Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

278results about How to "Not easy to foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-impact toughness man-made quartzite slab and preparation method thereof

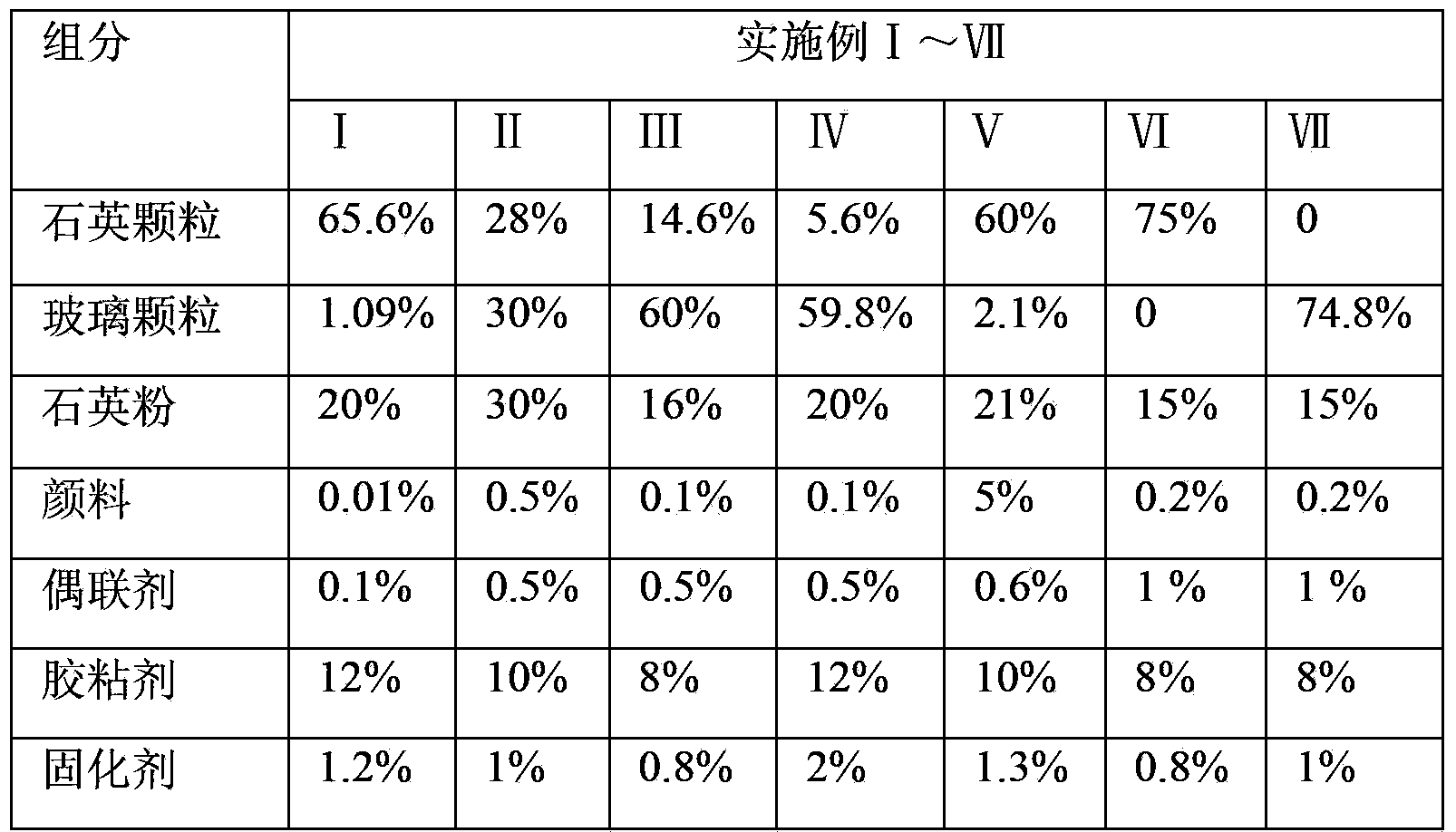

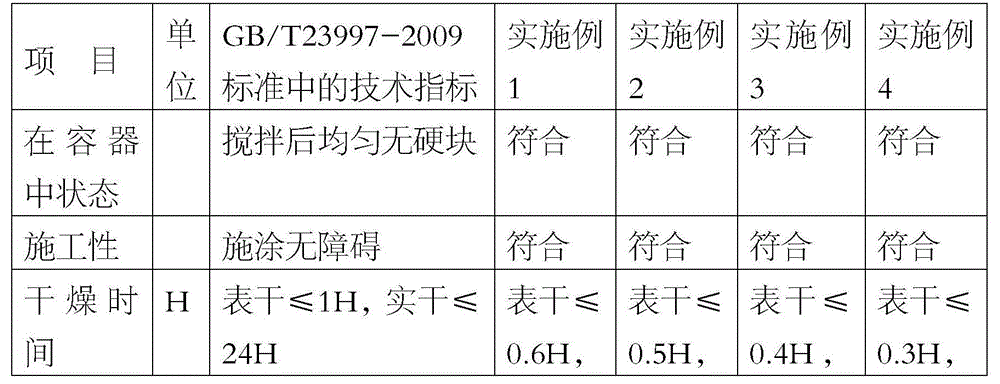

The invention provides a high-impact toughness man-made quartzite slab and a preparation method thereof. The man-made quartzite slab comprises the following components in percentage by weight: 58-75 percent of particle raw materials, 15-33 percent of quartz powder, 0.01-10 percent of paint, 0.1-1 percent of coupling agent, 8-12 percent of adhesive and 0.8-2 percent of curing agent, wherein the particle raw materials are quartz particles, glass particles, or a mixture of the two. The man-made quartzite slab provided by the invention has the characteristics of low probability of cracking and deformation, and the like.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Peacock blue jun porcelain glaze and preparation method

The invention discloses peacock blue jun porcelain glaze which is prepared from Hatoyama medicine, feldspar, calcite, quartz, talcum, ox bone ash, plant ash, clinker, stannic oxide, zinc oxide and copper oxide. The peacock blue jun porcelain glaze is transparent and good in flowability and luster and has stereoscopic sensation, and bubbles are not easily generated.

Owner:温书强

Graphene heating ink, preparation method and application thereof

InactiveCN108610736AHigh electrothermal conversion efficiencyImprove the normal emissivity of far-infrared raysInksCross-linkEmissivity

The invention discloses a graphene heating ink, a preparation method and application thereof. The graphene heating ink comprises the following raw materials by mass percent: 5-15% of carbon black, 10-25% of graphite, 0.1-5% of graphene powder, 0.1-8% of carbon nanotube powder, 25-40% of an adhesive, 1-5% of an assistant, and the balance a mixed solvent. Through combination of dotted carbon black,linear carbon nanotubes and planar graphene, a mutually cross-linked stable structure can be formed inside the ink, and the safety is high. Through improvement of the preparation process and the ink formula components, blistering does not occur easily in the stirring process, and the ink has good adhesion during printing, the electro-thermal conversion efficiency of the heating ink is remarkably improved, the far infrared normal emissivity of an electrothermal film is significantly enhanced, the service life of the electrothermal film is greatly increased, and the power change of 100,000h aging test is less than 2.6%. Also, the implementation process adopted by the invention is simple, efficient and practical.

Owner:山东暖匠智能电子科技有限公司

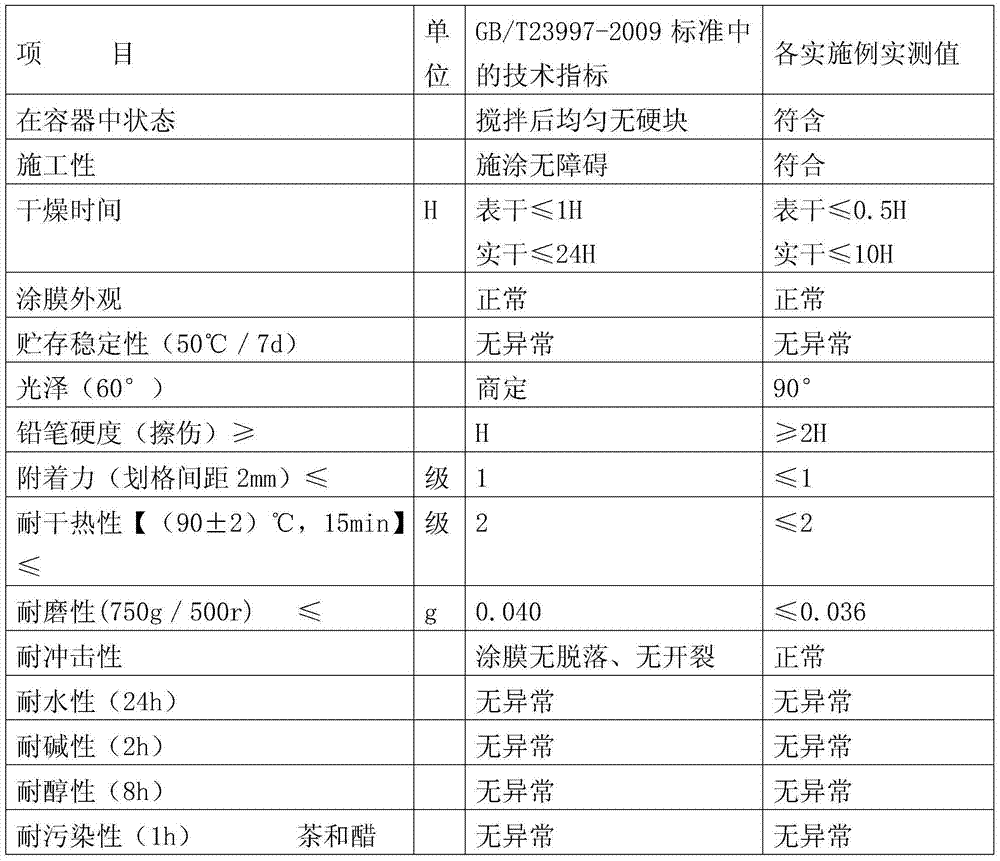

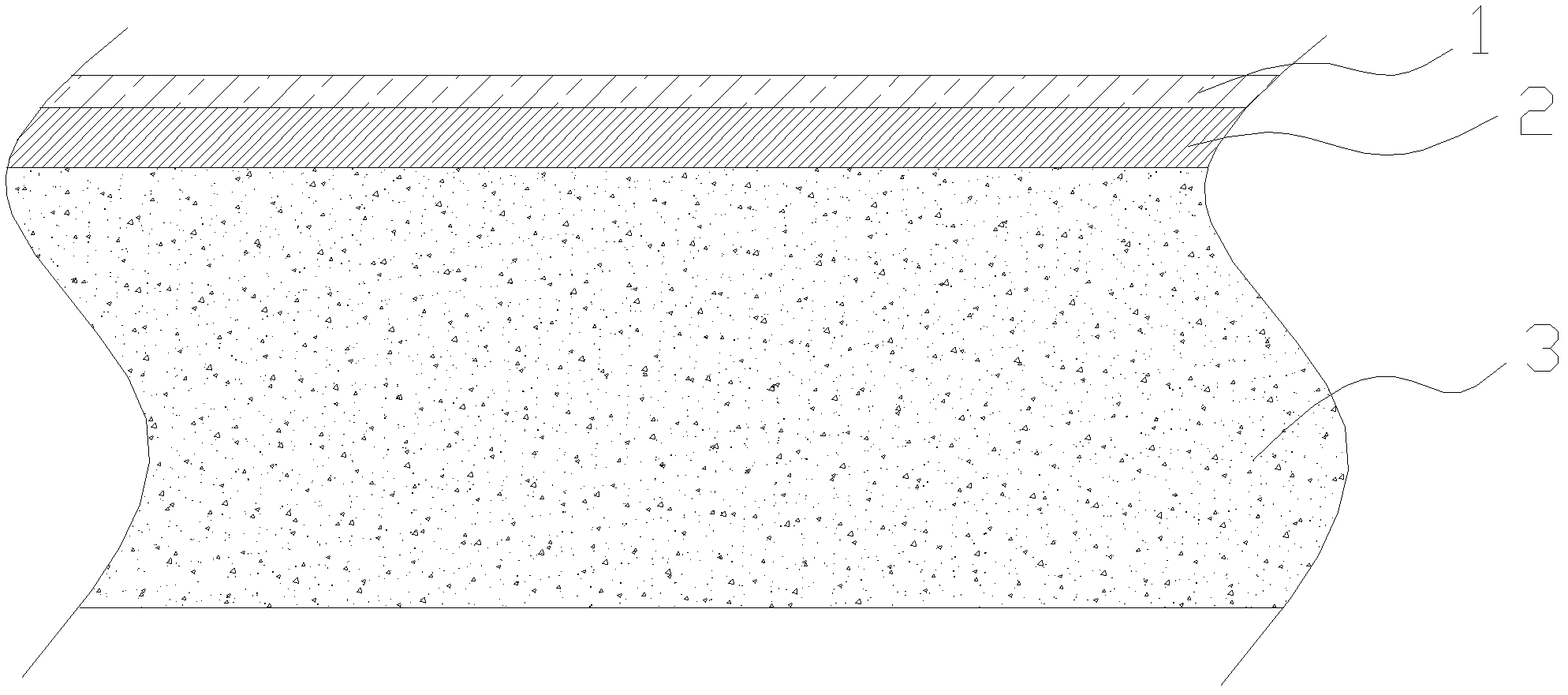

Stainless steel zipper manufactured by metal injection molding and preparation method thereof

The present invention provides a stainless steel zipper manufactured by metal injection molding. The stainless steel zipper comprises a zipper fastener 1, a pull ring 2, a pull piece 3 and pull teeth 4. The stainless steel zipper consists of stainless steel powder and at least one binder. The preparation method of the stainless steel zipper manufactured by metal injection molding comprises the following steps: 1, designing a mold; 2, selecting the metal powder; 3, selecting the binder; 4, preparing and compounding to uniform feeding material; 5, after injecting into a mold for heating at high temperature, cooling and forming; 6, cooling the binder for forming; and 7, sintering and forming the finished product. The stainless steel zipper manufactured by metal injection according to the invention has the advantages of suitability for manufacturing the zipper with random size, achieving the carving of complicated shape and three-dimensional forming characteristic, reducing the wastage, increasing the product performance, having fine surface, along with no easy generation of blistering, no oxidation, and no requirement of subsequent processing and auxiliary device.

Owner:刘世华

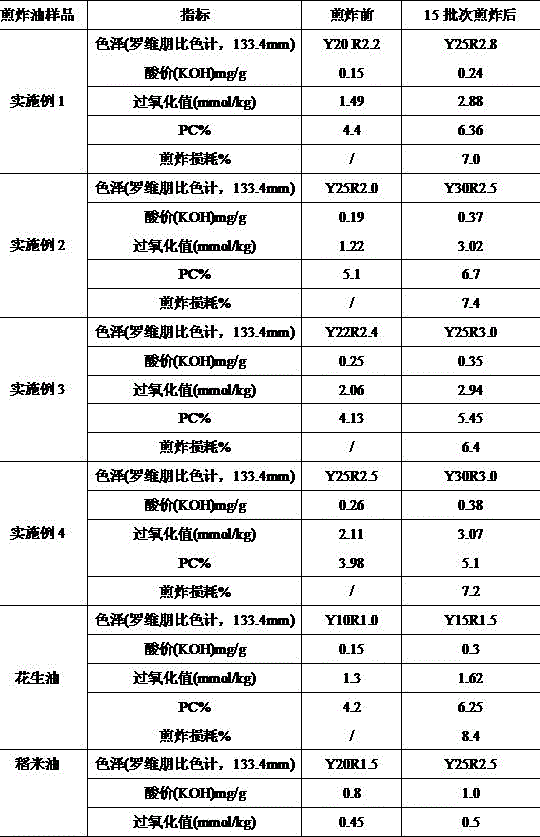

Special blend oil for frying and preparation method thereof

The invention discloses special blend oil for frying. The special blend oil for frying contains 10-50% by weight of high oleic acid peanut oil and 10-50% by weight of rice oil. The blend oil for frying is prepared by compounding any two or more than two of sunflower seed oil, olive oil, soybean oil, corn oil, cottonseed oil, palm oil, rapeseed oil, safflower oil, linseed oil and sesame oil in different proportions. The blend oil for frying is rich in fragrance, bright in color, high in content of oleic acid, rich in oryzanol and vitamin E, reasonable in composition of fatty acids and free of stickiness. Through a high-temperature frying test, the blend oil is high in smoke point, low in content of trans-fatty acids and high in frying stability. The fried food is small in oil content, good in crispy property, excellent in taste and nutritional and healthy. The blend oil disclosed by the invention can be used for frying different food materials, is suitable for being used as special fat for frying food in family and catering industry, is long in expiration date, and is novel nutritional and healthy special blend oil for frying.

Owner:山东金胜粮油食品有限公司

High-sinking-resistance transparent primer and preparation method thereof

The invention relates to a high-sinking-resistance transparent primer and a preparation method thereof. The high-sinking-resistance transparent primer is particularly suitable for application on a wood substrate and especially suitable for application on a substrate with deeper wood-grain guide tubes. The primer is prepared from a main paint, a curing agent and a diluter in a mass ratio of 1:0.5:(0.3-1):0.5:0.7. The main paint is prepared from the following raw materials in parts by mass: 55-70 parts of small-oil-length alkyd resin, 5-15 parts of castor oil modified alkyd resin, 3-10 parts of zinc stearate, 0-30 parts of talcum powder, 0.5-1 part of anti-settling agent, 0.3-1 part of defoamer, 0.2-0.5 part of leveling agent, 0.1-0.5 part of wetting and dispersing agent, 0.1-0.3 part of drier and 5-15 parts of environment-friendly mixed solvent. The primer can be well combined with the substrate after being applied, and has excellent properties in the aspect of wood grain / guide tube filling. After the primer is placed for a long time, the paint film of the finish paint can not shrink, and can not generate the phenomenon of sinking.

Owner:SKSHU PAINT

Method for preparing hydrophilic fluorine carbon metal paint

The present invention relates to a preparation method of hydrophilic fluorocarbon metal paint which includes the following process steps: 1. preparation of pre-emulsified mixture: add water, wedding agent, organosilicon autocopulation self-crosslinking monomer, acrylic monomers, acrylic ester monomers, fluorine acrylic ester monomer to the pre-emulsified reactor, and emulsifying to obtain pre-emulsified mixture; 2. preparation of nanometer modified fluorocarbon emulsion: take 1 / 5 of pre-emulsified mixture obtained in step 1; add it to reactor and elevate temperature; dropwise add mixture of evocating agent and water; then dropwise add the rest 4 / 5 pre-emulsified mixture to get nanometer modified fluorocarbon emulsion; 3. preparation of hydrophilic fluorocarbon metal paint: add mixture of nanometer modified fluorocarbon emulsion obtained in step 2, dispersants, wetting agents, anti-settle agent, propylene glycol, flatting agent, pigment, thickening agent and water to paint preparing reactor, stir and disperse for 10-15 min, filtrate and discharge. The hydrophilic fluorocarbon metal paint prepared through the method described in the invention has good stain resistance and long weather resistance, and has effect of the aluminum plate paint with film ventilating.

Owner:JIANGSU GUOLIAN TECH

Antibacterial glaze material

An antibacterial glaze material comprises a nano zirconium phosphate silver-loaded antibacterial agent, nano titanium dioxide, zinc oxide, copper oxide, Jiushan local glaze stone, quartz, talcum, copper ores and calcite. The antibacterial glaze material has the advantages that the nano zirconium phosphate silver-loaded antibacterial agent and the nano titanium dioxide are added into the glaze material, so that the glaze material has good antibacterial property, is non-toxic and pollution-free, and is suitable for the glaze formula of Jun porcelain kitchenware such as plates and bowls; the glaze material is good in fluidity, less prone to blistering and good in glossiness, and Jun porcelain glaze prepared by the glaze material is stable and uniform in color.

Owner:崔松伟

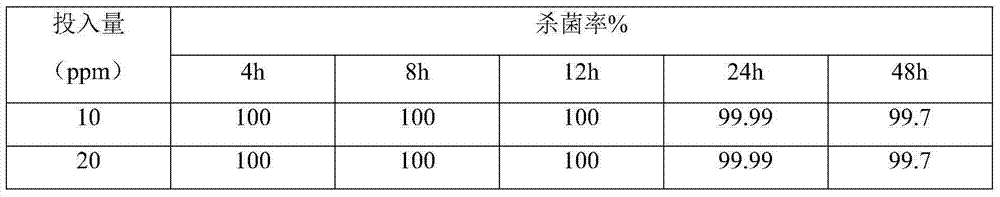

Efficient composite germicide for circulating water system and preparation method thereof

ActiveCN104488957AGood water solubilityImprove the bactericidal effectBiocideFungicidesIsothiazolinonePhosphonium

The invention discloses an efficient composite germicide for a circulating water system, which is composed of the following components: 15-18% of glutaraldehyde, 42-49% of quaternary phosphonium, 11-17% of isothiazolinone, 20-30% of deionized water, and 5-8% of dithiocyano-methane. The germicide has an extremely excellent bactericidal effect, can be used in circulating cooling water under high pH value conditions, has a good killing effect on heterotrophic bacteria, sulfate reducing bacteria and algae, and especially has an obvious killing effect on heterotrophic bacteria; and the germicide is high in killing speed, strong in killing force, and low in toxicity.

Owner:SHANDONG TIANQING TECH DEV

Method for producing pleocidin by adopting saccharopolyspora spinosa through fermentation

InactiveCN105506038AStable outputLess foamMicroorganism based processesFermentationSaccharopolysporaFermentation

The invention provides a method for producing pleocidin by adopting saccharopolyspora spinosa through fermentation. According to the method, saccharopolyspora spinosa Z68 is adopted as a fermentation strain, an improved fermentation medium is adopted, fermentation cultivation is carried out under the conditions that the temperature is 26-30 DEG C, the rotation speed is 150-220 rpm, the compression-ventilation ratio is 1 to (0.3-0.7), the pot pressure is 0.03-0.04 MPa, and the dissolved oxygen is controlled to be 40% or above, and pleocidin is extracted from the fermentation liquid. According to the method provided by the invention, staring from the physicochemical properties of the fermentation medium of saccharopolyspora spinosa, the fermentation medium with stable yield of pleocidin and little foaming amount, and a material supplementation method are provided. The soybean meal / soybean cake powder in the fermentation medium are replaced by high-temperature soybean cake powder, and the experiment proves that in the fermentation process, the high-temperature soybean cake powder has small possibility of foaming compared with the soybean meal and low-temperature soybean cake powder, while part of fat not available in the high-temperature soybean cake powder but available in the soybean meal and the low-temperature soybean cake powder can be added from the outside in the middle and later periods of fermentation, and the adding at the time can achieve the effect of eliminating foams and solve the problem that the carbon source is insufficient in the later period.

Owner:牡丹江佰佳信生物科技有限公司

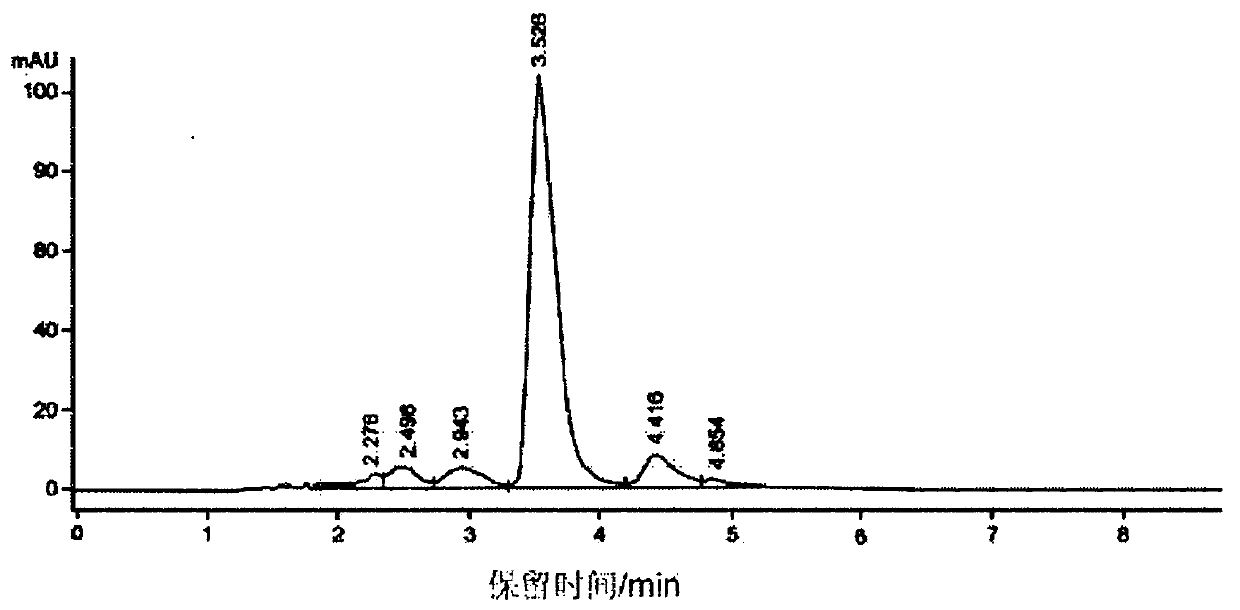

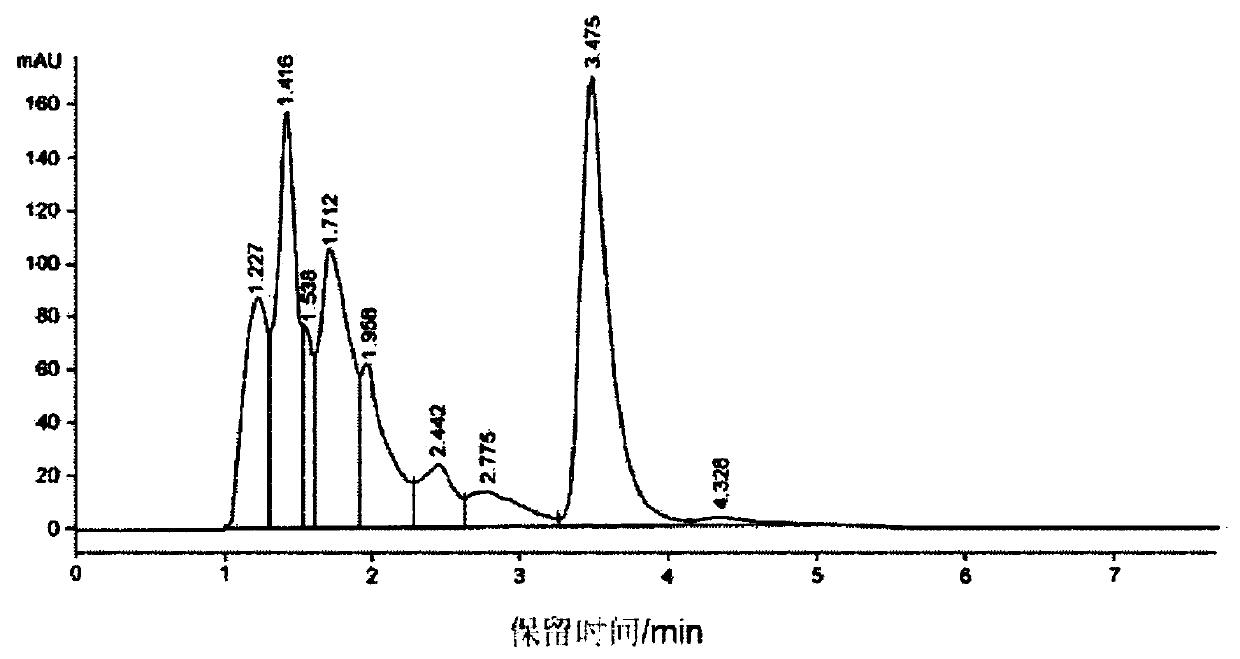

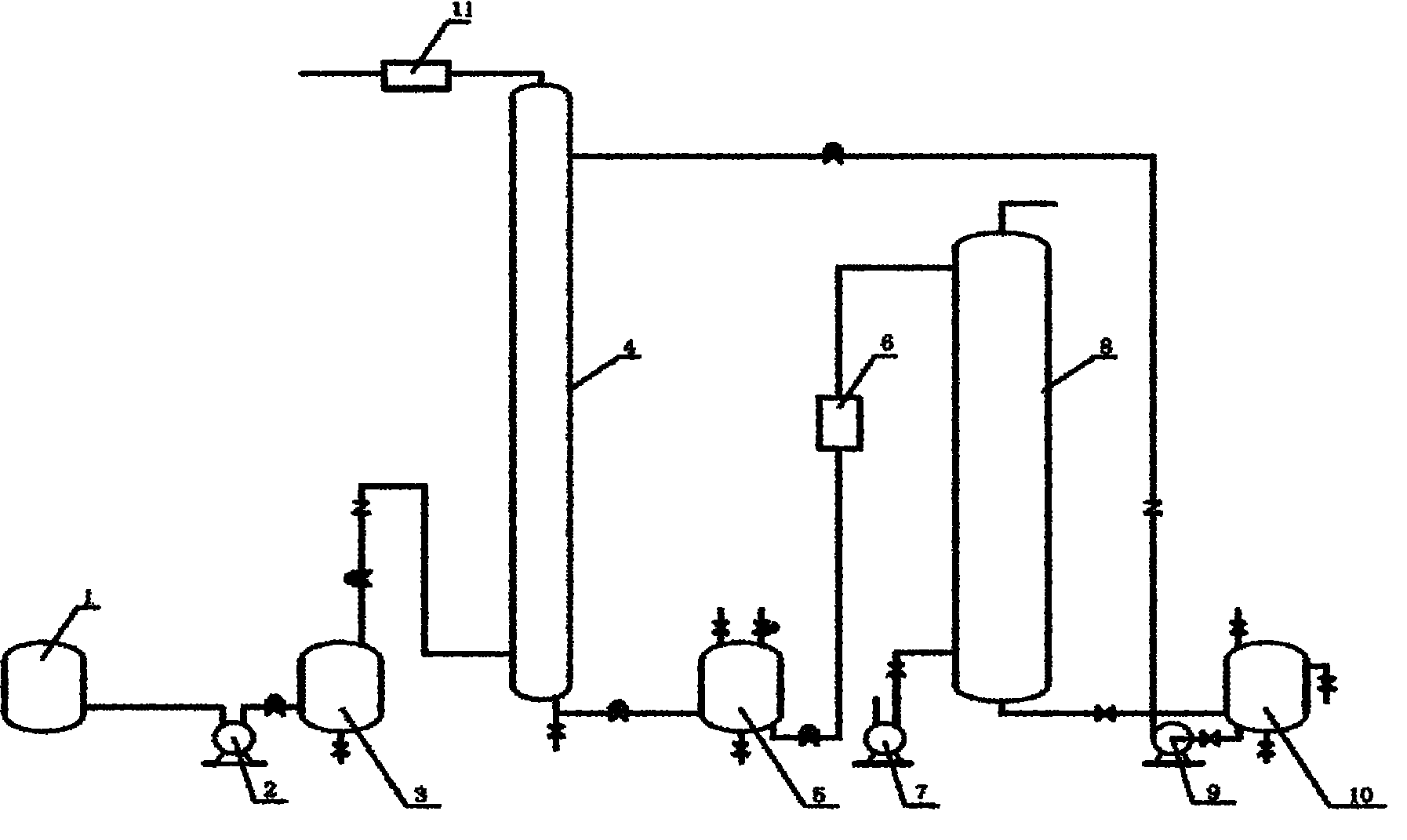

Device and method for removing carbon dioxide and hydrogen sulfide from methane by water dissolving method

ActiveCN102101001ALow viscosityNot easy to foamDispersed particle separationGaseous fuelsSolubilityAdditive ingredient

The invention provides a method and a device for removing carbon dioxide and hydrogen sulfide from methane by a water dissolving method. In the method, according to different solubility of various ingredients of the methane in water, carbon dioxide (CO2) and hydrogen sulfide (H2S) in the methane are dissolved in tap water by controlling pressure, liquid gas ratio and temperature of an absorption tower; and the water, in which the carbon dioxide and the hydrogen sulfide are dissolved, can be recycled through regeneration. The device is simple, convenient to operate, low in investment, and convenient in industrialized production; in particular, effect of removing CO2 and H2S is obviously improved through filling design in the absorption tower and use of a redistributor; and regeneration effect of the water is improved through use of a heat exchanger. In the methane treated by the device and the method, the methane content is obviously increased; the maximum of the methane content can reach 97 to 99 percent; and a heat value is obviously increased.

Owner:BEIJING UNIV OF CHEM TECH

Water-borne polyurethane matte finishing paint for locomotive interior and exterior decorations

InactiveCN108192481AThe product is less toxicEasy constructionPolyurea/polyurethane coatingsChemistryLacquer

The invention relates to water-borne polyurethane matte finishing paint for locomotive interior and exterior decorations and preparation method. The water-borne polyurethane matte finishing paint comprises two parts, namely finishing coat and a curing agent, wherein the finishing coat comprises a water-borne acrylic resin, a pigment paste, a filler, a cosolvent, an auxiliary agent and deionized water; the curing agent comprises water-borne HDI isocyanate and a small amount of an organic solvent. The water-borne polyurethane matte finishing paint is sprayed through wet-on-wet two-pass spraying,is baked and cured to form a film. The water-borne polyurethane matte finishing paint can fully meet design requirements of railway customers, is stable in color and luster control, does not containheavy metals such as chromium and lead, and reduces the environment pollution; the water-borne polyurethane matte finishing paint can provide coating with excellent aging resistance and water resistance and good mechanical properties and chemical properties, and can provide a comfortable and smooth hand feel; the water-borne polyurethane matte finishing paint is easy to construct, uses water as adiluent, is environment-friendly, has low VOC emission, and reduces harm to the environment and human health. The water-borne polyurethane matte finishing paint is mainly applied to surface coating ofrailway locomotives, urban rail transit vehicle bodies, interior decorations, chassises, frameworks and various accessories.

Owner:株洲市九华新材料涂装实业有限公司

Preparation method of thick paperboard with high bonding strength between paperboards

ActiveCN102877357AImprove interlayer bond strength effectHigh bonding strengthNon-fibrous pulp additionPaper/cardboardFiberPaperboard

The invention relates to a preparation method of a thick paperboard, in particular to a preparation method of a thick paperboard with high bonding strength between paperboards. In the preparation method, a fog-like adhesive water solution is sprayed between wet paper layers before the wet paper formed on a net by pulp with beating degree of 20-35oSR are mutually bonded; the adhesive water solution is one of starch, polyacrylamide modified substance or a mixture of starch and the polyacrylamide modified substance; and the concentration of the adhesive water solution is 0.5-6.0%. The preparation method has following advantages that: 1, manufacturing paper with pulp is easy, and energy can be saved; and 2, the effect of improving bonding strength is notable, and a certain effect in improving retention of the pulp and chemical materials is realized. In addition, the preparation method increases bonding point and bonding force between the adhesive and pulp fibers so as to greatly improve bonding strength between the paperboards.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

Environment-friendly polyurethane prepolymer and preparation method thereof

The invention belongs to the field of fine chemical engineering, and particularly relates to an environment-friendly polyurethane prepolymer and a preparation method thereof. Polypropylene carbonate polylol and isocyanates are used as raw materials to prepare a polyurethane adhesive, and the polyurethane adhesive is subjected to termination modification by organosilane to obtain the environment-friendly polyurethane prepolymer, thereby lowering the release of free isocyanates and other substances harmful to the human body, and implementing no pollution. The prepolymer has the advantages of high strength, hydrolysis resistance, low bubbling tendency and stable performance, and can be widely used in the fields of traditional production of adhesives, sealants, paints and elastomers and the like.

Owner:GUANGDONG UNIV OF TECH

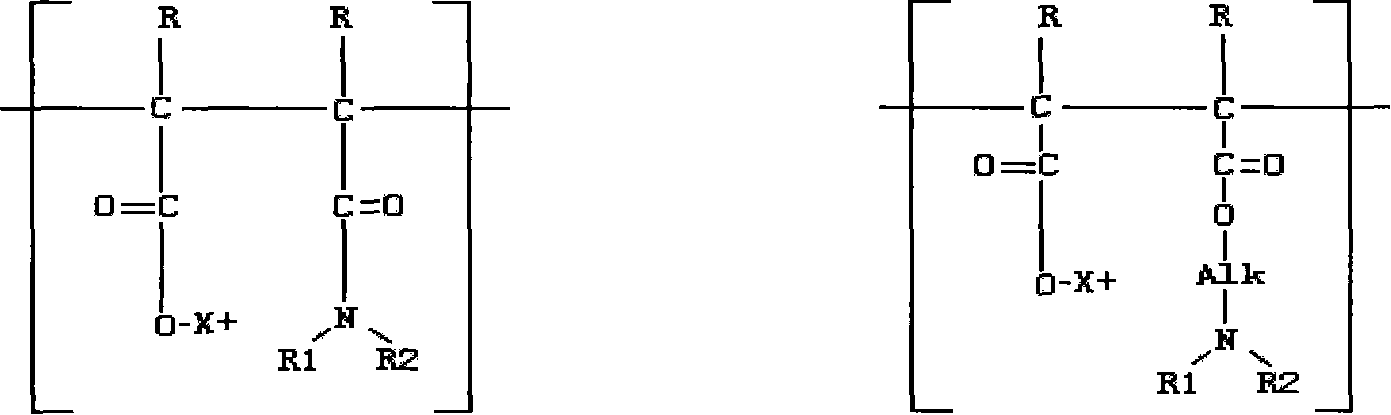

Method for preparing waterproofing agent of saponin-free cation paraffin emulsion artificial board

InactiveCN101649224AHigh molecular weightImprove hydrophobicityOther chemical processesWax physical treatmentParaffin waxFiber

The invention discloses a method for preparing a waterproofing agent of a saponin-free cation paraffin emulsion artificial board. The method comprises the following steps: under the function of a cosolvent which can be mutually soluble to water, taking vinyl monomers, such as styrene, an acrylate class monomer, a cation monomer, acrylamide and a derivative thereof and the like, as a copolymerization monomer and preparing a saponin-free benzene polymer with strong cation charges by a saponin-free emulsion polymerization method; taking the saponin-free benzene polymer as a high molecular emulsifying agent of solid paraffin, emulsifying and dispersing the paraffin and preparing the waterproofing agent of the saponin-free cation paraffin emulsion artificial board with favorable stability by homogenizing at high pressure. The invention overcomes the defects of poor waterproof effect, poor stability, easy bubbling of emulsion and the like due to the addition of a small molecular emulsifyingagent in the traditional paraffin emulsion; the product adopts the saponin-free benzene polymer with strong cation charges as the high molecular emulsifying agent of the solid paraffin, and the high molecular emulsifying agent which can generate a very strong hydrogen bond function with fibre in the artificial board not only enhances the water resistance of a board material but also can enhance the physical strength of the artificial board.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of ceramic crucible coating layer for ingoting polysilicon

The invention discloses a preparation method of a ceramic crucible coating layer for ingoting polysilicon, which comprises the steps of putting 26%-49% of deionized water into a stirrer, heating the water to be 80-90DEG C, and pouring 50%-70% of silicon nitride into the stirrer to be evenly stirred; slowly pouring 0.5%-4% of PVA (polyvinyl alcohol) into the stirrer, stirring and ultrasonically shaking for more than 30min, and abundantly stirring to prepare suspension liquid; brushing the stirred suspension liquid onto the inner wall of a ceramic crucible, wherein the depth of the coating layer is 200-400mum; and putting the brushed ceramic crucible into an oven for sintering, rising the temperature of the ceramic crucible to be 1050-1100 DEG C after 8-10h, keeping the temperature for 2-4h, and cooling to be at a room temperature with a furnace. The coating layer and the surface of the crucible has high adsorption capacity, and the coating layer is hard to bubble, fall off and strip off, so that the furnace bonding and the ingot cracking of a silicon ingot are reduced, the pollution of impurities in the crucible to the silicon ingot is effectively reduced, and the demolding effect of the silicon ingot is improved.

Owner:LIGHTWAY GREEN NEW ENERGY

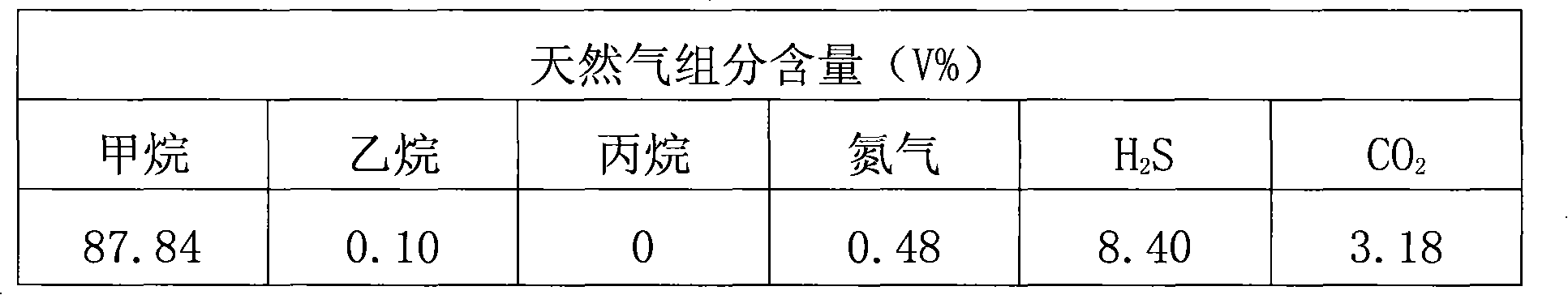

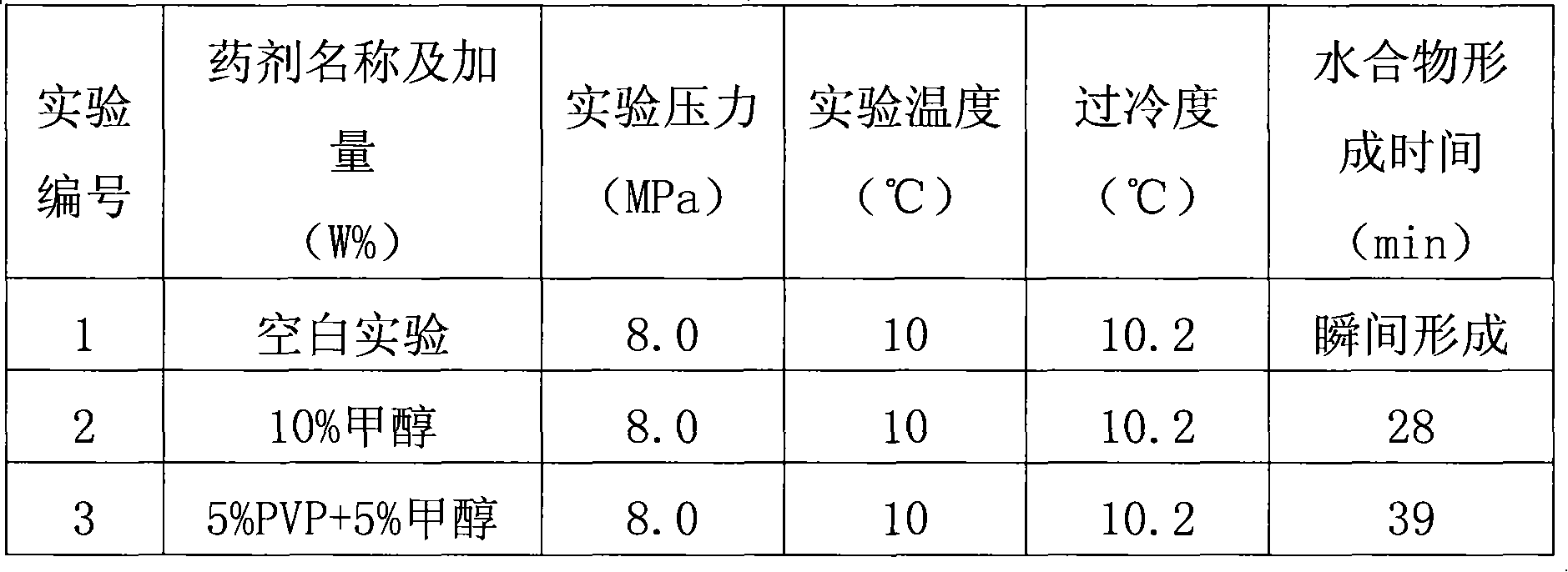

Inhibitor for preventing the formation of natural gas hydrates of high-sulfur acid gas fields

ActiveCN101608118APrevent anti-corrosion effectNot easy to aggregateGaseous fuelsFluid removalBiopolymerCO2 content

The invention relates to an inhibitor for preventing the formation of natural gas hydrate of high-sulfur acid gas fields, which comprises the following components in percentage by weight: 5 to 30 percent of biopolymer, which has the weight average molecular weight of between 3,000 and 10,000, of vinyl pyrrolidone and vinyl caprolactam or terpolymer, which has the weight average molecular weight of between 65,000 and 100,000,of the vinyl pyrrolidone, the vinyl caprolactam and N, N-(dimethylamino)ethyl methacrylate, 5 to 30 percent of amido group-containing and lipid group-containing polyesteramide or amidation product which is formed by polymerizing maleic anhydride, a derivative thereof and alkyl alcohol amine and has the number average molecular weight of between 1,000 and 15,000, 10 to 15 percent of surfactant and defoaming agent, and 50 to 70 percent of mixture of methanol or ethanol and glycol. The inhibitor has better inhibition effect on acid natural gas hydrate which has the H2S content between 0 and 8 percent, the CO2 content between 0 and 5 percent, and no hydrocarbon components above C2.

Owner:PETROCHINA CO LTD

Method for improving cellulose enzymatic hydrolysis and saccharification yield

The invention belongs to the field of lignocellulose enzymatic hydrolysis, and discloses a method for improving cellulose enzymatic hydrolysis and saccharification yield by using a mixture of lignin sulfonate and straight-chain alcohol as an enzymatic hydrolysis auxiliary agent. The method comprises the specific steps that: cellulose is dispersed in a buffering solution; the mixture of lignin sulfonate and straight-chain alcohol is added; 5-20 FPU / g of cellulase calculated according to glucan content in cellulose is added; a reaction is allowed for 48-96h under a temperature of 45-60 DEG C, such that a saccharide compound hydrolysate is obtained. According to the invention, through the addition of the mixture of lignin sulfonate and straight-chain alcohol, cellulose enzymatic hydrolysis and saccharification yield can be improved by 15.1-24.6%.

Owner:SOUTH CHINA UNIV OF TECH

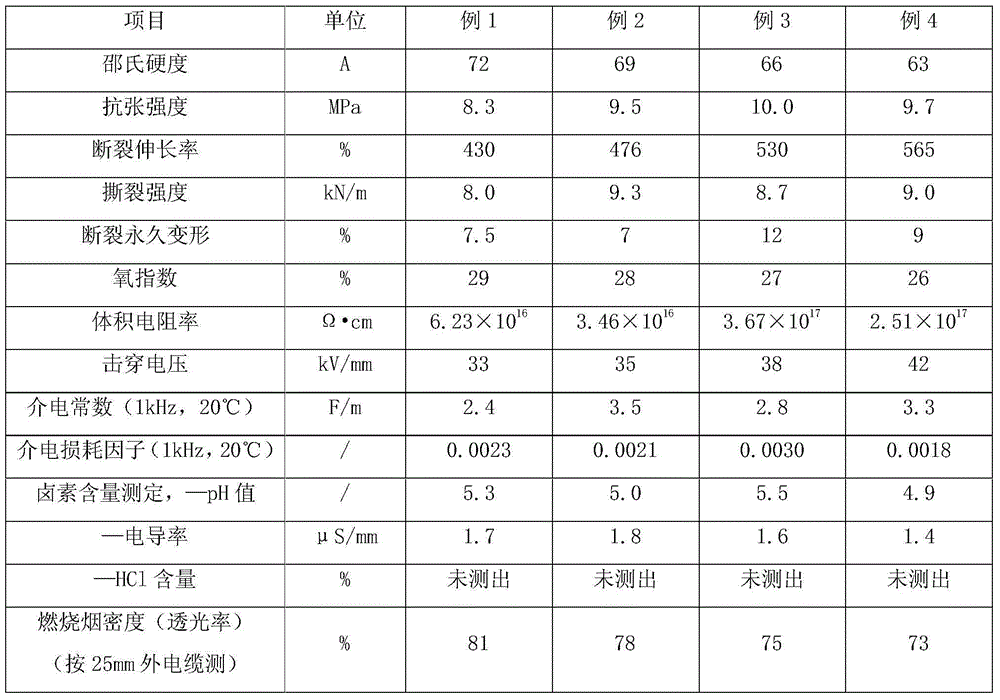

Intermediate pressure level low-smoke zero-halogen flame-retardant silicon rubber insulating material and manufacturing process thereof

ActiveCN104087001AIncrease elasticityImprove aging resistanceRubber insulatorsSilicone rubberIntermediate pressure

The invention discloses an intermediate pressure level low-smoke zero-halogen flame-retardant silicon rubber insulating material and a manufacturing process thereof. The material is characterized by being prepared from the following raw materials in parts by weight: 35-45 parts of methyl vinyl organic silicon rubber, 15-25 parts of white carbon black, 1.5-3 parts of nano-montmorillonite, 10-25 parts of aluminum hydroxide, 10-18 parts of magnesium hydroxide, 0.4-0.8 part of an across-linking agent, 2-5.8 parts of a structure control agent, 2-4 parts of iron oxide red and 0.80-1.5 parts of a coupling agent. The insulating material disclosed by the invention not only can satisfy the requirements on heat resistance, high electrical insulating performance and the like of an intermediate pressure level cable insulating material, a cable accessory and the like, but also has high mechanical strength, so that the novel application field of the silicon rubber material is opened up.

Owner:ANHUI HANGTIAN CABLE GROUP

Pressure-sensitive adhesive film

ActiveCN102015942AReduce adhesionStrong process adaptabilityAdhesive articlesSynthetic resin layered productsPolymer scienceSurface roughness

A pressure-sensitive adhesive film which is a stretched polypropylene-based resin film comprising a laminate consisting of a pressure-sensitive adhesive layer and a release layer provided on the surface of a base layer of a polypropylene-based resin, characterized in that the average surface roughness (SRa) of the surface of the above-described release layer is 0.200 [mu]m or less, the average surface layer (SRa) of the surface of the pressure-sensitive adhesive layer of the above-described film is 0.030 [mu]m or less, the contact area with the adherent, which is defined in the description, is 90% or more but not more than 100%, and the film haze falls within the range of 1 to 40%. This pressure-sensitive adhesive film suffers from little blocking and shows a good processing suitability even after storing in a rolled state. Further, this film shows little bubbling and a high transparency after bonding to an adherend and processing at a high temperature.

Owner:TOYOBO CO LTD

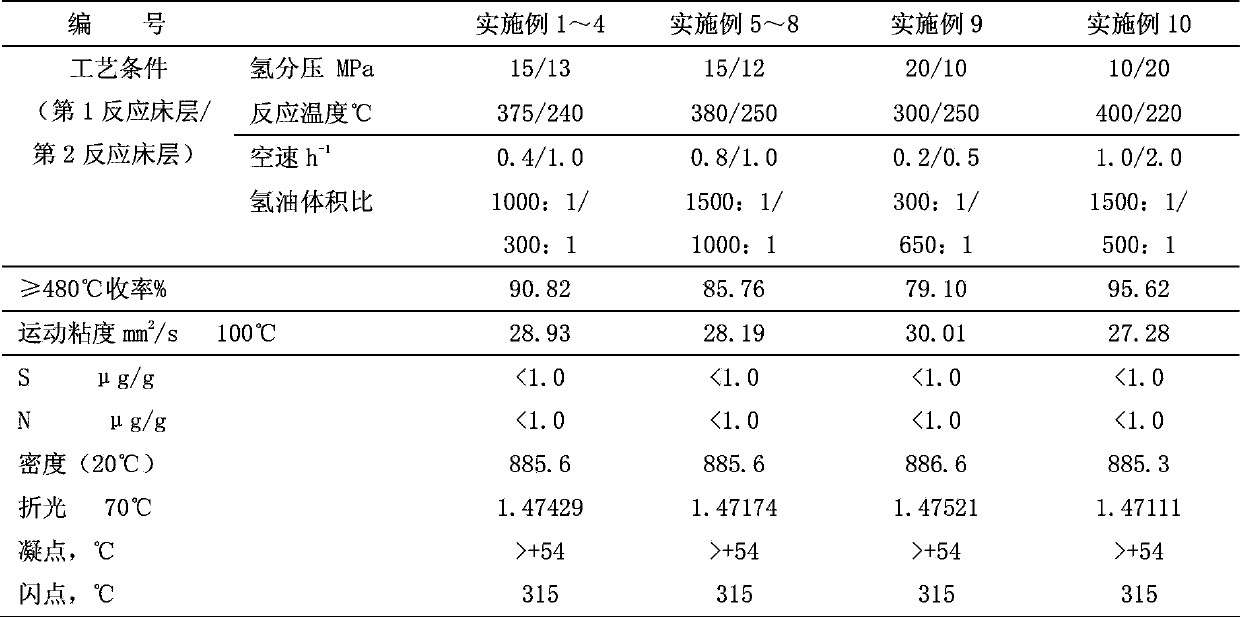

Preparation method of food-grade microcrystalline wax

InactiveCN103865580AExtended service lifeChange the rate of the hydrogenation reactionPetroleum wax refiningMicrocrystalline waxSlag

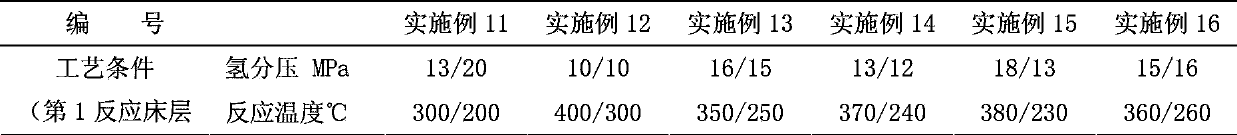

The invention relates to a preparation method of food-grade microcrystalline wax. The preparation method comprises the following steps that blended oil comprising paraffin-based slag-reduced deasphalted oil and naphthenic base slag-reduced deasphalted oil is used as a raw material, is fed into a first reaction bed layer and then undergoes a hydrotreatment modification reaction; the reaction product is fed into a stripping tower and the stripped product is fed into a second reaction bed layer and undergoes a hydrofining reaction to produce hydrofined product oil; the hydrofined product oil is cut by atmospheric and vacuum fractionation equipment to form a heavy lubricant component having a temperature of 480-750 DEG C; the heavy lubricant component and an acetone-benzol dewaxing solvent are mixed; the mixture is cooled to below -15 DEG C; the cooled mixture is filtered so that dewaxed filtrate and deoiled wax are obtained; the deoiled wax is mixed with carclazyte by stirring; and the mixture is filtered so that the carclazyte is removed and the food-grade microcrystalline wax is obtained. The food-grade microcrystalline wax has Seybolt color number greater than +25, a drop melting point of 67-92 DEG C, a needle penetration degree of 15-35(1 / 10mm), oil content of 0.85-3.0%, sulfur and nitrogen content less than 1 microgram per gram and heavy metal and arsenic content less than 1mg / kg.

Owner:PETROCHINA CO LTD

Hot metal pretreatment desilicication/dephosphorization agent and application method thereof

The invention discloses a hot metal pretreatment desilicication / dephosphorization agent. The hot metal pretreatment desilicication / dephosphorization agent is formed by mixing ferric red mud and lime particles according to the mass ratio of 1:(0.2-0.3). The content of TFe in the ferric red mud is 40-50 wt%, and the particle size of the ferric red mud is 0.088-0.5 mm. The particle size of the desilicication / dephosphorization agent is smaller than or equal to 3 mm, and the content of the desilicication / dephosphorization agent with the particle size of 1-3 mm is smaller than or equal to 5 wt%. The invention further discloses an application method of the hot metal pretreatment desilicication / dephosphorization agent. The method comprises the following steps that whether desilicication operation and dephosphorization operation are carried out independently or at the same time is determined according to the steelmaking smelting steel ball requirements and hot metal in-station conditions. When the ferric red mud is used as the desilicication / dephosphorization agent for hot metal pretreatment, furnace slag foaming can be avoided, furnace slag is prevented from overflowing out of a hot metal furnace, and the desilicication and dephosphorization effect is good.

Owner:SHANDONG IRON & STEEL CO LTD

Absorbent for selectively absorbing sulfur dioxide and application thereof

InactiveCN105983310AGood for recyclingLow viscosityDispersed particle separationExhaust gasAbsorption rate

The invention discloses an absorbent for selectively absorbing sulfur dioxide and an application thereof, which belong to the technical fields of environmental protection and gas purification. The absorbent comprises the following components by mass percentage: 5-80% of organic multi-amine; inorganic strong acid, wherein the mol ratio of the inorganic strong acid to the organic multi-amine is (0.3-1.2):1; 0.01-1.00%of an antioxidant, 0.01-8.00% of a desulfuration activator, and the balance of water; and the pH value of the absorbent is 4.0-6.5. The SO2 absorbent has high absorptivity and selectivity on SO2, SO2 can be absorbed from a mixing gas containing SO2 and CO2, but CO2 is not absorbed, the initial absorption rate can reach 100%, the absorption rate can still reach more than 99% in 30 minutes, and the absorbent is suitable for purifying the industrial exhaust gas containing SO2, especially the exhaust gas of a sulfur recovery device. The SO2 absorbent has good renewable performance and stability, and is in favor of cyclic utilization of the absorbent.

Owner:PETROCHINA CO LTD

Packaging bag manufacturing method

InactiveCN109849433ASmooth operationConsistent speedNon-macromolecular adhesive additivesHeat recovery systemsSolventSolvent free

The invention discloses a packaging bag manufacturing method. The packaging bag manufacturing method comprises the ten steps of gravure manufacturing, ink preparing, equipment installing, printing, energy-saving drying treatment, printing pattern detection, composite working procedures, drying and curing, slitting and bag making, wherein an energy-saving drying heat pump set is used in the step ofenergy-saving drying treatment; according to the step of printing pattern detection, a stroboflash lamp irradiates a packaging film to obtain synchronous static patterns; and a solvent-free compounding mode and specially-made glue are adopted in the step of composite working procedures. Printing equipment is stable in operation process, consistent in speed, uniform in printing and good in printing effect. The energy-saving drying heat pump set is used, so that lost heat is recovered, and the energy is saved. The solvent-free compounding mode is adopted, so that solvents are prevented from volatilizing and polluting the environment. The curing condition is changed, so that a packaging bag has a high-temperature-resistant effect, the performance of the packaging bag is improved, and the application range of the packaging bag is enlarged.

Owner:安徽省阜阳市国泰彩印包装有限公司

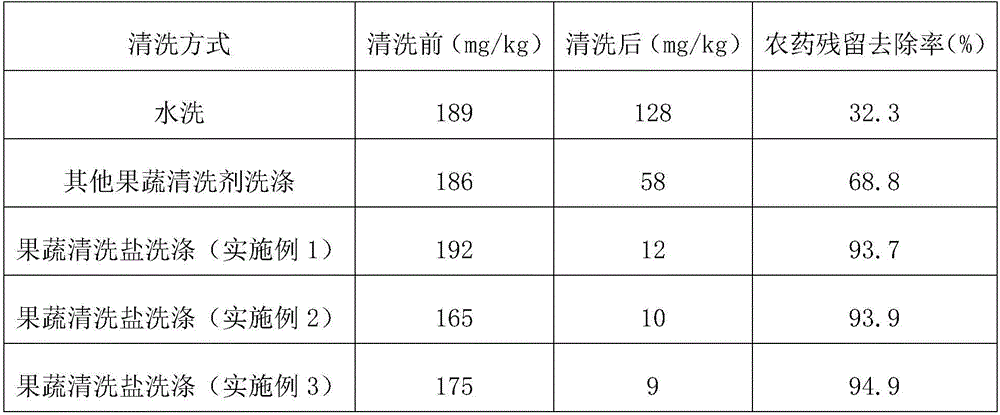

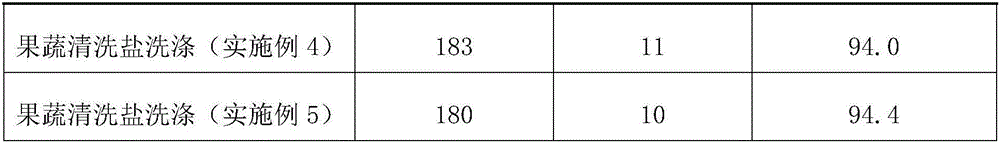

Fruit and vegetable washing salt for removing pesticide residues and preparation method thereof

InactiveCN106434028ADoes not destroy nutrientsHas the effect of sterilization and disinfectionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsMedicinal herbsPesticide residue

The invention belongs to the field of washing products, and particularly discloses fruit and vegetable washing salt for removing pesticide residues. The washing salt is prepared from the following raw materials: edible salt, shell powder, sodium percarbonate, sodium benzoate, hydroxypropyl methyl cellulose, ethanol solution, citric acid, orange peels, mangnolia, bamboo leaves, cortex dictamni, lonicera japonica, camellia, roots of japanese banana, rhodiola rosea, lysimachia christinae hance, loofah sponge, sodium alkyl benzene sulfonate, sodium lignin sulfonate, fatty acid diethanol amide, polyhexamethylene guanidine and deionized water. The fruit and vegetable washing salt is prepared from edible salt, multiple traditional Chinese medicinal herbs and other raw materials, which are mixed to achieve the synergized or resisted effect, so that the effect of removing pesticide residues can be improved, pesticide residue and stains on the surface of melons, fruits and vegetables can be effectively cleaned, nutrition of fruits and vegetables cannot be destroyed, and the requirement of people for washing fruits and vegetables can be met.

Owner:王泽铭

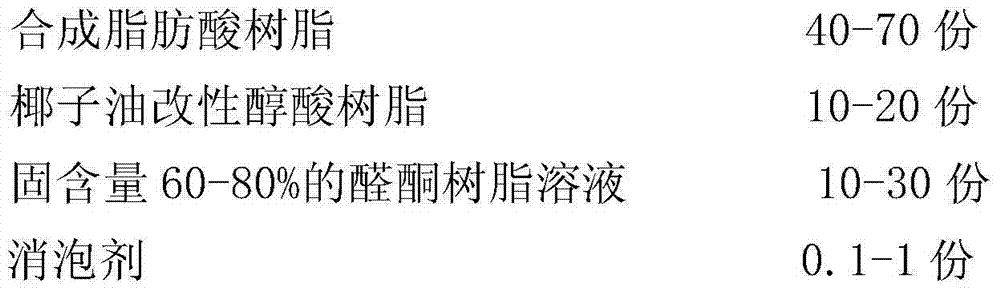

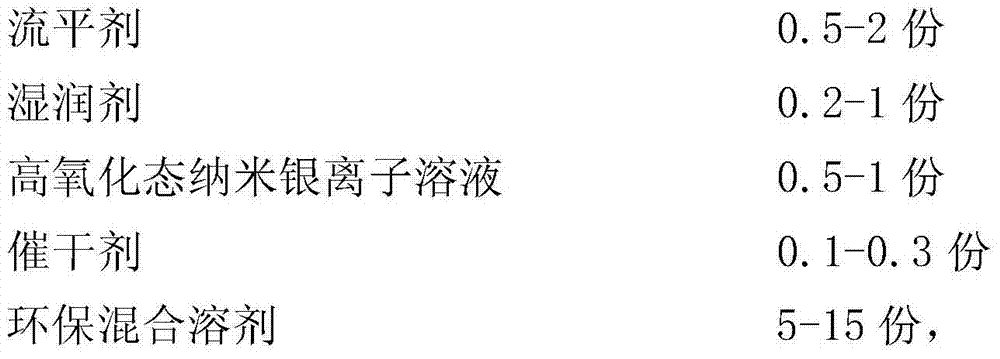

Special environment-friendly bright finishing coat with anti-bacterial function for children as well as preparation method thereof

ActiveCN103483999AGood gloss and color retentionNot easy to yellowAntifouling/underwater paintsPaints with biocidesOxidation stateKetone

The invention relates to special environment-friendly bright finishing coat with an anti-bacterial function for children as well as a preparation method thereof. The special environment-friendly bright finishing coat with the anti-bacterial function for children is prepared from the following components of main paint, a curing agent and a diluent by weight ratio of (0.8-1.2):(0.8-1.2):(0.2-0.4). The main paint is prepared from the following components in parts by weight: 40-70 parts of synthetic fatty acid resin, 10-20 parts of coconut oil modified alkyd resin, 10-30 parts of aldehyde ketone resin with solid content of 60-80%, 0.1-1 part of a defoamer, 0.5-2 parts of a flatting agent, 0.2-1 part of a wetting agent, 0.5-1 part of high oxidation state nano silver ionic liquor, 0.1-0.3 part of a drier and 5-15 parts of an environment-friendly mixed solvent. The special environment-friendly bright finishing coat with the anti-bacterial function for children is not only environment-friendly and healthy and prevents generation of harmful substances to physical health of children, but also can form a coating with the anti-bacterial function on the surface of a coated object after coating so as to protect the physical health of children.

Owner:SKSHU PAINT

Rust proof coating for machinery equipment and preparation method thereof

InactiveCN104130708AEffective protectionExtended service lifeAnti-corrosive paintsBituminous coatingsKaolin clayPhosphoric acid

The invention provides a rust proof coating for machinery equipment and a preparation method thereof. The coating contains the following components by weight: 30-45 parts of coal tar, 8-14 parts of maleic anhydride, 3-6 parts of modified phenolic resin, 10-20 parts of barium borate, 8-15 parts of molybdenum dioxide, 7-14 parts of aluminum tripolyphosphate, 1-3 parts of diatomite, 1-3 parts of kaolin, 1-3 parts of light calcium carbonate, 4-8 parts of propylene glycol, 0.6-1.1 parts of lead naphthenate, and 15-30 parts of deionized water. The coating provided by the invention has excellent rust resistance and wear resistance, hardly peels or blisters, has little environmental pollution, and can effectively protect the mechanical equipment, and prolong the service life of mechanical equipment.

Owner:SUZHOU JUKANG NEW MATERIAL TECH

Porcelain plastic decorative plate and its processing method

InactiveCN102991069AReduce manufacturing costGood mechanical propertiesSynthetic resin layered productsFiberStone dust

The invention relates to a decorative plate, and discloses a porcelain plastic decorative plate. The porcelain plastic decorative plate comprises, from top to bottom, a PVC transparent abrasion-resistant layer, a PVC pattern printing layer and a substrate layer which are sequentially stacked. The substrate layer comprises the following components, by weight, 100 parts of PVC resin, 15-20 parts of a plasticizer, 2.0-5.0 parts of a stabilizing agent, 60-70 parts of bead powder, 15-30 parts of a fiber, 5-10 parts of an impact improver, 15-30 parts of stone powder, 0.5-1.5 parts of rosin or PE wax, and a proper amount of a coloring agent. The invention also discloses a processing method of the decorative plate. The method comprises the following technological steps: 1, processing the substrate layer; 2, printing a pattern; 3, carrying out hot-press molding; 4, carrying out surface treatment; 5, carrying out heat treatment; and 6, carrying out product inspection and packaging. The decorative plate has the advantages of stable dimensional stability, low water absorption rate, difficult deformation, difficult shedding and foaming of the decorative layer, rich and colorful pattern, and stereoscopic effect.

Owner:SHENZHEN JIANCHEN INDAL

High-hardness and quick-drying water-based two-component filling clear primer and preparation method thereof

InactiveCN111961398AHigh hardnessHigh molecular weightPolyurea/polyurethane coatingsPriming paintsSolid woodPolymer science

The invention provides a high-hardness and quick-drying water-based two-component filling clear primer. The high-hardness and quick-drying water-based two-component filling clear primer comprises a component A and a component B which are uniformly mixed according to an equivalent ratio of n (-NCO) to n (-OH) of 1.5-1.8, wherein the component A is prepared from the following components in percentage by weight: 75.0 to 80.0 percent of water-based acrylic emulsion; 0.8%-1.0% of an antifoaming agent, 4.0%-6.0% of a coalescing agent, 3.0%-6.0% of filling powder, 0.2%-0.3% of a wetting leveling agent, 0.4%-0.6% of an anti-settling agent, 0.1%-0.5% of a thickener, 2.0%-5.0% of a polishing agent and 2.0%-10.0% of water. And the component B is prepared from the following components in percentage byweight: 30%-40% of modified IPDI polyisocyanate and 60%-70% of modified HDI polyisocyanate. The -OH in the primer emulsion component and -NCO in the curing agent component are subjected to a deep cross-linking reaction to generate a urethane bond, the coating film is compact, and the hardness of the paint film is improved. In addition, the minimum film forming temperature MFFT is larger than or equal to 30 DEG C, the high drying speed is provided for a product system, and the requirement for changing oil into water in solid wood paint can be met; the invention also provides a preparation method of the water-based two-component filling clear primer.

Owner:HUIZHOU CHANGRUNFA PAINT

Preparation method of bisphenol A modified paper-base glass cloth copper-clad foil single-sided copper-clad plate

ActiveCN103213356AGood bond strengthNot easy to layerSynthetic resin layered productsMetal layered productsChemistryBisphenol A

The invention relates to a preparation method of a bisphenol A modified paper-base glass cloth copper-clad foil single-sided copper-clad plate, which comprises the following steps of: (I) preparing an epoxy phenolic resin mixed solution; and (II) preparing a bisphenol A modified phenolic resin mixed solution; preparing a copper-clad foil laminated plate by using the epoxy phenolic resin mixed solution as a steeping binder for glass cloth and the bisphenol A modified phenolic resin mixed solution as a steeping binder for wood fiber paper,. The prepared copper-clad foil laminated plate has low production cost and strong aging resistance, and hardly peels off.

Owner:江阴市明康绝缘玻纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com