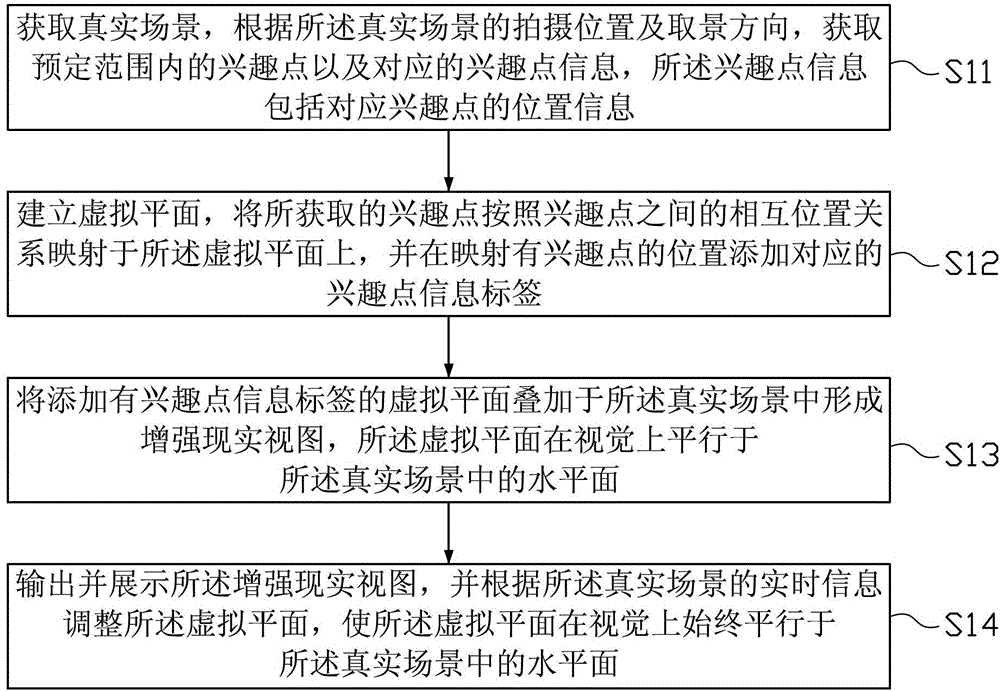

Method and device for realizing augmented reality

ActiveCN104102678AThree-dimensionalLayeredImage data processing detailsSpecial data processing applicationsTime informationComputer graphics (images)

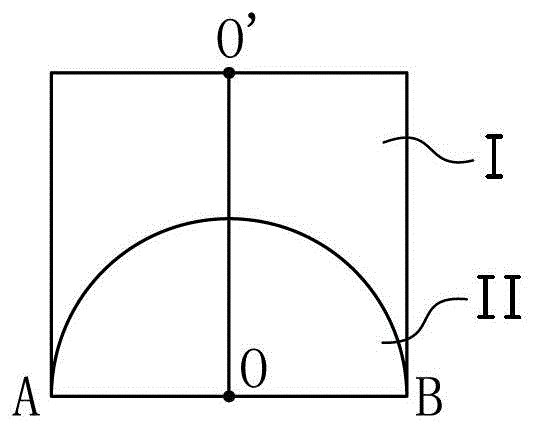

The invention provides a method and a device for realizing augmented reality. The method comprises the following steps of obtaining a real scene, and obtaining interest points in a preset range and corresponding interest point information according to a camera site and a viewing direction of the real scene; establishing a virtual plane, mapping the obtained interest points on the virtual plane according to a mutual position relation among the interest points, and adding corresponding interest point information labels at positions, at which the interest points are mapped; forming an augmented reality view by overlaying the virtual plane, to which the interest point information labels are added, in the real scene, wherein the virtual plane is in parallel to a horizontal plane in the real scene based on visual sense; outputting and showing the augmented reality view, and adjusting the virtual plane according to real-time information of the real scene to enable that the virtual plane always is in parallel to the horizontal plane in the real scene based on the visual sense. According to the method and the device for realizing the augmented reality, the distance relation among the interest points and the mutual position relation between the interest points and the users can be more intuitively shown for the users.

Owner:TENCENT TECH (SHENZHEN) CO LTD

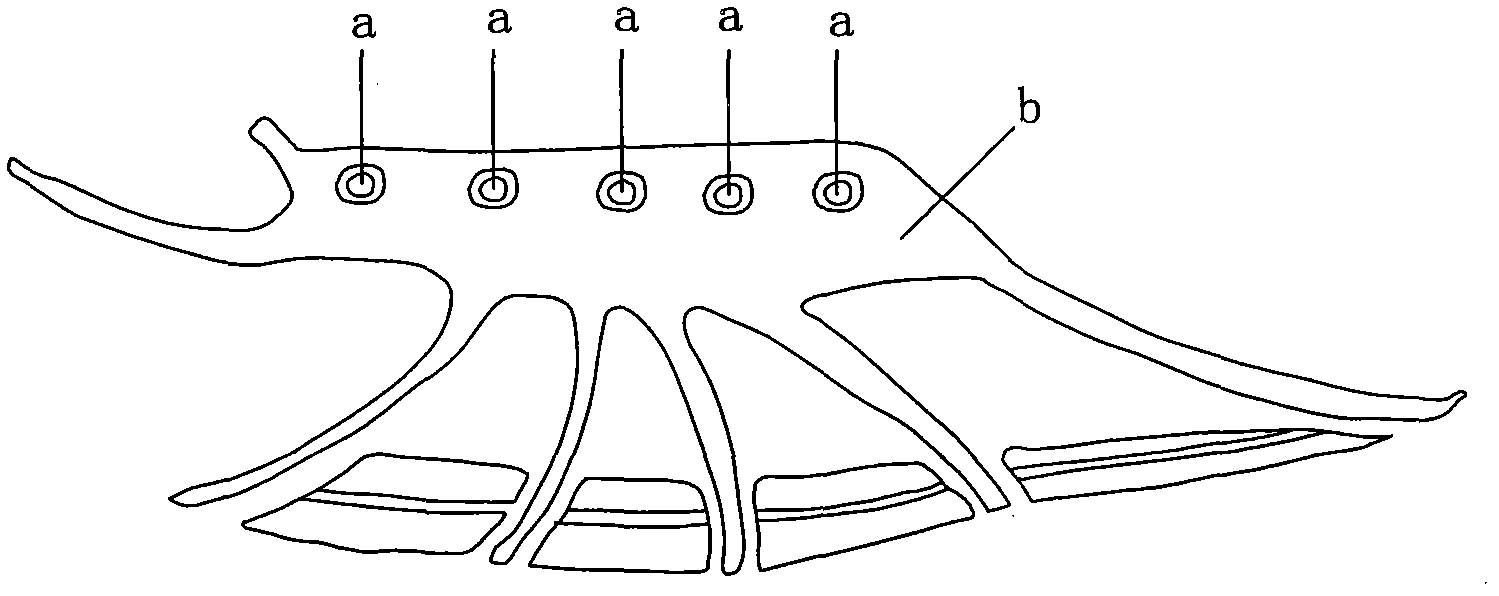

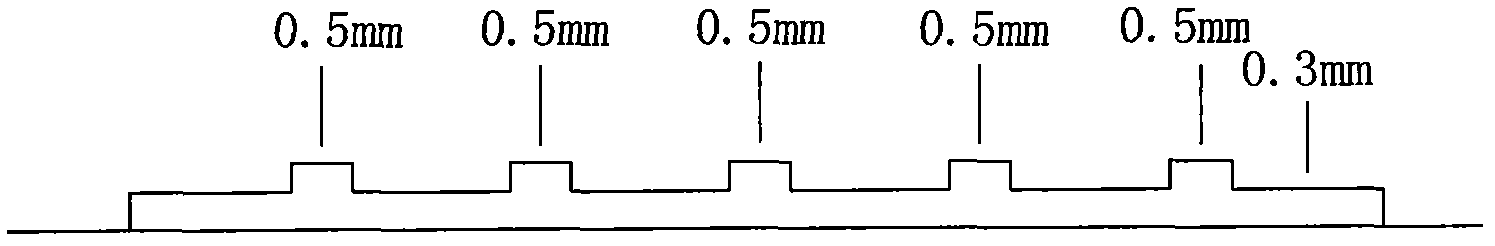

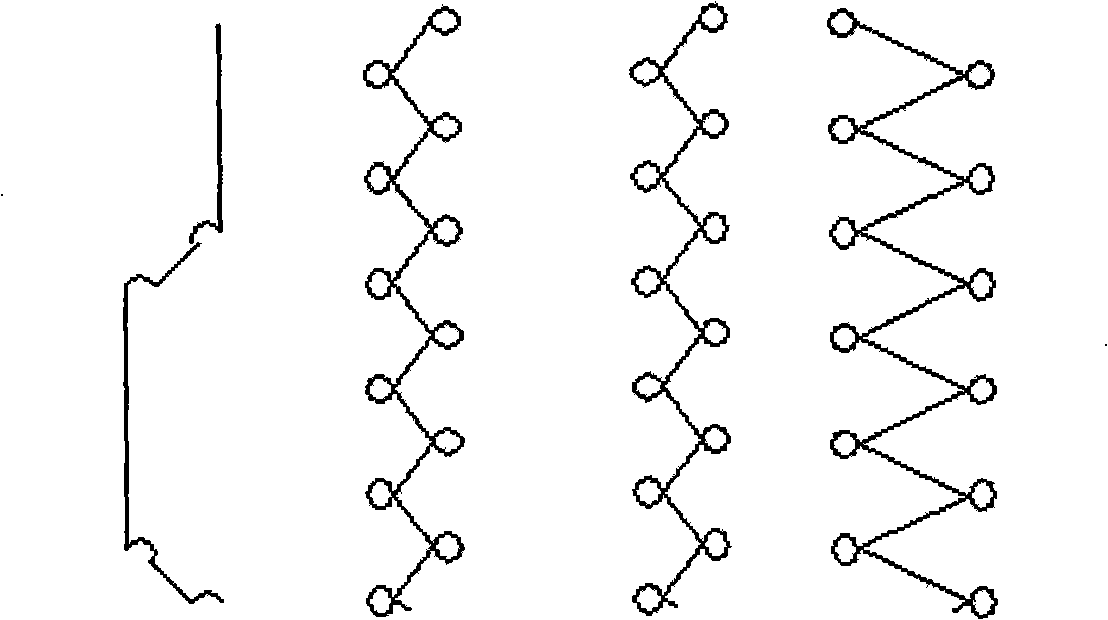

Dispensing stitching method and embroidery method for embroidery

ActiveCN101824714ANo "spot" phenomenonImprove visual effectsEmbroidering machines apparatusHair streamsEngineering

The invention relates to a needle dispensing method and an embroidery method for embroidery. In the embroidery, the stitch length between two needle eyes is twice more than the diameter of the stitching thread and less than or equal to ten times of the diameter of the stitching thread, so that the stitches of the embroidery thread is of a spotted shape or a short-line shape on the front face of the embroidery fabric; and the stitches of the spotted shape or the short-line shape form embroidery patterns in at least one of four organizational forms, i.e. separation, overlapping, connection and crossing, and the embroidery patterns are arranged in a density-changing way on the plane of the embroidery substrate. The invention overcomes traditional prejudices and creates a novel embroidery stitching method, which shows light and shadow changes with discrete spots in the embroidery picture, and is particularly suitable for sketch representation, in particular to the texture of toner particles in toner sketches, the texture of mist obscuration in ink paintings, drag marks in calligraphy and fine parts in various embroidery pictures such as the eyes and hair of human beings and animals, branches, rods and the like. When in use, the invention can bring more transparency and three-dimensional feeling into the embroidery work, so that the embroidery work is more delicate with nimbus.

Owner:邹英姿

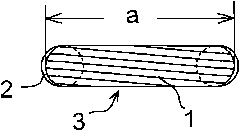

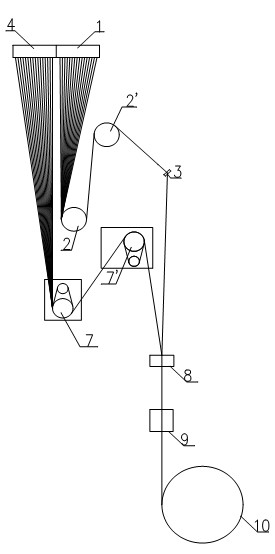

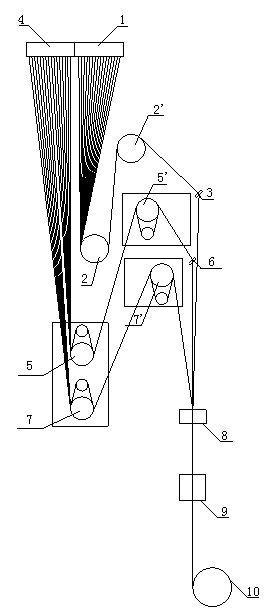

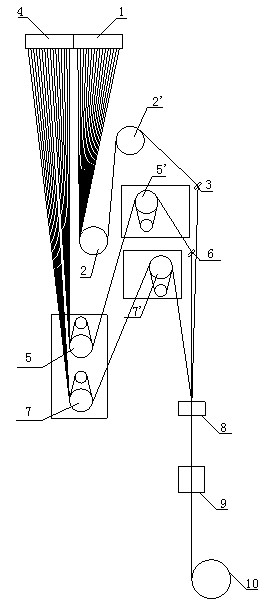

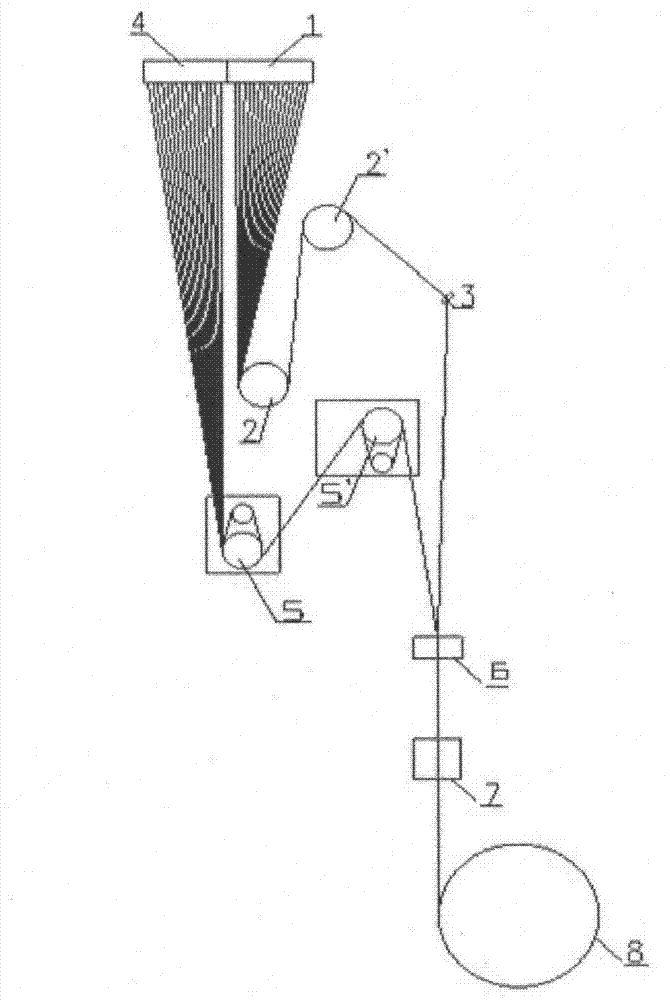

Preparation method and device of dual different-shrinkage combined filament yarn

InactiveCN102140700AFluffy appearanceFull of layersArtificial thread manufacturing machinesArtificial filament heat treatmentSpinningEngineering

The invention relates to a preparation method and device of dual different-shrinkage combined filament yarn. The device comprises a first spinning component, a second spinning component, a lower spinning reel, an upper spinning reel, a first hot roll, a second hot roll, a first redirector, a doubling machine, a netting device and a winding roll, and is characterized by also comprising a third hot roll, a fourth hot roll and a second redirector. The preparation method is characterized in that one part of yarn output by the second spinning component is input to the doubling machine through the first hot roll and the second hot roll; the other part of yarn output by the second spinning component is input to the doubling machine through the third hot roll, fourth hot roll and second redirector; and after the doubling machine merges all the input yarn, the yarn is processed by the netting device and the winding roll, thereby finally obtaining the dual different-shrinkage combined filament yarn. The looped piles formed on the surface of the dual different-shrinkage combined filament yarn are more stratified; and the loops with different sizes are tangled, so that the combined filament yarn looks fluffier, and the formed fabric is plumper and has stereo perception.

Owner:DONGHUA UNIV

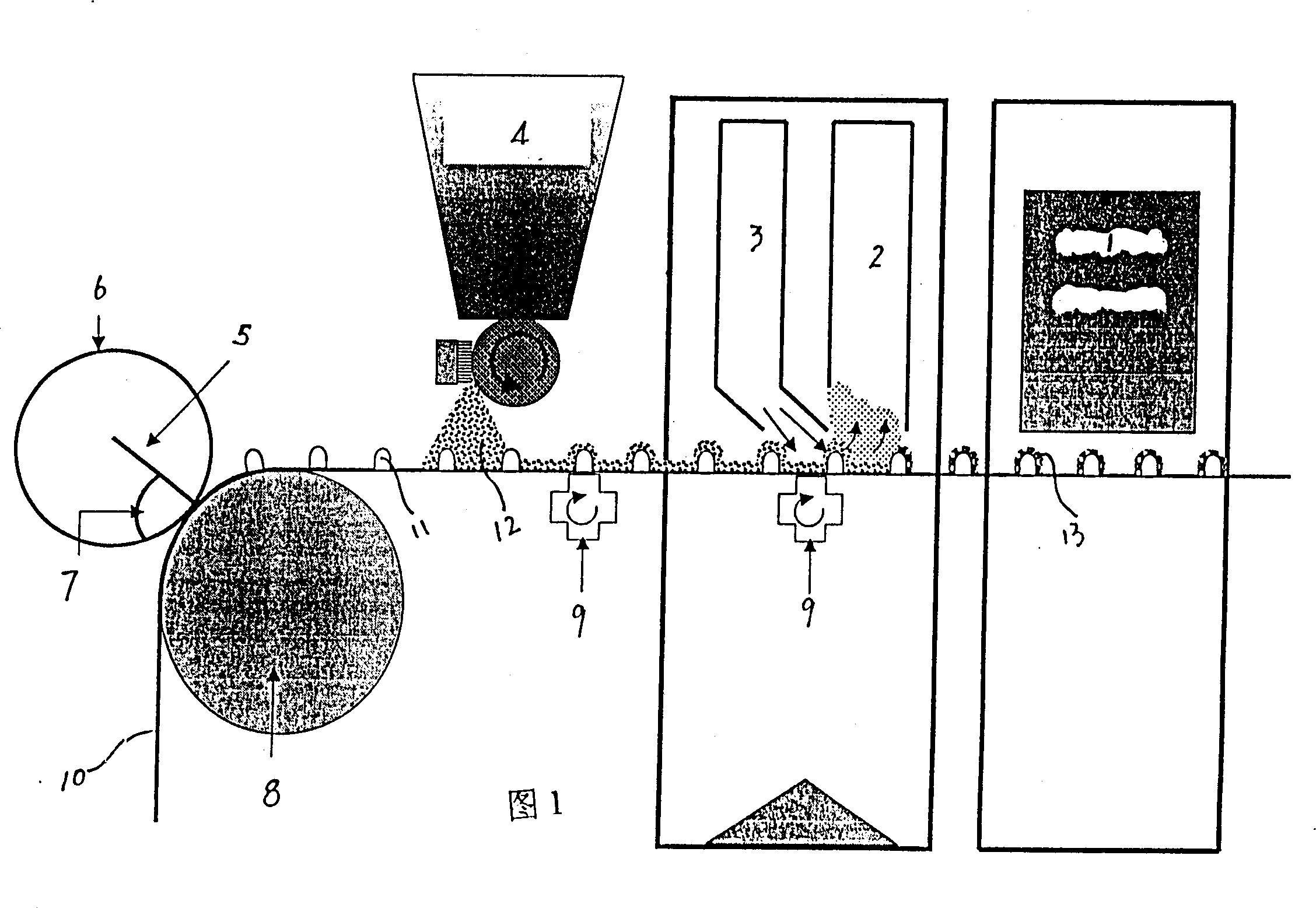

Crystal color ceramic, crystal color glass, composite material for crystal color illuminating layer and technical method thereof

The invention discloses a crystal colorized ceramic and crystal colorized glass, substantially composite materials and process method of crystal colorized decorative layer, which comprises the following weight materials: dry-powder glaze 6-60, bond 15-50, additive 0-70, glass micro-ball 20-90; in the invention the surfaces of the ceramic and glass product adopt the crystal colorized materials and then are ornamented with patterns, and then sintered for a plurality of times at 400-860 DEG C so as to form a crystal colorized decorative layer. The product has the advantages of brocade-like straight light, wool-like side light, light-shift color-change, and special optical effect with strong solid feeling.

Owner:邓念东 +1

Peacock blue jun porcelain glaze and preparation method

The invention discloses peacock blue jun porcelain glaze which is prepared from Hatoyama medicine, feldspar, calcite, quartz, talcum, ox bone ash, plant ash, clinker, stannic oxide, zinc oxide and copper oxide. The peacock blue jun porcelain glaze is transparent and good in flowability and luster and has stereoscopic sensation, and bubbles are not easily generated.

Owner:温书强

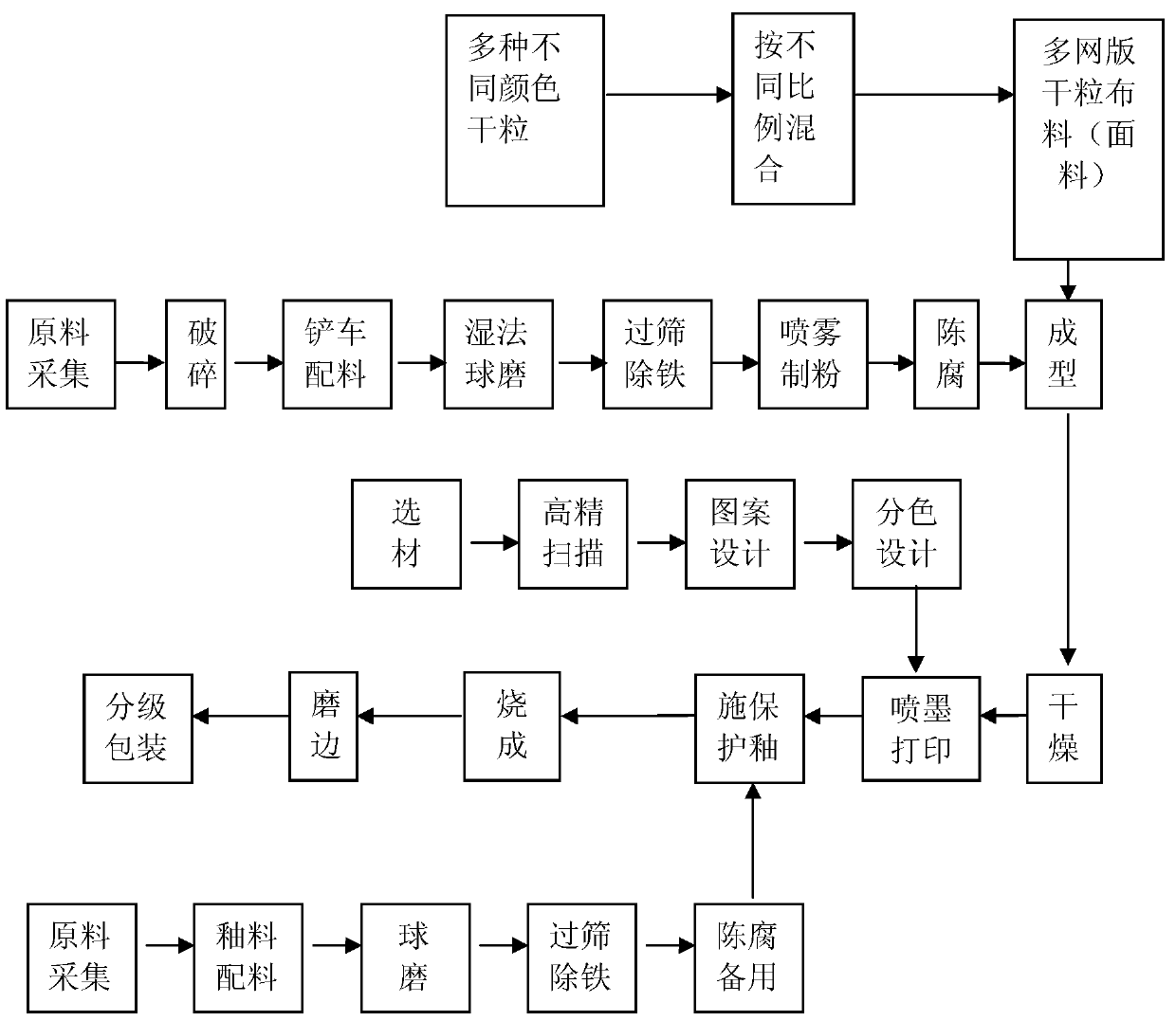

Dry grain glaze fabric stone imitating brick and preparing method thereof

ActiveCN107756608AThree-dimensionalRich layersNatural patternsCeramic shaping apparatusBrickMaterials science

The invention relates to a dry grain glaze fabric stone imitating brick and a preparing method thereof. The preparing method of the dry grain glaze fabric stone imitating brick includes the followingsteps that firstly, colored dry grain glaze is distributed on a blank in a layered manner according to a designed pattern; secondly, after glaze distributing is conducted, a raw brick is pressed; thirdly, after the raw brick is dried, an inkjet machine is used for jet printing of the design pattern; and fourthly, the obtained blank is fired. By means of the dry grain glaze fabric stone imitating brick and the preparing method thereof, a stone imitating effect that the pattern is changed randomly and is vivid and rich in layer, the texture is natural, and the third dimension and granular sensation are high can be achieved.

Owner:MONALISA GRP CO LTD

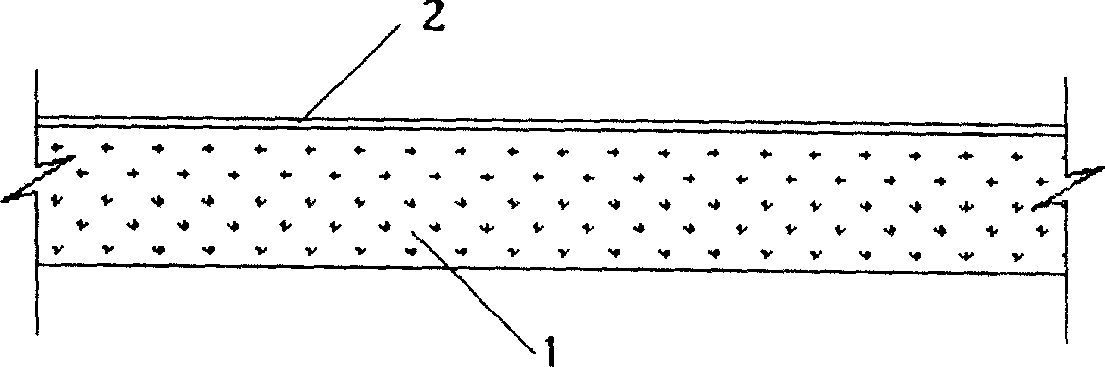

Composite lining cloth and its production method

InactiveCN1380462AThree-dimensionalGood feel and elasticityFilm/foil adhesivesGarmentsBond lineWeft yarn

The present invention relates to an adhesive-bonded lining fabric which has the effect of stiffness, smoothness and third dimension after the short fibre and be used as shell fabric and possesses soft hand feeling and elasticity after the long fibre is used as shell fabric. The warp yarn and weft yarn of base fabric of the adhesive-bonded lining fabric are respectively or simultaneously made up by selecting and using long fibre yarn and short fiber yarn through textile processing, and said base fabric is undergone the special processing treatment, then it can possesses the above-mentioned advantages.

Owner:NITTOBO CHINA CO LTD

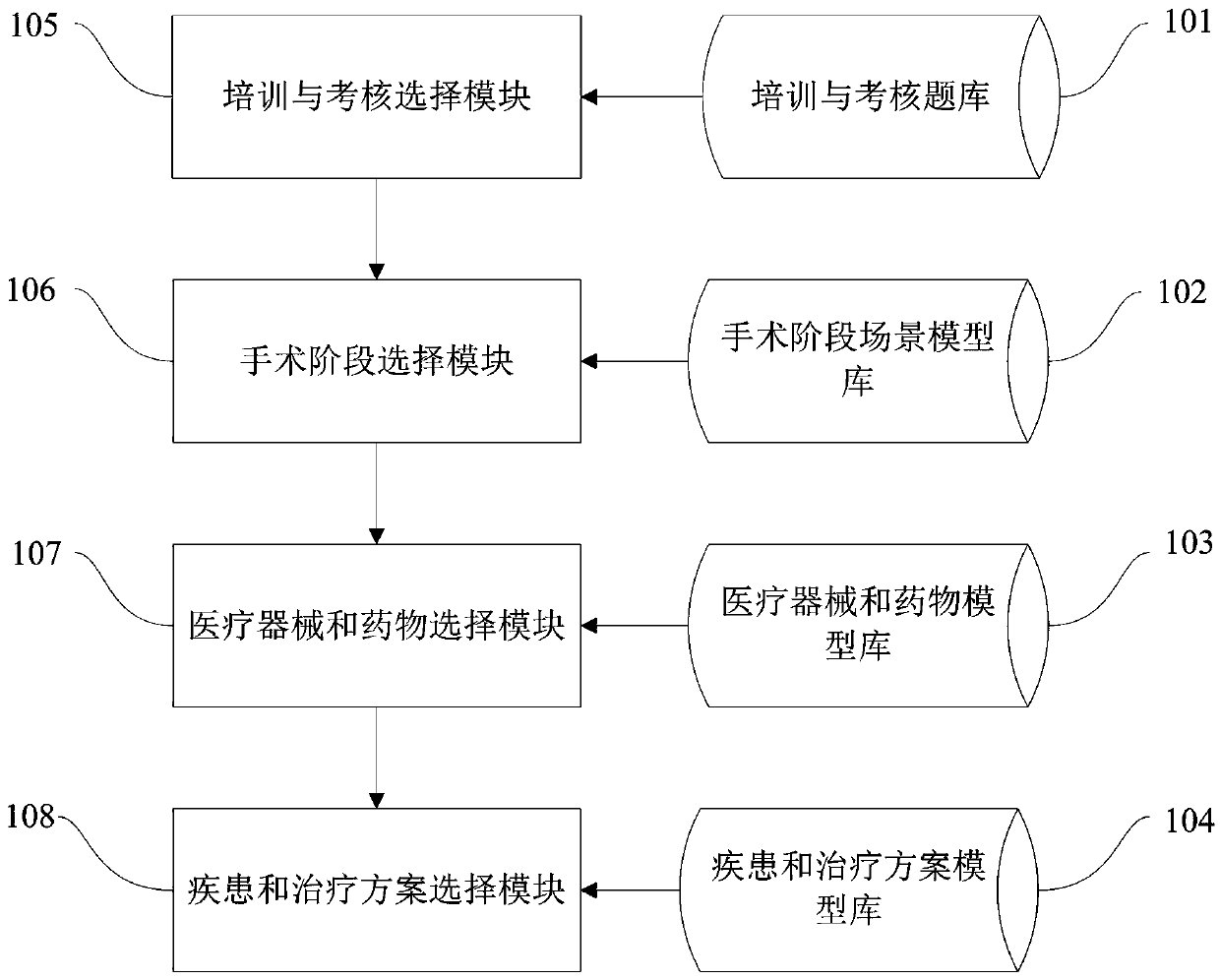

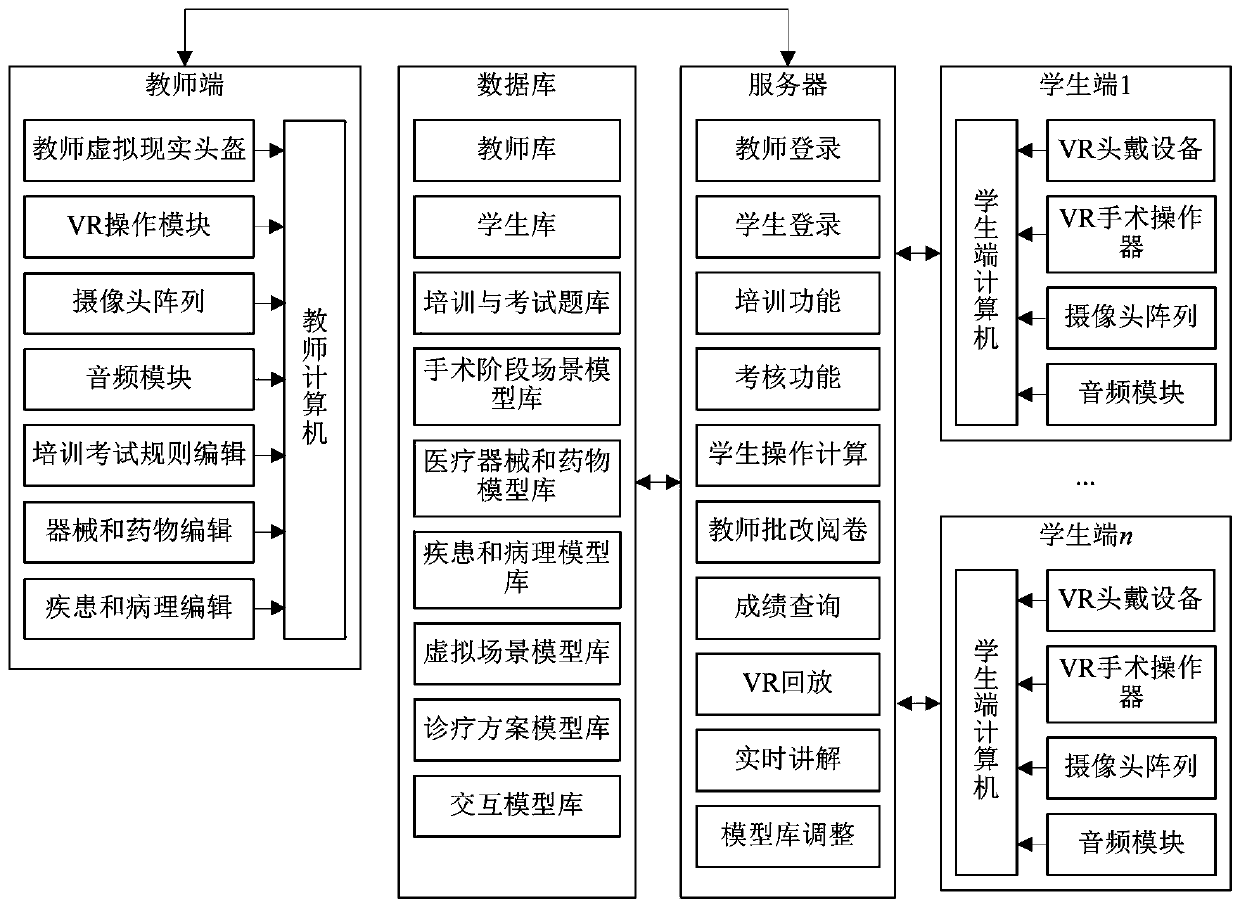

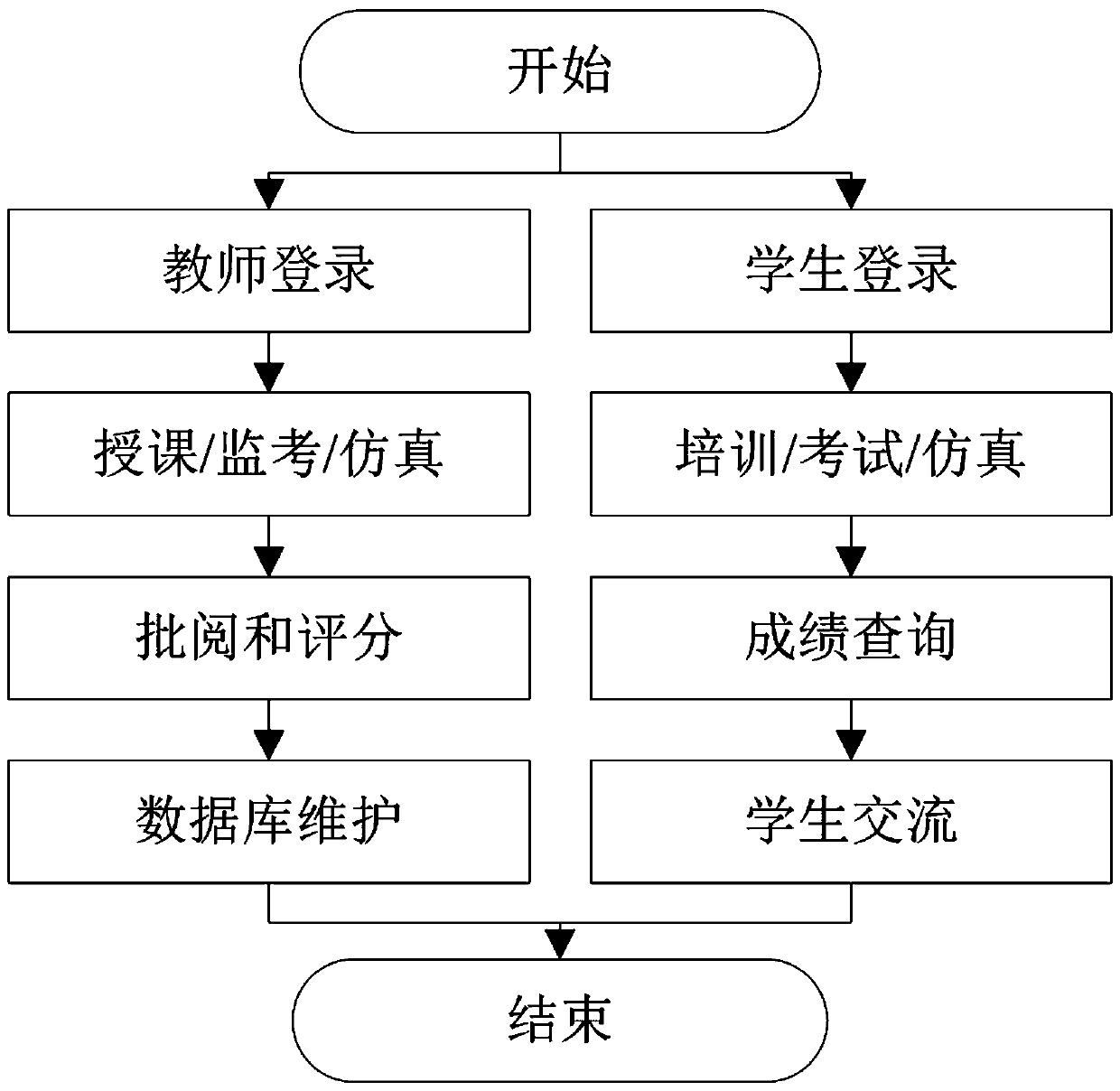

Surgical training and evaluation method on basis of virtual reality

ActiveCN109658772AImprove the effect of treatmentTo achieve the perfect effectCosmonautic condition simulationsElectrical appliancesSurgical skillsPhases of clinical research

The invention discloses a surgical training and evaluation method on the basis of virtual reality. The surgical training and evaluation method is implemented by a database module and execution modules. The database module is divided into a training and evaluation question bank, a surgical stage scene model library, a medical equipment and medicine model library and a disease and therapeutic schememodel library, the execution modules include a training and evaluation selection module, a surgical stage selection module, a medical equipment and medicine selection module and a disease and therapeutic scheme selection module, and the training and evaluation selection module is sequentially connected with the surgical stage selection module, the medical equipment and medicine selection module and the disease and therapeutic scheme selection module. The surgical training and evaluation method has the advantages that surgical training and evaluation can be accomplished by the aid of virtual reality systems, therapeutic schemes can be verified and simulated by the aid of the virtual reality systems, evolution mechanisms of diseases can be observed by the aid of the virtual reality systems,and environment-friendly and safe modes can be provided to surgical skill training and evaluation and therapeutic scheme design emulation; the technical problems of low efficiency, severe waste and high surgical risks of existing surgical training and evaluation methods can be solved by the aid of the surgical training and evaluation method.

Owner:CHINA THREE GORGES UNIV

Method for manufacturing wheat straw handicraft

InactiveCN101564963ANot afraid of moistureNot afraid of mildewDecorative surface effectsSpecial ornamental structuresBiotechnologyChange color

The invention relates to a method for manufacturing a handicraft, in particular to a method for manufacturing a wheat straw handicraft, which comprises the steps of: a. firing a green body with a shape the same as that of the handicraft; b. treating wheat straw raw materials: soaking the wheat straw in sterilizing lotion and soaking the wheat straw in water containing soda after being dried; fumigating the wheat straw with sulphur and then steaming the wheat straw in a pressure cooker or a steamer; bleaching and dyeing the wheat straw with oxydol and dye respectively; cleaving the wheat straw with a knife blade, back-scrolling the wheat straw and then placing the scrolled wheat straw for a certain time; spreading the scrolled wheat straw and scraping inner pulp; ironing the wheat straw into a plain film with an iron; and pressing the wheat straw plain film with a soldering iron to cause the plain film change color slightly; c. cleaving the wheat straw into filaments and cutting on the bias; or gluing the wheat straw into plain film; d. gluing the filaments and the plain films to the green body; and e. glazing the green body. The wheat straw handicraft manufactured by the method resists moisture, does not mildew or fade, can be preserved permanently, and presents stereo perception.

Owner:聂远征

Process for making a chinaware

The mold-eliminating engraved porcelain making process includes material processing, formation, sintering and other steps. Color slurry is poured onto the white mold for several times to form color layers in certain thickness, and the color layers are then engraved to make the engraved porcelain. The engraved porcelain has color determined on the proportion of pigments, thickness of color layers and other factors, and rich variation and stereo feeling. The mold is eliminated before sintering to make the engraved porcelain glittering and translucent and possessing special artistic effect.

Owner:焦作市金谷斋文化艺术传播有限责任公司

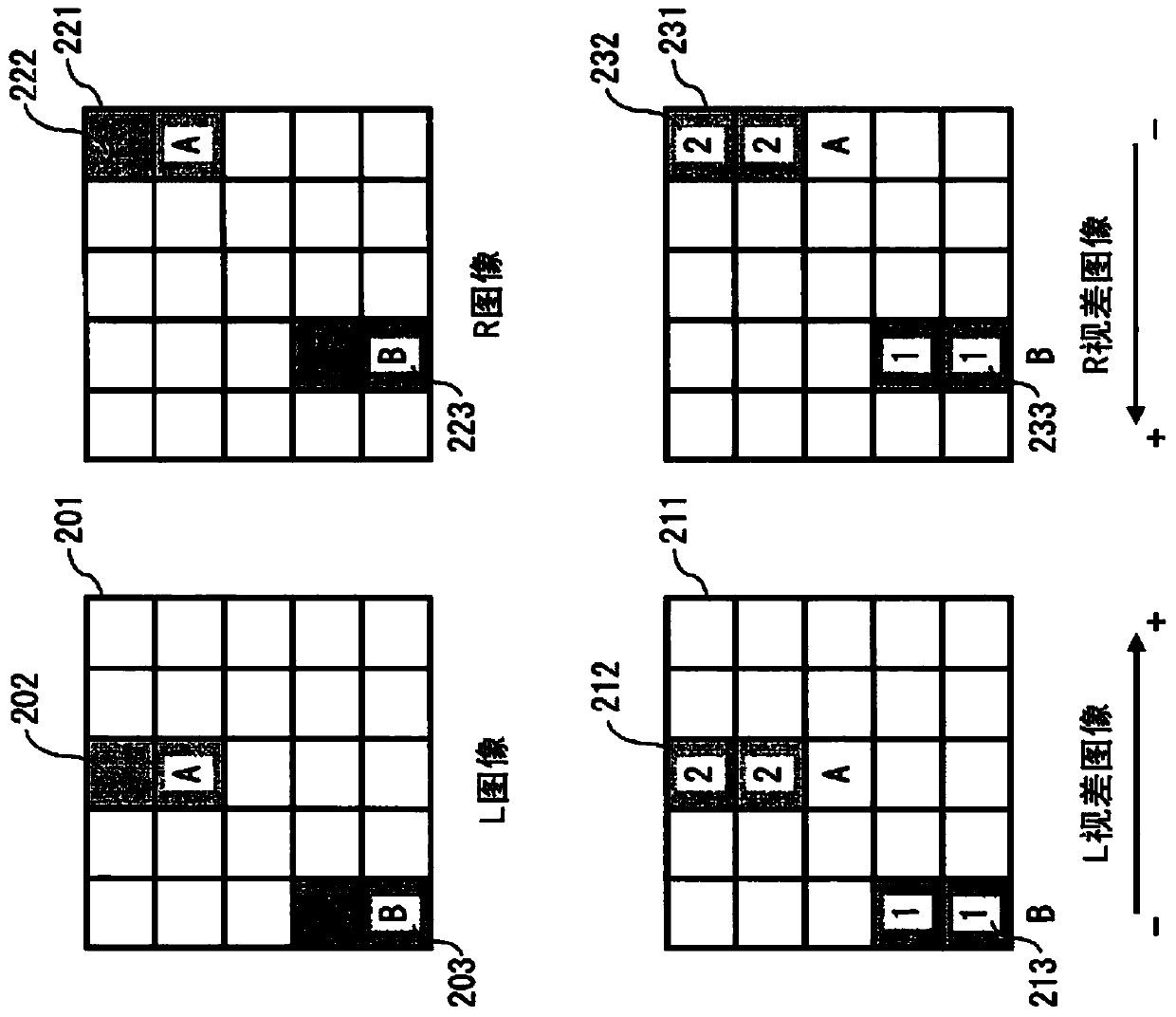

Multi-viewpoint image generation device and multi-viewpoint image generation method

InactiveCN103636200AThree-dimensionalSteroscopic systemsOptical elementsParallaxComputer graphics (images)

An image acquirer acquires paired left and right viewpoint images. A disparity calculator calculates a disparity between the left and right viewpoint images. A display properties memory stores naked-eye stereoscopic display properties such as recommended disparity values and a cross-talk rate. A disparity analyser reads the naked-eye stereoscopic display properties from the display properties memory and uses these properties to perform a disparity adjustment on the left and right viewpoint images. A multi-viewpoint image generator uses the disparity as adjusted by the disparity analyser to generate a multi-viewpoint image by performing a shift on each pixel of the left and right viewpoint images.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

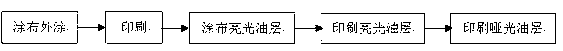

Method of printing high-resistance glossy-matte metal

ActiveCN103317870AThree-dimensionalWith textureOther printing apparatusPrinting after-treatmentHigh resistanceTextile

The invention relates to a method of printing high-resistance glossy-matte metal. The method includes: coating the outer surface of metal, printing, and coating a glossy oil layer. The method is characterized in that a step of printing the glossy oil layer and a step of printing a matte oil layer are used after the step of coating the glossy oil layer, printing plates which are the same need to be independently made for the step of printing the glossy oil layer and the step of printing the matte oil layer, glossy oil and matte oil are transferred to the surface of a product through rubber cloth, the glossy oil and the matte oil are respectively independently solidified and dried by heating at 140-160 DEG C, glossiness of the glossy surface of the finished product is partially larger than or equal to 80 DEG, and glossiness of the matte surface of the finished product is smaller than or equal to 40 DEG. The method has the advantages that metal print with the whole surface which is both glossy and matte can be made by the method and the printed surface is well adhesive, scratch-resistant, good in printing stereoscopic impression and good in texture.

Owner:HANGZHOU CPMC +1

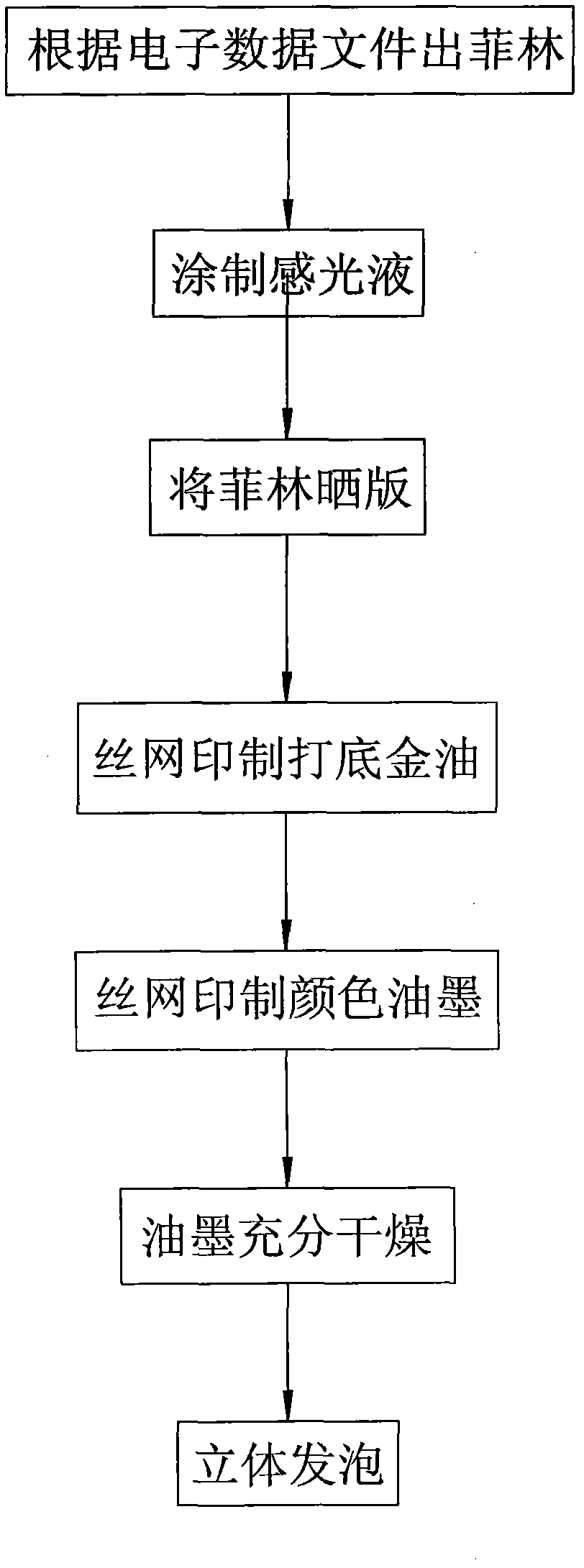

Three-dimensional foaming printing method

InactiveCN102848765AThree-dimensionalGood flexibilityPattern printingOther printing apparatusScreen printingEngineering

The invention discloses a three-dimensional foaming printing method which comprises the steps of producing films according to electronic data files; coating the films with light sensitive liquids; selecting suitable gauze and subjecting the films to printing down; printing bottoming gold oil on silk screens; printing color ink on the silk screens to obtain picture bases with a stereoscopic sense; fully drying the bottoming gold oil and the color ink to obtain pattern materials; and subjecting the pattern materials to three-dimensional foaming with a foaming machine. The pattern materials obtained finally through the method have the advantages that patterns have a stereoscopic sense and good softness, the definition and the accuracy are high, and defects that screen printing techniques in the prior art are only applied to print plane products are overcome.

Owner:刘丽华

Manufacturing technique of flour-linen jacquard interval fabric mesh cloth

ActiveCN106560538AHigh pattern precisionImprove stabilityFabric breaking/softeningWarp knittingFiberYarn

The invention discloses a manufacturing technique of flour-linen jacquard interval fabric mesh cloth. The manufacturing technique comprises the first step of production and manufacturing of chemical fiber yarn, the second step of flower-type process design of the flour-linen jacquard interval fabric mesh cloth, the third step of weaving and manufacturing, and the fourth step of dyeing and finishing and sizing, wherein in the second step, the upper layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB1 to guide bar GB3; the middle layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB4; the lower layer of the flour-linen jacquard interval fabric mesh cloth is knitted through the control of guide bar GB5 and guide bar GB6. According to the flour-linen jacquard interval fabric mesh cloth prepared through the manufacturing technique, distortion or deformation of the flower-type are not easily caused, the precision of the flower-type is high, the stability is good, after dyeing treatment of half matt gloss polyester yarn and terylene CD yarn on the upper layer of the mesh cloth, the surface of the finished product mesh cloth presents an effect of two-tone flour-linen, dyefastness is good, and a very good overall dyeing effect is achieved.

Owner:SINCETECH FUJIAN TECH CO LTD

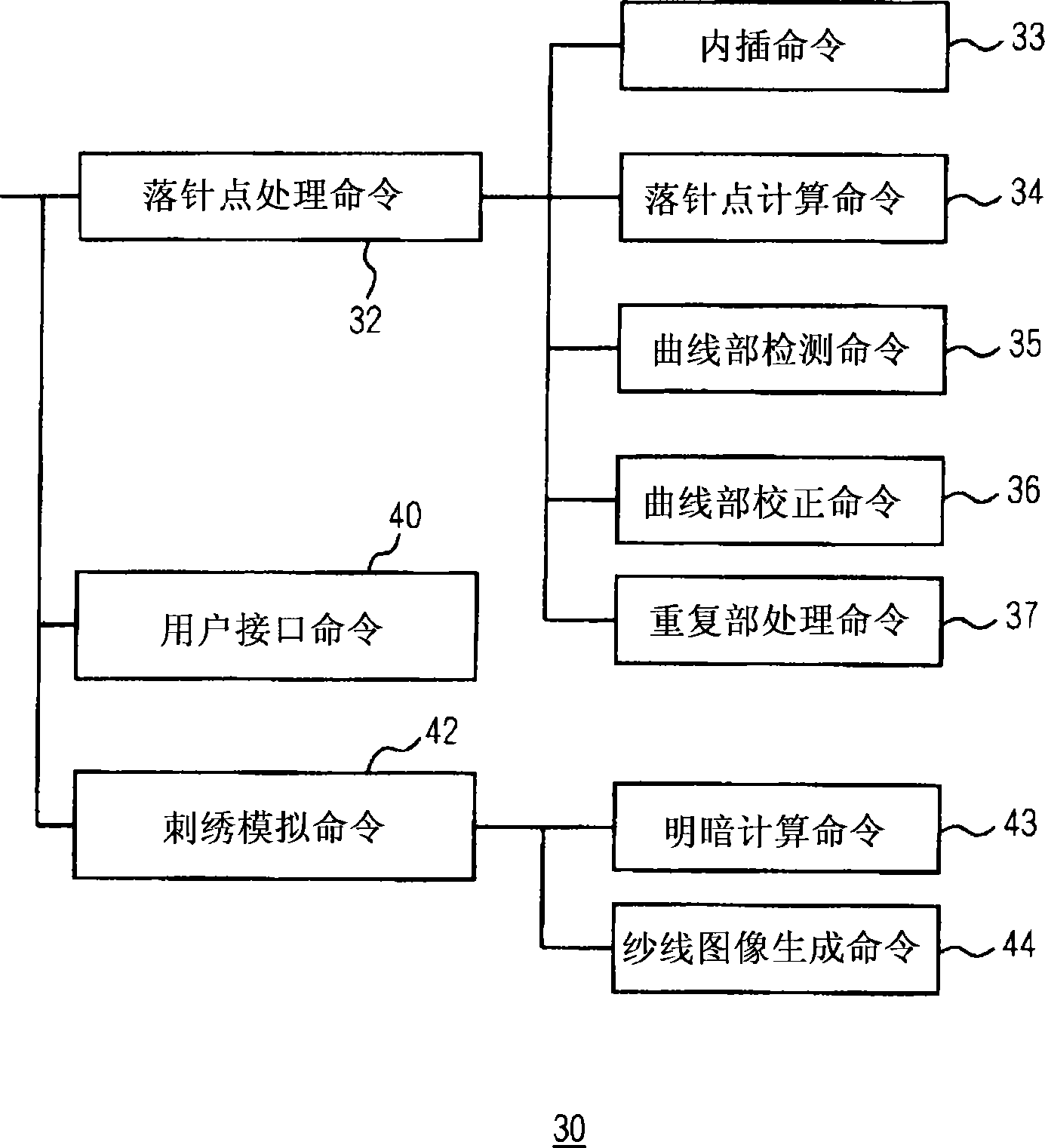

Embroidery data creation device, embroidery data creation method, and embroidery data creation program

InactiveCN1867723ASimple designFind out in real timeInput/output for user-computer interactionProgramme-controlled sewing machinesComputer science

Coordinates and the strength of pen-stroke are inputted from a stylus. The section between the coordinates inputted are interpolated and the needle fall point is determined so as to change the stitch width according to the strength of the pen-stroke. Moreover, the stitch angle and the stick density with respect to the stylus trace are inputted as parameters and they are used to determine the needle fall point. The stitch obtained is displayed in real time.

Owner:SHIMA SEIKI MFG LTD

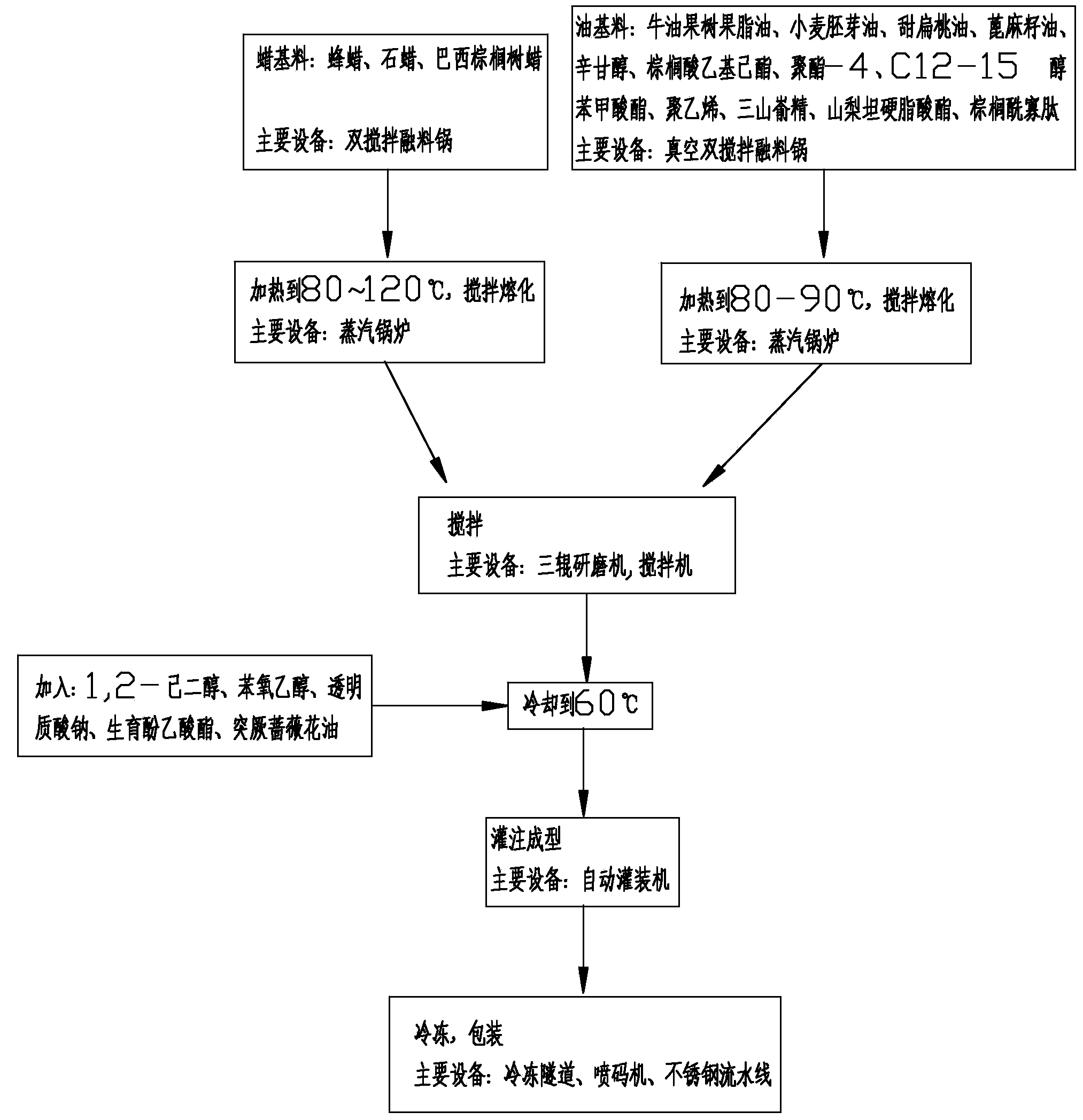

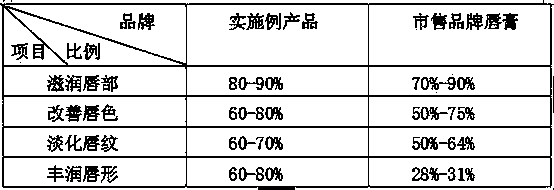

Lipstick and preparation method thereof

ActiveCN104027264AThree-dimensionalEasy to synthesizeCosmetic preparationsToilet preparationsPolyesterCastor Seed

The invention discloses a lipstick and a preparation method thereof. A plurality of plant extracts are taken as raw materials; the plant extracts mainly include ethylhexyl palmitate, tribehenin, sorbitan stearate, palmitoyl oligopeptide, polyester-4, C12-15 alkyl benzoate, persea Americana butter, paraffin, polyethylene, beewax, copernicia cerifera wax, 1,2-hexanediol, phenoxyethanol, tocopheryl acetate, caprylyl glycol, sodium hyaluronate, wheatgerm oil, prunus amygdalus dulcis oil, castor seed oil and rosa damascena flower oil. The lipstick is developed aiming at the shortcomings of the existing lipsticks; the active ingredients of the plant extracts are combined with the four raw materials, namely ethylhexyl palmitate, tribehenin, sorbitan stearate and palmitoyl oligopeptide, to form lip enhancement factors, and therefore, the lipstick is capable of promoting the synthesis of the collagen and the glycosaminoglycan of lips and fading cheilogramma so that the lips are moister and better in moisture preserving ability, full and smooth, and clearer in outline.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

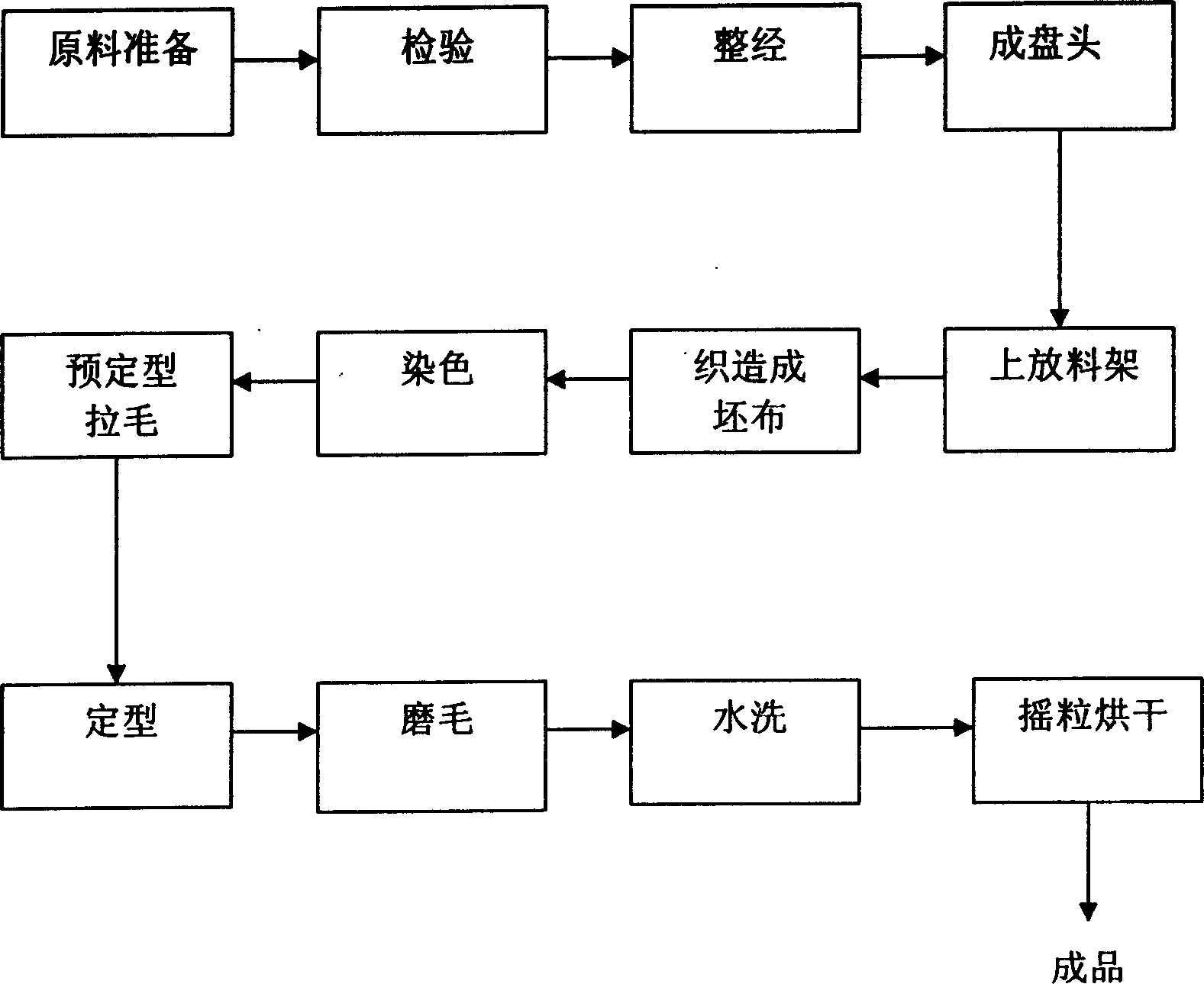

Production process of highly-compacted tricot-knitting sanded fabric

The invention relates the manufacturing technique of high sley abrasive material, comprising preparation of raw material, certification, warping, making grey cloth, dyeing, preboarding plucking, shaping, grinding hair, water scrubbing and drying. The face fabric made with the said technology is tight, thick, novel style, cubic effect, fashion and good hand feeling.

Owner:HAINING CHAODA WARP KNITTING

PU shoe sole laminating and forming process

InactiveCN106313409ASmooth and beautiful appearanceNo manual patchingDomestic articlesVacuum pumpingEngineering

The invention provides a PU shoe sole laminating and forming process which comprises the following steps of: flatly putting film paper on a bottom mould of a mould, and pressing a middle frame to cover the bottom mould, and fixing by tensioning hand fasteners; carrying out vacuum-pumping on an inner cavity of the mould and enabling the film paper to completely fit to the bottom mould; heating the mould for increasing the mould temperature to 60-70 DEG C; and finally, pouring a polyurethane foaming stock solution into the mould cavity for foaming and forming the polyurethane foaming stock solution in a mould cavity, and cooling and de-molding, thereby obtaining the laminated PU foamed shoe sole. The PU shoe sole laminating and forming process can effectively solve the problems of bubbles, material deficiency, foamed grains, pits and pores generated in a PU foamed shoe sole production process, so that bright effect of products is improved.

Owner:佛山市创意新材料科技有限公司

A laser marking method on wafer surface

InactiveCN101533771AEasy to operateGood durabilitySemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsMaterials science

A laser marking method on wafer surface includes: production of marking films, wherein, the matrix for marking films is glass sheets capable of permeating the laser, a metallic film layer with a certain thickness is formed on the single side surface of the glass sheet, the laser irradiates on the metallic film layer, and is blocked and accumulated by the metallic film layer, the thickness of the metallic film layer can ensure that the metallic film layer can be melted through by the laser irradiated by the laser marking machine; jointing of the marking film and the wafer surface, so that the metallic film layer surface on the marking film are jointed together with the position on the wafer surface required to mark; laser marking, using laser marking machine to irradiate laser to the position of the wafer required to mark from one side of the marking film without metallic film layer, the irradiated laser is blocked by the metallic film layer and accumulated at the metallic film layer, the accumulated laser can melt through the metallic film layer to ablate the wafer surface, for forming making on the wafer surface. So that three-dimensional effect makings can expediently be marked at wafer surfaces with various characteristics.

Owner:ZHEJIANG CRYSTAL OPTECH

One-step-process hydrophilic dacron/high-shrinkage dacron combined yarn and preparation method thereof

InactiveCN102965761AImprove thermal stabilityReduce crystallinityArtificial filament heat treatmentMelt spinning methodsYarnSulfonate

The invention discloses a one-step-process hydrophilic dacron / high-shrinkage dacron combined yarn and a preparation method thereof. The combined yarn is prepared from hydrophilic copolyester chips and high-shrinkage copolyester chips by using one-step-process spinning, wherein the hydrophilic copolyester chips comprise purified terephthalic acid, ethylene glycol, m-phenylene dihydric alcohol binary acid ester-5-sodium sulfonate, polydihydric alcohol and other dihydric alcohols, and the high-shrinkage copolyester chips comprise purified terephthalic acid, ethylene glycol and isophthalic acid. The combined yarn obtained according to the preparation method has the fiber moisture regain being 1.0-3.0% and the differential shrinkage rate being 10-60%, is improved in softness, hydrophily and dyeing property, and can be used in cotton-like and wool-like fabric.

Owner:DONGHUA UNIV

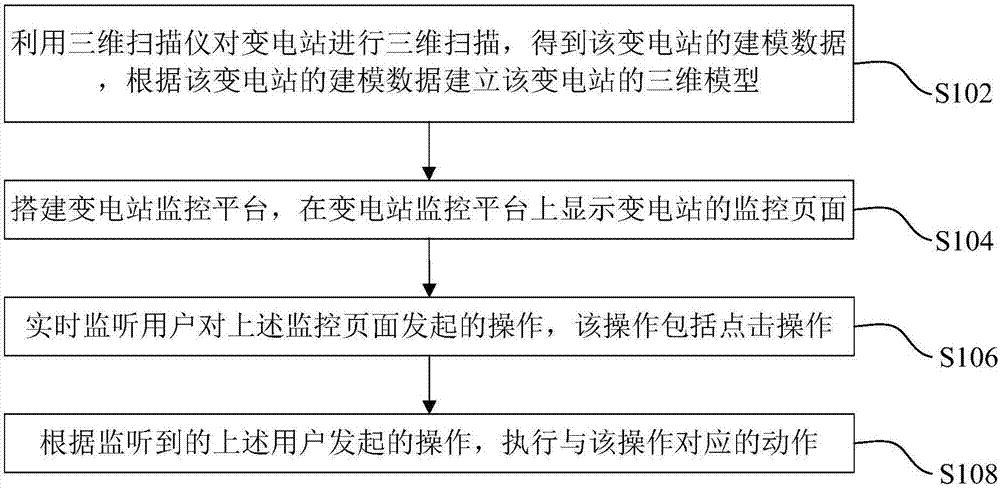

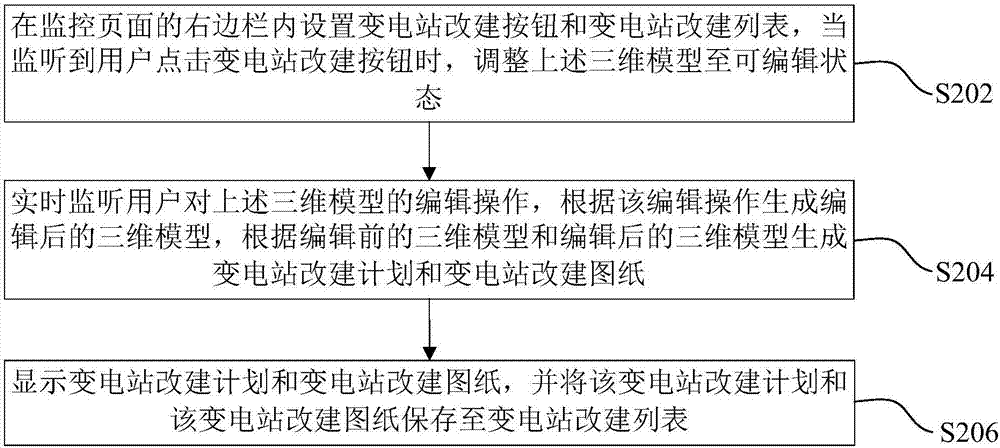

Transformer substation monitoring method and device

InactiveCN107085863AEfficient reproductionStart fastData processing applicationsInput/output processes for data processingTransformerSimulation

The invention provides a transformer substation monitoring method and device, and relates to the technical field of safety monitoring. The method comprises the steps that three-dimensional scanning is performed on a transformer substation by using a three-dimensional scanner so as to obtain the modeling data of the transformer substation, and the three-dimensional model of the transformer substation is established according to the modeling data of the transformer substation; a transformer substation monitoring platform is established, the monitoring page of the transformer substation is displayed on the transformer substation monitoring platform, the monitoring page includes a navigation bar, a tool bar, a left sidebar, a right sidebar and a middle area, and the three-dimensional model is displayed by using the middle area; operation initiated by the user for the monitoring page is monitored in real time; and the motion corresponding to the operation is performed according to the monitored operation initiated by the user for the monitoring page. According to the transformer substation monitoring method and device, the technical problems that the conventional transformer substation monitoring method can only be greatly performed by the monitoring personnel through professional training and the use requirements of the common work personnel cannot be met can be solved.

Owner:国网山东省电力公司临邑县供电公司 +1

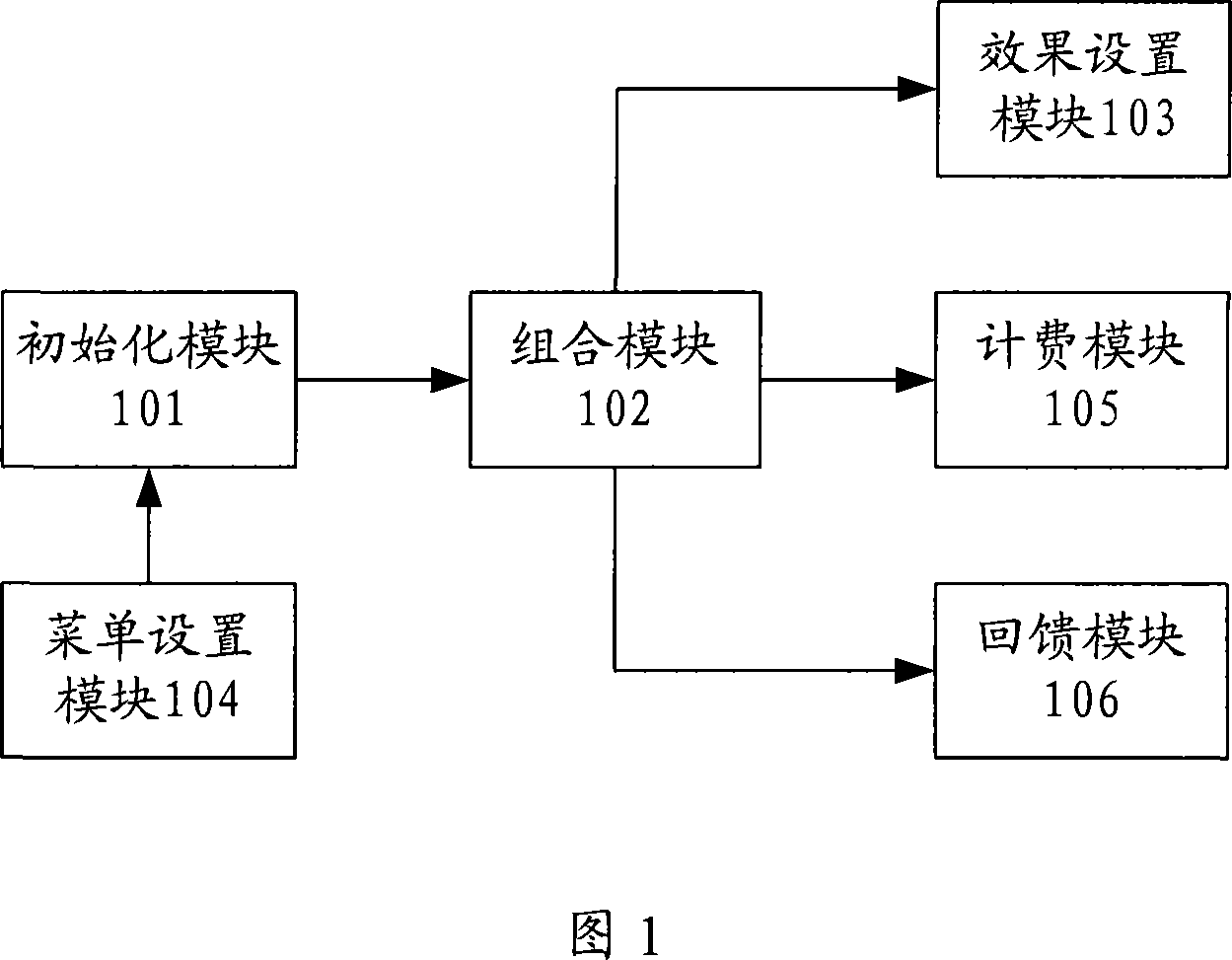

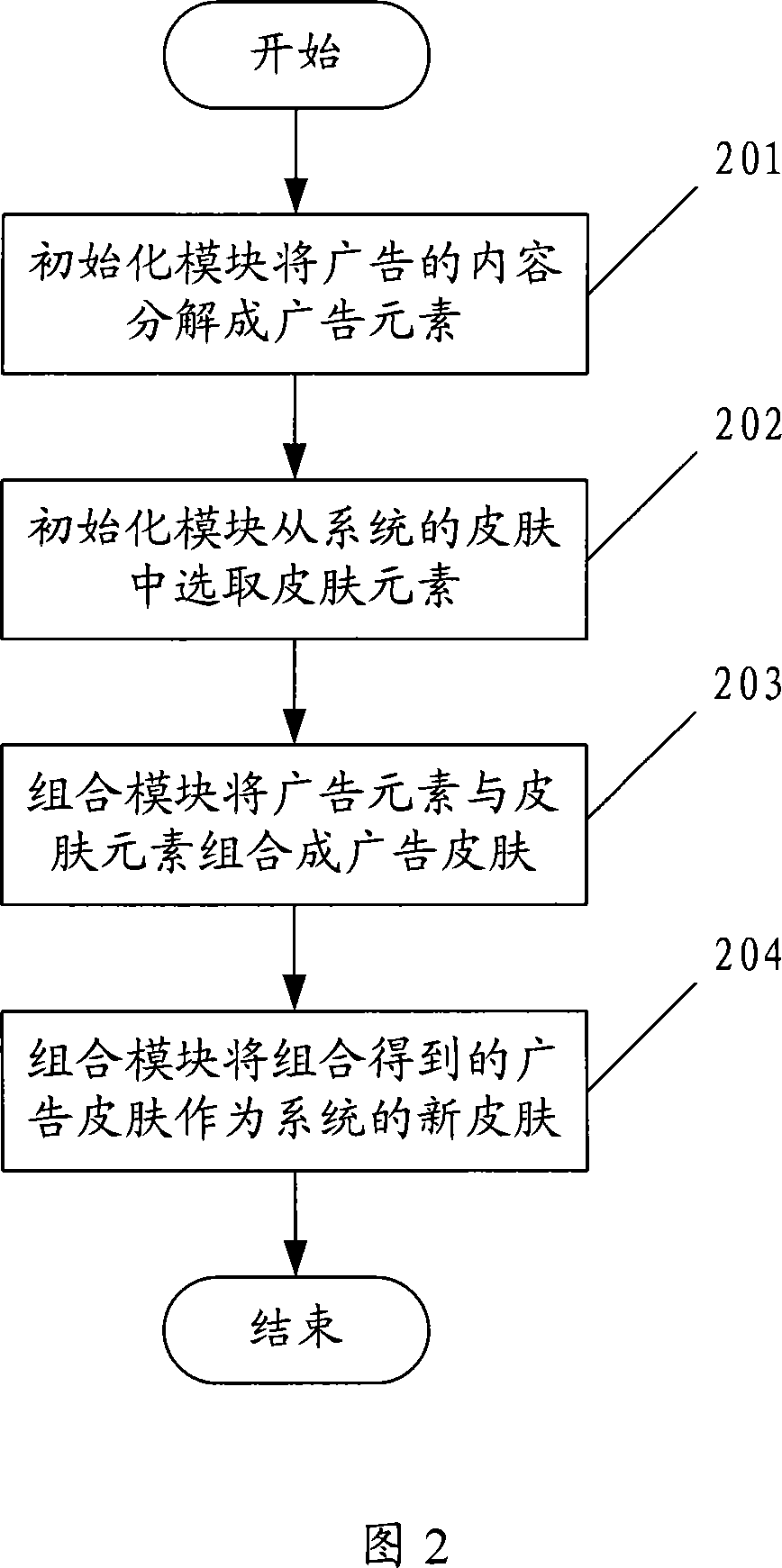

Method and apparatus for generating advertisement

InactiveCN101135968AReduce harassmentLower the level of disgustAdvertisementsSpecial data processing applicationsWorld Wide WebDuration of effect

The method comprises: dividing the advertising content into advertising elements; selecting a skin element from the system skin; combining said advertising element and said skin to form an advertising skin; using said advertising skin as a new skin of said system. The apparatus thereof comprises an initializing module and a combination module.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Large dense-weft jacquard gauze, clipped jacquard, colored woven cotton fabric

The invention discloses large dense-weft jacquard gauze, clipped jacquard and colored woven cotton fabric. The colored woven cotton fabric comprises a bottom plain part, a gauze part and a clipped large dense-weft jacquard; the gauze part and the clipped large dense-weft jacquard are woven on the bottom plain part; and the cover of the colored woven cotton fabric is in a concave-convex stereoscopic shape. The highly difficult technologies concerning the dense weft, the warp-weft jacquard, the large-jacquard gauze, the clipped large-jacquard and the like are integrated perfectly, thus the colored woven cotton fabric has diversified styles and patterns and more stereoscopic sense.

Owner:JIANGSU SHUNYUAN NEW MATERIAL TECH CO LTD

Archaized composite floor and its manufacturing method

ActiveCN1603551AUnique smoky colorObvious ups and downsDecorative surface effectsFlooringColor effectEngineering

The invention discloses in the style of antiquity compound floor and its the preparation method belongs to the compound floor technology, for may solve the traditional compound floor plane effect and the existing in the style of antiquity floor color effect bad, only pauses in the superficial question, the thermo-compression, after the polishing and opens, carries on smokes and scratches, the compound floor which makes has the unique smoking color and the clearer level obvious stereoscopic effect, the form is diverse, and the table board may fully use and so on the merit, in the style of antiquity compound floor which the class invents uses in the house decoration.

Owner:FUSONG QIANQIU WOOD CO LTD

Preparation method of pigment slurry for painting

The invention brings forward a preparation method of a pigment slurry for painting. Raw materials for preparation and the preparation process are as follows: a flexible acrylic acid emulsion and an aqueous adhesive are added into an acrylic acid elastic emulsion; after uniformly stirring, calcium powder, silicon powder, talcum powder and tourmalinite powder are added, and stirring is conducted; and after stirring, perfume, pigment and redispersible powder are added and then stirred and grounded to prepare the pigment slurry. According to the invention, water is used as a diluent of the pigment slurry prepared by the method. It is environmentally friendly and it is convenient to adjust. By adding the tourmalinite powder into a film forming matter, negative air ions can be generated. As the perfume is added into the pigment slurry, the prepared pigment slurry has fragrance. Paintings drawn by the use of the pigment slurry have stereo perception, can generate negative air ions and can continuously generate fragrance. The preparation method provided by the invention is suitable for the pigment slurry for painting.

Owner:崔艳明

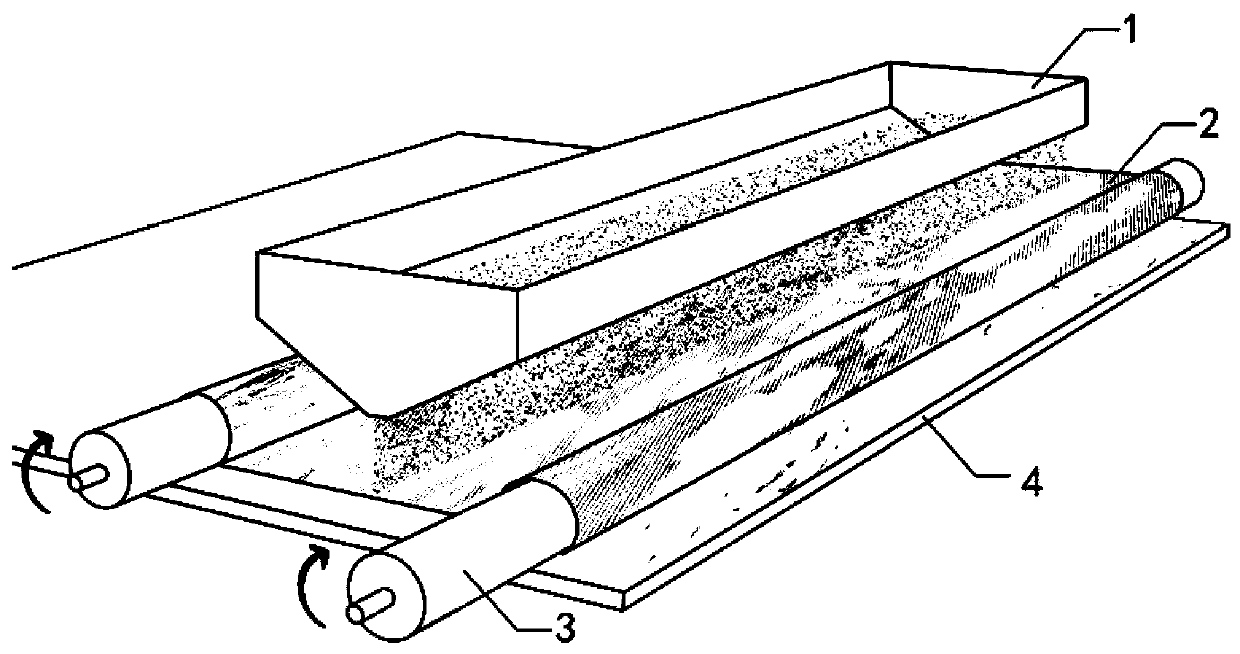

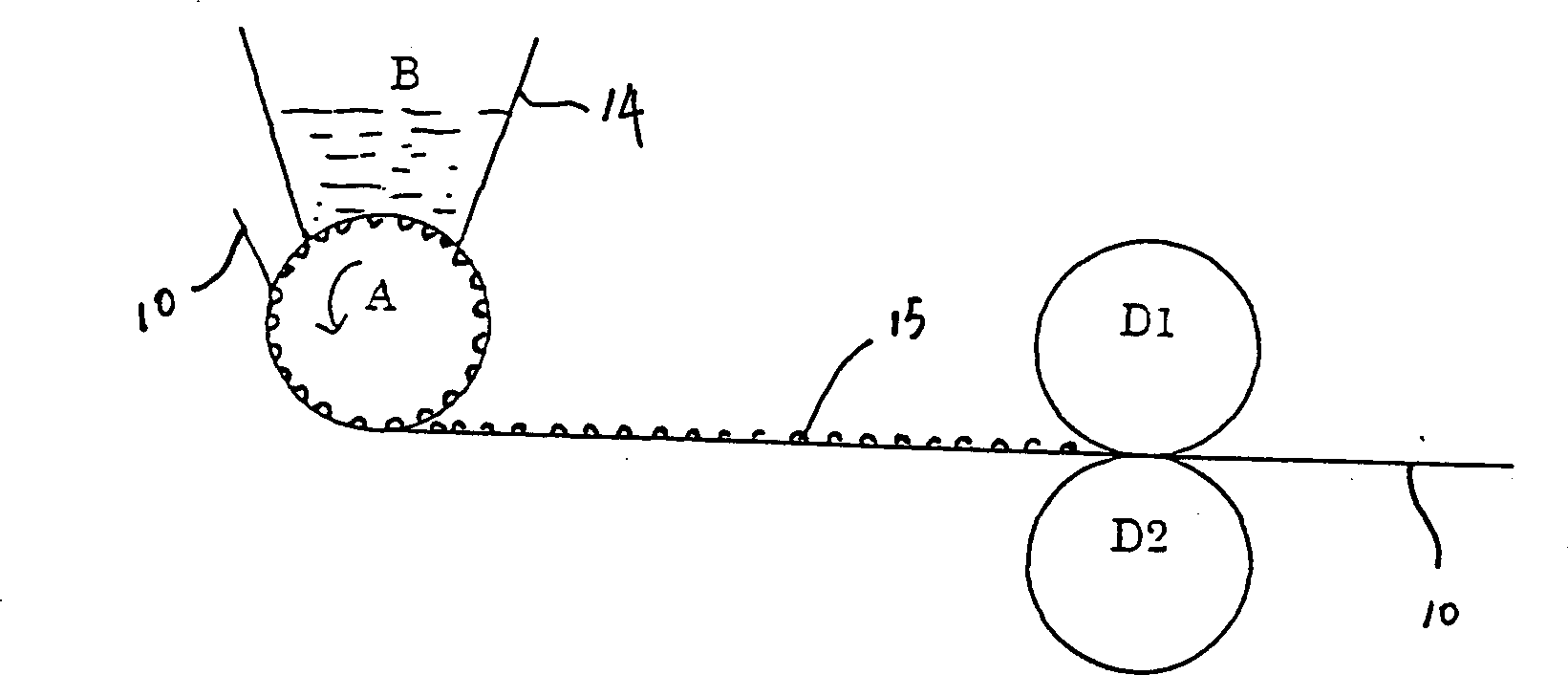

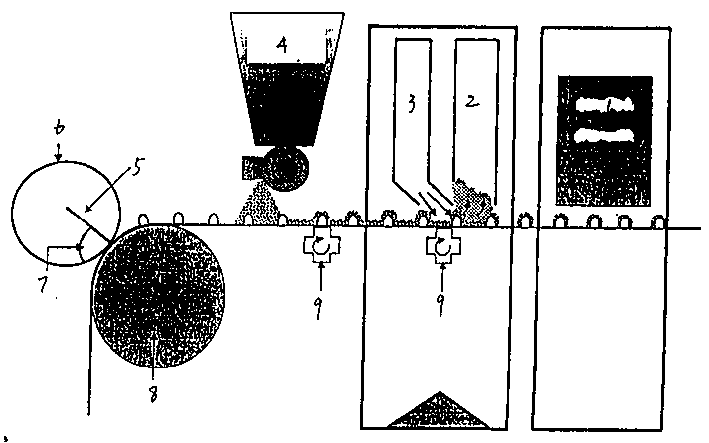

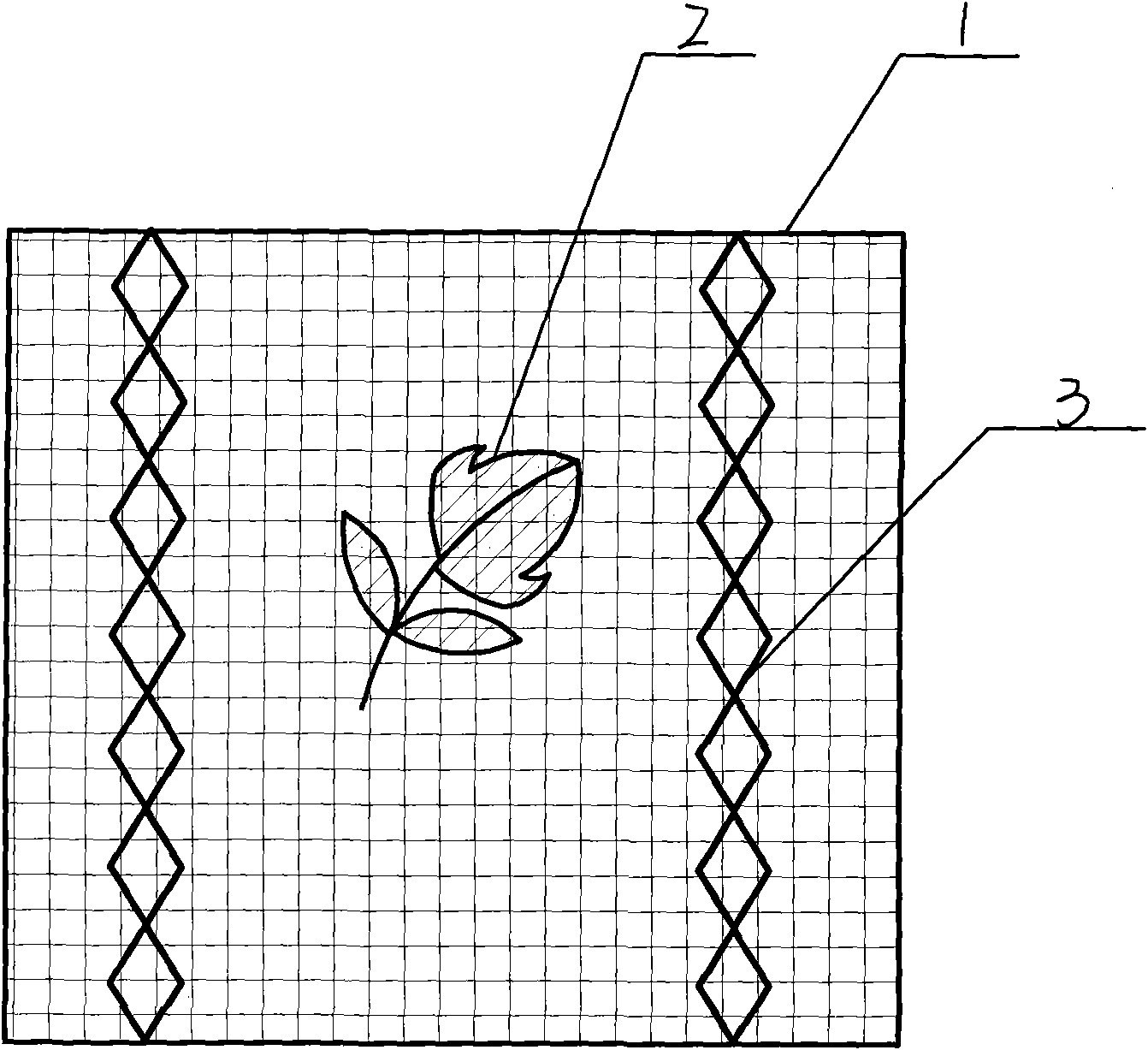

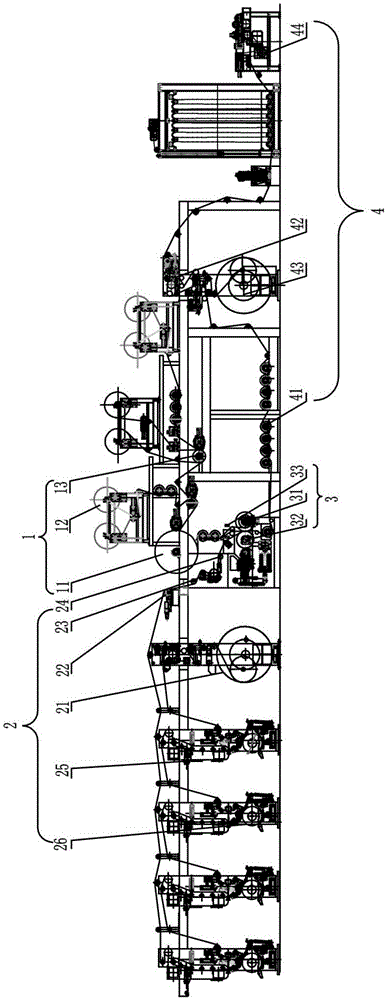

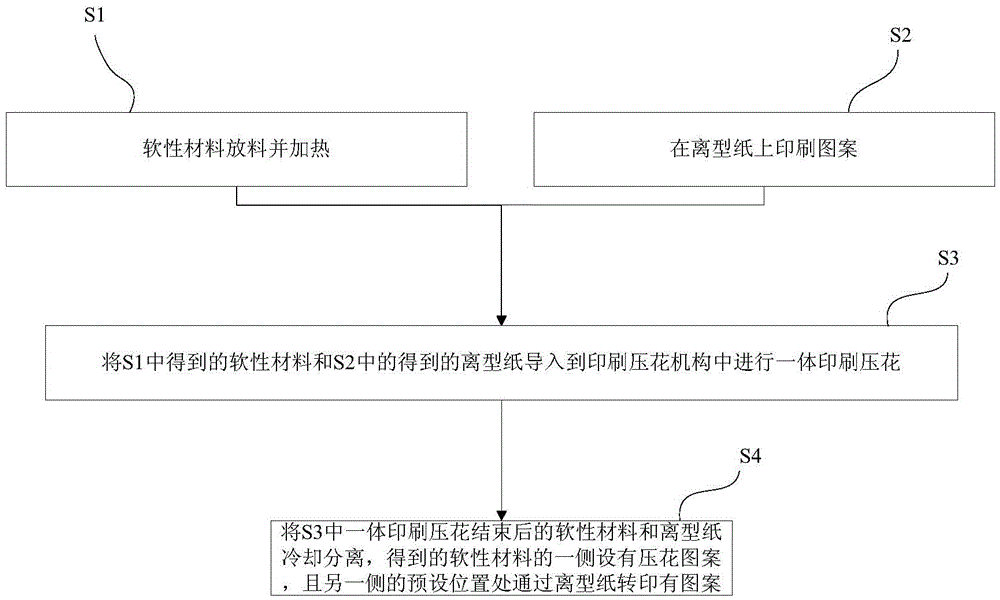

Printing, positioning and knurling production and manufacturing process and equipment of soft material

ActiveCN105599420AImprove matchSolve the problem of printing misalignmentTransfer printingLamination ancillary operationsKnurlingEngineering

The invention discloses a printing, positioning and knurling production and manufacturing process of a soft material. The printing, positioning and knurling production and manufacturing process comprises the following steps: S1, discharging and heating the soft material; S2, printing a pattern on release paper / film; S3, guiding the soft material obtained in the S1 and the release paper / film obtained in the S2 into a printing and knurling mechanism to carry out integrated printing and knurling; and S4, cooling and separating the soft material and the release paper / film, which are subjected to the integrated printing and knurling in the S3, so as to obtain the soft material with a knurled pattern on one side, and a pattern transferred on a pre-set position of the other side through the release paper / film. The printing, positioning and knurling production and manufacturing process of the soft material has accurate alignment on printing and knurling and has the beautiful printed pattern; and meanwhile, the invention further provides equipment for realizing the process.

Owner:广州高德塑胶制品有限公司

Production process of polyester-cotton gathering warp knitting uniform fabric

The invention relates to a manufacturing technique of fabrics of polyester-cotton plisse warp knitting western-style clothes, comprising the steps of the preparation of raw materials, warping, complete hair-coiling, the fabric manufacture of grey cloth, unwinding, dyeing and the typing of finished products. The step of the fabric manufacture of the grey cloth adopts four stripping combs for weaving, wherein, the first stripping comb adopts polyester filament in a way of 6 being penetrated and 3 being hollow, and crossband plisses are formed by a manner of combining woven flatness and pad lack; the second stripping comb adopts compact spinning cotton yarn in the way of 1 being penetrated, 6 being hollow, 1 being penetrated and 1 being hollow, and straight strips are formed in a manner of woven flat double stranded weaving; the third stripping comb adopts polyester low stretch yarn in the way of 1 being hollow, 6 being penetrated, 1 being hollow and 1 being penetrated, the blank penetrating part of the second stripping comb is filled up in the manner of woven flat weaving, and straight twin color effect is formed after dyeing; the fourth stripping comb also adopts the polyester low stretch yarn in the manner of symmetrical double needle woven flat weaving, mainly playing the role of solidification so as to cause the fabrics to be more compact. The fabrics have compact texture, novel style, and stereoscopic impression, and are rough while maintaining softness, and the application of the cotton yarn causes the fabrics to have the twin color effect, and enhances the wearing comfort of the fabrics.

Owner:HAINING CHAODA WARP KNITTING

New process method for manufacturing mold capable of ensuring size accuracy of cast blade for large-scale water turbine

ActiveCN101716654AUnique material selectionEasy to implementFoundry mouldsFoundry coresWater turbineCasting mold

The invention relates to a new process method for manufacturing a mold capable of ensuring the size accuracy of a cast blade for a large-scale water turbine. The method is characterized by comprising the following steps of: selecting materials; designing a technical scheme for manufacturing the mold; establishing a three-dimensional model for manufacturing the mold; manufacturing a mold blank; processing the mold; and detecting the mold. The process method of the invention is unique and solves the problem that a distorted-surface blade casting mold has low manufacturing efficiency and that the kind of casting mold manufactured by the traditional manual method cannot achieve the accuracy of a design size. The method solves the deformation problem of the mold per se and ensures the size accuracy of a blade-type mold through the research and application of a new material and a new method in a mold manufacturing process.

Owner:KOCEL EQUIP

Multilayer three-dimensional topping luminous character and production technique thereof

The invention relates to a multilayer three-dimensional topping luminous character and a production technique thereof. The multilayer three-dimensional topping luminous character comprises fonts, a light source arranged in the character and a bottom plate, wherein a border is arranged outside the font. The production technique comprises steps of die milling, surrounding types, border manufacture,font manufacture and the installation of the light source and the bottom plate. The invention solves the problems of single colour of the advertisement characters without stereovision, has the characteristics of attractive appearance, strong third dimension, simple production technique, low cost, quick and convenient production, and is suitable for manufacturing various advertising luminous characters and luminous identifiers.

Owner:张克强

Color pavement formed by spraying on porous polymer concrete facing and construction method therefor

A colorful road plated with porous polymer concrete face and relative construction first mix polymer, broken stone and stuff uniformly to form polymer porous concrete material, lay to form polymer porous concrete face 1, mix uniformly the colorful face, and plate colorful face on the face of porous polymer concrete face layer 1 to form a colorful face layer 2, while the colorful face layer 2 is adhered with the porous polymer concrete face layer 1, to form a colorful road. The inventive road has high strength, better deformation property, abrasion resistance or the like, while the color can adjust via different fields.

Owner:易志坚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com